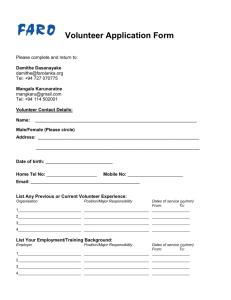

Nigerian Journal of Tropical Engineering Vol. 17 No. 1 |ISSN: 1595-5397| Dec. 2023 DOI: 10.59081/njte.17.1.008 EFFECTS OF MOISTURE CONTENT ON PHYSICAL PROPERTIES OF PADDY AND DEHUSKED RICE 1Moses Mazza, 2Lawan Garba Abubakar, 3M. Hamisu Muhammad, 2OlaosebikanLayi Akangbe, 2Bala Gambo Jahun, 2Mohammed Aminu, 4Abubakar Abdulkarim Jilima 1 Department of Agricultural Engineering, National Cereals Research Institute, Badegi, P.M.B. 8 Bida, Niger State, Nigeria, 2. Department of Agricultural and Bioresource Engineering, Abubakar Tafawa Balewa University, P.M.B. 0248, Bauchi, Nigeria, 3. Department of Mechanical and Production Engineering, Abubakar Tafawa Balewa University, P.M.B. 0248, Bauchi, Nigeria, 4. Department of Agricultural and Environmental Engineering, Modibbo Adama University, Yola, P.M.B 2076, Yola, Adamawa State, Nigeria Corresponding author’s email: mosesmazza@gmail.com Telephone: +2348032913213 Abstract The physical properties of rice are among the most important parameters for design of agricultural machine and other equipment for handling, planting, harvesting, processing, packaging and storing. This work is aimed at the determination of some of the physical properties of two varieties of rice at varying moisture content that are important in designing rice handling machine. The physical properties of two most popular produced rice varieties in Nigeria (FARO 44 and FARO 57) both paddy and dehusked at three different moisture content (5, 10 and 15%) were determined. Laboratory studies were carried out to determined physical properties of the two varieties of rice ((FARO 44 and FARO 57) important properties for the laboratory work includes: bulk density, unit density, roundness, axial dimensions, sphericity, projected areas, unit volume, unit weight, apparent density, were determined based on different moisture content and random sampling techniques. The results showed that minimum lengths of dehusked rice ranged from 4.57 - 5.29 mm while maximum lengths were between 8.21 - 8.25 mm. For paddy these lengths were minimally 7.65 - 8.78 mm and maximum lengths were 11.39 mm. The least range of minor diameters of dehusked rice was 4.57 - 5.29 mm and maximally these were 8.21 - 8.25 mm. Intermediate diameters were minimally 1.43 mm and maximally in the range of 2.71 - 2.78 mm for dehusked rice; for paddy these were 1.65 - 1.76 mm and 2.46 - 2.78 mm, respectively. Geometric mean diameters ranged between 3.31 - 4.05 mm. For paddy, projected area obtained within the range of 11.71 - 29.75 mm2. For dehusked rice, projected area obtained in the range of 8.79 - 21.19 mm2. Estimates of roundness were not higher than 33.6% for paddy or 54% for some grains of dehusked rice. The grains appeared more spherical than they were round since paddy were 35.3 - 48.3% spherical while dehusked grains were 39.8 - 59.4% spherical. Bulk densities ranged between 531.0 - 553.8 kg/m3 and 839.6 - 852.7 kg/m3 for dehusked forms of Faro 44 and Faro 57, respectively. True density was in the range of 1071.6 - 1566.2 kg/m3.This study concludes that moisture content and variety affect the engineering property and is useful in the design, development of machine for processing and handling of rice products. Keywords: physical properties; rice varieties, form and moisture content of paddy and dehusked Mazza M. et al. 72 Nigerian Journal of Tropical Engineering Vol. 17 No. 1 |ISSN: 1595-5397| Dec. 2023 DOI: 10.59081/njte.17.1.008 subjecting seeds to oven drying (either air or vacuum) at temperatures between 80 to 130 0 C for 8hrs to 24hrs by American Society of Agricultural and Biological Engineers (ASABE) S352.2 standard [9]. Abdul-Rasaq [10] reported that increase in moisture content was found to increase the linear dimensions, mass of 100 seeds, surface area, apparent volume, true volume and arithmetic mean diameter. Zareiforoush [11] Stated that in order to design harvesting, conveying and processing equipments, it is necessary to determine physical properties of grains. Zareiforoush [12] investigated the impact of moisture content on two Iranian paddy rice varieties (Alikazemi and Hashemi) at five moisture levels ranging from 8% to 21% (dry basis) and reported that increased moisture content led to: Increased grain dimensions (length, width, thickness), Higher equivalent diameter, Larger surface area and volume, Higher sphericity (roundness), Increased angle of repose (flowability), Decreased bulk density and true density. Arije [13] reported that the principal axial dimensions of rye seeds are useful in selecting sieve separators and in calculating power during the rye milling process. Mujumdar [14] reported that Knowing the grain’s bulk density, true density and porosity can be useful in sizing grain hoppers and storage facilities: they can affect the rate of heat and mass transfer of moisture during the aeration and drying processes. Cereal-grain kernel densities have been of interest in breakage susceptibility and hardness studies [15]. Researchers Nimkar [16] evaluated the physical properties of green gram (Phaseulus aureus L.) as a function of moisture content in the range of 8.39 to 33.40% d.b and reported that the average length, width, thickness and the mass of thousand seeds were 4.21 mm, 3.17 mm, 3.08 mm, and 28.19 g, respectively at 1. Introduction Rice (Oryza sativa) belongs to the grass family of Gramineae, it is among the major sources of carbohydrate, more than half of the human race regard and consume rice as their staple food [1 and 2]. It is highly valued and competitive commodity in the world trade over a decade’s [3 and 4]. Oryza-sativa is the dominant specie followed by Orizaglaberrima and is regarded third most popular crop after wheat and maize in world crop production [3]. More than four (4) billions of world population depends on rice as their major source of calories [5]. Information on the physical and mechanical properties of the agricultural products is an important tool for designing equipment for the purpose of planting, harvesting, dehulling, drying, handling as well as storing. Therefore, seed dimensions (width, thickness and length), 1000 seed mass (M1000), surface area, porosity, sphericity, static coefficient of friction against different materials, repose angle, hardness, true and bulk densities are among the properties that are considered “physical” by researchers as per seed [6]. These variables are central in classification of seeds and in the design of machines for processing or analyzing the behavior of the product in handling or grading [7 and 8]. They are central because they give technical information to the designer on what are the basic “inputs” for their design. All physical properties of seeds are dependent on the moisture content. They respond either in increasing or decreasing trend as the moisture content varies. The initial moisture content is determined by Mazza M. et al. 73 Nigerian Journal of Tropical Engineering Vol. 17 No. 1 |ISSN: 1595-5397| Dec. 2023 DOI: 10.59081/njte.17.1.008 moisture content of 8.39% (d.b.). Also, the geometric mean diameter increased from 3.45 to 3.77 mm, whereas sphericity decreased from 0.840 to 0.815. They observed that with the increase of moisture content the bulk and true densities decreased from 807 to 708 kg/m³ and from 1,363 to 1,292 kg /m³, respectively. The corresponding bulk porosity increased from 40.77 to 45.16%. The static coefficient of friction is used to determine the angle at which chutes must be positioned to achieve consistent flow of materials through the chute. The aim of this research is to determine the physical properties of FARO 44 and FARO 57 rice varieties both paddy and de-husked as influence by 5,10 and 15% moisture contents. 𝑊 −𝑊𝑏 𝑀𝐶𝑤𝑏 = 100 × [ 𝑎𝑊 2. MATERIALS AND METHODS The materials used in this research includes: Hot air oven, Weighing balance, Photographic enlarger, Planimeter, Drawing set, Toluene, density bottle, FARO 44 and FARO 57 both paddy and dehusked. Pycnometer, cold bath, ice block, dry bulb thermometer, distilled water and sensitive weighing balance. 𝑎 𝑊 −𝑊𝑏 𝑀𝐶𝑑𝑏 = 100 × [ 𝑎𝑊 𝑏 ] … (1) ] … (2) Where: 𝑀𝐶𝑤𝑏 is Moisture content, wet basis, % 𝑀𝐶𝑑𝑏 is Moisture content, dry basis, % 𝑊𝑎 is Weight of water in the sample, g 𝑊𝑏 is Weight of dry matter in the sample, g 2.1 Preparation of sample for the determination of the properties The two samples of rice (FARO 44 and FARO 57) were used for the laboratory analysis to determine the physical properties. The samples both paddy and dehusked of FARO 44 and FARO 57 were selected, cleaned and sorted by removing broken, split, spoiled and deformed seeds before the commencement of laboratory work. 2.3 Determination of the size of paddy and dehusked rice Major, minor and intermediate diameters of paddy and dehusked rice were measured as 𝐴, 𝐵, 𝐶 using photographic enlarger and graduated transparent ruler at the three different levels of moisture contents of 5, 10 and 15%. The tri-axial dimensions were used in Equation (3) to calculate the mean geometric diameter as reported by [18] 2.2 Moisture content determination; The moisture contents of the samples were determined using the procedure specified by ASABE S352.2 standard [9]. The sample were oven dried at 105oC for 72 hours, the weight loss of the samples were recorded and the moisture contents in percentage were determined on wet basis and dry basis using Equations (1 and 2) as reported by [17]. 1 𝐺𝑚 = ⌈𝐴 × 𝐵 × 𝐶⌉ ⁄3 ... (3) Where; 𝐺𝑚 𝑖𝑠 𝑔𝑒𝑜𝑚𝑒𝑡𝑟𝑖𝑐𝑎𝑙 𝑑𝑖𝑎𝑚𝑒𝑡𝑒𝑟, mm 𝐴 𝑖𝑠 𝑡ℎ𝑒 𝑚𝑎𝑗𝑜𝑟 𝑑𝑖𝑎𝑚𝑒𝑡𝑒𝑟, 𝑚𝑚 𝐵 𝑖𝑠 𝑚𝑖𝑛𝑜𝑟 𝑑𝑖𝑎𝑚𝑒𝑡𝑒𝑟, 𝑚𝑚 𝐶 𝑖𝑠 𝑡ℎ𝑒 𝑖𝑛𝑡𝑒𝑟𝑚𝑒𝑑𝑖𝑎𝑡𝑒 𝑑𝑖𝑎𝑚𝑒𝑡𝑒𝑟, 𝑚𝑚 Mazza M. et al. 74 Nigerian Journal of Tropical Engineering Vol. 17 No. 1 |ISSN: 1595-5397| Dec. 2023 DOI: 10.59081/njte.17.1.008 𝑉𝐶 𝑖𝑠 𝑡ℎ𝑒 𝑣𝑜𝑙𝑢𝑚𝑒 𝑜𝑓 𝑡ℎ𝑒 𝑐𝑜𝑛𝑡𝑎𝑖𝑛𝑒𝑟, 𝑐𝑚3 2.4 Determination of the roundness and sphericity of paddy and dehusked rice. A photographic enlarger was used to project the area of the rice on the vertical wall and trace the seeds shadow at their natural rest position and when the seeds were turn by 90o and twist vertically to 180o. Millimetre scales were also projected with the seeds and the area (𝐴𝑐 ) of circumscribed circle were then calculated using Equation (4). 𝐴𝑐 = 𝜋𝑑𝑐 2 2.7 Determination of true density Ratio of mass of sample of seeds to its true volume is called true density. It was determined by using toluene displacement method reported by [18]. The true density was then be calculated using Equation (8) available in [18]. 𝑇𝑟𝑢𝑒 𝑑𝑒𝑛𝑠𝑖𝑡𝑦 (𝜌𝑡 ) = … (4) 4 … (5) 𝑐 1 𝑆𝑝ℎ𝑒𝑟𝑖𝑐𝑖𝑡𝑦 = 100 × [ (𝐴×𝐵×𝐶) ⁄3 𝐴 ] … (6) 2.5 Determination of Seed weights Single seed weights and one thousand seed weights were determined for FARO 44 and FARO 57 (Paddy and dehusked) seeds following the method described by [18]. 2.6 Determination of bulk density The bulk density 𝜌𝑏 is the ratio of the sample mass of seeds to its total volume , The bulk density of the seeds was then calculated using Equation (7) as reported by [19. 𝑀 𝐵𝑢𝑙𝑘 𝑑𝑒𝑛𝑠𝑖𝑡𝑦 (𝜌𝑏 ) = 𝑉 𝑆 𝐶 ...8 2.8 Experimental Design A random sampling technique was carried out, Two varieties (FARO 44 and FARO 57), two form (paddy and de-husked) and moisture content at three levels (5, 10 and 15%) where used giving a total of 2x2x3=12 treatments at single replication. It was replicated 3 times making a total of 36 treatments for bulk density, true density. And 50 sample were randomly selected making a total of 50x2x2x3=600 experiment for size and shape. Total 600+36+36=672 experiment The Projected (𝐴𝑝 ) and circumscribed areas were used in Equations (5) and (6) to compute the roundness and sphericity of the grains respectively as reported by [18]. 𝐴𝑝 𝑉𝑤 Where: 𝑀𝑆 𝑖𝑠 𝑚𝑎𝑠𝑠 𝑜𝑓 𝑠𝑎𝑚𝑝𝑙𝑒 𝑠𝑢𝑠𝑝𝑒𝑛𝑑𝑒𝑑 𝑖𝑛 𝑎𝑖𝑟, 𝑔 𝑉𝑤 𝑖𝑠 𝑡ℎ𝑒 𝑣𝑜𝑙𝑢𝑚𝑒 𝑜𝑓 𝑤𝑎𝑡𝑒𝑟 𝑑𝑖𝑠𝑝𝑙𝑎𝑐𝑒𝑑, 𝑐𝑚3 Where: 𝐴𝑐 is area of circumscribed circle, mm2 𝑑𝑐 is diameter of circumscribed circle, mm 𝑅𝑜𝑢𝑛𝑑𝑛𝑒𝑠𝑠 = 100 × ( 𝐴 ) 𝑀𝑆 ... (7) Where: 𝑀𝑆 𝑖𝑠 𝑚𝑎𝑠𝑠 𝑜𝑓 𝑠𝑎𝑚𝑝𝑙𝑒 𝑓𝑖𝑙𝑙𝑒𝑑 𝑡ℎ𝑒 𝑐𝑜𝑛𝑡𝑎𝑖𝑛𝑒𝑟, 𝑔 Mazza M. et al. 75 3. Results and discussion Results of the analysis of variance (ANOVA) carried out on the data generated in the laboratory on physical properties of paddy and dehusked forms of Faro 44 and Faro 57 rice varieties at 5, 10 and 15% product moisture contents in wet basis are provided in Table 1. The main effects on rice form and moisture content each had highly significant effect on major diameter of rice grains and so did the interaction of rice form with moisture content and the interaction of rice variety, Nigerian Journal of Tropical Engineering Vol. 17 No. 1 |ISSN: 1595-5397| Dec. 2023 DOI: 10.59081/njte.17.1.008 rice form and moisture content with each other. Variety and its separate interactions with each of product form and moisture had no significant effect on observed variations in major diameters of rice grains. As for minor diameter, only the interaction of rice variety with rice form had no significant effect. All the main factors (that is, variety, form and moisture) and the other interactions had significant effects on variations observed in minor diameters of rice grains. All the factors considered, as well as their interactions, had highly significant effects on intermediate diameter, except for the effects of the interaction of rice variety with rice form and that of the interactions of the three main influence factors together, both of which had no significant effects on this property of rice grains. This last trend was observed to be true for the geometric mean diameter on which the interaction of rice variety and rice form and of rice variety, rice form and moisture content had no significant effect (Table 1). Again, all the factors considered in this study and their interactions had effect of the projected areas of rice grains. Only the level of moisture and the interaction of rice variety with rice form did not have significant effect on the roundness of rice grains. All main factors and the remaining interactions had highly significant effects on roundness of rice grains. Only rice variety, rice form, the interaction between rice form and moisture content and the interaction of rice variety with both of rice form and moisture content, together, had highly significant effect on the sphericity of rice grains. Rice form and moisture content did not have significant effect on bulk density, as also the interaction of the three factors (Table 1) Table 1: ANOVA on the effects of rice variety, rice form and moisture content on physical properties Source of variation Property Major diameter, a (mm) Minor diameter, b (mm) Intermediate diameter, c (mm) Geometric mean diameter, d (mm) Projected Area, Ap (mm2) Roundness, R (%) Sphericity, S (%) Bulk density, b (kg/m3) Variety 0.071 <0.001 <0.001 <0.001 Form <0.001 <0.001 <0.001 <0.001 Variety X Moisture Form <0.001 0.089 <0.001 0.321 <0.001 0.088 <0.001 0.291 <0.001 <0.001 <0.001 <0.001 <0.001 <0.001 <0.001 0.166 <0.001 0.175 0.101 0.242 Probability (p) values less than 0.05 indicate significance, at the 5% level and p values less than 0.01 indicate significance at the 1% <0.001 0.038 0.076 <0.001 Variety X Moisture 0.115 0.001 <0.001 <0.001 Form X Moisture <0.001 <0.001 <0.001 0.001 Variety X Form X Moisture <0.001 0.025 0.34 0.978 <0.001 <0.001 0.147 <0.001 0.019 0.001 <0.001 0.006 0.04 0.035 <0.001 0.098 level; where p values are greater than 0.05, observed effects are not significant statistically. Mazza M. et al. 76 Nigerian Journal of Tropical Engineering Vol. 17 No. 1 |ISSN: 1595-5397| Dec. 2023 DOI: 10.59081/njte.17.1.008 Table 2: Main effects of variety, form and moisture content on some properties of rice Property Major diameter, a (mm) Minor diameter, b (mm) Intermediate diameter, c (mm) Geometric mean diameter, d (mm) Projected Area, 𝐴𝑝 (mm2) Roundness, R (%) Sphericity, S (%) Bulk density, 𝜌𝑏 (kg/m3) True density, 𝜌𝑡 (kg/m3) Faro 57 8.379a 3.0183a Form Dehusked 6.793b 2.696b Paddy 9.884a 3.0233a Moisture content (%, dry basis) 5 10 8.054b 8.459a 2.7686c 2.8688b 2.0791b 2.1432a 1.9902b 2.2321a 2.0479c 2.1052b 2.1804a 3.5837b 3.7715a 3.3067b 4.0485a 3.557b 3.6972a 3.7786a 16.04b 27.73b 44.15b 552.6b 1191.89 18.578a 30.29a 45.77a 830.82a 1268.50 13.315b 34.75a 48.89a 693.13a 1357.27 21.303a 23.27b 41.03b 690.28a 1085.13 16.053b 29.24a 45.19a 691.3a 1175.58 17.869a 29.36a 44.62a 694a 1251.76 18.004a 28.43a 45.07a 689.82a 1263.24 Variety Faro 44 8.298a 2.7009b 15 8.502a 2.9414a Means comparison is restricted within factor subsets and is property-wise. Values with the same alphabets are not significantly different, statistically Major diameter of Faro 57 paddy ranged from 8.78 - 11.39 mm. Major diameter of 3.1 Effects of Variety, Form and Moisture dehusked Faro 57 rice ranged from 5.29 Content of Rice on Major Diameter 8.25 mm. Also, major diameter tended to The main effects of variety, form and increase as product moisture content moisture content on physical properties of the increased (Table 2). Empirical relating the varieties of rice used are presented in Table influence of moisture content on changes in 2. Mean major diameter of Faro 44 was 8.29 major diameter of rice grains tended to be mm while that of Faro 57 was 8.38 mm. either linear or parabolic in nature, depending Dehusked rice was 6.79 mm long while a on the form and variety (Figure 1). These grain of rice paddy was 9.88 mm, on the relationships are presented in Table 3. Based average. Apparently, paddy grains were on the coefficients of determination (R2) longer than grains of dehusked rice. Major values obtained, it may be seen (Table 3) that diameter of Faro 44 paddy ranged from 7.65 up to 85.36 - 100% of the changes in this - 11.39 mm while those of dehusked forms of property as a function of moisture content are this variety ranged from 4.57 - 8.21 mm. explained by these relationships Mazza M. et al. 77 Nigerian Journal of Tropical Engineering Vol. 17 No. 1 |ISSN: 1595-5397| Dec. 2023 DOI: 10.59081/njte.17.1.008 12 Major diameter (mm) 10 8 6 4 Faro 44 Paddy Faro 44 Dehusked 2 Faro 57 Paddy Faro 57 Dehusked 0 4 6 8 10 12 Moisture content (%) 14 16 Figure 1: Effect of moisture content on major diameter Table 3: Dependence of major diameter (mm) on moisture content Variety M2 M C R2 Faro 44 Paddy -0.0027 0.0473 9.7235 1.0000 0.0738 5.9765 0.8536 0.5160 7.5232 1.0000 0.0763 6.1096 0.9110 Faro 44 Dehusked Faro 57 Paddy -0.0240 Faro 57 Dehusked M = moisture content (%, dry basis 3.2 Effects of Variety, Form and Moisture Content of Rice on Minor Diameter As for minor diameters of rice grains, they ranged from 3.1-3.5 mm for paddy forms of Faro 57 and 2.5 – 2.6 mm of dehusked forms of the same variety. Paddy forms of Faro 44 variety of rice had minor diameters ranging between 2.7 – 2.8 mm and dehusked forms had minor diameters ranging between 2.5 – 2.6 mm. Faro 57 had significantly higher minor diameter than Faro 44 and minor diameters of paddy forms of the rice grains were significantly higher than those of the dehusked forms (Table 2). Minor diameter tended to increase as moisture content increased. When empirical relationships were fitted to these trends, it was observed that these trends differed by rice variety and form (Figure 2 and Table 4) Mazza M. et al. 78 Nigerian Journal of Tropical Engineering Vol. 17 No. 1 |ISSN: 1595-5397| Dec. 2023 DOI: 10.59081/njte.17.1.008 Table 4: Dependence of minor diameter (mm) on moisture content Variety Faro 44 Paddy M2 M 0.0250 C 2.6044 R2 0.8443 Faro 44 Dehusked Faro 57 Paddy -0.0020 0.0300 0.0360 2.4030 2.8321 1.0000 0.8413 0.0102 2.7429 M = moisture content (%, dry basis) 0.7732 Faro 57 Dehusked 4 3.5 Minor diameter (mm) 3 2.5 2 Faro 44 Paddy 1.5 Faro 44 Dehusked Faro 57 Paddy 1 0.5 0 4 6 8 10 12 Moisture content (%) 14 16 Figure 2: Effect of moisture content on minor diameter grains of rice while Faro 57 had significantly larger intermediate diameters than Faro 44. As moisture level increased, intermediate diameter Increased. Relationships fitted to intermediate diameters of these rice varieties in relation to the indicated moisture levels using the method of least squares are presented in Figure 3. The relationships fitted were purely linear in nature and appeared to explain between 78.8 - 100% of the changes 3.3 Effects of Variety, Form and Moisture Content of Rice on Intermediate Diameter Intermediate diameters of grains of Faro 44 ranged between 1.65 - 2.46 mm and 1.43 2.71 mm for paddy and dehusked forms, respectively. For Faro 57 however, intermediate diameters of grains of paddy and dehusked rice ranged between 1.76 - 2.78 mm and 1.43 - 2.68 mm, respectively. Intermediate diameters were significantly higher for paddy forms than for dehusked Mazza M. et al. 79 Nigerian Journal of Tropical Engineering Vol. 17 No. 1 |ISSN: 1595-5397| Dec. 2023 DOI: 10.59081/njte.17.1.008 in intermediate diameter as a function of changes in moisture content (Table5) Intermediate diameter (mm) 2.5 2 1.5 1 Faro 44 Paddy Faro 44 Dehusked Faro 57 Paddy Faro 57 Dehusked 0.5 0 4 6 8 10 12 Moisture content (%) 14 16 Figure 3: Effect of moisture content on intermediate diameter Table 5: Dependence of intermediate diameter (mm) on moisture content Variety Faro 44 Paddy Faro 44 Dehusked M2 M -0.0061 0.0182 Faro 57 Paddy Faro 57 Dehusked C 2.2491 1.7888 R2 0.8933 0.8022 0.0053 2.2234 0.7880 0.0357 1.6530 1.0000 M = moisture content (%, dry basis) mean diameter was 3.58 mm. Grains of paddy were significantly larger at 4.05 mm 3.4 Effects of Variety, Form and Moisture than grains of dehusked rice which had mean Content of Rice on Geometric Mean geometric diameter of 3.31 mm. Moisture Diameter increase tended to influence change in Geometric mean diameters of the grains of geometric mean diameter positively (Figure rice sampled are presented in Table 2. These 4). Moisture dependence relations of diameters differed significantly along geometric mean diameter are presented in varietal lines and with the form of rice. Faro Table 6. It was observed that although mean 57 had grains with significantly larger geometric diameter was least at the lowest representative geometric mean diameters moisture content (3.78 mm) than Faro 44 whose geometric Mazza M. et al. 80 Nigerian Journal of Tropical Engineering Vol. 17 No. 1 |ISSN: 1595-5397| Dec. 2023 DOI: 10.59081/njte.17.1.008 Geometric mean diameter (mm) 4.5 4 3.5 3 2.5 2 1.5 Faro 44 Paddy Faro 44 Dehusked Faro 57 Paddy Faro 57 Dehusked 1 0.5 0 4 6 8 10 12 Moisture content (%) 14 16 Figure 4: Effect of moisture content on geometric mean diameter Table 6: Dependence of geometric mean diameter (mm) on moisture content Variety Faro 44 Paddy Faro 44 Dehusked Faro 57 Paddy Faro 57 Dehusked M2 -0.0026 -0.0010 C 3.6576 2.9316 R2 1.0000 1.0000 0.0238 3.9133 0.0370 3.0220 M = moisture content (%, dry basis) 0.9617 0.9983 M 0.0595 0.0403 (Table 2), gains in geometric mean diameter as a result of increase in moisture content were similar at 10 and 15% moisture contents. Only curvilinear trends were found to fit the data for Faro 44 were Faro equations describing the dependence of geometric mean diameter in Faro 57 on moisture content were observed to be satisfactorily linear (Table 6). 3.5 Effects of Variety, Form and Moisture Content of Rice on Projected Area As for projected area (Table 2), it was significantly larger for Faro 57 being 18.58mm2 than for Faro 44 (which was 16.04 mm2). Mean projected area of paddy grain was larger at 21.3 mm than that of dehusked rice which was 13.32 mm. This property tended to be influenced significantly by moisture content (Figure 5). The relationships obtained are presented in Table 7 and all were only satisfactorily parabolic in nature. Mazza M. et al. 81 Nigerian Journal of Tropical Engineering Vol. 17 No. 1 |ISSN: 1595-5397| Dec. 2023 DOI: 10.59081/njte.17.1.008 30 Projected area (mm2) 25 20 15 10 Faro 44 Paddy Faro 44 Dehusked Faro 57 Paddy Faro 57 Dehusked 5 0 4 6 8 10 12 Moisture content (%) 14 16 Figure 5: Effect of moisture content on projected area Table 7: Dependence of projected area (mm2) on moisture content Variety Faro 44 Paddy M2 -0.0575 M 1.2621 C 13.6660 R2 1.0000 Faro 44 Dehusked Faro 57 Paddy -0.0557 -0.0452 1.2420 1.1284 6.5825 17.0180 1.0000 1.0000 0.0239 -0.1627 12.9610 M = moisture content (%, dry basis) 1.0000 Faro 57 Dehusked As to the bounds of the parameter determined, projected area ranged between 11.71 - 26.51 mm2 and 14.44 - 29.75 mm2 for paddy forms of Faro 44 and Faro 57, respectively. As for dehusked forms of Faro 44 and Faro 57, projected areas ranged between 9.00 - 18.24 mm2 and 8.79 - 21.19 mm2, respectively. roundness, it was observed that the seeds were hardly round since they possessed low roundness of values in the range of 10.19 37.67% and 11.07 - 33.60% for paddy forms of Faro 44 and Faro 57 varieties of rice. Dehusked grains of Faro 44 and Faro 57 had roundness values in the range of 18.22 46.15% and 17.10 - 54.11%, respectively. The values were however larger for Faro 57 than for Faro 44 and for paddy than for dehusked grains (Table 2). Moisture level within the range studies did not seem to modify the shape of rice grains much in terms 3.6 Effects of Variety, Form and Moisture Content of Rice on Shape When it was sought to describe the grains of the two varieties of rice in terms of Mazza M. et al. 82 Nigerian Journal of Tropical Engineering Vol. 17 No. 1 |ISSN: 1595-5397| Dec. 2023 DOI: 10.59081/njte.17.1.008 of their roundness as noticeable changes resulting from moisture variation were not statistically significant (Table 2). The relative differences in these proportions by factor subsets are indicated in Figure 6. However, relationships for changes that may be obtained in roundness proportions in terms of moisture content are presented in Table 8. 40 35 Roundness (%) 30 25 20 15 10 Faro 44 Paddy 5 Faro 44 Dehusked 0 4 6 8 10 12 Moisture content (%) 14 16 Figure 6: Effect of moisture content on roundness Table 8: Dependence of roundness (%) on moisture content Variety Faro 44 Paddy Faro 44 Dehusked Faro 57 Paddy Faro 57 Dehusked M2 0.0182 C 25.6960 R2 1.0000 0.1183 -2.4757 44.8800 -0.0997 1.7246 19.3950 -0.1207 2.7367 22.2910 M = moisture content (%, dry basis) 1.0000 1.0000 1.0000 M -0.6292 When it again it was sought to describe the shape of the grains in terms of their sphericities, not much improvement was recorded. Sphericity of rice grain of Faro 44 and Faro 57 varieties ranged respectively between 35.33 - 49.70% and 35.61 - 48.25% for paddy and 39.79 - 59.36% and 42.11 58.17%, also respectively, for dehusked grains.From the mean values, however, these varieties of Nigerian grown rice may be better defined in terms of their sphericities than in terms of their roundness since they possess larger values of sphericity than they do of roundness (Table 2). The comparative differences in these proportions are indicated in Figure 7. Changes that may be had in sphericity as moisture level increases, though not significant on the average (Table 2) may be determined using the empirical equations generated using the method of least squares and presented in Table 9. Mazza M. et al. 83 Nigerian Journal of Tropical Engineering Vol. 17 No. 1 |ISSN: 1595-5397| Dec. 2023 DOI: 10.59081/njte.17.1.008 60 Sphericity (%) 50 40 30 20 Faro 44 Paddy Faro 44 Dehusked Faro 57 Paddy Faro 57 Dehusked 10 0 4 6 8 10 12 Moisture content (%) 14 16 Figure 7: Effect of moisture content on sphericity Table 9: Dependence of sphericity (%) on moisture content Variety Faro 44 Paddy Faro 44 Dehusked Faro 57 Paddy Faro 57 Dehusked M2 -0.0148 C 37.7590 R2 1.0000 0.0656 1.5444 56.0670 0.0833 1.5798 48.1290 -0.0527 1.0495 45.1480 M = moisture content (%, dry basis) 1.0000 1.0000 1.0000 M 0.3990 the grains within the limits studied did not significantly alter the bulk density of any of the two varieties of rice investigated (Table 2). Bulk density ranged between 551.0 580.1 kg/m3 and 800.8 - 829.3 kg/m3 for paddy forms of Faro 44 and Faro 57, respectively and between 531.0 - 553.8 kg/m3 and 839.6 - 852.7 kg/m3 for dehusked forms of Faro 44 and Faro 57, respectively. The relative differences in bulk density for the different forms of rice are indicated in Figure 8. Within the range of moisture contents studied, empirical equations describing the 3.7 Volume, Mass and Density Relations For volume and mass relationships, bulk and true densities of grains of the two varieties of rice were determined in paddy and dehusked forms at the stated moisture levels. Bulk density of grains of Faro 57 was found to be significantly higher than that of Faro 44, both being 830.82 kg/m3 and 552.6 kg/m3, respectively. This property did not differ significantly for paddy and dehusked forms, on the average. Increasing moisture level in Mazza M. et al. 84 Nigerian Journal of Tropical Engineering Vol. 17 No. 1 |ISSN: 1595-5397| Dec. 2023 DOI: 10.59081/njte.17.1.008 relationship between bulk densities of the two rice varieties and changes in moisture content are given in table 10. 10 and 15% product moisture contents were 1175.58 kg/m3, 1251.76 kg/m3 and 1263.24 kg/m3, respectively. True density of Faro 44 variety of rice was found to occur within the range of 1071.63 - 1234.0 kg/m3 for paddy and 1272.56 - 1357.4 kg/m3 for dehusked grains. True density of grains of Faro 57 ranged between 1057.71 -1071.64 kg/m3 for paddy and 1428.85 - 1566.23 kg/m3 for dehusked grains. The comparative differences in true density for the forms of the grains and the relationships describing these are presented in Figure 9 and Table 11, respectively. Mean true density for Faro 44 was determined to be 1191.89kg/m3 while that for Faro 57 was found to be 1268.50 kg/m3. Paddy forms had mean true density of 1085.13 kg/m3 while dehusked grains had mean true density of 1357.27 kg/m3. Within the range of moisture contents evaluated, it was observed that true density tended to increase with increasing moisture content, on the average. Mean values of true density at 5, 900 800 Bulk density (kg/m3) 700 600 500 400 300 Faro 44 Paddy Faro 44 Dehusked Faro 57 Paddy Faro 57 Dehusked 200 100 0 4 6 8 10 12 Moisture content (%) 14 16 Figure 8: Effect of moisture content on bulk density Table 10: Dependence of bulk density (kg/m3) on moisture content Variety Faro 44 Paddy Faro 44 Dehusked Faro 57 Paddy Faro 57 Dehusked M2 -0.4145 M 8.6127 C 526.65 R2 1.0000 -0.2396 1.5780 -2.0534 4.3539 525.00 836.68 829.90 0.7681 0.9298 1.0000 Mazza M. et al. 85 Nigerian Journal of Tropical Engineering Vol. 17 No. 1 |ISSN: 1595-5397| Dec. 2023 DOI: 10.59081/njte.17.1.008 M = moisture content (%, dry basis) 1800 1600 True density (kg/m3) 1400 1200 1000 800 600 Faro 44 Paddy Faro 44 Dehusked Faro 57 Paddy Faro 57 Dehusked 400 200 0 4 6 8 10 Moisture content (%) 12 14 16 Figure 9: Effect of moisture content on true density Table 11: Dependence of true density (kg/m3) on moisture content Variety Faro 44 Paddy Faro 44 Dehusked Faro 57 Paddy Faro 57 Dehusked M2 -7.5664 M 156.6900 C 423.78 R2 1.0000 -0.5567 15.9690 11.1340 1116.20 1016.00 0.9987 1.0000 13.7390 1337.30 M = moisture content (%, dry basis) 0.7500 surge from 5 to 15%. Geometric mean diameters and projected area also increase as the moisture content increase while roundness, sphericity and bulk density were not significantly affected by increase in moisture content but true was found to be positively correlated to moisture content and increases from 1175.58 to 1263.24 kg/m3). This results will assist researchers and in designing machines for handling and processing of rice. 4. Conclusion In this study, some design-related physical properties of two varieties of rice commonly grown in Nigeria were determined using standard laboratory techniques and following standards recommended in literature. Major, minor and intermediate diameter of Faro 44 and 57 Dehusked and paddy increased from 8.05 to 8.51, 2.77 to 2.94 and 2.04 to 2.18 mm respectively as the moisture content Mazza M. et al. 86 Nigerian Journal of Tropical Engineering Vol. 17 No. 1 |ISSN: 1595-5397| Dec. 2023 DOI: 10.59081/njte.17.1.008 Recommendations 1. These results may only be employed for operations to be carried out within the range of moisture contents employed for their determination. 2. Caution should be exercised with the use of the geometric mean diameter. It is recommended that this property be limited in its use for the determination of aerodynamic parameters. Where size consideration is the object, it is appropriate to make direct employment of the major, minor and intermediate diameters and not a pooled average of the nature of the geometric mean diameter. [5] Mohidem, N. A., Hashim, N., Shamsudin, R., & Che Man, H. (2022). Rice for Food Security: Revisiting Its Production, Diversity, Rice Milling Process and Nutrient Content. Agriculture, 12(6), 741. https://www.mdpi.com/20770472/12/6/741: https://www.mdpi.com/20770472/12/6/741 [6] Bande YM, Adam NM, Azmi Y, Jamarei O (2012) Determination of selected physical properties of Egusi melon (Citrullus colocynthis lantus) seed. J Basic Appl Sci. 8: 257 – 265. [7] Zhang, W., Li, M., Liu, Y., Liu, Z., & He, D. (2023). Automatic rice grain classification using deep learning for broken rice detection. Computers and Electronics in Agriculture, 209, 108305. References [1] Awad M., Osama F., Wael F., Wael E. B., Mohsen E., Walied E. F. and Mahmoud O. (2022). A combined machine for collecting and chopping rice straw. [8] Li, R., Li, R., Li, F., Wang, R., Li, A., Liu, W., & Yang, M. (2023). Multi-sensor fusion for rice grain quality evaluation based on NIR, hyperspectral, and X-ray imaging. Sensors, 23(5), 2809. [2] Solaf A. E., Mahmoud A., Fatma A. E., Mokhtar C. and Mahmoud O. (2022). Influence of operating parameters on the milling quality of long-grain white rice. INMATEH - Agricultural Engineering, 68(3), 669–680. doi:http://dx.doi.org/10.35633/inmateh68-66: http://dx.doi.org/10.35633/inmateh-6866 [9] American Society of Agricultural and Biological Engineers (ASABE) S352.2 (2018). Moisture Measurement— Unground Grain and Seeds. American Society of Agricultural and Biological Engineers, St. Joseph. [3] Food and Agriculture Organization of the United Nations (FAO). (2023). World rice trade dynamics and rice price volatility. https://www.fao.org/marketsand-trade/commodities/rice/rmm/en/ [10] Abdul-Rasaq A. Adebowale & Lateef O. Sanni &Hameed O. Owo & Olayinka R. Karim 2010. Effect of variety and moisture content on some engineering properties of paddy rice. Journal of Food Sci Technology (September–October 2011) 48(5):551–559DOI 10.1007/s13197-010-0173- [4] International Rice Research Institute (IRRI). (2023). Rice: Production, trade, and consumption trends. http://books.irri.org/RT12_1_content.pdf Mazza M. et al. 87 Nigerian Journal of Tropical Engineering Vol. 17 No. 1 |ISSN: 1595-5397| Dec. 2023 DOI: 10.59081/njte.17.1.008 [11] Zareiforoush H., Hosseinzadeh B., Adabi M. E. and Motavali A. (2011). Moisture-dependent physical properties of paddy grains Journal of American Science, 2011;7(7) page 175-182. [17] Kabutey, A., Herak, D., Choteborsky, R., Mizera, Č., Sigalingging, R., & Akangbe, O. L. A. (2017). Oil point and mechanical behaviour of oil palm kernels in linear compression. International Agrophysics, 31(4), 427-434. doi:10.1515/intag-2016-0055 [12] Zareiforoush, M., Komarizadeh, M. H., & Khoshtaghaza, M. H. (2021). Effect of moisture content on some physical properties of paddy grains. Journal of Agricultural Science and Technology, 23(3), 349-359. [18] Mohsenin (1986). Physical Properties of Plant and Animal Materials. Gordon and Breach Scienece Publishers, Newyork. Pp. 79 – 127 [13] Arije, O. O., Adewumi, B. A., Olayanju, T. M. A., & Adetifa, B. O. (2019). A comparative study of physical properties of selected rice varieties in Nigeria. Foods and Raw Materials, 7(1), 4-9. doi:10.21603/2308-4057-2019-1-49 [19] Akangbe O. L. and Herak D. (2017). Oil Point Determination of Selected Bulk Oilseeds Under Compression Loading. Engineering for Rural Development. Vol. 24. Pp. 988 – 993. https://www.researchgate.net/profile/Da vidHerak/publication/317254782_Oil_point _determination_of_selected_bulk_oilsee ds_under_compression_loading/links/5a b965480f7e9b68ef532f4e/Oil-pointdetermination-of-selected-bulk-oilseedsunder-compression-loading.pdf [14] Mujumdar, A. S. (2014). Physical properties of grains. In Handbook of post-harvest operations and processing (pp. 75-120). CRC Press. [15] Yang, M., Wang, Y., Liu, Y., Li, Y., Zhang, Y., Xu, Y., & Tang, W. (2022). Grain density, hardness, and milling characteristics of waxy rice germplasm resources. Frontiers in Plant Science, 13, 345192. doi:10.3389/fpls.2022.345192 [16] Nimkar P.M. and Chattopadhyay P.K. PH—Postharvest Technology: Some physical properties of green gram. Journal of Agricultural Engineering Research, 2001, vol. 80, no. 1, pp. 183– 189. DOI: https://doi.org/10.1006/jaer.2000.0664 Mazza M. et al. 88