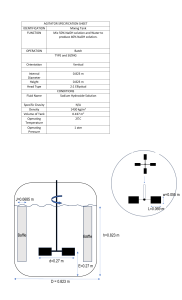

1 Ethiopian Defence University College of Engineering Department of Chemical Engineering MECHANICAL UNIT OPERATIONS (ChEg 3331) by Ashagrie L. (MSc, Chem.Eng.) Chapter Five 2 Mixing and Segregation Contents: • Liquid-Liquid Mixing • Solid-Solid Mixing • Solid-Liquid Mixing • Segregation causes, mechanisms, and its reduction Introduction 3 Many operations depend upon effective agitation and mixing of fluid or solid particles (components). Though often confused, agitation and mixing are not synonymous of each other, both having different meaning. Mixing is defined as: The reduction of inhomogeneinty in order to achieve a desired process result. Any operation used to change a non- uniform system into a uniform one (i.e., the random distribution of two or more initially separated phases). 4 A unit operation that aims to treat two or more components, initially in an unmixed or partially mixed state, so that each unit (particle, molecule, etc.) of the components lies as nearly as possible in contact with a unit of each of the other components. Main aim of the mixing process is the production of a blend whose sample reflects exactly, or at least by pre-defined accuracy, the ratio of the added base materials. In industrial process engineering, mixing is a unit operation that involves manipulation of a heterogeneous physical system with the intent to make it more homogeneous. 5 A single homogeneous material such as water in a tank can be agitated but not mixed until another material is added to tank. Concerned with all combinations of phases of which the most frequently occurring ones are: Gases with Gases. Gases into Liquids: Dispersion. Gases with Granular solids: fluidization, pneumatic conveying; drying Liquids into Gases: Spraying. Liquids with Liquids: Dissolution, Emulsification, Dispersion. 6 Liquids with Granular solids: Suspension. Pastes with each other and with Solids. Solids with Solids: Mixing of powders. Objectives of Mixing: Simple Physical Mixture: Simply the production of a blend of two or more miscible liquids or two or more uniformly divided solids. Physical Change: Mixing may aim at producing a change that is physical. The solution of a soluble substance. Lower efficiency of mixing will often be acceptable. Dispersion: dispersion of two immiscible liquids to form an emulsion or the dispersion of a solid in a liquid to give a suspension or paste. 7 Promotion of Reaction: Mixing will usually encourage (and control at the same time) a chemical reaction, so ensuring uniform products. Products or processes where accurate adjustment to pH is required and the degree of mixing will depend on the process. Usually good mixing is required to ensure stability. Agitation refers to: The induced motion of a material in a specified way, usually in a circulatory pattern inside some sort of container. whereby mixing of phases can be accomplished and by which mass and heat transfer can be enhanced between phases and with external surfaces. 8 Forcing a fluid by mechanical means to flow in a circulatory or other pattern inside a vessel. Whereby mixing of phases can be accomplished and by which mass and heat transfer can be enhanced between phases or with external surfaces. Agitation of Liquids Purposes of Agitation: Liquids are agitated for a number of purposes, depending on the objectives of the processing step. These purposes include: 1. Suspending solid particles 2. Blending miscible liquids, e.g., methyl alcohol and water. 3. Dispersing a gas through the liquid in the form of small bubbles 9 4. Dispersing a second liquid, immiscible with the first, to form an emulsion or suspension of fine drops. 5. Promoting heat transfer b/n the liquid and a coil or jacket. Agitation Equipment Generally, liquids are agitated in a cylindrical vessel which can be closed or open to the air. The height of liquid is approximately equal to the tank diameter. An impeller mounted on a shaft is driven by an electric motor. 10 Three-blade Propeller Agitator. The propeller can be a side-entering type in a tank or be clamped on the side of an open vessel in an off-center position. These propellers turn at high speeds of 400 to 1750 rpm and are used for liquids of low viscosity. The flow pattern in a baffled tank with a propeller positioned on the center of the tank shown below. This type of flow pattern is called axial flow since the fluid flows axially down the center axis or propeller shaft and up on the sides of the tank as shown. 2. Paddle agitator. Various types of paddle agitators are often used at low speeds b/n about 20 and 200 rpm. Two-bladed & four-bladed flat paddles are often used, as shown in fig. 5.2(a). 1. 11 Fig. (5.1) Baffled tank and 3-blade propeller agitator with axial-flow pattern: (a) Side view, (b) bottom view, 12 The total length of the paddle impeller is usually 60 to 80 % of the tank diameter and the width of the paddle 1/6 to 1/10 of its length. At low speeds mild agitation is obtained in unbaffled vessel. At higher speeds baffles are used, since, without baffles, the liquid is simply swirled around with little actual mixing. The paddle agitator is ineffective for suspending solids since good radial flow is present but little vertical or axial flow. An anchor or gate paddle (Fig. 5.2b), is often used. It sweeps or scraps the tank walls and sometimes the tank bottom. It is used with viscous liquids where deposits on walls can occur and to improve heat transfer to the walls. However, it is a poor mixer. These are often used to process starch pastes, paints, adhesives, and cosmetics. 13 Fig. (5.2) various types of agitators: (a) four-blade paddle, (b) gate or anchor paddle, (c) six-blade open turbine, (d) pitched-blade (45o) turbine. 14 3. Turbine Agitators. Turbines that resemble multibladed paddle agitators with shorter blades are used at high speeds for liquids with a very wide range of viscosities. The diameter of a turbine is normally b/n 30 and 50 % of the tank diameter. Normally, the turbines have 4 or 6 blades. The turbines with flat blades give radial flow. They are also useful for good gas dispersion where the gas is introduced just below the impeller at its axis and is drawn up to the blades and chopped into fine bubbles. In the pitched-blade turbine with the blades at 45o, some axial flow is imparted so that a combination of axial and radial flow is present. This type is useful in suspending solids since the currents flow downward and then sweep up the solids. 15 Fig. (5.3) Baffled tank with 6-blade turbine agitator with disk showing flow patterns: (a) side view, (b) bottom view, (c) dimensions of turbine and tank. 16 4. Helical-ribbon agitators. This type of agitator used in highly viscous solutions and operates at a low RPM in the laminar region. The ribbon is formed in a helical path and is attached to a central shaft. The liquid moves in a tortuous flow path down the center and up along the sides in a twisting motion. Similar types are the double helical ribbon and the helical ribbon with a screw. 5. Agitator selection and viscosity ranges. The viscosity of the fluid is one of several factors affecting the selection of the type of agitator. Indications of the viscosity ranges of these agitators are as follows. 17 Propellers are used for viscosities of the fluid below about 3 Pa.s; turbines can be used below about 100 Pa.s, modified paddles such as anchor agitators can be used above 50 Pa.s to about 500 Pa.s; helical and ribbon-type agitators are often used above this range to about 1000 Pa·s and have been used up to 25000 Pa·s. For viscosities greater than about 2.5 to 5 Pa·s and above, barnes are not needed since little swirling is present above these viscosities. Flow Patterns in Agitation 18 The flow patterns in an agitated tank depend upon the fluid properties, the geometry of the tank, types of barnes in the tank, and the agitator itself. If a propeller or other agitator is mounted vertically in the center of a tank with no barnes, a swirling flow pattern usually develops. Generally, this is undesirable, because of excessive air entrainment, development of a large vortex, surging, and the like, especially at high speeds. To prevent this, an angular off-center position can be used with propellers with small horsepower. However, for vigorous agitation at higher power, unbalanced forces can become severe and limit the use of higher power. 19 For vigorous agitation with vertical agitators, barnes are generally used to reduce swirling and still promote good mixing. Barnes installed vertically on the walls of the tank are shown in Fig. 5.3. The turbine impeller drives the liquid radially against the wall, where it divides, with one portion flowing upward near the surface and back to the impeller from above and the other flowing downward. Sometimes, in tanks with large liquid depths much greater than the tank diameter, two or three impellers are mounted on the same shaft, each acting as a separate mixer. 20 The bottom impeller is about 1.0 impeller diameter above the tank bottom. In an agitation system, the volume flow rate of fluid moved by the impeller, or circulation rate, is important to sweep out the whole volume of the mixer in a reasonable time. Also, turbulence in the moving stream is important for mixing, since it entrains the material from the bulk liquid in the tank into the flowing stream. Some agitation systems require high turbulence with low circulation rates, and others low turbulence and high circulation rates. This often depends on the types of fluids being mixed and on the amount of mixing needed. Typical “Standard" Design of Turbine 21 The turbine agitator shown in Fig. 8.3 is the most commonly used agitator in the process industries. For design of an ordinary agitation system, this type of agitator is often used in the initial design. The geometric proportions of the agitation system which are considered as a typical "standard" design are given in Table 1. These relative proportions are the basis of the major correlations of agitator performance in numerous publications (See Fig.5.3c for nomenclature). In some cases W/ DA = 1/8 for agitator correlations. The number of Barnes is 4 in most uses. Power Used in Agitated Vessels 22 In the design of an agitated vessel, an important factor is the power required to drive the impeller. Since the power required for a given system cannot be predicted theoretically, empirical correlations have been developed to predict the power required. The presence or absence of turbulence can be correlated with the impeller Reynolds number NRe defined as: NRe = DA2Nρ/μ Where D. is the impeller (agitator) diameter in m, N is rotational speed in rev/s ρ is fluid density in kg/m3 and μ is viscosity in kg/m·s. 23 The clearance or gap between the baffles and the wall is usually 0.10 to 0.15 J to ensure that liquid does not form stagnant pockets next to the baffle and wall. In a few correlations the ratio of baffle to tank diameter is J /DT = 1/10 instead of 1/12. Geometric proportions for a “standard” Agitation system, DA/DT = 0.3 to 0.5, H/DT = 1, C/DT = 1/3, W/DA = 1/5, L/DA = 1/4, J/DT = 1/12. H: Depth of liquid, DT: Tank diameter, DA: Impeller diameter, L: Blade length, W: Impeller width, J: Width of baffle, C: Clearance. 24 The flow is laminar in the tank for Nre < 10, turbulent for NRe > 104, and for a range between 10 and 104, the flow is transitional, being turbulent at the impeller and laminar in remote parts of the vessel. Power consumption is related to fluid density ρ, fluid viscosity, μ rotational speed N and impeller diameter DA by plots of power number NP versus NRe. The power number is: NP = P/ρN3DA5 Where, P = power in J/s or W. 25 Figure 5.4 is a correlation for frequently used impellers with Newtonian liquids contained in baffled, cylindrical vessels. Dimensional measurements of baffle, tank, and impeller sizes are given in Fig. 5.3c. these curves may also be used for the same impellers in unbaffled tanks when NRe is 300 or less. When NRe is above 300, the power consumption for an unbaffled vessel is considerably less than for a baffled Vessel. Curves for other impellers are also available. Curve 1. Flat six-blade turbine with disk (like Fig.8.3 but six blades); DA/W = 5; four baffles each DT/J = 12. 26 Fig 5.4: Power correlations for various impellers and baffle 27 Curve-2. Flat six-blade open turbine (like Fig.5.2e); DA/W = 8; four baffles each DT/J =12. Curve-3. Six-blade open turbine bile blades at 45° (like Fig.8.2d); DA/W = 8; four baffles each DT/J = 12. Curve-4. Propeller (like Fig.5.1); pitch = 2DA; four baffles each DT/J=10; also holds for same propeller in angular off-center position with no baffles. Curve-5. Propeller; pitch = DA; four baffles each DT/J = 10; also holds for same propeller in angular off-center position with no baffles. Examples 28 1. A flat-blade turbine agitator with disk having six blades is installed in a tank similar to fig. 8.3. The tank diameter, DT is 1.83 m, the turbine diameter, DA is 0.61 m, DT = H, and the width, W is 0.122 m. The tank contains four baffles, each having a width J of 0.15 m. The turbine is operated at 90 rpm and the liquid in the tank has a viscosity of 10 cp and a density of 929 kg/m3. (a) Calculate the required kW of the mixer. (b) For the same conditions, except for the solution having a viscosity of 100,000 cp, calculate the required kW. Solution 29 The following data are given: D = 0.61 m, W = 0.122 m, DT = 1.83 m, J = 0.15 m, N = 90/60 = 1.50 rev/s, ρ = 929 kg/m3, and μ = (10 cp) (1x10-3) = 0.01 kg/m.s = 0.01pa.s. The Reynolds number is (a) NRe = DA2Nρ/μ = (0.61)2(1.5)929/0.01 = 5.185 x 104 Using curve 1 in Fig. 5.4 since DA/W = 5 and DT/J = 12, NP = 5 for NRe = 5.185 x 104. Solving for P in, NP = P/ρN3DA5 and substituting known values, P = (NP) (ρN3DA5) = 5(929) (1.5)3(0.61)5 = 1324 J/s = 1.324 kW 30 (b) μ = 100,000(1 x 10-3) = 100 kg/m.s NRe = (0.61)2(1.5)929/100 = 5.185 This is in the laminar flow region, from fig. 8.4, NP = 14 P = 14(929) (1.5)3(0.61)5 = 3707 J/s = 3.71 kW Hence, a 100,000 fold increase in viscosity only increases the power from 1.324 to 3.71 kW Variations of various geometric ratios from the standard design can have different effects on the power number NP in the turbulent region of the various turbine agitators as follows For the flat six-blade open turbine, NP ≈ (W/DA) 31 For the flat, six-blade open turbine, varying DA/DT from 0.25 to 0.50 has practically no effect on NP. With two six-blade open turbines installed on the same shaft and the spacing b/n the two impellers (vertical distance b/n the bottom edges of the two turbines) being at least equal to DA, the total power is 1.9 times a single flat-blade impeller. For two six-blade pitched-blade (45o) turbines, the power is also about 1.9 times that of a single pitched-blade impeller. A baffled vertical square tank or a horizontal cylindrical tank has the same power number as a vertical cylindrical tank. However, marked changes in the flow patterns occur. 32 The power number for a plain anchor-type agitator similar to fig. 8.2b but without the two horizontal cross bars is as follows for NRe < 100: NP = 215(NRe)-0.955 Where DA/DT = 0.90, W/DT = 0.10, and C/DT = 0.05 The power number for a helical ribbon agitator for very viscous liquids for NRe < 20 is as follows: NP = 186(NRe)-1 (agitator pitch/tank diameter = 1) NP = 290(NRe)-1 (agitator pitch/tank diameter = 0.5) The typical dimensional ratios used are DA/DT = 0.95, with some ratios as low as 0.75, and W/DT = 0.095. Mixing of Solids 33 The mixing of solids, whether free flowing or cohesive, resembles to some extent the mixing of low-viscosity liquids. Both processes intermingle two or more separate components to form a more or less uniform product. Some of the equipment normally used for blending liquids may, on occasion, be used to mix solids. Yet there are significant differences between the two processes. Liquid blending depends on the creation of flow currents, which transport unmixed material to the mixing zone adjacent to the impeller. In heavy pastes or masses of particulate solids no such currents are possible, and mixing is accomplished by other means. 34 In consequence, much more power is normally required in mixing pastes and dry solids than in blending liquids. Another difference is that in blending liquids a "well-mixed" product usually means a truly homogeneous liquid phase, from which random samples, even of very small size, all have the same composition. In mixing pastes and powders the. product often consists of two or more easily identifiable phases, each of which may contain individual particles of considerable size. Power Requirements 35 Large amounts of mechanical energy are needed to mix heavy plastic masses. In continuous mixers the material must also be moved through the machine. Only part of the energy supplied to the mixer is directly useful for mixing, and in many machines the useful part is small. Probably mixers that work intensively on small quantities of material, dividing it into very small elements, make more effective use of energy than those that work more slowly on large quantities. Machines that weigh little per pound of material processed waste less energy than heavier machines. Regardless of the design of the machine, however, the power needed to drive a mixer for pastes and deformable solids is many times greater than that needed by a mixer for liquids. Criteria of Mixer Effectiveness 36 The energy supplied appears as heat, which must ordinarily be removed to avoid damaging the machine or the material. The performance of an industrial mixer is judged by the time required, the power load, and the properties of the product. Both the requirements of the mixing device and the properties desired in the mixed material vary widely from one problem to another. Sometimes a very high degree of uniformity is required; sometimes a rapid mixing action; sometimes a minimum amount of power. The degree of uniformity of a mixed product, as measured by analysis of a number of spot samples, is a valid quantitative measure of mixing effectiveness.