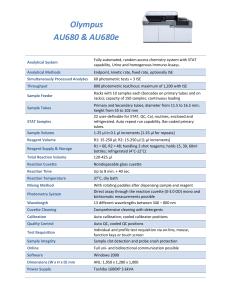

High Technology, Inc. 109 Production Road, Walpole MA 02081 USA Automatic Chemistry Analyzer HTI BioChem FC-360 Operator’s Manual Document Number Revision Level Effective Date : : : OM-E-FC-360-30 Rev. 3 8/15/2016 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Contents INTENDED USE ........................................................................................................................................................ 1 1 TRANSPORTATION, STORAGE AND UNPACKING ...................................................................................... 4 TRANSPORTATION AND STORAGE ....................................................................................................... 4 UNPACKING INSTRUCTIONS .................................................................................................................. 5 2 INSTALLATION ................................................................................................................................................. 7 ELECTRICAL REQUIREMENTS ............................................................................................................... 7 DIMENSIONS............................................................................................................................................. 7 ENVIRONMENTAL REQUIREMENTS ...................................................................................................... 8 MOVING THE INSTRUMENT .................................................................................................................... 8 PC MINIMUM REQUIREMENTS ............................................................................................................... 8 INSTRUMENT PLACEMENT AND PREPARATION ................................................................................. 8 WIRES AND TUBING CONNECTION ....................................................................................................... 9 Washing solution .............................................................................................................................. 11 2.7.1.1 2.7.1.2 Washing solution for probe and cuvettes ..................................................................................................................... 11 Washing solution for probe and cuvettes when running turbidimetric methods ......................................................... 12 INSTALLATION ........................................................................................................................................ 12 PC configuration ............................................................................................................................... 12 2.8.1.1 Install analyzer software. .............................................................................................................................................. 12 Analyzer setup.................................................................................................................................. 13 3 ANALYZER TECHNICAL SPECIFICATIONS ................................................................................................ 14 GENERAL SPECIFICATIONS ................................................................................................................. 15 SAMPLE/REAGENT TRAY...................................................................................................................... 15 CUVETTES/REACTION TRAY ................................................................................................................ 15 DISPENSING ARM AND HYDRAULIC SYSTEM.................................................................................... 16 CUVETTE WASHER ................................................................................................................................ 16 PHOTOMETER ........................................................................................................................................ 16 ISE MODULE (OPTIONAL) ..................................................................................................................... 16 SOFTWARE ............................................................................................................................................. 17 POWER REQUIREMENT ........................................................................................................................ 17 DESCRIPTION OF ELECTRONIC CIRCUITS ........................................................................................ 17 TYPES OF SAMPLES ............................................................................................................................. 18 TYPES OF REACTIONS ......................................................................................................................... 18 TYPES OF METHODS ............................................................................................................................ 18 4 GENERAL FUNCTIONS .................................................................................................................................. 18 MAIN PARTS OR MODULES .................................................................................................................. 18 Sample/Reagent Tray ...................................................................................................................... 19 Dispensing Arm and Probe .............................................................................................................. 20 Cuvette/Reaction Tray ..................................................................................................................... 20 Cuvette Washer................................................................................................................................ 22 Hydraulic System ............................................................................................................................. 23 Optical System ................................................................................................................................. 24 ISE Module (Optional) ...................................................................................................................... 25 DESCRIPTION OF THE OPERATING CYCLE ....................................................................................... 25 Reaction Preparation Cycle ............................................................................................................. 26 Incubation and Reading Cycle ......................................................................................................... 26 Cuvette Washing Cycle .................................................................................................................... 26 ISE processing cycle (Optional) ....................................................................................................... 26 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL I Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 5 BASIC OPERATIONS ..................................................................................................................................... 27 INITIAL CONFIGURATION OF THE PROGRAM .................................................................................... 27 DAILY OPERATION ................................................................................................................................. 27 PROGRAMMED MAINTENANCE ........................................................................................................... 28 6 SOFTWARE TABS .......................................................................................................................................... 29 MAIN WINDOW OF THE SOFTWARE .................................................................................................... 29 OPERATIONS TAB .................................................................................................................................. 30 REAGENTS TRAYS TAB ........................................................................................................................ 33 Reagent position .............................................................................................................................. 33 PAT RESULTS TAB ................................................................................................................................. 35 Patient results search ....................................................................................................................... 37 Advanced search .............................................................................................................................. 40 CAL RESULTS TAB ................................................................................................................................. 44 CON RESULTS TAB ................................................................................................................................ 45 SAMPLE POSITIONS TAB ...................................................................................................................... 47 7 OPERATIONS MENU ...................................................................................................................................... 48 ADD SAMPLES AND METHODS ............................................................................................................ 48 Add Sample ...................................................................................................................................... 49 7.1.1.1 Add Patient ................................................................................................................................... 50 7.1.1.2 Add Calibrator .............................................................................................................................. 52 7.1.1.3 Add Control .................................................................................................................................. 52 Add Methods .................................................................................................................................... 53 MODIFY SAMPLE .................................................................................................................................... 54 DELETE SAMPLES AND METHODS...................................................................................................... 55 Delete Sample .................................................................................................................................. 56 Delete Selected Method ................................................................................................................... 57 PENDING: SAVE, LOAD AND IMPORT PENDING REQUESTS ........................................................... 58 Save Pending ................................................................................................................................... 59 Load Pending ................................................................................................................................... 59 Import from CSV............................................................................................................................... 60 SAMPLES TO TRAY ................................................................................................................................ 60 SAMPLES TO TRAY (BARCODE) (OPTIONAL) ..................................................................................... 63 WASH CUVETTES .................................................................................................................................. 67 START ...................................................................................................................................................... 68 STOP ........................................................................................................................................................ 69 PAUSE ..................................................................................................................................................... 69 PRINT RESULTS ..................................................................................................................................... 71 REPEAT RESULTS ................................................................................................................................. 74 RELOAD SAMPLES ................................................................................................................................ 75 EXPORT RESULTS ................................................................................................................................. 75 8 METHODS MENU ............................................................................................................................................ 76 SETTINGS: METHODS CONFIGURATION ............................................................................................ 76 General Tab ..................................................................................................................................... 77 Factor Tab ........................................................................................................................................ 79 Reference Values Tab...................................................................................................................... 82 Specials Tab ..................................................................................................................................... 83 8.1.4.1 End Point Reagent Blank ............................................................................................................. 83 8.1.4.2 End Point Sample Blank .............................................................................................................. 85 8.1.4.3 Kinetics ......................................................................................................................................... 87 8.1.4.4 Fixed Time Kinetics ...................................................................................................................... 89 Advanced tab ................................................................................................................................... 91 ISE METHODS SETTINGS (OPTIONAL) ................................................................................................ 94 II HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 General Tab (ISE) ............................................................................................................................ 94 Factor tab (ISE) ................................................................................................................................ 96 Special Tab (ISE) ............................................................................................................................. 97 Advanced tab (ISE) .......................................................................................................................... 98 REAGENTS IN USE AND PROFILES ................................................................................................... 100 SAVING METHODS ............................................................................................................................... 101 LOADING METHODS ............................................................................................................................ 102 SAVING PROFILES ............................................................................................................................... 103 LOADING PROFILES ............................................................................................................................ 103 9 CALIBRATORS MENU ................................................................................................................................. 104 SETTINGS ............................................................................................................................................. 104 SAVING CALIBRATORS FILES ............................................................................................................ 106 LOADING CALIBRATORS FILES ......................................................................................................... 106 10 CONTROLS MENU ................................................................................................................................... 106 SETTINGS ............................................................................................................................................. 107 SAVING CONTROLS FILES.................................................................................................................. 108 LOADING CONTROLS FILES ............................................................................................................... 108 11 STATISTICS MENU ................................................................................................................................... 108 LEVY-JENNINGS OF PATIENTS .......................................................................................................... 108 LEVY-JENNINGS OF CALIBRATORS .................................................................................................. 110 LEVY-JENNINGS OF CONTROLS........................................................................................................ 111 QUALITY CONTROL ............................................................................................................................. 112 12 MAINTENANCE MENU ............................................................................................................................. 115 SETTINGS ............................................................................................................................................. 116 Serial Port Tab ............................................................................................................................... 116 Files Tab ......................................................................................................................................... 116 Database Tab ................................................................................................................................. 118 Ages Tab ........................................................................................................................................ 120 Reports Tab.................................................................................................................................... 121 Memory Tab ................................................................................................................................... 123 Language/ Style Tab ...................................................................................................................... 124 Access Control Tab ........................................................................................................................ 125 CUVETTES STATUS ............................................................................................................................. 125 CONTAINERS STATUS ........................................................................................................................ 127 PROGRAMMED WASHING .................................................................................................................. 127 TIP CLEANING ...................................................................................................................................... 128 COMMUNICATIONS .............................................................................................................................. 129 Commands Console ....................................................................................................................... 129 Serial Port Log................................................................................................................................ 130 VALIDATIONS........................................................................................................................................ 131 Stray Light ...................................................................................................................................... 132 Photometer Precision ..................................................................................................................... 133 Photometric Accuracy .................................................................................................................... 134 Photometric Linearity ..................................................................................................................... 135 6. Select Maintenance Validations Photometric Linearity Cuvette Number OK .............. 135 Diluter Precision ............................................................................................................................. 137 Precision test P150 and P250 ........................................................................................................ 139 12.7.6.1 P150 Method .............................................................................................................................. 141 12.7.6.2 P250 Method .............................................................................................................................. 143 INSTRUMENT ........................................................................................................................................ 145 Calibration ...................................................................................................................................... 145 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL III Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 12.8.1.1 Photometer calibration ............................................................................................................... 145 12.8.1.2 Cuvettes calibration .................................................................................................................... 146 Diluter purge ................................................................................................................................... 146 Washer purge ................................................................................................................................. 147 Initialize .......................................................................................................................................... 147 ISE (Optional) ................................................................................................................................. 147 12.8.5.1 Start up ....................................................................................................................................... 148 12.8.5.2 Calibrant A purge ....................................................................................................................... 149 12.8.5.3 Calibrant B purge ....................................................................................................................... 149 12.8.5.4 Calibration .................................................................................................................................. 149 12.8.5.5 Clean .......................................................................................................................................... 150 12.8.5.6 Pumps Calibration ...................................................................................................................... 150 12.8.5.7 Bubble Sensor Calibration ......................................................................................................... 151 12.8.5.8 Electrode replacement ............................................................................................................... 151 12.8.5.9 Reagent Kit Replacement .......................................................................................................... 152 12.8.5.10 Reconnect .............................................................................................................................. 153 13 ADVANCED OPERATIONS ...................................................................................................................... 153 CONFIGURATION OF THE PRINTING FORMATS .............................................................................. 153 FILE EXCHANGE................................................................................................................................... 156 IMPORTING SAMPLES FROM AN ADMINISTRATION PROGRAM ................................................... 156 EXPORTING RESULTS TO THE ADMINISTRATION PROGRAM ...................................................... 157 DETERMINATION OF PRECISION OF AN ANALYTIC METHOD ....................................................... 161 DIRECT READING OF THE SOLUTION ABSORBANCE..................................................................... 161 14 ISE MODULE: DESCRIPTION AND OPERATION (OPTIONAL) ............................................................ 163 ELECTRODES ....................................................................................................................................... 164 FLUID MANAGEMENT .......................................................................................................................... 165 SAMPLE TYPE ...................................................................................................................................... 165 Sample Handling and Collection .................................................................................................... 166 14.3.1.1 Serum ......................................................................................................................................... 166 14.3.1.2 Plasma ....................................................................................................................................... 166 14.3.1.3 Urine Samples ............................................................................................................................ 166 14.3.1.4 Matrix Effects.............................................................................................................................. 166 Reagent Kit Electronic Key ............................................................................................................ 167 SAMPLE ASPIRATING AND DISPENSING .......................................................................................... 167 CALIBRATION CYCLE .......................................................................................................................... 167 CLEAN CYCLE ...................................................................................................................................... 169 PURGE A CYCLE .................................................................................................................................. 169 PURGE B CYCLE .................................................................................................................................. 169 SIP CYCLE ............................................................................................................................................. 169 OFF CYCLE (UNDER ELECTRODE REPLACEMENT COMMAND) ............................................... 169 PUMP CALIBRATION CYCLE ........................................................................................................... 170 BUBBLE CAL CYCLE ........................................................................................................................ 170 MAINTENANCE ................................................................................................................................. 170 Before starting daily operation ................................................................................................... 170 Daily Maintenance ...................................................................................................................... 170 Shutdown Procedure .................................................................................................................. 171 ISE Module re-activation ............................................................................................................ 171 ISE TROUBLESHOOTING ................................................................................................................ 171 IV HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 15 MAINTENANCE PROGRAM ..................................................................................................................... 175 DAILY MAINTENANCE .......................................................................................................................... 175 Before starting daily operation ....................................................................................................... 175 Maintenance Instrument Diluter Purge ............................................................................................. 175 During the daily operation .............................................................................................................. 176 Upon finishing with the daily operation........................................................................................... 176 WEEKLY MAINTENANCE ..................................................................................................................... 176 MONTHLY MAINTENANCE .................................................................................................................. 176 External washing of cuvettes ......................................................................................................... 176 General cleaning of the instrument ................................................................................................ 177 Back-up of files in use .................................................................................................................... 177 ISE MODULE MAINTENANCE PROGRAM (OPTIONAL) .................................................................... 178 Recommended Component Replacement Schedule (low volume user) ....................................... 178 Recommended Replacement Schedule (high volume user) ......................................................... 178 MAINTENANCE ACCORDING TO PROGRAMMED ALARMS ............................................................ 179 Maintenance Levels according to cycles of use counters .............................................................. 179 Maintenance Level 1 ...................................................................................................................... 179 15.5.2.1 Disinfecting the reagent tray ...................................................................................................... 179 15.5.2.2 Disinfecting the tubing and cleaning of the containers............................................................... 180 15.5.2.3 General cleaning of the instrument ............................................................................................ 180 15.5.2.4 Axes lubrication .......................................................................................................................... 180 15.5.2.5 Cleaning of the washer circuit filter ............................................................................................ 181 15.5.2.6 Replacement of the Teflon seals in the piston pump ................................................................. 181 15.5.2.7 Flushing Pump Membrane replacement .................................................................................... 181 15.5.2.8 Diluter Liquid Diaphragm Pump Membrane replacement .......................................................... 181 Maintenance Level 2 ...................................................................................................................... 181 15.5.3.1 Disinfecting the reagent tray ...................................................................................................... 181 15.5.3.2 Disinfecting the tubing and cleaning of the containers............................................................... 181 15.5.3.3 General cleaning of the instrument ............................................................................................ 181 15.5.3.4 Axes lubrication .......................................................................................................................... 181 15.5.3.5 Cleaning of the washer circuit filter ............................................................................................ 181 15.5.3.6 Replacement of the Teflon seals in the piston pump ................................................................. 181 15.5.3.7 Flushing Pump Membrane Replacement ................................................................................... 181 15.5.3.8 Diluter Liquid Diaphragm Pump Membrane Replacement ........................................................ 182 15.5.3.9 Cuvettes replacement ................................................................................................................ 182 AS NEEDED MAINTENANCE ............................................................................................................... 182 Database Initialization (every 10.000 tests) ................................................................................... 182 Lamp replacement.......................................................................................................................... 183 Cuvettes Replacement (see item 15.5.3.8) .................................................................................... 185 15.6.3.1 Interferential filters replacement ................................................................................................. 185 Sample / Reagent probe replacement ........................................................................................... 185 Replacing the fuses ........................................................................................................................ 189 Special Wash ................................................................................................................................. 189 Replacing O-rings of piston pump .................................................................................................. 189 Replacing filters of washing system ............................................................................................... 189 Electrode replacement (For analyzers with ISE Module installed) ................................................ 190 15.6.9.1 Replacing ISE peristaltic pumps tubing (For analyzers with ISE Module installed) ................... 191 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL V Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 16 PREPARING SOLUTIONS ........................................................................................................................ 191 WASH SOLUTION. ................................................................................................................................ 191 Washing solution for probe and cuvettes ....................................................................................... 191 Washing solution for probe and cuvettes when running turbidimetric methods ............................ 192 TIP CLEANING SOLUTION ................................................................................................................... 192 SPECIAL WASHING SOLUTION FOR MAINTENANCE ACCORDING TO NEED .............................. 192 SPECIAL WASHING SOLUTION FOR TURBIDIMETRIC TECHNIQUES WITH LATEX ..................... 192 DISINFECTING SOLUTION .................................................................................................................. 192 17 TROUBLESHOOTING ............................................................................................................................... 192 INTRODUCTION .................................................................................................................................... 192 CHEMICAL PROBLEMS ........................................................................................................................ 194 High results .................................................................................................................................... 195 Low Results .................................................................................................................................... 196 Erratic Results ................................................................................................................................ 196 Only one affected sample for all of the methods ............................................................................ 197 Only one affected method for all of the samples ............................................................................ 198 INSTRUMENTAL PROBLEMS .............................................................................................................. 199 Connections and supplies .............................................................................................................. 199 Diluter ............................................................................................................................................. 200 Washer ........................................................................................................................................... 200 Sample/reagent probe .................................................................................................................... 200 Reaction Cuvettes Tray .................................................................................................................. 201 Sample/Reagent Tray .................................................................................................................... 201 Software ......................................................................................................................................... 201 HARDWARE MESSAGES ..................................................................................................................... 202 VI HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 INTENDED USE BioChem FC-360 is a photometric analyzer for clinical chemistry, it is meant to perform automated analytic procedures for “in vitro” diagnosis. Terms of use 1. 2. 3. 4. 5. 6. 7. 8. 9. The instrument must be installed by trained personnel. This instrument is Class 1, Type b, IPX0. The instrument must be used by trained personnel Operation room requirements: Room temperature 20-25ºC; Humidity: 20- 85% (no condensation). The instrument must be connected to a supply line according to current national regulations. This instrument must not be used for purposes other than the ones it has been built for. After switching on the instrument, wait 10 minutes before beginning analysis. After powering off, wait at least 20 seconds before restarting. If line variations are higher than 10%, a ferroresonant voltage regulator or a 1500 VA uninterruptible power supply (UPS) is recommended. 10. Read the entire User’s Manual before using the instrument 11. The laboratory must count on a special residues collection service, to handle wastes. 12. Do not discard the analyzer, neither its accessories, along with domestic residues. Check the local terms for its correct elimination. Is the user’s responsibility to deliver the analyzer in the indicated pickup point for recycling of electric and electronic devices, otherwise get in contact with HTI or its authorized agent to proceed to its removal in a safe and ecological way. 13. Use only expendables and spare parts provided by HTI or its authorized agent. 14. If any failure occurs, contact your local authorized technical service dept., or contact HTI. Precautions Electrical Risks As with any electronic equipment, electric shock is always a potential threat. Extreme caution should be used when working around the instrument to avoid contact with any electrical wire or components. DO NOT attempt to work in any electronic compartment while the power is ON. Mechanical Risks Keep lids closed when the instrument is working. Do not touch mechanical arms or other moving parts while the instrument is working. Do not wear rings, bracelets, necklaces, etc. as they may get caught in operating mechanical systems. Do not try to change or touch sample tubes, reagents, etc. when the instrument is running to prevent breakage and/or an accident when the Reagent Sample Tray moves. Make sure that the instrument is paused to add reagents, samples, etc. HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 1 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Chemical risks Always wear protective apparel when operating the analyzer (gloves, safety glasses, etc.). Follow specific recommendations on the bottles of each reagent or washing solution. Read safety information of materials provided by manufacturers to be aware of possible danger and to learn how to prevent it. Biological risks Rings and long nails can easily break gloves and increase exposure to biological risks. Always treat samples and reagents as potentially infectious. Waste and waste deposits must be treated as toxic and biologically hazardous. Handle them and eliminate them in accordance with routine laboratory protocols. Follow in force standards given by local sanitary authority. Eye risks Do not look straight at barcode detector light beams. Do not look straight at the light source of spectrophotometers since they can emit ultraviolet rays. Warnings about the instrument and laboratory practices The use of calibrators is recommended; refer to reagent manufacturer instructions for specific calibration instructions. Symbols used in the manual and the instrument Warning Ground Connection Manufacturing Date Consult instructions for use Biological risk Fuse This symbol denotes the Catalog number Page 2 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 The symbols for “SERIAL NUMBER”, The serial number shall be after or below the symbol, adjacent to it The symbol indicates the manufacturer and its address, after which are shown its name and address This symbol denotes to Consult instructions for use This symbol denotes that this product conforms to the directive 98/79/EC (IVD-directive) The symbol indicates EU representatives of the manufacturer and their addresses, after which are shown their names and addresses The symbol means the product is in vitro diagnostic medical device. Symbols used on the box This means that instrument should handle with care in the course of transportation, so as not to damage it. The symbol means that the environment of instruments must be damp-proof in the course of transport, and instrument must be kept in a dry environment. The symbol indicates temperature range of the analyzers during storage and transportation Warranty Terms HTI warrants the instrument for a period of 12 months as of the date the instrument leaves the factory. This warranty is only effective as long as the pertinent warranty card together with the installation record with all the data is duly completed and sent to us by certified mail. Warning: This warranty only covers defective materials or manufacturing defects, according to examination carried out in the factory and shall be limited to the replacement of defective materials. Accessories which are not provided by HTI, such as: wash solutions, standards, controls, reagents and consumables are not covered by the warranty. Furthermore, costs arising from mishandling the instrument and/or damage to the instrument are not covered by this warranty. This warranty shall not be valid if personnel not authorized by HTI attempt to repair the instrument. WARRANTY SERVICE: Without charge at HTI. Otherwise, transport and traveling expenses of a technician to the place where the instrument is to be repaired shall be paid. HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 3 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 HTI RESERVES THE RIGHT TO MODIFY THE INSTRUMENTS WITHOUT AFFECTING THEIR OPERATING PARAMETERS. NOTE: The following elements are not covered by warranty terms: halogen lamps, fuses, cuvettes, reagents bottles, tubes and tubing. 1 TRANSPORTATION, STORAGE AND UNPACKING Transportation and storage Do not pile up more than four wooden boxes Keep dry, protect from humidity and rain Fragile. Handle with care Store at 0°C – 50°C Move using forklift Page 4 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Unpacking instructions Warning: Unpacking shall be carried out by trained personnel. Carefully unpack the instrument to prevent damage. Labels indicating this operation are found on each side of the packaging box. Figure 1-1 Remove the wooden box lid by unscrewing the eight screws located in the front, back and sides. Figure 1-2 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 5 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 NOTE: Instrument remains fastened to the bottom. Remove the instrument from the bottom of the box as shown in Figure 1-2 and as explained below. On the upper part of the instrument you will find an Allen wrench Nº 6, which will be used to remove the screws joining the bottom to the instrument. Figure 1-3 Unscrew the four screws located on the sides. Figure 1-4 Screws are placed this way: Page 6 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Figure 1-5 Once the screws have been removed and the instrument is released, the protective Styrofoam is removed and the instrument can be placed on the working surface. 2 INSTALLATION Installation must be carried out by trained personnel. Electrical requirements A standard 100 Volts 60 Hz or 220 Volts 50 Hz socket for 400 VA consumption. The supply line has a third terminal to ensure proper ground connection. If line variations are higher than 10%, a ferroresonant voltage regulator, or a 1500 VA uninterruptible power supply (UPS sine wave output) is recommended. Dimensions & Weight Width: 800 mm, Height: 464 mm, Depth: 647 mm Weight: 48kg HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 7 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Environmental requirements Operating temperature: 20°C ~25°C Operating Humidity: 20~85% (no condensation) Storage Temperature: 0°C~50°C Storage Humidity: ≤80% Moving the instrument Avoid hitting the instrument as well as subjecting it to any kind of vibration while moving it. PC minimum requirements 2 GHz Pentium IV RAM Memory, 512 MB Independent video card 40 GB Hard Drive CD Rom CD Reader Windows XP Printer (optional) The PC must comply with safety regulations IEC 60950 and have a certified source. Instrument placement and preparation Warning: Avoid hitting the instrument as well as subjecting it to any kind of vibration while moving it. The instrument must be placed on a counter in a room free from dust and corrosive vapors to ensure its proper operation. The instrument must not be subject to vibrations or sudden changes of temperature. Leave a 20 centimeter separation between the equipment and the wall to ensure proper ventilation. Liquid containers must be under the counter. Avoid collapsing and/or curving of waste exit tubing. Avoid any centrifuge, lifts or x-ray supply lines or any other kind of noise-generating equipment in the supply line. Avoid direct sun light or illumination on the instrument. The supply line has a third ground conductor for protection purposes. Page 8 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Connect the instrument to the computer and its peripherals before connecting to the supply line. If the above requirements are not met, the quality of results may be affected. Warning: Make sure that ground connection in the line meets the standard requirements for its operating power. Not performing ground connection poses significant safety risk for the operator and may damage one or several parts of the equipment or the computer. Warning: Waste solution tubing must be placed correctly so that it drains by gravity. They must not be curved and/or collapsed. Warning: The instrument must be connected to a PC which meets the requirements previously mentioned. Warning: The instrument has been tested with a tensioactive solution which is added to the distilled water. Not using or altering the product or its dilution will affect the operation of the instrument. Wires and Tubing Connection Figure 2-1 1. Connect the interlock to 100~220V, 50~60Hz supply. If line variations are higher than 10%, a ferroresonant voltage regulator or a 1500 VA uninterruptible power supply (UPS sine wave output) is recommended. 2. Connect the RS-232 wire to the PC before switching on the instrument. For analyzers with ISE Module installed continue with step (3). Otherwise go to step (8) 3. Connect the ISE module connector to the reagent Kit. 4. Remove all electrodes from sealed bags. 5. Remove tape from K+ and Li+ electrode. HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 9 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 If necessary, soak the reference electrode in warm water until the lumen of the electrode has been cleared of salt build-up. 6. Depress the compression tray to install electrodes in position (as shown in Figure 2-2) Figure 2-2 7. Press the lock stick and move down the ISE module to put in place Warning: Do not turn off the analyzer by pressing general button unless maintenance cycle has been done and electrodes removed. NOTE: ISE module must be power on all time that the electrodes are in it. Purge cycles are performed by the ISE module automatically every 30 minutes. 8. Connect tubing to the appropriate containers. Page 10 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Figure 2-3 Warning: The tubing with the biggest diameter (waste funnel) must be kept straight downwards without curves to allow free drain of fluids. Washing solution Warning: Containers must be placed under the analyzer. Warning: Container must not be placed on the same analyzer level. 2.7.1.1 Washing solution for probe and cuvettes First wash concentrate solution has to be prepared from Triton X-100 Solution. Then, use wash concentrate solution to prepare washing solution for probe and cuvettes. Wash Concentrate: dilute 1 part v/v of Triton X-100 in 9 parts of distilled water, Ex: 100 ml Triton X100 in 900 ml of distilled water. The Triton X-100 is extremely viscous. It is suggested to pour the desired quantity into a graduated cylinder and gradually add the water. Heat the distilled water to 70 – 80 ºC to help dissolve the Triton X-100. Washing solution for probe and cuvettes: dilute 7 ml of wash concentrate in 1 liter of distilled water. Ex: 140 ml of wash concentrate per 20 liters of distilled water. HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 11 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 2.7.1.2 Washing solution for probe and cuvettes when running turbidimetric methods In those cases where latex reagents are used (most turbidimetric methods), is highly recommended to use the following washing solutions: Washing solution for probe: use only DI water Washing solution for cuvettes: dilute 3 ml of wash concentrate in 1 liter of distilled water. Ex: 70 ml of wash concentrate per 20 liters of distilled water. Warning: not following the instructions given above will affect the results. Installation PC configuration Open Control Panel Display Settings into Screen Resolution field set 1024x768 pixels Control Panel Date and Time Internet Time unselect Automatically synchronize with an Internet time server Uninstall antivirus Uninstall screensaver 2.8.1.1 Install analyzer software. 1. Open “Computer”. 2. Find the device where the software installer is. 3. Double Click on the analyzer software installer executable. 4. Press Next to continue with the installation or Cancel to exit. 5. Choose between “Everyone and Just Me” option (see NOTE). 6. Press Next to continue with the installation or Cancel to exit. In this step the file folder path can be changed. 7. Press Next to start installation process. 8. Press Close to close the window. NOTE: “Everyone” option means that the software will be installed in all the user accounts existing at the moment of installation. “Just Me” option means that the software will be installed in the account that the installer is being executed (if a new account is created then the analyzer software must be installed in the new account). If “Just Me” option is chosen the other users cannot use analyzer software, unless they install the analyzer software too, but they have to change the path of all the files when the software is being installed. Maintenance Settings Files tab: all path must be changed for a different location in this user account. 9. Open analyzer software from desktop. Page 12 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Analyzer setup Place the cuvettes in the reaction tray. Warning: Do not touch the external surface of the cuvette. Warning: avoid dropping the metal nuts into the interior of the instrument during this procedure. Turn on the instrument by the General Power button in the back of the analyzer, and then by pressing the Power button in the frontal panel from the analyzer (lower button) the button in the middle of the frontal panel turns on/off the reagents cooling system. Let the instrument warm up for ten minutes. NOTE: ISE module must be power on all time that the electrodes are in it (General Power button in the back of the analyzer must be ON) Purge cycles are performed by the ISE module automatically every 30 minutes. 10. 11. Run several diluter purge cycles, visually checking that there are no bubbles present in the diluter’s body (Maintenance Instrument Diluter Purge) Run several wash cycles with the first 10 cuvettes, verifying the flow of wash solution into the cuvettes and that there is no overflow. (Operations Wash cuvettes Cuvette range 1 to 12 Wash Warning: during this procedure visually check the wash station; if due to the great amount of air there is overfilling of the cuvettes, it’s advisable to remove the affected strips and wash with plenty DI water, dry the outside gently with a tissue, and put back on the strips. Verify this before moving on to the next step. 12. 13. 14. Wash all cuvettes (Operations Wash cuvettes All cuvettes Wash) Run two diluter purge cycles (Maintenance Instrument Diluter Purge) Calibrate the photometer and all the cuvettes (Maintenance Instrument Calibration select Calibrate photometer select Calibrate cuvettes Range 1 to 100 >select the position of the solution to use ex: Use container OK) HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 13 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 For instruments that don’t have ISE Module installed, the analyzer is now ready to use. Otherwise go to step 15. 15. 16. 17. 18. 19. 20. Run Reagent Kit Replacement command. (Maintenance Instrument ISE Reagent Kit Replacement) Run Calibrant A and B purge if necessary. (Maintenance Instrument ISE Calibrant A Purge/Calibrant B Purge) Run Bubble Sensor Calibration. (Maintenance Instrument ISE Bubble Sensor Calibration) Allow the electrodes to be exposed to fluid for 15 minutes. Run Calibration command (Maintenance Instrument ISE Calibration) Instrument is ready to use. Warning: Do not turn off the analyzer by pressing general button unless maintenance cycle had been done and electrodes removed. NOTE: ISE module must be power on all time that the electrodes are in it. Purge cycles are performed by the ISE module automatically every 30 minutes. 3 ANALYZER TECHNICAL SPECIFICATIONS Figure 3-1 Page 14 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 General specifications Average throughput with ISE: 450 test/hour Average throughput without ISE: 300 test/hour Automatic: Sample and reagents are taken and dispensed without the user's intervention. This also applies to the reading of reactions. Random access: Processing order is determined by the user and may be interrupted to allow the input of stats. Discrete: The reaction takes place in the same cuvette in which the reading will be performed. The use of separate cuvettes for every reaction reduces crossover contamination among samples. The Analyzer has 100 cuvettes for the reactions and readings to be carried out. Cuvettes are continuously and automatically washed by the instrument while it is running, as required by dispensing. Photometric: The Analyzer uses 10 optical filters. An eleventh filter may be added. Sample/Reagent Tray Number of positions for reagent bottles: 30 positions for single or double-reagent bottles, allowing 60 reagents. Volume of bottles: Single-reagent bottles 60ml, double-reagent bottles 28ml and 31ml. Number of positions for samples: Physical capacity for 60 tubes or sample cups. Positions become available and new samples can be added after the readings of the programmed methods have been completed. 12 or 13 x 75mm primary tubes, test tubes and/or sample cups may be used. Refrigeration of reagent tray is operated independently from main power switch. Bar-code ID samples reader: Optional Cuvettes/Reaction Tray Number of cuvettes: 100 PMMA cuvettes placed in 10 different segments. Reaction volume: minimum reading volume: 220 µl; maximum reaction volume (physical capacity of the cuvette): 600 µl Incubation: warm air thermal incubation Working temperature: 37ºC HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 15 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Dispensing Arm and Hydraulic System Samples and reagents preheated to 37ºC. High precision diluter Maximum aspiration volume: 500 µl (physical capacity of the diluter) Internal and external washing of the probe through liquid diaphragm pump Volume detection Probe impact sensors Cuvette washer Water consumption: 2.4 ml/cuvette Uninterrupted washing and drying of cuvettes as required by dispensing or maintenance process. Photometer Interferential filters: 340, 380, 405, 450, 505, 546, 578, 600, 650 and 700 nm and an extra filter as optional Krypton-halogen lamp: 12 volts 20 watts Optical path: 6 mm Photometric range: -0.100 to 3.600 A. Type of measurement: monochromatic and bichromatic ISE module (optional) Electrodes: four ion-selective electrodes Li+, Na+, K+, Cl- and one Reference electrode Peristaltic pumps: three Reagent Kit: Calibrant A, Calibrant B, Waste storage. Page 16 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Software Easy access menu, with buttons and icons. Continuous loading of patients, calibrators, controls and reagents during work sequence. Stat samples Unlimited number of methods in memory Statistics for controls, calibrators and patients Levy-Jennings plots Linear and nonlinear multipoint calibration Interpolation and adjustment of curves Calibration curve graph Extra washing option to avoid interference and self-interference Automatic sample re-dilution Verification of reagent condition Data import and export to interface with administration program Reagent consumption statistics Print outs of technical reports and patient reports QC graphics Power requirement 100~240V and 50-60Hz <400 VA Description of electronic circuits The Analyzer is a completely micro-controlled instrument. The fundamental concept regarding its operating way is that it carries out commands it receives through communication port. These commands are simple operations sent by the user’s software on a PC, and the instrument decides when they are to be carried out. In order to carry out all the commands received from the PC, the Analyzer has thirteen microcontrollers. The main microcontroller receives commands through the communication port and it sends the operations that correspond to the other twelve microcontrollers. Within the other microcontrollers, there are seven whose function is to operate the seven engines in the instrument, two which control temperature and three which communicate with internal devices of the instrument. The Analyzer has four power supplies: a 24 Volt power supply that provide power to the power circuits; a ±15 Volt power supply for supplying power to the lamp and the analogical circuits; a 15 Volt power supply for the refrigerated tray, a 24 Volt power supply with output of 24 volt for the ISE module and 5 volt for digital circuit. HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 17 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Types of Samples The samples to be analyzed may be: Plasma Serum Whole blood Urine Spinal Fluid Puncture Fluid Different biological fluids Chemical solutions Types of Reactions End point reagent blank End point sample blank Kinetics Fixed time kinetics Ion Selective Electrode (ISE) (Optional) Types of Methods Colorimetric Kinetics Turbidimetric Ion Selective Electrode (ISE) (Optional) 4 GENERAL FUNCTIONS Main parts or modules BioChem FC-360 Auto analyzer can be divided into the following main parts: Sample/ Reagent Tray Dispensing Arm and Probe Cuvette/Reaction Tray Cuvette Washer Hydraulic System Optical System ISE module (optional) Page 18 of 217 OM-E-FC-360-30 Revision Level HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Sample/Reagent Tray Figure 4-1 This tray can hold up to 60 refrigerated reagents, in 30 tray positions. Each reagent bottle can be single or double-mouthed. Only one tray position is occupied in methods with two reagents. The normal operating temperature of the reagent tray is 15ºC below room temperature, i.e. if room temperature is 25ºC, then the reagent temperature is 10ºC. The minimum temperature of the reagent tray is 10ºC; refrigeration is interrupted below that limit. The refrigeration system has a separate power on/off button The Sample/Reagent tray can hold up to 60 samples in one loading. The software allows the continuous loading of samples once the requested tests have been finished. Primary tubes can be used since the capillary of the probe only reaches 1 mm below the sample level. This increases laboratory biosafety. Cups for pediatric samples can also be used. HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 19 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Dispensing Arm and Probe Figure 4-2 The dispensing arm transports the reagents and samples through the probe to a cuvette in the reaction tray. Reagents and samples are preheated in this arm before being dispensed. The probe has a conductivity detection system. When the probe is 1 mm below the surface of a conductive liquid, it stops its movement. Due to this characteristic, it is important that samples do not have bubbles since the level would be detected and only air would be aspirated, producing an inaccurate result. It is also essential that samples are free of clots and fibrin. Cuvette/Reaction Tray Page 20 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Figure 4-3 This is where the reactions are carried out and read. It has 100 separate cuvettes, grouped in 10 strips of 10 cuvettes. The cuvettes are made of PMMA, which allows a good transmittance in the UV range. The tray is heated by an air bath to 37ºC. All reactions are carried out at 37ºC. Each cuvette has a minimum reading volume of 220 µl, and a maximum reaction volume (physical capacity of the cuvette) of 600 µl. HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 21 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Cuvette Washer Figure 4-4 Its function is to wash cuvettes once the reactions have been measured. This washing is also performed as required by dispensing: each time a new sample is dispensed by the probe, the washing system operates, and cuvettes are washed automatically and sequentially. The washer is divided into 4 double capillaries: one to aspirate, another to dispense liquid, and two drying capillaries. They carry out the cuvette washing and drying process. Washers: Four stainless steel capillaries which aspirate and dispense washing solution. The first capillar will aspirate the pure reaction. Dryers: Two stainless steel capillaries covered with silicone tubing that are placed on the left of the cuvette washer to dry the cuvettes which have already been washed. They work with two separate pumps. Each cuvette is washed by 2400 µl. This circuit operates sequentially, acting on the cuvette to be cleaned in six stages: In the first stage, the reaction liquid is aspirated and wash solution is dispensed into the cuvette. In the second, third and fourth stages; the wash solution dispensed in the previous stage is aspirated and new wash solution is dispensed. In the fifth stage, the wash solution dispensed in the fourth stage is aspirated, leaving the cuvette empty. In the sixth stage, the final drying is done, and the residual wash solution remaining from the previous stage is completely removed. Page 22 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Hydraulic System Figure 4-5 Its main components are the liquid diaphragm pump, the solenoid valve and the diluter, the washing station and the tubing that connects the wash solution container to the probe. The diluter aspirates the reagent and a sample volume required, and dispenses them into the reaction cuvette. The liquid diaphragm pump conveys the wash solution from the wash solution container to the end of the probe capillary. This allows the washing and purging of the tubing, the diluter and the probe. It is important to highlight that reagents never reach the diluter’s body. HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 23 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Optical System Light source: a 12-Volt 20-Watt krypton-halogen lamp is used which has a high emission in the UV range (320 nm-380 nm) Collimating lenses: 3 plane-convex lenses are used. Wavelengths: 340-380-405-450-505-546-578-600-650 and 700 nm and an extra filter as optional. Beam splitter: Divides the primary beam into two secondary beams: one goes towards the sample channel and the other goes to the reference channel. Sample channel: The sample channel beam passes through the cuvette to the sample photosensor, where the signal is read. Reference channel: The reference channel beam is read by the reference photosensor. The reference channel compensates possible light source fluctuations. Photometric Graph Figure 4-6 1. 2. 3. 4. 5. 6. 7. 8. Page 24 of 217 Lamp Plane-convex lens Stopper Filter wheel Beam splitter Sample cuvette Sample photosensor Reference photosensor HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 ISE Module (Optional) Figure 4-7 ISE Module includes ion selective electrodes and three peristaltic pumps. The ISE module measures the concentration of Li+, Na+, K+, Cl- in serum, plasma, and diluted urine. The module requires a minimum sample size of a 70 µl for serum samples and 140 µl for urine samples (urine samples must be diluted 1 urine part + 9 urine diluent part) Description of the Operating Cycle The operating cycle can be divided into four parts: Reaction Preparation Cycle Incubation and Reading Cycle Cuvette Washing and Reaction Dispensing Cycle ISE processing cycle HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 25 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Reaction Preparation Cycle The dispensing arm moves to the sample/reagent tray, and the probe places itself over the reagent to be aspirated. The arm lowers until the sensor of the probe finds liquid level and it aspirates the programmed reagent volume. The arm moves to the wash station, and the external washing of the probe capillary is carried out. The arm moves to the sample/reagent tray and it places itself over the sample to be aspirated. The arm lowers until the sensor of the probe finds liquid level and it aspirates the programmed sample volume. The arm moves to the cuvette/reaction tray and places itself over the cuvette where the reaction is going to be dispensed. It dispenses the sample and the reagent together. The dispensing arm moves to the washing station, and the internal washing of the tubing and the probe is carried out by the liquid diaphragm pump. Incubation and Reading Cycle In this cycle, incubation and photometric readings of the reaction are carried out at the appropriate wavelengths. The incubation and reading cycle occurs while a new reaction preparation cycle is beginning. Cuvette Washing Cycle While the cuvette tray is stopped and the next reaction is being dispensed, the cuvettes where reactions have already been measured are washed. As this is a continuous cycle, clean cuvettes will always be available and there is no need to interrupt the process. ISE processing cycle (Optional) The sample is aspirated by the analyzer from a sample cup and dispensed into the sample entry port on top of the ISE Module. The sample is then positioned in front of the electrodes for measurement. Four solutions are required to operate the ISE Module: Calibrant A, Calibrant B, Cleaning solution and Diluent for Urine samples. Page 26 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 5 BASIC OPERATIONS In this chapter, the necessary steps for operating the instrument are described, including initial configuration, daily operation and programmed maintenance. Initial configuration of the program Before beginning with the operation of the equipment, it is necessary to configure the following items: 1. Methods (Methods Menu) a) Settings b) Reagents in use and Profiles 2. Calibrators (Calibrators Menu) 3. Controls (Control Menu) 4. Reagent Tray (Tabs) Each of these steps is explained in the corresponding chapter. The methods configuration is run according to the instructions given by the reagent manufacturer and by following the guidelines in this manual. It is recommended to verify each configured method before reporting the patients’ results (Advanced Operations) Daily operation For the daily operation, follow the steps below: 1) 2) 3) 4) 5) Turn on the instrument by pressing analyzer frontal panel button and let it warm up for 10 minutes. Prepare the wash solution and place it in wash solutions containers (Maintenance Program). Empty the waste container. Purge the diluter 2 times. Wash the first 10 cuvettes. For analyzer with ISE Module follow the steps below. Otherwise go to step 7. 6) Run Start up commands for ISE module. 7) Verify macroscopically the absence of impurities and/or precipitates in the reagents bottles. 8) Check the reagent volume to be used, refill reagents if necessary. 9) Calibrate the methods to be used, verifying reagent blanks. 10) Verify calibration by running QC material. The use of two levels is recommended. 11) Enter the samples to be processed. 12) Send the entered samples to tray. 13) Run the programmed washing each time the “Programmed Process” screen appears on the instrument. For analyzers with ISE Module follow the steps below, otherwise go to step 15. HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 27 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 14) Run the ISE calibration and ISE cleaning each time the system ask to (every 8 hours or every 50 samples). 15) Evaluate the obtained results. 16) Print results and/or reports. For analyzers with ISE Module follow the steps below, otherwise go to step 18. 17) Run clean procedure for ISE module at the end of the work day. 18) Run a cleaning TIP procedure at the end of the work day. 19) Wash the cuvettes. 20) Turn the instrument off by pressing analyzer frontal panel button. Warning: For analyzer with ISE Module: do not turn off the analyzer by pressing general button unless maintenance cycle had been done and electrodes removed. NOTE: ISE module must be power on all time that the electrodes are in it. Purge cycles are performed by the ISE module automatically every 30 minutes. Programmed maintenance In addition to the maintenance processes run during daily operation, there are other weekly and monthly maintenance operations performed by the user, which are part of the instrument Maintenance Program. They are the following: 1) 2) 3) 4) 5) Calibration cuvettes once per week. Manual washing of the exterior and calibration of the cuvettes and photometer once per month. General cleaning of the instrument once per month. Back-up of files in use once per week, or per month, or after making modifications. Initialization of the results base after every 10,000 determinations. It is important to follow these maintenance instructions in order to ensure optimum performance and maximum life of the instrument. Other options reserved for a Service Technician, or those that are run according to need, are also described in the Maintenance Program Chapter. As additions to this Manual, the user will find a series of Quick Guides which will help in running the following procedures: - Method configuration Calibration and Control Daily Operation Entering and Processing Samples Backing-up Files Page 28 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 6 SOFTWARE TABS Main window of the software The following window will be displayed when opening the software. Figure 6-1 The menu will be accessed by the mouse or from the keyboard with the help of shortcut keys. These become active by pressing Alt on the keyboard. As shown in the following figure, a dash appears under some letters indicating which letter must be pressed to access the appropriate menu. Figure 6-2 For example: to enter the Operations menu press Alt+ letter p. the Operations Menu will be displayed. All menus work in the same way. The Title bar identifies the software and the software version number. Versions are constantly updated and modified, so the user must install current software updates. The Menu bar allows access to each menu by selecting the menu from this bar. When the menu is displayed, select the name of the command or submenu. There is a chapter for each menu. The Tools bar is a row of icons or keys that allow quick access to commonly used menu commands. For quick selection, each icon has an image which shows its function and name. By placing the mouse on each icon, text will appear with a description of the function of the icon. The Tab bar allows access, by selecting each “tab”, to different windows of the software as reagents Trays, Patient Results, etc. HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 29 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Operations Tab The software has tabs in which patients’ results, calibrators and/or controls, as well as samples and reagent positions will be observed. It has a main tab Operations, where process and status of determinations will be shown. These tabs can be accessed by selecting them with the mouse. Figure 6-3 Figure 6-4 Added processes, patients, calibrators and/or controls which are part of the working lists are shown in the frame “Entered Samples”. “Samples to be processed”, where pending processes remain, such as processes with a method which was not programmed in the reagent tray. Samples to be processed are those which are part of the working sequence and are being added to the lower frame by the program. “Samples in process”, are those samples which are being processed. This is where you can observe process characteristics, such as information of the cuvette where the reaction is being developed, results, reagents, status signs, etc. Status of sample processing is shown in this tab. In Figure 6-5, important parts of this window or tab are shown. Each column has a name, process #, type of sample, name, ID, etc., and are described below. Page 30 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Figure 6-5 Process Number This symbol represents the number assigned by the software to each sample when requested. This number corresponds to the time when the request is made. It is unique and it cannot be changed and has the following format: yy 05 / mm 10 / dd 05 / hh 41 / mm 34 / ss 34 / msmsms 672 / This process was carried out: Year: 2005 Month: 10 Date: 05 Hour: 12 Minutes: 41 Seconds: 34 Milliseconds: 672 Within this column a + sign and a – sign is shown next to the process number. A + sign means that this process has method(s) selected to be processed. By clicking on this sign you can see all methods requested. A – sign means that information of requested methods is being shown. HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 31 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Absence of any of these signs means that there are no selected methods for the process, and the frame will be Pending Samples. Type In this column are the types of process like samples, patients, calibrators and/or controls. They are identified with different symbols for a quick reference. Red symbols correspond to samples entered as stat. This symbol represents a patient. This symbol represents a calibrator. It is in red because it is urgent (stat), Calibrators are stat by default. This symbol represents a control. Name First and last names of patients are shown in this column if they have been entered. If you click on the + sign, the names of selected methods will be shown. ID This column shows the number previously assigned to the sample. Status This column shows the status of the selected method. The status shows the percentage of the total process of the method which has been completed so far, taking into account the elapsed reaction time and the reading(s) which have already been done. The number in brackets on the right of this percentage is the number of cuvette where the reaction was dispensed. There are also warning signs indicating lack of reagent, reagent deterioration, etc. Concentration Samples results obtained, as well as warning signs referring to that reaction, such as deteriorated reagent, No sample, repeated, re-diluted, re-dilute manually appear in the concentration column. Page 32 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Figure 6-6 Reagents Trays Tab Reagent position Reagent tray positions are configured in this tab. Figure 6-7 Numbers 1 to 30 on the left of each box correspond to the reagent positions on the tray. R1 is for the bottle located in the outer part of the tray, and R2 is for the bottle located in the inner part. When placing reagents on the tray, select on the right if it is a single reagent bottle (single mouth) or two reagents (double mouth) by indicating 1 or 2 respectively. If you selected 1 (single mouth), you will only be able to access the list to be displayed corresponding to reagent 1 column “R1”, if you selected 2 (double mouth), you will be able to access both columns “R1” and “R2”. Within those lists, select the reagent(s) to be positioned. HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 33 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Figure 6-8 Once all reagents have been positioned, type a name within the Tray File field and press Save. An indefinite number of tray files may be created, each with difference names, and then press Save. To load a stored reagent tray configuration, select from stored trays displayed in Tray File and then press Load. The tray file will be loaded and new reagent positions will appear on screen. To delete a reagent tray, it must first be loaded by means of the Load key and then deleted by means of the Delete key. Figure 6-9 When the volume in a reagent bottle is low, an error message “lack of reagent” will be displayed indicating which reagent(s) must be reloaded. This error windows has to be closed after reloaded process Figure 6-10 When a lack of reagent message is displayed, the working sequence must be paused. Press Pause for a few seconds until the instrument is paused. Page 34 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Figure 6-11 Reload the volume reagent bottle(s), press Reloaded button in the Tray and then press Pause again to continue with the pending work. Figure 6-12 Warning: probe arm robot will move if reagent 2 has to be dispensed. To prevent any human injury be careful with this procedure. PAT Results Tab Figure 6-13 Within this tab you have access to all processed patients’ results. It is divided in two parts. In the upper part you can find process numbers, ID, name and other data entered to identify that patient and in the lower part you can find results of all processed methods for each patient and the cuvette number on which each reaction was performed. HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 35 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 When you open the software and you access this tab, results will not be shown until you press the key With the following keys, different search processes of patients’ results, methods, calibrators and controls can be carried out. The following keys have the same functions in the PAT Results tab, CAL Results tab and CON Results tab. Figure 6-14 Press this key to access the patients list saved in the results base of the program. By pressing this key, the processed samples list will be shown. Page 36 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Patient results search To see patients’ results follow these steps: When the software is opened, results will not be shown. The screen will look like this: Figure 6-15 First: Press the key “Make a new search” so that all saved patients are shown. 200 patients can be seen in this window. To see the next 200 patients press the key To see the previous 200 patients press the key HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 37 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Figure 6-16 Second: To see results corresponding to each patient, first select the patient in the box on the upper part of the window. Results corresponding to the selected patient can be seen in the box on the lower part of the window. Figure 6-17 Third: Double click on the result of a method to access “Extended information” for that analyte. Page 38 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Figure 6-18 This “Extended Information” box will appear differently depending on the type of reaction. It will show whether the technique is bichromatic and/or if it is reagent blank. Main and bichromatic wavelength absorbance will be reported. Number of sample re-dilutions will also be reported. Figure 6-19 corresponds to an End Point Reagent Blank method. Figure 6-19 Figure 6-20 corresponds to a Kinetics method. HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 39 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Figure 6-20 Absorbances, time of measurements, readings plot, delta abs/min, redilutions, will be reported Advanced search Patients can be searched in different ways, such as: By process date: Figure 6-21 Select from the box Process Date and select a date and time range From/To, then press the key Search results will be shown on the upper box Page 40 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Figure 6-22 Advanced search parameters are shown or hidden by pressing this key both for a patient’s name and a method result. It has the same function in the CAL Results and CON Results tab. By pressing the same key these parameters will be hidden. Figure 6-23 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 41 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 The search keys in the lower part of the page work in the same way in the upper part and allow for the search for a specific assay or patient result. Advanced searches for patients can be carried out through the following search parameters: Process number, Name, Last Name, Age, Sex, ID, Doctor, and Bed. Each of these parameters can be simplified through a more precise selection such as: Same, Range, Contains Phrase, Similar, Contains Words, Contains Words in Order and Any word. Check the box of the search parameter that will be used to search for the patient. An example is shown in figure 6-24. A search of a patient whose last name is Stuart was made. The box corresponding to last name was checked. Same last name was searched and the exact name was typed (case sensitive). After completing the information, press Figure 6-24 Page 42 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Search results will be shown in the window box. Other advanced search parameters will operate in the same way. Warning: When the advanced search is not being used, REMOVE the check mark from the search parameter box. If it is not removed, and parameters are hidden, the advanced search will still operate and all results in the ordinary patients’ search will not be shown. Patient data from the upper window and/or results from the lower window can be exported by using this key, with no connection between them, are two different exported lists. The following window will be displayed: Figure 6-25 Name the file to be exported. By pressing Browse you can see the location where the file to be exported will be saved or you can change the location. You can select save All or Selection, which will allow you to select the columns that you would like to save (consecutive number from 0) HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 43 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 CAL Results Tab Figure 6-26 Calibration results and factors are shown in this tab. They can be sorted by process number, alphabetically (by calibrator name), or by method. To sort the calibrators, click on the name of the appropriate column and the calibrators will be listed in ascending order. By clicking again, they will be listed in descending order. The keys work as previously described. Within this screen, two types of results will be shown. 1. Reagent blank absorbance which corresponds with the calibrator point it was processed with. 2. Calibrator absorbance is shown In the Report column: By double clicking on any result line, you can open the extended information box, as previously described. Press Hide/Show search parameters key. The following screen will be displayed: Page 44 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Figure 6-27 Searches can be made by process date, name of calibrator, method, or by patient report. Warning: Remove check marks from search parameters before closing advanced searches. CON Results tab Figure 6-28 Controls results will be shown in this tab. They can be sorted by process number, alphabetically (by control name), or by method. To sort the controls, click on the name of the appropriate column and the controls will be listed in ascending order. By clicking again, they will be listed in descending order. The keys work as previously described. Within this screen two types of results will be shown. HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 45 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Figure 6-29 2. Result in control concentration is shown In the Report column Results will be reported with the text Right if the result is within the programmed control range, or Error if the result falls outside the programmed control range. The limits are the minimum (-2SD) and maximum (+2SD) programmed data. Warning: Limits has to be programmed in the same units as method and calibrator By double clicking on any result line, you can open the extended information box, as previously described. Press Hide/Show search parameters key. The following screen will be displayed. Figure 6-30 Searches can be made by process date, name of control, method, or by report. Warning: Remove check marks from search parameters before closing advanced searches. Page 46 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Sample Positions Tab Figure 6-31 This tab corresponds to the positions on the sample tray. Positions of tubes can be found here and identified by ID number or name. Processing status is shown with different colors Green: the position is available for samples or new samples Yellow: all processing for the sample has been completed Red: sample is in process Figure 6-32 Figure 6-33 shows that patients with ID number 47885, 33698, and 21556 are in position 3, 4 and 5, respectively. All processes have Ended. The sample in position 6 is in process, so the position is Busy. This tab allows for a quick view of patient position and working status. HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 47 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 7 OPERATIONS MENU Basic functions for the operation of the instrument are described in the Operations Menu, which can also be accessed from shortcut icons (Figure 7-1) Figure 7-1 Add Samples and Methods The entering of samples to be processed by the instrument as well as the addition of methods to samples already requested can be carried out from the submenu Add on the Operations Menu (Figure 7-2) Figure 7-2 Page 48 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Add Sample Patients, Calibrators and Controls samples can be carried out in two ways: from the Operations Menu (Figure 7-2) or from the icon Add New Sample (Figure 7-3) Figure 7-3 On the Operations Menu select Add Sample or click on the icon Add New Sample. The screen Add Process is displayed (Figure 7-4), where the kind of sample to be requested is selected: Patient, Calibrator or Control. Figure 7-4 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 49 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 7.1.1.1 Add Patient Select Patient on the screen Add Process. The fields Name, Surname, PID (Personal Identification), Age, Sex, ID, Tube, Doctor and Bed will appear. ID is the only mandatory field that has to be completed in order to save the request. The other fields can be completed so that patients’ data appear in the patients report, or for them to be saved in the database. Warning: ID name can be alphanumeric. The field Age can be completed with a number representing the age or by selecting the age group of the patient, configured according to Chapter 12 section 12.1.4 (Figure 7-5). The options Male or Female are configured in the field Sex. If no option is selected, Male will appear by default. Figure 7-5 Use the mouse to select the methods to be processed. The methods in use appear on the screen. A method profile can also be selected in the drop-down menu under the field Special (Figure 7-6). Only one profile can be selected for each request. Additional methods can be added from the list appearing on the Add Process screen. Also methods from a selected profile can be subtracted. Figure 7-6 Page 50 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Press Add to save the request, or Cancel if the operation is not carried out. If the Clear After Adding box is selected, the Add Process screen will be cleared after clicking on the Add button. If this option is not selected, all entered data and requested methods will remain on the screen to be modified upon the next request after pressing Add. ID increase box is useful when the requested methods are the same for different samples or when patients’ data is similar, for example: consecutive ID numbers. This option is alphanumeric. You can add several processes at the same time. In the box next to Add button you can choose between 1 and 99999 for different groups of patients Each added request will appear in the Operations tab with a process number that indicates the time when the request was made and the symbol that represents a patient sample. The entered patient can be checked as Stat. If the Stat option is selected, this symbol in red on the list of requested samples (Figure 7-7). will appear Figure 7-7 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 51 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 7.1.1.2 Add Calibrator Select Calibrator on the Add Process screen. All calibrators configured according to Chapter 9 point 9.1 will be displayed. Select the desired calibrator on the left column. The methods to be calibrated with the selected calibrator will appear in the right column since they have a configured concentration (Figure 7-8). Select the methods to be calibrated and press Add. Each calibrator that has been added will appear on the Operations tab with a process number indicating the time when the request was made and a symbol representing a calibrator . Figure 7-8 7.1.1.3 Add Control Select Control on the Add Process screen. All controls configured according to Chapter 10, section 10.1 will be displayed. Select the desired control on the left column. The methods for the selected control will appear in the right column since they have minimum and maximum configured concentrations (Figure 7-9). Select the methods to be run and press Add. The requested control can be selected as Stat. Each control that has been added will appear on the Operations tab with a process number indicating the time the request was made and a symbol representing a Control If the option Stat is selected, this symbol will appear in red on the requested samples list. Control Calibrator Page 52 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Patient Figure 7-9 Add Methods Methods can be added to samples already requested, Patients, Calibrators or Controls. This can be carried out in two ways: from the Operations Menu (Figure 7-2) or from the Add New Method to Sample icon (Figure 7-10). This option is only available for samples already entered, not for those pending or in process. Figure 7-10 Select the sample to be modified on the Operations Tab, press Operations Add Method or click on the Add New Method to Sample icon. A screen with all the available methods and profiles to be added will be displayed (Figure 7-11). Select the method/s you want to add, press Add to add them to the original sample, or Cancel if you do not wish the operation to be carried out. Warning: These processes can only be carried out before the entered samples are on the sample tray. Once in process, or when the process has finished, it is not possible to add new methods; the methods will have to be added in a new request for the sample. HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 53 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Figure 7-11 Modify Sample Patients’ data that has already been requested can be edited in two ways: from the Operations Menu (Figure 7-12) or from the Edit Sample icon (Figure 7-13) Figure 7-12 Figure 7-13 Select the sample to be modified on the Operations Tab, press Operations Modify Sample or click on the Edit Sample icon. A screen with the patient’s data available to be modified or added will be displayed, included the Stat status (Figure 7-14). Press Add to save the modifications, or Cancel if data is not saved. The Stat status for calibrators and/or controls can be modified following the same procedure (Figure 7-15) Page 54 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Warning: These processes can only be carried out before the entered samples are on the sample tray. Once in process, or when the process has finished, it is not possible to modify patients’ data or the Stat condition. Figure 7-14 Figure 7-15 Delete Samples and Methods Entered, pending or in-process samples and / or methods can be deleted from the submenu Delete in the Operations Menu (Figure 7-16) Figure 7-16 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 55 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Delete Sample An entered sample can be deleted in two ways: from the Operations Menu (Figure 7-16) or from the Delete Sample icon. (Figure 7-17) Figure 7-17 Select the sample to be deleted on the Operations Tab and press Operations Delete Sample or by clicking on the Delete Sample icon. To delete more than one sample, hold the Control key on the keyboard and select all the samples to be deleted (Figure 7-18). Before deleting all the requests, a screen will appear to confirm the operation (Figure 7-19). Press Yes to confirm the deletion, or No to cancel it. To delete samples which have been sent to tray and which appear as pending on the Operations Tab, the instrument must not be working. Press Stop to cancel the operation and then delete the selected pending samples. Samples that have already been processed can be deleted from the Operations Tab following the same procedure. However, the obtained results will be saved in the results database until it is initialized. Warning: It is not possible to delete results of samples that have already been processed and deleted from the Operations Tab. Results will be deleted only when the results database is initialized. Figure 7-18 Page 56 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Figure 7-19 Delete Selected Method A requested method for a Patient, Calibrator or Control sample can be deleted in two ways: from the Operations Menu (Figure 7-16) or from the Delete Method icon (Figure 7-20) Figure 7-20 Display the requested methods to the sample on the Operations tab by pressing the symbol next to the request process number. Select the method to be deleted and press Operations Delete Delete Selected Method or press the Delete Method icon (Figure 7-20). To delete more than one method, hold the Control key on the keyboard and select all the methods to be deleted (Figure 7-21). Before deleting the method/s, a screen will appear to confirm the operation (Figure 7-22). Press Yes to confirm or No to cancel it. To delete methods which have been sent to tray and which appear as pending on the Operations Tab, the instrument must not be working. Press Stop to cancel the operation and then delete the selected pending methods Warning: It is not possible to delete a method of a sample once results have been obtained. HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 57 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Figure 7-21 Figure 7-22 Pending: save, load and import pending requests Pending requests lists can be loaded, saved and imported from the Pending submenu in the Operations Menu. This operation is unavailable while patients, calibrators and/or controls are in process. Figure 7-23 Page 58 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Save Pending Samples which are not processed in the current run remain pending and can be saved in a file with the extension *.aop. This file can later be used in a new run to enter new requests into the system without the need to create them again (see 7.4.2). This can be carried out in two ways: from the Operations Menu press Pending Save (Figure 7-23) or press the icon Save Pending List Samples (Figure 724). Figure 7-24 In the save window, select the location where the file will be saved. Name it and press Save or Cancel. This way, all the data of pending requests is saved in a file with extension *.aop. Warning: During this process, all requests that hasn’t been processed will be saved (including pending or in process samples with pending results) Load Pending Pending sample lists saved in files with extensions *.aop (see 7.4.1) can be entered into the system again to be processed in a new run. This can be done in two ways: from the Operations Menu (Figure 7-23) and pressing Pending Load or by pressing the Load Samples in Pending icon (Figure 7-25). The exploration window will then be displayed to select the file with extension *.aop to be loaded. Press Open or Cancel. All pending sample saved in the file are now available in the Operations Tab to be processed by the instrument. Figure 7-25 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 59 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Warning: When sample requests are re-loaded from a saved file, the system will assign a new process number to each sample. Import from CSV Sample requests can be entered in the software from a laboratory information system software through a file with a standard CSV (comma, space, value) format. To accomplish this, a communication protocol between both programs must be created, which includes the requirements of this kind of file. The description of the data format of this file can be found in Chapter 13 Point 13.3 To import data from this file, select Pending Import from CSV on the Operations Menu (Figure 723). The exploration window will then be displayed to select the file with extension *.csv to be loaded. Press Open or Cancel. All sample requests made by the laboratory information system software are now available on the Operations Tab to be processed by the instrument. NOTE: The import of a work list in a csv format can be performed automatically. This has to be configured along with the laboratory information system software. For further information contact technical support. Samples to Tray Processing of samples requested on the Operations tab (Figure 7-26) can be started from Samples to Tray submenu or from the Samples to Tray icon. Figure 7-26 To start processing samples, follow these steps: 1. Select the samples to process on the Operations tab (Figure 7-27). Samples can be selected in two ways: -Correlative samples: place the cursor on the first sample and go to the bottom of the list, holding the left bottom of the mouse. Page 60 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 -Non-correlative samples: Holding the Control key on the keyboard, select each sample with the mouse. Either all or some of the requested samples can be selected; the remaining samples can be left for later process. Warning: Verify that the methods have been calibrated and controls have been run to determine validation of the calibration. After reagent blank values, calibrator absorbance and controls have been validated; continue with the processing of patients. Figure 7-27 2. Press the Samples to Tray icon. The Samples Position screen will be displayed (Figure 7-28), where Type of requested sample (patient, calibrator, control: PAT, CAL, CON), Name, ID and Position are indicated. 3. Check that the actual positioning of samples on the tray corresponds to what appears on the Samples Position screen. Sample positions can be modified by using the drop down window in the Position column. Figure 7-28 If the same position number is used by mistake for two different samples in the same run, an error message will be displayed requesting to correct the repeated positions (Figure 7-29). HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 61 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Figure 7-29 4. Select the execution options: by Selection, by Patients or by Reagents: Selection: This is the fastest option. The software organizes and establishes the work sequence, ordering of the methods and samples, optimizing processing speed. Patients: Processes samples in the order in which they were requested. Reagents: All tests of the same method are run before it continues with the tests for the next method. The user cannot select the methods’ processing order. The software establishes the optimal processing order. Processing is grouped as New Group by default. 5. Press Send to continue or Cancel send if the operation is not carried out. 6. Select the methods for reagent verification on the Reagents Verification screen (Figure 7-30) After sending samples to be processed, the Reagent Verification screen is displayed. In this screen, all methods where the verification time (configured in the Verification Time field) has elapsed are indicated with a check mark. It is recommended that the selected reagents are verified to ensure the integrity of the reagents before processing samples. Methods where the verification time has not elapsed can also be verified by selecting them on this screen. It is recommended that methods are verified after changes have been made. Some examples of changes that require verification are: when a new reagent is placed, when configuration of certain method parameter is modified, etc. Figure 7-30 Page 62 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 7. Press Verify Selected or Do not verify. If the option Do Not Verify is selected, the methods that are checked will not be verified. Warning: This is the last screen where processing of requested samples can be cancelled. 8. Press Start on the screen to put the samples in the tray (Figure 7-31) Warning: It is not possible to cancel processing of selected samples in this step. Figure 7-31 Samples to Tray (Barcode) (Optional) Processing of samples with barcodes can be initialized from the Samples to Tray (Barcode) submenu or from the Samples to Tray (Barcode) icon when the instrument is installed with the optional barcode reader (Figure 7-32) Figure 7-32 To begin processing samples, follow the next steps: 1. Add the daily work list of samples (either manually or imported from a pending file or a .csv) Warning: First methods should be calibrated and controlled, once the values for reagent blank, calibrator absorbance and quality controls are validated, then proceed to process patients’ samples. 2. Press Samples to Tray (Barcode) The analyzer will scan every sample position in the SR tray until it finds all the samples added in the work list, meaning, if the samples in the work list are in the first ten positions then the analyzer will find the samples HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 63 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 and stop the scanning process after finishing in position 10. If a barcode can’t be read by the analyzer, the sample corresponding to that barcode won’t be found, therefor the analyzer will continue scanning until it reaches position 60. Figure 7-33 Figure 7-34 Once the detecting process is finished, the window for Sample Positions will appear. Verify that the positions shown in the list match the ones in the SR tray. NOTE: Those samples with barcodes that can’t be read by the analyzer will remain in the work list (Entered Samples), not being sent to tray, the rest of the samples whose barcodes were read OK will be moved to tray. The samples that remain in the work list can be sent to tray manually or, previously correcting the barcode (positioning correctly, label, etc), using the barcode reader. If a new list of samples is scanned in positions that still have pending tests the following message will show: Figure 7-35 By pressing OK Position 2 will be scanned again until the original tube is detected. The analyzer won’t allow to move on until the original tube is placed in its position. Page 64 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 3. Check that the actual positioning of samples on the tray corresponds to what appears on the Samples Position screen. Sample positions can be modified by using the drop down window in the Position column. Figure 7-34 If the same position number is used by mistake for two different samples in the same run, an error message will be displayed requesting to correct the repeated positions (Figure 7-29). Figure 7-35 4. Select the execution options: by Selection, by Patients or by Reagents: Selection: This is the fastest option. The software organizes and establishes the work sequence, ordering of the methods and samples, optimizing processing speed. Patients: Processes samples in the order in which they were requested. Reagents: All tests of the same method are run before it continues with the tests for the next method. The user cannot select the methods’ processing order. The software establishes the optimal processing order. Processing is grouped as New Group by default. 5. Press Send to continue or Cancel send if the operation is not carried out. 6. Select the methods for reagent verification on the Reagents Verification screen (Figure 7-30) After sending samples to be processed, the Reagent Verification screen is displayed. In this screen, all methods where the verification time (configured in the Verification Time field) has elapsed are indicated HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 65 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 with a check mark. It is recommended that the selected reagents be verified to ensure the integrity of the reagents before processing samples. Methods where the verification time has not elapsed can also be verified by selecting them on this screen. It is recommended that methods be verified after changes have been made. Some examples of changes that require verification are: when a new reagent is placed, when configuration of certain method parameter is modified, etc. Figure 7-36 7. Press Verify Selected or Do not verify. If the option Do Not Verify is selected, the methods that are checked will not be verified. Warning: This is the last screen where processing of requested samples can be cancelled. 8. Press Start on the screen to put the samples in the tray (Figure 7-31) Warning: It is not possible to cancel processing of selected samples in this step. Page 66 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Wash Cuvettes Cuvette washing processes are carried out from the Operations Menu, Wash Cuvettes submenu or from the Wash Cuvettes icon on the main screen of the system (Figure 7-33) Figure 7-37 The different options to wash cuvettes are: All cuvettes: it washes all 100 cuvettes. Dirty cuvettes: it only washes dirty cuvettes which have just been used and which have been partially washed. Cuvettes range: select the range of cuvettes to wash. In the left box put the number of the initial cuvette and in the right box put the number of the final cuvette to be washed. Special Wash: A special wash solution is placed in a reagent bottle and is assigned a position in the Reagent Pos. box. During this wash cycle, the instrument starts washing cuvettes from 1 to 10 and then dispenses 300 µl special washing solution and 300 µl washing solution in each of the 100 cuvettes. This wash solution mixture remains in the cuvettes for approximately 10 minutes, and then it is automatically washed. A diluted solution of sodium hydroxide is used for the special wash. NOTE: This procedure must be performed after using latex reagents using a 2N NaOH solution. It can also be performed when needed using a 0.2N NaOH solution as a preventive maintenance of the cuvettes. From the Operations Menu, Wash Cuvettes submenu or by pressing the Wash Cuvettes icon, select the desired washing option on the Wash Cuvettes screen (Figure 7-34). Press Wash or Cancel. HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 67 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Figure 7-40 Start Operation of the instrument can be started from the Start submenu of the Operations Menu or from the Start icon (Figure 7-35) Figure 7-41 Start is used: Page 68 of 217 To initialize the instrument. To repeat a result when the instrument has already finished the run. To restart the processing of samples after having stopped the instrument by pressing Stop (see 7.9) HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Stop The instrument can be completely stopped by pressing Stop on the Operations Menu or the Stop icon (Figure 7-36). The processing of samples and the reading of reagents in process will stop completely as a result. Figure 7-42 Stop is used: When there is a mechanical error. For example, if there is a problem with the probe, cuvettes tray cover is out of place, washing solution is needed, etc. When there is an error in the processing. For example: a reagent has been positioned in the wrong place, samples are missing or they have been incorrectly placed, reagent deterioration index is out of range, etc. When there is an error sign on the screen that indicates Retry or Stop the process. When the instrument is running tests and the option Stop is pressed, a warning sign will appear (Figure 737) to confirm the operation by pressing Yes or No. Figure 7-38 Pause The instrument can be paused by pressing Pause on the Operations Menu or the Pause icon (Figure 738). Dispensing of samples will stop but reactions in process will continue, including R2 dispensing. HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 69 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Figure 7-39 Pause is used: to add samples on the samples tray to refill reagents bottles to refill the washing solution container or to empty the waste container After the desired operation has been carried out, restart processing of samples by pressing Pause again. Pause or not paused is evidenced by the icon: Paused Instrument: the key is pressed in the icon Page 70 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Print Results Patients, calibrators and controls results can be printed from the Operations Menu, Print PAT, CAL or CON Results or from the Icon Print View (Figure 7-45). Figure 7-40 Results to be printed must be first selected on the appropriate Tabs: PAT Results Tab, CAL Results Tab, CON Results Tab. Data can be grouped and ordered in each tab according to different criteria before printing. Once ordered and selected, results are printed by pressing Print View or from the Operations Menu, selecting the submenu corresponding to the type of results: Print PAT, CAL or CON Results. The Print View icon only prints the results selected on the tab in view at the time the print button is pressed. A screen will then appear to select the type of printout: Patient Report or Technical Report, and to filter the results that the user does not want in the printout (Figure 7-46) Figure 7-41 The Patient Report has an easy-to-read format designed to be delivered directly to patients or doctors. The report is printed on a separate sheet of paper for each patient. The Technical Report has a more compressed format and is used to generate a printed record of results. Results from multiple patients are printed on the same report. Patient and technical reports are configured in HTML format (Chapter 12 Point 12.1.5) HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 71 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 By pressing Preview the Patient Report or Technical Report format can be viewed on screen. By pressing Filter a new window will appears, through this window some results can be remove from printout process. Figure 7-42 To see all processed methods double click on the ID patient field. Uncheck the checkbox next to the methods name and press “Filter”, the preview will show only the results that remains checked. Page 72 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Figure 7-43 Press Preview, Print or Cancel. HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 73 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Repeat Results A method with a result already reported by the instrument can be repeated by pressing Repeat under the Operations Menu or the Repeat icon (Figure 7-41) Figure 7-44 The results to be repeated are selected from the Operations tab or the Samples in Process window and the Repeat icon is pressed. This option is used while the instrument is running. To repeat results when the instrument has already finished the complete operation, select them and press Repeat. Then, to initialize the new process press Start (see Chapter 7 point 7.8) Warning: Results of samples which do not appear on the Operations tab or which have been removed from their original position on the samples tray cannot be repeated. The last result obtained for each method is reported on the Operations Tab. All the results obtained for each sample are reported on the PAT, CAL or CON Results Tabs. Page 74 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Reload Samples Upon detection of insufficient sample an error notice will appear. The sample process identification is provided. Figure 7-50 Figure 7-51 A No Sample notice can be seen on the Operation Tab, Status field (Figure 7-43). Figure 7-52 When insufficient sample has been detected, the empty sample tube/cup must be refilled, press Pause button, refill sample tube, the patient must be selected on the Operations Tab then press the Reload Sample button and press Pause button again. Export Results Results obtained in the software can be exported to the laboratory information system software through a standard CSV file (comma, space, value). The file is created according to the process described in Chapter 12, section 12.1.3, and a description of this file data format can be found in Chapter 13, section 13.3 The process can be performed automatically along with the laboratory system software, for further information contact technical support. HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 75 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 8 METHODS MENU In the menu bar select “Methods” to display the Method Menu (Figure 8-1) Figure 8-1 Settings: Methods Configuration Test parameters are programmed in this menu, including: reaction types, wavelengths, sample and reagent volumes, incubation times, etc. This operation is unavailable while processing patients, calibrators and/or controls. Select Settings and enter the access code (provided at installation). To complete a method configuration, enter the information in all the fields of the respective Tabs. These tabs are: “General”, “Factor”, “Reference Values”, “Specials” and “Advanced”. IMPORTANT: After all the corresponding information for a method has been entered, press the Modify button. If the Modify button is not pressed before selecting another method, the following message will show: Figure 8-2 By clicking on Discard modifications the changes made to the method will be lost, if Back to method is pressed, it will return to the method configuration allowing to click on Modify to save changes. Exit the Methods Configuration by clicking on OK, otherwise the same message from above will appear. Page 76 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 General Tab Figure 8-3 Write the method’s name in the blank field on the top of the window (to the left of the Add button) then press Add. The method will appear in the field to the left of the Delete button, included in the general list of methods. NOTE: Do not change the size of the method name into the general list for one big. Software will cut the method name if you change to another one too big. For a new methods file, the name will appear in the field to the left of the Add button. For an already existing methods file, you have to overwrite the name of any method in the field left of the Add button, enter the new name and finally press Add Warning: When the first method is programmed, it will be displayed with the default values. When a new method is created, be sure to enter all of the desired parameter values, since the software will default to those values of the currently displayed method. Fill in different fields in the “General” Tab: Name: Enter the generic method name; this name will appear in the printed reports exactly as it’s been written in this field. Brand: Enter the name of the reagent manufacturer. Type: In this field, the methods are programmed according to the type of reaction. Software has five types of reactions, and each has its own options and characteristics. Each one will be explained in detail later. HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 77 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 End Point Reagent Blank End Point Sample Blank Kinetics Fixed Time Kinetics ISE (Parameters at the end of this Chapter) (Optional) Main Wavelength: Enter the main wavelength for the proper reaction, as provided by the reagent manufacturer. The software will select the filter that is closer to that value. Bichromatic Wavelength: Enter the bichromatic wavelength for the proper reaction, as provided by the reagent manufacturer. The software will select the filter that comes closest to that value. For monochromatic mode, enter “0”. Unit: Enter the units of measurement desired for the calculation and printout of the results. Decimals: Enter the number of decimal points desired for the calculation and printout of the results. Sample Volume: Enter the sample volume according to the reagent/sample ratio provided by the reagent manufacturer. The volume sample should not be less than 2 µl. R1 Volume: Enter the volume of reagent 1 according to the reagent/sample ratio provided by the reagent manufacturer. R2 Volume: Enter the volume of reagent 2 according to the reagent 1/reagent 2/sample ratio given by the reagent manufacturer if it corresponds. Leave it at “0” for single reagent methods. Warning: The total volume (R1+ R2 + sample) must be less than 500 µl. The minimum reading volume should be 220 µl. The maximum cuvette capacity is 600 µl. Time to Dispense Reagent 2: Enter the time to dispense the second reagent after the dispensing of reagent 1 and the sample. If 0 sec is entered the sample + R1 + R2 will be dispensed at the same time. Reagent Deterioration Index: The instrument checks the state of the reagents according to the reagent manufacturer’s instructions. This value corresponds to the reagent blank’s absorbance. If the measured absorbance value is outside the programmed range, a “deteriorated reagent” message will be shown in the operations tab beside each result. Min.: Enter the minimum absorbance value for the reagent blank according to the reagent manufacturer’s instructions. If a minimum absorbance is not given, enter 0 as the value. Note: With some bichromatic methods, a negative result is obtained for the reagent blank; in this case enter an absorbance value less than 0. Max.: Enter the maximum absorbance value for the reagent blank as indicated by the reagent manufacturer. If a maximum absorbance is not given, enter 2 as the value. Page 78 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Verification time: Enter the time (in hours) that is desired for checking the reagent deterioration index. Sixteen hours is recommended. NOTE: Always press the Modify and OK buttons if any change is made in the method configuration. If no parameter is changed, exit by pressing the OK button. If this is not done, the methods will not be programmed correctly and the results may be affected. Factor Tab Figure 8-4 In the Factor tab (Figure 8-3), select the Decreasing method option for reagents in which the absorbance decreases upon increasing the analyte concentration. If this option is programmed incorrectly, a Warning: Sign error message along with the calibrator concentration will appear during the method calibration. This will also be reflected in negative results. Select from the available methods for results calculation: Factor or Calibrator curve. If Factor option is selected, enter the corresponding value in the field to the right. If calibration curve option is selected, select Calibrator and complete the fields below. In the Point field assign a number for each point (starting from 1) Complete calibrator and absorbance field with the value “0”, since the concentration is taken from the input value in the concentration field of the calibration parameters, and the absorbance value will be adjusted automatically to the obtained value during the calibration. HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 79 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 If the calibration curve has more than one point repeat the previous steps until reaching the desired number of points. This step connects in the software the “Methods” window with the “Calibrators” window, where the calibrator concentration must be entered. There will be as many calibrators as points entered in the method settings. For that, go to the “Calibrator Parameters” section. If only one calibration point is programmed, the system will assume the second point of reference is“0”. If two or more points are programmed, the system stops using “0” as a point of reference, and a point of concentration “0” should be programmed. Possible Interpolation types are: Linear: Conc = a • Abs + b Potential: Conc = 10 (a • log (Abs) + b) Exponential: Conc = e (a • Abs + b) Polynomial: 2 n Conc = a0 + a1 • Abs + a2 • Abs + … + an • Abs where n is the number of programmed calibrators. Cubic Spline Multilinear When a method uses a calibration curve with more than 2 points, it’s recommended to evaluate the best interpolation for that set of calibrators. For example, notice the following set of concentrations and absorbances that constitute a calibration curve: Page 80 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Figure 8-5 To know which interpolation suits the best for that set of calibrators, click on Curve and you’ll see the following chart, where each colored curve represents each type of interpolation and in black circles are marked the calibration points. The curve that best fits these points must be selected. In this case it would be the Cubic Spline (in violet), a second option could be the Polynomial (in blue). Figure 8-6 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 81 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Reference Values Tab In the Reference Values tab (Figure 8-4) complete the fields with the corresponding values given by the reagent manufacturer or a population mean obtained from each laboratory. These reference values are listed in the patient and technical reports. Figure 8-7 Click in each of the lower fields and enter the corresponding values for Min Age, Max Age, Sex, Minimum Value and Maximum Value. Once all the information has been entered, press the “Enter” button and the whole data will appear in the upper field. More than one range of reference values can be entered for age and sex. These values will be shown in each case related to the age and sex data entered for each patient. If neither is entered as part of the information for the patient, the software will default to adult male. NOTE: Always press the Modify and OK buttons if any change is made in the method configuration, if no parameter is changed, exit by pressing the OK button. If this is not done, the methods will not be programmed correctly and the results may be affected. Page 82 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Specials Tab In the Specials tab enter the incubation times, minimum repetition and maximum re-dilution values, etc. The fields shown in this tab will depend on the type of reaction selected in the General tab. Each method has four different options (Figure 8-5). Figure 8-8 8.1.4.1 End Point Reagent Blank In this type of reaction, the instrument does a reagent blank in a separate cuvette from the test cuvette. The blank absorbance is stored and subtracted from each test absorbance. The same blank absorbance will be used until the reagent blank is measured again. Only one absorbance reading is taken at the end of the incubation period (end point). This type of measurement is mostly used for colorimetric tests such as Glucose, Cholesterol, etc. Figure 8-9 8.1.4.1.1 Times and values to enter Time for Reagent Blank: Enter the total time in seconds required for reading the reagent blank. Usually this value is the same as the Incubation Time. Incubation Time: Enter the total time in seconds required for reading the reaction. Generally this value is the same as the Time for Reagent Blank. The reagent blank is given priority, and therefore the incubation time can be the same. HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 83 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Interval between blanks: Enter the maximum possible time interval for the run of the reagent blank. 72 hours is recommended. The reagent blank should be run each time the reagent bottle is refilled, the reagent batch is changed, or the method is calibrated. Repetition: Enter a minimum concentration value, below which the Auto analyzer will repeat the test under identical sample and reagent(s) conditions, and will show that this result has been repeated. Linear Limit: Enter the upper linearity limit provided by the reagent manufacturer. If this value is exceeded, the instrument will dilute the sample to obtain a value within the linear range. The instrument will run the dilution using half the sample volume programmed in the General tab. The software will show that the sample has been re-diluted. The result will be calculated using a dilution factor for compensation. If the new result is still not within the programmed values, the sample will be diluted again until the minimum volume indicated in the Advanced tab is used. 8.1.4.1.2 Calculations Monochromatic Reading Ab = Reagent Blank Absorbance As = Sample Absorbance F= Factor programmed or obtained by the method calibration C = Concentration C= (As – Ab) • F Bichromatic Reading AB = Reagent Blank Absorbance AB’ = Reagent Blank Bichromatic Absorbance Ab = Reagent Blank Calculated Absorbance As = Sample Absorbance As’ = Sample Bichromatic Absorbance Am = Sample Calculated Absorbance F= Factor programmed or obtained by the method calibration C= Concentration Ab = AB - AB’ Am = As - As’ C = (As – Ab) • F Page 84 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 8.1.4.2 End Point Sample Blank In this type of measurement, the instrument takes a blank reading for each sample to be measured and the result is subtracted from the absorbance of the final reaction. The sample blank reading and reaction reading are run in the same cuvette. This type of reaction is used for methods like Bilirubin, where the sample itself absorbs at the wavelength being used for the assay. Figure 8-10 8.1.4.2.1 Entering Times and Values Time for Reagent 1 + Sample: Enter the total time in seconds required for reading the absorbance of Reagent 1 + sample which is the value for the sample blank. This time cannot be more than the time program in General Tab for Time to Dispense Reagent 2 Incubation Time: Enter the total time in seconds required for reading the reaction absorbance. The sample blank absorbance will be deducted from this value for each sample. Repetition: Enter a minimum concentration value, below which the Autoanalyzer will repeat the test under identical sample and reagent(s) conditions, and will show that this result has been repeated. Linear Limit: Enter the upper linearity limit provided by the reagent manufacturer. If this value is exceeded, the instrument will dilute the sample to obtain a value within the linear range. The instrument will run the dilution using half the sample volume programmed in the General tab. The software will show that the sample has been re-diluted. The result will be calculated using a dilution factor for compensation. If the new result is still not within the programmed values, the sample will be diluted again until the minimum volume indicated in the Advanced tab is used. 8.1.4.2.2. Calculations Monochromatic Reading Ab = Sample Blank Absorbance As = Sample Absorbance HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 85 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 F= Factor programmed or obtained by the method calibration C= Concentration VS = Sample Volume VR1 = Reagent 1 Volume VR2 = Reagent 2 Volume FD = Dilution Factor FD = (VM + VR1) / (VM + VR1 + VR2) C = (Am – Ab • FD) • F Bichromatic Reading AB = Sample Blank Absorbance AB’ = Sample Blank Bichromatic Absorbance Ab = Sample Blank Calculated Absorbance As = Sample Absorbance As’ = Sample Bichromatic Absorbance As = Sample Calculated Absorbance F= Factor programmed or obtained by the method calibration C= Concentration VS = Sample Volume VR1 = Reagent 1 Volume VR2 = Reagent 2 Volume FD = Dilution Factor FD = (VM + VR1) / (VM + VR1 + VR2) Ab = AB - AB’ As = As - As’ C = (Am – Ab • FD) • F Page 86 of 217 OM-E-FC-360-30 Revision Level HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 8.1.4.3 Kinetics In this type of reaction, a set of readings through a specified period is taken by the instrument, as programmed by the user. This method monitors the initial substrate consumption, and calculates by least squares the slope of the straight line that the Δabs/min determines. This type of reaction is used for tests like AST, ALT, etc., where the speed of production or consumption of NADH, etc. is measured. Figure 8-11 8.1.4.3.1 Entering Times and Values T. BDT (Bubble Dispersion Time): Time from the start of the reaction until the first absorbance reading. This absorbance will be used for the initial substrate consumption calculation, but not for the calculation of the end result. This absorbance is compared with the Time to start Readings absorbance. A T. BDT of 20 seconds is suggested. Time to start Readings: Time from the T.BDT, at which the absorbance reading should be started, according to the instructions given by the reagent manufacturer. Time to end Readings: Time from the T.BDT, at which the absorbance readings should be ended. N° of Measurements: Number of readings to be taken in the time between the Time to Start Readings and the Time to end Readings. 3 readings are recommended. 10 readings maximum. Initial Consumption: Maximum value permitted in Δabs/min for the method indicated by the reagent manufacturer. If the substrate initial consumption (Δabs/min) of the reaction is greater than the value entered here, the instrument will dilute the sample automatically. The absorbances used for this calculation are those measured between the “T.BDT” and the “Time to start Readings” and its value is extrapolated to Δabs/min. It is recommended to enter the reagent manufacturer’s suggested value. HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 87 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Linearity: This is the linear correlation coefficient of the absorbance readings according to the time of the reaction. If the coefficient is less than that programmed, the instrument will dilute the sample. It is recommended to enter a value between 0.8 and 0.95 Repetition: Enter a minimum concentration value, below which the Auto analyzer will repeat the test under identical sample and reagent(s) conditions, and will show that this result has been repeated. Linear Limit: Enter a maximum concentration value. The reagent linear limit value given by the manufacturer is one option. Another option is the higher laboratory limit for the test. However, if this value is exceeded, the instrument will dilute the sample to obtain a value within the linear limit. The instrument will run the dilution using half the sample volume programmed in the General Tab. The software will show that the sample has been re-diluted. The result will be calculated using a volume factor for compensation. If the new result is still not within the programmed values, the sample will be diluted again until the minimum volume indicated in the Advanced tab is used. Example for method configuration Figure 8-12 BDT: Bubble dispersion time = 20” TSR: Time to start readings = 100” TER: Time to end readings = 320” Measurements= 3 8.1.4.3.2 Calculations Monochromatic Reading st A1 = 1 Absorbance reading of the Sample A2 = 2 Absorbance reading of the Sample AN = nd nth Absorbance reading of the Sample ΔA/min = change per minute of the sample absorbance calculated by linear regression over “n” Absorbance readings F= Factor programmed or obtained by the method calibration C = Concentration Page 88 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 C= ΔA/min • F Bichromatic Reading A1 = 1st Absorbance Reading of the Sample A2 = 2 Absorbance Reading of the Sample AN = nth Absorbance Reading of the Sample nd ΔA/min = change per minute of the sample absorbance calculated by linear regression over “n” Absorbance readings A1 = st 1 Bichromatic Absorbance Reading of the Sample A2 = 2nd Bichromatic Absorbance reading of the Sample AN = nth Absorbance reading of the Sample ΔA/min = change per minute of the sample bichromatic absorbance calculated by linear regression over “n” Absorbance readings F= Factor programmed or obtained by the method calibration C= Concentration C = (ΔA/min - ΔA’/min) • F 8.1.4.4 Fixed Time Kinetics In this type of measurement the instrument makes only two readings, and calculates the abs. between both for the end result (Figure 8-10). This type of measurement is used for kinetic methods such as Urea, Creatinine, etc. Figure 8-2 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 89 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 8.1.4.4.1 Entering Times and Values Time to start Readings: Enter the total time in seconds for the first absorbance reading. Time between Readings: Enter the total time in seconds after the first absorbance reading, for the second absorbance reading. Repetition: Enter a minimum concentration value, below which the Autoanalyzer will repeat the test under identical sample and reagent(s) conditions, and will show that this result has been repeated. Linear Limit: Enter the upper linearity limit provided by the reagent manufacturer. If this value is exceeded, the instrument will dilute the sample to obtain a value within the linear range. The instrument will run the dilution using half the sample volume programmed in the General tab. The software will show that the sample has been diluted. The result will be calculated using a dilution factor for compensation. If the new result is still not within the programmed values, the sample will be diluted again until the minimum volume indicated in the Advanced tab is used. 8.1.4.4.2 Calculations Monochromatic Reading Ai = Initial Absorbance Reading of the Sample Af = Final Absorbance Reading of the Sample F= Factor programmed or obtained by the method calibration C= Concentration C= (Af – Ai) • F Bichromatic Reading AI = Initial Absorbance Reading of the Sample AI’ = Initial Bichromatic Absorbance Reading of the Sample Ai = Initial Calculated Absorbance Reading of the Sample AF = Final Absorbance Reading of the Sample AF’ = Final Bichromatic Absorbance Reading of the Sample Af = Final Calculated Absorbance Reading of the Sample F= Factor programmed or obtained by the method calibration Page 90 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 C= Concentration Ai = AI - AI’ Af = AF - AF’ C = (Af – Ai) • F NOTE: Always press the Modify and OK buttons if any change is made in the method configuration. If no parameter is changed, exit by pressing the OK button. If this is not done, the methods will not be programmed correctly and the results may be affected. Advanced tab Warning: Changes should only be made in this tab under supervision or only by trained personnel in advanced options. Figure 8-14 The purpose of modifying this part of the Methods Settings is to improve the performance of a certain reagent Within these options are found: Initial Air Gap: A volume of air drawn in the diluter. It is used to minimize contact between the reagent and the liquid inside the probe. The default value is 0 µl and it is recommended not to exceed a value of 20 µl. 2 µl are recommended. Initial Gap Speed: The speed with which the diluter draws in the initial air gap. The default value is 500 1 /6 µl / second. HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 91 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Gap Reagent/Sample: A volume of air drawn in by the diluter. It is used to minimize contact between the reagent and the sample. The default value is 0 µl. 2 µl are recommended. Reagent/Sample Gap Speed: The speed with which the diluter draws in the air gap. The default value 1 is 500 /6 µl / second. Reagent 1 + Sample Dispensing Speed: If bubbles are formed in the reaction cuvette during the dispensing, this speed can be reduced. The default value is 2500 1/6 µl / second. The minimum value is 1600 1/6 µl / second. Reagent 2 Dispensing Speed: If bubbles are formed in the reaction cuvette during the dispensing, this 1 1 speed can be reduced. The default value is 2500 /6 µl / second. The minimum value is 1600 /6µl/ second. Reagent 1 Aspiration Speed: If a viscous reagent is used, the aspiration speed can be reduced. The 1 1 default value is 2500 /6 µl / second. The minimum value is 1600 /6 µl / second. Reagent 2 Aspiration Speed: If a viscous reagent is used, the aspiration speed can be reduced. The default value is 2500 1/6 µl / second. The minimum value is 1600 1/6 µl / second. Dilution with: The dilution of the sample can be performed using half volume of sample or double volume of reagent. Only sample option is available at the moment. Dilutions with sample will be done when the result exceeds the maximum concentration value or linear limit, when the initial substrate consumption is exceeded, or when the linearity is not met. The instrument will use half volume sample than that programmed until reaching the Minimum Volume of Sample programmed in the Advanced tab. The diluter will only aspirate volumes in whole numbers. Minimum Volume of Sample: The minimum volume of sample required to make the re-dilutions. This value must be lower than the Sample Volume value programmed in the General Tab . 1 Sample Aspiration Speed: The default value is 500 /6 µl / second Extra volume: The default value is 0 µl. You can add some extra volume (for ISE methods this extra volume corresponds to sample, for other methods this extra volume correspond to Reagent 1) Mixing: This is performed inside the cuvette where the reaction was dispensed, it’s performed by the probe and the diluter (they aspire different volumes of the reaction and then dispense them back in the cuvette) The mixing can be programmed after dispensing R1 + Sample (if the value is written in the upper field) and/or after dispensing R2 (if the value is written in the bottom field) It’s recommended not to add more than 2 mixings. Page 92 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Figure 8-15 Washings to avoid Interference: Extra wash cycles of the probe can be programmed to prevent interference between reagents of different methods. This extra wash can be up to 2. Select from the general list of methods, the method that is being interfered. Select the Advanced tab, under Washings to avoid interference column, the interfering method. Then click in the number field to the right of the method name, and enter the extra number of washes. Press the Enter key. Washings to avoid self-interference: Self-interference washings can be added. If the method that presents self-interference is a single reagent method, the extra wash of the probe will be added between consecutive dispensing of the reagent. For example, if calcium presents selfinterferences, and two calcium tests are performed in a row, the extra washing will be between both tests. (The washing solution for this extra washing is taken from the 10 liters container by the liquid diaphragm pump) If the method that presents self-interference is a double reagent method, an extra wash of the probe will be added between the dispensing of both reagents, and between consecutive methods (as in the previous example). (The washing solution for this extra washing is also taken from the 10 liters container by the liquid diaphragm pump) This extra wash can be up to 2. Self-Inference Wash Solution: if a different solution from the one in the containers wants to be used, write a solution name, this solution name will now appear available in the drop down lists from the reagents tray, the reagent tray position has to be programmed for this solution. Self-Inference Wash Time: write a number in seconds that the wash solution will be inside the probe. HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 93 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 The same options are available for washings between different reagents. Select from the general list of methods the one that is causing the interference. Then click in the Washing field, enter the extra number of washes, press Enter. It is recommended to enter 1 or 2 extra washes and no more than 3. After that, click on Solution column and write the wash solution name, press the Enter key. Finally click on Time column enter a number in seconds that the wash solution will be inside the probe, press the Enter key. NOTE: The method that’s being interfered is the one that has to be programmed. For instance, let’s assume the glucose is interfering calcium. Go to methods’ configuration, select calcium from the list, and go to Advanced tab, in the list on the right search for glucose and add the number of extra washings and solution to use. This way each time a calcium is made after a glucose, and extra wash will be performed before running the calcium. (If the sequence is Glucose->Calcium, there will be an extra wash, if the sequence is Glucose-> method x-> Calcium, there won’t be an extra wash) Figure 8-16 ISE Methods Settings (Optional) ISE Module measures the potentials developed when the sample is positioned in the electrodes. Next, Calibrant A is positioned in the electrodes. The difference in the two potentials is related logarithmically to the concentration of the measured ions in the sample divided by their respective concentrations in the calibrant solution. General Tab (ISE) Write the method’s name (Ex: ISE) in the blank field on the top of the window (to the left of the Add button) Select in the drop down list ISE type. Fill in the Name field (Ex: ISE) and complete Brand fields. Press Add. The method will appear in the field to the left of the Delete button, included in the general list of methods. Page 94 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Figure 8-17 After adding the ISE type method a new check box and drop down list with the new ISE methods (Li, Na, K, Cl) appears. Figure 8-18 To complete each ion programming process follow this steps: In Name field erase the name that you wrote (Ex:ISE) and write the name of the ion shown in the drop down list (Li, Na, K, Cl), in this case write Lithium. Press Modify button Complete the next fields (most of them are disabled): Unit: Enter the units of measurement desired for the calculation and printout of the results. Decimals: Enter the number of decimal points desired for the calculation and printout of the results. HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 95 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Sample Volume: For serum sample is 70 µl for urine sample is 140 µl (diluted urine) Press Modify button NOTE: Always press the Modify and OK buttons if any change is made in the method configuration, if no parameter is changed, exit by pressing the OK button. If this is not done, the methods will not be programmed correctly and the results may be affected. Factor tab (ISE) ISE Module performs an internal calibration using its own reagents, nevertheless it has to be considered that there might be some dilution of the sample while aspirating and dispensing, and this is not contemplated during the internal calibration. So it’s recommended that each method be calibrated externally also, as in general methods. If Factor option is selected, enter the corresponding value in the field to the right. If calibration curve option is selected, select Calibrator and complete the fields below. In the Point field assign a number for each point (starting from 1) Complete calibrator and absorbance field with the value “0”, since the concentration is taken from the input value in the concentration field of the calibration parameters, and the absorbance value will be adjusted automatically to the obtained value during the calibration. If the calibration curve has more than one point repeat the previous steps until reaching the desired number of points. This step connects in the software the “Methods” window with the “Calibrators” window, where the calibrator concentration must be entered. There will be as many calibrators as points entered in the method settings. For that, go to the “Calibrator Parameters” section. If only one calibration point is programmed, the system will assume the second point of reference is“0”. If two or more points are programmed, the system stops using “0” as a point of reference, and a point of concentration “0” should be programmed. Possible Interpolation types are: Linear: Conc = a • Abs + b Potential: Conc = 10 Page 96 of 217 (a • log (Abs) + b) HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Exponential: Conc = e (a • Abs + b) Polynomial: Conc = a0 + a1 • Abs + a2 • Abs2 + … + an • Absn where n is the number of programmed calibrators. Cubic Spline Multilinear Special Tab (ISE) Figure 8-19 Select sample type between Serum/Plasma and Urine. Serum/Plasma: 70 µl Urine (diluted): 140 µl Remember each sample type has different sample volume parameter. Must be programmed in the General tab. 8.2.3.1.1 Calculations (ISE) Since the difference in potentials and the concentration of lithium, sodium, potassium, and chloride ions in the calibrant solution are known, the computer can calculate the concentration of the ions in the sample, in accordance with the Nernst equation, rewritten as: Ex - Es = S log (Cx / Cs) or Cx = Cs x 10^ [ (Ex-Es)/S ] Where: Ex = ISE potential developed in sample solution Es = ISE potential developed in the calibrant solution S = Electrode slope calculated during calibration HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 97 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Cx = Concentration of ion in the sample Cs = Concentration of ion in the calibrant solution “S”, the slope, is determined during calibration using Calibrants A and B, which have known levels of lithium, sodium, potassium, and chloride. When a two-point calibration is initiated, the slope is calculated from the difference between each Calibrant A and Calibrant B reading. Excessive drift or noisy readings will be flagged and the appropriate error message will be shown. NOTE: Always press the Modify and OK buttons if any change is made in the method configuration. If no parameter is changed, exit by pressing the OK button. If this is not done, the methods will not be programmed correctly and the results may be affected. Advanced tab (ISE) Warning: Changes should only be made in this tab under supervision or only by personnel trained in advanced options. Figure 8-20 The purpose of modifying this part of the Methods Settings is to improve the performance of a certain reagent (Figure 8-15) Within these options are found: Initial Air Gap: A volume of air drawn in the diluter. It is used to minimize contact between the reagent and the liquid inside the probe. The default value is 0 µl and it is recommended not to exceed a value of 20 µl. 2 µl are recommended. Page 98 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Initial Gap Speed: The speed with which the diluter draws in the initial air gap. The default value is 500 1 /6 µl / second. Gap Reagent/Sample: A volume of air drawn in by the diluter. It is used to minimize contact between the reagent and the sample. The default value is 0 µl. 2 µl are recommended. Reagent/Sample Gap Speed: The speed with which the diluter draws in the air gap. The default value 1 is 500 /6 µl / second. Reagent 1 + Sample Dispensing Speed: If bubbles are formed in the reaction cuvette during the dispensing, this speed can be reduced. The default value is 2500 1/6 µl / second. The minimum value is 1600 1/6 µl / second. For ISE we 1 recommend 1700 /6 µl / second. Reagent 2 Dispensing Speed: If bubbles are formed in the reaction cuvette during the dispensing, this 1 1 speed can be reduced. The default value is 2500 /6 µl / second. The minimum value is 1600 /6 µl / second. Reagent 1 Aspiration Speed: If a viscous reagent is used, the aspiration speed can be reduced. The 1 1 default value is 2500 /6 µl / second. The minimum value is 1600 /6 µl / second. Reagent 2 Aspiration Speed: If a viscous reagent is used, the aspiration speed can be reduced. The default value is 2500 1/6 µl / second. The minimum value is 1600 1/6 µl / second. Dilution with: The dilution of the sample can be performed using half volume of sample or double volume of reagent. Only sample option is active. Dilutions with sample will be done when the result exceeds the maximum concentration value or linear limit, when the initial substrate consumption is exceeded, or when the linearity is not met. The instrument will use half volume sample than that programmed until reaching the Minimum Volume of Sample programmed in the Advanced tab. The diluter will only aspirate volumes in whole numbers. Minimum Volume of Sample: The minimum volume of sample required to make the re-dilutions. This value must be lower than the Sample Volume value programmed in the General Tab. 1 Sample Aspiration Speed: The default value is 500 /6 µl / second Extra volume: The default value is 0 µl. You can added some extra volume (for ISE methods this extra volume correspond to sample, for other methods this extra volume correspond to Reagent 1) Washings to avoid Interference: Refer to section 8.1.5 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 99 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Reagents in Use and Profiles Figure 8-21 Within the Methods menu, select Reagents in Use and Profiles (Figure 8-16). Every time a method is programmed, it will appear on the In Use listing. Here is where the programmed methods should be set ‘in use’. The programmed methods can be: Available: They are seen in the column headed ‘Available’, and they will not appear in the selection options (when adding a sample, calibrator or control, in the reagents tray) In use: They are seen in the column headed ‘In Use’ and they will appear in the selection options (when adding a sample, calibrator or control, in the reagents tray) To change an Available method to In Use, select the chosen method from the Available list and press the key: To change an In Use method to Available, select the chosen method from the In Use list and press the key: After the change has been made, press the OK key. In the Profiles column, groups of methods called Profiles can be created. (Figure 8-17) Within the column, select the methods desired for the profile; enter a name in the field under this column as shown in the example, and then press the Add and OK keys. Note: If methods file is deleted, profiles will be shown anyway Page 100 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Figure 8-22 Saving Methods The configured methods in the software can be saved in a file or location different from that which the software uses. They are saved with the extension *.amf. This extension is only used for the BioChem FC-360 program, and is not able to be opened with any other application. This operation is unavailable while processing patients, calibrators and/or controls. Open the menu Methods and select Save (Figure 8-18) An explorer window will open. Select or create the location where the file will be saved. Give the file a name and press the Save button, or press the Cancel button if saving is not the desired operation. HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 101 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Figure 8-23 Loading Methods Methods are loaded from a different location than that used by the program. Only files with the *.amf extension are able to be loaded. This operation is unavailable while processing patients, calibrators and/or controls. Open the menu Methods and select Load (Figure 8-19) Figure 8-24 An explorer window will open. Select the desired *.amf file. Only files with this extension are able to be loaded. Press the Open button, or press the Close button if opening a file is not the desired operation. When loading a new file, it is added to the currently loaded file. The software saves this information when it is closed. Warning: The software saves certain information when it is closed. The method files are not replaced, but added together during the loading of a new file, giving a combined methods file as a result. To replace the method file in use by a new one (see Chapter 13 Point 13.2) Page 102 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Saving Profiles The created profiles can be saved in a different location than that used by the program. They are saved with the extension *.aef. This extension is used for the BioChem FC-360 program. This operation is unavailable while processing patients, calibrators and/or controls. Open the menu Methods and select Save Profiles (Figure 8-20) Figure 8-25 An explorer window will open. Select or create the location where the file will be saved. Give the file a name and press the Save button, or press the Cancel button if saving is not the desired operation. Loading Profiles Created profiles can be loaded from a different location than that used by the program. Only files with the *.aef extension are able to be loaded. This operation is unavailable while processing patients, calibrators and/or controls. Open the menu Methods and select Load Profiles (Figure 8-21) An explorer window will open. Select the desired *.aef file. Press the Open button, or press the Close button if opening a file is not the desired operation. Figure 8-26 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 103 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 9 CALIBRATORS MENU Calibrator parameters settings as well as calibrator files handling can be carried out from the Calibrators Menu. There is also a shortcut to parameters setting from the icon Calibrators Parameters (Figure 9-1) Figure 9-1 Settings Calibrator parameters are set on the Settings submenu. This operation is unavailable while processing patients, calibrators and/or controls. Press Settings on the Calibrators Menu or the Calibrators Parameters shortcut icon. The configuration screen will then be displayed (Figure 9-2) and the Name, Brand, Lot and Expiration date (dd/mm/yyyy) for the calibrator is entered. Press Add to add the calibrator. NOTE: Do not enter a name too big. Software will cut the name. Once the calibrator has been entered, concentration values for each analyte have to be programmed. In order to do this, select the calibrator in the column: Calibrator; select the method in the column Method and select the concentration fields in the column Conc. Type the concentration value assigned to the calibrator for the analyte and press Enter from the keyboard. To the right of the Concentration value, a number for repetitions can be added, in the column Repetitions (for example, if you write “1” in the repetition column, that method of that calibrator will be processed twice, an average of those results will be used later in the calibration curve) Finally, select in the column Point the related calibration curve point. When the method has different calibration points with different concentrations, a calibrator must be configured for each point. Press OK to save the data previously entered. Warning: Calibrator concentration values entered for each method must be expressed in the same units used in the method configuration to express the results. Page 104 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Figure 9-2 The remove a calibrator already entered, select the calibrator in the column Calibrator and press Delete and then OK. To modify a concentration already entered, place the cursor on the data and modify it. Then press Enter on the keyboard and OK to save modifications. When the calibration of a method is requested, the software uses the calibrator in use configured concentration for the calculation of the results. Figure 9-3 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 105 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Saving Calibrators Files Calibrators configuration data in use can be saved through the submenu Save. By pressing Calibrators Menu Save, an exploration window is displayed. Select the folder or location where the data will be saved. Name the file and press Save or Cancel if the operation will not be carried out. A file with extension *.acf will be created which can be used as a backup or to be installed in another PC. Loading Calibrators Files Calibrators configuration data can be obtained through the submenu Load from a different file than the file in use. By pressing Calibrators Menu Load, an exploration window is displayed. Select the folder or location from where the data will be obtained. Select the file with extension *.acf and press Open or Cancel if the operation will not be carried out. All the data of the calibrators that appear in the selected file will then be entered. Warning: By entering configuration data of new calibrators through the submenu Load, all the data of calibrators in use will be deleted. Additionally, if the methods configured in the loaded file are different from the methods in use, the calibrator value will appear as -1. Before this operation, back up the calibrators in use as indicated in Chapter 9 Point 9.2 10 CONTROLS MENU Controls parameters setting as well as controls files handling can be carried out from the Controls Menu. There is also a shortcut to parameters setting from the icon Controls Parameters (Figure 10 - 1) Figure 10-1 Page 106 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Settings Controls parameters are set on the Settings submenu. This operation is unavailable while processing patients, calibrators and/or controls. Press Settings on the Controls Menu or Controls Parameters shortcut icon. The configuration screen will then be displayed (Figure 10-2) and the data of the control is entered first in the pertinent fields: Name, Brand, Lot and Expiration date, in this format: dd/mm/yyyy. Press Add to add the new control. NOTE: Do not enter a name too big. Software will cut the name. Figure 10-2 Once the control has been entered, minimum and maximum concentration values are assigned. In order to do this, select the control in the column Control; select the method in the Method column and select the minimum concentration field in the column Min. C. Add the minimum concentration value assigned to the control and press Enter. Then select the maximum concentration field in the column Max. C. and enter the maximum concentration value and press Enter. Finally, press OK to save the data previously entered. During the controls process the software verifies that the results obtained are within the programmed ranges and the control results are reported as Correct or Error. Warning: Minimum and maximum concentration values entered for each method must be expressed in the same units used to express results in the general method configuration. Warning: Every time the control lot in use and its concentration values are changed, enter the new lot as a new control. To remove a control that has been entered, select the control in the column Control and press Delete and then OK. To modify a concentration that has been entered, place the cursor on the data and modify it. Then press Enter on the keyboard and OK to save modifications. HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 107 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Saving Controls Files Controls configuration data in use can be saved from the submenu Save. By pressing Controls Menu Save, an exploration window is displayed. Select the folder or location where the data will be saved. Name the file and Save or Cancel if the operation will not be carried out. A file with extension *.aof will be created which can be used as a backup or to be installed in another PC. Loading Controls Files Controls configuration data can be obtained through the submenu Load from a different file than the file in use. By pressing Controls Menu Load, an exploration window is displayed. Select the folder or location from where the data will be entered. Select the file with extension *.aof and press Open or Cancel if the operation will not be carried out. All the data of the controls that appear in the selected file will then be entered. Warning: By entering configuration data of new controls from the submenu Load, all the data of controls in use will be deleted. Before this operation, it is recommended to back up the controls in use as indicated in Chapter 10, section 10.2 11 STATISTICS MENU The Statistics Menu (Figure 11-1), which is accessed from the main screen, is where patients, calibrators and controls statistical analysis is carried out. There is also a shortcut to the statistical analysis of data from the Levy-Jennings Plot icon. Figure 11-1 Levy-Jennings of Patients Levy-Jennings plots can be made to represent values obtained in the same patient for a certain analyte. To do this, data must be previously ordered in the PAT Results Tab, performing an advanced search by Last Name and Name, so that all processes for the same patient are shown together. The following steps must be carried out: 1. Select the Process Date from/to which the search will be performed. 2. Perform an advanced search of the data of the same patient (Figure 11-3): For example: Name: Page 108 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 John, Last Name: Smith. The search can also be performed by Age, Sex, Protocol, Doctor or Bed 3. Select the data obtained, press Statistics Menu Levy-Jennings of Patients or press the shortcut Levy-Jennings Plot icon. 4. A screen will then appear to display all the methods performed to the selected processes (Figure 11-2). Select the method to be plotted and press OK or Cancel to cancel the operation. Figure 11-2 Figure 11-3 The graph is a Levy-Jennings Plot where the results obtained for each point are shown. The CV% and the Average for the data are also reported. In the plot different lines can be observed, which show the values corresponding to the average and +/- SD per line (Figure 11-4). The plotted data can be edited: place the cursor on the appropriate box, enter the new value and press Enter on the keyboard. By pressing Calculate, the statistical parameters will be calculated and a new graph will be obtained. Warning: Data can be temporarily edited, but will not be saved by the program. HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 109 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Figure 11-4 Levy-Jennings of Calibrators Levy-Jennings plots can be made to represent values obtained in the same calibrator for a certain analyte. To do this, data must be previously ordered in the CAL Results Tab, performing an advanced search by Calibrator and Method. The following steps must be carried out: 1. Select the Process Date from/to which the search will be performed. 2. Perform an advanced search of a particular calibrator data (Figure 11-5): For example: Calibrator: CAL 1, Method: GLUCO-DICO. The search can also be performed by Report that means by obtained result. 3. Select the data obtained, press Statistics Menu Levy Jennings of Calibrators or press the shortcut Levy-Jennings Plot icon. Page 110 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Figure 11-5 The graph obtained is a Levy-Jennings Plot where the results obtained for each point are indicated. The CV% and the Average for the data are also reported. In the plot, different lines can be observed, which show the values corresponding to the average and +/- SD per line (Figure 11-4). The plotted data can be edited: place the cursor on the appropriate box, enter the new value and press Enter on the keyboard. By pressing Calculate, the statistical parameters will be recalculated and a new graph will be obtained. Warning: Data can be temporarily edited, but will not be saved by the program. Levy-Jennings of Controls Levy-Jennings plots can be made to represent values obtained in the same control for a certain analyte. To do this, data must be previously ordered in the CON Results Tab, performing an advanced search by Control and Method, so that all results for the same method are shown together. The following steps must be carried out: 1. Select the Process Date from/to which the search will be performed. 2. Perform an advanced search of the data of a level or kind of control and a certain method: Example: CONTROL N, Method: ALBU-DICO (Figure 11-6). 3. Select the data obtained, press Statistics Menu Controls Levy-Jennings Plot or press the shortcut Levy-Jennings Plot icon. HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 111 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Figure 11-6 The graph obtained is a Levy-Jennings Plot where the results obtained for each point are indicated. The CV% and the Average for the data are also reported. In the plot, different lines can be observed, which show the values corresponding to the average and +/- SD per line (Figure 11-4). The plotted data can be edited: place the cursor on the appropriate box, enter the new value and press Enter on the keyboard. By pressing Calculate, the statistical parameters will be calculated and a new graph will be obtained. Warning: Data can be temporarily edited but will not be saved by the program. Quality Control This function allows a quality control graph of controls to be viewed and printed from the CON Results tab. Page 112 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Figure 11-7 The results of the controls will have to be selected before being drawn. Figure 11-8 If more than one method is selected, a method selection window will appear. Figure 11-9 In the same way, if more than one control is selected, a control selection window will appear. Figure 11-10 Observe between brackets the number of lot that was entered during control programming (in Controls Menu), and that it’s added to the name of the control. Thus, the controls of different lots are considered to be different controls for the quality control chart. NOTE: Control settings must be programmed with lot number HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 113 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Figure 11-11 In the upper side of the graph, control settings are shown. Figure 11-12 To the right side, the statistical information and the concentrations of the selected controls are shown. Figure 11-13 Page 114 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 In the lower left side, the quality control graph is shown. Programmed control values are shown in solid line: Gray = Mean value (this value is the average value between the programmed maximum and minimum control values) Green = ± 1SD (these values are obtained by considering the programmed maximum and minimum control values as ± 2SD) Yellow = ± 2SD (this values are obtained from the programmed maximum and minimum control values) Red = ± 3SD (these values are obtained by considering the programmed maximum and minimum control values as ± 2SD) Selected controls statistics are shown in dotted line Gray = Mean value Green = ± 1SD Yellow = ± 2SD Red = ± 3SD Figure 11-14 Lines can be individually hidden by pressing the related upper side reference. For example, by pressing on the -3SD Cont text, the bottom red line will be hidden. 12 MAINTENANCE MENU The Maintenance Menu is accessed from the main screen of software (Figure 12-1). In this menu general configuration options of the system, maintenance operations and validation tests are separately described. HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 115 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Figure 12-1 Settings Serial Port Tab Figure 12-2 Communication port configuration data is preset in the Serial Port Tab (Figure 12-2). Available Serial Port: the PC Communication Port is accessed by the software and communication is established between them. The message appears on a green frame. Warning: Do not make changes in the preset communication port configuration. Files Tab The names and addresses of the files the software uses to work on a daily basis appear on the Files tab (Figure 12-3). There are Methods, Calibrators, Trays, Tests and Log files. Each of them has a particular extension. Page 116 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 The log files are communication reports between the instrument and the PC. They contain a history of actions that have occurred every time there is an error message in the system. They have HTML format and they are used by technical support to determine the causes of errors whenever there is a failure. A log file is generated automatically on a daily basis. Figure 12-3 File locations: By pressing Browse, the explorer window displays the folder where the file in use is located. By using this command, the files that appear on screen are only those with the same extension as the pertinent file. For example, if Browse is pressed for Methods File and a folder is selected, the files that appear on screen when it is opened are only those with *.amf extension. File modification: The names of the files in use and/or their path on the PC may be modified in this screen. If such modifications will not be made, go back to the original name by pressing Reset. To save modifications, press OK or press Cancel. Modifications to the name and path of the files are automatically saved by the software every time it is closed. Warning: method files are not replaced. They are added with the change of name, creating as a result an integral method file. HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 117 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Database Tab Figure 12-4 The name and address of the results file in use with the extension *.adb appear in the Database tab (Figure 12-4) File location: by pressing Browse the exploration window will be displayed, and the file in use folder is shown. If another location is selected, the files shown when each folder is opened will only be those with *.adb extension. If you wish to see the results saved in another file, select it and press Save, the new name and address will appear on screen. To save modifications press OK or otherwise press Cancel. File modification: the name of the file in use and/or its addresses on the PC may be modified on this screen. If such modifications will not be made, go back to the original name by pressing Reset. To save modifications, press OK or otherwise, press Cancel. Modifications to the name and location of the file are automatically saved by the software every time it is closed. Export Results: the database may be saved in .csv format. Press Export Results and select the folder where the data will be saved. Name the file and press Save. A screen where the type of results to be saved can be selected appears: Patients, Controls and/or Calibrators results. Also Technical Information and/or Kinetics Points can be added (Figure 12-5). Choose the option/s and then press Export. Page 118 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Figure 12-5 The next screen allows selecting date and time or process numbers from/to save information range (Figure 12-6). Choose the required option/s, complete the initial and final data to be saved and then press Selection. To save all the available information of the file in use, press All. Then a file with *.csv extension will be created, and it can be read using Excel. This option allows to save separately every type of data or to make statistics, searches, etc., using Excel functions. Figure 12-6 Database Copy: This button will allow saving *.adb files that contain results in the database. The entire database is saved; no range or type can be individually selected. It is recommended that a back-up copy of the database be made before it is initialized. Initialize: Before initializing the database a Results Back-up and a Results Export should be made (see Results Export and Results Back-up). Once the results back-up and the results export have been carried out, press Initialize, all Patients results, calibrators, controls and methods are deleted from the system. The following message will show: Figure 12-7 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 119 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Press Yes to confirm or No to go back to the previous window. The latest calibration is saved in the configuration of methods and configuration data regarding calibrators, controls and method is not modified. Statistics: The number of Patient, Calibrator and Control results that have accumulated in the database in use is displayed. The total number of test results obtained with current run is shown to the left of the main window. In the adjacent box the number of test results obtained with every available method can be seen. In this box Total represents the Grand Total of all tests in the database in use. This counting is refreshed by pressing Refresh Statistics. Warning: The database must be initialized regularly so that the working speed of the software is not affected. This process should be carried out on a monthly basis or when the number of total determinations reaches 10,000 tests. Ages Tab Figure 12-8 The age groups are configured in the Age Tab (Figure 12-7). To enter a new age group, press Add, and fill in name of the group under Type, and the minimum and maximum ages (in years) in the From and To fields. This data is used in the Add Process screen to assign the appropriate age group to each patient. Operations Add Sample Patients Age select the age group (Figure 12-8). To delete an age group, click inside that box and press Delete. It is possible to set the printout of the Patient Report and/or Technical Report to show the reference values of every patient according to their age group (See Chapter 8, section 8.1.3, Reference Values Tab). Page 120 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Figure 12-9 Reports Tab The printout formats of Patient Reports and Technical Reports are configured in this tab (Figure 12-9) Figure 12-10 The Patient Report has an easy-to-read format designed to be delivered directly to patients or doctors. The report is printed on a separate sheet of paper for each patient. The Technical Report has a more compressed format and is used to generate a printed record of results. Results from multiple patients are printed on the same report. HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 121 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 By clicking on the box Patient’s Report/Page Heading, the different sections of the Patient’s Report/Technical Report to be configured are displayed (Figure 12-10). The configuration language is HTML. The final format appears at the bottom of the screen. The configuration is written in the text box in the middle of the page. If no modification is made, press Reset to go back to the original format. To save modifications press OK, otherwise press Cancel. Figure 12-11 By clicking on Configure Printer, a list of the available printers and their properties are shown. By clicking on Print Test Page, select the number of samples and methods to be printed (Figures12- 11 and 12-12). This allows test prints of the printer configuration. Then, select the printout format: Patient Report or Technical Report. The configured format can be seen on screen by pressing Preview or by printing it, by pressing Print (Figure 12-13) Figure 12-12 Page 122 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Figure 12-13 Figure 12-14 Memory Tab The technical data in the internal memory of the instrument can be viewed and modified in the Memory tab (Figure 12-14) In this tab the status of the variables related to each module of the instrument is shown. By pressing Get from Instrument, the software reads all the data saved in the internal memory of the equipment. This process takes several minutes and can be seen in the Status Bar. Warning: These processes are carried out only by Technical Support or personnel trained in advanced operations. Figure 12-15 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 123 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Language/ Style Tab In this tab the language and the style are selected (Figure 12-15). Language: Click on the desired language and press OK. For the language changes to be loaded in the system, close the software and open it again. Style: By displaying the Style menu, all the possible screen design style options appear on the screen. Select the desired style, and press OK. For changes of style to be loaded in the system, close the software and open it again. Warning: Do not make Language/Style changes while the instrument is running. Remember to close and open the software after making changes. Figure 12-16 Page 124 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Access Control Tab Access control can be changed by the software administrator. Admin: password to enter in Settings of Maintenance menu. Methods: password to enter in Settings of Methods, Calibrators and Controls menu. Service: password to enter in Commands Console of Maintenance Menu Select on the left side the option that one to be changed and the right side fill in with the new password, repeat new password and finally press Change Password button. Figure 12-17 Warning: in case of losing or forgetting passwords contact technical support Cuvettes Status By clicking on Maintenance and selecting Cuvettes Status, a screen will appear (Figure 12-17) which shows the number and status of each cuvette, represented by different colors: Green: Clean Light Red: Dirty Dark Red (6 different shades): In washing process and drying process: -Washing 1: Aspiration of liquid and dispensing of washing solution -Washing 2: Aspiration of liquid and dispensing of washing solution HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 125 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 -Washing 3: Aspiration of liquid and dispensing of washing solution -Washing 4: Aspiration of liquid and dispensing of washing solution -Washing 5: First drying step -Washing 6: Second drying step Light Blue: In Use Gray: Unknown status Cuvettes status is constantly refreshed as operations are carried out in the cuvettes tray. Warning: Every time the software is unexpectedly closed in unusual way, the instrument shows the status of the cuvettes as all dirty, this is a preventive action. Therefore, it is necessary to start sessions by washing dirty cuvettes or by carrying out the programmed washing. Otherwise, start the new session by washing the entire cuvettes tray (Wash cuvettes range of cuvettes to 100 wash) Figure 12-18 Page 126 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Containers Status By clicking on Maintenance and selecting Containers Status, a screen will appear which shows the volume of liquid in each container, expressed as a percentage of its total capacity. When the level of waste liquid is above 90% and/or that of the washing solution is below 10%, a red warning sign will automatically appear on this screen (Figure 12-18) Figure 12-19 To make changes in level of liquid of the bottles, the instrument must not be working. Once the waste bottle has been emptied, the instrument can work again. Once new washing solution has been added, make five purge cycles of the diluter (Maintenance Instrument Diluter Purge) Then wash cuvettes from 1-10 five times (Operations menu wash cuvettes Range 1-10 Wash) Warning: The level of liquid is only refreshed when processes that require the aspiration or dispensing of liquid are carried out. Programmed washing The Programmed Washing option appears on screen two minutes after the working sequence has finished and all the results have been shown (Figure 12-19) This process washes dirty cuvettes which have just been used and those which have not been fully washed, being executed in the indicated remaining time. If Execute is selected, the washing is carried out at that moment. If it were left some samples pending of process, passed 10 minutes an autostop will take place automatically; after that the sequence of programmed washing will be carried out. Warning: DO NOT cancel the programmed washing since it may affect next washings as well as cuvettes lifespan. HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 127 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Figure 12-20 TIP Cleaning This process consists in the internal and external washing of the TIP or probe which aspirates and dispenses samples and reagents. Select Cleaning TIP from the Maintenance Menu and place a tube containing 30% Sodium Hypochlorite in the chosen position. On the screen, position 60 appears as preset option. Click OK. This cleaning must be carried out after finishing work on a daily basis. Figure 12-21 Page 128 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Communications By clicking on Maintenance and selecting Communication, two communication options between the PC and the instrument are displayed: Commands Console and Serial Port Log (Figure 12-21) Figure 12-22 Commands Console This screen allows selecting working commands. The different commands allow for individual movements of the instrument components, reading of parameters, writing of parameters, working sequences, etc. The desired command can also be straightly written on the Terminal window through the initials of each operation. Warning: These operations should be carried out by Technical Support, but may be done by users in some particular cases by following precise instructions. Figure 12-23 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 129 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Serial Port Log All the operations between the instrument and the PC are registered by the Serial Port Log screen (Figure 12-23). This registration only occurs when the screen is open and the command AutoRef is active. The following options appear: Close: It closes the screen Highlight: the different operations carried out by the instrument are differentiated with colors for a better view. Refresh: it updates data AutoRef: data is constantly updated Save: it allows saving all the data obtained in the PC in HTML file format. This data may then be used to analyze processes, to determine causes of failure, etc. It is used by Technical Support. Clean: it deletes all data obtained until that moment. Figure 12-24 Page 130 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Validations By clicking on Maintenance and selecting Validations, some validation tests are displayed which are used to control how the components of the instrument are working (Figure 12-24). The spectrophotometer, the diluter and the washer are controlled through these tests. Each user can create an internal quality control program of their Autoanalyzer by using these tests. Warning: A Special Washing cycle with Sodium Hydroxide 0.2 N is recommended before making the Validation Tests (see Chapter 7 point: 7.7) Figure 12-25 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 131 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Stray Light Stray light is any electromagnetic radiation of a different wavelength from that selected wavelength reached by the detector and which is registered by the instrument. This test is based on the absorbance measurement of a Sodium Nitrite solution. The solutions of this substance absorb all wavelength radiation lower than 390 nm, that is why they are called optically opaque to UV light. Required materials: Sodium Nitrite Solution 50 g/l Automatic pipette Procedure: 1. Dispense manually 300 µl of the solution in cuvette 1 or in any cuvette, indicating it on the screen (Figure 12-25) 2. Wait for 5 minutes to reach thermal stability of the solution in the cuvette 3. Select Maintenance Validations Stray Light Cuvette number OK Filter OK 4. The instrument reads at the selected wavelength, informing the value in absorbance units AU. 5. Perform the reading in duplicates. Acceptable stray light: Abs. Higher tan 3AU Figure 12-26 Figure 12-27 Page 132 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Photometer Precision Photometric precision is the measurement of the dispersion of absorbance measurements around the mean and it is expressed as a variation coefficient. This measurement is always made in the same cuvette. Required materials: Copper Sulfate Solution 30 g/l in Sulfuric Acid 0.45 N Automatic Pipette Procedure: 1. Dispense manually 300 µl of the solution in cuvette 2 or in any cuvette, indicating it on the screen (Figure 12- 27) 2. Wait for 5 minutes to reach thermal stability of the solution in the cuvette 3. Select Maintenance Validations Photometer Precision Cuvette Number OK Filter OK 4. The instrument makes 30 correlative readings of the solution at the selected wavelength, reporting the obtained values in absorbance units AU, the arithmetic mean and the coefficient of variation CV% for this data. 5. Perform the test in duplicate. Acceptable photometric precision: CV% lower than 1.0% Figure 12-28 Figure 12-29 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 133 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Photometric Accuracy Photometric Accuracy means similarity between the absorbance unit and the real absorbance of a specific certified solution measured using reference standards. The error while reading the absorbance of this solution regarding the certified value is called Photometric inaccuracy. Required materials: 2 solutions of Potassium Dichromate in Perchloric Acid 0.001 N of different concentration and with known and certified absorbance, measured using NIST Reference Standards Certificates (National Institute of Standards and Technology). Example: solution A and B Automatic pipette Procedure: 1. Dispense manually 300 µl of the solution A in cuvette 3 or in any cuvette, indicating it on the screen (Figure 12-29) 2. Dispense manually 300 µl of the solution B in cuvette 4 or in any cuvette, indicating it on the screen (Figure 12-30) 3. Wait for 5 minutes to reach thermal stability of the solutions in the cuvette 4. Select Maintenance Validations Photometric Accuracy Cuvette number OK Cuvette Number OK Filter OK 5. The instrument makes the readings of both solutions at the selected wavelength, reporting the value in absorbance units AU. 6. Make the reading duplicate. 7. Calculate the % of photometric inaccuracy according to the following formula: % Photometric inaccuracy = [measured abs – reference abs] x 100 Reference abs. Acceptable photometric inaccuracy: lower than 5.0% Figure 12-30 Page 134 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Figure 12-31 Figure 12-32 Photometric Linearity Photometric linearity means the photometric capacity to make absorbance readings proportional to concentration changes for solutions of increasing concentrations of a substance which follows Beer’s law. Required materials: Potassium Dichromate solutions in Perchloric Acid 0.001 N of increasing concentrations and known and certified absorbance measured using NIST Reference Standards Certificates (National Institute of Standards and Technology). Example: 25, 50, 100 and 200 mg/l (solutions A, B, C and D respectively). Automatic Pipette. Procedure: 1. Dispense manually 300 µl of solution A in cuvette 5 or in any cuvette, indicating it on screen (Figure 12-32) 2. Dispense manually 300 µl of solution B in cuvette 6 or in any cuvette, indicating it on screen (Figure 12-33) 3. Dispense manually 300 µl of solution C in cuvette 7 or in any cuvette, indicating it on screen (Figure 12-34) 4. Dispense manually 300 µl of solution D in cuvette 6 or in any cuvette, indicating it on screen (Figure 12-35) 5. Wait for 5 minutes to reach thermal stability of the solutions in the cuvette 6. Select Maintenance Validations Photometric Linearity Cuvette Number OK Cuvette Number OK Cuvette Number OK Cuvette Number OK Filter OKThe instrument makes the reading of four solutions at the selected wavelength, informing the values in absorbance units AU. 7. Perform the test in duplicate. 8. With the results obtained, make a graph of absorbances found (y) in relation to reference absorbances (x) and calculate the correlation coefficient by linear regression. HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 135 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Acceptable photometric linearity: higher tha 0.9995 Figure 12-33 Figure 12-34 Figure 12-35 Figure 12-36 Figure 12-37 Page 136 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Diluter Precision This test allows to determine volume precision of the diluter hydraulic system by making repeated dilutions and readings of the same reaction at 340 nm. Required materials: Sample solution: Potassium Dichromate solution 5g/l in Perchloric Acid 0.001 N Reagent solution: Potassium Dichromate solution 0.25 g/l in Washing Solution (Triton X-100 diluted). It is prepared by diluting 5 ml of Sample Solution in one liter of Washing Solution. Procedure: 1. Set a new method with the parameters shown in Figure 12-38 Methods Settings 2. Place the Sample Solution in a sample tube and the Reagent Solution in a reagent bottle and assign a position in the reagents tray 3. Make the Diluter Precision test Maintenance Validations Diluter Precision mselect the method Dichromate Test assign a position to the Sample Solution: 1 define the number of replicates to be made, minimum 10 OK Make the test duplicate. Acceptable diluter precision: CV% lower than 1.5% Note: this test can also be used to validate methods in use, determining each test CV% at different concentration values. Figure 12-38 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 137 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 ADAPTATION GENERAL Name Type Main Wavelength Bicrom. Wavelength Dichromate End Point R.Blank 340 700 SPECIALS Time for Reagent blank Interval between blanks Incubation Time Repetition 60 72 60 0,4 Units -- Linear Limit 2,0 Decimals Sample Vol. R1 Vol. R2 Vol. Time to Disp R2 Min. Abs 4 6 300 0 0 0 ADVANCED Initial Air Gap Initial gap Speed Gap Reagent/Sample Reagent/Sample Gap Speed 2 500 2 500 Max. Abs Verification time 2 16 R1+ Sample Dispensing Speed R2 Dispensing Speed 2500 2500 R1 Aspiration Speed 2000 FACTOR Decreasing method Factor Calibrator No Yes/ 1 No R2 Aspiration Speed Dilution with Minimum sample volume 2000 Sample 2 Interpolation Linear Sample aspiration Speed 500 Figure 12-39 Page 138 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Precision test P150 and P250 The precision study is used to determine the repeatability of the measured parameters under unchanged conditions. You will test P150 and P250 as a sample, using DI water for the Reagent for these precision tests Using the Precision Test Dye solution program the methods referring to section 12.7.6.1 and 12.7.6.2. For the P150 and P250 Precision Tests, use DI water as the reagent and the P150 and P250 dyes as the samples. P150 solution active ingredients and concentration: Potassium Dichoramte Sulfuric Acid 30mM 0.01N P250 solution active ingredients and concentration: Potassium Dichoramte Sulfuric Acid 88mM 0.01N Run each solution (P150 and P250) 10 times Create a spreadsheet for the results of the P150 and P250 tests and include calculations for the Mean, Standard Deviation and CV% The following formulas are used to calculate the Mean, Standard Deviation and CV%: Mean = Sum of 10 results 10 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 139 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 The P150 CV% should be equal to or less than 1.5% and The P250 CV% should be equal to or less than 2.5% The following is an example of a precision study P150 Page 140 of 217 P250 1 2 3 4 5 6 7 8 9 10 0.9866 0.9950 0.9906 0.9776 0.9775 0.9741 0.9824 0.9770 0.9798 0.9827 1 2 3 4 5 6 7 8 9 10 1.7018 1.7215 1.7327 1.7220 1.7476 1.7450 1.7105 1.7218 1.7087 1.7184 MEAN SD CV% CV% Range 0.9823 0.01 0.67 ≤ 1.5 MEAN SD CV% CV% Range 1.7230 0.01 0.87 ≤ 2.5 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 12.7.6.1 P150 Method Program the P150 Method settings by the following screens. Figure 12-40 Figure 12-41 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 141 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Figure 12-42 Figure 12-43 Page 142 of 217 OM-E-FC-360-30 Revision Level HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 12.7.6.2 P250 Method Program the P250 Method settings by the following screens. Figure 12-44 Figure 12-45 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 143 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Figure 12-46 Figure 12-47 Page 144 of 217 OM-E-FC-360-30 Revision Level HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Instrument By clicking on Maintenance and selecting Instrument, the options Calibration, Diluter Purge, Washer Purge, Initialize and ISE are displayed (Figure 12-48) Figure 12-48 Calibration This option allows to calibrate the optical system, both photometer and cuvettes. 12.8.1.1 Photometer calibration Choose Calibrate Photometer and select the position for the solution to be used for the calibration in Use Solution in reagent pos. The photometer can be calibrated with new washing solution placed in a reagent bottle, or using the one in the probe washing container, in which case select Use container. Then press Calibrate. Photometric gain for each wavelength on the readings made in the cuvette which appears in the field Initial Cuvette on the screen. 0% and 100% T. data is also obtained, which will be later used for the Absorbance readings calculations. Warning: Make a diluter purge cycle before calibrating the photometer to make sure there are no bubbles in the circuit. Warning: Do not remove the cuvettes tray lid during this process. HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 145 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 12.8.1.2 Cuvettes calibration Choose Calibrate Cuvettes and select the Initial Cuvette and Final Cuvette range to be calibrated. Also select the position of the solution to be used for the calibration in Use solution in reagent pos. Cuvettes can be calibrated with new washing solution placed in a reagents bottle, or using the washing solution from the probe washing container, in which case select Use container. Then press Calibrate. During this process, the instrument reads blank absorbance of each cuvette and refreshes the value in the instrument memory to use it later in the calculation of reaction absorbance. Warning: It is recommended to calibrate all cuvettes tray (1 to 100) and not to make partial calibrations by sectors. Warning: Do not remove the cuvettes tray lid during this process. Figure 12-49 Diluter purge During this cycle, a volume of approximately 6 ml washing solution is pumped through the diluter. This procedure eliminates bubbles from the tubing and does the internal and external washing of the probe. This cycle is carried out: - Page 146 of 217 every time the daily work starts after cleaning the TIP after adding washing solution to the container before photometer and cuvettes calibration as part of other maintenance operations every time it is necessary to purge tubing and/or clean the probe HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Washer purge The washing of the first 10 cuvettes is carried out during this cycle, which allows the filling of all tubing of the washer circuit and the elimination of bubbles. This cycle is carried out: - after adding washing solution to the container every time it is necessary to purge tubing Initialize By clicking this command an individual initialization of each and every module will be executed, following a certain order: photometer, probe, probe arm, SR tray, diluter, washer and cuvettes tray. This cycle is performed: - At the beginning of daily work Automatically after an auto-stop sequence ISE (Optional) Through this menu different ISE maintenance options can be run. Figure 12-50 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 147 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Figure 12-51 12.8.5.1 Start up During this cycle, a volume of Calibrant A and Calibrant B is pumped through the ISE module. This procedure eliminates bubbles from the tubing. Then pumps calibration will be done (place a tube with pumps calibration solution and indicate the position). Finally Start up procedure ends with the Calibration of the module. Figure 12-52 This cycle must be carried out: - Page 148 of 217 every time the daily work starts every 8 hours HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 12.8.5.2 Calibrant A purge During this cycle, a volume of Calibrant A is pumped through the ISE module. This procedure eliminates bubbles from the tubing. Figure 12-53 12.8.5.3 Calibrant B purge During this cycle, a volume of Calibrant B is pumped through the ISE module. This procedure eliminates bubbles from the tubing. Figure 12-54 12.8.5.4 Calibration This cycle is used to calibrate the electrodes of the ISE Module. The ISE Module then cycles Calibrant B and Calibrant A solutions in front of the electrodes and measures the millivolt output of the electrodes for each of the respective solutions. The ISE Module Calibration Cycle performs two successive calibrations. Figure 12-55 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 149 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 This cycle must be carried out: 12.8.5.5 every 8 hours after each Clean Cycle if the QC sample results do not repeatedly fall within the proper ranges Clean Place a tube with cleaning solution in the required position, then press ok. This cycle is used to remove protein build-up from the ISE Module electrodes. Figure 12-56 This cycle must be carried out: - 12.8.5.6 once per 24-hour period after every 50 samples Pumps Calibration Place a tube with saline solution in the required position, and then press ok. This cycle is used to calibrate the peristaltic pumps of the ISE Module. Figure 12-57 This cycle must be carried out: -Once per day Page 150 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 12.8.5.7 Bubble Sensor Calibration The Bubble Cal command is used to allow the module to reestablish a baseline for detecting air-liquid interfaces. Figure 12-58 This cycle must be carried out: 12.8.5.8 Monthly Electrode replacement This cycle is used to clear fluid from the flow path of the ISE Module and to pause the Sip Cycle. Warning: This cycle is required before any electrode(s) is removed from the ISE Module. Failing to run this cycle will cause the fluid in the flow path to leak when electrodes are removed. Spilled fluid (or electrodes that are wet on the outside) can cause sporadic and/or erroneous results. Always dry each electrode when changing electrodes. It should be noted that every 30 minutes, a Sip Cycle is initiated, and 100 μL of Calibrant A is dispensed. If the electrodes are removed without initiating this maintenance Cycle (Electrode Replacement), a Sip Cycle may occur and the 100 μL of Calibrant A will flow into the empty module. This can cause significant damage to the ISE Module and/or other surrounding components. Never leave the Module in this status with the reference electrode in place for more than an hour after a Maintenance Cycle is initiated, as KCl will diffuse out of the reference electrode. Over time, the KCl will clog the flow path. As soon as the electrodes are reinstalled, run a Calibration command. Press Electrode Replacement command (module will be off and the lock stick will be released) Press the lock stick Move up the ISE module Depress the compression tray. Remove or/and install electrodes in positions Install electrodes into the ISE Module (electrode position as shown in Figure 12-51) Move Down the ISE module to put in place Run reconnect command Run Start Up procedure HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 151 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Figure 12-59 12.8.5.9 Reagent Kit Replacement Reagent kit should be replaced any time the system asks to, when controls do not fall within the range and/or when the calibration of the module shows error. A pop up window will appear, replace the reagent kit and press Accept. Figure 12-60 The system will start purging to eliminate bubbles from the tubing. Place a tube with saline solution in the required position, and then press Ok. This cycle is used to calibrate the peristaltic pumps of the ISE Module. Page 152 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Figure 12-61 Finally Start up procedure starts automatically. Figure 12-62 12.8.5.10 Reconnect This cycle is used to power on ISE module after maintenance procedure (Electrode Replacement) Figure 12-63 13 ADVANCED OPERATIONS In this chapter are described a series of operations reserved for advanced users. These include the configuration of the printing formats, the exchange of methods in use files, the description of communication files, the validation of analytical methods, and the solution absorbance readings, among others. Configuration of the printing formats The printing of results can be done using two different formats: Technical Report or Patient’s Report. The configuration of these two formats and the type, text, size and distribution of the data can be done from the Maintenance Menu Settings Reports. Patient’s Report and Technical Report consist of five fields to be programmed in HTML language. Fields are: HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 153 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Page Heading Results Heading Result Result’s Imprint Page’s Imprint The difference between Patient’s Report and Technical Report is that the first one prints the results corresponding to the selected patients as a constant list, whereas the second one does it printing a patient per sheet. In both cases, the following variables can be printed: datetime time timeiso timetext date Page 154 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 dateiso datetext protocol name lastname age sex dr bed methodname methodtecname unit limdown limup limflag pid comment result concentration redilutions id id_date id_dateiso id_datetext HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 155 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 id_time id_timeiso id_timetext File Exchange When the software is installed for the first time on the PC, the method files, calibrators, controls, and results, will be automatically generated in the start-up register, each with its own characteristic extension. In Maintenance Menu Settings Files are shown the locations of the method files, calibrators and controls. In Maintenance Menu Settings Database is shown the location of the result files. The calibrators and controls files are replaced one by the other with the Load command in each of the menus. The method files however, are additive, meaning that when loading a new method file using the Method Load, both files will be combined. For using a new method file discarding the file in use, follow the steps below: 1. Create a backup of the method file in use, sending it to another location in the computer or to a removable unit 2. Go to Maintenance Settings Files and see the exact location of the method file in use 3. Close the program 4. Go to the location of the method file in use and delete it 5. Open the software and verify that in Methods Settings there is no configured method. 6. Load the new method file going to Methods Load select the new file in the explorer window Open 7. Verify in Methods Settings, that the new methods have been loaded and press OK Caution: Whenever a new file is being used it is necessary to recalibrate all the configured techniques. Caution: Verify that the new methods have the calibrator and controller concentrations configured. Importing samples from an administration program From a laboratory central administration software sample requests can be entered into the software through a standard CSV (comma, space, value) formatted file. To do this, a communication protocol between both programs must be designed that takes into account the requirements of this file type. Page 156 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 The file is a text-type separated by commas; each line of the file must contain a Patient, a Calibrator or a Control along with all the methods to be used for the process. The format of each line should be the following: for Patients: PAC,protocol,Patient name,Patient surname,Age,SEX*,Doctor,Cama,TYPE*, PID,comment,Method1,Method2,...,MethodN for Controls: CON,Control name,TYPE*,Method1,Method2,...,MethodN for Calibrators: CAL,Calibrator Name,TIPO*,Method1,Method2,...,MethodN *SEX: one character (F or M) *TYPE: 0=Normal 1=STAT To import the information in this file, go to Operations Menu, then go to the option Pending Import form a CSV. The explore window will appear and select the file with the desired *.csv extension, and press Open, or press Cancel if this is not the desired operation. Following this, all the requested samples generated by the laboratory central administration software are now available in the Operations tab for being processed by the equipment. The import of the information can be done automatically. Contact Technical Support for more information. Exporting results to the administration program The results obtained in the equipment can be exported form the software to the laboratory central administration software through a standard CSV (comma, space, value) formatted file. The file will be generated following the procedure described in the Chapter12 point 12.1.3 Description of the exported results file: The results are exported in a text file separated by commas (*.csv) with each of the fields in quotations and with escape sequences for the “ (quotation marks) and the \ (inverted bars). Therefore, the values of the fields: - Will always be in quotations (“ ”) Example: “Value1”,”Value2”,…,”ValueN” The quotation marks (“”) should be replaced by the sequence \” HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 157 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Example: “this is a value that have \”quotationmarks\”,”Value1”,”Value2”,…,”ValueN” - The inverted bars (\) should be replaced by the sequence \\ Example: “this is an \\inverted\\ bar” The exported fields are the following ones: (The values in quotation are fixed data) Patients: Process number Order number Method’s name PID Patient’s name Patient’s surname Age Sex ID Doctor Bed Report Blank (1 blank, 0 determination) Number of re-dilutions Controls: Process number Order number Method’s name Control name “CON” “” Page 158 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 “” “” “” “” Report Blank (1 blank, 0 determination) Number of re-dilutions Calibrators: Process Number Order number Method’s name Calibrator Name “CAL” “” “” “” “” “” Report Blank (1 blank, 0 determination) Number of re-dilutions Technical Information: "TEC" HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 159 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Process Number Order number Method’s name Determination Type ("PAC", “CAL” or “CON”) Method Type (“EPRB”, “EPSB”, “K” or “FTK”) Concentration Main Absorbance Bichromatic Absorbance Number of re-dilutions Bichromatic (1 bichromatic, 0 monochromatic) Blank (1 blank, 0 determination) Maximum Value Minimum Value Unit Kinetics Points: "TEC K" Process Number Order number Method’s name Determination Type ("PAC", “CAL” or “CON”) Main Absorbance reading Time Main Absorbance Bichromatic Absorbance reading Time Page 160 of 217 OM-E-FC-360-30 Revision Level HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Bichromatic Absorbance The export of the results can be done automatically. Contact Technical Support for more information. Determination of precision of an analytic method For the validation of an analytic method, one of the parameters that should be stipulated is the CV% that estimates the imprecision of the methods for a given concentration. This parameter can be measured easily using the program. Go to Maintenance Validations Diluter precision Select the method indicate the position of the tube to use indicate the number of repetitions (10 minimum, 20 optimum) OK. It is recommended to choose the imprecision of the method for various concentrations levels, or at least, for the medical decision level for each analyte Caution: Do not process other samples while this procedure is being done. Caution: Use sample tubes with a total volume greater than 800 µl for the precision tests. Direct reading of the solution absorbance From the Maintenance menu Communications Commands console it is possible to read the solution absorbance without the intervention of the instrument’s hydraulic and the dispensing systems. In order to do this, the number of the cuvette should be recognized. Cuvette number 1 is located in cuvette strip aligned with the acrylic cuvettes tray positioning guide, and it’s indicated with a label. Following the direction of the arrow on the label (clockwise) you can identify the correlative numeration for all the other cuvettes. The procedure described below is used as an example for the reading of the instrumental control solutions, or for adapting analytic techniques and monitoring reactions. To make an absorbance reading, it is recommended to use externally washed cuvettes calibrated with washing solution. These are the steps to follow: 1) Start up the instrument Maintenance Instrument Initialize 2) Using an automatic pipette, dispense 250 to 500 µl of solution to be read, avoiding the formation of bubbles. 3) Place the lid on the cuvettes tray 4) Go to Maintenance Communications Commands console and in the terminal window write the following command (exactly as it’s written): disableVars A1 R HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 161 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Press the button on the right that says Execute 5) Select photoSetFilter (Figure 13-1) from the commands list, enter in the Parameters field the desired filter for carrying out the reading and press Execute. This way the photometer will be positioned in the chosen filter. Figure 13-1 6) Select the ReactionGoPhoto command and enter in the Parameters field, the cuvette number in which the solution was dispensed. Press Execute. Using this command the selected cuvette will be positioned in front of the photometer. 7) Select the command photoRead and press Execute. The absorbance value obtained for that cuvette and that filter will be shown in the screen above 8) For consecutive readings, press Execute several times. The time in which each operation is completed appears in the screen and corresponds to the hours, minutes, seconds and milliseconds from the moment the instrument was turned on. 9) Execute again the command written in the terminal window (disableVars A1 R) 10) Once all the readings have been made, wash the used cuvettes specifying in the program, the initial and final cuvettes to wash Operations Wash Cuvettes Cuvette range Wash Page 162 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Figure 13-2 14 ISE MODULE: DESCRIPTION AND OPERATION (OPTIONAL) ISE Module includes ion-selective electrodes and three peristaltic pumps. The ISE Module measures the concentration of Li+, Na+, K+, and Cl- in serum, plasma and diluted urine. The ISE Module contains the ion-selective electrodes and the reference electrode. A bubble detector is also included at the top of the electrodes. The three pumps that position the sample and wash/calibrating solutions. A waste storage is included in the reagent module. Calibrant A and Calibrant B are packaged in foil pouches within the reagent module. HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 163 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Figure 14-1 Electrodes Electrodes are maintenance-free. In their package the user will find the “Install-by date.” A pump calibration should be performed each day. Perform a two-point calibration every 8 hours. If the user is running more than 50 serum samples a day, both, cleaning and two-point calibration, must be performed after every 50 samples. To ensure reliable operation, the ISE Module performs calibrant aspiration every 30 minutes, beginning after the last sample is run. The ISE Module uses a double-junction reference electrode. The reference electrode is filled with saturated KCl. The reference electrode contains a small red sphere in the reservoir which normally resides on top of the filling solution. If the sphere begins to sink, the reference electrode must be replaced. Page 164 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Cleaning solution should be used at least once a day at the end of the work day to minimize protein buildup in the fluid lines and electrodes. Fluid Management The sample is aspirated by the analyzer from the sample tube and dispensed into the sample entry port on top of the ISE Module. The sample is then positioned in front of the electrodes for measurement. Four solutions are required to operate the ISE Module. 1. Calibrant A is used in both two-point and single-point calibrations for serum sample analysis. Calibrant A is pumped into the sample entry port by the Calibrant A pump and then positioned in front of the electrodes by the waste pump. Calibrant A solution is also used for Pump and Bubble Calibration. 2. Calibrant B is used in two-point and single-point calibrations for urine sample analysis. Calibrant B is pumped into the sample entry port by the Calibrant B pump and then positioned in front of the electrodes by the waste pump. 3. Cleaning Solution is used once a day to prevent protein buildup on the electrodes and fluid path. It must be used more frequently if the ISE Module performs greater than 50 sample measurements per day. 100 μL of cleaning solution must be aspirated by the host analyzer from a sample cup on the host analyzer and dispensed into the sample entry port. The sample cup must be covered to eliminate evaporation. NOTE: Medica pepsin/HCl cleaning solution must be prepared every four weeks and stored at 4º C. 4. Medica Urine Diluent. Urine samples must be diluted to perform urine measurement: 1 part urine sample to 9 parts urine diluent. The diluted specimen must be thoroughly mixed before aspirating a sample. Sample type Sample: Serum, Plasma, or Urine (Urine requires dilution) Minimum Sample Size: 70 μL serum; 140 μL diluted urine When measuring urine, the sample must be accurately diluted (1 part sample to 9 parts Medica urine diluent). The dilution must be performed before the sample is dispensed into the sample entry port. Warning: Sample volumes should never exceed 150 μL. Volumes greater than 150 μL will result in the sample mixing with the Calibrant B in the inlet tube. HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 165 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Sample Handling and Collection 14.3.1.1 Serum Serum may be analyzed immediately, stored at 4°C for 24 hours, or frozen at -20°C for up to one week. Samples must be brought to room temperature and homogenized well before assaying. To obtain accurate results, samples should be free of any clots, fibrin, etc., which would obstruct sample flow and affect results. The use of a serum clearing agent is strongly recommended. If a serum separator tube is utilized, care must be taken to avoid inserting the sample probe into the gel layer. This can create obstructions in the sample probe and the fluid path. 14.3.1.2 Plasma Plasma samples offer an advantage over whole blood specimens when short term storage is a factor. If the sample is to be stored, serum specimens are preferable. Collect the specimen by venipuncture into a Sodium-Heparin evacuated blood collection tube. The heparin level should not exceed 15 IU per mL of tube volume. Note the time of collection. Warning: DO NOT USE AMMONIUM HEPARIN, LITHIUM HEPARIN, EDTA, OR NaF TUBES. Mix the specimen by inverting the tube. Do not shake. When using Sodium-Heparin collection tubes, collect a full tube of specimen to minimize the effect of sodium heparin on the ISE Module sodium measurement. 14.3.1.3 Urine Samples The required minimum sample volume for a urine sample diluted (1 part urine and 9 parts diluent) with urine diluent is 140 μL (2 x 70 μL). Warning: Significant carryover into the subsequent serum sample will occur if a urine sample is inadvertently analyzed in an undiluted form. Potassium errors may exceed 1 mmol/L. Results are multiplied by 10, so the reported results will be multiplied by ten. Never dispense a volume greater than 150 μL because it may come in direct contact with the Calibrant B port on the side of the sample entry port. Contamination of subsequent samples and Calibrant B will result. 14.3.1.4 Matrix Effects Sample Matrix. The ISE Module is designed to analyze human serum, plasma and diluted urine. Page 166 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Surfactants. Virtually all surfactants can irreversibly harm ISE electrodes. Most oils, emulsions, many organic chemicals, as well as certain inorganic chemicals and buffers, can also harm the electrodes (sometimes QC Materials. Caution must be exercised when selecting quality control materials. QC materials specifically designed for use with ion-selective electrodes usually perform suitably, but we can only guarantee that QC materials it has validated are compatible with its electrodes. QC materials should be run after each calibration to ensure the integrity of sample results. Reagent Kit Electronic Key The ISE reagent kit uses a memory device in order to store module information. Update information will be stored in the device. Information includes such data as: expiration date, distributor code, module size, lot number, security key. The update information includes the install date, a means to calculate a countdown of reagent kit usage, and information about why a kit was designated as no longer acceptable (expiration, no remaining reagent, wrong distributor code). Sample Aspirating and Dispensing The sample delivered to the ISE Module must not be contaminated or further diluted. The wash solution, usually deionized water, is the most serious contaminant. Sample pickup and delivery to the ISE Module must be highly controlled and consistent. Samples and calibrators are positioned in front of the electrodes by three peristaltic pumps. Two separate pumps move Calibrant A and Calibrant B into the ISE Module’s sample entry port and a waste pump positions samples and calibrants in front of the electrodes. The sample is deposited into the sample entry port. After each sample measurement, calibrant is positioned in front of the electrodes for a single-point calibration. The removal of protein build-up on the electrodes and fluid path is accomplished by the use of cleaning solution. Cleaning solution is placed in a cup on the host analyzer sample tray, aspirated, and deposited into the sample entry port by the host analyzer. Calibration Cycle These millivolt readings are then used to set up a relationship between sample concentration and electrode millivolt output. The change in millivolts per change in concentration is the slope of the electrode. The slope of the electrodes is reported in mv/dec (millivolts per decade change in concentration), and should be within the following limits: Li+ 47-64 mV/dec Na+ 52-64 mV/dec K+ 52-64 mV/dec Cl- 40-55 mV/dec HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 167 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 The ISE Module Calibration Cycle performs two successive calibrations. The slopes should be repeatable within 1.5 mV/decade change; if not, a message error will be shown. Typical slopes are approximately 55 mV/decade for Li+, Na+ and K+ and 45 mV/decade for Cl-. In practice, electrode slopes may be higher than the ideally predicted value of 59.2 mV/decade at 25° C. Higher operating temperatures, interfering ions and other factors can raise the observed slope significantly. The slope changes with temperature. The slope of the electrodes is equal to (RT/nF) = 59.2 at 25° C, where R is the gas constant, T is the temperature in degrees K, n is the valence of the ion, and F is Faraday constant. If all of the factors are constant except T, one can calculate the ideal slope of the electrodes based on the temperature. Some examples of predicted slopes vs. temperature are listed below. Temp. (in deg. C) Slope (mV/decade) 20 58.2 22 58.6 24 59.0 26 59.4 28 59.8 30 60.2 32 60.6 If the module is calibrated at any temperature within its specification, and the same temperature is maintained during sample analysis, no error in the measurement will occur. Errors will occur only when calibration and sample analysis are performed at different temperatures. As electrodes age, slopes will decrease. Lower limits for acceptable slopes are set at the lowest value that insures good analyzer precision. The values of slopes between calibrations performed successively (one after the other) should not differ by more than 1.5 mV/decade for any of the channels, (Li+, Na+, K+, or Cl-). The calibration frequency should be once every 8 hours. A calibration should be performed after each Clean Cycle, or if the QC sample results do not repeatedly fall within the proper ranges. The analyzer will flag ISE results after the 8-hour interval is exceeded. Additionally, QC materials should be run after each calibration to ensure the accuracy of sample results. Page 168 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Clean Cycle This cycle is used to remove protein build-up from the ISE Module electrodes. The ISE Module positions cleaning solution in front of the electrodes for a period of time which will allow the enzyme to remove protein build-up on the electrodes. Once this is done, the ISE Module is then flushed with Calibrant A. The Clean Cycle should be performed once per 24-hour period. We strongly recommend that a Calibration Cycle be run after a Clean Cycle. We also recommend that the Clean Cycle be run at the end of the day to give the electrodes extra time to stabilize after the Clean Cycle. This is not required. However, users will experience slightly better performance if they give the electrodes some time to stabilize after the Clean Cycle. It is also recommended that high volume users run a Clean Cycle after every 50 serum samples. Purge A Cycle This cycle is used to purge Calibrant A solution through the tubing from the reagent kit to the ISE Module. The ISE Module pumps Calibrant A from the reagent kit through the ISE Module to wash out the flow path. Purge B Cycle This cycle is used to purge Calibrant B solution through the tubing from the reagent kit to the ISE Module. The ISE Module pumps Calibrant B from the reagent kit through the ISE Module to wash out the flow path. Sip Cycle Every 30 minutes after the last sample is run, the ISE Module will automatically run a Sip Cycle. The Sip Cycle is used to keep the calibrants in the tubing fresh, and to refresh the Calibrant A in front of the electrodes. Off Cycle (Under Electrode replacement command) This cycle is used to clear fluid from the flow path of the ISE Module, and to pause the Sip Cycle. The ISE Module then runs the waste pump until the electrode flow path is cleared of fluid. Warning: This cycle is required before any electrode(s) is removed from the ISE Module. Failing to run this cycle will cause the fluid in the flow path to leak when electrodes are removed. Spilled fluid (or electrodes that are wet on the outside) can cause sporadic and/or erroneous results. Always dry each electrode when changing electrodes. It should be noted that every 30 minutes, a Sip Cycle is initiated, and 100 μL of Calibrant A is dispensed. If the electrodes are removed without initiating a Maintenance Cycle, a Sip Cycle may occur and the 100 μL HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 169 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 of Calibrant A will flow Cycle may occur and the 100 μL of Calibrant A will flow into the empty module. This can cause significant damage to the ISE Module and/or other surrounding components. Never leave the Module in this status with the reference electrode in place for more than an hour after a Maintenance Cycle is initiated, as KCl will diffuse out of the reference electrode. Over time, the KCl will clog the flow path. As soon as the electrodes are reinstalled, run a Purge A, Purge B or Calibration cycle. Warning: Do not turn off the analyzer by pressing general button unless maintenance cycle had been done. Pump Calibration Cycle This cycle is used to calibrate the peristaltic pumps of the ISE Module. We recommend performing a Pump Calibration Cycle once per day. The Pump Calibration values of A and B should be within the range 1500 to 3000. Bubble Cal Cycle The Bubble Cal command is used to allow the module to reestablish a baseline for detecting air-liquid interfaces. It can also be used as a diagnostic tool to see if the bubble detector is functioning properly. Maintenance Maintenance Schedule The ISE Module has been designed to require very little operator maintenance. Before starting daily operation Allow the electrodes to be exposed to fluid for 15 minutes before calibrating. Calibrate the ISE Module by clicking on the Bubble Cal button. Click on the Pump Cal button. If the results from the Module are unacceptable, refer to the Troubleshooting Guide for assistance. Daily Maintenance The only daily maintenance required is to run the cleaning solution after the last sample of the day or after 50 patient samples, whichever is first. Clean the sample inlet port with a cotton swab and DI water once per month. All other parts and expendables are replacement items (see schedule below). Use only HTI approved components. Page 170 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Shutdown Procedure Preparing the ISE Module for Storage if the laboratory plans to store the ISE Module, the following steps should be performed: Before removing the electrodes, they should be cleaned using the cleaning solution and then 3 Purge A cycles should be run. Enter the Maintenance Cycle of the analyzer to purge the ISE Module fluid path. Maintenance Instrument ISE Electrode replacement. Depress the compression tray and remove all electrodes, including the reference electrode from the ISE Module. Place the Na+ and Cl- electrodes into individual sealed bags. Reinsert the Reference Electrode flow path line with yellow flag, if available, and then put into individual sealed bags. Aspirate a small volume of Calibrant A from the top port of the reagent kit into a syringe fitted with a blunt needle. Inject sufficient volume of Calibrant A into the lumen of the K+ and Li+ electrodes until fluid fills the lumen. Cover both ends of the lumen (both sides of the K+ and Li+ electrodes) with tape to hold the Calibrant A in place. Insert the K+ and Li+ electrodes into a sealed bag. Remove the reagent kit from the analyzer and discard. Remove all fluidic tubing and thoroughly rinse with DI water. ISE Module re-activation Remove all electrodes from sealed bags. Remove tape from K+ and Li+ electrode. If necessary, soak the reference electrode in warm water until the lumen of the electrode has been cleared of salt build-up. Install electrodes into the ISE Module. Connect new reagent kit to the ISE Module. Use Reagent Kit Replacement to prime the calibrants. Maintenance Instrument ISE Reagent Kit Replacement Calibrate ISE module. Maintenance Instrument ISE Calibrate ISE Troubleshooting Overview To enhance trouble-free operation of the ISE Module, it is important to follow the recommended component replacement schedule listed in the maintenance section of this manual. HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 171 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 When the ISE Module is not operating properly, approach troubleshooting as a logical sequence of events. Isolate the problem area to avoid unnecessary component replacement and down time. Troubleshooting can be categorized into three main areas. These areas are: Fluid delivery, electrode stability, and communication. Once your chemistry system is developed to a point that the communication is stable and the data transmission is properly interpreted, troubleshooting should focus primarily on fluid delivery and electrode stability. As these are related, sometimes the same symptoms can have different causes. Most problems can be corrected while the ISE Module is still installed in your chemistry system. Fluid Delivery It is necessary to perform a Pump Calibration cycle each day. This cycle will calibrate the pumps that dispense Cal A and Cal B, and position fluid in front of the electrodes. The waste pump moves solution from the Sample Entry port to the electrode area for measurement. As the tubing ages and samples are passed through the system, the positioning of the solution will change. The pump uses a stepper motor that counts how many steps it takes to move the solution to the correct position. By calibrating the pump each day, the ISE Module can now calculate the relationship between volume and number of pump steps. This will enable the pumps to dispense an accurate volume of calibrant, and for the solution to be accurately placed in the proper location for analysis. Problems can be caused by a partial obstruction from a clot in the tubing from the exit tube to the waste pump, a sharp bend in the waste tubing that restricts the flow, a misalignment of the electrodes, or from too great a length of tubing from the exit tube to the waste pump. As the pump tries to pull the fluid from the sample entry port into the electrodes, a vacuum develops because of the restriction. The bubble detector detects the trailing edge of the solution (sample, calibrant, etc.) and stops the waste pump so that the solution is in front of the electrodes. The vacuum will cause the solution to travel after the pump stops. One of the first indications of a flow problem will be the lithium electrode response. If, however, the solution slowly moves out of the electrodes when the pump has not been activated, there is either a leak between the electrodes, or along the flow path. This can be tested by placing solution into the sample entry port by hand and watch to see if the fluid level changes. In either case, the symptoms would be similar—the lithium or sodium millivolts would experience noise errors and the bubble detector would trigger an error. Electrode Stability Errors associated with electrode instability typically include drift, noise, and slope failures. While these errors may be caused by a failure of a particular electrode, it is necessary to explore other causes as well. Proper operation on a daily basis is the key to keeping the electrodes stable and the system working properly. Each day, it is necessary to perform a Cleaning Cycle. The cleaning solution removes protein build-up in the flow paths of both the electrodes and the tubing. In high sample volume instances, it may be necessary to perform this cycle more than once in a single day. Page 172 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 It is also necessary to replace the Reference Electrode every six months or when the red ball indicator no longer floats in the internal electrode solution, whichever comes first. Failure to replace the Reference Electrode at this interval will cause all three of the errors mentioned. Ensure that the ISE Module is properly grounded. Flow problem Observation Low Slope Na+ or K+ <52 mV/decade Cl- <40mV/decade, Li+<47mV mV/decade or High Slope Na+, K+, or Li+>64 mV/decade Cl- >55 mV/decade Noise Error Flag Single electrode. Noise Error Flag Multiple electrode. Drift Error Flag Single Electrode Probable cause Misalignment of the electrodes Action Remove electrodes. Inspect O-rings. Reassemble properly. Calibrator solutions Replace Reagent Pack. Electrode (low slope). Replace electrodes. Air bubble on reference Remove electrode, tap to electrode membrane. Dislodge bubble, replace, and recalibrate. Reference electrode. Replace reference electrode and retest. ISE Module or fluid temperatures exceed 32° C. (high slope). Electrode. Decrease the environment temperature. Electrode. Replace reference electrode and recalibrate. Electrical noise spike from environmental source. Contact Technical Support Component failure on ISE Module board. Contact Technical Support May occur when new electrode or Calibrant A is installed. Purge the Calibrant A and recalibrate the ISE Module. If the electrode is new it may initially drift as it rehydrates over the course of 15 minutes. Electrode. Replace the electrode and recalibrate. Replace problem electrode and recalibrate. HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 173 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Drift Error Flag Multiple electrodes Air in Sample May occur when new electrode or Reagent Kit is installed on system. Reference electrode. Purge Calibrant A and recalibrate. Electrical spike from environmental source. Contact Technical Support Component failure on ISE Module board. Insufficient sample pipetted into ISE Module sample Bubbles in Sample. entry port. Contact Technical Support Fluid leaks Contact Technical Support Sample not positioned. Electrodes not seated properly. Remove electrodes. Inspect O-rings and reassemble. Replace reference electrode and recalibrate. Contact Technical Support Probe with some blocked Sample must be free of bubbles. Replace pump tubing. Air in Sample and Calibrant A Pump tubing obstructed. Replace pump tubing. Sample and Calibrant A are segmented with air. Electrodes are not properly seated or compressed. Check compression tray, spring, and seal. Remove and reassemble electrodes. Fibrin or salt is plugging the electrode flow path. Bubble detector is malfunctioning. Use Cleaning procedure. Remove electrodes and clean or replace electrode with plugged flow path. Reinstall electrodes and recalibrate. Contact Technical Support Air in Calibrant B and Air in Calibrant A Page 174 of 217 Waste pump is malfunctioning. Calibrant B and Calibrant A are segmented with air. Contact Technical Support Electrodes are not properly seated. Check compression tray, spring and seal. HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Ensure that all electrodes and O-rings are properly installed. Ensure tubing between reagent kit and sample entry port is connected properly. Replace tubing between reagent kit and sample entry port. Fibrin or salt is plugging Electrode flow path. the Air in Calibrant A Reagent low or out. Use Cleaning procedure. Remove electrodes and clean or replace electrode with plugged flow path. Reinstall electrodes and recalibrate. Waste pump malfunction. Contact Technical Support Bubble Detector malfunction. Calibrant A. Contact Technical Support Tubing from reagent module is disconnected, plugged, or crimped. Reconnect or replace tubing. Calibrant A pump is not working properly. Contact Technical Support Replace reagent kit with a new one, prime, and recalibrate. 15 MAINTENANCE PROGRAM In order to ensure optimal performance and maximum useful life of the Autoanalyzer, it is important to follow the cleaning and maintenance instructions outlined in this section. Daily Maintenance Before starting daily operation 1. Verify that the levels of the waste and washing solution containers are adequate to start with the daily operation. 2. Run two diluter purge cycles, visually checking the absence of bubbles in the diluter body Maintenance Instrument Diluter Purge 3. Run one wash cycle of the first 10 cuvettes, checking the absence of bubbles, and overflow of HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 175 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 the liquid in the cuvettes Operations Wash cuvettes Cuvette range 1 to 10 Wash During the daily operation Run the washing program every time the message appears on the instrument. Programmed Washing Execute Upon finishing with the daily operation 1. Run one wash cycle of all the cuvettes: Operations Wash cuvettes All cuvettes Wash Caution: If the daily work included turbidimetric techniques that utilize latex in the composition of their reagents, perform a Special wash cycle of the cuvettes using special wash solution described in chapter 16. 2. Run the cleaning of the TIP using a 30% commercial sodium hypochlorite solution in the selected tube Maintenance TIP Cleaning OK Weekly Maintenance 1. Run one wash cycle of all the cuvettes: Operations Wash cuvettes All cuvettes Wash 2. Run two diluter purge cycles Maintenance Instrument Diluter Purge 3. Calibrate all the cuvettes Maintenance Instrument Calibration select Calibrate cuvettes Range 1 to 100 select the position of the solution to use ex: Use container OK Monthly Maintenance External washing of cuvettes 1. Turn off the instrument. 2. Remove all the cuvette strips, unscrewing the metal nuts. Caution: avoid dropping the metal nuts into the interior of instrument during this procedure. 3. Wash the external part of the cuvettes under the faucet with detergent and plenty of water. Rinse with plenty distilled water. 4. Dry the external part of the cuvettes gently with paper towel. Caution: avoid scratching or leaving traces of paper inside the cuvettes during this procedure. 5. Place the cuvette strips on the tray, tightening securely the metal nuts. 6. Turn on the instrument. 7. Run one wash cycle of all the cuvettes Operations Wash cuvettes All cuvettes Wash 8. Run two diluter purge cycles Maintenance Instrument Diluter Purge Page 176 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 9. Calibrate the photometer and all the cuvettes Maintenance Instrument Calibration select Calibrate photometer select Calibrate cuvettes Range 1 to 100 select the position of the solution to use ex: Use container OK General cleaning of the instrument 1. Washing the containers: disconnect the waste and washing solution tubes and clean the containers with plenty of water. Washing solution container: rinse with distilled water. Waste container: rinse with commercial sodium hydrochloride 30% solution and plenty of water. 2. Cleaning the reagent tray: turn off the instrument and the reagent refrigeration. Remove all the reagent bottles and clean the reagent tray and sample tray with a damp cloth. 3. Cleaning the cuvette tray: clean the black surface of the cuvette tray with a damp cloth. 4. Cleaning externally: with a damp cloth, clean the external covers, lids, hood of the pipetting arm. Caution: the instrument needs to be turned off during this procedure. Take care not to spill liquids on the instrument. 5. Cleaning the tip externally: clean the tip from top to bottom with paper towel dipped in isopropyl alcohol. Caution: When performing this procedure, avoid removing the PTFE cover of the volume sensor probe. Back-up of files in use 1. Select Methods Save an explore window will open select the back-up file destination for a removable drive, ex. USB (E:) name the method file in use as methods yymmdd.adb, where yy is the year, mm the month and dd the day for the date of the back-up Save 2. Repeat the same procedure for the calibrator and control files by going to the Calibrator and Control menus. 3. Back-up methods, calibrators and controls files when these are configured for the first time or whenever configuration changes are made. 4. Select Maintenance Menu Settings Enter password Database tab press Database Copy select the folder where the data will be saved Copy HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 177 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Figure 15-1 ISE Module Maintenance Program (Optional) Recommended Component Replacement Schedule (low volume user) Li+ Electrode Pump Tubing Na+ Electrode K+ Electrode Cl- Electrode Reference Electrode Fluidic Tubing: 12 months Recommended Replacement Schedule (high volume user) (Greater than 100 samples per day) Li+ Electrode: 3,000 samples Pump Tubing: 6 months Na+ Electrode: 10,000 samples K+ Electrode: 10,000 samples Cl- Electrode: 10,000 samples Page 178 of 217 OM-E-FC-360-30 Revision Level HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Reference Electrode: 10,000 samples Fluidic Tubing: 12 months Maintenance according to programmed alarms Maintenance Levels according to cycles of use counters The analyzer has implemented a system that keeps track of the own cycles of use. These systems keep record of the work performed by certain parts of the analyzer. This intelligent system allows to have a maintenance program based on the type of user and not on a time schedule. So once a certain limit is reached the system will show a window on the screen posting that a maintenance level has been reached. At this moment the user must call technical service to perform the necessary maintenance procedures. The system involves three independent cycles of use counters: one for the hours of work, other forcycles of use or tests performed, and a third one for lamp hours of use. This allows the maintenance program to be according to the volume of work that each user in particular handles. Figure 15-2 Warning: This message will continue showing until the established maintenance is done, if they’re not properly done the performance of the analyzer will be affected, and failures may occur. Warning: The maintenance must be done by HTI trained personnel. Contact authorized technical support for this purpose. There are two maintenance levels: 1 and 2. Next we detail the procedures carried out during these maintenances. Maintenance Level 1 15.5.2.1 1. 2. 3. 4. 5. Disinfecting the reagent tray Turn off the instrument and the refrigeration of the reagent tray Remove all the reagent flasks Pour a 30% Sodium Hypochlorite solution in all the compartments of the reagent tray Leave the solution for 30 minutes Wash with water, avoiding splatters HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 179 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Note: If necessary, repeat step 5. 15.5.2.2 Disinfecting the tubing and cleaning of the containers 1. Remove the tubing from the probe and cuvettes containers (NOTE: do not disconnect the tubing from the plastic connector, remove the filters) 2. Place the filters in a container with 30% Sodium Hypochlorite solution and leave for one hour 3. Place the filters back into the tubing and place the tubing in a container with 30% Sodium Hypochlorite solution 4. Purge the diluter twenty times 5. Wash all cuvettes twice (1 to 100) 6. Leave for one hour 7. Cleaning of the containers: Washing solution containers: rinse with plenty DI water Waste container: rinse with a 30% Sodium Hypochlorite solution and then rinse with plenty DI water. 8. Prepare new probe and cuvettes washing solutions 9. Remove the tubing from the Sodium Hypochlorite solution and rinse the extremes with DI water 10. Remove the filters from the Sodium Hypochlorite solution and rinse with plenty DI water 11. Connect the tubing back to the washing solution containers (make sure probe tubing go to probe container, and cuvettes tubing go to cuvettes container) 12. Purge the diluter thirty times 13. Wash all cuvettes three times (1-100) 14. Calibrate photometer and cuvettes 15.5.2.3 General cleaning of the instrument 1. Cleaning of the SR tray: turn off the analyzer and the reagent cooling system, remove all reagent bottles and clean with a damp cloth. 2. Cleaning of the cuvettes tray: using a damp cloth clean the black surface of the cuvettes tray. 3. External cleaning: with a damp cloth clean the external covers of the analyzer (gray and orange covers) Warning: the analyzer must be off during this procedure. Do not spill fluids on the instrument. 4. External cleaning of the tip: with a tissue embed in isopropyl alcohol clean the exterior of the probe from up to down. Warning: avoid removing the Teflon covering the volume sensor of the probe during this procedure. 15.5.2.4 Axes lubrication Contact Technical Support Page 180 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 15.5.2.5 Cleaning of the washer circuit filter Contact Technical Support 15.5.2.6 Replacement of the Teflon seals in the piston pump Contact Technical Support 15.5.2.7 Flushing Pump Membrane replacement Contact Technical Support 15.5.2.8 Diluter Liquid Diaphragm Pump Membrane replacement Contact Technical Support Maintenance Level 2 15.5.3.1 Disinfecting the reagent tray (See 15.5.2.1) 15.5.3.2 Disinfecting the tubing and cleaning of the containers (See 15.5.2.2) 15.5.3.3 General cleaning of the instrument (See 15.5.2.3) 15.5.3.4 Axes lubrication Contact Technical Support 15.5.3.5 Cleaning of the washer circuit filter Contact Technical Support 15.5.3.6 Replacement of the Teflon seals in the piston pump Contact Technical Support 15.5.3.7 Flushing Pump Membrane Replacement Contact Technical Support HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 181 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 15.5.3.8 Diluter Liquid Diaphragm Pump Membrane Replacement Contact Technical Support 15.5.3.9 Cuvettes replacement 1. Turn off the analyzer. 2. Remove the metal nuts that hold the cuvette strips. Remove all cuvette strips. Warning: avoid the metal nuts fall inside the analyzer during this procedure. 3. 4. 5. 6. Place the new cuvette strips and adjust the metal nuts properly. Turn on the analyzer. Purge the Diluter(Maintenance Instrument Diluter Purge) Calibrate all cuvettes (Maintenance Instrument Calibration select Calibrate Cuvettes Range 1 a 100 select the position of the solution that will be used for calibration Ex.: Use Container Calibrate) As needed maintenance Database Initialization (every 10.000 tests) 1. Select Maintenance Menu Settings Enter password Database Refresh Statistics In the lower part of the tab, are shown the numbers of patients, calibrators, and controls samples for the database in use. The Total is also shown, with the inclusion of the previous results. In the adjacent box the Total value corresponds to the sum of all the determinations in the database in use. These numbers are updated with the Refresh Statistics command. Before the total number of determinations reaches the 10.000, the database must be initialized: steps 2), 3) and 4) Figure 15-3 Page 182 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 2. Select Maintenance Menu Settings Enter password Database Export results select the folder where the data will be saved. Name the file as results yymmdd.csv, where yy is the year, mm is the month and dd is the day for the date of the back-up. Press Save and a window will open for selecting the type of results to be saved: patient, calibrator and control results. Select all the options and press Export. The next window allows the selection of the entire database or just a range given by the date and the hour, or the process numbers (initial and terminal) to use for saving the information. For the entire database select the option All. 3. Select Maintenance Menu Settings Enter password Database tab press Database Copy select the folder where the data will be saved Copy (this process may take several minutes, the interruption of the process may cause the corruption of the file created) 4. Select Maintenance Menu Settings Enter password Database Initialize: this is where the Patient results, Calibrators and Controls results are all erased. The last calibration is saved in the methods configuration, and the configuration dates of the calibrators, controls and methods are not modified. 5. Press Yes in this tab, close and open software. Lamp replacement 1. 2. 3. 4. 5. 6. Turn off the instrument. Remove the lids of the trays. Remove the main cover Remove the dissipater, removing the two screws manually. Disconnect the lamp from the air connector by loosening the fastening screw. Remove the light bulb. Install the new light bulb, positioning the filament horizontally. Caution: hold the light bulb by the base and don’t touch the glass of the bulb. Tighten the screw slightly and proceed with the adjustment of the focal distance. Caution: the filament should always be in a horizontal position. Once the proper adjustment has been made, secure the position of the light bulb with the fastening screw. 7. Reconnect the lamp to the air connector. 8. Place back the dissipater 9. Turn on the instrument. 10. Start up the photometer Maintenance Communications Console of commands select photoInit Execute 11. Select a visible wavelength range, ex. 546 nm Maintenance Communications Console of commands select photoSetFilter Parameters enter 546 Execute. Remove the part of the HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 183 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 cuvette in the optical path and place a white piece of paper against the lens of the photometer. Adjust the position of the lamp such that the filament can be seen sharply against the paper. In case of being necessary to fit the focal length moving the lamp, without rotating it (to be able to maintain the filament in horizontal position), It must look for to focus the beam in the center of the optical path of the cuvette. Once obtained the adjustment, fix the lamp. 12. Place back the main cover and lids. 13. Run a calibration of the photometer and all the cuvettes Maintenance Instrument Calibration select Calibrate photometer select Calibrate cuvettes First cuvette 1 Last cuvette 100 select the position of the solution to use for the calibration ex: Use container Calibrate Figure 15-4 Figure 15-5 Page 184 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Cuvettes Replacement (see item 15.5.3.8) 15.6.3.1 Interferential filters replacement a. Turn off the analyzer, remove the lids and the main cover of the autoanalyzer to have access to the photometer, located on the right back side. b. Remove the photometer’s dissipater. c. Spot the interferential filter to be replaced and manually turn the filter’s wheel clockwise to find and to easily remove the interferential filter holder from the filter wheel. d. Place the holder with the new filter in the filter wheel. Figure 15-6 e. Place back the lids and main cover, switch on the equipment. f. Run a calibration of the photometer and all the cuvettes Maintenance Instrument Calibration select Calibrate photometer select Calibrate cuvettes First cuvette 1 Last cuvette 100 select the position of the solution to use for the calibration ex: Use container Calibrate Sample / Reagent probe replacement a. Keep the equipment off, remove the hood of the probe arm. b. Disconnect the Teflon tubing from the hydraulic connector. HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 185 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Figure 15-7 c. Disconnect the connector from PCB and remove the fixing screws on the PCB. To remove the Sample / Reagent probe remove the PCB Figure 15-8 d. Replace the Sample / Reagent probe. The new probe has a polarizing pin to make assembly easier. Page 186 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Figure 15-9 e. Assembly the PCB and connect the Teflon tubing. f. Perform several purge cycles and check that there is no leak. Caution: when assembling check the following items for proper replaces Check distance I is the same as distance II Figure 15-10 Check angle of 90 º HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 187 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Figure 15-11 Correct position Figure 15-12 Incorrect position Page 188 of 217 OM-E-FC-360-30 Revision Level HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Figure 15-13 Replacing the fuses 1. 2. 3. 4. 5. 6. 7. Turn off the instrument Remove the feed cable from the line filter Remove the lid of the fuse-box located in the upper part of the line filter Remove the burnt fuses and replace them with new ones Replace the lid of the fuse box Reconnect the feed cable to the line filter Turn on the instrument Special Wash 1. Fill a single mouth reagent container with special washing solution (see chapter 16 point 16.3 and 16.4) 2. Place the container in the reagent tray 3. In the Wash cuvettes screen, select Special Wash and enter in Reagent Pos. the position of the container 4. Press Wash 5. Once the special wash is finished, the cuvettes are ready to be used as usual Replacing O-rings of piston pump Contact Technical Support Replacing filters of washing system Contact Technical Support HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 189 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Electrode replacement (For analyzers with ISE Module installed) This cycle is used to clear fluid from the flow path of the ISE Module and to pause the Sip Cycle. Warning: This cycle is required before any electrode(s) is removed from the ISE Module. Failing to run this cycle will cause the fluid in the flow path to leak when electrodes are removed. Spilled fluid (or electrodes that are wet on the outside) can cause sporadic and/or erroneous results. Always dry each electrode when changing electrodes. It should be noted that every 30 minutes, a Sip Cycle is initiated, and 100 μL of Calibrant A is dispensed. If the electrodes are removed without initiating this maintenance Cycle, a Sip Cycle may occur and the 100 μL of Calibrant A will flow into the empty module. This can cause significant damage to the ISE Module and/or other surrounding components. Never leave the Module in this status with the reference electrode in place for more than an hour after a Maintenance Cycle is initiated, as KCl will diffuse out of the reference electrode. Over time, the KCl will clog the flow path. As soon as the electrodes are reinstalled, run a Calibration command. Press electrode replacement command (module will be off and the lock stick will be release) Press the lock stick Move up the ISE module Depress the compression tray. Remove or/and install electrodes in positions Install electrodes into the ISE Module (electrode position as shown in Figure 15-9) Run reconnect command Run Start Up procedure Calibrate the module Figure 15-14 Page 190 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 15.6.9.1 Replacing ISE peristaltic pumps tubing (For analyzers with ISE Module installed) Figure 15-15 1. Remove the reaction Tray cover. 2. Locate the front black plate supporting the three peristaltic pumps and remove the tubing connection from the yellow connectors. 3. Remove the Peristaltic Pumps to release the Peristaltic Tubing. 16 PREPARING SOLUTIONS Wash solution. Warning: Containers must be placed under the level of the analyzer, never on the same level Washing solution for probe and cuvettes First, Wash Concentrate Solution (mother solution) has to be prepared from Solution of Triton X- 100, this concentrate solution will be used to prepare washing solution for probe and cuvettes. Wash Concentrate (mother solution): dilute 1 part v/v of Triton X-100 in 9 parts of distilled water, Ex: 100 ml Triton X-100 in 900 ml of distilled water. The Triton X-100 is extremely viscous. It is suggested to pour the desired quantity into a graduated cylinder and gradually add the water. Heat the distilled water to 70 – 80 ºC to help dissolve the Triton X100. Washing solution for probe and cuvettes: dilute 7 ml of the mother solution in 1 liter of distilled water. Ex: 140 ml of wash concentrate for 20 liters of distilled water. HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 191 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Washing solution for probe and cuvettes when running turbidimetric methods In those cases where latex reagents are used, is highly recommended to use the following washing solutions: Washing solution for probe: use distilled water alone Washing solution for cuvettes: dilute 3 ml of wash concentrate in 1 liter of distilled water. Ex: 70 ml of wash concentrate for each 20 liters of distilled water. Warning: not following the instructions given above will affect the results. TIP cleaning solution Use a 30% commercial sodium hypochlorite solution (bleach solution) Special washing solution for maintenance according to need Use 0.2 Normal sodium hydroxide. Weigh out 8 gr. of dry sodium hydroxide and dissolve it in 1 liter of distilled water. Special washing solution for turbidimetric techniques with latex Use 2 Normal sodium hydroxide. Weigh out 80 gr. of dry sodium hydroxide and dissolve it in 1 liter of distilled water. Disinfecting solution Use a 30% commercial sodium hypochlorite solution 17 TROUBLESHOOTING Introduction This chapter gives instructions and guides for isolating and identifying problems quickly. In the majority of cases the users will be able to find and fix the problem themselves, and resume the daily workload. When this is not possible, contact the Technical Support. For identifying and solving problems, the user should be familiar with the theory of the instrument operation, the operating procedures, the maintenance procedures, and the fundamentals of the chemical test methods described in this Manual. The primary responsibility of the operator in the resolution of problems falls into the following categories: Page 192 of 217 Preparation and storage of reagents Preparation and location of samples HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 - Basic operation of the instrument - General operation of the software - General maintenance and replacement of basic components Problems can be divided into two major groups: Chemical problems Instrumental problems If it becomes necessary to call the Technical Support in order to solve a chemical or instrumental problem, have ready the following information: Chemical problems: - Serial number of the instrument Methods affected Description of the problem Expiration date for the reagents, calibrators and controls in use Absorbance information for the last run calibration Absorbance information for the last run blank Patient results affected Error messages reported by the instrument for the methods affected Instrumental problems: - Serial number of the instrument Description of the problem Error messages reported by the instrument Information about the last maintenance procedures run on the instrument Log file for the day Having this information ready will help solve the problem more quickly. How to find the log file for the day Log files are located in a particular folder in the computer, and they’re named by the date the file was created. To know which folder is keeping the log files go to Maintenance -> Settings -> Files and look for the path indicated under Log File Folder. HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 193 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Figure 17-1 Once located the path, minimize BioChem FC-360 software. Search for the folder indicated in the path. Once located the folder, look for the type of files log.html. They are identified by year, month and day (for example, the file from day 21 of August 2007 will have the name: 2007-08-21.log.html). Figure 17-2 Once the file is located, send it by mail to technical support or follow the instructions by them given. Chemical Problems Chemical problems may appear with an error message along with the results, or by unexpected results for the processed samples. They may appear in the following situations: Page 194 of 217 Calibration errors Alarms with control or patient results Quality control results outside the defined ranges Unexpected patient results HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 From the results obtained from the method calibration, quality controls, and patient samples tested, decide which of the following conditions best describe the problem encountered and run the checks and actions associated with each case: - High results Low results Erratic results Only one affected sample for all the methods Only one affected method for all the samples High results Observation Incubation temperature > 37ºC Low calibrator absorbance results Probable cause High cuvette tray temperature Action Contact Technical Support High ambient temperature Reduce the ambient temp to < 25 ºC Incorrect preparation of the calibrator dilution Presence of bubbles or fibrin in the calibrator tube High blank reagent absorbance Use a calibrator reconstituted correctly Use a calibrator free of bubbles and/or fibrin Verify the blank reagent Insufficient calibrator volume Use a minimum volume of 200 µl Insufficient sample and control volumes Use a minimum volume of 200 µl Samples concentrated by evaporation Inadequate sample and control storage Use fresh samples and controls Inadequate reagent preparation Deteriorated reagent Refilled reagent not homogenized, or not checked Incorrect information in the cc of the calibrator Incorrect aspiration or dispensing of samples and reagents Insufficient reagent volume or bubbles into the reagent bottle Physical and/or chemical deterioration of the reagent Calibrator concentration configured incorrectly Prepare new reagent Mix the reagent gently and verify the blank Avoid foaming Prepare new reagent Configure the calibrator concentration correctly Adjust connections and purge the Losses in the diluter circuit connections diluter Obstruction of the TIP Purge the diluter Run a TIP cleaning Adjust connections and run a TIP cleaning Sensing failure See error solving 109 Reagent volume less than 2 ml or more Refill the reagent bottle or change it than 55 ml without any bubbles Inadequate purge of the hydraulic Purge the diluter Purge the washer system Bubbles in the tubing or diluter HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 195 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Low Results Observation Probable cause Low cuvette tray temperature Action Contact Technical Support Low ambient temperature Increase the ambient temp to > 15 ºC Incorrect preparation of the calibrator dilution Use a calibrator reconstituted correctly Low blank reagent absorbance Verify the blank reagent Insufficient sample and control volumes Use a minimum volume of 200 µl Presence of bubbles or fibrin in the sample tubes Absence of the sample in the assigned position Inadequate reagent preparation Use samples free of bubbles and/or fibrin Place the samples in the correct positions Prepare new reagent Refilled reagent not homogenized, or not checked Mix the reagent gently and verify the blank. Avoid foaming Physical and/or chemical deterioration of the reagent Prepare new reagent and verify the blank Incorrect information in the configuration of the calibrator Calibrator concentration configured incorrectly Configure the calibrator concentration correctly Insufficient reagent volume or bubbles into the reagent bottle Reagent volume less than 2 ml or more than 55 ml Inadequate purge of the hydraulic system Refill the reagent bottle or change it without any bubbles Incubation temperature < 37ºC High calibrator absorbance results Inadequate samples Deteriorated reagent Incorrect aspiration or dispensing of samples and reagents Purge the diluter Purge the washer Losses in the diluter circuit connections Adjust connections and purge the diluter Obstruction of the TIP Purge the diluter Run a TIP cleaning Bubbles in the tubing or diluter Sensing failure Adjust connections and run a TIP cleaning See error solving 109 Erratic Results Observation Incorrect information in the method configuration Incorrect calibration Inadequate samples Page 196 of 217 Probable cause Incorrect type of reaction chosen for each method Method parameters configured incorrectly Calibrator concentration configured incorrectly Action Sample volumes less than 200 µl Use a minimum volume of 200 µl Select the correct type of reaction Configure the parameters adequately Configure the calibrator cc correctly HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Presence of bubbles or fibrin in the sample tubes Absence of the sample in the assigned position Reagent volume less than 2 ml or more Insufficient reagent volume or than 55 ml bubbles into the reagent bottle Inadequate purge of the hydraulic system Use samples free of bubbles and/or fibrin Place the samples in the correct positions Refill the reagent bottle or change it without any bubbles Purge the diluter Purge the washer Incorrect purge of the diluter circuit Purge the diluter Incorrect purge of the washer circuit Purge the washer Insufficient washing solution Refill the washing solution and purge the hydraulic system completely Maintenance program did not finish completely Run the remaining maintenance operations Dirty cuvettes Contamination of the cuvettes Run a special wash cycle with NaOH 0.2 N (See Chapter 7 point 7.7) Failure of the optical system Failure of the washing and/or drying of the cuvettes Burned lamp Deteriorated cuvettes Inadequate calibration of the optical system Contamination of the circuits Prolonged non-use of the instrument Presence of air in the hydraulic system Erratic incubation temperature Erratic cuvette tray temperature Losses in the diluter circuit connections Incorrect aspiration or dispensing of samples and reagents Obstruction of the probe and/or of the pre-heater Bubbles in the tubing or diluter Sensing failure Contact Technical Support Replace the lamp Replace the cuvettes Calibrate the photometer Calibrate the cuvettes Run a decontamination process Contact Technical Support Adjust connections and purge the diluter Purge the diluter and run a TIP cleaning Adjust connections and run a TIP cleaning See error solving 109 Only one affected sample for all of the methods Observation Probable cause Action Place the sample in the correct position Incorrect sample position Sample incorrectly positioned Incorrect control configuration Incorrect assignment of the concentrations limits to the controls Configure the controls concentrations limits correctly Incorrect selection of methods Selection of methods inadequate for the type of sample Select the correct methods for the type of sample HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 197 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Incorrect preparation of the sample Inadequate sample integrity Sample reconstituted with an inadequate volume or poorly homogenized Sample diluted incorrectly Reconstitute a new vial correctly Dilute the sample correctly Insufficient volume Use a minimum volume of 200 µl Inadequate storage Use fresh or well preserved samples Presence of bubbles and/or fibrin in the Use a sample free of bubbles and sample tubes fibrin Presence of sample interferences: Use a new sample free of hemolysis, jaundice, lipemic specimen, interferences turbidity Only one affected method for all of the samples Observation Probable cause Insufficient reagent volume or bubbles into the reagent bottle Reagent volume less than 2 ml or more Refill the reagent bottle or change it than 55 ml without any bubbles Inadequate reagent Deteriorated reagent Incorrect information in the configuration Incorrect positioning of the reagent in the tray Assign the reagent position correctly Inadequate reagent container Use only the reagent bottles designed for the instrument Dirty reagent bottles Wash the reagent bottles periodically Insufficient reagent volume Inadequate reagent preparation Refill the reagent bottle Prepare new reagent Refilled reagent not homogenized, or not verified Mix the reagent gently and verify the blank. Avoid foaming Physical and/or chemical deterioration Prepare new reagent and verify the of the reagent blank Incorrect type of reaction chosen for the Select the correct type of reaction method Method parameters configured Configure the parameters adequately incorrectly Incorrect assignment of the concentrations limits to the controls Inadequate calibration Page 198 of 217 Action Calibrator concentration configured incorrectly Incorrect preparation of the calibrator dilution Configure the controls concentrations limits correctly Configure the calibrator cc correctly Use a calibrator reconstituted correctly Incorrect blank reagent absorbance Verify the blank reagent Incorrect calibrator absorbance Calibrate the method HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Message of a re-diluted result or re-dilute manually with results within the linear limit Linearity configured incorrectly Configure the linearity correctly: a value between 0.80 y 0.95 Initial consumption configured incorrectly Configure the method’s initial consumption correctly Instrumental Problems Instrumental problems may appear with visible failures in its components or by malfunction errors that are shown up in the software. As well, instrumental problems may often be inferred from the analysis of observed chemical problems. Based on these observations, instrumental problems can be grouped according to the affected module or component of the instrument. Decide which of the following components is probably affected and run the associated checks and actions in each case: - Connections and supplies Hydraulic system Washer Diluter Sample/Reagent probe Reaction cuvette tray Sample/Reagent tray Software If this does not solve the problem, contact Technical Support Connections and supplies Observation Failure in the startup of the instrument Failure in the PC- instrument communication Probable cause Action Instrument disconnected Plug the cable into the power source Burnt out start up fuse Replace the fuses No electricity from the power source Reestablish the electricity Damaged start-up button Instrument turned off Instrument turned off and on without initialization procedure Contact Technical Support Turn on the instrument Run initialization procedure Invalid communication port Close all open applications that might be using the communication port and re- open the software PC disconnected from the instrument Connect the PC-instrument communication cable 17.3.1 Hydraulic system HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 199 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Observation Probable cause Connections adjusted inadequately Partial obstruction of the probe Presence of bubbles/air in the Incorrect purge of the diluter circuit tubing Incorrect purge of the washer circuit Insufficient washing solution Overflowing of the probe wash station. Presence of water Drain hose bent or obstructed under the instrument Action Adjust the connections Purge the diluter Purge the diluter Run a TIP cleaning cycle Purge the diluter Wash cuvettes Refill the wash solution and purge the diluter five times and wash cuvettes Straighten or un-obstruct the drain hose Diluter Observation Probable cause Connections adjusted inadequately Presence of bubbles or air in the diluter Damaged tubing Blocked probe Action Adjust the connections Purge the diluter Contact Technical Support Run a TIP cleaning cycle Purge the diluter Washer Observation Colored dryer tips Horizontal movement of the washer head Dripping washer tips Probable cause Washer failure Action Contact Technical Support Washer head adjusted incorrectly Contact Technical Support Washer failure Contact Technical Support Probable cause Action Run a TIP cleaning cycle Purge the diluter Contact Technical Support Contact Technical Support Clean the probe tips with paper towel dipped in ethyl alcohol Purge the diluter Sample/reagent probe Observation Blocked probe Dripping probe Pre-heater failure Faulty connections Unusual noise with upward movement Presence of bubbles between the two ends of the probe Damaged probe: aspiration tip and sensor tip of the same length Collision of the probe Page 200 of 217 Contact Technical Support HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Probe and its capillary dirty Clean the exterior of the probe with Adhesion of remains of samples and/or paper towel dipped in ethyl alcohol. reagents Purge the diluter Reaction Cuvettes Tray Observation Probable cause Action Formation of crystals in the upper part of the cuvettes Incomplete run of the wash program Run an external wash and calibration of the cuvettes Inadequate purge of the washer Presence of water on the cuvette strips Insufficient washing solution Presence of bubbles in the cuvettes during the wash Damaged/opaque cuvettes Air entering the tubing Prolonged use Cuvettes still dirty after washing Washer failure Purge the washer 5 times Refill the washing solution container and purge the diluter and washer five times Check the connection of the hoses to the washing solution container Purge the washer Change the cuvettes and calibrate them Contact Technical Support Sample/Reagent Tray Observation Probable cause Action Refrigeration unit turned off Turn on unit Refrigeration system failure Contact a Technical Support Presence of dark stains in the reagent tray Fungal contamination Disinfect with 33% sodium hypochlorite for 30 minutes Unusual noises Mechanical failures Contact Technical Support Probable cause Action Press Retry, if this does not correct the error, press Cancel Retry the operation No refrigeration of the reagents Software Observation Error message: Processing error # Process xxxxxxxxxxx Attempt to make an operation outside of the specified time (Time out) Retry/Cancel Results expressed as a nan (not Error in the calculation of the a number) calibration or the sample result Contact Technical Support Verify settings methods, the blank reagent and recalibrate the method HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 201 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Failure to update a calibration Error message: The instrument cannot be initialized Calibration made with the method setting screen open Recalibrate with the method setting screen closed or edit the value obtained for the calibration Instrument turned off Instrument turned off and on without initialization procedure Burnt out start up fuse Turn on the instrument No electricity from the power source Reestablish the electricity Damaged Analyzer on/off button Contact Technical Support Instrument disconnected Plug the cable into the power source Invalid communication port Close all open applications that might be using the communication port and re- open the software PC disconnected from the instrument Connect the PC-instrument communication cable Mechanical failure Contact Technical Support Run initialization procedure Replace the fuses For any problem other than those described here, contact exclusively the Technical Support authorized by HTI Hardware Messages Error messages will be displayed on the screen like this: Figure 17-1 Figure 17-2 Page 202 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 There are two types of messages: Error messages, this error stops the running (Figure 17-1) Warning messages, this is just a warning, it will not stop the running (Figure 17-2) This kind of flags report the Message ID number (the number between (xxxx)) and a brief description of the problem. Below, there’s a list with all the Hardware Messages, including a probable cause and a possible solution. NOTE: This tool is useful in most cases, but it is not a definitive solution for all the problems. START UP Message ID Number and Description Probable cause Possible Solution (0001) The Analyzer has been Execute the command to initialize or The analyzer has been powered on with powered on. An initialization wait for software automatic initialization software session active. sequence will be required sequence. (0002) A general power down happened to the Analyzer, it The Analyzer general power has been could affect the ISE module interrupted. performance. Please purge, calibrate and control it Long term general power interruptions will affect the ISE electrodes life expectancy and performance. Avoid using the general power key. Purge, calibrate and control the ISE module. EEPROM Message ID Number and Description Probable cause Possible Solution (0031) EEPROM writing error Wrong direction or defective EEPROM Contact Technical Support. (0032) EEPROM reading error Wrong direction or defective EEPROM Contact Technical Support. (0033)EEPROM writing disabled Contact Technical Support. Enabling command not executed (0034) EEPROM erasing error Defective EEPROM Contact Technical Support. (0035) EEPROM absorbances Defective EEPROM clearing error Contact Technical Support. (0036) EEPROM writing error Wrong Direction (variable does not exist) Contact Technical Support. HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 203 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 (0037) EEPROM reading error Wrong Direction (variable does not exist) Contact Technical Support. VERTICAL Message ID Number and Description (0101) Probe Impact (Vertical Movement) Probable cause Possible Solution Physical impact Verify possible obstacles along the path of header movement. Impact switches failures (preheater board) Poor contacts Contact Technical Support. Contact Technical Support. Home sensing Failure (0102)Probe Vertical Mechanical failure Movement not initialized or initialization error (Home active) Vertical movement not initialized. Contact Technical Support. (0103)Probe Vertical Movement not initialized or initialization error (Home inactive) Sensing failure home Contact Technical Support. Mechanical failure (0104) Probe Vertical Movement error (Home not found) Home sensing failure Contact Technical Support. Execute the commands to initialize the movement Contact Technical Support. Mechanical failure. Contact Technical Support. Vertical movement not initialized (0105) Probe vertical movement Home sensing failure error (Home active) Mechanical failure Contact Technical Support. Execute the commands to initialize the movement Contact Technical Support. Contact Technical Support. (0106) Upgrade Vertical Movement Controller Controller old version. Contact Technical Support. (0107) Probe level not detected(level inactive) Wiring failure Probe failure. Preheater PCB failure Contact Technical Support. Contact Technical Support. Contact Technical Support. (0108) Probe Impact (Vertical Movement) and incorrect Probe See error solving 101 and 109. Level Detection (Level active) (0109) Incorrect Probe Level Detection (Level active) Sensing failure Clean the probe in case of possible dirtiness or a drop between the auxiliary and the main capillary. Probe failure Contact Technical Support. Module preheater failure Contact Technical Support. Wiring failure Contact Technical Support. HORIZONTAL Page 204 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Message ID Number and Description (0151) Probe impact (Horizontal Movement) Probable cause Possible Solution Physical impact Verify possible obstacles in the movement Contact Technical Support. Impact switches failures (preheater board) Poor contacts Contact Technical Support. (0152) Probe Horizontal Movement not initialized or initialization error (Home active) Home Sensing failure Contact Technical Support. Mechanical failure Horizontal movement not initialized Contact Technical Support. Execute the command to initialize. (0153) Probe Horizontal Movement not initialized or initialization error (Home inactive) Home sensing failure Contact Technical Support. Mechanical failure Contact Technical Support. Horizontal movement not initialized Execute the command to initialize. (0154) Probe Horizontal Home sensing failure Movement error (Home active) Mechanical failure Contact Technical Support. (0155) Probe Horizontal Home sensing failure Movement error (Home Mechanical failure inactive) (0156) Upgrade Horizontal Old Controller version. Movement Controller Contact Technical Support. Contact Technical Support. Contact Technical Support. Contact Technical Support. REACTION TRAY Message ID Number and Description (0201) Probe Impact (Reaction Tray) Probable cause Possible Solution Physical impact Verify possible obstacles in the movement. Impact switches failure (preheater board) Poor contacts Home sensing failure Mechanical failure (0202) Reaction Tray not initialized or initialization error Reaction tray not initialized (Home active) Home sensing failure. (0203) Reaction Tray not initialized or initialization error Mechanical failure (Home inactive) Reaction tray not initialized. (0204) Reaction Tray not initialized Module not initialized. Contact Technical Support. Contact Technical Support. Contact Technical Support. Contact Technical Support. Execute the command to initialize. Contact Technical Support. Contact Technical Support. Execute the command to initialize. Execute the command to initialize. HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 205 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 (0205) Reaction Tray error (slotted tray counting error) (0206) Reaction Tray error (Home active) (0207) Reaction Tray error (Home inactive) Home sensing error. Contact Technical Support. Mechanical failure. Contact Technical Support. Sensor P out of counting position. Contact Technical Support. Mechanical failure Sensing failure Mechanical failure. Contact Technical Support. Contact Technical Support. Contact Technical Support. Sensing failure. Contact Technical Support. Mechanical failure. Contact Technical Support. Sensing failure of W-UP and W(0208) Reaction Tray Contact Technical Support. movement inadequate safety DOWN. NOTE: the equipment verifies the state of the washer before moving the reaction conditions (Washer) tray. (0209) Reaction Tray Same values for dispensed offset and programming error Contact Technical Support. (Dispensing and Photometer photometer offset. offset) SAMPLE/REAGENT TRAY Message ID Number and Description (0251) Probe Impact (Samples and Reagents Tray) (0252) Samples and Reagents Tray not initialized or initialization error (Home active) (0253) Samples and Reagents Tray not initialized or initialization error (Home inactive) (0254) Samples and Reagents Tray not initialized (0255) Samples and Reagents Tray error (slotted tray counting error) Page 206 of 217 Probable cause Possible Solution Physical impact. Verify possible obstacles in the movement. Impact switches failures (preheater board) Poor contacts Home sensing failure. Mechanical failure Contact Technical Support. Contact Technical Support. Contact Technical Support. Contact Technical Support. Sample-reagent tray not initialized. Execute the command to initialize. Home sensing failure Contact Technical Support. Mechanical failure. Reagent and samples tray not initialized. Contact Technical Support. Module not initialized Initialize module. Home sensing failure Contact Technical Support. Mechanical failure. Contact Technical Support. Sensor- P out of the counting position. Contact Technical Support. Mechanical failure. Contact Technical Support. Execute the command to initialize. HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 (0256) Samples and Reagents Tray error (Home active) (0257) Samples and Reagents Tray error (Home inactive) Sensing failure. Contact Technical Support. Mechanical failure Contact Technical Support. Sensing failure Contact Technical Support. Probable cause Possible Solution FILTER WHEEL Message ID Number and Description Home sensing failure. (0302) Filter Wheel not Mechanical failure. initialized or initialization error (Home active) Filter wheel not initialized. Contact Technical Support. Home sensing failure (0303) Filter Wheel not initialized or initialization error Mechanical failure (Home inactive) Filter wheel not initialized. Contact Technical Support. (0304) Filter Wheel not initialized (0305) Filter Wheel error (slotted tray counting error) (0306) Filter Wheel error (Home active) (0307) Filter Wheel error (Home inactive) Contact Technical Support. Execute the command to initialize. Contact Technical Support. Execute the command to initialize. Module not initialized. Initialize module Home sensing failure. Contact Technical Support. Mechanical failure Contact Technical Support. Sensor F out of the counting position. Contact Technical Support. Poor contacts. Contact Technical Support. Mechanical failure Contact Technical Support. Sensing failure Contact Technical Support. Poor contacts Contact Technical Support. Mechanical failure Contact Technical Support. Sensing failure. Contact Technical Support. READING (AMPLIFIERS) Message ID Number and Description Probable cause Possible Solution HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 207 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 (0321) The time is not enough A reading was performed before for thermal stabilization. Please reaching the time of thermal repeat the test after some stabilization. minutes (0322) Reaction Tray uncovered. Please place the cover (0323) Lamp error (burned, unconnected or power failure) (0324) Lamp powered off (0325) Internal CRC error (Amplifier) (0326) Low energy in Reference Beam. Calibrate Photometer (0327) Low energy in Sample Beam. Check Sample absorbance (0328) Saturated Reference Amplifier Wait .(it is recommended at least 10 minutes) It has been intended to carry out a reading operation without placing the Place the cover of the reaction tray. cover of the reaction tray. Light sensor failure. Contact Technical Support. Lamp burned out. Replace the lamp. Lamp disconnected or without any supplies. Contact Technical Support. The lamp turned off and the analyzer Contact Technical Support. attempts to read. Communication error between amplifier controller and Main controller. Lack of calibration. Contact Technical Support. Run photometer calibration. Exit Lens of the reference channel Contact Technical Support. Defective Lamp Contact Technical Support. Defective Beam Filter Lack of calibration. Contact Technical Support. Run photometer calibration. Scratch Cuvette or not aligned. Contact Technical Support. Exit Lens of the reference channel Contact Technical Support. Defective Lamp Contact Technical Support. Defective Beam Filter Contact Technical Support. Reaction tray uncover Place the cover of the reaction tray. Reference amplifier disconnected. Contact Technical Support. Reference amplifier failure. Contact Technical Support. Filter missing. Contact Technical Support. Incorrect positioning of a Beam Filter. Contact Technical Support. (0329) Saturated Sample Amplifier Page 208 of 217 Reaction tray uncovered Place the cover of the reaction tray. Reference amplifier disconnected Contact Technical Support. HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Reference amplifier failure. Contact Technical Support. Filter missing Contact Technical Support. Incorrect positioning of a Beam Filter. Contact Technical Support. (0330) High energy Reference Beam Reaction tray lid not placed. Place the lid of the reaction tray. Amplifiers disconnected. Contact Technical Support. Filter missing Contact Technical Support. Incorrect positioning of a Beam Filter. Contact Technical Support. Lamp failure (0331) High energy Sample Beam (0332) Saturated Sample Contact Technical Support. Incorrect positioning of a Beam Filter. Contact Technical Support. Defective filter Contact Technical Support. Lamp failure Contact Technical Support. Incorrect positioning of a Beam Filter. Contact Technical Support. and Reference Amplifiers Defective filter Contact Technical Support. PHOTOMETER CALIBRATION Message ID Number and Description Probable cause (0351) Photometer Calibration error (no filters programmed in Filter ID values set on the EEPROM EEPROM) Possible Solution Contact Technical Support. (0352) Photometer Calibration error (Filter Wheel Controller Possible failure in filter wheel controller. Contact Technical Support. communication) (0353) Photometer Calibration error (Amplifier Controller Possible failure in amplifier IC controller. Contact Technical Support. communication) (0354) Photometer Calibration Calibration logic error. error Contact Technical Support. (0355) Photometer Calibration error (low energy in Sample Scratched cuvette or not aligned. Beam) Replace the cuvette or try to calibrate another cuvette. (Anyway, it is recommended to replace defective cuvettes) HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 209 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Contact Technical Support. Exit lens of the reference channel. Contact Technical Support. Amplifier sample Failure. Contact Technical Support. (0356) Photometer Calibration Exit lens of the reference channel. error (low energy in Reference Failure in the amplifier reference. Beam) Defective lamp Contact Technical Support. Contact Technical Support. Contact Technical Support. (0357) Photometer Calibration Exit lens. error (low energy in Sample and References Beams) Incorrect positioning of a Beam Filter. Contact Technical Support. Defective filter (0358) Photometer Calibration Alignment failure in the optical path error (high Contact Technical Support. energy in Sample Beam) Contact Technical Support. Sample Amplifier Failure. (0359) Photometer Calibration error (high energy in Reference Amplifier Failure. Reference Beam) Incorrect positioning of a Beam Filter. (0360) Photometer Calibration error (high energy in Sample Lamp failure and Reference Beams) Defective filter Amplifiers failure Contact Technical Support. Contact Technical Support. Contact Technical Support. Contact Technical Support. Contact Technical Support. Contact Technical Support. Contact Technical Support. Stray light. (0361) Photometer Calibration error (high Zero in Sample Amplifier) Sample Amplifier Failure. Contact Technical Support. (0362) Photometer Calibration Stray light. error (high Zero in Reference Reference Amplifier Failure. Amplifier) Contact Technical Support. Incorrect positioning of a Beam Filter. (0363) Photometer Calibration Lamp failure error (high Zero in Sample Defective filter and Reference Amplifiers) Missing filter Amplifiers failures Page 210 of 217 Contact Technical Support. Contact Technical Support. Contact Technical Support. Contact Technical Support. Contact Technical Support. Contact Technical Support. Contact Technical Support. HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 (0364) Photometer Calibration Defective EEPROM error (EEPROM writing error) (0365) Photometer Calibration (High gain Sample Amplifier) Scratched cuvette or not aligned. Contact Technical Support. Replace the cuvette or try to calibrate another cuvette. (Anyway, it is recommended to replace defective cuvettes) Contact Technical Support. Exit lens of the reference channel. Contact Technical Support. (0366) Photometer Calibration Exit lens of the reference channel. (High gain Reference Amplifier) Contact Technical Support. Defective lamp Exit lens. (0367) Photometer Calibration Incorrect positioning of a Beam (High gain Sample and Reference Amplifiers) Filter. Contact Technical Support. Defective filter CUVETTE CALIBRATION Message ID Number and Description Probable cause Possible Solution (0381) Cuvettes Calibration error (no filters programmed in EEPROM) Filter ID values set on the EEPROM Contact Technical Support. (0382) Cuvettes Calibration Possible failure in IC filter-wheel error (Filter Wheel Controller controller. communication) Contact Technical Support. (0383) Cuvettes Calibration error (Amplifier Controller communication) Possible failure in IC controller (Amplifier). Contact Technical Support. (0384) Cuvettes Calibration error Error in the logic of calibration. Contact Technical Support. Lack of calibration. Run photometer calibration. Contact Technical Support. (0385) Cuvettes Calibration error (low energy in Sample Beam) Scratched cuvette or poorly aligned. Replace the cuvette.(it is recommended to replace the defective cuvettes) Exit lens of the sample channel Contact Technical Support. Lack of calibration. Run photometer calibration. HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 211 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 (0386) Cuvettes Calibration error (low energy in Reference Beam) (0387) Cuvettes Calibration error (Cuvette absorbance too high, replace the cuvettes) Exit lens of the reference channel. Contact Technical Support. Scratched cuvette or poorly aligned. Replace the cuvette.(it is recommended to replace the defective cuvettes) Lack of calibration Lack of calibration Contact Technical Support. Run photometer calibration Do photometer calibration (0388) Cuvettes Calibration error (Cuvette absorbance too low, Calibrate Photometer Cuvette not aligned. in a different cuvette or replace de cuvettes) (0389) Cuvettes Calibration (Cuvette absorbance too high, replace the cuvettes when possible) Replace the cuvette.(it is recommended to replace the defective cuvettes) Contact Technical Support. Check the alignment of the beam with the cuvette. Striped cuvette or misaligned Lack of calibration Lack of calibration (0390) Cuvettes Calibration (Cuvette absorbance too low, Calibrate Photometer in a Cuvette poorly aligned. different cuvette or replace de cuvettes when possible) (0391) Cuvettes Calibration Defective EEPROM. error (EEPROM writing error) Replace the cuvette.(it is recommended to replace the defective cuvettes) Run photometer calibration Run photometer calibration Replace the cuvette.(it is recommended to replace the defective cuvettes) Contact Technical Support. Contact Technical Support. HEATER AND PREHEATER Message ID Number and Description Probable cause (0401) Temperature reading Wiring failure error (can't read Reaction A/D defective Tray A/D converter) (0451) Temperature reading Wiring failure error (can't read Preheater A/D defective A/D converter) Possible Solution Contact Technical Support. Contact Technical Support. Contact Technical Support. DILUTER Page 212 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Message ID Number and Description (0501) Diluter Initialization error Probable cause Possible Solution Wiring failure Contact Technical Support. Mechanical failure Contact Technical Support. (0502) Diluter invalid Contact Technical Support. command (0503) Diluter invalid operand Incorrect Volume Contact Technical Support. (0504) Diluter invalid command sequence Contact Technical Support. Verify the aspiration Volume in the Method parameters. Contact Technical Support. (0505) Diluter not initialized Diluter not initialized. Execute initialization commands. (0506) Diluter Plunger overload Mechanical failure Check possible obstacles in the movement of the diluter plunger. Contact Technical Support. (0507) Diluter Valve overload Mechanical failure Contact Technical Support. (0508) Diluter Plunger move not allowed (0509) Diluter command overflow Wrong position of the valve. Contact Technical Support. Contact Technical Support. Contact Technical Support. Probable cause Possible Solution Sensing failure. Contact Technical Support. Mechanical failure. Contact Technical Support. Sensing failure. Contact Technical Support. Mechanical failure Contact Technical Support. Sensing failure. (0554) Washer Header movement error (Down active) Mechanical failure. Contact Technical Support. (0555) Washer Header movement error (Down inactive) Home sensing failure. Contact Technical Support. Mechanical failure. Contact Technical Support. Message ID Number and Description Probable cause Possible Solution (0571) Washer Flushing HOME sensing failure Contact Technical Support. WASHER Message ID Number and Description (0552) Washer not initialized or initialization error (Up active) (0553) Washer not initialized or initialization error (Up inactive) Contact Technical Support. FLUSHING PUMP HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 213 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Pump initialization error (Home active) Electrical failure Contact Technical Support. Mechanical failure Contact Technical Support. 0572) Washer Flushing Pump HOME sensing failure initialization error (Home Mechanical failure inactive) Contact Technical Support. (0573) Washer Flushing Pump moving error (Home active) (0574) Washer Flushing Pump moving error (Home inactive) Wiring failure. Contact Technical Support. Mechanical failure. Contact Technical Support. Wiring failure. Contact Technical Support. Mechanical failure. Contact Technical Support. Wiring failure or sensing home Contact Technical Support. Electrical failure. Contact Technical Support. Mechanical failure. Contact Technical Support. HOME sensing Failure Contact Technical Support. Electrical failure. Contact Technical Support. Mechanical failure. Contact Technical Support. Probable cause Possible Solution HOME sensing Failure Contact Technical Support. Electrical failure. Contact Technical Support. Mechanical failure Contact Technical Support. Wiring failure or sensing home Contact Technical Support. Electrical failure. Contact Technical Support. Mechanical failure Contact Technical Support. Wiring failure or sensing home Contact Technical Support. Electrical failure. Contact Technical Support. Mechanical failure Contact Technical Support. Wiring failure or sensing home Contact Technical Support. Electrical failure Contact Technical Support. Mechanical failure. Contact Technical Support. (0575) Washer Flushing Pump error (Home active) (0576) Washer Flushing Pump error (Home inactive) Contact Technical Support. FILLING PUMP Message ID Number and Description (0581) Washer Filling Pump moving error (Home active) (0582) Washer Filling Pump moving error (Home inactive) (0583) Washer Filling Pump error (Home active) (0584) Washer Filling Pump error (Home inactive) Page 214 of 217 HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 ISE Message ID Number and Description (0701) mV Out in Serum/Plasma Probable cause Possible Solution Salt is plugging the electrode flow path. Remove electrodes and clean or replace electrode with plugged flow path. Reinstall electrodes and recalibrate. If single electrode is flagged Replace problem electrode and recalibrate. If multiple electrode are flagged Replace reference electrode and recalibrate. Electrical noise spike from environmental source. Contact Technical Support. Salt is plugging the electrode flow path. Remove electrodes and clean or replace electrode with plugged flow path. Reinstall electrodes and recalibrate. If single electrode is flagged: May occur when new electrode or Calibrant A are installed. Purge Calibrant A and recalibrate the ISE module. If the electrode is new it may initially drift as it rehydrates over the course of 15 minutes. If single electrode is flagged Replace the electrode and recalibrate. If multiple electrode are flagged May occur when new electrode or Reagent Kit is installed. Purge the Calibrant A and recalibrate the ISE module. If multiple electrode are flagged Reference electrode. Replace reference electrode and recalibrate. If single electrode is flagged Replace problem electrode and recalibrate. If multiple electrode are flagged Replace reference electrode and recalibrate. Electrical noise spike from environmental source. Contact Technical Support. Component failure on ISE Module board. Contact Technical Support (0702) mV Out in Calibrant A (0703) Noise in Serum/Plasma If single electrode is flagged (0704) Noise in Calibrant A If multiple electrode are flagged Replace problem electrode and recalibrate. Replace reference electrode and recalibrate. HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 215 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Electrical noise spike from environmental source. Component failure on ISE Module board. (0705) Drift in Serum/Plasma Contact Technical Support. Contact Technical Support If single electrode is flagged: May occur when new electrode or Calibrant A is installed. Purge the Calibrant A and recalibrate the ISE module. If the electrode is new it may initially drift as it rehydrates over the course of 15 minutes. If single electrode is flagged: Replace the electrode and recalibrate. If multiple electrode are flagged: May occur when new electrode or Reagent Kit is installed. If multiple electrode are flagged: Reference electrode. Electrical noise spike from environmental source. Component failure on ISE Module board. Samples results are out of range limits: Purge the Calibrant A and recalibrate the ISE module. Replace reference electrode and recalibrate. Contact Technical Support. Contact Technical Support Check quality of sample. Whole blood, serum, plasma (0706) Out of range in Serum/Plasma Li+ 0.20 – 3.50 mmol/L Na+ 100.0 – 200.0 mmol/L K+ 1.00 – 10.00 mmol/L Cl- 50.0 – 150.0 mmol/L Salt is plugging the electrode flow path. (0707) mV Out in Urine If single electrode is flagged If multiple electrodes are flagged (0708) mV Out in Calibrant B Page 216 of 217 Run Calibration procedure, run control samples and retest. Remove electrodes and clean or replace electrode with plugged flow path. Reinstall electrodes and recalibrate. Replace problem electrode and recalibrate. Replace reference electrode and recalibrate. Electrical noise spike from environmental source. Contact Technical Support. If single electrode is flagged: May occur when new electrode or Calibrant A/B are installed. Purge Calibrant B and recalibrate the ISE module. If the electrode is new it may initially drift as it rehydrates over the course of 15 minutes. HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 If single electrode is flagged If multiple electrodes are flagged May occur when new electrode or Reagent Kit is installed. If multiple electrodes are flagged Reference electrode. Replace the electrode and recalibrate. Purge the Calibrant A and recalibrate the ISE module. Replace reference electrode and recalibrate. If single electrode is flagged Replace problem electrode and recalibrate. If multiple electrodes are flagged Replace reference electrode and recalibrate. Electrical noise spike from environmental source. Contact Technical Support. Component failure on ISE Module board. Contact Technical Support (0709) Noise in Urine If single electrodes is flagged If multiple electrodes are flagged (0710) Noise in Calibrant B (0711) Drift in Urine Electrical noise spike from environmental source. Component failure on ISE Module board. Replace problem electrode and recalibrate. Replace reference electrode and recalibrate. Contact Technical Support. Contact Technical Support If single electrode is flagged: May occur when new electrode or Calibrant B is installed. Purge the Calibrant B and recalibrate the ISE module. If the electrode is new it may initially drift as it rehydrates over the course of 15 minutes. If single electrode is flagged Replace the electrode and recalibrate. If multiple electrodes are flagged: May occur when new electrode or Reagent Kit is installed. Purge the Calibrant A and recalibrate the ISE module. If multiple electrodes are flagged: Reference electrode. Replace reference electrode and recalibrate. Samples results are out of range limits: Urine diluted must be used. (0712) Out of range in Urine Urine Check quality of sample. HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 217 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 (0713) mV Out in Calibrant B Na+ 10 – 500 mmol/L K+ 5 – 200 mmol/L Cl- 15 – 400 mmol/L If single electrode is flagged: May occur when new electrode or Calibrant B are installed. Purge Calibrant B and recalibrate the ISE module. If the electrode is new it may initially drift as it rehydrates over the course of 15 minutes. If single electrode is flagged Replace the electrode and recalibrate. If multiple electrode are flagged May occur when new electrode or Reagent Kit is installed. Purge the Calibrant B and recalibrate the ISE module. If multiple electrode are flagged Reference electrode. Salt is plugging the electrode flow path. (0714) mV Out in Calibrant A Purge Calibrant A and recalibrate the ISE module. If the electrode is new it may initially drift as it rehydrates over the course of 15 minutes. If single electrode is flagged Replace the electrode and recalibrate. If single electrode is flagged If multiple electrode are flagged Electrical noise spike from environmental source. Component failure on ISE Module board. If single electrode is flagged (0716) Noise in Calibrant A If multiple electrode are flagged Electrical noise spike from environmental source. Page 218 of 217 Replace reference electrode and recalibrate. Remove electrodes and clean or replace electrode with plugged flow path. Reinstall electrodes and recalibrate. If single electrode is flagged: May occur when new electrode or Calibrant A are installed. If multiple electrode are flagged May occur when new electrode or Reagent Kit is installed. If multiple electrode are flagged Reference electrode. (0715) Noise in Calibrant B Run Calibration procedure, run control samples and retest. Purge the Calibrant A and recalibrate the ISE module. Replace reference electrode and recalibrate. Replace problem electrode and recalibrate. Replace reference electrode and recalibrate. Contact Technical Support. Contact Technical Support Replace problem electrode and recalibrate. Replace reference electrode and recalibrate. Contact Technical Support. HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 (0717) Drift in Calibration Component failure on ISE Module board. Contact Technical Support Salt is plugging the electrode flow path. Remove electrodes and clean or replace electrode with plugged flow path. Reinstall electrodes and recalibrate. If single electrode is flagged: May occur when new electrode or Calibrant A/B are installed. Purge Calibrant A/B and recalibrate the ISE module. If the electrode is new it may initially drift as it rehydrates over the course of 15 minutes. If single electrode is flagged Replace the electrode and recalibrate. If multiple electrode are flagged May occur when new electrode or Reagent Kit is installed. If multiple electrode are flagged Reference electrode. Purge the Calibrant A and recalibrate the ISE module. Replace reference electrode and recalibrate. Acceptable slope limits are: Slope (mV/decade) Li+ (0718) Out of Range in Calibration 47–64 Na+ 52–64 (0731)ISE Module - Air in Sample/Urine (automatically repeated) K+ 52–64 Cl- 40–55 Replace the electrode and recalibrate. Insufficient sample pipette into ISE module sample entry port Check method settings (Sample volume must be 70 µl for serum/plasma and 140 µl for diluted urine) Bubbles in sample Sample must be free of bubbles. Fluid leaks Contact Technical Support. Sample not positioned Electrodes not seated properly. Remove electrodes. Inspect o- rings and reassemble. Contact Technical Support. (0732) ISE Module - Air in Calibrant A (automatically repeated) Pump tubing obstructed Contact Technical Support. Calibrant A Replace reagent kit with a new one. Purge, and recalibrate. Tubing from reagent module is disconnected, plugged, or crimped. Contact Technical Support. HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 219 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 Fibrin or salt is plugging the electrode flow path. Remove electrodes and clean or replace electrode with plugged flow path. Reinstall electrodes and recalibrate. Calibrant A pump is not working properly. Contact Technical Support. Electrodes are not properly seated. Check compression plate, spring and seal. Ensure that all electrodes and o- rings are properly installed. Calibrant B is segmented with air Ensure tubing between reagent kit and sample entry port is connected properly. Replace tubing between reagent kit and sample entry port. (0733) ISE Module - Air in Calibrant B (automatically repeated) Reagent low or out. Use cleaning procedure. Waste pump malfunction Remove electrodes and clean or replace electrode with plugged flow path. Reinstall electrodes and recalibrate. Contact Technical Support. Bubble detector malfunction Contact Technical Support. (0734) ISE Module Temperature higher than 32ºC. Please decrease the environment temperature, otherwise the Electrodes life expectancy could be reduced ISE Module Temperature higher than 32ºC. Room temperature must be reduced. (0735) ISE Module Temperature drift higher than 4ºC. Please Calibrate the Module and repeat the test Processing temperature is +/- 4ª since last calibration. Calibrate the ISE Module and repeat the test. Internal error. Contact Technical Support. Internal error. Contact Technical Support. Fibrin or salt is plugging the electrode flow path. (0751) ISE Module - Invalid Answer (0752) ISE Module Unknown Error (0753) ISE Module - Air in Sample (0754) ISE Module - Air in Calibrant A (0755) ISE Module - Air in Calibrant B Page 220 of 217 See possible solution for 0731. See possible solution for 0732. See possible solution for 0733. HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Document Number High Technology, Inc. 109 Production Road, Walpole MA 02081 USA OM-E-FC-360-30 Revision Level Rev. 3 Prepared by J.S. Bolio Approved by S. Titov Effective Date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 (0756) ISE Module - Air in Cleaner Insufficient cleaning solution pipette into ISE module sample entry port. Check cleaning solution tube Waste peristaltic pump failure. Contact Technical Support. Use cleaning procedure. Fibrin or salt is plugging the electrode flow path. (0757) ISE Module - Air in Segment (0758) ISE Module - Pump Calibration error Contact Technical Support. Remove electrodes and clean or replace electrode with plugged flow path. Reinstall electrodes and recalibrate. Sample cup contamination. The sample cup may become dirty (i.e. possible protein buildup, salt from reagent, dust falling in from above) during normal use. A cotton tip applicator dipped in DIH20 to clean around and in the sample cup, being careful not to dislodge any particles that may obstruct the flow path. Air bubble in sample – if the sample probe delivering the sample or any reagent is to fast or forceful air bubbles can be created and drawn into the flow path. Contact Technical Support. Insufficient saline solution pipette into ISE module sample entry port. Check saline solution tube Waste peristaltic pump failure. Contact Technical Support. Contact Technical Support. Use cleaning procedure. Pump tubing obstructed Remove electrodes and clean or replace electrode with plugged flow path. Reinstall electrodes and recalibrate. Contact Technical Support. Peristaltic pump failure Contact Technical Support. Fluid leaks Contact Technical Support. Pump tubing obstructed Contact Technical Support. Internal error. Contact Technical Support. Internal error. Contact Technical Support. Internal error. Contact Technical Support. Fibrin or salt is plugging the electrode flow path. (0759) ISE Module - No Flow (0760) ISE Module - Bubble Detector (0761) ISE Module Reagents Kit Electronic Key Read (0762) ISE Module Reagents Kit Electronic Key Write (0763) ISE Module - Invalid Command HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL Page 221 of 222 Document Number High Technology, Inc. 109 Production Road, Walpole MA USA 02081 OM-E-FC-360-30 Revision Level Rev. 3 Prepared By J.S. Bolio Approved By S. Titov Effective date 8/15/2016 Operator’s Manual: HTI BioChem FC-360 (0764) ISE Module calibration out of time. Please Calibrate it Calibration time expired (more than 8 hours from last) Run a calibration procedure. Module has been turned off. (0765) ISE Module uncalibrated. Please Calibrate it ISE module has been under Mant command Run a calibration procedure. Calibration ended with errors Electrode has been enabled by hardware option (0766) ISE Module communication Checksum error (0767) ISE Module answer parsing error Internal error Contact Technical Support. Internal error Contact Technical Support. (0768) ISE Module cleaning out of time. Please Clean it Cleaning time expired (more than 8 hours or 50 samples from last) Run cleaning procedure. (0769) ISE Module out of position. Please reposition the Module ISE module in a wrong position. Reposition module. (0770) ISE Pack changed ISE Reagent Kit has been changed. Run Reagent Kit replacement. Kit electronic key failure Change ISE reagent kit. (0771) ISE Pack Security Code error (0772) ISE Pack Wrong Distributor Code Invalid Reagent Kit (0773) ISE Pack Expired ISE Reagent Kit expired. (0774) ISE Pack Not Good Kit electronic key failure (0775) ISE Module in Maintenance Mode. Run a Purge Cycle or a Calibration Cycle (0776) ISE Module Off. Position the module properly and Reconnect it (0777) ISE Pack not connected (0778) ISE Pack no more Calibrant (0779) ISE Module Calibration successful (0780) Last ISE Module Calibration finished with warnings Page 222 of 217 5420-0104 ISE reagent kit must be used. Change ISE reagent kit. Run Reagent Kit replacement Change ISE reagent kit. Run Reagent Kit replacement ISE module in Maintenance Mode. Run Calibrant A Purge or Calibration procedure. ISE module is off. Run Reconnect procedure and then Star up. ISE Reagent Kit is not connected. Connect ISE reagent kit ISE Reagent Kit connector out of place. Check ISE reagent Kit connector. Lack of Calibrant Replace ISE reagent kit. ISE Calibration finished successfully No action is required Last ISE Calibration ended with warnings Check last ISE Calibration warning messages, correct them and recalibrate the ISE Module. HIGH TECHNOLOGY, INC. PROPRIETARY AND CONFIDENTIAL