2024 Review on synergistic damage effect of irradiation and corrosion on reactor structural alloys

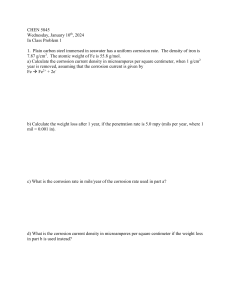

advertisement