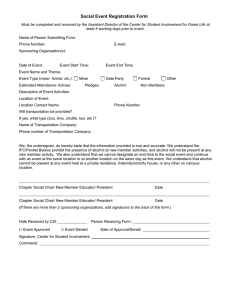

Cheese Mixer User guide Company: Delta Instruments Kelvinlaan 3 9207 JB Drachten The Netherlands Tel: +31 512 582222 Fax: +31 512 582220 E-mail: service@deltainstruments.com Version: Rev. 1 Copyright © Delta Instruments www.deltainstruments.com Cheese Mixer User guide Table of contents Table of contents Introduction ............................................................................................................................... 2 Unpacking.................................................................................................................................... 2 Installation ................................................................................................................................. 2 Intended use .............................................................................................................................. 2 Description of the Cheese Mixer ........................................................................................ 3 Safety ............................................................................................................................................ 4 Steps before starting the mixer:........................................................................................ 5 Homogenizing of samples..................................................................................................... 5 Troubleshooting........................................................................................................................ 6 Care of the instrument........................................................................................................... 6 Service .......................................................................................................................................... 6 Technical specification........................................................................................................... 7 Copyright Delta Instruments Page 1 of 7 Cheese Mixer User guide Introduction Introduction Read the Cheese mixer directions for use completely and carefully before starting operation. Keep the directions for use easily accessible to all those who will use the instrument. The warning in the manual (and on the instrument) means that precautions must be taken and triangle that the user should be acquainted with the contents of all warning before starting operation. Unpacking The mixer should be carefully unpacked. The mixer weighs 23 kg. To lift the mixer, support the mixer with one hand under the front base of the mixer and the other hand in the back. Maintain a proper balance by distributing the weight evenly while lifting. Use conventional tilting techniques to avoid back strain. Installation Cheese mixer should be placed on a surface which is stable and free from vibrations, like a lab bench. The recommended area for the mixer is 600 x 400 mm. Ensure that there is adequate air circulation around the mixer. Place the mixer 20 cm away from any wall or divider. Do not place the mixer close to a source of heat or in direct sunshine which can cause a temperature increase in the mixer. Before starting the mixer allow the equipment to attain room temperature to avoid condensation in the electronics. Use only the enclosed cable for connecting the instrument and only connect to a grounded outlet. Intended use Cheese mixer is a mechanical homogenizer, specifically designed for laboratory use. The mixer homogenizes foods, such as daily products (cheese, butter arid so on), deboned meat and deboned fish. Max volume to be processed is 250 ml. Optimal volume is l 50 ml. When liquidifiers are added to food samples and processed, a homogenous suspension/emulsion is created. Only The resulting product can be analyzed chemically or biochemically. Chemical (Röse-Gottlieb, Kjeldahl etc.) and physical methods (lR, VIS-UV etc.) can be made. Copyright Delta Instruments Page 2 of 7 Cheese Mixer User guide Description of the Cheese Mixer Description of the Cheese Mixer The Cheese mixer has a cylindrical grinder (1), which is anchored with tightening screws (2). The inner part of the cylinder is provided with bars. On the top of the cylinder (3) is a pipe (4) provided with a plug (5) and a pressure regulating hole. A circuit breaker switch (6) is located on the top of the cylinder. The circuit breaker switch must be securely connected to the circuit breaker (7) to start the mixer. At the bottom of the cylinder is a drain cock (8) and a vibration plug (9). Connection for thermostatic water, one inlet and one outlet (16) is placed at the bottoms of the cylinder. The mixers has a programmable timer (10) and starts (11) and stop (12) buttons. On the rear panel of the mixer is a knob (1 3) for adjusting the frequency of the rotor between 3000-7000 rpm. The switch to turn on the electricity is also located on the rear panel (14) and an electrical outlet with a fuse holder (15). The mixer is provided with a three phase asynchronous motors and a frequency converter. Ventilation outlets are located under the mixer and on the rear panel. This ventilation must never be covered with paper or any other materials. Only personnel familiar and trained in the functions of the mixer should be permitted to open the mixer to repair or service parts. 10 12 7 11 6 5 4 3 1 2 16 8 9 13 14 15 Copyright Delta Instruments Page 3 of 7 Cheese Mixer User guide Safety Safety The Cheese mixer meets the general standards for safety and technical efficiency. As for all other laboratory equipment the mixer should be handled with caution. Always follow the standard safety procedures at your laboratory. The 23 kg-mixer requires care when removing from the emballage. Lift while supporting the rear and front parts of the instrument to obtain the best handling. Do not leave the mixer unattended. The intended use of the mixer is outlined in these directions for use. Other uses are not appropriate. Connect the mixer only to grounded wall sockets with the voltage recommended on the mixer and in the directions. Use only the enclosed cable for connecting the mixer. Do not operate the mixer if the rare protective sheet is loose. The rubber-encased feet ensure that vibration is reduced and balance maintained. To ensure safety, the machine will not start if the circuit breaker switch on the top of the cylinder not is securely in place (6). lf the machine starts without the circuit breaker switch I in place, the machine should immediately be sent for service. If this precaution is not taken no responsibility for any injuries and damages which may occur. Test the circuit breather switch at least weekly. To test the circuit breaker switch: Place the top on the cylinder, do not put the circuit breaker switch in place. Attempt starting the mixer. lf the mixer starts without the circuit breaker switch is securely in place, the outlined service measures should be carried out. When the red lamp lights and the green lamp blinks (10), while the mixer is under operation, great precautions should be observed. Always remove the electrical cable when cleaning the mixer or doing other work with the inner part of the cylinder or the grinder. The stop-time for the mixer is 1-2 seconds at 3000 rpm and 2-3 seconds at 7000 rpm, Do not open the top or touch moving parts until the mixer is completely stopped. lf the mixer continuous to operate after a stop, immediately break the electrical current. The mixer must be serviced before it can be used again. The mixer has all electronic overloading protection. If the grinder stops by itself in the middle of homogenizing, the overloading protection has been tripped. Measures: Turn off the mixer using the switch on the rear panel. Remove the electrical cord. Do not attempt any work on the mixer before the electrical connection is broken. If not the directions are followed, the manufacturer takes no responsibility for any injuries or damages. When the circuit breaker at the back panel is off-due to an emergency stop, wait at least ten minutes before reinstating the current. Inspect instrument and identify the reason for the emergency stop (see below under trouble – shooting) Hearing protectors are recommended since the noise level is > 70 and < 80 dB(A). The manufacturer and distributors take no responsibility for injuries damages if the instrument is used for purposes other than those outlined in Intended Use. Copyright Delta Instruments Page 4 of 7 Cheese Mixer User guide Steps before starting the mixer: Steps before starting the mixer: Ensure the tightening screws are properly tightened. Ensure the cylinder and the top of the cylinder are well-cleaned. Ensure all samples and dissolving solutions are prepared and ready for use. Ensure desired settings are chosen. Homogenizing of samples Personal safety precautions When alkaline solutions are used with the Cheese mixer observe special precautions. The flamepoint for the solutions is t-25⁰C (IEC 1010-l; 9.2.2). Safety precautions as outlined for your laboratory should always be followed carefully. General preparation The food samples should be finely chopped, cheese cut into small pieces, deboned meat and fish should be ground. Water-soluble detergents are recommended. Optimal results are reached at a solution temperature of 40-50⁰C. Cooling-water temperature of 40-50⁰C is recommended. Optimal sample volume is 120-150 ml. Maximal volume is 250 ml. Optimal time for homogenizing is 45-60 seconds. lf the cooling-water not is connected maximal time is three minutes. The timer should thus be set between 0-3 minutes. When homogenizing for longer periods, without the water cooling, stop after three minutes, then wait 30 seconds, then continue for a further three minutes. lf the mixer homogenizes continuously for longer periods without water cooling, there is a risk that the solution will boil. The recommended rpm is 7000 rpm/minute. Adjust the frequency knob on the back panel of the instrument turning the knob completely clockwise. Procedure Weigh the sample so that the desired dilution can be obtained. For example a 1 - l 0 ratio will include 12-gram sample mixed with 108 grams dissolver. Turn off the draining spigot (8) (turn to the right). Set the vibration plug (9) in place. Set the timer (1 0). Add the sample. Place the plug (5) in the pipe (4). Make certain the vibration plug does not block the ventilation hole. Otherwise, pressure will not be reduced. However with a detergent that generates much foam, the ventilation hole should be completely covered. Place the top (3) on the Cylinder and make sure the circuit breaker (6) is in the proper position Turn on the machine (1 l ) and homogenize the sample during the desired time. When the machine stops, Carefully open the plug on the top (5). The pressurized foam can explode through the ventilation hole. This is specially important when working with alkaline solutions. Add two drops of antifoam solution and run the sample 3-5 seconds longer. Copyright Delta Instruments Page 5 of 7 Cheese Mixer User guide When working with different dissolving solutions ensure following the directions at your laboratory. Use eye protectors, gloves and protective clothing. lf the ventilation hole has been covered observe greatest caution since a pressure may have been created in the cylinder As a precaution, hold a piece of paper over the ventilation hole and open the cover slowly so the pressure can be equilibrated. If liquid is spilled on the mixer, dry immediately with a dry rag. Wait 5-10 seconds after the mixer has stopped before opening the top. Examine the underside of the top and make sure no traces of suspension remain. During repeated runs, the instrument may overheat. Immerse the cylinder in cold water The temperature in the cylinder should not exceed 60⁰C. Carry out the analyses according to the recommendation for the specific analytical instrument and method . After homogenizing When cleaning the instrument the electrical cable should be removed and the power supply shut off. Shut and disconnect the cooling-water. Troubleshooting The cylinder has become overheated. Overheating of the inner parts of the mixer. Incorrect volume of the sample solution. The sample preparation is not suitable for homogenizing. Care of the instrument Before every new operation, check that all parts are clean and in working order. Damaged parts may cause accidents The rubber packing on the top (3), the plug (5), the vibration plug (9) and under the cylinder (1) should be lubricated frequently with paraffin oil. Use only solvents adapted for the instrument. The bars in the cylinder will be damaged by weak or strong acids, oxidizing acids hydrogen fluoride, esters, ketones, hydrocarbons or petrol. Flammable solvents may never be used when homogenizing samples with the Cheese mixer The mixer should be cleaned using weak detergents. The mixer should never be rinsed cleaned under running water. When washing, use a damp rag. Service Only trained personnel should service the mixer. Use only original parts for replacement. Screws, washes and other parts should only be replaced by the same type and the same dimension. The screws in the chassis should never exceed 12 mm. All electrical service should be done by a certified electrician. The safety fuse is placed down to the left just above power in. Only safety fuses of the same type and voltage should be used, i.e. T 6.3 A 250 Vac. if another type of safety fuse is used the manufacturer and distributor will not take any responsibility for fire or other Copyright Delta Instruments Page 6 of 7 Cheese Mixer User guide Technical specification damages that may occur. Spare parts can be ordered from the manufacturer. Change of spare parts should be done according to the manufacturers' directions. Technical specification Dimensions (lxwxh): Weight: Rotations: Decibel level: 41 0x 295 x 3 80 mm. 23,5 kg Rotations are adjustable between 3000 and 7000 rpm < 80 dB(A) Feeding ~ Mains voltage: 220-230 ( ) +- 10% Mains frequency: 50/60 Hz, +- 2% Power consumption: 5.7 A Safeties fuse: T 6.3 A 250 Vac IP class according to IEC 529: IP30 Operating conditions : Temperature of environs: Storing temperature: Relative humidity: Ventilation: +5⁰C to +30⁰C. The mixer shall never be placed in direct sunlight or close to any source of heat. -40⁰C to + 50⁰C max 80% RH up to 31⁰ C linear decreasing to 50% at 40⁰C Ensure proper ventilation around the instrument Fulfilled standards: LVD directive: EMC directive: Machine directive: Electrical security: 73/23/EEC 89/336/EEC 89/392/EEC EN 61010-1 (Class I, Over voltage Cat. II, Pollution deg. 2) General emission standard: EN 50081 -1 Standard and level EN 5501 l group l , Class B and EN55022 Class B General durability standard: EN 50082-1 ESD 1EC1000-4-2, level 3 Rapid transients IEC1000-4-4, level 3 Field strength: IEC 80l-3,>3V/m, Copyright Delta Instruments Page 7 of 7