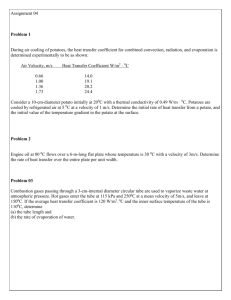

1 University of Balamand Faculty of engineering Department of Mechanical engineering INSTRUMENTATION AND EXPERIMENTATION 2 MECH244 – Fall 2022/2023 The Venturimeter Group 1 A report submitted to dr. Michel Daaboul Submitted by: Elias Jehi Hayat Jaber Michael Jdaidany Ryan Nasr 2 Table of Contents Abstract ........................................................................................................................................................ 4 Introduction and Objectives ....................................................................................................................... 5 Theoretical ............................................................................................................................................... 6 Test description ........................................................................................................................................... 7 Materials used ............................................................................................................................................. 8 Experimental procedure ............................................................................................................................. 9 Results and calculations .............................................................................................................................. 9 Conclusion/Discussion ............................................................................................................................... 14 References .................................................................................................................................................. 16 Appendix: ................................................................................................................................................... 17 3 List of Figures: Figure 1: A picture showing the tapings on the venturi as well as the direction of flow. ........................................................... 5 Figure 2: The apparatus. .............................................................................................................................................................. 7 Figure 3: Detailed picture of the valve. ....................................................................................................................................... 8 Figure 4: Graph showing the variation of the actual flowrate with respect to the theoretical flowrate. ................................... 11 Figure 5: Graph showing the variation of coefficient of discharge with respect to the actual flowrate.................................... 12 Figure 6: Graph showing the variation of Cp ideal, Cp actual, Q1 and Cp actual Q2 as a function of distance. ..................... 13 List of tables: Table (1): Table showing the collected data as well as the flowrates and discharge coefficients…….11 Table (2): Table showing the collected data as well as the different pressure coefficients.............. 13 4 Abstract: The fundamental goal of this experiment is to compare total volumetric flow rates at different periods while retaining the predicted theoretical flow rate in order to correlate them and quantify any errors. Then, calculate and compare the actual pressure distribution coefficient to the ideal coefficient to identify errors and improve the experiment. Following a study of the data, small errors were discovered due to human and instrument accuracy, resulting in deviations between projected and actual values. In the diverging zone, the pressure distribution coefficient changed slightly more than in the others. It was also determined that pressure is related to velocity, and the lowest pressure associated with the highest velocity was observed in the tube connecting to the venturi meter’s throat. 5 Introduction and Objectives: The goal of this experiment is to study the water flow in venturi to find its effect on the flow of water and its benefits for actual use in real life applications, by measuring pressure differentials, calculating the theoretical flow rates and comparing with the actual flow rates and check for errors. Figure 1: A picture showing the tapings on the venturi as well as the direction of flow. Historical: In 1797, the science behind this flow measurement device was reported by J.B Venturi in Italy. The main principle under which these devices function is that pressure is converted to velocity when the cross-sectional area of flow decreases. (Bernoulli equation). Bernoulli’s equation (dates back to 1738, which was documented by the swiss physicist Daniel Bernoulli. It explains the laws of motion of fluids commonly used in pipes with varying diameters. Mainly, when pressure drops the velocity increases and vice versa because this equation proves that the relation between these 2 factors is constant. 6 Theoretical: This formula is used to calculate the theoretical flow rates through the venturi With no losses and a steady flow, bernoulli’s equation requires (1) Due to flow continuity, (2) Equations (1) and (2) result in equation (3), And (4) is the rearrangement of (3) And finally, due to equation (2) as well as equation (4), Q is determined as in the main equation above. This formula calculates the local pressure coefficient along the axis of a venturi. Q: volumetric flow rate V: velocity h: height of water in venturimeter tube A: area in the pipe p: pressure 7 P(rho): density. [1], [2], [3]. Test description: The apparatus that we have used to perform this experiment is "the venturi meter", which is a machine that is composed from a number of tubes with water flowing through them showing different levels of pressure distribution to show different pressure differentials. Each set of tubes represent a section of the venturi meter, and they are divided into 3 sections which will be explained furthermore into the report. Figure 2: The apparatus. 8 Materials used: Manometer Tubes Manifold Safety Valve Gate Valve Venturimeter Tank Water Cellphone’s stopwatch Figure 3: Detailed picture of the valve. Using these instruments, we need to get the values of the static pressure in all the different tubes and the flow rate. Concerning the conditions, this experiment was done in normal conditions meaning at atmospheric pressure and the water at room temperature. 9 Experimental procedure: This experiment was divided into two sections, and for each we had a different goal and a different procedure that we have followed. These sections are "Flow Rate Measurement" and "Pressure Distribution". Flow Rate Measurement: Before turning on the pump, we doubled-check two things: the intake valve is fully open and the output control valve is roughly one turn open. Then we ensured that the height difference between both tapping A and B is exactly 50 mm, with A being the inlet portion of the venturi meter and D indicating the throat section. Once everything is in order, the experiment begins by allowing the working fluid which in our case was water to enter the apparatus, causing a rise in the manometer tubes. If we detected any air bubbles in the tubes, we slightly tapped on the tubes in order to let the air out to the surface and have exact and correct values. The water, begins to move out of the venturi tube and into the measurement tank. Afterwards we lock the tank and observed how long it takes to fill 8L. We repeated the same procedure for 7 more times, making sure that on the sixth and seventh repe titions to note down all of the measures appeared in all eleven points. Pressure distribution: We opened the valve and closed the tank with our stopwatch we saw how much time it took the 8L and 10L to fill giving us the value of the flow rate (Qact), we repeated this process once for each quantity of water, and took notes of the height of the water in all of the tubes in the apparatus in order to calculate the value of the Cp actual and compare it with Cp ideal and draw our graphs. Results and calculations: Discharge coefficient For tapings 1 and 2, we took a picture of the reading and we trapped the water in the measuring tank to fill up 8 liters. So, we calculated the actual flowrate by using a stop watch and divide the volume by the time it took for it to get filled. 10 For the theoretical flow rate, we used the equation derived from Bernoulli’s equation: Plus, the coefficient of discharge is the difference between the actual and theoretical flow, which is due to assuming ideal conditions in the theoretical calculations. We noted the height of the water in each tube from the photos we took for the two different flowrates, so we can deduce the pressure along the venturimeter. Time for 8 Liters (s) h1 (mm) h2 (mm) Actual Flowrate (L/s) Theoretical Flowrate (L/s) Discharge coefficient 69.6 160 135 0.1149 0.14543 0.79007 50.75 187 127 0.1555 0.2253 0.69019 51.43 195 118 0.1576 0.25523 0.61748 48.16 200 100 0.1662 0.29087 0.57139 Table (1): Table showing the collected data as well as the flowrates and discharge coefficient. 11 Figure 4: Graph showing the variation of the actual flowrate with respect to the theoretical flowrate. 12 Figure 5: Graph showing the variation of coefficient of discharge with respect to the actual flowrate. We also got the pressure coefficients from Bernoulli’s equation: In addition, we calculated the speed at point D by comparing the pressues in both flowrates which led to these results: Qactual-1= 0.69331 L/s and Qactual-2= 0.5179 L/s, then we get the velocity, by dividing the flow rate with the specific area which gave us V1= 3.4482 m/s and V2= 3.287 m/s. 13 Table (2): Table showing the collected data as well as the different pressure coefficients Figure 6: Graph showing the variation of Cp ideal, Cp actual, Q1 and Cp actual Q2 as a function of distance. 14 Conclusion/Discussion: A- First experiment: The main goal of this experiment is to study the change of the static pressure in the venturi tube and to see if changing the mass flow rate will affect the results that we had in the initial case. Starting off this experiment, we were able to recognize a huge difference in pressure between the first point of the venturi tube (which is the inlet) and the fourth point (throat). While taking the values of 8L when it took 48.16 seconds to drain, when h2 was approximately 100 mm, h1 was equal to 200 mm. In addition, we already know that the maximum velocity in the tube is when the water circulates through the throat, which makes sense, because we could be able to demonstrate that the Bernoulli’s theorem is being applied, because, when the pressure decreases, the velocity increases, knowing that rho,g,h are constants. Hence the mass flow rate would be equal to the volume over time. After seeing the diagram, we were able to say that, when raising the flow rate, the pressure at the throat decreases, whereas it increases at the inlet, and vice versa. Concerning the error, we can detect an error by looking at the difference between the actual flow rates and the theoretical flow rates, and between the coefficient of discharge and the actual flow rate. On the other hand, we measure the period it takes for the water to drain. We can notice that there is a difference between the theoretical flow rate and the real f low rate. We use the discharge coefficient (actual/theoretical) to show the error and inaccuracy between these two ways. It is proper to say that these errors may be human errors. First of all, humans are not so fast to be able to register values in the same second, we should have taken our values when the water completely drained. Second, we are writing the values we got after we saw them with the human eye, nothing professional, which may lead to a certain error. And another way that may lead to an error, is the presence of air bubbles in the tubes that measure the heights. B- Second experiment Table 2 results indicate that the greatest elevation of water in the tubes is found at point A (inlet). These values (shown above) begin to drop in both measurements for Qactual 1 and Qactual 2 until they reach a minimum height in the tube connecting to point D. Although we know that the 15 inlet is a convergent area, as the position (x) increases, the diameter of the cross sectional (d ) area at each point decreases, and so the area of the cross section decreases as well. Having stated so, we know that the shortest diameter corresponds to the cross-sectional area of the neck, in which the lowest height of water in the correspondent tube was measured. That being stated, we can determine from Graph (3) that the minimum of all three curves happened at the same location (as shown in figure 6), which is D's coordinate along the axis. We conclude that the lowest pressure was in tube D, and so in the Venturi meter’s throat. This is confirmed by the Cp ideal formula, where the velocity V2 is constant, hence everything depends on (hn h1). By Bernoulli’s, higher velocity means lower pressure. As a result, the maximum flow rate will occur at point D. We also found that the pressure distribution was expected to be zero at point L, the final point on the axis. However, Cp actual was found to be more than zero in both computations. This is the result of either human or machine mistake. Concerning the error, it is usual that there will be small difference between theoretical and real values since we ignore several factors while computing theoretical values such as the friction, viscosity... The Cp ideal and Cp actual computations in Tables 2 and 3 reveal a minor variation. This difference was obvious in Graph 3 when none of the three curves matched. The error might be due to several factors, like the human eye, where it should be placed precisely in the center of the tube. Also, we have the instrument, which is not 100% accurate, therefore it is obvious to have some errors in measuring the fluctuating water height. 16 References: https://www.princeton.edu/~asmits/Bicycle_web/Bernoulli.html [1] TecQuipment: H5 Reference Manual, Nottingham, England. [2] Jadayel, O.C.: CIV 203-Fluid Mechanics Lecture Notes, University of Balamand, Lebanon, 1998. [3] All the pictures were taken by the writers of this report. All the graphs and tables were obtained using Microsoft excel. 17 Appendix: 18 19 20 21 Title page Hayat Jaber Abstract Hayat Jaber Introduction & objectives Michael Jdaidany Background Michael Jdaidany Test description Ryan Nasr Results Ryan Nasr Discussion/ Conclusion Elias Jehi References & Appendix Hayat Jaber