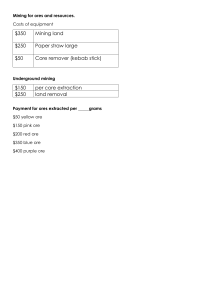

We are Metallurgists, Not Magicians Landmark Papers by Practising Metallurgists Edited by D Pollard, G Dunlop and J Herzig Spectrum 23 We are Metallurgists, Not Magicians Landmark papers by practising metallurgists Spectrum 23 Edited by D Pollard, G Dunlop and J Herzig Published by: The Australasian Institute of Mining and Metallurgy, Ground Floor, 204 Lygon Street, Carlton Victoria 3053, Australia © The Australasian Institute of Mining and Metallurgy 2017 No part of this publication may be reproduced, stored in a retrieval system or transmitted in any form by any means without permission in writing from the publisher. All papers published in this volume were peer reviewed before publication. The Institute is not responsible as a body for the facts and opinions advanced in any of its publications. ISBN 978 1 925100 62 4 Desktop published by Belle Doley, Ross Palmer, Kelly Steele, Alexandra Talbot and Mia Wotherspoon Printed by: Focus Print Group 2 McIntyre Street, Burwood Victoria 3125, Australia Front cover image (top): Construction at Newmont Boddington Gold, photo courtesy of Newmont Australia. Back cover image: Just before sunrise at the Phu Kham Copper-Gold Operation process plant, photo courtesy of PanAust Limited. introduction The majority of papers included in this volume have been selected from AusIMM MetPlant and MillOps conferences from 2008 to 2016. The compilation was inspired by the realisation that the Institute’s metallurgy conferences deliver papers of enormous value to practising metallurgists and, unless they happen to be conference delegates, the information contained in them is otherwise lost to the wider metallurgical community. They provide a unique resource for professionals at all career stages, whether working in design, construction or the operation of metallurgical processing plants. The editors reviewed over 40 AusIMM conferences identifying metallurgy papers relevant to the objectives of the present publication, viz: • • • they are relevant to good design, construction and operation of metallurgical processing plants they do not have an ‘expiry date’ they pass on relevant experience and inspiration to the next generation of plant designers and operators. The papers have been updated, a few are new for the volume, and some have been re-written to combine the core narrative of two or more conference papers. This compilation presents them in themed chapters, grouped with relevance to the challenges of the future as well as the present. Most authors expressed how privileged they were to have their papers included and how the initiative to have this wisdom distilled in one place was a noble one. Many responded with additional comments, some of which are incorporated overleaf as testimonials. Through this publication the editors hope that fewer wheels will be re-invented, and the accounts of successful ideas and innovative thinking will inspire pathways to improved plant designs, operating efficiencies and profitability. Metallurgists in planning, plant design, construction, operation, improvement and management will find the volume essential reading. ACKNOWLEDGEMENTS The editors are grateful for the suggestions and feedback from members and ex-members of the Metallurgical Society Committee, including Dean David, Aidan Giblett, Andrew Newell, Philip Stewart and Peter Tilyard. Janine Herzig joined the original editors as the paper selections were being finalised. The three editors worked together, contacting and liaising with authors and securing the generous sponsorship from industry necessary to ensuring a hardcopy as well as electronic version. Janine edited all of the revised papers, making an invaluable contribution. David Pollard, Geoff Dunlop and Janine Herzig, Editors testimonials “A splendid outcome and a worthwhile contribution to the industry.” E McLean “My fellow authors and I are honoured that our papers are considered for inclusion. The list of papers is very impressive.” D Bennett (PanAust) “I’m honoured to have some of my papers considered as ‘landmark papers’ and to be included as a ‘Practical Metallurgist’! A very worthy project.” T Napier-Munn “I would be honoured … I see it as a great idea.” P Thwaites (XPS) “It is a great honour to be included in a such august company and I must congratulate you on this wonderful outcome and legacy to your vision, drive and management skills.” A Newell “Honoured to be included and love the title.” P Bartsch about the editors David Pollard is a consultant metallurgist with an interest in education and professional development. His employment after graduation was with the Port Kembla steelworks, and later as a metallurgy lecturer at University of Melbourne and the South Australian Institute of Technology (now UniSA). For over a decade he managed the professional development activities of the Australian Mineral Foundation (AMF), providing short courses and conferences across Australia and internationally, across a range of high level technical and management topics. Many of these courses were offered in association with AusIMM conferences. David brought the Metallurgical Plant Design (MetPlant) conference series to the AusIMM when AMF closed, and has convened the series with Geoff Dunlop since 2002, and from 2017 with Janine Herzig. He has twice been Chair of the Adelaide Branch, and was Chair of the AusIMM Metallurgical Society (MetSoc) from 2008 to 2013.During this time MetSoc initiated the groundwork for AusIMM to publish the third edition of the Sir Maurice Mawby volumes, Australasian Mining and Metallurgical Operating Practices. We are Metallurgists, Not Magicians was initially undertaken by David and Geoff, with the support of MetSoc, and will add to the professional development resources for practising metallurgists and processing plant designers. Geoff Dunlop is a metallurgical engineer who began his career at Mt Isa, rose to Concentrator Superintendent, and moved to a site research role where he carried out early investigations on the geometallurgy of the Mt Isa orebodies. He characterised the ‘3000’ and Lead/Zinc orebodies. He moved to AMDEL in 1970 as a project metallurgist, and developed process flow sheets and systems to provide financial information about performance. In the early 1990s he worked with AMDEL collaborating with MIM Process Control and JKTech to develop instrumentation for Indian, Burmese and Iranian processing plants. He continued to consult for some years following his retirement, including for BOC gases regarding automated equipment for plants, as well as for international clients. In 1998 Geoff edited, with Norton Jackson and Peter Cameron, the AMF Conference proceedings for ’Mineral Processing and Hydrometallurgy Plant Design‘, a conference convened by David Pollard. This collaboration led into the partnership between David and Geoff on the AusIMM MetPlant conference series from 2002. Janine Herzig began her graduate career in Mount Isa as a metallurgical engineer with MIM in the Lead/Zinc Concentrator. She then moved into the mineral sands sector with Iluka in various locations across Queensland and Western Australia, before being appointed Principal Metallurgist for the Murray Basin Operations feasibility work and execution. After ten years with Iluka, Janine accepted the role of Mineral Processing Manager with AMDEL and ultimately as the General Manager of the Minerals and Industrial Division, where she oversaw programs spanning multiple commodities and mineralisation styles. Key projects included the first major ODX geometallurgy program under WMC then BHP, which involved establishment of a major new metallurgical and geochemical testing facility, the Prominent Hill feasibility study, and management of a major expansion of the on-site laboratories for the Whyalla steelworks and processing plants. Janine established a consulting business after leaving AMDEL in 2009 conducting due diligence, desktop reviews and project management across a range of commodities including industrial minerals, graphite, precious and base metals. She has served on the AusIMM Adelaide Branch Committee since 2005, holding the positions of Chair, Secretary, newsletter editor, and member on the South Australian scholarship interview panel. She continues to serve on a range of AusIMM conference organising committees and other specialist taskforces. She was honoured to be invited to assist David Pollard and Geoff Dunlop with this publication, and believes that it will become the essential reference for all metallurgists, plant designers, consultants, students and new professionals for many years to come. Sponsors Platinum Sponsors Gold Sponsor Silver Sponsor Bronze Sponsors Our purpose is to create value and improve lives through sustainable and responsible mining Follow us on: www.newmont.com PanAust is an Australian-headquartered copper and gold producer with producing assets in Laos and a portfolio of organic growth projects in Laos, Papua New Guinea, Myanmar and Chile. PanAust’s producing assets are the Phu Kham Copper-Gold Operation and the Ban Houayxai Gold-Silver Operation, both located in the Company’s 2,600 square-kilometre Phu Bia Contract Area in Laos. In Papua New Guinea, PanAust holds an 80 per cent interest in the Frieda River Copper-Gold Project, with the remaining 20 per cent held by joint venture partner, Highlands Pacific. In Myanmar, PanAust holds an 80 per cent interest in Wuntho Resources Company Limited (WRCL) and has established a joint venture with Myanmar Energy Resources Group International Company Limited (MERG), a Myanmar-based company which holds the remaining 20 per cent of WRCL. WRCL owns 100 per cent of the rights to areas covered by three Exploration Licences in the Sagaing Division of Myanmar. At PanAust, operational excellence and sustainable business outcomes are pursued in a complementary manner. This strategy, which sees excellence in one area underpin, encourage and facilitate excellence in the other, has been the driving force behind PanAust’s success. PanAust is determined to remain Way Ahead. For more information, visit www.panaust.com.au. gold SPONSOR – Ausenco Ausenco is a world leading engineering company providing consulting, project delivery and asset management and optimisation solutions to the resources, energy and infrastructure sectors. We add value to our clients’ projects and deliver results even in the most challenging environments. Ausenco has a global footprint with offices and current projects in Australia, the Pacific, Asia, Africa and North and South America. Our experts thrive on their ability to create ingenious solutions that improve our clients’ return on investment. We’re proud to be a Gold Sponsor of this publication and support the continued development of excellence in Minerals Processing. CONTENTS Overview ‘We’re metallurgists, not magicians!’ E McLean 3 Back to the future – why change doesn’t necessarily mean progress P D Munro and P A Tilyard 11 Back to the future – still on the dark side P D Munro 19 Undermining productivity – when good key performance indicators go bad J Pease 27 Presented at MetPlant 2011, this paper has been updated and edited for this compilation. Presented at MillOps 2009, this paper has been updated and edited for this compilation. Presented at MillOps 2016 as a follow-on to the paper: ‘Back to the future - why change doesn’t necessarily mean progress’, this paper has been updated and edited for this compilation. Presented at MillOps 2014 as a PowerPoint presentation, this paper has been written specifically for this publication. Geometallurgy Geometallurgy – what do you really need to know from exploration through to production? K Ehrig 33 Integrating geometallurgy with copper concentrator design and operation G Harbort, K Jones, D Morgan and C Sola 37 Integrated mining and metallurgical planning and operation P L McCarthy 55 Presented at MetPlant 2013, this paper has undergone minor edits for this compilation. This paper was presented in various forms at MetPlant 2011, MillOps 2014 and MillOps 2016. It has been updated with a new geometallurgy model, undergone significant edits and is the integration of the papers presented at the three events outlined above. This is a compilation of three papers presented and published for MetPlant 2011, MetPlant 2013 and MetPlant 2015. Project economics Guidelines for economic evaluation of projects P Card 65 Sensible cost cutting for resource projects D Connelly 69 When does further processing at the mine site make sense? C Fountain, S La Brooy and G Lane 75 The ABC of Mine-to-Mill and metal price cycles P Cameron, D Drinkwater and J D Pease 85 Base metals concentrate sales contracts – change Pavlov and the dog P D Munro and S E Munro 91 Presented and published at MetPlant 2011, this paper has been significantly reviewed and updated for this compilation. Presented at MetPlant 2011, this paper has undergone significant edits and updates for this compilation. Presented at MetPlant 2008, this paper has had minor edits for this compilation. Presented at MillOps 2016, this paper has been reviewed and abridged for this compilation. Presented at MetPlant 2015, this paper has undergone minor edits for this compilation. Project design Karouni Gold Project from drill core to commissioning K Nilsson and D Connelly 101 Upgrades, modernisations, automation and expansions … where will the expertise, capability and skills come from in the future? R Coleman, J King and T Hunter 107 Presented at MetPlant 2015, this paper has undergone minor edits for this compilation. Presented at MillOps 2016, this paper has undergone minor edits for this compilation. x 115 Is an 80th percentile design point logical? D David Presented at MetPlant 2013, this paper has undergone significant edits for this compilation. Measuring and taking notice of orebody variability – an essential ingredient for reliable plant design D David 121 Presented at MetPlant 2015, this paper has undergone significant edits for this compilation. Getting optimum value from ore characterisation programs in design and geometallurgical projects associated with comminution circuits S Morrell 131 Presented at MillOps 2009, this paper has been updated and edited for this compilation. 137 Cost-effective concentrator design G Lane, P Dakin and D Elwin Presented at MetPlant 2011, this paper has undergone minor edits for this compilation. Project management and delivery 145 Fatal flaws in technical due diligences A J H Newell Presented at MetPlant 2015, this paper has undergone significant updates and edits for this compilation. 155 Guidelines for mineral process plant development studies P R Whincup Presented at MetPlant 2008, this paper has undergone minor edits for this compilation. 163 Project delivery G Lane and E Skinner Presented at MetPlant 2013, this paper has undergone minor edits for this compilation. 173 Mineral project management – a perspective from four decades in the industry J S Dunlop Presented at MetPlant 2013, this paper has been updated and edited for this compilation. 183 Keeping projects on the rails J Canterford Presented at MetPlant 2011, this paper has undergone significant edits for this compilation. 187 Operations versus projects – how do people think and what are the implications? G Lane and B Clements Presented at MillOps 2012, this paper has undergone minor edits for this compilation. 193 Performance testing – when, what and how? G Lane, M Davis, E McLean and J Fleay Presented at the Project Evaluation 2007 conference, this paper has undergone minor edits for this compilation. Unit design and development Process development and throughput forecasting at the Phu Kham copper-gold operation, Laos PDR D Bennett, I Crnkovic, P Walker, A Hoyle, A Tordoir, D La Rosa, W Valery and K Duffy 201 The subject matter for this paper was written, published and presented at three AusIMM conferences: MillOps 2012, MillOps 2014 and MetPlant 2015. Significant effort has gone into combining, updating and editing this combination of the three papers for this compilation. 235 What can go wrong in comminution circuit design? C Bailey, G Lane, S Morrell and P Staples Presented at MillOps 2009, this paper has undergone significant edits for this compilation. 243 Do we need a gravity circuit or not? A case study in applying best practice A Giblett and K Afewu Presented at MetPlant 2015, this paper has undergone minor edits for this compilation. Solvent extraction of uranium – towards good practice in design, operation and management P Bartsch and S Hall 249 Presented at MetPlant 2011, this paper has been updated and edited for this compilation. 257 Design of copper-cobalt hydrometallurgical circuits G Miller Presented at MetPlant 2008, this paper has undergone minor edits for this compilation. 263 A review of best practice in gravity circuit design and operation A Giblett, A Bax, G Wardell-Johnson and W Staunton Presented at MetPlant 2013, this paper has undergone minor edits for this compilation. xi Leach residue and pregnant liquor separation – process and capital comparison of counter-current decantation and counter-current washing with vacuum filtration R Klepper and P McCurdie 273 Presented at MetPlant 2011, this paper has been updated and edited for this compilation. 285 Filtration test work – extracting the whole story for studies and design G Bickert and B Länger Presented at MetPlant 2011, this paper has been updated and edited for this compilation. 297 Considerations for effective gold process development A Giblett, D Appelhans and R Dunne Presented at MetPlant 2013, this paper has undergone minor edits for this compilation. 307 Energy efficient ball mill circuit – equipment sizing considerations A Jankovic and W Valery Presented at MetPlant 2013, this paper has been updated and edited for this compilation. 315 Advances in dense medium cyclone plant design T J Napier-Munn, G Gibson and B Bessen Presented at MillOps 2009, this paper has undergone minor edits for this compilation. Sampling, metallurgical accounting and control 327 Using metallurgical data to drive continuous improvement R Dunne Presented at MillOps 2016, this paper has been updated and edited for this compilation. 333 The importance of sampling in the mineral industry R J Holmes Presented at MetPlant 2013, this paper has been updated and edited for this compilation. A progressive, iterative approach leading to reliable metallurgical accounting sampling systems F F Pitard 343 This paper was written for MetPlant 2015 but not presented at the conference. It has undergone significant edits for this compilation. 349 Sampling, corporate governance and risk analysis G J Lyman and F S Bourgeois Presented at MetPlant 2015, this paper has been significantly edited and updated for this compilation. 355 Metallurgical management tools for continuous improvement W McCallum and R Dunne Presented at MillOps 2012, this paper has undergone minor edits for this compilation. Measuring the influence of sample size on the precision and accuracy of gravity gold estimation A Giblett and T J Napier-Munn 361 Presented at MetPlant 2015, this paper has been updated and edited for this compilation. 365 Defining practical metallurgical accounting discrepancy limits for gold operations A Giblett, R Dunne and K McCaffery Presented at MillOps 2012, this paper has undergone minor edits for this compilation. Manual control, process automation or operational performance excellence – what is the difference? P Thwaites 373 Presented at MillOps 2014, this paper has been significantly updated with new information for this compilation. 401 Unlocking processing potential by empowering our operators X Li, M S Powell and W McKeague Presented at MillOps 2012, this paper has been updated and edited for this compilation. Current developments in the operation and control of autogenous and semi-autogenous grinding mills in Australia J Karageorgos, Y Atasoy and D Baas 411 Presented at MetPlant 2008, this paper has undergone minor edits for this compilation. Environmental management and sustainability Mine waste risk minimisation by integrated waste management and process optimisation D Brett 419 Presented at MetPlant 2013, this paper has been updated and edited for this compilation. 427 Sustainability, made easy – a business improvement case study G Corder, N Currey and G Becker Presented at MetPlant 2013, this paper has been updated and edited for this compilation. xii Continuous improvement – how changes in metallurgy can have a substantive impact on environmental impact and closure: lessons learnt from environmental auditing P Mulvey and G McMillan 437 Presented at MetPlant 2013, this paper has undergone minor edits for this compilation. Process improvements and case studies Improving fines recovery by grinding finer J D Pease, M F Young and N W Johnson 445 Cunning solutions to process improvement T J Napier-Munn 455 How to prioritise process improvements D J Hill 461 Some practical problems in running statistically valid plant trials and their solution T J Napier-Munn 469 Presented at MetPlant 2004, this paper has had significant updates and edits for this compilation. Presented at MillOps 2014, this paper has undergone minor edits for this compilation. Presented at MillOps 2014, this paper has had a significant update for this compilation. Presented at MetPlant 2008, this paper has undergone minor edits for this compilation. The optimisation of semi-autogenous grinding and ball mill based circuits for mineral processing by means of versatile and efficient high pressure grinding roll technology S W Kirsch and M J Daniel 475 Presented at MillOps 2009, this paper has been significantly updated for this compilation. Optimisation opportunities for high pressure grinding rolls circuits M S Powell, M M Hilden, C M Evertsson, G Asbjörnsson, A H Benzer, A N Mainza, L M Tavares, B Davis, N Plint and C Rule 483 An update on applications of high frequency screens in closed grinding circuits S B Valine, J E Wheeler, B Packer and A N Cavendor 499 The influence of liner wear on milling efficiency P Toor, T Perkins, M S Powell and J Franke 509 Development of the Fosterville gold mine heated leach process M Binks and P Wemyss 523 Collector – addition point and consumption C J Greet, W J Bruckard and D MacKay 529 The Ausenco carbon reactivation kiln initiative J K Claflin and S R La Brooy 537 Lessons learnt and performance – installing and commissioning an Ausenco carbon reactivation kiln in Africa J K Claflin, S R La Brooy and D Preedy 541 Carbon management in a high gold price environment S R La Brooy and J K Claflin 549 The impact of gravity gold recovery at Kalgoorlie Consolidated Gold Mines A Giblett, D Hillier, K Parker and V Ramsell 559 Agglomeration – the key to success for the Murrin Murrin heap leach D Readett and J Fox 569 Author index 575 Presented at MillOps 2012, this paper has been significantly updated for this compilation. This paper is a compilation of two papers from MetPlant 2011 and MillOps 2012. It has been significantly updated with additional case studies and information obtained for the Alban Lynch publication Comminution Handbook. Presented at MetPlant 2011, this paper has been significantly updated for this compilation. Presented at MetPlant 2011, this paper has been significantly updated for this compilation. Presented at MetPlant 2008, this paper was revised several years later for Transactions of the Institutions of Mining and Metallurgy – Mineral Processing and Extractive Metallurgy, and has been further updated and edited for this compilation. This paper was specifically written for this compilation as an author foreword to the following two papers. This paper was presented at MetPlant 2015. Context for this paper and the paper immediately below has been provided via an author foreword (above), which also provides significant new insights and updates. This paper was presented at MetPlant 2013. Context for this paper and the paper immediately above has been provided via an author foreword (above), which also provides significant new insights and updates. Presented at MillOps 2012, this paper has undergone very minor edits for this compilation at KCGM’s request. Presented at MetPlant 2011, this paper has been updated and edited for this compilation. xiii Overview Contents ‘We’re metallurgists, not magicians!’ E McLean1 ABSTRACT The decision-making checklists and the hierarchy of information for process and plant design are generally wide-ranging and complex. Grades, mineralisation and ore types in an orebody, the mine development sequence and results from metallurgical and physical test work present complex and competing influences for flow sheet development, values for design, equipment selection, extraction/recovery performance and operating strategy. Challenges are presented on several fronts: how to manage these variables; understand their impacts on performance; and best provide a cost-effective plant design and robust process that meets daily, weekly and monthly operating objectives. Throughput, production and grade or product specifications need to be met. The orebody is not homogeneous; its range of metallurgical and physical characteristics may be moderately to highly variable. Average values derived from test work results are unlikely to be suitable for design purposes. This paper assesses some of the competing influences and conflicting issues in design and equipment selection, and their effect on production and performance expectations. THE DESIGN SEQUENCE Each item of process equipment, the flow sheet, process logic and the operating strategy for the treatment plant are there by design and purpose. This is because a sequence of process engineering activities has led to their implementation, installation and construction in the project. The development activities for the project follow the staged sequences shown in Table 1. Although not exhaustive, this table simplifies a complex procedure and identifies the main process and engineering decision-making activities. In practice, iterations following reviews, revisions at each stage and the linked sequence of stages increase the complexity in project delivery. Reviewers of the performance of project delivery, plant start-up and operation (Agarwal, Brown and Katrak, 1983; Performance Associates International Inc, 2017) identified fundamental issues that contributed to financial shock, whether it was due to attaining nameplate capacity at a slower rate than anticipated, or not achieving this at all. They noted that, notwithstanding experienced and competent mining, design and planning personnel on the project, the chief technical problems, start-up difficulties and poor performance for new mineral processing operations, occurred across all stages of the project from the following items: •• representativity of samples – high heterogeneity of orebodies, difficulties with adequate sampling, extent of testing was inadequate (stage I in Table 1) •• definition of the process – complexities of the process route, influence of process water (stage II) •• engineering – design deficiencies with mechanical equipment, equipment design and/or installation is inappropriate (stage III) •• operation – operators lack knowledge and skills to properly operate the plant, management is unable to cope with the problems experienced during initial operation, maintenance is not executed properly, particularly during the initial operation (stage IV). The authors stated that although problems with mechanical equipment were expected, these risks can be reduced through efficient design and scale-up. They attributed a number of these problems to basic design deficiencies such as incorrect specifications, unit capacity and duty. 1. FAusIMM, Manager Minerals Consulting, Ausenco Minerals & Metals, South Brisbane Qld 4101. Email: eddie.mclean@ausenco.com The activities in Table 1 match elements in the schematic project flow chart (Lane et al, 2008) in Figure 1, which shows the relationship between design inputs and project outcomes: •• stage I input = design inputs (green boxes) 3 E McLean Table 1 Development sequence for principal process design and engineering activities. Stage Development activities I – Input Geology, mineralisation, resource model Description of key activities in development stage Discuss deposit(s) with exploration geologists Review long- and cross-sections showing lithology and structures Geological interpretation, reconcile metallurgical classification for zones or domains Sample selection and sampling protocols Representative samples and the basis for selection Characterisation – metallurgical and physical, of the major ore types, ore zones or domains Variability – metallurgical and physical, of parameters that influence design and production Production composites, as required, for selected periods during the initial two to three years of operation Test work, by laboratory and vendor II – Definition III – Engineering IV – Deliver Project Preparation of samples, ensuring integrity of sample, preventing oxidation Batch or semi-continuous small or large scale (pilot) for flow sheet development and to obtain data for process design Reproducibility and robustness of tests; simulation of operating conditions; check/repeat and diagnostic tests Analysis of data Collate and compare, interrogate for trends and relationships, investigate outlier data Ore sequence in likely mine plan and weighting by ore characterisation Processing strategy and process alternatives, flow sheet development Design value Recommend value/specification for unit process and for process stages Define duty point in range of operating conditions, considers variability Calculation – size and select equipment Text book or standard methodology, with efficiency factors Include equipment factors – industry applicable, vendor recommended Include operating factors – experience, reconciliation of operation with previous design and performance Include agreed or nominated engineering margin, owner margin, allowance for engineering risk Tender and select for procurement Vendor receives engineering specification, criteria, data sheets, drawings Vendor uses proprietary modelling, calculations and database to size and recommend Vendor submits equipment that complies with throughput and duty required Vendor selection also considers commercial aspects: performance warranties, penalties for non-performance, reputation, competition (cost) New or second-hand equipment may be offered Technical and commercial evaluation by engineer – recommend to purchase Install, start-up and ramp-up operations Implementation plan to coordinate and schedule activities Install and commission in accordance with standards and procedures Maintenance – planned and in accordance with recommendations Operator experience and training FIG 1 – Relationship between design inputs and project outcomes (from Lane et al, 2008). 4 we are metallurgists, not magicians ‘We’re metallurgists, not magicians!’ •• stage II definition = project design concept (orange oval) •• stage III engineering = project outcomes: engineering design equipment selection and quantities and take-offs (blue boxes) •• stage IV delivery = project execution: implementation, procurement, construction and commissioning (yellow boxes). The project design concept and definition stage are pivotal: all information channels through here for interpretation and analysis, and then forms the basis for subsequent engineering design and planning for the execution phases of the project. Activities and decisions in this stage are able to impact on the project cost, schedule and plant performance. Although all items are integral to a successful project outcome and some are critically important such as ore representativity and sampling, this paper reviews the following activities described in Table 1 that have a high ability to influence the final project outcome: •• analysis of the data to develop a viable processing strategy •• values for design to specify the duties for the unit processes •• calculations to size and select the process plant and equipment. THE DATA SEQUENCE Practical and robust interrogation, and interpretation and analysis of the data from the body of metallurgical information available are fundamental to successful design. The quality of data at various stages of project development is also of consequence with respect to its validity and applicability for design. Samples and data Samples for metallurgical and physical testing are usually domain-orientated and can be categorised as characterisation samples and variability samples. Characterisation samples normally represent a lithology, oxidation, alteration, mineralogy, grade, or spatial property of the ore, as appropriate, for which metallurgical or physical unit parameters are determined by the test work for that specific ore classification. Variability samples are usually from each domain or ore classification in which one property varies with, for example, metal grade, sulfur grade, depth, location in the geological structure. Data generated from tests on both these types of samples can be associated with blocks of ore in a resource model; some of the more common applications are described as follows: •• hardness and competency values populate blocks of ore in which the dominant lithology or alteration type is identified (characterisation) •• leach recovery values populate blocks of free-milling gold ore in which the extent of oxidation is identified, ie for wholly oxidised, partially oxidised or transition, or fresh ore (characterisation) •• a relationship of recovery with a variable (or variables) can be described by an algorithm to populate blocks of ore; for example, in gold ores, relationships may be established between leach extraction and feed grade, leach extraction and sulfur grade, and extent of refractory gold and arsenic grade (variability) •• mill feed from a mine plan and ore schedule can be interrogated to provide information over a period we are metallurgists, not magicians (month, quarter, half-year) to support production and cash flow forecasting. Resource composites which are blended by ore types and grade to represent samples such as whole-of-pit, life-of-mine and annual averages do not necessarily provide the basic information and ‘building blocks’ for flow sheet development and design that characterisation and variability samples do. Plant operation is unlikely, if ever, to treat such samples on a sustained basis. Specific ore properties that may cause metallurgical and operational difficulties are diluted in a composite sample and any impact these have on performance is dampened, or perhaps not identified in the test results. For a design based on average values plus allowances for mechanical and vendor margins, there is a high likelihood that the expected performance and corresponding production will not meet planned targets when treating ores over sustained operating periods with characteristics significantly above the average value. Furthermore, the opportunity to catch up production when ore with characteristic values below the average are treated may be constrained by physical and volumetric limits in the plant and equipment; for example, pump capacity, launder size, screen area, thickener area, filter rate. Data analysis In the early stages of project development when drilling and geological interpretations are ongoing and resource definition is in its formative stages, the body of test work data is limited. Data is generally in small sets of information and the data selected is typically the maximum or the average of the range. Incremental increases in input data values may be made to assess trends and to assess sizes of plant and equipment. As well, benchmarking of the values may be made with comparable industry data or in-house data from similar ore types and similar applications to improve confidence at this early stage. As the project develops, not only does the volume of data available from several stages and iterations of metallurgical test work programs increase, but so too does the complexity of information from the amount of detail available with an improved understanding of ore characteristics and variability. Superimposed on these are a number of ore feed schedules to the plant with variable tonnage, grade, mineralisation and lithology, and different ore exploitation sequences depending on the mining strategy, mine development plan, pit financial modelling and resource constraints. Analysis of the characterisation and variability data by ore type to determine values for design includes: •• a statistical analysis which identifies the average, the standard deviation, minimum and maximum values, values at nominated percentiles (default is typically 75th or 80th) of the data population •• an assessment of outlier low/high data, analysis and inclusion with basis and comments noted, or discard with justification •• a plot of values in an ordered sequence which graphically shows the distribution, the location of the bulk of the values, and where the outliers or sparsely populated values lie •• identification of values, which characterise the major ore types, unit process performance, process streams and water quality •• determination of a weighted value appropriate for principal blends of ore in the feed to the plant. 5 E McLean Sources of data Input data and information for studies from concept to final feasibility, for basic engineer packages (BEP) or front-end engineering design (FEED) are from several sources. These can be grouped as follows: •• Project, operating and production parameters, which are set by the client. These are based on financial and organisation parameters. These are usually agreed and fixed, and form part of the design basis, such as operating schedule and availabilities. •• Test work (by laboratories, vendors, and specialists), resource models and consultants’ reports. These are the main sources of data for the project as they contain detailed test work and analyses for the resource, its geology, mine plan, all unit processes, the water quality and environmental controls. This body of work also contains reports from client’s specialists, processing specialists, other consultants and third-party audits. •• Operating practice and industry standards. Sources of data are in-house experience, operating history on similar treatment plants, published or confirmed operating information. •• Public domain information such as vendor data, handbooks, regulatory and environmental standards, industry codes, service and performance catalogues on like-for-like applications, published engineering or discipline text books, and published regulations. •• Engineers’ database, operating and commissioning experience. This would apply in instances, typically as follows: if data from previous sources are not available; if the number of test samples and testing is considered limited and/or incomplete; if the test work does not replicate the unit process performance well enough; if test data is from batch operation and needs adjustment for a continuous basis; if scale-up factors need to be allowed for based on previous experience. As a guideline, the hierarchy of sources of information and data for process and plant design is usually in the order listed (above). The client parameters (first group) normally form the financial, operational and production basis for the project. Test work data (second group) are ore and deposit specific and consequently form the prime source of information for flow sheet development and unit process design. Data from the remaining three groups of information would be used in preference where these could be demonstrated to be more applicable and more representative than those in the first two groups. Design value The design value is the input value used in calculations to size and select the processing equipment item (eg crusher, grinding mill, hydrocyclone, thickener, float cell, filter) or a unit process (eg carbon adsorption circuit, counter current wash circuit). The value can be a grade or an ore/mineral characteristic, an attainable unit parameter, a rate or capacity for the nominated duty and operating conditions for a unit of process equipment or a specific circuit. The design value does not necessarily relate to production schedules or integrate to a mass balance. The mass balance for the plant represents an operating condition for a continuous circuit in steady state in which inputs equal outputs for all items (ie solids, water, metals and elements). Plant mass balances are prepared for an average ore condition and for a series of cases which represent specific feed parameters or operating conditions. 6 The design value does not include factors such as catchup capacity, any additional design margins, factors or other allowances. Design factors and margins should be assessed and identified in the calculation where necessary to achieve the design objective, specific equipment duty or operating condition. Factors include allowances for items such as wear, screen pegging, minor surges, emergency relief, certain startup or shutdown conditions or short-circuiting. Operating margins are allowed for materials handling and in selected process equipment such as conveyors, cyclone feed pumps, other slurry pumps, reagent pumps, water pumps and air services. Equipment sizing and selection Calculations for equipment sizing show the design value, the input flow(s) and additional factors where these materially affect the equipment size and basis of selection. The input flow(s) for the calculation are normally from a nominated (usually at, or near maximum) operating case or from a shortterm event which may include a step-change due to a batch flow stream addition. The calculation using the average mass balance condition is also normally carried out to provide a measure of the range of operating performance for the unit. Selection and recommendation of the unit process equipment or plant should meet two main criteria: 1. function efficiently in accordance with the parameters and specifications nominated 2. be cost-effective from both initial capital and life cycle assessments. Selecting the unit process equipment or plant achieves the desired balance between the competing demands of: •• undersizing equipment to minimise costs, which may increase the risk of underperformance, and •• oversizing equipment which, whilst providing a measure of confidence to meet the operating duty, not only over-commits initial capital for the equipment item (or unit process) but also can increase costs for concrete works and steel structure to install this item. CASE STUDIES Case studies for selection of design values for key process criteria and for the design basis of process areas in gold plants are described in the following sections. Selection of design values The selection of a design value from their population of data is described for comminution, gravity and feed grade cases. An example of variability data analysis for gold recovery with sulfur is given. Data sets are from different projects and provide examples of the basis used to select a value for design. Comminution – competency The drop weight test parameters ‘A’ and ‘b’ are measures of the competency of an ore used in grinding calculations for semi-autogenous and autogenous grinding mills. Figure 2 shows the distributions of Axb values with samples tested for three ore types in a supergene/hypogene type orebody with skarn mineralisation. The Axb value selected for design from the distribution plots for each ore type was based on the 25th percentile in each ore type (lower Axb values represent more competent ore). The design value for each ore type and the characteristic blend of ore types in the mine plan are shown in Table 2. we are metallurgists, not magicians ‘We’re metallurgists, not magicians!’ FIG 2 – Correlation Axb values with samples tested for three ore types. Table 2 Distribution of ore types by the principal mine plan blends. Lithology Axb (ore type) Work index ball kWh/t Mine plan (wt %) years 1–3 Mine plan (wt %) years 4–8 Type 1 77 12.8 50 0 Type 2 76 11.5 20 20 Type 3 38 15.9 30 80 Total -- -- 100 100 The (weighted) Axb design value for each mine plan blend is 65 for the 1–3 year period and 46 for the 4–8 year period. The corresponding Bond ball mill work indices are 13.5 kWh/t and 15.0 kWh/t, respectively. The ore blend is less competent (higher Axb value) and less hard (lower work index) in the initial three years, and consequently the unit power requirements for the semiautogenous grinding (SAG) mill and ball mill are lower during that period compared to the latter five years. Operating options allow either: 1. ability to treat higher tonnages during the initial years based on the installed power and nominated throughput for years 4–8 2. expansion of facilities and increase grinding capacity to maintain the nominated throughput for years 4–8. In this project, option (1) was determined to provide more value to the project. FIG 3 – Bond ball mill and rod mill work indices (WI) for samples from the dominant type. Gravity recovery Gravity recovery tests on ground samples (5 to 10 kg per sample) using laboratory scale centrifugal bowls together with shaking tables or vanners measure the gravity recoverable gold from steams in a ball mill circuit closed with cyclones. The grind size for these types of gravity tests is usually at the design P80 grind size, or it may be up to two to three times this value which recognises that the bleed stream from the grinding circuit is coarser than the cyclone overflow final product size. The weight recovered to the final gravity concentrate in this type of test is normally in the range 0.03–0.09 per cent by weight from feed. Figure 4 shows the results from standard gravity recovery tests on three ore types with auriferous quartz vein stockwork mineralisation. Gravity recovery was moderately high and variable; no trend was observed by ore type or by feed grade. Recoveries at the 90th percentile, 15th percentile and average were assessed. The laboratory recovery at the 90th percentile was 49 per cent; this was rounded up to 50 per cent for design of metal recovery in downstream processing of the gravity concentrate. Gravity recoveries for the average and 15th percentile from the laboratory tests were 39 per cent and 29 per cent, respectively. These results from laboratory tests, which Comminution – hardness Standard Bond work index rod mill and ball mill tests are measures of the hardness of an ore and are used in grinding calculations for rod and ball mills; they also form an integral component of SAG mill grinding calculations. Figure 3 shows the distribution of work indices with samples tested for a volcanic, volcaniclastic, co-magmatic intrusive type orebody. The work index values selected for design from the distribution plots, based on the 75th percentile, were rod mill work index 28.9 kWh/t and ball mill work index 21.9 kWh/t. These values provide sufficient flexibility for the mill to accommodate the majority of ore types and ore feed conditions (with blending). Work index values at higher percentiles would add capital cost and an additional margin over the required feed rate case. we are metallurgists, not magicians FIG 4 – Gravity recoverable gold from three ore types in quartz-veined gold deposit. 7 E McLean were carried out in ideal, batch conditions, were discounted to account for the lower mass pull by weight per cent to concentrate in the plant, the type of gravity circuit installed, the recovery effort, continuous operation and ore variability in the plant. The discount factor for low-sulfide and low specific gravity gangue is typically in the range 0.60 to 0.80. The adjusted average gravity recovery for the mass balance was 30 per cent. For downstream leaching, carbon-in-leach (CIL) and carbon in pulp, the carbon circuit and metal recovery were designed for periods of lower gravity recovery and a gravity recovery of 20 per cent was adopted. The silver in feed and to gravity was tracked to assess its deportment and accountability. As in many gold and gold/ silver ores, silver recovery to the gravity concentrate was very low, and significantly less than that for gold. Front-end engineering design grades The cumulative distribution of copper feed grades from the mine plan and ore schedule for a long-life copper-gold porphyry mine is shown in Figure 5. The copper feed grade distribution in years 4–12 was selected as the basis for design for the flotation and concentrate handling areas. The 75th percentile was used for the design copper value. Although gold grades in this copper-gold ore were higher in the initial three years than in the year 4–12 operating period, gold has an economic contribution but no material influence on the sizing of the copper concentrator equipment. Although the copper feed grade was lower in the initial three years, it was preferred that higher unit capacity was installed at the outset to avoid future disruptions to ongoing operations from construction of additional flotation and concentrate handling facilities. Additional capacity was therefore available in the initial years of operation for catch-up and ability to cope with any short-term grade or mineralisation fluctuations. Gold recovery variability An apparent scatter of gold recovery results from a number of routine, standard grind and cyanide leach tests on the gravity tail for a large open pit gold resource, was resolved (Smith, 2005) by assessing the response by sulfur grade increments. The leach residue versus leach feed grade trends for four sulfur increments were plotted, shown in Figure 6. Each sulfur grade represented approximately equal proportions of the sulfur distribution in the mine model for the ore reserves. FIG 6 – Gold residue and leach feed grade relationship by sulfur increments. A relationship of residue gold grade with feed grade for sulfur grade levels was obtained. Further statistical analysis of this database was required to develop a model which estimated the leach residue gold grade for the range of sulfur grades expected in the ore schedule, and thus to calculate gold recovery from the corresponding feed gold grade. Design basis A case study for the design basis for areas in a conventional gold plant is described. The circuit comprised the following key process stages: crushing, semi-autogenous and ball mill (grinding) with pebble crusher (SABC), gravity, leach/CIL, thickening, cyanide detoxification, desorption, regeneration, gold room cathode, gravity preparation and smelting. Plant feed characteristics FEED distributions by tonnage and by feed grades for ore to the mill, sourced from three open pits are shown in Table 3. The yearly intervals correspond to optimised pit development to maximise gold and silver grades, as well as revenue. The majority of the ore comes from Pit 1, with ore from Pit 2 boosting gold and silver grades in the first two years. Pit 3 is the lowest grade and is developed towards the end of the project life. Characterisation – comminution and recovery Ores from all pits were characterised by lithology and alteration types and tested for their comminution competency, hardness and abrasion properties. Three categories were identified and grouped as ‘hard’, ‘medium’, ‘soft’ according to unconfined compressive strength (UCS), Axb, rod mill work index and ball mill work index values. Ore type distribution in the mill feed tonnages by period is shown in Table 4. The corresponding recoveries of gold and silver, based on the characteristic gravity and leach/CIL recovery performance Table 3 Mill feed from open pits – distribution by weight and average grades. FIG 5 – Copper cumulative distribution from mine and ore schedule (LOM: life-of-mine). 8 Year Pit 1 (wt %) Pit 2 (wt %) Pit 3 (wt %) Total (wt %) Grade Grade Au (g/t) Ag (g/t) 1–2 80 20 0 100 2.2 20 3–7 95 5 0 100 1.6 9 8–9 60 15 25 100 1.6 6 10–12 0 20 80 100 1.1 2 we are metallurgists, not magicians ‘We’re metallurgists, not magicians!’ Table 4 Distribution ore competency/hardness and recoveries by year. Year Hard (%) Medium (%) Soft (%) Total (%) Recovery Ag (%) Au-equivalent index 1–2 20 60 20 100 Throughput index Recovery Au (%) 0.90 88 60 1.35 3–7 10 60 30 100 1.00 84 50 1.00 8–9 10 40 50 100 1.05 84 50 1.03 10–12 0 5 95 100 1.25 80 40 0.78 by ore type for the blend of ores in each mill feed category, are shown in this table. Comparative throughput and production performances are expressed as a throughput index and a gold-equivalent index (converts silver value to equivalent gold) in the table. Grinding The ore hardness variability in the mine resource block model showed that a significant number of blocks in the first two years of operation had a predicted work index above those expected for the following five to seven years. The design values for comminution were based on treatment of ores for years 3–7 in the schedule which comprised nearly threequarters of all ore scheduled for the initial seven years. The comminution circuit power and mill sizes were selected based on comminution parameters for this period and a throughput index of 1.0 was assigned. Although the average throughput during this initial two-year period was 90 per cent of the design throughput based on the installed power of the selected mills, production for the first two years on an equivalent recovered gold basis (Table 4) was 35 per cent higher than at the design throughput due to the higher grades and higher recoveries with the harder ore blend. This strategy avoided oversizing and over-capitalising the grinding circuit and underutilisation of grinding power in subsequent years at the design throughput rate. This also prevented a flow-on of higher capital costs if the downstream process plant and equipment were increased in size to match the grinding circuit throughput. Gravity Gravity recovery tests showed that gold recovery was moderately low and highly variable for all ore types. Gold recovery was about 20 per cent for the lower grade main pits and approximately 10 per cent for ores from the (smaller) highgrade pit. The impact of gold deportment to gravity ahead of the leach/CIL circuit was relatively minor, particularly in the initial years treating the higher grade ore. For design of the leach/CIL circuit, it was assumed that the leach circuit would treat all gold in feed, that is, no gravity gold recovery. This ensured that all gold was recovered in leaching and adsorption when the gravity circuit was not operating and also provided a small operating margin for variability in gold grades to leaching. Silver gravity recovery was consistently very low, typically less than five per cent to a final gravity concentrate in all tests on various ore types. For design purposes, it was assumed that all silver in the feed was available for leaching and carbon adsorption. Precious metal recovery A carbon adsorption and desorption circuit which met the duty required for the initial two years was selected for this operation. Although the throughput rate was lower, ore grades and recoveries were highest in this period and we are metallurgists, not magicians thus directly affected solution and carbon inventories. The maximum gold and silver inventories, and the resulting carbon transfer, desorption and regeneration systems to manage these metal inventories occurred during the initial two years of operation (Table 4). Consequently, this period was the basis for the design of the carbon adsorption, elution and regeneration circuits. As the soluble ratio of silver to gold during the initial two years was about 6:1, silver management was the main design consideration and determinant for the carbon circuit design and operating strategy. Gold room Design of the gold room and smelting activities was based on treating peak weekly inventories of gravity recoverable gold and electrowinning cathode clean-up. Volumetric capacity The amount of ore classified as ‘soft’ increased with mine life and is the major to dominant proportion of ore feed to the mill towards the end of operations, in years 8–12. During this period the grinding circuit was able to treat above-design throughputs and most likely up to treating a 25 per cent higher feed rate. This helped to offset the loss in production due to falling grades and decrease in recovery. Slurry viscosity and rheology tests on all ore types, particularly the characteristic moderate- to high-alteration ores in the soft category, provided comparative information on pulp density, viscosity, slurry transportation properties and hydraulic gradients in the circuit. The slurry characteristics and flow properties directly affected duty and specifications for equipment such as slurry pumps, trash and safety screens, launders, intertank screens and the thickener. Hence, provision was made in the initial design for equipment, pipes and launders to handle larger flows for periods when poor or adverse slurry properties dictated, or allowances were made to subsequently add to or upgrade existing equipment. CONCLUSIONS Data obtained from metallurgical and physical ore testing programs is appropriate and applicable to the extent that the sample selection is representative and correct preparation protocols are practiced. The recommended methodology for sample selection as a basis for flow sheet development and process design is by characterisation and variability categories. Characterisation accounts for metallurgical and physical properties of the ore by domain, zone, ore type or specific geological classification. Variability encompasses subsets of domains such as mineralisation, range of grades of economic metal, range of grades of deleterious or penalty elements, ratio of grades of metals, spatial location along strike and at depth. Practical and robust interrogation, interpretation and analysis of the complex database of information and detailed 9 E McLean data available are fundamental to successful design. This is not possible without an understanding and an iterative assessment in conjunction with the mine planning group of ore feed schedules to the plant by tonnage, grade, mineralisation and lithology; of ore exploitation sequences, mining strategy, mine development plan, pit financial modelling and resource constraints. The selection of the appropriate design value for each unit process or process stage is critical. Coupled with relevant design margins, calculation factors, scale-up, benchmarking, operating experience and input flow conditions, the unit process equipment or plant selected should meet two main criteria: to function efficiently in accordance with the parameters and specifications nominated; and to be costeffective from both initial capital and life cycle assessments. The engineer, scientist, or metallurgist who can make apparently impractical things happen and is able to produce outcomes that achieve objectives shows initiative, is innovative, creative and resourceful. The inexplicable or impossible events outside these parameters are magic. 10 ACKNOWLEDGEMENTS The inspiration for this paper comes from beleaguered colleagues, many of whom have been in the firing line from project managers and production superintendents to explain ‘why’, ‘why not’ and ‘when’. REFERENCES Agarwal, J C, Brown, S R and Katrak, S E, 1983. Taking the sting out of out of project start-up problems, adapted from a presentation at The American Mining Congress, September 1983, San Francisco. Lane, G, Staples, P, Dickie, M and Fleay, J, 2008. Engineering design of concentrators in Australia, Asia and Africa – what drives the capital cost?, in Proceedings Procemin 2008 V International Mineral Processing Seminar (ed: R Kuyvenhoven, C Gómez and A Casali), pp 30–38 (GECAMIN: Santiago). Performance Associates International Inc, 2017. So you are investing in a mining project – what usually goes wrong [online]. Available from: <http://www.perfnet.com/wp/white-papers/investingmining-project-usually-goes-wrong/> [Accessed: 20 July 2017]. we are metallurgists, not magicians Contents Back to the future – why change doesn’t necessarily mean progress P D Munro1 and P A Tilyard2 ABSTRACT There have been enormous changes in mineral processing in the past four decades. For example, grinding mill power has increased by an order of magnitude, regrinding is done to -10 µm and flotation machines are 100 times bigger. Operating staff have unprecedented opportunities for online monitoring and performance control of mineral processing plants. Sophisticated instruments can provide a plethora of data characterising the mineralogy and surfaces of particles. Digital computers allow complex calculations on huge amounts of data including modelling and simulation of machine and plant performance. However, all these changes have not necessarily led to better metallurgical results. An analogy can be drawn with the thoroughbred racing industry in Australia. Significant advances in scientific knowledge in animal genetics, physiology, biomechanics and nutrition applied to the business have resulted in only a two per cent reduction in winning times for the Melbourne Cup and Caulfield Cup since the 1920s. A critical look at some mineral processing metrics suggests similar failures to improve performance despite putting in more resources. In fact, certain parameters such as operating times and plant start-up performance are considered to have remained static or even deteriorated. There has been an emphasis on ‘process’ at the expense of ‘outcomes’. The industry’s strength has been in finding technical (or ‘hardware’) solutions while its weakness has been at the people end of the business in maximising and consolidating the gains from the technologies. Some trends in plant design over these years have exacerbated the apparent deskilling of operating and technical staff. Despite unparalleled options for communications, some staff are embarrassingly uninformed about technical developments in their fields. The ‘boom and bust’ cycles of the industry, together with trends in tertiary education and the effects of fly-in, fly-out (FIFO) operations, raise serious questions about the sustainability of human capital in the mineral processing sector. This paper by two experienced mineral processing engineers, with contributions from other senior practitioners, reviews these trends. While there may be an element of ‘the older we are, the better we were’, it is an attempt to identify the issues and propose solutions. INTRODUCTION The terms ‘mineral processing engineer’, ‘metallurgist’ and ‘graduate’ are used interchangeably in this paper. Most observations and examples have been drawn from base metals sulfide concentrators using flotation as the separation method. However, the authors have enough experience with other operations, such as gold leaching and iron ore processing, to expect that these have similar issues. The authors have attempted to contrast the mineral processing sector that they entered as new graduates at the beginning of the 1970s with the current situation in 2009. While there may be an element of ‘the older we are, the better we were’ in this paper, it is an attempt to identify the issues and propose some solutions. 1. FAusIMM, Senior Principal Consulting Engineer, Mineralurgy Pty Ltd, Taringa Qld 4068. Email: pdmunro@bigpond.com.au 2. FAusIMM(CP), Former Group Metallurgist, MMG (now retired). Email: tilyards@bigpond.net.au AROUND 40 YEARS AGO An industry snapshot in 1970: •• The typical starting salary for a graduate mineral processing engineer was ~$3500/a; accounting for overhead makes the cost to the employer ~$5000/a, which after six weeks’ annual leave and 8 h/d = $2.72/h cost to the employer. Using the Australian Consumer Price Index as a multiplier gives a cost in 11 P D Munro and P A Tilyard 2009 of $26/h. Another way of looking at this is that at 1970 metal prices of US$1300/t for copper, US$35/t oz for gold, US$350/t for lead, US$2750/t for nickel, US$1.88/t oz for silver and US$300/t for zinc with the exchange rate of A$1 = US$1.12, the graduate’s annual salary including overhead had the following approximate metal equivalents: •• 4.3 t of copper •• 161 t oz of gold •• 16 t of lead •• 2 t of nickel •• 2988 t oz of silver •• 18.7 t of zinc. •• Employment conditions relative to Australian norms were generous and encouraged young people to seek a professional career in the industry; McCarthy (2006) has commented on this issue. •• Fly-in fly-out (FIFO) did not exist. People lived in mining towns where socialising and talking ‘shop’ gave you a good appreciation of other disciplines such as mining engineering and geology. •• Joining the Australasian Institute of Mining and Metallurgy (the AusIMM) was almost a condition of employment and contributing to local branch activities was expected. •• There were no personal computers. •• The internet did not exist, with no time consumed reading emails! •• Telephone calls were expensive and making an STD (subscriber trunk dialling) call required permission. •• Fax machines did not exist. •• Copying was changing over from wet process duplication to ‘Xeroxing’. •• Process control computers had just arrived with 4–8 KB of memory, programmed in Assembler. •• 4 KB of memory cost $4000 (these are 1970 dollars). •• There were a few electronic calculators around. One of the paper’s authors was hugely impressed as a new graduate to find out that the mill clerk at Mount Isa Mines Limited (MIM) had one with a square root function! •• Companies had on-site technical capabilities with the larger ones such as CRA and MIM doing world-class research. •• Information was provided through a company technical library. This housed all significant reports and circulated journals. Graduates were expected to read the technical literature in their professions. •• The assay function had not been ‘outsourced’ and the company’s chief chemist was a source of wise counsel on all analytical and chemical matters. •• Large complex sulfide flotation concentrators could be competently run by three metallurgists: control metallurgist, metallurgist control plus one graduate. The mill clerk adequately coped with most data collecting and reporting functions. •• Flotation was controlled using the vanning plaque (or ‘pan’) confirmed by wet chemical assays every two hours. This was a skill that the metallurgist had to master to acquire any credibility with the operators. The ‘pan’ had the advantage of providing real-time semiquantitative mineralogy as well as an estimated ‘assay’. 12 •• The design of flotation plants brought the operators and metallurgists close to the froth allowing observation and giving an excellent ‘feel’ for the process. As the American baseball commentator Yogi Berra once said ‘you can see a lot by looking’. •• Comminution was done by multistage crushing with rod milling plus ball milling giving stable grinding throughput so the metallurgical ‘narrative’ focused on separation performance. •• ‘Running time’ was the only thing that mattered, with both maintenance and operational groups zealously guarding their reputation on minimising downtime. There was significant focus at a high level on areas for improvement. •• The flotation section was operated under a strict ‘theory x’ (command and control) set of guidelines with operators allowed to adjust parameters (such as air, froth depth, reagent additions etc) only within limits set by the metallurgist. This reflected the high level of accountability the metallurgist had for separation performance. •• Prototype on-stream analysers (OSA) started appearing in flotation plants. •• Quantitative mineralogical data were collected by manual point counting. It was not uncommon for a site to have a mineralogical laboratory. •• Computer models of mineral processes were empirical and run on main frame machines, programmed on punched cards. Conclusions from the models were tentative because of their novelty. •• Metallurgists routinely: •• were held accountable for metallurgical performance daily and subjected to relentless queries; this may not be in accord with current ‘warm and fuzzy’ human relations approaches but it certainly provided focus and was character-building – the authors observed that those metallurgists who survived and thrived in this trial by ordeal had the potential to become competent plant managers •• had to be very sceptical about the veracity of instrument readings as much of the technology was in its infancy. Pneumatic control with 3–15 psi air was the norm •• checked crusher gaps with the ‘leads’ •• checked mill power draw •• checked hydrocyclone spigots with callipers putting in a maintenance work request when the wear exceeded 6 mm (¼ inch) •• routinely inspected mill and flotation banks on plant shutdowns, putting in maintenance work requests. Decisions on equipment repair issues possibly affecting throughput and metallurgical performance were not abdicated to the maintenance department or even the purchasing department •• produced a detailed monthly metallurgical report, commenting on performance on a sized basis •• produced detailed cost comments – costing systems were logically divided up into ‘cost centres’ for unit processes such as ‘crushing’ and ‘grinding’ comprising expense accounts (such as ‘electric power’, ‘50 mm diameter grinding balls’ etc). •• The monthly metal balance was done manually and expeditiously, often by the mill clerk. we are metallurgists, not magicians Back to the future – why change doesn’t necessarily mean progress •• Meetings were relatively infrequent and brief. Senior staff generally exercised strict control to ensure they did not become ‘talk fests’. •• Despite the lack of the internet and without cheap telephone calls, staff at remote sites were well aware of technical developments in other locations. Publications such as Jim Woodcock’s annual review Mineral Processing in Australia (Woodcock, 1978) were eagerly anticipated to provide details on operating practices. Similar enthusiasm greeted other review articles such those in the Mining Annual Review and World Mining. •• Graduates were expected to be literate and numerate. Memoranda and reports were carefully vetted by superiors for both their technical and English content. Senior staff were then competent enough in their own literary skills to identify errors in grammar and deficiencies in expression. Rewrites of offending sections were obligatory and frequent. •• Reports were written in long hand and subsequently typed by a secretary. Graphs were hand drawn in India Ink with the aid of ‘french curves’. •• Future ore testing looked at the ore sources the plant would process in future years. •• Graduate training at larger operations was structured with around six months spent doing ‘hands on’ jobs in the plant including supervisory positions. The next step was project work leading to time being responsible for metallurgical performance. There seemed to be more emphasis on achieving competency in core skills though such jargon terms were not then used. •• There were more opportunities for mentoring. It was not uncommon to find metallurgists over the age of 50 at a mine site. IN 2009 Observations on the situation in 2009: •• Typical salary for a second-year graduate mineral processing engineer on a FIFO basis was ~$102 000/a; assume 8/6 roster with 0.5 d travelling each way gives seven effective working days on-site. Subtracting four weeks’ holiday per annum gives 24 effective working weeks at 12 h/d = ~$50/h cost to the employer. Applying the same overhead as in the 1970 case gives ~$70/h. At 2009 metal prices of US$4300/t for copper, US$900/t oz for gold, US$1350/t for lead, US$13 000/t for nickel, US$12.50/t oz for silver and US$1500/t for zinc with the exchange rate of A$1 = US$0.75, the graduate’s salary including overhead had the following approximate metal equivalents: •• 25.3 t of copper (~6 × the 1970 value) •• 120 t oz of gold (~0.8 × the 1970 value) •• 80.6 t of lead (~5 × the 1970 value) •• 8.4 t of nickel (~4 × the 1970 value) •• 8700 t oz of silver (~3 × the 1970 value) •• 72.5 t of zinc (~4 × the 1970 value). •• Employment conditions relative to Australian norms are less generous, discouraging young people to seek a professional career in the industry (McCarthy, 2006). •• FIFO operations are increasingly the norm. •• People do not tend to live in mining towns and do not socialise much after work. Even on-site the 12 hour day leaves little time for interdisciplinary interaction. An unkind observation is that the solution to any problem we are metallurgists, not magicians is never further than the next rotation out. Support staff are seen as a cost with harangues from accountants and managers about the ‘head count’ and cost of supporting people in the camp but neglecting to consider the value they add. •• There seems to be a lower level of participation in the activities of the AusIMM. FIFO does not encourage this, as attending technical meetings when a person is rostered off is often viewed as ‘work’. •• Everyone has access to a personal computer and the internet with most of a person’s time spent in front of it dealing with emails is a major preoccupation. •• Process control computers are ubiquitous with the cost of memory and data storage still falling in accordance with Moore’s Law. •• Very few companies have significant technical capabilities, and most rely on research institutes, consultants and less frequently inhouse technical groups. •• The technical library was generally a victim of cost cutting in the late 1980s and 1990s. Anecdotes tell of the few remaining professional information technologists (ie ‘technical librarians’) falling victim to the downsizing that occurred following the global financial crisis of 2008. Historical technical work is usually imperfectly filed and collated, often with important omissions. The unspoken belief appears to be that everything you need to know can be sourced from the internet. An unkind comment from one senior engineer was that ‘the level of inquiry was so basic that the answer is often found on the internet!’ Conversations with metallurgists quickly reveal significant lacunae in their knowledge. Nothing more technical than the introductory textbook ‘Mineral Processing Technology’ (Wills and Napier-Munn, 2006) is found on most bookshelves. Those metallurgists with an interest in reading the technical literature struggle to convince senior management of the benefit of a subscription to a data search/retrieval facility. •• The assay function has been ‘outsourced’, sometimes to the ludicrous point where it is no longer possible to have any ‘spot samples’ processed! Some sites don’t even have a rudimentary metallurgical laboratory. •• A large complex sulfide flotation concentrator requires six to eight metallurgists with no seeming improvement in the quality of operation. The extra numbers are needed because of FIFO, as support staff were culled during the hard times and with metallurgists now often performing clerical functions. •• Flotation is controlled using OSA and (surprisingly) still by two-hour assays in some plants. The current design vogue of open air flotation plants, having the cells packed together with walkways over the top, has distanced the operators and metallurgists from the process. A dissenting opinion on the ergonomics of flotation plant design is contained in a paper on the design of the Prominent Hill concentrator (Colbert, Munro and Yeowart, 2009). •• Comminution by autogenous grinding/semi-autogenous grinding (AG/SAG) mills gives varying grinding throughput with the ‘narrative’ focused more on the grinding section to the neglect of evaluating separation performance. •• Previous simple classifications of plant downtime such as ‘planned maintenance’, ‘unplanned maintenance/ breakdown’ and ‘operational’, ‘lack of ore, water or 13 P D Munro and P A Tilyard power’ have become more complicated including definitions such as ‘readiness’. the mineral liberation and beneficiation process. It seems to be for ornament rather than use. •• The end result is that often no one is accountable for actual running time, which used to be the mill manager’s responsibility. Running times seem to have deteriorated from values achieved in the 1970s and early 1980s. •• It is disappointing to observe that quantitative mineralogical data are usually one of the items discarded as a response to low metals prices; however, this is understandable if the metallurgists receiving such data can’t use it effectively. •• One nostalgic observation is that as soon as the industry went away from fine crushing and rod and/ or ball mills the ‘rot’ set in. Availability of the ball mills at Bougainville Copper Limited (BCL) inched up to 99.1 per cent in 1983, utilisation of available time was 99.7 per cent and total run time was 98.8 per cent, equivalent to 8655 h/a. Compare this to the current common SAG mill design run time of 8000 h/a (91.3 per cent) and actual operating run time not much better in many cases. •• In 2006, one large mining company was designing its iron ore plants for a run time of 74 per cent and probably still is. It seems to have learned nothing from the BCL crushing plant experience where line run time was 96 per cent and secondary crusher run time was 91 per cent. Even experienced iron ore metallurgists found these numbers difficult to believe. The secondary and tertiary crushers and the tertiary screens were fed from large surge bins which significantly contributed to the operating efficiency of the BCL plant. •• Flotation is now run under a laissez-faire regime where seemingly everyone’s opinions are valued, regardless of skill and knowledge, to avoid upsetting individuals. •• Operators are allowed wide scope to adjust parameters (such as air, froth depth, reagent additions etc) and even to make circuit changes. One hears statements like ‘someone changed the collector addition last night’ at the daily production meeting which doesn’t encourage a culture of responsibility. •• Democracy has been substituted for the scientific method, eg the fact that in the 14th century most people believed that the world was flat did not mean it was correct! •• There doesn’t seem to be much accountability for performance. •• OSA and particle size monitors are supposed to be standard equipment though there are some curious exceptions. At some sites the OSA and/or particle size measurement system is no longer operational through systematic neglect or produces questionable data from poor calibration procedures. •• It is depressing to hear announcements trumpeting the purchase of an OSA system or online particle measurement as a technical breakthrough when such items are assumed to be standard equipment in the 21st century. The old adage ‘if you can’t measure it, you can’t control it’ surely applies. •• Quantitative mineralogical data can be rapidly produced by automated X-ray methods such as QEMSCAN (Quantitative Evaluation of Minerals by Scanning Electron Microscopy) or mineral liberation analyser (MLA; both, incidentally, are Australian innovations); however, manual and automated point counting still survive, with the practitioners of these supposedly outdated techniques able to offer interpretation and information as opposed to the data produced by the automated X-ray systems. •• Despite having the luxury of quantitative mineralogical data few metallurgists are able to use the data to manage 14 •• Computer models of mineral processes are increasingly phenomenological and can be run on powerful laptop computers •• Metallurgists less commonly: •• are held accountable for metallurgical performance daily and subjected to relentless queries •• master the fundamentals of their profession, which detracts from their later performance as plant managers •• disbelieve instrument readings •• check crusher gaps, mill power draw or hydrocyclone spigot dimensions •• routinely inspect grinding mills, hydrocyclones and flotation banks on plant shutdowns, then submit maintenance work requests when required •• make decisions on equipment repair issues possibly affecting throughput and metallurgical performance and often abdicate these decisions to the maintenance department •• produce a detailed monthly metallurgical report commenting on performance on a sized basis •• exploit the power of the spreadsheet which is ideal for manipulating mineral processing data to produce a thorough understanding of the performance of the plant according to the axiom of ‘size-by-size mineral particle behaviour by liberation class’ •• are held to account for operating costs •• read the technical literature of the profession. •• The monthly metal balance is done in many cases on expensive computer packages with no seeming improvement in accuracy or speed. The computer can’t tell you that the head sampler is not in its correct rest position and is getting constant splash into it. •• Meetings are much more frequent and last longer. •• Despite the so-called communications revolution from the availability of the internet, staff seem to be totally unaware of past industry paradigms. •• The authors have been astounded to find plants using rubber or polyurethane spigots in hydrocyclones taking SAG mill discharge. Hydrocyclone spigots were supposedly ‘standardised’ to long-wearing ceramic units during the late 1960s (Munro, Eaton and Burton, 1982). •• Even when company intranets are set-up with a metallurgical site and discussion page, there is a reluctance to seek advice and/or information from the wider pool of metallurgical expertise in the group. •• Graduates often lack literacy and numeracy, and when memoranda and reports are written (which isn’t often enough in FIFO operations), they are often not well constructed and painful to read. •• With the exception of engineering design companies, version control of reports and spreadsheets is almost unheard of. •• A recurrent theme is the disregard of the statistics of variation as evidenced by claims of observed we are metallurgists, not magicians Back to the future – why change doesn’t necessarily mean progress improvement well within the normal ‘noise band’ of plant and laboratory performance. •• Verbal communication is resolutely qualitative rather than quantitative with numbers replaced by ‘larger’ versus ‘smaller’, ‘faster’ versus ‘slower’ etc. •• It seems to be easier to get to the geologists’ office at the mine site from head office in a capital city or from the consultant’s office than it does from the nearby concentrator office. ‘Future ore testing’ may have been repackaged as ‘geometallurgy’ but you still have to talk to the geologists. •• Graduates spend around 25 per cent of the time doing ‘hands on’ training compared with 40 years ago. •• Many operations supposedly have detailed programs for the development of graduates; however, there is often a gap between rhetoric and reality when the authors have examined the knowledge and competencies of people coming out of these schemes. •• The age spread of site metallurgists is narrow, rarely finding one over the age of 45. •• The head office support function also appears to be reducing with major mining companies cutting back on experienced metallurgists in technical services functions. •• Mentoring does not seem to be valued as much, and while there may be ‘motherhood’ statements about it, along with a supposed commitment to staff development, the lack of any demonstrated commitment to actually providing the resources for mentoring and staff development belies this point. IF THIS IS PROGRESS …? Below are examples supporting the contention that mineral processing outcomes are not uniformly improving: •• Throughput variations as ascribed to the ore being ‘harder’ or ‘softer’. It is a long time since we heard a metallurgist say something like ‘our current feed is from bench ‘AB’ where the predominant rock type is ‘andesite/granite etc’; grindability data for this shows a bond ball mill work index of ‘A’ kWh/t, drop weight index a × b of ‘B’ etc’. Despite all the excellent tools for data collection, manipulation and display, people seem resolved to be qualitative rather than quantitative. It was hoped that the Australian Minerals Industries Research Association (AMIRA) P843 geometallurgy project would change this, but it seemed to be driven more by geologists than metallurgists when it ran its course. •• In 2004, a large copper producer in a foreign country asked a respected Australian research institute to investigate why there was a difference in metallurgical performance between its new plant with one type of flotation machine for rougher duty and the older plant which had another machine. After a detailed campaign including measuring parameters such as superficial gas velocity and bubble surface area flux it was found that the rougher flotation cells in the newer plant had significantly lower effective volumes because of the accumulation of tramp oversized ore particles from ‘upsets’ in the grinding section. After the cells were cleaned out copper recovery increased from 83 per cent to the target of 90 per cent. It is a telling commentary on how removed people now are from the flotation process that someone has to come from another country to tell you that your cells are full of rocks! we are metallurgists, not magicians •• In early 2006, a large copper concentrator did a thorough maintenance overhaul of its flotation cells including replacing worn impellers and stators, refurbishing level control equipment and cleaning cell lips. On restarting the plant the sulfide grade of the concentrate increased from 78 per cent to 82 per cent with 2.5 per cent abs higher copper recovery. Such a significant deterioration in the condition of the flotation cells would and would have been noticed much earlier if the metallurgists had looked at the froth surface on the cells. One of the authors had a similar experience in a copper zinc concentrator where he suggested that the flotation cells be drained and inspected on the next shutdown. The appalling state of the impellers and stators (some had ceased to exist) showed that no interest had been taken in the flotation cells by metallurgical staff for years. •• Daily data for mill products of ‘silver nitrate soluble copper’, ‘acetate soluble copper’, ‘cyanide soluble copper’ and ‘total copper’ were not used to explain the performance of a large copper-gold concentrator. Management’s concern and displeasure at high rougher tailings losses could have been mollified by pointing out that the proportion of acid soluble copper in the feed had increased. The copper minerals in this category are not recoverable by conventional sulfide copper flotation. •• At a review meeting examining design options for a major upgrade of a venerable concentrator, none of the senior operating staff present knew the current plant operating cost in $/t of ore treated or its components according to activity. •• At an overseas copper concentrator, a cost saving initiative was suggested by a group of non-technical employees assigned the task of improving plant performance and was accepted by the metallurgical staff. The instrument air compressor was decommissioned. In due course the wet air from the plant compressors destroyed the level controllers in the flotation section. •• Two very large overseas copper concentrators do not own a cyclosiser and the metallurgical staff stoutly defend the fact that they have no data in the -37 µ size region. •• At an overseas copper concentrator, a graduate metallurgist disputed the visiting consultant’s opinion that, in the absence of OSA (the equipment had fallen into disuse), two hourly spot assays would be useful. •• Very few operations are able to present in a single document, the performance of the plant over the past say five to ten years. MINERAL PROCESSING BASICS The fundamental data requirements for managing a mineral processing plant are the following: •• The target metallurgical performance (eg concentrates grade, metals recoveries, what you want to reject and the priority for these targets). •• An equipment list. •• A mass balances for solids, elements, minerals and water •• A simulation model of the comminution circuit with grindability data for current ores. •• Quantification of ore types (both grinding and metallurgical performance) in the plant feed for future years and relation to past performance. •• Knowledge of the processing characteristics of the orebody in a spatial sense. This should include 15 P D Munro and P A Tilyard grindability, quantitative mineralogy, metallurgical performance, distribution of precious and impurity elements and minerals (eg Au, Ag, As, F, Hg, organic carbon, talc etc) where applicable. •• Grinding and regrinding mill power consumptions. •• Element and mineral particle behaviour on a sized basis. •• Mineral particle behaviour on a sized basis by liberation class on a monthly basis. •• Trade-off between concentrate grade versus recovery and plant throughput versus separation section (eg flotation) feed sizing. •• Effect of concentrate grade and recovery on net smelter returns (NSR). •• Detailed chemical analysis of concentrates and concentrate physical data such as transportable moisture limit. •• A history of the metal balance/metal accounting with accompanying narrative on all adjustments made to the ‘first pass’ numbers. This should also include reconciliation of data from dispatches and receipts of products to customers. •• Regular analyses of process and effluent waters. •• Consumables usage, eg grinding media (also reported as weight loss per kWh of mill power), reagents and including water. •• Operating cost data: •• on Pareto graphs •• by activity (eg crushing, grinding etc) •• by expense account. •• A simple financial model of the plant which incorporates the technical drivers and their effect on NSR. •• A metallurgical development plan which incorporates the above trade-offs and outcome drivers etc. •• An enthusiasm for capturing plant data on an ongoing basis. Unfortunately, a compendium of the above data is rarely seen when visiting a plant. It is interesting to note that concentrator staff are likely to have compiled job safety analysis documents for many physical tasks in the plant but have minimal cogent documentation on how to do the metal balance, production forecasts or metallurgical planning. GEOLOGISTS AS EXEMPLARS FOR DATA AND INFORMATION We should take a lesson in data collection and information management from our geological compatriots. Mineral deposits can be discovered and mines can operate for decades going through multiple ownerships with the geological database remaining intact and up to date. You hardly ever encounter situations where there isn’t any data for a drill hole because the assay sheet was shredded five years ago when the project geologists were ‘outplaced’ during the last cut-backs or the samples weren’t analysed to save money. Chief geologists are not in the habit of throwing away drill core to eliminate the cost of storing it. Contrast this to the metallurgical test reports on those same geological samples. You would be an optimist to expect that they would still be found in the concentrator department. Essential fittings for many metallurgists’ offices are a plethora of seemingly important test work and survey reports covered in grime and the circular marks of beverage containers haphazardly scattered over flat surfaces. Electronic copies of reports when archived on computer servers have cryptic and sometimes unintelligible titles and are not filed systematically 16 making retrieval a laborious and daunting undertaking. Electronic files of plant operating parameters from process measurement and control systems frequently have long periods of missing or erroneous data. Sometimes complete archives of metallurgical reports and plant data have gone missing when a computer system was upgraded. Are mineral processing engineers condemned to be ‘children of lesser data’? THOROUGHBRED RACING Versus DENTISTRY – A CAUTIONARY TALE Quirk (2006) made some trenchant observations on the performance of the thoroughbred racing industry. Winning times for the Melbourne Cup, which is an open handicap event and not a race of equals, have improved only three per cent since the 1920s. Similarly, the W S Cox Plate, which is weighted for age and supposedly a classic race for the best horses, has shown only a two per cent improvement over the same time period. These data are shown in Figure 1. Similarly, analyses in the 1980s of the classic English races the St Leger, the Derby and the Oaks showed that little or no improvement in winning times had occurred in the previous 70 years. By comparison, human athletes in the Olympic Games over the same time period had an eight per cent improvement in winning times for the 100 m, ten per cent for the 1500 m and 12 per cent for the 5000 m. So, despite having an array of modern technologies in genetics, nutrition, biomechanics, equine physiology etc available, the thoroughbred racing industry, as measured by winning times, has not improved its performance. The reason given for this is the limited equine gene pool available for development. The authors are not currently suggesting that the gene pool of metallurgists is the cause of our perceived dissatisfaction with the performance of mineral processing professionals; however, the cautionary message from the thoroughbred racing industry is that merely applying modern scientific techniques does not ensure the desired outcome. This is sharply contrasted to advances in modern dentistry over the same time period where technology and innovation have clearly improved the patient’s physical (if not his/her fiscal) well-being (O’Rourke, 1995). THE CONTEMPORARY MINERAL PROCESSING SITUATION There have been significant improvements in mineral processing technologies over the past four decades as per the following examples: •• Machines have become much larger, eg 20 MW SAG mill compared with a 3 MW (max) ball mill. This has allowed FIG 1 – Melbourne Cup and Cox Plate winning times (ten year averages). we are metallurgists, not magicians Back to the future – why change doesn’t necessarily mean progress a single unit to replace a multiplicity of very small ones for both comminution and separation duties. •• Capital efficient AG and SAG mills instead of crushing plants plus rod mills plus ball mills for comminution (though some would argue this has been at the expense of rapid plant start-up, fluctuating metallurgical performance and increased downtime). •• High-pressure grinding rolls (HPGR). •• Comminution technologies that can economically grind down to -10 µ. •• Sorting technologies using sensing of multiple mineral characteristics. •• Very high field strength magnetic separators. •• ‘High g’ gravity separators. •• Carbon-in-pulp (CIP) and carbon-in-leach (CIL) replacing solid liquid separation plus Merrill-Crowe process for gold extraction. •• Pressure oxidation and bioleaching for refractory gold ores. •• Solvent extraction plus electrowinning for copper leach pregnant leach solution. •• Selective flocculation. •• OSA; online measurement of both coarse and fine particle size distributions; online measurement of chemical parameters such as redox potential, cyanide concentration, dissolved oxygen level etc. •• Expert control systems. •• Ability to collect detailed quantitative mineralogical data including QEMSCAN plus MLA, infra-red (IR) for alteration etc. •• Proven models for the simulation and control of mineral comminution and to a lesser extent separation processes. •• Computer aided design (CAD) for 3D visualisation of plant layouts with accompanying efficiencies in fabrication and plant construction. •• The capacity to collect, analyse, manipulate, store and retrieve data plus information on a scale unimaginable in 1969–1970. We should be wary about confusing: •• movement with action •• activity with achievement •• change with progress. The contention is that all this extra hardware and software is not necessarily giving uniformly better performances across the mineral processing sector. There is some truth in the retorts to the above complaints that: •• some of the orebodies currently being treated are more refractory than those processed 40 years ago •• metallurgists are relatively more expensive to employ than they were in 1969–1970 for most commodity producers. The most significant contributor to this is the dominance of electronic information technology in the working life of a metallurgist. This area, which without a doubt has experienced the greatest advances over the last 40 years, is the prime cause of process overcoming outcome. MANAGEMENT RESPONSE If management fails to comprehend and master the technical basics of plant operation it will not understand the outcome ‘drivers’ and be less capable of directing the available metallurgical talent pool. The authors rarely encounter a coherent plan of metallurgical development for a mineral processing plant with the most precious resource on-site of ‘Competent Person hours’ appropriately focused on the most productive opportunities. Management must recognise metallurgist’s time from: this ‘black •• the ‘bureaucratisation’ of overwhelming ‘outcome’ work with hole’ of ‘process’ •• producing abundant data but a paucity of information. What value does a metallurgist add to the understanding of a mineral processing operation by spending three hours per day producing the daily report with a plethora of egregious irrelevant details? Surely this is not an intellectually satisfying outcome after spending four years at university? Why such atrocious wastes of professional time occur in this supposed ‘information age’ and are tolerated, considering the higher ‘metal equivalents’ of metallurgist’s time, are questions for serious reflection. Corrective actions must include: •• Putting the ‘mineral processing basics’ in place. •• Freeing up metallurgists’ time; eg automatic collection and processing of online measurements and hiring sufficient clerical and support staff. With metallurgists being relatively more expensive to employ than 40 years ago, there is even less excuse to waste their time doing jobs that can be farmed out to others. •• Focusing the available professional time on a strictly prioritised list of metallurgical opportunities with quantifiable outcomes. Further development of the ‘Mineral Processing Toolbox’ section of the AusIMM website to include examples of good practice for some of the mineral processing basics cited, may be an appropriate method to focus on the real issues driving mineral processing outcomes. Such a web-based facilitation mechanism could lift industry performance, especially if companies would be prepared to contribute suitable examples in a collaborative spirit, similar to an AMIRA project. CONCLUSIONS By some criteria, the standard of operation of mineral processing plants has not significantly improved in the last 40 years despite the ‘information technology revolution’. Yet instances of poor metallurgical outcomes seem to be too frequent and too serious to be classed as aberrations. The suspicion is that the industry has some systemic problems that have to be addressed. Professional time for process monitoring and improvement has been eroded by the ‘bureaucratisation’ of the metallurgist’s work, despite the fact that, for most commodity producers, process engineers are now relatively more expensive to employ than in 1969–1970. The authors contend that the decline in the productive output of metallurgists is the erosion of the limited time available to do professional work. Metallurgists need to get back to the basics of their profession to produce outcomes rather than being overwhelmed by processes. There is a risk that information technology we are metallurgists, not magicians 17 P D Munro and P A Tilyard can ‘enslave’ rather than ‘liberate’ with data displacing fundamental mineral processing information. The concentrator manager has to take the leading role in turning around the current unsatisfactory state of affairs. ACKNOWLEDGEMENTS The authors thank Mineralurgy Pty Ltd and MMG Ltd for permission to publish this paper. The following individuals are thanked for their observations on these matters over the years: Gary Chilman, John Glen, Greg Lane, Rolly Nice, Joe Pease, Geoff Richmond, Peter Rohner, Stuart Smith and Michael Young. The authors stress that the ideas, opinions and biases in this paper are their own. REFERENCES Colbert, P J, Munro, P D and Yeowart, G, 2009. Prominent Hill Concentrator – designed for operators and maintainers, in Proceedings AusIMM Tenth Mill Operators’ Conference, pp 23–32 (The Australasian Institute of Mining and Metallurgy: Melbourne). 18 McCarthy, P, 2006. Message from the Managing Director [online], Digging Deeper, AMC Consultants. Available from: <http:// www. amcconsultants.com.au> [Accessed: 5 June 2009]. Munro, P D, Eaton, R and Burton, E, 1982. Wear materials experience in Mount Isa concentrators, in Proceedings Second AusIMM Mill Operators’ Conference, pp 327–335 (The Australasian Institute of Mining and Metallurgy: Melbourne). O’Rourke, P J, 1995. All the Trouble in the World: The Lighter Side of Overpopulation, Famine, Ecological Disaster, Ethnic Hatred, Plague, and Poverty, 340 p (Atlantic Monthly Press: New York). Quirk, T, 2006. Correct weight [online]. Available from: <http:// www.onlineopinion.com.au/view.asp?article=5282&page=0> [Accessed: 26 July 2017]. Wills, B A and Napier-Munn, T J, 2006. Wills’ Mineral Processing Technology, Seventh Edition: An Introduction to the Practical Aspects of Ore Treatment and Mineral Recovery, 456 p (ButterworthHeinemann). Woodcock, J T, 1978. Mineral processing in Australasia 1978, Australian Mining, pp 16–90. we are metallurgists, not magicians Contents Back to the future – still on the dark side P D Munro1 ABSTRACT This is a reprise of the paper ‘Back to the future – why change doesn’t necessarily mean progress’ presented to the Tenth AusIMM Mill Operators’ Conference in 2009. It was observed that the ‘boom and bust’ cycles of the industry, together with trends in tertiary education and the effects of fly-in fly-out (FIFO) operations raised serious questions about the sustainability of human capital in the mineral processing sector. In 2016, the industry found itself in a ‘bust’ after enjoying a decade of the longest commodity price ‘boom’ in a century. In the boom did the industry make any technological breakthroughs, and/or put measures in place to improve its human capital, especially in the area of ‘professional formation’? This paper makes observations on the current performance of mineral processing engineers and the organisational milieu in which they operate. It questions whether mineral processing engineers are actually ‘adding value’ at some sites given their organisational and operational practices. Some technical trends are examined and what they might mean for mineral processing engineers. Given the above, and demographic trends for mineral industry professionals, changes to the seemingly current laissez-faire model of professional development are proposed. INTRODUCTION At the Tenth Mill Operators Conference held in Adelaide in 2009 Peter Tilyard and this author looked at ‘human capital’ in the mineral processing sector contrasting the situation with the industry that it had entered at the beginning of the 1970s (Munro and Tilyard, 2009). After seven years, it felt timely to reconsider the position, and to see if the industry had improved the situation, especially given the perception that the ‘minerals boom’ driven by China’s massive demand for raw materials was now over and the mining industry seemed be coupled with the word ‘crisis’ in the media. This is a personal view derived from over 45 years of experience in the business. In the paper, the author uses the term ‘metallurgist’ to generically cover the job titles/descriptions of primary metallurgist, mineral processor and process engineer, while ‘concentrator’ and ‘mineral processing plant’ are used interchangeably. Concentrator references are to a sulfide flotation plant but are just as applicable to any mineral processing operation. HUMAN CAPITAL – LESS ‘KNOW-HOW’ IN 2016 The lost decade From 2000 the minerals industry enjoyed the longest commodity boom in a century. In Australia for the 12 years to 2012, the world price of its mining exports more than tripled and investment spending by the mining industry increased from two per cent of gross domestic product (GDP) to eight per cent. Mackenzie and Cusworth (2016) stated that from 2005 to 2012 private new capital expenditure in the Australian mining industry grew from A$14.2 B in 2005 to A$94.5 B in 2012 for a mean annual growth rate of 31 per cent. Did the industry: •• make any real technological breakthroughs? •• improve the quality of its human capital by strengthening educational institutions and skill development schemes for graduates? 1. FAusIMM, Senior Principal Consulting Engineer, Mineralurgy Pty Ltd, Taringa Qld 4068. Email: pdmunro@bigpond.com.au In the context of an industry that was intent on increasing production at any cost, the answer to both of the above questions is ‘no’. While other economies with strong mining industries in Africa and the Americas also enjoyed felicitous times, this author believes that the industry’s processing knowledge base continued to erode. 19 P D Munro Consider the following: •• Decline in technical competency – we complained about this in 2009 and it has continued to be noticed by others (McCaffery, Giblett and Dunne, 2014). •• Decreased research and development capability: •• Closure of corporate research laboratories – Australian examples are BHP Billiton, MIM Holdings, Pasminco and WMC with diminished capability at what remains. The conversion of former corporate research and development facilities to commercial units offering services to external customers must emphasise investigating current problems at the expense of longer term ones. Major companies, who traditionally were major technical innovators are now very risk averse and obsessive about intellectual property (IP) rights. They have created bureaucracies in research and development (R&D) making it unlikely that they will ever achieve much by comparison with past efforts. •• Reduced government activity for minerals research – the United States Bureau of Mines closed in 1995 with the loss of US$100 million/a in funding. Environmental and sustainability issues are more likely to attract governmental R&D dollars than minerals industry ones. This is confirmed by looking at the respective numbers of Cooperative Research Centres (CRCs) in each sector in Australia. •• One unsettling snapshot on the current status of mineral processing is to compare the technical content on processing of the third edition Australasian Mining and Metallurgical Operating Practices, third edition (Rankin, 2013) with that in the first two editions (Woodcock, 1980; Woodcock and Hamilton, 1993). While the third edition should still be in every metallurgist’s library, it doesn’t have as much detail as the first two. The author wonders if the lack of content from operations of some major companies indicates waning interest in, and commitment to technical excellence from senior management. •• Drivel spouted by mining companies about ‘people being our greatest asset’ is just nonsense considering examples such as the lack of meaningful industry funding put into education and training, the usual knee jerk responses in the economic downturn of not hiring new graduates, not offering permanent jobs to those coming off graduate training schemes and stopping technical skills programs for professional development. Peter McCarthy of AMC Consultants was right when he said that real business improvement and value creation comes from experts who have a deep understanding of how a mining operation makes money (Anon, 2015). That is, the industry needs more technical people doing meaningful things, not less. The human resources sections of companies don’t seem to make much noise about the long-term effects on the organisation’s human capital stock when these ‘downsizings’ happen. In 1998, the Minerals Council of Australia published Back from the Brink: Reshaping Minerals Tertiary Education, the National Tertiary Education Taskforce discussion paper. With regard to the issues raised in that document short-term measures got us through the early 2000s but here we are in 2016 with reports of mineral industry related courses at universities still under continuing threat of closure. Why would a university run a mineral processing course for a small number of students requiring expensive laboratory facilities when it could fill a lecture hall with full-fee paying international students on a subject like ‘business studies’? The author is also concerned about anecdotes 20 that computer simulation studies are being substituted for laboratory time on subjects such as ‘unit operations’ to save money in process engineering courses. The situation is now worse than in 1998, considering that the demographics of the population of metallurgists will result in imminent loss of technical expertise as older people leave the industry. Professional formation and development The usual suspects of authors (Drinkwater et al, 2011; Drinkwater and Bianco, 2013; Drinkwater and Napier-Munn, 2014; McCaffery, Giblett and Dunne, 2014) have discussed the need for professional formation and development. This author will examine, in more detail, the conversion of chemical engineers into metallurgists. Quoting directly from Drinkwater (2015): Data collected in Australia in 2011 (Lind, 2013) showed that most metallurgists in Australia took their first degrees in chemical engineering, chemistry, materials science or engineering and a variety of other disciplines; only 25 per cent studied in programs with the words ‘mineral process’ or ‘metallurgy’ in the name. It may be surprising to some of our younger colleagues to learn that this is not a new phenomenon. Many of our most prominent senior metallurgists started out 30 or more years ago as analytical chemists, materials scientists, steel-works cadets, instrument technicians and (of course) chemical engineers. Chemical engineers are the largest and most reliable source of supply of new metallurgists. Chemical engineering educators and practitioners point out that dealing with solids is more difficult than gases and liquids (Merow, Phillips and Myers, 1981; Nelson, Davies and Jacob, 1995; Merow, 2000). In the minerals business, the solid (ie ore) tends to be heterogeneous and to change over time. Metallurgists spend more time than chemical engineers in their tertiary studies dealing with solids. The industry successfully converted chemical engineers into metallurgists through a combination of on-site training and formal courses. FIFO operations do not meet the industry’s requirements for the development of a metallurgist’s technical skills. Formal continuing education programs such as Metskill (Drinkwater and Bianco, 2013) are struggling in an economic environment that has put cost reduction ahead of developing its people. In 2016, there are diminished employment and professional development opportunities for metallurgists. STILL GOING BAD The author includes a list of some examples of egregious operating practices, malfeasances and misunderstandings to move the reader out of his/her comfort zone about how the industry is running plants and offer a quantum of solace through Schadenfreude (ie ‘well at least we aren’t as bad as that’): •• The bizarre concept of ‘value engineering’ in plant design, where the norm is to leave 25 per cent ‘fat’ in the design for later removal – another way to look at it is the art of rendering an economically marginal project technically unviable by taking ‘bold’ decisions on equipment sizing, selection and layout. For an alternative view on plant design refer to a paper on the design of the Prominent Hill concentrator (Colbert, Munro and Yeowart, 2009). •• An acceptance of mediocrity in equipment running times – Bougainville Copper showed what could be done by understanding the basics (Tilyard, 2009; Tilyard we are metallurgists, not magicians Back to the future – still on the dark side and Clarke, 2010). Alternatively there are managements that expect Bougainville-type outcomes after reducing the maintenance workforce. •• The existence of three large concentrators without ore:water ratio control on the primary grinding mill, something that had supposedly become standard in the 1960s. •• The fact that at a recent international conference a colleague underwent the torture of listening to a presentation extolling the virtues of adding a hydrocyclone to a grinding mill and operating in closed circuit. What will they think of next…gasp! •• The installation of hydrocyclones without vortex finders, enduring a long run of bad metallurgical results, only to find out that poor classification in the grinding section was the cause. •• A new flotation circuit that experienced 99 flotation cell ‘sanding’ events in 120 days and even more ‘near sanding’ ones, causing poor metallurgy and resulting in some blocks of cells decreed to be inoperable and thus bypassed – the concentrator operating staff whinged about the cells ‘having problems’ and being ‘no good’ but couldn’t trouble themselves to quantify the problem. They did not share these facts with the engineers who were designing an expansion of the flotation section which was proceeding based on using the same cells. This author expected that the operating staff would have shown a modicum of interest and initiative in resolving a problem that they would end up having to live with. •• Incorrect maintenance decisions and practices affecting metallurgical performance. At times, it seems as if all the good words spoken and written about the need to stop people operating in ‘silos’, and the dangers of inappropriate key performance indicators, have been ignored. When this author sees lowering maintenance costs by increasing equipment service intervals causing poor metallurgical performance, the author wonders if concentrators operate in some parallel universe. Peter Tilyard and the author commented on this in their 2009 paper and as soon as metal prices dropped, on too many occasions, it has been ‘back to the future again’! •• Metallurgists willingly abdicating important decisions affecting metallurgical performance to the maintenance/ reliability engineering section – a probable contributor to such aberrant outcomes is that while operating costs can be measured to A$0.01/t, metallurgical benefits are sometimes expressed more nebulously. This results from a lack of data prescribed in the section ‘Mineral processing basics’ below and the reluctance of too many metallurgists to tear themselves away from their computer screens and see what is happening in the concentrator. Two examples suffice to demonstrate the problem: 1. A very large copper concentrator increased recovery by three per cent after improved maintenance restored the rougher flotation cells to the original installed condition. 2. A maintenance section decided to cut the baffles out of a flash flotation cell to reduce wear, resulting in no feed going to the gravity concentration section. •• Achieving 50 per cent running time for regrind mills where the copper sulfide minerals in the final concentrate were only 70 per cent liberated. The predominant copper minerals were secondary sulfides, so the operating staff comforted themselves that they were making a concentrate assaying 22–25 per cent Cu we are metallurgists, not magicians when it was actually a low quality one with less than 50 per cent w/w copper sulfide minerals. •• The testing of a new supposedly stronger flotation collector, which actually had a shorter length carbon chain than the existing collector – Sutherland and Wark’s classic text Principles of Flotation (1955) states that contact angle is dependent on the length of the carbon chain. Knowing the chemical composition and structure of reagents would prevent time being wasted on meaningless testing of reagents. Two other irritants are metallurgists trying to fix a mineral liberation problem with reagents and not understanding the statistics of testing. With a supposed sound grounding in statistics during tertiary education and the availability of Tim Napier-Munn’s seminal book Statistical Methods for Mineral Engineers: How to Design Experiments and Analyse Data (Napier-Munn, 2014) there is no excuse for not doing tests rigorously. If the metallurgists can’t lever off their education and training to add value, then as mentioned below, why have them on-site? •• The act of doing locked cycle flotation tests to ‘save time’ before establishing conditions using batch tests and compositing drill core over unmineable intervals. •• The installation of a new plate and frame filter press at a cost of A$7.5 million to replace existing disc filters for concentrate dewatering, only to find out that the latter could do the duty when the concentrate thickener underflow pump was upgraded, to allow delivery of higher density slurry to the disc filters. BIG DATA – A DIRGE ON PLANT INSTRUMENTATION: LET’S DO GEOMETALLURGY INSTEAD Instrumentation reality check Mining company executives and the technical press extol the virtues of ‘big data’ and the wonders this concept will supposedly achieve towards improving operating outcomes. There is a credibility chasm between the lofty concept of ‘big data’ and the reality in the current general unsatisfactory state of plant measurement instrumentation and process control systems. These are too often characterised by low availabilities, inaccurate calibrations, discarded process control strategies etc. The author distinguishes between ‘embedded instrumentation’ in a piece of equipment eg ammeter, voltage, electric motor rev/min versus instrumentation specific to a concentrator. Problems with the measuring and sensing elements such as density gauges, flowmeters, level sensors, on-stream analyser streams etc are the inevitable result of reducing maintenance input; the author can’t see how you can expect high running times from part-time instrumentation support on a FIFO basis. Another concern in larger companies is the tyranny of enterprise data management systems typified by the persistent encroachment of corporate information technology (IT) interests into the process control area. IT people seem to think that if it’s a computer then they want to own and manage it. Too often the result is the imposition of inappropriate software standards by people who may know something about computers but very little about process engineering. This ‘top down’ approach stifles innovation in process control. This author has yet to hear of a mineral processing plant controlled in real-time by SAP. 21 P D Munro Geometallurgy Consider one area where the industry actually does have data but lag woefully in turning it into information resulting in actions for the plant operators. As mentioned in Munro and Tilyard (2009), geologists are better custodians of data than metallurgists. They collect a plethora of data from drill core, such as the following: •• assays •• rock type and alteration from •• geological logging •• petrological examination •• photographs •• mineralogy and textural analysis from •• hyperspectral logging •• mineragraphy •• XRD (X-ray diffraction) •• automated methods such as QEMSCAN and MLA •• geotechnical data •• rock strength data eg UCS, PLI •• competence RQD. To this should be added the location in 3D mineralised space of every sample taken for mineralogical examination, comminution and flotation tests etc. Unfortunately, current operations often make little use of the extensive metallurgical test work done for a feasibility study and fail to properly integrate subsequent test work into this body of knowledge. They seem to be two separate ‘silos’ rather than being regarded as a continuum of knowledge. The author wonders how interested people are in their profession when one encounters operating metallurgists who either have not read the feasibility study or, if done so, failed to understand it. People talk about geometallurgy, but when all is said and done there is a great deal more said than done. Some operations do use geometallurgy in managing plant operations (Butler et al, 2016) but remarkably few have fully integrated it into their way of doing business. In 2016, the fact that too many geologists and metallurgists are still operating in ‘silos’ is totally the fault of the latter. The author hasn’t observed any significant improvement in this over the last seven years with people continuing to be resolutely qualitative rather than quantitative. For example, throughput variations continue to be ascribed to the ore being ‘harder’ or ‘softer’ rather than hearing a metallurgist at the morning/ daily meeting say something like ‘our current feed is now from bench/stope ‘AB’ where the predominant rock type is andesite; grindability data for this rock type shows a Bond Ball Mill Work Index of ‘A’ kWh/t, JK Drop Weight/SMC a × b of ‘B’ etc so the predicted throughput from the grinding simulation model should be ‘X’ t/h’. This author dreams of people at the daily meeting in every concentrator reviewing a 3D representation of the orebody on a screen that incorporates the data described, explaining both yesterday’s performance and predicting future results. We have the technology to do this, but don’t use it. Bureaucratisation of the metal balance Another gripe is the bureaucratisation of the metal balance; it has become integrated into an enterprise data management system promoted by accountants and the IT department. There are very high ownership costs of these metallurgical accounting add-ons to the enterprise data management 22 system. Claims that they are better supported than Excel are just tosh; hasn’t anyone heard of Microsoft? This author fears that they further encourage metallurgists to spend even more time in the office rather than in the plant, as they won’t tell you that: •• the head sampler is stuck at the edge of the stream and is receiving splash •• the flotation operator is decanting the slurry sample and losing the higher grade fines before filtration. We are missing the point if the industry is looking for an IT solution to what has always been an equipment and people problem. A realistic treatment of measurement errors is often lacking in these systems, a concept that many accountants who drive them can’t comprehend as they deal in money, which can be counted; rather than tonnes or assays which, are measured. CONCENTRATOR OPERATIONS Mineral processing basics Nothing has changed from Munro and Tilyard (2009) in the fundamental data requirements for managing a mineral processing plant. A particular peeve is the absence of a credible metallurgical development plan. Some of the documents that claim to be one are laughably unfit for purpose. Below are common examples of bad practice: •• A bewilderingly large number of ‘metallurgical initiatives’ – some operations have hundreds of them. The manager and technical superintendent should allocate the professional time required to complete each initiative then relate the total to the ‘discretionary hours’ available for the metallurgists from both internal and external resources. Going through such a list with ‘competent person hours’ as the limiting resource leads to the realisation that the deposit will have been mined out before even a small fraction of the initiatives have been completed. •• Competing priorities – this author has seen a set of metallurgical initiatives with 30 ‘priority 1’ items. The compilers of such a list must have lacked the basic mineral processing data listed above to appropriately allocate priorities according to ‘pay-off’, ‘time to complete’ etc. •• Vague targets – an example would be ‘increase copper recovery by two per cent’ or slightly better, ‘increase copper recovery in rougher flotation by two per cent’. What this author wants to see is something like ‘increase recovery by four per cent of composite particles that are 50 per cent chalcopyrite or more with non-sulfide gangue in the +75 μm -106 μm size fraction in rougher flotation’. The first two examples above are ‘motherhood’ statements. They risk that if a metallurgical initiative is implemented to ‘increase copper recovery by two per cent’, its benefit could be diminished by factors such as a change in ore type or operating practices. It is much easier to demonstrate to senior management that you actually did ‘increase recovery by four per cent of composite particles that are 50 per cent chalcopyrite or more with non-sulfide gangue in the +75 μm -106 μm size fraction in rougher flotation’ as opposed to not achieving the more general target. You retain credibility with senior management who are rightly sceptical of previous promises about metallurgical improvements which, if aggregated, often would give a metal recovery over 100 per cent. This leads you to understand the process according to the axiom of size-by-size mineral we are metallurgists, not magicians Back to the future – still on the dark side particle behaviour by liberation class but this a fundamental of the profession. This author wants a focused target instead of a general one where the result can be obscured by the ‘noise’ of plant operations. If the concentrator manager doesn’t have a credible metallurgical plan based on process fundamentals then one will be imposed by senior management, generally with unsatisfactory results. An excellent management book is Moneyball: The Art of Winning an Unfair Game by Michael Lewis (2003), which describes how the Oakland Athletics baseball team managed by Billy Beane successfully competed with a player roster that lacked the stars fielded by other teams and had a budget only one-third of that of the New York Yankees (read the book – the Hollywood movie left out the mathematics, which was the really interesting part). Quoting directly from the book: One cliché is the ‘five-tool player’, a player who can hit for average and power, and run, field and throw like a demon. You still hear it all the time. Right. And everyone wants five-tool players. There’s just very few of them on the planet! But virtually every player has one tool. So, we started saying, ‘Well, let’s investigate each player’s strength. Is there a way to combine all these strengths and cover up some of their deficiencies? We’re not going to be able to do away with their deficiencies. But as a team, can we do it all?’ It was about piecing together players we had on our roster and building a team that could do everything. You had to find value where it wasn’t readily apparent. One lesson from Moneyball was that you can’t assume that a collection of apparently talented individuals will serendipitously give the required result. Hiring someone who looks like the ‘complete metallurgist’, analogous to the ‘fivetool player’, and just leaving him/her to it under a ‘laissezfaire’ approach isn’t getting us the required outcomes listed above under ‘Mineral processing basics’. A second learning from Moneyball is that you can compete by focusing on the separate components that contribute to the desired outcomes. If you accept that you need the items in the ‘Mineral processing basics’ list then you should prescribe that they have to be produced, it’s not some kind of an option; then work out the processes and actions required from both internal and external resources to make it happen. Running under the premise that a ‘champion will somehow spontaneously emerge’ isn’t delivering the goods. Meetings – still the practical alternative to work The limiting resource to getting anything done is ‘competent person hours’ so it’s a wonder that too many concentrator managers have a long and unfocused morning/daily meeting. While such gatherings can be social successes, I deplore the waste of time of having up to 20 people milling around for an hour. The morning/daily meeting should not be an exercise in participatory democracy if you have to endure a junior metallurgist drone on for ten minutes explaining 24 hours of ‘screen grabs’ of primary crusher operating variables in 15 pastel colours. All the people at the meeting need to know about the crusher is the tonnes in the run-of-mine stockpile, crusher operating hours and the tonnes in the crushed ore stockpile. In this author’s dream world, the geometallurgy section of the meeting should not be a long-winded discourse on geology, but emphasise the nature of the future ore feed and what actions the operators should take in the next 24 hours to meet the metallurgical performance targets. As a young we are metallurgists, not magicians metallurgist, the author witnessed a senior manager fully comprehending the operations of two large concentrators and two smelters in a little over an hour including travelling time between each plant. The emphasis was on information rather than data, the future rather than past, with metallurgists held accountable for performance and subjected to ruthless questioning about any deviations. We can learn from the ‘orders group’ concept used in military forces on how to run a successful meeting but if you want ‘participatory democracy then …’. This author has not sighted any evidence showing that the workforce has superior skills in chemistry, physics and mechanical aptitude compared to 45 years ago, excluding the ability to send text messages. Indeed, with respect to issues like vaccination, ‘organic’ food and homeopathy etc, one could believe that society has become more technologically illiterate! SOLID LIQUID SEPARATIONS – NEGLECTED UNIT OPERATIONS Solid liquid separations – uninteresting and unloved? Mineral processing is simplistically described as ‘LSD’, that is: •• liberation •• separation •• disposal. The ‘disposal’ part of the business for both product and waste streams has been ancillary to the other two sectors of ‘liberation’ viz comminution + classification and ‘separation’ as done by gravity concentration, flotation and other methods. Taking the case of a sulfide flotation concentrator, previously mineral processing engineers have tended to focus their intellectual efforts on the ‘interesting’ activities of grinding and flotation; the former is usually the highest cost unit operation and the latter the bit where it is easily discerned if money has been made or lost. An example of neglect in solid-liquid separations is the indifference about the operation of clarifiers and thickeners (the two duties hereafter combined in the single unit operation of ‘thickening’) which are ubiquitous in concentrators and extractive metallurgical plants. Now into my fifth decade in the business, this author has seen a considerable number of them, and the operation of many could only be described as ‘poor’ to ‘appalling’. Depressingly, it doesn’t appear to be getting any better with the passage of time. Malfunctioning solid-liquid separation unit operations threaten the viability of hydrometallurgical process plants and recycled thickener overflows containing fine solids can materially affect flotation performance. Thickening is a good example of this neglect. Consider the following thickener fundamentals: •• In a thickener, there are two flows: simplistically solid going downwards and liquid going upwards. Calculation of the rise velocity of the liquid going upwards gives a number that is usually higher than the settling velocity of the finest particles in the feed. Note that the settling rate of a ten micron quartz sphere in water is 0.6 cm/min at 25°C (Dorr and Bosqui, 1950). Hence the importance of adequate flocculation (and coagulation in water treatment) to create agglomerates with a higher settling velocity than the rise velocity. •• Hydrometallurgical plants often have multiple thickener operations eg counter-current decantation. Taking a desired 92.5 per cent operating time with a total of five thickeners in series in the flow sheet means that each thickener has to be performing as specified 98.5 per cent 23 P D Munro of the time ignoring all other causes of downtime and poor operation! qualities. Water treatment could become common in concentrators. In a mineral processing world of finer particle sizings, due to the nature of ores treated, leading to more difficult solid-liquid separation duties, the following are some of the depressing realities of thickener operations: 2. Tailings – this is the ‘big one’. The mining industry has a poor and increasingly indefensible record managing tailings dams; this author prefers the word ‘dams’ to the euphemism ‘tailings storage facilities’. Doubters about this should spend time on the internet using the search term ‘tailings dam failures’. To dismal incidents such as Certej (Romania) 1971, Buffalo Creek (USA) 1972, Val di Stava (Italy) 1985, Omai (Guyana) 1994, Merriespruit (South Africa) 1994, Los Frailes (Spain) 1998 and Baia Mare (Romania) 2000 we can now add the recent events of Mount Polley (Canada) 2014 and Samarco (Brazil) 2015. Over the last century Azam and Li (2010) estimated the failure rate of tailing dams at 1.2 per cent compared with 0.01 per cent for conventional water retention dams. What an indictment on our industry! This author sees a future where dry stacking of tailings will be enforced by regulation. An example is the proposed 72 000 t/d Rosemont copper-molybdenum-silver operation of Hudbay Minerals near Tucson, Arizona, USA, which will only be permitted if tailings are dry stacked. If dry stacking is mandated then the unit operation of filtering tailings will become as important as grinding in terms of plant throughput and operating cost. Metallurgists are the best qualified people to design and operate such dewatering facilities. If this industry continues its current lack of interest in the ‘back end’, the civil/ geotechnical engineers will ‘eat our lunch’ just as the mining/geotechnical engineers have got into the paste fill business. •• Flocculent systems malfunctioning with incorrect addition and subsequent dilution; flocculents once formed are ‘maltreated’ in their passage to, and through, the thickener feedwell. •• Feedwells in poor condition leading to excessive turbulence damaging flocs, side feeding etc. •• Thickeners acting as a further stage of cleaner flotation with voluminous froths on the surface exacerbated by upwelling air bubbles; technologies to de-aerate flotation concentrate froths have been available for over 15 years (Garraway and Kaboth, 2001) and should be standard for such duties. •• Solid-laden concentrate thickener overflows reminding one of the Dutch farm adage ‘too wet to plough, too dry to drink’. •• Thickener overflow launders choked with deposited solids. •• Thickener underflow density reduced to cope with inadequate pumping systems: this author has to suppress a tirade of vituperation when told by a process engineer that the downstream filtration stage ‘works better at lower solids density’ when what he meant was that the underflow pumping system was undersized and couldn’t deliver a high density slurry to the filters. How could someone claim to be a professional metallurgist after making such an asinine statement? •• Too often the suggested remedy is to install additional instrumentation when the problems are caused by flawed process fundamentals. Process engineers are encouraged to get ‘back to basics’ (has anyone ever made a credible case for leaving them?) on thickening. This includes learning from the excellent work done by CSIRO in the AMIRA P266 Project ‘Improving Thickener Operations’. Paradigm revolution in concentrator operations – driven from the ‘back end’ The author discerns a trend that processing aspects of mining operations and projects will be increasingly driven from the ‘back end’ influenced by two main issues: 1. Water – generally, the mining industry will not be allowed access to water until competing demands for human, agricultural and pastoral uses have been met. The result is that the industry has to maximise both water recovery from tailings and recycling of water. This is not a novelty for Australian mineral processing plants, but it is for some of the jurisdictions where we work. The move to dry stacking of tailings discussed below means operating the plant with a higher proportion of recycled water than the industry has considered the ‘norm’. This reduces the ability to maintain water quality by bleeding out deleterious chemical species via the tailings stream. A build-up of certain chemical species will affect the metallurgical performance of flotation which is a separation process dependent on the quality of mineral surfaces. Johnson (2013) has discussed treatment of recycled process water to achieve specific chemical 24 THE FUTURE FOR METALLURGISTS Metallurgists – are they needed? McCaffery, Giblett and Dunne (2004) asked whether we still needed metallurgists. This author accepts that we still do, but would like to see more evidence that they are making a positive economic contribution as this author is currently unconvinced about the value of much of the ‘on-site professional hours’, particularly in FIFO operations. Consider a typical FIFO site with the following professional staff: •• concentrator manager •• metallurgical superintendent •• two plant metallurgists •• two project metallurgists. Annual cost to the employer would be at least A$1 million/a. If the reality of the metallurgists on-site: •• have gaping deficiencies in the list of ‘Mineral processing basics’ •• are being used for clerical rather than technical tasks. Managers and senior professionals are to blame for the allocation of metallurgists to routine and mundane tasks instead of process improvement ie ‘discretionary time’ (Munro and Tilyard, 2009). Consider things such as not being able to manage a good plant survey and not doing statistically valid test work. (This author has difficulty remembering when he last went to a concentrator and the metallurgists could show him actual corrected and reduced efficiency curves for the hydrocyclone classifiers) •• are unable to sustain gains •• lack process or corporate memory we are metallurgists, not magicians Back to the future – still on the dark side •• have no awareness of current and past operating practices for the type of ore being processed and seemingly little interest in finding out Metallurgists are too narrowly focused on liberation and separation; solid-liquid separations are likely to be the future ‘drivers’ of concentrator design and performance. •• are guilty of other technical malfeasances as mentioned has been mentioned. A new model for the deployment of metallurgists could have less technical people on-site using experienced external technical people in a scenario that provides genuine professional development of junior metallurgists. If metallurgists on-site aren’t using the technical skills they supposedly acquired during four years of tertiary education, then how could a company justify having them? Is their presence some kind of ‘Potemkin village’ to reassure outsiders that metallurgy matters? A possible new model A person more interested in outcomes than appearances might consider how he/she might alternatively spend the A$1 million/a outlaid for the metallurgical team. Here are some heresies to current practices: •• the concentrator manager could be either a metallurgist or a skilled production superintendent •• the metallurgical development plan is produced and monitored by head office metallurgists and/or external consultants •• clerks perform many of the tasks of the plant metallurgists •• one can buy a lot of external ‘Competent Person hours’ for the yearly salary of a metallurgist on-site who is effectively a clerk and should be quite demotivated acting as one. This new model has less technical people on-site and uses experienced external technical people in a scenario that provides genuine professional development of junior metallurgists. There are analogies to the South African ‘mining house’ model where site managers had a reporting line on technical issues to consulting engineers and practices in the oil industry where much of the expertise comes from specialist consultants. CONCLUSIONS The ‘mineral boom’ since 2000 has not led to any technological breakthroughs nor improved the quality of our human capital by strengthening educational institutions and skill development schemes for graduates. It is the author’s opinion that the situation is now worse than in 1998, considering that the demographics of the population of metallurgists will result in imminent loss of technical expertise as older people leave the industry. The industry is not behaving appropriately to both improve the skills of its metallurgists and ‘convert’ chemical engineers to metallurgists. This is particularly so given the large number of FIFO operations. A meaningful use of ‘big data’ would be to fully integrate geological and metallurgical databases to make geometallurgy a practical reality. Concentrators are still running with the usual glaring examples of egregious operating practices, malfeasances and misunderstandings. Poor metallurgical results due to illinformed maintenance cost savings make you wonder if the industry will ever learn from previous mistakes. Having the basics of mineral processing on-site to effectively operate a concentrator is still the exception rather than the rule. ACKNOWLEDGEMENTS The author thanks Mineralurgy Pty Ltd for permission to publish this paper. The following individuals are thanked for their continuing observations on these matters over the years: Peter Colbert, John Glen, Rolly Nice, Joe Pease, Peter Rohner, Tom Shouldice, Stuart Smith, Jorma Tuppurainen and Michael Young. The author stresses that the ideas, opinions and biases in this paper are his own. REFERENCES Anon, 2015. Mining consultant rejects rivals’ advance, Mining Magazine, November. Azam, S and Li, Q, 2010. Tailings dam failures: a review of the last one hundred years, Geotechnical News, December, pp 50–53. Butler, C, Dale, R, Robinson, S and Turner, A, 2016. Geometallurgy – bridging the gap between mine and mill: a case study of the Degrussa geometallurgy program, in Proceedings GeoMet 2016, pp 77–88 (The Australasian Institute of Mining and Metallurgy: Melbourne). Colbert, P J, Munro, P D and Yeowart, G, 2009. Prominent Hill concentrator – designed for operators and maintainers, in Proceedings Tenth AusIMM Mill Operators’ Conference, pp 23–32 (The Australasian Institute of Mining and Metallurgy: Melbourne). Dorr, J V N and Bosqui, F L, 1950. Cyanidation and Concentration of Gold and Silver Ores, second edition, p 23 (McGraw-Hill: New York). Drinkwater, D, 2015. What should be in the Mineral Processing curriculum?, The AusIMM Bulletin, 2:44–47. Drinkwater, D and Bianco, N, 2013. Developing technical excellence in young Australian metallurgical professionals – a new graduate development program, in Minerals Industry: Education and Training, IMPC Monograph (eds: J Cilliers, D Drinkwater and K Heiskanen), pp 117–129 (Indian Institute of Minerals Engineers: Jamshedpur). Drinkwater, D, Bradshaw, D, Tilyard, P and Munro, P, 2011. Professional development for metallurgists – improving technical skills, in Proceedings Metallurgical Plant Design and Operating Strategies (MetPlant 2011), pp 39–48 (The Australasian Institute of Mining and Metallurgy: Melbourne). Drinkwater, D and Napier-Munn, T, 2014. Why good professional development is key to profitability in the mining industry, Chapter 20: Mineral economics and human capital, in Proceedings XXVII International Mineral Processing Congress (IMPC 2014) (ed: J Yianatos), pp 28–37, Chile. Garraway, B and Kaboth, K, 2001. The Frothbuster – innovative thickener froth reduction technology, in Proceedings 33rd Annual Operator’s Conference Canadian Mineral Processors, pp 17–24, (The Canadian Institute of Mining, Metallurgy and Petroleum: Montreal). Time management to ‘create Competent Person hours’ is still a problem. Johnson, N W, 2003. Issues in maximization of recycling of water in a mineral processing plant, in Proceedings Water in Mining 2003, pp 239–246 (The Australasian Institute of Mining and Metallurgy: Melbourne). Many metallurgical development plans need to be trimmed down to reflect the ‘possible’ and to have meaningful priorities. Lewis, M, 2003. Moneyball: The Art of Winning an Unfair Game (W W Norton & Company: New York). we are metallurgists, not magicians 25 P D Munro Lind, G, 2013. Minerals industry engagement in metallurgical education in Australia’, in Minerals Industry: Education and Training (eds: J Cilliers, D Drinkwater and K Heiskanen) pp 87– 104 (Institute of Minerals Engineers: Jamshedpur). Napier-Munn, T J, 2014. Statistical Methods for Mineral Engineers, How to Design Experiments and Analyse Data, JKMRC Monographs No 5 (Julius Kruttschnitt Mineral Research Centre University of Queensland: Indooroopilly). Mackenzie, W R and Cusworth, N, 2016. The use and abuse of feasibility studies – has anything changed, in Project Evaluation 2016, pp 133–148 (The Australasian Institute of Mining and Metallurgy: Melbourne). Nelson, R D, Davies, R and Jacob, K, 1995. Teach’em particle technology, Chemical Engineering Education, 29:12–16. McCaffery, K M, Giblett, A and Dunne, R, 2014. Sustaining metallurgical competencies, Chapter 20: Mineral economics and human capital, in Proceedings XXVII International Mineral Processing Congress (ed: J Yianatos), pp 15–27, Chile. Merow, E W, 2000. Problems and progress in particle processing, Chemical Innovation, 30:35–41. Merow, E W, Phillips, K E and Myers, C W, 1981. Understanding Cost Growth and Performance Shortfalls in Pioneer Process Plants (The Rand Corporation: Santa Monica). Minerals Council of Australia, 1998. Back from the Brink: Reshaping Minerals Tertiary Education, National Tertiary Education Taskforce Discussion Paper, February. Munro, P D and Tilyard, P J, 2009. Back to the future – why change doesn’t necessarily mean progress, in Proceedings Tenth AusIMM Mill Operators’ Conference, pp 5–11 (The Australasian Institute of Mining and Metallurgy: Melbourne). 26 Rankin, W J (ed), 2013. Australasian Mining and Metallurgical Operating Practices, third edition (The Australasian Institute of Mining and Metallurgy: Melbourne). Sutherland, K L and Wark, I W, 1955. Principles of Flotation, pp 98– 100 (The Australasian Institute of Mining and Metallurgy: Melbourne). Tilyard, P J, 2009. The Bougainville Copper concentrator: a retrospective – part 1, The AusIMM Bulletin, 5:73–81. Tilyard, P J and Clark, N, 2010. The Bougainville Copper concentrator: a retrospective – part 2, The AusIMM Bulletin, 6:69–74. Woodcock, J T (ed), 1980. Mining and Metallurgical Practices in Australasia, third edition (The Australasian Institute of Mining and Metallurgy: Melbourne). Woodcock, J T and Hamilton, J K (eds), 1993. Australasian Mining and Metallurgy, second edition (The Australasian Institute of Mining and Metallurgy: Melbourne). we are metallurgists, not magicians Contents Undermining productivity – when good key performance indicators go bad J D Pease1 ABSTRACT All organisations, from businesses to sports teams, have key performance indicators (KPIs). These are always well-intentioned. A small number are crucial – indeed, they are ‘key’. But without constant vigilance KPIs grow like weeds and do more harm than good. It takes strict discipline and a deep business understanding to maintain truly ‘key’ performance indicators that benefit the organisation. ON ARCHAEOLOGY, TREES AND HOME INSULATION An archaeological team had uncovered the remains of an ancient settlement, and needed to recover as much as it could before the next wet season. Luckily there was a local population of poor, hardworking villagers who enthusiastically joined the dig. As the work progressed, the organisers were initially excited by the large amount of ancient pottery recovered. But gradually they became disappointed that they rarely recovered a complete piece – almost everything was broken. As ever more fragments were returned, this moved from disappointing to perplexing to statistically inexplicable. The archaeologists checked their numbers, reviewed data from other sites, considered all the technical factors. Finally – and sadly too late – someone asked them how they paid the villagers. ‘Well, we pay them for each piece they bring us’. The villagers may not have had much formal education, but they certainly understood management KPIs. A small Australian town had become a desirable destination for ‘tree changers’. A new council was elected with a mandate to protect the town’s leafy green image. They passed a by-law that all trees over a certain girth would be listed and protected by the council. Special approval would be needed to cut or even prune them. That weekend the sound of chainsaws rang out around the town. Some owners with trees above the girth cut them down before they were listed, fearing the development restrictions of a ‘listed’ tree would reduce their property value. Worse, many young smaller trees were cut down too. These should have been the next generation of trees, but their owners opted to remove them while it was legal. The most well-intended laws had precisely the opposite effect. Recent governments have excelled at this art of unintended consequences. From roof insulation to solar feed-in tariffs to training schemes, programs have been introduced that are as well-intended as they are wasteful. They seem to say ‘here is a bucket of money, you can help yourselves, but we can trust you all to do the right thing …can’t we?’ It is alarming how often well-intended KPIs cause disastrous outcomes. It is not that they are simply inefficient or ineffective. Their careless design encourages the worst behaviour. It would have been better not to have any KPIs at all. Sometimes this is called the law of unintended consequences. I just call it lazy and dumb. Thoughtless. Honestly, what did they think was going to happen? OF BANKERS, MINERS AND FOUNDING FATHERS We would like to think big business is smarter than that. But consider the Global Financial Crisis (GFC). How many bankers paid back the bonuses they ‘earned’ by writing the bad mortgages that led to the GFC? Or consider miners. Though, here the story takes longer to unfold. 1. FAusIMM, Senior Principal Consulting Engineer, Mineralis Consultants Pty Ltd, Brisbane Qld 4066. Email: jpease@mineralis.com.au In the 1950s, the underground mine at Mount Isa was one of the richest in the world. Work was hard – mining relied on hand-held drills and considerable manual labour. It was tough work in a cramped space at over 40°C and high humidity. It was quite reasonable that miners were paid relative to effort – metres drilled or tonnes mucked. The miners worked hard and both they and the company were rewarded. This was capitalism at work, aided by an appropriate KPI and reward system. But technology 27 J Pease changed, as it does. New drill rigs, new underground vehicles were developed. Everyone knew that if the company bought an expensive new drill rig to double productivity, then the operator’s rate per metre should halve. But people are people so that was hard to negotiate. There was only one manager to negotiate with maybe 50 miners each with a deep personal interest in capturing some of the productivity gain for themselves. The manager was busy, had his own KPIs to meet and couldn’t afford industrial unrest. Even if some of the benefits leaked to bonuses the company was still much better off and production wasn’t interrupted. That seems okay – until it happens over several generations of technology change. After about 40 years of this ‘creep’ underground miners in air-conditioned cabins were doing less arduous work than road workers or truck drivers but were paid three times as much. They also argued that they shouldn’t lose money when the equipment broke down – it wasn’t their fault the company couldn’t maintain it. So, they negotiated a formula to pay them the average rate of the last six shifts if the equipment wasn’t available. This encouraged them to get a high ‘run rate’ for six consecutive shifts – even if it meant pushing the equipment so hard it broke down on the seventh shift; but that wasn’t their problem. Perhaps the later generation of miners were simply lucky to be in the right place at the right time. But the system was broken. The mine was older and ore was lower grade and more complex. Some ore zones had to be excluded because they disrupted the plant. We asked the miners to avoid it or tip it to waste. But at the same time, we paid them a handsome bonus to mine it. What did we think was going to happen when no one was looking? In this case the original KPIs – simple $/metre – worked well for a while. But they didn’t stand the test of time. The founding fathers of the bonus scheme were not visionary enough in their design. Once a bonus scheme is in place it is really hard to change. You are trying to change the rules during the game, in a way that costs people money. That is not going to happen. Considered in this context, the founding fathers of democratic Constitutions deserve enormous respect. They didn’t get everything right; no-one could foresee 200 years of technological advances. But they had a wisdom about people and what drives behaviour. Constitutions have stood the test of time much better than most management KPIs. THE PRODUCTIVITY CHALLENGE After every mining boom we focus again on productivity. We cut costs where we can, we reduce staff and we look for new innovations. Yet most operating people know we can do a lot better with the equipment we already have. We don’t need a big scientific breakthrough or lots of new equipment. Most managers can list the improvements they could make. If only they could focus on the things they know to be important rather than all the other ‘bumph’ they have to do. So why can’t smart people do what they know they need to? THE ANT AND THE GRASSHOPPER Once a grasshopper managed a mill. Rather than understand minerals, it understood the company. Instead of surveying the plant, it studied the KPIs. Rather than understand the client, the smelter, the grasshopper read the marketing contract. It increased tonnage, reduced unit cost and outnegotiated the smelter. The grasshopper was promoted and lived a prosperous life. 28 In a nearby village, an industrious ant managed the mill. It strived to understand how all minerals behaved. It sampled the plant and studied real mineralogical data. This took up most of the ant’s time, but it refused to trust the Big Bad Data on the office monitor. One summer, after studying mineralogy and smelting thermodynamics, the ant installed more equipment and improved concentrate quality. It became even busier with more equipment mouths to feed, but the smelter danced for joy. Overall far less energy and cost was needed to make metal. Yet the ant missed its KPIs because unit costs increased and recovery didn’t. One day the ant missed a process-improvement meeting because it was busy doing a plant survey. This disappointed management and the ant was quietly moved to the safety department. KENTROPY We all know the second law of thermodynamics: without the constant input of energy a system will move towards disorder – entropy. Our organisations are the same with KPIs. Without significant energy and discipline our KPIs multiply and proliferate. They are weeds that get out of control. It isn’t because our organisations lack intelligent and hard-working people. It is because they are filled with intelligent, hardworking people. As a group, that is what we do. Everyone wants to make a ‘process improvement’. We all know that others would work better if only they did things our way. The more people we have in an organisation the more layers we have and the more KPIs we have. And the less relevant they become to our essential tasks. How many readers can say they have a succinct set of KPIs that enable them to focus on the few critically important aspects of their job? Our organisations aren’t stupid, but they end up doing stupid things because they don’t apply constant energy into resisting the inexorable sprouting of well-intentioned KPI weeds. Without that constant energy, Kentropy prevails. HAS ANYONE SEEN MY KEY? The K in KPI stands for key. It must be the most overused word in business. See if you can find a business memo not peppered with ‘keys’. People now even talk about ‘the key KPIs’. Readers are encouraged to google ‘KPIs’. There are scores of titles such as ’20 000 KPIs used in practice’. Twenty thousand KPIs? Seriously? Yes, business is more complex and we all need to manage multiple things. But most of us have so many KPIs it feels like carrying a huge bunch of keys. Most of them just get in the way. Without the right one it doesn’t matter how many others you have in your back pocket. THE WISDEN OF CRICKET? In the 2000s, the Australian cricket team dominated the sport. They had rare skills. With their coach they took the game to a new professional level and made a science out of analysing opposition teams, field placements, nutrition and mental disintegration of opponents. They didn’t need much coaching on the basics of the game because they were excellent at that already. The performance focus was on other areas. But over a couple of years the champions left the team. Slowly it lost its aura. In response, management set more and more targets and goals, training and nutrition regimes. This culminated in four of the best players being sent home before a crucial game because they didn’t submit written we are metallurgists, not magicians Undermining productivity – when good key performance indicators go bad homework. Gradually two factors became apparent. First, the game wasn’t fun for them anymore. But more importantly, they simply weren’t good enough at batting, bowling and fielding. Team management previously could take that for granted. Now, without the basics, no amount of sports science and psychology and KPIs were going to help. Does this remind anyone of their own workplace? You are probably overwhelmed by KPIs and standardisation. It wears you down. You respond because you are queried about them and your performance review and bonus depends on them. But when was the last time management asked you about your grind size distribution, your cyclone efficiency curve, your mineral liberation, the source of diluents in your concentrate? These are the very basics of running a concentrator but if management doesn’t ask about them people won’t focus on them. New graduates won’t embrace them. Gradually the skills fade away. We no longer know the basics. We can’t win. Of course, other indicators are important and need your attention. But they are not ‘key’. They are not the handful of things you absolutely must get right for the business. Just as cricket in its Wisden has volumes of statistics. But a batsman at the crease only needs to know a few things: how many runs, how many wickets, how many overs? Those true KPIs need their full attention. If they get them right, the other statistics look after themselves. This is the difference between big data and the right data. SOMETIMES IT IS BETTER TO BE SUBJECTIVE One of the reasons we have so many distracting KPIs is our beloved performance reviews. As rational and numerate people, we eschew subjective measures. If something is important we must be able to measure it. So we can’t measure ore quality online but we can measure tonnes. We can’t measure valueadded at each step but we can measure $/tonne. What do we think will happen then? The most important characteristics of employees can’t be measured numerically – their integrity; how they cooperate and mentor others; their tenacity and willingness to do whatever it takes; to work across the silos abandoning their own KPIs and bonus because a higher priority arose in another department. We know these people when we see them, but we can’t put a number on it. They are the employees we want; not the grasshoppers who argue about their score for ‘cooperation’ and assiduously manage their KPI spreadsheet to maximise their bonus. We don’t like the grasshoppers, but we reward them nevertheless. We all complain about the silos in our organisation. Management says it wants to break them down. It says that, but it pays us to do otherwise. we are metallurgists, not magicians The silos we bemoan are constructed from our very own KPIs. THE KEYS TO COPING WITH KEYS The devaluation of KPIs is caused by the good intentions of intelligent people. There is hope because it is well-intended. Your approach depends on your role. For researchers and suppliers: you can’t change your client’s KPIs. But you need to understand them. If your business proposition requires the client to work across the silos, then find out if their KPIs will encourage and reward people to do this. If they don’t find another client. If an organisation can’t work across silos for its own benefit then it certainly won’t do it for yours. For supervisors and middle management: maybe your own KPIs are exhausting and you can’t change them. But you can simplify them for your own people. Give them goals that let them focus on the basics of the business – and then hold them accountable to that. Allow for enough subjectivity to encourage the types of important and positive conduct and performance that are hard to measure. Like a sports coach you know that if your team gets the basics right, your job will be easier and more secure regardless of your own KPIs. For senior management: you can’t be an expert at everything. You don’t have to have played elite sports to manage them. But you need to understand the basics of the game and how people behave and respond to incentives. You need to know who to listen to in order to pick and develop a team who are good at the basics. Then let your people focus on the basics and hold them accountable for delivering them. You must have KPIs that encourage – or at least don’t discourage – people to work across the silos for the benefit of the whole business. This is so obvious that it is rarely done. The simple concept conceals devilish design and is resisted by grasshoppers who like the simplicity of being able to manage their own KPIs and bonus independent of the organisation. Finally, you need constant vigilance against Kentropy. Like the second law of thermodynamics it is relentless and immutable. Your intelligent people (and our beloved management consultants) will constantly propose helpful new KPIs and systems. They will ask you to replace subjective measures with ‘hard numbers’ that they have developed. Everyone has a compelling argument, but the cumulative effect will smother your organisation. You need constant energy and conviction not to adopt them. Just because you pulled out the weeds last year doesn’t mean you don’t have to do it again this year. 29 Geometallurgy Contents Geometallurgy – what do you really need to know from exploration through to production? K Ehrig1 ABSTRACT You are a metallurgist, geologist, geometallurgist or processing engineer and are fortunate enough to work for an organisation who asks you to design and execute a geometallurgy program. What seems like a simple request is actually not a trivial exercise. ‘Recipe’ style manuals are not readily available. However, many ‘experts’ are lurking around willing to deliver solutions they claim will solve all of your problems. Even though similar ore deposit styles (eg porphyry Cu, Fe-oxide Cu-Au, Ni-laterites, calcrete hosted U etc) have many similar characteristics, each ore deposit is unique. Hence your geometallurgy program needs to be fit-for-purpose. This paper offers some insights gained via designing and executing geometallurgy programs from exploration through to production, and working at a mine where you are held accountable for your metallurgical performance predictors. INTRODUCTION Metal grades, mineralogy, rock and mineral texture are variably distributed across all ‘world-class’ mineral deposits. Hence the metallurgical performance of ores mined and processed throughout the production life of an ore deposit will also vary. Mining industry experience over the past 100+ years has shown that: •• ‘recovery’ = f (mineralogy, grade, ore texture, process conditions) (Bojcevski, 2004) •• future performance ≠ f (historical performance). ‘Recovery’ in this paper refers to any metallurgical performance parameter (eg ore hardness, mill throughput, flotation recovery, leach recovery, concentrate grade, reagent consumption etc). Mineralogy exerts the primary control on metallurgical performance. Recovery assumptions, based on a lack of data, usually prove to be misleading and imprecise. These points are obvious, but we (as an industry) seem to be constantly trying to convince ourselves that the above do not apply to our deposits. Think about the revenue impacts and opportunity losses when we get it wrong. The failure (or under performance) rate for mining projects remains relatively high. More importantly, the failure rates have remained relatively unchanged for decades (McCarthy, 2003). Based on numerous surveys to identify the reasons behind new mining projects and brownfield expansions not delivering to forecast, McCarthy (2003) identified the following feasibility study problem areas which lead to commissioning and operational under performance: •• mine design and scheduling (32 per cent frequency) •• geology, resource and reserve estimation (17 per cent) •• metallurgical test work, sampling and scale-up (15 per cent) •• process plant equipment design and selection (12 per cent) •• geotechnical analysis (9 per cent) •• cost estimation (7 per cent) •• hydrology (4 per cent). The driver behind geometallurgy at Olympic Dam is to reduce the technical risk to the current operations and future expansions caused by unexpected mining and process performance issues due to variable ore properties. 1. MAusIMM, Principal Geometallurgist, BHP Billiton Olympic Dam, Adelaide SA 5000. Email: kathy.ehrig@bhpbilliton.com The primary objective of Olympic Dam geometallurgy is to develop metallurgical performance predictors that reliably describe the process performance of different ore types and spatially distribute these into the resource block model for use as a fundamental input into mine planning. The geomet models are predictive mineralogy and recovery models which are applied to blocks in the mineral resource model to 33 K Ehrig enable the estimation of mineralogy, metallurgical recovery, and real value on a block-per-block basis. The secondary objectives are to identify any ores which may be ‘problematic’ to the current plant, and provide variability data of suitable quality for process plant design and future plant optimisations. And finally, the chemical, mineralogical, physical property, and ‘recovery models’, collectively called the geometallurgical model, provide the data required to support the JORC Code (2012) ‘modifying factors’. GEOMETALLURGY FUNDAMENTALS There has been a rapid increase in the volume of published geometallurgy literature over the past ten years. Numerous papers are available which describe the definition, purpose, benefits, and methodologies used in geometallurgy from the perspectives of geologists, metallurgists, and process design engineers. A few of these papers are listed with the references. This section provides highlights regarding the links between minerals and populating the resource block model and the mine plan with geometallurgical data. Minerals Metals and elements occur in ore deposits as minerals. Minerals, not elements or metals, are mined. Extractive metallurgy, in particular, mineral processing, hydrometallurgy, and pyrometallurgy extracts metals and elements from minerals. Grades or concentrations of metals and elements have been extensively used as proxies for mineral abundances. Historically, it has been easier and more cost-effective to assay a sample for a limited suite of elements than it is to measure mineral abundances. However, over the past decade relatively rapid mineralogy detection and measurement methods such as automated scanning electron microscopy (eg MLA, QEMSCAN etc) and short wave infrared (eg PIMA, HyLogger, CoreScan etc) methods have become more readily available thus permitting the measurement of mineral abundances at an unprecedented scale. In addition to the recovery relationship described above, another critical yet useful relationship is: mineral (wt per cent) = f (sample composition) The relatively low cost of obtaining multiple element assays via inductively coupled plasma optical emission (ICP-OES) and inductively coupled plasma mass spectroscopy (ICP-MS) methods opens the path to estimate mineral abundances on a sample-by-sample basis based on multielement assays using the above relationship. Obviously, the above relationship needs to be calibrated against measured mineralogy. If the recovery and mineral (wt per cent) relationships for your deposit can be established and the distribution of the process critical minerals can be quantified and mapped, then a logical conclusion is that metallurgical performance can be predicted across a deposit. The geological database, mineral resource block model and mine plan Our understanding of the mineral deposit comes from the systematic sampling provided primarily via drilling. In general, as the sampling density increases, the confidence level also increases. The geological database (includes drilling, assaying, rock mass properties etc) is very likely to be the largest data set (~100 000 to >2 million assayed drill core samples) available to a project or operation. Typical resource block models contain geostatistically estimated concentrations 34 of economic metals and deleterious elements along with some minerals. The next level of ore characterisation beyond assaying and geological/geotechnical/geophysical data is the acquisition of quantitative mineralogy and metallurgical performance parameters collected at a sufficient spatial frequency to be incorporated into various block models. If you are incredibly fortunate, the number of quantitative mineralogy and metallurgical samples is only one to two and two to three orders of magnitude less than the geological assay samples, respectively. The geostatistical techniques to estimate mineral abundances into the space between the drill holes (typically 20–200 m spacing) or samples are straightforward because mineral abundances are additive. However, this may, or may not, be the case for metallurgical parameters. One way around the potential problem of non-additivity is to develop mathematical relationships which express each metallurgical parameter as a function of additive properties such as metal grades and mineral abundances. This has been the approach taken to populate every block in the Olympic Dam resource model (~20 million blocks) with abundances of 15 minerals and >50 metallurgical performance parameters, in addition to 26 elements and metals and bulk density. This allows for the assessment of a block’s real value to recover metal. To achieve maximum benefit from your valuable geometallurgical data, it must be incorporated into the mineral resource block model because the resource block model is the primary input into the mine plan. Mine planning transforms the block model (eg 3D orebody information) into a time-based 1D ‘metallurgical or process engineer friendly form’ suitable for process design and production planning. A well designed mine plan is produced via an iterative process involving inputs from the geology, geometallurgy, geotechnical, hydrology, mine design, metallurgy, infrastructure, environmental, business valuation, and financial teams. Once a mine plan (there will be a continual stream of mine plans) is available, where each block in the resource model is tagged with a mining period, cumulative distribution curves can be generated for any variable in the block model. The curves can be produced to represent any mining period and can also be filtered based on any variable in the block model. This is a very powerful tool and provides the process design engineer with some of the data necessary to design the processing plant. THE FIT-FOR-PURPOSE GEOMETALLURGY PROGRAM In describing the fundamental aspect of geometallurgy, Sola and Harbort (2012) quoted the following which was originally sourced from Harry and Schroeder (2000): You don’t know what you don’t know You don’t measure what you don’t value You can’t value what you don’t measure If you can’t measure it you can’t control it If you can’t control it you can’t improve it. Several questions need to be considered when scoping and then addressed in a geometallurgy program: •• What, if any, are the technical confidence levels required by your project funding institution? What are the measures of the confidence levels? •• Is the project time-constrained or resource-constrained? •• What learnings (ie free lessons) are available from similar deposit styles (or other deposit styles with similar mineralogy) in the district, region, or globally? We are metallurgists, not magicians Geometallurgy – what do you really need to know from exploration through to production? •• What are the market specifications for the final products? What are the penalty elements/minerals and their limits? •• What are the payable elements/minerals subeconomic elements/minerals? and •• Which minerals and concentration ranges are deleterious to the process? change with time. Waste today may become ore tomorrow. Metallurgical performance is almost always impacted by variations in mineralogy and grade. The number of samples and variety of ore types required for testing will likely decrease as the project advances into production where the focus shifts to better understanding and managing local (production) scale variability. •• How do the process and deleterious minerals/elements occur in the mineral deposit? Model validation •• How does mineral and textural variability across the known extent of the mineral resource impact on metallurgical performance? Geometallurgy models should be treated with scepticism until they are shown to be useful. Early in the geometallurgy program, initially developed metallurgical performance predictors can be used to predict the outcomes of future laboratory testing outcomes. Model validation and model updates should evolve as testing continues during the various studies. The initial models can be used to predict the outcomes of future laboratory testing. Full scale production is the real validation of the metallurgical performance predictors. During production, there will be repeated opportunities and business requirements to improve the precision of the geomet models so that they are useful for short-term production planning! Resource understanding and project evolution From exploration into various project development stages through to the end of production, resource classification terminology such as inferred, indicated, and measured is an attempt to demonstrate the level of geological knowledge and confidence in the resource. This knowledge and confidence should be increasing as the drilling metres increase. An analogy in the engineering studies space is the increasing level of cost accuracy required when progressing from conceptual to prefeasibility (PFS) and feasibility studies through to construction, commissioning and finally into production. In an ideal world, resource confidence should be sufficient to support the next stage of project development. However, in the real world, drilling to support geological (and geometallurgical) knowledge and confidence in the resource to a level suitable for a PFS usually starts at the same time as the PFS for mine planning and process design. The same is true for the feasibility study, and even into production. More simply put, the entire project team commences their individual studies at the same time. The impact on the project is that the mine plan and cut-off grade strategy are likely to continually change as the geologists continue to discover and improve the definition of ore zones within the deposit and the geomet team continues to identify more potential constraints or new revenue streams. Hence new ore types are likely to be discovered, and more importantly the perceived relative proportions of the ore types will also continue to change. The impact on process design is that the ‘goal-posts’ will continue to move during the engineering studies and a process plant is often built which cannot meet project expectations. Geometallurgy sampling strategy Geological and resource ore types and domains may not necessarily equate to equivalent metallurgical ore types and domains. The metallurgist or process engineer needs to understand that geological ore types are based on qualitative visual estimates of mineral abundances, or as in the case of alteration zones, simply the presence or absence of a specific mineral or groups of minerals. Most geological descriptions of host lithology, alteration, and mineralisation zones are for the purposes of understanding the genesis of the ore deposit, not defining metallurgical ore types. Resource domains are usually linked to geological boundaries, but may be further refined based on metal distribution patterns within an ore or alteration type. However, when commencing sampling for geometallurgical testing, the geology and resource ore types and domains are all that is available. Initially geometallurgical sampling must be designed to gain a deposit scale understanding of the resource, so all mineral combinations across the grade spectra require sampling and testing. Remember that the classification of waste, marginal, low, and high-grade ore is based on economic criteria which We are metallurgists, not magicians ‘All models are wrong, but some are useful…’. (Box, 1979) Data integrity and security Spreadsheets should not be allowed for data storage solutions. Spreadsheets can be used to analyse the data. Properly designed and managed databases protect the integrity of the data and also allow for full integration and interrogation of all the technical data. CONCLUSIONS Back to the title of this paper, ‘Geometallurgy – what do you really need to know from exploration through to production?’ •• mineralogy, mineralogy, mineralogy •• how the mineralogy responds to likely extraction processes across all grade ranges •• the concentration of process and final product deleterious elements and minerals •• how the mineralogy changes, hence how the metallurgical performance changes over the life of the asset. Remember that the primary purpose of geometallurgy is to develop metallurgical performance predictors and to incorporate expected performance into the block model and mine plan. Geometallurgy is not process flow sheet development, this still requires traditional metallurgical testing programs. REFERENCES Bojcevski, D, 2004. Metallurgical characterisation of George Fisher mesotextures and microtextures, MSc thesis (unpublished), University of Queensland, Brisbane. Box, G, 1979. Robustness in the strategy of scientific model building, in Robustness in Statistics (eds: R L Launer and G N Wilkison), 312 p (Academic Press). Harry, M and Schroeder, R, 2000. Six Sigma: The Breakthrough Strategy Revolutionizing the World’s Top Corporation (Doubleday: New York). JORC Code, 2012. Australasian Code for Reporting of Exploration Results, Mineral Resources and Ore Reserves (The JORC Code) [online]. Available from: <http://www.jorc.org> (The Joint Ore Reserves Committee of The Australasian Institute of Mining and Metallurgy, Australian Institute of Geoscientists and Minerals Council of Australia). 35 K Ehrig McCarthy, P, 2003. Managing technical risk for mine feasibility studies, in Proceedings Mining Risk Management Conference, pp 21–27 (The Australasian Institute and Mining and Metallurgy: Melbourne). 36 Sola, C and Harbort, G, 2012. Geometallurgy – tricks, traps and treasures, in Proceedings 11th AusIMM Mill Operators’ Conference 2012, pp 187–196 (The Australasian Institute and Mining and Metallurgy: Melbourne). We are metallurgists, not magicians Contents Integrating geometallurgy with copper concentrator design and operation G Harbort1, K Jones2, D Morgan3 and C Sola4 ABSTRACT The use of geometallurgical modelling with flotability component simulation provides a design methodology with significantly less associated risk. The use of geological data for optimisation of operating plants has become a significant part of the modern process mindset. The underlying principle is to use spatial metallurgical information to drive production planning, mine planning, blast design, blending strategies and plant set-up. At a design stage the process designer can use geometallurgical information to evaluate bottlenecks and potential design flaws and propose the best investment strategy for the benefit of the project. This paper provides a brief review of various copper sites that have implemented geometallurgical studies. Two case studies are also presented. The first details the geometallurgical characterisation of the Andash deposit and methodology used to review the project’s detail design and projected production. The second discusses the geometallurgical approach undertaken at the operating Northparkes mine, both for circuit optimisation and life-of-mine planning. INTRODUCTION Early evolution of geometallurgy Geometallurgy is considered a relatively recent development. It has been suggested (Williams, 2013) that it evolved in the late 1980s or early 1990s. In reality, geometallurgy, both as a practice and a science is far older. The practice of copper geometallurgy can be dated to the first decade of the twentieth century. Dwindling stocks of high-grade ore for direct smelting or gravity concentration, coupled with the discovery of massive, low-grade Chilean porphyries were key drivers for its development (Yeatman, 1932). This led to increased cooperation between geologists and metallurgists to achieve economic extraction of copper from low-grade ores. Although practised by numerous porphyry copper mines in an ad hoc manner, geometallurgy was not to gain favour as a science for several decades. Its initial academic development was to take the form of a collaborative research project between the University of Melbourne and the University of Queensland (O’Malley and McGhie, 1939). This investigation centred on the mineralogy of the Black Star orebody at Mount Isa and its implications for mill practice. At the time it was considered outstanding ‘…in focussing upon the mind of the reader, in a lucid and emphatic manner, the metallurgical problems that result from complex sulphide intergrowths …’ (Blanchard and Hall, 1939). Not only did the work correctly predict metallurgical operation decades into the future, it also produced one of the first theses on geometallurgy. 1. FAusIMM(CP), Technical Director, Amec Foster Wheeler Australia East, Brisbane Qld 4000. Email: greg.harbort@amecfosterwheeler.com 2. Senior Analytical and Evaluation Metallurgist, Northparkes Mines, Parkes NSW 2870. Email: kellie.jones@northparkes.com 3. MAusIMM, Technical Superintendent, Northparkes Mines, Parkes NSW 2870. Email: dylan.morgan@northparkes.com 4. Process Engineer – Geometallurgy, Amec Foster Wheeler Australia East, Brisbane Qld 4000. By the 1950s geometallurgy was becoming an established concept. The first symposium on geometallurgy was held in Salt Lake City in 1955 (Anon, 1956). Discussions were very similar to those held at modern geometallurgy conferences. Key issues were considered to be the need for greater interdisciplinary communication and research (McQuiston, 1956; Kirkland, 1956; Reno Sales, 1956). In the same era geometallurgical concepts played a crucial role in the formation of resource reporting in the Soviet Union. Raw commodities were considered strategic assets, with their treatment to provide maximum national benefit (Arden and Tverdov, 2014). Soviet geometallurgy, or technico economicheskiye obosnovaniye (technical economic characterisation), included factors such as mineral complexity, treatment options, product quality and economic performance (Tverdov and Mikishichev, 2014). During this period detailed geometallurgical analysis at operating mine sites was often constrained by a lack of resources. To quote Mount Isa Mines project metallurgist A E O’Meara (1953): 37 G Harbort et al The mill research metallurgical staff has endeavoured to incorporate mineragraphy in solving mill problems and determining the effectiveness of laboratory tests, as well as examining minerals sent in by the geology department. For many years the amount of equipment available was limited and much of it locally made or improvised. This would change in 1950 when a fully equipped microscopy laboratory commenced operation at Mount Isa Mines. Geologists and metallurgists shared offices, evaluating the effects of comminution on mineral liberation and flotation performance. Another example of geometallurgical success was the Brunswick concentrator program detailed by Petruk and Schnarr (1981). In 1968 Quiston and Beachaud published their comprehensive review of sampling and testing a virgin deposit from a metallurgical perspective. They proposed ‘geometallurgy’ as a term to describe this perspective: … since geology is inextricably interwoven with metallurgy in gaining an understanding of the complexities of a deposit, eventually leading to a definition of mineable reserves, with the development of a flowsheet and engineering criteria for the planning of a successful and profitable operation. Further publications of note included the use of geometallurgy for comminution (MacPherson, 1976) and plant design (Young, 1983). The appearance of automated mineralogy and the vast amount of information it supplied was to have a major effect on geometallurgical development. In the 1970s various groups in Canada (Petruk, 1984), the United Kingdom (Jones, 1984), South Africa (Oosthuyzen, 1983) and Australia (Reid and Zuiderwyk, 1983; Reid et al, 1984; Reid and Wittenberg, 1984) began to develop optical and electron beam methods of automating the collection of point counting data. This led to the development of the QEM*SEM, later renamed QEMSCAN, and the Mineral Liberation Analyser (MLA), automated instruments that allowed the rapid identification and measurement of a desired number of mineral grains, drill core or ore sample sections. The modern era of geometallurgy The modern era of geometallurgy can be considered to have commenced circa 1985, where automated mineralogy and increasing computer availability laid the groundwork for it to become a common practice. QEMSCAN and later MLA units were installed in commercial laboratories around the world in addition to research departments in major mining companies. It has become commonplace not only to interpret the performance of operating plants by use of QEMSCAN or MLA measurements but also to assess orebody composition, including block models, and to predict plant performance from drill core and ore samples. In this process, not only the mineral abundances, but the nature of the gangue minerals, the mineral associations and the natural grain sizes are all important in predicting grind size, the design of flotation circuits and the likely recoveries and losses. Relationships between ore characteristics and concentrate grade and recovery were obtained for ‘best practice’ of the day (Jackson, Gottlieb and Sutherland, 1988). A further outcome of the QEMSCAN and MLA interpretive capabilities was the reliable prediction from studies of feedstock for grind size and liberation (Gottlieb, Adair and Wilkie, 1994). This type of study was used by the Hellyer mine in Tasmania to build up a mine model related to plant performance and the creation of stockpiles based on ore type (Lane and Richmond, 1993). Used at an early stage in the mining life cycle the resultant data allows prediction of 38 processing behaviour and processing properties for stockpiling, blending and block models (Fennel et al, 2005). In the last ten years, there has been a flurry of activity relating to geometallurgy. Excellent reviews of geometallurgy methodologies have been published by Dunham and Vann (2007), Walters (2008), Coward et al (2009), Williams (2013), Dominy and O’Connor (2016) and McKay et al (2016). The assigning of geometallurgical domains and their importance has also been detailed by a number of authors, including David (2007), Johnson and Munro (2008), Hunt, Berry and Bradshaw (2011) and Sola and Harbort (2012). A useful benchmarking of geometallurgy programs by type and depth of usage was discussed by Lund and Lamberg (2014) and Lishchuk et al (2015). Other areas of interest have included comminution geometallurgy (Alruiz et al, 2009; Suazo, Kracht and Alruiz, 2010; Mwanga, Rosenkranz and Lamberg, 2015) and process mineralogy (Evans et al, 2011; Kuhar et al, 2013). Although most of the recent publications focus on geometallurgical successes, a number also discuss potential problems (Kittler et al, 2011; Sola and Harbort, 2012). Copper geometallurgy Australia Within Australia, copper geometallurgy was initially centred at Mount Isa Mines. Hoffmann (1964) reviews the development of flotation treatment of Mount Isa’s chalcopyrite ore between 1941 and 1963. Part of the development process included microscopic examination of ore to reveal features of metallurgical significance. Subsequent test programs considered these features in terms of reagent addition and flow sheet design. During operation, liberation studies were also conducted to allow optimisation of concentrate grade and copper recovery. Geometallurgical evaluations have been conducted on Australia’s iron oxide copper-gold (IOCG) deposits. Expansive geometallurgy programs were conducted both for the design of the Ernest Henry copper concentrator (Strohmayr et al, 1998) and subsequent optimisation (Tew et al, 2003). The former studies involved core mineralogy and flotation tests on 42 drill holes. Although the drill holes represented a good cross-section of the orebody, it was reported that their compositing resulted in performance prediction issues due to underestimating the microvariability of the orebody. Latter investigations during operation used monthly modal composites to calibrate and predict performance. Each mineral was given a predicted flotation response in terms of grade and recovery. In addition, samples were composited from each mining block, with X-ray diffraction (XRD) conducted and correlated with plant performance. Investigation showed that feldspar and albite had a negative impact on throughput, while quartz and magnetite had a positive influence. For the Prominent Hill IOCG deposit, geometallurgy was used for optimising mining block models, plant design and operations trouble shooting. Khosrowshahi, Shaw and McKevitt (2009) discuss the use of transfer functions to assist in mine plan optimisation including copper speciation, gangue mineralogy, contaminants, processing parameters and concentrate quality. Barns, Colbert and Munro (2009) discuss the mineralogy approach used for geometallurgical domaining, test work and flow sheet development. Bradshaw et al (2012) consider geometallurgy in their investigation of variable performance when treating different ore blends. Perhaps the most comprehensive IOCG geometallurgical study has been that for Olympic Dam. The deposit has over 70 ore and gangue minerals, each with associated metallurgical WE are metallurgists, not magicians Integrating geometallurgy with copper concentrator design and operation properties. In the initial comprehensive geometallurgy program 500 to 1000 samples were used for full metallurgical characterisation, with approximately 10 000 samples for mineralogical characterisation (Liebezeit et al, 2011; Boisvert, Rossi and Ehrig, 2013). Olympic Dam Operations maintain a geometallurgy program to provide technical support to both the mining and processing departments. Metallurgical and mineralogical assessment is conducted on drill core within five-year production plans. Predictive mineralogy algorithms are used to estimate throughput, copper recovery and concentrate grade (Nzama and Kapo, 2014). Although the geometallurgy programs for the larger producing Australian copper mines have received significant recognition, much work has also been done on the smaller polymetallic copper operations. A number of these relate to mines within the Cobar Basin, New South Wales. The basin is characterised by metal assemblages dominated by Pb-ZnAg ± Cu at the Endeavour Mine, Cu-Zn-Pb-Ag at the CSA Mine and Cu-Ag at the Peak Mine. Loidl (2012) published a thesis on the geometallurgy of Endeavour. The comprehensive study included analysis of lithology and alteration, mineralogy and petrography, grain size distributions and liberation and their implication for processing. The CSA mine has transitioned from being a lead and zinc producer to a copper producer. This required extensive changes to the design of the grinding and flotation circuits. Ongoing optimisation has utilised scanning electron microscope analysis (James and Scamardella, 2000). The Peak mine treats ore blends from five different deposits, with significant challenges due to the inherent variability between each of the orebodies (Hartog et al, 2014; Taylor, 2011). Other polymetallic copper geometallurgy programs of note included those of Hellyer mine (Richmond and Campbell, 1992) and the Thalanga operations (Gregory, Hartley and Wills, 1987). At Hellyer core logging and mapping recorded geological and geotechnical data which was considered of importance to mining, metallurgy and exploration from the onset. By selectively extracting various textures from the mineralisation data set it was possible to construct plans and sections showing the distribution of textural zones and thus predict the ore type for each stope. These aided mine planning and production scheduling. Ore types which were difficult to treat were stockpiled separately and then blended with other ore types to optimise metallurgical performance (Downs, 1990). Diamond drill core was subjected to extensive mineralogy to determine implications for possible processing routes. The samples were further examined for evidence of ore zones or mineralogical differences between different areas of the orebody. This allowed the orebody to be classified into several categories on the basis of texture with various flow sheets tested for design purposes (Richmond and Lai, 1988). The Thalanga operations provide an example where even detailed geometallurgical analysis may not achieve targeted performance. The primary ore zone consisted of massive and semi-massive sulfides containing copper, lead, zinc and silver, as well as gold mineralisation. Three supergene ore types were designated originally according to the proportions of the valuable sulfide minerals. Liberation data and test work allowed a flow sheet to be developed for the recovery of separate copper, lead and zinc concentrates in a threestage sequential flotation process. The major difficulty in treating the Thalanga supergene ores was the separation of copper sulfides and sphalerite. The poor flotation selectivity existed in all three types of supergene. It appeared that in situ activation of sphalerite has taken place during the process of supergene alteration of the Central Thalanga deposit. This was confirmed by the presence of copper sulfate in the supergene ores and evidence of copper sulfate precipitation WE are metallurgists, not magicians occurring during stockpiling of the supergene ores after mining (Wong et al, 1991). The same situation reoccurred with treatment of the Reward deposit. Laboratory test work found that there was deterioration in flotation performance after only five days of ore aging and that this continued to adversely affect performance the longer the aging. The strategy to reduce this oxidation and subsequent deleterious effects to plant performance was to mine at a rate consistent with plant throughput, minimising stockpiles at both the mine and plant. This strategy to minimise stockpiles impacted on plant performance, as blending of ore for mixing of ore types and to minimise head grade fluctuations was not possible. Recovery loss due to the higher Fe:Cu ratios was investigated by conducting mineralogy on flotation tails samples by X-ray diffraction and electron microscope techniques. The investigation found that there was no obvious mineralogical reason for the difference in flotation response between the high Fe and low Fe samples (Kilgariff, 2003). South America Yeatman in 1932 discussed two early examples of copper geometallurgy from South America. The first was at Chuquicamata in 1911–1912. Although drilling had identified a large deposit of copper ore the mineralisation in the form of brochantite was something entirely new in large commercial copper deposits and presented new problems in ore treatment. It was found that the oxidised ore could be leached by sulfuric acid, a treatment method held with suspicion at the time. Laboratory tests were conducted on 100 t of ore taken from different sections of the deposit to determine solubility, amount of sulfuric acid available and percentages of chlorine, nitrate, iron etc. Construction of a 10 000 t/d copper leach / precipitation plant was started in 1913, with operation commencing in May 1915. The second case was that of the El Teniente deposit. The original 400 t/d gravity plant only achieved 65 per cent recovery with a feed grade of 2.5 per cent Cu, principally as chalcopyrite and, to a limited extent, bornite and chalcocite. Samples were dispatched to London for testing with the new minerals separation flotation technology. The initial tests were not successful with investigation showing that a considerable portion of the copper in the samples had oxidised during transit. This led to one of the first protocols for preservation of samples between collection and testing. Additional fresh and protected samples of ore were sent to London, with tests achieving a copper recovery of 85 per cent to 90 per cent. This evaluation would lead to the installation of flotation and form a basis for all large porphyry properties that would follow. South American copper geometallurgy has typically focused on porphyry deposits, with CODELCO having a significant role. At the Chuquicamata processing plant recovery was modelled as a function of geomining and metallurgical data and ore characteristics obtained from a historical database (Compan, Pizarro and Videla, 2015). Operational data on mill feed grades, ore hardness, particle size, mineralogy, pH and reagents, representing several months of operation, was collected and using multivariate regression techniques was used to predict recovery. The recovery model was validated using monthly plant data between January and July 2014. The model prediction shows a correlation coefficient of 89.7 per cent and a mean absolute error of 2.75 per cent. Other major geometallurgical studies by CODELCO were reviewed by Beniscelli (2011) and included El Teniente, Radomiro Tomic and Ministro Hales. The Radomiro Tomic study commenced in 1996. Mineral samples were analysed for total Cu (CuT), acidsoluble Cu (CuS), total Fe, Cl, S, Mn, Mg, Al, P, Ca, Na, F and SiO2. Also, pH leach and acid dosage tests carried out prior to 39 G Harbort et al a bench scale column leaching characterised the metallurgical behaviour of two geological units. At El Teniente, a study was conducted based on geological mapping information, optical mineralogy and metallurgical data from 731 samples. This allowed the generation of a model relating rock texture and grindability for the main igneous lithologies. For the Ministro Hales project geometallurgical characterisation allowed the identification of key process issues in terms of mineralogical species and major and minor chemical elements. These issues included low copper recovery in the mixed minerals zone and high final concentrate quality variability. In addition, Carrasco et al (2005) presented the results of several heterogeneity and Ingamells’ tests done in CODELCO deposits including Chuquicamata, Mina Sur, Radomiro Tomic, El Salvador, Andina and El Teniente. Tests considering the natural variability were used to develop accurate sampling protocols for further geometallurgical analysis. At the Minera Escondida concentrator metallurgical issues became apparent soon after start-up of the first phase of expansion: The orebody was proving to be more variable than expected and the limitations of predicting behavior from the widely spaced original diamond drill holes were apparent. Additional drilling programs were initiated, and a joint mining and metallurgy program of oreblock testing was commenced, to determine mineralogical characteristics and grinding and flotation response. This data was used to schedule the mining sequence and allow blending, so as to avoid peaks in hardness and clay content, however ore exposure was often limited which meant high variations in mill feed characteristics. (Kilgour, 1995) The Sierra Gorda deposit was identified as having three main zones of sulfide mineralisation. The hypogene zone consists of chalcopyrite, pyrite, molybdenite and bornite. Gold typically accompanies the copper sulfides. Atacamite, brochantite, chrysocolla, vermicullite, lindgrenite, powellite, ferrimolybdenite are minerals of note in the leached/oxide zone. The supergene zone contains chalcocite, covelite, digenite, bornite and chalcopyrite. The original flotation circuit product recoveries and grades were developed by Aminpro based on their proprietary simulation computer model. The final flotation circuit design criteria used in detailed engineering included modifications based on benchmarking and additional ore kinetic and variability data (Comi et al, 2013). The Candelaria mine implemented a geometallurgical project to increase the plant throughput by optimising rock breakage from blasting, crushing and grinding. The ore was characterised, and drilling, blasting, crushing and grinding processes audited to develop site-specific models for each process. Simulations were conducted to identify integrated operating strategies in the mine and plant to increase mill throughput. Recommended changes were implemented, achieving throughput increases of ten to 20 per cent, depending on the ore hardness (Muñoz et al, 2008). A number of geometallurgical studies have been published for Peruvian operations. At the Collahuasi operations studies have been conducted on both comminution (Alruiz et al, 2009) and flotation (Suazo, Kracht and Alruiz, 2010). The flotation geometallurgy model evaluated flotation as a function of air dispersion properties, the feed particle size distribution and introducing a parameter (Ф), which represented the inherent geometallurgical floatability of the ore. At industrial scale the model was able to predict metallurgical results in a time frame of several weeks with an average relative error of less than two per cent. 40 Baumgartner, Gomez and Escobar (2016) discuss the mineralogical characterisation and implications at the Cerro Corona Cu-Au porphyry mine. The operation uses a suite of geometallurgical tools including quantitative mineralogical analysis (modal mineralogy, grain size liberation and association), semi-quantitative XRD and rougher laboratory flotation tests to determine clay types and their effect on performance. At Toquepala the orebody was characterised according to lithology, mineralisation and alteration. The use of size by mineral mineralogy allows ongoing optimisation of the operating plant (Quiñones and Mattos, 2001). During the design phase for the La Constancia project (Klohn, Stephenson and Granados, 2016) a geometallurgical study was undertaken to evaluate comminution and flotation options. The study identified dendritic growths of sphalerite and chalcopyrite into pyrite, the presence of copper oxides in the supergene zone with associated recovery implications and the copper activation of sphalerite both in situ and during blending of supergene and skarn ores (Greig et al, 2009). The initial geometallurgical model estimated copper recoveries and concentrate grade and quality over two week periods for the mine life to assist in mine planning and metallurgical strategies. Antamina is a complex, highly variable polymetallic deposit. Ore is treated by campaign, where one of eight ore types is treated over periods lasting from two to 30 days. Each ore type has distinct mineralogical characteristics resulting in variable metallurgical performance and treatment. In one geometallurgical study, an assessment of mineralogical deportment and texture led to effective penalty element strategies being developed by metallurgical staff (Kormos et al, 2010). In Argentina, at the Minera Alumbrera operation, geometallurgical studies commenced approximately ten years before project development (Matar et al, 1986). They continued through plant design (Keran et al, 1998) and into operating philosophy (Harbort et al, 2000). The Instituto de Investigaciones Mineras conducted an integrated study on the deposit which included geological, geochemical and topographic modelling, geostatistical reserve estimation, mineralogical behaviour and prefeasibility studies. During the design phase mineralogy was conducted on both bench and pilot plant samples to determine optimum design. Operation has used both monthly and survey specific modal mineralogy and liberation data to optimise performance. The Technological Characterisation Laboratory in the Department of Mining and Petroleum Engineering – University of Sao Paulo conducted a significant geometallurgy program for the Sossego copper mine in Brazil (Kahn et al, 2014). The study included classifying samples by X-ray cluster analysis and detailed automated mineralogy. The study by Bergerman et al (2008) evaluated SAG mill variability via ore characterisation, JKSimMet comminution modelling and blast design methodology. Samples from both core and plant feed were submitted for Drop Weight tests. Core representing two years of the mine plan, along with plant samples were taken as part of comminution surveys. The study allowed modifications to be progressively implemented into both blasting patterns and the comminution circuit, with good correspondence to simulated results. Fonseca and Sá (2005) published results from a geometallurgical study on the Alemão IOCG deposit, Carajás, Brazil. The basis of the program was a liberation study on coarse and fine particles correlated with the performance of a mini pilot plant. The results were used to indicate the primary WE are metallurgists, not magicians Integrating geometallurgy with copper concentrator design and operation target size for grinding and to predict copper recovery from the flotation rougher stage. The liberation by grade class was used to indicate the particle size for the regrinding stage, prior to flotation cleaning stages. North America The Colorado geometallurgy symposium gives an indication of the significant focus on copper porphyry geometallurgy in North America during the 1950s. A number of presenters stressed the importance of a geometallurgical approach from initial deposit discovery through exploration and into mine planning and product (Clemmer, 1956; Richard, 1956). In addition, Kildale (1956) discussed the more complex Cu-PbZn deposits, providing examples of the effect of mineral grain size on both flotation and comminution performance. The Cyprus Pima orebody in Nevada contained chalcopyrite, bornite, native copper, chrysocolla and cuprite. In the first year of operation, a geometallurgical program was run in an effort to determine the best operating conditions on Cyprus Pima ore. Seven operating strategies were developed for the seven ore conditions that commonly occurred. Two of these ore conditions had variations depending on the tarnishing of sulfide particles. The ore types corresponded to specific areas of the pit, allowing selective mining and treatment (Ramsey, 1976). Geometallurgy at the Lavender Hill concentrator was driven by the complex copper mineralogy of the orebody. Chalcocite occurred as rims around pyrite grains and as minute veinlets along fractures within the pyrite grains, many contained a network of chalcocite veinlets. Microscopic examination of polished sections showed the chalcocite veinlets to be 10 µm thick, or less. Oxide copper formed very thin coatings on the chalcocite, barely perceptible under the microscope. Oxidation took place rapidly after the ore was broken, particularly when it was hot and humid. There was little oxidation during crushing, but significant oxidation during grinding (Martin, 1957). Geometallurgy at the Anaconda C E Weed concentrator was instigated due to variability in the Berkeley Pit. The pit was a very non-homogeneous mine with respect to ore type and mineralisation. An understanding of the geology and mine led to separate slimes and sands circuits and strategies for the treatment of ‘sweet’, ‘sour’ and ‘hard’ ores (Palagi and Stillar, 1976; Wraith and Fulmor, 1964). A more recent geometallurgy study is that of Bingham Canyon which was designed as a proof-of-concept test to develop a method of quantifying key geometallurgical properties. The deposit was divided into 33 ore domains by mine geologists and metallurgists on the basis of lithology, alteration assemblages, fracture density, copper mineralisation and metallurgical properties. This allowed a combination of geological and mineralogical characteristics to be determined that, when combined, impacted processing (Ross et al, 2009). operations was undertaken. An extensive laboratory program was developed to assess the metallurgical response of the various ores produced from the underground mine. In some cases of extremely poor performance some ore types were removed from ore reserves. In other cases, the process had to be modified to optimise circuit response to the particular ore feed. A considerable amount of mineralogical and microscopic work was completed, indicating the need for better liberation. In addition to the metallurgical laboratory work, pilot plant campaigns were undertaken to confirm the conclusions reached from bench scale studies (Urbanoski, 1993). Kidd mine conducted detailed geometallurgical analysis in 2010–2011 to determine optimum plant performance. The analysis showed that the net revenue impact of copper recovery improvement was neutral while zinc revenue decreased due to the increased losses to the copper concentrate. The key revenue driver for the project was found to be silver due to higher than anticipated recoveries and prices (Leggett and Morin, 2013). The complex Laronde ores require a series of grinding, copper/lead flotation and separation, zinc flotation, zinc tails precious metals leaching, followed by a countercurrent decantation circuit and Merrill Crowe precipitation. The plant treats a range of ore types requiring multiple metallurgical processes and optimisations, as well as operational and metallurgical philosophies that have changed to adapt to custom centralised milling (Blatter, Cayouette and Cousin, 2011). Metallurgical results indicated slight differences when ore from the Matagami Lake Cu-Zn mine was ground with different grinding media. The grinds are compared on the basis of size analyses and of the free pyrite, sphalerite, chalcopyrite and galena grains in the flotation feeds. The sizes of the free grains in all flotation feeds were different for each mineral, decreasing in the approximate order pyritesphalerite-chalcopyrite-galena. This order corresponds to the order of decreasing hardness for the minerals. In addition the grain sizes for specific minerals were different when different grinding media was used (Petruk and Hughson, 1977). The Highland Valley Copper geometallurgical study (Mitchell and Holowachuk, 1996) provides a classic example of throughput optimisation via geometallurgy. The study involved analysis of historical data and the comparison of the different intensities of alterations and rock types with actual milling rates. Milling rates derived from these studies were further defined by processing many of the ore types individually and in combination with one another. This data was supplemented by both historic Drop Weight tests and future ore tests. The study allowed an effective blending strategy to be developed with mine operations, engineering and geology personnel meeting daily to determine specific blending strategies for each 24 hour period. The approach used to produce geometallurgical domains at the Pebble porphyry Cu-Au-Mo deposit in Alaska was to first characterise representative samples from each geologically distinct area of the deposit. The samples from each area were studied using a combination of optical petrography and automated mineral mapping to define the silicate and sulfide mineralogy and the copper and gold deportment. This allowed assessment of changes in gold deportment as a function of alteration across the deposit (Gregory et al, 2013). At the Kemess Cu-Au porphyry operation, concentrate regrinding requirements were evaluated using a geometallurgical approach. Treatment towards the end of mine life resulted in a 22 per cent increase in grinding energy, a seven per cent decrease in copper recovery, a 20 per cent decrease in gold recovery and a three per cent Cu decrease in concentrate grade. Mineralogical studies indicated poor chalcopyrite/pyrite liberation, with finer grinding required in concentrate regrind (Brissette and Roman, 2012). Copper geometallurgy in Canada has a significantly higher focus on polymetallic deposits than the rest of the Americas. In order to achieve metallurgical improvements at the Brunswick Cu-Pb-Zn mine a thorough review of the concentrator The Mount Polley porphyry copper mine makes use of onsite automated mineralogy, both for optimisation and strategic planning. An initial study compiled daily mineralogy data for several weeks to generate mineral balances around the circuit. WE are metallurgists, not magicians 41 G Harbort et al This allowed strategies for mine planning, forecasting and operational tuning to be developed (Dobbe et al, 2014). The Bismark, Sabinas 2 and Tizapas concentrators in Mexico have produced copper concentrates from polymetallic deposits. In the last 15 years, emphasis has been placed on the use of modal mineralogy, mineral association and liberation characteristics to optimise operations and metallurgical performance (Magallanes-Hernández and Espinosa-Gómez, 2005). Asia Pacific The complexity of the Ok Tedi orebody resulted in numerous geometallurgical studies being conducted over its history. Sulfide porphyry ore consisted of chalcocite, digenite and chalcopyrite with typical copper recoveries of 90 per cent. Oxidation led to localised formation of malachite, azurite and chrysocolla with lower and more variable recovery. Skarn mineralogy is varied and includes magnetite skarns, massive sulfides, gossans and calc-silicate skarns. In massive sulfides and magnetite skarns, pyrite is abundant with copper present as chalcopyrite, chalcocite, digenite and bornite. The close association of copper and pyrite reduces both recovery and concentrate grade. Recovery of copper and gold from gossanous material was poorest of all the ore types. Specific reagent regimes are required to achieve optimum performance for the various ore types. In addition, ore hardness varies with ore type and degree of weathering. A high level of cooperation between geology, mining and metallurgy departments was necessary in order to deliver blends of ore which gave satisfactory metallurgical performance (England, Kilgour and Kanau, 1991). Initial electron microprobe analysis of porphyry samples confirmed the presence of fresh chalcopyrite, bornite and pyrite and also showed that weathering products of chalcopyrite vary in composition between chalcocite, covellite, digenite, geerite and blaubleiblender ‘synthetic’ covellite. Fresh pyrite was found to exhibit natural floatability (Afenya and Mwaba, 1991). Later work focused on the mineralogical and metallurgical examination of fluorosilicate to define and implement strategy for the reduction of fluorine in concentrates (Pangum et al, 1998). One landmark geometallurgy study was that of predicting ore aging within potential new block caves and its effect on metallurgical performance (Morey and Cantrell, 2011). At the time of development Batu Hijau was the largest mining project that has ever been undertaken. Detailed production planning for the concentrator commenced in the middle of 1997, two years before production commenced. The planned production ramp-up was reviewed alongside actual production experience from more than 30 new mining projects dating back to the 1970s. The geometallurgical model for copper recovery was based on lithology, mineralogy, and depth with reference to 500 bench scale flotation tests (DeMull, Spenceley and Hickey, 2001). Later work focused on throughput prediction using a geometallurgy approach. The deposit’s lithologies, their distributions and association with mineralisation and geotechnical measurements served as the basis for ongoing metallurgical studies. This allowed models of Bond Crushing Work, Ball Work, Rod Work and Abrasion indices, JKMRC impact breakage resistance and the JKMRC abrasion resistance to be developed. The Canatuan Cu-Zn deposit in the Philippines is comprised of an iron oxide gossan underlain by massive sulfide. The sulfide occurs as either massive or banded sulfide. The massive sulfide is composed of >50 per cent coarse-grained pyrite, chalcopyrite sphalerite, galena and tennantite. The banded sulfide has lower pyrite content with bornite and covellite. 42 Chalcocite occurs as sooty coatings throughout the massive sulfides, mainly in the interval immediately underlying the current water table. This has resulted in complex association of sulfides in the supergene-enriched zones as well as in areas that are highly fractured and structurally exposed to water penetration. A geometallurgical study involving mineralogy, hydrology, structural geology and extensive metallurgical tests was undertaken to evaluate the reasons for elevated zinc content in copper concentrate. This indicated the presence of in situ zinc and pyrite activation by copper, within zones of the orebody. This resulted in a reagent scheme which exploited the varying preferences of copper and zinc in relation to pulp potential, allowing significantly greater selectivity to be achieved (Umipig et al, 2012). The King-king porphyry deposit copper mineralogy consists of chalcopyrite, bornite, chalcocite, digenite and covellite. Copper silicates are the most abundant copper minerals in the oxide zone of the deposit. Gold is relatively abundant in the oxide zone, with lesser abundance in the sulfides. Native gold is occasionally observed on fractures and in quartz veinlets. The King-king metallurgical study was based on an extended sequential assay procedure to determine copper speciation, correlated with the results of extensive flotation tests. The model allowed prediction of copper and gold recoveries throughout the deposit, based on sequential assay results (Snider et al, 2013). At the Sepon operations in Laos, geological logging uses a set of predetermined tables for lithology, structure, mineralisation, geotech, oxidation and alteration, in addition to site developed metallurgical codes (metcode). These metcodes are based on the metallurgical behaviour in the Sepon processing plant. In addition the resource model is coded by geometallurgical type for scheduling the process plant and by lithology for determining mining costs and geotechnical domains (Quigley, Hackhan and Broome, 2008). At the Phu Kham concentrator, mineralogical examination of monthly composites has been conducted since operations commenced in 2008. This information, together with targeted mineralogy, is routinely used for process understanding and improvement. Evidence was provided of chalcocite-covellite intergrowth with pyrite and rimming of pyrite. There was also indication of copper activation of pyrite from soluble copper species in weathered and transition ores. The mineralogy data demonstrated that since primary chalcopyrite ores had become the dominant source of plant feed, the major cause of loss of copper in-plant tailings had changed from slow floating finely liberated copper minerals to chalcopyrite locked in poor quality coarse binary particles with non-sulfide gangue. This knowledge, coupled with flotation modelling and simulation, led to an increase in total recovery of both copper and gold by six per cent into final concentrate by increasing mass recovery into rougher concentrate, and debottlenecking of rougher concentrate regrind, cleaning, and final concentrate dewatering plants (Bennett, Crnkovic and Walker, 2011). Variability in concentrate grades (24.7–37.6 per cent Cu) and copper recoveries (60–90 per cent) during treatment of ore from the Malanjkhand porphyry deposit, India, reflect its geology. To obtain higher copper recoveries, a geometallurgical study was undertaken to define the ore characteristics that affected metallurgy and to assess applicable processes for recovering the metals. It was found that chalcopyrite tarnished readily and oxidised to chalcocite within several months. The presence of both the tarnished chalcopyrite and chalcocite affected chalcopyrite flotation and reduced copper recoveries (Petruk and Sikka, 1987). WE are metallurgists, not magicians Integrating geometallurgy with copper concentrator design and operation Europe – Middle East In 2006 the Chelopech mine in Bulgaria commenced a geometallurgical project to study the metallurgical complexity of the ore and the key aspects of its treatment. A major aim of the project was justification of possible changes in the process flow sheet to achieve higher recoveries. The basis of the program was samples collected during two full plant surveys of the grinding, classification and flotation circuits. Sample analysis included elemental and mineral composition, size and nature of intergrowths, liberation, grindability and floatability (Baltov et al, 2008). Mikheevskoye in Russia undertook a study to improve metallurgical performance through better understanding of the variation in the porphyry orebody and mine planning. Thirteen geometallurgical domains were established for the ore zones which had similar characteristics during processing. The study predicted that a geometallurgical approach could potentially decrease the payback period for the project by 1.5 years and significantly increase the net present value (Lishchuk et al, 2015). The Sarcheshmeh concentrator in Iran implemented a geometallurgical study to diagnose the reasons for fluctuating copper recoveries. The study was instigated following reagent and ball charge changes which were implemented as part of a recovery improvement project. Five months of mineralogy data was reviewed, with specific focus on the liberation of chalcopyrite, covellite and chalcocite (Banisi et al, 2003). Africa The Mufulira copper mine in Zambia represented an earlier age geometallurgy endeavour. Its copper minerals included chalcocite, bornite, malachite, native copper, azurite, covellite and chrysocolla. Gold was also present throughout the orebody, as was graphitic carbon, which caused significant difficulties in the flotation circuit. Geometallurgical planning led to extensive efforts at blending, both underground and in the crushing plant, to minimise the effect of ore variability (White and Adair, 1948). At the Tsumeb polymetallic mine in Namibia, the presence of 40 economic minerals, some refractory, led to treatment difficulties, even with high grades present. They included chalcocite, bornite, tennantite, malachite, native copper, cuprite, galena, cerunnite, sphalerite, native silver, germanite, renierite, conichalcite, duftite, mottramite, miretite, anglenite, smithsonite and willemite. To quote Boyce, Venter and Adam (1970): The distinct flotation characteristics of the different minerals in the ore, and the rapid changes in ore grade and mineral type, made the development of the current flow sheet a long and at times, exasperating undertaking. Over the concentrator’s history, multiple geometallurgical studies were undertaken including in situ sphalerite activation, overgrinding of chalcocite, tennantite selectivity, galena flotation variability, intimate mineral locking and associations. The implementation of an on-site daily mineralogical analysis at Nchanga in Zambia allowed sharing of information within the processing department, and between departments. The geometallurgy program assisted in the diagnosis and solution of processing problems. In one instance the program was credited with achieving a one per cent increase in sulfide recovery (Siddiqui, 2000). The Ruashi mine in the Democratic Republic of Congo (DRC) has significant variability in both copper and cobalt grades across the resource. The constraint on acid availability and cost, coupled with the need to stabilise plant performance, were the WE are metallurgists, not magicians financial drivers to focus on geometallurgical issues within the orebody. This led to a strategy of ensuring a consistent metal production profile, as a result of managed plant feed, in terms of grade and geometallurgical characteristics, with a mine to stockpile to plant philosophy built into the life-ofmine plans (Macfarlane and Williams, 2014). Interestingly, there are similarities between Ruashi and the Kolwezi concentrator 50 years earlier. Kolwezi, a Cu-Co mine in the DRC also used early geometallurgy to stabilise ore variability in its comminution and flotation plant. The variable crushing requirements led to both in-pit and stockpile strategies. Understanding of gangue variability assisted in selecting and optimising flotation reagents (Saquet et al, 1962). Another geometallurgy program in the DRC was conducted on the Kamoa Copper deposit. The expansive study initially demonstrated that representative, true samples of drill core had been extracted from the drill core inventory. Copper mineralogical studies identified bornite, chalcopyrite, chalcocite, with lesser covellite and azurite. The variation in copper speciation led to a mixed collector flotation test program to optimise flotation of all of these species. Liberation studies were used to define both primary grinding and concentrate regrind requirements (Lotter et al, 2013). Methods of integrating of geometallurgy with plant design Traditional engineering design for flotation circuits uses the ‘Rule of Thumb’ approach. Typically this uses a nominated maximum head grade for design. A scale-up factor is applied to laboratory flotation tests for residence time. This scaleup factor is usually based on a designer’s experience at other flotation sites and may or may not be relevant to the circuit being designed, or the flotation equipment being used. A small number of locked cycle tests are assumed to represent the orebody and the results of these are often used for financial analysis, independent of changes in mine plan throughput and mineralogy. The engineering ‘rule of thumb’ approach is only strictly accurate where there is very little variability in throughput, head grade and mineralogy. It may provide accurate design for mature established operations where a brownfield expansion is being considered but is unlikely to provide accurate design for a new, greenfield site. To overcome this Rule of Thumb approach to design, geometallurgical test programs and data review have been developed to provide realistic information into simulation packages to provide data for process evaluation and plant design. This approach was applied to the Andash project to aid final design and risk minimisation. A number of geometallurgical modelling techniques exist and can be divided into three approaches as discussed by Lishchuk et al (2015): 1. In the traditional approach the metallurgical response of an ore in the mineral processing plant is calculated from the chemical assays using mathematical functions, which are often called recovery functions. The functions are developed using variability testing and statistical analysis to define the correlation between the metallurgical response and feed properties. 2. The proxies approach uses geometallurgical tests for large numbers of samples. The geometallurgical test is a smallscale test which indirectly measures the metallurgical response. Normally the geometallurgical test results must be converted with certain correction factors to give estimates on the metallurgical results of plant. 3. The mineralogical approach’s main characteristic is the continuous and systematic collection of quantitative mineralogical information. 43 G Harbort et al The geometallurgical development discussed in this paper was conducted in a number of stages: •• incorporation of mineral data, either from sequential copper assays or mineralogy, into the resource model and mine plan •• development of floatability parameters based on the rougher performance in either locked cycle tests or rougher batch tests •• generation of a floatability component model to simulate the locked cycle tests or existing plant performance •• calibration of the model so that model results equate to either actual locked cycle test results or historical plant performance •• development of a JKSimFloat simulator incorporating floatability data, proposed circuit design, flotation feed rates and flotation machine characteristics •• determination of mineral recovery with ores of various copper mineralogies, based on variability tests and mine plans. CASE STUDIES Two previously published case studies are reviewed in this paper. The first is the Andash study (Harbort, Cordingley and Phillips, 2011), a greenfields geometallurgical study. The second is Northparkes Mines (Clarke et al, 2014; Jones and Morgan, 2016), an operating site with both brownfield and greenfield components. The brownfield component relates to optimising the plant operation, while the greenfield component relates to the prediction of future performance with various circuit and mine plan options. Andash Location The Andash Gold-Copper Project is located in the Kyrgyz Republic, approximately 260 km from the capital Bishkek in the Talas region of Kyrgyzstan. Geological description The Andash deposit is formed by the stratified sediments of the Tohtonisai and Jangiturmush formations. These formations are characterised by bodies and dykes of the Taldysui monzo-diorite, granite and Permian dyke complexes. The Tohtonisai formations, which forms the south-west part of the deposit with a thickness of 300 m, comprises of moderate alkaline basalts, trachy-andesites and associated tuffs, beds of agglomerate basalts, tuff conglomerates and sandstone layers. The Jangiturmush Formation forms the majority of the deposit’s area with a thickness of 450–500 m. The formation is formed by tuff conglomerates, tuff-gravelites, tuff-sandstone with interlayers of tuffite, tuff-andesites and agglomerate tuff of basalts. The Andash copper-gold mineralisation is structurally confined to a hydrothermally silicified tectonic breccia and quartz alteration, extending from and terminating into granodiorite. The orebody is zoned as follows: •• The upper section of the ore zone spreads from surface to a depth of 40 to 75 m and is composed mainly of cataclasised granodiorite porphyry. Hydrothermally imposed ore minerals include chalcopyrite, native gold and with hypergene minerals including cuprite, covelline, bornite, native copper, chalcosine and hydrotite. •• The middle section of the ore zone stretches from 40–105 m with sharply increased gold and copper 44 content. The ore is formed by carbonate-chloritesericite-quartz alterations. Hypergene minerals are significant and are represented by malachite, azurite, covelline, cuprite, native copper, drogoethite, bornite and chalcosine. •• The lower ore zone is at depths of 60–175 m. This zone is mainly formed by chloritised and sericitised cataclasised granodiorite porphyry with increasing chalcopyrite and pyrite content. Numerous barren dykes of various compositions are present within the orebody. Treatment The proposed Andash ore processing flow sheet, as shown in Figures 1 and 2, was designed to recover gold bearing copper concentrate through the following principal unit processes: •• three-stage crushing, ore storage and reclaim •• single stage ball milling (expanded to primary and secondary ball milling in Phase 2) •• flash flotation (Phase 2) •• sequential rougher flotation (utilising split sulfide and oxide circuits) •• combined cleaner, cleaner scavenger and recleaner flotation •• sulfide concentrate regrind (Phase 2) •• concentrate dewatering, filtration, storage and load-out and tailings thickening (Phase 2) •• disposal and decant water return. Geometallurgical evaluation During the development and design of the Andash concentrator, numerous flotation tests were undertaken including variability tests. The variability tests confirmed that the orebody exhibits significant variability in total copper rougher recovery and minor variability in rougher gold recovery. The wide copper variability was directly related to copper mineral variability. The recovery of copper sulfides was relatively robust with 96 per cent rougher recovery when no copper oxides were present, declining to 90 per cent at a copper oxide to copper sulfide ratio of 0.8. At very high oxide copper content the sulfide recovery decreased significantly. The rougher copper oxide recovery was heavily dependent on the ratio of acetic acid-soluble copper, eg malachite to weak acid-soluble oxides such as tenorite. When copper carbonates were the only oxide copper minerals present, their recovery approached 75 per cent and declined with higher weak acid-soluble copper content. Due to the wide variability, it was determined that the locked cycle tests could not effectively be used as a measure of life-of-mine performance. At this stage the test sample was approaching exhaustion, with limited sample available to conduct further flotation tests. A geometallurgical approach was adopted to evaluate performance over the mine life. Resource and mine plan development Sequential assay results were input into the resource model. Development of a mine plan based on this geometallurgical resource model allowed a mine plan and concentrator schedule to be developed based on copper mineral species (sequential copper extractions). The scheduled feed grade to the concentrator on a copper species basis is shown in Figure 3. WE are metallurgists, not magicians Integrating geometallurgy with copper concentrator design and operation FIG 1 – Andash Phase 1 circuit flow sheet. FIG 2 – Three-dimensional view of the Andash circuit. WE are metallurgists, not magicians 45 G Harbort et al Key points in the schedule are: •• At the commencement of mining, heavily oxidised material was stockpiled for end of mine life treatment. This resulted in an initial concentrator feed where the majority of copper was acetic acid-soluble, eg malachite. •• During the second year of operation, the starter pit penetrated a high-grade sulfide pod, with a significant increase in both feed grade and aqua regia-soluble copper, ie chalcopyrite. Year three represents a significant mine expansion with lower grade copper carbonate material feeding the concentrator. This period coincided with the planned expansion of the concentrator facilities. •• During the fourth year, increased amounts of copper oxides and copper carbonates are mined from the expanded pit and presented to the concentrator. The deepening pit also results in significant amounts of chalcopyrite being mined and treated. •• In the ensuing three years, the head grade to the concentrator remains relatively constant, although the copper mineralogy changes significantly. Acetic acid-soluble copper is progressively replaced with chalcopyrite as the pit deepens. The amount of copper oxide material also decreases. •• Year seven represents treatment of stockpiled material with substantial amounts of copper oxides, although acetic acid-soluble copper still represents 50 per cent of the concentrator feed. Floatability component modelling Ore floatability components were calculated from the sulfide dominant composite rougher kinetic locked cycle test results. As no bubble size measurements were conducted, a bubble size of 1.1 mm was assumed. It was also assumed that the batch cell froth recovery was 100 per cent and entrainment was zero. As the model utilised a mineral based system it was assumed that acetic acid-soluble copper was malachite, weak sulfuric acid copper was tenorite, cyanide soluble copper was chalcocite and the copper extracted in the final aqua regia was chalcopyrite. The floatability parameters indicated that chalcopyrite was highly floatable in the sulfide rougher feed and was depressed in the oxide flotation stage. Both malachite and tenorite had low floatability in the sulfide rougher. Both became floatable in the oxide rougher with the weighted floatability of malachite being approximately double that tenorite. A simulation was the created to match the configuration of the locked cycle test, including cleaner stages. The model results were then compared to the measured locked cycle FIG 3 – Life-of-mine mineral grade in the concentrator feed schedule. 46 results to see if floatability was constant across the locked cycle test. The comparison indicated that mineral flotabilities in the respective rougher concentrates were not constant across their respective cleaner circuit feeds. Flotabilities in the cleaner concentrate were, however, conserved into recleaner feeds. The major variations in the cleaner feeds were: •• a decrease in the floatability of tenorite and malachite in the sulfide cleaner feed •• an increase in the floatability of chalcopyrite in the sulfide cleaner feed •• a decrease in the floatability of tenorite in the oxide cleaner feed. A series of floatability transfer matrices were incorporated into the model to calibrate it against the locked cycle test. This provided acceptable recoveries of copper and sulfur, with the modelled final concentrate grade matching the locked cycle test in terms of copper and sulfur. Modelled iron grades were lower in the final concentrate however and this resulted in over estimation of non-sulfide gangue. To correct the iron imbalance non-sulfide gangue was adjusted in the model to contain iron. (Later QEMSCAN – Quantitative Evaluation of Minerals by Scanning Electron Microscopy – analysis of the concentrate indicated the higher iron levels were caused by the flotation of copper-goethite). The calibrated model was then compared against the second locked cycle test and showed good agreement. A further two locked cycle tests were conducted with different configurations and simulated. The simulated results agreed with actual results and it was decided that the model could effectively be used to replace further locked cycle tests and simulate full circuit operation. Integration with plant design Seventy-eight simulations were conducted on the Andash flotation circuit developed during the DFS. This circuit consisted of sequential sulfide and oxide circuits and split sulfide and oxide cleaner circuits. Each simulation was conducted on the basis of one month of the concentrator feed schedule. These simulations were initially conducted to determine the variability of copper and gold recovery and concentrate grade throughout the planned operating life. They also provided detailed mass balances across each month of the mine plan and were used as a cross-check of the DFS design. A number of significant problems soon became apparent from using a rule of thumb approach. Although the simulations showed only minor variation in recoveries, they indicated major variation in stream pulp flow on a month-to-month basis. It was expected that these variations would become worse over shorter time frames. The sulfide cleaner and recleaner circuits typically operated within acceptable limits. This was not the case with the oxide cleaner circuit where significant variations were evident and circuit stability was expected to cause operating difficulties and loss of metallurgical performance. The oxide recleaner circuit would never have operated to design without major modifications. An initial solution evaluated was to combine sulfide rougher concentrate and oxide rougher concentrate and treat them in a combined cleaner circuit utilising the same amount of flotation equipment specified in the DFS design. This provided a major improvement in the ratio of anticipated residence time to the nominated design residence time and hence circuit stability. Simulations, however, failed to match those of the test work, with any recovery benefit undermined by large decreases in concentrate grade caused by the copper oxide flotation chemicals generating high levels of gangue entrainment. A modified combined cleaner circuit was simulated with staged addition of rougher sulfide concentrate and rougher oxide WE are metallurgists, not magicians Integrating geometallurgy with copper concentrator design and operation concentrate to the cleaner circuit. This provided an increase in copper recovery of approximately 2.5 per cent when treating sulfide ore and little tangible benefit when treating oxide ore. Considering the ore mineral split would represent an overall improvement in copper recovery over the mine life of 0.5 per cent. In addition, the revised circuit required two less flotation cells and was expected to be overwhelmingly more stable than the DFS split-cleaner circuit design. The modified circuit was incorporated into the Andash detail design. In addition, the simulation mass balances were used to calculate cleaner circuit make-up water requirements. This resulted in all water addition piping to the cleaner circuit being changed in the detailed design to further maximise circuit stability. •• The cleaner Jameson cell tailing is treated by the cleaner scavenger mechanical cells, where the concentrate discharges to recleaner Jameson cell flotation. The tailing from the cleaner scavenger is pumped back to the feed of the rougher scavengers. •• Concentrate from the recleaner Jameson cell discharges to the final concentrate hopper. Tailing from the recleaner Jameson cell is returned to the feed of the cleaner Jameson cell. Geometallurgical evaluation The copper-gold porphyry mineralisation at Northparkes is hosted by the Late Ordovician Goonumbla Volcanics and occurs in stockwork quartz veins and disseminations associated with potassic alteration. Sulfides are zoned laterally from the centres of mineralisation. The central portions are bornite-rich with minor chalcopyrite, zoning outward through equal portions of bornite + chalcopyrite, to a chalcopyrite-rich zone. Pyrite increases outward at the expense of bornite. Beyond the chalcopyrite zone, pyrite is the main sulfide and copper sulfides are minor to absent. From June 2011 to November 2013 Northparkes conducted mineralogical evaluation of monthly composites to evaluate plant performance. Conducted by the Rio Tinto Technology and Innovation group, these production investigations were complemented by analysis of comminution samples, selected flotation survey samples and drill core samples from potential future concentrator feed sources. Historical plant surveys resulted in the ongoing development of model simulations. In 2013, the 2012 un-sized, copper only JKSimFloat simulator was expanded to include mineralogy and a floatability component and used to check the accuracy of performance estimates for the future. Simulations were conducted over the period of 2011 to 2013 to confirm validity of the model. In March 2015, Northparkes installed a process mineralogy facility on-site. The laboratory included a TESCAN TIMA scanning electron microscope (SEM) and was the first SEM facility to be commissioned on a mine site in Australia. The facility has not only continued with the analysis of monthly plant composites, but has also supported: metallurgical test work programs; the evaluation of alternative ores and feed material; plant and laboratory reagent trials; grinding media trials; plant optimisation and improvement; changes to plant configuration and provided laboratory support to external consultants working on NPM projects. Treatment Optimisation Northparkes Location Northparkes Mines (Northparkes), an unincorporated joint venture between the China Molybdenum Company (80 per cent), Sumitomo Metal Mining Oceania (13.3 per cent) and Sumitomo Corporation (6.75 per cent), operates block cave and open cut mines and an ore processing plant located 27 km north of Parkes in central New South Wales. Geology The Northparkes ore processing flow sheet is shown in Figure 4 and Figure 5. The concentrator consists of two modules. Each module has its own grinding circuit, flotation circuit, concentrate thickening circuit and filtration circuit. The tailings from the two modules are combined in a single tailing thickener before being deposited in tailing facilities. Flotation takes place in two distinct but similarly configured modules, each fed by its own grinding circuit. The tertiary cyclone overflows of each module feed the main flotation circuits with the following configuration: •• Preflotation is performed in tank cells, with frother, sodium hydrosulfide and thiocarbamate promoter added. •• The preflotation tailing is further treated with xanthate collector and frother. The conditioned pulp flows through a series of banks of mechanical rougher and scavenger cells, wherein down-the-bank xanthate is also employed. •• Further scavenging in a post-flotation stage is conducted in large tank cells. The resulting post-flotation concentrates are recirculated back to the tertiary grinding circuit, while the post-flotation tailings are combined in a single thickener before being deposited in the tailing facilities. •• Concentrates from preflotation, roughers and rougher scavengers are combined to feed the cleaner Jameson cell. Concentrate from the Jameson cleaner cell discharges to the final concentrate hopper. WE are metallurgists, not magicians Routine analysis of monthly plant composites has allowed the measurement of plant performance over time and provided a baseline of feed characteristics versus performance for comparison. Northparkes have been conducting quantitative mineralogical analysis of plant composites for more than 11 years. Important information obtained from this data has included a measure of the variation in the mineral make-up, ratios and copper source minerals of the plant feed; individual mineral recoveries by size; liberation and locking characteristics; grain size versus particle size; mineral association and mineral maps. Monthly mineralogy is routinely input into the circuit flotation simulations, together with other operating data to calibrate and validate the model accuracy. The data has shown the reality of actual recoverable copper versus the actual non-recoverable copper. This is an important distinction when evaluating performance and changes to the circuit. Analysis of the concentrate has illustrated the nature of impurities and levels of penalty elements and facilitated the development of a test work program or strategy, to reduce these. The microchemical analysis of gold particles by energy dispersive X-ray (EDX) analysis has detected the presence of gold and silver tellurides in the ore. This data has driven a phase of laboratory method development to improve the fireassay process and quality of NPM gold analysis, particularly in regard to shipment assays. Both equipment changes and circuit improvement projects have incorporated geometallurgical data. This has driven a reduction in the technical risk of specific projects with the 47 G Harbort et al FIG 4 – Northparkes Module 1 circuit flow sheet (shaded areas represent potential future changes). FIG 5 – Three-dimensional view of the Northparkes circuit. 48 WE are metallurgists, not magicians Integrating geometallurgy with copper concentrator design and operation data used to evaluate, justify, test and validate major plant upgrades. This has proven to be a major drawcard when justifying funding for an expensive project. As an example, installation of additional scavenger flotation cell capacity demonstrated recovery improvements of around one per cent. Mineralogy information plus simulations using mineralogical inputs were involved in all aspects of the project, with data used to successfully evaluate the risk, drive decision-making, optimise and validate changes. Mineralogy was also used to critically review the post-commissioning performance of the new cells. Additional implementations have included installation of froth washing and subsequent optimisation to decrease entrainment. The bypass of a primary cyclone to reduce overgrinding of already liberated copper minerals and optimisation of reagents once the bypass was implemented. The Northparkes on-site laboratory has frequently been utilised to support work programs. Mineralogical analysis is used to evaluate change in reagents and grinding media from bench tests and in-plant. Performing the mineralogy and some of the assay components of the test work in-house has given the site control over quality assurance and project integrity. In addition to optimisation in the concentrator, geometallurgy has also been used for mine optimisation. Northparkes are currently mining the Endeavour 48 (E48) orebody via a modified block cave technique. This orebody still has 15 years of mining life, yet up until recently there was very little mineralogical information available. To remedy this, mineralogical analysis has commenced on material from the current drawpoints to gain information about the samples that make up the daily feed blend. The mineralogy and assay combination is used to provide mineral abundance, elemental deportment and textural data to map cave drawpoints. The data shows the mineralogical variability of the orebody which is currently mined according to fragmentation, caving characteristics and copper grade inputs. The long-term objective would be to add mineralogy data to that criteria. Some drawpoints contain very fine clay-bearing material that has the ability to move like a liquid. This is extremely dangerous in the cave environment as the material has the potential to cause a fines rush. This fine material was investigated using SEM imaging and EDX microchemical analysis techniques to infer the size, illustrate the morphology and measure chemical composition. Based on this data, additional mining controls including exclusion zones have been implemented where similar mineralogy indicators exist. Life-of-mine planning The incorporation of mineralogical data and floatability components into simulations to predict future performance for analysis has provided a more robust method of prediction than the historical method of prediction using only a head grade and throughput relationship to predict recovery, based purely on laboratory flotation results. This improved understanding allows for the development of circuit modifications and circuit options earlier in the planning process as well as supporting the development of future concentrate specifications. The simulation of future performance provides an improved ability to manage future expectations and ore reserves, becoming a critical tool in optimising the mining sequence over the life-of-mine. Further expansion of the model will introduce the ability to predict gold and impurity behaviour as well as the copper sulfides. WE are metallurgists, not magicians CONCLUSIONS The use of geometallurgy with copper concentrator design and operation has a long history. Recent years have seen it move from an ad hoc methodology at a few sites to a wellestablished procedure. The Andash case study details the use of geometallurgy in greenfield plant design with limited information available. Geometallurgical modelling using sequential copper assays and floatability component modelling provided a design methodology with significantly less associated risk than traditional design. The Northparkes case study illustrates the use of geometallurgy, via process mineralogy and mineral component modelling. The use of geometallurgy has facilitated a common goal of mill optimisation, stability and more realistic forecasting through orebody knowledge and the sharing of information between disciplines. ACKNOWLEDGEMENTS The authors would like to thank Northparkes Mines and Amec Foster Wheeler for allowing this paper to be published. The case studies utilise three papers previously published by the AusIMM and the authors are grateful for the permission to extract the content from these. Previous authors of those papers are also acknowledged, namely Guy Cordingley, Marius Phillips and Danica Clarke. Sections of the introduction were extracted from an unpublished paper – ‘Technological advances in flotation’, written with the guidance of Professor Alban Lynch in 2011. REFERENCES Afenya, P M and Mwaba, C C, 1991. Flotation of Ok Tedi sulphide minerals, in Proceedings PNG Geology, Exploration and Mining Conference, pp 191–196 (The Australasian Institute of Mining and Metallurgy: Melbourne). Alruiz, O M, Morrell, S, Suazo, C J and Naranjo, A, 2009. A novel approach to the geometallurgical modelling of the Collahuasi grinding circuit, Minerals Engineering, 22:1060–1067. Anon, 1956. Success depends on: geologists, mining engineers, metallurgists, presented to Symposium on Greater Cooperation for Metallurgical Planning; Second Annual Rocky Mountain Minerals Conference, Salt Lake City, October, Mining Engineering, July, p 698. Arden, H and Tverdov, A, 2014. Resource and reserve valuation practices in CIS countries, in Mineral Resource and Ore Reserve Estimation: The AusIMM Guide to Good Practice, second edition pp 825–834 (The Australasian Institute of Mining and Metallurgy: Melbourne). Baltov, I, Hristov, N, Evtiminova, K, Dontchev, I and Kuzev, L, 2008. Metallurgical challenges in the recovery of copper and gold from the Chelopech mine, Bulgaria, in Proceedings XXIVth International Minerals Processing Congress (ed: W D Duo and S C Yao), pp 1785– 1792 (Science Press: Beijing). Banisi, S, Iran-Manesh, H R, Shayestefar, M R and Shekarchyan, H, 2013. Mineralogical tracing of metallurgical results – the Sarcheshmeh copper mine case, in Proceedings 35th Annual Meeting of the Canadian Mineral Processors, Ottawa, 21–23 January, pp 417–433 (Canadian Institute of Mining, Metallurgy and Petroleum: Montreal). Barns, K E, Colbert, P J and Munro, P D, 2009. Designing the optimal flotation circuit – the Prominent Hill case, in Proceedings Tenth AusIMM Mill Operators’ Conference, pp 173–182 (The Australasian Institute of Mining and Metallurgy: Melbourne). 49 G Harbort et al Baumgartner, R, Gomez, P and Escobar, G, 2016. Comprehensive mineralogical characterisation at the Cerro Corona Cu-Au porphyry mine – the fundamental key for geometallurgical applications, in Proceedings The Third AusIMM International Geometallurgy Conference, pp 221–230 (The Australasian Institute of Mining and Metallurgy: Melbourne). Beniscelli, J, 2011. Geometallurgy – fifteen years of developments in Codelco: Pedro Carrasco contributions, in Proceedings The First AusIMM International Geometallurgy Conference, pp 3–7 (The Australasian Institute of Mining and Metallurgy: Melbourne). Bennett, D, Crnkovic, I and Walker, P, 2011. Recent process developments at the Phu Kham copper-gold concentrator, Laos, in Proceedings 11th Mill Operators’ Conference 2012, pp 257–272 (The Australasian Institute of Mining and Metallurgy: Melbourne). Bergerman, M G, Morais, J, Castro Rosa, M A N and Delboni Jr, H, 2008. Variability studies for the Sossego 41 ktpd grinding circuit, in Proceedings International Mineral Processing Conference (ed: W D Duo and S C Yao) volume 1, pp 407–416 (Science Press: Beijing). Blanchard, R and Hall, G, 1939. Discussion – the mineralogy of the Black Star ore body and its relation to milling practice at Mount Isa, The AusIMM Proceedings, 116:487–490. Blatter, P, Cayouette, J and Cousin, P, 2011. Agnico-Eagle Laronde plant: metallurgical challenges present and future, in Proceedings 43rd Annual Canadian Mineral Processors Conference, pp 3–15 (Canadian Institute of Mining, Metallurgy and Petroleum: Montreal). Boisvert, J, Rossi, M and Ehrig, K, 2013. Geometallurgical modelling at Olympic Dam Mine, South Australia, Mathematical Geosciences, 45:901–925. Boyce, J H, Venter, W J and Adam, J, 1970. Beneficiation practice at Tsumeb concentrator, in Lead and Zinc (eds: D O Rausch and B C Mariacher), vol 1, pp 542–570 (American Institute of Mining, Metallurgical, and Petroleum Engineers: New York). Bradshaw, D J, Wightman, E M, Evans, C L and Triffett, B, 2012. Characterising the reasons for the difference in performance of two ore blends in early processing at OZ Minerals Prominent Hill operation, in Proceedings 11th AusIMM Mill Operators’ Conference 2012, pp 373–278 (The Australasian Institute of Mining and Metallurgy: Melbourne). Brissette, M and Roman, E, 2012. Concentrate grade and regrind size improvement on the east pit hypogene ore at Kemess Mine, in Proceedings 44th Annual Canadian Mineral Processors Conference, pp 27–38 (Canadian Institute of Mining, Metallurgy and Petroleum: Montreal). Carrasco, P, Campos, M, Tapia, J and Menichetti, E, 2005. Heterogeneity and Ingamells’s tests of some Chilean porphyry ores, in Proceedings Second World Conference on Sampling and Blending, pp 139–150 (The Australasian Institute of Mining and Metallurgy: Melbourne). Clarke, D, Harbort, G, Morgan, D and Sola, C, 2014. Northparkes Mines – flotation and planning for the future, in Proceedings 12th AusIMM Mill Operators’ Conference, pp 203–208 (The Australasian Institute of Mining and Metallurgy: Melbourne). Clemmer, J B, 1956. Metallurgical planning for porphyry copper ores, presented to Symposium on Greater Cooperation for Metallurgical Planning; Second Annual Rocky Mountain Minerals Conference, Salt Lake City, October 1955, Mining Engineering, July, pp 701–702. Comi, T, Garcia, C, Kaleta, R and Kurzydło, P, 2013. Sierra Gorda – the most modern Cu-Mo mine in Chile, in Proceedings Mineral Engineering Conference MEC2013 (ed: P B Kowalczuk), SwieradowZdroj, 16–19 September, pp 109–121 (Wroclaw University of Technology: Wroclaw). Compan, G, Pizarro, E and Videla, A, 2015. Geometallurgical model of a copper sulphide mine for long-term planning, Journal of The Southern African Institute of Mining and Metallurgy, 115:549–556. Coward, S, Vann, J, Dunham, S and Stewart, M, 2009. The primaryresponse framework for geometallurgical variables, in Proceedings Seventh International Mining Geology Conference, pp 109–113 (The Australasian Institute of Mining and Metallurgy: Melbourne). 50 David, D, 2007. The importance of geometallurgical analysis in plant study, design and operational phases, in Proceedings Ninth AusIMM Mill Operators’ Conference, pp 241–248 (The Australasian Institute of Mining and Metallurgy: Melbourne). DeMull, T J, Spenceley, J and Hickey, P, 2001. Planning and teamwork lead to successful start-up at Batu Hijau, presented to SME Annual Meeting, Denver, 26–28 February, SME Preprint 01–159. Dobbe, R, Bajic, S, Kalstrom, M, Palko, A, Martin, C, Thorpe, R, Lamson, G and Baron, J, 2014. On site automated mineralogical analysis at the Mount Polley porphyry copper mine, Canada, presented to XXVII International Mineral Processing Congress, Santiago. Dominy, S C and O’Connor, L, 2016. Geometallurgy – beyond conception, in Proceedings Third AusIMM International Geometallurgy Conference, pp 3–10 (The Australasian Institute of Mining and Metallurgy: Melbourne). Downs, R C, 1990. Geological mapping and logging at Hellyer, in Proceedings Mine Geologists’ Conference, pp 1–7 (The Australasian Institute of Mining and Metallurgy: Melbourne). Dunham, D and Vann, J, 2007. Geometallurgy, geostatistics and project value – does your block model tell you what you need to know?, in Proceedings Project Evaluation 2007, pp 189–196 (The Australasian Institute of Mining and Metallurgy: Melbourne). England, J K, Kilgour, I and Kanau, J L, 1991. Processing copper-gold ore at Ok Tedi, in Proceedings PNG Geology, Exploration and Mining Conference, pp 183–190 (The Australasian Institute of Mining and Metallurgy: Melbourne). Evans, C L, Wightman, E M, Manlapig, E V and Coulter, B L, 2011. Application of process mineralogy as a tool in sustainable processing, Minerals Engineering, 24(12):1242–1248. Fennel, M, Guevara, J, Canchaya, S, Velarde, G, Baum, W and Gottlieb, P, 2005. QEMSCAN Mineral Analysis for Ore Characterisation and Plant Support at Cerro Verde, in XXVII Convencion Minera, Arequipa, Peru, pp 1-11 (Instituto de Ingenieros de Minas del Perú: Lima) Fonseca, E and Sá, L R B M, 2005. Methodological evaluation of a liberation study in sulfide copper ore, in Proceedings Centenary of Flotation Symposium, pp 953–958 (The Australasian Institute of Mining and Metallurgy: Melbourne). Gottlieb, P, Adair, B J and Wilkie, G J, 1994. QEM*SEM liberation indices for grinding classification and flotation, in Proceedings Fifth Mill Operators’ Conference, pp 5–14 (The Australasian Institute of Mining and Metallurgy: Melbourne). Gregory, M J, Lang, J R, Gilbert, S and Hoal, K O, 2013. Geometallurgy of the Pebble porphyry copper-gold-molybdenum deposit, Alaska: implications for gold distribution and paragenesis, Economic Geology, 108:463–482. Gregory, P W, Hartley, J S and Wills, J A, 1987. The Thalanga massive sulphide deposit, in Proceedings Pacific Rim Congress 87, pp 573–577 (The Australasian Institute of Mining and Metallurgy: Melbourne). Greig, D, Widenbar, L, Oliver, R, Harbort, G, Cuttriss, C, Kerr, T F and Cummings, R, 2009. Mineral processing and metallurgical testwork (Section 16), in Constancia Copper Project, Definitive Feasibility Study technical report NI 43–101, Rev 0, 28 September. Harbort, G, Cordingley, G and Phillips, M, 2011. The integration of geometallurgy with plant design, in Proceedings MetPlant 2011, pp 339–363 (The Australasian Institute of Mining and Metallurgy: Melbourne). Harbort, G, Lauder, D, Miranda, J and Murphy, A, 2000. Size by size analysis of operating characteristics of Jameson Cell cleaners at the Bajo de Alumbrera copper/gold concentrator, in Proceedings Seventh Mill Operators’ Conference, pp 207–220 (The Australasian Institute of Mining and Metallurgy: Melbourne). Hartog, J, Beehan, V, Karageorgos, J and Beeson, D, 2014. Optimisation of the Peak Gold Mine’s processing plant through advanced process control, in Proceedings 12th AusIMM Mill Operators’ Conference, pp 335–344 (The Australasian Institute of Mining and Metallurgy: Melbourne). WE are metallurgists, not magicians Integrating geometallurgy with copper concentrator design and operation Hoffman, C W, 1964. A review of developments in flotation treatment of Mount Isa chalcopyrite ores, AusIMM Proceedings, 103. Hunt, J, Berry, R and Bradshaw, D, 2011. Characterising chalcopyrite liberation and flotation potential: examples from an IOCG deposit, Minerals Engineering, 24(12):1271–1276. Jackson, B R, Gottlieb, P and Sutherland, D N, 1988. A method for measuring and comparing the mineral grain sizes of ores from different origins, in Proceedings Third Mill Operators’ Conference, p 61 (The Australasian Institute of Mining and Metallurgy: Melbourne). James, B and Scamardella, M, 2000. The Re-opening of CSA Mine, Cobar NSW, in Proceedings Seventh Mill Operators’ Conference, pp 137-147 (The Australasian Institute of Mining and Metallurgy: Melbourne). Johnson, N W and Munro, P D, 2008. Methods for assigning domains in the primary sulphide zone of a sulphide orebody, in Proceedings Ninth International Congress for Applied Mineralogy, pp 597–603 (The Australasian Institute of Mining and Metallurgy: Melbourne). Jones, K and Morgan, D, 2016. On-site process mineralogy – linking departments and disciplines with the common goal of increasing plant performance, in Proceedings 13th AusIMM Mill Operators’ Conference, pp 149–156 (The Australasian Institute of Mining and Metallurgy: Melbourne). Kuhar, L L, McFarlane, A J, Chapman, N M, Meakin, R L, Martin, R, Turner, N L and Robinson, D J, 2013. Calibration and testing of a geometallurgical leaching protocol for determining copper mineralogical deportment, in Proceedings Second AusIMM International Geometallurgy Conference, pp 177–186 (The Australasian Institute of Mining and Metallurgy: Melbourne). Lane, G S and Richmond, G D, 1993. Improving fine particle flotation selectivity at Hellyer, in Proceedings XVIII International Mineral Processing Congress, pp 897–904 (The Australasian Institute of Mining and Metallurgy: Melbourne). Leggett, A R and Morin, G R, 2013. Maximising concentrate revenues at the Xstrata Copper Kidd concentrator, in Proceedings 45th Annual Canadian Mineral Processors Operators’ Conference, pp 465– 478 (Canadian Institute of Mining, Metallurgy and Petroleum: Montreal). Liebezeit, V, Smith, M, Kittler, P, Macmillan, E and Lower, C, 2011. Geometallurgy data management – a significant consideration, in Proceedings First AusIMM International Geometallurgy Conference, pp 237–246 (The Australasian Institute of Mining and Metallurgy: Melbourne). Lishchuk, V, Koch, P-H, Lund, C and Lamberg, P, 2015. The geometallurgical framework: Malmberget and Mikheevskoye case studies, Mining Science, 22:57−66. Jones, M P, 1984. Recent developments in the rapid collection of quantitative mineral data, in Proceedings Second International Congress on Applied Mineralogy, pp 449–464 (Metallurgical Society of AIME: Warrendale, Pa). Loidl, G, 2012. The Elura orebody: a multidisciplinary study investigating geochemical mineralogical and geometallurgical ore characteristics, PhD thesis, University of Adelaide, School of Earth and Environmental Sciences. Kahn, H, Antoniassi, J, Shimizu, V and Uliana, D, 2014. X-ray diffraction cluster analysis and automated mineralogy of Sossego copper ore, Brazil, presented to XXVII International Mineral Processing Congress, Santiago. Lotter, N O, Oliveira, J F, Hannaford, A L, Amos, S R and Broughton, D W, 2013. Flowsheet development for the hypogene geomet unit in the Ivanplats Kamoa copper project, in Proceedings 45th Annual Canadian Mineral Processors Operators’ Conference, pp 71–85 (Canadian Institute of Mining, Metallurgy and Petroleum: Montreal). Keran, V P, Zumwalt, F and Palmers, J, 1998. Design aspects of the Minera Alumbrera concentrator circuit, presented to SME Annual Meeting, Orlando, 9–11 March. Khosrowshahi, S, Shaw, W J and McKevitt, M B, 2009. Ore block optimisation for open pit grade control, in Proceedings Seventh International Mining Geology Conference, pp 141–146 (The Australasian Institute of Mining and Metallurgy: Melbourne). Kildale, M B, 1956. Metallurgical planning in connection with leadzinc or lead-zinc-copper mines, presented to Symposium on Greater Cooperation for Metallurgical Planning; Second Annual Rocky Mountain Minerals Conference, Salt Lake City, October 1955, in Mining Engineering, July, pp 706–707. Kilgariff, B, 2003. Thalanga processing plant – as many lives as a cat and just as curious, in Proceedings Eighth AusIMM Mill Operators’ Conference, pp 129–141 (The Australasian Institute of Mining and Metallurgy: Melbourne). Kilgour, I, 1995. Development of the Escondida Concentrator 1990– 1995, in Proceedings XIX IMPC, pp 145–148 (Society for Mining, Metallurgy and Exploration: Littleton). Lund, C and Lamberg, P, 2014. Geometallurgy – a tool for better resource efficiency, European Geologist, 37:39–43. Macfarlane, A S and Williams, T P, 2014. Optimizing value on a copper mine by adopting a geometallurgical solution, The Journal of The Southern African Institute of Mining and Metallurgy, 114:929–936. MacPherson, A R, 1976. A simple method to predict the autogenous grinding mill requirements for processing ore from a new deposit, Presented to SME-AIME Fall Meeting, Denver, September. Magallanes-Hernández, L and Espinosa-Gómez, R, 2005. Mineralogical and metallurgical results at Peñoles’s mining operations, Mexico, in Proceedings Centenary of Flotation Symposium, pp 887–894 (The Australasian Institute of Mining and Metallurgy: Melbourne). Martin, H K, 1957. Milling practice at the Lavender pit concentrator, Mining Engineering, November, pp 1229–1235. Kirkland, A G, 1956. Mining engineer’s view of cooperation, presented to Symposium on Greater Cooperation for Metallurgical Planning; Second Annual Rocky Mountain Minerals Conference, Salt Lake City, October 1955, Mining Engineering, July, pp 707–708. Matar, J A, Perucca, J C, de Salmuni, N S, Berenguer, T and Carrizo, M, 1986. Geological research as a basis to define metallurgical behaviour of the disseminated Cu-Au orebody of the Bajo la Alumbrera, presented to SME Annual Meeting, New Orleans, 2–6 March. Kittler, P, Liebezeit, V, Ehrig, K, Macmillan, E and Lower, C, 2011. ‘It Seemed like a good idea at the time …’ common mistakes in geometallurgy, in Proceedings First AusIMM International Geometallurgy Conference, pp 133–138 (The Australasian Institute of Mining and Metallurgy: Melbourne). McCaffery, K and Wirfiyata, F, 2011. Applied Geo-metallurgical characterisation for life of mine throughput prediction at Batu Hijau, presented to Fifth International Conference on Autogenous and Semiautogenous Grinding Technology, Vancouver, 25–29 September. Klohn, S, Stephenson, D and Granados, H, 2016. Constancia project process plant design and start up, in Proceedings 48th Canadian Mineral Processors Operators’ Conference, Ottawa, January, pp 100–112 (Canadian Institute of Mining, Metallurgy and Petroleum: Montreal). McKay, N, Vann, J, Ware, W, Morley, C and Podkiewicz, P, 2016. Strategic and tactical geometallurgy – a systematic process to add and sustain resource value, in Proceedings Third AusIMM International Geometallurgy Conference, pp 29–36 (The Australasian Institute of Mining and Metallurgy: Melbourne). Kormos, L, Oliveira, J, Fragomeni, D, Whiteman, E and De la Cruz, J C, 2010. Process diagnosis using quantitative mineralogy, in Proceedings 42nd Meeting of Canadian Mineral Processors, pp 97– 119 (Canadian Institute of Mining, Metallurgy and Petroleum: Montreal) McQuiston Jr, F W, 1968. Metallurgist’s view on milling base metal ores, presented to Symposium on Greater Cooperation for Metallurgical Planning; Second Annual Rocky Mountain Minerals Conference, Salt Lake City, October 1955, Mining Engineering, July, pp 698–700. WE are metallurgists, not magicians 51 G Harbort et al McQuiston Jr, F W and Bechaud Jr, J, 1956. Metallurgical sampling and testing, in Chapter 3.2 – Mine Development, in Surface Mining (ed: E P Pfeider), pp 103–121 (The American Institute of Mining, Metallurgical, and Petroleum Engineers: New York). Mitchell, J and Holowachuk, N V, 1996. Ore blending at Highland Valley Copper, its necessity, effects, and benefits, in Proceedings SAG 1996, vol 1, pp 1–24 (Canadian Institute of Mining, Metallurgy and Petroleum: Montreal). Morey, M and Cantrell, R, 2011. Ore ageing test work for the Ok Tedi skarns, in Proceedings MetPlant 2011, pp 615–629 (The Australasian Institute of Mining and Metallurgy: Melbourne). Muñoz, A, Álvarez, L, Colacioppo, J and Valery, W, 2008. Process integration and optimisation at Freeport-McMoran Candelaria mine, Copiapo, Chile, in Proceedings PROCEMIN 2008, Santiago, pp 303–315 (Gecamin Digital Publications: Santiago). Mwanga, A, Rosenkranz, J and Lamberg, P, 2015. Testing of ore comminution behavior in the geometallurgical context – a review, Minerals, 5:276–297. Nzama, S C and Kapo, M K, 2014. Managing the giant – a mine geologist’s perspective to the mining of the Olympic Dam deposit, in Proceedings Ninth International Mining Geology Conference, pp 451–459 (The Australasian Institute of Mining and Metallurgy: Melbourne). O’Malley, G B and McGhie, R R, 1939. The mineralogy of the Black Star ore body and its relation to milling practice at Mount Isa, The AusIMM Proceedings, 116:459–486. O’Meara, A E, 1953. New microscope laboratory at Mount Isa, The AusIMM Proceedings, 171:219–229. Oosthuyzen, E J, 1983. The Application of Automatic Image Analysis to Mineralogy and Extractive Metallurgy, special publication 7, pp 449–464 (Geological Society of South Africa). Palagi, C G and Stillar, S S, 1976. The Anaconda C. E. Weed concentrator, in Flotation A M Gaudin Memorial Volume (ed: M C Fuerstenau), second edition, pp 1029–1042 (Society for Mining, Metallurgy & Exploration – American Institute of Mining Engineers: New York). Pangum, L S, Lauder, W, Manlapig, E V, Mackinnon, I R and Glatthaar, J W, 1998. Mineralogical and metallurgical examination of fluorosilicate mineral flotation in the Ok Tedi Circuit, in Proceedings Mine to Mill 1998, pp 19–28 (The Australasian Institute of Mining and Metallurgy: Melbourne). Petruk, W, 1984. Image analysis measurements and data presentation for mineral dressing applications, in Proceedings Second International Congress on Applied Mineralogy, Los Angeles, 22–25 February, pp 127–140 (Metallurgical Society of AIME: Warrendale, Pa). Petruk, W and Hughson, M R, 1977. Image analysis evaluation of the effect of grinding media on selective flotation of two zinc-leadcopper ores, ClM Bulletin, June, pp 128–135. Petruk, W and Schnarr, J R, 1981. An evaluation of the recovery of free and unliberated mineral grains, metals and trace elements in the concentrator at Brunswick Mining and Smelting Corp Ltd, CIM Bulletin, 74(833):132–159. Petruk, W and Sikka, D B, 1987. The formation of oxidized copper minerals at the Malanjkhand porphyry copper deposit in India, and implications on metallurgy, in Process Mineralogy VII (eds: A H Vassilou, D M Hausen and D J T Carson), pp 403–420 (The Minerals, Metals and Materials Society: Warrendale). Quigley, P, Hackhan, D and Broome, J, 2008. Sepon Copper Mineral Resource statement, in OZ Minerals Limited Mineral Resources explanatory notes, 30 June, pp 8–26. Quiñones, S and Mattos, R, 2001. Metallurgical control through mineralogy in the Toquepala concentrating plant, XXV Convencion de Ingenieros de Minas – Arequipa, Septembre. Ramsey, T, 1976. The Cyprus Pima concentrator, in Proceedings A M Gaudin Memorial Symposium, pp 1079–1099 (American Institute of Mining, Metallurgical, and Petroleum Engineers: New York). 52 Reid, A F, Gottlieb, P, MacDonald, K J and Miller, P R, 1984. QEM*SEM image analysis of ore minerals: volume fraction, liberation and observational variances, in Proceedings Second International Congress on Applied Mineralogy in the Minerals Industry, pp 191–204 (Metallurgical Society of AIME: Warrendale, Pa). Reid, A F and Wittenberg, J C, 1984. Technical note – rapid production of high quality polished sections for automated image analysis of minerals, The AusIMM Proceedings, 289:93–97. Reid, A F and Zuiderwyk, M A, 1983. QEM*SEM: automated image analysis and stereological applications to mineral processing and ore characterization, Acta Sterol 1983; 2/Suppl I, in Proceedings Sixth International Congress, Gainesville, 9–14 October, pp 205–208. Reno Sales, R H, 1956. Full cooperation between departments is a must policy for mining enterprises, presented to Symposium on Greater Cooperation for Metallurgical Planning; Second Annual Rocky Mountain Minerals Conference, Salt Lake City, October 1955, Mining Engineering, July, pp 709–711. Richard, K, 1956. Geologist-metallurgist cooperation in porphyry copper exploration, presented to Symposium on Greater Cooperation for Metallurgical Planning; Second Annual Rocky Mountain Minerals Conference, Salt Lake City, October 1955, Mining Engineering, July, pp 703–705. Richmond, G D and Campbell, J J, 1992. Innovation at the Hellyer Concentrator, in Proceedings AuslMM Annual Conference, pp 191–196 (The Australasian Institute of Mining and Metallurgy: Melbourne). Richmond, G D and Lai, K F, 1988. Metallurgical development of the Hellyer Ore, in Proceedings Third AusIMM Mill Operators’ Conference, pp 9–14 (The Australasian Institute of Mining and Metallurgy: Melbourne). Ross, J, Appleby, S K, Hoal, K and Botha, P, 2009. Quantitative mineralogical study of ore domains at Bingham Canyon, Utah, USA, presented to SME Annual Meeting, Denver, 22–25 February. Saquet, J J, Apraxine, V, Lakaye, J and Troch, P, 1962. Kolwezi mining and metallurgical operations of Union Miniere du Haut-Katanga, Mining Engineering, December, pp 70–81. Siddiqui, F, 2000. On-site mineralogy – SIDMIN program, in Proceedings 32nd Annual Meeting of Canadian Mineral Processors, Ottawa, 18–20 January, pp 459–475 (Canadian Institute of Mining, Metallurgy and Petroleum: Montreal). Snider, J W, Ibrado, A S, Hester, M G, Earnest, D, Aronson, J G, Roman, R J, Rehn, C C and Harbort, G J, 2013. Mineral processing and metallurgical testing, in King-king copper-gold project preliminary feasibility study, NI 43-101 technical report, Rev 0, 25 February, pp 90–104. Sola, C and Harbort, G, 2012. Geometallurgy – tricks, traps and treasures, in Proceedings 11th AusIMM Mill Operators’ Conference, pp 187–196 (The Australasian Institute of Mining and Metallurgy: Melbourne). Strohmayr, S J, Barns, K E, Brindley, S K and Munro, P D, 1998. Mineralogy controlling metallurgy at Ernest Henry Mining, in Proceedings Mine to Mill 1988, pp 13–18 (The Australasian Institute of Mining and Metallurgy: Melbourne). Suazo, C J, Kracht, W and Alruiz, O M, 2010. Geometallurgical modelling of the Collahuasi flotation circuit, Minerals Engineering, 23:137–142. Taylor, B, 2011. The Perseverance gold copper deposit – a new Peak Mines challenge, in Proceedings Eighth International Mining Geology Conference, pp 367–378 (The Australasian Institute of Mining and Metallurgy: Melbourne). Tew, A, Strohmayr, S, See, A and Harvey, R, 2003. Mineralogy controlling metallurgy at Ernest Henry Mining revisited, in Proceedings Eighth AusIMM Mill Operators’ Conference, pp 211– 217 (The Australasian Institute of Mining and Metallurgy: Melbourne). Tverdov, A and Nikishichev, S, 2014. Mine design stages in Russia, in Mineral Resource and Ore Reserve Estimation – The AusIMM Guide to Good Practice, second edition, pp 815–824 (The Australasian Institute of Mining and Metallurgy: Melbourne). WE are metallurgists, not magicians Integrating geometallurgy with copper concentrator design and operation Umipig, C V, Israel, E E, Hutalle, G G and Williams, S R, 2012. Canatuan Cu/Zn flotation metallurgy – dealing with zinc preactivation, in Proceedings 44th Annual Canadian Mineral Processors Operators’ Conference, pp 155–168 (Canadian Institute of Mining, Metallurgy and Petroleum: Montreal). Urbanoski, L S, 1993. Road to recovery – metallurgical improvements at Brunswick Mining and Smelting Corporation Limited, in Proceedings International Symposium World Zinc’93, pp 205–212 (The Australasian Institute of Mining and Metallurgy: Melbourne). Walters, S G, 2008. An overview of new integrated geometallurgical research, in Proceedings Ninth International Congress for Applied Mineralogy, pp 79–82 (The Australasian Institute of Mining and Metallurgy: Melbourne). White, J and Adair, R B, 1948. Mufulira Copper Mines Limited, Concentrator, Northern Rhodesia, presented to AIME New York Meeting, February 1948, technical publication no 2250, Class B, Mining Technology, January (American Institute of Mining and Metallurgical Engineers: New York). WE are metallurgists, not magicians Williams, S R, 2013. A historical perspective of the application and success of geometallurgical methodologies, in Proceedings The Second AusIMM International Geometallurgy Conference, pp 37–47 (The Australasian Institute of Mining and Metallurgy: Melbourne). Wong, K Y, Breem, A M, Doherty, R J and Phelan, J M, 1991. Flotation treatment of supergene complex sulphide ores at Thalanga, in Proceedings Fourth AusIMM Mill Operators’ Conference, pp 205– 212 (The Australasian Institute of Mining and Metallurgy: Melbourne). Wraith Jr, W and Fulmor, T G, 1964. Anaconda’s Butte Concentrator, Mining Engineering, May, pp 55–73. Yeatman, P, 1932. Problems at the Chuquicamata and Braden copper properties, in Choice of Methods in Mining and Metallurgy: a Record of Experience in Making Engineering Decisions, pp 1–34 (McGrawHill: New York; London: published for American Institute of Mining and Metallurgical Engineers). Young, K A, 1983, Metallurgical aspects of mining – project development, in Proceedings AusIMM Sydney Branch, Project Development Symposium, pp 221–228 (The Australasian Institute of Mining and Metallurgy: Sydney Branch). 53 Contents Integrated mining and metallurgical planning and operation P L McCarthy1 ABSTRACT To design and operate a successful mine the technical specialists must agree on what is ore, what is not ore, and how quickly the orebody is to be mined and processed. These seemingly simple questions defy easy analysis and can push mining engineers, geologists, metallurgists and others to the limit of their capabilities. The questions are rarely addressed adequately in feasibility studies or in operational planning. To optimise the mine and processing plant requires proper determination of cut-off grades or values, prediction of feed variability on an hourly, daily or longer basis, right-sizing the mining rate for optimum product quality, understanding the cost of capital and the expectations of investors, and many other considerations that involve geology, geotechnical engineering, mining, metallurgy, environmental effects and economics. This paper addresses the key matters that should be considered as inputs to the practical issues of metallurgical plant design and operation. INTRODUCTION The mine planning process includes the mining, processing, infrastructure, environmental and social aspects of an operation. It begins with a sequence of increasingly detailed feasibility studies and continues throughout the life of the mine through several long-term and short-term planning processes. These processes all require the selection of a value descriptor that best reflects the value that can be obtained from the material, which may be expressed as a metal grade, dollar value or other measure. At various points in the sequence of mining and processing activities there is a need to choose a particular value of the value descriptor, called a cut-off, to enable decisions to be made about what to do next with raw or semi-processed material. Table 1 of The Australasian Code for Reporting of Exploration Results, Mineral Resources and Ore Reserves (‘the JORC Code’, 2012) provides a useful checklist of the many considerations that determine whether in situ mineralisation that is above the mining cut-off is ore (and should be processed) or is not. Selection of appropriate cut-offs is an outcome of the mine planning and optimisation process. While approximate cut-off grades may be used early in the resource estimation process, these are superseded by better, value maximising cut-off grades as planning progresses. The process is iterative and cut-offs are influenced, among other things, by the chosen mining and processing rate. The two variables, cut‑off and mining processing rate are the primary levers that can be used by planners to optimise the mining and processing plan. The selected mining rate determines how much of the above cut-off material can practically be recovered, how much below cut-off material is included in the feed sent to the processing plant, and the quality and variability of that feed on various time scales. Slow mining allows careful selectivity; fast mining generally reduces recovery and increases dilution. MINING CUT-OFF The optimum rate of mining is closely tied to the cut-off grade chosen. Hall and Hall (2006) observe that: 1. HonFAusIMM(CP), Chairman, Principal Mining Consultant, AMC Consultants Pty Ltd, Melbourne Vic 3000. Email: pmccarthy@amcconsultants.com …the major parameters that a mining company can make independent decisions about are typically the mining method(s), mining sequencing, production rate, and cut-off grade (or ‘cut-off’). Since the size and shape of the orebody and hence possible mining methods and the range of feasible production rates may vary significantly with cut-off, it is often the cut-off that is the key driver of value of the operation. This is illustrated in Figure 1, which shows that a smaller operation optimised using a higher cut-off grade is more robust than an operation optimised using high price assumptions. 55 P L McCarthy mine more carefully and selectively. While quick progress can be made in a single year, longer term averages should be considered when sizing the processing plant. The floor of an open pit can be advanced quickly but, as a rule of thumb, the open pit production limit is around eight benches per annum, or 80 m vertical advance using ten metre benches. Though some very large pits and small, short-life gold pits can achieve over 100 m per annum within the operating area. However, an average sink rate of 40–60 m per annum is more likely for longer term planning in most pits. The vertical rate of advance in a pit is influenced by the: FIG 1 – Risks and rewards of optimum cut-offs (Hall and Hall, 2006). CONSIDERATIONS ON MINING AND PROCESSING RATE A design rate of mining and processing is selected in every mine feasibility study, although any attempt to optimise that rate is rarely documented. To maximise return on investment, it has long been recognised that both the capital investment per unit of output and the operating cost per unit of output should be minimised. In general, both cost measures decrease as the scale of the project increases, so the initial temptation is to ‘push the orebody to the limit’. However, the technical and commercial risk both increase as the scale of the project increases. Hoover (1909) states that the lower the production rate, the lower the required investment, the longer the income stream and the lower the risk to the investor. While this was well before the advent of discounted cash flow (DCF) analysis, the point made by Hoover remains a good one. Until the last third of the twentieth century, most mine developers did not have ready access to project capital and so they had to develop projects using mainly a combination of new shareholders’ funds and retained earnings. Available capital was a key consideration in sizing a new project. More recently, and particularly during the ‘mining boom’, there has been an assumption that any scale of project will attract project finance if it satisfies the hurdles set by bankers. Capital constraints were not commonly included in the project optimisation process. Bigger projects were generally thought to be better. In reality, the interests of existing shareholder owners of a mineral deposit may be best served by a modest scale of development, with restricted use of external capital. The value of a smaller project as measured by net present value (NPV) may be lower, but the risk-adjusted value to existing shareholders may be greater. The uncertainties in mining investment are many. Mineral prices are cyclical and to a large extent unpredictable. Over the life of a mine, these prices usually fall in real terms. The mineral resources being mined are finite and can be highly variable in both size and quality, while ground conditions can vary significantly with depth and location. Costs are difficult to predict and subject to periods of rapid escalation. These uncertainties tend to favour a more modest capital investment and hence exposure to risk, provided the expected product cost falls within an acceptable range. MINING RATE LIMITATIONS There are physical limits to the rate that any orebody can be mined. High rates of mining are associated with greater day-to-day or month to month production volatility, with a tendency for dilution of the ore to become excessive at high rates as the pressure of production reduces the ability to 56 •• number of activities that are included in the mining cycle, eg grade control, presplitting, drill and blast, loading •• rate at which each activity can be carried out, as determined by the size and number of equipment •• total available floor area •• bench height, as this determines the vertical advance per mining cycle •• need to develop a drop cut to establish the bench, or a sump for dewatering, as is the case in mining in the base of pits compared to a mining a cut-back. Once the vertical advance rate is established, the average production rate can be determined from the available tonnes of ore per vertical metre (t/vm) within the pit design. Similar considerations apply to underground mines. The production rate from an underground mine is not usually limited by the rate at which ramp or decline development can be advanced, as a decline face can typically be advanced at 40 m per week on a 1-in-7 (14.3 per cent) grade, which is a vertical advance rate of 297 m/a. Rather, the production rate is limited by the number of available working faces which in turn depends on the amount of predevelopment, possible rates of ongoing lateral development, infill drilling, stope turnaround times, backfilling and so on, with interference between these activities. In steeply dipping deposits underground mining can occur on several levels simultaneously, but the mine production rate can still be related to the ore t/vm that will be mined. This relationship can be expressed as the ‘effective vertical advance rate’, or the relationship between actual mining rate and the t/vm available in the deposit. For example, a 1 000 000 t/a mine with an average 20 000 t/vm would have an effective vertical advance rate of 1 000 000/20 000 or 50 vertical metres per annum (vm/a). Work by the author and others has shown that the risk of failure increases as the vm/a increases. A century ago, a rate equivalent to one level per annum or approximately 30 vm/a was considered a reasonable basis for planning. Tatman (2001) was able to derive an empirical formula relating the risk of failure to the geometry of the deposit and the rate of mining and to conclude that for modern mines in steeply dipping tabular deposits thicker than 10 m, risks were: <30 vm/a low risk 30–70 vm/a moderate risk >70 vm/a high risk. In a 2014 confidential study of 12 current Australian mines using sublevel open stoping methods, the author found that average vertical advance rates varied from 23–71 vm/a with an average of 43 vm/a, while the maximum single-year rates varied from 31–79 vm/a with an average of 56 vm/a. Only one mine sustained a rate higher than 61 vm/a. As a generalisation, We are metallurgists, not magicians Integrated mining and metallurgical planning and operation special circumstances are required for any underground mine to sustain a rate above 60 vm/a. These observations describe the limits that might apply to mining rates for open pit and underground mines. The optimum rate can only be determined after detailed scheduling of alternative mining plans and the completion of an optimisation study that balances revenue against capital and operating costs for the entire mining and processing operation. MINING RATE AND HEAD GRADE The assumption that ‘economies of scale’ will result from increasing throughput rates needs to be balanced by an awareness of the adverse effects of increasing the rate beyond a level that is supportable by the resource. For each scale of operation considered, it is a reality that for any intended head grade, at the associated intended cut-off grade, the actual head grade achieved will fall as the mining rate increases. This effect is known to people at operations but is not generally recognised in current ore reserve estimation methodology. Once recognised, this dependence of head grade on mining rate can be quantified and used to establish the economically optimum mining and processing rate (McCarthy, 2010). MINING FLEXIBILITY It is unfortunately true that a mining operation presents challenges on every time scale from daily to annually. The failure of many ‘mine to mill’ studies to deliver promised improvements is largely because the mining engineers are fully absorbed in meeting existing challenges and have limited capacity to vary the method and sequence of mining to deliver a better or more predicable product to the process plant. Monthly, quarterly or annual mining schedules are based on the ore reserve model, which is frequently found to be deficient at those scales. Changes to the mining sequence are made on the run, and the challenge for the mining engineer is to deliver the scheduled tonnes, of any quality, above the mining cut-off. Some mining methods, such as sublevel and block caving, allow of no short-term control of product quality, although differential draw may be possible on a timescale of years. Provided it is above the mining cut-off, in the short-term the ore is delivered as it presents at the drawpoints. While other methods in both open pit and underground mines can be more selective, the pressure to deliver the tonnes to schedule often precludes any management of product quality by scheduling a blend of material from several mining areas. Of course, the higher the rate of mining, the less selective the mining can be. ORE STOCKPILES Nineteenth-century mines used hand-pushed rail trucks, typically of around 400 kg capacity, to move ore from chutes to the shaft and up to surface. Each truck could be marked with chalk as to its source. Stamp batteries were fed separately in groups of five stamp heads. It was possible to blend ore from different sources to achieve a steady quality in each stamper box. Alternatively and more commonly, parts of the mill were tuned to run on ore from different stopes or orebodies. In a gold mill, high-arsenic ores might be run over strakes and gravity tables into barrels, while clean ores were first mercury amalgamated on copper plates. Thus the mine and mill were closely aligned, with feedback on ore grade being given to the miners for individual stopes or areas. The many ore trucks formed a stockpile which decoupled the stopes from the hoisting and processing system. Old illustrations show trucks lined up at the plat, waiting to be hoisted, with empties ready to be refilled (Figure 2). By the mid-twentieth century orepasses acted as stockpiles at each stope to the haulage level, and from there, in parallel with the hoisting shaft, down to a skip-loading station. This allowed for a great deal of blending of ore from different sources, while decoupling the mining activity from hoisting and processing. The ability to reconcile stope grades and to run parallel lines through the mill had been lost, but cost savings and greater throughput were achieved. Today many mines are designed without significant stockpiles. Block caving mines in particular may have no effective stockpile capacity between the drawpoint and the surface stockpile. Even the surface stockpile may be eliminated in normal operation, with the inclined conveyor from the underground mine delivering crushed ore directly to the secondary crusher. In these circumstances the miners have no ability to manage product quality. In other operations such as sublevel open stoping or longhole retreat stoping without shaft hoisting, the old approach of using orepasses as stockpiles has been eliminated and ore is hauled to the surface in trucks. This provides an opportunity to manage ore quality by blending using two or more dump points at the run-ofmine (ROM) stockpile (or dump at a low-grade stockpile for future processing). Management of ore quality then becomes the responsibility of the reclaim operator, but may require resampling to establish the variability and location of material within the stockpiles. The more challenging the mining situation, the greater the stock levels need to be including developed (exposed) ore stocks, drilled stocks, broken stocks and ROM pad stocks. If these stock levels are adequate then variability and volatility There is evidence that more selective mining is possible if it is designed into the process from the outset and the planned mining rate is adjusted downward to allow it to take place. A good example is the selective mining of acid-generating and benign waste from a pit, with the benign waste used for capping. This is a legislative requirement which cannot be compromised, so it is given appropriate attention. The best way to achieve predictable feed for the process plant is to develop an accurate orebody model in which all the variables of consequence are modelled faithfully, and to set the mining rate low enough so that selective mining can be practiced on every time scale. This requires competence in the emerging specialty of geometallurgy, a healthy geological budget for drilling and modelling, and an uncommon appreciation of the benefits of mining at a rate lower than the maximum possible. We are metallurgists, not magicians FIG 2 – Ore trucks at the plat (from Dicker’s Mining Record, 1867). 57 P L McCarthy can be reduced to a minimum. The mine should be designed so that all stockpiles, including orepasses in an underground mine, have adequate capacity to smooth the short-term surges to a level acceptable for the entire system, including ore processing. This is a commonly overlooked requirement. variability in ore quality or of the distribution in space of valuable material, process contaminants, ore hardness and so on. At best, the mining schedules are presented as monthly averages for the initial few years and as quarterly or annual averages thereafter. Some orebodies are amenable to visual grade control; others require assays on a short turnaround to allow ore selection decisions to be made. The latter can suffer from dilution and high-grade volatility if the grade control program is not well designed and given priority at the laboratory. As initially constructed, the processing circuit must be designed to cope with or be adapted to the expected range of ore qualities, with an ability to respond quickly to any changes. Alternatively, with a less flexible circuit, the cost and revenue impacts of possible variations in ore quality must be examined to ensure they fall within acceptable limits. The impact may be greatest in the first year, when orebody knowledge is weakest and cash flow is critical. As experience is gained during mining, and infill or grade-control drilling advances, the orebody model can be greatly improved and the processing circuit adapted to reality. The reliability of mining equipment has an effect on ore quality. Delays in mine development (accessing ore in an underground mine or prestripping in a pit) can lead to periods when low-grade or high-impurity ore is all that is available. Breakdowns in ore-production equipment can lead to increased dilution because it is human nature to be less concerned about dilution when there is insufficient ore available to feed the mill. Hence the old saying ‘waste plus ore equals more ore!’ Proper mine design, planning, scheduling and maintenance require good management. Ultimately, the capabilities of the mine management team will determine the quality and regularity of mill feed. PROCESSING RATE Unlike the mining rate, the processing rate is not physically limited by geology. A plant of any capacity can be built, at a cost, although there are step changes in the capacity of available components that make particular rates more attractive. Sometimes environmental constraints limit the hours for activities such as stockpile reclaim and crushing but this can be addressed by using larger equipment. The availability of services such as power or water may place an absolute limit on the size of plant, or impose a large capital cost burden for going beyond that point. Once a plant is operating, the processing rate may be limited by feed characteristics. For example, harder ore than expected may limit the milling rate while wet, clayey ore may limit the crushing rate. The copper to sulfur ratio may limit throughput in a smelter. For these reasons plant components and the overall plant capacity may be oversized to some extent as compared to the selected mining rate. If this is recognised by management as an allowance for variable ore quality then no problem arises, but invariably when the ore quality is good the higher capacity is pushed back to the mine as a demand for a higher mining rate, with adverse consequences. For some products the production rate may be limited by the market. The output of large individual producers of products such as iron ore may influence the market price, so that the optimum production rate is less than it would be in an unlimited market. In some circumstances there may be a limit to the road or rail haulage capacity for concentrate, or the availability of ship loading facilities. OREBODY MODELLING A resource model is initially based on exploration drilling only. Its accuracy is limited by the exploration budget, by difficulty of access to the mineralisation, and by a lack of experience with the deposit. This resource model is used by mining engineers to design a mine at the feasibility study level, with their predictions of mining dilution and mining recovery used to estimate an ore reserve. The mining schedules produced in the feasibility study are used by the plant engineers and metallurgists to design the plant. At this stage there may be a very poor understanding of the hourly, daily or weekly 58 The planning process begins with a good 3D geological (resource) model developed by an experienced geologist familiar with the deposit type. Geological domains are identified, such that a common set of rules can be applied to determine local variations in metallurgical responses within each domain. The domain boundaries may be structural, mineralogical, alteration or lithological. Poor geological modelling and domaining are the leading causes of failure in geostatistical modelling for grade estimation and for modelling metallurgical parameters. Domains should be defined beyond the ‘orebody’ to include all material that could find its way into the ore stream. Metallurgically, adjacent domains may have little or nothing in common. For example, the waste rock adjacent to the orebody across a sharp contact may be much harder and more abrasive than the ore, and if the mining method will cause 25 per cent mining dilution of ore with waste rock then the crushing, grinding and wet plant performance of the waste rock must be thoroughly understood. Similarly, dilution from nearby carbonaceous shales (such as a hanging wall zone) may be preg-robbing or a talc-rich fault zone may impact on filtration, although neither is considered part of the orebody proper. Once the domains (both within and near the orebody) have been described (as ‘wire frames’ or solid objects in a 3D computer model), representative samples from each domain can be subjected to laboratory-scale test work to determine the rock’s response to each mineral processing operation. Conventional geostatistics can then be used to model the distribution of metallurgical responses throughout each geological domain. This results in a model comprising a large number of blocks in 3D space, each block being assigned all the geological, geotechnical, geometallurgical and other characteristics needed for mine planning and scheduling. The mine scheduling process can then produce from the geological block model not only a schedule of tonnes and grade but also a schedule of metallurgical performance and other characteristics such as ground support requirements or even water inflows to the mine. The geostatistical approach used to model metallurgical performance need not be complex. Even the simplest approaches using the ‘rule of nearest neighbours’ (which says each block in the model is likely to perform in a similar way to the nearest sample) or the ‘rule of gradual change’ (which calculates a distance-weighted average of characteristics based on nearby samples) is likely to provide a significant improvement in predictability of plant performance when compared with having no geometallurgical model. However, the more advanced geostatistical methods are not difficult to apply and will further refine the result. Selection of the best techniques is the subject of ongoing research. We are metallurgists, not magicians Integrated mining and metallurgical planning and operation Samples for metallurgical testing are usually composited from diamond drill core. Hardness testing (for crushing and grinding) typically requires 10–20 kg of sample, with some tests requiring 100 kg, while flotation testing usually requires at least several kilograms of sample (Barratt and Doll, 2008). Large metallurgical samples excavated from near the surface of a deposit are unlikely to be representative of the orebody at depth. Shafts sunk for the purpose of obtaining large metallurgical samples may also yield unrepresentative samples, or samples that represent performance in only one geological domain. Such exercises may be compared to searching for a lost wallet under a streetlight, because it is too dark to search elsewhere. In order to be useful in developing a geometallurgical model, test results must satisfy the following (ibid): •• results must reflect the properties of a ‘small’, identifiable interval of drill core •• the location of the interval must be identifiable in 3D space (to connect it to the block model) •• the values being distributed through the orebody must be reasonably additive, allowing unknown blocks in the model to be estimated by interpolating two or more known samples. Sufficient sample material to achieve these aims may be available from drill core for a large porphyry copper open pit which has a large selective mining unit (SMU or minimum mining block size). For smaller, more complex deposits and many underground mines where assays are obtained for each one-metre sample interval, the production of composite samples of sufficient size for metallurgical testing may defeat these aims and blur the modelling results. For example Barratt and Doll (2008) propose sample intervals of 15 m of HQ (63 mm) core for a JK SMC® (drop weight) test and 45–105 m of HQ core for a Bond test. It may be necessary to develop local correlations between the large-scale tests and other properties such as point load strength, rock quality designation (RQD), fracture frequency and mineralogy in order to obtain sufficient data to create a meaningful 3D model. The new techniques of geometallurgical modelling are useful in improving process plant performance and predictability in large orebodies such as porphyries, mined with big equipment. In these situations zoning may allow prediction of changes over a period of years. However, many medium to small-scale mines may not be amenable to the techniques being developed. The problem is that variability of the factors affecting metallurgical performance occurs at a scale smaller than can be sampled for metallurgical testing, and at that scale the measured properties are not well correlated with performance. The same problem exists for geotechnical modelling, where very limited success has been achieved in predicting ground conditions and stability using geostatistical methods. mined, stockpiled and processed separately. The premining block grades were estimated from diamond drill assays by geostatistical methods using a 150 g/t Au top cut. Overall, Gill Reef was estimated from drilling to have a grade of 7.5 g/t Au which reconciled (for comparable blocks) with a mine head grade of 7.6 g/t Au. Individual block reconciliations, with a linear best-fit line, are shown in Figure 3. It was possible to reconcile mill recovered grade against mine head grade for 45 blocks ranging from 2064–9799 t, with a mean size of 4426 t. Head grades ranged from 2.2–12.6 g/t with a weighted mean of 7.6 g/t. Reconciled metallurgical recoveries ranged from 71.5–96.7 per cent with a weighted mean of 89.1 per cent. Individual block reconciliations, with a logarithmic best-fit line, are shown in Figure 4. A constant tail grade model was not a good fit to the data. With sufficient experience in similar orebodies it should have been possible to predict from the drill results that mining about 240 000 t of ore would yield a head grade of about 7.5 g/t Au and a metallurgical recovery of about 90 per cent. However, these long-term averages would be of little use in predicting or optimising process plant performance on a daily or weekly basis at the actual mining rate from Gill Reef of 2000–3000 t per week. Figure 5 shows the predicted metallurgical recovery for each mining block (based on the predicted head grade and the grade-recovery relationship) and the actual metallurgical recovery, with a weak linear bestfit relationship. It is clear that metallurgical performance was not predictable at a useful level. While attempts could be made to improve the metallurgical model by modelling other geological features such as carbonaceous shales or associated sulfides, the innate geological variability makes success unlikely at the actual scale and rate of mining. At much higher mining rates, or FIG 3 – Predicted and actual block grades, Gill Reef. CASE STUDY – PREDICTING THE UNPREDICTABLE IN GILL REEF The Bendigo orebodies have been shown to suffer from an extreme nugget effect, making prediction of grades from drill data difficult. For this reason Gill Reef was mined, processed and reconciled in small batches and provides a more detailed picture of ore variability and plant performance than is usually available. The author examined the data to see whether metallurgical recovery could have been predicted from the predicted head grade of each batch. Gill Reef is a distinct quartz reef at the Kangaroo Flat mine that was mined between 2009 and 2011. A total of 55 discrete ore blocks totalling 243 497 t from Gill Reef were We are metallurgists, not magicians FIG 4 – Head grade and metallurgical recovery, Gill Reef. 59 P L McCarthy •• Surface mines suffer significantly higher variability in ore production from budget than underground mines. This is surprising, but reflects the ability to switch the mining fleet from ore to low-grade to waste in reaction to changed circumstances, including geological variations, weather and equipment downtime. Another reason may be that open pit schedules are less conservative than underground schedules. •• Despite the mining variability, processing rates in surface mines run closer to budget, perhaps due to having larger stockpiles. •• Variability in mined and processed grades is similar, suggesting that little use is made of stockpiles for blending and that grade control outcomes are similar in the surface and underground mines studied. FIG 5 – Predicted and actual metallurgical recovery. when considered over longer periods, the volume-variance relation would allow greatly improved predictability. VOLATILITY AND VARIABILITY Production volatility refers to the relative variation in a parameter from one time period to the next, while variability refers to the variation from budget or plan from one time period to the next. The volatility of parameters such as feed tonnage, head grade, metallurgical recovery, throughput or product output can be measured hourly, daily, monthly etc. The more volatile the measure, the less use is being made of the installed capacity and hence of the capital invested and of the fixed component of operating cost. One of the key symptoms of a system that has been pushed beyond its stable capacity is an increase in production volatility. A mining project designed for a 1.0 Mt/a rate with five per cent volatility needs an installed capacity of 1.05 Mt/a. If a decision to increase the rate by ten per cent to 1.1 Mt/a leads to an increase in volatility to 15 per cent, then the installed capacity must be increased to 1.27 Mt/a, an increase of 20 per cent. If the capacity is only increased by ten per cent, the increased volatility could lead to a slight reduction in output when the mine and mill are considered together as a system. Another useful measure is volatility, the average percentage change in a measure from one time period to the next. The level of planned and actual volatility drives the stock requirements and levels. When volatility is low, mining and processing are efficient and capacity is being used effectively with costs minimised. Table 2 shows the month to month volatility from the benchmark study mentioned above. It can be concluded that: •• ore tonnage mined is nearly twice as volatile in surface mines compared with underground mines •• on other measures, underground mines are more volatile than surface mines. Carter (2010) observes that volatility and variation in any business process creates uncertainty, whether in determining mining volumes and plant feed or in optimising maintenance schedules and supply chain management. The same holds for the management of working relationships. It is this variation and volatility which skews outcomes, and which can be reduced by implementing rigorous planning, scheduling, resourcing and execution processes, and most importantly, by clarifying roles and accountabilities at each level. The specifications for the processing plant should reflect real hourly or daily mining outcomes, not a smoothed and idealised schedule. Table 1 summarises the unpublished results of benchmark studies of 44 underground mines and 21 open pit mines conducted by AMC Consultants. The monthly variability shown is the average absolute difference (as per cent of budget) between the mine budget and production over a 12 month period. High variability indicates that a mine is not operating as intended, and that daily variability may be much greater than the steady hourly throughput for which the plant was designed. It can be concluded that: When volatility and variability are assessed on an hourly or daily basis they are seen to be much greater than the monthly measures in Tables 1 and 2. For example, Figure 6 shows daily plant tonnes at Anglogold Ashanti’s Mponeng mine. The figure also shows the results of a business improvement initiative which contributed to a 15 per cent increase in throughput over the historical average. This is an especially significant result at the Mponeng plant, long regarded as the flagship operation within the group. Before the initiative, ore from the Mponeng mine would regularly be trucked to neighbouring plants for processing, as the mill struggled to cope. After the initiative the plant had improved productivity to the point that it now had spare capacity. Emphasis on stabilised processes also resulted in a 20 per cent reduction in sodium cyanide consumption. Table 1 Monthly variability from budget over a 12 month period. Table 2 Month-to-month volatility over a 12 month period. Underground mines Underground mines Surface mines Min (%) Max (%) Ave (%) Min (%) Max (%) Ave (%) Ore mined (t) 5 43 14 7 68 29 Head grade 7 33 13 3 38 11 Ore processed (t) 5 54 12 4 39 Processed grade 3 33 13 2 31 60 Surface mines Min (%) Max (%) Ave (%) Min (%) Max (%) Ave (%) Ore mined (t) 6 34 14 11 62 25 Head grade 5 28 11 3 22 9 9 Ore processed (t) 3 32 13 4 22 10 10 Processed grade 5 23 12 3 16 8 We are metallurgists, not magicians Integrated mining and metallurgical planning and operation FIG 6 – Mponeng mine daily plant tonnes (over 12 months) (after Carter, 2010). OPTIMISING THE MINE AND PROCESSING PLANT MANAGING THE DOWNSIDE RISK The key parameters over which a mining company has control are the size of mine (large or small, low or high-grade, as determined by the cut-off grade), the mining method, the production rate, the mining sequence, the processing method and the amount of money that will be spent on getting these things right, which includes exploration drilling, geological modelling and bench and pilot plant testing. Other aspects such as power supply, water supply, concentrate transport and logistics generally have a more obvious engineering solution and are ancillary to the optimisation process. The need to manage risk was well understood in the past. A small project was built, often with second-hand plant, and then cash flow from the operation, or equity funding from the now-reassured investors, was used for a series of expansions and optimisations. If there was a problem with the initial ore reserve or cost estimates, the exposure of shareholders to this problem was minimised and managed. The objectives of optimisation must be aligned with the corporate objectives of the owner. Some stated corporate objectives, such as maximising annual ounces of gold production or maximising mine life, cannot be optimised. Clearly, increasingly large subeconomic projects will satisfy the former objective while decreasingly large subeconomic projects will satisfy the latter. Short-life projects carry the risk that most of the production will be delivered into a trough in the product price. Sensitivity analysis based on a range of price scenarios will identify the parameters that yield an acceptable risk. There is also the problem of capital allocation between competing projects. If there is no restriction on the available capital then corporate value is maximised by maximising the NPV of every available viable project and carrying all of them through to production. In the real world, where available capital is restricted, the corporation must select projects for investment using some ranking technique. Economic theory says that projects should be ranked using the present value ratio (PVR), which is the ratio of NPV to initial capital investment. For simplicity, the capital investment is usually taken to be the total of negative cash flows prior to achieving positive cash flows. If the perceived risks are similar, projects with higher PVRs are selected before those with lower PVRs. A project with a high NPV but a low PVR may require more capital than the corporation (or the investment community) is able or willing to risk, or if developed it may displace alternatives which would have provided a better aggregate return on investment. From the above, the project should be designed to maximise the project NPV at the corporation’s agreed discount rate, provided this leaves it with a PVR that will make it an attractive investment. Arguably, the plan should be changed to improve the PVR, even at the expense of NPV, if this will allow the project to proceed in competition with others. We are metallurgists, not magicians The author was involved in a large gold project that had high geological risk. It could be initially developed using a nearby idle plant, either by purchasing the plant for a modest sum or by toll milling, before building a full-scale plant. This plan did not give a satisfactory project NPV because it delayed full-scale production by several years. A compromise was found whereby a small plant would be built on-site and later expanded. However, as the time for construction approached, deteriorating estimates again made the NPV unattractive. This was addressed by deleting the smaller stage and building the larger plant immediately. This enhanced the NPV substantially in spreadsheet models. When the geological problem proved intractable the project failed, with capital losses around three times what they might have been with the original toll-milling proposal. This outcome might have been avoided using the value at risk (VaR) approach which is widely used in the financial sector. VaR is the maximum loss not exceeded with a given probability defined as the confidence level, over a given period of time. It is commonly used by security houses or investment banks to measure the market risk of their asset portfolios (market VaR), over time periods of one day to a few days. However VaR is a very general concept that has broad applications. For example, a Monte Carlo approach to modelling net cash flow outcomes for a particular project development option might show that 95 per cent of outcomes have a net cash result better than minus $50 M. In other words, the cash loss is expected to be greater than $50 M only five per cent of the time. This approach must have a constrained time period applied, such as the time to project payback or a fixed number of years. The various project development options can be modelled and a decision made based on both the expected NPV and the VaR for each development option. Ultimately, the corporation must be able to absorb and manage the ‘worst-case’ outcome. CONCLUSIONS The design of metallurgical plants should be undertaken in the context of the broader optimisation of the mining 61 P L McCarthy project. Often the appropriate metallurgical process can be selected early in the optimisation process and thereafter the plant design is simply a matter of good engineering, without strategic options. By contrast the size of mine (large or small, low or high-grade, as determined by the cut-off grade), the mining method, the production rate and the mining sequence are strategic decisions which form critical inputs to the engineering design of the metallurgical plant. These strategic decisions should be made by a team which includes members who have an appreciation of the implications of those decisions to every part of the proposed operation. Subsequent engineering design for the mine, processing plant and infrastructure can then proceed within appropriate constraints. In recent years, many project investment decisions have been made on the assumption that unlimited project finance is available. Due to global economic circumstances this is no longer the case, and a more traditional approach to project optimisation is called for. After consideration of risk, a modest-sized, staged development may provide better shareholder returns than the largest project that an orebody can theoretically support. Staged development may require multiple parallel processing circuits and smaller, more selective mining machines operating at higher cut-off grades. The VaR approach is one way of quantifying the downside when considering alternative project scales and development paths. Its use, in combination with tradition NPV analysis, provides a more complete picture of the options available to a company when it sets out to develop an orebody. ACKNOWLEDGEMENTS The author acknowledges AMC Consultants Pty Ltd for permission to publish benchmarking results and Unity Mining Limited for permission to publish the Gill Reef data. REFERENCES Barratt, D J and Doll, A G, 2008. Testwork programs that deliver multiple data sets of comminution parameters for use in mine planning and project engineering, in Proceedings Procemin 2008, Santiago, Chile. Carter, C, 2010. Project one holistic transformation plan to achieve strategic goals, Anglogold Ashanti. Dicker’s Mining Record, 1867. Dicker’s Mining Record and Guide to Gold Mines of Australia (newspaper), 28 November. Hall, B and Hall, A, 2006. Doing the right things right: identifying and implementing the mine plan that delivers the corporate goals, in Proceedings International Mine Management Conference 2006, CDROM (The Australasian Institute of Mining and Metallurgy: Melbourne). Hoover, H C, 1909. Principles of Mining, pp 153–160 (McGraw-Hill: New York). JORC Code, 2012. Australasian Code for Reporting of Exploration Results, Mineral Resources and Ore Reserves (The JORC Code) [online]. Available from: <http://www.jorc.org> (The Joint Ore Reserves Committee of The Australasian Institute of Mining and Metallurgy, Australian Institute of Geoscientists and Minerals Council of Australia). McCarthy, P L, 2010. Setting plant capacity, Transactions of the Institutions of Mining and Metallurgy, Mineral Processing and Extractive Metallurgy, 119(4):C184–C190. Tatman, C R, 2001. Production rate selection for steeply dipping tabular deposits, Mining Engineering, October, pp 62–64. 62 We are metallurgists, not magicians Project economics Contents Guidelines for economic evaluation of projects P Card1 ABSTRACT ‘Let’s get discipline and quality into easy to understand evaluations!’ Project managers and metallurgical plant operators accept poor quality evaluations because they are generally unaware of what they should expect. To provide guidance, the Australasian Institute of Mining and Metallurgy (the AusIMM) established a subcommittee of practitioners that collated evaluation systems and procedures regarded as best practice. This has been developed into a free website for the greater mining industry: <www.economicevaluation.com.au>, which is maintained by the author. It offers a range of modules and worked examples that describe in plain language, the step by step sequence of conducting an economic evaluation. These practices apply directly to projects and metallurgical plant evaluations, including those with a heavy technical basis. They can be applied to technical problem solving where there are no monetary computations. Project managers and metallurgical plant operators should demand that economic models and evaluations follow the six principles. They should become working tools which are easy to understand, fit for purpose, consistent, rigorous, record sources of input data, have key graphs and are rapid to audit. INTRODUCTION Poor workmanship is common but usually accepted If industry made an award for the worst performance in metallurgical plant project design and plant operation then the odds-on favourite would be the economic evaluation! If an economic evaluation is sophisticated, complex and terribly clever with Excel so that only one or two experts can use it, then it probably is worst practice. But if anyone with only basic knowledge of evaluation can readily follow it, sees the correct data being employed and feels it is easy to understand then it is on the way to best practice. Project managers and plant operators need to take control and demand economic evaluations they can quickly follow during their busy working day. The world’s best practices are readily available on the internet and are in active use in the mining industry. But for historical reasons most project managers and plant operators will accept poor quality work in this arena. What is accepted for economic evaluation would not be tolerated in its sister disciplines of geology, mining, metallurgy, engineering and accounting. Fortunately this is rarely due to sloppy management by project managers and plant operators, but due to lack of awareness of what they should expect and demand. As a horrible start, most professionals do not even call it by its correct name of ‘economic evaluation’ but talk of ‘financial modelling’ or even more incorrectly ‘financial analysis’ (more later). Project managers and plant operators would insist on metallurgists doing the processing study work, insist on engineers doing the design and Engineering, Procurement, Construction Management (EPCM), would want accountants to do the books, but probably would accept almost anyone willing and able to perform the economic evaluation. This person probably would be allowed to do the evaluation, however they believed was best. This is because the discipline of economic evaluation has evolved over recent decades to bridge between operations/ engineering and accounting without an academic or professional foundation. 1. MAusIMM, Consultant – Economic Evaluations, Aspendale Vic 3195. Email: mpcard@tpg.com.au Older style project managers and plant operators see economic evaluation as a back room activity to be hurriedly completed, typically when the last of the cost estimates are finished the night before the submission is due to management. They see the activity as a mathematical computation to fill in the paperwork with net present value (NPV), internal rate of return (IRR), payback etc. Fortunately, these are a dying breed. 65 P Card These older style managers do not really understand they are designing or operating a business, but live in a closed world of professional engineering or hands-on plant operating. They are very confident that they are ‘working on the important stuff’ and ‘getting things done!’ They do not realise that contemporary managers demand an economic evaluation up and running from Day One as a tool to steer the project or operating plant through the study process into the optimum state of business. The economic evaluation specialist should be the second-best role in the team; after the leader. Mantras of best practice A few mantras of best practice in economic evaluation are: •• ‘If you do not readily understand and comprehend my evaluation then you do not have a problem, I do!’ •• ‘Every worksheet should be as easy to read as a school text book!’ •• ‘Do not try to impress with sophisticated Excel functions, but use your intelligence to convert complex interactions into simple steps on the worksheet.’ •• And definitely not ‘Trust me! I am the expert in evaluation modelling!’ Financial analysis versus economic evaluation Completion of a project requires two separate money-focused activities: 1. economic evaluation 2. financial modelling. The first, economic evaluation, is all about understanding the business health of the project. What cash will be required to establish, operate and pay taxes versus the cash generated or saved by the project. This is the simple economics of cashin and cash-out over time. Economic evaluation does not worry where the cash comes from (that is, financing) but rather it wants to understand the cash generating power of the underlying project including what sort of prices and operating environment is required to cover costs and generate an economic return (the discount rate is usually before financing). Everything is computed in cash in the year it is actually spent or received. There is no accounting depreciation, no accounting charges for future closure and no other non-cash items. There is no equity raisings nor company borrowings, and so no financing charges on borrowings during construction. Taxes are included and computed before the apparent benefit of debt. The second, financial modelling, is all about sourcing the cash to establish and run the project until it becomes selfsustaining. What mix of company internal cash flow, debt, new equity, convertible notes, derivatives and hedging will the company use to progressively pay for owner’s costs, EPCM, first fills, commissioning, ramp-up to commercial operations and interest on these borrowings? How will each type of capital raising impact company profits, its balance sheet and share price? Economic evaluation might be best lead by a person with a technical-operating background whereas financing might be best lead by an accountant. Both perform spreadsheet modelling of the future business but they are very different in purpose and process. Both should be presented in simple language and easy-to-understand concepts. The two activities should not be woven together because: •• each is a stand-alone decision 66 •• combining their mathematics is very tricky, especially adjusting the discount rate as debt is introduced (do people still get fooled by false claims of improving project returns by using debt?) •• the spreadsheets will become unnecessarily complex to use and audit and so alienate all in the team except specialists in finance. The financing spreadsheets could be appended to the end of the economic evaluation workbook providing the flow is one-way and nothing feeds back to the economic evaluation worksheets. Evaluation, valuation, modelling ‘Modelling’ is a component of, but not all of ‘valuation’ which is a component of, but not all of ‘evaluation’. They form a hierarchy with ‘modelling’ at the bottom providing the hands-on computations that feed results for various cases and scenarios up into ‘valuation’. This ‘valuation’ quantifies and characterises the value of the project or metallurgical plant. In turn this ‘valuation’ feeds up as one element in the intellectual activity of ‘evaluation’ by fully understanding the project or metallurgical plant as a business. Anyone thinking that economic evaluation is all about pouring numbers into a spreadsheet model to get NPV and IRR is living in the past. Today it is all about having a working knowledge of the whole project or metallurgical plant from ore in the ground through all activities and influences to the market. It encompasses nearly everything from engineering to paying taxes. It is about understanding the key drivers and key interactions of the business. It is getting a helicopter view of the total entity, deciding how it fits the existing business and helping to test ideas and create better projects and metallurgical plants. It is all about putting the ‘E’ into Evaluation. Yes, the economic evaluation specialist should have the second-best job in the team: after the leader. Best practice in economic evaluation There are six principles at the top of the hierarchy. KEY PRINCIPLES The key principles to which one should adhere when performing spreadsheet modelling are simple but extremely effective. They are: •• easy to follow •• tailored-to-purpose •• transparent •• disciplined, rigorous and consistent •• recording sources of all data •• rapid to audit. KEY PRACTICES Flowing down from these six principles are key practices to be incorporated in an economic model. They are: •• A non-expert should readily understand the function of each worksheet, how it is arranged into component parts, how the data is entered, the computations and the relative importance of the parts. •• The visual flow down and across each worksheet should be intuitive and logical. •• Each worksheet should have a bold heading followed by a brief outline of its purpose, and where helpful, its important links with other worksheets. We are metallurgists, not magicians Guidelines for economic evaluation of projects •• Sections within each worksheet should be in discrete work blocks, with obvious subsections and subheadings using a cascading layout for subtitles. •• starts with a brief overview of results including multiple graphs of the four cash flows (see below) and all important inputs and outputs •• Visually each work block should be self-contained with an obvious step-by-step development toward a bold subtotal for that work block. •• is audited by the specialist, by experts in their areas (example: metallurgist audited the processing section) and usually an external specialist •• The separate work blocks should be in a logical sequence down and across the worksheet and their aggregation is obvious. •• is intuitive •• Complex and extended computations should be shown in a series of small steps so that the logic is visible and the input parameters are obvious. There is no need to interrogate the algorithm. Explain the logic of complex algorithms in a note. •• Usually if a row of data that has already been presented above is needed again in a work block then the entire row should be repeated so that there is visual flow of the logic. If referenced from another worksheet then it should be coloured coded. •• Key inputs and results should be shown in graphs as a self-check and for rapid understanding. •• The ‘Data Group and Outline’ facility can be used to define worksheet structure, collapse related groups of rows or columns to reduce visual clutter, and aid navigation. WORKED EXAMPLE OF MODELLING Worked examples of economic models in Excel for concept studies, prefeasibility studies and final feasibility studies can be downloaded (free) from the website: <www.economicevaluation.com.au>. READY-MADE EVALUATION MODELS There was unanimity amongst the AusIMM practitioners that ready-made economic evaluation models, where users fill in the blanks, were too dangerous to use. Experience is that these black-box models transgress the six principles of best practice, but more importantly have a bad history. Their computations cannot be audited, the models must be exceedingly complex (or deficient) to accept a wide variety of scenarios and they simply cannot be trusted. WHAT TO EXPECT FROM SPREADSHEET MODELLING A project manager or metallurgical plant operator should demand that every economic evaluation model under his/ her management: •• is absolutely rigorous in its construction •• is in discrete blocks of simple steps with clear headings and obvious end results •• has input data coloured (example: blue) so that it is immediately visible and the project manager can skim across it to quickly check validity of all inputs •• has input data with a source (when, who and what) typed in the row above so the project manager can immediately see if it is the correct version •• has data referenced across from another sheet coloured (example: green) so it is immediately recognised •• is absolutely consistent across rows, so that algorithms do not have hidden changes •• has every item of input data exposed in a row before being used and absolutely no fresh data entered as data hidden in algorithms We are metallurgists, not magicians •• provides trust in what you see without drilling down into algorithms. USING EVALUATIONS IN FEASIBILITY STUDIES Project managers and metallurgical plant operators appear to use three phases of study for projects: 1. Concept or scoping studies to assess if the project fits company strategy and at least one alternative has a reasonable likelihood of being economically viable: •• For these brief studies the modelling and evaluation usually can be relatively coarse and simple. It needs to explore the range of outcomes and key drivers of success and failure. It needs to weed out pet projects and support only quality concepts. •• The evaluation person needs to work cooperatively between the project manager and the many experts inside and outside the company who have the knowledge. The specialist may be a ‘back room’ type from any background, but better if an active specialist with an operating/engineering background. •• The project manager is likely to work closely with the evaluation specialist interacting every day or two. 2. Prefeasibility studies that assess the complete range of project alternatives. The divergent thinking in this phase generates the most value: •• For these studies the modelling and valuation needs to be detailed enough to differentiate the economics and character of each alternative. This phase excites those who are creative but objective. It needs to confirm the attractiveness of the selected alternative and define its business character. •• The evaluation person needs to frequently interact with specialists inside the project team and outside, drawing out the complete information, going back and confirming it has been correctly modelled (audits) and being absolutely objective. The evaluation specialist must resist the temptation to be too clever with Excel functions but keep the model simple so everyone can readily understand, audit and feel it represents the alternative truly. The specialist should not be a ‘back room’ type but probably from an operating/technical/ engineering background with a broad understanding of the business and a work ethic that is energetic, collaborative, creative and accurate. •• The project manager is likely to see the evaluation model as an engine to assess alternatives and generate ideas. He/she is likely to rely heavily on the evaluation specialist to understand where each of the alternatives is heading and to help steer the study activities to best effect. Daily contact, with creative thinking, would be common. 3. Final feasibility studies that thoroughly assess and define the alternative to be taken into execution or construction. This is convergent thinking with lots of detail: •• For these studies the modelling and evaluation will become quite detailed. The whole business needs to 67 P Card be thoroughly defined. The modelling will evaluate different methods and different equipment within the selected alternative. It may need to work in nominal terms in some areas and integrate with company’s accounting and financing activities. •• The evaluation person needs to work in detail as part of the enlarged study team. •• By this time the project manager should know if the existing evaluation person is the right fit for this phase. Contact may become periodic but the evaluation model would continue as a vehicle to help steer the Feasibility Study. FOUR CASH FLOWS Anyone opening a worst practice evaluation model is faced with a myriad of parameters and a convoluted array of computations that are understood only by the evaluation specialist. Key outputs such as NPV are buried amongst the worksheets. Auditing would be tedious and take days. Best practice has simplified valuations into four streams of cash flow: 1. revenue cash stream (production, stocks, sales, prices, debtors) 2. capital cash stream (capital expenditure (CAPEX), creditors, tax deductions) 3. operating cost cash stream (operating expenditure (OPEX), creditors) 4. taxes cash stream (royalties and income tax). Their sum represents the net cash flow each year and this can be simply discounted to give NPV, or used to compute IRR. Second and third level computations such as working stocks, debtors, creditors and tax deductions for CAPEX (‘tax depreciation’) are computed as high-level calculations within these four cash streams. Their impact on project managers’ and metallurgical plant operators’ decision-making will be minimal so should be reduced to a few simplified rows. THE TWO BOOKENDS OF ECONOMIC VALUE In most mining industry businesses there are two ‘bookends’ which dominate the economics: the ore resources in the ground and the market. One end determines how big and good the business can be and the other end determines how profitable it will be. In between are all the very important and exciting projects and operations to make it happen and make it improve. It has been joked that a whole team of engineers and metallurgists slave for ages on production, CAPEX and OPEX while somewhere in a back office a few people generate price forecasts that swamp the valuation. None-the-less the production, CAPEX and OPEX are critical and must be forecast with appropriate quality. 68 DO BIGGER PROJECTS NEED BIGGER ECONOMIC MODELS? One of the world’s greatest iron ore mines was acquired in the 1970s with the economic evaluation model provided to the company’s Board being just one page of very easy-tofollow, manual computations. Contrast it with the volumes of modelling and synthesis that would be required today. In a strange way that one page from the 1970s was as potent as all the evaluation study work that we generate today. There in amazing simplicity for the Board members was the heart of the acquisition decision, namely the risks in the forecasts of price, mineral resource, production and costs over the years. Senior executives in the world’s biggest mining companies have made it clear they would love simple one page models of major investments, major acquisitions and life-of-mine plans. This is not to suggest that all evaluation models should be one page. Quite the reverse: a detailed evaluation model should be a centre-piece of a major project or metallurgical plant. It should draw together all the component parts as a business so the team understands the relative importance of each part, where to focus and how to optimise the overall design. It should be a tool used every day by members of the project team/metallurgical plant to challenge and test their ideas. Detailed evaluation models are needed to steer the project toward the best configuration and to assess the risks. Ironically, Management/Board need a simple, easy-tounderstand evaluation ‘one page’ model to help it understand the big decision of whether to invest in the project whereas the project team might need a big, detailed, working model to optimise the project’s configuration and the design of its component parts. HALL MARKS OF BEST PRACTICE ECONOMIC EVALUATION From day one, project managers and metallurgical plant operators must set their expectations and demand that economic evaluation is: •• easy to follow – it may not be simple but anyone in the team should be able to follow it like a school text book •• fit-for-purpose in that detail matches importance – begin as simply as possible and add complexity only when warranted •• rigorous, transparent and intuitive – trust what you see •• fully documented – readily see where every piece of data was sourced •• graphs – to find errors and to give quick visual understanding •• audited – both the mechanical computations and the results. We are metallurgists, not magicians Contents Sensible cost cutting for resource projects D Connelly1 ABSTRACT As the resources industry becomes tougher with rising costs and cyclical metal prices, mining companies need to continue to reduce their costs and do more with less. Many new resource projects fail to come in under or on budget based on feasibility studies. In particular, capital expenditure (CAPEX) proves difficult to achieve for resource projects. Many resource projects have failed because of aggressive plant CAPEX cost cutting, which results in projects with no surge capacity and an inability to achieve design throughput. In addition, the plants are not operable because of the omissions. In recent times, many businesses have also experienced the ‘costs’ of simply implementing aggressive operating cost-cutting measures as a strategy for solving business performance problems. This paper looks at technologydriven, employment-related luxury, department and restructuring cuts. In the past, companies used an incremental approach based on the use of past budget information as an integral part of the budget construction process. The use of performance reports and management information systems (MIS) is examined, along with the role of continuous improvement in achieving sensible cost cutting. INTRODUCTION All companies look for ways to reduce costs and increase profits, and resource companies are no different. With the scale of mining projects, a cost saving of a few per cent could mean millions of dollars for the company. Budgets are prepared to determine where money is spent and where it could possibly be saved. This applies to all resource companies, whether an exploration company looking to build a plant, an engineering design company or a mining company in production. Historically, the resources industry has always gone through peaks and troughs. Understandably, mining companies want to take advantage of the good times by maximising output of existing mines or constructing new ones. Designing a plant to these favourable market conditions during a mining boom can be a dangerous exercise. If the metal price suddenly drops, a low ore grade or high processing cost prospect that was previously viable, could result in a mine closure. To avoid this, companies must look at cost-cutting measures to increase the viability of their project for a range of commodity prices. A plant in the design stage has a much larger scope for cutting costs from the CAPEX and operating expenditure (OPEX) than an existing operation through circuit optimisation or process changes; however, overly aggressive process cuts to reduce the CAPEX may cause the process to run inefficiently during operation and could reduce the overall availability of the plant, causing extra costs and less revenue. Process changes and their operability implications must be thoroughly considered by the design company. Mining companies should not simply cut costs to the design process as this may cause greater costs to the project in the future (for example, Murrin Murrin, Browns project, Ravensthorpe nickel project, Port Hedland hot briquetted iron project, Rapu Rapu copper zinc project). 1. MAusIMM(CP), Director/Principal Consulting Engineer, Mineral Engineering Technical Services Pty Ltd (METS), Midas Engineering Group, Perth WA 6000. Email: damian.connelly@metsengineering.com An existing operation that is struggling to be profitable may need to make some significant operating cuts. Rather than one large cut, which could have serious negative implications to the personnel or process, several small cuts should be implemented to achieve an overall significant saving. These cuts could be related to employment, luxury, department or restructuring, and are applicable to both engineering design companies and production companies. Production companies also have scope to refine the operating costs through power conservation, process automation and consumables optimisation. It is important that prior to implementation, all cuts be assessed to ensure that the negative impacts are minimised. Continuous improvement (CI) plays an important role in the cost-cutting procedure. Streamlining information communication using MIS is just one aspect that could be included for CI. 69 D Connelly BUDGETING AND BUDGET CUTS Creating a budget should be the first stage of any project. It is a process of predicting and controlling the expenditure over the life of any given project. Budgets are the foundation of an organisation’s financial success. The importance of creating a budget is that it forces an organisation to consider the expectation for its products and services with the required resources to meet that expectation. In addition, budgets can transform an organisation’s higher priorities into the appropriate resources required to achieve those aforementioned priorities. The potential problems could be highlighted in a sufficient time to acquire the corrective actions to be performed. A baseline can be created against which the actual results can be compared. Due to the variability of the resources industry and the difficulty in predicting future costs, the budget is a document which should be continually monitored. When a planned budget is overshot, the consequences can vary from mere frustration to anger or even litigation, if it involves a new engineering design and construction project with other companies. Overspending an allocated budget will result in the reputation of the company being marred and good business relationships being severed. (See Figure 1, which highlights impact of changing budget). Strategic budget cuts Strategic budget cutting is a common organisational policy. Applying the right combination of budget cutting and strategic growth is a fundamental input for the long-term success of any resource organisation. It is vital for managers to approach budget cuts practically so as not to affect the organisation’s capability. There are many ways to perform a budget cut, yet extreme cut-backs can eventually affect the growth of an organisation. Many organisations today have come to understand how an overly enthusiastic implementation of budget cuts can have the unintended effect of inhibiting their revenues. Profits were increased in the short-term due to the severe budget cut, but the overall revenues were then decreased due to the lack of growth. In some cases, budget cuts have caused the subsequent declines in customer service and product quality. There are several types of budget cuts and these include luxury cuts, employment status related cuts, technology driven cuts, department cuts and restructuring cuts. Luxury cuts An approach to reduce the budget is to focus on the costs of supplies and services along with employee related expenses. Travel and other related benefits spending can be minimised; for instance, by employees only being offered economy class when travelling instead of business. Additionally, many organisations often spend a good deal of money on office spaces or other items to impress their clients and competitors (for example, the use of hire cars, video conferencing instead of travel, mobile phone calls, alcohol, dining expenses). Employment status related cuts By employing consultants and independent contractors, organisations will be able to minimise the overhead salaries spent on permanent employees. Although independent contractor arrangements can make a significant saving to an organisation, there are some downsides that need to be taken into consideration. An unintentional effect of converting several former employees into independent status may create unfortunate tax complications in an organisation. Some organisations offer year-end bonuses instead of pay rises to avoid a fixed commitment. There is a growing trend to utilise temporary workers to support some parts of an organisation’s operations such as during the shutdown period of an operating plant. Certainly, temporary workers will never be as fully invested in the company as would permanent employees and this could result in less efficiency and productivity. Technology driven cuts With the advancement of technology, organisations have started to find ways to reduce the current workload. The application of technology will help to reduce the number of employees needed and other associated costs to perform the tasks. It may even allow employees time to be in part redirected to improving the efficiency of other areas of the operations. Although technology can be a good way to reduce the operating budget, it is costly to establish and requires time to implement new technologies. The initial investment may discourage some companies from implementing the technology. Technology is a capital investment and consideration of the depreciation, ongoing maintenance and replacement should be assessed adjacent to the realistic savings. New technology introduces risks and is not applicable for new projects unless piloted first. Department cuts Department cuts usually involve a participatory process where managers of each operation unit will identify the prospects to reduce their budgets without affecting the operation of an organisation. Managers can start by checking the surplus funding in the past that may have been given but is not entirely essential to maintain the level of services. When there is a vacant position available, managers will decide whether it can be held without affecting the everyday operation of the organisation. Managers should make sure that the budget cut does not affect the organisation’s core strategies or the key clients, customers and constituencies’ interest. Restructuring cuts FIG 1 – The cost of not getting the budget right. 70 When an organisation undergoes a major restructure, this generally entails a shift from budgeting to strategic planning. This change occurs as the demand from the market has changed. Restructuring an organisation is not an easy process and it involves the re-examination of the services it offers, re-evaluating the departments and managers it should keep, and the determination of the employees it needs depending on their role in delivering new services and the application of technology as an alternative to additional employees in its operations. The result of the restructuring cut is usually a significant cost reduction. The organisational changes in the 1990s where whole layers of middle management were we are metallurgists, not magicians Sensible cost cutting for resource projects retrenched including specialists with long-term business knowledge is a specific example. Continuous improvement Continuous improvement can be described in several ways. In the simplest terms, CI is the development of ongoing improvement in quality and efficiency within a company. The objectives of CI are to: •• provide a more disciplined approach to CI projects and initiatives •• allow for greater consistency across global sites with a standard methodology and tools •• allow for a quicker response to CI opportunities by facilitating the organisation of teams and the development of both teams and individuals •• improve safety, cost, production and productivity performance •• help all employees understand the importance of, and the ways to, improve processes and organisational relationships •• help capitalise on global best-practices and share knowledge across sites. The steps of CI are: 1. identify the opportunity that will lead to continuous improvement 2. study the opportunity with respect to the key business needs for the organisation 3. define the current state by researching and understanding the current process, system or organisation 4. develop the future state then develop and test an implementation plan 5. implement the solution and maintain high levels of communication to monitor the status of scheduled activities 6. follow up and document the new procedures that have been implements and assess the effectiveness. Together these points seek to improve existing operating procedures, quality and efficiency. Management Information System Management Information System is the practice of managing data so that information can be delivered with insight, understanding and value for the employees in an organisation. It is the process of organising an information database which is easily accessible, well defined and flexible. Although techniques and technologies will change, these principles will remain in the core information management model. Through the MIS, information is primarily delivered to the right person in the right structure at the right time with a cost that adds net value to the organisation. For those that apply their knowledge gained through experience it will produce a result with more effective outcomes. MIS is an important tool to streamline communication throughout an organisation and serves to reduce time generally used to search for information. This time saving ultimately makes an organisation more efficient and hence more profitable. Design Stage Cost Cutting Optimisation during the design stage of a project is an important measure in reducing the CAPEX of a new project. However, reducing the CAPEX of the project does not mean we are metallurgists, not magicians reducing the cost spent on design. Mining companies may be reluctant to spend large amounts of money on the design stage of a project because until production commences they will see no revenue for all their expenditure. Cutting corners at this early stage, although saving in the short-term could prove costly in the future. A high quality plant design can ultimately save on plant CAPEX and reduce unexpected costs in the future. Typically, in the early stages of design for a mineral processing operation a number of options will be investigated to determine the best possible design for the plant. These options will be compared on the basis of process performance, CAPEX and OPEX. Unit design It can be tempting for mining companies to only design a plant to the nominal operating conditions in order to save on CAPEX. Ultimately this could be detrimental to plant performance and result in less availability or throughput. Increased flow rates due to surges need to be accounted for around the plant and it is important that the equipment is able to handle this. Pumps are a typical example of this and the design should incorporate a 10–15 per cent allowance for surges. Another trap is designing equipment to handle the average rather than the maximum ore characteristics. Ore hardness is one characteristic where the maximum value should be taken when designing equipment. Although sizing to these specifications may result in larger, more expensive pieces of equipment being required, designing the plant to handle average ore hardness can result in lower crusher throughputs, higher recirculating loads and less overall plant utilisation. Similarly, individual equipment availability needs to be considered. In a processing system with little surge capacity, the overall availability is equal to the lowest availability, not the average. If a critical piece of equipment is offline the entire process stops. A high maintenance piece of equipment like belt filters may have an availability of 65–70 per cent due to cloth replacement and cleaning. If an overall plant availability of 90 per cent is desired, standby filters would be needed to achieve this. Removing these standby units to save on CAPEX will ultimately result in lower plant throughputs and smaller revenue. Alternatively if there is equipment which is known to have a low availability, but the capital required makes the use of multiple units unviable, instead of expecting unreasonable availabilities these units could be decoupled from the process. That is, placing adequate surge capacity before or after the units to allow for the increased downtime. These units will require a higher throughput than the rest of the processing plant to maintain the overall plant throughput with less uptime. A common example of this in a minerals processing operation will be a crushing circuit which has been decoupled from the processing plant through the use of a crushed ore stockpile. A crushing circuit will generally have an availability of around 80 per cent. Plant layout Plant layout can affect the CAPEX for a project. Optimising the plant location and plant layout can produce significant saving when considering access and plant roads, material handling distances, electrical and communications infrastructure, and plumbing. The design must be optimised with these factors in mind without having the equipment so close that access for maintenance is compromised. Computer-aided design packages (for example, SolidWorks by Dassault Systèmes) can be used to virtually construct 71 D Connelly the plant and be used to produce quantities. Optimising the design in the virtual world can enable direct savings in the real world. A more compact plant but with room for later expansion flows through to savings on civil, piping, electrical and construction costs in both the short and long-terms. Contingency Mineral processing projects in development will always have a contingency added to the price. Although this may seem like an ambiguous addition to the price it is in fact an important item in the project cost. This cost represents the project unknowns which experience tells us will eventuate as the project progresses. Contingency is directly related to the risk of the project whether that is political, environmental or otherwise. The more risk associated with a project the higher the contingency will need to be. For example, if a project is to be constructed in an area with political instability or a tropical area that is prone to cyclones, an allowance will need to be made in the event that the project becomes delayed or requires extra capital to complete. As the project develops and gets closer to production, the chances of one of these events occurring suddenly decreases, as does the contingency. The contingency for a project in the prefeasibility stage may be between 20–30 per cent of the direct costs. However, as the project gets to the detailed design stage, it would be expected that this number will drop to 10–20 per cent. This contingency must be determined on a case-by-case basis and these numbers can vary. Estimating contingencies can be a black art. To reduce the CAPEX of the project it may be tempting for some companies to reduce or remove the contingency. Although there is a possibility that the contingency will not be needed, it is there for a reason and cannot simply be dismissed. Reducing or removing this could prove costly if the contingency is required (see Figure 2). Engineering Shortcuts Engineers have a duty to provide their services in a manner consistent with the standard of care of their profession. A good working definition of the standard of care of a professional is that level or quality of service ordinarily provided by other normally competent practitioners of good standing in that field, contemporaneously providing similar services in the same locality and under the same circumstances. An engineer’s service need not be perfect. As the engineer is using judgement gained from experience and learning when providing professional services, and is usually doing so in situations where a certain amount of unknown or uncontrollable factors are common, some level of error is allowed. When you hire an engineer you purchase service, not insurance, so you are not justified in expecting perfection or infallibility, only reasonable care and competence. An engineer who makes a mistake causing injury or damage is not sufficient reason to lead to professional liability on the part of the engineer. For there to be professional liability, it must be proven that the services were professionally negligent, that is, they fell beneath the standard of care of the profession. When hiring an engineer, there is an expectation of risk acceptance that this professional engineer potentially may make a mistake whilst using reasonable diligence and best judgement. The standard of care is not what an engineer should have done in a particular instance; it is not what others believe an engineer should do, or how others say they would have done. It is what competent engineers have actually done in similar circumstances. Operability Operability is the ability to keep equipment, a system or a whole industrial installation in a safe and reliable functioning condition, according to predefined operational requirements such as: •• consideration of the operator •• distributed control •• slopes on sump floors – too flat is a problem •• access to power, air and water points •• walkways and access •• flat launders, which lead to sanding •• skirting – spillage •• dust control •• clean up in crushing plants •• surge between unit operations •• low head height •• clear signage, pipes labelled •• attention to particular areas such as reagent mixing and lime mixing •• floor space around mills •• absence of or insufficient bunding height •• insufficient process water storage •• ball charging •• telemetry etc. Maintainability In engineering, maintainability is the ease with which a product can be maintained to: •• correct defects •• meet new requirements •• make future maintenance or expansion easier •• cope with a change to maintain the plant •• access to pumps for repairs or change out •• gain access for mobile equipment and personnel for maintenance, clean up etc •• prevent lubrication of equipment under spillage or placement well outside the area of operation •• provide spare cyclones FIG 2 – Value-adding through project life. 72 •• have common equipment we are metallurgists, not magicians Sensible cost cutting for resource projects •• install cranes in grinding area, flotation area •• install bypass facilities (thickeners, trash screens) •• separate the acid wash column or hopper •• avoid the obvious (for example, vent exhaust next to a high voltage switchyard etc). CONSTRUCTION COST CUTTING hand sales, sourcing of appropriate equipment is generally done during the definitive feasibility study (DFS), the last of the project before construction. There are four factors that should be considered when determining the viability of using second-hand equipment, and these are: 1. equipment costs 2. the condition of equipment Labour costs 3. suitability for process requirements Labour represents a significant percentage of the construction costs. When looking to reducing these costs the ‘per hour’ labour rate should not be the determining factor; rather the efficiency of the workforce. It may be tempting for some companies to hire cheaper, unskilled or foreign workers for plant construction to reduce the labour rate. However, if one of these workers is half the price but takes three times as long to do the work, it is not a cost-effective decision. 4. spares. Examples exist of projects where cheap, foreign electricians have been used for African projects and poor supervision resulted in extended commissioning problems, the need for rewiring and damage to equipment. Plant modularisation Plant accommodation and site buildings have used modular design for some time now to save on construction and installation costs. The same benefits are now being seen with plant and equipment modularisation. Companies that produce modular equipment have a standard design and modify it as per the process requirements, reducing engineering costs. The equipment is commissioned off-site before being dismantled and packed into shipping containers. Once at site the equipment can simply be ‘bolted together’ and it is ready for use. Using equipment modularisation can significantly reduce construction times and hence capital cost. Innovative construction techniques With construction costs representing a significant portion of the CAPEX, there are companies that are marketing innovative techniques and materials to reduce the cost of the project. There are several products and construction methods that look to reduce the amount of concrete used in construction. One method uses earth retaining walls constructed from steel mesh. Another is the use of steel arches overlaid with earth to form bridges, underpasses and stockpile tunnels. Both save time and money which is associated with the concrete structures that would otherwise be required. Reducing construction capital through unit hire It is possible to reduce the CAPEX of a processing operation through the hire of equipment and infrastructure. However, the reduced initial cost comes at the price of an increased OPEX. This could be an option investigated by junior miners looking to enter production but are finding it difficult to raise the initial capital. The mining fleet, mobile plant and the accommodation camp are typical examples of units that can be hired for this purpose. Second-hand plants The option of using second-hand equipment in the construction of a processing plant can mean considerable savings to the overall CAPEX of the project. However, this needs to be considered on a case-by-case basis as it is possible for the costs to outweigh the savings. The use of second-hand equipment can be considered at any stage of the project. However, due to the project timeline compared to the urgency of most secondwe are metallurgists, not magicians Equipment costs The equipment cost does not only include the purchase of the equipment but also the dismantling, re-conditioning, transportation and re-assembling at site. This should be considered carefully if the equipment is located in a remote mine site or is difficult to dismantle and transport, it may be cheaper to purchase new equipment. The condition of equipment Although second-hand equipment may be cheaper than new, its condition needs to be considered. If substantial refurbishing is going to be required, the initial saving on CAPEX will be outweighed by the cost required for the plant to become operational. In addition, used equipment may require extra maintenance during operation and this possibility must be taken into account. Suitability for process requirements Second-hand equipment is unlikely to meet the exact specifications as detailed by the proposed equipment list. Some concessions may need to be made and it must be determined whether the equipment can handle the process requirements. The concept is fine; however there are numerous examples where the execution has been poorly handled resulting in the savings being less than originally considered. Other issues include a lack of drawings, lack of vendor support or unknown historical problems with the equipment. Spare parts This is necessary to avoid the cost of having to specifically manufacture one-off parts. OPERATIONAL COST CUTTING It can be difficult to achieve any one cost cut on an existing operation that is going to make a great deal of impact on the overall operating cost. Also, a large cut will inevitably impact negatively on the process or personnel of the organisation. Therefore, the most sensible way of achieving any significant saving is to implement several small cuts. With regards to resources, the sector can be broken up into two distinct industries; these are mineral consulting companies and the production companies. Consulting companies would use the strategic budget cuts as detailed previously to achieve costs cuts in the organisation. Production companies can also use these strategic budget cuts; however they also have scope to reduce the operating costs of the processing plant. Reagents and consumables Optimising the operating costs with regards to plant reagents and consumables needs to begin at the first contract tendering phase. The tenders need to be reviewed to obtain the best product supplier and this may not always be the cheapest option. The lead time for the products needs to be considered 73 D Connelly and also the supplier’s production rate, particularly if they are supplying to an ever increasing market. It is necessary that supply can be maintained to the plant, especially if that product is critical to the process. This has been the case with cyanide when a global shortage impacted on the smaller supply companies. The operations holding contracts with these smaller companies were paying enormous margins at the time because of the difficulty to get the product. The larger companies, on the other hand, were able to maintain supply to their clients but would not provide product to the companies without existing contracts in place. It is also important to watch the usage of reagents and consumables, particularly with the more expensive ones such as cyanide in a gold plant. High usages should be investigated and lowered if possible. In some cases it may be appropriate to use automatic control to moderate reagent and consumable use. It should be investigated whether the capital outlay will be repaid through cost savings. operation; however the capital to implement these changes could be significant. These improvements could be related to automation of sampling, online analysis or automatic reagent addition. These methods would be categorised under ‘technology driven cuts’ as mentioned previously. Although the improved efficiency could reduce the operating costs this needs to be weighed against the, often substantial, capital that must be outlaid for their installation. Flexibility to cope with changing ore types and flow sheets is a must. CONCLUSIONS Power saving Sensible cost cutting is an important measure in ensuring the viability of an organisation through a range of market conditions. This is particularly important in the resources industry where the cyclical metal prices mean that boom and busts are inevitable. Cutting costs to remain profitable during the busy times is often necessary to avoid business or mine closures. Careful budgeting, implementing an MIS and CI are just a few of the measures that should be implemented to keep costs down at all times. If budget cuts are required, large cuts should be avoided due to the detrimental effect upon personnel or the process. Several small and well considered cuts should be implemented, as discussed in this paper. These small savings can cumulatively produce an overall significant saving to the CAPEX and/or OPEX costs. Using power efficiently and saving energy where possible can result in decent operating cost savings, especially if this power supply is diesel generated. In some cases an external contractor can be brought in to determine the savings achievable through power saving. However, it is necessary to assess whether the cost of engaging an expert is worth the savings. The author would like to thank Robert Hanna from METS, various companies, colleagues, engineers at various sites, METS staff and other consultants for their contribution. Also the management of METS for their permission to publish this paper and the constructive criticism of various drafts. There are numerous examples of reducing cyanide or flocculant consumption where considerable savings have been made because technical people were prepared to challenge what had been used historically and undertake test work to support the case for reducing reagent usage. One way of saving power is to ensure that the operating curves of process pumps are within the most efficient range. Depending on the size of the pumps in the system this could equate to a significant cost saving. There are numerous examples of cost savings for semi-autogenous grinding (SAG) mills and crushing circuits by using circuit surveys and simulation studies. External contractors It is important that costs for external contractors are monitored. If contractors are not managed closely, they may charge more than budgeted for the job. One provision would be to never hire a contractor for a large job on an hourly rate. Over the life of the project, the cost blowout could be substantial. Improved control Improving the control systems of an existing processing plant does have the ability to increase the efficiency of the 74 ACKNOWLEDGEMENTS REFERENCES Australian and New Zealand College of Anaesthetists (ANZCA), n/d. How to carry out a continuous improvement project, Guidelines on continuous quality improvement [online]. Available from: <http://fpm.anzca.edu.au/resources/ educational-documents/guidelines-on-continuous-qualityimprovement> [Accessed: 2 March, 2011]. Mackenzie, W and Cusworth, N, 2007. The use and abuse of feasibility studies, in Proceedings Project Evaluation Conference, pp 65–76 (The Australasian Institute of Mining and Metallurgy: Melbourne). Maddox, D, 1999. Strategic budget cutting [online], The Grantsmanship Center. Available from: <https://www.tgci. com/sites/default/files/pdf/Strategic%20Budget%20Cutting_1. pdf> [Accessed: 17 July 2017] (John Wiley & Sons). Petty, J, n/d. Budgeting and one day reporting: developing and managing a budget, towards one day monthly management reporting, Course notes. we are metallurgists, not magicians Contents When does further processing at the mine site make sense? C Fountain1, S La Brooy2 and G Lane3 ABSTRACT A century ago, new mines were often accompanied by smelters. In Australia, smelters were built at the Daydream mine near Broken Hill; at Kuridala and Mount Elliott near Mount Isa; Broken Hill; Mount Lyell; Mount Morgan; Mount Isa; and more recently at Tennant Creek; Kalgoorlie; and Olympic Dam. Now the big miners eschew site-based processing in favour of shipping concentrate to smelters in Europe and Asia. Yet there are times when on-site processing clearly makes sense. Few companies ship gold ore or concentrate to China for gold extraction. New smelters are being built in Zambia. Solvent extraction and electrowinning plants frequently produce copper from oxide ores and concentrates while pressure leaching is increasingly being considered for copper sulfide ores. Some argue that on-site processing is best because the waste products can be returned to the ground from whence they came, avoiding potentially large disposal costs in more-populated areas. Treatment and refining charges could once again turn in favour of the smelter operators. This paper examines when it makes sense to use on-site pyro- or hydrometallurgical processes in today’s environment and comments on how current trends might alter the balance in future. INTRODUCTION In a keynote address to the Ecological Society of Australia’s annual conference in November 2007, Paul Ehrlich said: … Australia is still, in the 40-some years I’ve been coming here, striving to become a third-world country, to be a place that just exports its natural capital as fast as possible, unworked upon, until it becomes truly poverty stricken. (Ehrlich, 2007) In the same year, Chip Goodyear was in the process of vacating his leadership role at BHP Billiton Limited (BHP). He was quoted as saying that BHP should concentrate on mining and ore, and leave ‘to others the skill set of processing that material’ (Roberts, 2007). It was not always the case. When the Broken Hill Proprietary Company Limited was floated in June 1885 to develop the deposit that gave BHP its name, a smelter was not far behind, opening in May 1886 (Blainey, 1968a). Other companies built their own, so there were at least five smelters operating along Broken Hill’s line of lode by 1891. BHP’s first smelter was preceded in the district by a smelter at the Daydream mine near Silverton, which treated the small ore arisings from the district. Other early smelters included copper smelters at Burra in South Australia; Mount Morgan, Mount Elliott, and Mount Cuthbert in Queensland; and Mount Lyell in Tasmania. Lead and copper smelters were later developed at Mount Isa; a nickel smelter at Kalgoorlie; and copper smelters built at Tennant Creek and Olympic Dam. A short-lived nickel-copper smelter was built at the Radio Hill mine near Karratha in Western Australia. 1. MAusIMM, Operational Readiness Manager, Nyrstar Port Pirie Smelter, Port Pirie SA 5540. Email: chrisjan@iinet.net.au 2. FAusIMM, Principal Process Consultant, Ausenco, Perth WA 6000. Email: stephen.labrooy@ausenco.com 3. FAusIMM, Chief Technical Officer, Ausenco Minerals & Metals, South Brisbane Qld 4101. Email: greg.lane@ausenco.com Similar stories can be told in North America and other parts of the world. In 1978, a survey of converter practices elicited responses from 16 copper smelters in the United States (Johnson, Themelis and Eltringham, 1979), most of them near the deposits that provided their feed. Today only three remain. Most mining companies today follow Goodyear’s injunction and sell concentrate to others. However, there are some who are still building processing facilities at or near mine sites: new smelters have recently been constructed in Zambia; pressure leaching, and roast, leaching and electrowinning plants are being built at some sites; and hundreds of millions of dollars have been spent on nickel-laterite leaching plants. 75 C Fountain, S La Brooy and G Lane This paper considers the drivers for site-based processing and outlines guidelines for project developers to assist in their choice between on- and off-site processing options. The developers of new mining projects need to decide how much processing there will be at the mine site. The options range from direct shipment of ore with virtually no processing (for example, hematite lumps and nickel-laterite ore) through to the production of a finished commercial product (for example, magnesium alloy wheels at Solikamsk in Russia). Table 1 lists examples of different degrees of mine site processing. Hardly any mine sites take processing further than refined metal to fabrication of finished products. The operation at Solikamsk in Russia, where magnesium alloy automotive wheels were produced for export at a magnesium chloride mine, is an exception to the rule. In most cases, the selection of the degree of further processing will be made on economic grounds. In some cases, it might be dictated by political considerations; the former Soviet Union is not the only place where economics might be ignored for ‘social’ reasons. However, it is the economic case that is the focus of this paper. DISCUSSION The economics of on-site processing changed dramatically during the twentieth century. Some of the changes favour reduced on-site processing, while others have worked to increase it. Factors limiting on-site processing The factors limiting on-site processing include: •• technological change Table 1 Examples of materials shipped from mine sites. Type of material Examples of materials Examples of locations 1 Ore Iron ore Nickel laterite Bauxite Pilbara, New Caledonia, Indonesia, Philippines, Weipa 2 Concentrates (flotation, gravity, dense medium separation, magnetic, electrostatic etc) Cu Ni Zn Sn Mineral sands Cadia, Cosmos, Century, Renison (when operating), Bemax, Iluka Eucla Basin 3 Intermediate products Alumina Nickel sulfide matte Nickel hydroxide Nickel oxide Wagerup, Pinjarra, Kalgoorlie nickel smelter, Ravensthorpe, Goro 4 Crude metal Lead Gold bullion Blister copper Anode copper Mount Isa, Kalgoorlie Cons gold mine, Mount Isa (before 1979), Mount Isa 5 Refined metal Ni Cu Murrin Murrin, Olympic Dam 6 Manufactured product Mg alloy wheels Solikamsk, Russia 76 •• lower transport costs •• falling product prices •• higher labour costs FURTHER PROCESSING Category •• higher capital costs •• higher employee turnover •• lack of infrastructure •• changing orebodies •• spare capacity in existing processing facilities. Technological change Concentration techniques significantly improved over the past 120 years. Remember that the froth flotation process was developed to treat sulfide ore and tailings in Broken Hill. Before then, practically all the copper mined in the United States came from underground mines chasing high-grade veins, averaging 2.5 per cent copper (Wills and Atkinson, 1991). The high cost of transport could cripple lower-grade deposits. Smelting was often a means of concentrating the valuable metals to reduce transport costs. The past century has seen the invention and improvement of froth flotation, improved grinding technologies allowing better liberation of minerals (the development of the McArthur River deposit depended on the development of ultra-fine grinding techniques such as the IsaMillTM), the development of solvent extraction – electrowinning (SX–EW), carbon-inpulp, pressure oxidation, and heap leaching technologies. Improved concentration techniques have lessened the need for local smelters. The fine grain of the Mount Isa lead–zinc deposit made it impossible to produce high-grade lead concentrate, so a lead smelter was built at the mine. The McArthur River mine, developed following the invention of the IsaMillTM finegrinding technology, ships concentrate to smelters. On the other hand, SX–EW has allowed the economic production of copper metal at site from low-grade oxide deposits. Higher capital costs Smelters were once cheap to build. The Daydream smelter was little more than a blast furnace and a chimney. Smallscale smelters built to last only a short time could be viable. However, they had their costs: Blainey (1986b) wrote of the problems of lead poisoning in Broken Hill – once strong men throwing lead fits, the difficulty of raising kittens or puppies … or even children. Such conditions are unacceptable today in nearly every corner of the world. When the Mount Isa lead smelter was commissioned in 1931, it was fitted with a baghouse to limit lead emissions and so the citizens of Mount Isa were spared the lead problems encountered by the early residents of Broken Hill. Emission controls increase the capital costs of smelting and have contributed to a trend to build larger smelters. High production rates reduce the relative cost of emission controls by spreading their unproductive imposts over larger quantities of product. Ramachandran et al (2003) showed that the size distribution of smelters has increased in most countries over the years. These higher capital costs have made it impractical to build smelters for small mines with short lives and encouraged the sharing of capital expenditure through toll smelting by large, often significantly depreciated smelters. It would be difficult for an MIM to justify a copper smelter with the initial capacity of 15 000 t/a of the Mount Isa smelter (Pritchard, 1980). AGIP Australia attempted such a feat with its Radio Hill smelter near we are metallurgists, not magicians When does further processing at the mine site make sense? Karratha in 1990, with the IsasmeltTM plant there designed to produce 1.5 t/h of nickel–copper matte (Bartsch et al, 1990), but this plant was quickly closed by low nickel prices (Player, Fountain and Tuppurainen, 1992). Lower transport costs Lower effective energy costs and larger, more efficient trains, trucks and ships have reduced the cost of transport. They make possible the shipment of lower-grade (and hence value) products from mines, particularly those near coasts and ports. Thus, it is possible for nickel mines in New Caledonia and the Philippines to ship ore containing about 1.6 per cent nickel to Townsville for processing (Fittock, 2006). Lower transport costs have reduced the benefit of mine site processing. Falling product prices Until recently, there has been long-term downward pressure on metal prices (Fountain, 2002). In the mid-1990s, WMC Limited allowed an average 1 per cent real fall in prices each year (Morgan, 1995). This downward pressure, combined with rising costs, compressed margins, made it harder to justify new capital and increased the need to use existing facilities that had already depreciated capital. It encouraged brownfield rather than greenfield smelter capacity expansion. Higher labour costs Metal prices have fallen relative to labour costs. In 1900, it took an American on the average 84 minutes to earn the equivalent, before tax, of the price of a pound of copper; in 2002, it was just over three minutes (Fountain, 2002). The resulting increased standard of living in the developed world has reduced the incentive for people to work in remote, undesirable regions. The consequent workforce shortages have been compounded by the actions struggling mining companies took to survive: reducing their support of universities and apprentice-training schemes, and reducing their hiring and training of graduates and other young people. To attract and retain a skilled workforce in residential mine site processing plants a premium must be paid to them. This leads to a further incentive to ship the material to a location where such a workforce is more prepared to live or is cheaper to employ. Higher employee turnover An increase in career opportunities has resulted in higher employee turnover. The workforce was very stable at the Broken Hill mines throughout most of the twentieth century. The mines paid well and the Barrier Industrial Council’s policies favoured employing local men and single women over married women and those people ‘from away’. and action at the expense of understanding and planning. Processing plants with a stable workforce will be at an advantage over those with high-turnover and chaos. Lack of infrastructure Mine sites in remote locations usually lack the infrastructure that is commonly available in industrial areas of the world. The need to build power stations or long power lines, water storage and treatment facilities, and perhaps oxygen and other industrial gas production facilities, raises the capital investment required for further processing. Many of these facilities are available almost on tap in developed industrial areas. Government assistance to single companies is often constrained by international trade agreements, but governments are less constrained when it comes to providing infrastructure that will service multiple customers. It is difficult for a state or national government to provide a connection for a remote project to an electricity grid, but it can do so more easily if it is setting up an industrial estate that will attract many companies. Changing orebodies Mining companies normally mine the easy deposits and the easy parts of deposits first. The shallow Broken Hill ores mined in the 1880s were oxidised and readily smelted in cheap blast furnaces. As the surface mineralisation was depleted, the miners reached the deeper sulfide deposits from which the zinc minerals had not been leached. The lead–zinc ores could not be smelted economically with existing technology and the ‘sulfide problem’ provided the incentive to develop the flotation process. Many of the orebodies discovered today are complex. Complex orebodies can require complex treatment processes and complexity increases capital cost. The McArthur River deposit did not become an orebody until the IsaMillTM fine-grinding technology was developed (Fountain, 2002). Even with grinding to an 80 per cent passing size of 7 µm, McArthur River produced a bulk leadzinc concentrate that needed to be treated by the Imperial Smelting Process (Nihill, Stewart and Bowen, 1998). MIM Holdings (now Glencore) bought the existing Avonmouth and Duisburg lead-zinc smelters to treat McArthur River bulk concentrate rather than building a new smelter for the task. It subsequently sold the Duisburg smelter and closed the Avonmouth smelter, and sold the bulk concentrate to smelters operated outside the original MIM Holdings group of companies. Spare capacity in existing facilities The situation is further complicated by a management philosophy that assumes that plant managers do not need to understand how the plant works – they just need to be able to manage the people who do. Such managers, who rely on others for the technical knowledge, often cannot tell when they are getting poor advice. To make matters worse, managers often change jobs frequently. There are many established processing facilities around the world. Construction of a new processing facility must be weighed against using an existing facility with largely depreciated capital. Some of these facilities were constructed to process ores or concentrates from local sources that have been depleted or are too high cost to compete with cheaper imported feedstocks. Others sought to reduce their unit costs by importing concentrate to supplement local sources. Examples included the Queensland Nickel nickel production plant at Yabulu; north of Townsville in Queensland; and the New Boliden smelters at Skelleftehamn in Sweden and Harjavalta in Finland. High employee turnover makes it difficult to optimise complicated processes and creates a culture of fire-fighting The existing facilities most likely to be able to accept imported materials are those near a port. These days, however, mining companies that do recruit skilled people are struggling to retain them. It takes time for people to learn how to run a complicated process well. Many employees leave before providing employers with a return on the time and money invested in their training and development. we are metallurgists, not magicians 77 C Fountain, S La Brooy and G Lane Other considerations Smelting sulfide ores and concentrates these days usually results in sulfuric acid by-product. Smelters with local markets for sulfuric acid, such as an established chemical industry or an acid-consuming leaching process, have an advantage over those that must transport acid over long distances, particularly over land. Local acid demand helped the profitability of Japanese smelters in the 1980s and the production of acid for heap leaching helped the Miami smelter survive when many other American copper smelters were closing. Smelters and other complex processing technologies can have long ramp-up times, disadvantaging them against existing plants. Ramp-up times can be decreased by using well-established technologies with good training programs (McNulty, 1998; Arthur and Hunt, 2005). Factors promoting further on-site processing Despite these disadvantages, there are circumstances that promote on-site processing. These include: •• difficulty producing a saleable product •• problems concentrating valuable minerals •• high transport costs •• additional transport problems •• government subsidies •• high treatment and refining charges •• new technologies •• simple, low-cost process flow sheets •• environmental considerations •• government decree. Product saleability It is sometimes not possible to produce a salable product from a mineral deposit without further processing. This is particularly the case at times of surplus supply when smelters and refiners can be selective in their feedstock purchasing and can afford to eschew concentrates containing minor element assemblages that are costly to treat or handle. A zinc smelter might reject a high-manganese zinc concentrate when times are good but purchase and blend it with other low-manganese concentrates when zinc concentrate is scarce. Western Australian mineral sands miners adopted the Becher synthetic rutile process to convert almost unsalable grades of ilmenite into a premium synthetic rutile product (George, 1993). St. Joe Minerals Corporation installed a multiple-hearth roaster at its El Indio mine in the Chilean Andes to remove arsenic from its copper concentrate to make it marketable (Smith et al, 1985). Ability to produce a concentrate Some ores are difficult to concentrate with economic recoveries. Fine gold does not respond well to conventional concentration techniques. Consequently, many gold operations use some form of leaching followed by fire-refining to produce gold bullion. Gold can be produced economically from gold grades as low as 0.5 parts per million (Wills and Atkinson, 1991). This would not be viable without on-site processing. Even at $1500 per ounce, it would be uneconomic to transport ore containing such a low concentration of gold any significant distance. The Teck CESL hydrometallurgy process might be suitable for treating low-grade bulk copper-nickel concentrates (Teck78 Cominco, 2008a) but Teck-Cominco (now Teck Resources) could not justify its use at its Highland Valley mine, which produces readily marketable, high-grade concentrate (TeckCominco, 2007). Vale built a 10 000 t/a CESL demonstration plant to process copper-gold concentrate at its Sossego mine in Brazil’s Carajás region (Teck-Cominco, 2008b) with a view to applying it to the high-fluoride Salobo concentrate (Defreyne and Cabral, 2009). Vale’s website makes no mention of using the process in its current Salobo flow sheet. High transport costs There are still parts of the world where transport costs are high. Zambia, for example, is a landlocked African country with transport routes through other African countries. Mopani Copper Mines, Konkola Copper Mines, First Quantum Minerals, and a joint venture between China Nonferrous Metal Mining (Group) Company Limited and Yunnan Copper Industry (Group) Company Limited have either refurbished existing smelters or built new ones this century. The Mopani smelter at Mufulira (Ross and de Vries, 2005), the First Quantum Minerals smelter (Glencore Technology, 2016) and the Chinese smelter at Chambishi use Glencore’s Copper IsasmeltTM technology. The Konkola smelter at Nchanga is using an Outokumpu flash furnace (Konkola Copper Mines, 2006). Another example might be the Kennecott smelter near the Bingham Canyon mine in Utah. Rio Tinto spent US$1.1 billion on the new smelter and refinery that was commissioned near Salt Lake City in 1996 (West, 1999). Improvements in recovery Additional on-site processing might improve recoveries of valuable minerals. Concentrator operators are sometimes forced to sacrifice recovery to achieve a concentrate grade that is economic to transport. Additional on-site processing steps could allow higher recoveries by providing the ability to treat lower-grade concentrates. The Mount Isa lead smelter, for example, was designed for lead concentrate grades lower than typically transported due to the fine nature of the Mount Isa ore and the difficulties experienced producing high-grade concentrate. As a result, the blast furnace is fluxed using higher levels of lime than commonly used in lead smelting (McLoughlin, Riley and McKean, 1980). Additional transport problems Materials with high uranium levels can be difficult to permit for transport. WMC (now BHP) reduced the transport issues for its copper product by building a processing plant at Olympic Dam to remove the uranium from the concentrate and to produce cathode copper at the site. Government subsidies Governments sometimes offer subsidies to persuade companies to maximise local processing. These might include assistance with infrastructure development, royalty discounts, tax-free holidays, or outright cash grants. The Queensland government, for example, offered a royalty discount for downstream processing of nickel, cobalt, copper lead and zinc ores in the past (Queensland Government, 2003). The government of Trinidad and Tobago has offered tax-holidays to companies building smelters and petrochemical plants using local natural gas. High treatment and refining charges Treatment and refining charges vary, depending on the balance between concentrate supply and smelter demand. The construction and expansion of copper smelters in China has we are metallurgists, not magicians When does further processing at the mine site make sense? placed downward pressure on these charges, to the benefit of concentrate sellers. In the June 2005 – June 2006 period, BHP was paying US$115 per t for treatment of its copper concentrate and US$0.115 per pound for refining. They were able to reduce these charges to US$60 and US$0.06 for the period June 2006 – June 2007 (Carlisle, 2006). Spot sales have achieved even lower prices and The Sydney Morning Herald reported a settlement at US$45 and US$0.045 between ‘an Indian smelter and a major Western miner’ (Reuters, 2007). Treatment charges subsequently rose progressively to be over US$100 and refining charges over US$0.10 by 2015 (Outotec, 2015). Low treatment and refining charges make justification of further on-site processing difficult, but high treatment charges tilt the balance in favour of building additional capacity. It is easier to justify building a smelter at a mine site when the industry as a whole needs additional capacity, although greenfield capacity still needs to compete with cheaper brownfield expansions. New technologies New technologies can favour additional mine site processing. The development of SX–EW technology led to increased production of cathode copper at mine sites, particularly from low-grade oxidised copper orebodies. The development of IsasmeltTM technology has lowered the cost of copper smelting. Carbon-in-pulp, BIOX® and other new technologies have resulted in more gold mines being developed, mines at which on-site processing is a necessity. Relatively new technologies such as BioheapTM and variations on pressure oxidation are emerging as potential competitors to the established secondary processing options, principally smelting, for copper sulfides. One of the driving forces for the recent implementation of pressure oxidation technology for copper concentrate treatment at Freeport McMoran’s Cyprus Bagdad operation was the production of acid on-site for use in its oxide heap leach operation. Similarly, the Sepon operation in Laos uses the pressure oxidation of pyrite to provide ferric ion and acid to the copper leaching process. Simple, low-cost process flow sheets Given the difficulty in attracting and retaining skilled operators and professionals to mine sites, it is an advantage if the process is simple and robust. Simplicity tends to mean low-capital flow sheets. Low-capital reduces the economic risks of on-site processing. Environmental considerations Processing concentrate to extract valuable metals produces waste products, whether the process is smelting or hydrometallurgical. Waste disposal can be difficult in heavily populated areas. A mine site is often the best place to dispose of those wastes. The slags from the Mount Isa smelters can be used as underground fill (their pozzolanic properties make them a substitute for cement). Slags and other metallurgical wastes can also be deposited in mine site tailings storage facilities. Titanium dioxide pigment producers in developed countries prefer to use the chloride process with high-grade feed (rutile, synthetic rutile or highgrade titania slag) because the waste disposal costs of the older sulfate route are significantly higher. This has encouraged the production of synthetic rutile in Western Australia and upgraded slag at Rio Tinto Iron and Titanium Inc in Quebec. Transporting ores or concentrates uses more energy than transporting final product. If human emissions of carbon dioxide are causing the world to warm, it would often be more sensible to produce metals at the mine site than transporting we are metallurgists, not magicians gangue minerals half-way around the world, perhaps to a less-efficient plant. However, imposing strict carbon emission caps on resource industries developed-world nations is likely to have the perverse effect of driving metals processing activities to countries without caps, potentially resulting in an increase in total emissions. Government decree In some instances, governments require further processing to be undertaken as a condition of mining rights. Development of Voisey’s Bay nickel deposit was delayed over the insistence by the provincial government of Newfoundland and Labrador that Inco build a processing plant in the province. In 2008, the Zambian government introduced a 15 per cent levy on the export of copper concentrates to encourage further processing in Zambia (Montia, 2008). In such circumstances, the developer must determine whether the deposit can withstand the additional capital impost, and either comply or walk away. Comments on specific metals Aluminium Aluminium is produced from bauxite ores. Some mines have associated refineries that produce alumina as an intermediate product (for example, Alcan’s Gove operations), while others ship bauxite to refineries (for example, Comalco’s Weipa operations). Aluminium smelting consumes large amounts of electrical power (Australian smelters consumed about 15 MWh for every tonne of aluminium produced in 2006 (Australian Aluminium Council, 2006)). Consequently, smelters tend to be built where electricity prices were cheap at the time of construction – near hydroelectricity in Washington state, Quebec, Tasmania and Norway, and increasingly through natural gas production in Gulf states. Copper In the past few decades, most owners of new sulfide copper mines have elected to install concentrators at mine sites and ship concentrates to smelters located elsewhere. As discussed earlier, smelters have become larger and more capitalintensive with time, making them less likely to be built on-site. China’s late start to heavy industrialisation, its extreme demand for materials, and a focus on economic growth ahead of environmental concerns has allowed smaller Chinese smelters to remain economically viable for longer. However, economic, governmental and environmental pressures are driving the move to larger production plants with associated oxygen and acid plants. Sulfur capture in Chinese smelters was around 85 per cent in 2006, the same as the Chilean rate, but below the world average of 90 per cent, and 95–97 per cent level in developed countries (Diaz and Mackey, 2007). Except for Zambia and possibly China, most recent increases in capacity have come through upgrades of existing smelters, including the expansion of Southern Copper’s Ilo smelter and Vedanta’s Tuticorin smelter using new, large-capacity IsasmeltTM furnaces. Hydrometallurgical processing options for copper minerals increased in importance following the development of solvent extraction, which largely eliminated the cementing process with its transport of scrap iron. Processing is still limited by the acid consumption of the ore and availability of acid, but new technological developments, such as pressure leaching, might lead to additional on-site processing. One way of coping with 79 C Fountain, S La Brooy and G Lane acid demand is integration of different processes so that acid generated in one is available for leaching in another, reducing net acid requirements and avoiding transport issues. BHP’s Olympic Dam complex uses smelter acid to leach uranium. Another approach, recently implemented, is to use pressure oxidation of sulfide concentrates to generate acid for leaching, thus avoiding the cost of an acid plant; examples include Sepon in Laos (Sherrit, Pavlides and Weekes, 2005), Kansanshi in the Congo, and Phelps Dodges’ Baghdad and Morenci mines in Arizona (Dreisinger, 2006). Current hydrometallurgical technologies offer a range of processes – biological, fine grinding, ferric leaching and pressure oxidation (Dreisinger, 2006) – that between them cater for different feeds (ore or concentrate) and different levels of acid demand from other on-site processes. No one process suits all applications. For sites with existing SX–EW facilities that are running out of oxide ore, hydrometallurgical processing offers a way of continuing on-site processing using existing equipment. Gold Gold metal is conventionally produced at the mine site; payable ore grades are at the g/t level and the capital cost of cyanide leaching and associated gold recovery is low unless the ore is refractory. Even when refractory ores require pretreatment to make them amenable to conventional cyanidation, on-site processing is still better than transporting ores long distances. This is normally the case even when the contained value in the concentrate exceeds that of base metal concentrates. An exception occurs when such an ore can be concentrated and transported to an existing facility close enough that the capital saved offsets the transport costs. Oceana Gold’s Reefton (New Zealand) mine is an example: Reefton produced a pyritic flotation concentrate containing highly-refractory, sulfide-encapsulated gold at about 30 g/t; the concentrate was transported 600 km by rail to Oceana’s plant at Macraes Flat for treatment by pressure oxidation in an existing autoclave. The Reefton operation was placed on care and maintenance at the end of 2015 (OceanaGold, 2016). Payment for precious metal values in concentrates can be a factor. Smelters normally pay for gold and silver recovered during smelting or refining. However, treatment charges and the effective costs of late payment can be avoided if the gold can be recovered by gravity treatment (Gray, Katsikaros and Fallon, 1999) and as practiced at Newcrest’s Cadia and Telfer operations. There is no payment of gold value in antimony concentrates, making alternative on-site processing more favourable. New England Antimony Mines Limited used a thiourea leach to extract gold from its antimony concentrate (Hisshion and Waller, 1984). Iron Extensive economies of scale enable long-distance rail and maritime hematite ore transport. Between 1997 and 2000 Australian free-on-board (FOB) costs fell from US$9.71– 7.08/t of iron ore (AME, 2002). With the failure of BHP’s hotbriquetted iron process, there is currently little appetite for further processing of hematite ore near the mine site. On the other hand, upgrading magnetite ore to produce concentrate pellets can reduce transport costs sufficiently to justify the investment (for example, the Savage River and Port Latta complex in Tasmania). 80 Lead Most lead concentrates are exported to distant smelters. However, mine site smelters might be warranted if the concentrate grade is low, incurring high transport costs, or if the ore is composed of oxidised lead minerals. In the latter case, lead metal poses less risk to communities than moving more-soluble forms of lead, such as lead carbonate. Oxidised lead minerals can be smelted with a relatively low capital cost using technologies such as rotary furnaces, which are commonly used for recycling lead sulfate battery materials (Rao, 2006). The product is crude lead bullion that can be exported for refining. Nickel Limonite nickel-laterite (low-grade iron ore with around 1–1.5 per cent Ni) suitable for pressure acid-leaching (PAL) or Caron processing have typically traded at 10 per cent of the nickel value in the ore, while saprolite (magnesium silicate ores with around 2–2.5 per cent Ni) suitable for smelting to ferronickel or matte have typically traded at 25 per cent of the value of the nickel content (Australian Mining Journal, 2001). With development of PAL, the economics of laterite shipping are becoming marginal. Guidelines for decision-making The authors offer the following guidelines to help organisations with their decisions about the extent of on-site processing. Is there an existing facility that will buy an unprocessed product? This is the first question that should always be asked. Using existing facilities limits the capital expenditure for a new mining project. However, treatment charges and transport costs might make new processing facilities attractive relative to existing ones. Shortages in existing processing capacity will result in higher treatment charges and a better case for building new capacity. However, new capacity needs to come in at the lower end of the operating cost-curve so that the operator is not left with a high-cost asset when the shortage abates and treatment charges fall. Special issues, such as the presence of deleterious minor elements (for example, fluorine, arsenic or radioactive elements), might make a product difficult to market in an untreated form. Undertake a value-chain analysis It is important that mining companies understand where the value is added to their products. This means examining the potential net profit at each step of the processing chain and the total return on capital invested. It would include considering the cost of transport and relative energy costs at the mine site and at potential alternative sites. Such an analysis will usually identify a logical point to hand processing to another facility. Is the project capital-constrained? If a project is capital-constrained, it is often better to sell lower-grade products than spend additional capital to upgrade them. The situation can change over time as a positive cash flow develops and provides financial resources for further investment. we are metallurgists, not magicians When does further processing at the mine site make sense? Are there government incentives or mandates for further processing? Determine whether any government incentives or mandates tilt the balance in favour of further processing. Are the incentives sufficient to provide a return on investment that justifies the additional processing? If there are further processing mandates, is the project robust enough to withstand any opportunity costs created by this mandate? If not, the opportunity to lose money is probably better left to someone else. Care needs to be taken to ensure that government incentives are incentives. Tax-holidays to encourage companies to a region might not be as valuable as first thought once the tax effects of plant depreciation in the early years of operation are considered. Consider the valuable metal content of the product Table 2 shows typical metal contents in various materials. Most materials transported have a valuable metal content greater than 25 per cent. Materials containing less valuable metal than this would normally require further processing. Mount Isa over a period of six months and, as a result, set a new benchmark for smelter commissioning (Arthur and Hunt, 2005). A new processing plant is more likely to be successful if the plant’s owner can find a similar plant on which to train its workforce before commissioning. Consider the complexity of the process Simple processes are more likely to be successful at the mine site. The greater the complexity, the more difficult it will be to find a workforce capable of sustaining the process and plant performance used in the initial economic justification. It is difficult to achieve high plant availabilities with highlycomplex processing systems with minimal surge capacity, and long ramp-up times reduce or destroy a project’s net present value. Avoid the economies-of-scale trap Long inland transport routes are more likely to favour onsite processing. Economies of scale and dedicated railways might mitigate this effect, as in the case of the Pilbara railways owned and operated by Rio Tinto and BHP. When a project is uneconomic at the initial scale, the temptation is to increase output to reduce unit costs through economies of scale. This can produce significant benefits, but increasing size to achieve a target rate of return carries risks. These include an increased financial loss if the project fails to achieve its cost, quality and throughput targets, and the possibility that increasing the scale of production will alter the supply–demand balance, depressing the price of the product. This latter effect increases the risk to the project. Are there environmental reasons for further processing at site? What is the projected mine life? Transport distances As discussed, there might be environmental reasons to upgrade a product at site. If there is an environmental driver, site-based processing might make the difference between receiving regulatory approval to proceed and a refusal. As with government mandates for further processing for social reasons, the project proponent will need to determine whether the project is sufficiently robust to proceed under these circumstances. The mine life needs to be sufficient to allow a reasonable return on the investment in additional processing. The larger the capital expenditure and the more complex the process, the greater the mine life needs to be. If the project is near a port, it is possible that the processing plant could operate well beyond the life of the orebody by treating imported ore or concentrate. Resist justifying on-site processing by selling potential by-products Consider the ability to attract a workforce If it is relatively easy to attract a high-quality workforce, additional processing options are more likely to be successful. It is better to have an experienced core group to build the rest of the workforce around than to try to train an entire staff with no experience. Inexperienced employees will make mistakes, extend ramp-up times, and perhaps develop a culture that prevents the project ever realising its potential. Opportunities for training Good training, particularly hands-on training, is important when commissioning new processes. When the Yunnan Copper Corporation chose to build an IsasmeltTM plant at its smelter in Kunming, it sent metallurgists and operators to The authors are aware of projects where the principals were keen to undertake further processing. The proposed processing plants were not economic in their own right, so their ‘project champions’ sought to bolster the economics by selling by-products. In one case, this led to a scenario of a billion dollar (1990s dollars) industrial complex in the Australian outback to develop an 8 Mt tonne mineral deposit. In another case, there was a short period of wild enthusiasm when it was thought that by-products previously regarded as wastes (with associated disposal costs) had such a huge return that they converted a marginal project into a potential bonanza … until it was realised that overly optimistic assumptions had been made about the value of the by-products and the capital and operating costs of producing them. Table 2 Relative metal contents. Class of material Ore Iron Aluminium Ore (55% Fe) Bauxite (26–30% Al) Concentrate Magnetite pellets Intermediate DRI or HBI (93% Fe), HIron™ (96% Fe) Crude metal Pig iron (93–95% Fe) Refined metal Steel Copper Nickel Lead Limonite (1.5% Ni), Saprolite (2.5% Ni) Concentrate (25–37% Cu) Concentrate (12–27% Ni) Alumina (52% Al) Matte (40–80% Cu) Precipitated mixed sulfides (23% Ni), Oxide or hydroxide (40% Ni), Matte (45–72% Ni) Refined Al (>99.7% Al) Refined Cu (>99.85% Cu) Blister Cu (95–99.5% Cu) Sulfide (50–70% Pb), Carbonate (60–70% Pb) Lead bullion (97% Pb) Refined Ni Refined Pb (>99.9% Pb) Note: DRI – direct-reduced iron; HBI – hot-briquetted iron. we are metallurgists, not magicians 81 C Fountain, S La Brooy and G Lane Miners can feel offended by lack of payment of ‘full value’ for minor elements (for example, gold, silver, indium, and cobalt). However, extracting these elements requires additional processing steps that add to complexity (Fountain, 2013). Careful consideration of the capital and operating costs of these additional steps is needed to justify their construction. One of the key actions that a company developing a new deposit need to undertake is a value-chain analysis to understand the logical end point of processing. The end point will depend on the type of mineral mined and the location of the mine. It might be affected by government incentives or subsidies. By-products might provide a supplementary income stream, but projects that depend on this stream are often not robust. Exceptions include the use of sulfuric acid for leaching. On-site processing facilities will be easier to justify in times when demand for processing exceeds global capacity (as occurred during the decades of rapid growth after World War II) than times with surplus processing capacity. Consider the quality of the existing infrastructure at the mine site Additional mine site processing will increase the demand for water and electricity in particular. The availability of plentiful water and cheap electricity can make the difference between shipping a relatively low-grade material and upgrading it at the mine site. The need to install additional electricity generating capacity or power lines can often kill upgrading projects in remote areas. Will further processing improve metal recoveries? If further processing results in higher recoveries, are they sufficient to justify the additional capital and operating costs? What effect will complexity have on development schedule? Increasing the complexity of the project will increase the complexity of the permitting and ultimate financing of the project, and increase the development duration. Does this fit with the owner’s capability and expectation? When should novel processes be considered? Novel processes are sometimes considered as a saviour for processing difficulties with complex orebodies. When used in greenfield locations, the application of novel technologies can suffer from over enthusiastic expectations of performance, operating cost and capital cost. A recent example was the development of the PAL technology in Western Australia, which resulted in underachievement of expectations for onsite nickel production from laterite ores on three simultaneous projects. Extensive pilot and demonstration plants are required to establish the technical and cost drivers for novel processes and applications, particularly where the project is the only or major source of cash flow for the company. CONCLUSIONS While many lament the export of relatively unprocessed products from mines, the decline in mine site processing in recent years has been driven by a variety of economic and social factors. These include increasing capital costs associated with emissions controls, the existence of large facilities that toll-smelt or buy concentrates or ores, the rise of Chinese smelters over the past decade, poor mine site infrastructure, and an increasing reluctance by skilled people to work in remote areas. There are still circumstances that favour mine site processing. These include: •• difficulty of producing a marketable product without it •• problems concentrating valuable minerals (such as fine, disseminated gold) •• high transport costs •• simple, low-cost process flow sheets •• environmental considerations •• government sanction and approval. 82 Advocates of additional mine site processing need to keep a clear focus on the economics of the process. Increasing economies of scale or earning additional income through selling by-products might not be as attractive as at first glance. Lowcost and simple flow sheets are easier to operate and expose the company to less risk than complex, high-cost flow sheets. REFERENCES AME Mineral Economics, 2002. Australia boasts lowest iron ore production costs in 2001 [online], Reed Business Information. Available from: <http://www.ferret.com.au/> [Accessed: 11 March 2008]. Arthur, P S and Hunt, S P, 2005. IsasmeltTM – 25 years of continuous evolution, in Sustainable Developments in Metals Processing (eds: M Nilmani and W J Rankin), pp 73–94 (The Australasian Institute of Mining and Metallurgy: Melbourne). Australian Aluminium Council, 2006. Sustainability report 2006 [online]. Available from: <http://www.aluminium.org.au/> [Accessed: 28 March 2008]. Australian Mining Journal, 2001. Trade in nickel-cobalt laterite ores [online]. Available from: <http://www.theajmonline.com/> [Accessed: 9 March 2008]. Bartsch, P, Fountain, C and Anselmi, B, 1990. Radio Hill project, in Pyrosem WA (eds: E J Grimsey and N D Stockton), pp 232–250 (Murdoch University Press: Perth). Blainey, G, 1968a. The Rise of Broken Hill, pp 20, 24 and 63 (Macmillan of Australia: Melbourne). Blainey, G, 1968b. The Rise of Broken Hill, pp 86–95 (Macmillan of Australia: Melbourne). Carlisle, C, 2006. BHP Billiton secures big drop in Japan copper smelter charges, Mineweb, 5 October 2006. Defreyne, J and Cabral, T, 2009. Early copper production results from Vale’s hydrometallurgical CESL refinery [online]. Available from: <http://www.teck.com/media/CESL-Publication-Copper-ValeMetallurigcal-Results-ALTA-2009.pdf> [Accessed: 18 July 2017]. Diaz, C and Mackey P, 2007. Discussion of copper smelting technology practice and innovation [online], in Proceedings The Carlos Diaz Symposium on Pyrometallurgy – Cu 2007, vol 3. Available from: <http://cim.v1.myvirtualpaper.com/ report/2007061901/?page=10> [Accessed: 9 March 2008]. Dreisinger, D, 2006. Copper leaching from primary sulfides: Options for biological and chemical extraction of copper, Hydrometallurgy, 83:10–20. Ehrlich, P R, 2007. Keynote address to the Ecological Society of Australia’s annual conference, Perth, 25–30 November 2007 [online]. Available from: <http://www.abc.net.au/ rn/inconversation/stories/2007/2109181.htm#transcript> [Accessed: 24 February 2008]. Fittock, J, 2006. Nickel and cobalt refining by QNI Pty Ltd, Yabulu, Qld, in AusIMM Monograph 19 Volume. Available from: <http:// www.ausimm.com.au/Content/docs/mono19model_paper. pdf> [Accessed: 24 February 2008]. Fountain, C, 2002. IsasmeltTM and IsaMillsTM—models of successful R&D, in Proceedings AusIMM 2002 Young Leaders’ Conference (The Australasian Institute of Mining and Metallurgy: Melbourne). we are metallurgists, not magicians When does further processing at the mine site make sense? Fountain, C, 2013. The whys and wherefores of penalty elements in copper concentrates, in Proceedings MetPlant 2013 (The Australasian Institute of Mining and Metallurgy: Melbourne). George, I W, 1993. Synthetic rutile operations of RGC Mineral Sands Limited at Capel and Narngulu, WA, in Australasian Mining and Metallurgy – The Sir Maurice Mawby Memorial Volume, Second Edition (eds: J T Woodcock and J K Hamilton), pp 1301–1304 (The Australasian Institute of Mining and Metallurgy: Melbourne). Glencore Technology, 2016. Installations – IsasmeltTM [online]. Available from: <http://www.isasmelt.com/EN/Installations/ Pages/Installations.aspx> [Accessed: 20 November 2016]. Gray, S, Katsikaros, N and Fallon, P, 1999. Gold recovery from copper gold gravity concentrates using the Inline Leach reactor and weak base resin [online], in Proceedings Oretest Copper Gold Symposium. Available from: <http://www.gekkos.com/documents/17-gold recoveryfromcoppergoldgravityconcentratesusingtheinlineleach reactorandweakbaseresin.pdf> [Accessed: 9 March 2008]. Hisshion, R G and Waller, C G, 1984. Recovering gold with thiourea, Mining Magazine, September: 237–243. Johnson, R E, Themelis, N J and Eltringham, G A, 1979. A survey of worldwide copper converter practices, in Copper and Nickel Converters (ed: R E Johnson), pp 1–32 (The Metallurgical Society of the American Institute of Mining, Metallurgical, and Petroleum Engineers: New York). Konkola Copper Mines Plc, 2006. Expansion projects [online]. Available from: <http://www.kcm.co.zm/expansion_projects. php> [Accessed: 28 March 2008]. McLoughlin, B C, Riley, J F and McKean, G R, 1980. Development of optimum fluxing procedures for Isamine lead concentrates, in Lead-Zinc-Tin’80 (eds: J M Cigan, T S Mackey and T J O’Keefe) pp 309–320 (The Minerals, Metals & Materials Society: Warrendale, Pennsylvania). McNulty, T, 1998. Developing innovative technology, Mining Engineering, 50(10):50–55. Montia, G, 2008. Zambia introduces 15% copper concentrates levy [online]. Available from: <http://www.metalmarkets.org. uk/2008/03/10/zambia-introduces-15-copper-concentrateslevy/> [Accessed: 29 March 2008]. Morgan, H, 1995. Interview on The Bottom Line, Australian Broadcasting Corporation Television, 18 February 1995. Nihill, D, Stewart, C M and Bowen, P, 1998. The McArthur River mine – the first years of operation, in Proceedings 1998 Annual Conference, pp 73–82 (The Australasian Institute of Mining and Metallurgy: Melbourne). OceanaGold, 2016. OceanaGold operates mines in the three largest goldfields in New Zealand [online]. Available from: <https:// www.oceanagold.com/our-business/new-zealand/> [Accessed: 20 November 2016]. Outotec, 2015. Copper markets and TC/RCs [online]. Available from: <http://www.outotec.com/en/Search-material/Customernewsletter-Smelting-News/Issue-1-February-2015/Coppermarkets-and-TCRCs/> [Accessed: 20 November 2016]. Player, R L, Fountain, C R and Tuppurainen, J M I T, 1992. IsasmeltTM developments, in Mervyn Willis Symposium and Smelting & Refining Course, July, pp 20:1–20:13 (The University of Melbourne). Pritchard, J, 1980. Copper smelting at Mount Isa Mines Ltd, Mount Isa, Qld, in Mining and Metallurgy Practices in Australasia (ed: J T Woodcock), pp 340–344 (The Australasian Institute of Mining and Metallurgy: Melbourne). Queensland Government, 2003. Explanatory notes for SL 2003 No. 174, Mineral Resources Regulation 2003 [online]. Available from: <http://www.legislation.qld.gov.au/legisltn/sls/ris_ en/2003/03sl174e.pdf> [Accessed: 9 March 2008]. Ramachandran, V R, Diaz, C, Eltringham, T, Jiang, C Y, Lehner, T, Mackey, P J, Newman, C J and Tarasov, A, 2003. Primary copper production – a survey of world copper smelters [online], in: Volume IV: Proceedings Pyrometallurgy of Copper, Herman Schwarze Symposium, Book 1, pp 3–106 (Canadian Institute: Montreal Canada). Available from: <http://www.hatch. ca/non_ferrous/articles/primary_copper_production.pdf> [Accessed: 9 March 2008]. Smith, E H, Foster, J W, Minet, P H and Cauwe, P H, 1985. Selective roasting to de-arsenify enargite/pyrite concentrate from St. Joe’s El Indio Mine – from pilot plant to commercial operation, in Complex Sulfides: Processing of Ores, Concentrates and By-products (eds: A D Zunkel, R S Boorman, A E Morris and R J Wesely), pp 421–440 (The Metallurgical Society: Warrendale, Pennsylvania). Rao, S R, 2006. Resource Recovery and Recycling from Metallurgical Wastes, pp 199–200 (Elsevier: Oxford). Reuters, 2007. Japanese smelters, BHP discuss copper fees [online], The Sydney Morning Herald, 6 December. Available from: <http://www.smh.com.au/news/Business/Japan-smeltersBHP-discuss-copper-fees/2007/12/06/1196812912011.html> [Accessed: 28 March 2008]. Roberts, J, 2007. BHP denies delays at Olympic mine [online], The Australian, 8 September. Available from: <http://www. theaustralian.news.com.au/story/0,25197,22382128–5005200,00. html> [Accessed: 24 February 2008]. Ross, J and de Vries, D, 2005. Mufulira smelter upgrade project – ‘Industry’ smelting on the Zambian copper belt [online]. Available from: <http://www.isasmelt.com/downloads/ XTpaper_Mopani_MSUPyromet05.pdf> [Accessed: 9 March 2008]. Sherrit, R, Pavlides, A G and Weekes, B L, 2005. Design and commissioning of the Sepon copper pressure oxidation circuit, in Proceedings First Extractive Metallurgy Operators Conference, pp 21–27 (The Australasian Institute of Mining and Metallurgy: Melbourne). Teck-Cominco, 2007. Annual Report 2006 [online]. Available from: <http://www.teckcominco.com/DocumentViewer.aspx?eleme ntId=115704&portalName=tc>, p 21 [Accessed: 31 March 2008]. Teck-Cominco, 2008a. Annual Report 2007 [online]. Available from: <http://www.teckcominco.com/DocumentViewer.aspx?eleme ntId=124227&portalName=tc>, p 26 [Accessed: 31 March 2008]. Teck-Cominco, 2008b. Applied technology [online]. Available from: <http://www.teckcominco.com/Generic.aspx?PAGE=Technolo gy+%26+Innovation+Pages%2FResearch+Centre+Pages%2FCES L&portalName=tc> [Accessed: 31 March 2008]. West, G, 1999. Breakdown leaves giant copper furnace out of action, The Australian Financial Review, 12 January, p 22. Wills, B A and Atkinson, K, 1991. The development of minerals engineering in the 20th Century, Minerals Engineering, 4:643–652. we are metallurgists, not magicians 83 Contents The ABC of Mine-to-Mill and metal price cycles P Cameron1, D Drinkwater2 and J D Pease3 ABSTRACT In the 1990s metal prices were trending in a long-term decline and the usual cost-cutting exercises were adopted. Cuts to research and development made innovation difficult and the outlook was grim. But necessity is a strong motivator, and these conditions spurred the Mine-to-Mill movement, which optimised across organisational silos and utilised new technology tools, innovative software and increased computing power. Many applications of Mine-to-Mill exploited the fact that comminution is usually the site processing bottleneck, and that blasting is more efficient at breaking rock than grinding. This approach sought to: •• understand and characterise rock breakage from mining to the mill •• develop models and simulators for blast design, fragmentation, crusher and mill circuits •• develop tools to measure in real-time the particle size distribution of rocks on conveyors and run-of-mine (ROM) muck piles •• ensure effective communication across the silos between geologists, blast design engineers, mining engineers and metallurgists. These methods and the technology tools available in the 1990s were widely adopted at numerous sites around the world with significant benefits. Semi-autogenous grinding (SAG) mill throughput increases of 10–20 per cent were common. This was the advance the industry desperately needed. It was low capital cost; it was obvious. It was here to stay. Except, in too many cases, it didn’t. In the minerals price boom of the 2000s Mineto-Mill was no longer necessary to ‘survive’, even though it was still good business. Some operations, including some of the early success stories, slipped back to old habits of optimising within organisation silos instead of across them. Fortunately, other operators still embraced Mine-to-Mill and developed new techniques. Mine-toMill was still successful, but not as widely adopted as expected. Now the boom has ended and operations are again under cost pressure. Since these are the same circumstances that created Mine-to-Mill, it seems time to achieve the wider adoption. Since the 1990s many new or advanced technology tools are available for Mine-toMill projects: blasthole sensors, new explosives formulations, new blasting techniques and modelling, ore tracking devices, improved image analysis to determine size, texture and colour of coarse ore, grade sensors, whole-stream simulation tools, even more powerful computing hardware and data analysis software. If we could achieve so much in the 1990s, how much more can we achieve today when we have the same imperative, the same potential and a larger number of high technology tools? INTRODUCTION The Mine-to-Mill methodology was developed during the commodity price downturn of the 1990s and was widely adopted at numerous sites around the world. Mine-toMill relies on the fact that comminution is usually the site processing bottleneck, and that blasting is more efficient at breaking rock than grinding. 1. MAusIMM, General Manager Australia, Split Engineering, Mission Beach Qld 4852. Email: pcameron@spliteng.com 2. MAusIMM, Principal Consulting Engineer, Mineralis Consultants Pty Ltd, Brisbane Qld 4066. Email: ddrinkwater@mineralis.com.au 3. FAusIMM, Senior Principal Consulting Engineer, Mineralis Consultants Pty Ltd, Brisbane Qld 4066. Email: jpease@mineralis.com.au This approach and the technology tools available in the 1990s were widely adopted around the world with significant benefits. Semi-autogenous grinding mill throughput increases of 10–20 per cent were common. We thought this approach to managing operations was here to stay, since it appeared to be free money for operators; however during the subsequent boom and focus on ‘production at any cost’, while some operators advanced the approach, many reverted to old habits of optimising within organisation silos. Mine-to-Mill wasn’t crucial to their survival. Now that the commodity cycle is back in downturn, the simple productivity gains offered by Mine-to-Mill look attractive again. Since the 1990s many new or advanced 85 P Cameron, D Drinkwater and J Pease technology tools have been developed to enhance the approach. Now is the time to adopt the new technologies, and to embed them into a more universal and lasting industry change. TABLE 1 Mine-to-Mill case studies 1996 to 2002. Mine site Metals produced Country Product increase PAST PRACTICE AND ESSENTIAL REQUIREMENTS Highland Valley Cu Canada 10% In its broadest sense, Mine-to-Mill integrates all aspects of geometallurgy and production steps with processing and marketing. In this paper, the authors confine their comments to the subset of Mine-to-Mill that focuses on the integration of blasting with comminution and separation. They refer to this as ‘Advanced Blasting for Comminution’ – the ABC of Mine-to-Mill. Alumbrera Cu Au Argentina 13% Porgera Au Papua New Guinea 15% KCGM Fimiston Au Australia 18% Cadia Au Cu Australia 14% Red Dog Zn USA 12% An excellent summary of the steps involved in any Mine-toMill project groups them into three main areas (McKee, 2013): BHP Iron Ore Fe Australia 3% increase in lump 1. First and foremost, good data. Data needs to be collected about the ore before it is mined and as it passes through the production chain, about the equipment and processes used in production, and the process performance and cost. 2. Good, robust analytical tools and models to evaluate options and identify optimum operating points for a range of feed types and conditions. The best models also account for economic factors such as metal price and operating cost. 3. Finally, any Mine-to-Mill project requires tools for ongoing monitoring, assessment and evaluation. Findings need to be validated and optimisation kept ontrack to fully realise the benefits. Further, these non-technical factors are critical: •• sustained management support •• availability of staff with specialist skills •• an enabling organisation structure. Early Mine-to-Mill projects included scheduling to smooth ore variations, building stockpiles to ‘campaign’ different ore types, or redesigning underground activities to eliminate ‘cash negative’ ore while rescheduling surface operations to eliminate the supposedly ‘fixed’ costs associated with them. These examples show that Mine-to-Mill projects did whatever was required to improve overall mine site performance. They were orebody and situation specific. Many case studies reported significant gains, typically in the range 10–20 per cent productivity improvement across the mine site, with little or no capital expenditure. These were dramatic improvements by any measure compared with working in isolated silos (McKee, 2013). MINE-TO-MILL IN 1996 By 1990 higher speed computational power enabled innovative software for mathematical modelling and simulation of industrial processes including mining and mineral processing. The AMIRA Project ‘Optimisation of Fragmentation for Downstream Processing’ (1996 to 2002; Table 1) was a collaborative research project to exploit this capability and develop operating strategies to enhance mining and downstream processing activities. The history, concepts and case study projects are presented in McKee (2013). In 1996 the technology tools available to Mine-to-Mill were limited to elementary versions of tools such as (or similar to): • JKSimBlast blast design software • Kuz–Ram fragmentation model to predict particle size distribution of the blast in the stockpile • Split-Online, or other image analysis of the particle size distribution at the truck tip to the primary crusher, 86 KCGM – Kalgoorlie Consolidated gold mine. and on the conveyors from the primary crusher to the SAG mill feed • JKSimMet, simulation software for comminution circuits. There was minimal information about mineralogy, and work-arounds had to be devised to deal with complex, multicomponent ore types and non-standard mining and processing scenarios. Early Mine-to-Mill projects relied heavily on the knowledge, experience and desire for cooperation of the project team. Refer to Figure 1 for a schematic representation of the work process. Importantly, the projects and the survival imperative of the times engendered dialogue, collaboration and cooperation between geologists, blast and mining engineers, metallurgists and General Managers (Kanchibotla et al, 1998; Lam et al, 2001; Valery et al, 2001). In 2012, Karen McCaffery suggested: Mine-to-Mill (and geometallurgy) is just code for making the effort and putting the processes in place to record, in an accessible format, an understanding of the orebody, how changes in the orebody and operating practice drive productivity and production, and understanding the operating parameters in the mine and mill which can be manipulated to improve productivity and operating cost. It is what people in mining and processing at sites should be doing as a normal part of their day-to-day business. (personal communication, 2012) NEW TOOLS AND NEXT GENERATION OF MINE-TO-MILL PROJECTS Since 2002, there have been marked developments in image analysis, GPS, simulation software, radio-frequency tracking devices for ore, in-plant instrumentation to measure flows, online particle size monitors, mineral liberation analysis, geometallurgy and equipment monitoring instrumentation. Though some early adopters lost their way, new adopters achieved outstanding improvements, such as Antamina’s 45 per cent increase in SAG mill throughput followed by a further 10 per cent later (Rybinsky et al, 2011; Valery et al, 2012). Other case studies have been discussed by Bennett et al (2014); Hart et al (2011); Dance et al (2007); Diaz et al (2015); Renner et al (2006); McCaffery et al (2006) and Gomes et al (2010). Now the productivity imperative has returned it is time for more operators to learn from the old and the recent successes and adopt the ABC approach using the new technology tools, which include: •• more complex software for blast design, analysis and management •• advances in fragmentation modelling •• image analysis with comprehensive rock fragmentation software for automated particle sizing at truck dump and conveyor belt locations we are metallurgists, not magicians The ABC of Mine-to-Mill and metal price cycles FIG 1 – Extract from the Julius Kruttschnitt Mineral Research Centre (JKMRC) Mine-to-Mill brochure 1999. •• end-to-end modelling packages such as the Integrated Extraction Simulator (IES) developed by CRC ORE (Cooperative Research Centre Optimising Resource Extraction) and provided by JKTech •• high energy explosives to improve post fragmentation (Hawke and Dominguez, 2015) •• tools such as Split FX® that processes 3D point clouds from LIDAR (light detection and ranging) scans and photogrammetry to automatically characterise fracture attributes •• rock tracking devices such as Metso SmartTagTM (La Rosa et al, 2007) to track ore from blasthole through mining, handling, stockpiling and mill feed. Combined with mill performance and online size data, the effects of ore and blast changes can be correlated with their impact on processing, refer to Figure 2 •• GPS digital drilling systems to guide, monitor and save drill hole patterns •• measured-while-drilling (MWD) data that captures rock hardness measurements from blasthole drills to reliably categorise rock types •• blast movement monitors accurately measure threedimensional blast movement to minimise ore loss and dilution and significantly increase ore yield (LaRosa and Thornton, 2011) we are metallurgists, not magicians blast •• electronic detonators programmable in one millisecond steps to provide blast flexibility and precision •• image analysis of particle size distribution in the stockpile •• MineWare’s Argus shovel monitor to improve shovel and operator performance, optimise truckloads and reduce costs •• prompt gamma neutron activation analysis (PGNAA) like GeoScan or CB Omni for online measurement of 87 P Cameron, D Drinkwater and J Pease FIG 2 – Using a SmartTagTM to track ore batches from blasting (Metso image, from La Rosa et al, 2007). elements in rock streams on belt conveyors for grade engineering or stockpile blending •• safe, accurate and quick measurements of the Crusher Closed Side Setting (CSS) from 6 to 220 mm through the ‘C-Gap’ digital measurement tool •• accurate and reliable online particle size monitors (PSM) and sampling stations to sample and measure the particle size distribution and per cent solids of the total grinding circuit classifier product •• acoustic monitoring software to monitor operating conditions in SAG mills and allow optimisation •• automated quantitative mineralogy provides mineral liberation and association data (using area scan of particles) and elemental distributions of ore and waste minerals •• geometallurgy – the integration of geological, mining, metallurgical, environmental and economic information to maximise the net present value (NPV) of an orebody while minimising technical and operational risk. 20 YEARS LATER – WHAT HAVE WE LEARNED? For many of the early adopters, the initial success with Mineto-Mill fell victim to organisation systems and personal incentives that ‘sprang back’ to default when survival was no longer in doubt. Any reinvention of Mine-to-Mill needs to recognise why we failed to hold the gains first time, then set about to fix those flaws. The fatal flaw was that earlier designs didn’t lock the new operating methodology into organisational and management systems. When profits rose in the boom, attention was focused on expanding output and resources. Blasting engineers were rewarded for reducing their cost per tonne and miners were rewarded for increasing tonnage. Metallurgists were incentivised to increase tons and recovery and to reduce costs, but were rarely encouraged to increase product quality beyond ‘good enough to sell’. Smelters remove impurities at much higher cost than the concentrator – but that was the smelter’s problem. If we are to truly succeed with Mine-to-Mill in future, implementation must be supported, not undermined, by our organisation systems. We need to design key performance indicators (KPIs) that encourage integration and work across the silos to provide mine site targets. Mining operations are complex. We need as many good measures as we can find; they are getting better but are still imperfect. We need to distil the complexity to the simple fundamental basics of what makes a good integrated organisational team, and then set the minimum few KPIs that let clever people get on with their own jobs while using their initiative for the group benefit. This will keep the shareholders onside. TABLE 2 Mine-to-Mill case studies 2003 to 2016. Antamina and Cerro Corona demonstrated what can be achieved by applying some of the new tools in a Mine-to-Mill project. Models of drilling and blasting, crushing and grinding were combined with a knowledge of different ore domains, plant surveys and SmartTagTM tracking of blasting changes. The result was a significant increase in mill throughput from 2750 to 4400 t/h and a 25 per cent reduction in specific energy (kWh/t) (Valery et al, 2012). While at Cerro Corona, throughput was increased by 6 per cent overall (as much as 15 per cent for harder ores) and the SAG specific energy was reduced by over 9 per cent (Diaz et al, 2015). Mine site Metals produced Country Product increase Batu Hiju Cu Indonesia 10 to 15% Antamina Cu Peru 45 to 60% Los Bronces Cu Chile 15 to 20% Cerro Corona Au Peru 15% hard ore, 6% overall Phu Kham Cu Laos 8% Ahafo Au Ghana 8% Morila Au Mali 10% Case studies from 2003 to 2016 are listed in Table 2, and there are even further operations that have benefited from Mine-to-Mill but chosen not to publish the results. Oyo Tolgoi Cu Mongolia 25% Iduapriem Au Ghana 21 to 32% 88 we are metallurgists, not magicians The ABC of Mine-to-Mill and metal price cycles CONCLUSION We know Mine-to-Mill works. We made it work well with old technology. We have more tools and more appropriate data now. We have a business imperative, so we can make it work much better again. We have to recognise the complexity of sites and the differences between sites. The principles of integration will work everywhere, but the crucial components will be site-specific. Off-the-shelf solutions provided by external management groups won’t work; the components of the solutions need to be specifically assembled by multidisciplinary teams of people who know the details and constraints of each site, and who understand the difference between minimising costs in silos and maximising mine site profits. This time we need to support Mine-to-Mill with an understanding of human and organisational behaviour, and lock that into our incentive systems. We need to greatly simplify the overwhelming list of performance targets and distil them to the critical few that encourage the behaviour needed to integrate the operation. Then we can allow our clever people to get on with the job. ACKNOWLEDGEMENTS This paper was inspired by observation and comments from many people that Mine-to-Mill is often overlooked, yet the same problems which drove the original AMIRA Project are now repeating themselves. The authors thank the contributions made by the many suppliers of the technology tools that are now available for Mine-to-Mill projects. Valuable contributions were made by Walter Valery and Sarma Kanchibotla, both of whom have been associated with Mine-to-Mill projects almost since their inception. REFERENCES Bennett, D, Tordoir, A, Walker, P, La Rosa, D, Valery, W and Duffy, K, 2014. Throughput forecasting and optimisation at the Phu Kham Copper-Gold operation, in Proceedings 12th AusIMM Mill Operators’ Conference 2014, (The Australasian Institute of Mining and Metallurgy: Melbourne). Dance, A, Valery, W, Jankovic, A, La Rosa, D and Esen, S, 2007. Maintaining the benefit – how to ensure mine-to-mill continues to work for you, in Proceedings Ninth AusIMM Mill Operators’ Conference, (The Australasian Institute of Mining and Metallurgy: Melbourne). we are metallurgists, not magicians Diaz, R, Mamani, H, Valery, W, Jankovic, A, Valle, R, and Duffy, K, 2015. Diagnosis of process health, its treatment and improvement to maximise plant throughput at Goldfields Cerro Corona, in SAG 2015 Conference Proceedings, Vancouver, Canada. Gomes, M P, Tavarez Jnr, L, Nunes, E, Colacioppo, J, Jankovic, A and Valery, W, 2010. Optimization of the SAG Mill Circuit at Kinross Paracatu, Brazil, Comminution 10. Hart, S, Rees, T, Tavani, S, Valery, W and Jankovic, A, 2011. Process integration and optimisation of Boddington, in SAG 2011 Conference Proceedings, Vancouver, Canada, 25–28 September. Hawke, S J and Dominguez, L A, 2015. A simple technique for using high energy, in Proceedings 11th International Symposium on Rock Fragmentation by Blasting, Sydney, Australia, pp 321–326. Kanchibotla, S S, Morrell, S, Valery Jnr, W and O’Laughlin, P, 1998. Exploring the effect of blast design on SAG Mill throughput at KCGM, presented at the Mine to Mill Conference, Brisbane, Australia. La Rosa, D, Valery, W, Wortley, M and Ozkocak, T, 2007. The use of radio frequency id tags to track ore in mining operations, in Proceedings 31st International Symposium on Computer Applications in the Mineral Industries (APCOM), Santiago, Chile, 23–25 April 2007. Lam, M, Jankovic, A, Valery, W and Kanchibotla, S, 2001. Increasing SAG mill circuit throughput at Porgera gold mine by optimising blast fragmentation, in Proceedings SAG 2001 Conference, Vancouver, Canada. McCaffery, K, Mahon, J, Arif, J and Burger, B, 2006. Batu Hijau – controlled mine blasting and blending to optimise process production at Batu Hijau, in Proceedings SAG 2006 Conference, Vancouver, Canada. McKee, D J, 2013. Understanding Mine-to-Mill, 96 p (Cooperative Research Centre for Optimising Resource Extraction: Brisbane). Renner, D, La Rosa, D, DeKlerk, W, Valery, W, Sampson, P, Bonney Noi, S and Jankovic, A, 2006. Anglogold Ashanti Iduapriem mining and milling process integration and optimisation, in Proceedings SAG 2006 Conference, pp 249–264, Vancouver. Valery, W and Rybinski, E, 2012. Optimisation process at Antamina boosts production and energy efficiency: helping a large copper/ zinc mine meet the economic challenge of processing harder ore types, Engineering and Mining Journal, September 2012. Valery, W, Morrell, S, Kovovic, T, Kanchibotla, S and Thornton, D, 2001. Modelling and simulation techniques applied for optimisation of Mine to Mill operations and case studies, in Proceedings of VI Southern Hemisphere Conference on Minerals Technology, Rio de Janeiro, Brazil, 27–30 May. 89 Contents Base metals concentrate sales contracts – change Pavlov and the dog P D Munro1 and S E Munro2 ABSTRACT The commonly traded base metals concentrates of copper, lead, tin and zinc are sold by miners to custom smelters using contracts whose terms were generally established at the beginning of the 20th century or even earlier. Technical clauses in these concentrates for items such as payable metals and penalty elements do not reflect current realities of extractive metallurgical technologies and hygiene/environmental issues. It is an axiom that the miners and smelters have a symbiotic relationship. While the existing antique and arcane commercial arrangements serve the purpose of transferring money from the buyer to the seller, they are not likely to result in the industry achieving better overall technical and economic outcomes. By examining the cases for copper concentrates and zinc concentrates in particular, it will be shown that the practical application of these antiquated technical clauses does not drive the miners to produce the better quality concentrates that should be desired by the smelters. This is despite development of mineral beneficiation and hydrometallurgical technologies that would allow the miners to make better products. The adage that any extractive metallurgical problem in the smelter is cheaper to solve in the concentrator still generally holds. While nickel concentrates are only touched on lightly in this discussion because sales terms are more opaque than those for the other base metals, it is expected that the same conclusions will apply. INTRODUCTION The commonly traded base metals concentrates of copper, lead, tin and zinc are sold by miners to custom smelters using contract terms generally established at the beginning of the 20th century or even earlier. Technical clauses in these concentrates for items such as payable metals and penalty elements do not reflect current realities of extractive metallurgical technologies and hygiene/environmental issues. The discussion is confined to the consequences of these technical clauses rather than commercial ones such as treatment and refining charge, price participation, quotation period for metal pricing and so on. This paper focuses on the situation for the traditional base metals because of the greater transparency of sales terms and the common use of flotation as the beneficiation method (tin being the exception by using mostly gravity concentration). Nickel concentrates are only touched on lightly in this discussion. The cases of other metals such as molybdenum, tantalum and tungsten are not discussed except where it relates to flotation performance. Lewis and Streets (1979) provided a comprehensive and masterly review of base metal smelter terms from the miner’s point of view which is a good primer for the novice in the area. Details on the contracts for the individual metals are found in the Australasian Institute of Mining and Metallurgy publications Cost Estimation Handbook for the Australasian Mining Industry, Monograph No 20 (1993) and Cost Estimation Handbook, 2nd Edition, Monograph No 27 (2012). The reader is referred to the relevant sections for individual concentrates from these publications cited in the references list of this paper as follows: •• copper – Wilson and Chanroux (1993a); de Sousa (2012) •• lead – Wilson and Chanroux (1993b); Watters (2012) 1. FAusIMM, Senior Principal Consulting Engineer, Mineralurgy Pty Ltd, Taringa Qld 4068. Email: pdmunro@bigpond.com.au 2. MAusIMM, Senior Process Engineer, Mineralurgy Pty Ltd, Taringa Qld 4068. Email: semunro@bigpond.com •• tin – Lewis (1993); Kettle (2012) •• nickel – Cunningham (1993); Selby and White (2012) •• zinc – Wilson and Chanroux (1993c); Wise (2012). On reviewing the sales terms cited in the above papers and those for current contracts sighted in the course of our work, the striking impression is the continuity ie the lack 91 P D Munro and S E Munro of change over the last 20 years. The reader does not get the impression that the base metals industry is now operating in a situation where it has to deal with vastly heightened public concerns about toxic elements such as arsenic, lead, and mercury plus the issue of safely disposing of smelting and refining residues and wastes etc. Taking a holistic approach, it seems wrong to make concentrates containing excessive waste and toxic elements thereby moving the associated disposal and containment issues from a remote mine site to a smelter located near a population centre. A significant proportion of base metals concentrates are low quality as measured by ‘weight per cent valuable mineral’. Quantitative mineralogy often shows both high amounts of misplaced free diluent minerals and unliberated valuable minerals in composite particles with both non-sulfide and sulfide gangue minerals. The base metals industry is inherently flawed if current commercial arrangements encourage the miners to make low quality concentrates without appropriate incentives to use the best available technologies to make better ones. THE QUALITY OF BASE METALS CONCENTRATES Measuring up to an industry benchmark? The industry usually measures the quality of base metals concentrates by chemical content of the valuable constituent for example per cent Cu, per cent Zn etc. A more appropriate measure of the efficiency of the mineral beneficiation process (flotation for sulfide minerals or mostly gravity in the case of tin) is by per cent valuable mineral in the concentrate. Examining the particular case of sulfide mineral flotation we use the benchmark of Johnson (February 2015, personal communication) that an industrial flotation process should be able to make a concentrate with 85 per cent w/w valuable mineral from a feed with >80 per cent mineral liberation (liberation is defined as particles of composition ≥98 per cent w/w of the target mineral). Table 1 shows the grade of base metal concentrates using a composition of 85 per cent w/w valuable mineral. Contrast the above base metal sulfide concentrate with a magnetite concentrate (magnetite 72.4 per cent Fe) assaying 68 per cent Fe which contains 94 per cent w/w magnetite. Some comments on Table 1 are warranted: •• Molybdenum concentrate – quality is emphasized probably from the element’s major use as an alloying element in steel and the situation of a relatively few ‘converters’ roasting the sulfide concentrate to molybdic oxide (MoO3). By-product molybdenum concentrates from porphyry copper mines are often subjected to a chloride leach at the mine site (The Brenda Process – Jennings, Stanley and Ames, 1973) to reduce copper and lead levels. Molybdenum concentrates are often ≥55 per cent Mo. •• Zinc concentrate – while sphalerites in volcanogenic massive sulfide and Mississippi Valley-type deposits are relatively ‘pure’, others contain significant amounts of iron with the mineral being more appropriately described as marmatite ([Zn, Fe]S). This is the case for Broken Hill ore. Manganese can also be present in the sphalerite as is the case for Broken Hill, Dugald River and Gamsberg. Many zinc concentrates contain >90 per cent w/w sphalerite or marmatite. A preceding flotation step for copper and/or lead usually prevents other sulfide minerals reporting to the zinc concentrate. •• Copper concentrate – copper concentrates can be surprisingly poor quality with some of the world’s largest producers having <60 per cent w/w copper sulfides in their products despite hubristically quoting grades over 30 per cent Cu. This is because of the presence of the high copper value supergene copper minerals chalcocitedigenite (79.9 per cent Cu), covellite (66.4 per cent Cu) and bornite (63.3 per cent Cu). •• Lead concentrate – those from Mississippi Valley-type and carbonate-hosted ores can be high quality but those produced from texturally complex ores such the sedextype deposits in the Carpentaria – Mount Isa Inlier of Queensland and the Northern Territory, Australia plus certain volcanogenic massive sulfide deposits such as Hellyer and Woodlawn struggle to reach 50 per cent Pb. •• Nickel concentrate – a distinction is made between concentrates produced from ores with a significant amount of pyrrhotite gangue such at Sudbury in Canada and deposits common in Western Australia. The latter mostly komatiite-hosted nickel deposits are sulfur-poor and magnesium-rich with altered phyllosilicate minerals of concern being: •• the end product ta •• the end products of the serpentine subgroup such as chrysotile, antigorite, lizardite etc. Ores with a high pyrrhotite content can have a significant amount of nickel associated with the pyrrhotite in pentlandite ‘flames’ and in solid solution so rejecting pyrrhotite decreases nickel recovery. Concentrate with high per cent Fe is desired to maintain the required Fe:MgO ratio in the feed of flash smelting to matte which treats ~75 per cent of nickel sulfide concentrate (Crundwell et al, 2011). The high MgO concentrates come from those deposits with altered phyllosilicate minerals. The mineral separation problem is difficult under circumstances where the non-ssulfide gangue can be hydrophobic in the case of talc and with serpentine minerals positively charged at alkaline pH while sulfide minerals are negatively charged causing agglomeration of the mineral species. As a consequence of the mineralogical factors for these two types of deposits concentrate grades above TABLE 1 Base metal concentrate quality as per cent valuable mineral. Concentrate Mineral % w/w Valuable mineral Grade Molybdenum Molybdenite 59.9% Mo 85 50.9% Mo Zinc Sphalerite 67% Zn 85 56.9% Zn Copper Chalcopyrite 34.6% Cu 85 29.4% Cu Lead Galena 86.6% Pb 85 73.3% Pb Nickel Pentlandite 34.2% Ni 85 29.1% Ni 92 We are metallurgists, not magicians Base metals concentrate sales contracts – change Pavlov and the dog 20 per cent Ni are rare. The sulfide nickel segment of the industry is more integrated than copper, lead or zinc with major smelters such as Falconbridge, Kalgoorlie, Norilsk and Copper Cliff receiving most of their feed from the companies’ own mines. NEED FOR DIALOGUE Miners versus smelters Many participants in the base metals sector do not understand the technical situations facing both the miners and smelters; ‘technical’ in this context includes environmental factors. This is compounded by the lack of meaningful dialogue between the participants. The tremendous growth in the custom base metals smelting and refining sector in China over the last 20 years has been accompanied by a retreat from the smelting and refining business by ‘western’ or ‘first world’ mining companies. Companies with fully integrated mining + concentrating + smelting + refining assets seem to becoming rarer along with possession of the associated ‘in-house’ technical knowledge across the whole sector. Contact between miners and smelters is increasingly through the marketing department of the former meeting the concentrate buying department of the latter where the ‘deliverable’ is the concentrate sales contract. The participants in this dialogue/ negotiation are naturally focused on commercial issues rather than technical ones. Myths, misconceptions and misunderstandings Miners Some common misconceptions that miners have about smelters that we have encountered are as follows: •• Smelting and refining is a profitable business that makes money by ‘gouging’ the miner. This myth is demolished for copper concentrate by looking at the history of treatment charge (TC) + refining charge (RC) from say 1987 to 2014. Up to 2006 the smelters received 15–25 per cent of the value of the contained copper but since 2007 coinciding with the disappearance of price participation, their share has fallen to only ~5–8 per cent due to a concentrate supply deficit caused by the huge expansion of smelting + refining capacity in China. Thus the miners have appropriated 50–80 per cent of the value of the copper in the concentrate that formerly went to the smelters. The economics of smelting lead, nickel, tin and zinc concentrates can be expected to be similarly less attractive than mining the ores containing these elements. For all base metals the miner receives the largest share of the value of the contained metal in the concentrate and operators of high-grade deposits get superior returns because of their higher comparative advantage. Compare this to the position of the smelters who receive a minor and diminishing proportion of the value of the metal in the concentrate and have limited comparative advantage as they use the same technologies for smelting and refining. •• Smelters ‘want sulfur in the concentrate because it is free fuel’. It is reasonable to assume that if sulfur is a desirable constituent in a concentrate then it would receive a payment. We have never seen a payment made for sulfur after reviewing hundreds of base metals concentrates sales contracts over the last five decades. •• Smelters ‘want silica because it slags out the iron thus removing the need to buy flux’. See comment for sulfur We are metallurgists, not magicians above. Using copper concentrate as an example it is a fruitless exercise to attempt to optimise the content of copper, sulfur and silica for a given grade-recovery curve in a particular beneficiation system. Selecting the target copper grade of the concentrates fixes the copper recovery and the sulfur and silica grades. Miners may not appreciate the increasing environmental and industrial hygiene pressures applying to the smelters. These are genuine problems exacerbated by the proximity of many smelters to population centres. Some smelters operate in jurisdictions that impose a yearly site limit for particular elements/compounds, ie limiting the total amount of the element or compound allowed on the site for the year. Fountain (2013) has reviewed the situation for elements of concern in copper smelting and refining. This is an evolving situation with a seemingly endless procession of new issues. Some years ago we were aware that a smelter was concerned about the chromium level in a zinc concentrate. This seemed strange because chromium is not known to affect the performance of the conventional roastleach-electrowinning process. However, the leach residue of this zinc smelter was treated pyrometallurgically to fume out remaining zinc and lead leaving a discard slag possibly used as construction fill material. We surmised that because hexavalent chromium (Cr6+) is a known carcinogen, it would an easier for the smelter to state that there was negligible chromium in the slag than to expect that the relevant regulatory authorities could draw a distinction between Cr3+, which is not a carcinogen, and Cr6+. Smelters The misunderstanding that smelters have about miners is ignorance that many of them could actually make better quality concentrates given appropriate incentives. The miner has the choice of moving along a given graderecovery curve in a particular beneficiation system to make a higher grade concentrate at a lower recovery or conversely a lower grade concentrate at a higher recovery. Taking copper as an example, for at least the past 50 years the economics have always favoured recovery at the expenses of concentrate grade. The miner can move to a new grade-recovery curve (conventionally drawn with concentrate grade on the y-axis and recovery on the x-axis) pushing the curve up and to the right by changing the flow sheet and operating conditions. In many cases the higher concentrate grade from operating on this new grade-recovery curve will not be accompanied by a significant recovery loss. This is because the flow sheet and operating conditions changes can be confined to the cleaner flotation block. The major loss of the valuable mineral is usually from the rougher flotation block with the cleaner flotation block usually contributing less than a third of the total. CONCENTRATES IN PARTICULAR Copper Payment disincentive for superior quality Normal payment is for 96.5 per cent of the copper content subject to a minimum deduction of one unit (Lewis and Streets, 1979; Wilson and Chanroux, 1993a; de Sousa, 2012). Table 2 shows how payment terms vary with the copper content of the concentrate. Miners making a low-grade concentrate at 15–20 per cent Cu appear to be treated relatively generously compared with producers of higher grade materials. Lower grade concentrates 93 P D Munro and S E Munro A 1.7 per cent absolute increase in metal payment seems inadequate recompense for the miner who makes a 75 per cent Pb concentrate compared with one at 45 per cent Pb that has only 60 per cent of the lead per tonne of concentrate. The lower grade material probably leaves the smelter with more sulfur to be eliminated as sulfuric acid. So-called ‘black acid’ from lead and zinc smelters is disadvantaged in the market because of concerns about toxic elements such as mercury, cadmium etc entering the food chain via phosphate fertiliser. Other usual diluent elements such as zinc and iron must be removed as slag, increasing lead loss and subsequent disposal cost of what must be considered a ‘sensitive’ material as it contains elements such as lead, zinc, and cadmium. will produce more sulfuric acid and/or make more slag increasing copper loss. The higher slag volume increases disposal cost and requires more silica flux if the concentrate isn’t self-fluxing. Arsenic problem Current ‘world scale’ copper smelters produce ~300 000– 500 000 t/a of copper (Schlesinger et al, 2011). Assuming a mean feed concentrate grade of 25 per cent Cu then the 500 000 t/a unit requires >2 000 000 t/a of concentrate feed. Using the limit of <0.5 per cent As content for concentrates imported into China (Anon, 2006) means such a smelter has to deal with up to 10 000 t/a of arsenic or 13 200 t/a as arsenic trioxide. Halving the arsenic content of the feed to 0.25 per cent As still produces an alarmingly high amount of arsenic that has to be stored because of insufficient demand for it. Technology changes The conventional lead smelting and refining route is as follows (Sinclair, 2009): Arsenic does not assist in the smelting of concentrate to anode copper with its only technical function needing to be of sufficient concentration in the electrolyte when electrorefining anodes to eliminate the formation of floating slimes and assist the precipitation of antimony and bismuth in the slimes layer. •• sulfur elimination in a sinter plant •• bullion production in a blast furnace •• thermal refining: •• drossing in two stages to remove copper and arsenic Some very large copper deposits such as La Granja and Tampakan remain undeveloped because metallurgical test work has shown unacceptably high levels of arsenic in the copper concentrate. •• oxygen softening or Harris process to remove arsenic, antimony and tin •• desilvering by the Parkes process •• vacuum dezincing Arsenic penalties (Wilson and Chanroux, 1993a; de Sousa, 2012) are generally in the range US$2.50–5.00 per 0.1 per cent As over 0.2 per cent As. Concentrate >0.5 per cent As cannot be imported into China with the Japanese and South Korean smelters unwilling to take material above 0.15–0.2 per cent As. High arsenic concentrates enter the market by incurring a negotiated higher treatment charge reflecting the cost of shipping to a destination and the cost of supplying ‘clean’ material to blend down the arsenic content. This is usually done through a trading house. •• bismuth removal by the Kroll-Betterton process, and •• caustic refining. New lead smelting technologies include bath smelting processes such as the popular Shui Kou Shan (SKS) process from China (15 plants operating and a further 15 under construction as of 2013), Ausmelt, Isasmelt and less commonly the Queneau-Schuhmann-Lurgi (QSL) process with minor contributions from other technologies such the Kivcet and Boliden Kaldo processes. Thus the industry’s tactics of dealing with the arsenic issue are the somewhat passive responses of rejecting ‘high arsenic’ material and limited attempts at blending down the arsenic level. Electrolytic refining by the Betts process has never been as well accepted by ‘western’ countries as in Japan and China. The enormous growth of the Chinese lead smelting industry means that the Betts process with associated limited thermal treatment is now probably the dominant refining process. Lead Normal payment is for 95 per cent of the lead content subject to a minimum deduction of three units (Lewis and Streets, 1979; Wilson and Chanroux, 1993b; Watters, 2012). For the conventional lead smelting process a certain amount of zinc in the concentrate improves sinter quality (Sinclair, 2009) as the formation of an appropriate proportion of zinc melilite (hardystonite) gives the desired microstructure for optimum blast furnace operation with high softening temperature and open porosity (McLoughlin, Riley and McKean, 1980). Table 3 taken from Sinclair (2009) shows how payment terms vary with the lead content of the concentrate. New lead smelting technologies do not make sinter thus removing the need for zinc in the concentrate. The now Payment disincentive for superior quality TABLE 2 Copper concentrate metal payments. Concentrate copper content (%) Copper in concentrate paid for (%) Copper content paid for (%) 50 48.25 96.5 45 43.425 96.5 40 38.6 96.5 35 33.775 96.5 30 28.95 96.5 25 24 96 20 19 95 15 14 93.3 94 We are metallurgists, not magicians Base metals concentrate sales contracts – change Pavlov and the dog TABLE 3 Lead concentrate metal payments (after Sinclair, 2009). Lead in concentrate paid for (%) Lead content paid for (%) 75 Concentrate lead content (%) 71.25 95 65 61.75 95 60 57 95 55 52 94.5 50 47 94 45 42 93.3 dominant SKS process treats the lead-rich slag from the firststage bath smelting process in a conventional blast furnace. J Tuppurainen (February 2015, personal communication) advises that blast furnace practice is to maintain a zinc:iron ratio of feed material less than 0.7:1 to effectively remove the zinc in the discard slag. Zinc contained in the blast furnace slag can be recovered by fuming but maintaining reducing conditions at high temperatures is an expensive process. Zinc in lead concentrate has moved from being a ‘necessary evil’ in the conventional sinter plant + blast furnace process route to being a nuisance in processing by the current dominant lead smelting technologies. This leads to the question whether zinc contained in lead concentrate is being penalised too lightly by the smelters. Conversely, the predominance of electrolytic refining over thermal refining calls into question the validity of a severe penalty charge for an element such as bismuth which is readily removed by the Betts process. Bismuth and antimony are usually intimately associated with the lead mineralisation and not rejected by physical beneficiation. Tin Tin concentrate contract terms affected by quality The deductions and charges for tin concentrates shown in Lewis and Streets (1979) and later papers (Lewis, 1993; Kettle, 2012) are generally more variable than for other base metals concentrates. This reflects tin contents varying from 20 per cent Sn to 70 per cent Sn; a range rarely encountered in other concentrates. Charges for penalty elements such as US$120–150 per 1 per cent As and $300–500 per 1 per cent Cu are very high compared with other concentrates. Tin concentrate sales contracts increase the base deduction with increasing iron content which is logical considering the difficulties of recovering tin from the tin-iron alloy called ‘hardhead’. Quality change from hard rock source Glen (February 2015, personal communication) notes that depletion of alluvial tin resources means that relatively more tin concentrates are being produced from ‘hard rock’ deposits with custom tin smelters concerned about elevated levels of arsenic levels (Glen, 2015). Arsenic is a real issue in tin smelting as its removal from molten tin is by the addition of aluminium which forms a dross containing the two impurities. Wright (1966) describes this dross as ‘… probably the most dangerous substance met in classical metallurgy’ because of its propensity to evolve arsine on contact with water or moisture in the air. Arsine is 50 times more toxic than hydrogen cyanide. Custom tin smelters are examining treatment of incoming tin concentrates at their plants by flotation to reduce arsenic (presumably contained in arsenopyrite) to acceptable levels. We are metallurgists, not magicians While it would be preferable that this would be done at the mines, the small-scale of many operations may make it impractical. Zinc Payment disincentive for superior quality Zinc concentrate sales terms pay for 85 per cent of the contained zinc subject to a minimum deduction or free metal allowance of eight units. This deduction is an antique term, possibly related to the relatively low first pass recovery of zinc in the now obsolete horizontal retort process dating from the 18th and 19th centuries. Modern electrolytic plants which produce over 90 per cent of the world’s zinc (Sinclair 2005), achieve well over 95 per cent zinc recovery. Table 4 taken from Sinclair (2005) shows how payment terms vary with the zinc content of the concentrate. Thus the smelter provides little incentive for the miner to make a concentrate much over 52 per cent Zn except to save transport costs to the smelter. Lewis and Streets (1979) observed a similar ‘flattening’ out of payable zinc for concentrate grades above 54–55 per cent Zn. The elimination of by-product revenue has changed the economics of the zinc smelting business. In the 1980s zinc smelters could expect to receive payment for products such as cadmium, cobalt, copper residue, and mercury, lead residue containing silver and sulfuric acid extracted during processing of the concentrate (Hamdorf and Woodward, 1980). Few zinc plants in the ‘western’ world are currently paid for these byproducts and it is reasonable to assume that the Chinese smelters will reach this position in future. Toxic elements associated with the extractive metallurgy of zinc such as cadmium, lead, mercury and thallium are other ‘hot-button’ issues for the public. Iron problem Table 5 taken from Sinclair (2005) for a conventional roast-leachelectrowinning plant shows the dependence of zinc extraction in primary leaching on the iron content of the zinc concentrate. High iron levels in the concentrate increase both the amount of primary leach residue that has to be processed by secondary leaching and the amount of leach residue for ultimate disposal. It is anomalous that payment terms shown in Table 4 level out for concentrates assaying 52 per cent Zn and above considering that disposal of iron-rich residue from acid leaching of calcine and/or concentrate is a major problem for zinc smelters (the term ‘smelters’ includes all zinc extractive metallurgical plants). This is particularly true for zinc smelters located near population centres. Storage of jarosite or goethite-type leach residue in ponds is under regulatory pressure. Conversion of the leach residue to hematite or alternatively making a relatively benign slag by 95 P D Munro and S E Munro TABLE 4 Zinc concentrate metal payments (after Sinclair, 2005). Concentrate zinc content (%) Zinc content paid for (%) Zinc content as free metal to smelter (%) Zinc content paid for (%) 46 38 8 82.6 48 40 8 83.3 50 42 8 84.0 52 44 8 84.6 54 45.9 8.1 85.0 56 47.6 8.4 85.0 TABLE 5 Primary leach zinc recovery and residue composition (after Sinclair, 2005). Zinc in concentrate % Iron in concentrate % Zinc recovery % Zinc in primary leach residue % Primary residue amount % of concentrate 48 12 82.8 22.8 36 50 10 85.6 22.8 32 52 8 88.3 22.5 28 54 6 90.7 21.7 24 56 4 92.9 20.9 19 pyrometallurgical treatment such as the Waelz process or fuming by smelting is expensive. The case of the Budel zinc smelter in The Netherlands is a portent for the future of leach residue disposal. Since 1999 on-site storage of residue has been banned with the former leach residue ‘waste’ now mandated to be a ‘lead product’ sent for smelting by another party. Budel has achieved this by using low iron zinc concentrate from the Century Mine in Queensland as its major feed source to minimise the amount of this ‘lead product’ (Sinclair, 2007). bearing their full share of downstream processing costs. In a situation where the industry has a finite capacity to deal with input iron in concentrate, removing some iron from highgrade concentrates allows more room for iron in low-grade concentrates albeit at lower returns for miners producing such materials. Ameliorating the iron issue does not resolve the problem of elements such as cadmium, mercury and thallium which are usually too closely associated with the sphalerite/marmatite to be removed by physical beneficiation. Given this concern about iron it seems surprising that the penalty for iron in a zinc concentrate hasn’t changed in nearly 20 years being US$1.50 per 1 per cent Fe above 8 per cent Fe (Wilson and Chanroux, 1993c; Wise, 2012). Greater use of existing technologies and practices A new zinc concentrate contract? Miners can often make higher grade base metals concentrates from flotation by: We suggest that the zinc industry move to a new zinc concentrate sales contract that more appropriately aligns the capabilities of the miners with the needs of the smelters. This new contract would comprise the following: •• Treatment charge reflecting the actual cost of producing zinc metal from concentrate. Sinclair (2005) estimated operating costs for a 200 000 t/a electrolytic plant as of June 2000 to be US$383/t (or US$191.50/t of zinc concentrate with 50 per cent recoverable metal content). Power in his calculation was US$0.04/kWh. Cost of jarosite leach residue disposal into rubber-lined ponds holding up to five years of production was US$6.42/t of zinc. •• Realistic payment for contained zinc eliminating the ‘hocus pocus’ of ‘eight units of free metal’ and adjustments to the treatment charge. •• Iron penalty commensurate with the cost of dealing with the leach residue. A concentrate with 50 per cent recoverable zinc and 8 per cent Fe generates at least 0.3 t of residue per tonne of zinc metal produced. Obviously there are going to be ‘winners’ and ‘losers’ among the miners from such a contract. Miners with deposits of high iron sphalerites will receive a lower return than miners able to make high-grade concentrates. However, this is required to achieve a better overall industry outcome. We could argue that currently producers of low-grade concentrates are not 96 MINERAL PROCESSING SOLUTIONS •• increasing mineral liberation of the target mineral feed going to the cleaner flotation block; too often the benchmark condition mentioned above of >80 per cent mineral liberation for the valuable mineral in the feed is not achieved •• improving mineral separation; this is evidenced by the presence of excessive amounts of free diluents such as iron sulfide minerals and non-sulfide gangue. Johnson and Munro (2002) have reviewed the technologies and plant practices developed to treat complex sulfide ores such as the zinc-lead-silver ores of the Mount Isa Inlier (Young et al, 1997) and difficult volcanogenic massive sulfide ores such as Hellyer (Lane and Richmond, 1993). Better understanding of pulp chemistry together with using ultra-fine grinding and washed froth cleaning have been successfully applied in concentrators such as Century Zinc (Barham and Kirby, 2001; Obeng et al, 2013), McArthur River (Rossberg and Pafumi, 2013), Mount Isa – George Fisher (Pafumi et al, 2013), Phu Kham (Bennett, Crnkovic and Walker, 2012) and Prominent Hill (Barns, Colbert and Munro, 2009). A seemingly forgotten powerful flotation practice is reverse flotation as exemplified by the so-called Brunswick process (McTavish, 1980) which was used at Brunswick Mining and Smelting and later at Kidd Creek. Sphalerite was depressed by heat and sulfur dioxide addition with pyrite removed We are metallurgists, not magicians Base metals concentrate sales contracts – change Pavlov and the dog as the concentrate. The standard by-product molybdenum separation from copper-molybdenum ores can be considered to be a type of reverse flotation process upgrading the copper concentrate. If these existing technologies and plant practices have to be applied to ‘difficult’ ores to achieve ‘ordinary’ metallurgical outcomes then using them on ‘easy’ ores such as a porphyry copper deposit would achieve ‘extraordinary’ metallurgical outcomes compared with current ones. One consequence of better quality concentrates will probably mean miners and smelters having to cope with finer particle size distributions. For the miners this means froth pumping and concentrate dewatering. This shouldn’t be alarming as the plants mentioned above are successfully dealing with these issues. A far bigger potential problem is the solid-liquid separation issues with the movement to dry stacking of tailings if regulators ban the conventional ‘wet’ tailings dam. For the smelters finer concentrate particle size distribution means more dust. The reason that these technologies and practices aren’t used more widely by the miners to make better quality concentrates is because technical terms in the sales contracts do not provide any monetary incentive to do so. As mentioned above a magnetite concentrate at 68 per cent Fe contains 94 per cent w/w magnetite which is much higher quality than the base metal concentrates in Table 1. Higher capital and operating costs are needed to produce magnetite concentrate compared with direct shipping ore (DSO) so a high quality product has to be made to get the premium offered over the DSO material. Blast furnace iron producers are much more conscious of feed quality than base metals smelters. An argument against using iron ore sector practice as a parable for base metals is that iron ore is a low value commodity mined from very large deposits where recovery isn’t important. One tonne of iron ore at 30 per cent Fe with iron ore at US$100/t has the same in situ value as one tonne of copper ore at 0.5 per cent Cu with copper at US$6000/t. Large porphyry copper deposits can be the same size as iron ore deposits. Magnetite concentrates are high quality because they have to be, customers won’t accept poor quality. It exemplifies Sinclair’s reiteration (2007) of the business truism ‘that if you don’t have customers you really don’t have a viable project’. A viable technical solution to the arsenic problem? High arsenic levels in copper concentrate are usually caused by the presence of the copper arsenic sulfide minerals enargite (Cu3AsS4) and tennantite ([Cu, Fe]12As4S13 or Cu13As4S13). These minerals behave in flotation like other copper sulfide minerals and report to the concentrate. Arsenic in the form of arsenopyrite should be readily dealt with as it behaves like pyrite. The proven mine site solution to high arsenic concentrates is roasting to remove the element as arsenic trioxide. This was done at Lepanto and El Indio and is currently practised at Codelco’s Ministro Alejandro Hales operation (formerly known as Mansa Mina). A less appealing solution from both the point of view of the miner and custom smelter is for the former to produce copper metal on-site by smelting or the pressure oxidation + solvent extraction + electrowinning route. •• Separation of the copper concentrate into a high tonnage lower arsenic portion and a low tonnage higher arsenic portion by exploiting Eh-pH flotation separation ‘windows’ for the different copper mineral present. Ametov has demonstrated the possibility of a reasonable separation of chalcopyrite + pyrite versus chalcocite + bornite (Ametov et al, 2014). Ma and Bruckard (2009) show that similar ‘windows’ exist for the arsenic carriers. It is unreasonable to expect that there will be clean separation with all the copper arsenic minerals reporting to one product. •• Hydrometallurgical treatment of the high arsenic concentrate by an emerging technology such as the Toowong process (Nakon and Way, 2014; Turner, 2015) which uses an alkaline leach. This has the advantage over roasting of leaving the main copper sulfide minerals substantially unchanged. Arsenic is fixed using a range of conventional methods and the stabilised product can be disposed into a suitable engineered facility. Alternatively all the copper concentrate is treated through the Toowong process reducing the arsenic content to 0.05 per cent As. SUMMARY The technical terms in contracts for the sales of for base metals concentrates show little change over the last 20 years or even the last 50 years. This is despite all sectors of the primary base metals industry now operating in a situation where they have to deal with vastly heightened public concerns about toxic elements such as arsenic, lead, and mercury plus the issue of safely disposing of smelting and refining residues and wastes etc. For mineral beneficiation by sulfide mineral flotation, many miners including some of the world’s largest producers do not achieve our benchmark that an industrial flotation process should be able to make a concentrate with 85 per cent w/w valuable mineral from a feed with >80 per cent mineral liberation. Mineral processing developments over the past 20 years, such as better understanding of pulp chemistry, ultra-fine grinding and washed froth cleaning have been successfully applied to the treatment of complex or ‘difficult’ ores. Using them on ‘easy’ ores such as porphyry copper deposits would achieve ‘extraordinary’ metallurgical outcomes compared with some current mediocre ones leading to a general improvement in the quality of base metals concentrates. The smelters, after appropriate dialogue with the miners, should alter the technical clauses in base metals concentrate sales contracts appropriately affecting economic returns. This should elicit the appropriate Pavlovian response in terms of concentrate quality. If the industry doesn’t hang together on this then its constituent components will hang separately! ACKNOWLEDGEMENTS The authors would like to acknowledge Mineralurgy Pty Ltd for the permission to publish this paper. Examination of the technical literature suggests the interesting possibility of a mine site treatment route as follows: We thank Mr Craig Walter formerly of MIM Holdings Limited and later of Trafigura Beheer BV for his acute observations, wise guidance and patient mentoring in the areas of concentrate sales and metals marketing over 30 years. •• Product of a copper concentrate by conventional or enhanced means. Mr Jorma Tuppurainen Senior Principal Consulting Engineer with Mineralurgy Pty Ltd kindly provided technical advice We are metallurgists, not magicians 97 P D Munro and S E Munro from his considerable expertise in the extractive metallurgy of copper, lead, nickel and zinc. Mr Roderick Sinclair is thanked for his very useful publications The Extractive Metallurgy of Lead (2009) and The Extractive Metallurgy of Zinc (2005) from which we have drawn heavily in writing this paper. REFERENCES Ametov, I, Harmer, S, Grano, S and Alford, R, 2014. Selective flotation of chalcopyrite and pyrite from a mixed copper mineral concentrate under controlled redox potential condition, in Proceedings 12th AusIMM Mill Operators’ Conference, pp 131–140 (The Australasian Institute of Mining and Metallurgy: Melbourne). Anon, 2006. The specification for limit on harmful element content of the heavy metal concentrates products (English trans) National Standard of the People’s Republic of China GB 2044–2006. Barns, K E, Colbert, P J and Munro, P D, 2009. Designing the optimal flotation circuit – the Prominent Hill case, in Proceedings Tenth AusIMM Mill Operators’ Conference, pp 173–182 (The Australasian Institute of Mining and Metallurgy: Melbourne). Bennett, D, Crnkovic, I and Walker, P, 2012. Recent process improvements at the Phu Kham Copper-Gold concentrator, Laos, in 11th AusIMM Mill Operators’ Conference, pp 257–272 (The Australasian Institute of Mining and Metallurgy: Melbourne). Crundwell, F K, Moats, M S, Ramachndaran, V, Robinson, T G and Davenport, W G, 2011. Extractive Metallurgy of Nickel, Cobalt and Platinum-Group Metals (Elsevier: Amsterdam). Cunningham, W H, 1993. Nickel, in Cost Estimation Handbook for the Australian Mining Industry (eds: M Noakes and T Lanz) (Chapter 16) pp 356–358 (The Australasian Institute of Mining and Metallurgy: Melbourne). de Sousa, A, 2012. Copper, in Cost Estimation Handbook, Second Edition (Chapter 20) pp 483–486 (The Australasian Institute of Mining and Metallurgy: Melbourne). Fountain, C, 2013. The whys and wherefores of penalty elements in copper concentrates, in Proceedings MetPlant 2013, pp 502–518 (The Australasian Institute of Mining and Metallurgy: Melbourne). Hamdorf, C J and Woodward, O H, 1980. Zinc production by electrolytic zinc company of Australasia Ltd, Risdon, Tas, in Mining and Metallurgical Practices in Australia (ed: J T Woodcock), pp 254–261 (The Australasian Institute of Mining and Metallurgy: Melbourne). Jennings, P H, Stanley, R W and Ames, H L, 1973. Development of a process for purifying molybdenite concentrates, in Proceedings International Symposium on Hydrometallurgy (eds: D J I Evans and R S Shoemaker), pp 868–883 (Society of Mining Engineers of AIME: New York). Johnson, N W and Munro, P D, 2002. Overview of flotation technology and plant practice for complex sulfide ores, in Mineral Processing Plant Design, Practice and Control Volume 1 (eds: A L Mular, D N Halbe and D J Barratt), pp 1097–1123 (Society for Mining, Metallurgy and Exploration: Littleton). Ma, X and Bruckard, W J, 2009. Rejection of arsenic minerals in sulphide flotation – A literature review, International Journal of Mineral Processing, 93:9–94. McLoughlin, B C, Riley, J F and McKean, G R, 1980. Development of optimum fluxing procedures for isamine lead concentrates, in Lead-Zinc-Tin ‘80 (eds: J M Cigan, T S Mackey and T J O’Keefe), pp 309–320 (Metallurgical Society of AIME: Warrendale, Pennsylvania). McTavish, S, 1980. Flotation practice at Brunswick Mining, CIM Bulletin, 115:115–120. Nakon, D and Way, D M, 2014. Method for Treating Arsenic Containing Materials, US Patent 8771619 B2 (Xstrata Queensland Ltd). Obeng, D, Twining, D, Milsom, J, Brown, M, Smith, M, Horton, R, Ackroyd, T and Smith, W, 2013. Century Mine MMG, in Australasian Mining and Metallurgical Operating Practices (ed: W J Rankin), pp 1661–1682 (The Australasian Institute of Mining and Metallurgy: Melbourne). Pafumi, J, Rossberg, F, Golling, J, Armstrong, C, Walker, R, Grobler, J, Boyer, J, Meyer, R and Beer, A, 2013. George Fisher Mine Xstrata Zinc, in Australasian Mining and Metallurgical Operating Practices (ed: W J Rankin), pp 1639–1660 (The Australasian Institute of Mining and Metallurgy: Melbourne). Rossberg, F and Pafumi, J, 2013. McArthur River mine xstrata zinc, in Australasian Mining and Metallurgical Operating Practices (ed: W J Rankin), pp 1543–1668 (The Australasian Institute of Mining and Metallurgy: Melbourne). Schlesinger, M E, King, M J, Sole, K C and Davenport, W G, 2011. Extractive Metallurgy of Copper, 5th edition (Elsevier: Amsterdam). Selby, M and White, D T, 2012. Nickel, in Cost Estimation Handbook, Second Edition (Chapter 20), pp 502–507 (The Australasian Institute of Mining and Metallurgy: Melbourne). Sinclair, D F, 2007. Project evaluation – the customer’s perspective, in Proceedings Project Evaluation 2007, pp 203–208 (The Australasian Institute of Mining and Metallurgy: Melbourne). Sinclair, R J, 2005. The Extractive Metallurgy of Zinc (The Australasian Institute of Mining and Metallurgy: Melbourne). Sinclair, R J, 2009. The Extractive Metallurgy of Lead (The Australasian Institute of Mining and Metallurgy: Melbourne). Turner, D, 2015. The Toowong Process, Core Resources Pty Limited, Albion, Queensland. Watters, T, 2012. Lead, in Cost Estimation Handbook, Second Edition (Chapter 20), pp 493–495 (The Australasian Institute of Mining and Metallurgy: Melbourne). Wilson, P C and Chanroux, C, 1993a. Copper, in Cost Estimation Handbook for the Australian Mining Industry (eds: M Noakes and T Lanz) (Chapter 16), pp 346–348 (The Australasian Institute of Mining and Metallurgy: Melbourne). Wilson, P C and Chanroux, C, 1993b. Lead in Revenue Calculations and Marketing of Cost Estimation Handbook for the Australian Mining Industry (eds: M Noakes and T Lanz), (Chapter 16) pp 337–339 (The Australasian Institute of Mining and Metallurgy: Melbourne). Kettle, P, 2012. Tin, in Cost Estimation Handbook, Second Edition (Chapter 20), pp 511–514, (The Australasian Institute of Mining and Metallurgy: Melbourne). Wilson, P C and Chanroux, C, 1993c. Zinc, in Cost Estimation Handbook for the Australian Mining Industry (eds: M Noakes and T Lanz) (Chapter 16), pp 364–367 (The Australasian Institute of Mining and Metallurgy: Melbourne). Lane, G S and Richmond, G D, 1993. Improving fine particle flotation selectivity at Hellyer, in Proceedings XVIII International Mineral Processing Congress, vol 3, Flotation 1, pp 887–905 (The Australasian Institute of Mining and Metallurgy: Melbourne). Wise, W, 2012. Zinc, in Commodity Marketing of Cost Estimation Handbook Second Edition, (Chapter 20) pp 516–521 (The Australasian Institute of Mining and Metallurgy: Melbourne). Lewis, P, 1993. Tin, in Cost Estimation Handbook for the Australian Mining Industry (eds: M Noakes and T Lanz) (Chapter 16) pp 360– 362, (The Australasian Institute of Mining and Metallurgy: Melbourne). Lewis, P K and Streets, G C, 1979. An analysis of base-metal smelter terms, in Proceedings Eleventh Commonwealth Mining and Metallurgical Congress (ed: M J Jones), pp 753–767 (The Institution of Mining and Metallurgy: London). 98 Wright, P A, 1966. Extractive Metallurgy of Tin, pp 138–139 (Elsevier: Amsterdam). Young, M F, Pease, J D, Johnson, N W and Munro, P D, 1997. Developments in milling practice at the lead/zinc concentrator of Mount Isa mines limited from 1990, in Proceedings Sixth AusIMM Mill Operators’ Conference, pp 3–12 (The Australasian Institute of Mining and Metallurgy: Melbourne). We are metallurgists, not magicians Project design Contents Karouni Gold Project from drill core to commissioning K Nilsson1 and D Connelly2 ABSTRACT Troy Resources acquired the Karouni Gold project in Guyana, South America in 2014 and immediately proceeded to a Pre-Feasibility Study and project implementation. The study considered two open pit mines feeding a conventional carbon-in-leach (CIL) gold plant with a capacity of 1 Mt/a. The study assumed a total of 2.61 Mt of ore with an average grade of 3.84 g/t gold with a recovered gold production of 303 526 oz over a three year mine life. The project development involved drilling metallurgical test holes, securing second-hand major pieces of equipment where suitable and arranging shipping to Guyana. The remote location meant logistical considerations were paramount. The plant consists of conventional two-stage crushing with single stage ball milling and a gravity circuit. The tailings circuit includes cyanide detoxification (DETOX). The extremely high rainfall presented challenges with water management and the necessity to dispose of clean water to the environment. The DETOX was also mandatory due to the highly sensitive environment and past history in the area. The criticality of this meant that in the design, any cyanide in the tailings would precipitate in a plant shutdown. Lessons were learned and the project has been both profitable and successful for Troy Resources in a new operating location. In addition, the project has created jobs, delivered royalties and brought new skills into an area where previously there was little current mining activity. PROJECT HISTORY The Karouni project was previously owned by Azimuth Resources. The project transferred to Troy Resources following their acquisition of Azimuth Resources in July 2013. DDrilling by Azimuth established inferred resources of 1.6 Moz for the combined Smarts and Hicks deposits, with Smarts being the higher grade of the two (see Figure 1). Guyana is host to several active junior mining companies, and also has activity from the major minors as well, including BHP, Newmont and Lamgold. In 2012, mining in Guyana produced over 400 000 oz of gold. A majority of the population of Guyana lives along the coastal areas, with a growing amount of exploration occurring in the interior of the country. Resources within the interior include diamonds, semi-precious stones and gold (see Figure 1). GEOLOGY The Guyana Shield has been correlated with the Leo-Man Shield of West Africa and it is generally accepted that prior to the opening of the Atlantic during the Mesozoic, the two shields formed a contiguous craton. The Archaean Imataca Complex can be correlated with the Archaean Liberian Province, the Central Guyana Granulite Belt with the Dimbroko Zone in Ivory Coast, the Barama-Mazaruni greenstones with the Birimian greenstones and the Trans-Amazonian tectono-thermal event with the Eburnean Orogeny. METALLURGICAL TEST WORK 1. Project Director, Troy Resources Ltd, West Perth WA 6005. 2. MAusIMM(CP), Director/Principal Consulting Engineer, Mineral Engineering Technical Services Pty Ltd (METS), Midas Engineering Group, Perth WA 6000. Email: damian.connelly@metsengineering.com The test work program investigated three ore zones; primary, shear and oxide, over a range of processing parameters. This included comminution, gravity, cyanide leaching, variability test work and ore process characterisation. Additionally, some tests were conducted on material classified as sulfide. This material was subjected to preliminary comminution testing and checked for gold grades. Samples were selected based on geological data, orebody cross-sections and a review of the core logs and assays as provided by Troy Resources to METS. Composites were 101 K Nilsson and D Connelly FIG 1 – Karouni Gold project location. formed based on this information including assay data for further testing, both for variability and master composites. one of the sulfide samples, with the high sulfide result being classified as hard (see Table 2). Comminution results SAG mill comminution Comminution testing was conducted on all areas of the orebody. SAG mill comminution testing is conducted to further evaluate ore hardness and competency for size reduction, with a smaller starting size than that of the crushing tests. The shear material was seen to be the least competent, being classified as soft–medium. The primary and sulfide materials were seen to be more competent as hard to very hard. These rankings were achieved on the basis of the A*b values (material hardness), and the ta. values (resistance to abrasion) (see Table 3). Unconfined compressive strength The oxide material was classified as very weak, while the primary and shear materials were classed in the range of weak to medium-strong. The sulfide ore tested was seen to be the most competent material, being classified as mediumstrong (see Table 1). Simulations indicated SAG milling was an option for the process plant. Crushing work index Bond ball mill work index The crushing work index results showed that all material was classified as ‘very soft’. There will be no identified issues as a result of processing this through the crushing circuit. The results ranged from 0.4 kWh/t through to 17.9 kWh/t for The Bond ball mill work index results indicated that all samples were medium to hard, across all zones tested. The range of values was between 12.57 kWh/t and 15.28 kWh/t, Table 1 Unconfined compressive strength (UCS) results summary. 102 Hole Zone UCS ranking Average Max Min Std dev 99 Primary Medium-strong 25.65 45.62 12.93 14.29 100 Oxide Very weak 2.75 3.30 2.20 0.55 100 Primary Weak 8.85 14.35 3.50 4.43 101 Shear Medium-strong 29.53 80.57 8.37 27.08 102a Primary Weak 21.76 39.56 10.59 7.52 102a Shear Weak 16.67 45.50 4.48 14.60 103 Primary Medium-strong 28.14 32.52 20.75 5.26 103 Sulfide Medium-strong 34.62 133.31 6.55 31.66 We are metallurgists, not magicians Karouni Gold Project from drill core to commissioning Table 2 Crushing work index (CWi) results summary. Hole Zone #CWi CWi(kWh/t, average) Max Min Std dev Ranking 99 Primary 21 3.13 4.79 2.39 0.73 Very soft 100 Oxide 20 1.46 3.52 0.37 1.05 Very soft 101 Primary 15 3.87 6.01 3.38 0.73 Very soft 101 Shear 20 4.64 9.62 3.77 1.80 Very soft 102a Primary 30 4.24 7.25 3.44 1.12 Very soft 102a Shear 15 5.14 11.21 2.41 2.18 Very soft 103 Primary 21 4.42 9.51 2.64 1.97 Very soft 103 Sulfide 34 5.87 17.93 2.37 3.03 Very soft 103 Shear 19 5.12 7.69 2.36 1.43 Very soft Table 3 SAG mill comminution (SMC) results summary. Sample ID A b A*b Rank ta Rank SDD102a – Primary 58.7 0.63 37.0 Hard 0.35 Hard/mod hard SDD103 – Primary 54.6 0.53 28.9 Very hard 0.28 Very hard SDD103 – Shear 51.9 0.95 49.3 Medium 0.48 Medium SDD103 – Sulfide 69.9 0.36 25.2 Very hard 0.24 Hard SDD102a – Shear 46.3 1.81 83.8 Soft 0.83 Soft with the highest value being recorded by the sulfide ore, and the lowest by the shear ore. Bond rod mill work index Rod mill work index testing was conducted on the primary and shear master composites. Both results showed the material to be hard, with results of 19.9 kWh/t and 17.5 kWh/t for the primary and shear zones respectively. Bond abrasion index The primary and shear master composites were tested. The primary material returned a result of 0.13, which classifies this ore as mildly abrasive. The shear material returned a value of 0.09, which is non-abrasive. These results indicate that there will not be any undue wear experienced in a crushing circuit. Master composite testing The gravity recovery varied between the three composites, with the oxide displaying a gravity recovery of around 30 per cent, the shear 40 per cent and the primary 60 per cent. Given the high gravity performance, it was recommended that a gravity stage be included in the processing circuit flow sheet. Quantitative Evaluation of Minerals by SCANning Electron Microscopy (QEMSCAN) – mineralogy A QEMSCAN analysis was carried out on heavy liquid separation sinks and floats following desliming of a subsample of the primary master composite material. The floats contained a majority of quartz, feldspar and other silicates. Based on work conducted in the test work program, the inclusion of the feldspar and silicates shows negligible negative effect on the rheological properties of the primary ore. Master composites of primary, shear and oxide ores were formed. While not all tests were conducted on all composites, the primary, shear and oxide master composites were used to assess optimal leaching conditions and determine process performance. The analysis of the sinks showed that the sulfides, identified in the head assays, were present as pyrite. Other major minerals present in the sinks included iron oxides/ hydroxides, and iron silicates. These results give basis to the assumption that the unleached gold remaining in the leach residue may be locked in pyrite. Gravity – cyanidation leach optimisation The QEMSCAN results showed no major cause for concern from a processing point of view. A series of tests were conducted to determine the optimal grind size and cyanide dosage for the leaching process. It was determined, after the first round of testing, that a 24 hour leach time would be adopted due to negligible improvements in leach recovery being achieved from longer leach times. Cyanide was very low and lime consumption as expected. The test work program, conducted on the oxide, primary and shear master composites, determined that a P80 of 63 microns would be used for subsequent testing and throughout the process plant, with a cyanide dosage of 250 ppm. Under these conditions all samples displayed fast leaching kinetics and high recoveries. We are metallurgists, not magicians Oxygen uptake testing The oxygen consumption ranged between maximum values of -0.024 mg/L/min for the oxide and -0.035 mg/L/min as a maximum value seen for both the shear and primary ore types. As a result air sparging will suffice. Carbon loading testing Carbon loading tests were conducted on the primary and shear master composites, with the slurry from a bulk leach on gravity tailings being used to generate a representative carbon loading feed. 103 K Nilsson and D Connelly The primary material had a k value of 177 h-1, and an n value of 0.74. Table 5 Outotec thickener test results summary. The k and n values for the shear test were 202 h-1 and 0.70 respectively, and therefore indicate no issues for processing. Parameter Rheology Rheology testing was conducted on all three master composites. Based on the expected design of the process plant, the tests were conducted at a P80 of 63 micron, at 40, 50 and 60 per cent solids by weight. A range of shear rates was applied to the slurries, with shear rates of 5 s-1 and 200 s-1 being taken as low shear and high shear conditions respectively for the analysis. Based on the current process plant design, with correct thickener control it is not expected that any viscosity issues will be seen through the process plant. Thickening The tests were conducted on RC chip samples (SRC730 and SRC711) provided by Troy Resources, with three flocculants being tested. It was hence recommended to proceed with the Magnafloc 351 as the preferred flocculant in the design work (see Table 4). Outotec thickening test work Thickener design test work was conducted by Outotec in two stages; initially flocculant screening was conducted on five flocculants including the previously tested Magnafloc 351. From this testing it was determined that Magnafloc 155 would be used for the dynamic settling tests. The test work results showed that the optimal feed density for all ore types tested was 15 per cent solids. Other parameters from the test work are summarised in Table 5. Based on the results of this work, there should be no issues in thickening the Karouni ore or cyclone overflow. Bulk leach and detoxification In order to conduct the detoxification test work, a 10 kg amount of sample from the primary and shear master composites was used as feed slurry. The primary material showed strong performance at all ratios, with the cyanide level, both free and WAD cyanide, being below 1 ppm after two hours. The shear material was unable to achieve free or WAD cyanide levels below 1 ppm after eight hours at the lowest ratio, however at ratios of 3 and 4 both the free and WAD cyanide was seen to be below 1 ppm. Cyanide destruction testing was based on the INCO sulfur dioxide system. VARIABILITY TESTING Variability testing was conducted on five primary samples only, due to the amount of available mass for this ore zone, and the limited mass of the other ore zones (see Table 6). Ore Type Oxide Shear Primary Feed density (% w/w) 15 15 15 Flocculant dosage (g/t) 30 30 20 U/F density range (% w/w) 47.4–53.2 49.0–63.4 55.9–63.5 Overflow clarity (mg/l) ~100 ~100 ~350 The cyanide consumption was low for all samples tested, while the lime consumption was at levels below concern. PROCESS PLANT DESIGN The process plant design is based on two-stage crushing to a covered crushed ore stockpile with a nominal 3800 t live. The primary jaw crusher is a Metso C120 and a Nordberg HP 500 secondary crusher. This is based on operating 6500 hr/a. The product will be a P80 of 10.3 mm from a double deck screen. Crushing was selected based on low wear rates, energy efficiency and process certainty compared to a SAG mill. A second-hand ball mill 5 m diameter by 7.32 m long was sourced out of Canada using a 40 per cent ball charge with a 3.1 MW motor. The mill is close circuited by cyclones with the cyclone overflow going to a 25 m preleach thickener. The thickener underflow is pumped to the first CIL tank. A preleach thickener was included to allow flexibility of cyclone overflow and grind size, increased residence time in the CIL and reduced cyanide and lime consumption. This also assists in clean-up of spills inside the bunded areas of a high rainfall area. Two Knelson XC30’s gravity concentrators are used to recover coarse gold before being processed using intense leach reactors. The high gravity gold recovery made this essential for higher overall recovery, faster cash flow and improved gold security. Cyanide leaching is using six CIL tanks. The nominal leach residence time is 24 hours. The loaded carbon is stripped in a pressure Zadra stripping column. The gold is electrowon and smelted in the gold room. The carbon is regenerated after stripping on an as-needed basis. DETOX The sensitive environmental area required a DETOX to minimise the potential impact on the environment. The leached slurry in CIL tank 6 will pass from the final launder into the DETOX circuit, at DETOX tank 1 (300-TK008) for cyanide destruction. The DETOX circuit contains three agitated tanks, (DETOX tank 1, 2 and 3 – 300-TK-008/009/010) and will be bunded Table 4 Reverse circulation chip settling results. Property 104 SRC 730 SRC 711 Magnafloc 351 Magnafloc 345 Magnafloc 351 Magnafloc 345 Free settling velocity m/h 25.50 27.06 25.88 27.85 Hindered settling velocity m/h 1.14 0.78 0.72 0.60 Underflow % solids w/w 55.3% 51.6% 56.2% 44.9% We are metallurgists, not magicians Karouni Gold Project from drill core to commissioning Table 6 Variability leach results summary. Sample Head grade (Au g/t) Gold recovery (%) Leach time (h) 0 2 4 8 24 NaCN consumption (kg/t) Lime consumption (kg/t) P-V1 2.59 58.4 76.1 77.9 79.5 80.4 0.09 1.25 P-V2 11.12 42.6 78.8 87.3 92.4 92.8 0.12 1.15 P-V3 3.94 43.5 70.0 75.5 76.4 79.2 0.08 0.91 P-V4 7.80 79.3 88.4 92.2 95.6 97.4 0.10 0.83 P-V5 4.58 58.2 78.5 84.8 87.9 95.2 0.07 1.03 separately to the CIL tanks and operate in series. This will provide three stages of DETOX to ensure that the cyanide is completely removed through the 7.5 hours total residence time. As with the CIL circuit the DETOX tanks will be able to have a tank bypassed as required for maintenance. The DETOX tanks will all be dosed with sodium metabisulfite (SMBS), while DETOX tank 1 will also receive a feed of copper sulfate (CuSO4) to maintain a minimum 50 ppm Cu2+ as part of the detoxification process. Spent hydrochloric acid (HCl) and acid wash water from the elution circuit will also be pumped into DETOX tank 3. The DETOX tanks will be highly agitated and be air sparged to drive the reaction which destroys the cyanide. The slurry will gravitate between the tanks in this circuit. Controls are in place to alarm and even shut the plant down if cyanide is detected in tanks 2 and 3 above a preset level. Tailings A conventional tailings dam will be constructed on-site. Due to the high rainfall run-off water collected around the process plant and TSF, or from mine dewatering activities, will be handled in stilling ponds prior to discharge into the river system. This will ensure the water released is treated and hence suitable for release. The tailings are not acid forming (benign sulfides) and this is a positive for the project. Water management Water will be fed to both the raw water dam (700-DM-001) and the water purification feed tank (700-TK-001) from the river or bore field. The raw water dam will provide water to be used as both feed throughout certain areas of the process plant (elution circuit, gravity fluidisation and reagents), and for top up water for the process water dam (700-DM-002). Mine dewatering water will be used preferentially for processing and the water balance indicates excess water will need to go to stilling ponds, tested and then disposed of into the environment. Reagents The reagents and services area of the process plant will be used for both reagent preparation and storage prior to distribution throughout the process plant. The reagents will be mixed in a bunded area in covered tanks to prevent heavy rain damaging or causing losses to the reagents. Bunding will be placed around key areas to also provide additional levels of separation between reactive reagents. Air Air is used throughout the process plant. This includes air for the workshop, sparged into the leach circuit to improve leaching kinetics, and instrument air. Air will also be used in the Detox circuit. This will be provided by blowers installed in this area of the process plant. Air will be supplied from one of two air compressors (800-CP-001/800-CP-002). This air will be stored in the air receiver (800-RA-001) until required throughout the process plant. Diesel Diesel will be used on-site as the primary source of fuel and heating. Diesel will be used for the power station, the smelting furnace, elution heater and the carbon regeneration kiln, as well as fuel for site vehicles. Power supply is based on packaged sets using diesel fuel. This will supply power to the camp, process plant and facilities. Troy Resources will own and operate the power station. CONCLUSIONS Small resource gold projects can be profitable and the risks can be managed using suitable second-hand equipment. The concept of minimal engineering, that is, project management of a group of subconsultants to execute the project did result in substantial savings in time and money. The use of a secondhand ball mill (never used) saved time and money. The simple flow sheet has low technical risk and can be readily expanded should the need arise. The DETOX circuit was critical given past problems in Guyana with cyanide spills. Troy Resources has gained valuable experience in project development in a new international area and has established a presence which will allow the evaluation of other resource opportunities in the immediate area of the plant. The project impact will be very positive for Troy and the local community. Exploration in the region is likely to find new resources within proximity to the process plant and the operations future may continue beyond the present resources. ACKNOWLEDGEMENTS The author would like to thank colleagues and persons associated with the Karouni Gold project for the education and life experience received during this exciting period of the development, birth, nurturing and growth of a new gold project in Guyana, South America. Thanks are also due to the management of Troy Resources for permission to publish this paper. Cyanide, hydrochloric acid, sodium hydroxide, flocculant, copper sulfate, sodium metabisulfite and antiscalant will be mixed on-site for delivery and use within the plant. We are metallurgists, not magicians 105 Contents Upgrades, modernisations, automation and expansions … where will the expertise, capability and skills come from in the future? R Coleman1, J King2 and T Hunter3 ABSTRACT The industry that supports operations and new projects is suffering a rapid decline in the current severely curtailed capital investment environment. This is evident by a decline in the number of skilled teams, who are now centred in fewer locations. Other features are an aging and retiring ‘baby boomer’ generation, coupled with a low uptake of new graduates and the uncertainty in predicting future capital expenditure programs and requirements. Combine this with a reluctance of cash-poor operations to modernise and adapt in an environment of low metal prices, and there is a real uncertainty as to how service providers will meet industry needs as they evolve. Trends amongst service providers will be put forward as well as developing options and alternatives. These embrace a whole gamut of agile alternatives in the areas of partnering, alliances, commercial and shared risk models and mutual innovations. These will be discussed with some case studies and suggested approaches. Particular emphasis will be upon brownfield expansions and upgrades which have emerged recently as a preferred lower capital and focused way to achieve the best practical outcome at lowest cost. There are several specific features of such brownfields projects including the requirement for very close cooperation between the execution team, operators, maintenance and suppliers and a maximum usage of site resources and ingenuity. Often, required investment hurdle rates are high, downtime allowed is minimal and site resources usage is maximised. This requires mutual trust, good planning and high health, safety, environmental and community (HSEC) standards and practice. In many ways, the practices and skills needed are the exact opposite of the historical ‘big Greenfields’ project with which the industry has been geared for more recently. Another developing area has been with innovative commercial models and practices. This is a direct result of the more challenging investment criteria being adopted and the relative hunger of service providers. It has become more common to look at these commercial-costing alternatives very early in the project cycle as an essential project tool and not just as a possible option. These commercial solutions cover such alternatives as: •• leasing and rental •• deferred payments •• build–own–operate–transfer and build–own–operate •• whole-of-mine preferred spares and maintenance terms •• aggressive performance targets with real assurance penalties. Once again this requires very close mutual dealings and trust, and sufficient time allocation compared to a conventional approach. INTRODUCTION 1. MAusIMM, Account Director, South East Asia Pacific, Outotec, West End Qld 4101. Email: rob.coleman@outotec.com 2. Head of Sales Minerals Processing, Outotec, Frenchs Forest NSW 2086. Email: jason.king@outotec.com 3. FAusIMM(CP), Senior Consultant, Clayfield Qld 4011. Email: tomhunter134@gmail.com The broader Mining Equipment Technology and Services (METS) industry has grown since the early 2000s in response to the demand from the industry and is a significant employer and economic contributor in its own right. This has recently been documented and recognised particularly by governments (Hunter, 2014; Austmine, 2013). The METS subsector dealing with metallurgical technology development, process plant upgrades and new projects, had grown at a real pace and likely peaked in 2012. It is now in serious decline and losing capacity, capability and confidence. There are several reasons for the decline, which include: •• the well-documented and recognised step change in metal prices since 2013 from previous buoyant levels (Fiscor, 2015) 107 R Coleman, J King and T Hunter •• the ‘hangover’ psychology from the project excesses, in terms of bloated capital cost compared to expectations, delayed deliveries and fierce project competition for scarce engineering and construction resources •• the generational change occurring as the ‘Baby Boomers’ move on from active project involvement •• the severe contraction in the skill level and number of teams now available for projects (Federation University Australia, 2014). So the challenge is how to provide the level of service demanded by our industry in a sustainable and competent manner. This paper looks at the challenges, some potential solutions, illustrated by some recent project examples, particularly in the ‘new’ environment since 2012. BACKGROUND There is a wide range of options available to operations and projects wanting to spend capital (Luxford, 2006; Hunter and Broome, 2008; Revy, 2008; Lane and Clements, 2012). Looking through them, one can identify the following six points: 1. The classic ‘in-house’ owner’s team with several ongoing projects, who know the owner requirements well and have developed systems and techniques attuned to the site. 2. The ‘hybrid owner’ model where a trusted outside small group coordinates the project. This has many of the advantages of the classic ‘in-house’ but can be more flexible in handling a variable project portfolio. 3. The ‘owner project team’ where a specific team is recruited for the project. Typically, this works well for a substantial complete project cycle of some years, for example prefeasibility study (PFS) to definitive feasibility study (DFS) (Hunter et al, 2009), to execution and commissioning. 4. The traditional ‘engineering, procurement, construction and management’ (EPCM) approach where the owner’s team engages a substantial study-execution team on a reimbursable basis (Loots and Henchie, 2007). The EPCM acts as the project’s ‘arms and legs’ under the direction of the small owner’s team. The owner is ultimately responsible for the project. The ‘long-term reimbursable alliance model’ is a variation of this, where the EPCM imbeds a long-term core team into the owner structure and uses that to generate project deliverables and services. 5. The lump sum, engineering, procurement and construction (EPC) or design and construct (D&C) approach where the owner’s team carries out substantial definition and invites lump sum prices for a well-defined scope-of-work with the intention of having minimal variations upon execution. This involves potential risk for both parties because of the tight contract definition, transfer of risk and the issue of variations (if and when they occur). 6. The technology driven project where the owner’s desire to involve a new, improved, or even revolutionary technology provider or partner in the project (Wasmund et al, 2011). The driver here is the technology provider and the execution model is ‘adapted’ to meet the needs of the researcher/technology owner or developer as the owner deems the greater execution risk is outweighed by the perceived advantages of the technology. The chosen model will be governed by: •• company policy 108 •• practice and history •• options available in the market place •• degree of technical innovation •• competitive climate •• owner preferences. The above list is not exhaustive and often combinations and hybrids are adopted to fit. In the current climate of minimal capital expenditure, fierce competition and an industry demand for predictability and economy there has been a strong trend towards lump sum and well-defined scopes rather than the more flexible reimbursable models. This approach, however, does demand larger and more skilled owner teams and may also involve greater preparation time and earlier project expenditure on early contractor involvement (ECI). A key (and often overlooked) consideration for a project typically going through the phases of studies, early involvement and approvals, engineering and execution, is that of trust and predictability between the parties. This is much treasured and encapsulated in the salutation ‘no surprises’. Constant multilevel open communication, sharing openly the inevitable project challenges, and accurate forecasting, are intrinsic to achieving this aim. In summary, there are many project models and a large number and variety of providers who are hungry and keen for work. DRIVERS AND TRENDS Drivers in the new environment The industry itself and the associated METS area are acutely aware of how the industry has changed since 2012. The previous extraordinary emphasis on capital expenditure (and poor discipline in operating costs) in the drive to maximise production and capacity in the buoyant price environment has been very rapidly replaced by a completely new discipline and ethos. This is where capital expenditure is very constrained and mainly focused on essential HSEC drivers and often only where there can be a very rapid return on expenditure. ‘Brownfields’ has become the main area of focus with the aim of minimising operating costs with particular emphasis on ‘debottlenecking’ and ‘incremental efficiencies’. Many areas of previous outsourcing and use of contractors have now been returned to owner involvement as this is perceived (often correctly) as adding value and promoting increased owner awareness of operations and options. Particular drivers that can be identified include: •• a complete change in focus from production and tonnage maximisation to capital and operating cost discipline (Clarke, 2015) •• an acute bottom down driven capital expenditure discipline and budget •• a fundamental review of operating practices and expenditure on operating costs •• changed philosophies towards outsourcing and service provider models •• changed perceptions by financiers and investors on the sector’s prospects, relative attractiveness, future profitability and drivers; this has totally changed the environment for the industry at all levels •• the owner/operator view that the extraordinary demands up to 2012 for services had resulted in bloated costs (and charges) from the METS sector and we are metallurgists, not magicians Upgrades, modernisations, automation and expansions … where will the expertise, capability and skills come from in the future? poor performance in terms of productivity, relative international costs and project efficiency •• competition for resources (particularly in engineering, project management and construction resourcing) was a particular factor with coincident buoyant commodity pricing in energy and the ‘once in a generation’ establishment of the huge regional liquefied natural gas (LNG) projects in Western Australia, Queensland, Northern Territory and Papua New Guinea •• commercial discipline was viewed by many owner/ operator organisations as having been compromised during the boom and needed to be ‘normalised’ •• many services organisations had expanded laterally, usually in response to client demand, into extra services outside their traditional core business. This was therefore a new paradigm for many in the industry. There were memories of years like 1987, 1992–1993 and 2001–2002 where downturns had occurred, but the speed, depth and completeness of the 2013–2016 downturn has been viewed as almost unique probably due to rapid industry growth in the decade to 2012. Recent trends This paper has not tried to identify specific trends, which can vary by company size, history and specific practices, geography and commodity, but have chosen those that in our view are the most germane and relevant to the Australian industry in 2016. Obviously in the current environment, we are faced with issues, such as high industry unemployment and underemployment particularly at graduate level, and also in geosciences, engineering and construction, as well as much reduced overall spend on services by the industry. Relevant trends include: •• a much reduced new project study and execution capacity and capability •• capability and project teams becoming concentrated into fewer regional and global centres (for example, Perth, Brisbane, Toronto, Vancouver, Santiago and Johannesburg), and many former ‘powerhouses’ having little real capability now (for example, Melbourne) •• the increasing usage (particularly with demonstrated and consistent performance) of ‘best value engineering centres’, such as those in Mumbai, Delhi, Dubai, Shanghai, Kolkata and Manila. It does take time and real corporate commitment to incorporate this potential into reality and to achieve consistent performance •• in-sourcing of many aspects for projects and execution, and the re-emergence of some internal engineering teams within organisations •• a much more rigorous contractual, commercial and cost environment •• a trend back to longer term alliancing often with innovative and open commercial arrangements •• a very open dialogue between owners and potential or incumbent service providers •• opportunities for small and single-person consultants and contractors, particularly for studies, audits and upgrades •• realisation by owners that significant technical and productivity gains can only be achieved by longterm alliances and joint developments with ‘original equipment manufacturers’ (OEMs), research and technology developers and leading edge service we are metallurgists, not magicians providers. These arrangements tend to be more specific and early results driven compared to those of the early 2000s which were more industry wide and often driven by the research or developer partner •• a much higher degree of accountability in providing services or solutions is being demanded •• the highly competitive new environment has concentrated the industry to fewer large providers and several new smaller entrants. The more junior sector for instance, looks for early study engagement with commitment to their project and financing demanding a lump sum or EPC approach. This requires a nimble, client centric and innovative execution model well removed from the reimbursable EPCM model of the early 2000s. WANTS, NEEDS AND ISSUES We have previously discussed the industry trends and drivers, and will now focus on the wants, needs and issues of the models presented earlier. Classic ‘in-house’ owners team Generally, a larger organisation with multiple sites and a history/confidence in client knowledge/alignment and projects delivery coupled with well-developed systems. This requires: •• competence and alignment •• commercial/contract agreement •• a predictable costing model justifiable to management •• ability to align with corporate HSEC imperatives •• comprehensive systems aligned to the owners •• adherence to project milestone expectations/ commitments. Hybrid owner model Here a specific outside team is recruited to act as the owner, usually on a single project or program. What is required includes: •• a high degree of comfort and trust in the service providers •• a willingness to align and provide/source the areas that the owner team are unable to provide •• a staged and flexible commercial arrangement with a high degree of openness/transparency •• ability/willingness/appetite for varying execution models and partners (note that systems alignment can be an issue as can process coordination, so specialist help in these areas may be needed. Often metallurgical process expertise is provided by an outside expert who may have historical owner links.) Owner project team The owner project team may be used for a longer term or larger project of a cycle of some years. This is particularly so for a larger EPCM project where the owner team needs the authority and expertise and risk assumption inherent is such arrangements. Special owner challenges exist for this case, which is basically a combination or version of the two already considered, and includes: •• the use of systems and procedures that fit both the parent owner and the contracted EPCM •• retention and alignment of the team 109 R Coleman, J King and T Hunter •• decisions as to the degree of intrusion/checking into the EPCM and the degree of alignment and trust with the EPCM (the ‘man matching’ syndrome) •• project manager alignment, retention and drivers can be an issue. There are many contractors who are very comfortable to work on the owner side in this team environment and it fits well in career development. One challenge is that each brings a unique experience, preferences and skill set and that team alignment particularly on systems use can be a challenge. Traditional engineering, procurement, construction and management The EPCM approach is where the owner’s team essentially uses an ‘agent’ to perform most of the tasks under the direction of the owner team. This has worked well in the past but perceived shortcomings were evident to many in the period of 2002 to 2014 (Walker, 2015; Moore, 2015). These issues involved: •• a shortage of skilled project personnel for both EPCM’s and owners led to issues with team retention, incentivisation, alignment and performance •• intense competition for people driving up rates and affecting productivity and quality •• excessive ‘project churn’ exacerbated these issues of people (turnover) •• the traditional clear delineation of owner and contractor roles, functions and responsibilities became a real issue. It should be remembered that EPCM had evolved in the industry to provide a solution to the need to efficiently exercise projects in a timely manner with maximum owner control and accountability. When properly done by competent teams in a ‘normal’ market it is still an efficient and well understood project mechanism. A recent trend has been to use the EPCM model and expertise for longer term ‘alliancing’ where the client selects one or more alliance partners (usually from traditional EPCM practitioners) to work on a longer term embedded basis in the owner team. The intention is to have a dedicated team that is able to cover internal project generation, definition, approvals, execution, commissioning and alignment. This has long been the norm in the oil-gas-petrochemical area and combines the advantages of a competitive contracting environment with dedicated owner teams who build-up client and project familiarity and expertise, and project execution efficiency. Lump sum engineering, procurement and construction The lump sum, EPC or D&C approach involves slight variations on a simple execution method namely that the project is defined by the owner who invites bids to do the complete job. The issue for the owner is in defining the scope of the project in sufficient detail to enable a contractor to cost and price their bid. Likewise, such an effort by the bidders is very expensive in terms of dollars, commitment of experts, the level of detail and clarifications needed, and in time taken. It would not be unusual for a mid-size concentrator (if defined to a 30 per cent engineering level) to take six to nine months to arrive at a bidding cost commitment of some millions. The issues here are: •• the level and certainty of pre-work by the owner’s team to reach the stage where it can be bid •• the discipline required by the owner’s team in resisting change, documenting and affirming variations and using the systems needed for project tracking 110 •• for the contractor, the commitment to bid will only be made with a good certainty of project actually happening, a high probability of bidding success and a level of comfort as to the owner’s competence and financial strength; often a contractor will strive to have an ECI status where they are paid (partially or wholly) to invest the resources to give a bid •• a lump sum bid by a substantial competent contractor is very important to project participants such as banks and other lenders/financiers. Some owners believe the risk is lowered once this approach is adopted and that all risk is now with the contractor. This is certainly not the case as a good owner’s team needs to check quality and progress, ensure what is being built is consistent with owner expectations and the contractors obligations, and to track and document inevitable variations. Technology-driven project All the above approaches have assumed conventional, well-proven technology and process and would be greatly complicated by new, first-of-a-kind or largest-yet-built technology. The main driver in such projects is the special needs of the process or technology provider and the degree to which the execution strategy and practice needs to be adapted. These particular technology drivers may mean that the OEM or technology provider (TP) may adopt any of the above roles in addition to their speciality one and may have a great influence on the project model adopted and the project participants. Areas of particular importance are: •• the relationship, confidence and trust between owners and OEM/TP •• the level of development and maturity of the technology – there is a vast difference between a larger sized piece of conventional equipment and a completely new multiphased, integrated hybrid process only proven at demonstration scale; for example, mineral processing with hydrometallurgical and pyrometallurgical downstream steps (Mezei, Todd and Molnar, 2006). •• clear definitions of roles and responsibilities need to be agreed and formalised with minimal number of interfaces •• the program needing to recognise the complexities by having good ‘float’ and a realistic commissioning/ ramp-up schedule •• multiparty involvement imperatives and complex reporting •• each participant needing a technology ‘champion’ who believes that the project/process complexities are outweighed by the advantages and potential. COMMERCIAL CONSIDERATIONS The typical execution models and study/practitioner issues have been examined but often of overriding importance will be the broader and detailed commercial matters. For the asset owner, these include: •• Risk profile and factors – a formal risk register needs to be completed early and agreed internally by stakeholders. It is often useful to do two; one from the owner viewpoint and the other from that of potential contractors. This helps in alignment later and identifying/quantifying areas of potential dispute. A fundamental element of risk mitigation on a project is that the particular risk should always be allocated to the party best able (or willing) to manage that risk. If a party is uncomfortable we are metallurgists, not magicians Upgrades, modernisations, automation and expansions … where will the expertise, capability and skills come from in the future? or unfamiliar with the particular risk it will be the subject of excessive provisioning and uncertainty. •• Is the potential contractor capable of completing the task through to a satisfactory outcome? Factors such as: history, capability, capacity, team competence, contractor internal execution model, subcontractors, reference projects, reliance on variations for commercial means should all be considered. This is often referred to as ‘the smell test’. •• The importance of project staging, particularly with a large venture or one involving greenfields or new technology features. This could involve multiple stages from initial study/PFS/test work/pilot plant through DFS, engineering, execution and commissioning. Is the contractor capable of these? •• Is the owner potentially committed for some years of working productively with that contractor? •• Should an execution model be adopted which plans for use of multiple contractors at different stages whilst ensuring project knowledge is not lost? •• The execution model commercial/contract environment will be fundamentally determined by whether it is reimbursable or lump sum. For a lump sum, very careful and detailed definition of scope is required and intrinsically the contractor will build in a risk premium and the cost of detailing variations. Conventionally this is estimated at about 15 per cent above that estimated with a reimbursable contract where the owner has a much higher risk commitment but also greater flexibility in changing scope. •• The contract set-up needs to reflect the fundamentals of how the job is being done and be consistent with the practicalities of the parties’ performance. If it is too one-sided, it will engender undesirable outcomes as the lesser party protects its interests eg excessive liability penalties will mean a behaviour focused on avoiding those outcomes and this may be inconsistent with the best overall project result. There are many studies into project performance and the factors behind underperformance or failure in the oilgas-petrochemicals area and more latterly in the minerals industry. The major conclusion for successful performance was the degree of front-end loading (FEL) on a project; the more resources, effort, project team involvement and early engagement of the contractor(s), the better. This would be backed up by rigorous benchmarking and stage gate approval processes. Such systems have been adopted more widely in the minerals industry over the last ten years, with some notable successes. The system does, however, add earlier time and costs to a project, but this is ultimately vastly cheaper than making the mistakes later in execution. It does require a high degree of owner discipline and commitment, systems and project team talent and input. EXAMPLES Some indicative examples of recent projects will now be provided. We acknowledge that there are many competing models, companies and service providers in our industry who energetically compete and this is very healthy. The project developer faces the task of deciding how best to do the project and with whom. As a global supplier of equipment, industry solutions and services, and a developer of new technology and techniques, we are metallurgists, not magicians Outotec itself adapts with its customers and for specific applications the preferred execution models, partners and commercial model. There is no ideal single solution. We acknowledge that there are very competent competitors and alternatives, ensuring owners have good choice with their projects. The opinions expressed on these selected examples are those of the authors and are intended to generate ideas on project improvement and how the optimal execution strategy can be selected. Alliances ‘Alliances’ are very case- company- and site-specific and can cover the whole gamut of studies, engineering, approvals and review, construction and execution, and commissioning, upgrades, modifications, debottlenecking and operations/ maintenance. There are many advantages for these arrangements particularly for larger, multisite operations such as Tronox, Alcoa, South 32, Rio Tinto and BHP. Owner management of the Alliance is best done with a specific dedicated internal resource and an appropriate sponsorship and hierarchy. The ability to Alliance with global miners is seen as a key business imperative with many service providers who also emphasize the need to align with the customer’s systems, procedures, standards, reporting systems, approval hierarchy and build-up ‘corporate and plant knowledge’ amongst the seconded employees. A key issue with the seconded team can be that they, over time, identify more strongly with the owner than with their parent service organisation. Jacobs is a good example of the effective use of Alliances. Jacobs have 30 years of experience in creating value within the framework of alliance relationships which has led to the development of their alliance approach (Jacobs, 2013). Their approach is based on the understanding that there is no ‘one size fits all’ formula to forming a successful alliance/ partnership. Each one has to be tailored to the objectives and goals as well as the needs of the client. Jacobs have developed a range of models of Alliances. They all have somewhat different characteristics but all have the common goals of continuous improvement and bringing best practices and lessons learned to their client’s business. More than 60 per cent of their revenue is currently generated through Alliance-type relationships. Therefore, forming and maintaining healthy alliances that continually deliver value to their clients is key to their success. Owner project team Masan Resources (MR) in Vietnam has developed the Nui Phao polymetallic project some 70 km NW of Hanoi and this is a large modern project producing a large range of tungsten products, chemical grade fluorspar, bismuth metal and copper-gold as a concentrate (Masan Resources, 2016). The process plant is specific and complex involving many process steps and unique metallurgically (Morgan, 2016). Establishment of the project emphasized local capability with western (Australia-India) engineering, along with procurement and construction by the owner. For the rampup/debottlenecking/process optimisation phase, MR chose to use a model of a strong plant site metallurgical team, supported by a specialist engineering owner’s team in Australia. Emphasis was put on partnering with OEMs /service providers and maximising the use of in-country construction capability. Projects are fast-tracked, fit-forpurpose and aggressively managed to align operations, plant improvement, OEMs and technology suppliers and the in-house team. This has enabled stepwise and regular 111 R Coleman, J King and T Hunter improvements in plant performance at appropriate cost and tight capital control. A similar approach has worked very well recently at the Didipio project in Luzon, Philippines, operated by OceanaGold (Walker, 2013). Hybrid model Carmen Copper Corporation (CCC) is a copper concentrator situated on Cebu Island in the Philippines. The concentrator was originally commissioned in 1955, and operated until 1994, when low copper prices forced the mine to cease production. The mine was rehabilitated in 2007 and brought back into production at a rate of 40 000 t/d, as outlined by Morgan et al (2014). The decision was then made to increase the production from 40 000 t/d to 60 000 t/d. The decision was also made to utilise existing installed equipment as far as possible to reduce costs. The client wanted a world-class project, with modern process controls, utilising in-house capacity for construction, and low cost detailed engineering. This resulted in a hybrid model being utilised for the project: •• metallurgical test work program designed and managed by CCC •• Outotec contracted to carry out the detailed design, including a 3D model of the plant •• a local Philippine company contracted by CCC to do the detailed engineering •• Outotec supplied and installed all the proprietary equipment •• CCC procured all non-Outotec proprietary equipment •• construction carried out and managed by CCC •• Outotec provided expert advice including construction where requested •• CCC managed the commissioning supported by vendors and expert advice from Outotec when required. CCC selected the above contractual model to fast track the project compared to the standard EPC/EPCM model. This enabled early works to be carried out facilitated by utilising existing labour structures, circumventing the usual mobilisation phase of traditional projects. The project was designed, constructed and commissioned in 20 months from receipt of a letter of intent. This was an excellent result considering that the base starting document was a PFS, compared to the standard practice of first doing a DFS as a minimum. Lump sum early contractor involvement Alkane Resources Dubbo Zirconia Project (DZP) has one of the world’s largest in-ground resources of rare metals and rare earths (Alkane Resources, 2016). The mine is expected to process 1 Mt/a over a period of 70 years or more. The DZP will produce zirconium, hafnium, niobium, yttrium and rare earth elements. This complex metallurgical plant flow sheet fits in very neatly with the suite of process technology that Outotec has developed over many years. Outotec was engaged on an early contractor involvement (ECI) basis for the project. The set-up is as follows: •• initial value engineering phase – reviewing the front-end engineering design (FEED) study carried out by others, identifying gaps and opportunities for cost savings, and process enhancements •• technical input into the pilot plant test work program ensuring that the process is fully tested, and all market and vendor sample needs addressed 112 •• sufficient basic engineering on an open book basis to derive an EPC cost for the project •• fixing a mutually agreed EPC price •• EPC project execution. This represents a very flexible contracting model aimed at reducing the risks for both parties, and therefore reducing the risk premium associated with a traditional EPC contractual model. This approach facilitates the client operating with a small owner’s team, in line with an EPC strategy. The initial design phase to produce a fixed EPC price is based on a collaborative open book basis ensuring that Alkane has sufficient input into the plant design and the costs, before signing the EPC contract. This staged approach is designed to reduce the risks of both contractor and client, utilising the prior client knowledge in the design, then agreeing on a mutually acceptable EPC price. Build–own–operate and build–own–operate–transfer models Outotec has recently delivered a total system solution for a client in Australia to meet their underground mine backfill and operational needs (Suvio et al, 2016). The contract included an extensive backfill test work program, backfill plant and underground piping EPC, system commissioning, complete mine backfill system operation and maintenance. This represents a classic build–own–operate (BOO) contract. This contract contains a higher level of backfill engineering and expertise and provides the customer with unique expertise in state-of-the-art mine backfill engineering and plant operation. The major customer advantage is a lower cost operation, operated entirely by Outotec and providing the customer with lower risk to their mining operations throughout the life-of-mine. This type of contract represents the ‘Ultimate Process Guarantee’ as the contractor carries the full financial, performance, operating and maintenance risk providing an over the fence service to the client. THE FUTURE Looking to the future, we need to make some assumptions before venturing into this crystal-ball space. We have assumed a period of three to four years, with the industry capital activity relatively restrained as it is at present. Whilst this is hopefully a pessimistic view, we believe it is prudent and consistent with many of the industry commentators and the predictions made below: •• more contractual, commercial disputes than hitherto •• the EPC model will continue to be more attractive than the reimbursable EPCM method •• alliancing in all its forms will be a growing trend •• dedicated owner teams for projects will be more widely recognised as vital in terms of project success, necessity and continuity •• there will be very few ‘new technology’ projects and plants as a result of owner conservatism and the muchdiminished recent capacity of in-house and industry collaborative research, development initiatives •• process plants will become more complex and often incorporate ‘hybrid processes’ eg mineral processing with hydrometallurgy •• innovation will be directed to ‘peripheral’ areas such as water recycling/treatment, energy usage, advanced process control, remote operation and control, and we are metallurgists, not magicians Upgrades, modernisations, automation and expansions … where will the expertise, capability and skills come from in the future? tailings management, as areas to give the greatest predictable advantages. Alternatively, if there is an appreciable recovery in metals prices and market demand, we would expect that many of the recent excesses and problems that emerged in 2008 to 2013 will be repeated or even exaggerated. The capacity of the industry for projects, from a skills and coordination viewpoint, will be much reduced due to recent events. One could foresee a need for strong self-discipline and clear thinking to avoid past issues. ACKNOWLEDGEMENTS The authors thank several Outotec and industry practitioners for their input and comments, with special thanks to Alan Dennis. The support of Outotec’s management is acknowledged. As the authors collectively come from backgrounds covering operations, research and development, project development, equipment and solutions supply, services delivery and studies, we have tried to use that experience to give a balanced and wide view. A keynote opinion piece does involve judgement and personal opinions and is intended to engender debate and discussion. As such, it is acknowledged that there will be a necessary degree of interpretation and personal opinion. The authors are happy to discuss this aspect and are open to further elaboration or modification of their stated positions in this paper. REFERENCES Alkane Resources, 2016. Website homepage [online]. Available from: <http://www.alkane.com.au/index.php/projects/currentprojects/dubbo/project-overview> [Accessed: 14 April 2016]. Austmine, 2013. METS National Survey [online], in Australia’s New Driver for Growth, funded by the Department of Industry, Innovation, Climate Change, Science Research and Tertiary Education, p 2. Available from: <http://www.austmine.com. au/Portals/25/Content/Documents/Austmine%20Survey%20 Highlights.pdf>. Clarke, N, 2015. Improving productivity in processing operations, paper presented at The International Mining and Resource Conference (IMARC), Melbourne, November. Federation University, 2014. Skills and Innovation in the Resources and Mining Sectors. Fiscor, S, 2015. Copper at the crossroads [online], Engineering & Mining Journal. Available from: <www.e-mj.com/features/5307copper-at-the-crossroads> [Accessed: 12 June 2015]. Hunter, T C, 2014. Concentrators – past, present and future trends for operators and service providers, in Proceedings 12th AusIMM Mill Operators Conference 2014, Townsville, p 3 (The Australasian Institute of Mining and Metallurgy: Melbourne). Hunter, T C and Broome, A J, 2008. Current trends in project delivery to the minerals industry, paper presented at The AusIMM New Zealand Branch Annual Conference. we are metallurgists, not magicians Hunter, T C, Borthwick, J, Douge, M and Yusi, M, 2009. Project feasibility studies – a necessary step or the best opportunity to add value and certainty?, in Proceedings Project Evaluation 2009 Conference, pp 35–48 (The Australasian Institute of Mining and Metallurgy: Melbourne). Jacobs, 2013. Partnering/Alliances white paper, Jacobs. Lane, G and Clements, B, 2012. Operations versus projects – how do people think and what are the implications?, in Proceedings 11th AusIMM Mill Operators’ Conference 2012, pp 11–15 (The Australasian Institute of Mining and Metallurgy: Melbourne). Loots, P and Henchie, N, 2007. Mayer Brown article, worlds apart – EPC and EPCM contracts: risk issues and allocation [online]. Available from: <http://fidic.org/sites/default/files/epcm_ loots_2007.pdf>. Luxford, J, 2006. Project development and construction management, in Proceedings International Mine Management Conference, pp 97–105 (The Australasian Institute of Mining and Metallurgy: Melbourne). Masan Resources, 2016. Website homepage [online]. Available from: <http://www.masangroup.com/masanresources/en/projects/ nui-phao/highlights> [Accessed: 10 April 2016]. Mezei, A, Todd, I and Molnar, R, 2006. Can complex hydrometallurgical pilot plants effectively reduce project risks? Part 1 [online], SGS technical paper 2006-2004. Available from: <http://www.sgs.com/en/mining/metallurgy-and-processdesign/pilot-plants>. Moore, P, 2015. EPCM and contracting – adapting to conditions, International Mining, February, pp 78–86. Morgan, S, Serdzeff, S, Malaloy-On, C and Pagdalian, L C, 2014. The benefits of technology partnerships during brownfield upgrades, in Proceedings 12th AusIMM Mill Operators’ Conference, pp 471–476 (The Australasian Institute of Mining and Metallurgy: Melbourne). Morgan, S, 2016. Performance and safety optimisation in Vietnamese operations, in Proceedings Regional Technical Conference Mining Vietnam 2016 (Mining Media International: Melbourne). Revy, T, 2008. Trends in project development: where are they heading? [online]. Available from: <http://www.ibram.org.br/ sites/1400/1457/00000190.pdf>. Suvio, P, Palmer, J, del Omo, A and Kauppi, J, 2016. Holistic tailings management solutions [online]. Available from: <www.outotec. com>. Walker, S, 2013. Didipio: a Philippines success story [online], Engineering & Mining Journal. Available from: <www.e-mj.com/ features/3502-didipio-a-phillipines-success-story> [Accessed: 10 December 2013]. Walker, S, 2015. The EPCM perspective [online], Engineering & Mining Journal. Available from: <www.e-mj.com/features/5029the-epcm-perspective> [Accessed: 05 March 2015]. Wasmund, B, Voermann, N, Haneman, B, Sarvinis, J and Sheehan, G, 2011. Implementing new technologies in metallurgical processes: building plants that work, in Proceedings 50th Conference of Metallurgists, pp 1–19 (Canadian Institute of Mining, Metallurgy and Petroleum: Montreal). 113 Contents Is an 80th percentile design point logical? D David1 ABSTRACT Clearly, a plant designed only to treat average ore at the nameplate rate will fail to achieve nameplate in any typical year. To insert the necessary capability to achieve nameplate it is common process engineering design practice that a plant must be able to treat an ore with 80th percentile value (hardness or competence values for example) at the nameplate rate. In the author’s experience, apart from a couple of notable cases, this has been applied reasonably well as a principle, with widespread success. However, in a number of recent instances it became clear that the use of the 80th percentile number would have resulted in significant under-design of the plant. This paper makes the case that the 80th percentile, as a principle, can have serious flaws and its use needs to be assessed on a case-by-case basis. The discussion in this paper is the first step in developing a new design principle, and the associated methodology for selection of a design value, that will ensure plants are designed to achieve their nameplate capacities. INTRODUCTION Designing a process plant has many conventions that are often taken for granted. One of these is that the 80th percentile value of a key measure, like the Bond ball mill work index (BWI), will provide an unquestionable margin of design safety in the plant. The normal procedure is to take a set of test results, for example 20 individual BWI values from around the orebody, arrange them largest to smallest and take the 16th largest value. This is placed in the design criteria as the 80th percentile, usually alongside the average BWI value, and is subsequently used to design the ball mill. Many years later that number can assume almost legendary status as the work index of the deposit or it may have assumed infamous status as being the main cause of the failure of the plant to achieve nameplate throughput or grind size. The purpose of this paper is to explore circumstances where the 80th percentile value will not provide a definitive design point. Guidelines for avoiding being fooled by a false design value are provided, together with the basis for alternative design methodologies. PROBLEMATIC DATA SETS The annual plan If the 20 values of a particular measurement are provided from a 20-year annual mine plan, then failure to design for variability for that measure is virtually assured. One of the most common values that dangerously makes its way into design criteria from mine plans is head grade. 1. FAusIMM(CP), Technical Director – Process, Amec Foster Wheeler, Perth WA 6000. Email: dean.david@amecfw.com A recent analysis of copper (Cu) head grade for a project determined the variability of a number of related data sets ranging from the most inherently variable to the least. The most variable data sets are those that look at the orebody in individual parcels that may represent minutes or hours of plant feed. Two examples of such data (present in virtually all projects) are the drill database and the block model. At the other end of the variability scale is the annual mine plan. To arrive at the annual mine plan it is normal to use the individual ore blocks contained in the block model in an orderly and controlled fashion. The use of blocks (in an open pit example) is orderly because it commences at the surface and must progress downward in some logical mining sequence. The use of blocks is controlled because it is typical to attempt to obtain a target head grade to the process plant when making selections from the blocks that are immediately available to be ‘mined’. In many cases there is also a stockpiling system in place (usually incorporated into the block sequencing procedures) between to the mine and process plant to allow grade control to be achieved when the mine cannot directly provide it. Usually the measure being controlled is the head grade of the most valuable component, and this also is the measure for which believable variability information is required for design. 115 D David Almost immediately upon arrival at a copper mine for commissioning the author was greeted with the bunded flotation area of the plant freshly filled with copper concentrate, mostly from the cleaners and recleaners. The launders and pumps were continuing to overflow. On asking what had caused the problem, the response was that the plant had been processing 8 per cent Cu in feed for the last day and they couldn’t do much about the problem immediately as the stockpile was full of 8 per cent Cu ore! The design criteria for this project were, in theory, prepared on an even more conservative basis than the 80th percentile because the ‘maximum’ grade had been used (100th percentile). This value was 1.6 per cent Cu and, obviously, nowhere near what was being dealt with by the plant. Although this value was in the design criteria, the maximum case mass balance assumed a head grade of only 1.39 per cent Cu, the 80th percentile value. Both the 100th percentile and the 80th percentile values were selected based on the data in the annual mine plan. An actual example from a design study of the variability levels for the various data sets described at the commencement of this section is shown in Figure 1. The ‘upper and lower limit 95 per cent’ lines represent the range that contains 95 per cent of the data within that particular set. Note that this is not the same project that had the 8 per cent Cu in flotation feed problem. This ore has less variability and an average grade of only 0.51 per cent Cu. The 80th percentile value for the shift data set is 0.91 per cent Cu and this would be a reasonable value to use for design purposes. The shift data set also predicts that the plant can expect to treat 1 per cent Cu (or greater) in feed for 2.5 per cent of the time (the ‘Upper Limit 95’ is actually the 97.5th percentile value) which is 27 × 8 hour shifts per annum, or more than two per month. Clearly choosing to use the 80th percentile annual, monthly or weekly mine plan Cu grades for design purposes would dangerously underestimate the real Cu grade variability that the plant must be able to process. Interestingly, the core database 80th percentile would also underestimate the shift 80th percentile value, while both the metallurgical test data set and the block data 80th percentile values would be acceptable estimates. However, all three small-sample data sets overestimate the Upper Limit 95 value by at least 100 per cent compared to the shift data. When put in the context of real operational requirements for a process plant, it becomes clear that the even a weekly mine plan is not a valid source of process design information, let alone an annual plan. The composited sample To save money, a recent client had only conducted five sets of metallurgical tests at laboratory scale for a definitive feasibility study (DFS) level design. Minimal background information, apart from the data itself, was provided for a review. The five BWI values provided all lay between 11.1 kWh/t and 11.8 kWh/t. The standard deviation (SD) between the six tests was 0.3 kWh/t, approximately what is accepted to be the inherent repeatability of the BWI test itself. The standard deviation of the drop weight index (DWI) results was only 0.4 kWh/m3, which is again similar to the level of repeatability expected of that test. The 80th percentile of the five BWI values was only 2 per cent greater than the average value and the maximum value was only 3.5 per cent above the average. For the DWI result set, the 80th percentile value was only 10 per cent higher than average and the maximum value was not much higher at 13 per cent above average. There were two possibilities to explain these results, either the orebody was the first one in the author’s experience where the material was ‘all the same’ or, something very strange had happened in the constitution of the samples. In response to requesting more information, the core intervals making up each of the samples were provided. The source of the problem was immediately obvious and it was composite preparation. Through compositing all semblance of variability had been eliminated from the test samples. Each FIG 1 – Variability bands for grade data sets from a single orebody. 116 we are metallurgists, not magicians Is an 80th percentile design point logical? test sample was a composite of a minimum of 60 core intervals from a minimum of four different drill holes. The stated aim of this particular piece of work had been to define the properties of five different areas in the orebody. Obviously, it was confirmed that the five areas can be considered virtually identical, on average, with respect to ball milling. However, the test data set contains compositing that is equivalent to, at least, the level of compositing inherent in an annual mine plan (and maybe even equivalent to a five-year mine plan basis). As demonstrated in the last section, annual plan data is unsuitable because it contains a level of variability far below what is needed for safe design. Applying the relationship between annual variability and shift variability from Figure 1, it is possible to provide an estimate of what the true variability of BWI values might have been, had multiple contiguous samples been tested individually. From Figure 1 the 80th percentile value from annual mine plan data is only 10 per cent above the average value. In contrast, the 80th percentile on a shift basis is 74 per cent above the average value. Therefore, with the benefit of having all data sets available, a reasonable estimate of the design point, the shift 80th percentile, can be made from the annual BWI 80th percentile as follows: 80th BWI Shift = Average BWI + (80th BWI Annual – Average BWI Annual) × 7.4 This equation has been applied to the five-sample case above where the only data available has annual-plan-equivalent variability and is unsuitable for design purposes. The outcome of this calculation is a more believable 80th percentile BWI value of 13.2 kWh/t, 16 per cent above the average value of 11.4 kWh/t. Given the uncertainty in what the original data set actually represents, the real 80th percentile value on a production shift basis could be even higher. This example clearly shows the danger of relying on composited samples for design purposes. The circumstances behind these composites are extreme, but it must be recognised that any compositing reduces the inherent variability that will exist in the set of test results. Knowing how samples have been selected and prepared is essential to understanding the design implications of test data. As a variation on the compositing theme, in many projects tests have been carried out on annual composites (for example Year 1 composite, Year 2 composite etc). Taking an 80th or 100th percentile value from the set of annual composite results will, again, dangerously underestimate the variability the process design needs to cope with. Multi-modal ore properties Few orebodies consist of a single lithology or a single geological classification of material. In many instances (but not all) the comminution and separation properties of the different geological units can be distinctly different and need to be understood separately. If the geological differences also correspond to metallurgical differences, then the geological ore types are also valid geometallurgical ore types. In addition, each geometallurgical ore type will display a range of properties, and the proportions of each ore type in plant feed will vary from shift to shift and year to year. A classic example would be where the orebody has an oxidised cap, a transition zone and fresh rock at depth. The approach often seen by the author is for the fresh rock to be represented by 20 or more samples, the transition by five samples and the oxide by two, neatly matching their proportion in the orebody. we are metallurgists, not magicians Provided the samples have been selected correctly, it is certainly possible to derive a reasonable 80th percentile value for the fresh ore. Conversely, it is not even possible to estimate the degree of variability in key properties (let alone the 80th percentile values) that characterise the oxide cap using only two samples. If the oxide cap represents 100 per cent of plant feed for the first six months, then understanding the properties of that material is of reasonably high importance. The plant will be commissioned on that ore and it may play a significant role when banker’s tests and warranty tests are being conducted. In this situation, a minimum of ten spatially distributed samples of oxide ore need to be tested before the variability can be estimated. There is usually one guarantee with oxide ore, it will be more variable than the fresh rock from which it is derived. The transition ore presents similar problems, not least of which is definition. An ore is called transition because it is part way between the original rock (in this case fresh ore) and the geological layer above it (in this case the oxide cap). Invariably, the transition ore will contain examples of the end members (fresh and oxide) together with everything in between. The high degree of variability in typical transition ore demands that a reasonable number of samples be tested, provided of course that the transition ore type represents a substantial plant feed component for a long enough time period to be considered separately in the design process. The more components in the ore the more important it is to have detailed mine plans guiding the design process. The most common misconception for the inexperienced is that the proportions of each ore type in plant feed can be taken directly from the monthly or annual mine plan. The only way a realistic appreciation of the variability in ore type proportions can be gained is to understand how such ore gets from the mine to the plant. As an example, an orebody has two ore types with distinctly different comminution properties and these ore types are planned to be, on an annual basis, delivered to the plant in a 50:50 ratio. Simplistically the ore type properties can be averaged and then used for design. However, discussions with the geologists reveal that the first ore type is on one side of the orebody and the other ore type is on the other side of the open pit. Discussions with the miners reveal that they are only intending to have one shovel in ore at any one time and that there is no intention to set up blending stockpiles, as it is too expensive to double-handle all the ore. The 50:50 ratio is not a controlled 50:50 blend and will be sequential processing of one ore type, followed by the other. The resulting design requirements are totally different to the requirements for processing a controlled 50:50 blend. Where does the 80th percentile come into this discussion? The 80th percentile of the blend is obviously of little use. Each ore type now needs to be understood individually in terms of variability, and the number of test samples required has probably doubled. If the 80th percentile value is to be the basis of design, then the properties of each ore type need to be measured to the degree where a reliable 80th percentile value can be extracted from the results for each ore type. Before proceeding to design the plant to treat each ore type separately, a constructive discussion is needed across all three disciplines to explore the implications of alternative mining strategies. For example, introducing blending before the primary crusher or reducing the shovel size and having two (or more) ore faces supplying plant feed at all times. Beware of the argument that often comes up in such discussions that blending is happening in the coarse ore stockpile after primary 117 D David crushing. Unless the coarse ore stockpile is a bed blending arrangement where ore is stacked in layers and reclaimed across the layers, then it can be safely assumed that no blending of any consequence occurs in the coarse ore stockpile. VARIABILITY EXPECTATIONS Steve Morrell (2011) published the distribution of variability levels that exists within the sag mill competence (SMC) test database. Typically, SMC test samples are from contiguous core intervals and are done in numbers large enough (per orebody) to derive reasonable statistics. The variabilities of the drop weight index (DWI, in kWh/m3) results from the 650 orebodies represented in the database (at the time of his writing) were distributed as shown in Figure 2. For an orebody with an average DWI value of 5 kWh/m3 and a coefficient of variation (COV) value of 25 per cent, the 80th percentile value must lie between 25 per cent and 50 per cent greater than the mean value (between one and two standard deviations greater than the mean). An 80th percentile value of 7 kWh/m3 would not be unreasonable for this example. However, the COV could be any value in the range from 5 per cent to 60 per cent, so 80th percentile values of 10 kWh/ m3 and 5.4 kWh/m3 are also possibilities for a 5 kWh/m3 ore. All critical measures used for design will have a similar (but usually less broadly spread) range of possible variability values. Without having enough actual measurements from tests performed in the correct manner on appropriate samples, it is not possible to achieve a reliable estimate of variability for a particular property in an orebody. This statement also excludes the method applied in the compositing exercise discussed previously. Although the final 80th percentile estimate was superior to the estimate from the original data, it was also far from definitive. AN ALTERNATIVE APPROACH As has been demonstrated in the examples above, the 80th percentile value can be totally misleading and dangerous as a design point if the data set from which it is derived is not suitable for design purposes. In any data set typically available as a foundation for design, the average value will be a much more reliable number than the 80th percentile or the SD. In the example given for the effect of compositing, an estimate was made of a believable 80th percentile value based on an assumption about the variability differences known to exist between data sets calculated on varying time scales of production. Notably the adjustment was made relative to this well-defined value, the average of the data set. The method employing scaling of variability (or 80th percentile) between data sets is one alternative approach to selecting the design point. The concept of the 80th percentile is one that provides some comfort in design, but it is also one that is arbitrary. Why not use the 90th percentile, the 75th percentile or some other value? In a recent design project some criticism was provided in a review that the 80th percentile had not been used and reliance was placed on what was considered a riskier value, the 75th percentile. Regardless of the fact that the 75th percentile was the agreed design point with the client, the results database was revisited and the design outcome recalculated using the 80th percentile value. In this instance the difference was less than 0.5 per cent in the mill power, insignificant in the accuracy of the design. For this particular deposit the SD of the value in question was very low but the variability in the data set was considered valid for design. The data set consisted of about 50 results, all from individual contiguous samples according to an Australian Mining Exploration Companies (AMEC) sample selection plan. The insensitivity, in this instance, of the design outcome to the selected percentile value was of concern, mainly because the design point was not all that much greater than the data set average. This particular instance has led to a re-focusing of the basis of design towards using the mean value, rather than any high percentile derivative (80th or 75th) of the data set. Once the focus is on the mean value then the concept of ‘confidence’ can be introduced to design process. It is possible mathematically to derive the upper and lower confidence limits for a given mean value of a data population by knowing the number of samples in the population, the SD of FIG 2 – Distribution of orebody COV* values for competence measurement (after Morrell, 2011). *The coefficient of variation (COV) is the standard deviation divided by the average value, expressed as a percentage. 118 we are metallurgists, not magicians Is an 80th percentile design point logical? the population and the degree of confidence that is required in the mean value. The higher is the required confidence level, the wider the range of possible mean values for any data set. A range of possible mean values exists because, if exactly the same sample selection process was conducted on the same orebody, but different core intervals were chosen, the mean result from testing this second sample set is almost certain to be different to the mean result from testing the first sample set. Therefore, it is possible to know what the highest likely mean value is (the upper confidence limit of the mean) and Microsoft Excel provides a function to simplify this estimation. As the SD is an integral part of the calculation it is still necessary to re-estimate the SD to a higher value if compositing or annual planning has smoothed the available data set. Confidence can be thought of as the inverse of risk. You have selected good test samples, generated a result data set and you have averaged it. How do you know if your measured average value is a good estimate of the real average for the orebody? As an example, a set of ten results give a mean BWI of 9.1 kWh/t and the individual test results range from 7 to 12 kWh/t. As a designer, you are happy to work with a confidence level in the mean value of 90 per cent, as this means that the risk of your measured average being materially wrong is 10 per cent. A one-in-ten risk of being wrong is unacceptable to most designers but the catastrophic design risk level is more acceptable at one in 20. The 10 per cent risk associated with applying 90 per cent confidence limits is actually made up of two components. The first 5 per cent risk component is that the measured average is outside of acceptable limits on the high side. As a result, the real work index of the orebody is found to be even lower than the lower confidence limit. The design risk is that a mill that is unnecessarily large and powerful will be selected by using the 9.1 kWh/t average value. The second 5 per cent risk component is that the real average work index of the orebody is found to be much higher than the upper confidence limit. In this case the risk is that the selected mill will be too small and consequently nameplate throughput at nameplate grind size will not be achieved. Mill under-sizing can be a major risk to project viability because the revenue stream is likely to be compromised. For the set of ten test results in the example above, the 90 per cent confidence limits were calculated to be 10.1 and 8.1 kWh/t respectively. In accordance with the discussion above, there is a 5 per cent chance the real mean BWI for the orebody is greater than 10.1 kWh/t and the 9.1 kWh/t average value is too low and will compromise the design. There is also a 5 per cent chance the real mean is less than 8.1 kWh/t and a design based on 9.1 kWh/t will be conservative. As the catastrophic risk lies in under-sizing the mill the sensible designer will take 10.1 kWh/t as the average work index, rather than 9.1 kWh/t. The risk of overdesign is increased significantly but the risk of under-design is acceptable. Now consider if 40 samples were tested and the individual results all lay within the same range, 7 to 12 kWh/t, and the average was again 9.1 kWh/t. The 90 per cent confidence limits around this average value are much tighter and calculate to 8.6 and 9.6 kWh/t. The increased number of samples tested has increased our confidence in the measured mean and reduced the associated design risks. The sensible designer can now use 9.6 kWh/t as a safe average value with exactly the same risk level that existed when choosing 10.1 kWh/t based on ten samples. In selecting a safe design point the ten sample set forces the designer to assume that the average could be as high as 10.1 kWh/t. The 40 sample set allows the designer to lower we are metallurgists, not magicians the average by 0.5 kWh/t to 9.6 kWh/t. The 30 extra tests have probably saved $1.5 M in capital costs by allowing a smaller mill to be installed without compromising on design confidence. It is also clear that using the measured average of a data set always incurs higher risk than using the calculated upper confidence level for the mean value. Another good thing to check is if the upper confidence limit for the mean value calculates to be greater than the 80th percentile of the data set. Consequently, by using the 80th percentile value the designer is inadvertently designing with a number that may actually turn out to be less than the upper possible orebody average. This simple check shows definitively that too few samples have been tested for the inherent variability that exists in the orebody. Having demonstrated a method to find a safe average value (the upper confidence limit) it is now possible to construct a new design methodology based on estimation of data set SD coupled with the statistically-derived upper confidence limit of the mean value. It will be argued (in a follow-up paper) that such an approach is more robust than the tried, and often wanting, 80th percentile based method. CONCLUSION The 80th percentile value can be a useful design number, provided all the correct prerequisites are present in the population that it is derived from. These are: 1. The samples that the individual test results represent must consist of individual lengths of contiguous core, or something close to this ideal. 2. There must be some understanding of how the variability of the available data set is related to the variability that needs to be catered for in plant design. If a pathway to estimating shift-by-shift production variability (for any variable) is available, then this can provide useful guidance and should be followed. 3. There must be some relationship between the available data and the time sequence of presentation of ore to the plant. For example, if the ore that the plant is to be commissioned on is not clearly understood, then an adequate number of samples of commissioning ore need to be tested before commencing definitive design. 4. The relationship between the mining practices to be employed and the distributions of the various ores in the deposit need to be understood at an operational level, and not a smoothed monthly or annual ideal. It is essential that the process design engineers have access to all raw test data, and that they understand the basis of sample selection, they understand any compositing that has been performed on the samples and why it was done that way, and they have confidence in the testing that has been conducted. It is also essential to link the test results to the ore types and to the time sequence in which the ore is likely to be mined. Finally, the process engineers must understand the operational reality of ore access and delivery to the plant, including any assumptions regarding blending. A good start to gaining these necessary understandings is to ask the geologists for the drill database and to ask the mining engineers for a sequenced block list. The resulting conversations are usually very enlightening. If a valid 80th percentile design value is not obtainable from the available raw data, then a relatively simple pathway for estimating a useful 80th percentile value (based on the relative variabilities within available data sets) has been demonstrated. 119 D David To increase the confidence that can be placed in a design outcome, the basis for a new and robust design methodology has been proposed that is linked to a worst-case estimate of the mean value (at a desired accuracy level) and with a defined confidence level based on the client’s appetite for risk. gooey ore and the crunchy blue rock, they are both the same geological classification. Acknowledgement is also given to Steve Morrell, who has followed (and sometimes built) the pathway to understanding variability. ACKNOWLEDGEMENTS Morrell, S, 2011. Mapping orebody hardness variability for AG/ SAG/crushing and HPGR circuits, in Proceedings International Autogenous Grinding, Semiautogenous Grinding and High Pressure Grinding Roll Technology 2011 (eds: K Major, B C Flintoff, B Klein and K McLeod) paper 154 (Canadian Institute of Mining, Metallurgy and Petroleum: Montreal). Anonymous acknowledgement is given to those projects supplying examples, good and bad, used in this paper. Special acknowledgement is given to the geologist who advised (in an operating pit) that there was no difference between the brown 120 REFERENCE we are metallurgists, not magicians Contents Measuring and taking notice of orebody variability – an essential ingredient for reliable plant design D David1 ABSTRACT The majority of semi-autogenous grinding (SAG) and ball mill design methodologies are applied using a single design value for mill selection, such as the 80th percentile ball mill work index or SAG mill comminution (SMC) value. Inherent in the selection of this design value is a desire for the mill to accommodate unfavourable, but not absolute worst-case, feed conditions. It has been observed in numerous ‘postmortems’ of unsuccessful designs and also in many optimisation studies, that the selection of the design value has been poor. Statistical analysis of test work data sets shows that inherent variability in the data can, by itself, lead to design errors. Metallurgical testing is an attempt to measure the characteristics of millions of tonnes of ore using only a few kilograms of sample. In this paper, some realistic but synthetic test work data sets are used to explore old and new methods of defining the design envelope and subsequently selecting a reliable point. The aim of the paper is to provide practitioners with tools that reveal the adequacy (or otherwise) of metallurgical test programs intended to support various levels of project design. It also provides guidance as to how it is possible to statistically justify a comparatively high design point in the absence of adequate test data. INTRODUCTION The words ‘it’s all the same’ are regularly heard in relation to orebody properties and this phrase should always be an alarm bell to a mineral processing plant designer. Nature does not provide orebodies that have consistent properties and this means there will always be a range of values for any measure, be it for hardness or separation characteristics. Some of that variation in measurement comes from the repeatability of the measurement technique itself and this should not be confused with ore property variation. Test repeatability must be known and understood before using any test results for design purposes. The variation that will be discussed in this paper is the spread of test results that naturally occurs when a set of samples, each sourced from a different threedimensional location in an orebody, is tested. The degree of variability that is measured for the material will determine both the design envelope and the safe design point for that measure. It is easy to incorrectly measure variability through poor sample selection and through compositing of samples inappropriately. Correctly measuring variability leads to appropriate selection of design property values and this, in turn, leads to a process plant design that can achieve its nameplate performance requirements. QUANTIFYING VARIABILITY Ore variability measurement has two components. The magnitude of variability that is measured and the belief you can place in that answer. The magnitude of variability in a set of numbers is typically described as its standard deviation (SD). The SD is almost always stated together with the average or mean value. A typical example would be 10±1.0 where the average or mean is 10 and the SD is 1. 1. FAusIMM (CP), Technical Director – Process, Amec Foster Wheeler, Perth WA 6000. Email: dean.david@amecfw.com The belief you can place in that average value is called the Confidence Level. This is mathematically determined using an equation that includes the number of test results (n) and the SD value. As you conduct more tests you get more confident that you have actually measured the mean value and also that the SD magnitude is correct. A typical statement of confidence is that there is 90 per cent confidence in the mean to an accuracy of ±5 per cent. The statement ‘90 per cent confidence’ can also be 121 D David written as ‘one time out of ten’. So, if the mean was measured ten times (If the original calculations were based on a set of 20 correctly selected test samples then it is necessary to repeat this by measuring another nine sets of 20 correctly selected samples, 200 samples in all) we would expect nine of those mean values to be within 5 per cent of this first mean value. One of those readings would be expected to be greater than 5 per cent different from this first mean value. TABLE 1 Synthetic grindability data set. Sample Result (kWh/t) 1 10.5 2 9.5 3 8.8 Now if a 5 per cent error is enough to cause serious problems in the design then you have a one in ten chance of getting the design wrong. If a 5 per cent high result is acceptable but a 5 per cent low result is not, then things improve because confidence works both ways. The one in ten problem result could be a high result or it could be a low one. There is a one in 20 chance that the result will be high (greater than the original mean +5 per cent) and a one in 20 chance it will be low (less than the original mean – 5 per cent). Because only a low result is a problem we now have a situation where there is a one in 20 chance of the design failing. 4 11.0 5 12.2 6 10.2 7 10.5 8 11.6 9 8.4 10 8.8 11 7.9 Is this acceptable or do we need to be more accurate? Do we need to reduce the risk further? Do we simply overdesign and mitigate the risk? 12 10.6 13 10.2 14 9.8 15 9.5 The answers to all these questions depend upon the risk profile of both the project and the client. For new technology, a one in 20 chance of failure may be an acceptable risk level. For the application of well-established technology, it is usually expected that the design should have effectively no risk of failure, say a confidence level of 99 per cent or one in 100. 16 9.9 17 10.0 18 10.0 For a major mining house, where the project is one of many and access to expertise is relatively easy then perhaps a confidence level of one in 100 is also required. Often such a project will be competing with other projects in which the probability of success is similarly high. 19 11.1 20 9.7 For a junior miner with a single potential project and a high degree of capital sensitivity and time pressure, perhaps a one in 20 chance of failure is acceptable. It is up to those that would supply the money to determine if they should ‘take the chance’. Mean or average 10.0 kWh/t Standard deviation 1.05 kWh/t 90% confidence in average 0.39 kWh/t The unfortunate part about statistics is that uncertainty is not removed by analysis, it is simply quantified. For example, a one in 20 chance of failure means that the set of data you have generated and analysed could represent that one in 20 problem, but there is no way to identify this without more testing. Variability example To demonstrate the quantification and implications of variability a constructed example has been prepared. A set of 20 ‘results’ of Bond testing is listed in Table 1, but in fact, these numbers have simply been fabricated by the author to illustrate the points. The data set is plotted using an S-plot in Figure 1 to show its variability in a visual fashion. For comparison, a normal distribution line having the same mean and SD is also plotted. The comparison shows that the data set can be considered as closely following a normal distribution pattern. In other words, the data is regularly distributed above and below the mean according to known mathematical principles and that the SD is statistically valid. The 90 per cent confidence level in the average or mean value is 0.39 kWh/t. This means that if another 20 samples were selected and tested there is a 9 in 10 chance the mean will be between 9.61 kWh/t and 10.39 kWh/t. There is a one in 20 chance the new mean will be greater than 10.39 kWh/t and a one in 20 chance it will be less than 9.61 kWh/t. Literally, we have 90 per cent confidence after analysing these 20 122 FIG 1 – S-curve of Bond work index result set with normal distribution for comparison. samples that we know the mean of the orebody hardness to within 4 per cent either side of the measured mean value of 10 kWh/t. Making the simplistic assumption that SD can be applied across the full range of the data set, a first-pass design envelope can be prepared as is shown graphically in Figure 2. Because only 20 samples have been tested out of countless millions of possibilities in an orebody, we do not know exactly what the average Bond work index (BWI) is, we only know that it probably lies within the two red lines on the 50 per cent rank horizontal line in the graph. To draw Figure 2, it has been assumed that the confidence band remains unchanged at 0.78 kWh/t (2 × 0.39 kWh/t) across the entire range of the measurements in the data set. This is convenient and looks we are metallurgists, not magicians Measuring and taking notice of orebody variability – an essential ingredient for reliable plant design FIG 2 – 90 per cent confidence envelope around Bond work index data set assuming consistent standard deviation. FIG 4 – Design envelope after considering 90 per cent confidence in mean value and 95 per cent confidence limit in the standard deviation. sensible on the graph, but it is not correct as the confidence calculation has only provided information about the mean value, not the remainder of the distribution. There will also be uncertainty in the value of the SD. As will be demonstrated, the uncertainty in SD is more of a problem for traditional design methodologies than is the uncertainty in the mean value. Rank Confidence Limit (RankCL) at various ranking levels. The RankCL value is half the span from the upper line to the lower line. At the mean the 90 per cent confidence interval and the RankCL values are almost identical (0.39 kWh/t 90 per cent CI versus 0.41 kWh/t RankCL). Upper and lower limits to the value of the SD can be calculated from the data set using the method described by Sheskin (2007). From this BWI data set the calculated SD is 1.05 kWh/t but the upper limit for SD (to 95 per cent confidence) is 1.55 kWh/t. The lower 95 per cent confidence limit to the SD is 0.80 kWh/t. This method provides us with a measure of uncertainty about the level of uncertainty we think we have measured. When the design envelope is now modified (selectively) using this information Figure 3 is the result. The term ‘selectively’ is used because the envelope could have been drawn in a number of ways, but the calculation that maximises the possible data spread in the upper half of the graph has been used. This analysis clearly demonstrates that the range of possible values for a typical design number, like the 80th percentile value, are significantly less certain than the range of possibilities for the mean value. An alternative drawing of the envelope to emphasise the effect at the lower end of the data range would demonstrate a similar level of uncertainty in the 20th percentile ranking value as has been demonstrated for the 80th percentile ranking. When the maximum level of uncertainty is estimated across the full distribution the envelope can now be realistically drawn as per Figure 4. Figure 4 represents a much more realistic understanding of the uncertainty associated with choosing any percentile value in the distribution than is represented by Figure 2. This issue is further quantified by plotting what has been termed the In this data set the uncertainty in knowing the 80th percentile value is 0.71 kWh/t which is 75 per cent higher than the uncertainty at the mean. Uncertainty in knowing the 90th percentile is more than double the uncertainty in the mean. From Figure 3 and Figure 4, the lower limit (with 95 per cent confidence) for the 80th percentile design point is only just above the measured mean at 10.3 kWh/t. The upper limit is 11.7 kWh/t. The difference between these two values represents a 14 per cent difference in power requirement ultimately selected for plant design. The statistical analysis is indicating that these 20 measurements give a particular picture of the distribution of hardness in the orebody. However, testing another 20 samples from this same orebody and simply choosing the P80 value for design could have just as easily resulted in design points anywhere from 10.3 kWh/t to 11.7 kWh/t without being statistically inconsistent with the data set that has been analysed here. In a traditional analysis, the actual 80th percentile ranked data point is towards the lower limit of this statistical band at 10.6 kWh/t. The mathematically calculated 80th percentile value (using the Percentile function in Microsoft Excel for example) is consistent with the normal distribution curve at 10.9 kWh/t. The major point of this paper is to argue that these traditional estimates are inadequate for design using this data set because this orebody, sampled and tested in the traditional way could just as easily have provided a design point as high as 11.7 kWh/t. Alternative design point selection methods One obvious alternative is to choose a percentile rank higher than the 80th percentile that gets closer to the statistically valid upper limit of 11.7 kWh/t. The 90th percentile point is only 11.1 kWh/t and the 95th percentile point is 11.6 kWh/t. Therefore, in this data set the second highest measured value would become the design value. However, from Figure 5 it has also been shown that this 95th percentile point could easily be 1 kWh/t higher. FIG 3 – Effect on the design envelope of applying the upper standard deviation (SD) limit to the upper mean value and the lower SD limit to the lower mean value. we are metallurgists, not magicians If the normal distribution curve was used in mathematically calculating a percentile (rather than simply choosing the second highest measurement) it would be very safe to adopt the 95th percentile point (11.74 kWh/t). If the Excel percentile function was used, then the 90th percentile would also appear to be suitable as it gives a value of 11.55 kWh/t. 123 D David The ultra-conservative approach equation Design point = UCL90 + UCL95SD [2] where: UCL95SD is the upper limit, at 95 per cent confidence, of the SD of the data set For the example data set this approach gives a design value of 11.93 kWh/t. This approach is recommended where the data does not follow a normal distribution and is especially applicable when insufficient tests (say less than 10) have been conducted to establish the true mean and variability in the design property. The outcomes of the various design point selection methods are compared in Table 2. FIG 5 – Calculated confidence in measured Bond work index value either side of the mean (50th percentile) value. The first option, choosing a measured point, is the least favoured method. In this data set, choosing a particular measured point is relatively simple and presents few problems apart from the relatively low confidence level that has been identified when choosing points far from the mean. But this data set is regular in its shape while many other real sets are not. One or two outlying points at the top of the distribution would invalidate any method where an upper measured point is simply chosen. The second method, calculating percentiles based on a fitted standard distribution, also assumes regularity in the data set. If the set follows the normal distribution curve closely, then using the basic normal distribution techniques are appropriate, although a value ranked higher than the traditional 80th percentile is needed to be prudent in design. This comparison suggests that the traditional design method is likely to underestimate the power requirements of the circuit by at least 7 per cent. A plant failing by 7 per cent to achieve its nameplate throughput rate may be enough to reduce the profitability of the project to zero, or even to a lossmaking scenario. Detailed equations The equations behind the two methods will be explained in a form suitable for use in Microsoft Excel. It is assumed the 20 measured data values are in a single range of 20 cells that has been assigned the name BWI. This means that the SD term in Equation 1 is calculated as STDEV.S(BWI). The capitalised function name STDEV.S is a new function in Office 365 version of Microsoft Excel and has equivalents in older Excel versions. UCL90 can be calculated as: UCL90 = AVERAGE(BWI) + Conf90[BWImean] [3] Conf90[BWImean] = CONFIDENCE.NORM(0.1,BWISD,20) [4] The third method (using the percentile function) seems to lie somewhere between the first two and is subject to the constraints of the normal distribution assumption. where: The recommended method for choosing a safe and justifiable design point is to apply some of the statistical calculations used to analyse the problem above. The difference between this approach and the traditional methods is that it recognises both the uncertainty in the mean value and the uncertainty in the degree of variability of the data. for 20 samples, and where: Recommended design point selection procedures Elsewhere, the author proposed alternative methods for selection of the design point based on the mean value and variability in the data set (David, 2017). Equation 1 is the recommended method and is considered a prudent conservative approach. Equation 2 represents an ultraconservative approach and is advisable when risk tolerance is very low or the data set has high uncertainty. This allows Equation 1 to be rewritten as: Design Point = AVERAGE(BWI) + CONFIDENCE. NORM(0.1, STDEV.S(BWI),20) + STDEV.S(BWI) [6] The value 0.1 is derived from the choice of confidence level of 90 per cent. The value 20 is the number of test samples. Equation 6 is the recommended equation for selecting the design point. The calculation of UCL95SD for Equation 2 is more complicated, as described here. UCL95SD = BWISD*((n-1)/CHIINV((0.05/2), n-1))0.5 [1] [7] UCL95SD = BWISD*((19)/CHIINV((0.025), 19))0.5 where: UCL90 is the upper limit, at 90 per cent confidence, of the likely values for the mean value of the data set. Method For the example data set this approach gives a design point of 11.44 kWh/t. This approach is recommended where the data follows the normal distribution to a reasonable degree and also where sufficient tests have been carried out to establish the variability in the SD. [8] TABLE 2 Comparison of design point selections. SD is the standard deviation of the data set 124 [5] For 20 samples this equation simplifies to: The conservative approach equation Design point = UCL90 mean + SD BWISD = STDEV.S(BWI) Design value (kWh/t) Relative magnitude (%) 80th ranked point 10.3 90 80th percentile() calculation 10.6 93 Conservative recommendation 11.44 100 Ultra-conservative approach 11.93 104 we are metallurgists, not magicians Measuring and taking notice of orebody variability – an essential ingredient for reliable plant design FIG 6 – Hard and soft ore random data sets. And as a result, Equation 2 can be written as such: Design Point = AVERAGE(BWI) + CONFIDENCE. NORM(0.1, STDEV.S(BWI),20) + STDEV.S(BWI)*((19)/ CHIINV((0.025), 19))0.5 based on the mean and SD of each set individually, are shown for comparison. [9] where: 0.025 is derived from the choice of SD confidence level (in this example at 95 per cent) and 19 is the number of samples minus one Problems with the data set For convenience and clarity, a fabricated data set that closely complies with normal distribution parameters was used in the preceding discussion. Many data sets generated in mineral processing test work do not comply with this convenient structure and can lead to problems with design, ranging from minor to catastrophic. Multimodal data When two or more separate populations of properties are embedded in the one set of data many simplistic analysis assumptions are no longer valid. To illustrate multimodal data the statistics (mean, SD and assumption of normal distribution) of the example data set were used to generate 20 new random results representing what is a soft ore. A second set of 20 hard-ore results were generated, also somewhat randomly, by adding an amount varying between 4 and 6 kWh/t to the first set. Normal distribution curves, To illustrate the resulting bimodality, all 40 values are treated as a single set and shown as an S-curve in Figure 7. An overall calculated normal distribution line has been added that obviously does not represent the set well. A closer fitting trendline has also been added using the polynomial function in Excel. The distribution cannot be considered to follow the normal pattern and presents a few problems for design thinking. To see the effect of the increase variability across the 40 samples, the upper and lower 90 per cent confidence values for the mean and the upper and lower 95 per cent confidence values for the SD were used to construct the potential upper design envelope as per Figure 3. The resulting bimodal envelope can be seen in Figure 8. The 80th percentile could statistically be anywhere in the range 13.9 to 16.3 kWh/t. The four calculation methods used to generate Table 2 were applied to this new 40-point data set. The results are compared in Table 3. Again, the ‘conservative recommendation’ calculation method is preferred to the traditional 80th percentile methods as the result is closer to the upper end of the statistically valid range. In this instance, the degree of potential underestimation of design point using the conventional methodologies is about 5 per cent. FIG 7 – Bimodal combined data set. we are metallurgists, not magicians 125 D David FIG 8 – Multimodal upper design envelope. Small data sets To illustrate the effect of using smaller and smaller data sets, subsets of the 40 bimodal data points used in the above example were used as the basis for design calculations. A random selection method was again used to avoid bias. The base case for comparison in this analysis is the outcome achieved using 40 data points. Example calculations have been conducted selecting approximately 20 samples, 10 samples and five samples out of the 40. Note that five samples are generally considered a reasonable number of samples on which to base a scoping study. Note that the subset numbers are only approximate. This is because the random selection process as it has been applied cannot (by definition), result in a fixed subset size. Each time the calculation is updated the selections change as does the apparent shape of the S-curves. This is illustrated by a selection of five graph updates shown in Figure 9. On all five graphs the original blue data set is constant. All other data sets are random plausible outcomes when less than the full 40 samples are tested. As statistically expected, if three to seven samples are selected for testing (the ‘Approximately five samples’ cases ranged from three to seven samples) the range of possibilities for the design point outcome is highly variable. Even choosing the maximum test result may not get close to being a safe design value as Figure 9a illustrates. measurement or mathematically calculating the 80th percentile, always underestimate compared to the maximum envelope value. The conservative method either overestimates this value or estimates a design point consistent with the value (it gave 16.0 kWh/t but only after 40 samples had been tested). The ultra-conservative method provided an extreme result (35.2 kWh/t) when only three samples were tested. This result is a warning of the statistical inadequacy of testing only a few samples and then trying to infer too much from the results. The ultra-conservative method provided reasonable design points when nine or more samples were tested. It may seem unreasonable to adopt 21.6 kWh/t as a design value after testing nine points and when the 80th percentile value of the set is much lower at 15.1 kWh/t (Table 4). However, the statistical analysis is saying that after nine samples have been tested the variability at the top end of the distribution is extremely poorly defined. It is feasible (without knowing anything about the next samples to be tested) that there is a significant amount of 20 kWh/t and harder material in the orebody that could be detected when more tests are carried out. Design calculations were also conducted according to the four methods previously described. The outcomes for the full and reduced sample number cases represented in Figure 9e are shown in Table 4. In line with the naming of the methods, the conservative and ultra-conservative approaches give higher design points the fewer tests that have been conducted. This provides an improved, some would say excessive, level of safety (compared to traditional methods) if minimal testing is conducted. Most importantly these high design points provide real incentive for conducting more tests as the capital cost is most likely to reduce as confidence improves. From Figure 8, the upper boundary of the design envelope is known to be 16.3 kWh/t. However, this value can only be known after 40 samples have been tested. Each subset result needs to be assessed as if the 40 samples have not been tested. The first two methods, selecting the 80th percentile A number of additional random calculations were captured showing the potential for problems with small sample sets In figure 10 and the associated Table 5 it can be seen that only conducting six tests leads to a potentially problematic hardness underestimation even using the conservative TABLE 3 Comparison of design point selections – bimodal data. TABLE 4 Comparison of design point selections for reduced sample numbers – graphical case (E). Method Design value (kWh/t) Relative magnitude (%) Samples tested 40 21 9 3 80th ranked point 15.3 95.1 80th point 15.3 15.8 14.8 15.8 80th percentile() calculation 15.3 95.2 Percentile (80) 15.3 16.0 15.1 14.9 Conservative recommendation 16.0 100.0 Conservative 16.0 17.0 17.8 19.0 Ultra-conservative approach 16.6 103.6 Ultra-conservative 18.8 19.4 21.6 35.2 126 we are metallurgists, not magicians Measuring and taking notice of orebody variability – an essential ingredient for reliable plant design A B C D E FIG 9 – (A–E) Random subset expectations if bimodal data set was only partially sampled. TABLE 5 Comparison of design point selections for reduced sample numbers – graphical case (F). Samples tested 40 20 9 6 80th point 15.3 14.8 13.6 11.1 Percentile (80) 15.3 15.1 14.3 11.1 Conservative 16.0 16.8 16.4 14.8 Ultra-conservative 18.8 20.0 20.1 19.1 we are metallurgists, not magicians method. The ultra-conservative method is the only one to give a safe answer. The traditional methods provide dangerously low design values. The results are a strong argument for doing at least nine tests. Another random cycle of the same calculation is shown in Figure 11 and summarised in Table 6. Again, the conservative method is preferred to the traditional selection methods. Based on conducting this calculation a number of times it is recommended that if less than ten samples have been tested 127 D David FIG 10 – Random subset expectations if bimodal data set was only partially sampled, case (F). FIG 11 – Random subset expectations if bimodal data set was only partially sampled, case (G). TABLE 6 Comparison of design point selections for reduced sample numbers – graphical case (G). TABLE 7 Guide for use of conservative design methods. Stage Scope PFS DFS 4 to 8 samples C UC N/A 9 to 16 samples C C UC C C C Samples tested 40 20 13 4 80th point 15.3 14.8 16.0 13.6 Percentile (80) 15.3 15.3 15.7 14.5 17+ samples Conservative 16.0 16.1 17.0 17.7 Ultra-conservative 18.8 19.0 20.5 26.3 Notes: PFS = prefeasibility study; DFS = definitive feasibility study; UC = ultra-conservative; C = conservative; N/A = not recommended. the ultra-conservative method is required. However, if the ultra-conservative method is arriving at design points twice the magnitude suggested by traditional methods this should be taken as a warning that inadequate sample numbers have been selected for design purposes. increase the sample numbers in the first column of Table 7 in line with the increase in uncertainty in the data. It is proposed that the 90 per cent confidence value, as a percentage of the mean value, be used as a guide to sample numbers. However, at a scoping level it is often not possible to test more samples, and the implications of slight underestimation of power are not significant. This suggests a better approach is to vary the design method according to the project stage and available sample numbers. A guide for designers is proposed in Table 7. In the bimodal data example described above the confidence level in the mean can be expressed as a fixed value for the unchanging set of 40 samples but as ranges for the subset cases (as these change randomly) when the sheet is recalculated. The confidence levels (as a percentage of the hardness measurement) are compared in Table 8. This analysis appears to suggest that 16 samples is sufficient for a definitive design. Using the conservative method and with an orebody that appears to give test results of similar variability to these examples the guidelines are useful. Where the orebody is less variable the methods will simply work better. Where the variability is much higher than these randomly generated sets, then it is likely to be necessary to Designers can use Table 8 as a reference to see if their data set is similar to this example or if it is much worse than the example. Simply calculate the 90 per cent confidence limit in the mean for the data set and compare it with the table. If, for example, 15 samples have been tested for project XYZ and the 90 per cent confidence limit is 15 per cent of the mean value, then the XYZ data set (and more importantly, the XYZ orebody) is much 128 we are metallurgists, not magicians Measuring and taking notice of orebody variability – an essential ingredient for reliable plant design TABLE 8 The 90 per cent confidence limit in the mean measured value as a percentage of the mean hardness measure – relationship to number of samples tested. Samples Average confidence as percentage of mean Range 4 21.5 18–26 5 15.0 11–21 6–8 15.2 12–20 9–12 11.4 9–13 13–16 9.0 7–10 17–25 8.0 40 7–10 5.6 more variable than the bimodal example. Fifteen samples of XYZ ore have only given the statistical confidence level that six to eight samples of the fictitious bimodal ore provided. A new version of Table 7 would result for XYZ ore in which the column one sample numbers would double. For orebody XYZ the 15 samples do not provide enough confidence to even use the ultra-conservative method for a definitive feasibility study (DFS) design. More XYZ samples must be tested before a DFS can be contemplated. The analysis shows that the confidence in the mean is strongly related to sample numbers. However, the calculated SD values were relatively independent of the number of samples tested. This is useful because it means that the SD is a guide to overall variability, regardless of how much testing has been performed. It follows that Sample XYZ would display a higher SD than the bimodal sample under all circumstances. CONCLUSIONS The analysis in this paper shows that the inherent variability in a measured data set is not considered fully in a traditional design point selection method, such as calculating an 80th percentile value. It has also been shown that as the number of samples tested decreases the traditional method is relatively poor at providing a design point that can be considered safe. Two statistical measures not typically invoked in traditional design methods are the inherent uncertainty in the calculated mean value and the uncertainty in the SD for the measured sample set. Traditionally the mean and SD values are taken as measured and the 80th percentile value is considered a reliable indicator of where the plant needs to be designed to operate. In the synthetic examples analysed here the uncertainty in knowing the mean of a measured data set is quantified and the uncertainty in knowing a value like the 80th percentile we are metallurgists, not magicians is shown to approach twice the uncertainty of knowing the mean. Any measured data sets’ inherent variability can be evaluated using these same readily available statistical tools. The mean value of any data set is its best-defined characteristic. The level of confidence inherent in values distant from the mean (such as the 80th or 90th percentile) is much lower than the confidence that can be placed in the mean. Design difficulties arising from variability issues are exacerbated when the ore is bimodal and multimodal. Design difficulties are also exacerbated when small numbers of samples have been tested. The number of samples needed to be tested to provide design confidence is directly proportional to the inherent ore property variability. In a sort of catch-22, the number of samples that need to be tested to develop a reliable design for a particular orebody can only be determined once enough samples (typically seven or more) have been selected and tested. Two methods of selecting design points have been proposed and compared with traditional and simple methods. The conservative method employs the confidence limit calculated for the mean value coupled with the SD of the data set. An ultra-conservative method has also been proposed which considers both the confidence limit in the mean and the confidence level the data set provides in the measured SD. Traditional design methods are prone to design point underestimation at all sample sizes and are particularly poor with sample sets of six or less. The conservative method is reasonably good for estimating reliable design points with sample sets of eight or more in the examples analysed. With samples sets of four to eight the conservative method is prone to some underestimation, but less severe than using traditional design methods. The ultra-conservative method is prone to conservative overdesign with sample sets of eight to fifteen. The method is unreliable for sample sets less than eight and may randomly return a conservative or optimistic result. The traditional and proposed methods can be usefully compared when selecting design points with real data sets. They can also be used to analyse under or overdesign situations in operating plants as this may provide a guide to avoiding mistakes in future projects. Simply performing the statistical confidence calculations and plotting the design envelope is a useful guide to the adequacy of the number of samples tested and can be used to justify conducting additional tests. REFERENCES David, D, 2017. Is an 80th percentile design point logical?, in We are Metallurgists, Not Magicians (eds: D Pollard, G Dunlop and J Herzig), pp 115–120 (The Australasian Institute of Mining and Metallurgy: Melbourne). Sheskin, D J, 2007. Handbook of Parametric and Nonparametric Statistical Procedures, fourth edition, pp 197–198 (Chapman and Hall/CRC). 129 Contents Getting optimum value from ore characterisation programs in design and geometallurgical projects associated with comminution circuits S Morrell1 ABSTRACT It is extremely difficult if not impossible to ensure optimum process efficiency without having a thorough knowledge of the orebody. For the comminution circuit this means having detailed data on the breakage characteristics of the ore, in particular how it varies spatially. When planning campaigns to determine this information, questions such as ‘What breakage tests should be used?’, ‘How many samples are required?’ and ‘What equations should be used to forecast comminution circuit performance?’ are often asked. The following paper presents a series of statistical analyses to help answer these questions. Perhaps not surprisingly there are no simple answers, as it depends upon how the characterisation data are planning to be used, as well as the inherent variability of the orebody. Guidance is provided to help metallurgists make informed decisions, which should result in a characterisation programme that is cost-effective and statistically sound, providing a clear picture of the comminution behaviour of the orebody in question. INTRODUCTION Inevitably the post-boom era has changed the emphasis of many mining companies away from new project development and expansion to optimisation of existing operations. However, regardless of the project, high quality laboratory ore characterisation will remain of the utmost importance. In the case of new project development, the need to understand the breakage characteristics will remain as important as it has always been. In optimisation projects, however, where it will be required to get the very best from existing comminution circuits, accurate geometallurgical modelling will take on an increasingly important role. However, these requirements, in both new development and optimisation projects, are likely to be at odds with budgets as these will be tight. However, this does not necessarily mean that accuracy should suffer, only that the ore characterisation test work program must be more focused and streamlined. The following paper discusses several factors and guidelines that should be considered when faced with developing such programs. NECESSARY ATTRIBUTES OF A TEST WORK PROGRAM From a comminution perspective, an effective model, whether used for design or for geometallurgical purposes should be able to accurately predict the throughput of the grinding circuit from information concerning the breakage characteristics of ores that are planned to be delivered to the processing plant. To do so there are at least five important requirements: 1. sufficient and relevant samples have been identified, extracted and tested 2. appropriate ore characterisation tests have been chosen to describe the comminution properties of the orebody 3. the model(s)/equations chosen to describe the comminution equipment in the circuit respond realistically to the values obtained from the chosen ore characterisation tests 4. all of the above are integrated into an overall description of the operational response of the grinding circuit that also takes into account non-ore related influences eg equipment size, speed, ball load etc 1. Managing Director, SMCC Pty Ltd, Chapel Hill Qld 4068. Email: steve@smccx.com 5. the final model/equations can convincingly demonstrate their accuracy through validation using real plant data. 131 S Morrell HOW MANY SAMPLES? There is no easy answer to this question though it is true to say ‘the more – the better’. If the deposit is highly variable the required number of samples will be higher. Also, the end use will also drive the number of samples required. Hence if samples are required for a prefeasibility study the number will be relatively low, whilst if samples are required for the development of a geometallurgical model that can accurately forecast daily grinding circuit throughput, the number required will be at least an order of magnitude higher. In all cases a staged approach to sample selection and laboratory test work is recommended to ensure that costs are kept to a minimum. Each stage should be designed to build on the knowledge gained from preceding ones, particularly concerning variability, both spatially within the pit as well as in terms of absolute hardness values. The prefeasibility study level is often the best opportunity to start accumulating useful information of the comminution properties of the orebody. At this stage, little or no information is likely to exist on the comminution properties of the orebody and hence the metallurgist is faced with the decision of how many samples should be treated for this very first investigation. A good starting point is to use the distribution shown in Figure 1. This comes from the semiautogenous grinding (SAG) mill comminution (SMC) Test® database which currently numbers over 40 000 separate test results covering over 1500 different ore deposits. The figure shows the coefficient of variation (standard deviation/mean expressed as a percentage) of the measured drop weight index (DWi) values from each deposit (Figure 2 shows the distribution of mean DWi values from each deposit). The DWi has been shown to be a very accurate measurement of the hardness from an autogenous grinding (AG)/SAG and high-pressure grinding rolls (HPGR) perspective and hence is highly relevant in this context. The distribution of coefficients of variation is bimodal, modal values being at 20 per cent and 30 per cent, the average being 30 per cent. Unfortunately the database does not contain information other than SMC Test® values and hence unfortunately the author is not in a position to determine whether this bi-modality can be traced back to broad geological descriptions of the nature and genesis of the orebodies. However, it is tempting to hypothesise that there is a very good physical reason why the distribution should have such a bimodal shape. The data in Figure 1 can provide the basis for some simple calculations that can be used to guide the metallurgist’s choice of how many samples should be taken and analysed in this first step to investigate the orebody. Using classical statistics and assuming the orebody has a variability of 20 per cent (ie the lower of the modal values), then choosing a total of 10–15 samples should provide a mean hardness value for the deposit with a precision of approximately 10 per cent at the 90 per cent confidence level. However, if the variability is in the 30 per cent class, to obtain the same level of precision the requisite number increases to about 30 and if the variability is 40 per cent then sample requirement escalates to 45. The minimum initial number of samples is therefore recommended to be 10–15. Analysis of the data from these samples will provide an indication of the true variability and can then be used to estimate how many more samples (if any) are need to satisfy the accuracy for the prefeasibility stage. If, for example, the indicated variability from the initial 10–15 samples is 40 per cent then an additional 30–35 samples will be required. As the design stages progress through to a final bankable study, more definition is required to enable more accurate forecasts of ore properties and hence throughput to be made during at least the first few critical years of production. This requires further ore characterisation. However, the results from the initial stage of testing should provide a firm basis on which to choose both the numbers and locations where the samples should be taken. It is pointed out that these guidelines assume that the samples are representative of the whole orebody and should be suitable to provide mean hardness values that relate to the deposit in a global context only. For the development of a geometallurgical model much more detailed information FIG 1 – Distribution of drop weight index (DWi) variability values from the semi-autogenous grinding (SAG) mill comminution (SMC) Test® database (based on 40 000 SMC Tests® covering over 1500 deposits). 132 we are metallurgists, not magicians Getting optimum value from ore characterisation programs in design and geometallurgical projects associated with comminution circuits FIG 2 – Distribution of drop weight index (DWi) mean values from the semi-autogenous grinding (SAG) mill comminution (SMC) Test® database (based on 40 000 SMC Tests® covering over 1500 deposits). is required, eg such a model may need to predict the week-by-week or month-by-month throughput. In such cases much more definition in terms of the hardness in specific parts of the deposit is required. In relation to this, knowing how hardness varies with depth is particularly important as it indicates the extent to which throughput of the comminution circuit will increase or decrease as time progresses. Such knowledge is vital both for day-to-day and long-term planning and is critical to the continued financial success of the mine. As a result it is not uncommon for mines to conduct ore hardness testing on hundreds of samples per annum throughout the life-of-mine. WHICH TESTS? Clearly, the laboratory tests that are chosen need to be compatible with the modelling approaches subsequently used at the design stage or in the development of the geometallurgical model; for example, if the AG/SAG mill model in the JKSimMet software (by Julius Kruttschnitt Mineral Research Centre (JKMRC), University of Queensland) is to be used the laboratory test has to generate an A and b value as well as the specific gravity. In addition to this, the metallurgist should also be aware of what are the inaccuracies inherent in the laboratory tests that have been chosen. The study conducted by Dunne and Angove (1997) helps to illustrate this point. Table 1 has been generated from the data given in their study which looked at the variability in results from sending the same samples to three different labs and having Bond crushing, rod and ball mill work index tests carried out. It is clear from their results that the inherent variability in the crushing work index test is very large, values from some laboratories being half those of others. Rod mill and ball mill tests fared much better, the results from the ball mill test showing a very good precision of 3.4 per cent on average. The reasons for the very high variability in the crushing work index test results is quite likely due to the we are metallurgists, not magicians use of non-standard equipment. This problem recently arose when analysing the data shown in Figure 3. When considering crushing work index (CWi) data from machines conforming to Bond’s original design a reasonably good correlation had been found between the parameter CWi*sg (specific gravity) and the DWi (DWi units are in kWh/m3 so the use of CWi*sg gives the same units). However, when data were added from a modified machine design a very different correlation was found. The differences between the CWi values from the two types of machine are of the same order as those obtained from the Dunne and Angove program. Metallurgists involved in ore characterisation test work need to be aware of such biases to ensure that the laboratory chosen to conduct the relevant test are using standard equipment as well as understanding TABLE 1 Accuracy of Bond tests (after Dunne and Angove, 1997). Sample P G R Av Min (kWh/t) 12.4 8.1 12.1 10.9 Max (kWh/t) 21.3 17.2 25.6 21.4 Coefficient variation (%) 27.3 43.5 40.9 37.2 Min (kWh/t) 15.9 16.9 15.8 16.2 Max (kWh/t) 20.9 18.2 17.9 19.0 Coefficient variation (%) 11.4 3.8 6.3 7.2 Min (kWh/t) 17.1 16.4 15.5 16.3 Max (kWh/t) 19.3 17.6 16.2 17.7 Coefficient variation (%) 4.6 3.6 2.2 3.4 Crushing work index (CWi) Rod mill work index (RWi) Ball mill work index (BWi) 133 S Morrell FIG 3 – Correlation between drop weight index (DWi) and crushing work index (CWi*sg), where sg – specific gravity. that even when using standard equipment, some tests are inherently less accurate than others. In a study where the same sample was sent to eight different labs to ascertain the variability from SMC Tests®, the results shown in Table 2 were obtained and reflect the variability of the test itself plus variability associated with any differences between labs in testing machine or operating standards. As can be seen the coefficient of variation was only 3.9 per cent for estimates of the DWi and 3.8 per cent for the estimated A*b value. It should be noted that the SMC Test® estimates of A*b were done without reference to associated drop-weight tests, ie they were not ‘calibrated’ with actual drop-weight test data but used the raw SMC Test® results and global factors TABLE 2 Accuracy of semi-autogenous grinding (SAG) mill comminution (SMC) Tests®. Lab 1 Drop weight index (DWi) A*b 9.6 29.2 9.5 29.3 Lab 2 8.9 31.6 8.7 32.2 Lab 3 9.7 28.8 9.5 29.5 9.0 31.2 8.8 32.0 Lab 4 9.3 30.0 Lab 5 9.4 29.9 9.6 29.3 Lab 6 9.1 30.9 8.6 32.5 9.6 29.3 9.5 29.5 Lab 8 9.1 30.8 9.1 30.9 Mean 9.2 30.4 Standard deviation 0.36 1.2 Coefficient variation 3.9 3.8 Lab 7 134 derived from the SMC Test® database. The magnitude of the coefficient of variation is very low, indicating a very precise test. The result can be compared with the value of 5.7 per cent quoted by Stark, Perkins and Napier Munn (2008) from doing repeat full drop-weight tests using the same drop-weight machine at JKTech, University of Queensland. WHICH MODELS/EQUATIONS? The choice of which models or equations to be used should be driven by their demonstrable ability to predict the performance of existing plants. Once again ‘the more – the better’ rule applies. The more (and varied) data that exists to prove the accuracy of the technique, the stronger is the argument to adopt it. In design studies the most relevant data with which to evaluate the suitability of a technique should be those from existing comminution circuits whose performance has been predicted then checked against high quality operating data from the same circuit. Developers of design and geometallurgical models will claim their techniques and models to be suitable and accurate, but if a large volume of appropriately varied data cannot be presented to validate the claimed accuracy, the metallurgist should be extremely wary of utilising such models and techniques. The development of the SMC Test® and the use of the parameters that it generates in predicting comminution circuit equipment and circuit performance has been well publicised in respected international technical journals (Morrell, 2004a, 2004b, 2008, 2009, 2010). Figures 4–6 demonstrate its accuracy in each of these roles using a large database of operating plants. More recently the Global Mining Standards and Guidelines (GMSG) Group has adopted the so-called ‘Morrell method’ as one of its guidelines for predicting comminution circuit specific energy (GMSG Group, 2016). The SMC Test® is unique in that from the one test a number of parameters are generated which can be used for a variety of equipment, thus saving money which would otherwise have to spent on separate tests for each different type of equipment. Such is the case with Bond’s suite of tests which need separate tests for crushers, rod mills and ball mills. For validation of geometallurgical models, the most appropriate data are from production records over relatively long periods. Such an example is shown in Figure 7 and demonstrates the accuracy of a model based on the use of SMC Test® and Bond ball mill work index data. we are metallurgists, not magicians Getting optimum value from ore characterisation programs in design and geometallurgical projects associated with comminution circuits FIG 4 – Observed versus predicted tumbling mill circuit specific energy. (Note: ab – ag/ball; ag –autogenous grinding; abc – ag/ball/crusher; sab – sag/ball; sag – semi-autogenous grinding; sabc – sag/ball/crusher; ss ag – single-stage ag; cr-ball – crushing ball, hpgr – high pressure grinding.) FIG 5 – Observed versus predicted crusher specific energy. FIG 6 – Observed versus predicted high pressure grinding rolls (HPGR) specific energy. we are metallurgists, not magicians 135 S Morrell FIG 7 – Example of the accuracy of a geometallurgical model (after Alruiz et al, 2009). CONCLUSIONS Given the tighter constraints on finances for ore characterisation programs, metallurgists will need to be far more selective in their choice of tests in future to ensure that accuracy is not unnecessarily sacrificed. The choice of appropriate test(s) should be made based on measured precision as well as demonstrated accuracy of the techniques that subsequently use the test results to predict plant performance. This accuracy can only be truly demonstrated from analysing large varied databases of relevant plant performances. Regardless of claims by the developers of various design and geometallurgical models and techniques, about their suitability and accuracy, if data cannot be presented to validate this claimed accuracy, metallurgists should be extremely wary of utilising such models and techniques. In terms of the required number of tests, a staged approach is recommended in which, as projects develop from the prefeasibility stage, knowledge of the variability of the deposit is progressively built and used to drive the number of tests required in subsequent stages. REFERENCES Alruiz, O M, Morrell, S, Suarzo, C J and Naranjo, A, 2009. A novel approach to the geometallurgical modelling of the Collahuasi grinding circuit, Minerals Engineering, 22(12):1060–1067. Dunne, R C and Angove, J E, 1997. A review of standard physical ore property determinations, in Proceedings World Gold ’97 Conference, Singapore, September, p 139. Global Mining Standards and Guidelines (GMSG) Group, 2016. Morrell method for determining comminution circuit specific energy and assessing energy utilization efficiency of existing circuits [online]. Available from: <http://www.globalminingstandards.org/wp-content/ uploads/2016/08/20150821_Morrell_Method-GMSG-ICEv01-r01-.pdf> [Accessed: 29 May 2017]. Morrell, S, 2004a. Predicting the specific energy of autogenous and semi-autogenous mills from small diameter drill core samples [online], Minerals Engineering, 17(3):447–451. Available from: <https://doi.org/10.1016/j.mineng.2003.10.019> [Accessed: 29 May 2017]. Morrell, S, 2004b. An alternative energy–size relationship to that proposed by Bond for the design and optimisation of grinding circuits [online], International Journal of Mineral Processing, 74(1–4):133–141. Available from: <https://doi.org/10.1016/j. minpro.2003.10.002> [Accessed: 29 May 2017]. Morrell, S, 2008. A method for predicting the specific energy requirement of comminution circuits and assessing their energy utilisation efficiency [online], Minerals Engineering, 21(3):224–233. Available from: <https://doi.org/10.1016/j.mineng.2007.10.001> [Accessed: 29 May 2017]. Morrell, S, 2009. Predicting the overall specific energy requirement of crushing, high pressure grinding roll and tumbling mill circuits [online], Minerals Engineering, 22(6):544–549. Available from: <https://doi.org/10.1016/j.mineng.2009.01.005> [Accessed: 29 May 2017]. Morrell, S, 2010. Predicting the specific energy required for size reduction of relatively coarse feeds in conventional crushers and high pressure grinding rolls [online], Minerals Engineering, 23(2):151–153. Available from: <https://doi.org/10.1016/j.mineng.2009.10.003> [Accessed: 29 May 2017]. Stark, S, Perkins, T and Napier-Munn, T J, 2008. JK drop weight parameters – a statistical analysis of their accuracy and precision and the effect on SAG mill comminution circuit design, in Proceedings MetPlant 2008, pp 147–156 (The Australasian Institute of Mining and Metallurgy: Melbourne). 136 we are metallurgists, not magicians Contents Cost-effective concentrator design G Lane1, P Dakin2 and D Elwin3 ABSTRACT This paper discusses the factors that contribute to the cost-effective design of a concentrator. Concentrator design and layout outcomes are functions of the team (engineer’s and owner’s) participating in each particular project. The benchmark for relatively modest projects was set in the 1980s and 1990s during the ‘gold boom’ when numerous cost-effective plants were designed and constructed on a lump sum basis in a very competitive market. A number of factors contribute to lack of transference of the lessons learnt in gold plant design to concentrator design including established paradigms in the design and layout of concentrators, lack of experience in costeffective design, operator’s preferences for flow sheet and layout and simple lack of appreciation of the impact of plant footprint on materials quantities and resultant capital costs. Experiences with recent copper concentrator projects (both small and large) are used as case studies. INTRODUCTION Cost-effective concentrator design is not an isolated paradigm. It needs to interface with the project infrastructure constraints, owner’s needs, vendor’s capabilities, constructor’s logic and operator’s and maintenance team’s preferences. However, cost-effective design has some ‘rules of thumb’, namely: •• keep the execution strategy and plan simple, sift the ‘baggage’ from the facts early, have a plan (and agreed scope) and stick to it •• minimise the number of interfaces across all parties as every interface requires ‘management’ •• invest in good equipment as it saves you money •• reduce plant footprint as capital and operating costs increase with increasing plant footprint. Capital costs will escalate if: •• scope is poorly defined and the execution strategy meanders (scope and design are not frozen) •• simplicity is replaced with opportunism (hope) •• pipe rack locations are used as the basis of plant layout •• ‘expandability’ is a necessity. SETTING THE SCENE 1. FAusIMM, Chief Technical Officer, Ausenco Minerals & Metals, South Brisbane Qld 4101. Email: greg.lane@ausenco.com 2. Principal Designer, Ausenco Minerals & Metals, South Brisbane Qld 4101. Email: phil.dakin@ausenco.com 3. Principal Designer, Ausenco Minerals & Metals, South Brisbane Qld 4101. Email: derek.elwin@ausenco.com Nirvana for the project developer and plant designer is a ‘cost-effective plant’ that meets expectations. There are many approaches to plant design that range from the grandiose to the shoddy and mean. ‘Cost-effectiveness’ is a different paradigm. It relies on sound judgement and a balanced assessment of what is required for the circumstance. The ‘art’ of designing cost-effective carbon-in-leach (CIL) plants was mastered in the late 1980s by Australian engineering companies who competed on a lump sum turn key basis for plants in the 100 kt/a to 5 Mt/a throughput range. The need for these plants arose through the development of CIL technology, the plethora of modest grade opportunities in Western Australia in particular, the high gold price and the flexible nature of gold metal marketing (Close, 2002). These circumstances resulted in the need for innovation, short project schedules, low project capital costs and a ‘money making machine’ approach. On occasions the commercial and design ‘recipe’ came unstuck. Notable projects, such as Three Mile Hill, initially failed to meet throughput targets due, in part, to a ‘one size fits all’ approach and insufficient test work to define the design. 137 G Lane, P Dakin and D Elwin The lessons learnt from the ‘cost-effective’ design examples of the Australian gold industry in the 1980s and 1990s are still the basis of sound CIL plant design although the frequency of projects in Australia is now low and there is greater focus on Africa. The ‘art’ is practiced by some of the same individuals and mostly in small to medium sized engineering companies. Interestingly, as the size of the engineering company increases the ‘art’ is diluted by other commercial imperatives. Larger engineering businesses target Tier 1 mining clients. These clients may express interest in cost-effective engineering but the demands of their business, the number of interfaces and the physical size of the projects makes meeting the aspirations much more difficult. Tier 1 companies generally have long life projects where the desire for durability, flexibility, life cycle optimisation from the outset override the urgency and design practicalities often associated with smaller projects. ‘Value engineering’ is often used to trim scope and cost but the fundamentals and paradigm of the project are often immovable or have a large coefficient of restitution (or resistance) due to complex standards, systems and approvals processes. Cost-effective design needs good engineers and designs and motivation from the client. For their six large copper concentrators, Xstata has opted for a ‘standard concentrator’ approach as a method of reducing design costs. Another project in South America opted for a ‘low cost’ design. However, the design failed to meet many of the ‘rules of thumb’ and the plant is struggling to meet throughput. Another copper concentrator currently in design has had an interesting history where the initial ‘high value centre’ design failed to deliver a cost-effective outcome. Subsequent external review raised a number of pertinent issues and proposed an alternative design that went to the other extreme and was too ‘low cost’ to meet process needs. The final outcome will be a balance between capital cost aspirations and sound design. KEY DRIVERS Typical concentrator layouts tend to be designed very conservatively because designers: •• Either don’t know how ‘close to the wind you can sail’ (fit for design) or aren’t sufficiently experienced to understand the cost/risk/benefit relationships. This results in the additional elevation of equipment based on false ‘standards’ or previous practices, eg concentrate launder slopes, setting height of mills and flotation cells. •• Lack of innovation in design (as this requires experience and effective risk management). This can include using the topography and gravity instead of pumps, not using pipe racks to dominate layouts or building close-stacked vertical processes. Good examples are placing the mixing tank on top of a storage tank or the motor control centre (MCC) under the mill feed platform. •• Tend to ‘re-invent the wheel’ instead of re-using, improving or adapting previous proven design. Existing design libraries aren’t well known about or published. •• Don’t have field installation, commissioning and site as-built experience, particularly on projects they have designed. Designers with this experience are better equipped to understand the basics of layout and operability and then implement these lessons in future designs. •• Come from other industries, eg petrochemical or oil and gas industries. As a result of their prior history they have little or no relevant commissioning or operational experience relevant to flexible but compact plant design. 138 Key drivers for a cost-effective plant design are listed below: •• Optimise the plant footprint with the aim of reducing concrete, structural steel, piping and electrical/control cable and raceways. Push all areas close together, eg grinding close to CIL/flotation, desorption and reagents close to CIL/flotation, air /water services close to plant, big drives close to the switchroom. •• Keep elevation of the equipment to a workable minimum. The elevation of run-of-mine bins, mills, cyclones, flotation cells and thickeners are key drivers (Lane et al, 2005). •• Do not use dominating piperacks or large platform areas. •• Have common platforms, stairs, pipe and cable ladder supports. •• Platework and lining should be kept lean, eg only put wear liners in the chute areas exposed to wear and not all internals. •• Design with a fit for purpose attitude as though it is your money you are spending. •• Do not accept second best. To progress design in a cost-effective manner the following guidelines need to be applied (Lane and Dickie, 2009): •• The orebody and its mineralogy, geometallurgy and process responses need to be sufficiently understood to allow process and market risks to be managed effectively. •• Process flow sheets need to be ‘signed off’ in the first few weeks of design. Any changes result in design change notices that cause rework and administrative churn within the project. If the flow sheets cannot be ‘signed off’, detailed design is not ready to commence. •• Duty/standby equipment needs should be defined in the process flow sheets. •• Process instrumentation and preliminary piping diagrams need to commence early and be frozen from a scope perspective at the 40 per cent design complete stage. •• Survey and geotechnical data generally hold up progress when finalising the location and earthworks detail. Site survey and geotechnical studies need to be completed in the study and front end engineering phases. •• Client maintenance preferences and local crane availability impact on the decisions to use overhead cranes, tower cranes, monorails or davit cranes for various duties. These decisions need to be made early in the plant layout process to avoid rework in all disciplines. •• Local weather or environmental issues may define the need for a plant under roof, inside buildings or with other protection. Clear definition of environmental needs is required prior to commencement of detailed layout design. •• The cost of installing plant in buildings, particularly in the typical South American style, is high. Clear definition of client preferences is needed prior to commencement of layout design. •• In-country materials of construction costs need to be understood in order to make cost-effective structural decisions (eg concrete versus steel). •• Project expansion requirements and timing need to be clearly defined in the front-end engineering design (FEED) phase. •• Concentrate transportation methods need to be defined in the FEED phase (eg truck, rail or donkey). we are metallurgists, not magicians Cost-effective concentrator design •• Reagent delivery and on-site storage requirements need to be defined in the FEED phase based on plant access limitations (seasonal weather and/or other social and environmental factors). •• The water balance needs to be finalised by area as the design is developed with particular focus on the storage method (ponds versus tanks). •• Environmental approvals need to be finalised and permitting requirements (traffic, run-off, dust, noise, fumes, and materials safety) need to be clearly defined in the FEED phase. From project management and execution perspectives the following issues need to be considered: •• The ‘options’ need to be considered and evaluated prior to detailed engineering and project execution proper. Value engineering assessments can occur during the design process but these need to be limited to low level issues and not matters of scope or issues material to the schedule. Value engineering exercises to contain capital cost after 30 per cent engineering completion mean that the project was not set-up initially with the correct capital and/or design expectations. •• Critical vendor equipment certified data needs to be expedited. Detailed design can continue without vendor data if the team has sufficient experience to understand the impact that vendor data can have on design. Vendor specifications by the engineering company may need to be prescriptive to accelerate schedule. This compliments the use of good equipment as if this equipment is similar to that used on other jobs the vendor information can be more easily expedited. •• Simplicity in approach is ‘king’. Packaging aspects of the engineering for completion by ‘low cost engineering centres’ can be a recipe for disaster unless the packages are well defined and managed. Engineering needs to be progressed to between 40 per cent and 70 per cent complete prior to remote completion, and slightly less if key lead engineers migrate with the packages. •• The fabrication strategy needs to be developed cognisant of local (to the project) capability and capacity, low cost offshore alternatives and logistical issues such as the consolidation of equipment and fabricated items. Preassembled modules may provide opportunities for some locations where on-site fabrication costs are high or people with the requisite skills are in short supply. A logistics study is required at an early stage. •• Steel sections standards differ between countries and need to be reconciled with fabricator’s norms. •• Project manager capability ‘to support the team to perform at maximum capability’ is a key driver particularly in maintaining a high level of clarity from the client interface to the drawing floor. •• Engineering managers need to be able ‘to lock down the scope’, understand ‘fit for purpose design’, assign responsibility, support the leads and motivate the team. CASE STUDIES Introduction Project names are not used when discussing most of the case study examples herein. Photographs from other publications and the public domain are used as examples to illustrate particular design features. Large and small concentrators present different challenges. Small concentrators (less than say 10 Mt/a and single concentrate) are simpler to arrange as there is typically one crusher, stockpile, semi-autogenous grinding (SAG) mill, ball mill, flotation train and tailings thickener. Larger concentrators with multiple SAG and ball mills, multiple flotation trains and large service runs demand an additional level of complexity for maintenance access, service equipment and service runs. Small concentrators In many respects, small concentrators of less than 10 Mt/a and particularly less than 5 Mt/a are easier to layout in a costeffective manner provided that all contributors are of a like mind. The following examples indicate what to avoid in order to optimise project value. Figure 1 illustrates a number of design features that increase plant footprint. The space between the unit process operations are for mobile crane access and potential expansion (regrind mills). Mobile crane access is most effective when there is no impact on plant arrangement. If pipe racks need to be installed or FIG 1 – An example of a possible small concentrator layout. we are metallurgists, not magicians 139 G Lane, P Dakin and D Elwin extended to allow adequate access, the use of mobile cranes may not be cost-effective and alternatives such as tower or portal cranes should be considered. The arrangement of the unit processes in Figure 1 requires extensive pumping of slurry between unit processes and the installation of large pipe rack ways. These can be avoided by thoughtful design in most circumstances. The derivation of the Figure 1 design is interesting in that the original definitive feasibility study (DFS) design and layout was a typical open air design on relatively small footprint that had small pipe racks between facilities and maintenance access by local davits and monorails. A metallurgical review with about 15 per cent of the engineering completed resulted in the inclusion of flash flotation and this changed the cyclone tower design substantially. In addition, it was decided to leave room for a possible regrind mill and the milling facility and flotation circuit were separated to affect this change. Flash flotation cleaning was added when engineering was about 25 per cent completed and installed in the location allowed for the future regrind mill. A maintenance study was conducted at about 40 per cent engineering complete and access for mobile cranes increased the separation between the unit processes and pipe rack lengths increased. In addition, overhead gantry cranes were allowed over cyclones and the primary crusher requiring significant structural strengthening due to the local seismic conditions. Hence, this is a good example of a project where a design approach was not frozen and maintained throughout the engineering design and where a series of relatively minor modifications led to a less than optimum outcome due to their incremental impact on the layout. leads to a more complex decision-making process and a greater tendency to conservatism. The approach to design can also change to one that is driven by key engineers and designers to one that is driven by a more over-arching approach based on ‘proven track record’ or prior designs. At 12 Mt/a capacity with a single train SAG and ball mills in the grinding circuit it is relatively easy to design a costeffective concentrator (Figure 2). These projects generally require modest size teams and can be lead effectively by a competent engineering manager using simple engineering systems. As projects become larger, the team grows and the infrastructure and technical issues increase, particularly when equipment selection considers large capacities and/or novel design features. However, it is still possible to design concentrators with twin train grinding circuits with up to 25 Mt/a capacity with relatively simple and compact layouts (Figure 3 for example) if the concept is set early, agreed by the owner and conveyed effectively to the engineering group. There are numerous examples of different approaches to concentrator design throughout the world. Plants with large Large concentrators The design of large concentrators requires a large team of designers, often multiple parallel lines of equipment and critical consideration of operating and maintenance activities due to the size of the wear items, the weight of replacement equipment and the volume of consumables. In general, this FIG 2 – The 12 Mt/a concentrator (Lane et al, 2008). FIG 3 – The simple layout of a 25 Mt/a twin train SABC (semi-autogenous grinding/ball/crushing) concentrator. 140 we are metallurgists, not magicians Cost-effective concentrator design capacities, such as at <http://www.citicpacificmining.com>, with multiple trains of the largest grinding mills have large footprints. The grinding area layout is at the other end of the spectrum from the concepts promoted in this paper. The mills are elevated and separated and as a consequence the bulk materials quantities are high. This combined with locationrelated costs for materials leads to high capital cost outcomes. There are reasons for the layout, particularly associated with the mill erection process where the mills were assembled overseas, transported to site and lifted into place using a purpose designed system, but the proportional costs of civil and structural works associated with this style of plant design are significantly greater than those for smaller plants such as in Figure 2. The South American market benchmark for large concentrators has been set by Bechtel, eg Los Pelambres and La Candelaria. However, the style of these plants leads to high capital cost due to relatively large footprints compared to Australian counterparts such as Cadia (Staples et al, 2008). One of the more recent concentrators constructed in South America is illustrated at <http://www.amec.com/andacollo> and is said to be an ‘innovative, low cost design due to the low-grade of the copper deposit’. However, there are aspects of the comminution circuit layout and maintenance strategy that offer opportunities for further improvement in the context of cost-effectiveness. For example, the use of a Tower Crane may have allowed a significant reduction in structural steel in the cyclone tower by allowing overhead cranes to be removed while the grinding floor layout is ‘relatively spacious’. CONCLUSION There is no panacea solution but there are some key issues to consider in the design and layout of any plant as pointed we are metallurgists, not magicians out in this paper. However, the critical consideration is to give the owner(s) what they want in meeting targets, budgets and project timing. To achieve this, it is the engineer’s role to optimise the design within the owner’s constraints to achieve maximum value from the project. ACKNOWLEDGEMENTS The authors would like to acknowledge Eddie McLean for reviewing the paper and providing suggestions for improvement. As well as all those engineers and designers who have contributed to the authors experience over the years, including those from Ausenco. REFERENCES Close, S E, 2002. The Great Gold Renaissance, 282 p (Surbiton and Associates: Melbourne). Lane, G and Dickie, M, 2009. What is required for a low cost project? in Proceedings Project Evaluation 2009, pp 199–204 (The Australasian Institute of Mining and Metallurgy: Melbourne). Lane, G, Green, S, Brindley, S and McLeod, D, 2005. Design and engineering of flotation circuits in Australia, in Proceedings Centenary of Flotation Symposium, pp 127–140 (The Australasian Institute of Mining and Metallurgy: Melbourne). Lane, G, Staples, P, Dickie, M and Fleay, J, 2008. Engineering design of concentrators in Australia, Asia and Africa – what drives the capital cost, in Proceedings Procemin 2008, p 29 (Gecamin: Santiago). Staples, P, Lane, G and Messenger, P, 2008. Horses for courses – tailoring front end design to project requirements, in Proceedings 40th Annual Meeting of the Canadian Mineral Processors, Ottawa, (Canadian Mineral Processors: Toronto). 141 Project management and delivery Contents Fatal flaws in technical due diligences A J H Newell1 ABSTRACT The background and the basis for conducting a technical due diligence are discussed as well as the source information, typical studies and potential limitations. Typical short comings including ‘show-stoppers’ are presented for the metallurgical area, with examples. Issues found in other areas such as geology, mining, infrastructure and financial evaluations are briefly reviewed, highlighting the input and interaction required by metallurgists with these disciplines. A checklist is provided as a guide to maximise the success of a due diligence as well as a check on the quality of a Feasibility Study. INTRODUCTION A due diligence is primarily required when funds are sought to develop a new project or expand an existing operation or when there is a proposed merger or acquisition. An investor, typically a bank and occasionally a trading house and/or the merging or acquiring entity (usually a mining company or group of companies), will select and appoint consultants to assist in the assessment of the project or evaluation of the target asset. There are two types of due diligence, namely legal/financial and technical, both equally as important and both need to be found satisfactory before an acquisition or merger can be progressed. Historically, most technical due diligences conducted by RPM Global (RPM) have been for financial institutions. Today, there are more potential operators (ie mining companies) in the mix. LEGAL/FINANCIAL DUE DILIGENCE In a legal/financial due diligence, the investor conducts an investigation into both the financial and legal status of the company, in an attempt to identify any current and legacy issues, such as financial commitments, legal and ownership arrangements of the company and the directors. It should be noted that the desirability for a merger or acquisition can quickly evaporate with poor findings. This type of due diligence should be conducted prior to undertaking a technical due diligence. As an example, a client in the industrial minerals space planned a merger with a Chinese producer. The technical due diligence went fairly well as one would expect with an existing operation, except that the resources were not compliant with JORC standards. However, the legal/financial due diligence (in this case completed in parallel with the technical due diligence) discovered that not all of the shareholders had been disclosed and moreover that there was money owed. Needless to say, the merger did not go ahead. TECHNICAL DUE DILIGENCE A technical due diligence assesses the reasonableness of the technical and economic aspects of a project in terms of practicality, viability and risks (RPM Global, 2011). It examines the methodologies, supporting data and underlying assumptions used for evaluating or managing a project based on supplied information, technical and operating data from similar projects, site visits and interviews with key project or operating personnel. 1. MAusIMM(CP), Executive Consultant, Processing, RPM Global, Brisbane Qld 4000. Email: anewell@rpmglobal.com The main purpose of a technical due diligence is to identify ‘show-stoppers’ – aspects of the project that make it impractical or unviable – and thus protect the investor from potentially losing money by investing the project. Often the technical due diligence uncovers a raft of assumptions or unusual methodologies – ‘devils that you don’t know’ – that seriously undermine the project. This does not necessarily mean that the investor would not become involved in the project, particularly when the underlying asset has significant potential (eg good orebody); it usually encourages a re-development of the project by the owners. 145 A J H Newell A successful and timely technical due diligence relies on experienced personnel with a background in project development as well as operations and an overlap with other disciplines. For example, a metallurgist, besides being competent in the processing technology associated with that commodity as well as typical metallurgical responses and costs, would require some knowledge of geology (the geometallurgical aspects, such as ore types, as applied in the resource model etc) as well as mining (mainly mine scheduling, potential for and nature of dilution etc) to assist in a more accurate and timely assessment. Depending upon an individuals’ experience, a metallurgist is often involved in assessing site infrastructure, except that power stations, tailings storage facilities and rail are the domain of infrastructure specialists. In addition, a metallurgist often reviews the marketing arrangements and the nature of the smelter/buyer contracts. Technical due diligences are typically high level and conducted over the time span of three to four weeks, depending upon the size of the project and the number of assets. For a major acquisition, a high level technical due diligence may run into eight weeks or so. Occasionally a detailed technical due diligence may be requested, which would take at least six months or longer. Two types of assets are the target of a technical due diligence. Most assets that are investigated in technical due diligences are projects supported by a Feasibility Study. Consequently the main technical due diligence activities are based around examining the reasonableness of the study, approach/methodologies, supporting data and assumptions and thus the likelihood of the project being technically and economically feasible. In addition, attention is paid to the nature of the project’s potential/upside as well as whether risks and potential mitigations have been adequately considered. The other asset types considered in a technical due diligence are an existing operation or operations, often becoming available for either merger or acquisition at either the top or the bottom of the mining cycle. These types of technical due diligences are in some ways easier to conduct, since the asset has passed the Feasibility Study stage and a body of industrial data and actual costs is available for review. Occasionally, an operating asset under technical due diligence is planning an expansion. The expansion, which would be generally based on an internal study, would hopefully follow the rigour and accuracy of a Feasibility Study. As a final comment, a generally less intense variation on a technical due diligence is an independent technical review (ITR) or independent engineer’s report (IER), which are mainly used for an initial public offering (IPO) or stock market listing. ITR/IERs have a similar content and approach to that of a due diligence, however, are conducted at a higher level (ie less depth) and often take the form of a fatal flaw analysis. The nature of a Feasibility Study is discussed in some detail in Appendix 1 since in the assessment of a project, the quality of a Feasibility Study has a significant bearing on the outcome of a technical due diligence. Some typical characteristics of non-Western feasibility studies are also presented. When technical due diligences are conducted on nonWestern Feasibility Studies, projects need to be evaluated within the context of the local commercial, technical and political environment and not necessarily compared with the standard Western approach which addresses the risks raised by Western investors and developers. 146 A Feasibility Study, when properly developed, has progressed through the Scoping Study and Pre-Feasibility Study stages. When a study stage has been bypassed, it is quickly revealed in a Technical Due Diligence; there is a general lack of methodology in the study approach, only a focus on selected areas, various options remain open and unresolved, marketing studies are not as advanced as they should be, insufficient test work to support the study level – captured in a document that is incomplete, contains gaps and does not flow. It goes without saying that studies should be conducted by competent and experienced personnel with a proven track record, either within the company or outside (eg consulting companies or engineering, procurement, construction management – EPCMs). As an example, a recent due diligence of an industrial operation wishing to expand revealed a very poor quality Feasibility Study, conducted by a fabricator. It was the show stopper of all show-stoppers, fatally flawed in many ways, as highlighted later in this paper. Technically, it lacked metallurgical detail, such as mass balances, design criteria, flow sheets, process and instrumentation drawings (P&IDs), design criteria etc and was based on limited test work employing samples from another deposit. Financially, there was no breakdown of the capital and operating costs, while the methodology and supporting data was poor. The main areas examined in a technical due diligence parallel those presented in a Feasibility Study, namely: •• Geology – is often the most important area and has significant potential for a fatal flaw; there needs to be a high level of certainty that an orebody exists and supports economic extraction, allowing subsequent recovery of any project expenditures. Some significant flaws that can be encountered include: •• geological interpretation and the subsequent conversion of drilling core data into a model •• basis for classification of resources (inferred and indicated). •• Mining – has potential for fatal flaws, particularly underground mines; major shortcomings include: •• mine design and schedule – output not in terms of ore types and is ‘lumpy’; significant variations in ore grades, ore type blends and volumes •• the optimum mining rate has not been determined •• inappropriate underground mining method •• proposed levels of costing accuracy not achievable •• limited supporting geotechnical and hydrogeological studies (particularly pit slope assumptions). •• Metallurgy – often has a multitude of minor flaws and occasionally some fatal flaws; suitable flow sheet and equipment with reasonable costs are the main considerations; more details are presented in the following section. •• Environmental – is a potential show stopper, sufficient studies need to have been conducted and permitting must be in place. •• Infrastructure – can become a significant show stopper, particularly for larger projects in remote locations and typically for industrial minerals; inadequate water and power supply studies; inadequate tailings disposal planning; trade-off studies have not been conducted; local climatic, seasonal or seismic conditions have not been fully considered. In addition, the lack of or limited sterilisation drilling as well as geotechnical studies for the locations of the processing plant and tailings storage we are metallurgists, not magicians Fatal flaws in technical due diligences facility can introduce unexpected costs and significantly delay a project or limit production (eg Escondida). •• Social/indigenous – has potential to be a show stopper (cf Garg Island); local support for the project needs to demonstrated. •• Marketing – occasionally a show stopper (eg product quality and or volumes not accepted by market). •• Financial evaluation – only as good as the quality and reliability of the inputs. Note that any project valuation (eg net present value (NPV)) must be based on at least Indicated Reserves if a public document and for a Feasibility Study financiers generally like to see at least six years of reserves. •• Project execution – potential for flaws, occasionally fatal flaw, generally due to optimistic construction schedules (impact of seasons and climate has not been fully considered), equipment delivery schedules and ramp-up times. An issue that can initially arise when conducting a technical due diligence is getting access to documentation and data in a timely fashion. This information is typically provided via an online data room through a series of access protocols. The quality of data can vary greatly and be in unusual places; for example, in a recent technical due diligence of a large nickel operation, some metallurgical studies were in geological reports – which is not a place that a metallurgist would naturally search. Another strategy employed by target companies is the provision of copious quantities of data, of variable relevance and often out of date. Often the site visit produces the critical data sought, however due to bureaucratic protocols, there may be delays, some of which can be a strategy employed by the target company. Both of these approaches were experienced in a previously mentioned technical due diligence. While site personnel tend to be knowledgeable, helpful and communicative, this is not always the case. A relatively recent technical due diligence site visit to a moderately large eastern Australian copper operation revealed that a complete turnover of technical staff had occurred within the previous nine months or so and that site personnel had limited detailed knowledge. executed, then the flow sheet may be fatally compromised and, as a consequence, the process design and associated costs. •• Test work sample issues: •• samples for separation test work not being representative •• limited range of samples comminution testing used to conduct •• suitable test work sample locations for bench scale, locked cycle and pilot plant test work. •• Limited mineralogical studies: •• particularly for more complex ores and subsequent test work. •• Limited comminution test work: •• none – common in Russian and Chinese work •• only Bond ball mill work index (BBMWi) and Bond abrasion index (Ai) •• poor understanding of liberation requirements. •• No preconcentration test work (potential not identified). •• Poor understanding of metallurgical losses. •• Limited amount of separation test work: •• insufficient amount of test work to convincingly support flow sheet interpretation and metallurgical response •• bench scale flotation test work – no locked cycle test work (LCT) •• no reproducibility studies, particularly when results are variable – test work and thus flow sheet decisions being made based on one result •• no establishment of feed grade-recovery relationships (important for financial model). •• Limited amount of dewatering test work: •• insufficient body of data to convincingly size and select dewatering equipment •• where concentrates are produced, no transportable moisture limit (TML) studies •• where ‘dry stacking’ is selected for the tailings, a range of tailings samples reflecting the likely range in the quantity of fines needs to be tested. •• Flow sheet: Generic flaws, which often prove fatal, result from: •• not finalised •• insufficient or unavailability of supporting data (eg geological data, metallurgical samples etc) •• unresolved technical issues •• insufficient test work to support flow sheet selection •• optimistic, incorrect or poorly based interpretations of data (eg geological data, future metal prices, metal recoveries etc) •• not suitable for all ore types/blends that would be presented to the plant •• proposed levels of accuracy not achieved (eg capital and operating costs). •• ‘novel’ flow sheets: A processing technical due diligence checklist has been provided in Appendix 2 highlighting the many elements that need to be considered. For a project, it is also a guide to what a successful Feasibility Study should be addressing. PROCESSING FLAWS The most commonly encountered processing flaws are related to the flow sheet. The flow sheet attracts much attention because it is the basis for the processing plant design through the mass and water balance, design criteria, equipment sizing and selection as well as the determination of consumable and labour requirements and finally operating and capital costs. A flow sheet is based on test work samples, mineralogy and the test work program. If any of these tasks are poorly we are metallurgists, not magicians •• insufficient flexibility •• not been proven on a demonstration scale (cf pilot plant and bench scale tests). Other areas that are often flawed include: •• Metallurgical recoveries: •• limited understanding of sample or test work error (reproducibility) •• no establishment of feed grade-recovery relationships •• no allowance for scale-up. •• Plant design: •• design criteria does not allow for the full range of processing requirements over the life-of-mine (LOM) and may require a later expansion •• equipment selection and sizing unsatisfactory and not well supported 147 A J H Newell •• limited or lack of modelling particularly for milling circuits; eg transfer sizing (semi-autogenous grinding (SAB) / ball mill circuits). •• Operating costs: •• consumable estimates not based on first principles (eg test work or simulation results), however not always an issue, benchmarking may be acceptable •• no current consumable unit cost quotations including power •• proposed levels of costing accuracy not achieved •• no personnel list (employees and on-site contractors). ‘SHOW STOPPER’ PROCESSING CASE STUDIES Three case studies are presented based on process development issues concerning flow sheet design and equipment selection. Each technical due diligences found a ‘show stopper’ that was caused by the equipment vendor being involved in test work and the flow sheet selection. Notably, the test work was designed around the equipment proposed to be supplied. As a result of the due diligence findings, the interest of the investor waned and in two cases, the projects were not developed. The key issues found were: •• some misrepresentation about the capability of the equipment •• some misinterpretation of the test work results •• metallurgical ignorance by the project owners (no technical competency). Case study 1 The Chinese client (an investor without any technical personnel) was proposing to invest in an iron ore project in Australia (hematite property in Western Australia). Initial test work had been conducted with known equipment (Eriez wet high intensity magnetic separation; WHIMS) with positive results; however, these units have high unit capital costs, high power requirements and low unit capacities. The equipment vendor proposed to change the equipment to conventional drum wet magnetic separators with rare earth magnets, which would have significantly lower unit capital and operating costs. However, they would be unable to generate the magnetic forces required to recover the hematite. The proposed equipment was not tested and the metallurgy generated with the WHIMS test work was adopted for the proposed equipment which indicated a very robust project value (NPV) for the project. Case study 2 A major Western gold producer allowed geological staff to conduct a metallurgical study without metallurgical staff input. An equipment vendor conducted the test work (centrifugal concentrator). While the gravity concentration stage was investigated, the remainder of the proposed flow sheet, namely crushing, grinding, gravity concentration, direct smelting of gravity concentrate and cyanidation of gravity tailings, was not tested. Furthermore, no mineralogical studies were undertaken on feed samples or intermediate products eg gravity concentrate. In a subsequent study, it was assumed that it would be technically and economically possible to direct smelt the gravity concentrate with 100 per cent gold recovery. When the technical due diligence challenged this assumption, further test work was undertaken and it was discovered that the gravity concentrate: 148 •• was mainly pyrite, assaying only 30 to 80 g/t Au when 5000 to 8000 g/t (0.5–0.8 per cent Au) is the threshold for direct smelting •• could not be easily upgraded •• had poor gold recovery downstream (low gold recoveries found with intensive leaching). Case study 3 The project assessed was a multibase metal deposit (Cu-PbZn-Ag-Au) in Peru. The gravity concentration vendor had taken over the test work program and not surprisingly, the proposed flow sheet had eight stages of gravity separation, some differential flotation and no tailings stream. Needless to say, this flow sheet was fatally flawed and completely undermined the Feasibility Study. CONCLUSIONS Technical due diligences are often challenging experiences that generally reveal flaws, sometimes fatal, that justify the expense of conducting such investigations. ‘Forearmed is forewarned’ and identifying fatal flaws or ‘show-stoppers’ provides the investor or potential owner with the opportunity to either walk away from the project or become involved by applying a new approach to the project development or operation. While it is difficult to predict general fatal flaws or ‘showstoppers’ for specific projects, they typically arise from: •• insufficient or lack of supporting data •• optimistic, incorrect or poorly based interpretations of data •• poor costing methodologies •• proposed levels of study accuracy not being achieved. For processing, when assessing a project, the primary source of potentially fatal flaws is associated with the development and interpretation of the flow sheet, which is in turn based on the nature of samples and the adequacy of test work. Process design including equipment selection and sizing and the development of capital and operating costs represent two other areas where potential flaws may be found. It is important that technically competent people manage the test work program and subsequent process design and study. In the case of existing operations, the availability of records and the ability to inspect the operation makes conducting a technical due diligence relatively straightforward. Potential flaws may arise through current or potential bottlenecks, the quality of operational staff, the condition of the plant and the ability of the plant to handle future ore types. ACKNOWLEDGEMENTS The author wishes to acknowledge assistance and input from RPM colleagues namely Dick Addison and Don Larsen (Principal Metallurgical Engineers, Denver) as well as Bob Denis (Executive Geological Consultant, Brisbane). REFERENCES Pincock (now RPM Global), 2011. Independent engineer/due diligence reviews [online], Perspectives 111. Available from: <http://www.rpmglobal.com/wp-content/uploads/2015/08/ Issue111-IndependentEngineer.pdf>. we are metallurgists, not magicians Fatal flaws in technical due diligences Pincock (now RPM Global), 2015. Minimum study requirements update [online]. Available from: <http://rpmglobal.com/wp-content/ uploads/2015/08/Issue128-UPDATE-Minimum-EngineeringStudy-Requirements.pdf>. APPENDIX 1 – FEASIBILITY STUDY A Feasibility Study, whether claimed to be Bankable, Definitive or some other rarely met descriptor, is the culmination of a series of studies, typically starting with Conceptual and progressing through Scoping and PreFeasibility. The intent of the study process is to decrease the project risk with increasingly thorough technical studies that define an optimal project development with accurate costings and financial evaluation. Note that the major mining houses, which typically conduct these studies in-house, use different terminologies for these study phases however employ the same processes in determining the optimum project solution. Some companies (eg Vale) have a preference for the front end engineering design, which typically involves three front end loading (FEL) stages (FEL 1, FEL 2 and FEL 3). This approach has a primary focus on establishing the engineering design and subsequent capital and operating costs; it relies on a body of information (eg metallurgical test work) of Feasibility Study standard that needs to be completed before the preliminary study (FEL 1) commences. FEL 1 typically consists of a mass, water and energy balance while FEL 2 prepares the preliminary equipment design, layout, schedule and cost estimates. FEL 3 is more akin to the final design phase (the EPCM stage in Figure 1), where major equipment specifications are prepared, definitive estimates are prepared as well as electrical equipment, line and instrument lists, preliminary 3D model and project execution plan. Unlike a Feasibility Study, where all of the project information is located in one document, this body of information is separate to the FEL study process and generally not readily accessible. For the assessment of projects, Feasibility Studies are the main source of information while supplemented by site visits, other documentation as well as meetings with managers and subject experts, the outcome of a technical due diligence depends heavily on the quality and accuracy of the associated Feasibility Study. Table 1 presents a summary of the study progress, showing the decreasing level of risk and increasing level of detail and accuracy by decreasing the number of options through trade-off studies, particularly in mining, processing and infrastructure. As in a technical due diligence, a Feasibility Study address each major study discipline, that is geology, mining, processing, infrastructure, social/indigenous, environmental and financial analysis, except that in a technical due diligence, it tends to be undertaken by individual subject experts rather than a team. The relationship between studies, with a metallurgical flavour, and the project development cycle is presented in Figure 1. A number of projects experience problems when a study stage is bypassed, for example jumping from a Scoping Study to Feasibility Study or from a Conceptual Study to a PreFeasibility Study. This occurrence lies almost exclusively in the domain of junior mining companies and appears to occur due to a combination of inexperience, attempts to save money and decrease the project development period. In fact it rarely does and often substantially increases both costs and the chances of FIG 1 – Relationship between project studies and project development cycle. we are metallurgists, not magicians 149 A J H Newell TABLE 1 Project studies. Project Stage Conceptual Study Scoping Study Pre-Feasibility Study Feasibility Study EPCM Activity Examine concept Examine options Trade-off studies One option Construction Resource Internal Internal/consultants Internal/consultants/EPCM contractor Internal/consultants/EPCM contractor EPCM contractor Basis Comparable projects Experience Benchmarked costs Database Probable flow sheet Estimate based on data from similar projects Some cost factoring Fixed flow sheet Layout drawings Preliminary process and information drawings Some estimates based on similar projects Budget quotations (key equipment and consumables and contract rates) 20% of the engineering Engineering drawings Process and information drawings Material take-offs Firm quotations (most equipment, all consumables and contract rates) 100% of the engineering Engineering drawings Material take-offs Contracts ±25 ±15 ±5 Capex accuracy ±100 ±50 Contingency ±50 ±20 ±15 ±10 ±10 Opex accuracy ±50 ±40 ±20 to ±25 ±10 to ±15 ±5 Study/activity costs 12.5–25 k 125–250 k 625–1500 k 2.5–5 million 25–50 million Duration 4 weeks 3–6 months 6–12 months 12–18 months 18–36 months Geology Limited drilling Geological understanding More drilling Develop resource model Ore types Inferred Resources Geotechnical and hydrological studies Infill drilling Indicated Resources Inferred Resources Exploration potential Geotechnical and hydrological studies Infill drilling Resource model Condemnation drilling Measured and Indicated Resources Geotechnical and hydrological studies Drilling Continue to upgrade resources Mining Desktop study Probable production rate Probable mining method Equipment and labour requirements Typical capex and opex Whittle Studies Mining options Mine scheduling studies Capex and opex Whittle Studies Optimum production rate Mine scheduling studies Reserves Blast fragmentation studies Capex and opex Mine design Schedules Mining fleet Reserves Detailed capex and opex Prestripping Developing audits and drives/shafts Purchase equipment/ hire contractor Processing Desktop study Typical flow sheet and plant Product volumes Typical flow sheet Mass and water balance Typical capex and opex Mineralogy Limited bench-scale testing Ore characterisation Basic comminution data Process options Probable flow sheet Mass and water balance Equipment selection and sizing Power and water requirements Develop capex and opex: budget quotations for key equipment and consumables, labour Bench-scale testing Variability testing Comminution testing Dewatering testing Flow sheet fixed Mass and water balance Equipment selection and sizing Power and water requirements Develop capex and opex: budget quotations for key equipment and consumables, labour Pilot plant (if required) Detailed comminution testing Comminution and process modelling Mass and water balance Equipment selection and sizing Power and water requirements Detailed capex and opex firm quotations: equipment, consumables Site preparation Source equipment/ installing equipment/building and commissioning plant Training operators Infrastructure Review Outline Infrastructure requirements: sources of power and water Roads, accommodation, logistics Infrastructure options Infrastructure design Indicative contracts for power and water (if appropriate) Install infrastructure (tailings dam) Environmental Regulatory requirements Data collection and baseline studies (usually takes two years) Prepare and submit environmental impact statement Monitoring programs Social and Indigenous Review Discussions with locals Establish needs Develop strategy and initiate negotiations Continued negotiations Signed agreements Marketing Desktop study Product uses/potential for substitution Identify market and buyers Existing and future market size Competitors: existing producers and future projects Future prices Discussions with potential buyers Refine study Product samples for buyers Negotiations Financial analyses Assumed values Exchange rates Exchange rates Detailed NPV analysis: various scenarios High level analysis Discount rate Discount rate NPV: used to compare options (tradeoff studies) and sensitivity analysis NPV: used to compare options (tradeoff studies) and sensitivity analysis Preliminary Detailed Risk and mitigation analysis Identify Off-take agreements Review Based on Pincock (now RPM) (2007, 2009). EPCM – engineering procurement construction management; NPV – net present value. project failure. Moreover, this approach assumes that the project is technically and economically viable, which undermines the purpose of the study process. The Pre-Feasibility Study, 150 for example, serves a very important role and represents a critical stage where the options are investigated, tested and resolved (so-called trade-off studies), allowing a single project we are metallurgists, not magicians Fatal flaws in technical due diligences development pathway to be interrogated in greater depth with regards to costs during the Feasibility Study. •• No comminution (also with Russian TEOs) or dewatering test work conducted. A problem often encountered with studies conducted by junior mining companies is that they have been conducted in a haphazard fashion, typically by different groups of consultants assigned with a particular section obviously working in isolation. This is typically driven by ‘the rush to market’ syndrome, where attracting finance overshadows the need for a thorough understanding and study of the project. This approach is often characterised by the presence of conflicting data indifferent parts of the study as well as limited test work, general lack of supporting detail, optimistic capital and operating cost estimates and the use of current and unrealistic metal prices for revenue calculations. •• Equipment sizes are generally much smaller in size and more numerous: Employing adjectives such as Definitive (should be by definition) or Bankable (confirmed by a bank?) to a Feasibility Study does sound warning bells, suggesting a marketing rather than a study document. •• the value of the mined material is included in the mining operating cost, which is included as a cost in the processing operating cost Often significant differences in critical numbers are found in various parts of the study and other supporting documents, making it difficult to form an opinion. In these cases, there would not appear to have been a study manager controlling and integrating the overall study process, resulting in little or no communication occurring between the disciplines. Studies are an iterative process and require integration through review and communication by all disciplines. For a processing engineer, knowledge of the geological (or block) model, the mining schedule as well as what constitutes a marketable product are critical elements in developing and designing a flow sheet that would successfully process LOM feed and thus maximise the project value. Note that there are so-called Western and non-Western type Feasibility Studies; in most cases, non-Western Feasibility Studies, with the general exception of the Russian TechnioEconomicheskiye Obosnovaniye (TEO), do not meet the standards of a Western Scoping Study let alone a Western type Pre-Feasibility Study. They tend to follow a formulaic approach as prescribed by guidelines held by the Design Institutes. The main differences encountered with non-Western Feasibility Studies are: •• Often a geological model may not exist (except Russian TEOs): •• does not include ore types •• issues with quality assurance / quality control (QA/ QC) procedures as well as assaying methods. •• Resources are not JORC compliant; while other methods of estimating resource are reasonable (for example, Russian), they cannot be simply ‘converted’ into a JORC classification without undertaking a full review, which is very difficult to do when: •• the drill core has been destroyed or lost (cf when the metal is classified by a country as strategic eg uranium in the USSR or tungsten and rare earths in China) •• the actual coordinate system used to locate drill holes is not known. •• Limited mine planning and lack of detailed mining schedules. •• Source of samples not always revealed and often some uncertainty about representativity: •• where samples cannot be obtained for test work (mainly occurs earlier study phases examining underground deposits), metallurgical responses are based either on local, provincial or country metallurgy for that deposit type. we are metallurgists, not magicians •• spiral classifiers commonly used; unusual to see hydrocyclones •• thickeners are rarely used. •• Marketable product grades are lower with higher levels of penalty elements accepted (eg 18 per cent Cu, 40 per cent Zn and 55 per cent Pb). •• Rarely issues with infrastructure – sources power and water are typically provided by the state. •• Different methodology for calculating operating costs: •• depreciation is included as an operating cost which is normally considered as a separate cost in typical Western financial analyses •• product transport costs for projects located in development regions are typically subsidised by the buyer. A Feasibility Study considers the following disciplines, which parallel the technical due diligence assessment process: •• Geology – ownership of tenures; regional and deposit descriptions; geological or block model; data acquisition (drilling methods, core recovery, logging, sampling, assaying, twinning etc); density determinations; quality of the resource estimate (inferred and indicated – data validation, modelling method, QA/QC, interpretation (‘geo-imaginitus’), grade/tonnage relationships etc), exploration history and upside. •• Mining – open cut relatively straightforward, underground more complicated and depends upon the deposit style (cf thin veins and need for backfilling), mining permits, mining design, waste dumps and stockpiles, trade-off studies, mine schedule and production plans, pit wall slope, rock stability and strength (geotechnical studies), dewatering requirements (hydrogeology), equipment, capital and operating costs (methodology, budget quotations, quantity take-offs, consumable and personnel estimates, accuracy, contingencies, equipment/services sources (currency), transport and insurance, dewatering and reserves (proven and probable)). •• Metallurgy – location and nature of samples, test work program, mineralogy, preconcentration, comminution parameters, separation and dewatering; water quality; technical management of waste streams (eg detoxification); flow sheet; mass and water balances; design criteria; equipment selection, sizing and list; comminution and preferably flow sheet modelling; process description; drawings – general arrangement, process flow diagram (PFD), P&IDs and one-line electrical; consumable requirements (power, water, labour, milling media etc); capital and operating costs (methodology, budget quotations, quantity take-offs, factoring, accuracy, contingencies, mobile equipment, equipment/services sources (currency), transport and insurance etc); product schedule. •• Environmental – suitable and sufficient baseline studies have been conducted; appropriate regulatory approvals, permitting and licences eg details of environmental impact assessment or statement (EIA/EIS); stakeholder 151 A J H Newell engagement, environmental management systems (EMS) and environmental/social management plans (EMP) completed; reclamation and closure plan; operating costs; closure costs. •• Infrastructure – requirements/sources/distribution/ reticulation of power and water; if connected to grid power, route map; logistics (roads, rail, airports, ports etc – getting equipment, consumables and personnel to site; getting product to market); buildings (offices, warehouses, maintenance/repair shops, accommodation); allowance for location, climate and seismicity (buildings); construction schedule. •• Social/indigenous – needs to demonstrate a good relationship with local people; support for the project, program of assistance and ongoing interaction. •• Marketing – suitability of product and product specifications, size of market, future of market (competition, growth, substitution etc), product terms (penalties, credits etc), smelting and refining terms, future product prices, product transport route map, arrangements and costs etc. •• Financial evaluation – typically based on discounted cash flow methodology, with NPV used as the measure; only as good as the quality and reliability of the inputs: capital and operating costs (eg estimate basis, nature of the contingencies), future metal prices, exchange rates, inflation rates, discount factor etc). Any NPV must be based on at least Indicated Reserves if a public document and for a Feasibility Study bankers like to generally see at least six years of reserves. •• Project execution – management plan and procedures (owner/EPCM structure and organisation, key personnel and qualifications, project responsibility list (owner-managed and EPCM-managed projects), EPCM contractor procedures (engineering, procurement, construction and reporting etc)), implementation schedule, list of probable contracts and facilities, likelyqualified contractor listings, equipment delivery (long lead items, logistical plans etc). In addition, bankers considering projects in non-Western parts of the world also like to know that the project would meet the Equator Principles (Equator Principles Association, 2011). These are series of guidelines adopted by financial institutions for determining, assessing and managing environmental and social risks. Site inspection Operation •• how the plant is being operated – number of operators, operator activity, housekeeping etc •• condition of the plant – need for equipment replacement, nature and magnitude of maintenance costs •• process bottlenecks •• review sample collection including final concentrates, assay facility, laboratory (routine and future ore testing). Future plans – ore sources, grades, ore types, mineralogy etc. •• Will future ores have different characteristics or grades that will affect the metallurgical performance in terms: •• throughput •• recoveries •• product grades •• What procedures are in place to measure and record any changes in ore types? For instance: •• weekly testing on site •• off-site testing •• frequency •• How would the current flow sheet and equipment handle any changes in ore characteristics? •• Any potential bottlenecks? •• increased hardness – comminution circuits •• grade changes – separation and dewatering circuits •• Flow sheet changes required? •• potential costs •• downtime for installation •• Equipment changes or upgrades required? •• potential costs •• downtime for installation. Future water and power supplies – quantities, availability, supply agreements. Reconciliation between mine and plant Tailings Storage Facility (TSF) capacity – need for another TSF. Future costs – basis for sustaining capital, any capital upgrades/expansions, supporting studies, production and revenue forecasts etc. Project (largely based on a Feasibility Study) Nature of Feasibility Study •• internal or external? REFERENCES Equator Principles Association, 2011. Equator Principles [online]. Available from: <http://www.equator-principles.com/>. Pincock (now RPM), 2007. Minimum report contents for engineering studies, Perspectives, 70 (December). Pincock (now RPM), 2009. Minimum engineering study requirements, Perspectives, 95 (March). APPENDIX 2 – PROCESSING DUE DILIGENCE CHECKLIST Existing operation Historical and current records – production, operating costs, recoveries, product grades etc. 152 •• where they suitably competent to conduct or manage the Feasibility Study? Ore types •• have they been identified? •• reasonableness of classification (degree of oxidation, degree of alteration, mineral gangue ratios (eg chalcopyrite/pyrite ratio), mineral/mineral ratios, impurity or gangue mineral (eg As level)) •• included the geological model (and thus the mine schedule)? Samples – nature of samples and composites: number, type (drill core, air core etc), location, representative in nature, mining year etc. we are metallurgists, not magicians Fatal flaws in technical due diligences Mineralogy – conducted for all ore types and composites; identified economic and impurity types, associations, grain size and rock types; degree of liberation. Test work program •• undertaken by reputable and independent test work provider (cf equipment vendor – under some circumstances) •• conventional or ‘novel’ or using ‘novel’ equipment •• if ‘novel’, a pilot plant or pilot scale test and demonstration plant required •• has addressed the obvious flow sheet options •• sufficient test work has been conducted on an appropriate range and number of samples •• has preconcentration been examined •• has site water or synthetic water been used in test work •• ore variability test work been conducted •• material handling – flow, rill angles, abrasiveness, slurry viscosity etc •• other characteristics: oxygen demand etc •• feed grade-recovery relationship been established for each ore type and mining composite •• has the product been satisfactorily characterised in terms of: •• source for values used in calculations (eg ore, water, product and intermediate stream specific gravity (SGs), mass and metal stage recoveries). •• sufficient flexibility to handle potential variations (‘average’ and ‘design’ cases). process Metal losses •• metal losses for each ore type has been satisfactorily identified: •• addressed the potential for improved recoveries or concentrate grades. Metal recoveries and product grades •• demonstrated as a function of ore types, mining composite types and head grades •• full analysis of final concentrate (credit and penalty elements and levels identified). Design criteria •• basis and source for selection of Design Criteria; is it reasonable and supported? •• transfer sizing for SAG – ball mill circuits •• circulating loads •• product and intermediate product per cent solids •• full assay – credit and penalty elements •• media and reagent consumption rates •• dewatering requirements and equipment requirements •• scale-up factors used to estimate residence time (eg conditioning, flotation, heap leaching etc). •• if a concentrate, TML •• other properties such as size range, friability etc. •• have the tailings been satisfactorily characterised for range of ore types and blends in terms of: •• mineralogical characteristics: •• potential for pollution and acid generation. •• dewatering properties •• backfill and ‘dry stacking’ (where the size range, particularly the amount of fines, is important). •• environmental studies such as detoxification of process water for release into the environment. Flow sheet •• basis for and reasonableness of flow sheet selection •• conventional or ‘novel’ •• unnecessarily complex •• appropriate use of surge capacity within the flow sheet (eg stockpiles, bins or holding tanks with sufficient residence to decouple critical parts of the flow sheet) •• potential bottlenecks. Modelling •• conducted in a satisfactory fashion for the comminution circuit: •• basis for circuit and equipment sizing and selection? •• identified behaviour and impact upon design criteria of different ore types and mine composites. •• where appropriate, for the separation circuit. Mass, water and energy balance •• basis: optimum mining rate study, flow sheet, other data or sources: we are metallurgists, not magicians •• addresses needs of climatic and operating culture requirements (eg cold climate, regulated holiday periods etc). Equipment •• basis for selection, number and sizing: reasonable •• equipment source •• equipment vendor: reputable, critical spares identified, process and equipment warranties, availability for commissioning •• duty specifications: reasonable. Mine schedule •• an optimum mining rate has been determined: •• basis: process capital and operating costs used •• limited by market. •• includes ore types and thus mining composites. Water •• water quality: •• impact upon separation and final product: •• need to wash final product •• need to produce pure water. •• fresh and process water circuits: •• complexity •• adequate storage. •• recovered water: assumptions, recovery from TSF, allowances for evaporation losses etc •• water sources available to sustainability supply processing water requirements (including mine water). 153 A J H Newell Power requirements •• basis (installed equipment, typical operating load, simulations etc). Trade-off studies •• have been applied in a satisfactory manner to select between processing, flow sheet or equipment options: •• for example, ‘dry’ stacking, finer grind etc •• comminution circuits. Product schedule •• basis: •• appropriate mine schedule •• reasonable metal recoveries •• achievable product grades •• varies appropriately with ore types or mine blends. Process description •• cost elements: •• quantities reasonable: consumables, power, water, labour schedule •• unit prices reasonable: with quotations for key equipment; based on data from similar, current projects •• EPCM costs – reasonable for the location and complexity of the project •• what has been factored: piping, installation, commissioning, first fill etc – reasonable and supported. •• basis for determination of sustaining capital costs and is it reasonable? •• contingency: appropriate for commodity, complexity and country location. project Marketing •• has a marketing study been conducted? •• suitable standard? •• has it satisfactorily identified: •• current market, uses and growth •• satisfactorily describes the process flow sheet. •• potential buyers and actual market size for proposed product quality and volumes Operating cost •• methodology/basis: reasonableness (benchmark against similar projects in same operating environment) •• competition: •• other operations (expansions) or projects starting up •• accuracy (typically ±10 per cent feasibility study (FS)): has it been achieved or demonstrated? •• potential substitution. •• cost elements: •• what has been included? •• product specifications and terms (credits, penalties, size ranges, moisture content, other properties) •• quantities reasonable: consumable, labour schedule •• price history and future prices. •• unit prices reasonable with quotations for key consumables including power •• labour costs: salaries and on-cost reasonable •• maintenance cost basis: factoring, reasonable. Capital cost •• methodology/basis: reasonableness (benchmark against similar projects in same operating environment) •• accuracy (typically ±10 per cent FS): has it been achieved or demonstrated? 154 Risks •• has a risk analysis been conducted? •• how does it assess the degree of risk? •• does it identify and rank all potential risks? •• does it provide any recommended mitigating measures? •• does it analyse residual risk (after application of the mitigation)? we are metallurgists, not magicians Contents Guidelines for mineral process plant development studies P R Whincup1 ABSTRACT This paper presents guidelines for studies required for the development of mineral processing facilities from initial feasibility studies through to commissioning. Mining project schedule and cost overruns can often be attributed to inadequate metallurgical test work, engineering and cost estimating leading up to commitment to the project. In some cases this may result from lack of understanding of, and commitment by the project proponent to, the requisite metallurgical and engineering studies during the development stages. Guidelines for metallurgical test work, process development, engineering and estimating requirements for each stage of precommitment studies are described together with those for the engineering phase. INTRODUCTION The continuing rapid rise in metal prices has resulted in an unprecedented global increase in the number of mineral project developments. There have however been instances where companies in their rush to exploit resources, have overlooked or cut short some of the necessary metallurgical and processing studies necessary to ensure that a project is properly implemented and performs in line with expectations. Consequences have included cost and schedule overruns and less than optimal plant performance. This has led to disaffected shareholders, non-performing loans and involuntary and disruptive changes at board and senior management level. Requirements for the various levels of study leading to commitment of funding for mineral project construction have been well documented (White, 2001; Noort and Adams, 2006; Cusworth, 1993; Warren, 1991). This paper focuses on the mineral processing aspects of these studies for which the outputs are: •• throughput and recovery models as well as operating cost and capital cost estimates for the project financial model •• realisation cost information comprising transport cost, treatment and refining charge (TC and RC) data including penalty element deductions and paid metal recoveries •• process plant operating costs to mine planners for pit shells/cut-off grade determination and mining schedules, which are used in an iterative financial modelling process to determine the project scale •• flow sheet and design criteria for the process plant that provides for process variability. These outputs result from metallurgical test programs, engineering cost studies and this paper provides guidelines for the study managers and project metallurgists at each study level: •• scoping •• prefeasibility •• feasibility •• engineering. Processing studies will usually interact closely with other studies contributing to an assessment of project feasibility, which include mineral resource, mining, infrastructure, environmental and marketing studies. SCOPING STUDIES 1. FAusIMM, Whincup and Associates, Lower Templestowe Vic 3107. Email: whincup@optusnet.com.au A scoping study would typically commence following an exploration success to: •• define the range of process options •• establish the project scale 155 P R Whincup •• provide first pass metallurgical recoveries and ore processing costs for resource cut-off grade estimates •• provide first pass cost estimates for a preliminary evaluation of the prospect. Expenditure on extensive sampling and metallurgical test work is usually not justified at this stage. It could be limited to optical mineralogy followed by the minimum bench scale test work necessary to establish indicative metallurgical parameters and would be based on an assumed flow sheet. Examples include an agitated cyanide leach or a roughing/ cleaning flotation test at one or two grind sizes with a typical reagent regime. Limited comminution would be undertaken, which may include determination of approximate work indices using comparative methods. Samples would typically be diamond drill hole quarter core covering identified major mineralisation types and should be selected in consultation with study geologists. For most projects a sample weight of between 5 and 10 kg for each mineralisation type should be sufficient. Scoping study test work would typically cost US$30 000 to US$50 000 including sample collection and freight. Results of test work would provide the basis on which to develop process options. For each option a strengths, weaknesses, opportunities and threats (SWOT) analysis is recommended as at a low level of cost certainty this may be the only way to differentiate between options. From these options a process route would be selected as the basis for the scoping study. It is important to focus on selecting a processing rate or project scale at this time. It is surprising how often detailed studies are attempted without serious efforts to establish the project scale. It requires capital and operating estimates to be conducted over a range of treatment rates for the entire project including the mine, infrastructure and services. The ‘base case’ mining and treatment rate may be determined by: •• Observing the best project net present value (NPV) return over the range examined, although sometimes the numbers are too approximate and unless there is an obvious NPV difference or ‘step change’, this method may be unreliable. •• Using a rule of thumb by assuming a mine life (no less than five years or greater than ten years) and applying this to the expected mining inventory size. For example, the base case treatment rate of a potential base metal resource of 80 Mt could be 8 Mt/a based on a ten-year project life. In this case a range of preliminary capital and processing cost estimates at say 4, 6, 8, 10 and 12 Mt/a would be conducted. During the preliminary evaluation one also needs to consider the likely price cycle of the commodity. In the above example the life of the project would be expected to see production through at least one base metals ‘low cycle’. Unless capital data are available from a recent ore processing plant of the type and capacity envisaged, preliminary capital estimates will usually require some engineering and vendor pricing, which would typically cost US$50 000 to US$100 000. Capital estimates would be based on: •• direct cost estimates for other commodities (for example, steelwork, concrete and piping) factored from the estimated mechanical equipment cost and/ or estimated installed electrical load; most mineral process plant engineers will have in-house factors for determining these, for example, percentages of the mechanical equipment cost or $ kW-1 installed •• indirect costs (for example, engineering, procurement and project management) determined as percentages of the directs total •• from the ‘base case’ capital estimate, estimates covering the range of treatment rates would be made by scaling ‘base case’ capital using, for example, the 6/10 rule: Capital 2 = Capital 1 × (Rate 2/Rate 1)0.6 •• review of step changes in capital. These could be additional costs arising from issues such as additional process lines, change in water supply or electricity sources. Figure 1 shows an example of the capital estimating process for a large simple base metals mineral processing plant covering the required range of processing rates for the example described. In this example a contingency of 20 per cent was allowed and represents the lower limit of the range of contingency allowances applicable to a properly conducted scoping study. At this and subsequent stages of the project an enthusiastic but inexperienced project proponent may be tempted to delete or reduce the contingency. This is an early warning sign that a project could be heading for cost overruns. Benchmarking at this level of study is valuable as a check but care needs to be taken that a comparative project and scope are being examined. Capital estimates using this methodology are considered to be accurate to no better than ±30 per cent. Preliminary processing cost estimates for each treatment rate would be produced from either current cost data from similar operations or from first principles. The setting-up of a processing cost model that reflects fixed and variable cost components is recommended. Once established, the model can then be used over a range of processing rates and refined as the project develops. Table 1 shows typical sources of scoping level processing cost estimates. For projects where a concentrate would be produced for transport to a downstream processing facility realisation costs must be taken into account at the scoping study stage as they usually impact materially on project economics and resource cut-off grade. Realisation costs include concentrate transport, treatment and refining charges and can amount to 10– 15 per cent of the in situ ore value. Indicative transport costs can be obtained from specialist road transport and rail freight operators. Treatment and refining charges are available from commodities research groups. It is recommended that at the scoping stage a risk and opportunity register be established and reviewed during each subsequent study stage. Time required for a scoping level processing study will be dependent on availability of data; however, for planning purposes a minimum of six months is recommended. •• assumed flow sheet showing all major mechanical equipment and ‘base case’ major process flows PREFEASIBILITY STUDIES •• preliminary layout sketches The prefeasibility study (PFS) has three functions: •• ‘base case’ mechanical equipment and electrical load lists •• mechanical equipment pricing using recent pricing from other projects or single vendor budget pricing 156 1. evaluate all process options by establishing preliminary financials for each 2. select one or two options for more detailed cost analysis we are metallurgists, not magicians Guidelines for mineral process plant development studies FIG 1 – Scoping level comparative capital estimates (US$M). Table 1 Basis for preliminary ore processing cost estimates. Expense element (notional, simple base metals plant) Basis Operating and maintenance labour Conceptual manning schedule. Total employment costs from recent industry remuneration surveys or similar operations. Employee related government charges can be sourced from government websites. Grinding metal Annual grinding mill relines cost from other similar projects or single vendor pricing. Annual crusher relines cost from other similar projects or single vendor pricing. Typical grinding media consumption and current pricing. Consumables Typical or preliminary test work consumptions and current pricing. Maintenance materials and services 5 per cent of direct capital cost. Allowance for lubricants. Technical services (eg assays, metallurgical consultants, audits) Allowances based on similar projects. Services (eg freight, engineering, other consultants) Allowances based on similar projects. Energy Preliminary electrical load list, diversified load or an allowance of 35 kWh t-1 of plant throughput. For grid power use available gazetted prices. For diesel generated power use current or recent comparable buildown-operate vendor pricing and the diesel price selected for the project. Water Allowances for other energy sources. Project unit cost based on a consumption of 1 kL t-1 treated. 3. refine capital and operating cost estimates, metallurgical recoveries and concentrate quality ranges for project financial modelling. These objectives would be met by metallurgical test work, and engineering and cost studies. Test work would be aimed at providing sufficient data on which to: •• undertake comparative evaluations of process options •• establish the key preliminary design criteria on which to base the engineering work needed to upgrade capital and processing cost estimates to prefeasibility level. Test work will typically also produce samples for tailing storage, environmental and marketing studies. The source of sample material for prefeasibility test work would be as for the scoping study test work, drill core. However, a minimum total sample weight for each mineralisation type of ~50 kg would be required for bench scale we are metallurgists, not magicians concentration or extraction testing. An additional 80–100 kg of unbroken composite core sample material would be required for comminution testing. Residual sample and selected test products should be retained in storage until at least completion of plant performance testing or abandonment of the project. It is strongly recommended that the detailed test program be developed well in advance of sample selection, in consultation with the selected laboratory and with one or more specialist metallurgical consultants to reduce the risk of significant additional sample material and test work being required at detailed feasibility or design stage to resolve flow sheet uncertainties. The scope of comminution test work on a composite sample or, depending on variability of the lithology, a number of individual samples of the major lithology types, should be sufficient to establish the comminution circuit. Test work would usually include: 157 P R Whincup •• unconfined compressive strength (UCS) •• Bond crushing work index (CWI) •• Bond rod mill work index (RWI) •• Bond ball mill work index (BWI) •• abrasion index (AI). SAG Mill Comminution Tests (SMC Tests®) may not be required at this stage if there are other strong indicators that the mineralisation would or would not be suitable for SAG milling: •• mineralisation is not from a very competent uniform zone or a fully oxidised clayey zone •• UCS >180 MPa •• BWI >20 kWh t-1 •• RWI is not significantly higher than the BWI and both are not significantly >15 kWh t-1. Morrell (2009) has provided guidelines for the number of comminution samples required using classical statistical analysis of comminution parameters starting with a minimum of ten samples, respectively representative of each production year, if possible, as well as guidance on selection of tests, test equipment and modelling techniques. It is advisable to have preliminary comminution parameters of potential ore types benchmarked for SAG milling amenability using a specialist comminution consultant. Initial prefeasibility leaching, flotation, gravity and other beneficiation test work would focus on elimination of process options. For example, combinations of flotation, gravity and cyanide leach tests on a copper–gold ore would be aimed at resolving questions such as whether to include a gravity circuit for gold removal, merits of intensive cyanide leach on a gravity gold concentrate or cyanidation of an auriferous pyrite flotation concentrate. Comparative capital and processing costs may be required to identify preferred process options. Bench-scale batch tests will usually suffice but the number and complexity of tests required will be specific to the mineralogy of the prospect. Following determination of a preferred process route some optimisation test work should be undertaken, particularly to determine the grind/recovery relationship for major mineralisation types, and in the case of a concentrate, the grind/recovery/concentrate grade relationship. A single locked cycle test and single test on reground middling for each major mineralisation type would usually be the limit of prefeasibility test work. Reagent optimisation would not normally be done at this stage unless reagent selection has potential to materially impact project viability. The study metallurgist should consider engaging an independent third party to review the metallurgy and processing aspects of PFS and subsequent studies leading up to commitment to the project. An allowance of at least US$70 000 to US$100 000 is recommended for prefeasibility level test work for simple metallurgical processes. Complex processes such as those for refractory gold mineralisation treatment would need to be estimated on a case by case basis but a cost within a range of US$200 000 to US$500 000 would not be unexpected. Engineering at prefeasibility level would usually be undertaken by an engineering consultancy experienced in the design type of the mineral processing facility anticipated. For most ores any one of over 20 internationally recognised engineers would be appropriate. Selection of the engineer would be based on considerations of cost, relevant experience, quality, availability of people and location. 158 Prefeasibility engineering would typically cover delivery of an engineering and cost study covering: •• key design criteria •• preliminary flow sheets and piping and instrumentation diagrams (PIDs) •• preliminary mass balance, including a water balance •• site selection and layout drawings •• a limited number of preliminary general arrangement (GA) drawings, plans and sections taking into account safety, operability and maintainability; it is not unusual to commence the development of 2D and, in some instances, 3D computer-aided design (CAD) models at this stage to provide GA and plan layouts with sufficient detail, enabling preliminary materials takeoffs (MTOs) for cost estimating •• preliminary mechanical and electrical equipment lists •• preliminary electrical load list •• preliminary commodity pricing •• capital cost estimate •• processing cost estimate •• preliminary schedule including a capital disbursement schedule •• study report. Engineering design should take into account known environmental and regulatory constraints. Capital estimates would be typically based on: •• mechanical and electrical equipment pricing using a single vendor quotation •• structural steelwork, plate work, concrete, major piping and architectural MTOs and single vendor written quotation •• factored costs for other commodities shown in Figure 1, including architectural – use of factors for prefeasibility direct capital estimates assumes that the process plant is typical of those from which the engineer has derived the factors; however, if the process plant is known, for example, to have an unusual amount of pipe work or speciality pipe or plate work, MTOs and pricing should be used for that commodity •• owner’s preproduction capital from preliminary quantities and current rates, and should contain an allowance for spare parts based on a percentage of mechanical equipment capital •• estimated feasibility level metallurgical test work and engineering costs •• an assessment of working capital •• other indirect costs as percentages of directs •• a preliminary engineering and construction schedule. It is recommended that during prefeasibility engineering a work breakdown structure (WBS) be developed for the entire project (including mining, infrastructure and indirect costs) and the estimating package set-up. Capital estimates produced for a PFS should have an overall accuracy in the range from ±20 to ±25 per cent. The processing cost model developed at the scoping study stage would be updated and refined, and include: •• a preliminary ore processing and production schedule •• a revised manning schedule and current industry rates applicable to the location we are metallurgists, not magicians Guidelines for mineral process plant development studies •• estimates associated with on-site accommodation and rotational travel •• consumable costs determined using rates from test work and current vendor pricing •• maintenance materials as a percentage of the direct capital cost •• allowances for services •• electrical energy costs based on electrical load list and written vendor pricing •• other energy from estimated consumption derived from preliminary equipment vendor data, engineering and current pricing, taking into account freight and storage for items such as diesel fuel oil and liquefied petroleum gas (LPG). The processing cost model should be extended to cover preproduction capitalised processing costs and set-up on a quarter by quarter basis for at least four years from project commitment and annually thereafter. The required time to commission the process plant and ramp-up to capacity needs to be considered at this stage to assist in assessing working capital requirements. Realisation costs should be updated based on: •• product quality determined from metallurgical test work •• preliminary transport studies including vendor budget pricing •• current or predicted industry treatment and refining costs, penalties, deductions and price participation arrangements; for smaller companies, use of a mineral commodity marketing consultant is suggested. At this point the financial and technical aspects of the project are reviewed and further test work, options evaluation and value engineering may be required before committing to feasibility level studies. Corporate self-discipline may be required so as not to rush into a detailed feasibility study with significant technical issues unresolved. A time of 8–12 months for the PFS could be assumed for study planning purposes. Detailed feasibility studies At this stage of the project there is a reasonable expectation that the project will proceed and metallurgical test work and process plant engineering would be undertaken on this basis. Study results may form the basis for a project funding request. During the process plant feasibility study all design level metallurgical test work should be completed together with 30 per cent of the engineering. Dependent on equipment lead times, it may be prudent to complete sufficient test work and engineering to allow ordering of long delivery equipment (eg grinding mills) prior to project approval. On more than one occasion urgent additional comminution test work and grinding mill specification work have been required after project commitment to allow the mills to be ordered to meet the committed project schedule. Design level metallurgical test work should be commenced early in the study and should be scoped in consultation with the proposed laboratories, a recognised comminution consultant and, if applicable, a metallurgical consultant specialising in the subject metallurgy and processing techniques (for example, flotation). Early in the feasibility study dedicated metallurgical samples should be taken. Sample locations should be selected in consultation with resource geologists and a consulting mineralogist. Samples should include dilution waste rock. we are metallurgists, not magicians Morrell (personal communication, 2008) has advised that while large diameter diamond core PQ (85 mm diameter) size samples may be taken, use of smaller diameter core, for example, NQ (50 mm diameter) as comminution sample material is satisfactory. Generally few contemporary test procedures, in particular the drop weight test that forms the basis for the SMC Test®, make any practical use of the information from larger rocks. Sample weight for comminution testing would typically be 700–1000 kg for each lithological domain. Ideally the domain should be defined in terms of comminution properties, which may not necessarily coincide with the mineralogical domains. The additional sample weight required for other design level test work and variability testing is likely to be an additional 200–500 kg per geological/mineralogical domain if these domains are not the same as those identified by comminution properties. Mineralogical investigations should be conducted on samples or specimens from each geological/mineralogical domain before finalisation of the test program and include: •• mineralogical examination including multiple optical evaluations •• mineral liberation analyser (MLA) or quantitative evaluation of minerals by scanning electron microscopy (QEMSCAN) bulk modal analysis. The following two-stage approach to comminution testing is also suggested by Morrell (2009). In the first, limited stage, sufficient samples are tested to carry out a statistical analysis, following which a more extensive program is undertaken, based on results of the first. The wider the spread of results from the first stage, the more samples would be needed for the second. The first stage would typically involve four to five samples from each domain. Comminution test requirements for samples from each domain are as for the comminution testing recommended for PFS together with: •• Bond AI and UCS if not included in previous test programs. •• JK Mineral Research Centre (JKMRC) drop weight tests or the recently developed JK rotary breakage tests (JKRBT). •• SMC Test®. •• If geotechnical core is being point load tested then consideration could be given to having point load testing done on comminution test samples to provide a link between the two databases. Point load tests correlate quite well with the SMC Test® results and hence the geotechnical data can provide a good indication of SAG mill competency variability. The crushed products from the drop weight and SMC Test® can be reused for the Bond mill work index work if sample quantity is a problem. Pilot scale comminution testing is not generally required as comminution consultant databases are now sufficiently large to preclude the need for pilot scale testing; unless rarer circuits are being designed (eg single stage autogenous grinding milling or high pressure grinding rolls). Other feasibility bench scale test work is process specific but, for example, for a large copper–gold orebody for which treatment by flotation to produce a saleable concentrate is proposed, the test work should include for each ore type as a minimum: 159 P R Whincup •• roughing and cleaning batch tests to establish baseline flotation conditions •• providing any necessary processing cost input data (for example, manning schedule). •• bench scale locked cycle tests to establish optimum grind sizes, flotation conditions and reagent regime leading to definition of a standard test flow sheet. Engineering deliverables will include: Variability testing for the recovery and throughput using the standard test flow sheets should be undertaken: •• by production year in which composites representing production periods are evaluated •• characterisation of the deposit by testing a variety of samples representing the spatial distribution of each mineralogical and lithological zone within the deposit. Pilot scale beneficiation testing needs to be considered. For simple mineralogy, and established unit processes, pilot scale test work is usually not justified. Indicators of the need for pilot scale testing include unusually complex mineralogy and use of new or uncommon technology. Between a clear case for not including pilot scale testing and clear necessity lies a range of situations for which consideration would be given to time, cost and risk to arrive at a decision. As a general principle pilot scale testing hydrometallurgical processes must be considered as issues such as penalty element buildup and side reactions leading to scaling may not be apparent during bench scale testing. Test work samples should be made available to equipment vendors to enable equipment specification and pricing. These will include, for example, settling test work for thickener sizing and viscosity testing for pump selection. Samples of test work residues should be retained for testing by the tailing storage facility engineer. The cost of feasibility level test work will vary but the following may be taken as a general guide for a large orebody with three domains: Mineralogy US$100 000 Comminution US$250 000 Bench scale testing US$300 000 to US$400 000 Vendor test work US$50 000 Pilot scale test work US$250 000 to >US$1 000 000 These allowances exclude the cost of sample collection and freight. Feasibility process plant engineering should be awarded to an appropriately qualified and experienced process plant engineer in a process where tenders are evaluated on: •• ability to meet the scope and deliverables •• detailed design criteria •• detailed flow sheets •• mass balances for both design and operating departures •• life-of-mine ore treatment and production schedule by ore type •• PIDs •• detailed site layout drawings showing site roads, hardstand, plant service buildings and services (consideration may need to be given at this stage of the project to provision for future expansion of the ore processing facilities) •• GA and plan/section drawings taking into account safety, constructability, operability and maintainability. The applicable CAD 2D or 3D model would be considerably refined and optimised from that commenced at prefeasibility level •• mechanical and electrical equipment lists •• electrical load list •• data sheets and specifications for any critical long delivery equipment (eg grinding mills and large transformers) •• MTOs and written quotation pricing for all commodities •• estimated construction hours and construction labour rates •• detailed capital cost estimate in the WBS format to an accuracy of no less than ±15 per cent •• processing cost estimate to an overall accuracy of no less than ±15 per cent •• engineering, construction and commissioning plans and schedules including a quarter by quarter capital disbursement schedule •• plant and unit process performance guarantees •• study report. The design criteria and mass balance should provide for a certain amount of variability however to accommodate shortterm variability may be unjustified from a capital perspective and this variability would be taken up in operations by stockpile management. The process plant production and processing cost models should be refined and updated to include: •• price •• ore processing and production schedule by ore type on a quarter by quarter basis for at least two years following commissioning and semiannually thereafter •• acceptability to proposed financiers (usually decided at the prequalification stage) •• metallurgical parameters determined from test work (recoveries and product quality) for each ore type •• quality of the proposed study team •• realistic ramp-up factors (recovery, plant availability and product quality) •• experience in the type of facilities proposed •• availability and timing •• location. The project metallurgist plays a role in the engineering and cost study by: •• timely provision of results of metallurgical test work •• providing input to the plant design operating and maintenance philosophies •• making process related decisions •• participating in hazard and operability (HAZOP) studies •• initiating value engineering, if required •• signing off key process documents 160 •• labour costs from feasibility study manning schedule and rates agreed with operations management •• consumables usage determined from metallurgical test work results and process engineering (metal wear, power and reagent consumptions) and written vendor pricing •• maintenance materials as a percentage of the feasibility capital •• energy costs from feasibility engineering, electrical load list and written vendor pricing •• services costs (eg laboratory, freight and consultants) from written vendor pricing. we are metallurgists, not magicians Guidelines for mineral process plant development studies During the feasibility study revision of the resource model may be required to take account of updated metallurgical parameters and processing costs. Realisation costs should be updated based on: •• product quality determined from metallurgical test work •• detailed transport studies and vendor written pricing •• negotiated offtake agreements with product purchasers (for example, smelters). The updated capital, processing and realisation cost estimates will be included in the project financial model. The project metallurgist should be proactive in reviewing the total model to ensure its completeness and accuracy from a processing perspective and to reduce the risk of items being omitted or double counted, particularly at the process plant/ mine and process plant/infrastructure interfaces. The feasibility study should include a project risk analysis of risks associated with the delivery and operation of the process plant. For planning purposes a minimum of 12 months should be allowed for completion of processing facilities feasibility studies. ENGINEERING AND CONSTRUCTION Engineering and construction is usually managed by an engineering and construction company under, for example an Engineering, Procurement and Construction Management (EPCM) contract. This may include commissioning in conjunction with the owner’s operations team. The quality of the preceding feasibility study notwithstanding the success of a project is very dependent on selection and management of, in this example, the EPCM contractor. As with the feasibility engineer, the EPCM contractor must be selected on the ability to meet key performance criteria. A dedicated owner’s team with experience in project delivery (as opposed to operations experience) would be formed to support and manage the EPCM contractor. For the study metallurgist the engineering phase in the development of a project commences the transition from providing input to the final design and engineering of the process plant to preparation for commissioning and operations. During detailed engineering the study metallurgist will assist with equipment selection, layout and process control we are metallurgists, not magicians and will review critical documents such as process design criteria, mass balance and flow sheets and recommend these for sign-off for construction. Some additional metallurgical test work may be required for which sample material from the preceding feasibility study test work would be used. During the engineering phase facilities required for process monitoring and control will be defined and there may be the temptation to include all the control systems that might be required. On the other hand, there will sometimes be pressure by others in the owner’s team to remove control systems, including sampling systems as the capital cost increases, often without undertaking any value engineering. One approach to resolve the potential conflict is to include all facilities that are normally or typically included for the type of process plus any for which there is demonstrated short-term economic value. In cases where uncertainty exists, allowances should be made in the estimate outside of the normal project contingencies for inclusion of these items post-commissioning and where economic benefit can be demonstrated. At a point where ~60 per cent of engineering has been completed, the estimate should be to an accuracy of no less than ±10 per cent, and becomes the control budget for construction. REFERENCES Cusworth, N, 1993. Predevelopment expenditure, in Cost Estimation Handbook for the Australian Mining Industry (eds: M Noakes and T Lanz) pp 252–259 (The Australasian Institute of Mining and Metallurgy: Melbourne). Morrell, S, 2009. Generating optimum value from ore characterisation programs in design and geometallurgical projects associated with comminution circuits, in Proceedings Tenth Mill Operators’ Conference, pp 167–170 (The Australasian Institute of Mining and Metallurgy: Melbourne). Noort, D J and Adams, C, 2006. Effective mining project management systems, in Proceedings International Mine Management Conference, pp 87–96 (The Australasian Institute of Mining and Metallurgy: Melbourne). Warren, M J, 1991. Pre-feasibility and feasibility studies: a case for improvements, in Proceedings Mining Industry Optimisation Conference, pp 1–11 (The Australasian Institute of Mining and Metallurgy: Melbourne). White, M E, 2001. Feasibility studies-scope and accuracy, in Mineral Resource and Ore Reserve Estimation – The AusIMM Guide to Good Practice (ed: A C Edwards), pp 412–434 (The Australasian Institute of Mining and Metallurgy: Melbourne). 161 Contents Project delivery G Lane1 and E Skinner2 ABSTRACT Project delivery strategies are determined by project context, business case requirements, scale of project, market conditions, owner’s capability and preference, contractor’s experience, resource and skill availability, project location and type of project or facility. Successful project management requires the setting of coherent, effective and realistic business objectives and success criteria. The management team needs to lead, prioritise, resource, align, plan, track and communicate the processes that enable the realisation of these business objectives and success criteria. For any given project, there is a unique balance between selection of a simple project delivery strategy that minimises interfaces and a complex strategy that necessarily engages the use of expertise and experience from numerous parties. The right balance for a project between these ‘book-end cases’ is a function of how the project owner or managing contractor defines its objectives and chooses to manage risk, cost, schedule and project quality, in the context of the conditions affecting the project. Selection of an effective project delivery strategy requires a detailed appreciation of the range of external and internal environmental factors which shape and influence the project. These factors include the project constraints imposed by the business, market or operational environments and the selection of an effective mix of primary (head contract), secondary (mix of vertical and horizontal packages) and tertiary (type of individual contract) strategies. The selection of the primary, secondary and tertiary strategies also shapes the project, the size and responsibilities of the owner’s team and the framework for delivery of outcomes. How does an owner or prime contractor decide? What is the optimum for a given project? Those with operations management backgrounds will have different views to those with project and construction management backgrounds. Is the simplest practical approach the best approach? Each and every interface needs to be managed. The owner will want a very experienced team that is engaged directly with the owner. The team will have a track record of successfully performing projects using contractors skilled in their respective disciplines and selected using competitive tendering on brilliantly designed scopes of work and good contract terms, with a fully defined project scope and appropriate schedule, for which all significant risks have been addressed and no scope changes are outstanding. Budget and schedule will be expected to have been developed with a full understanding of the scope, situation, risk management requirements and so on. The problem is that these conditions rarely exist. The challenge in selection of a project delivery strategy is to resolve how best to address the inadequacies between the ideal case and the present reality. The mechanism for addressing the inadequacies defines the likely outcome of the project. INTRODUCTION Project delivery strategies are often discussed in the context of the advantages and disadvantages of the common primary strategies: •• reimbursable engineering •• procurement •• engineering, procurement, construction and management (EPCM) versus lump sum engineering 1. FAusIMM, Chief Technical Officer, Ausenco Minerals & Metals, South Brisbane Qld 4101. Email: greg.lane@ausenco.com 2. Vice President, Project Delivery, Ausenco. Email: ed.skinner@ausenco.com •• engineering, procurement, and construction (EPC) (for example Gabrielson, 2007; Hundertmake et al, 2008; Loots and Henchie, 2007). These advantages and disadvantages usually revolve around the key criteria for project delivery: •• cost •• schedule 163 G Lane and E Skinner •• quality. Notionally, EPC provides cost security, but a poorly defined EPC scope can lead to additional claims. EPC contracts generally impose a quantum of risk on the contractor which may invite a significant cost premium. Poorly managed EPC contracts may see either the owner bearing more costs, or the contractor seeking to cut costs at risk of schedule or quality outcomes for the owner. EPCM has the advantage of flexibility, transparency and quality control with the potential disadvantages of cost and schedule growth where project definition and/or controls are inadequate. Beneath this primary strategy level there are a multitude of options that determine the shape and outcomes of the project. Selection of a complex packaging and delivery strategy in the interests of say, cost economy or community engagement leads to an increased number of interfaces. Increased interfaces lead to complexity for the owner and contractors requiring higher levels of management and control. This often provides fertile ground for interface related claims from contractors. A small project using proven technology and applying a simple project delivery strategy can be managed with a small team and simplified systems. Increased scale of project, the introduction of one or more novel technologies or more complex interfaces often demand corresponding modifications to team size and competency, and the complexity of systems required to deliver the project. Interface management often becomes a key determinant of team size and project systems for larger, more complex projects. Team capability needs to be matched by trust and accountability by the team to deliver a large project successfully. This paper discusses the project delivery options that are available to a project developer/owner. The various levels of delivery strategy are summarised to provide context for how factors that are internal and external to the project drive strategy selection. Finally, some case study examples of strategy selection processes are provided to illustrate both success and where improvement is possible. PROJECT DELIVERY OPTIONS Each project is unique, as are the factors affecting the business case for the project, the market conditions predicted to prevail during the production life cycle and the owner’s circumstances. In forming a business case for a project, owners need to take a long-term view with careful and holistic consideration of all the factors affecting a financial investment decision. These considerations may include the following interrelated factors: •• size and richness of the resource •• costs of extraction of the resource •• return on investment (ROI) •• market for the product •• production scale of the project •• costs of establishment of production facilities •• sources of labour skills for construction and operation •• sources of construction materials and operating consumables •• external factors (government, community, competitors, stakeholders) •• time to market •• long-term positioning of the owner’s operating cost profile in context of the market. 164 Decisions around the factors affecting the business case have a significant bearing on the investment decision, the project delivery strategy, project timing requirements and subsequent operations. For any given project, there is a unique balance between selection of a simple project delivery strategy that minimises interfaces and a complex strategy that necessarily engages the use of expertise and experience from numerous parties. The right balance for a project between these ‘book-end cases’ is a function of how the project owner or managing contractor defines its objectives and chooses to manage risk, cost, schedule and project quality, in the context of the conditions affecting the project. Post the business case planning phase, the commonly applied options available to the project are summarised below in the context of primary, secondary and tertiary level strategies that address the head contract, management method and delivery approach, respectively. Primary delivery strategies At the primary level the delivery options are: •• Owner self-perform – the project owner’s team directly manages and controls contractors or employees that complete the works. •• Augmentation strategies – the owner’s team is supported by a specialist project delivery team to directly manage and control contractors or employees that complete the works. The supporting mechanism may be one of the following: •• Program management – adopts a holistic approach to project delivery, with capabilities extending across the complete project life cycle. Hence, program management is used in the context where a contractor takes on a broader role than just a project to deliver multiple interrelated outcomes (Table 1). Program management is sometimes also used to address a series of concurrent projects which together form a program of works (eg complex sustaining capital works projects). By contrast, ‘project management’ usually refers to a single project which can be delivered independently of any concurrent activities by an owner and which for purposes of this paper, does not extend across the project life cycle. •• Alliance arrangements – can result from the owner incorporating contractor’s personnel into the project management team. True alliances result in ‘salt and pepper’ teams where project outcomes are shared on a pain/gain basis. Pseudo-alliances can result from ‘body-hire’ style models where the contractors risk exposure is negligible. •• Outsourcing strategies – the most common primary strategies: •• EPC (fixed price) or lump sum turnkey (LSTK) approaches are used to transfer the bulk of the project design and construction risk (and potential reward) to the contractor. To be successful, the realised rewards need to be significant for both parties and the scope of delivery needs to be well-defined. LSTK projects may involve extended performance warranties over and above typical EPC delivery where the contractor accepts responsibility for performance of the entire project as a functional unit. EPC delivery may include nearly all project scope of work, or subelements of the project which can be adequately segregated and tested for performance in isolation from the interfacing We are metallurgists, not magicians Project delivery Table 1 Comparison of projects with programs. Project management Program management Fixed duration Undetermined duration, or determined across a suite of deliverables which may have imprecise delivery timeframes Defined objectives Defined/negotiated objectives accommodating a broader delivery framework Task focused Goal focused Focused on specific task/project Focused on multiple projects or across multiple phases in a single project life-cycle Manager as overseer Leader as creative thinker in addition to manager as overseer role Single deliverable Multiple interrelated outcomes elements of the project. In such cases, contractors are reluctant to accept risk of performance outside their control. This classically arises where the feed products from one subelement of the production chain are required in sufficient quality, quantity and feed rate to performance test another system. •• EPCM (fee for service) is the most common head contract model used in the minerals business. All services expended to meet the scope of services defined in the head contract are reimbursable and performance warranties are typically diminished when compared with EPC contracts due to increased owner input to engineering design and construction. EPCM delivery is generally for a scope that includes the majority of design and construction works within a project. Some elements may be retained by the owner, typically those related to mining and external authorities. Secondary delivery strategies Secondary level strategies relate to the method of managing the scope of services. The packaging strategy is tied to the primary delivery strategies and may be constrained to respond to external factors (eg financing, equity partner requirements, permitting, community requirements, time to market) or internal factors (eg owner organisation, capacity, level of project definition). Secondary level strategies can relate to front end engineering design (FEED), organisation of early site works, or permitting. Activities may be tied to the packaging approach and selection between vertically integrated packages, horizontal discipline based packages and/or ‘EPCM self-perform’ delivery. Vertical packages are typically for blocks of work that are supplied as complete systems, where the contractor is required to perform all works from the ground up to point of handover of a functioning asset. Examples include accommodation villages, primary crushing stations, power stations, technology packages or other similar elements of project that can be effectively designed, procured and constructed as a packaged scope of work. Vertical packaging is viable where the contractor can economically perform an entire package of works and operate relatively independently from other interfacing works. Horizontal packages represent a practical solution where quantities are large and/or scope overlaps between packages provide a viable case for deploying contractors geared for performance of works on a bulk scale. Examples include site survey, bulk earthworks and drainage, roads, concrete, steelwork, site erected tanks forming part of a broader system, electrical bulk scopes or combination works such as steelwork, mechanical equipment, platework and piping (SMP) or bulk electrical and instrumentation packages (E&I). We are metallurgists, not magicians Project framing considerations will determine logical selection of compensation methods. Common choices include schedule of rates, cost plus and lump sum basis. The pros and cons of these approaches are provided in Table 2. As seen in Table 2, increasing time risk for lump sum compensation arrangements relates to time investment by the owner to achieve sufficient definition to support a lump sum contract. Given that the lump sum contractor is accepting cost and time risk, lump sum compensation arrangements represent an incentive for contractors to complete works at high levels of efficiency. Owners and EPCM contractors can choose to ‘self-perform’ project works. This typically occurs: •• when the owner or EPCM contractor has access to equipment and can perform certain works economically (eg use of a mine fleet for bulk earthworks) •• for minor works which may not justify costs of equipment mobilisation and demobilisation •• where contractors have their own integrated or related workforce •• where contractors are unwilling or unable to accept the risk associated with location, scope or supply. Mixtures of the above and hybrid approaches are also common. Table 3 illustrates the contracting approach used by a major copper-gold project. This model included a head contract with an EPCM contractor. Tertiary strategies Tertiary level strategies relate to the mix of methods of delivery. These include: •• design only •• supply (and fabricate) only •• design and supply •• design, supply and construct (D&C) •• construct only •• hybrid types. An example of the mix of delivery methods for a large copper concentrator within an EPCM contract and using various horizontal, vertical and EPCM self-perform delivery models is provided in Table 4. The selection of the primary, secondary and tertiary strategies shape the project, the size and responsibilities of the owner’s team and the framework for delivery of outcomes. At the tertiary level, the owner may choose (for a range of reasons), to combine supply and fabrication or fabrication and installation scope, free-issue equipment and/or materials by the owner or the head contractor, and a myriad of other procurement, fabrication and contracting options. 165 G Lane and E Skinner Table 2 Pros and cons of contract types. Contract type Cost plus Schedule of rates Lump sum Positives Can begin very quickly Certainty on unit rates (for example, $/t steel, $/m3 concrete etc) Certainty of price Can commence quickly while design is being completed Negatives • no certainty of price • no incentive by Contractor to minimise cost or time • owner takes the risk on quantities • must define what each rate includes (for example, for concrete) • detail excavation • formwork • rebar • concrete • hold down bolts etc Needs a higher level of engineering and scope definition prior to contract bid Increasing cost risk Increasing schedule risk Table 3 Example of contracting strategy – used for a major copper-gold project. Area Vertical, D&C Fixed price Concentrate and return water lines Horizontal Fixed price Direct hire/sub-contract Site preparation Horizontal Fixed price 132/33 kV substation Vertical, D&C Fixed price HV distribution Vertical, D&C Fixed price Administration building Vertical, D&C Fixed price Store and workshop Vertical, D&C Fixed price Field erected tanks Horizontal Fixed price Primary crusher facility Vertical, D&C Fixed price Conveyors and pebble crusher facility Vertical, D&C Fixed price Concentrator area concrete Horizontal Fixed price Concentrator structural steel Horizontal Fixed price Mills installation Horizontal Fixed price Mechanical – piping installation Horizontal Fixed price Concentrator electrical and control Horizontal Fixed price Tailings and water pipelines Horizontal Fixed price Concentrate dewatering facility (Blayney) Vertical, D&C Fixed price Process water ponds Horizontal Fixed price Site access road Self-perform SHAPING FACTORS THAT INFLUENCE THE STRATEGY The selection of the best delivery strategy depends on the significant factors affecting the project and the strategic elements related to the assembly of the selected solutions. Early attention to shaping factors drives project stability (Merrow, 2011). The early sharing of knowledge regarding shaping factors and structure facilitates coherent alignment among the project delivery team and stakeholders. Significant factors include: •• project business case 166 •• financing requirements •• context and location Type Water storage Tailings dam •• market conditions (revenue side considerations) •• external environmental variables with potential to affect project delivery •• market conditions (availability of owner/contractor resources/competition for these resources, offshore versus on-shore supply, stick build versus modular construction) •• technical factors •• operational needs •• project scope •• level of definition around basic data (process material quality/morphology, services, geotechnical conditions, permitting etc). All the above can be quantified and valued as inputs into the assembly of the delivery strategy. Additionally, several known but unquantifiable factors may be significant in strategy selection. ‘Unknown unknowns’ are generally considered as part of contingency assessment for the project and do not form part of a packaging strategy. The strategic element in conceptualisation relates to the ability of the team to identify the issues (and opportunities) that are impacting and/or may impact on the project, to diagnose the causes, to develop solution frameworks and to map these against the available options. On some occasions project owners/managers/directors come to a project with experiences (‘baggage’) that predetermine the strategy for the project. Some prefer the selfperform approach, some EPC, others favour alliances, and still others choose hybrid approaches that have worked in the past. Whilst experience from past projects is highly valuable, a healthy project climate is one in which decisions are based on facts and robust debate occurs around appropriate strategies to address the facts. Strategy complexity The size of the combined owner’s and EPCM teams will be driven by the complexity of the strategy and the accompanying management systems and protocols. Simple contracting strategies need a high level of clarity, accountability and trust to be successful. The advantages We are metallurgists, not magicians Project delivery Table 4 An example of a mix of contract types for a large copper concentrator. Activity Facility Primary crusher O/L conveyer Stockpile and reclaim Grinding Pebble crusher Site preparation Flotation Thickening Moly plant Concrete handling HV power supply Tailings piping C3 C5 Water supply C1 Engineering C6 Concrete C7 C8 Steelwork – fabrication C9 C10 Steelwork – installation C11 Site tanks C12 Platework – fabrication C13 C14 C2 Platework – installation Mechanical installation C15 C4 C16 Piping – installation C16A Piping – spool fab C17 Electrical and control C18 Major equipment Free issue to contractors and disadvantages of simple and complex strategies are summarised in Table 5. Larger (owner) companies attempt to manage risk through complex systems and, on some occasions, complex management structures. If not well managed, these risk management strategies can hinder project success due to the inherent lack of clarity and accountability, combined with complex decisionmaking and approval processes. The decision process becomes defensive rather than balanced and accountable. An example of simple contracting strategies working successfully is in the West Australian goldfields where the construction of small gold plants has predominantly been based on simple LSTK or EPC contracts to experienced small to mid-tier engineering companies. There were relatively few failures in this model in a very competitive market place (Close, 2002). One example where an EPC contract failed to deliver to expectations, in the same geographical area, was the Murrin Murrin Nickel Project (Taylor, 2000) where the contractor bid a project containing relatively novel technology on a lump sum basis and completed engineering in several engineering hubs. This mix of simple head contract and complex engineering delivery, combined with the novel technology caused the project substantial hardship in construction and early operation. Owner capacity and structure Unless an owner’s business is structured for planning and delivery of successive projects as occurs in the construction industry and elements of the minerals and resources sectors, several considerations arise for an owner embarking on a development project: •• What is the execution of the works program ‘core business’? •• What are the requirements of investors/partners? •• What is the legacy requirement for the business after the work is complete (eg completed asset or ongoing project delivery capability)? Table 5 Summary of advantages and disadvantages of simple and complex strategies. Packaging Advantages approach Disadvantages Simple Owner’s team can be smaller where the level of confidence in contractor delivery is high. Low levels of complexity in interfaces lead to leaner control structures. Very successful with experienced contractors. If the project is complex, higher levels of risk are assumed by the contractor and higher levels of cost are implicit in contractor’s price. A contractor who fails to perform their obligations represents a risk to the owner, which may be difficult to address. Not suitable for novel technologies. Complex Opportunity for owner to more significantly affect cost and risk outcomes to potential advantages. Opportunity for owner to share work where a contractor may be under-performing. Higher numbers of interfaces invite commercial complexity and higher levels of complexity in control interfaces with consequent increase in project management systems and resources. Owner needs to invest more in up front definition work to mitigate commercial exposure to claims arising from poorly defined scope interfaces. We are metallurgists, not magicians 167 G Lane and E Skinner •• How well can the owner’s team perform the works? •• What is time criticality? •• What is the level of outsourced support required? •• Management of delivery risk. Secondary considerations include: •• What organisation structure is required to manage the project delivery and adequately deal with risks the owner envisages could arise? •• What technical requirements and controls should be applied? •• What are the key implementation risks and how should they be managed? •• adequacy of resources, utilities and services required for the project •• governance and security around achievement of the project deliverables in accordance with the business case, cost and time parameters •• tranched investment structures which are tied to achievement of certain milestones (approvals, permits, progress), capacity of contractor/supplier market to deliver equipment and services in context of the project program •• level of certainty around repayment (strength/depth of market, probable fluctuations in revenue, defensive measures against unforeseen events) •• The impact of external factors on the project and how best to manage them. •• controls around surety of contractor performance, cash flow and milestone payments •• What processes, procedures, tools and systems are required? •• insurance conditions imposed on the project delivery •• interface/external environmental risk management •• Management of quality. •• cost implications arising from key risks occurring (sovereign risks, schedule slip, commodity movements, labour/resource costs. Gearing an organisation to deal with project delivery consistently represents a substantial commitment on the part of the owner. The sustainment of this organisational capability between projects represents a carrying cost which must be traded off against alternative strategies. Common considerations in organisational planning are listed in Table 6. Two examples of owners who have successfully delivered self-managed projects are First Quantum and PanAust. Both have outsourced engineering and self-managed construction. The success of this methodology is linked to the ability of the owner’s project team to maintain a project focus and resist operational mindsets (Lane and Clements, 2012). Financing structures Capital requirements are significant for large projects. Where an owner requires recourse to external funding for project delivery, conditions may be imposed by equity partners or lenders on how the project is shaped. Typically these will be related to: •• capacity of owner to succeed in its objectives •• confidence in business case and factors critical to the business case •• off-take sales contracts secured •• proof of concept where novel solutions or technologies are proposed (eg prototyping, ore processing trials) •• permitting and required approvals in place •• community and governmental support for the project Figures 1 and 2 illustrate the linkages between project financing and the contracting strategy. Figure 1 compares simple and complex financing arrangements and Figure 2 provides a simplified view of the payment interactions between financing and contracted services and goods. As the financing structure becomes more complex, the owner’s ability to prescribe the contracting strategy reduces and the financier’s influences increase. Export credit finance may represent an attractive source of funding for projects incorporating international contractor content. Export credit finance arrangements are usually linked to governmental incentives from the contractor’s country of origin and commonly are tied to incorporation of goods and services in the export contract from the contractor’s country of origin. Terms are generally attractive for projects in that the financing terms are generally low interest, long-term and the opportunity to leverage imported goods and services may represent an attractive alternative to locally sourced goods and services. A disadvantage of this form of finance is the time it takes to secure arrangements with the relevant foreign governments via the selected contractor. Insurance Risk appetite varies between owners and is a function of the owner’s capacity to absorb costs in respect of unplanned outcomes affecting a project. The addition of equity partners and lenders in a project financing strategy imposes additional Table 6 Common considerations in organisational planning. Considerations Owner Self Perform Integrated Team PMC Level of owner control Full Shared Shared/devolved High on owner controlled facilities/services, lower on execution of works Time to build/develop team Slow Slow to moderate Fast Mgmt team required to overview contractor (Owner/Integrated/PMC) Develop in house Build/adapt from contractor standards Adapt from PMC Standards Owner/ contractor Owner/ contractor Owner/ contractor Low unless proven track record Depends on calibre of contractor and team org structure Higher Higher Higher Depends on level of project definition and package structure Procedures Credibility for external investors Cost of team Lower Higher Higher Holding cost of team Higher Medium Lower (flexible pool) 168 EPC EPCM Construct Only Blend of owner's mgmt team and contractors mgmt team indirects Contractor risk Contractor risk Contractor risk We are metallurgists, not magicians Project delivery FIG 1 – Simple and complex financing instruments. FIG 2 – Sample payment release process incorporating banker’s engineer. complexity around the conditions required to secure financing for a project. An owner will need to balance the amount of cost it bears in context of an insurable event, against how much risk a contractor and a third-party insurer would bear. On large projects it is common to engage a broker for advice around a risk management framework as package conceptualisation occurs. This assures that contracts are structured with a considered position around leveraging contractor standard insurance programs as an integral part of the overall risk management program the owner will assume. Early engagement of the underwriter market is often cost beneficial as costs of the overall risk management program and their effect on the project can be tempered from the pretender period. Owners typically need to think horizontally in terms of phases of work (supplier works insurance, marine transit, construction, commissioning and operations phase) and vertically in terms of the classes of cover required to form an adequate ‘wrap’ across the project. We are metallurgists, not magicians A typical project insurance scheme as used on the Goro (New Caledonia) and Telfer (WA) projects is shown in Figure 3. Stakeholders and local content The owner is often developing and operating an asset which will have a macro effect on local communities for a significant period of time. Large projects can substantially distort factors affecting employment opportunities, compete with or disrupt local business and community, create demands on community infrastructure which did not exist prior to the project, introduce nuisance factors related to emissions/effluents, noise and dust, competition for local resources, create disruption of cultures and/or religious traditions, create fly-in fly-out (FIFO) cultures where they may not have previously existed. Conversely, the owner is also faced with needing to assure itself of adequate access to utilities, services, transport infrastructure and skilled/unskilled resources required to sustainably operate the production assets. A sensitivity analysis of the needs and wants of stakeholders and affected communities is essential to sustainable project 169 G Lane and E Skinner FIG 3 – Project insurance scheme. construction and subsequent operations activities. Early conditioning of the project to engage the affected groups in an empathetic and constructive manner and an ongoing positive engagement with these groups is essential to good project governance and leads to reduced possibility of disruption and related costs. For the Telfer gold project in WA, care was taken to genuinely engage local communities early through a combination of Indigenous land user access agreements, positive engagement strategies through a local community engagement plan against which contractor performance was measured and active engagement plans affording local communities early access to information concerning opportunities to participate in the project. For the Goro project in New Caledonia, a range of Indigenous community groups and a small number of monopolistic businesses heavily influenced project delivery/ contracting strategy. Additionally, regular engagement sessions with the local community and government were required in addition to periodic reporting on local contractor engagement to the territorial government. Permitting Permitting is integral to the selection of the contracting strategy. Permit applications in Australia typically involve federal, state, local government and often land-owner tiers, with various classes of construction phase permits required. Large projects in Australia commonly require several thousand permit applications and the processes can be lengthy. Often traditional-owner groups will also impose certain conditions on the project and the negotiations can be lengthy and cost intensive. Whilst environmental and access controls vary in jurisdictions outside Australia, the permitting process is often of similar complexity. It is important to consider the timing of activities for project delivery and to periodically take stock of true project progress (toll-gating reviews). A measured and gated approach forces 170 a process of assessment as to the true progression of key activities and will assure that resourcing and expenditure is matched to activities most necessary to progress the project and keep within the cost and schedule parameters. On the first stage of the Goro nickel project, permitting requirements were substantially underestimated and engineering required to support permit applications was intensive. Construction activity at the site commenced early and the unexpected delays in engineering delivery resulted in cost blowouts associated with construction activity until the project was suspended and the costly process of demobilising contractors and re-assessment of the ‘go forward’ plan was completed. DELIVERY STRATEGY SELECTION How does an owner or prime contractor decide which project delivery strategy is most appropriate? What is the optimum for a given project? Personal experience and personality plays a significant role. For example, those with operations management backgrounds will have different views from those with project and construction management backgrounds (Lane and Clements, 2012). Financiers want certainty of outcome (cost and schedule). Major mining companies tend to be protocol driven and risk averse. Their businesses are often sufficiently large that they have a macro effect on the regions or even countries in which they operate. They are therefore burdened with complex regulatory arrangements and protocols around their systems of business, financial arrangements, community engagement, project delivery and operations which may not apply for a junior mining company. Junior mining companies are often capital constrained and more accepting of risk. By contrast with the major miners who often have established finance facilities and large asset bases against which to leverage credit, junior miners are more likely to need to take a flexible approach to project financing We are metallurgists, not magicians Project delivery and the concessions such arrangements may impose. Equity partnerships are more common with the junior mining houses and often a mix of credit and debt facilities are required. •• the capacity of each contractor, based on shop visits and discussion with existing clients (some local contractors oversell their capacity) The challenge in selection of a project delivery strategy is to resolve how best to address the inadequacies between the ideal case and the present reality. The mechanism for addressing the inadequacies defines the likely outcome of the project. •• track record for similar works It is therefore beneficial to keep an open mind in the early stages of project definition with regard to delivery strategy and solutions. As project definition improves, options for delivery become constrained to the point (usually when a financial investment decision is made) where the project execution plan can be finalised. Good projects are characterised by solid basic data, high levels of definition around the factors affecting project delivery, a robust design with a well-defined production system and aligned and appropriately motivated delivery resources among the owner management and contractor teams. Projects which are founded on a solid business case, a well-articulated delivery plan and a skilled and experienced team which is encouraged to work within the project plan and regularly challenge the project to deliver on and improve the factors underlying the business case are likely to be more successful. As an example, consider a 5 to 8 Mt/a concentrator. An established mining house may have sufficient income/ assets to substantially self-fund the project, perhaps with minor assistance from banks or forward sales agreements. As the banks would have ample surety, the owner is free to determine the project delivery strategy which would typically be EPCM where the owner can maintain substantial control over the project with a modest project team, supported by the corporate and operations team as needed. A junior explorer would need to interest other parties through equity arrangements, but maintaining control would require substantial financiers’ support. This support would be provided at increased risk and necessitate that the owner passes as much risk as possible on to supporting contractors. This scenario leads to LSTK or EPC contracting arrangements involving performance warranties that mirror, in part, the financiers’ needs (Lane et al, 2007). As well as derisking the project for the financier, the owner’s team is smaller and the contracting environment is simpler (if project definition is sufficient). This approach can be extended to single sourcing equipment and contractors where existing relationships add value to the project (shorten schedule and increased confidence in delivery). •• capacity to innovate/add value for the owner •• financial strength, including recent commercial history •• other issues that may impact on cost and schedule such as location, rates etc. Contracting strategy There are four key components to developing a viable contracting strategy for a project: 1. understand contractor capability 2. determine the capacity and regulatory constraints to mobilising suitable contractor resources (which may include resources from other countries) 3. deeply understand the project 4. develop a work breakdown structure based on the above. Local contracting capability One of the deliverables from the feasibility study for a large project should be a contractor capability report that clearly defines the contracting capabilities of local fabrication and construction contractors with respect to the following: •• type of contractor by discipline, eg concrete, steel fabrication, plate work, electrical etc •• the capacity of each contractor, based on shop visits and discussion with existing clients (local contractors oversell their capacity) •• the ability of the contractor to requirements, based on shop visits meet QA/QC •• financial strength, including recent commercial history. Transport and logistics should be included in the contractor framework. The above data is required to assess whether/how local contractors can support a large project and to define the requirement for external contractors (higher cost). Note that the use of external contractors as opposed to local contractors needs to be justified and the basis of the justification explained. External contractors External contractors may be sourced from neighbouring countries or overseas. For example, for projects in South-East Asia, heavy steel fabrication may be sourced out of China, Thailand, Vietnam etc. EPCM and LSTK approaches considerations for a 5 Mt/a project are summarised in Table 7. Some external sourced contractors may have local offices, for example electrical contractors, and may source their workforce from a combination of national and international sources. CONTRACTOR SELECTION Once the local and external contracting opportunities have been identified, the project manager will be able to make an assessment of the most effective contracting strategy for the project. Definition of project parameters is typically undertaken during a feasibility study. The project activities are defined on an area and activity basis to allow a contracting breakdown structure to be prepared. Thus, the key role of the project director/manager is to ensure that all scope items are identified and key issues, critical paths and required actions are clearly defined. CONCLUSIONS The contracting capabilities of local and other pertinent fabrication and construction contractors need to be defined with respect to the following: Successful project management requires the setting of coherent, effective and realistic business objectives and success criteria. The management team needs to lead, prioritise, resource, align, plan, track and communicate the processes that enable the realisation of these business objectives and success criteria. •• type of contractor by discipline, eg concrete, steel fabrication, platework, electrical etc Success requires a viable business case coupled with clearly articulated project delivery strategies. The project delivery We are metallurgists, not magicians 171 G Lane and E Skinner Table 7 Engineering, Procurement, Construction and Management (EPCM) versus Lump Sum, Turn Key (LSTK) (self-perform) for a 5 Mt/a concentrator. Parameter EPCM LSTK (self-perform) Owner’s team size Up to 10 Up to 5 Owner’s team capability Sufficient to report to owner’s corporate management and provide technical input/review Sufficient to deal with variations in contract and monitor adherence to scope Contract complexity Higher, primary, secondary and tertiary contracts and associated interfaces Low, only one contract if head contractor has construction delivery capability Suitability for simple technology OK OK Suitability for novel processes More suitable Less suitable Cost structure Reimbursable Fixed price with variations Contractor’s fee structure Up to 3% direct costs plus multiplier on cost of employment Hidden, but typically cost of employment plus 12% to 25% of direct costs Process/performance risk Process risk borne by owner Additional fees for process risk strategies are the product of adequately funded project definition processes with respect to basic data, external environmental variables, process requirements, resourcing, community requirements, capital and operating funds. For any given project, there is a unique balance between selection of a simple project delivery strategy that minimises interfaces and a complex strategy that necessarily engages the use of expertise and experience from numerous parties. The balance between these ‘book-end cases’ is a function of how the financier, project owner or managing contractor defines its objectives and chooses to manage risk, cost, schedule and project quality, in the context of the conditions affecting the project. An experienced project delivery team with a proven track record on similar projects is essential for successful delivery of large projects. Projects with the best levels of definition and coherence of vision among the team will still generate a wide range of unforeseeable challenges through the execution process. Teams able to rapidly and effectively identify and mitigate adverse conditions or risks are essential to minimisation/avoidance of consequent delays and costs. In general, simple contracting strategies are adequate to deliver smaller projects of known technology and low complexity. This approach should be extended to single sourcing equipment and contractors where existing relationships add value to the project (shorten schedule and increased confidence in delivery). Complex delivery strategies should be carefully articulated and managed. They require higher levels of interface definition and control and, hence, more management, higher cost and result in greater ‘churn’. However, they do offer the ability to include specialist (owner’s, contractor’s and consultant’s) expertise and capabilities that can add substantial value to the overall project. REFERENCES Close, S E, 2002. The Great Gold Renaissance (Surbiton and Assoc: Melb). Gabrielson, A, 2007. Current trends in project delivery, CIM Bulletin, 2(7). Hundertmake, T, Valle Silva, A O and Shulman, J A, 2008. Managing capital projects for competitive advantage, McKinsey Quarterly, June. Lane, G S and Clements, B, 2012. Operations versus projects – how do people think and what are the implications? in Proceedings 11th AusIMM Mill Operators’ Conference (The Australasian Institute of Mining and Metallurgy: Melbourne). 172 Lane, G S, Davis, M, McLean, E J and Fleay, J, 2007. Performance testing – when, what and how?, in Proceedings Project Evaluation Conference (The Australasian Institute of Mining and Metallurgy: Melbourne). Loots, P and Henchie, N, 2007. Worlds Apart: EPC and EPCM Contracts: Risk issues and Allocation (Mayer Brown: London). Merrow, E W, 2011. Industrial Mega Projects, Concepts, Strategies and Practices for Success (Wiley: USA). Taylor, A, 2000. The outlook for the PAL process [online], in Proceedings World Nickel Congress, Melbourne. Available from: <http://www. altamet.com.au/wp-content/uploads/2012/12/The-Outlook-forthe-PAL-Process.pdf> [Accessed: 1 August 2017]. GLOSSARY OF TERMS Alliance – where the owner and contractor work as a common team to achieve performance outcomes agreed using open and transparent decision-making processes and shared goals. A good application of alliances arises where project definition is poor, or where the capacity of the parties to segregate and allocate risk is poor. In such cases, alliances seek to draw upon the best resources of the owner and contractor teams to achieve outcomes required for achievement of the project. D&C – A variation on the EPC formula where conceptualisation of the scope may be provided under a separate contract and the contractor’s responsibilities are limited to design finalisation and supply/construction and usually, commissioning duties. E&I – Electrical and Instrumentation – a typical aggregation of construction services provided by contractors. EPC – Engineering, Procurement and Construction – these contracts place responsibility for delivery of the scope and deliverables in the hands of the contractor with minimal owner interface. EPCM – Engineering, Procurement, Construction, Management – delivery of scope and deliverables is placed with the contractor however owner involvement can range from minimal to significant levels. Where owner involvement is significant, it can be challenging for owners to hold the EPCM contractor to account for adverse outcomes with the project. FEED – Front End Engineering Design – typically follows a feasibility study as the lead in phase to project engineering. LSTK – Lump Sum, Turn Key – such projects are generally designed around a contractor delivering an entire production system which must meet performance requirements across multiple subelements. SMP – Structural, Mechanical, Piping – a typical aggregation of construction services provided by contractors. We are metallurgists, not magicians Contents Mineral project management – a perspective from four decades in the industry J S Dunlop1 ABSTRACT At its most basic level, minerals project management may be broken down into a series of logical chronological phases, described in this paper as: exploration, discovery; scoping and prefeasibility; feasibility and approval; project financing and commissioning; operation; expansion and closure. Each phase has its own peculiarities and challenges, any one of which can potentially upset the forward progress of a minerals project. Reference is made to each of these project phases based on the author’s many years of firsthand experience, to identify issues within the project management spectrum where additional caution may be warranted. Left unaddressed, these issues can cause undue delays in the project timeline, ultimately delaying approval at significant project cost. Finally, reference is made to the Mine Manager’s Handbook (MMH), published by the AusIMM. This is an excellent project management resource and is considered to be very relevant for minerals treatment plant managers, whether the context be constructing, operating, expanding or shutting down. INTRODUCTION We all recognise that minerals projects don’t just happen. They usually span years from discovery to stable production, during which time many obstacles arise, each having to be overcome whether they be technical, economic, environmental, regulatory or various external factors. It is not surprising, therefore, that many projects do not survive this process. Given that mineral deposits are becoming more elusive and either deeper or harder to find, logic suggests that worthwhile projects should not be shelved simply because they could not overcome the manageable post-discovery hurdles. Care therefore needs to be taken to identify the possible project ‘stoppers’ and manage them effectively before they materialise. The concept of project phases is developed in this paper with appropriate reference to previous publications on this subject. The identified chronological phases of a mineral project are frequently referred to in published literature. For example, Noort and Adams (2006) refer to project phases in relation to the feasibility study process. Van der Merwe (2008) presented a very similar view. In this paper, a somewhat broader view is taken, commencing with a mineral deposit discovery and ending in mine closure. Each project phase is summarised in the list below. They are expanded on by some personal observations under each section which follows. Where relevant, reference will also be made to previous MetPlant keynote addresses on this subject, with the aim of providing continuity with some of the excellent previous papers which touch on some of the themes discussed in this paper. The project development phases discussed here are as follows: •• exploration •• discovery •• scoping, prefeasibility and definitive feasibility •• project approval •• project financing and commissioning •• operations •• expansion •• project closure. 1. FAusIMM(CP), Chairman, Alliance Resources Limited, El Arish Qld 4855. Email: jsdunlop@bigpond.com Additional observations will be made in relation to: •• capital markets •• government understanding of the minerals industry. 173 J S Dunlop EXPLORATION Reference here to mineral exploration is made in the general context of exploration activities carried out prior to the making of an economic mineral discovery. More specifically, reference here is to the exploration budget and how to manage it. From a project management perspective, the questions often asked are, ‘How much should we spend and over what period?’ This issue often arises at the annual budget approval process. A theoretical approach to these questions was proposed by Binon (1981) who described how to arrive at a budget figure after establishing an agreed profit level and time frame. In actual practice however, the theoretical or optimum budget may not be available due to a shortage of funds, especially for small capital explorers in a depressed share market. In such a situation, the above questions remain unanswered. This author has found it useful to start with the same objective (deposit size, type etc) and then to assign an acceptable maximum exploration cost, such as unit cost/oz of precious metal or unit cost/t of economic mineral resource. In this way, the project manager may determine the point where acquisition may be a cheaper alternative to grass roots exploration. For example, if the exploration budget implies a gold discovery cost exceeding $50/oz (in the ground), it might be cheaper to acquire already discovered mineral resources. Unit discovery cost benchmarks are also recommended as a management tool when testing the effectiveness of an exploration campaign. Exploration funding can also be managed by introducing a joint venture (JV) partner to assume exploration costs by way of a ‘farm-in’. This subject will be addressed later in this paper. DISCOVERY A mineral deposit discovery is the natural (though seldom achieved) end point of a mineral exploration program. When a discovery is made however, additional management issues can arise. For example, is the deposit immediately economic or are there remaining issues (such as metallurgical) unknowns? Is the market fully informed (as the discovery is clearly material)? What are the next steps? Frequently, the market loses sight of the lead time to bring a project to production, with the consequence that it loses interest, further impeding the availability of capital required for mineral resource delineation, let alone feasibility. A useful perspective on this can be gained from a paper by Duncan (1985), who described the development plans for the Olympic Dam discovery at Roxby Downs, some ten years after the initial discovery hole, (RD1) was drilled in 1975. Another worthwhile example would be the history of the Paddington gold mine in Western Australia, still working at the time or writing. The early history is described by Nice (1986): the discovery was made in 1981, the decision to develop in 1984, based on Measured and Indicated Resources of 5.6 Mt which later were drilled out to reveal an orebody of 8.4 Mt @ 3.2 g/t (based on a gold price of $310). The plant was commissioned in 1985 at a throughput rate of 850 000 t/a. Being a less complex and smaller project to Olympic Dam, the project lead time from discovery was approximately five years, 18 months of which was taken up by approval and construction. This latter point is significant in the light of today’s far slower project approval/construction timelines. It has been this author’s experience that stakeholder expectations (not just the public and the local community, but also the regulators, permit issuers and engineers) need to be actively monitored and addressed both widely and early. For this reason, 174 specialists in this area should be added to the management team as soon as the feasibility process seems inevitable. SCOPING, PREFEASIBILITY AND DEFINITIVE FEASIBILITY STUDIES The feasibility stages of project development are well understood and will be reiterated upon here. Noort and Adams (2006) provide a very appropriate refresher which includes orders of accuracy for each stage of the study advancement towards final or ‘definitive’ status. Table 1 depicts the development study process, in terms of option identification and estimation accuracy. Aspects of the 2012 edition of the Joint Ore Reserves Committee (JORC) Mineral Resource and Ore Reserve reporting code (JORC, 2012) are relevant here, and readers are directed to clauses 37–40 of the new code. The use of discounted cash flow (DCF) methods to arrive at a net present value (NPV) of a project during the scoping and prefeasibility stages is common practice in the minerals industry. If such estimates of project value are used in these stages, it is likely that they will be based primarily on Indicated and Inferred Resources (as was the case in the Paddington example above). Such estimates should be for internal use only and not for external or public reporting. The new code requires a prefeasibility study to have been completed before an Ore Reserve may be reported (clauses 38 and 39). It follows from this that a DCF analysis could be reported along with such an Ore Reserve announcement. Still being debated, however, are the conditions wherein Inferred Resources should be included in the production schedule underpinning the DCF model. In a previous MetPlant keynote, Card (2011) provided extensive reference to the AusIMM’s emerging economic modelling guidelines. It is the author’s view that Inferred Resources only be used in DCF-based project evaluations under the following conditions: •• scoping studies – not at all •• prefeasibility studies – in conjunction with (and following) Measured and Indicated Resources, but only to assess ‘upside cases’ and not be included in the ‘base-case’ (Some stock exchanges, for example Hong Kong and Singapore have strict rules concerning inclusion of Inferred Resources in DCF models. Hong Kong forbids their use entirely) •• definitive feasibility studies (DFS) – as for prefeasibility studies. In the case of mineral project valuations under the VALMIN Code (VALMIN, 2005), Inferred Resources should similarly only be included in ‘upside cases’ and not be included in the ‘base-case’ evaluation (The code was updated in 2015, and clarified this point, tending to support this interpretation.). Another potential issue arising from the 2012 JORC Code is centred on clause 51. This clause refers to the inclusion of ‘in ground’ mineral value in public reports. Such in situ or in ground financial valuations must not be reported by companies in relation to Exploration Results, Mineral Table 1 Project development phases (after Noort and Adams, 2006). Study phase Scoping study Prefeasibility Definitive FS Iterations Multiple 2–5 1 or 2 Accuracy ±30–50% ±20–25% ±10% Contingency ~ 25% ~15% ~1% Options Full range 2–5 1–2 we are metallurgists, not magicians Mineral project management – a perspective from four decades in the industry Resources or deposit size. Whilst this is well overdue, a potential problem arises in relation to compliant use of the VALMIN Code for mineral deposit evaluation. In this instance, ‘in ground’ mineral value is still used as one of the rules-of-thumb, described by Lawrence (1994). This author argues that in situ value still be retained as a valid rule-ofthumb in mineral asset valuation work, but not in the context of mineral resource reporting under the JORC Code. PROJECT APPROVAL Whether a project advances to the ‘go-ahead’ stage is largely dependent on three factors: 1. the inherent techno-economic strength of the DFS, primarily through its financial argument 2. the completeness of the DFS, often referred to as its ‘bankability’ 3. the speed of its approval by the project owners and regulators. These will now be discussed in the following subsections. Feasibility studies The content of the DFS is not usually the cause of a project delay. The most likely causal factor is the quality of the content. No attempt will be made here to discuss the optimal or recommended DFS format. A detailed outline of this may be found in the MMH (AusIMM, 2012). Feasibility studies can be weakened by two critical factors: excessive contingency and failure to recognise and satisfy the critical ‘bankability’ issues. The first of these two factors has two components: 1. excessive conservatism in ore grade, productivity and costs 2. layer upon layer of uncontrolled contingency. The second of these factors comes into play when the DFS is completed without establishing achievement of critical bankability issues (sometimes referred to as ‘fatal flaws’). Usually these include: Unfortunately, some benchmarks may not be known, such as the required liquidity ratios, hedging levels and debt service requirements of the lender. Ultimately, these gaps may materially reduce the debt level that the project can achieve. In a tight capital market, this factor alone may be a potential project stopper. Feasibility studies and joint ventures Readers will be familiar with the very common joint venture ‘earn in’ condition, referred to in joint venture agreements as the ‘completion of a bankable feasibility study’. Despite what this author considers to be a professionally sound understanding in the minerals industry as to what a BFS requires, there has been much JV litigation resulting from farm-in partners ‘passing off’ feasibility studies which were claimed to be, but later shown not to be bankable. It is therefore recommended that where JV agreements in the future require this sort of clause, the agreement should set out clearly the minimum standards for bankability status to be achieved, and preferably with reference to an agreed independent third party to arbitrate, should there be no agreement. Readers will be familiar with the term ‘fast-tracking’ where feasibility study preparation, engineering and approval are integrated to reduce project commencement delays. Often, this situation results from a deadline of some sort to be met, such as tenure of the project tenements or logistic or climatic issues. An excellent account of fast-tracking was prepared by Hinz and Aseervatham (1999), citing Rio Tinto’s experience with its Hail Creek, Baranji and Gokwe projects. The compression of tasks which results from fast-tracking increases the overall risk of a successful project risk and should, in the author’s view, be avoided if possible. Project approval Project approval in this context has four significant stakeholders: 1. project owners who are responsible for the equity funding 2. banks (or others) who are to provide the project debt •• an inadequate ‘resource tail’ for the project 3. regulators (government or government agencies) •• unproven metallurgy 4. the general public whose support for the project must be obtained. •• half-committed market arrangements with customers •• a failure to recognise the minimum set of environmental standards •• an unclear position as to the lender’s minimum lending terms. For an account of project estimation conservatism leading to a complete project re-think, readers are referred to Needham (1985), who described in detail why the original Kidston gold project was uneconomic until a leaner approach was taken to every facet of the project. It was subsequently successfully built and commissioned and operated successfully for many years. It is suggested that detailed analysis of key project development and operating assumptions aimed at discerning the true base-case parameters, free of all contingency. Allocation of the project contingency should then be added only when the absolutely bare base-case has been attained and validated. Metallurgists have a key role to play here, as described by Whincup (2008), McCarthy (2002, 2011) and other previous MetPlant keynote speakers. Finally, the author recommends that, to avoid bankability gaps, a list of all key bankability benchmarks (potential fatal flaws) are established for each section of the feasibility study, and systematically addressed as the study advances. we are metallurgists, not magicians It is worth remembering that the project owners cannot approve a technically and financially sound project if their company is not capable of raising the equity proportion of the total project funding. Often the equity to debt ratio is only known as negotiations for the project debt are advanced, and in recent times, debt ratios as low as 20 to 25 per cent have been offered as a maximum funding level. Investment banks, which traditionally have offered project finance, are becoming less popular since the Global Financial Crisis (GFC) as they have become progressively more risk averse and some would say, more aggressive towards minerals ventures. Term sheets and loan agreements, in the author’s view, have of late been characterised by unattractive terms such as: high fees; intrusive security demands; tough liquidity coverage; challenging project ratios and recourse that places the borrowing entity’s directors at significant risk. Compounding this funding dilemma is the emerging issue of excessive project approval lead times. In one recent example, approval for a NSW based gold project (Alkane’s Tomingley gold project; despite this delay, the mine was constructed and commissioned, achieving target head grade and production guidance in its first two years of operation) took more than 18 months for its DFS and environmental plan to achieve final 175 J S Dunlop approval for site earthworks. By this time, the capital cost of the project had increased by about $25 M and the gold price was in retreat. The subsequent ramifications were significant as the reduced cash available for debt service (CADS) reduced the available debt level, increased the required hedge cover whilst reducing the overall project rate of return (IRR). •• detailed loan agreement •• drawdown of the loan funds •• post-drawdown monitoring of repayments. Project finance has lost much of its appeal in recent years for a range of reasons, which the author considers include: A notable description of the conventional regulatory process appeared in 1997 (Chamberlain, Johnston and Joyce, 1997), where the concept of stakeholder groups was identified in the context of the approval of the Cadia mine project in NSW. Readers interested in this subject in more detail are referred also to chapter 4 of the MMH (AusIMM, 2012). •• high fees Approvals can also be overturned by regulators, thus increasing uncertainty and project risk. This was illustrated in 2010 when the Northern Territory government reversed its approvals and support for the Angela Pamela uranium project (Australian Uranium Association, 2010), citing concerns expressed by local residents. At the time of writing, the project remains stalled, further disadvantaged by a low uranium price. •• operational needs. Finally, the importance of the support of the general public cannot be underestimated. The example above serves to illustrate how pressure can be brought to bear on the regulators by a range of project opponents. It is therefore considered essential to monitor, establish and maintain public support for new projects if potential delays are to be avoided. The need for allocating high priority for this activity is currently clearly reflected in the current opposition to coal seam gas (CSG) exploration on pastoral land (no literature reference is suggested here, as any online CSG search will produce a plethora of argument both for and against). PROJECT FINANCING, CONSTRUCTION AND COMMISSIONING Project financing, construction and commissioning are given mention here because they each play a more important role than perhaps was the case in the past. The comments below attempt to answer the question, ‘Why is this so?’ Project finance mix The term project financing mix refers to the various component parts of a total project financing package. Most typically, such a package consists of equity and debt, though other forms of finance are emerging as conventional debt has begun to lose its appeal. Murray (1995) provides more background on this theme and expands on frequently used banking terms. Equity finance The common forms of equity are: •• free cash within the project company •• cash raised by sale of existing assets •• cash inflow from a farm-out •• cash raised by rights issue or placement (dilutive) •• cash raised by share purchase plan (SPP) (not dilutive). Equity raising is vulnerable to the state of the share market and the project company’s share price. In short, when the capital markets dry up, it is very difficult to raise the level of equity demanded by the lenders of debt. This is one reason why funding is more complex than in the past, and why high levels of project debt are becoming less attractive. Bank finance Conventional project debt arrangements consist of: •• project funding term sheet •• credit approval 176 •• high levels of security •• onerous debt service arrangements •• conservatism •• inflexibility to the client’s time frame Other forms of finance Other forms of finance discussed here include: •• convertible notes and bonds •• export credit funding •• customer terms. These are all alternative funding options which have arisen to offer alternatives to conventional project debt. Convertible notes allow major shareholders (with available cash) to retain an option to convert loaned funds to shares in the project company or alternatively to redeem the loaned funds (with interest, referred to as a coupon rate). Export credit funding arises where the project’s product customer is able to make use of funds provided by its host government (usually at a lower interest rate compared to conventional debt). For example, the Ichthys liquid natural gas (LNG) project in Darwin has an estimated US$20 B capital cost. Of this, US$11.2 B is to be provided by Japanese Bank for International Cooperation (JBIC), Export Finance for Australian Companies (EFIC), Nexi and five other export credit authority (ECA) agencies in the form of direct loans or guarantees. This actually resulted in the conventional debt being scaled back (Schuler, 2013). Finally, customer terms might include advance payment for mineral output (sometimes referred to as a ‘prepay’), a capital contribution to the project itself, tied to supply arrangements, technology sharing or the purchase of an equity share in the project itself. Construction and commissioning It is generally accepted that over the last decade, capital and operating costs have escalated at rates which exceed the traditionally enjoyed operating margins, based on the prevailing metal prices. This, together with the project funding challenges referred to above has caused a sharper focus to be drawn on project construction and commissioning costs. An excellent account of these activities was presented by Luxford (2006), from which this author’s principal learnings are summarised in the following sections. Construction (project implementation) Firstly, there is the engineering, procurement and construction management (EPCM) decision. Do you outsource it, share it or execute the roles in-house? Outsourced or shared EPCM is the most frequent choice, usually where the owner assumes EPCM responsibility for the mine plan and mining fleet acquisition and the processing plant and infrastructure is handled by a specialist engineering firm. Next comes the selection of the owner’s management team. Here the essential points, as suggested by Luxford, are: we are metallurgists, not magicians Mineral project management – a perspective from four decades in the industry •• knowledge and experience in what is to be designed and built •• demonstrated track record in similar projects •• honesty and integrity •• intellectual and practical ability •• ability to work well in a team. It is considered essential to recognise that an owner’s project team, separate to any ongoing operations or company administration, be appointed. The project manager need not be, and more often than not is not, the eventual operations manager of the project. This arises from the fact that the project construction manager has specialised skills in managing the construction processes (such as contract management and liaison with the EPCM engineers), which are themselves different to the operations skill set. The need for a project execution plan (PEP) is obvious but often treated in an ad hoc manner. Luxford provides a comprehensive outline of what such a plan entails. In the author’s view a detailed PEP is essential, with clearly allocated responsibilities for each set of tasks. Engineering management responsibilities are also well outlined by Luxford, who makes the point that, in addition, the project management team must, in a timely manner: •• provide user requirement specifications •• examine and approve concepts and designs •• review and approve equipment selections •• approve standards. Commissioning (AusIMM, 2012). Of the various headings dealt with in that text, the author sets out below his observations of what are perhaps areas of potentially major project impact. Regulatory considerations For many years there has been confusion caused by the lack of congruence between the various metalliferous and coal mining regulations across the Australian states. This began to change from the 2002 Conference of Chief Inspectors of Mines and has now reached the point where in April 2009 the Workplace Relations Minister’s Council (WRMC) endorsed the creation of Safe Work Australia (SWA), a new independent body charged with progressing the concept of harmonised work health and safety laws. Following on from that, the National Mine Safety Framework (NMSF) steering group is working with SWA to develop mine specific regulations with national outreach and application. In effect, each state was to have ‘mirror legislation’ in place by 1 January 2012, though only the NT and the ACT actually met that deadline (as recently as 2016, complete harmonisation has yet to be achieved). The end result will be that all states will adopt ‘core drafting instructions’ but retain some freedom in ‘non-core areas’. The resulting legislative approach has been termed harmonised legislation. The three areas of key harmonisation may be summarised as follows: 1. roles, functions and powers under the model legislation (such as managers and mines inspectors) for mining operations Project commissioning is often misunderstood by operating management. There are several stages involved in this process. Luxford describes this process below: 2. management plans and records under the model (such as hazard analyses) Construction completion involves completing installation and erection work. The phase is complete when all components of the completed system have successfully passed inspection and testing to verify they comply with the contract. The only equipment operation at this point is to check motor rotation. These three points are expanded upon in the MMH (AusIMM, 2012) at chapter 7, and familiarisation with them is recommended. The harmonisation process will be completed before too long and it is recommended that minerals professionals keep apprised of developments. No-load commissioning involves testing and verifying that all equipment is ready to run, followed by operation of all equipment under zero-load conditions. At the completion of this phase, the plant has achieved mechanical completion and is ready for commissioning. The plant is ready for handover and is accepted by the owner. At this point, ownership is usually transferred to the owner and the defects liability period commences. Wet commissioning then follows with the introduction of loads to the plant. In the case of a process plant this would involve the loading of process media and introduction of ore followed by: •• adjustments and minor modifications •• process guarantee performance testing 3. duties (such as duty of care) and other requirements. Operations management Perhaps the most controversial aspects of operations management in the author’s experience has surrounded issues to do with owner versus contract mining and joint ventures. Some observations on these are offered below. Owner mining versus contract operations Detailed accounts of the main issues dictating a decision on which operating methodology to adopt may be found in Dunlop (2002) in the case of open pits, and Luxford (2005) in the case of underground works. The arguments for and against each operating strategy are clearly set out in these papers, along with the operational backgrounds dictating each situation. OPERATIONS In recent times, commodity prices have been falling whilst operating costs, capital costs and foreign exchange rates have all been moving adversely, thus threatening operating margins and making the economic viability of minerals projects all the more challenging (In 2017, we are again seeing effects of this in the so called ‘end of the mining boom’). As a direct result, most operations in this country are now back on a cost cutting footing. This has caused owners once again to look at the contractor’s margin and demand that the advantages of contracting out still justify the additional cost. An excellent account of mine (and mineral processing plant) operations management may be found in the MMH Whilst this is a natural consequence of the economic times, the author is still of the view that the reasons for and against •• completion of as-built documentation •• final punch list completion. Finally, it is recommended that the construction handover phase include a checking that all as aspects of the PEP have been completed and that the EPCM engineer’s list of deliverables has been completed and that those deliverables are in place. we are metallurgists, not magicians 177 J S Dunlop contracting services out are still not sufficiently recognised or understood. It is therefore recommended that decisions to contract out or owner-operate are taken following a detailed cost and benefit analysis following a careful review of the literature on this subject. Joint ventures The next issue of potential major project impact centres on JV. For an excellent general overview of JVs in the minerals industry, readers are referred to Reynolds (1983). In Reynolds’ view, the principal reason for the creation of JVs is the need to share project risk. He then describes the (presumably most significant) risks as: •• project size in relation to the market •• financial magnitude of the project •• whether new technology is involved •• lack of certainty. In this author’s experience, a large proportion of minerals industry litigation has arisen out of JV arrangements, simply because these unincorporated vehicles offer the greatest potential for divergent participant interests. A worthwhile example is that of the original Ok Tedi JV where the three major participants, BHPB, Amoco Minerals and the PNG Government had differing project development priorities. Namely these were capital cost minimisation; maximised NPV and early production, respectively. It is probably a truism to suggest that farm-outs are only born of necessity – that is, when all other options have been investigated and shown to be impracticable. The party farmingout has to cede some control (often total management) in order to see the project proceed, exacerbated by the farming-in party assuming autonomous control and paying scant regard to the new ‘minor participant’. Unless, therefore, there is good will on both sides and strictly ethical behaviour, disputation is highly likely. Should such disputation proceed to litigation, the possibility is real that the project may be delayed for years. The areas of disputation considered by this author to be most common include: •• failure to prepare and adequate JV agreement •• failure to provide for equitable voting rights on the JV operating committee (with regard to key decisions such as the life-of-mine plan and annual budgets) •• wilful abuse of JV terms as defined in the agreement Substandard or otherwise deficient reporting has had the result that many mines have no adequately detailed, permanent record of their month-by-month operations, going back in time. It is simply a matter of sound management that adequate operation reports be prepared and appropriately backed up and stored. Readers are urged to adopt, as a minimum standard the pro forma operations report format set out in Appendix 3 of the MMH. Offshore projects Minerals professionals of all disciplines will readily recognise the importance of identifying, monitoring, fostering, maintaining and always improving stakeholder relationships on their project. These issues are discussed in some detail in chapter four of the MMH. Offshore projects introduce another dimension to the picture, where cultural or other norms may not be as we, the expatriate skills providers, may well expect. It goes without saying that great care and sensitivity is required in this situation and careful choice of staffing for foreign work is advisable. Another issue that often arises is that of the project establishment coming ahead of basic regional infrastructure such as power and water supplies, communications and associated basic services. In the author’s experience, it is essential that the project address this imbalance in some meaningful and ongoing way, accepting that, in principle, the prosperity of the regional stakeholder must advance in line with the project itself, if stakeholder harmony and trust is to be maintained. ‘Sustainable development’ was studied by the Mines and Minerals Sustainability Development Project (MMSD), which reported its findings (International Institute for Environment and Development, 2002). There are useful observations in that report which are still considered relevant more than ten years after its publication. Ethics A simple definition of a professional (courtesy of the Oxford dictionary) is: ...a person engaged or qualified in a profession: professionals such as lawyers and surveyors; a person engaged in a specified activity, especially a sport, as a main paid occupation rather than as a pastime; a person competent or skilled in a particular activity: she was a real professional on stage. •• lack of good faith by the manager, possibly coupled with a failure to exercise a fiduciary duty to the other party (after writing this paper, the author became aware of a landmark Supreme Court judgement in South Australia where it was held that a manager had no fiduciary duty to a minor JV participant – details upon request). Perhaps a more relevant definition for the minerals industry might read something along these lines: ‘a person of specialised training or skills who, acting always with ethics, applies those skills for the betterment of society and the industry, before him or herself’. This definition is manifest in the first bullet point of the AusIMM Code of Ethics (AusIMM, 2013). At the outset, therefore, it is strongly recommended that a detailed and painstaking review be applied to all JV agreement drafts, and that expert advice be obtained before they are executed. It is also suggested that the disputes clauses in the agreement be broadly worded and provide for specialist, binding arbitration as opposed to litigation. In this latter definition, it is implied that a professional is a person with a degree; one qualified to become a Member of the AusIMM or an equivalent professional institution, though there is no reason why tradesmen, para-professionals and other service providers should not act ‘professionally’. Operations reporting Brief reference is made here to operations reporting, which, in the view of the author, have lacked consistency over many years. There are many reasons for this, but at the very least, there has never been a widely adopted template or other reporting convention to guide site operations personnel. 178 It is often assumed in general trade and commerce that the rules of ethics do not apply – or at the very least have low priority – whatever those rules may be. Consequently, circumstances can arise where a professional is confronted with disingenuous behaviour by others, and thus be tempted to adopt the same tactics. The Commonwealth Trade Practices Act (TPA) and its more recent replacement, The Competition and Consumer Act 2010 we are metallurgists, not magicians Mineral project management – a perspective from four decades in the industry (CCA, 2010), are silent on ethics but make the following requirement very clear: in trade and commerce it is expressly prohibited to intentionally or unintentionally to engage in any conduct which might mislead or deceive another party. This requirement covers a key part of professional ethics (not acting in a misleading or deceptive way), but does not cover the entire spectrum of ethical practices a professional must follow. As a general rule, the best defence is what is termed the ‘due diligence defence’ which, in plain language holds that you cannot be guilty of misleading or deceptive conduct if you can show that every effort was made not to do so. For example, peer review of reports or opinions, risk audits and other forms of due diligence will be taken into account in this context. Mere disclaimers, absent the above actions, will not achieve the same level of protection. The obvious dilemma which emerges for professionals leading public companies is embodied in the question: is his or her primary obligation to the (profit of) company shareholders or to the (betterment of) the public? As long as company directors and executives continue to disregard this dual obligation, corporate ethics will continue to lag behind the required standards of profession ethics. PROJECT EXPANSIONS Project expansions are becoming more and more commonplace, probably for two major reasons: the high capital cost of start-ups making the ‘start small’ approach attractive; and the simple economics of increased capacity reducing unit production costs. Consequently, expansions of operating plants are becoming a feature of a minerals project’s normal operating life. In the past, however, the obviously disruptive practice of expanding an existing plant whilst continuing operation at the old rate until ‘cut-ins’ were complete, was rare. This is no longer the case and it is suggested that modern day mining managers need to be equipped with the skills to recognise the key requirements of an ‘internal’ expansion and to resource the work appropriately. In practice, all of the guidance set out under the construction and commissioning headings (earlier in this paper) apply equally in this context, though operations managers often fail to recognise the fact sufficiently. There is a tendency for operational and construction responsibilities to overlap unless the operations manager takes organisational steps to separate the two activities, as recommended by Luxford (2006). These construction projects also require special care regarding fitness-for-work and inductions for casual contractors associated with the construction work. Contractors who come onto the designated construction-site (as distinct from the mine site) need to be inducted and cleared for work even though their site residence time may be as short as one day. Time must therefore be allowed for medical screening and drug clearance, so as to ensure contractors do not commence work whilst their prestart screening results are awaited. Finally, it is essential that any additional site regulations that apply pursuant to construction-related (non-mining) regulations are clearly understood by all concerned. PROJECT CLOSURE Project closure (and, perhaps suspension of operations) is an integral part of the overall mining cycle. Despite this, a search of the published literature on ‘mine closure’ reveals most papers which focus on the environmental compliance issue post-operations. Whilst such compliance sits well as part of the MMSD principles referred to earlier, the literature has we are metallurgists, not magicians little to say about sustainability in general in the locations where mining has ceased. For example, it is difficult to find accounts of communities which have not only benefitted from the mining operations themselves, but have also benefitted thereafter, by virtue of sustainable small business ventures and the like which have endured post-closure (The Bougainville Copper and Ok Tedi projects, (the author worked at both) when looked at today, have achieved little for the local communities in which the projects were established, despite the best intentions). Readers interested in this aspect of the mining cycle are referred to McGuire (2003) who describes the mine closure process at Rio Tinto’s Kelian gold mine in East Kalimantan. In that paper, the concept of a ‘Mine Closure Committee’ is introduced, along with the concept of involvement by the local (and broader, regional) stakeholders in the committee’s work. Today, a key part of annual audit requirements is a review of mine closure plans and financial provision for those plans. It is evident that much greater thought and detailed planning and resourcing needs to be applied to this phase of the mining cycle in the future. The sustainable mining principles dictate that when mines close, the land and the communities left where the mine once occupied ought to be better off for the mine having been there, not just while the mine was in operation. THE CAPITAL MARKETS The changing pattern of investment in world mining is constant and the effects of those changes have a profound and continuing effect here in our Australian minerals industry. These observations were made by Aldous (1993) whose paper is still recommended for those wishing to understand the concept of mineral capital allocation in the world’s capital markets. If we were to consider Aldous’ view in 1993 that capital comes from where it is most available and goes to where it is most welcome, and compare that view with the situation today, it is clear that these fundamentals have not changed. Suppose we were to rank Australia’s ‘capital attractiveness’ according to Aldous, we might well be disturbed by the list of negatives, which currently include: •• lengthy project approval timelines •• relatively high project capital and operating costs •• inflationary trends which outpace metal price growth •• relatively high environmental and other compliance costs •• relatively low rates of return compared to the risk profile •• a small capital market compared to the rest of the world •• an uncompetitive foreign currency exchange rate. The combination of these factors, coupled with financial instability in most of Europe and a sluggish US economy, has caused the minerals equity and debt markets to dry up almost completely for ‘small cap’ and mid-tier companies on the Australian Stock Exchange (ASX) and the Toronto Venture Exchange (TSXV). If this situation is allowed to continue, significant damage will be done to what some would refer to as our country’s cornerstone industry. Whilst the capital markets will recover, following the endless cycles we all recognise, the industry needs to find ways to continue in the meantime. The solutions, it is suggested, lie in the following strategies: •• operating cost reduction •• continuous improvement to lift productivity per employee •• leading in the application of advanced technology 179 J S Dunlop •• faster project approval mechanisms •• favourable government policies for projects of ‘national importance’ •• favourable taxation incentives for small cap explorers •• further development of Free Trade Agreements (FTAs) with our closer trading nations, to further unlock additional export credit. GOVERNMENT UNDERSTANDING OF THE INDUSTRY Following on from the aforementioned observations, there is likely to be little disagreement with the proposition that the current mining boom in Australia has stalled, to a greater or lesser degree, due to the lack of capital attractiveness, to which has been referred. The Minerals Council of Australia (MCA) addressed this in a paper by Ergas and Owen (2012), which concluded: The easy gains from Australia’s early 21st century mining boom are over, though large and enduring benefits are still there to be secured from further resource-intensive growth in emerging Asia. Rebooting the mining boom calls for renewed policy focus on securing the next generation of mining project investment and delivering on potential export volume growth out to 2025 (Author’s note: Very pertinent still in 2016. Perhaps the ‘transition from the mining boom’ will not be to something else but rather back to the next mining boom in the endless minerals cycle). That focus should be on tackling the ‘unfinished business’ across Australia’s export supply-chain, from exploration and initial development through to final shipment, where cost control, timeliness, flexibility and adaptability present critical challenges. It is only by stripping out inefficiencies across our export supply-chain that Australia can reap the rewards on offer from the next phase of the boom. As Marius Kloppers (then CEO of BHP Billiton) has observed, companies themselves need to do the heavy lifting to make our mining projects more cost competitive. But they can only do so if the policy environment provides the framework and tools for this to occur. At the moment, it doesn’t. To ‘re-boot the boom’, then, governments at all levels must improve their understanding of the industry – particularly now when it contributes to approximately 50 per cent of national exports and is increasing. At present, its level understanding, in the author’s view, is superficial at best and, at worst, lacking in both breadth and depth when viewed in the context of its national economic significance. To illustrate the proposition, the industry can be viewed in a range of ways: •• commodity (base metals, precious commodities, industrials and so on) metals, bulk •• industry grouping (metalliferous, coal, petroleum, industrial) •• activity (exploration, processing) production or downstream •• size (small caps, mid-tiers producers and multinationals). Each of these groupings require a profound understanding to formulate policy settings which will not only be of benefit to those concerned, but will also address the structural efficiency areas referred to by Ergas and Owen. It is the view of this author that those responsible for governing and setting minerals policies must improve their understanding of, and 180 liaison with our industry at all levels and commit to a much higher priority level being accorded to the industry’s needs. CONCLUSIONS The personal observations of critical issues presented in this paper span the many phases of mineral project development from exploration, through development, operation, expansion and finally closure. In summary form, the critical issue identified are as follows: •• exploration – the market continues to lose site of the real lead time to develop a project following its discovery •• discovery – stakeholders need to be identified and engaged with as soon as possible •• scoping, prefeasibility and definitive feasibility – potential fatal flaws need to be identified and resolved early in the process •• project approval – current processes are far too slow and completely uncompetitive when seen in an international context •• project financing and commissioning – conventional debt funding is losing its attraction, in favour of alternative financing means •• operations – issues of concern relate to JV and corporate ethics •• expansion – operational and construction responsibilities to overlap unless the operations manager takes organisational steps to separate the two activities •• project closure – mine closure plans need to be detailed and involve a mine closure group of all relevant shareholders. Additional observations have been made in relation to: •• capital markets – emphasizing the Australian minerals industry’s current capital unattractiveness, and corrective measures •• government understanding of the minerals industry – some thoughts on how the government might better view and assist the industry. ACKNOWLEDGEMENTS The author wishes to thank the organising committee of MetPlant 2013 for the opportunity to present this keynote paper. He also gratefully acknowledges the many authors cited in the paper, whose contributions to the topics discussed in the paper provide an expanding pathway for those wishing to concentrate further on any of the issues touched upon. REFERENCES As far as practicable, all references cited in this paper may be found on <www.onemine.org> and downloaded for free by members of the AusIMM, SME or SAIMM. Aldous, R T H, 1993. The changing pattern of world mining investment and the implications for Australia and her mining industry, in Proceedings Centenary Conference, p 267 (The Australasian Institute of Mining and Metallurgy: Melbourne). AusIMM, 2013. Code of Ethics [online]. Available from: <http:// www.ausimm.com.au/content/docs/code_of_ethics_stand_ alone.pdf> [Accessed: July 20, 2017]. AusIMM, 2012. Mine Managers’ Handbook, Appendix 3 (The Australasian Institute of Mining and Metallurgy: Melbourne). Australian Uranium Association, 2010. NT decision on Angela Pamela causes uncertainty [online], press release, 28 September. Available from: <www.aua.org.au> [Accessed: 8 May 2013]. we are metallurgists, not magicians Mineral project management – a perspective from four decades in the industry Binon, L C, 1981. Determining the exploration budget, in Proceedings SME-AIME Fall Meeting and Exhibit, Denver, November, Preprint No 81–311 (Society for Mining, Metallurgy and Exploration; American Institute of Mining, Metallurgical, and Petroleum Engineers: Englewood). Card, P, 2011. Guidelines for economic evaluation of mineral projects, in Proceedings MetPlant 2011, August, 12 p. CCA, 2010. The Commonwealth Consumer Act [online]. Available from: <http://www.comlaw.gov.au/Details/C2007C00619> [Accessed: May 2013]. Chamberlain, C, Johnston, G and Joyce, C, 1997. Regulatory framework for Mine Project Permitting, in Proceedings Mindev 97, November, pp 193–198 (The Australasian Institute of Mining and Metallurgy: Melbourne). Duncan, I J, 1985. The competitive challenge in marketing Olympic Dam copper, uranium and gold, in Proceedings The AusIMM Annual Conference, p 6. Dunlop, J S, 2002. Contract versus owner mining – an update on Australasian open pit mining practice, in Proceedings Iron Ore 2002, Perth, p 205 (The Australasian Institute of Mining and Metallurgy: Melbourne). Ergas, H and Owen, J, 2012. Rebooting the boom: unfinished business on the supply side. Available from: <http://www.minerals. org.au/file_upload/files/publications/mca_rebooting_the_ boom_FINAL.pdf> (Minerals Council of Australia: Canberra) [Accessed: May 2013]. Hinz, R and Aseervatham, R, 1999. Feasibility studies, EPCM and the environment – case studies in integrated mine development, in Proceedings PACRIM 99, Bali, October, p 123 (The Australasian Institute of Mining and Metallurgy: Melbourne). JORC, 2012. Australasian Code for Reporting of Exploration Results, Mineral Resources and Ore Reserves (The JORC Code) [online]. Available from: <http://www.jorc.org> (The Joint Ore Reserves Committee of The Australasian Institute of Mining and Metallurgy, Australian Institute of Geoscientists and Minerals Council of Australia). McCarthy, P, 2002. Setting plant capacity, in Proceedings MetPlant 2002, Perth, pp 21–30 (The Australasian Institute of Mining and Metallurgy: Melbourne). McCarthy, P, 2011. Predicting variations in mill feed, in Proceedings MetPlant 2011, pp 19–25 (The Australasian Institute of Mining and Metallurgy: Melbourne). Lawrence, M J, 1994. An overview of valuation methods for exploration properties, in Proceedings Mineral Valuation Methodologies, p 205 (The Australasian Institute of Mining and Metallurgy: Melbourne, in conjunction with The Mineral Industry Consultants Association: Sydney). Luxford, J, 2006. Project development and construction management, in Proceedings International Mine Management Conference, p 97 (The Australasian Institute of Mining and Metallurgy: Melbourne). International Institute for Environment and Development, 2002. Breaking New Ground: Mining, Minerals and Sustainable Development [online], 450 p. Available from: <http://pubs.iied.org/9084IIED. html> [Accessed: May 2013]. McGuire, G M, 2003. Managing mine closure risks in developing communities – a case study, Kelian Equatorial Mining, Indonesia, in Proceedings Mining Risk Management Conference, p 385 (The Australasian Institute of Mining and Metallurgy: Melbourne). Murray, J, 1995. Project finance in the minerals industry, in Proceedings Young Professionals Conference, p 59 (The Australasian Institute of Mining and Metallurgy: Melbourne). Needham, R, 1985. The Kidston Gold Mine: a development challenge of a low grade deposit, in Proceedings AusIMM Annual Conference, p 121 (The Australasian Institute of Mining and Metallurgy: Melbourne). Nice, R W, 1986. The Paddington Gold Mine Project – a case study, in Proceedings Second Project Development Symposium, Sydney, p 299 (The Australasian Institute of Mining and Metallurgy: Melbourne). Noort, D J and Adams, C, 2006. Effective mining project management systems, in Proceedings International Mine Management Conference, p 87 (The Australasian Institute of Mining and Metallurgy: Melbourne). Reynolds, G C, 1983. Unincorporated joint ventures in project developments in the mining industry, in Proceedings Project Development Symposium, Sydney, p 349 (The Australasian Institute of Mining and Metallurgy: Melbourne). Schuler, S, 2013. Financing projects in hard times: export credit agencies are the smart alternative [online]. Available from: <http:// www.corrs.com.au/thinking/insights/financing-projects-inhard-times-export-credit-agencies-are-the-smart-alternative> [Accessed: May 2013]. VALMIN, 2015. Australasian Code for Public Reporting of Technical Assessments and Valuations of Mineral Assets (The VALMIN Code) [online]. Available from: <http://www.valmin.org/docs/ VALMIN_Code_2015_final.pdf> (The VALMIN Committee, a joint committee of the Australasian Institute of Mining and Metallurgy and the Australian Institute of Geoscientists). Van Der Merwe, M J, Vegter, N M and Momberg, N 2008. Value driven resource allocation and focus in the early stages of project development, in Proceedings Lead and Zinc 2008, p 255 (The South African Institute of Mining and Metallurgy: Johannesburg). Whincup, P R, 2008. The role of the metallurgist in project development, in Proceedings MetPlant 2008, p 25 (The Australasian Institute of Mining and Metallurgy: Melbourne). Luxford, J, 2005. Future directions in Australian contract mining, in Proceedings Underground Operators, p 3 (The Australasian Institute of Mining and Metallurgy: Melbourne). we are metallurgists, not magicians 181 Contents Keeping projects on the rails J Canterford1 ABSTRACT Although we have access to a wide range of sophisticated process design and improvement tools in combination with a significant range of case studies, the mineral resource industry still manages to be plagued by the negative publicity surrounding operating plant failures because they were neither smart nor safe, together with proposed projects that fail at the first or second hurdle. The public and the finance industry are generally totally uninformed about projects that ramp-up to name-plate capacity on-time and on-budget and even more so when ahead of schedule and under-budget. As the saying goes, good news does not ‘cut the mustard’. The following is a summary of the author’s sometimes jaundiced view about why metallurgical plants do not live up to their technical and commercial expectations. In no way should the summary be construed as a negative reflection on the skills of the metallurgical profession. Rather, it is to be taken as a positive acknowledgement of those skills and is intended to highlight some of the major considerations that need to be assessed as a potential project transforms into a sustainable technical and commercial reality. While a considerable portion of the summary is directed at developing hydrometallurgical flow sheets, the general principles are equally important to all aspects of extractive metallurgy. For convenience, the summary covers the following five basic discussion points – project, people, process, patents and politicians. INTRODUCTION On any given day, every successful metallurgical plant can be characterised as being a positive compromise between a series of potentially conflicting criteria, the more significant including: •• the mineralogical complexity of the feedstock •• market requirements •• owner/developer expectations •• technical complexity •• ongoing operating cost scenarios •• sustainable environmental footprint. Although we can talk about generic flow sheets, no two flow sheets are identical when dissected in detail. While we certainly can and should learn from past and current experience, what we must accept is that the balance between the conflicting criteria will almost certainly alter during the life of any individual project. In turn, this means that the ‘best’ flow sheet should have a reasonable level of flexibility to cater for a realistic range of inputs and outputs, both metallurgical/environmental as well as corporate. Some of the anticipated variations may be self-induced while others will be a result of external forces over which the project owner and/or developer has no control. If the conflicting criteria cannot be balanced and that balance maintained, then the outcome will almost certainly be closure or at least the requirement for major modifications to plant layout, operating procedures, changes to volume and specifications of outputs etc. The capital and operating cost implications of such modifications can be mind blowing. Without going into any detail, experiences at Ravensthorpe and Goro are stark reminders of what can go wrong. 1. FAusIMM(CP), Process Technologies Australia Pty Ltd, Deloraine Tas 7304. Email: pr37666@bigpond.net.au As a person with no practical metallurgical plant design experience but who is sometimes asked to comment on what, how and why a flow sheet appears to have failed or at least throw enough hand grenades at the evaluation stage of flow sheet development, the simplistic answer provided is itself multifaceted covering: •• the chemical/mineralogical integrity of all test work •• realistic technical risk analysis 183 J Canterford •• treatment of process and financial models with a fairly high degree of scepticism •• understanding what the market will buy and why and how these requirements can be met. It will come as no surprise that this author is very strongly of the view that throwing hand grenades and proper evaluation of the metallurgical plant design should be initiated at the scoping stage and should be a continuing exercise well into the operating phase and until name-plate capacity has been achieved or exceeded. SUCCESSFUL PLANT DESIGN DRIVERS First and foremost, it is essential to match output volumes and qualities with a realistic assessment of market requirements. As noted below, some 15 years ago magnesium metal was the metal of the future. Numerous proposals were being bandied about. In Australia alone, the combined capacities of the proposed magnesium metal projects in Tasmania, Queensland, Victoria, South Australia and Western Australia between 1995 and 2005 was in excess of the 300 per cent of then total world consumption and more than 200 per cent of the projected demand in 2015. Individually each of the proponents considered their proposed projects to be superior to all others and that only they would attain commercial status. Of course reality was quite different and not one of those proposed Australian projects has seen the light of day. As the author of this paper participated in some of these proposed projects he must confess to being guilty by association. Consistent with his novice status as a metallurgical plant ‘expert’, he would like to put forward what he has termed the ‘Five P’ set of criteria that should be seen as one of several sets of criteria that need to be considered when developing and maintaining a state-of-the-art metallurgical plant. This set of criteria is made up of Project, People, Process, Patents and Politicians. Clearly there is a strong interplay between each of these components and each may individually or in combination lead to initiation of an outstanding technical and commercial success but conversely to an absolute failure. From the author’s perspective it is important to expect the unexpected and avoid any major deviation from the KISS (‘keep it simple’) principle. The title of this presentation indicates acquisition of information by osmosis and as such the following comments cover some of the more relevant observations made over the past 40 years. Project Geometallurgy is now properly recognised as a critical evaluation step in establishing a technically and commercially viable process flow sheet. Unless a detailed evaluation of the chemical and mineralogical complexity of the resource under consideration is executed then failure in some form is highly likely to follow. One of the real challenges is to ensure that test work samples should be properly characterised and that the selected samples are representative of the expected resource overall aspects of the entire project life. This means that there must be close cooperation and coordination between the mine planners (including the geologists), the client’s project team and the process flow sheet developers. While the distribution of the marketable metal(s) and product(s) has a major influence on mining and processing options, in reality it is how, where and in what form the non-value components are present and how to reject them efficiently that will be the key to success or failure. Geometallurgy is also a major factor that assists in the determination of realistic product outputs. Projects that can 184 be described as conventional in that they yield standard products such as gold bullion via heap leaching of an oxide gold ore or cathode copper via smelting/electro-refining of high-grade chalcopyrite concentrates can be relatively straightforward in that product specifications are well known and there is an active, open market. The situation with projects where each end-user sets their own specific product specifications is quite different. For example, virtually every end-user of dead burned magnesia will have quite specific requirements for crystallite size and shape in addition to other chemical and physical properties. There are no universal product specifications. While magnesite calcination may seem to be a relatively straightforward metallurgical process, it is the physical structure of the magnesium carbonate raw material as well as the calcination conditions that determine the properties of the magnesium oxide product. It follows that the owner/developer of a magnesia production facility must be fully aware of detailed market requirements and understand that it may not be practical to service a broad spectrum of customers. Thus there has to be an ongoing assessment of potential markets as it is not a good option to tie production to a very limited number of customers. Practical metallurgical projects are generally based upon consumables that are widely available although some, such as sodium cyanide, will require a high level of process control and mitigation strategies to be put in place to overcome any plant failures however caused. People As practicing metallurgists, it is important to maintain a high level of realistic technical input into senior management considerations and, where appropriate, curb the misplaced conviction by the technically illiterate that reliance on simplistic in-ground evaluations and avoidance of locked cycle continuous test work at the pilot and demonstration level are just two of several ways of achieving a project that is not technically and commercially sustainable. It is not unusual for initial capital and operating costs to be considerably higher than originally anticipated so that cost-cutting procedures are instigated, particularly by the corporate finance management team. This may involve, for example, reduction in pipe and cable runs, reducing overhead access, reduction of automation and monitoring instrumentation etc. While there may be a saving on structural steel, concrete, process control facilities etc, the result will ultimately lead to increased maintenance costs, more complex occupational health and safety issues, less reliable adherence to operation within the designated bandwidth and potentially extended shutdown periods. These technical issues must be properly flagged. The project’s technical champion has a very significant role to play. ‘Bean counters’ need to be controlled to avoid equipment selection based on simple cost and availability terms, rather than on a genuine ‘fit for purpose’ basis. There is no point in gold plating the processing plant, but it should not be deficient in practical operational and safety terms. Similarly, there is no value in over-promoting the economic benefits that might accrue. Process It is possible to develop a process flow sheet that is chemically sustainable, at least at the theoretical and initial pilot/ demonstration scale, but which never reaches commercial status because it is ‘impossible’ to engineer and operate it and/or economic reality sets in. There are quite a few We are metallurgists, not magicians Keeping projects on the rails proposed processing flow sheets that are best described as the ‘tail wagging the dog’. This is particularly the case where the flow sheet incorporates recovery of every possible product in the purest possible form. For example, many of the proposed nickel laterite flow sheets incorporated recovery of metallic magnesium, given that the magnesium content of the pregnant leach liquor is many times greater than that of nickel. Only a little bit of evaluation from the other side of the fence clearly indicates that this approach is not sustainable. If the project does not make commercial sense based on the nickel cash flow with a nominal cobalt credit then the presumed financial benefits from additional by-products will just be an illusion. As a general but not totally universal comment, the ‘best’ process flow sheets are developed and commercialised by project owners/developers. This is particularly the case with mineralogically complex resources since exploitation of the resource will not proceed without the successful development of the required flow sheet. This comment should not be taken as an unqualified criticism of research and development (R&D) undertaken by universities, research organisations and independent companies. They certainly generate some great concepts. However, such groups rarely have the financial and technical expertise and abilities to undertake and achieve commercial status for their concepts and are reliant on selling their knowhow. One must always question their ability to provide the necessary support when their know-how is implemented by others. In other words, the end-user should always very seriously question the real value (technical and commercial) of the licence to use purchased technology. As noted above, magnesium metal has been vigourously promoted as the metal of the future. Australia was at the forefront of developing what was being claimed as novel state-of-the-art processing regimes. Three major areas of sustained R&D centred on: 1. purification and dehydration magnesium chloride liquors of concentrated 2. development of alternative electrowinning electrolytes 3. improved cover gas technology. Despite spending more than $50 M on their demonstration facility, amongst other things the Australian Magnesium Corporation (AMC) purification and dehydration technology failed to deliver the anticipated outcomes. The chemical/ thermal decomposition of the organic dehydration agents was soon found to be quite deleterious. Electrowinning magnesium from fused salt electrolytes is highly energy intensive as well as challenging in engineering and operational terms. Molten magnesium metal is not the simplest material to handle. Energy consumption during electrowinning can be reduced by modification to the composition of the fused salt electrolyte. One such option is to add neodymium chloride. Unfortunately one side effect is that rather than pure magnesium being produced at the cathode, the end product is a magnesium-neodymium alloy. Such alloys have several useful physical properties, but it was soon worked out that the ‘loss’ of neodymium to the alloy product was such that the volume of make-up neodymium chloride would soon exceed that currently available. In other words, the proposed magnesium metal production facility would be dependent upon the establishment of an ongoing rare earth production facility with a significant neodymium output. The technical and commercial constraints so imposed basically canned the concept of the use of neodymium chloride additives to the magnesium electrowinning cell house. We are metallurgists, not magicians The cover gas technology developed by AMC and CSIRO was and remains technically astute – it is unfortunate that it has not been commercialised due to the total collapse of the AMC project. As noted previously, it is important to expect the unexpected, especially when considering some of the more complex hydrometallurgical flow sheets. For example, during carbon dioxide leaching of several caustic calcined magnesia feedstocks it was found that the resultant liquors had quite a high soluble ferric concentration (several g/L) even through the bulk pH was greater than 9.5. Under the operating conditions it is possible to form soluble iron (III) carbonato complexes even though all the available thermodynamic data suggested that this was ‘impossible’. Development of a suitable technique for selective iron removal from the pregnant liquor proved to be quite challenging. During the 1970s and 1980s the majority of hydromet flow sheet development centred on the initial leach step, with less emphasis on the downstream purification and recovery steps. For example, chloride hydrometallurgy of base metal sulfide ores was seen as the panacea of all environmental ills associated with sulfur dioxide abatement with conventional pyrometallurgical operations, although it is appropriate to note that commercial reality is yet to be achieved. While detailed knowledge of the leach step was generated, many of the challenges with chloride hydrometallurgy relating to separation and recovery of elemental sulfur, recovery of precious metals from leach residues, deportment of nasties such as arsenic, regeneration and recycle of the leachant, sulfate control etc, were subjected to far less rigourous evaluation. Fortunately this situation of unbalanced unit step development for most hydrometallurgical flow sheets is now being corrected. Two of the driving forces for a balanced assessment of all hydromet unit steps are the need for and influence of a range of internal recycle stages and the maintenance of a workable process water balance. In some locations and for some flow sheets there may be an excess of process water that needs to be discharged into the local environment in an acceptable, benign manner. In other situations, there will be a potential deficiency of fresh suitable process water at reasonable cost, so recovery and recycle of process water is a requirement that adds to both capital and operating costs. Desalination plants have their own problems including power supply, plant duplication for continuation of supply and waste disposal. For hydrometallurgical flow sheets in particular, all definitive test work from feed preparation, which may involve grinding and flotation, right through to final product recovery, must be carried out using process water that will be available at site. The physical and chemical properties of the process water will have a significant effect on parameters such density, viscosity, redox potential, oxygen solubility, ionic strength, leach and precipitation kinetics etc, let alone materials of construction considerations and actual equipment design. It also follows that care must be taken in preparing process models since many of the thermodynamic inputs for most models are clearly deficient. Infrastructure requirements and power generation (particularly if ‘peak’ oil status is fact not fiction) will impact on all remote sites as a cost burden as governments continue to bail out of these areas. Patents While it is not unreasonable to protect intellectual property (IP) by means of filing and executing patent applications, from a practical perspective the situation is tending to get ‘out-of-hand’. For example, since 2000 more than 90 patent 185 J Canterford applications on sulfuric acid leaching of nickel laterites have been filed via the World Intellectual Property Organisation (WIPO). The claimed flow sheets cover heap, vat, atmospheric and high-pressure leach circuits, sometimes in combination with downstream unit steps such as iron precipitation, intermediate product recovery, solvent extraction and electrowinning. Sometimes it is quite difficult to discern any realistic technical differences between two or more claimed flow sheets. Part of the problem relates to the definition of patent laws and concepts such as novelty and inventiveness. It must also be remembered that a patent is basically an idea – it is not necessary to prove chemically and/or physically that the concept actually works. In fact in some instances a little technical nous indicates that the concept cannot work. Another feature of patent law that is sometimes difficult to fathom in technical terms is that known processes and concepts can be incorporated into primary and subordinate claims. For example, many of the nickel laterite sulfuric acid leach applications incorporate current commercial practice such as nickel-cobalt separation by solvent extraction using Cyanex 272. From a practical perspective, it seems difficult to understand how any claims relating to the use of this reagent in recent applications are sustainable. One apparent reason for the proliferation of patent applications relates to the fact that patent challenges/ litigation is extremely costly in terms of time, money and user licence fees, and conditions are often unacceptably onerous. Thus ‘new’ flow sheets are devised to overcome claims of existing novelty/inventiveness even though such flow sheets may not be technically and/or commercially optimal. It is now common practice to initiate a ‘freedom to operate’ review of potential patent infringement as part of the overall risk analysis procedures during completion of feasibility studies. There are numerous examples of what are best described as ‘nonsense’ patents. Probably the most technically ‘challenging’ – and that description is certainly offered with 186 a high level of derision – relates to the ‘neutralisation of an acidic stream using sized limestone’. It was originally allowed by the United States Patent and Trademark Office (USPTO) on the basis of the word sized. Fortunately, industry finally got the USPTO to accept a dose of technical reality and the application was forced to lapse. Politicians The mining and metallurgical industries face several challenges as they are forced to cope with ever increasing volumes of more and more diverse bureaucracy. It is unfortunate that the majority of our politicians and their advisers are technically illiterate and are easily persuaded by pseudo-scientific commentary. This can and does lead to constrained operating parameters because of the imposition of illogical rules and regulations as a means of placating vocal opponents of our industries. Perhaps the most bizarre was the push to ban the use of stainless steel because nickel has some rather ill-defined carcinogenic properties. Our industries must and do accept the imposition of logical environmental constraints but it is a pity that the overall record of compliance is not recognised by our politicians and the public. Accidents do happen, but it would be safe to assume that our record is somewhat more positive compared with those of many other primary and secondary industries. The challenge for us is to educate our politicians. CONCLUSIONS To continue to learn by osmosis it is constructive to periodically assess why and how ‘wayward’ metallurgical plants come into being. This paper indicates that this occurs because of scientific-engineering incompetence, project owner/developer avarice, insufficient attention to future markets and product requirements, imposition of impossible operating constraints, right through to obvious bad luck, but it is more likely to be a combination of all such factors. We are metallurgists, not magicians Contents Operations versus projects – how do people think and what are the implications? G Lane1 and B Clements2 ABSTRACT The operations and project environments are very different, but overlap in many areas. The development of mineral processing projects is goal oriented, schedule focused and a contractual environment. The operating environment for a mineral processing plant is oriented around longer-term commitments, focused on delivery against budget expectations, and an environment heavily influenced by long-term personal relationships, community relationships and people issues. Further contrast is evident in the way expenditure is managed. Projects commit large amounts of money quickly to meet schedule-based objectives. Operations manage expenditure to minimise operating costs and are able to, or are forced to delay decisions on large expenditures. However, these two environments need to come together in many ways, ranging from greenfields plant handover to a new operations and maintenance crew, to day-to-day interaction and management of brownfields projects, often in close proximity. This paper considers the different perspectives people bring to projects and early operations, including the advantages and disadvantages of ‘operations’ input to a project and models for managing value adding during project development, implementation and debottlenecking. INTRODUCTION This paper is about the way people need to respond to the management of operations and projects. The mining environment in 2012 was characterised by a shortage of engineers and managers with project experience. This situation has existed for at least three of the preceding five years with a short hiatus driven by the Global Financial Crisis (GFC). The shortage caused a significant movement of personnel from mining operations into projects, on either the owner’s or the contractor’s side of the fence. The consequences of this are numerous but this paper focuses on one area key to the delivery of a successful project, the behavioural characteristics of the project management and leadership team. Experience in mineral processing plant operations brings substantial value to a project in terms of quality of outcome; however, the mindset associated with operations is not the same as that required for a project. The development of mineral processing projects is goal oriented, schedule focused and a contractual environment. Because projects are not just driven by the quality of the outcome, schedule and cost are the key measures of success up to, and including, commissioning. Quality is heavily influenced by the design, procurement and contracting strategies. The simplicity and effectiveness of the management systems, alignment of, and trust between, the participants and speed of (correct) decision-making, become the key behavioural requirements. PROJECT MANAGEMENT 101 A successful project is one that meets or out-performs the project criteria agreed by the contracting parties in terms of cost, schedule and quality (performance). The project criteria are often based on the outcomes of a feasibility study, adapted to meet financing and other external drivers. Successful project outcomes are based on the following: 1. FAusIMM, Chief Technical Officer, Ausenco Minerals & Metals, South Brisbane Qld 4101. Email: greg.lane@ausenco.com 2. Former President/General Manager, Sociedad Minera Cerro Verde, Freeport McMoRan Copper and Gold, Arequipa, Peru. •• a well-gated feasibility study (Biery, Hollands and Young, 2009) •• an experienced project team •• sound project planning and effective communication •• simple interfaces (contracting and execution) •• fast and effective macro-scale decisions. 187 G Lane and B Clements The different types of execution strategy require very different behavioural needs (Gabrielson, 2007; Hundertmark, Siliva and Shulamn, 2008). Engineering, procurement, construction, management (EPCM) style projects require ongoing collaboration and interfacing with the project owner and the associated operational team. This contract style is characterised by ongoing scope change and continuous change management. EPC or lump sum turnkey (LSTK) contracts require much more rigid scope management and change is managed on a contractual basis (rather than a ‘trend register’ used for reimbursable EPCM projects). Hence, the EPC approach gives cost surety, but is less flexible than the EPCM approach, and quality outcomes can be sacrificed in a poorly managed EPC environment. Operations management is about managing continual change on a relatively micro scale. Trends are compared with annual budgets in a personalised environment that is subject to continual change. Whilst the annual budget sets a time frame for performance (and reward), the operating environment requires management on a long-term horizon to optimise project net present value (NPV) and other issues such as community relations. In a simplistic sense, there is a continuum of behavioural environments that stretch from the microscale, continuous improvement environment of operations, through various forms for collaborative and reimbursable project management, to the heavily contractual and short-term focus of EPC/LSTK delivery. For the purposes of simplicity, we have characterised this continuum using the three aforementioned examples: the technical scope and simplifying and clarifying the interfaces between the service providers. KEY REQUIREMENTS OF A GOOD OPERATIONS MANAGER An operations manager’s performance is measured against a budget that is usually based on previous performance (benchmarked or historical). Behaviour is heavily long-term people oriented with a clear focus on incremental operating and maintenance costs. This results in a thinking process, which is heavily expenditure-driven and uses tools, such as systems applications and products (SAP) in data processing, to focus on cost management. Incremental improvement is a critical part of operations management. Reducing the time taken for effective maintenance increases plant availability and revenue. The balance between maintenance and availability is often the key focus of the incremental improvement process and the management process is more ‘microscale’. In this process, the speed of decision-making is not critical. Making a quick decision may result in an adverse outcome that is easily compared with expected budget outcomes. In this environment, it is more important to make the right or optimised decision, than the quick decision. Because of the long-term focus on availability and ease of maintenance, operations personnel are typically much more focused on installations designed for long-term performance than on project deadlines and delivery to scope and budget. 1. operations management KEY REQUIREMENTS OF A GOOD PROJECT MANAGER 2. EPCM reimbursable project management Due to the nature of their roles, project managers are more transient and less risk adverse. They are used to spending large amounts of money quickly in order expedite the job or maintain the schedule. Schedule often takes precedence over cost, in part due to the high cost of delayed production. 3. EPC or LSTK project management. The EPCM reimbursable approach also includes the owner’s self-perform approach where an owner’s team takes on the role of EPCM management rather than contracting to a separate party. PROJECT ENVIRONMENTS In addition to the three management scenarios listed in the previous section there are other factors that influence the type of behaviour required for a successful project outcome. These include: •• greenfields and brownfields project environments – brownfields projects typically require greater operations input •• small or large owner’s team environments – larger owner’s teams typically include more operations and maintenance experience/focus •• conventional or novel technology environments – novel technologies require an additional level of risk management through test work, scale-up, engineering design and start-up and are accompanied by increased complexity in project relationship management. A well-defined (and gated) greenfields project utilising conventional technology with a small owner’s team is much more likely to be a successful project than a brownfields project with a large owner’s team using novel technology, simply due to the complexity of the latter case and the number of interfaces that require managing (personnel and technical). Clear project definition becomes increasingly more important as the complexity of the project increases. Clear project definition is not a function of increased management, increased complexity of procedures or layering of approvals. Clear project definition is brought about by reducing the uncertainties associated with 188 A good project manager is milestone driven and requires a management tool that is heavily focused on schedule and work breakdown structure (WBS). Hence, SAP systems are not appropriate and are replaced by project delivery systems and other suitable workflow management tools that are cost and schedule focused. Time is a key differentiator between operations thinking and project management thinking. During a design phase, a typical medium sized copper concentrator project will burn $2 M to $4 M per month. This excludes the cost of lost production due to delayed delivery. Hence, delays in project decision-making and poor decisions that result in rework need to be avoided. Micromanagement is to be avoided and it is important that decision-making authorities are set at the lowest practical and effective level. This requires an experienced team capable of managing issues at the lowest level. Without a high quality team, project managers find more and more of their time taken up by low-level issues, to the extent that the focus on the broader issues may be lost. This is a major challenge in the current project environment as the large number of projects and lack of experienced personnel mean there is little chance of truly having an experienced team on your project. If people from an ‘operations environment’ fill these project management positions without adjusting their behaviour, the result is extended schedule and increased cost. Unlike operations managers, project managers are not interested in process or maintenance optimisation once the scope of work and services is agreed. Generally, a successful project has a high-level of definition during its design phases We are metallurgists, not magicians Operations versus projects – how do people think and what are the implications? and manages project execution to a defined scope. Variations cost time (and money). One small design change, such as a change in valve size may require modification of 50 engineering documents. With associated approvals and sign-offs this will cost much more than the new valve. Hence, whilst ‘fit for purpose’ is a paramount criterion, changes that refine this concept are not critical in a project manager’s paradigm. The contractual and cost environment for a project manager is demanding. Performance against contract timelines is critical and if an existing strategy needs to be changed, alternative suppliers are not easily sourced. Similar strategies as those of an operations manager may be engaged, for example using two suppliers for one commodity, but the complexities of transferring structural steel fabrication or erection scope from one supplier to another are far greater than, for example, sourcing an alternative grinding media supplier (in most cases). The implications of the above for an EPC contract are greatly magnified. Profit in a competitive bid environment is driven by completion ahead of schedule, cutting corners and maximising the margin in variations to the contract. This environment magnifies the differences between the operations paradigm and the project management paradigm. OPERATIONS INVOLVEMENT – WHEN AND HOW MUCH? Key questions from a project owner’s perspective are: •• When is the best time to freeze design? •• What defines a change outside the defined scope? At some point during project execution the ambitions of operations and the project collide. From the operations perspective, operating knowledge needs to be embedded in the project so that the plant can be effectively maintained and operated. However, from the project perspective, early involvement of the operations team will lead to increased capital cost and extensions to schedule. From both owner’s and EPCM contractor’s perspectives, one of the biggest issues is when to get the operations representatives involved in the project. If the operations and maintenance personnel are brought on too late in the execution process their input is not able to be included in the design. If they are brought on too early and the input is not critically assessed against project needs, the project cost generally increases. The best approach is to have plenty of operations and maintenance input during the feasibility stages of the project. This is much more easily done on a brownfields project or where the owner has existing operations, because the operations and maintenance groups are well established and are aware of the types of issues created by existing designs. In general, any change creates rework and can delay the project. The design usually needs to be frozen in parallel with the receipt of vendor data, at about 20–25 per cent engineering complete. After this point even minor changes result in numerous changes to documents. This is often an issue at the time when the client’s operating team joins a project as their preferences and paradigms are often not met by an existing design. The resultant tension needs to be carefully managed. The first stage of managing this process is mutual understanding of the needs of each party. This was one of the drivers for this paper. Operations team involvement is most effective: •• during the project feasibility study when the operations wish list can be assessed based on a cost/benefit analysis without impacting on project schedule We are metallurgists, not magicians •• during project review to check for any fatal flaws that may creep in during detailed design •• as part of the operations readiness planning where ‘mod-squad’ projects can be identified early and plans put in place to address serious defects. WHAT CAN GO WRONG? Input from operations is crucial to ensure rigorous project design and without it projects can encounter trouble over issues that could easily have been avoided. For example, poor chute designs can create plugging segregation, or high-wear areas. More critical are designs that have not considered maintenance access to equipment. In some cases, poor access to maintenance equipment can create safety hazards where maintenance teams have to handle heavy materials in areas with little room to manoeuvre. Finally, it is important to review the flow sheet and layout for ‘fatal flaws’, ie design flaws that will prevent the plant from performing as desired. The best time to catch these is in the prefeasibility phase or at the latest during the feasibility study. Safety issues and lack of access are issues where it can be necessary to make design modifications post-20 per cent engineering complete, even if it impacts the schedule. Hence, it is important to include operations and maintenance thinking prior to freezing the design. For greenfields projects it is usually more difficult to finalise operator input because the operations team is often not assembled until engineering has begun, or sometimes during construction. In these cases the success of the design is dependent on the quality of the design team. For the best results, it makes sense to have people on the design team that have been involved in the post-commissioning, operations and maintenance processes, but who understand the project implications. Otherwise designs can be very logical, but not consider common operations/maintenance issues. Above all, clarity regarding cause and effect is a key requirement to manage change during the reliability, accessibility, maintainability, build-ability and operability (RAMBO) process. ‘Wish list’ changes need to be differentiated from fatal flaws in the design. Strong and consensus leadership from the owner’s and Contractor’s teams is necessary to ensure that design change is minimised once critical commitments are made. Designers must understand the impact of their design on plant operation and operations personnel must understand the cost and schedule (cash flow) impact of design change. Another common problem, especially in greenfields projects, is that operational maintenance management systems are implemented too late in the process or are incomplete. This can cause many problems during the commissioning phase because critical spare parts or warehouse stocks may not be available. This problem can be magnified if the feasibility study does not consider or underestimates the cost and time involved for operating spares. Cutting operational spares is an easy way to reduce capital spending, but is a false economy if operating time is lower during the commissioning/early operating phase of the project. There is nearly always a tension on the project between what the operational team would like to have, what the project can afford and what the designer would like to supply. The degree of tension is a function of the contract type. Fixed price contracts necessitate a highly contractual (and clear) decision-making and change control process. This makes owner input more difficult once contracts are let and requires a more detailed and extended design period with associated project schedule risk. Reimbursable contracts tend to be less 189 G Lane and B Clements rigorously managed and even though change control is in place, issues can arise due to poor decision-making processes and rework and wasted time within the project. Projects with large owner’s teams tend to have greater issues with decisionmaking than projects with small owner’s teams. Hence, major mining houses have more issues controlling their project budgets and schedules than junior mining houses (irrespective of the size of the project). CASE STUDIES These case studies are based on the authors’ recent experiences with major projects. They represent a contractors’ perspective and an owners’ perspective of typical issues that arise during project execution, mostly due to the way the various parties react to project issues. Contractor’s perspective From an EPCM contractor’s perspective there are three broad categories of project owner: 1. major mining house 2. mid-tier mining house 3. junior mining house (and explorers). The extent of owner input, review and approval process differs across this spectrum with major mining houses being the most demanding and complex in terms of owner’s team interface and impact on the control of project schedule and cost. The following case study pertains to an experience with a project with an owner in the range of mid-tier to major mining house. Cost-effective design is the aspiration of most project owners. Several years ago when considering project development options for a major new mine, discussions between the owner and the EPCM contractor occurred around the nature of the plant design for a new processing plant. The owner had several operating plants and one of these was in the vicinity of the new project. The agreed concept at executive level was to design and build a ‘cost-effective’ plant and critically assess operations and maintenance input to the design prior to inclusion of ‘nice to haves’ in the design. Several option studies were completed that focused on the process flow sheet and whether to upgrade a nearby concentrator to treat the ore from the new mine or build a new stand-alone plant. The upgrade option (brownfield) allowed the use of existing capital equipment and associated infrastructure. The stand-alone plant option (greenfield) allowed some of the existing paradigms to be tested, so both had pros and cons. there was substantial cost escalation associated with the plant design in the transition from option study to execution that was related to the growth in bulk quantities in the concentrator design to meet the expectations of the contractor’s and owner’s teams as they evolved. Construction and commissioning of the brownfields project adversely impacted on the operating environment and production from the existing plant. Although this was anticipated, the extent of the disruption caused by the addition of new front end processes was underestimated. This was particularly true of the amount of relearning required by the operators as the plant changed over a period of 12 months. Lessons learnt included: •• keep the project execution plan simple and minimise the contractor’s interfaces •• clearly identify and continually communicate the vision for the project •• critically review and assess the project direction and make courageous decisions (as a team) and thus avoid the need to ‘cost-cut’ to maintain budget •• unless tightly controlled by the project and owner’s project directors, brownfields projects will maintain the paradigm set by the plant operators •• brownfields projects impact adversely and materially on existing plant operations and are harder to commission and ramp-up than a separate stand-alone (pseudogreenfields project). Owner’s perspective As previously stated, project schedule is arguably the most critical factor in determining the success of a project. This argument is supported by the economic drivers of almost every project. A large-scale concentrator project has a high capital cost and the best economic return of the project is achieved by completing the project on time and ramping it up smoothly to design productivity, including both design performance of the equipment as well as design asset efficiencies. So it is important, once the project scope is locked down, for the operating and maintenance team to focus on ensuring a smooth start-up. A complex execution strategy further complicated the execution phase and made project communications and interfaces more complex. One of the most valuable activities for the operations/ maintenance team to engage in is what is commonly called ‘operational readiness’. This involves ensuring that all of the necessary resources are ready for the handover of the plant. This involves hiring and training of the team, assembling the required operational spares, and developing the maintenance system such that surprises can be minimised. It is essential during the commissioning phase that routine maintenance activities are handled effectively. The best outcome is when these activities can be planned into the scheduled outages required by vendor run-ins. What needs to be avoided is having a critical piece of equipment breakdown and not to have the required materials on hand to complete the repairs efficiently. Since cash flow is so critical during this period, lots of time and money can be wasted in having to rush materials in, including priority freight etc. In the worst-case, when starting a project in a remote location, parts can take weeks or longer to arrive on-site. The effort of finding work-arounds for these issues is draining, and the lost opportunity can be financially disastrous to the project. The final outcome was a plant design that was robust and flexible rather than ‘lean and mean’. Given the cost profile of the project where the process plant costs are small when compared with the mine infrastructure, this outcome is reasonable in the context of the overall project. However, In this case study, the operators’ team was involved early on with the feasibility design. As a result, once the scope was locked down, they were able to focus on the operational readiness phase of the project. The start-up team was hired and they used a local technical school to train a large number As the work progressed from option studies to prefeasibility to feasibility to implementation, the objective of establishing a new paradigm became more and more diluted as new people came onto the project. New people in the EPCM contractor’s team brought their design experiences and preferences that tended to be conservative rather than aggressive. As the owner’s team grew, influence from the operations side of the owner’s business increased and the pre-existing design paradigm re-established itself within the project. 190 We are metallurgists, not magicians Operations versus projects – how do people think and what are the implications? of workers to be used in both operating and maintenance activities. They also ensured a sufficient number of experienced workers were on-board (hired from other operations) to operate and maintain the equipment effectively. Numerous operating and maintenance manuals were used to gain awareness of the specific equipment used in the plant. One of the challenges in this particular start-up was that the plant was designed with equipment that was novel to almost everyone on the team, so there were many unknowns creating distractions from the establishment of routine maintenance activity. Another challenge encountered in this case was that despite it being a brownfields project, the projected plant was a concentrator being constructed on a site with an existing leaching plant. This minimised the amount of site knowledge available to enhance the design. In addition, the projected plant was much larger than the existing operation, so existing resources were ill-prepared for the size and scope of the project. Whatever the causes, the maintenance systems for the new plant were not completely addressed during the precommissioning phase. This made the routine maintenance functions much more difficult than usual, because the maintenance team were not always able to find the necessary materials to repair the equipment. This resulted in many instances of having to use suboptimum materials to repair equipment or to rush materials to site, including air-freight in some instances, in order to keep the equipment operating. Since the correct materials were not always available, and because of the lack of experience with the high-wear environment in a concentrator, ‘breakdown maintenance’ (rather than preventative maintenance) became more common, reducing operating time of the plant. Over time, the systems were implemented and the team was able to install high-level maintenance systems including reliability centred maintenance (RCM) techniques, predictive maintenance etc. As a result the plant is currently achieving excellent asset efficiency numbers. However, the same results could have been achieved earlier if the maintenance systems had been in place prior to the always-hectic commissioning period. In the end, a very successful debottlenecking project was implemented. Many of the experiences and lessons from commissioning and early operation were used in this project. Some of those were probably thought of during the later engineering phases and construction. But it is unlikely that many of these plant modifications could have been imagined prior to start-up. So, trying to implement these ideas during the engineering phase could have improved some areas marginally, but would have been costly, and a debottlenecking phase would still have been necessary. Lessons learnt: •• experienced personnel who can focus on the operations and maintenance needs and not be distracted by the construction phase of the project •• a dedicated budget. •• Project debottlenecking is an important part of project development and can’t be avoided by late design changes during the initial project execution. •• Plants containing new technology are more complex to design, engineer, construct and commission due to the learning curve. CONCLUSIONS In a recent communication, a senior project executive from an owner’s team commented: ‘lessons are never learnt’ and without an ‘A-team’, project teams will observe ‘that stuff will never happen to me’ and ignore wisdom gained from experience. This paper states ‘the obvious’ in many ways, but ‘the obvious’ only becomes obvious through experience. The pressure on the current project development environment means that experience can be in short supply. The behaviours of, and interactions between, key project personnel drive the outcomes of projects. Project managers need clarity and a clear path to timely completion. Operations managers need a plant that is easily operated and maintained, supported by a robust operational readiness program. The tension between the two sets of needs can add tremendous value to a well-managed project when all those contributing to a project understand and respect the diverse requirements of a successful project. ACKNOWLEDGEMENTS The authors would like to acknowledge Ausenco and Freeport McMoRan for permission to publish this paper and the various people who contributed insights from within and outside these and other organisations. REFERENCES Biery, F, Hollands, A and Young, R, 2009. Minerals and metals project performance and improvement opportunities, in Proceedings Project Evaluation 2009, pp 21–26 (The Australasian Institute of Mining and Metallurgy: Melbourne). Gabrielson, A, 2007. Eye on business – Current trends in project delivery, CIM Magazine/Bulletin, 2(7). Hundertmark, T, Siliva, A and Shulamn, J, 2008. Managing capital projects for competitive advantage, McKinsey Quarterly, June. •• Operational readiness requires: We are metallurgists, not magicians 191 Contents Performance testing – when, what and how? G Lane1, M Davis2, E McLean3 and J Fleay4 ABSTRACT Performance testing is often used by project owners and financiers to provide protection from, or assessment of, technical aspects of project design, procurement, construction and commissioning. The performance tests can range from comprehensive performance warranties relating to process performance and production in the case of lump sum turn key (LSTK) projects to less onerous demonstration tests for cost reimbursable contracts. This paper will discuss performance testing from both the contractor’s and owner’s perspectives and focuses on: •• when performance tests are required •• what type of performance test/warranty is optimum for each type of project •• how project performance should be evaluated. The requirement for performance testing can be driven by the project financiers, particularly in the case of smaller resource development companies. In such cases, differentiation between owner’s risk and contractor’s risk can become contentious. At the other end of the spectrum, larger mining houses may choose to heavily influence the engineering and design process with the contractor supplying services on a reimbursable basis. In that case, the performance testing process is often limited to demonstration tests that validate performance for the owner’s corporate governance requirements. This paper was prepared due to the lack of published benchmarking of performance testing and the resultant differences in expectations between a contractor and a project owner that often surface late in the contract negotiation process. The paper provides a checklist of requirements for both the owner and the contractor that may be used to provide ‘common purpose’ early in the contract negotiation process. INTRODUCTION Process plant performance testing is often used by project owners and financiers to provide protection from, or assessment of, technical aspects of project design, procurement, construction and commissioning. This paper was prepared in response to the lack of benchmarking of performance testing and the resultant differences in expectations between technology vendors, contractors, project owners and financiers that often surface late in the project contract negotiation process. The discussion pertains mainly to minerals processing projects, for example gold plants, base metals concentrators and hydrometallurgical plants, and minerals sands plants. 1. FAusIMM, Chief Technical Officer, Ausenco Minerals & Metals, South Brisbane Qld 4101. Email: greg.lane@ausenco.com 2. FAusIMM, Managing Director, Sivad Resources Pty Ltd, Darlington WA 6070. Email: michael.davis@sivadresources.com.au 3. FAusIMM, Manager Minerals Consulting, Ausenco Minerals & Metals, South Brisbane Qld 4101. Email: eddie.mclean@ausenco.com 4. FAusIMM, Manager Metallurgy, Minnovo Pty Ltd, Leederville WA 6007. Email: john.fleay@minnovo.com.au Performance testing obligations vary with the type of contact. For LSTK work, performance warranties and resulting performance test requirements are used to define the minimum performance required for a plant or project soon after commissioning. For engineering, procurement, construction and management (EPCM) work, performance testing is typically conducted within 12 months of the completion of plant commissioning. Achieving minimum performance is particularly important for LSTK contracts where a contractor is generally given more freedom inflow sheet definition and equipment selection, and uses this freedom to optimise between plant performance and plant capital cost. For reimbursable contracts, where the owner’s input into plant design can be extensive, the role of performance testing is more complex, and the testing process can be linked to contractual bonuses and/or be used to protect the contractor from ad hoc claims by the owner. Performance tests are expensive to undertake and should only ever be conducted if aspects of the plant or project, during the pretrial period post-ore commissioning, are underperforming with respect to the warranted criteria. Poor performance can be due 193 G Lane et al to obligations not being met by the project owner as well as poor performance by the contractor. A clearer understanding of the issues may result in additional and more cost-effective rectification work being completed prior to a reassessment of whether actual performance testing is required. This paper discusses performance testing from the technology vendor’s, contractor’s and owner’s perspectives. The testing processes associated with plant preoperational testing and commissioning are not specifically addressed, other than where they interface with performance testing post-commissioning. HISTORICAL PERSPECTIVE IN AUSTRALIA From a historical perspective, performance warranties played a notable role in the early development of some major mining companies and the, now ‘mid-tier’, Australian engineering companies. Close (2002), in reporting the recent history of the development of the Australian gold mining industry, noted that the developing Australian engineering companies in the 1980s: … provided a completion guarantee that the plant would function to the specifications set out in the contract that … this significantly reduced the risk for project owners and made it easier for them to procure funding … … significantly reduced the need for technical expertise in the newly emerging gold mining companies ... and that ... … the large firms were simply unable to compete with the keen pricing and aggressive smaller local suppliers for the design and construction of smaller plants. Neither were the large traditional design and construction engineering firms such as Fluor, Davy McKee, Bechtel and Dravo willing to provide the completion and performance guarantees and the financing options that the smaller companies such as Minproc offered their clients. The early 1980s saw the emergence of the LSTK contract and accompanying performance warranty in preference to the traditional EPCM contract. These were generally preferred and commonly used by emerging, junior and new mid-tier companies. Typically the project was their first, or among the first of their ‘company makers’. Nearly all were for gold projects. In the 1990s, the proportion of LSTK projects decreased and there was a return to EPCM type contracts favoured by the newly established companies and major mining houses. These companies had larger technical resource bases, either in-house or at-call from their portfolio of operations. Projects were typically carried out by personnel with project development experience (from the LSTK days). Many of the aspects of performance warranties were retained in the EPCM work. This period saw extension of performance warranties to base metal projects. Toward the end of the 1990s, several nickel laterite projects were developed with varying contract types and associated warranties. Despite relatively onerous warranties and claims on some of the engineers, the project owners and shareholders were not protected from financial distress following poor initial performance of some of these operations, whatever the cause. The trend in the first part of the 2000s has seen a continued dominance in EPCM type jobs with increased technical participation and project direction by owners as well as a tightening of expectations and expansion of scope for performance warranties by owners and financiers. This period has seen further extension of performance warranties to the mineral sands industry. 194 Over a 25 year period from the early 1980s to the current time, the use and application of performance warranties has departed significantly with respect to the purpose and intent from those initially used by the industry. Of course, performance testing has been used for many years to ensure unit process performance where technology packages have been provided by vendors to projects, no matter what the size and style of the project. AIMS OF PERFORMANCE TESTING A performance warranty, and the associated testing process, is a method of risk management and quality control for project development. The requirement for performance testing can be driven by: •• the project financiers, particularly in the case of smaller resource development companies •• larger mining houses where the testing process is often limited to demonstration tests that validate performance for the owner’s corporate governance requirements •• engineering contractors where a vertical package LSTK subcontracting approach is used •• engineering contractors where equipment performance criteria, such as mill power draw, are critical components of a vendor supply package. It is not uncommon for junior resource companies and their financiers to attempt to manage process risk by using the LSTK contracting approach and passing on as much of the process risk to the contractor as possible. This approach is only successful if the project and process design criteria have been adequately defined in preceding feasibility study assessments and the ore reserve and mine plan are well defined. TYPES OF TESTS The types of performance tests range from comprehensive performance warranties relating to process performance and production in the case of LSTK projects, to less onerous demonstration tests of major equipment for reimbursable contracts. The consequences of failing a performance test vary and are typically defined in the head contract or term sheet. Failure by the contractor can require full rectification in the case of LSTK works or re-performance of services in the case of a reimbursable EPCM contract. The consequence of test failure by equipment vendors is typically limited to the maximum liability under the liquated damages clause of the contract. The styles and types of tests are numerous. However, to simplify matters for discussion, the performance tests can be categorised into: •• financier’s tests – typically between a financing body and the project owner and linked to the conditions of the loan (for example interest rate) to the project owner •• LSTK performance tests – typically between the project owner and the LSTK contractor •• EPCM performance tests – typically between the project owner and the EPCM contractor for reimbursable contracts •• vendor tests – required from major equipment vendors to demonstrate that the supplied equipment performs in accordance with the contract (for example power draw for grinding mills). Each of these is discussed in further detail in the following sections. We are metallurgists, not magicians Performance testing – when, what and how? FINANCIER’S TESTS Financier’s or banker’s performance tests can be the most extensive form of performance tests, as they can cover an extensive range of project activities. These tests are typically linked to the financing conditions for a project with a pass resulting in reduction in project risk and a lower interest rate for project financing to the project owner. The following list is indicative of the type and extent of tests that may be required: •• mine reserve test – validation of the mine reserve estimate based on early mine development and production •• ore to waste ratio test – based on early mine performance comparing the basis of the financial model with mine practice •• ore delivery test – based on early mine performance comparing the predicted delivery rates with mine practice •• operating cost tests – based on early project performance comparing the basis of the financial model with actual project performance •• environmental/social compliance – based on project performance comparing the environmental/social management plan with actual project performance •• management and staffing – comparing actual management and staffing levels with planned performance; both under and over manning may require explanation •• contract compliance and close-out – evaluation of whether financial obligations have been met and contracts closed in a satisfactory manner •• financial management tests – assessment of project financial management processes •• product quantity and quality tests – assessment of plant production and product quality compared with forecasts, typically with a focus on measures of plant throughput and metal recovery and quality •• insurances in place – assessment of whether appropriate insurances are in place •• marketing tests – assessment of whether product marketing systems are in place and capable of marketing product as planned •• power supply test – assessment of whether power supply provides adequate starting and operating capacity and reliability •• water supply test – assessment of whether water supply provides adequate operating capacity and reliability •• tailings disposal test – assessment of tailings storage performance against plan with a focus on settled densities and impacts on any indicated sustaining capital requirements above plan. There are occasional attempts to ‘back to back’ as many as possible of the financier’s tests requirements with LSTK contractor performance. However, in practice, many of the above tests are related to aspects of the project that are not within the contractor’s scope, for example how well the project was assessed in the feasibility stages, and how well the plant is operated post commissioning. As a result, ‘back to back’ or tripartite agreements offer little advantage other than to bring the interested parties together (often at a stage that is too late for beneficial effect). The cost of financier’s performance testing is met by the project owner. LUMP SUM TURN KEY PERFORMANCE TESTS LSTK or vertical contracts are used in the following cases: We are metallurgists, not magicians •• where the owner, typically a junior company, does not have adequate technical expertise and experience to manage a reimbursable contract •• where a financing institution insists on a LSTK contract for the above reasons •• where a separable portion of a larger contract can be identified and a specialist contractor can supply a packaged plant at a lower cost to the project. In all the above cases, the bidding process will force the contractor to cut costs by simplifying the process flow sheet, simplifying the engineering and construction services and by procuring low-cost equipment, where possible. The aim of the performance warranty is to ensure that the outcome of the LSTK contract is a plant that delivers the required performance. The performance may be measured by items such as: •• plant throughput •• grind size (P ) 80 •• for a gold plant: •• leach efficiency •• adsorption efficiency •• elution circuit efficiency •• WAD cyanide reduction circuit efficiency. •• for a concentrator: •• recovery of metal(s) to concentrate •• concentrate grade •• filtration circuit performance. •• process or project specific performance criteria. Thus, the LSTK performance warranty provides a measurable quality control step at contract completion. In the 1980s, it was relatively common for the performance tests to be completed even though the plant was meeting performance targets. More recently, best practice is to demonstrate performance targets have been achieved using plant operating records and waive the performance tests, thus saving on the testing costs and upset to overall project operation. The costs associated with LSTK performance tests in the first instance are typically met by the project owner. Repeat test costs are typically met by the party at fault in the preceding test. With LSTK performance warranties the consequence of failure by the contractor typically requires the contractor to complete all necessary rectification works at no cost to the owner. ENGINEERING, PROCUREMENT, CONSTRUCTION AND MANAGEMENT PERFORMANCE TESTS EPCM performance warranties have a much reduced consequence for the contractor as failure to achieve required performance typically requires that the contractor provide only the EPCM services for rectification at no cost to the owner. Reimbursable EPCM contracts typically have substantially more input from the owner into the flow sheet, process and plant design and engineering. Plant equipment is typically purchased by the owner and all drawings are reviewed and signed-off by the owner. As a consequence, poor plant performance that results from a reimbursable EPCM contract is the outcome of shared responsibility, with the owner and contractor contributing to the outcome. There is a recent trend toward EPCM project owners asking for more detailed and onerous warranties, while still 195 G Lane et al having substantial input to design and equipment selection. This can lead to conflict during the design phase where the engineer may raise issues with client design or equipment preferences and seek written instructions from the client that effectively waive the contractor’s warranty obligations. This process needs to be thought through by both parties prior to commencement of the project. •• additional definitions The bulk of the risk associated with poor performance of this type of contract is with the project owner in the form of lower than expected cash flow due to reduced throughput or lower than expected metal recovery. Performance warranties are typically aimed at ensuring that materials handling systems (conveyors, pumps and pipelines) and services (water and power systems) have adequate capacity. Thus, the performance tests are restricted to throughput and capacity tests rather than metallurgical performance tests based on metal recovery or product quality. •• test reporting and warranty claims EPCM performance warranties are often associated with a ‘fee at risk’. In many cases the project owner may do better to expend the cost of the fee on quality control and technical review during the EPCM phase rather than entering into performance warranties with a contractor. VENDOR TESTS Vendor warranty tests include all tests specified in contracts between the owner or contractor and equipment vendors for major equipment items, such as mills and filtration equipment. The contractor typically supervises the conduct and assessment of these tests and provides a written report to the owner on the outcome of each test. Typical vendor warranties are listed below: •• primary crusher – throughput •• semi-autogenous grinding (SAG) mill – power draw •• ball mill – power draw •• regrind mills – power draw •• flotation cells – solid suspension and air dispersion •• thickeners – overflow clarity •• filters – throughput and moisture content of filter cake •• blower performance •• vendor package performance – for example lime slaking and flocculant system. Some of the listed vendor warranties require that test work is conducted on ‘representative samples’ to enable the vendor to size the equipment and measure commercial risk. Vendor warranties enable the process risk to be shared but do not necessarily obviate the owner’s risk. If the representative nature of the sample tested is poor, lack of technical precedents and poor risk management can result in relatively minor cost to a vendor and large ongoing losses to the project owner until the process is upgraded or rectified. STRUCTURE OF PERFORMANCE WARRANTIES AND CONTRACT ISSUES The structure of the performance warranty can be made reasonably consistent across all contract types and circumstances. The performance warranty document is typically a schedule to the contract documentation. As such, the principal definitions and references are in the contract rather than the performance warranty schedule. There a number of key components to the performance warranty schedule, typically consisting of: •• introduction 196 •• warrantor’s obligations and warranties •• warrantee’s obligations and warranties •• procedures for testing (sampling, characterisation, data capture and data analysis) •• performance assessment and pass criteria •• limits of liability •• arbitration. Aspects such as payment of costs, access to data and access to site are best addressed under the obligations section of the document. A few ‘rules of thumb’ apply: •• keep the document simple •• don’t repeat information that can be referenced to the main contract •• don’t refer to other documents, such as design criteria unless they are attached as schedules to the contract •• clearly state the obligations of the warrantor and warrantee with respect to services and work required prior to and during the performance tests •• clearly quantify the warranties required of both the warrantor and warrantee for each relevant component of the plant and whether these warranties are to be met independently or collectively; each warranty should be associated with a clear definition of the data required to demonstrate compliance •• clearly state the period over which each performance test shall be run •• detailed procedures are not necessarily as long as a method of agreement and arbitration; agree immediately on detailed procedures prior to the commencement of the performance test •• clearly define the pass/fail criteria for each performance test, including the timeline and process for test completion, reporting of warranty claims, arbitration and rectification activities •• refer to limits of liability as stated in the contract. PERFORMANCE EVALUATION The desired outcome for performance warranties is that all tests are waived by the warrantee on the basis that project operating records, during the pretrial period post-ore commissioning, demonstrate warranted performance by the warrantor (Lane and Messenger, 2005). This avoids the cost and imposition of performance testing for all parties involved. The failure of a performance test is of little benefit to either party unless the relationship between the parties has broken down to an extent that obvious areas of underperformance cannot be negotiated (in the absence of legal teams) to a mutually successful conclusion. The effort associated with undertaking the performance test is better directed at the engineering solution. Performance testing places significant obligations and warrantee requirements on the project owner as well as the contractor. Churchill and Lane (1997) noted that for an EPCM contract: (Successful) Performance testing is reliant on the owner supplying suitable material for testing. Failure to do so within a reasonable period will result in default completion of performance testing. We are metallurgists, not magicians Performance testing – when, what and how? Of course, the perspective given to performance data and project outcomes differs between parties and as a consequence, performance tests are, on occasion, necessary. To minimise the likelihood of disagreement over whether the plant has reached performance targets during the pretrial period, the following process is recommended: •• prior to plant commissioning, jointly agree the data that is to be used for assessing performance compliance and agree to collate the data on a periodic basis •• periodically, jointly review and evaluate plant performance data to determine the nature of any cause of poor performance •• as warranted levels of performance are met, each party should inform the other of the compliance •• any outstanding warranties should be discussed and plans to rectify performance developed. The above process differs from the more common outcome for LSTK, EPCM and vendor contracts where the warrantor demobilises from site and lays low waiting for the liability period to lapse if there is an indication of poor project performance. This approach involves less cost (for both parties) in the short-term but can lead to acrimony and a more costly outcome in the longer term. TIMING AND DURATION OF PERFORMANCE TESTS The timing and duration of plant performance tests varies with the test type and parameters. Vendor equipment testing may be conducted over short durations, for example grinding mill power draw tests, while financier’s or banker’s performance tests are often over extended periods (months) to allow assessment of operational and financial performance. LSTK performance testing is often carried out soon after commissioning and prior to final handover of the facility to the owner. The test durations are sufficient to demonstrate a suitable level of operability and availability (usually seven to 14 days, sometimes longer). LSTK contracts in the late 1980s and early 1990s required completion of performance tests We are metallurgists, not magicians prior to the contractor demobilising from site. This model is suited to owners who are new to the mining business and benefit from the handover of a near-fully operational plant. Alternatively, both parties may be best served by divorcing initial handover of plant operations and completion of performance tests. In this case, demonstration of compliance is based on plant operating data. The best model is usually project specific and dependent on location, the availability of technical support, owner’s experience and the project contracting risk/reward model. Reimbursable EPCM contract performance tests may be completed after the plant has been operating for an extended period, and typically within the first 12 months of operation. As the objective is to demonstrate compliance with the tests’ objectives based on operating data, it suits all parties to work toward test compliance without the cost and potential upset to normal operation of actually running performance tests. The durations of reimbursable EPCM contract performance tests are typically shorter (24 hours) than LSTK contract performance tests with the focus on throughput testing rather than operational/availability issues. As discussed earlier, this change of focus is due to the much greater owner input into plant design and equipment selection. A CHECKLIST FOR FINANCIERS, OWNERS AND CONTRACTORS A checklist of requirements for each of the various types of performance tests is provided in Table 1 over the page. REFERENCES Churchill, S and Lane, G, 1997. Effective commissioning, in Proceedings Mindev 97 Conference (ed: E Barnes), p 247 (The Australasian Institute of Mining and Metallurgy: Melbourne). Close, S E, 2002. The Great Gold Renaissance, The Untold Story of the Modern Australian Gold Boom 1982–2002, p 141 (Surbiton Associates Pty Ltd). Lane, G and Messenger, P, 2005. Commissioning, in Advances in Gold Ore Processing (ed: M Adams), Volume 15, p 176 (Elsevier). 197 G Lane et al TABLE 1 A checklist of requirements for each of the various types of performance tests. Performance test type Banker Lump sum turn key Reimbursable Vendor Parties Banks and owner Owner and contractor Owner and contractor Owner or contractor and vendor Participant B O O O/C O C C V Document structure Interface with head contract or term sheet Description of purpose Definitions and terminology Warrantor’s obligations Warrantee’s obligations Warrantor’s warranties Warrantee’s warranties Procedures • sampling and test duration • characterisation test work • data capture • data analysis Can be agreed at a later date and subject to arbitration. Arbitrating party to be named in Performance Testing document. Performance assessment and pass criteria Test reporting and warranty claims Limits of liability † Plant performance warranty types Throughput Grind size Plant availability Process metallurgy • metal recovery • concentrate grade (concentrators) • solution losses (gold plants) • concentrate moisture (concentrators) • equipment performance • rheology • head grade • ore characteristics • elution efficiency • cyanide destruction Power draw or equipment specific performance ? (mills) Non-process engineering related tests Mine reserve test Ore delivery test Mine performance tests Operating cost tests Environmental compliance Management and staffing Contract compliance and close-out Product quantity and quality tests Financial management tests Insurances in place Marketing tests Power supply test Water supply test Tailings disposal test B = banker, O = owner, C = contractor, V = vendor. † – Typically covered in head contract. 198 We are metallurgists, not magicians Unit design and development Contents Process development and throughput forecasting at the Phu Kham copper-gold operation, Laos PDR D Bennett1, I Crnkovic2, P Walker3, A Hoyle4, A Tordoir5, D La Rosa6, W Valery7 and K Duffy8 The Phu Kham deposit in Laos People’s Democratic Republic (PDR) represents a highly variable and complex copper-gold porphyry system, and the original 12 Mt/a concentrator commissioned in April 2008 lagged a long way behind most others in terms of recovery of copper and gold into concentrate. A focus during the original Phu Kham concentrator design stage was to counter the expected metallurgical challenges by including first class instrumentation, on-stream analysis and sampling systems to be able to provide process measurement and collection of data. Once in production, gathering key variability data from daily laboratory test work and monthly mineralogical composites helped to unlock the secrets of the ore, and laid the foundations for the subsequent capital investments in extra capacity and increased recovery. Process control opportunities have been advanced in parallel to manage the ore variability and to further enhance throughput and copper-gold concentrate production. The involvement of people with the right skills and experience throughout all stages of the Phu Kham operations development has always been considered as critical to success. The results of all the process development and enhancements from commissioning until June 2016 is presented in Figure 1, with throughput increasing from 12 Mt/a to 19 Mt/a, copper recovery increasing from approximately 60 per cent to 80 per cent, and gold recovery increasing from approximately 35 per cent to over 50 per cent. ABSTRACT 1. MAusIMM, Principal Metallurgist, PanAust Limited, Fortitude Valley Qld 4006. Email: duncan.bennett@panaust.com.au 2. MAusIMM, Manager Process Technical Services, Ok Tedi Mining Limited, Tabubil, Western Province, Papua New Guinea. Email: ivan.crnkovic@oktedi.com 3. MAusIMM, Director, Minmet Services Pty Ltd, Wilson Beach Qld 4800. Email: peter29walker@yahoo.com.au 4. MAusIMM(CP), Manager Minerals and Metals, Ausenco, San Isidro, Lima 27, Perú. Email: andrew.hoyle@ausenco.com 5. Lead Drill and Blast, Group Mining Technical and Sustainability, AngloAmerican, London SW1Y 5AN, UK. Email: alan.tordoir@angloamerican.com 6. Principal Mining Engineer, CRC ORE, Queensland Centre for Advanced Technologies (QCAT), Pullenvale Qld 4069. Email: david.la.rosa@crcore.org.au 7. FAusIMM, Global Director – Consulting and Technology, Hatch – Mining and Minerals Processing, Brisbane Qld 4000. Email: walter.valery@hatch.com 8. MAusIMM, Process Consultant / Mining and Mineral Processing, Hatch, Brisbane Qld 4000. Email: kristy.duffy@hatch.com The Phu Kham deposit represents a copper-gold porphyry system, with mineralisation present in skarn, stockwork and disseminated styles. Significant folding and alteration events have created a complex heterogeneous geotechnical and mineralogy horizon, which affect plant throughput and metallurgical performance. Weathering and water table contact have created a leached zone, overlying transition zones with supergene chalcocite-dominant secondary copper mineralisation and clay-rich gangue. Primary ore copper mineralisation is mainly chalcopyrite with minor bornite. The major challenges to the copper-gold flotation process are a wide size distribution of chalcopyrite mineralisation and poor primary grind liberation, a high pyrite content in skarn ore requiring aggressive pyrite depression conditions, clay-rich gangue and non-sulfide copper mineralisation in weathered zones, and a significant association of gold with pyrite. The Phu Kham concentrator has been developed as a conventional semi-autogenous grinding (SAG) and ball milling circuit followed by rougher flotation, regrinding and cleaner flotation to produce a copper concentrate containing payable gold and silver values. The original 12 Mt/a copper-gold concentrator flow sheet design offered a capital efficient compromise between high copper recovery bulk sulfide flotation with large cleaning capacity, and lower recovery copper selective rougher flotation to ensure concentrate specification of 24 per cent copper grade could be achieved. Phu Kham commenced production of copper-gold concentrate in April 2008. Flotation copper and gold recovery from commissioning was consistently poor, due to the high levels of pyrite and problematic secondary and oxide copper species and non-sulfide gangue. Incremental improvements in copper recovery were achieved by 2011 through conversion of conditioning cells to flotation cells in both roughing and first cleaning and increased cleaner capacity through the installation of a Jameson Cell. In 2012 the Phu Kham Upgrade Project (PKU) was commissioned to increase mill throughput, along with additional rougher and cleaner capacity to increase residence times and maintain copper production at the nominal 16 Mt/a throughput. The marginal reduction in primary grind size due to the additional ball milling power also provided a small recovery improvement. 201 D Bennett et al FIG 1 – Phu Kham mill throughput and copper and gold recovery from commissioning until June 2016. The Increased Recovery Project (IRP) commissioned in April 2013 targeted the major causes of copper and gold loss from the circuit. Based on fundamental and detailed test work and mineralogical analysis of concentrator streams, an optimised design was developed which has increased copper and gold recoveries by over five per cent and ten per cent respectively. The IRP positioned the concentrator to process high pyrite ores that were previously considered untreatable, and opened further opportunities for maximising flotation recovery by debottlenecking plant regrind and cleaning capacity. To evaluate how to maintain design throughput rates with increasing ore hardness over the life-of-mine (LOM), Phu Bia Mining Limited conducted a throughput forecasting and optimisation project for Phu Kham with the assistance of Metso Process Technology and Innovation (PTI). The project involved a review of the blasting, crushing and grinding processes and development of a throughput prediction model based on geometallurgical modelling for long-term planning. The scope also included identifying opportunities for increasing throughput and improving overall comminution circuit performance when treating the most competent ore types. A shorter term objective was to identify if and when secondary crushing or other process changes will be required to maintain the target throughput over the LOM. This paper examines and discusses process and concentrator flow sheet development, including projects implemented since commissioning in 2008 to improve throughput and copper and gold recovery with decreasing copper grade and increasing pyrite content of ore feed, and increasing hardness of primary ore. Introduction The Phu Kham operation consists of a copper-gold mine using conventional shovel mining and truck haulage to a flotation 202 concentrator. The project is owned and operated by Phu Bia Mining Limited. PanAust Ltd based in Brisbane, Australia holds a 90 per cent interest in PBM through its wholly owned subsidiary Pan Mekong Exploration Pty Ltd, with the remaining ten per cent held by the Government of Laos PDR. The Phu Kham copper-gold deposit is located in the Xaisoumboun province as shown in Figure 2, approximately 120 km north of the Lao capital Vientiane. Access to the mine is approximately four hours by road from Vientiane. The Phu Kham 12 Mt/a concentrator was commissioned in 2008 for a capital cost of approximately US$150 M, placing it in the lowest quartile for capital intensity for copper mineral processing projects. The installed plant was a compromise between a high recovery but high capital intensity design, and a lower recovery but technically lower risk and low capital intensity design. The selective rougher flotation design was driven by the complex and variable mineralogy and high pyrite content, with over 90 per cent of pyrite required to be rejected in order to produce a final concentrate of over 23 per cent copper. With increasing depth of the pit since the commencement of operations, the weathering profile of the feed has changed such that the ore became primary dominant in 2010, with chalcopyrite the main copper sulfide mineral. The complex folding and alteration of the ore zones has meant continued mining of supergene and oxidised areas within the pit, with the copper mineralogy remaining diverse and varying from native, oxide, secondary and primary copper species within short time periods. The development of the Phu Kham flow sheet was driven by the poor recovery in comparison to other low-grade copper-gold ores, and a need to counter decreasing ore grades from 2013. Major projects implemented up until 2011 included increasing rougher capacity by 25 per cent and increasing first cleaner We are metallurgists, not magicians Process development and throughput forecasting at the Phu Kham copper-gold operation, Laos PDR FIG 2 – Location of the Phu Kham copper-gold mine. capacity by 16 per cent, and the installation of a Jameson Cell in a cleaner scalper duty. In 2012 the operation was upgraded to a nominal throughput of 16 Mt/a with installation of a second 13 MW ball mill, a further 33 per cent increase in rougher capacity, 40 per cent increase in second cleaner capacity, and 33 per cent increase in third cleaner capacity. In 2009 a project to achieve step-change in copper and gold recovery from Phu Kham was initiated. A process development study was completed in 2011, which showed that it was technically feasible to generate a low-grade copper and gold mineral concentrate by bulk sulfide flotation of concentrator tailings suitable for leaching for recovery of copper and gold into high-grade products. During the study, opportunities for increasing copper and gold recovery in the existing concentrator using standard processing methods became apparent, and detailed mineralogical work and metallurgical test work was undertaken to determine the causes of copper and gold loss to tailings. The mineralogical work revealed that up to 60 per cent of copper sulfide mineral lost was in coarse non-sulfide gangue composites, and over 50 per cent of gold loss was in gold-pyrite composites. The work presented an opportunity to recover these composites by less selective rougher flotation, before upgrade and additional recovery for both copper and gold into a We are metallurgists, not magicians 23 per cent copper concentrate by regrinding of rougher concentrate to 20 µm and additional cleaning flotation capacity. Following extensive test work at bench, pilot, and full scale which proved the concept and led to investment approval, in 2013 the operation increased total recovery of both copper and gold by approximately six per cent into final concentrate through the Increased Recovery Project (IRP). A second filter was installed during the project to dewater the additional concentrate produced. As mining extends deeper into the deposit, the operation will experience an increased proportion of highly competent ores which will have the potential to limit plant throughput, through the semi-autogenous grinding (SAG) mill. Phu Bia Mining commenced a throughput forecasting and optimisation project in 2012 to evaluate how to maintain design throughput over the LOM. Insufficient comminution data in the mine block model created a lack of confidence in the ability to predict mill throughput, particularly in the later years of the mine life. Geology and mineralogy The Phu Kham geology is highly variable due to weathering, alteration, faulting and folding. The deposit consists of complex heterogeneous mineralogy horizons of copper-gold 203 D Bennett et al stockwork and skarn mineralisation as shown in Figure 3. Weathering and water table contact have created a soft leached zone, overlying transition zones with supergene chalcocite-dominant secondary copper mineralisation and clay-rich gangue. The rock mass strength and degree of weathering vary considerably across the deposit with extremely competent (hard) rock found in the deeper levels. Such variability causes a large range of plant throughput and metallurgical performances. Mineralisation is present in iron-rich skarns, silica-rich stockwork and altered disseminated styles. Chalcopyrite and bornite are the dominant primary copper minerals in skarn, stockwork and disseminated mineralisation. Gangue mineralogy is mainly quartz, mica and pyrite, with significant kaolinite clay and talc-related magnesium silicate content within the weathered zones. A gold-enriched oxide zone on the Phu Kham orebody was the resource for the heap leach gold mine which was built and operated by Phu Bia Mining during the 2005 to 2010 period. Below the oxide zone, there is a zone of supergene weathering, with copper leached from the oxide zone re-precipitated in contact with pyrite grains as particles and coatings of chalcocite and covellite, with minor enargite and tennantite copper arsenic sulfides. Significant copper enrichment in the oxide and supergene zones is also present as oxide and native copper species. Skarns are present as replacement of carbonate minerals, with disseminated grains of chalcopyrite and bornite in banded to massive pyrite skarns and veinlets containing pyrite, chalcopyrite and bornite in garnet, magnetite and hematite-chlorite skarns. Pyrite skarns are common throughout the mineralised system. Stockwork mineralisation is present as fine fractures in quartz veins. The fractures host pyrite, chalcopyrite and bornite sulfide minerals. Minor chalcopyrite mineralisation is also present in quartz-carbonate veins. Disseminated mineralisation consists of scattered grains of bornite and chalcopyrite in sericite altered host rock. Gold occurs as small grains associated with pyrite and copper sulfides throughout the mineralised system. CIRCUIT DESCRIPTION The original 12 Mt/a concentrator design and commissioning in 2008 has been described in detail by Crnkovic et al (2009). The description of the 2016 concentrator following the PKU and IRP is provided in this section and the simplified flow sheet is presented in Figure 4. The crushing plant consists of a primary 55 in × 77 in gyratory crusher, with single truck dump point above a pocket designed to hold 200 t capacity equivalent to two 777D haul trucks. Crusher discharge drops to a crushed ore bin of 200 t capacity. The crushed ore bin is emptied by a variable speed apron feeder onto a crushed ore transfer conveyor belt (CV001). The CV-001 conveyor transfers the ore to an 890 m long overland conveyor CV-002, which moves ore to the coarse ore FIG 3 – Phu Kham geological zones. 204 We are metallurgists, not magicians Process development and throughput forecasting at the Phu Kham copper-gold operation, Laos PDR FIG 4 – 2016 Phu Kham 18 Mt/a concentrator simplified flow diagram. stockpile with a live capacity of approximately 24 000 t. There is additional dead capacity for storage of up to 300 000 t of ore. Ore is reclaimed from the crushed ore stockpile by two variable speed apron feeders onto a SAG mill feed conveyor. SAG mill grinding media is added to the ore feed conveyor via a spillage return hopper. Primary grinding is achieved in a dual pinion 13 MW variable speed slip energy recovery/ hyper-synchronous drive 34 ft × 20 ft SAG mill in closed circuit with scats return conveying including a high-lift conveyor to overcome topography constraints. SAG mill discharge is classified using an integral mill trommel, with minus 12 mm product reporting to a 1.85 MW cyclone feed pump. In the original circuit, cyclone feed was classified in a single cluster of 18 × 650 mm diameter cyclones, with cyclone underflow reporting to the No 1 dual pinion 13 MW drive 40 ft × 24 ft ball mill in closed circuit. In the upgraded plant, a bleed stream of approximately 50 per cent of the SAG mill feed mass is diverted via a transfer pump to a 1.85 MW cyclone feed pump reporting to a cluster of 17 × 650 mm diameter cyclones, with cyclone underflow reporting to the No 2 dual pinion 13 MW drive 40 ft × 24 ft ball mill in closed circuit. Quicklime slurry is added to the SAG mill and ball mills for flotation pH control to depress pyrite. Cyclone overflow from the No 1 milling circuit reports to a mixing box, where it joins a bleed of cyclone overflow from the No 2 circuit to balance the volumetric feed split to the No 1 rougher bank. The mixed cyclone overflow passes through a multiple stage feed sampler before the No 1 bank of ten 200 m3 tank cell roughers. The original plant had a single 200 m3 rougher feed conditioning tank before eight 200 m3 We are metallurgists, not magicians rougher cells in the No 1 rougher bank, with the conditioning tank converted to a ninth flotation cell in 2009. In early 2011, a tenth 200 m3 rougher cell was installed and commissioned in the No 1 rougher bank. Cyclone overflow from the No 2 milling circuit reports to a 70 m3 agitated tank with two discharge pumps, one which reports to the mixing box before the No 1 rougher bank, and another which reports to the No 2 rougher bank of five 200 m3 tank cells via a multiple stage feed sampler. Dithiophosphate collector is used to recover copper sulfide minerals in flotation while maintaining selectivity against pyrite. Rougher banks tailings pass through static dual fin pipe samplers before reporting to final tailings mixing box where it is combined with cleaner scavenger tailings. The mixed tailings discharge to a metallurgical multiple stage sampler and a final tailings sump. The final tailings sump discharges slurry by gravity through two 750 mm diameter tailings lines, which transport tailings approximately 1.5 km to a crossvalley subaqueous tailings storage facility (TSF). Rougher concentrate from both rougher banks reports to a common cyclone feed pump hopper before classification in a cluster of 12 × 400 mm diameter cyclones, with cyclone overflow reporting to a Jameson Cell feed hopper. Cyclone underflow reports to two open circuit M10000 IsaMill™ regrind mills operating in parallel. IsaMill™ discharges report to the Jameson Cell feed hopper. The 24 downcomer, 6500 mm diameter Jameson Cell operates in a cleaner feed scalping duty, with concentrate passing through a pipe sampler for process control, before reporting to the final 205 D Bennett et al concentrate thickener feed sampler, and tailings reporting to the conventional cleaning circuit. The conventional cleaning circuit consists of three stages, with the first stage in open circuit. The first stage of cleaning/ cleaner scavenging consists of two parallel banks of seven 70 m3 tank cells for a total of 14 cells. Cleaner scavenger tailings pass through static dual fin samplers before reporting to the final tailings mixing box. First cleaner and cleaner scavenger concentrates report to the second cleaner, which consists of seven 20 m3 cells. Second cleaner concentrate advances to the third cleaner of four 20 m3 cells, while second cleaner tailings return to the first cleaner feed pump hopper. Third cleaner concentrate passes through a pipe sampler, before reporting to the final concentrate thickener feed sampler. Third cleaner tailings return to the second cleaners. Final concentrate (combined Jameson Cell and third cleaner concentrates) is sampled in a multiple stage metallurgical sampler, before gravitating to a 15 m diameter high-rate thickener. Thickener supernatant flows to a thickener overflow process water tank. Thickener underflow at a nominal density of 65–70 per cent solids is pumped to a mechanically agitated filter feed tank of approximately 24 hours surge capacity, with excess production bled to a second mechanically agitated filter feed tank of approximately 8 hours capacity. The thickened concentrate slurry in the 24 hour capacity tank is dewatered using a 64-plate horizontal filter, with filter discharging into a covered storage shed of nominal 8000 t capacity. The thickened concentrate slurry in the eight hour capacity tank is dewatered using a 40 plate horizontal filter, with the filter discharging into a separate covered storage shed of nominal 5000 t capacity. Concentrate is loaded into 25 t containers for transport by truck to the Sriracha port in Thailand or ports in Vietnam. Concentrator raw water is harvested from the Nam Mo River before being pumped to a crusher process water tank and mill header tank. The raw water is mainly used for cooling, pump glands, flotation froth wash showers and fire water. Process water is recovered from the TSF supernatant, and transferred to a process water tank via two transfer stations. process improvements and FLOW SHEET DEVELOPMENT The Phu Kham 12 Mt/a concentrator was designed and built to treat a high pyrite copper-gold skarn ore with significant clay content, as described by Meka and Lane (2010). The plant was commissioned in April 2008 and had ramped up to meet nameplate capacity and operating time design by November 2008. A simplified flow sheet for the original 12 Mt/a concentrator is shown in Figure 5. A photograph of the 12 Mt/a concentrator in June 2008 is shown in Figure 6. 2009–2010 Flotation cell conversions In September 2009, the existing rougher conditioner and cleaner conditioner tanks were retrofitted with flotation mechanisms, thereby increasing the roughing capacity from eight to nine 200 m3 cells, and increasing the cleaner capacity from six to seven 70 m3 cells. The benefits arising from these changes amounted to increased copper recovery in the rougher flotation circuit by 3.5 per cent, and increased copper recovery in the cleaner circuit by 2.5 per cent. The increased residence time in each of the circuits resulted in higher recovery of slow floating secondary copper minerals, and composite particles FIG 5 – 2008 Phu Kham 12 Mt/a concentrator simplified flow diagram. 206 We are metallurgists, not magicians Process development and throughput forecasting at the Phu Kham copper-gold operation, Laos PDR rougher residence time by 2.4 minutes at maximum design throughput of 1750 t/h. In late January 2011, the tenth 200 m3 rougher tank cell was installed at the head of the rougher circuit. At the time that the tenth rougher cell was installed, the flotation feed rate was increased by about four per cent, which effectively reduced the overall rougher residence time increase from an expected 11 per cent to seven per cent. The overall surveyed copper recovery improvement was between 0.4 per cent and 0.6 per cent, depending on throughput rate, which met the project criteria. FIG 6 – Southern view of the Phu Kham concentrator in June 2008. particularly while transitional ore types were dominant at this time. The improved recovery performance was validated from using the database of daily rougher tail and cleaner scavenger tail re-flotation tests. FloatForceTM mechanisms An investigation into using Outotec FloatForce™ rotor-stator mechanisms in the rougher flotation circuit commenced in 2009, starting with the first rougher cell 1B. The design of the new mechanism was to deliver improved recovery from increased mixing efficiency, by not allowing any air in the central mixing area of the impellor thereby improving mixing efficiency without affecting slurry pumping. The installation of the FloatForce™ mechanism was simple, and was commissioned without any issues. The conclusions, drawn from extensive survey data around rougher cell 1B (before and after installation), demonstrated an improvement in rougher cell 1B copper recovery of 0.2 per cent. On the basis of the survey data, the total predicted rougher copper recovery increase for the nine rougher cells with FloatForce™ mechanisms was 0.3 per cent. The installation of the remaining eight mechanisms was completed in June 2011. 2011 Tenth rougher cell installation The ongoing rougher tail re-flotation tests continued to highlight that there was a further copper recovery benefit of approximately 0.6 per cent to be gained with the addition of another 200 m3 tank cell, which would increase Cleaner circuit debottlenecking One of the major limitations in the original plant design had been a lack of cleaning capacity, particularly with respect to the second cleaner bank of four 20 m3 cells. The limitation was that of carrying capacity, rather than residence time. The cleaner circuit performance would generally deteriorate when the cleaner feed copper metal units exceeded 9.1 t/h copper, limiting copper metal production to a sustainable maximum of approximately 8.5 t/h. To further investigate the cleaning circuit capacity, a cleaner circuit optimisation study was completed in February 2010. From plant data, a mineral based floatability component model was developed which allowed different cleaner circuit configurations to be simulated. The option which gave the optimum copper grade and recovery result was to install additional cleaning capacity ahead of the existing cleaner circuit, so effectively cleaner feed scalping. Different flotation cell technologies were considered for this application, with the Xstrata Jameson Cell meeting design criteria. The simulations indicated that a 0.6 per cent improvement in cleaner recovery could be achieved. The Jameson Cell was chosen because of low installed cost, confidence in simulated performance results, low performance risk, moderate installation risk and low production continuity risk during installation. The circuit simulations including the Jameson Cell as a cleaner feed scalper indicated substantial recovery improvement over the existing circuit at circuit feed rates greater than 150 t/h, due to elimination of the carrying capacity limitation as shown in Figure 7. On this basis, it was decided to proceed with this design, the Jameson Cell in a cleaner feed scalping simulation recovering approximately 60 per cent of the copper present in the FIG 7 – Effect of cleaner circuit feed tonnage on copper recovery for Jameson Cell cleaner feed scalping simulations. We are metallurgists, not magicians 207 D Bennett et al cleaner circuit feed across a cleaner circuit feed rate range of 100 t/h to 300 t/h. The Jameson Cell concentrate grade from the simulation was 27 per cent copper, against a target of 25 per cent copper. The simulations showed that substantial unloading of the remainder of the cleaner circuit would occur. The result of this was that the third cleaner concentrate grade was low at less than 22 per cent copper, however the net effect was to produce an overall circuit final concentrate grade of 24 per cent copper. Although there was a small cleaner recovery improvement shown from the simulations performed using a cleaner scalper, the real benefit was in maintaining cleaner recovery when the cleaner feed rate is greater than 150 t/h. The cleaner scalper cell was commissioned in March 2011. Commissioning was carried out over a period of one week, and no significant problems were encountered. The performance evaluation of the Jameson Cell was remarkably consistent with the expected performance from the equipment vendor, the simulation data and from Phu Kham Metallurgical Laboratory flotation tests simulating performance of the Jameson Cell prior to commissioning. From surveys carried out in February 2012, with the Jameson Cell online and offline, the benefit of having the Jameson Cell in circuit was determined to be 0.8 per cent increase in copper recovery. In terms of overall cleaner circuit debottlenecking, the objectives were achieved. The cleaner circuit with cleaner feed scalping capacity is 10.1 t/h copper metal at 24 per cent concentrate grade for a total 16 per cent copper metal production increase. 2012 Phu Kham Upgrade project The Phu Kham Upgrade (PKU) project commenced in March 2010 with a study to develop designs to ensure that copper in concentrate production was maintained over 60 kt/a after 2013 when plant copper feed grade was expected to decrease. In order to maintain copper metal production, plant nominal design throughput increased from 12 to 16 Mt/a (1500 to 2000 t/h) and maximum instantaneous design throughput increased to 2250 t/h. The plant upgrade concept was not original, and had been studied in 2008 as part of a copper production expansion project concept. Key aspects of the upgrade designs for Phu Kham were the limitation of available space for additional equipment, as the original 12 Mt/a plant design had not specifically made allowance for any expandability. The initial phase of the PKU included a plant debottlenecking study, which consisted of analysis of the actual plant performance and capacity data from 2008 to March 2010 against the original plant process design criteria. The purpose of the bottleneck study was to determine aspects of the original plant that either were, or would become bottlenecks with the 25 per cent increase in mill throughput. The key findings from the plant bottleneck study are shown in Figure 8, which shows that rougher copper recovery was 16 per cent below design, cleaner copper recovery was seven per cent below design, and mill throughput was three per cent below design at 12 Mt/a. The mill throughput variance was a function of rougher copper recovery and cleaning circuit capacity rather than limitations in the grinding circuit. The crushing and concentrate dewatering plant capacities were also considered during the PKU bottleneck study. The bottleneck study indicated that additional crushing capacity would be required with capability for handling wet and sticky ore which is a common feature of the transition zones of the orebody. A mineral sizer in parallel to the existing crushing plant, with product reporting directly to the coarse ore stockpile was included in the PKU designs. Although the concentrate thickener and filter performance had not indicated that future concentrate production rate would exceed capacity, limited data was available to confirm the capacity against upgraded plant design criteria. Test work was conducted to determine settling rates and filtration rates for concentrate during the PKU to obtain the required data. The basis of design for the grinding circuit upgrade has been described by Hadaway and Bennett (2011). Two options for increasing grinding circuit throughput after the SAG mill to a nominal design of 16 Mt/a and primary grind at 80 per cent passing 106 µm or 75 µm were reviewed. The first option was based on the original 2008 plant upgrade design incorporating an additional 6.5 MW single pinion ball mill, and the second for another 13 MW ball mill. Data from JKTech grinding circuit modelling in 2009 was extrapolated using the Phu Kham mine schedule to determine throughput estimates at 106 µm and 75 µm for the two mill FIG 8 – Phu Kham 12 Mt/a concentrator actual performance variances against design 2008–2010. 208 We are metallurgists, not magicians Process development and throughput forecasting at the Phu Kham copper-gold operation, Laos PDR options. Pebble crushing was not considered in the evaluation. The 6.5 MW mill was able to increase throughput at a 106 µm primary grind to above the 16 Mt/a nominal design, however was unable to meet the 16 Mt/a target at a significantly finer primary grind. The 13 MW mill was able to achieve above 18 Mt/a for the 106 µm primary grind, and could achieve above nominal design throughput at a 75 µm primary grind. The effect of primary grind on flotation recovery was reviewed based on feasibility study work from bench scale batch tests in 2005. The study work indicated that the major primary ore sources, in particular stockwork primary, were relatively insensitive to primary grind size. Plant operations mineralogy data from 2008 to 2011 monthly composites indicated that minor sensitivity existed, with increases of over five per cent in copper sulfide liberation with a primary grind size decrease from 80 per cent passing 106 µm to 75 µm. An economic analysis was conducted based on differences in capital and operating costs for the two options at 16 Mt/a throughput and 106 µm and 75 µm primary grind. The increase in operating cost for finer grinding versus revenue benefits in copper recovery showed that above $2.50/lb copper price, the finer primary grind increased gross margin. Capital cost per installed megawatt was 26 per cent less for the 13 MW mill option, and the capital payback period for the 13 MW option was significantly shorter. A risk assessment was conducted for the 6.5 MW option and the 13 MW option. The risk of the 13 MW option was considerably lower than for the 6.5 MW option, mainly due to the operating flexibility for periods of low-grade ore and ore types with higher sensitivity of recovery to primary grind. The 6.5 MW option was not able to take advantage of economies of scale gained by increased throughput, or the estimated one per cent increase in copper recovery at the finer grinds, and would not be able to reach the nominal 16 Mt/a throughput at 106 µm primary grind after 2014. The throughput at 106 µm and 75 µm primary grinds for the two mill options is shown in Figure 9. Based on the results of the risk assessment, the recommendation for installation of an additional 13 MW ball was accepted. Procurement of a second dual pinion 13 MW drive 40 ft × 24 ft ball mill commenced in November 2010. The dominant cause of the 16 per cent rougher copper recovery shortfall shown in Figure 8 was a combination of lower than design rougher residence time due to five per cent lower rougher feed density, and a cleaner circuit capacity constraint which limited the rougher mass recovery. The dominance of transition ores with significant slow floating secondary copper mineral content milled during the March 2009 to February 2010 period and the under-representation of these ore types in the feasibility study test work provide explanation for some of the copper recovery shortfall in cleaning stages against design. The debottlenecking study was developed for the flotation circuit to determine increased capacity requirement at the PKU design 16 Mt/a throughput. Rougher flotation feed density design for the 12 Mt/a plant was 35 per cent solids. Actual operation rougher feed density averaged 30 per cent solids due to the higher slurry viscosity from kaolinite clay content not quantified during the feasibility study. An extra 200 m3 rougher cell was required to achieve the same residence time as at 35 per cent solids, which was achieved by conversion of the rougher conditioning tank to a cell in 2009. The reduced residence time from operating at the lower rougher density at design tonnage throughput resulted in a three per cent decrease in copper recovery, based upon plant residence time–recovery data from July 2009 to February 2010. The PKU design therefore allowed for reduced rougher feed pulp density, and a residence time calculation confirmed that a 33 per cent increase in rougher capacity was required for the 25 per cent increase in mill throughput at 16 Mt/a, which would also provide an additional one per cent copper recovery. A total of five 200 m3 rougher cells in addition to the existing ten cells were included in the design, for a total of 15 cells. The cleaning circuit was not expected to require significant expansion as a result of the 16 Mt/a upgrade, as the lower grade mill feed would result in equivalent concentrate production to the 12 Mt/a design throughput rate. The PKU design for the cleaner flotation circuit also included the Jameson Cell cleaner scalper although this had not been installed at this time. However, cleaner circuit mass balance simulation data including the Jameson Cell indicated that 40 per cent increase in the existing second cleaner residence time and lip length was required at 16 Mt/a. To gain this increase in second cleaner capacity, the existing three 20 m3 third cleaner cells FIG 9 – Throughput at 106 µm and 75 µm primary grind for additional 6.5 MW and 13 MW ball mill options. We are metallurgists, not magicians 209 D Bennett et al were combined with the four 20 m3 second cleaner cells to create a second cleaner bank of seven 20 m3 cells, and four new 20 m3 third cleaner cells were added for the PKU. The simulation data for the cleaners also demonstrated that upgrade of the first cleaner capacity was not warranted, as the fine low-grade middlings recovered in the final cells were not able to be upgraded to near final concentrate specification. Prior to commencement of the detailed design phase of the PKU study, maximum sustainable production rate (MSPR) analyses were undertaken for the crushing and concentrate dewatering plants to determine whether capacity expansion was required for these areas of plant based on 16 Mt/a production schedules. The MSPR was defined as the best consecutive five days of performance, normalised using plant-specific industry standards for annual availability to allow for major scheduled maintenance. The MSPR for the crushing plant also included seasonal variation due to the tropical environment and the wet season impacts on crusher productivity. The primary conclusions from the performance review of the Phu Kham crushing plant were that it had demonstrated the target PKU production rate of 16 Mt/a over the June 2010 period, and approximately one-third of total crushing plant downtime had been caused by events up and downstream of the crushing plant while the plant was available to crush. The low crusher utilisation of 64 per cent as a result of these operating standby periods was equivalent to over 2.4 Mt/a of additional crushing capacity at the target throughput of 2400 t/h and target utilisation of 75 per cent of total time. With increases in haul fleet numbers for the PKU, improvements in run-of-mine stockpile inventory, and a standby loader available when there were delays in truck presentation to the crusher, the MSPR demonstrated that increasing crushing capacity was not required. The design specifications for the 64 plate and frame filter were for a filtration rate of 225 kg/m2/h, with an annual design production rate of 311 000 t of concentrate. Actual filter plant operating data was analysed to check filter performance against the design capacity. MSPR for the filter was determined to be 18 per cent above the life-of-mine maximum concentrate production schedule, leading to deferral of capital expenditure for the filtration plant. The main reasons for the higher than design performance were; optimisation of filter cycle settings following an improvement program including operations, maintenance, and vendor support input and change to filter cloth media type. Following the review of the PKU design, engineering and procurement services commenced for the 16 Mt/a PKU project in January 2011, with commissioning commencing in the third quarter of 2012. Ramp-up to nameplate capacity was achieved within two months, and over 17 Mt/a annualised throughput rate was achieved in the fourth quarter of 2012. A simplified flow diagram for the PKU plant is shown in Figure 10, with new equipment highlighted in mauve. FIG 10 – 16 Mt/a PKU simplified flow diagram. 210 We are metallurgists, not magicians Process development and throughput forecasting at the Phu Kham copper-gold operation, Laos PDR flotation option consistently achieved over 22 per cent copper final concentrate grade, however ultimate copper recoveries to final concentrate were lower than the bulk flotation option. 2013 Increased Recovery Project The Phu Kham feasibility studies between 2004 and 2006 identified two options for flotation processing of Phu Kham ore. The first option involved bulk flotation of the rougher feed targeting a 25 per cent mass recovery into rougher concentrate using non-selective amyl xanthate sulfide mineral collector. The rougher concentrate was then reground to 80 per cent passing 38 µm and subjected to cleaner flotation at pH 12 for pyrite depression. This process produced high copper recovery results, however there was difficulty achieving final concentrate grade of greater than 22 per cent copper across all ore types, particularly transition chalcocitecovellite secondary copper mineral dominant ores. A rougher feed photomicrograph is shown in Figure 11 with chalcocitecovellite intergrowth with pyrite and rimming of pyrite. There was also indication of copper activation of pyrite from soluble copper species in weathered and transition ores. The second process option involved selective flotation in roughing at pH 11–12 using a copper sulfide selective collector. The rougher concentrates were again reground to 80 per cent passing 38 µm and lime to pH 12 and sodium cyanide was added to the cleaning stages to depress pyrite. The selective The design of the original 12 Mt/a Phu Kham concentrator was a compromise between the two process options, with partially selective roughing being applied to minimise pyrite gangue recovery into cleaner flotation feed. Sodium cyanide addition to the cleaners was included in the original design, however was never used with concentrate grade over 22 per cent copper consistently achieved following commissioning. This partially selective flotation process had significant capital cost advantages over bulk flotation at a time when the long-term copper price forecast was less than $2.00/ lb, due to the lower rougher concentrate regrind and cleaning capacity required, and provided the best cost-benefit process alternative while reducing risk of being unable to achieve concentrate specifications using bulk rougher flotation. Minimal work was performed during the feasibility studies to test the sensitivity of final copper grade and recovery on rougher concentrate regrind product particle size. Grind size analysis was limited to two mineralogical examinations which concluded that reasonable copper and gold recoveries to rougher concentrate would result from a primary grind of 80 per cent passing 106 µm, and that a rougher concentrate regrind to less than 45 µm was required to achieve an acceptable final concentrate grade. Mineral and liberation analysis showed that associations between copper sulfide minerals and pyrite did not indicate complex or fine intergrowths that would adversely impact on the metallurgy. The Phu Kham IRP commenced in 2009 as part of a concept study to develop a process to increase copper and gold recovery from Phu Kham ore. Since commencement of operations in 2008, copper recovery had increased with increasing proportion of chalcopyrite-dominant primary ores replacing the chalcocite-covellite secondary copper mineral dominant high clay and talc transition ores. The increasing plant throughput and poor primary liberation with increasing pyrite content caused copper and gold recovery to ‘flat-line’ as shown in Figure 12. FIG 11 – Phu Kham transition ore rougher feed photomicrograph. Cp – chalcopyrite, Ch/Cv – chalcocite/covellite, Py – pyrite, Gn – non-sulfide gangue. Bulk sulfide flotation bench tests in 2009 using isopropyl xanthate collector on Phu Kham rougher tailings indicated that up to ten per cent additional copper recovery and 70 per cent additional gold recovery could be achieved into a scavenger concentrate of approximately 0.8 per cent copper. FIG 12 – Phu Kham concentrator copper and gold recovery by year 2008 to 2011. We are metallurgists, not magicians 211 D Bennett et al The initial test program was designed to determine whether a low-grade copper-gold concentrate suitable for downstream hydrometallurgical processing to saleable products could be recovered from the concentrator tailings. The preliminary test program showed that a bulk sulfide concentrate from plant tailings flotation could be upgraded to over ten per cent copper concentrate grade, depending upon copper sulfide mineral liberation, using a roughing, regrind and two stage cleaning process similar to the Phu Kham concentrator process. Figure 13 shows the copper graderecovery relationships with varying rougher concentrate regrind power input of 10, 20 and 40 kWh/t. The test results presented in Figure 13 clearly demonstrated that finer regrinding of rougher concentrates from plant tailings flotation would improve both copper grade and recovery. Further flotation tests on plant final tailings samples using roughing at pH 9 with amyl xanthate, followed by regrinding of concentrate at 10 kWh/t power input, and two stages of cleaning consistently produced a low-grade flotation concentrate of approximately three per cent copper and 2 g/t gold. Average copper recovery was 69.6 per cent and average gold recovery was 54.1 per cent from 24 flotation tests as shown in Table 1. Since 2008, monthly plant composites had been submitted for quantitative mineralogical analysis, and this data provided the critical information used for recovery improvement process development. The mineralogy data demonstrated that since primary chalcopyrite ores had become the dominant source of plant feed, the major cause of loss of copper in plant tailings had changed from slow floating fine liberated copper minerals (Crnkovic et al, 2009) to chalcopyrite locked in poor quality coarse binary particles with non-sulfide gangue. The copper loss in plant tailings from November 2011, representing a typical month, is shown in Figure 14. A digital photomicrograph of flotation tailings is shown in Figure 15. The wide size range of the chalcopyrite particles in non-sulfide gangue is evident. Copper sulfide mineral grain size data for rougher tailings is presented in Table 2. The data showed that under selective rougher flotation conditions, recovery of coarse low quality binary copper sulfide and gangue composite particles was poor due to the fine copper sulfide grain size. TABLE 1 Plant tailings flotation test results summary. Copper Gold Stream Grade % Cu Distribution % Grade Au ppm Distribution % Plant tailings (feed) 0.17 100.0 0.15 100.0 Concentrate 2.81 69.6 1.87 54.1 Final tailings 0.05 30.4 0.07 45.9 Gold recovery by flotation at Phu Kham had been poor since commissioning, averaging approximately 40 per cent to final copper concentrate product. Prediction of gold recovery had also been demonstrated to be inaccurate during plant operation, due to a lack of understanding of the key mineralogical characteristics of gold occurrence and the variability of gold occurrence across different Phu Kham mineral assemblages. As part of the recovery improvement study, the mineralogical reasons for gold loss into Phu Kham tailings were examined to determine any potential opportunities to increase gold recovery. Diagnostic leach tests were conducted on Phu Kham plant tailings samples. Results of the diagnostic leaching are presented in Table 3. The diagnostic leaching results in Table 3 demonstrated that over 60 per cent of the gold in tailings was available for cyanide leaching, either as free gold or partially liberated gold. This was supported by the Albion gold leach test work on acid Albion copper leach residues, which demonstrated that extraction of gold to solution did not significantly increase with increasing sulfide sulfur oxidation, as shown in Figure 16. Laser ablation testing was conducted on the rougher tailings to determine the proportion of gold locked with pyrite and other sulfide mineral species. The laser ablation test results were combined with the results from the diagnostic leaching to provide a total gold association for the rougher tailings as presented in Table 4. Diagnostic leaching provided a measure of the unlocked (cyanide soluble) and locked gold deportment, but the total unlocked gold could not be split between fully liberated gold FIG 13 – Phu Kham tailings flotation rougher concentrate regrind power grade – recovery relationships. 212 We are metallurgists, not magicians Process development and throughput forecasting at the Phu Kham copper-gold operation, Laos PDR FIG 14 – Copper sulfide loss in Phu Kham flotation tailings by size and mineral association. TABLE 3 Results of diagnostic gold leaching of Phu Kham flotation tailings. Plant tailings stream % gold cyanide soluble % gold locked in sulfide minerals % gold locked in non-sulfide gangue Cleaner tailings 72 21 7 Rougher tailings 57 42 1 Final tailings 64 35 1 sample from the IRP laboratory test work was also conducted to produce a gold-rich concentrate by gravity concentration suitable for ADIS and photomicrograph analysis. FIG 15 – Phu Kham flotation tailings photomicrograph. TABLE 2 Rougher tailings copper sulfide grain size by size fraction. Size fraction Copper sulfide grain size (µm) >106 µm 19.6 <106 >75 µm 13.0 <75 >53 µm 11.4 <53 >38 µm 9.1 <38 µm >C2 9.1 <C2 >C4 9.8 <C4 >C5 8.1 <C5 3.7 particles, and partially liberated (exposed in composites) gold particles. Therefore, the diagnostic leach measure of 57 per cent cyanide soluble gold in Table 4 could not provide definitive information for the cause of gold loss to tailings. Final Phu Kham copper concentrate monthly plant composites were analysed in 2012 by automated digital image scanning (ADIS) at G&T Metallurgical Services to determine the characteristics of gold and gold composite particles recovered in flotation. Laboratory work on rougher tailings We are metallurgists, not magicians The ADIS work on the final concentrate showed an average recovered gold particle size of 7.9 µm. The class and mass distribution summary and area as a percentage of the observed gold particles is presented in Table 5. Binary particles of gold locked with pyrite in concentrate were of particular interest. Only 8 per cent of the observed particles were gold-pyrite binary composite particles, however 71 per cent of the total mass of observed gold was in these particles. The average surface area of the gold in the gold-pyrite binary particles was 87 per cent of the total particle surface area. An interpretation of this data indicated that for a gold-pyrite particle to float into concentrate, the gold:pyrite surface area ratio must be sufficiently large to overcome the depression of the attached pyrite particle under high pH flotation cleaning conditions. The liberated gold recovered was typically fine, with an average particle size of 7 µm. Photomicrographs of the gold showing some typical particles in concentrate are presented in Figure 17. The ADIS work found that the average gold particle size was 19 µm in rougher tailings, approximately 13 times larger than the average gold particle in final concentrate. No binary particles were observed, only liberated gold and gold-chalcopyrite-pyrite-gangue multiphase particles as summarised by mass distribution in Table 6. The liberated gold particles in tailings had a mean size of 35 µm, with the data indicating that liberated gold particles above 20 µm in size are unlikely to be recovered to final flotation concentrate, with a 13 µm particle the largest 213 D Bennett et al FIG 16 – Copper and gold extraction in Albion leaching as a function of sulfide sulfur oxidation. TABLE 4 Phu Kham rougher tailings gold deportment. TABLE 5 Phu Kham final concentrate gold distribution data. Gold mineral association % of total gold Data Gold locked in binary particles with: Liberated gold Cp Ch/Cv Te Py Goe Gn 38% 30% 8% 5% 8% 3% 3% 5% Multiphase Cyanide soluble 57 Pyrite locked 25 Association class Other sulfide locked 17 Gold mass by association class 11% 16% <1% 1% 71% <1% 1% <1% Non-sulfide gangue locked 1 Particle area % gold 100% 73% 52% 51% 87% 98% 9% Total 100 Cp – chalcopyrite; Ch – chalcocite; Cv – covellite; Te – tennantite; Py – pyrite; Goe – goethite; Gn – gangue; MP – multiphase. 89% FIG 17 – Phu Kham August 2011 final concentrate gold photomicrographs. NB: Au – gold, Py – pyrite. TABLE 6 Flotation rougher tailing gold mode of occurrence, size and mass data. Gold mode of occurrence 214 Average particle diameter (µm) Average % of particle mass Au Gn Au Cp Py Cp Py Gn Gold liberated 35 - - - 100 - - - Gold adhesion multiphase 6 17 151 15 <1 <1 99 <1 Gold locked multiphase 8 28 104 27 3 2 80 15 Gold adhesion/locked multiphase 17 14 125 61 2 1 94 3 We are metallurgists, not magicians Process development and throughput forecasting at the Phu Kham copper-gold operation, Laos PDR observed in the concentrate. Cyanide leaching would have extracted 69 per cent of the gold particles observed. The significant characteristic of the multiphase particles observed in tailings was that greater than 95 per cent of the total mass of the particles were gangue mass. The gold in the multiphase particles had an average diameter of 9 µm, while the pyrite gangue had an average diameter of 121 µm. Photomicrographs of the gold showing some typical particles in rougher tailings are presented in Figure 18. Based on the concentrate and rougher tailings ADIS data, a summary of the estimated recoveries of the main Phu Kham ore gold association classes is presented in Table 7. The downstream extraction of copper and gold from a low-grade pyrite-rich concentrate produced by bulk tailings flotation was developed to a prefeasibility level during 2010 and 2011 using Albion Process™ atmospheric leaching technology. The Albion test work showed that copper extraction of over 95 per cent using acid Albion leaching, and gold extraction of over 85 per cent using a standard carbonin-leach process was achievable from a flotation concentrate TABLE 7 Phu Kham indicative gold recovery by mineral association class. Gold association class Parameter Liberated Au Au-copper sulfide Au-pyrite Au-gangue Gold recovery 70% 100% 10% 0% of three per cent copper and 2 g/t gold, providing an overall 15 per cent copper recovery and 25 per cent gold recovery increase for Phu Kham operations. The process concept utilised bulk sulfide flotation with potassium amyl xanthate collector (PAX), with the bulk concentrate reground to 18 µm before cleaning flotation to produce a three per cent copper concentrate. The concentrate would then be leached in an Albion leach process with copper cathode produced from the pregnant Albion leach solution via a solvent extraction-electrowinning process. The Albion leach residue would then be neutralised prior to carbon-inleach processing to produce gold dore. The Albion test work program included a flotation pilot plant at Phu Kham in order to produce a concentrate from the plant tailings for pilot plant testing at the HRL/Core Resources Albion pilot facility in Brisbane. The pilot facility consisted of an M20 pilot IsaMill and a 1.5 t/h three stage flotation plant. During the early stages of the pilot testing in October 2011, an updated capital estimate for the tailings retreatment flotation and Albion hydrometallurgical process plants was developed, with the updated estimate significantly higher than previous estimates. The change in the project cost base, coupled with the higher project risks for a tailings retreatment plant incorporating hydrometallurgical processes, led to a review of alternative recovery improvement strategies. The prefeasibility tailings flotation study results had indicated that there was potential for increasing copper and gold recovery by mineral processing methods alone, with reduced technical risk and capital intensity compared FIG 18 – Phu Kham rougher tailings gold photomicrographs. NB: Au – gold; Cp – chalcopyrite; Py – pyrite; He – hematite; Ma – magnetite; Gn – gangue. We are metallurgists, not magicians 215 D Bennett et al to hydrometallurgical processing. The results from the detailed mineralogical examination of Phu Kham tailings during the Albion prefeasibility study were used to improve understanding of the mechanisms of copper and gold loss and develop a simplified process for improving recovery. The first alternative was a ‘mainstream inert grinding’ process which classified the rougher tailings from the plant to recover the plus 53 µm fraction containing the low quality copper sulfide and gangue composites. This coarse fraction of tailings would then be reground to 80 per cent passing 53 µm in order to further liberate the chalcopyrite prior to an additional scavenging flotation stage, with scavenger concentrate to report to regrinding with rougher concentrate. Although the process was highly predictable (as it was based on particle size rather than mineralogy), the capital and power costs for the coarse fraction grinding were very high due to the large tonnage of liberated and coarse silicate and pyrite gangue in the rougher tailings required to be ground for no value. The second alternative was a ‘less selective’ sulfide rougher flotation process followed by increased regrind capacity in order to liberate the copper sulfide from coarse and low quality composites, and increased cleaner circuit capacity in order to treat the additional and lower grade rougher concentrate mass. Absolute recovery improvement estimates based on the test work for the ‘mainstream grinding’ and ‘less selective flotation’ processes were similar at approximately 5–10 per cent for copper and gold. The advantage of the ‘less selective flotation’ process was that it was not a tailings retreatment process and project value could not be eroded with improvements in existing plant performance. Whilst it was acknowledged that the mainstream inert grinding process could also be performed on the plant feed, the ‘less selective flotation’ process had significantly lower capital and operating costs providing higher return on investment, so was selected as the priority for further study. The disadvantage of the ‘less selective flotation’ process was that it was based on ore feed mineralogy, and therefore generated a higher risk of mass balance errors during the process design and uncertainty of achieving target copper and gold recovery. The ‘less selective flotation’ process development risks required that further test work be conducted to confirm the recovery estimates and improve the certainty of the economic case. Project selection The Phu Kham Albion flotation pilot plant work program was changed to test the ‘less selective flotation’ process, which successfully demonstrated that significantly increasing the copper and gold recovery from roughing was achievable utilising PAX with over 90 per cent copper recovery achieved at 30 per cent mass recovery. The rougher concentrate grade was significantly reduced due to the bulk sulfide flotation regime employed during the test. The pilot scale tests proved the concept that increasing mass recovery would lead to increased copper recovery, whilst highlighting the pitfalls of recovering too much liberated pyrite which would require extremely aggressive pyrite depression conditions in cleaning to produce a saleable grade concentrate. In developing the design for a bulk sulfide rougher, regrind and selective cleaning flotation process, three key parameters were required to be identified; rougher mass recovery to achieve maximum copper recovery across all ore types, rougher concentrate regrind product size, and cleaner capacity. Due to the high variability in plant rougher copper and gold recovery between the low and high pyrite content ores, the rougher mass recovery likewise varied depending on feed mineralogy. In order to develop the design rougher mass recovery target, a review of the flotation recovery data from daily rougher flotation testing of plant rougher feed over a three-month period in 2011 was used to allow for the variability in mineralogy of plant feed. Extensive rougher flotation rate test data that had been used to develop early Phu Kham recovery models were statistically analysed in order to determine the mass recovery and copper recovery curves for differing ore types, from weathered and altered high pyrite (high S/Cu) material to chalcopyrite dominant and low pyrite (low S/Cu) primary material. The statistical analysis showed that rougher copper recovery could be increased to 85 per cent by targeting a maximum 20–25 per cent mass recovery from rougher flotation across all ore types, as presented in Figure 19. FIG 19 – Rougher copper recovery and mass recovery for major ore types showing original mass recovery design and IRP mass recovery design. 216 We are metallurgists, not magicians Process development and throughput forecasting at the Phu Kham copper-gold operation, Laos PDR The results show that the original design for rougher mass recovery of 11 per cent of rougher feed was suitable for the chalcopyrite-dominant primary ore types, but gave lower copper recovery from the high pyrite and non-sulfide copper species in chalcocite-rich transition ores. The results indicated potential for an additional six per cent copper recovery in roughing by increasing mass recovery to a maximum 25 per cent of rougher feed for all ore types. observed as shown in Figure 13. Samples of plant feed were tested at bench scale using roughing, rougher concentrate regrind at increasing power input, and three stages of cleaning to produce the copper and gold grade-recovery response curves in Figure 21. The increase in rougher concentrate regrind power input shows the benefit of the increased liberation for both copper and gold grade and recovery into flotation concentrates. The results for rougher flotation gold recovery from the same test work are shown in Figure 20. The gold recovery increase in roughing with the higher mass recovery is more consistent across primary, high pyrite and transition ore types than for copper, which reflects the association of gold with copper sulfide minerals and pyrite. The mineralogical analysis of gold deportment and bench scale test work results concluded that with the design rougher mass recovery increase and finer regrind, gold recovery to final concentrate could be expected to rise by at least six per cent. With the variable mineralogy of Phu Kham ore, the monthly composite mineralogy and laboratory scale test work was used to determine the rougher concentrate regrind size required to achieve maximum copper sulfide liberation in cleaner feed, with a target of 80 per cent copper sulfide liberation considered to be required to maximise recovery and maintain final concentrate specification. Scan data on two samples representing different Phu Kham ore types in Figure 22 showed that maximum copper sulfide liberation was typically achieved at 20 µm particle size, although 80 per cent liberation was not necessarily achieved for all ore types. Rougher concentrate regrind size optimisation work commenced in 2011 to support the IRP process design. The benefits for copper recovery of finer grinding of concentrates from bulk flotation of Phu Kham tailings had previously been Power input to achieve 20 µm regrind product size was calculated from laboratory regrind signature plot data, and daily surveys of the existing M10000 IsaMill to be 18– FIG 20 – Rougher gold recovery and mass recovery for major ore types showing original mass recovery design and IRP mass recovery design. FIG 21 – Copper and gold flotation grade-recovery responses as a function of rougher concentrate regrind power input. We are metallurgists, not magicians 217 D Bennett et al FIG 22 – Copper sulfide mineral liberation with particle size. 25 kWh/t, with an additional 3 MW M10000 IsaMill included in the design to provide a total of 6 MW power input at the maximum rougher concentrate mass recovery of 25 per cent. First cleaner design The increase in rougher concentrate mass recovery to 25 per cent of rougher feed, and the reduction in cleaner feed particle size to 20 µm required a corresponding increase in first cleaner flotation capacity. The 12 Mt/a plant had 25 minutes total first cleaner residence time for a 38 µm cleaner feed size, and test work was designed to determine whether this residence time needed to increase at the 20 µm cleaner feed size due to potentially reduced kinetics of the finer particles. Bench scale flotation cleaning tests and cleaner circuit model simulations indicated that flotation kinetics remained similar for copper sulfide minerals due to improved liberation, and that no increase in residence time was required for first cleaning until regrind product size was below 10 µm. Figure 23 shows the plant cleaner circuit chalcopyrite recovery by particle class and size. The recovery of liberated chalcopyrite remained high with decreasing particle size, which confirmed that the increased chalcopyrite liberation from gangue at a 20 µm regrind size would improve copper recovery. The design included 100 per cent increase in first cleaner capacity to allow for the increased rougher mass recovery, and lower slurry density to provide improved dilution cleaning to minimise fine gangue particle entrainment. To validate the extensive test work and mineralogy data results, four full-scale process plant ‘less selective flotation’ trials were conducted at Phu Kham between January 2012 and April 2012. The trial method used was to decrease SAG mill throughput by 50 per cent to avoid overloading the cleaning circuit, reduce rougher cell residence time to the equivalent post-PKU 16 Mt/a time of 30 minutes by reducing levels and air in three of the ten cells, and using increased collector and frother addition to increase rougher mass recovery to 25 per cent. The IsaMill power draw was increased to 2.8 MW to target a 20 µm regrind product size. Immediately prior to the trial periods, baseline plant surveys were undertaken to obtain comparison data for the same ore type. The key results of the four plant trials are summarised in Table 8. The first plant trial period was over four hours to ensure critical test criteria could be achieved with rougher mass recovery target of 25 per cent. Although this was a preliminary trial, survey results for the IRP process were positive compared to baseline survey results, with eight per cent overall copper recovery and 19 per cent overall gold recovery achieved FIG 23 – Phu Kham cleaner circuit chalcopyrite recovery by particle class and size. 218 We are metallurgists, not magicians Process development and throughput forecasting at the Phu Kham copper-gold operation, Laos PDR TABLE 8 Phu Kham ‘less selective flotation’ plant trial results. Preliminary trials Trial 1 – 15 January 2012 Trial 2 – 27 January 2012 Baseline IRP Difference Baseline IRP Difference Rougher recovery (%) 83 92 +9 76 88 +12 Overall copper recovery (%) 71 79 +8 68 79 +11 Overall gold recovery (%) 48 66 +19 45 56 +11 Concentrate grade (%) 22.1 24.1 +2.0 24.2 24.8 +0.6 Variability trials Trial 3 – 21 March 2012 Baseline IRP Trial 4 – 24 April 2012 Difference Baseline IRP Difference Rougher recovery (%) 87 93 +6 81 87 +6 Overall copper recovery (%) 81 87 +6 75 80 +5 Overall gold recovery (%) 40 53 +13 36 56 +20 Concentrate grade (%) 25.7 23.8 -2.0 25.5 21.7 -3.8 into a two per cent higher copper grade final concentrate. The second plant trial was conducted over a full 12-hour shift period, with improvement in both overall copper and gold recovery of 11 per cent at a 0.6 per cent copper grade improvement in final concentrate. March 2012, following PanAust Ltd board approval for the IRP, the M10000 IsaMill was ordered as a turnkey package including all the peripheral equipment to the mill along with instrumentation. The package also included all steelwork but specifically excluded mill foundations. Two short four-hour variability trails were conducted in March and April 2012 on primary ore with a good flotation response and high pyrite ore with a poor flotation response. Copper recovery improvement was consistent at over five per cent for both ores, and gold recovery improvement was 13 per cent and 20 per cent into final concentrate. The short duration of the trials did not allow time for optimisation of cleaner circuit performance. The project schedule was developed to include the completion of a front-end engineering phase (FEED) level design and cost estimate by May 2012 using an external engineering consultant. The FEED phase fixed the design criteria, mass and water balances and tagged equipment lists which were then be used in the detailed engineering and procurement (EP) phase. The economic evaluation at 6 per cent increase in copper and gold recovery after the initial plant trials provided a compelling investment case, resulting in PanAust Ltd board approval in February 2012 for the development of the re-named IRP at Phu Kham to allow early procurement of long-lead equipment. The plant trial results also provided significant confidence in the IRP basis of design. Compression of the IRP schedule During the early process design and project scoping, the project case for the IRP was determined to be compelling enough for the project development to be fast tracked with commitment for long-lead capital items approved before completion of the feasibility study. In addition to achieving the increased plant recovery earlier, reducing the project schedule had the added benefit that the PanAust construction team would be able to commence work on the IRP immediately following completion of the PKU in August 2012. The longest lead item for the project was the M10000 IsaMill with a delivery period of approximately 11 months. In early We are metallurgists, not magicians Chalcopyrite Recovery (%) The trials were not used to confirm design mass recoveries or regrind size. Higher final copper concentrate grades were achieved despite the higher rougher mass recovery, although the minor difference against baseline values was not considered significant during the short trial. The ability to conduct a plant trial and successfully demonstrate a consistent metallurgical benefit at laboratory, pilot, and full plant scale prior to implementation underpinned the high degree of confidence in the ‘less selective flotation’ concept. The detailed mineralogy-based understanding of the causes of copper and gold loss to tailings developed over many years was fundamental in gaining this confidence. 100.0 During the EP phase, the engineering consultant was responsible 95.0 for engineering design and equipment selection up to the recommendation for purchase decision, with approval 90.0 and procurement performed by PanAust staff in Brisbane and Laos. To avoid issues identified during the PKU with delays 85.0 in receipt of vendor data, the engineering consultant was responsible for liaison with vendors once the purchase order 80.0 was raised to ensure the engineering consultant maintained 75.0 control. schedule The basic project schedule for the IRP is presented in 70.0 Figure 24. 65.0 PROJECT DESIGN 60.0 Feasibility 55.0 In order to develop a business case for the project, initial 50.0 design was developed by PanAust during the process 1 stage along with factored capital and operating 10 prefeasibility Particle cost estimates. The cost estimate was considered toSize be (µm) at a higher level of accuracy than a normal prefeasibility stage due Liberated Chalcopyrite Chalcopy to the recent completion of the engineering for the PKU and Chalcopyrite‐Gangue Binary Multipha construction of the Ban Houayxai CIL plant by PanAust Ltd. Fig 23 – Phu Kham cleaner circuit chalcopyrite recovery by particle class and size 2012 Project Stage Q1 Q2 2013 Q3 Q4 Q1 Q2 Q3 Q4 Feasibility Study/FEED Long Lead Procurement Engineering and Procurement Construction Commissioning and Ramp-up Fig 24 – Increased Recovery Project schedule FIG 24 – Increased Recovery Project schedule. 219 23 D Bennett et al In addition to process design criteria, the equipment lists and brownfield plant layouts and integration plans were developed to a detailed level by PanAust so that the FEED stage was mainly focused on engineering detail and minor equipment sizing rather than process design. Plant survey work was performed during this stage to improve the mass balance which was used to confirm pump and piping specifications. The initial flow diagram showing the additional equipment planned to be installed as part of the IRP in red is shown in Figure 25. Front-end engineering GR Engineering Services (GRES) was selected as the FEED engineer for the IRP. During the FEED phase a number of details in the plant design were resolved which resulted in minor changes to the process flow sheet. The most significant change was the change to a second parallel bank instead of additional series cells to the first cleaners. This was changed mainly due to limited dart capacity in the first cleaner cells as well as the cost associated with upgrading the first cleaner feed pumps. The change resulted in a lower project capital cost as capital was moved from debottlenecking the existing first cleaner cells to installing a parallel bank of cells. The process flow sheet was also simplified due to the change. The change also reduced the associated tie-in time for construction as the new equipment could be added in discrete modules, and did not impact on the existing plant which was a key learning from the PKU for brownfields plant expansions. In parallel with the FEED phase, additional metallurgical test work was performed in order to assess the effect of the expected finer concentrate size on the settling rate of the existing concentrate thickener. The settling tests performed on concentrate produced from the variability trials showed that the existing 15 m diameter concentrate thickener would be able to handle the concentrate produced from the IRP, however settling efficiency could be improved over current operation by reducing the amount of entrained air in the feed. Site investigation determined that air was being entrained through the trash screen collection box, so the decision was made to add a de-aeration box prior to the thickener to improve thickener performance of the thickener. Challenges in brownfields plant upgrades were highlighted during the FEED phase with the marriage of new equipment with existing equipment which cannot be relocated. Specific design principles were included to minimise capital and operating cost based on the learnings from the original plant design and PKU. The design was developed with a focus on the use of gravity flow wherever possible and gravity lines were used in most tie-in locations despite the additional engineering design required. This design philosophy increased the complexity of the design effort, however increased operability was achieved. The existing plant concentrate production capacity was analysed, with the existing filter able to produce concentrate below the transport moisture limit at a rate of approximately 330 000 t/a. This was determined to be marginal at the increased concentrate production rates as shown in Figure 26. This was a key risk for the project as the filtration rate was expected to decrease due to the finer concentrate size distribution. To eliminate this risk a second filter was included in the design. Although the second filter had fewer plates than the original filter, the same plate size was maintained to allow common spares with the existing filter. FIG 25 – Initial process flow diagram for the Increased Recovery Project. 220 We are metallurgists, not magicians Process development and throughput forecasting at the Phu Kham copper-gold operation, Laos PDR FIG 26 – Filter performance against increased recovery project concentrate production targets. A design review was conducted during the FEED to look at installing a second filter in the existing shed without disruption of the existing filter operations. The review determined that disruption would be significant, so an additional smaller storage shed was included in the design to allow for additional storage capacity during the wet season. The design of the new storage shed and filtration area was leveraged from the existing engineering designs to reduce costs for installation. Some minor modifications were made during the FEED phase to shorten the length of the shed in order to reduce storage capacity in line with the additional concentrate production. An additional item of risk which was identified during the FEED was the second cleaner flotation cell tailings darts capacity not having sufficient margin above maximum flows predicted for the IRP. Due to the lack of mitigation measures available, contingency was allowed for in the estimate to install inter-cell bypasses should the flow rate significantly exceed darts capacity. It was anticipated that the second cleaner would become the circuit bottleneck in the IRP circuit, and if liberation was not achieved in the regrind mills, a recirculating load of middlings particles would buildup between the second cleaner and third cleaner banks. This would result in recovery losses or below specification concentrate grade. The FEED phase was completed on schedule with the capital cost reduced by $10 M due to additional savings identified during the design, and a reduction in the project contingency due to better project definition. The reduction in capital was achieved despite an increase in the scope of the project in order to minimise risk. As the project was brownfields integration, additional capital was allowed in the estimate for resolution of legacy pumping and spillage issues which had affected the Phu Kham concentrator since the original design and the PKU. Following completion of the FEED phase the final equipment list was confirmed along with the changes to the process flow diagram (shown in red) in Figure 27 to optimise both cost and design: •• twelve 400 mm diameter regrind cyclone pack •• M10000 IsaMill •• seven Outotec TC70 tank cells •• thickener de-aeration box •• concentrate filter feed tank We are metallurgists, not magicians •• 40 plate Ishigaki filter •• concentrate storage shed. Increased Recovery Project COMMISSIONING AND RAMP-UP Plant tie-ins were performed progressively as equipment was delivered to site and in line with the project schedules which were integrated with the planned shutdown schedules. The majority of construction and tie-in activities were completed by March 2013. IsaMill commissioning Commissioning of the new IsaMill concluded with a 72 hour acceptance test which commenced on the 26 March 2013 with both the new and old mills run in parallel for the first time. Operational conditions during the period were identical for each of the mills. During the period, the new IsaMill was run over a range of power draws, with the ultimate design power of 2500 kW being achieved. During the test, no external signs of any problems were detected, however upon completion of the test period, the mill was inspected and damage to the shell liner (Figure 28), feed end liner and three discs was identified. The root cause of the damage to the mill liners was overheating of the mill slurry due to the high recycle of IsaMill discharge to the feed. The high recycle was caused by insufficient flow from the regrind cyclones which were exacerbated by a biased flow from the underflow splitter box to the existing IsaMill. The new regrind cyclones had also been modified by operations due to the need to run them prior to IRP commissioning and did not have the design spigots installed prior to start-up. The high temperature in the IsaMill would have normally been detected by the process control system however the resistance temperature device (RTDs), which were installed to protect the mill in such instances of low feed, were found to be providing an inaccurate output. The RTDs were replaced along with the shell liner, and the discs and feed end liner were reused. The mill acceptance test was re-run with additional wear identified in the regrind mill due to media compression. The media compression had been caused by a high slurry feed density which was attributed to an incorrect and high solids specific gravity input into the nuclear density gauge. In addition, the output value of the density gauge had been mistakenly assumed to be a calculation of per cent solids. 221 D Bennett et al FIG 27 – Simplified Phu Kham process flow diagram including Increased Recovery Project expansion. extensive. Existing equipment, particularly slurry pumps, were utilised within the new circuit. FIG 28 – Damage to the shell liner during the first 72 hour acceptance test. This meant that the density in the mill was approximately eight per cent higher than the actual density target, with the subsequent high viscosity in the mill causing the media compression. In order to ensure that this didn’t recur, the target pulp density was decreased to 45 per cent solids and the viscosity was monitored at hourly intervals with a Marsh Funnel. Once the control measures were put into place the decision was made on the 18 April to run the mill for a 24-hour test. At the completion of this test, the mill was inspected and no further wear detected on the liners. The final acceptance test was then performed for 48 hours at power draws of up to 2600 kW. On the 21 April, the mill was inspected for the final time. No wear had occurred over the final trial period and the mill was handed over by Xstrata Technology personnel to PanAust operations. Plant ramp-up Even with the modular design of the IRP which aided constructability, the integration with the existing circuit was 222 During the ramp-up phase a number of issues with slurry pumping were encountered. These were mainly confined to original pumps which had been upgraded or had duty changed as part of the IRP or earlier improvement projects. The IRP construction and precommissioning phases had not generally considered the condition or status of existing equipment and as it had been previously operating satisfactorily, and no program of inspection was initiated prior to IRP commissioning. This resulted in delays in reaching design capacity. As an example, the rougher concentrate pump system had the common discharge pipeline upgraded to match the higher IRP design flow rates, with the existing duty and standby pumps and motors assessed as suitable for the higher design duty. During the ramp-up phase the pumps were not able to reach design flow rate which resulted in both the duty and standby pumps being run to meet design flow rate. Investigation of the pump variable speed drive systems discovered that the original overload and frequency limit settings had been retained for the original motors, although the motors had been upgraded prior to the IRP. These settings were limiting the pump speed and power draw to a level well below maximum operating capability. Once the limit was removed the pumps were found to be easily able to meet design flow rate. Ramp-up was also hindered by power supply continuity to site, as there was often insufficient power able to be supplied from the hydroelectric schemes which provide all power to We are metallurgists, not magicians Process development and throughput forecasting at the Phu Kham copper-gold operation, Laos PDR the Phu Bia Mining operations. This was due to low water levels in the reservoir at the end of the dry season coinciding with the IRP ramp-up and extended planned maintenance periods on generating units. Operation response to power limitation was to load-shed power across the plant with power draw being lowered in the ball mills and IsaMills to maintain throughput. This increased primary grind size and regrind size lowering copper mineral liberation and reducing plant copper recovery. The problem continued until June with the onset of the wet season replenishing reservoir levels. INcreased Recovery Project PERFORMANCE Rougher recovery Despite the described issues during ramp-up, rougher mass recovery was quickly increased to 20 per cent of feed mass following completion of commissioning. At an early stage of ramp-up the operating strategy was to effectively ‘fill up’ the cleaner circuit by recovering as much mass as possible from the rougher banks. Cleaner circuit performance and overall copper recovery were generally compromised by this strategy because excessive gangue was recovered in roughing requiring rejection in cleaning, and the regrind product size to achieve liberation targets was not being met. In addition, the feed ore quality was generally challenging during ramp-up due to the requirement to mine ore from the upper areas of the pit which had very high pyrite and clay content, and a high proportion of easily oxidised secondary copper sulfide species. During this period, operational strategies were redefined and training undertaken with site personnel to ensure that copper recovery was maximised from the rougher banks and the cleaning circuit was not overloaded with liberated gangue. Back-to-basics improvements were undertaken on operating parameters; in particular work was completed with Outotec on optimising the rougher cell level and air addition profiles which were then set to avoid excessive water and gangue recovery and improve low quality coarse composite recovery. Process control improvements were also implemented during the ramp-up period, including commissioning of automated rougher mass recovery control through use of froth velocity measurements and level and air controls. With the improvements in control, equipment performance and operating knowledge for the new circuit, the rampup of the IRP was mainly completed by June 2013. Copper rougher recovery increased from an average of 78 per cent to 83 per cent within the first month of operation, in line with expectations. The increase in gold rougher recovery was very significant from an average of 55 per cent to 78 per cent as shown in Figure 29. Gold recovery at Phu Kham had always been highly variable, which led to a conservative estimate of gold recovery increase used for the IRP investment case, however the observed increase in gold recovery exceeded the results achieved during the plant trials and even the most optimistic estimates. The reasons for the improvement were likely the improved rougher recovery of lower quality copper sulfide and pyrite composites containing gold and improved fine gold recovery. Once operational control was improved and selectivity against liberated pyrite and non-sulfide gangue was improved in the rougher circuit, the increased copper recovery was confirmed though a consistent reduction in the quality of the copper sulfide-gangue binary particles in the rougher tailings. Following the implementation of the IRP, the copper sulfide content of these particles decreased from approximately 15 per cent to seven per cent copper sulfide indicating that the IRP target low quality copper sulfide-gangue composite particles were being recovered (Figure 30). A photomicrograph of typical rougher tailings is presented in Figure 31, indicating the lean quality of copper sulfidegangue composites following the IRP. Overall recovery The ramp-up in overall recovery was achieved in June 2013 with 76.4 per cent average weekly recovery being achieved. This was 3.8 per cent above the baseline PKU recovery of 72.6 per cent. In addition during this time the variability of the overall recovery decreased with the standard deviation of weekly recovery reducing from six per cent to 4.6 per cent of the mean. As presented in Figure 32, the number of weeks with recovery below 70 per cent has decreased over time as the operational strategies implemented during the IRP have been further reinforced. As for copper, initial increases in the rougher gold recovery did not correspond to a significant increase in overall gold FIG 29 – Rougher mass, gold and copper recovery following the Phu Kham Upgrade and Increased Recovery Projects. We are metallurgists, not magicians 223 D Bennett et al FIG 30 – Quality of the copper sulfide gangue binary composites in the rougher tailings following the Phu Kham Upgrade and Increased Recovery Projects. recovery. Gold losses in the cleaner tailings were investigated during this period in order to determine the mechanisms of gold loss from the cleaner circuit. FIG 31 – Photomicrograph of the typical rougher tailings following Phu Kham Upgrade and Increased Recovery Projects. Cp – chalcopyrite; Py – pyrite; Gn – non-sulfide gangue. Analysis concluded that although 25 per cent of the identified gold containing particles lost from the cleaner tailings were liberated gold, the majority of these particles were less than 10 µm in size. Almost 50 per cent of the particles were liberated or high quality composites with pyrite or copper sulfide minerals. The other 50 per cent of gold particles lost were in extremely low quality binary composites with pyrite (Figure 33). These composites were required to be rejected to maintain acceptable final copper concentrate grade. As gold particles even in binary composites were fine (Figure 34), gold recovery to the final concentrate relies on liberation from pyrite due to the high lime pH environment for pyrite depression, which also reduces fine gold flotation kinetics. FIG 32 – Overall copper recovery mean and standard deviation following implementation of the Increased Recovery Projects. 224 We are metallurgists, not magicians Process development and throughput forecasting at the Phu Kham copper-gold operation, Laos PDR FIG 33 – Quality of the gold particles lost from the cleaner tailings. FIG 34 – Examples of poor quality composites and fine liberated gold losses in the cleaner tailings. With improvement in plant performance, overall gold recovery increased, with weekly gold recovery averaging over 50 per cent by September 2013 (Figure 35). No decrease in the variability of the gold recovery was achieved because the gold recovery is mainly affected by the variable mineralogy, liberation and gold feed grades to the plant. High gold recovery was maintained throughout the year following the IRP even though the plant experienced a significant change in the gold head grade from 0.3 g/t to 0.2 g/t from September 2013 to September 2014 (Figure 36). Once head grades returned to normal levels in late 2013, overall gold recoveries of 60 per cent were being achieved which was almost a 20 per cent increase over the pre-IRP recoveries. Recovery against increased recovery project investment case The initial analysis of the plant data shows that the average increase in copper recovery was less than the six per cent which was originally predicted for the project and the increase in gold recovery was above the original six per cent target. This was despite other design targets (eg mass pull rate and rougher recovery) within the plant being achieved. The source of the copper recovery difference was due to a number of other operational and ore quality factors which were impacting on production during the period as discussed below. It can be seen in Figure 37 that during the period of the ramp-up, the quantity of pyrite in the ore as measured by the sulfur to copper content fraction (known as the S/Cu ratio) We are metallurgists, not magicians increased from over 16 during the PKU ramp-up period to 21 during the IRP ramp-up. In addition, head grades declined over the period which allowed the throughput to be increased in order to maintain the copper production rates. Pivotal in this increase in mill throughput was the implementation of new plant control strategies (Baas, Bennett and Walker, 2014) along with the additional rougher concentrate, regrind and cleaner capacities provided by the IRP. The S/Cu ratio has been used at Phu Kham in recovery modelling as a proxy for pyrite in the ore, which is the dominant driver of metallurgical performance. Increased S/Cu ratios result in decreased copper recovery, due to the requirement to be highly selective against pyrite. On a S/ Cu ratio basis, the increased copper recovery achieved by the IRP varies from seven per cent at a S/Cu ratio of over 30 to four per cent at a S/Cu ratio of less than 20 (Figure 38). The increase achieved by the project was determined to have reached the six per cent goal when the ore quality schedule was compared on a like for like basis. FUTURE OPPORTUNITIES Since the IRP has been implemented, a number of further opportunities for recovery improvement have been pursued. Major additional improvement in reducing the variation in overall recovery has since been achieved through implementation of a mass recovery control system which utilises froth cameras on the rougher banks and first cleaner 225 D Bennett et al FIG 35 – Overall gold recovery following commissioning of the Increased Recovery Projects. FIG 36 – CUSUM chart for gold showing increase gold recovery despite declining head grades. FIG 37 – CUSUM chart for copper recovery showing changes to operation and ore quality indicators. 226 We are metallurgists, not magicians Process development and throughput forecasting at the Phu Kham copper-gold operation, Laos PDR FIG 38 – Copper recovery against S/Cu ratio in plant feed. banks. This system has allowed maintenance of mass and copper recovery based on concentrate grade targets and metal input. The integration of second cleaner and third cleaner control to maximise copper recovery and trim concentrate grade with the Jameson Cell concentrate grade to achieve a final concentrate grade target has been implemented, with a particle size analyser used to control IsaMill regrind power draw. Finally, work has progressed to improve cleaner circuit pulp chemistry following regrind. This body of work was identified by site metallurgists during Jameson Cell optimisation test work where it was found that the copper sulfides in regrind cyclone overflow exhibit significantly faster flotation kinetics than the IsaMill regrind discharge. This has been attributed to oxygen depletion via reaction of pyrite in the closed milling system. Automated analysis of the pulp chemistry has been implemented and a trial using peroxide (dosed to the regrind discharge to modify the pulp redox potential in the cleaner feed) is currently being advanced. CONCLUSIONS The installed 2008 Phu Kham 12 Mt/a concentrator was a compromise between a high recovery but high capital intensity design, and a lower recovery but technically low risk and low capital intensity design suitable for the prevailing low copper price market. The chosen selective rougher flotation design was driven by the complex and highly variable mineralogy particularly in the transition ore zones, and high pyrite content. Over 90 per cent of pyrite is required to be rejected in order to produce a final concentrate of over 23 per cent copper. The optimisation of the Phu Kham flow sheet was been driven by low copper and gold recoveries and the requirement to maximise copper production by increasing plant throughput. Flotation circuit improvements and debottlenecking projects including additional roughing capacity and cleaner feed scalping had increased copper metal production by 16 per cent since 2009, while maintaining copper recovery at the original maximum design throughput of 14 Mt/a. In 2012 the operation was upgraded and debottlenecked during the We are metallurgists, not magicians Phu Kham Upgrade Project to process a nominal throughput of 16 Mt/a with installation of a second 13 MW ball mill, a 33 per cent increase in rougher flotation capacity, a 40 per cent increase in second cleaner capacity, and 33 per cent increase in third cleaner capacity. The Phu Kham IRP was completed under budget and schedule in 2013, resulting in increased copper recovery of five per cent and increased gold recovery of at least ten per cent over the first year of operation at ore throughput rates exceeding maximum design of 2250 t/h by up to ten per cent. The increased recovery was achieved despite decreasing ore quality over the period. In addition, the extra cleaner capacity allowed throughput to be increased in order to increase copper feed tonnes to the plant despite the lower head grades. The plant optimisation and development programs and major plant designs at Phu Kham have been supported by extensive mineralogy, mineral association and mineral liberation data from plant monthly composites and bench scale test products. The collection and analysis of this data has revealed reasons for copper and gold losses and mineral deportment, and significant opportunities for increasing recovery of copper and gold have been identified. Throughput Forecasting and Optimisation Project Background and Scope Following the completion of the PKU and IRP circuit expansions in 2013, the processing plant capacity was increased to a design maximum capacity of 2250 t/h, equivalent to 18 Mt/a. As mining extends deeper into the deposit, the operation will experience an increased proportion of highly competent ores which have the potential to limit plant throughput, in particular through the 13 MW SAG mill. Insufficient comminution data in the mine block model created a lack of confidence in the ability to predict mill throughput, particularly in the later years of the mine life. Phu Bia Mining commenced a throughput forecasting and optimisation project in 2012 to evaluate how to maintain the 227 D Bennett et al target throughput over the LOM. Metso PTI was engaged to conduct a full process integration and optimisation (PIO) project. The main objectives were to: •• review the current blasting, crushing and grinding processes, identify opportunities for increasing throughput, and improve overall comminution circuit performance when treating very competent ore types •• develop a throughput prediction model based on geometallurgical modelling for long-term planning and optimisation •• identify if and when secondary crushing or other process changes will be required over the LOM to maximise plant throughput. Methodology overview Metso’s PIO methodology involves the development of integrated operating and control strategies from the mine to the plant that maximise throughput, minimise the overall energy consumption, cost per ton and maximise profitability. This requires an understanding of the physical properties and composition of the orebody, where the valuable mineral is located within it, and what mineral associations exist between the ore and gangue. The process starts with ore characterisation to define domains within the orebody that will behave similarly throughout the blasting and comminution processes. The SmartTag™ ore tracking system developed by Metso PTI (La Rosa et al, 2007) is used to track the characterised ore from the mine, through the crusher and finally into the grinding mills. With the ore source and characteristics known, detailed audits of the blasting and processing operations are used to develop site-specific predictive models for each operation (blasting, comminution, separation). Using these predictive models, the blast design is optimised to generate optimal run-of-mine (ROM) fragmentation for all ore types, and downstream processes can be adjusted accordingly. The models also allow prediction of throughput and recovery performance for each ore domain, and when combined with the mine plan can be used for forecasting, planning and optimisation purposes. The SmartTag™ system is also used to increase the accuracy of geometallurgical modelling and update the block model automatically. The ore is tracked from the mine through the process with SmartTags™ and linked with the plant control system (DCS) to provide actual plant performance data (throughput, recovery, grade etc) for each ore type and associated blast conditions. These data are automatically compared with model predictions and updated in the block model using the SmartTag™ software. Incorporation of the actual plant data into the block model in real-time eliminates the need for further expensive ore characterisation tests. More accurate data in the block model improves mine planning, and the plant receives advance notice of the ore type about to be processed. Adjustments can then be made to blast designs and operating conditions to optimise performance. can be measured with laboratory tests such as Point Load Index (PLI), Drop Weight or SMC tests (DWi), and Bond ball mill work index (BWi). The unconfined compressive strength (UCS) is a common measure of strength and can be estimated from PLI values to reduce laboratory testing requirements. In general terms, the rock structure affects the coarse end of the ROM fragmentation, while the strength (hardness) affects the generation of fines. Improved plant throughput can be achieved by manipulating ROM fragmentation through optimisation of blasting to reduce top size and increase fines, especially for SAG mills. At Phu Kham, ore domains were defined based on the RQD (for structure) and PLI (for strength) values in the geotechnical block model. This resulted in a matrix of nine ore domains as shown in Figure 39. Ore within a domain will produce similar ROM fragmentation for a given blast design. An increase in harder ores is expected in the future at Phu Kham as the pit deepens, and has the potential to reduce throughput. Consequently, the focus of the project was on increasing throughput and improving overall comminution circuit performance when treating the hardest ore types. Therefore, the hardest ore available was selected for a trial blast and was followed by detailed auditing of the blasting and processing operations. For the trial blast, RQD data was obtained from the geotechnical block model, and point load tests were conducted on stockpile samples. These indicated that the trial blast consisted of moderately hard, but reasonably low quality, jointed and fractured rock. Blast modelling and simulations One of the main objectives of the project was to develop strategies to maximise mill throughput to maintain LOM operational targets even when treating harder ores. This can be achieved by improving ROM fragmentation through optimisation of blasting practices. A reliable model of blast fragmentation is required to determine the effect of changing blast parameters on ROM fragmentation. The Metso PTI blast fragmentation model, which is sensitive to the major parameters known to affect blasting performance, was calibrated using the ore characterisation data and design parameters from the audited blast. Image analysis of the ROM size distribution produced by the trial blast was used to calibrate the coarse size fractions. A limitation of image analysis techniques to determine ROM size distributions is that they cannot effectively delineate fines; therefore, the size distribution of the primary crusher product belt cut sample was used to correct the fine portion of the curve. A comparison between the measured and model generated ROM size distribution is shown in Figure 40. The model Ore characterisation The optimisation methodology starts with ore characterisation in terms of structure, strength and comminution properties. These are used to define ore domains within the geotechnical block model with similar blastability and fragmentation properties. Rock structure is determined by the in situ joints and fractures and can be quantified with rock quality designation (RQD), fracture frequency and joint mapping. Rock strength 228 FIG 39 – Definition and distribution of ore domains at Phu Kham. We are metallurgists, not magicians Process development and throughput forecasting at the Phu Kham copper-gold operation, Laos PDR FIG 40 – Blast fragmentation model. predictions correlated well with measured values at both the coarse and fine ends of the particle size distribution. This demonstrated that the model was quite accurate in predicting ROM fragmentation, and suitable for simulation studies. Simulations were conducted using the blast fragmentation model to investigate the impact of changes in spacing, burden, stemming length and blasthole diameter on ROM fragmentation. The parameters of the current blast design and five selected scenarios (with 115 mm diameter blastholes) are provided in Table 9. The corresponding model predictions of ROM size distribution are shown in Figure 41. As expected, simulations indicated that tightening the blast pattern to increase the powder factor (PF) resulted in a significant increase in the fines generated in the blast. Reduction of stemming length also generated more fines and reduced the top size of the rock due to the increased explosive energy at the stemming horizon. These simulations indicated potential to increase throughput by increasing the fines and reducing the top size of the ROM fragmentation by optimising the blasting parameters. Simulations were conducted for each of the nine ore domains (using both 115 mm and 127 mm blasthole diameters). This allows the blast design to optimised for each of the ore domains, and a ‘cookbook’ is generated which provides a ‘recipe’ (ie an optimised blast design for each ore domain). Blasting according to this cookbook provides a more consistent and optimised feed size distribution to the downstream processes, increasing throughput, process stability and efficiency. Following the FIG 41 – Selected blast fragmentation simulation results. cookbook avoids excessive blasting in softer ore domains, thus reducing energy consumption and costs, and preventing the excessive production of ultra-fines that can be detrimental to some downstream processes. This has been successfully applied by PTI at several other large open pit operations globally (Rybinski et al, 2011; Burger et al, 2006). The final definition of the blasting cookbook at Phu Kham is ongoing. SmartTagTM Ore Tracking To link the process performance with ore characterisation and blasting outcomes, the ore from the trial blast was tracked from the mine through the process using SmartTagTM ore tracking. The SmartTag™ ore tracking system developed by Metso PTI allows parcels of ore to be tracked from the mine, through the crusher and finally into the grinding mills, as shown in Figure 42. The SmartTags™ are built around robust passive radio frequency (RFID) transponders. They do not have an internal power source, so they can remain in stockpiles and ROM pads for extended periods of time. Antennas to detect the SmartTags™ are located at critical points in the process ahead of the milling circuit; tags can be detected a number of times and provide valuable information on material movements. In particular, they make it possible to link the spatial data associated with the ore in the mine to the timebased data of the concentrator. At Phu Kham, SmartTag™ antennas were installed under the crusher product and SAG mill feed conveyors. The installation TABLE 9 Selected blast designs. Current design Scenario 1 Scenario 5 RQD (%) 25 UCS (MPa) 60 Bench height (m) Scenario 9 Scenario 13 Scenario 17 10 Burden (m) 3.5 2.6 3 3.4 3.8 4.2 Spacing (m) 4 3.2 3.6 4 4.5 4.9 Subdrill (m) 1 Stemming length (m) 3 1.8 2.2 2.5 2.8 3.2 Explosive type 70% emulsion Density (g/cc) 1.15 Powder factor (kg/m3) 0.69 1.34 0.99 0.76 0.58 0.46 Powder factor (kg/t) 0.26 0.5 0.36 0.28 0.21 0.17 Change in powder factor (%) -- 94.2 43.5 10.1 -15.9 -33.3 We are metallurgists, not magicians 229 D Bennett et al FIG 42 – SmartTag™ ore tracking. on the SAG feed belt is shown in Figure 43. SmartTags™ were inserted into the stemming column of every blasthole for the audited blast. The origin of each SmartTag™ is saved with its unique identification number (ID). As the SmartTags™ and associated orepass the antennas in the process plant, the system automatically records the time and tag ID, thus the source of the ore being processed at any given time is known. During the project at Phu Kham, this ensured that ore from the trial blast was being fed to the concentrator during the plant audits, and allowed correlations to be established between ore origin and process performance. Comminution modelling and simulations A comprehensive grinding circuit survey was successfully conducted on 4 February 2013 when the circuit was treating ore from the trial blast (as determined by SmartTag™ ore tracking). At the time of the grinding survey the plant was operating under SAG mill limiting conditions, with a total mill load of 29 per cent and mill power draw of 12.0 MW. Ore samples collected during the site survey were sent for ore characterisation tests, including drop weight (DWT) and Bond ball mill work index (BWi) testing. These tests provide ore parameters required for comminution modelling, and the results from the survey sample are provided in Table 10. The A*b and ta parameters are determined from the DWT. The A*b value for the ore puts it in the ‘moderately soft’ category in terms of resistance to impact breakage, and the ta value falls into the ‘soft’ range for abrasion resistance. The BWi test conducted at a closing sieve size of 106 µm resulted in a BWi TABLE 10 DWT and BWi test r