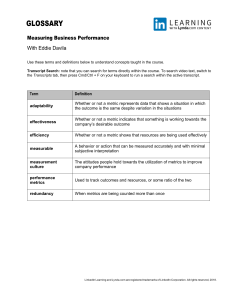

SMRP Best Practice Metrics Workshop Measuring Asset Reliability SMRP Headquarters 1100 Johnson Ferry Road, Suite 300 Atlanta, GA 30342 USA www.smrp.org Copyright © 2014 Society for Maintenance & Reliability Professionals Best Practices Committee- Metrics Workshop © 2014 SMRP Page 2 of 14 Best Practices Committee- Metrics Workshop Measuring Asset Reliability for a Mock Company Introduction You will be calculating a set of SMRP Best Practice metrics for a mock company: “Speedy Mac Reliable Products” The name of the company shortens to SMRP. The company is based in St. Louis. SMRP has several plants located in Missouri and Illinois. The company is in the business of manufacturing reliable widgets for general application. The company’s CEO, Seymour Profit, envisions starting a reliability initiative, since he has heard that such efforts can improve the bottom line. He has charged Noah Lott, the Director of Corporate Reliability, with program implementation. Noah has extensive experience with the Asset Reliability Process (Figure 1), and decides to calculate a set of SMRP Best Practice metrics to identify the current state and then determine some focussed initiatives to propose for implemenation. These metrics are mapped to the process in Figure 2. plan improve Identify Business Goals Asset Work Identification maintenance control Plan Schedule resource control Requisition Procure Asset Identification Continuous Improvement Loop Sustained Maintenance Loop Sustained Resource Loop Asset Prioritization Asset Performance Targets Asset Performance Analysis Follow-up Execute Fulfill Store assess Figure 1. Asset Reliability Process © 2014 SMRP Page 3 of 14 Best Practices Committee- Metrics Workshop Figure 2 SMRP Best Practices Metrics Mapped to the Asset Reliability Process Mr. Lott forms an Asset Reliability Assessment Team consisting of the Maintenance Manager, Ben Ignored, the Operations Manager, Maury Ficiency, and the Maintenance Planner, Claire Voyant from the Louisville facility. Together, they select the appropriate metrics and map them to the Asset Reliability Process. They then set about calculating the current values. Noah has collected data from two sister plants as well, which will be used to determine which plant is the best investment for the program. The data for the three facilities is provided in the following section. Your teams assignment is to calculate the specific metrics chosen from the mapped process and make recommendation on how to improve the facilities. You also recognize that these are snapshots, and you may have to look at the combination of metrics and make educated guesses about the state of the plant and utlize that information to assist your initiative selection. You may also determine that additional metrics must be calculated to identify the real problem. © 2014 SMRP Page 4 of 14 Best Practices Committee- Metrics Workshop Plant Data Table 1. Data from the Finance Department: No. Data 1-1 1-2 1-3 1-4 1-5 1-6 1-7 1-8 1-9 1-10 RAV Maintenance Labor Cost Materials Cost Overtime Labor Cost Training Cost Contractor Costs Total Maintenance Cost Stores Inventory Value Value of Stock Purchased Capital Improvement Costs Units $ Millions $/year $/year $/year $/year $/year $/year $ $/year $/year Plant A Plant B Plant C $293.5 $2,015,634 $2,157,428 $308,428 $125,728 $380,723 $4,987,940 $880,225 $2,640,674 $135,000 $293.5 $7,528,986 $8,058,626 $1,152,069 $325,806 $1,565,935 $18,631,422 $9,389,063 $10,327,970 $504,265 $293.5 $11,204,554 $11,992,759 $1,714,497 $262,087 $2,116,369 $27,290,266 $19,511,647 $9,755,823 $275,000 Units No. No. No. Hrs/year Hrs/year Hrs/year Plant A 36 2 1 2,880 3,744 7,919 Plant B 134 8 4 7,463 27,970 32,571 Plant C 200 25 4 6,004 83,249 44,021 82,799 311,291 460,021 Table 2. Data From HR: No. 2-1 2-2 2-3 2-4 2-5 2-6 2-7 Data Craft Employees Supervisors Planners Training Hours Overtime Hours Contractor Hours Total Maintenance Labor Hours Hrs/year Note: Shaded entries are subtotals © 2014 SMRP Page 5 of 14 Best Practices Committee- Metrics Workshop Table 3. Operations Data No. 3-1 3-2 3-3 3-4 3-5 3-6 3-7 3-8 3-9 Data Scheduled Downtime Unscheduled Downtime Total Downtime Idle Time Operating Time Availability Average Operating speed Maximum Achievable speed Performance Efficiency Units Hrs/month Hrs/month Hrs/month Hrs/month Hrs/month % fpm fpm % 3-10 3-11 Defect rate Quality Rate Plant A Plant B Plant C 14 7 21 0 699 97.1% 200 203 98.8% 42 36 78 69 574 79.7% 195 203 96.3% 83 65 148 206 366 50.9% 190 203 93.8% Dfct/100u % 2.5 97.5% 9.0 91.0% 15.0 85.0% Units Hrs/month Hrs/month Hrs/month Hrs/month Hrs/month Hrs/month Plant A 5,493 969 6,462 1,939 323 5,170 Plant B 15,173 10,115 25,288 2,529 5,058 7,333 Plant C 4,105 36,949 41,054 411 26,685 2,463 Hrs/month Hrs/month Hrs/month Hrs/month Hrs/month Hrs/month $/month $/month 6,139 2,480 2,456 1,745 1,998 975 $48,638 $18,447 19,977 5,708 3,995 13,706 3,450 2,568 $83,985 $48,586 17,653 4,413 1,765 12,193 1,202 346 $8,422 $6,546 Table 4. Work Management Data No. 4-1 4-2 4-3 4-4 4-5 4-6 4-7 4-8 4-9 4-10 4-11 4-12 4-13 4-14 Data Planned Work Unplanned Work Total Work Corrective Work Identified Reactive Work Proactive Work (includes 4-11 and 4-12) Scheduled work completed PM/PdM Work Planned PM/PdM Work Completed Project Work Predictive Work Operator Predictive Work Predictive Work Costs Operator Predictive Work Costs © 2014 SMRP Page 6 of 14 Best Practices Committee- Metrics Workshop Table 5. Planner Data No. 5-1 5-2 5-3 5-4 5-5 5-6 5-7 5-8 Data Ready to Schedule Backlog On Hold Backlog Planned Backlog Total Backlog Work Orders in Backlog Work Orders > 90 days old Work Orders Processed Repeat work orders (Rework) Units man-days man-days man-days man-days No. No. No./month No./month Plant A 617.7 205.8 822.9 1028.6 1006 50 1796 27 Plant B 5378.8 205.8 1536.8 6915.6 6770 677 2694 135 Plant C 11435.3 205.8 1143.5 13722.4 19125 3825 6286 658 Units No/month No/month Plant A 300 6 Plant B 450 22 Plant C 1050 105 Units $/year Plant A $125,000 Plant B $108,000 Plant C $52,000 Units Hrs/shift Hrs/shift Hrs/shift Hrs/shift Hrs/shift Hrs/shift Hrs/shift Hrs/shift Plant A 0.50 0.25 0.38 0.50 0.50 0.38 0.25 5.24 Plant B Plant C 1.75 0.25 0.66 0.88 0.88 0.66 0.25 2.67 Table 6. Storeroom data No. 6-1 6-2 Data Transactions Transactions not filled Table 7. Cost Improvement Analysis Data No. 7-1 Data Training Benefit Table 8. Work Study Data No. 8-1 8-2 8-3 8.4 8-5 8-6 8-7 8-8 Data Travel time Personal Time Wait Time Obtaining Materials Obtaining Tools Planning Administrative Working © 2014 SMRP 1.00 0.25 0.56 0.75 0.75 0.56 0.56 3.57 Page 7 of 14 Best Practices Committee- Metrics Workshop Table 9. Reliability Study on Pump Group 9 No. 9-1 9-2 9-3 9-4 9-5 9-6 9-7 Data Number of Pumps Failures (Repair Event) Total Repair Time Work Orders (Maint. Action) Downtime events Estimated repair cost Actual repair cost 9-8 Est.repair hours (Pump 9-3) 9-9 9-10 Actual repair hours (Pump 9-3) Total Asset Downtime Units No. No/year Hrs/year No/year No/year $/repair $/repair Hrs/repai r Hrs/repai r hrs/year Plant A Plant B Units Hrs Hrs Days Weeks Hrs Hrs No. Plant A 720 8760 365 52 40 8 1 Plant C 52 12 48 24 24 2500 2000 52 24 144 72 60 2500 2600 52 36 288 144 120 2500 3500 6 6 6 4 252 6 936 8 1776 Table 10. Constants No. 10-1 10-2 10-3 10-4 10-5 10-6 10-7 © 2014 SMRP Data Hours in a Month Hours in a Year Days per year Weeks per Year Hours Available per Work week Hours per shift Shifts per Day Plant B 720 8760 365 52 40 8 1 Plant C 720 8760 365 52 40 8 1 Page 8 of 14 Best Practices Committee- Metrics Workshop Acknowledgements The workshop was developed by the 2006 SMRP Best Practices Conference Track Subcommittee, whose members were Dick Olver, Jay Padesky, Bob DiStefano, Scotty McLean, Neil Waugh, Ricky Smith, Jeff Stegemiller, Bruce Hawkins and Jerry Kahn. The concept for this workshop is based on the “Workshops on Maintenance Indicators” conducted in Europe by Maintenance Benchmarking Committee of the European Federation of National Maintenance Societies (EFNMS). Tom Svantesson of the Danish Maintenance Society, who is the EFNMS committee’s liaison with the SMRP Best Practices Committee, is gratefully acknowledged for his guidance during the development of this SMRP workshop © 2014 SMRP Page 9 of 14 Best Practices Committee- Metrics Workshop Calculation of the metrics for Breakout Session 1 Please calculate the maintenance Metrics for each SMRP Plant facility █ Strategic Planning Metrics Metrics to Calculate: 1.1, 1.5, 2.1.1, and 5.5.71 ------------------------------------------------------------------------------------------------------------------------------Metric 1.1 RAV per Craft/Wage Headcount Replacement Asset Value Metric 1.1 Formula: Craft/Wage Headcount Metric 1.1 Calculation: Plant A Plant B Plant C Metric 1.1 Result: ______ ______ _______ per maintenance employee ------------------------------------------------------------------------------------------------------------------------------Metric 1.5 Maintenance Cost per RAV(Harmonized with EFNMS E1) Annual Maintenance Cost * 100 Metric 1.5 Formula: Replacement Asset Value Metric 1.5 Calculation: Metric 1.5 Result: Plant A ______ Plant B ______ Plant C ______ % ------------------------------------------------------------------------------------------------------------------------------Metric 2.1.1 OEE Metric 2.1.1 Formula: Availability * Performance Efficiency * Quality Rate Metric 2.1.1 Calculation: Metric 2.1.1 Result: © 2014 SMRP Plant A ______ Plant B ______ Plant C ______ % Page 10 of 14 Best Practices Committee- Metrics Workshop Metric 5.5.71 Contractor Cost (Harmonized with EFNMS E10) [Annual Contactor Cost] * 100 Metric 5.5.71 Formula: Annual Maintenance Cost Metric 5.5.71 Calculation: Metric 5.5.71 Result: Plant A _____ Plant B ______ Plant C ______ % Calculation of the metrics for Breakout Session 2 Please calculate the maintenance indicators for each SMRP Plant facility █ Work Identification Metrics Metrics to Calculate: 5.3.1, 5.4.1, and 5.1.5 Metric 5.3.1 Planned Work Planned Work Performed * 100 Metric 5.3.1 Formula: Total Work Performed Metric 5.3.12 Calculation: Metric 5.3.1 Result Plant A ______ Plant B ______ Plant C ______ % ------------------------------------------------------------------------------------------------------------------------------Metric 5.4.1 Reactive Work (Harmonized with EFNMS O17) Reactive Work Performed * 100 Metric 5.4.1 Formula: Total Work Performed Metric 5.4.1 Calculation: Plant A © 2014 SMRP Plant B Plant C Page 11 of 14 Best Practices Committee- Metrics Workshop Metric 5.4.1 Result: ______ ______ ______ % ------------------------------------------------------------------------------------------------------------------------------Metric 5.1.5 Condition Based Maintenance Cost (Harmonized with EFNMS E17) [Condition Based Maintenance Cost] * 100 Metric 5.1.5 Formula: Annual Maintenance Cost Metric 5.1.5 Calculation: Metric 5.1.5 Result: Plant A ______ Plant B ______ Plant C ______ % █ Work Planning Metrics Metrics to Calculate: 5.4.9 ------------------------------------------------------------------------------------------------------------------------------Metric 5.4.9 Ready Backlog (based on a 40 hour workweek) Ready to Schedule Backlog (weeks) Metric 5.4.9 Formula: Craft Available Metric 5.4.9 Calculation: Metric 5.4.9 Result: Plant A ______ Plant B ______ Plant C _____ weeks █ Work Scheduling Metrics Metrics to Calculate: 5.4.3 Metric 5.4.3 Schedule Compliance - Hours Scheduled Work Performed * 100 Metric 5.4.4 Formula: Total Time Available © 2014 SMRP Page 12 of 14 Best Practices Committee- Metrics Workshop Metric 5.4.4 Calculation: Metric 5.4.4 Result: Plant A ______ Plant B ______ Plant C ______ % Calculation of the metrics for Breakout Session 3 Please calculate the maintenance indicators for each SMRP Plant facility █ Materials Control Metrics Metrics to Calculate: 1.4 Metric 1.4 Stocked MRO Inventory per RAV (Harmonized with EFNMS E7) Stocked Inventory Value * 100 Metric 1.4 Formula: Replacement Asset Value Metric 1.4 Calculation: Metric 1.4 Result: Plant A ______ Plant B ______ Plant C ______ % █ Work Execution Metrics Metrics to Calculate: 5.6.1 Metric 5.6.1 Wrench Time Productive Work Time * 100 Metric 5.6.1 Formula: Total Work Time Scheduled Metric 5.6.1 Calculation: © 2014 SMRP Page 13 of 14 Best Practices Committee- Metrics Workshop Plant A Plant B Metric 5.6.1 Result: Plant C ______ % █ Analysis Metrics Metrics to calculate: 3.5.1, and 3.5.2 Metric 3.5.1 Mean Time Between Failures (MTBF) for Pump Group No. 9 (Harmonized with EFNMS T17) Operating Time Metric 3.5.1 Formula: Number of Failures Metric 3.5.1 Calculation: Metric 3.5.1 Result: Plant A ______ Plant B _______ Plant C ______ months ------------------------------------------------------------------------------------------------------------------------------Metric 3.5.2 Mean Time To Repair (MTTR) for Pump Group No. 9 (Harmonized with EFNMS T21) Repair Time Metric 3.5.2 Formula: Number of Repair Events Metric 3.5.2 Calculation: Metric 3.5.2 Result: © 2014 SMRP Plant A ______ Plant B ______ Plant C ______ hours Page 14 of 14