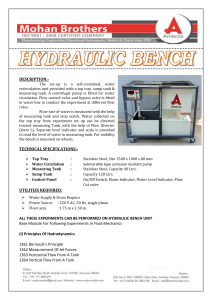

UNIVERSITY OF ENGINEERING AND TECHNOLOGY, PESHAWAR DEPARTMENT OF CIVIL ENGINEERING FINAL LAB REPORT Fluid Mechanics-II (LAB.) CE-212L Name Osama Wali Class No. 165 Registration No. 20pwCIV5433 Section “P” Date of submission February 2023 Submit to Engr. Tabinda Masood FINAL LAB. REPORT FLUID MECHANICS-II (LAB.) It is intended that this report provides with a clear and thorough presentation of the whole course of Fluid Mechanics-II (LAB.) we studied in the class. It covers all the relevant information related to the lectures in detail with the help of illustrations. The relevance of knowing the topics matter is reflected by the real-world applications and for this purpose photos are also added. These photos generally are used to explain how the relevant principles apply to real-world situations. Department Of Civil Engineering UET Peshawar 2 FINAL LAB. REPORT FLUID MECHANICS-II (LAB.) Table of Contents Experiment No. 01 ........................................................................................................................................ 7 “To demonstrate different parts and the working principle of Hydraulic Bench” .................................... 7 1.1. Theoretical background: ........................................................................................................... 7 1.2. APPARATUS ................................................................................................................................ 7 1.3. Description of Different Parts of Hydraulic Bench: ...................................................................... 7 1.4. Procedure: ...................................................................................................................................... 9 1.5. Purpose:.......................................................................................................................................... 9 1.6. Applications of Hydraulic Bench:.................................................................................................. 9 1.7. Observations and Calculations: ...................................................................................................... 9 Experiment No. 02 ...................................................................................................................................... 11 “To Determine the Discharge and Coefficient of Discharge over Rectangular Notch” ......................... 11 2.1. Apparatus: .................................................................................................................................... 11 2.2. Theoretical background: .............................................................................................................. 11 2.3. Observation and Calculation ........................................................................................................ 13 Experiment No. 03 ...................................................................................................................................... 14 “Determine the Discharge and Coefficient of Discharge over Triangular Notch” ................................. 14 3.1. Triangular Notch .......................................................................................................................... 14 3.2. Observations and Calculations ..................................................................................................... 15 Experiment No. 04 ...................................................................................................................................... 16 “Investigation of different types of flows using Osborne Reynold’s apparatus by visual observation” . 16 4.1. Objective: ..................................................................................................................................... 16 4.2. Apparatus ..................................................................................................................................... 16 4.3. Types of Flow .............................................................................................................................. 17 4.5. Observations and Calculations: .................................................................................................... 18 Experiment No. 05 ...................................................................................................................................... 19 “Investigation of different types of flow by using Osborne Reynold’s Apparatus by (Reynolds number formula)” ................................................................................................................................................. 19 5.1. Apparatus: .................................................................................................................................... 19 5.2. Procedure: .................................................................................................................................... 19 Department Of Civil Engineering UET Peshawar 3 FINAL LAB. REPORT FLUID MECHANICS-II (LAB.) 5.3. Observations and Calculations: .................................................................................................... 19 Experiment No. 06 ...................................................................................................................................... 21 “To Determine Theoretical and Actual Center of Pressure on Partially Submerged Body” ............... 21 6.1. Objective ...................................................................................................................................... 21 6.2. Apparatus ..................................................................................................................................... 21 6.3. Hydrostatic Force Theory ............................................................................................................ 21 6.4. Centre of Pressure ........................................................................................................................ 21 6.5. Hydrostatic Centre of Pressure .................................................................................................... 23 6.6. Actual Centre of Pressure ............................................................................................................ 23 6.7. Procedure: .................................................................................................................................... 23 6.8. Precautions ................................................................................................................................... 24 6.9. Conclusion ................................................................................................................................... 24 6.10. Observations and Calculations: .................................................................................................. 24 Experiment No. 07 ...................................................................................................................................... 25 “To determine the hydraulic coefficients (Cv, Cc and Cd) for small circular orifice provided at the side of the tank”.............................................................................................................................................. 25 7.1. Theoretical background................................................................................................................ 25 7.2. Objective: ..................................................................................................................................... 26 7.3. Apparatus and parts of the apparatus: .......................................................................................... 26 7.4. Procedure: .................................................................................................................................... 26 7.4. Conclusion: .................................................................................................................................. 27 7.5. Observations and Calculations: .................................................................................................... 28 Experiment No. 8 ........................................................................................................................................ 30 “To determine the hydraulic coefficients (Cv , Cc and Cd) for a small circular orifice provided at the bottem of the tank”.................................................................................................................................. 30 8.1. Theoretical background: .............................................................................................................. 30 8.2. Objective: ..................................................................................................................................... 30 8.3. Apparatus: .................................................................................................................................... 30 8.4. Procedure: .................................................................................................................................... 30 8.5. Observations and Calculations: .................................................................................................... 31 Experiment No. 9 ........................................................................................................................................ 33 Department Of Civil Engineering UET Peshawar 4 FINAL LAB. REPORT FLUID MECHANICS-II (LAB.) “To investigate the validity of Bernoulli’s theorem as applied to the flow of water by Bernoulli’s theorem demonstration” .......................................................................................................................... 33 9.1. Theoretical background: .............................................................................................................. 33 9.2. Apparatus: .................................................................................................................................... 33 9.3. Different parts of the Bernoulli’s apparatus: ................................................................................ 33 9.4. Procedure: .................................................................................................................................... 34 Experiment No. 10 ...................................................................................................................................... 35 “To determine the relationship between head loss due to friction and velocity of the flow of water through smooth bore pipe”...................................................................................................................... 35 10.1. Objective: ................................................................................................................................... 35 10.2. Theoretical background.............................................................................................................. 35 10.3. Apparatus: .................................................................................................................................. 35 10.4. Parts of the fluid friction apparatus: ........................................................................................... 35 10.5. Procedure: .................................................................................................................................. 37 10.6. Observation and Calculations: ................................................................................................... 37 Department Of Civil Engineering UET Peshawar 5 FINAL LAB. REPORT Department Of Civil Engineering UET Peshawar FLUID MECHANICS-II (LAB.) 6 FINAL LAB. REPORT FLUID MECHANICS-II (LAB.) Experiment No. 01 “To demonstrate different parts and the working principle of Hydraulic Bench” 1.1. Theoretical background: Hydraulic Bench: A Hydraulic Bench is a self-contained water supply device that allows recirculating of water from a Sump Tank into different hydraulic devices. Centrifugal pump: A centrifugal Pump moves water from the Sump Tank through a hose into a Water Inlet at the top of the bench. 1.2. APPARATUS • • • • • • • • • • • • • • • • Sight Tube and Scale Flow Control Valve Motor On\Off Button Centrifugal Pump Dump Valve and Dump Valve Handle Drain Valve Sump Tank Pump and Motor Quick Release Connector Side Wall Slots Inlet Stilling Baffle Valve Open Channel Weir Carrier Tank Stilling Baffle Volume Measuring Tank Over flow 1.3. Description of Different Parts of Hydraulic Bench: Sight tube and Scale: A sight tube and scale is connected to tapping in the base of the volumetric tank and give an instantaneous indication of water flow. Flow Control Valve: It is used to regulate the flow in the pipe i.e. to increase or decrease the inflow of water in hydraulic bench. When it is rotated clockwise it reduces the water flow and when it is moved counterclockwise it increase the water flow. Department Of Civil Engineering UET Peshawar 7 FINAL LAB. REPORT FLUID MECHANICS-II (LAB.) Motor On\Off Button: This button is used to start or close the motor. Centrifugal Pump: It draws water from sump tank and supplies it for performing experiment. Dump Valve and dump Valve Handle: Dump valve is in the base of the volumetric tank opening the dump valve with dump valve handle allows the entrained water to return to the sump tank to recycling and closing the dump valve gathers the water in the volumetric tank. Drain Valve: Drain valve is used for discharging of water form sump tank. Sump Tank: The fluid used in hydraulic bench is stored in sump tank located at the bottom of hydraulic bench. The water from the sump tank is supplied through pump. Sump tank has the capacity of 160 liters. Quick Release Connector: The connector allows flow for rapid substitution of accessories. Special purpose terminations may be connected to the pump supply by screwing connector. No hand tools are required for doing so. Side Wall Slots\Channel: Side channels are provided to support the accessory on test. Inlet Stilling Baffle Valve: Inlet stilling baffle valve is used to supply water in the open channel. Open Channel: It is used in number of experiments. It provides passage for water for different experiments. Weir Carrier: Two types of weirs are used frequently • • Rectangular weir Triangular weir Department Of Civil Engineering UET Peshawar 8 FINAL LAB. REPORT FLUID MECHANICS-II (LAB.) Tank Stilling Baffle: Volumetric measuring tank incorporates a stilling baffle inclined to reduce turbulence. Volumetric Tank: Water discharging form the accessory (channels) on test is collected in a volumetric measuring tank. This tank is stepped to accommodate low or high flow rates. Overflow: An over flow adjacent to the sump returns the water to the sump tank in the event of incorrect use of water. 1.4. Procedure: a) To start with, make sure the Pump is off. b) Set up the device to be tested, either a close-conduit device or water supply for open channel flow, attached to the Water Inlet. Make sure all the connections are secured. c) Ensure that the Supply Valve is closed, and that the Dump Valve is open. Switch the Pump on. d) Once the Pump is on, slowly open the Supply Valve to allow water to circulate through the Bench. e) Close the dump valve and gather some water in the volumetric tank. f) Now measure the volume gathered through the sight tube and scale and note the time required to fill the desirable volume of water on the stopwatch. g) Open the dump valve to return water to sump tank. h) Then again close he dump valve to take readings and repeat the procedure to take different readings. 1.5. Purpose: To find the discharge of water. 1.6. Applications of Hydraulic Bench: • • • • • • Discharge of water "Q" Co-efficient of discharge "Cd" Co-efficient of velocity "Cv" Co-efficient of contraction "C" To study the characteristics flow of water over notches To find head losses through pipes Verification of Bernoulli’s theorem 1.7. Observations and Calculations: To find out discharge, we have Discharge = Volume \ Time Department Of Civil Engineering UET Peshawar 9 FINAL LAB. REPORT FLUID MECHANICS-II (LAB.) 𝐐= 𝐯 𝐭 TABLE NO. 01: Discharge Calculations S.No Volume (liter) Time (sec) Discharge(Q) 1 25 20.29 1.2 lit\sec 2 25 20.54 1.21 lit\sec 3 25 21.43 1.16 lit\sec Sump Tank Flow Control Valve Motor ON/OFF Button Graduation Scale FIGURE 1: HYDRAULIC BENCH Department Of Civil Engineering UET Peshawar 10 FINAL LAB. REPORT FLUID MECHANICS-II (LAB.) Experiment No. 02 “To Determine the Discharge and Coefficient of Discharge over Rectangular Notch” 2.1. Apparatus: • • • • Hydraulic Bench Hook and Point Gauge Stop Watch Rectangular notch plate 2.2. Theoretical background: Notch: An opening in a tank/vessel in which the top edge of opening lies above the water surface. It is used to find discharge in open channel. FIGURE 2: NOTCH Orifice: An opening in a tank/vessel in which the top edge of the opening lies below the water surface. It is used to find discharge in open channel. Department Of Civil Engineering UET Peshawar 11 FINAL LAB. REPORT FLUID MECHANICS-II (LAB.) Figure 3: Orifice Rectangular Notch: A rectangular weir is used to meter flow in an open channel. The head over the rectangular weir is measured and correlated with the water flow rate through the open channel (and over the weir). A rectangular weir equation gives water flow rate as a function of head over the rectangular weir. The discharge can be calculated with following formula. Figure 4: Rectangular Notch Department Of Civil Engineering UET Peshawar 12 FINAL LAB. REPORT FLUID MECHANICS-II (LAB.) 2.3. Observation and Calculation TABLE NO. 02: S.No Volume Time Q H2 H1 H=H2-H1 Log(Q) 1 20 17.29 1.156738 152 84 0.68 2 15 13.29 1.128668 150 84 0.66 3 15 15.4 0.974026 145 84 0.61 Log(H) 0.063235 -0.16749 -0.01143 -0.21467 𝐶𝑑=0.76 0.8 0.6 y = 1.515x + 0.3141 0.4 0.2 0 -0.8 -0.6 -0.4 -0.2 0 0.2 0.4 0.6 0.8 -0.2 -0.4 -0.6 -0.8 Figure 5: Rectangular Notch Department Of Civil Engineering UET Peshawar 13 FINAL LAB. REPORT FLUID MECHANICS-II (LAB.) Experiment No. 03 “Determine the Discharge and Coefficient of Discharge over Triangular Notch” 3.1. Triangular Notch A triangular notch is also called a V-notch. Consider a triangular notch, in one side of the tank, over which water is flowing as shown in figure. Let, H = Height of the liquid above the apex of the notch. θ = Angle of the notch. Figure 6: Triangular Notch To calculate discharge through triangular notch following formula is use. Department Of Civil Engineering UET Peshawar 14 FINAL LAB. REPORT FLUID MECHANICS-II (LAB.) 3.2. Observations and Calculations TABLE NO. 03: S/N0 Vol(L) Time(sec) 𝑄𝑎𝑐𝑡(L/s) 𝐻1 𝐻2 𝐻 LogQ 1 30 50.54 0.593589 127 161 34 -0.2265 1.5315 2 20 58 0.344828 127 161 34 -0.4624 1.5315 3 10 129.8 0.077042 127 146 19 -1.1135 1.2788 LogH 0.5 0.3 0.1 -0.8 -0.7 -0.6 -0.5 -0.4 -0.3 -0.2 -0.1 -0.1 0 0.1 -0.3 -0.5 y = 2.5764x + 0.7447 -0.7 -0.9 -1.1 -1.3 FIGURE 7: GRAPH OF FLOW OF THROUGH TRIANGULAR NOTCH 𝐶𝑑 = 0.75 Department Of Civil Engineering UET Peshawar 15 FINAL LAB. REPORT FLUID MECHANICS-II (LAB.) Experiment No. 04 “Investigation of different types of flows using Osborne Reynold’s apparatus by visual observation” 4.1. Objective: In this experiment we investigated the type of flow, using the Osborne Reynolds apparatus. 4.2. Apparatus Osborne Reynold’s apparatus Hydraulic bench Glass marbles. FIGURE 8: OSBORNE REYNOLDS APPARATUS Department Of Civil Engineering UET Peshawar 16 FINAL LAB. REPORT FLUID MECHANICS-II (LAB.) 4.3. Types of Flow Laminar Flow The flow in which fluid moves in liquid particles moves in form of thin sheets in which the particles are not intersecting the path lines of each other such type of flow is known as laminar flow. In this flow streamlines follow parallel path. The dye remains easily identifiable as solid core, denote steady condition. R≤2000 Turbulent Flow The flow in which liquid particles move in zig zag path and intersecting the path lines of each other is called as turbulent flow. In this flow streamlines interacts and completely disperses in flow of water, denotes highly unsteady condition. R>4000 Transition Flow The flow that takes place during the inter-conversion of laminar and turbulent flow is called transition flow or transition zone between laminar flow and turbulent flow is called transition flow. In this flow the streamlines interact and partial mixing of flow occurs. Dye form eddies while flowing through water, denotes unsteady condition. 4000≥R>2000 FIGURE 9: FLOW TYPES Department Of Civil Engineering UET Peshawar 17 FINAL LAB. REPORT FLUID MECHANICS-II (LAB.) 4.5. Observations and Calculations: TABLE NO. 04: Serial No. Observation Type of flow 1 Solid line of dye laminar 2 Discontinuity, partial mixing transition 3 Dye disappears, complete mixing turbulent Department Of Civil Engineering UET Peshawar 18 FINAL LAB. REPORT FLUID MECHANICS-II (LAB.) Experiment No. 05 “Investigation of different types of flow by using Osborne Reynold’s Apparatus by (Reynolds number formula)” 5.1. Apparatus: • • • • Hydraulic Bench Osborne Reynolds Apparatus Dye Reservoir Thermometer 5.2. Procedure: Fill the dye reservoir with dye. Then lowered the dye injector until it just above the bell mouth. Turn on the pump to supply water to the head tank. Slowly fill head tank to the overflow level. Closed the inlet valve. Open the control value so that the dye mixes with the water. Open and close the velocity control valve to admit the water to the flow visualization pipe. Open the inlet valve slightly until water travelled from outlet pipe. 5.3. Observations and Calculations: Diameter of pipe = 1 cm = 0.01 m Area of pipe = 0.0000785 𝑚² Temperature of water = 25 ̊C Kinematic viscosity of water =1.003x10−6 m²/sec TABLE NO. 05: Department Of Civil Engineering UET Peshawar 19 FINAL LAB. REPORT FLUID MECHANICS-II (LAB.) S.NO Volume (m3) Time (Sec) Temperature ( ̊C ) Discharge (m3/sec) Reynolds Remarks number 01 0.0002 87.05 20 0.029 289 Laminar 02 0.0008 20 0.25 2492 Transition 03 0.003 20 0.73 7278 Turbulent 40.00 51.78 Department Of Civil Engineering UET Peshawar 20 FINAL LAB. REPORT FLUID MECHANICS-II (LAB.) Experiment No. 06 “To Determine Theoretical and Actual Center of Pressure on Partially Submerged Body” 6.1. Objective To determine the theoretical and actual center of pressure 6.2. Apparatus • Different Weights • Hydrostatic pressure apparatus • Graduated cylinders 6.3. Hydrostatic Force Theory Fluid force is constant at any particular depth but varies vertically. This force is calculated as liquid weight per unit volume times the depth. The total force exerted by the liquid on the ring section is non-uniformly applied vertically. When the quadrant is immersed in water it is possible to analyze the forces acting on the surfaces of the quadrant as follows: Hydrostatic forces on the upper and lower curved surfaces therefore have no net effect – no torque to affect the equilibrium of the assembly because all of these forces pass through the pivot. The forces on the sides of the quadrant are horizontal and cancel out The hydrostatic force on the vertical submerged face is counteracted by the balanced weight W. The resultant hydrostatic force on the face can therefore be calculated from the value of the balance weight and the depth of the water. 6.4. Centre of Pressure All submerged surfaces experience a hydrostatic force. The point through which this force acts is called the center of pressure. The total force vector acting at the center of pressure is the value of the integrated vectoral pressure field. The resultant force and center of pressure location produce equivalent force and moment on the body as the original pressure field. Department Of Civil Engineering UET Peshawar 21 FINAL LAB. REPORT FLUID MECHANICS-II (LAB.) FIGURE 10: WEIGHT AND HYDROSTATIC PRESSURE APPARATUS FIGURE 11: WEIGHT AND HYDROSTATIC PRESSURE APPARATUS Department Of Civil Engineering UET Peshawar 22 FINAL LAB. REPORT FLUID MECHANICS-II (LAB.) 6.5. Hydrostatic Centre of Pressure The theoretical center of pressure can be calculated as 𝐇𝐩 = 𝟐 𝐲+𝐚 𝟑 Where y = Depth of water a = Distance of water level from pivot 6.6. Actual Centre of Pressure 𝑭𝒓 = 𝑷 ∗ 𝑨 𝒉𝒃 = 𝒓 ∗ 𝟐 = 𝟏 ∗ 𝒉𝟐 ∗ 𝒃 𝟐𝒓 According to condition of equilibrium we know that 𝐖 ∗ 𝐋 = 𝐅𝐫 ∗ 𝐇𝐩 𝐇𝒑 = 𝐖 ∗ 𝐋 𝐅𝐫 Where W= weight Fr= Resultant force L = Moment arm =27.5cm a= distance of water level from pivot=20-y y= depth of water r=9.81KN/m^3 6.7. Procedure: Check the bench is leveled properly with the use of spirit level. • Add a small mass (50g) to the weight hanger. • Get tap water using steel vessel and fill up the flotation tank. • Fill the floatation tank with water initially until the balance arm rises. Department Of Civil Engineering UET Peshawar 23 FINAL LAB. REPORT FLUID MECHANICS-II (LAB.) • Continue to add water until the balance arm is horizontal, checking this by aligning the flat of the balance arm with the central mark on the level indicator. • When the arm is horizontal read the depth of immersion from the scale on the face of the quadrant. • Repeat the above procedure for different load increments by adding further weights to the weight hanger • Repeat the procedure in order to get accurate result. 6.8. Precautions • First of all, clean the apparatus. • Level the apparatus with the help of screws. • Balance the apparatus. 6.9. Conclusion By the above experiment we are able to determine the theoretical as well as actual center of pressure on partially submerged body. 6.10. Observations and Calculations: TABLE NO. 06: S.No Weight (kg) Depth of water (mm) Distance of water level from pivot (q) (mm) Resultant force (N) Hp (actual) (mm) Hp (theoretical) (mm) 1 0.05 45 155 0.74 181 185 2 0.10 66 134 1.60 172 178 3 0.15 83 117 2.53 163 172 Department Of Civil Engineering UET Peshawar 24 FINAL LAB. REPORT FLUID MECHANICS-II (LAB.) Experiment No. 07 “To determine the hydraulic coefficients (Cv, Cc and Cd) for small circular orifice provided at the side of the tank” 7.1. Theoretical background Orifice: An opening in the vessel through which water flows is known as orifice. Orifice may small and large depending upon the diameter of the orifice and the diameter of the vessel or tank. Orifice is used to determine the discharge through it. Discharge through the orifice depends upon the head of the water above the center of the orifice which is denoted by “ho”. An orifice is called as small orifice when the diameter of the tank is larger than five times the diameter of the orifice. Vena contracta: It is the portion of the jet with least diameter. Hydraulic coefficients: Hydraulic coefficients are three in number, denoted as Cc, Cd and Cv. The ratio of the area of the jet at vena contracta to the area of the orifice is known as coefficient of contraction i.e. Cc. Cc = Ac Ao The ratio of the actual discharge to the theoretical discharge is known as coefficient of discharge i.e. Cd. Cd = Qact. Vol./time = Qth. Ao√2𝑔𝐻𝑜 The ratio of the actual velocity to the theoretical velocity is called as coefficient of velocity i.e. Cv. Cd = √2𝑔𝐻𝑐. √2𝑔𝐻𝑜. = Hc Ho Do = Diameter of the orifice = 6mm Department Of Civil Engineering UET Peshawar 25 FINAL LAB. REPORT FLUID MECHANICS-II (LAB.) 7.2. Objective: To determine the hydraulic coefficients and to study the jet profile. 7.3. Apparatus and parts of the apparatus: i. ii. iii. iv. v. vi. vii. Constant head inlet tank Circular orifice Hydraulic bench Needle apparatus Clip board A3 size white paper sheet Stop watch Different parts of the apparatus are: i. Turbulancy diminisher ii. Orifice iii. Supply iv. Pipe for static head measurement v. Micrometer and pitot tube vi. Scales overflow 7.4. Procedure: Adjust the appartus which is going to be used in this very experiment. Open the inlet valve and adjust the inflow to make the head of the water above the orifice be constant. Water will come from the orifice and the discharge i.e. actual discharge can be found by using hydraulic bench volumetric tank and stopwatch to measure the volume and time and the discharge will be found as: 𝑉𝑜𝑙. 𝑄𝑎𝑐𝑡 = 𝑡𝑖𝑚𝑒 The water coming out of the orifice follow certain trajactory. This trajactory is traced by using needles. The path is traced on an A3 size paper sheet. The coordinates of these points which are eight in number are then found in terms of x and y coordinates. Needles are 5cm apart, so x distances will differ by 5 starting from zero. Then Cv is found by using the formula: 𝑋2 4𝑌𝐻𝑜 Cd is found by dividing the actual discharge by the theoretical discharge. And at the last Cc is found from Cd and Cv already computed. Here we cannot use the direct formulas for the computations of Cv and Cc due to the limitations of the current experiment. Repeat the same procedure for three times. 𝐶𝑣 = √ Department Of Civil Engineering UET Peshawar 26 FINAL LAB. REPORT FLUID MECHANICS-II (LAB.) 7.4. Conclusion: With the help of this experiment we found the hydraulic coefficients by using the formulas and also studied the jet profile by using the needles arrangement. FIGURE 12: NEEDLE APPARATUS AND CONSTANT HEAD INLET TANK FIGURE 13: NEEDLE APPARATUS Department Of Civil Engineering UET Peshawar 27 FINAL LAB. REPORT FLUID MECHANICS-II (LAB.) 7.5. Observations and Calculations: Table No. 07(a) Reading No. 01: Do = 6 mm ho = 300 mm Vol. = 3 lit. Time = 76.22 s Qact. = 0.0394 lit./s Qth. = 0.0686 lit./s X Y X2 0 0 0 5 0.75 25 10 1.75 100 15 3.2 225 20 5 400 25 7.45 625 Cc = 0.66 30 10.35 900 Slope = 93.077 35 13.3 1225 Cv = 0.869 Cd = 0.574 1400 1200 y = 93,077x - 48,828 1000 X2 800 600 400 200 0 -200 0 2 4 6 8 10 12 14 Y FIGURE 14: RELATIONSHIP BETWEEN X2 AND Y Department Of Civil Engineering UET Peshawar 28 FINAL LAB. REPORT FLUID MECHANICS-II (LAB.) Reading No. 02: Table No. 07(b) Do = 6 mm ho = 283 mm Vol. = 2 lit. Time = 56.87 s Qact. = 0.03517 lit./s Qth. = 0.06662 lit./s Cv = 0.883 Cd = 0.528 Cc = 0.598 Slope = 88.321 X Y X2 0 0 0 5 0.7 25 10 1.85 100 15 3.4 225 20 5.6 400 25 7.95 625 30 10.8 900 35 14 1225 1400 1200 y = 88,321x - 51,579 1000 X2 800 600 400 200 0 0 2 4 6 -200 8 10 12 14 16 Y FIGURE 15: RELATIONSHIP BETWEEN X2 AND Y Department Of Civil Engineering UET Peshawar 29 FINAL LAB. REPORT FLUID MECHANICS-II (LAB.) Experiment No. 8 “To determine the hydraulic coefficients (Cv , Cc and Cd) for a small circular orifice provided at the bottem of the tank” 8.1. Theoretical background: Orifice: An opening in the vessel through which water flows is known as orifice. Orifice may small and large depending upon the diameter of the orifice and the diameter of the vessel or tank. Vena contracta: It is the portion of the jet with least diameter. Pitot tube: It is a tube used to measure the static pressure head plus elevation head and also the velocity head, kept in the direction of the upstream side. 8.2. Objective: To determine the hydraulic coefficients without studying the jet profile from the proposed formulas. That is done by using a pitot tube. 8.3. Apparatus: i. ii. iii. iv. v. Hydraulic bench Constant head inlet tank Piezometer Pitot tube Stop watch 8.4. Procedure: Adjust the apparatus for the experiment. Open the inlet valve and maintain the head constant (at supply tank) over the orifice. Adjust the inflow in such a way that a constant head is maintained. Allow water to flow through the orifice and note the maximum head over the orifice that permits the water jet to flow into the measuring tank. Department Of Civil Engineering UET Peshawar 30 FINAL LAB. REPORT FLUID MECHANICS-II (LAB.) Regulate the inlet valve to obtain a constant head over the orifice and note the time taken for collecting water to a height ‘h’ in the measuring tank. Then calculate the actual discharge by dividing the volume collected by time. Revolve the micrometer of the pitot tube and bring the hollow needle to the center of the jet flow so that velocity head can be calculated. To measure the diameter at the vena contracta revolve the micrometer from one side of the jet to the other side and note the number of revolution micrometer as one 1mm movement of the revolution gives to the hollow needle. So in this way calculate the diameter of vena contracta. FIGURE 16 8.5. Observations and Calculations: Table No. 08: S.No. Do (mm) Dc (mm) ho (mm) hc (mm) Vol. (lit.) Time (sec.) Cv Cd Cc 01 02 14 14 12 358 372 354 367 15 15 56.41 56.58 0.994 0.993 0.652 0.638 0.735 0.862 13 Department Of Civil Engineering UET Peshawar 31 FINAL LAB. REPORT 03 14 FLUID MECHANICS-II (LAB.) 13 373 363 Department Of Civil Engineering UET Peshawar 10 38.27 0.995 0.630 0.862 32 FINAL LAB. REPORT FLUID MECHANICS-II (LAB.) Experiment No. 9 “To investigate the validity of Bernoulli’s theorem as applied to the flow of water by Bernoulli’s theorem demonstration” 9.1. Theoretical background: Bernoulli’s Theorem: The total head of the flowing liquid between two points remains constant provided that there is no loss due to friction and no gain due to an application of outside work between these two points. Total head is given by: 𝑯= 𝒑 𝒗𝟐 + +𝒛 𝜸 𝟐𝒈 Where; p/ϒ = static pressure head v2/2g = velocity head z = elevation head Flow control valve: It is a valve used to control the amount of i.e. velocity of the fluid through a certain pipe or flow channel. 9.2. Apparatus: i. ii. Bernoulli’s Apparatus Hydraulic Bench 9.3. Different parts of the Bernoulli’s apparatus: i. ii. iii. iv. v. vi. vii. viii. ix. x. Air bleed screw Monometer tubes Unions Gland nuts Test section Water inlet Hypodermic probe Water outlet Flow control valve Tapping Points Department Of Civil Engineering UET Peshawar 33 FINAL LAB. REPORT FLUID MECHANICS-II (LAB.) 9.4. Procedure: Close the inlet and outlet valves. Open the air bled screw before starting the experiment. Slowly open inlet valve and the water will rise in the manometer tube and will escape through air bled screw. Adjust the pressure in the pipes to remove the air bubbles by several trials. Adjust the pressure heads in the tubes. Find the actual static head with the help of the scales attached to the back of the tubes. Find the total actual head by using gland nut at each of the tapping points. Actual velocity head is calculated is from the above two heads. Theoretical static head is calculated as follows: 𝒑𝟐 𝒑𝟏 𝒗𝟏 𝟐 𝒗𝟐 𝟐 = + − 𝜸 𝜸 𝟐𝒈 𝟐𝒈 The theoretical velocity head is given by: 𝒗𝟐 𝟖(𝒗𝒐𝒍. )𝟐 = 𝟐 𝟐 𝟒 𝟐𝒈 𝝅 𝒈𝒕 𝑫 Theoretical total head is equal to the sum of these two heads. 9.5. Observations and Calculations: Table No. 09: Tapping Actual Actual Actual Theoretical position static velocit total static/pressu head y head head re head Theoretical Velocity head Theoretic al total head Head loss b/w two point s Total head loss up to point s A 244 2 246 244 3.3 247.3 1.3 1.3 B 209 36 245 209 34.2 243.2 4.1 5.4 C 150 94 244 150 65.5 220.4 22.8 28.2 D 143 98 241 143 97.4 240.4 20 48.2 E 92 147 239 92 127 219 21.4 69.6 F 132 33 165 132 33 165 54 123.6 Department Of Civil Engineering UET Peshawar 34 FINAL LAB. REPORT FLUID MECHANICS-II (LAB.) Experiment No. 10 “To determine the relationship between head loss due to friction and velocity of the flow of water through smooth bore pipe” 10.1. Objective: To study the laminar flow and turbulent flow. With the help of this experiment we can determine the head loss due to friction at different velocities and eventually obtain the relationship between these two parameters. 10.2. Theoretical background Head: Head is defined as the energy of the fluid per unit weight of the fluid and its unit is “meter (m)” in S.I. Head loss: Head loss due to friction is the loss of the head of fluid while flowing through a pipe (i.e. smooth pipe in present case) due to the viscous effect in the fluid. The relationship for head loss due to friction is given by Darcy Weisbach; 𝒉𝒇 = 𝒇𝑳𝒗𝟐 𝑫𝟐𝒈 Head loss and velocity relationship: Its relationship depends on the type of the flow i.e. whether the flow is laminar or turbulent. For laminar the relationship is given by; 𝒉𝜶𝒗 For turbulent flow the relationship is given by; 𝒉 𝜶 𝒗𝒏 10.3. Apparatus: Fluid friction apparatus Hydraulic bench Stop watch Thermometer 10.4. Parts of the fluid friction apparatus: Smooth bore pipe Artificially roughened pipe Department Of Civil Engineering UET Peshawar 35 FINAL LAB. REPORT FLUID MECHANICS-II (LAB.) Long and short radii bends Y, elbow and T-joints Sudden contraction Sudden enlargement Transparent pipe section with pitot tube Transparent venturi meter Transparent orifice meter Ball valve Isolating valve Globe valve Control valve Gate valve Water inlet and outlet Strainer Pressure tapping points Tubing and connectors Flexible tubes and monometer FIGURE 17: FLUID FRICTION APPARATUS Department Of Civil Engineering UET Peshawar 36 FINAL LAB. REPORT FLUID MECHANICS-II (LAB.) 10.5. Procedure: First of all remove air from pipes i-e open all valves Now close all valves except the pipe under observation Close the screw above the mercury manometer such that all air is removed Close the isolating valve Not the head loss from the difference in mercury column of mercury manometer Measure the discharge of water from outlet by graduated beaker and stopwatch. Increase the velocity of flow from inlet control valve and repeat the process again Thus we can observe that by increasing the velocity of flow of water, the head loss increase. 10.6. Observation and Calculations: Table No. 10: S.no 1 Diameter(mm) 2 3 1 6mm 2 3 1 10mm 2 3 17mm Volume(lit) 1 1 2 10 10 10 10 20 20 Time(sec) 43.7 8 25.9 9 44.02 76.17 56.65 43.09 21.72 29.68 25.36 Discharge(lit/sec ) .023 .038 5 .0454 .131 .176 .232 .46 .67 .78 Velocity(m/sec) .801 1.36 1.61 1.67 2.25 2.25 2.03 2.97 3.48 Reynolds No 5757 9729 1147 1 20,47 6 26,75 0 35,17 9 41,08 5 6010 7 7034 8 Friction factor(f) .036 .031 .029 .0256 .024 .0225 .0217 .0199 .0192 Measured head loss(mm) 198 490 653 365 617 1000 456 895 252 Calculated head loss(mm) 130 241 351 142 184 295 84 348 397 Department Of Civil Engineering UET Peshawar 37