Competency Matrix for Mechanical Engineers in Chemical Plants

advertisement

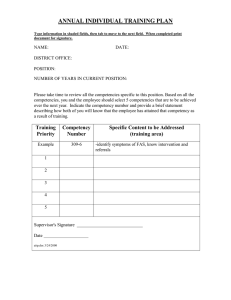

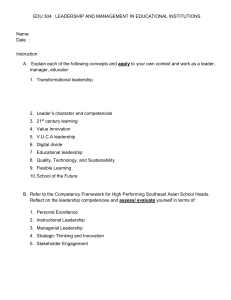

Designing a competency matrix for a mechanical engineer in a chemical plant involves identifying the key skills, knowledge areas, and behaviours necessary for success in that specific environment. Here's a step-by-step guide to designing a competency matrix: 1. Identify Core Competencies: Begin by identifying the core competencies required for a mechanical engineer working in a chemical plant. These may include technical skills, safety awareness, regulatory compliance knowledge, project management abilities, and communication skills. 2. Consult Stakeholders: Engage with relevant stakeholders such as senior engineers, plant managers, safety officers, and HR professionals to understand the specific requirements of the role and the expectations for competence. 3. Define Competency Levels: Establish competency levels that align with different stages of proficiency, such as beginner, intermediate, advanced, and expert. Clearly define the criteria for each level, including skill proficiency, experience, and demonstrated performance. 4. Create Competency Categories: Organize competencies into categories or domains to facilitate assessment and development. Common categories for a mechanical engineer in a chemical plant may include technical skills, safety, regulatory compliance, teamwork, problem-solving, and leadership. 5. Develop a Matrix Structure: Design a matrix that maps competencies against competency levels. Each competency should be listed vertically, while competency levels are displayed horizontally. This structure allows for easy visualization of proficiency levels for each competency. 6. Define Assessment Methods: Determine how competency levels will be assessed. This may involve a combination of methods such as self-assessment, supervisor evaluation, peer review, skills tests, performance reviews, and observations in the workplace. 7. Establish Performance Indicators: Clearly define performance indicators or behavioural descriptors for each competency level to guide assessment and provide clarity on expectations. These indicators should describe observable behaviours or outcomes associated with each competency level. 8. Set Development Goals: Use the competency matrix to identify areas for improvement and set development goals for individual engineers. Provide resources, training, and support to help employees progress to higher competency levels. 9. Regularly Review and Update: Competencies and job requirements may evolve over time due to technological advancements, industry changes, or organizational needs. Regularly review and update the competency matrix to ensure it remains relevant and aligned with current standards. 10. Integrate with Performance Management: Integrate the competency matrix with the performance management process to assess employee performance, provide feedback, and support career development initiatives. By following these steps, you can design a competency matrix tailored to the specific needs of mechanical engineers working in a chemical plant, enabling effective assessment, development, and performance management. For a mechanical engineer working in a chemical plant, core competencies typically span technical skills, safety awareness, regulatory compliance knowledge, project management abilities, and effective communication. Here's a breakdown of these core competencies: 1. Technical Skills: Proficiency in mechanical engineering principles, including thermodynamics, fluid mechanics, heat transfer, and materials science. Knowledge of equipment design, maintenance, and troubleshooting, including pumps, compressors, heat exchangers, reactors, and piping systems. Familiarity with process instrumentation and control systems, such as Distributed Control Systems (DCS) and Programmable Logic Controllers (PLCs). Ability to interpret engineering drawings, schematics, and P&IDs (Piping and Instrumentation Diagrams). 2. Safety Awareness: Understanding of chemical hazards and safety protocols inherent to the chemical industry, including risk assessment, process safety management (PSM), and hazard analysis techniques (e.g., HAZOP, FMEA). Adherence to occupational health and safety regulations, standards, and best practices, such as OSHA regulations and industry-specific guidelines (e.g., API, ASME). Implementation of safety procedures, emergency response plans, and preventive maintenance practices to mitigate risks and ensure a safe working environment. 3. Regulatory Compliance Knowledge: Knowledge of relevant regulations and standards governing the chemical industry, including environmental regulations (e.g., EPA regulations), building codes, and industry-specific codes and standards (e.g., ASME Boiler and Pressure Vessel Code). Understanding of permit requirements, emissions controls, and waste management regulations to ensure compliance with legal and regulatory obligations. 4. Project Management Abilities: Ability to manage engineering projects from conception to completion, including scope definition, scheduling, budgeting, resource allocation, and risk management. Proficiency in project planning tools and techniques, such as Gantt charts, critical path method (CPM), and risk assessment methodologies. Collaboration with multidisciplinary teams, contractors, vendors, and stakeholders to achieve project objectives effectively and efficiently. 5. Effective Communication: Clear and concise communication skills, both written and verbal, to convey technical information, instructions, and reports to colleagues, supervisors, and other stakeholders. Ability to communicate with non-technical personnel and translate complex engineering concepts into understandable terms. Active listening skills to understand requirements, concerns, and feedback from team members and stakeholders. These core competencies form the foundation for success as a mechanical engineer in a chemical plant, enabling professionals to contribute effectively to plant operations, safety, and project execution.