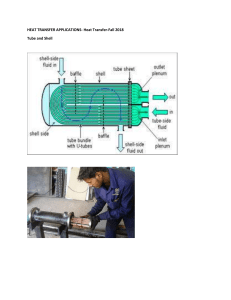

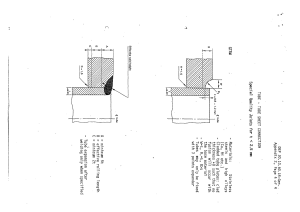

PROBLEM 11.22 KNOWN: Inlet and outlet temperatures for a shell-and-tube heat exchanger with 10 tubes making eight passes. Heat transfer coefficient for oil flowing in shell. Mass flow rate of water in tubes. Tube diameter. FIND: Oil flow rate required to achieve specified outlet temperature. Tube length required to achieve specified water heating. SCHEMATIC: &h m Th,i = 160°C Th,o = 100°C Tc,o = 85°C & c = 2.5 kg / s m Shell and tube hx 1 shell pass 8 tube passes 10 tubes D = 25 mm ho = 400 W/m2⋅K Tc,i = 15°C ASSUMPTIONS: (1) Negligible heat loss to the surroundings, (2) Constant properties, (3) Negligible tube wall thermal resistance and fouling effects, (4) Fully developed water flow in tubes. PROPERTIES: Table A.5, unused engine oil: ( Th = 130°C): cp = 2350 J/kg⋅K. Table A.6, water ( Tc = 50°C): cp = 4181 J/kg⋅K, μ = 548 × 10-6 N⋅s/m2, k = 0.643 W/m⋅K, Pr = 3.56. ANALYSIS: From the overall energy balance, Eq. 11.7b, the heat transfer required of the exchanger is & cc p,c (Tc,o − Tc,i ) = 2.5 kg / s × 4181 J / kg ⋅ K(85 − 15)°C = 7.317 × 105 W q=m Hence from Eq. 11.6b, &h= m q c p,h (Th,i − Th,o ) = 7.317 × 105 W = 5.19 kg / s 2350 J / kg ⋅ K(160 − 100)°C < The required tube length may be obtained using the ε-NTU method. We first calculate the heat & cc p,c =10,453 W/K. Thus, Cmin = Cc, and & hc p,h = 12,195 W/K, Cc = m capacity rates, C h = m Cr = Cmin/Cmax = 0.857. Then from Eq. 11.21, ε= Tc,o − Tc,i Th,i − Tc,i = (85 − 15)°C = 0.483 (160 − 15)°C Using Eqs. 11.30b,c for one shell pass and an even number of tube passes, we find Continued… PROBLEM 11.22 (Cont.) E= 2 / ε − (1 + Cr ) (1 + C2r )1/ 2 = 2 / 0.483 − (1 + 0.857) (1 + 0.8572 )1/ 2 = 1.74 ⎛ E −1⎞ 2 −1/ 2 ln ⎛ 1.74 − 1 ⎞ = 0.997 NTU = −(1 + C2r ) −1/ 2 ln ⎜ ⎟ = −(1 + 0.857 ) ⎜ ⎟ ⎝ E +1⎠ ⎝ 1.74 + 1 ⎠ Thus UA = NTU×Cmin = 10,420 W/K. To find the required tube length, we must know the heat &1 = m &c/N= transfer coefficients for the water flow. We calculate the Reynolds number, with m 0.25 kg/s defined as the water flow rate per tube, Eq. 8.6 yields Re D = &1 4m 4 × 0.25 kg / s = = 23, 234 πDμc π(0.025 m)548 × 10−6 N ⋅ s/m2 Hence the flow is turbulent, and from Eq. 8.60, Nu D = 0.023Re4D/ 5 Pr 0.4 = 0.023(23, 234)4 / 5 (3.56)0.4 = 119 and k 0.643 W / m ⋅ K h c = c Nu D = 119 = 3060 W / m2 ⋅ K D 0.025 m Hence U = [1/hc + 1/hh]-1 = 354 W/m2⋅K and we can find the required tube length from L= UA 10, 420 W / K = = 37.5 m UNπD 354 W / m2 ⋅ K × 10 × π × 0.025 m < COMMENTS: (1) With L/D = 1516, the assumption of fully developed conditions throughout the tube is justified. (2) With eight passes, the shell length is approximately L/8 = 4.7 m.