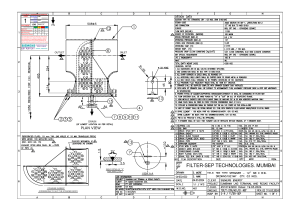

Automatic counter-flushing water strainer Usage specification (Mechanical) WUXI HUATONG EP. EQUIPMENT CO.,LTD 2007.1 电动滤水器 Automatic counter-flushing water strainer 使用说明书 operational manual Table of Contents 1 Introduction .............................................................................................................................. 3 2 Function ..................................................................................................................................... 3 3 Technical features and technical specifications ..................................................................... 3 4 Working principle and structure features .............................................................................. 7 5 Water pipe system..................................................................................................................... 8 6 Monitoring system and operation mode ................................................................................. 9 7 Installation requirements ....................................................................................................... 11 8 Operation requirements ......................................................................................................... 12 9 Maintenance ............................................................................................................................ 13 10 Transportation and storage ................................................................................................. 13 无锡市华通环保设备有限公司 WUXI HUATONG EP EQUIPMENT CO.,LTD 地址(Add):无锡市江海东路 1899 号 1899 No. Jianghai east road ,wuxi city ,Jiangsu Province, China 电话(Tel):0510-82100129, 传真(Fax):0510-82126280, 邮编(Post code):214027, E-mail: hthb@vip.163.com HTHB(JG).05.07-2007-01 2 电动滤水器 Automatic counter-flushing water strainer 使用说明书 operational manual 1 Introduction The full-automatic and counter-flushing electric-driven water strainer of model LS902 is a kind of new generation product based on design, manufacturing and operation experience of former product and absorbing advanced technology of similar products in China and other countries by Wuxi Huatong EP Equipment Co., Ltd. The product is of high technology, and meets the demand of supporting and technology improvement for power plant and nuclear plant with introduced or imported machine group. 2 Function The full-automatic counter-flushing water strainer of model LS902 is specially designed for power plant or nuclear plant, which is applicable for water straining for plant taking seawater or fresh water as cooling water source to prevent solid particles and dirt water from entering the downstream water consumption system and equipment, and purifies the water and protects the equipment for safe operation. 3 Technical features and technical specifications 3.1 Technical features 3.1.1 Flow area of the strain net is large, the resistance is small and the cleaning cycle is long. 3.1.2 Complete cleaning system: besides the counter-flushing equipment of automatic control, cleaning measures are used without opening the big cover (strainer with larger diameter) to ensure operation, easy maintenance and improve utilization rate. Counter-flushing is featured in small water quantity, good cleaning effect and water saving. 3.1.3 To perform cleaning without opening the big cover, the equipment against water splashing are equipped for the motor and electric devices (installed close to the electric-driven strainer 无锡市华通环保设备有限公司 WUXI HUATONG EP EQUIPMENT CO.,LTD 地址(Add):无锡市江海东路 1899 号 1899 No. Jianghai east road ,wuxi city ,Jiangsu Province, China 电话(Tel):0510-82100129, 传真(Fax):0510-82126280, 邮编(Post code):214027, E-mail: hthb@vip.163.com HTHB(JG).05.07-2007-01 3 电动滤水器 Automatic counter-flushing water strainer 使用说明书 operational manual and electric equipment). 3.1.4 The equipment is designed for seawater, and surface of the water flow employs 316L: stainless steel of sound seawater corrosion resistance. 3.1.5 Automatic control function of the equipment is complete, and the supporting parts are of high quality. a. The automatic control system employs DCS system control of the control cabinet manufacturer. Other components, like AC contact, thermal protection relay are made outside China, the pressure difference switch is from SOR, America and the pressure difference transmitter is from ROSEMOUNT, America. The practice proves that it has high reliability and service life and utilization rate are highly increased. b. Complete automatic control functions: Automatic control mode: resistance over-pressure cleaning system for automatic operation and lock.. Set interval and operation time for automatic operation and lock. Long-term cleaning system. Manual mode: manual electric-driven mode to operate strainer rotation, valve opening, valve closing and etc. 3.2 Technical specifications: No. Item Unit Data Remark Vertical full-automatic 1 Type counter-flushing water strainer 2 Model LS902AS0.4-500 无锡市华通环保设备有限公司 WUXI HUATONG EP EQUIPMENT CO.,LTD 地址(Add):无锡市江海东路 1899 号 1899 No. Jianghai east road ,wuxi city ,Jiangsu Province, China 电话(Tel):0510-82100129, 传真(Fax):0510-82126280, 邮编(Post code):214027, E-mail: hthb@vip.163.com HTHB(JG).05.07-2007-01 4 电动滤水器 Automatic counter-flushing water strainer 3 使用说明书 operational manual Working media Seawater Nominal diameter of 4 mm DN500 MPa 0.4 MPa 0.4 MPa 0.6 m3/h 1700 MPa 0.004~0007 mm DN125 inlet and outlet Maximum working 5 pressure 6 Design pressure Water pressure test 7 pressure 8 Rated flow Resistance under 9 rated flow and cleaning conditions Counter-flushing 10 sewage drainage door 11 Straining precision mm 2 12 Flowing rate Times 6 M For earthquake of 7 degree r/m 1.1 Performance against 13 earthquake Revolution of water 14 strainer 16 Main drive structure Germany SEW motor+ reducer 无锡市华通环保设备有限公司 WUXI HUATONG EP EQUIPMENT CO.,LTD 地址(Add):无锡市江海东路 1899 号 1899 No. Jianghai east road ,wuxi city ,Jiangsu Province, China 电话(Tel):0510-82100129, 传真(Fax):0510-82126280, 邮编(Post code):214027, E-mail: hthb@vip.163.com HTHB(JG).05.07-2007-01 5 电动滤水器 Automatic counter-flushing water strainer 17 Motor power 使用说明书 operational manual Kw 0.37 Stream trap valve 18 Manual ball G2’’ mm for stop valve Pressure difference 20 SOR gauge Model 101NN-K3-H4-C1A-TTX371 Setting range of pressure difference MPa 0.025~0.10 value Maximum value of Lower limit 0.02/Upper limit switching pressure MPa 0.21 difference Pressure gauge 21 ROSEMOUNT switch Model 3051CD3A23A1AB4DF Setting range of pressure difference MPa 0.025~0.10 value Maximum value of Lower limit-0.248/Upper limit switching pressure MPa 0.248 difference 无锡市华通环保设备有限公司 WUXI HUATONG EP EQUIPMENT CO.,LTD 地址(Add):无锡市江海东路 1899 号 1899 No. Jianghai east road ,wuxi city ,Jiangsu Province, China 电话(Tel):0510-82100129, 传真(Fax):0510-82126280, 邮编(Post code):214027, E-mail: hthb@vip.163.com HTHB(JG).05.07-2007-01 6 电动滤水器 Automatic counter-flushing water strainer 使用说明书 operational manual Maximum pressure 22 resistance of MPa 0.1 MPa 0.6 kg ~2120 filtration net Pressure level of flanges for water 23 incoming and outgoing 24 Net weight 4 Working principle and structure features 4.1Working principle The circulating water enters the lower cabinet of the shell through the lower incoming flange, flows into internal part of the wire winding tube of the cylinder and the filtrated water is collected at the external part of the wire winding tube and flows out from the upper flange. The dirt is trapped on the internal wall surface of the wire winding tube. When counter-flushing is performed, the water enters external part of the wire winding pipe in reverse flow. The sewage with dirt flows into water drainage point with low pressure from the drainage outlet for counter-flushing at the lower part. The filtration component is made up of 18 wire winding pipes, which correspond to 18 holes. During continuous rotation of the strainer, it opens and closes continuously to form pulse water flow, which increases impulsive force and improves counter-flushing. For the strainer is divided into many wire winding pipes, it needs less water and saves water. 4.2 Structure features: 无锡市华通环保设备有限公司 WUXI HUATONG EP EQUIPMENT CO.,LTD 地址(Add):无锡市江海东路 1899 号 1899 No. Jianghai east road ,wuxi city ,Jiangsu Province, China 电话(Tel):0510-82100129, 传真(Fax):0510-82126280, 邮编(Post code):214027, E-mail: hthb@vip.163.com HTHB(JG).05.07-2007-01 7 电动滤水器 Automatic counter-flushing water strainer 使用说明书 operational manual The strainer is vertical and cylinder structure. The water incoming flange is at the lower part and the water outgoing flange is at the upper part of the other side. Manhole is set on the shell (the strainer with small diameter is flat hole) for clearing. The wire winding pipe for filtration is easy to be replaced during overhaul after opening the big cover. Besides drive unit on the straining net, the joint for discharging air is set and sewage drainage port for counter-flushing is set at lower part of the shell. The drive unit for driving the strainer is inclined gear reduction device RF97R57DT71D4 made by SEW Company of Germany, which is featured in compact structure, high efficiency, low noise, long service and etc. For the circulating water is seawater, 316L(00Cr17Ni14Mo2)of American standard is used. To reduce leakage as much as possible, upper and lower part of the strain net is equipped with sealing ring. Bearing on the rotating shaft of the strain net is made of oil-free bearing of 316L. 5 Water pipe system Incoming water of the strainer is from outlet of the circulating pump or the pressure increasing pump. The filtrated water is transported to thermal exchanger or other water consumption devices. The sewage for counter-flushing is connected to the circulating outgoing water pipe system of the condenser to make the water drainage point at lower pressure to form large pressure difference with designed value of 0.04Mpa or above. Low pressure difference will affect the counter-flushing. Two valves in series connection will be set on the drainage pipe for counter-flushing. One is electric-driven ball valve, which is connected to control system of the equipment to open or close the counter-flushing pipe. The other is manual ball valve (not supplied by the manufacturer) for flow adjustment and flow control. Strainer of the system will 无锡市华通环保设备有限公司 WUXI HUATONG EP EQUIPMENT CO.,LTD 地址(Add):无锡市江海东路 1899 号 1899 No. Jianghai east road ,wuxi city ,Jiangsu Province, China 电话(Tel):0510-82100129, 传真(Fax):0510-82126280, 邮编(Post code):214027, E-mail: hthb@vip.163.com HTHB(JG).05.07-2007-01 8 电动滤水器 Automatic counter-flushing water strainer 使用说明书 operational manual consume about 5% of the rated flow for counter-flushing, which has something to do with dirt and the drainage system. When the above water is drained, water supply of downstream equipment will be slightly affected. Schematic diagram of water pipe of electric-driven strainer 进水 Incoming water 放空气 Discharge air 出水 Outgoing water 反冲洗污水 Sewage for counter-flushing 停机放水 Drain during stoppage 6 Monitoring system and operation mode 6.1 Automatic programming system: The system employs PLC as core control component, greatly improves reliability of the control system, simplifies the system, improves performance and extends service. 6.2 Operation mode: 无锡市华通环保设备有限公司 WUXI HUATONG EP EQUIPMENT CO.,LTD 地址(Add):无锡市江海东路 1899 号 1899 No. Jianghai east road ,wuxi city ,Jiangsu Province, China 电话(Tel):0510-82100129, 传真(Fax):0510-82126280, 邮编(Post code):214027, E-mail: hthb@vip.163.com HTHB(JG).05.07-2007-01 9 电动滤水器 Automatic counter-flushing water strainer 使用说明书 operational manual 6.2.1Full-automatic operation: 6.2.1.1When dirt in the inside surface of the straining net reaches specified extent, pressure difference value of inlet and outlet exceeds setting value of the pressure difference transmitter, the pressure difference switch (pressure difference transmitter) sends signals, and the counter-flushing system starts, the drive structure rotates and the sewage drainage valve for counter-flushing is opened. After washing, when the pressure difference is below the setting value, after one minute’s delay, the counter-flushing system stops and the sewage drainage valve is closed. Setting value of the pressure difference switch (pressure difference transmitter): 0.025MPa(2.5mH2O) See attachment 1 on technical specifications, use, commissioning and installation requirements of the pressure difference switch (pressure difference transmitter). 6.2.1.2 According to dirty extent in the power plant, interval between two operations and operation time of counter-flushing can be set for automatic cleaning circularly. Adjustment range of the interval is 1-99hours, with default setting 6 hours. When the machine is put into operation, counter-flushing system shall be used first. The straining net rotates and the sewage drainage valve for counter-flushing is opened. After finishing, the straining net stop rotating and the sewage drainage valve for counter-flushing is closed. 6.2.2Manual operation: Set the selection switch at the manual position and the automatic control system is locked. Manual control operation is available to control each point separately and the automatic control 无锡市华通环保设备有限公司 WUXI HUATONG EP EQUIPMENT CO.,LTD 地址(Add):无锡市江海东路 1899 号 1899 No. Jianghai east road ,wuxi city ,Jiangsu Province, China 电话(Tel):0510-82100129, 传真(Fax):0510-82126280, 邮编(Post code):214027, E-mail: hthb@vip.163.com HTHB(JG).05.07-2007-01 10 电动滤水器 Automatic counter-flushing water strainer 使用说明书 operational manual system and protection function are not available. 6.3 Automatic programming device (control box) The device adapts PLC as core component including starting, protection component, switch and etc. of the motor, and is an independent system. The power supply of 400V, 3 phases and 50Hz is connected. The control box is installed locally. 6.4 Instrument monitoring system: 6.4.1 Pressure gauges are installed at the inlet and outlet to monitor pressure of the outgoing and incoming water. 6.4.2 Setting of pressure difference switch (pressure difference transmitter) is automatic control system with required monitoring adjustment to ensure that the automatic operation is performed as required. 6.4.3 To ensure accurate pressure adjustment, protection measures are employed at the pressure sampling point of the water inlet and outlet to avoid block. 7 Installation requirements 7.1Overall check shall be performed for the equipment. The water inlet is set at the lower part and the water outlet is set at the upper part, which can not be connected oppositely. 7.2The connecting parts like foundation size, embedded part and foundation bolt shall be checked. 7.3To keep the strainer vertical, adjust it with mat iron. Electric welding machine is used to weld the mat iron firmly, after tighten the foundation bolt, secondary pouring can be performed. 7.4 Fill in lubricant as per instructions for the reducer. 无锡市华通环保设备有限公司 WUXI HUATONG EP EQUIPMENT CO.,LTD 地址(Add):无锡市江海东路 1899 号 1899 No. Jianghai east road ,wuxi city ,Jiangsu Province, China 电话(Tel):0510-82100129, 传真(Fax):0510-82126280, 邮编(Post code):214027, E-mail: hthb@vip.163.com HTHB(JG).05.07-2007-01 11 电动滤水器 Automatic counter-flushing water strainer 使用说明书 operational manual 7.5 To ensure water pressure difference for counter-flushing, according to requirements of water pipe system, sewage drainage point shall be paid attention to and low pressure point shall be selected as much as possible. 7.6Wiring shall be carried out according to connection requirements of the control box, electric-driven device of valve and drive motor of the reducer and the grounding wire joint must be focused on. 7.7After the circuit is ready, test insulation and grounding wire are conformed or not, then get through the power supply. 7.8Test shall be performed for varieties of working conditions of the control box (See attachment 1). 7.9Adjust interval and operation time of circulating flushing according to requirements stipulated in instruction manual for the automatic control device. 7.10Check operation conditions, interval and continuous time and confirm the water strainer is blocked or not. Opening and closing of the valve shall be normal and there should be no leakage on all the sealing surfaces. 7.11The machine can be put into operation after all the troubles are removed. 8 Operation requirements 8.1After installation, the working conditions must be normal. 8.2Open the air drainage valve, open the water incoming valve of the strainer slightly, after residual air in the shell of the water strainer is completely pressed out by the water in the shell, then there is no air in the air drainage valve, then open the water incoming valve and close the air valve. Get the control box powered, the strainer is ready, open the outlet valve and the 无锡市华通环保设备有限公司 WUXI HUATONG EP EQUIPMENT CO.,LTD 地址(Add):无锡市江海东路 1899 号 1899 No. Jianghai east road ,wuxi city ,Jiangsu Province, China 电话(Tel):0510-82100129, 传真(Fax):0510-82126280, 邮编(Post code):214027, E-mail: hthb@vip.163.com HTHB(JG).05.07-2007-01 12 电动滤水器 Automatic counter-flushing water strainer 使用说明书 operational manual strainer should be in normal operation. 8.3After the strainer stops, close the inlet and outlet valves and sewage drainage valve for counter-flushing, and open the air drainage valve and water drainage valve of the shell. 8.4To reduce sewage drainage amount for counter-flushing, one manual ball valve is installed after the electric-driven sewage drainage valve for counter-flushing. Adjust sewage drainage amount, generally, the valve shall be 56% opening when starting. 9 Maintenance 9.1The fillings shall be replaced according to leakage of fillings of the main shaft of the water strainer. The fillings shall be replaced in case of overhaul and sealing pad of the valve rod of the water pipe system shall be handled according to the above methods. 9.2Lubricant shall be replaced regularly for the reducer. See the instruction manual for the reducer for the procedures. 10 Transportation and storage 10.1 During transportation, collision shall be avoided, otherwise, it may lead to deformation or damage. Fix the product on the transportation tool with rope. 10.2Besides the requirements stipulated in 10.1, damp-proof is required for the motor, electric-driven valve, automatic control device and other electric components, and vibration-proof is available for the automatic control box. 10.3All the components in the equipment shall be placed in the ventilated cabinet. The electric equipment shall be placed in the electric or instrument warehouse. 无锡市华通环保设备有限公司 WUXI HUATONG EP EQUIPMENT CO.,LTD 地址(Add):无锡市江海东路 1899 号 1899 No. Jianghai east road ,wuxi city ,Jiangsu Province, China 电话(Tel):0510-82100129, 传真(Fax):0510-82126280, 邮编(Post code):214027, E-mail: hthb@vip.163.com HTHB(JG).05.07-2007-01 13