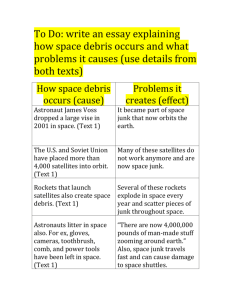

Satellite Launch Mechanics: Space Debris & Design

advertisement