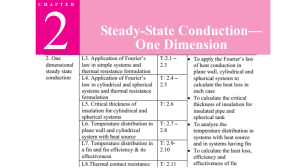

CHENG 314 Heat Transfer Dr. Zakir Hossain E.mail: zhossain@uob.edu.bh Office: 15-312 Tel: 1787-6374 Department of Chemical Engineering University of Bahrain 1 2 Part 1 1-Dimensional, Steady-State Conduction without Heat Generation 3 The Plane wall Consider a plane wall between two fluids of different temperature. Heat flux and heat rate: dT k q k (T T ) dx L " x s ,1 s,2 dT k A q k A (T T ) dx L x s ,1 s,2 4 Wall g KAT2) = R - Plain wall En = cylindrical qu = 2πkT2) > - cylindrical wall 1/2) -e & & ↑ I P Inue = o o resistance solid Cylinder spherican qV = 4 πK(T1 - T2) (i i) TT R R = (I - -2) /YπK & Uz - V - 4πkv , Vz R = R = > - Plain wall MV) > - Cylindrical 2πkL R = r-r - > - spherical ukrivz - The Plane wall Thermal Resistances and Thermal Circuits qx k A ΔT q R T T L L k A x t , cond . R t ,cond . thermal resistance L kA ohn' s law, i T q h A T 1 h A R conv t ,conv . V R 1 hA Radiation resistance R t , rad . 1 R h A rad h T T r s surr " t , rad . 1 h T T 2 s rad 2 surr 5 The Plane wall Thermal circuit for plane wall with adjoining fluids: R t , total 1 L 1 h A kA h A 1 2 (T T ) T q R R ,1 ,2 x t , total t , total 6 6 Thermal resistance for unit surface area: R " t , cond . L k R " t , conv . 1 h 7 Composite Wall k A k A k A T T T T T T q x x x A B 1 C 2 2 A 3 3 B 4 C Solving each equation for ΔT x T T q k A x T T q k A A 1 B 2 2 A 3 B T T q 3 4 x k A C C Adding the equations for T1 – T2, T2 – T3, and T3 – T4, the final rearranged equation is q cond T T x x x k A k A k A 1 4 A A q cond B T T R R R 1 A C B 4 B C T T q R 1 C 4 8 Composite Wall T T T T T T T T T T q R R R R R ,1 s,1 s,1 2 2 3 3 s,4 ,4 s,4 x 1 q 2 T T R R R s ,1 cond 2 q T 4 5 s,4 3 4 T R ,1 x 3 ,4 total R total 11 L L L 1 Ah k k k h 1 A B C A B C 4 9 Series – Parallel Composite Wall Writing Fourier's equation for each solid and summing; ΔT T1 T2 q Rt RE RF RG RH RF RG L R kA i i i i 10 Overall Heat Transfer Coefficient q x h1 A(T,1 Ts,1) kA / L(Ts,1 Ts,2 ) h2 A(Ts,2 T,2 ) Overall HT: q Toverall (1) 1 L 1 h1 A kA h2 A The overall HT by combined convection and conduction is expressed in terms of overall HT coefficient, U (analogus to newton’s law of cooling) q UAToverall (2) From eq 1 & 2 1 U 1 / h1 L / k 1 / h2 11 Radial System- Cylinder Fourier's law for radially form q dT k A dr The cross-sectional area normal to the heat flow is : A = 2 π r L q dr k dT 2πL r q r2 Ts, 2 r1 Ts, 1 2π L k (T T ) r ln r s, 1 s, 2 2 1 q (T T ) (T T ) R r ln r 2π k L s, 2 s, 1 s, 2 s, 1 2 1 r2 ln r1 where, R t, cond 2πk L 12 Radial System- Cylinder q (T,1 T,2 ) R 13 Composite Cylindrical Wall qt (T,1 T,4 ) UA(T,1 T,4 ) R Note that UA Rtot 1 is a constant independent of radius, 14 Radial System-Hollow Sphere Fourier's law for radially form q dT k A dr The cross-sectional area normal to the heat flow is: A = 4 π r2 q t 4π k T T 1 1 r r s,1 1 2 s,2 15 Spherical Shell q t T T s,1 s,2 R t R t, cond 1 1 r r 4π k 1 2 r2 r1 R t, cond 4 π kr2 r1 16 Contact Resistance Handhetrue RI RC Values depend on: Materials A and B, surface finishes, interstitial conditions, and contact pressure (Tables 3.1 and 3.2) q q TA TB T (x / kA) R TA TB T (x / k ) Rt,c Rt,c Rc = x (m 2 .k / W ) k · KA 17 Contact Resistance T1 T2 Tc1 k1 k2 Tc2 LA q LB T1 T2 LA LB Rt ,c k1 k2 18 Contact Resistance 19 Critical Thickness of Insulation insulation Consider a metallic cylinder pipe with high thermal conductivity, radius r1 and a fixed length of L. the cylinder is covered with a layer of insulation. The inside wall temperature is T1 and is exposed to an environment at To. K r2 To r1 ho q T1 T2 Does adding more insulation with a thermal conductivity of k will decrease/increase the heat transfer rate? 20 Critical Thickness of Insulation To determine this, we write the equation of q using the two resistance, assuming the drop in temperature within the metallic wall is negligible (i,e . Twi = Two = T1) q 2 π L (T1 To ) r2 ln r1 1 k r2 h o 21 Critical Thickness of Insulation To determine the effect of thickness of insulation on q, we take the derivative of q with respect to r2, equate this result to zero, and obtain the following maximum heat flow dq dr2 - 2 π L (T1 To ) ( 1 1 2 ) r2 k r2 h o r2 ln r 1 1 k r2 h o 2 0 solving r k 2 crit. h (r2)crit is the critical radius when q is maximum o 22 Critical thickness of insulation Ronv q dominant > - Rins R cond dominant Uz (a) If the outer radius r2 is less than rcrit then adding more insulation will actually increase q. (b) If the outer radius r2 is greater than rcrit then adding more insulation will decrease q. 23 What happens when adding more insulation to wall, cylinder and spherical shell Wall: We know that adding more insulation to a wall always decreases heat transfer. The thicker the insulation, the lower the heat transfer rate. This is expected, since the heat transfer area A is constant, and adding insulation always increases the thermal resistance (due to increases of L) of the wall without increasing the convection resistance. Cylinder & Sphere Adding insulation to a cylindrical pipe or a spherical shell, however, is a different matter. The additional insulation increases the conduction resistance of the insulation layer but decreases the convection resistance of the surface because of the increase in the outer surface area for convection. The heat transfer from the pipe may increase or decrease, depending on which effect dominates. 24 • Part 2 General Heat Equation with and Without Heat source (Chap 2 +Chap 3) 25 Multidimensional Conduction • Scalar quantity vs Vector quantity -scalar: measure magnitude - Vector: measure both magnitude and direction • • Heat flux is a vector quantity • General statement of conduction rate equation: Where is the 3D del operator and T(x, y, z) is the scalar temperature field 26 Heat Flux Components T x, y , z T T T q k i k jk k x y z • Cartesian Coordinates: q x (2.3) q z q y • Cylindrical Coordinates: T r , , z T T T q k i k jk k r r z qr q (2.24) q z • Spherical Coordinates: T r , , T T T q k i k jk k r r r sin qr q (2.27) q 27 General Heat Equation or Heat Diffusion Equation • Wish to know the T distribution, which represents how T varies with position in the medium. • A differential equation whose solution provides the temperature distribution in a stationary medium. • Cartesian Coordinates: E in E out E g E st 28 General Heat Equation • Cartesian Coordinates: one dimensional constant property ↑ My Cancels if / T T T T k k k q c p x x y y z z t Net transfer of thermal energy into the control volume (inflow-outflow) Thermal energy Ex() generation = no heat generation steady state (2.19) Change in thermal energy storage 0 Where 29 > - find distribution T Assumptions Steady-state 1 En(tt) 2 E /GT) + = = B C . . 1 . 2 T : Tz : Substract T - = dimensional one . constant 3. It end Integration . 2 property - st integration B2 0 . -q x T = 4 - 2 = = = - + xt + + 4x a 2 4, L + egl -e92 T2 4 = 0 24 , L - T T TE = 2L - T - TET - = c = T + TT + e . 12 - TET 222 + x = - T= TI L L > - & - C I B 2k · O L B - C . 2 X = L TITZ > - When T1 T = E 2k > - find To = T2 = TS 11 -22) s + delta To = E + s • Cylindrical Coordinates: 1 T 1 T T T kr k k q c p r r r r 2 z z t (2.26) where 30 • Spherical Coordinates: 1 2 T 1 T 1 T T kr k k sin q c p r r 2 sin 2 r 2 sin t r 2 r (2.29) where 31 Assume : state steady > > - one > - no · dimensional T heat generation property T2 constant > - - one ⑳o 1 /kr22) E(22 dimensional 0 = 1st Integration : 0 ~ ST C = - da # = and Integration T -1 = + (2 V V T+ C : = I z > - general Solution r2 B. C 1 : . T = = -4 + , T = C2 T - - 2/ B C . . 2 V = V2 : T2 T -T2 = T= , Tz ET V2 heatouration steady State 22 = vo subtract T - T2 c = 4)-tc) = Substitute substitute i T C in , and TAt Equation c in + I or general 2 solution The Heat Equation-Special cases • One-Dimensional Conduction in a Planar Medium with Constant Properties and No Generation T T k c p x x t becomes 2T x 2 1 T t k thermal diffusivity of the medium m 2 /s c p ↑ 32 Boundary and Initial Conditions • For transient conduction, heat equation is first order in time, requiring specification of an initial temperature distribution: T x,t t=0 = T x,0 • Since heat equation is second order in space, two boundary conditions must be specified. Some common cases: Constant Surface Temperature: T 0,t = Ts Constant Heat Flux: Applied Flux -k T |x=0= qs x 33 Boundary and Initial Conditions Convection: -k T |x=0= h T - T 0,t x Insulated Surface T |x=0= 0 x 34 1 2 3 One dimensional . steady state Uniform properties . . Y No . T generation heat g TX N /kuz) G(r(t) Integration 0 = = 0 C : = ST 2nd I = Tr Integration J Plnr T= : B C . I <2 + - . V= V Econd , conv = kd = h/T +) - di k2 c = = h(TX T) - hv Th x , - k 4 = 4 B. C . i TS cylinder Is t V = h (To -[414 (2) c (n r , n) , T - 2 T V = Vz = Ts (, / = C2 = Ts TS U2 + (2 -clnUz + 2 general Solution 4 h = 4k (T1-414 TX = 4 lur - - - T+ TS + c , /NU <Inrz hu 4k 4 4 /InVz -Invi) + R = 4lV2) - 4) K - = T= = T 122) as Tx-TS inve Inv -In T = U + is i TI InrlInv It 4r / T = Un TATSnr - UV In -FGsInin e -Inv is a / E) + Ts T distribution e Boundary and Initial Conditions Radiation: Interface B.C: 35 Temperature Distribution in ID, SS Plane wall with no Heat generation • Consider a plane wall between two fluids of different temperature: Heat Equation: • d dT k 0 dx dx (3.1) General solution: T(x)=C1x + C2 X=0 Boundary Conditions: • • x=L T 0 Ts ,1, T L Ts ,2 Temperature Distribution for Constant k K : x T x Ts ,1 Ts ,2 Ts ,1 L (3.3) 36 Temperature Distribution in ID, SS Plane wall with no Heat generation T x Ts ,1 Ts ,2 Ts ,1 x L Heat flux qx is independent of x. Heat rate qx is independent of x. 37 Temperature Distribution in ID, SS Plane wall with Heat generation Heat flux, q and heat rate, q x x is independent of x or not ? Prove it 38 General Heat conduction equation: T T T T k k k q c p x x y y z z t Assumption: SS, 1D, constant properties . d dT q 0 dx dx k Integrating once with respect to x yield . q dT x C1 k dx Integration once again, we obtain . T(x ) q 2 x C1 x C2 2k Where C1 and C2 are an arbitrary constants 39 If B. C. 1 1) x =0; T = Ts1 then C2=Ts1 2) x=L; T = Ts2 then Ts 2 . q L2 C1 L Ts1 2k . q 2 C1 Ts 2 Ts1 L / L 2k The temperature profile is: . T(x ) . q 2 Ts 2 Ts1 q x ( L) x Ts1 2k L 2k Non linear equation Note: Heat flux, q and heat rate, q x x are dependent on x 40 If B. C. 2 1) T(x =0) = T0 (center temperature) and, 2) T(x = -L) = Ts1 and T(x = L) = Ts2 , Then; T distribution If then T distribution . q 2 x2 T( x ) L 1 2 Ts 2k L The center temperature . q L2 T T o s 2k 41 Radial Systems Cylindrical (Tube) Wall Solid Cylinder (Circular Rod) • Heat Equations: Cylindrical 1 d dT kr q0 r dr dr Spherical Wall (Shell) Solid Sphere Spherical 1 d 2 dT kr q0 r 2 dr dr Temperature Distribution in SS cylindrical system Heat flux, q and heat rate, q x x is independent of r or not ? Prove it 43 Radial Systems; heat generation in a hollow cylinder When the cylinder is hollow, the boundary conditions are: at r = r1, T = T1 and at r = r2, T = T2 , and . q r 2 T (r ) C1 ln( r ) C2 4k which reduce to T1 r1 T2 r r2 r . . ln 2 2 2 2 q (r1 r ) q (r2 r1 ) r1 T (r ) T1 [(T1 T2 ) ] r1 4k 4k ln r2 44 Hollow cylinder with outside surface insulated (adiabatic) Te general solution for temperature distribution . q r 2 T (r ) C1 ln( r ) C2 4k (1) . dT q r C1 dr 2k r (2) The constants of the integration are determined from the relevant boundary conditions which are T = T1 at r = r1 and at r = r2 , the conduction region is perfectly insulated and hence heat flow, q=0 dT From Fourier’s law q k A dr and accordingly dT 0 at r = r2 dr 45 Applying the boundary conditions to expressions (1) and (2) , the general solution for temperature distribution becomes . r q (r12 r 2 ) 2 T (r ) T1 r2 ln 2k 2 r1 Apparently the temperature distribution is parabolic 46 Electrical to Thermal Energy Involves a local (volumetric) source of thermal energy due to conversion from another form of energy in a conducting medium. The source may be uniformly distributed, as in the conversion from electrical to thermal energy (Ohmic heating): I2 R q q V V . q Is the volumetric generation heat transfer rate = W/m 3 Generation affects the temperature distribution in the medium and causes the heat rate to vary with location, thereby precluding inclusion of the medium in a thermal circuit. 47 Radial Systems; heat generation in a solid cylinder . d (r dT ) q r dr dr k 0 Solid Cylinder (Circular Rod) Upon integration . r dT q r 2 C1 dr 2k (1) . and dT q r C1 dr 2k r . q r 2 T (r ) C1 ln( r ) C2 4k B.C. 1) r = 0, dT/dr = 0 ; then C1= 0 2) r=ro, T=Ts Solid Cylinder 48 Radial Systems; heat generation in a solid cylinder . q ro2 Ts C2 4k (2) . and ro2 q C 2 Ts 4k Now the temperature distribution is: . q ( ro2 r 2 ) T ( r ) Ts 4k 49 Radial Systems; heat generation in a solid cylinder The temperature at the center of the solid cylinder (r= 0) will be . 2 o r q To Ts 4k 50 Heat conduction equation in a sphere Consider a sphere with cylinder ρ, specific heat is C, and outer radius R, the area of the sphere normal to the direction of heat transfer at any 0 location is A= 4 π r2 where r is the value of the radius at that location. R r Note that the heat transfer area A depends on r in this case, and thus varies with location. Volume element Fig. 3 51 Heat conduction equation in a sphere One dimensional heat conduction equation for sphere (constant k) is determined to be 1 T r 0 r r r 2 2 After simplification T (r ) r1 r2 r r2 r1 T1 T2 r2 T2 r1T1 r2 r1 T1 T2 q sphere (4 π k r1 r2 ) r2 r1 52 Example 1 Find the heat transfer through the composite wall sketched. > - > - find Teand Ts Draw T-Profile .... 53 RA 1 = Ka A = 0 1 67 x . = RB 10-3 k/W 0 05 = . ox = o = PD /W 0 /2 = Rc 1 . 0 - k/w 01 . 0 = ot 0 = Reg K/W 0214 - RRP = RD 0 = . 05/0 0214) - 0 05 + 0 . ER Ra + = . 0 = q = . 0214 0 - 0149 + 0 01 - 02657 o = : Reg + Ra 1 67y 103 + = : 0 = /1400 = 370 0 W . - 66 02657 0149 k/W > - finding q Tz T = RA 11400 30To -3 = T2 = > - 350 finding E . ° 9 C TB T3T4 = RC 11400 T3 = = To e 180 ° L Example 2 54 Example (a) 2 v 525 = 22 V3 683 = 3 = King E ER 65 X10 m 3015x10 = m . 015 + 2 0 = 5 . 015x10-2 Wim k 43 = = T . . 150 = T3 04 m = % C 25 ° # = Assume ER R = . R2 + 2 = kpipe 2 = Pipe RPipe C= 1 m Rins + In = 2πk 3015x104/2 65X10 ) in = . = 4 26 x10 . 2π x 43 Rins Instea = In I 015x10 /3 015x10-2) (5. . 2πX 0 06 . q= 13 5 + I 92 58 . 4 776 x 10 . W/m - Y = 1 . 35 (b) < TT = 91 34 . 10 x10 = Tz pe = 149 . 50 C Example 3 Steam at T∞,1 = 320°C flows in a cast iron pipe (k = 80 W/m.K) whose inner and outer diameters are D1 = 5 cm and D2 = 5.5 cm, respectively. The pipe is covered with 3cm-thick glass wool insulation with k = 0.05 W/m.K. Heat is lost to the surroundings at T∞, = 5°C by natural convection and radiation with a combined heat transfer coefficient of h2 = 18 W/m2.K. Taking the heat transfer coefficient inside the pipe to be h1 = 60W/m2.K, 1) Determine the rate of heat loss from the steam per unit length of the pipe. 2) Also determine the temperature drops across the pipe shell and the insulation. 55 Example 3 1 TI TI T3 Fentantmum Ronr Tal 2 5/2 = 5/2 5 ~ 22 + = . Kins 5 0 = Pipe q . = . 75 Assume ( cr thickness - = 2 = RConvA2 <M . 2 75 + = Rins 2 5 = W2 = 3 Rpipe , 3 75 Cm . 05 Tai So Th2 = 320 ° 5 = 1 = 2R R Conv I = , > - Sconr he Al I I 60 x 2π X 2 5 x 10:2 = host . 0 = & Pipe . R 104 2πkL = 12 75/2 5) In . . - 2TTX 80 X = 1 84 x . t ha tri I = = 18 / -Y i R = 1 m Rins Inrscr l = in = (5 <5/2 75) . . + 1 x 0 05 2 2 I R Conve . . 35 L = H2Az ↳ I 18 X 2π U3L Fix 5C5x10-2 = 0 I E R q = . 154 2 61 . Tar-Tai = - ER I 5220 2 = - 120 61 Wim 2) find 9 > - T2 and T3 Tai-Te = - R CONVI 120 32 = 0 T1 > - 9 . 104 307 28 . = · T pe = 120 = e 308 - > - T2 = q = 307 26 . Y ° C TEB Rins 120 = B 307 . 35 2 Tz = 25 26 . · L Example 4: Problem 3.26 Stainless Steel (AISI): k= 25.4 W/m.K) Beryllium oxide: k= 21.5 W/m.K 56 898 Liquich Tx = ↓ = 2600 ° 50 I Taz w/m" . K h2 ki d k2 = K Ta 21 TH m" K/W 0 05 - . = 4 Wlmik 5 . 22 m = 25 . 4 TU T3 TI 20X10-3 = K2 RBO RONUI T22 Rss Rc R CONVz Do - I 2600 - 100 + 1 4/ A K, A + RC" + A + 50 = IA 1 naA 2500 -100-3 - 34,600 Wlmk + -entkat -Me & = m the M E wim 2. K SS 10x10 = 1000 = R BO H 100 ° = . 9 Wimt 0 05 + . 200 I 1000 find > - > - T2 , T3 , Th bubon = Ther e 150 T > - 1907 48 % . = 34600 4 . IT2 = 34600 9 190 e . Tz > - = 1891 9 = ° . C 34600 9 = * T3 I 34600 9 1891 9 . RC . = : T3 - - 0 T 3 > - 161 = 34600 9 . = . 86 : 05 oc TO0 R conv2 34600. 4 Ty = = o Th 134 6 . % C Example 5: Calculate heat loss per unit length of pipe using: a) Overall Ui b) Overall Uo c) Are the heat loss values same? 57 K kz = = Btu/h ft of 26 0 . . 037 Al - = = V2 -i no = Btu/hift of 2πVL πDL 2 A ITTV L = vo W steam Thi 261 of = m vi 1000 - = 22 Vo 0 ui Ai = = = - = . 216 f72 ITTVoL 2 iTx 0 1 : . . 062 169 f+ 2 n = /p fin = (1 5/12) : F Taz +MKM+M Pipe ins 00343 At 12 :N 169 ft CONVI 2πx 0 0343 . 0438 + + 2πTViL 0 ° . MK Y ERAi = = Ao * 269 . 0 = = 1 05 = I V2 + t = = UASA 0824 if / = Conve 00438 +t ↑ Conv , 1 = hi A ; I I = 4 63 x 10-3 . 1000 X 0 216 . R pipe (n/22/vi) = 2πKL In = 100438/00343) 1 49 . = x10-3 2πx 24 Rins Inoes = 2πKL 0438) 1069/0 - . 5 = . 81 2π X 0 037 . R conv2 1 = no to 1 = = 2 x 2π x 0 ER 169 6 284 = ni . . = 6 28 x 0 216 . . = Yo = = 0 . 737 . YER Ho Y 6 28 . = BtU/n +2 of 0 15 . x 1062 Btu/lft2 of 0 . 471 hi f/Btu Example 6 An electrical wire having a outer radius of insulation r1 = 1.5 mm and covered with a plastic insulation (thickness = 2.5 mm) is exposed to air at 300 K and ho = 20 W/m2.K. The insulation has a k of 0.4 W/m.k . It is assumed that wire surface temperature(T1) is constant at 400 K and is not affected by K r2 q To= 300 K r1 ho= 20 W/m2K T1 T2 covering. (a) Calculate the value of critical insulation. (b) Calculate the heat loss per m of wire length with no insulation (c ) Repeat (b) for the insulation present. 58 VI 1 5 Ve = (a) Ycrit mm . = = 1 5 + 2 5 . 4 = . mm 1 ins L 0 I . 04 - 20 0 02 I q (b) u . ~ AT = convection and 0 I mm only > - Rconv q 20 no insulation don't har we 2 r's Rond calculating /A E = I HOXITTU / q o I T L Y20x2πX 1 5x 10 = - Wim 18 8 . 3 . 400 (c) - Rins 300 + You ne = Ronv e 100 it > - Not + I 42 02 . = 20X2πX Ux10-3 good design because 2 z in umm f comm f < U crit wim for Example 7 Calculate the critical radius of insulation for asbestos [k = 0.17 W/m.K] surrounding a pipe and exposed to a room air at 20oC with h = 3 W/m2K. Calculate the heat loss from a 200oC, 5 cm diameter pipe when: 1) covered with the critical radius of insulation and 2) without insulation. 59 Ucrit Assume I = 3 = 2 I = 1)E . 056 5/2 n = V2 0 . 5 m 10 2 x Vcrit = m 0 056 m . # = R Conr + Rins Peo - is + no 2TTU2h + 2πkL -oooo 105 = 2) = = . 7 Win Extric 200 - 20 3 x 2T X 2 = 84 8 . . 5 xc0-2 wIm trixos e Im L Example 8 Use the following schematic process , calculate the heat loss per tube length and the outer temperature of the steel pipe: a) with no insulation and b) with insulation if the heat loss to the surrounding is reduced by 95% . T(i) ? Insulation k = 0.1 W/mK Steam T = 250oC h = 500 W/m2K SS pipe > ri ID = 60 mm > U2 OD = 75 mm k = 16 W/mK T (ii) ? Air, 20oC, 25 W/m2K 60 T2 =? Ti ? TXI + 4) Ronv , q TA : ER R convi Ronvz RPipe 1T = TX2 + m M Im 2 & RPipe Conr + RonV2 + HA = YuzTV L = , 1 - - 500XITTX30X10-3 Ppipe-Auris os = 0 . 0104 2 22x10-3 = . 2 TX /P R conv2 - = h2// -I L [sxTx3 5x10-3 . q 25020 = + 2 22 x 103 x 0 1 . 1260 = outer WIm temperature T22T = 16 0 - 1260 T2 = = IiG 234 ° C 6 = 0 . 1698 T = T = 234 250 T =? T = 20 TMFt Ronv , b) 1260x0 05 q WIm It = ↳ 63 = . RonV2 Rins RPipe ERO - RPipe + Rins + Ron an 63 250 = - 20 - Inuri) + K/A / 63 In + I heAz 230 = 0 . 2 0106 + 22x103 + 5 o Inr13 . using solver Us 0 = 6273 . 627 3 = Outer o 2πkzL . temperature 63 = = z 63 = /25 2πx x T = 20 64 . ° C 0 . 623 m mm - 25 x 2π x V3 x 10 3 Example 9: Exercise 2.3 Temperature Unit: in K 61 > - - & q(x T = ET qx = 1 2 9 + bx + = q 0 cx b+ = q = - KALI Ex = Elx = O - = = KA(b + 22x) kAb - - 9/x = = = 2 . - 1 = 40X10X-300 120 KW = - ka/b + 22) YOX101-300 - 100) 160 kW Ein-Eont + Eg = Est 120kW -160kw + 1000 40xmB , Est = -30 kw Kw te = Est . 3 = SCP * (10X1) It - 30kW I Ot = 1600 x 4 x 10 = - 4 : 67 x 10" K/s x It Ot m = Example 10: heat loss through a steam pipe Consider a steam pipe of length L = 20 m, inner radius r1 = 6 cm, outer radius r2 = 8 cm, and thermal conductivity k = 20 W/m.K (as in Fig. 2) . The inner and outer surface of the pipes are maintained at average temperatures of T1 = 150oC and T2 = 60oC, respectively. Obtain a general relation for the temperature distribution inside the pipe under steady state conditions, and determine the rate of heat loss from the steam through the pipe. Solution: the mathematical formulation of this problem can be expressed as 1 T r 0 r r r 62 VI = 6 Cm -2 = 8 Cm (v) (v) 1st = ↑ 0 W - 7 T= ° 20 steam & T= n 60 ° m C T Integration C rt = and Integration B- C . + Cl J (vc + C2 = General solution - 1 2 = V T = 150 ° I 150 = /NV1 150 = In = 150 C2 41 + C2 106) 4 + C2 In 10 06) CI . - . 2 B. C V = 22 T= , 60 ° C 60 = In U2C1 + C2 60 = In 10.08) < , + [150 - In 10063 (17 solver using 3/2 85 . c 22 = = T= - 312 . - = 150 - 85/Mr In 10 6) ( - 730 - . . - 3/2 . 85) 2 130 · 2 ↑ distribution . K 1 i 150 0 = ZowIm k= Example 11 A hollow cylinder (k = 30 W/mK) of inner radius 3 cm and outside radius 4.5 cm has a heat generation rate of 5×106 W/m3. the inner and outer surfaces are maintained at temperatures of 380oC and 360oC respectively. Determine the temperature at the mid radius. r . . ln 2 2 2 2 q (r1 r ) q (r2 r1 ) r1 T (r ) T1 [(T1 T2 ) ] r1 4k 4k ln r2 > - temp distribution equation 0.0375 ln 5 10 6 (0.03 0.03752 ) 5 10 6 (0.0452 0.032 ) 0.03 T (r 3.75 cm) 380 [(380 360) ] 4 30 4 30 0.03 ln 0.045 r = (3+4.5)/2 = 3.75 . 2 . T(r = 3.75 cm) = 373.69oC 63 Example 12 A hollow cylindrical conductor with r1 = 0.6 cm and r2 = 0.75 cm is made of a metal of thermal conductivity 17.5 W/m.K and electrical resistance of 2.5×10-2 Ω/m. Find the maximum allowable current if the temperature Tmax is not exceeding 48.5oC anywhere in the conductor. The cooling fluid at the inside is at 37.5oC. insulated . r q (r12 r 2 ) 2 T (r ) T1 r ln 2 2k 2 r1 Tmax occurs at the insulated surface, i.e. at the outside radius and is equal . r2 q (r12 r22 ) 2 48.5 Tmax T1 r ln 2 2k 2 r1 I . q 1584105 W m3 q.V R 64 Insulated B.C . hollow Cylinder C I ~ = VI Maximum TITI , 9 B. C . 82 Tnax/rere . FR M = . + + solver q 1584 x105 = 1564 x = /(2) + v In/v) is /1000600052) =T 634 9 . A + 6 - 0075 n Z WIm3 Volume-Tr, -To = = 40-2 = R/volume I Ct , 37 5 = using I = 2 ~ = 48 5 case = 0 = π(/v22 - TX//0 00152 - - 42) Example 13 An electric current of 200 A is passed through a stainless steel wire having a radius ro of 0.001268 m. the wire is L = 0.91 m long and has a resistance R of 0.126 Ω. The outer surface temperature Ts is held at 422.1 K. the average thermal conductivity is k = 22.5 W/m.K. calculate the center temperature. . q ro2 T0 T s 4k Since power = I2 R = q (Watt) . . 2 = q V q r L = 1.096 ×109 W/m3 q . q ro2 T0 T s 4k To = 441.7 K 65 Example 14 Consider a spherical container of inner radius r1 = 8 cm, outer radius r2 = 10 cm, and thermal conductivity k = 45 W/m.K (as in Fig. 3) . The inner and outer surface of the pipes are maintained at average temperatures of T 1 = 200oC and T2 = 80oC, respectively. Obtain a general relation for the temperature distribution inside the shell under steady state conditions, and determine the rate of heat loss from the steam through the container. Hints: the mathematical formulation of this problem can be expressed as 1 T r 0 r r r 2 2 66 -(v) (2) 1st = 0 = Integration 2 I : 21 = Of o and Integration . B T= : C = -1 + C2 - I . C V=V, T= , 200 T H = 0 (1 . 08 200 + = C2 + = 4 0 . 08 .C 2 B - V= - T= 1 2 U2 80 = - 4 + 0 80 - 1 -2 = using 22 + /200 C08] + solver c = 12 = - 48 200 - U8 - 0 08 . = T = 48-400 y - 400 T distribution general solution Acknowledgement 67 Cartesian Coordinates /167) 9 + Site) st Integration - = & -Exc = and Integration T - = - <2 o + <, K + 12 - general Solution o . ( B C . T = T T B C . . C2 = 2 T= T2 T2 = = - E + T2 ci T + / T2 = It + = = -[22 T L x= , - = 4 q" x = 0 , 1 + 942) 2 + kd dx = - k)-Zx + TET + Ite T T distribution o coordinates cylindrical (kv , ) q + = 0 (v) = 1st Integration UI - : Du T by and Integration Solid .C B . c * I r + I . c . E + Cylinder , U= 0 B c T Er = 0 0 = 2 V = Vo Ts T= , Ts -So = e (2 Ts + = T= -qu T Ts + = (V0 = + Uk ro is + - &e 22) ↑ distribution Cylinder Hollow Insulated . I B C . V = T B . C . VI T = , -Ev = Ti 4 Ini + 2 ~= 22 o - = c I , = o q Insulated - 0 = KAST = O = 0 - If I zr T 2 En e = ·FF- art & I e 2k 2 e F = -gr2 + q Inr + i + invi Ev -gr n e FFtCrrtEr/Mrndistribution Spherical coordinates 3 = -(kv2z) E(v2() = + = 1st Integration = - Af A and Integration T <3 + Cl 3k t Er = - 22 3k I = - qV - 6K -1 ↓ + <