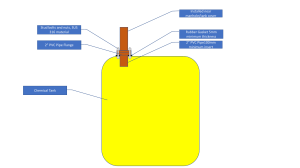

Facts At Your Fingertips Bolted Flange Joint Assemblies Department Editor: Scott Jenkins F lange-bolted joints enable connections of singular segments of pipes into more complex sections, as well as joining measuring and process devices, such as flowmeters, pumps, fans and pressure vessels. These joints are potential sources of leakage, which can introduce safety and environmental hazards, as well as process inefficiencies. This one-page reference reviews concepts associated with preventing leaks in flangebolted joints. Design considerations The design of flange-bolted joints depends on the selection of a gasket, as well as the proper assembly. Required design data include the nominal diameter of the pipeline, the temperature and pressure of the process fluid and the chemical and physical properties of the transported medium. Additional data are external loads on joint (and their variations in time), required tightness and durability of the joint. Over the past several decades, computational algorithms have been developed to help achieve the desired bolt tightness. In most cases, the algorithms apply to flange-bolted joints with circular gaskets, and the results of the calculations provide the torque at which the nuts should be tightened to ensure sufficient tightness [1]. Forces on joints Three main forces act upon a bolted flange joint assembly (BFJA; Figure 1). The flange/bolt load acts to compress the gasket enough to fill any serrations or imperfections on the sealing surface. This helps prevent potential leak paths. The hydrostatic end load, caused by the internal pressure of the fluid in the system, acts to push the two flanges apart. The internal blowout pressure acts upon the gasket and tries to push it out through the gap between the flanges. A main concern surrounding the design and installation of the BFJA is determining the gasket stress or load that will be applied to the gasket (the flange/bolt load minus the hydrostatic end load). This remaining CHEMICAL ENGINEERING gasket load must then be greater than the internal blowout pressure to ensure the integrity of the seal. If it is not, a leak or gasket blowout can occur [2]. Leakage rate Bolt load Hydrostatic end force Gasket Blowout/ internal The leakage rate refers pressure to the quantity of fluid that passes through the body and over the faces of a gasket per unit periphery of the gasket over FIGURE 1. The three main forces at play in a bolted flange joint asa specified time [3]. The sembly (shown here) act to prevent leaks and gasket blowouts leakage rate is highly influenced by process media, pressure, calibrated torque-control device temperature, surface pressure and to ensure proper torque values other factors. It is usually measured are applied under a specific gasket load and at a • Keep assembly records to verify that specific fluid pressure. For given set proper procedures were followed of conditions, the lower the leakage rate, the better the fluid is retained by Gasket materials Common gasket materials include the gasket material. As a general guideline, increas- elastomers, polytetrafluoroethylene ing internal pressure leads to higher (PTFE), flexible graphite, natural fileakage rates. Increasing surface bers or mineral-based materials. pressure results in lower leakage Gasket manufacturers provide presrates. Increasing molecular size gen- sure-versus-temperature charts to erally means lower leakage rates. help determine whether or not the Increasing temperature gives lower material is safe to use for a particuleakage rates for some gasket ma- lar application. terials, although toward the end of service life, the leakage rate is likely Flange compressibility Flange compressibility is considto increase [3]. ered to be the percentage reducInstallation tips tion in thickness of a flange under The following are tips to consider compressive pressure (applied at a when installing BFJAs [2]. constant rate, at ambient tempera• Make sure the flange sealing sur- ture). This value provides a means to faces are clean and free of dings, measure the deformation properties marks or indentations of a gasket, and is an indication of • Flanges should be aligned to maxi- the ability of the material to conform mize sealing contact and to pro- to the flange surface irregularities [3]. vide a uniform gasket load Gasket materials with higher com• Working surfaces of bolts, nuts and pressibilities will more effectively fill washers should be lubricated to surface roughness. n ensure uniform friction • Verify the material, grade and con- References dition of the bolts. Nuts should 1. Jaszak, P. and Adamek, K., Design and analysis of the flangebolted join with respect to required tightness and strength, Open spin freely onto the bolt thread Engineering, 2019. https://doi.org/10.1515/eng-2019-0031 without binding 2. Norton, C., Back to Basics: Soft Gaskets, Fluid Sealing Association (FSA), Sealing Sense, 2016. • Number and tighten bolts using a proven tightening sequence or 3. European Sealing Association (ESA) and the Fluid Sealing Association (FSA). Flange Gaskets: Glossary of Terms, ESA/FSA, assembly pattern, and use a Publication 018/09. 2009. WWW.CHEMENGONLINE.COM OCTOBER 2023 31 Reproduced with permission of copyright owner. Further reproduction prohibited without permission.