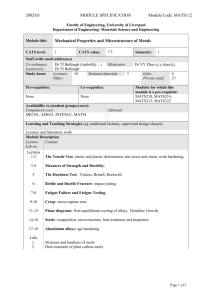

A brief investigation of Hardness and Microstructure of a Thermo-Mechanically Treated (TMT) Bar by Different Heat Treatment Process. Golam Mostafa Nipua, Rodro Sahaa, Md Bayzid Hossaina, Tanvir Shakha, Anando Haldera,* a Department of Materials Science and Engineering Khulna University of Engineering & Technology, Khulna-3206, Bangladesh *E-mail: halder1927051@stud.kuet.ac.bd; Tel.: +880 1718111891 ABSTRACT Steel is the most common material used for engineering materials, and these materials are heat treated to change their physical and mechanical qualities to fit specific engineering purposes. In this investigation, the impact of heat treatment on the microstructure and a few chosen mechanical characteristics of TMT bar was investigated. A steel sample was collected from the local market, and spectrometry analysis was done on it. In an electric furnace, the steel samples underwent heat treatment at various temperatures and holding durations, followed by cooling in various media. Standard techniques were used to measure the hardness of the treated and untreated samples, and a metallographic microscope with a camera was used to study the materials' microstructure. The results demonstrated that different heat treatments for a specific application can alter and enhance the mechanical characteristics of TMT bar. It was also discovered that the annealed samples, which primarily had ferrite structure, had the lowest tensile strength and hardness values and the highest ductility and toughness values, whereas the hardened samples, which primarily had martensite, had the highest tensile strength and hardness values and the lowest ductility and toughness values. Keywords: Heat treatment; Mechanical Properties; Microstructure; Thermo-Mechanically Treated (TMT) Bar INTRODUCTION In order to produce a specific microstructure and desired mechanical properties (hardness, toughness, yield strength, ultimate tensile strength, Young's modulus, percentage elongation, and percentage reduction), a particular metal or alloy is subjected to heat treatment, which consists of timed heating and cooling. The most significant heat treatments which is often used to change the microstructure and mechanical properties of engineering materials particularly steels are annealing, normalizing, hardening and tempering. Because of the ferrite-pearlite microstructure, annealing is the heat treatment technique most usually used to soften iron or steel materials and refines the grain size. It is employed when engineering materials need to exhibit significant elongations and tensile strength [1]. In normalizing, the steel or its alloy is heated to the austenitic temperature range and then holding in this temperature for a certain time period and the cooled with air. The major goal of this treatment is to create a pearlite-dominated matrix, which increases strength and hardness compared to the raw material. It is also utilized to get rid of unwanted free carbide that was in the sample when it was received [2]. A steel is frequently quenched and tempered in order to improve its mechanical properties, particularly its strength and wear resistance. In hardening, the steel and its alloy is heated to a elevated temperature high enough to the austenite formation range, held at this temperature until desired amount of carbon is dissolved and then cooled in oil or water at an appropriate rate. The steel must contain 100% martensite for maximum performance to attain maximum yield strength, but it is very brittle in the hardened state and, therefore, as hardened steel is used for very little engineering application. By tempering, the properties of quenched steel can be changed to decrease hardness and gradually increase ductility and impact strength. The resulting microstructure is bainite or carbide precipitates in the ferrite matrix depending on the tempering temperature . Steel is an alloy of iron and carbon containing ranges from 0.15-1.5% [3]. Steel is widely utilized for two primary reasons: (i) It is abundantly present as Fe2O3 in the crust of the planet and converts to Fe with minimal effort. (ii) It can be designed to have a wide range of microstructures and mechanical characteristics. Its utility can be explained by its accessibility, ductility, and acceptable casting, working, and machining qualities. It is also susceptible to straightforward thermal treatments to produce a variety of properties [2]. Increased operating parameters, i.e., operating at temperatures and pressures greater than 600˚C and 27 MPa, respectively, [4–9] can be used in thermal power plants to increase efficiency and reduce carbon dioxide emissions [10–12]. They are used in advanced high-strength steel, railways lines, boiler tubes, and protective armor steel, among other things [13]. Even though guidelines only recommend basing it on chemical composition, the heat treatment cycle needs to be adjusted based on both the chemical content and thickness of the material. The key goal of the current study is to examine how different heat treatment techniques modify the microstructure and mechanical properties of low alloy steel. Two of the suggested heat treatment cycles in this study include solutionizing at 1150 °C and tempering at 460 °C. A thorough analysis of the microstructure is undertaken together with an assessment of the mechanical properties to identify the appropriate mechanical attributes. EXPERIMENTAL PROCEDURE Steel reinforcing bar samples were taken from a lab. Metallographic preparation was done on the samples. After 120 minutes of holding at three different temperatures, 890°C, 904°C, and 910°C, the sample specimens were then normalized and quenched in a salt bath. This employed temperature range will demonstrate how heat treatment affects metals below and above austenizing temperatures. On the raw and heat-treated samples, a hardness test and a microstructural examination were done. The outcomes were then contrasted with the original data. This will make it easier to choose the optimal quenching media and achieve the desired mechanical qualities. Table 1 shows the chemical constituent of the bar as obtained from an optical emission spectrometer. The heat treatment conditions are listed in Table 2. Table 1: Chemical composition of the steel bar samples Elements Weight % C Si Mn P S Cu Ni Cr Al Mo B 0.367 0.389 1.770 0.034 0.032 0.478 0.097 0.120 0.005 0.01 0.001 Table 2: Heat Treatment Conditions Annealing Normalizing Quenching Condition Tempering Temperature, °C 890 904 910 460 Holding time, min Cooling medium 90 120 120 100 Furnace Air Salt Bath Air RESULT AND DISCUSSION Effect of Heat Treatment on Hardness: The hardness of the steel bar in different heat treatment techniques are also given in Table 3. The plots of hardness at different heating temperatures and media is presented in Figures 1 while the micrographs for the as-received samples are shown in Figure 4. Table 3: Mechanical Properties of heat treated and untreated steel Heat Treatment Hardness, HRB As Received Sample 88.1 Annealed 60.1 Normalized 80.67 Quenched 109.7 Tempered 98.5 120 100 Hardness, HRB 80 60 40 20 0 As Received Sample Annealed Sample Normalized Sample Hardened Sample Tempered Sample Heat Treatment Fig 1: Hardness of treated and received samples of steel The hardness value of the received sample was 88.1 HRB. Comparing the mechanical properties of annealed sample with the received sample, annealed sample showed lower hardness (60.1 HRB). The decrease hardness can be associated with the formation of soft ferrite matrix in the microstructure of the annealed sample by cooling. The hardness value of the normalized sample was to be found 80.67 HRB. The increase in hardness as compared to annealed and received sample was due to proper austenizing temperature at 904oC and higher cooling rate, which resulted in decrease in elongation and toughness, which was lower than those obtained for untreated and annealed samples due to pearlitic matrix structure obtained during normalization. The hardness value of the quenched sample revealed that highest hardness (109.7 HRB). The specimen was austenised at 910oC for 120 minutes and then water quenched. The hardness value of the tempered sample was 98.5 HRB. Effect of Heat Treatment on Microstructure: The microstructure of received specimen showed a combination of ferrite (white) and pearlite (black) in the core (Figure 2) and martensite in the edge (Figure 3). The microstructure of the annealed sample is shown in Figure 4. As it can be seen in Figure 4, the grain size of Ferrite and Pearlite is bigger than before. Because of furnace cooling recrystallization happen in the sample and previous grains are transformed into new stress-free big grain. Figure 5 shows the microstructure of the normalized sample. The normalized sample showed that the shape and size of the original austenite grains were influenced to a remarkable extent. It was observed that there was many short graphite flakes surrounded with patches of uniformly distributed pearlite grains as seen in Figure 5. Figure 6 shows the massive martensite structure of quenched sample, when medium carbon steels are rapidly quenched from its austenite temperature to room temperature, the austenite will decompose into a mixture of some medium carbon martensite and fewer pearlite as a result of this microstructure which is hard. The microstructure of tempered specimen (Figure 7) consisted of a number of appreciable carbide particles precipitated out from the matrix, which indicated that the precipitate carbide particles decomposed by a process of solution in ferrite matrix. Figure 2:Microstructure of TMT bar-Core(100X) Figure 3: Microstructure of TMT bar Edge(100X) Figure 4: Microstructure of annealed sample(100X) Figure 5 :Microstructure of normalized sample (100X) Figure 6: Microstructure of quenched sample (100X) Figure 7 : Microstructure of tempered sample(100X). CONCLUSIONS In summary, heat treatment significantly influences the properties of TMT (Thermo Mechanically Treated) bars. Annealing enhances ductility, normalizing balances strength and toughness, quenching boosts strength but reduces ductility, and tempering maintains strength while increasing toughness. Choosing the right treatment depends on desired properties. These methods ensure TMT bars meet specific performance requirements in construction, manufacturing, and infrastructure projects. REFERENCE: [1] D.A Fadare, T.G. Fadara and O.Y. Akanbi, “Effect of Heat Treatment on Mechanical Properties and Microstructure of NST 37-2 Steel,” Journal of Minerals Characterization & Engineering, vol. 10, no. 3, (2011), pp. 299-308. [2] Bhaskar Chandra Kandpal, D.K. Gupta, Ashok Kumar, Ashish Kumar Jaisal, Atul Kumar Ranjan, Ankit Srivastava, Prashant Chaudhary, “Effect of Heat Treatment on Properties and Microstructure of Steels,” Materials Today: Proceeding, vol.44, part 1, (2021), pp. 199-205. [3] John, V.B., “Introduction to engineering materials,” 2nd edition., Macmillan Publishing Company Ltd., (1980), pp. 321-324. [4] J. Cao, Y. Gong, K. Zhu, Z.G. Yang , X.M. Luo, and F.M. Luo and F.M. Gu, “Effect of Precipatates on Long – Term Creep Deformation Properties of P92 and P122 Type Advanced Ferritic Steels for USC Power plant,” Materials Science and Engineering: A, vol. 32, (2011), pp. 2763-2770. [5] P. J. Ennis and A. Czyrska – Filemonowicz, “ Recent Advances in Creep – Resistant Steels for Power Plant Applications,” Sadhana A, vol. 28, (2003), pp. 709-730. [6] Z. Zhang, G. Holloway and A. Marshall, “ Properties of T/P92 Weld Metals for ULTRA Super Critical (USC) Power Plant,” Int. J. Microstructure and Materials Properties, vol. 6, (2011), pp. 2039. [7] M Abd El-Rahman Abd El-Salam, I EI-Mahallawi and M R El-Koussy, “Influence of Heat Input and Post-Weld Heat Treatment on Boiler Steel P91 (9Cr - 1 Mo –V- Nb) Weld Joints Part 2 – Mechanical properties,” International Heat Treatment Surface Engineering., vol. 7, (2013), pp. 3237. [8] S A David, J.A Siefert and Z Feng, “Welding and Weldability of Candidate Ferrtic Alloys for Future Advanced ultrasupercritical Fossil Power Plants,” Science Technology Weld. Joint, vol. 18, (2013), pp. 631-651. [9] P.J.Ennis , A. Zielinska-Lipiec and A. Czyrska – Filemonowicz, “Influence of Heat Treatments on the Microstructural Parameters and Mechanical Properties of P92 Steel,” Materials Science and Technology, vol. 16, (2000), pp. 1226-1233. [10] J. Hald, “Microstructure and Long- Term Creep Properties of 9 – 12 % Cr steels,” International Journal of Pressure Vessels and Piping, vol. 85, (2018), pp. 30-37. [11] Wei Yan, Wei Wang, Yi-Yin Shan & Ke Yang, “Microstructural Stability of 9-12% Cr Ferritie/Martensite Heat – Resistant Steels,” Frontiers of Materials Science, vol. 7, (2013), pp. 127. [12] M. Yoshizawa, M. lgarashi , K. Moriguchi, A. Iseda, H.G. Armaki and K. Maruyama, Effect of Precipitates on Long – Term Creep Deformation Properties of P92 and P122 Type advanced Ferritic Steels for USC Power plants,” Materials Science and Engineering: A, vol. 510 - 511, (2009), pp. 162-168. [13] A.J. Alawode, M.B. Adeyemi, “Effect of Degrees of Deformation and Stress - Relief Temperatures on the Mechanical Properties and Residual Stresses of Cold Drawn Mild Steel Rods,” Journal of Materials Processing Technology, vol.160, (2005), pp. 112–118.