Rules and Regulations to be followed in the

SOM laboratory

All students must wear shoes during the laboratory practical classes.

Do not handle the machineries/instruments/tools/equipments inside the

laboratory without taking prior permission and instructions.

Keep your mobile phones switched off during the laboratory class.

Students must avoid unnecessary gossiping during the laboratory class.

All students must pay full attention in order to avoid any damage to the

machines and their accessories.

Students should not loiter inside the laboratory.

Students working with impact machine should never stand in the direction of

moving pendulum. Students should stand outside the safety fence.

Weights should be handled with extreme care in Brinell hardness test.

Do not handle the extensometer without permission of technical staff.

Anybody found violating the above rules will not be allowed to

continue the class and will be given absent for that class.

Your safety is more important.

Senior Technical Superintendent

Sanjib Sarma

Ph:2689

Faculty In-charge

Dr. Nelson Muthu

Ph:3440

INDIAN INSTITUTE OF TECHNOLOGY, GUWAHATI

DEPARTMENT OF MECHANICAL ENGINEERING

LABORATORY SHEET

NAME:

ROLL No:

DATE OF EXPERIMENT:

Gr. No:

DATE OF SUBMISSION:

EXPERIMENT: UNI-AXIAL TENSION TEST.

OBJECTIVE: To obtain the stress-strain relation of mild steel using a circular cylindrical

specimen and determine Young’s modulus (E), proportional limit (σp), yield stress (σy),

0.2% offset yield strength, ultimate tensile stress (σu), true fracture stress, and nominal

and true fracture strain and percentage elongation.

APPARATUS: The Universal Testing Machine (UTM) is a machine with which several

tests can be performed, namely, Tension, Compression, Bending, Buckling and Hardness.

The movement is controlled by rate of pumping of fluid into a hydraulic cylinder whose

piston controls the movement of the moving plate. The load ranges available on the

machine are 0-8 ton and 8-20 ton with resolution of 2 kgf and 5 kgf respectively. The ram

must be right down before the capacity is changed or the motor is switched off.

An electronic clip on type extensometer with gauge length 25mm and 50mm is used to

indicate the extension between the end points of the gauge length of the specimen to

which it is attached. It must be very carefully and should be used only for yield / proof

studies and not for specimen failure or breakage (i.e. it must be removed immediately

after yield point to avoid damage to the extensometer).

The specimen has a larger diameter at the ends with a smooth fillet connecting to the

reduced diameter of the central portion to ensure that the effect of the holding jaws is not

significant on the state of stress within the gauge length. The diameter at the middle of

the gauge length is reduced by about 20mm to ensure that neck forms in this region so

that a meaningful value of percentage elongation is obtained.

The machine frame consists of two cross-heads and lower table. The lower cross-head is

adjustable by means of geared motor. Tension test is carried out between lower and upper

cross-head. Sensing of the load is done by means of precision pressure transducer of

strain gauge type.

The loading unit consists of a robust base. The main hydraulic cylinder is fitted in the

center of the base and piston slides in the cylinder. The lower table is connected to the

main piston. This lower table is rigidly connected to the upper cross-head by two straight

columns. The chain and sprocket driven by a motor fitted in the base rotates the two

straight columns mounted on the base which enables movement of the lower cross-head.

The jaws inserted for tensile test specimen along with the rack jaws slide in the lower and

1

upper cross-heads. Jaw locking handle is provided to lock the jaws of the lower crosshead after the specimen is clamped. An elongation scale is kept sliding on the rod which

is fixed between the lower table and upper crosshead. The elongation indicating pointer is

fixed to the lower cross-head.

The control panel has two control valves to control oil flow in the hydraulic system, one

at the right side and the other at the left. The right side valve is a pressure compensated

flow control valve. The left side valve is a return valve, i.e. it allows the oil from the

cylinder to go back to the tank. Pressure compensation of the flow control keeps a

constant rate of straining regardless of the total load on the specimen.

PROCEDURE: Before testing, adjust the load range according to the capacity of the test

piece. Measure the diameter of the specimen. Mark the gauge length of the specimen.

Select the proper jaw inserts and complete the upper and lower chuck assemblies. Then

operate the upper cross-head grip operation handle and grip fully the upper end of the test

piece. Attach the extensometer to the specimen. Apply the load gradually and read the

extension from the extensometer at equal increments of load till yield occurs. Remove the

extensometer. Increase the displacement of the movable jaw till the specimen fractures in

into two pieces. Note down the maximum load applied. Measure the minimum diameter

of the necked section and final deformed lengths between the marked gauge points by

assembling together the fractured pieces.

LOADING / UNLOADING: The left valve is kept in fully closed position and the right

valve in normal open position. Open the right valve and close it after the lower table is

slightly lifted. Now adjust the load to zero by Tare push button. (this is necessary to

remove the dead weight of the lower table, upper cross-head and connecting parts from

the load). Operate the lower grip operation handle and lift the lower cross-head up and

grip fully the lower part of the specimen. Then lock the jaws in this position by operating

the jaw locking handle then turn the right control valve solely to open position, (i.e.

anticlockwise) until you get a desired loading rate. After this you will find that the

specimen is under load and then unclasp the locking handle. Now the jaws will not slide

down due to their own weight. Then go on increasing the load when the test piece is

broken. Then open the left control valve to take the piston down.

OBSERVATION AND CALCULATION:

Diameter of specimen d o =

Gauge length

Lo=

mm

mm

Maximum load, P max =

N

Load at fracture, P f =

N

Minimum diameter of the neck, df =

Undeformed Area Ao =

πd o2

4

=

m

m2

2

The load P (N) versus extension / displacement curve is obtained from the plotter. Slope

of the straight-line portion is determined from load versus extension curve as

In linear range, E =

∆PLo

=

Ao ∆δ

N / m2

From the computer plot, the loads Ppl, Py corresponding to proportional limit and yield

point are

Ppl =

N,

Py =

Proportional limit, σ pl =

σy =

Yield stress,

N

Ppl

Ao

Py

Ao

=

Pa

=

Pa

A permanent strain of 0.002 corresponds to the following displacement between the jaws

∆δ p = 0.002 L

Take the origin in the computer plot (load-displacement curve) at the point of intersection

of the straight line fitted to the data with displacement axis. From the point (∆δ p , 0 )

(where permanent displacement corresponding to 0.2% strain0 w.r.t. this origin, a line is

drawn parallel to the fitted line which intersects the curve at a load P1

P1 =

N

0.2% offset yield strength = P1/Ao =

Pa

Ultimate stress, σu= Pmax / Ao =

Pa

True fracture stress, σf = Pf / Af =

Pa

Final deformed gauge length, Lf=

m

Nominal average strain at fracture = (Lf – Lo) / Lo=

d

True strain at fracture = 2 ln o =

d

f

For Lo =

m,

and do=

Percentage elongation =

( L f − Lo )

Lo

m, we have for mild steel,

100 =

%

3

Percentage reduction in area = 100

(A − A )

o

f

Ao

2

df

= 1 − 100 =

d o

%

Draw the sketch of the final deformed specimen.

DISCUSSION OF RESULTS AND SOURCES OF ERROR:

Lack of calibration of machine, improper alignment, initial curvature of specimen, error

in measurement of extension, etc., are the sources of error.

EXERCISE:

1. Draw nominal σ – ε relation for a ductile material and indicate properly in the

diagram E, proportional limit, yield stress, ultimate tensile strength σu, normal

fracture stress σf, 0.2% offset yield strength (0.2% proof stress), modulus of

resilience. For a stress level σ such that σy< σ < σu, show that the elastic part εo

and plastic part εp of strain.

2. Draw σ-ε relation for cast iron and mild steel in the same figure.

3. Classify the following into brittle and ductile: mild steel, C.I, rock, concrete, Al,

copper, Perspex, brass, brick wood, chalk.

4. Draw the tensile flow curve ( True stress vs, True strain) from the load-elongation

curve during the tension test. Assume the displacement values from the loaddisplacement plot that was obtained using a 2” extensometer. Determine the work

hardening exponent for the sample tested.

5. What are the types of test that can be conducted on U.T.M.

6. What is the Bauschinger effect? Illustrate by σ-ε graph.

7. Why is the state of stress in the local neck formed in a uni-axial tension test of

cylindrical specimen of ductile metal neither uni-axial nor uniform?

8. Ductile metals in a uni-axial tension test have a cup cone fracture whereas brittle

ones have flat fracture surface. Why?

9. Percentage elongation of material has been quoted as 17%. What is wrong with

this statement?

10. Sketch on the same graph, σ-ε curves for uni-axial test of ductile metal for rate of

strain ε- very small, intermediate value, very large.

11. Sketch on the same graph, σ-ε curves for uni-axial test of mild steel at room

temperature and at temperature below the brittle-ductile transition temperature.

12. a) Define true strain εt (logarithmic strain) and obtain its expression in terms :(i)Lo & L (ii) Nominal strain ε.

b) Assuming volume constancy, relate nominal and true strains ε, εt to areas Ao

and A.

c) Which expression should be used to obtain εt before necking and after necking?

4

R 10 type

O 12.5

O 18

90

100

100

Tensile Specimen (Plain)

Material: 1) MS

2) Al

(Tensile test sample of MS was heated to 7300C and held for 45 minutes and allowed to cooled in the furnace)

All dimensions are in mm.

5

INDIAN INSTITUTE OF TECHNOLOGY, GUWAHATI

DEPARTMENT

OF MECHANICAL

ENGINEERING

LABORATORY SHEET

NAME:

ROLL NO & Or. No:

DATE:

EXPERIMENT:

Buckling Load of as Pinned-End Strut

SECTION 1.0 INTRODUCTION AND DESCRIPTION

Introduction

This guide describes how to set up and perform experiments related to the Buckling of Struts. The

equipment clearly demonstrates the principles involved and gives practical support to your studies.

Description

Figure 1 shows the Buckling of Struts experiment. It consists of a back plate with a load cell at one end

and a device to load the struts at the top. There are five aluminium alloy struts included in a holder on the

back plate Printed on the equipment are a number of equations and pieces of information that you will find

useful while using the equipment.

How to Set up the EQuipment

The Buckling of Struts experiment fits into a test frame. Figure 2 shows the Buckling of Struts experiment

in the Structures Test Frame. Before setting up and using the equipment, always:

• Visually inspect all parts (including electricalleads).for

damage or wear. Replace as necessary.

• Check electrical connections are correct and secure. Only a competent person must carry out electrical

maintenance.

• Check all components are secured correctly and fastenings are sufficiently tight.

• Position the Test Frame safely. Make sure it is on a solid, level surface, is steady, and easily accessible.

Important:

Never apply excessive loads to any part of the equipment.

The following instructions may have already been completed for you. If so, go straight to Section 2.

1. Place an assembled Test Frame (refer to the separate instructions supplied with the Test Frame if necessary) on a

workbench. Make sure the 'window' of the Test Frame is easily accessible.

2. On the Test Frame there are securing nuts in the bottom groove of the top member and the top grove

of the bottom member. In each member slide two of these to approximately

the positions shown in Figure 2

3. Lift up the STR12 unit onto the frame and have an assistant secure the unit to the frame using the

thumbscrews and washers provided.

4. Make sure the Digital Force Display is 'on'. Connect the mini DIN lead from 'Force Input l' on the

Digital Force Display to the socket marked 'Force Output' on the right-hand side of the unit

5. Carefully zero the force meter using the dial on the front panel of the experiment. Gently apply a small

load with a finger to the top of the load cell mechanism and release. Zero the meter again ifnecessary.

Repeat to ensure the meter returns to zero.

Note: If the meter is only ±l N, lightly tap the frame (there may be a little 'stiction' and this should

overcome it).

1

Runners fQr

sJld:<l<la$s~mbly

A(lJuslable

CrO$$l'Itiad

~o<1dI119

assembl)

Top fiXeel chuch

(remOVC,jl)lc)

BCoUoml"'''jhl.

chllr.:~

d cd

St,tZem'

«. tr :1

Figura

1 Buckling of SliUtS oxpOn'mCil{

2

~

t

sC.:lla

fest struts

Digl!AI

~

.

fOlef'!

c::JN

..

_-~.

Figure 2 Buckling of struts

3

SECTION 2 EXPERIMENTS

1: Buckling Load of a Pinned-End

Experiment

Compressive

They

members can be seen

Strut

ill many slructures.

worK, The struts provided have an /Ik ratio of between

520 nod 870 to show clearly t.he buckling load and the

ddlccled slwpe of the struts. In practice StJ'Ul.'; with an

Ilk ralio of more thnn 200 MC of little use in real

cnu form part of n fcsll1ework for instance in a

tl1lSS, or they can stand-alone;

•• wnler lower

roof

support is fin example of tbis.

Unlike 0 tension member which will g.cnerally (lnly

fail if the ultimme

tensile

stress is exceeded,

a

compressive member can 1':111 in t\VO ways. The fir~1 is

via rupture dllC to the direct stress, and the sec('lnd is by

an clastic mode of Failure called Buckling, Generally,

hort wide compressive

mcmber:Slhaltend

tmetureS.

\Ve willllse

trot:

10 fail by the

n~nt('rial crusbing <Ire cnlled columns. Long. thin

compressive ll1etllb~rs Ihat tenLl to [nil by buc.:klillg are

p. = Euler buck.ling load (N)~

l? =- Young'~ modulus (Nm-t);

I = Second moment of area (m,l);

= Length 1.)[ stHll (m).

cnlled struts.

'''bell bllckling occurs Ihe Mrul will no longer Clm)'

any more loao it will ~imply continue 10 Jispl;lce i.e. iL"

stiFfnes.s

then

becOJllc~

zero

and

it

d1e Euler buckling formula for a pinned

b

uscle~~

t

a~ u

R~f~rril1g co Figure 3. fit the bottom chuck [0 the

machine and fl'move th~ top chuck (10 give:? pinned

t.n.lctul"nll1lt:mher.

ends). Select the shoJ1~lil ~Irut. number

section using the vC:l'11icr

the cross

I, and Olt'asure

provided

and

cakullltC' the ~ccolld moment of area, I. for che su·uI.

Ad.iu~[ the position of the shcljl1~ cro,shend to <'lccept

the strut using (be lhurnbnuts

to lock off Ihe slid~r.

En~un: Ihill there i<; the maximum amount or Ir:wel

<Jvuilablc.OIl the llilndwhccl (hre<td to compress the strut.

Finally tighten the J()(.;king :,crew!>.

Carefully

back off the h:mdwheel ~o that the :-lnJl i~

rc,tint: in lht' notch but not lr(Hl~miuin!: :'Iny 10;1d: l'e7.cro

the forcemcter

lISlng Ihe front p~tncl control.

Carefu II)' <..tart to load the strut. ]f the SU1.Jt begins to

Place lest strul

in 'V' nolcl1es

lIdk: to lhe left, "nick" the slrut to the right 3nd vice

er,a

(Ihi" reduce!> any ",rrun. associ;ltcd with the

<;tr;lightnes~ of Lh\.'~lnil).'rUIll the 11Ilndwheei untillhcJ\~

is no fUrl her increase in load (the to:..u may nc.:Jk and

Ihell t1wp a~ it ,)cllk':, inlQ tlw notc:;hc.<i).

Record the liml1 IOl.lcl in Table I under 'buckling

load'. Ra;:rl<:!;'l with <.trUI number!'.~. 3, j and 5 'IlJjll~lil1g

lhe <:ro~:,"ead ;j~ r-::quired to fitlhe

"'11"\11. Takc

as thl; clifference!

\\-1lh Ihe !ihorLcr ;;tnltS.

more c:ln:

l>Clw~~l'lI lhe

buckling

load and the lo[rd nccdcrl 10 obtam plastic

lh..rormatiOIl

i::.

'111lle 'il11rllL Try loading each "Inn

o,c\lcrdl lilTle~ ulIlil a consi~t~'nt re::.ull for ctll:h strut is

rlcbievetl.

d

Strut

5

;1

Figure 3 Expenmentaf

the

I

--

320

470

a20

520

370

Length

(mill)

{N} load

Buckling

:3

\\i.' \\.'ill I~};KJstrul~ unlil Ill!:')' buckle

In [hi." cxp<:rimem

inV~S(l~Wlinp

I numberends)

layout (pinned

eIFc •.:1 or IIw

Il'll);lh III 111<:,lfU!.

Tn

pn..:dkt the l>w:lling load .••.~ \\ ill u;,t: 111e Euler buckling

formulae. CriticLlI It' the LIS': (.rr till.! ELllel' fQnnuLl<:' i~ lhe

rnlio. \\hlch I'" Ihe ratio or lh~ lenglh ur lll.:

~lrul llJ ib n1diu~of g) ration tl/~). The Euler 10n11111,1I'

!;Jcndcl'ncss

Table 1 Results for Experiment

becum..: imtc.:cUt·ale Ill! "lrut:. \\'Ilh a (I/.. ratio 01 k:,,;, lhun

125 and thi~ ,houlcl

",allline

be: wken inln ac<.:ounl ill any dc"i~n

llppropriutc

4

[he ElIler huekling

parameter

1

cqUtlll11n

and ,dect

tll (;'~t.lbli~h a lincar

<In

relalion<;hi p

between the Ol.lckling IOJld and the length of the strut

(Him: remember rt, E and I arc ,III constan.ts).

Calculate Ihe\fuilles and enter t£lem into Table 1

Wilh an appropriate

tille. I'lot a graph to prove the

rcl.arionship is .linear. Compare your experimental value

to those c..'llclllaled from the ELller formula by entering n

theoretic<ll line OJllo the graph. Does the Euler formulu

predict the buckling load?

It wOllld be IIseful at Ihis stage to calculate the

gradient

of

the

experimental

results

for

use

ill

Experiment 2.

5

INDIAN INSTITUTE OF TECHNOLOGY, GUWAHATI

DEPARTMENT OF MECHANICAL ENGINEERING

LABORATORY SHEET

NAME:

ROLL No:

DATE OF EXPERIMENT:

Gr. No. :

DATE OF SUBMISSION:

EXPERIMENT: TORSION TEST.

OBJECTIVE: To obtain twisting moment-twist relationship of a mild steel specimen.

To determine shear modulus G, yield stress τy in pure shear, theoretical and experimental

ultimate torque based on elastic-perfectly plastic model of material.

APPARATUS AND PROCEDURE: Torsion Testing machine is used for conducting

torsion test on various metal wires, tubes and sheets. Mechanical machines have been

invariably used till now. To get more accurate results with convenience, electronic model

is utilized here. The torsion/ twist can be read on the read-out directly. The specimen is

held in chucks at both ends. The required torque is applied by the motor. Torque

transducer is fitted at the opposite end of the gear box. The angle of twist is obtained with

the help this assembly.

Suitable grips for the specimen should be inserted into the driving and driven chucks and

the specimen is griped. The ultimate torque shown on the read out is the maximum

capacity of the specimen.

OBSERVATION AND CALCULATION:

Diameter of the circular specimen D =

Length of specimen L =

m

m

The plot of T v/s θ is obtained from the attached printer.

In the linear elastic range, for small deformation, the twisting moment T, rate of twist

θ/L, shear modulus G and shear stress σxθ at radius r in a circular body subjected to pure

end torques is related by

σ xθ

r

=

T Gθ

,

=

J

L

J=

1

πR 4

2

=

πD 4

32

(1)

The shear modulus is obtained from equation (1), as

G=

32TL

=

θπD 4

Gpa.

For rectangular cross section shaft (a x b)

TL

kab 3 G

Where k is a constant which depends on the ratio a/b and is given below:

θ=

a/b

k

1.0

0.141

1.2

0.166

1.5

0.196

Twisting moment Ty =

2.0

0.209

2.5

0.249

kgf-m=

16T y

πD 3

=

4.0

0.281

5.0

0.291

10.0

0.312

Nm

∴τ y in shear =

Eq. (1) => For Ty, σxθ at R= yield stress,

τy =

3.0

0.263

Ty R

J

Mpa

Ultimate Torque Tu from experiment =

Kgf-m =

Nm

Fully plastic twisting moment Tp (also called as theoretical ultimate torque), for perfectly

elastic material is given by

R

T p = ∫ r {τ y 2πrdr} =

0

2πR 3τ y

3

=

Nm

Compute the ratios (Tp/Ty), (Tu/Ty) and (Tu/Tp)

Exercise:

i)

ii)

Compare τy from torsion test with τy from UTM test and comment on your

result.

Derive the analytical expression for torque v/s angle, i.e. T v/s θ for an elasticplastic (perfectly) material with torque lying between Ty and Tp i.e.

Ty<T<Tp

2

60 deg center hole (type)

O 7.1

14.2

10

35

120

35

Specimen for Torsion Test

Material: MS

(Torsion test sample is made from 10 mm sq bars of MS and Annealed at 7450C for 45 minutes and then Furnace Cooled.)

All dimensions are in mm.

3

INDIAN INSTITUTE OF TECHNOLOGY, GUWAHATI

DEPARTMENT OF MECHANICAL ENGINEERING

LABORATORY SHEET

NAME:

ROLL NO:

Gr. No:

DATE OF EXPERIMENT :

DATE OF SUBMISSION :

EXPERIMENT: Thin Cylinder apparatus

SECTION 1.0 INTRODUCTION AND DESCRIPTION

Introduction

All engineers need to know how to predict the effects of stress on common shapes. They can use this

information to decide the right type and thickness of materials for their own designs. This Thin Cylinder

shows students the strains in the surface of a, thin-walled cylinder when it is under stress from an internal

pressure. This arrangement is similar to many 'real world' applications, including

pressure pipes, aircraft fuselages and compressed gas cylinders.

The Thin Cylinder apparatus also teaches students about:

• A biaxial stress system.

• The use of strain gauges.

• Young's Modulus.

• Poisson's Ratio.

• Construction and use of a Mohr's Circle.

Description

The Thin Cylinder (SMl 007) is a thin-walled aluminium alloy cylinder. Inside each end of the cylinder is

a free-moving piston. The cylinder sits inside a sturdy frame, on the top of a steel box. The steel box

contains electrical equipment that works the electronic strain gauge display and circuits that can link to

1

TecQuipment's optional VDAS. VDAS will allow data acquisition with the use of a suitable computer.

Fixed to the surface of the cylinder is a set of electrical strain gauges. A digital display on the front of the

apparatus shows the strain measured by each gauge.

To apply internal pressure to the cylinder, students use a hydraulic Hand Pump to force oil into the

cylinder. A mechanical Bourdon type pressure gauge shows the oil pressure in the cylinder. Fitted as

standard to the pressure line is an electronic pressure transducer, for connection to TecQuipment's

optional VDAS. The Hand Pump includes a Pressure Control for the operator to control the pressure in

the cylinder and a built-in pressure relief valve to help prevent damage to the equipment. The body of

the Hand Pump is the oil reservoir.

Open and Closed Ends

A Hand Wheel at the end of the frame sets the cylinder for the open and Closed Ends experiments.

• When the user screws in the Hand Wheel, it clamps the free-moving pistons in the cylinder.

The frame then takes the axial (longitudinal) stress and not the cylinder wall, as if the cylinder

has no ends. This allows 'Open Ends' experiments (see Figure 3).

• When the user unscrews the Hand Wheel, the pistons push against caps at the end of the

cylinder and become 'Closed Ends' of the cylinder. The cylinder wall then takes the axial

(longitudinal) stress (see Figure 4).

2

Strain Gauges

Figure 5 Strain Gauge Positions

The Strain Gauges are sensors that measure the strains in the walls of the thin cylinder. Their use is

important to engineers that work with structures. Strain gauges are electrical sensors. Their electrical

resistance changes when an external force stretches or compresses them. This change in resistance has a

direct relationship with displacement (strain). Strain gauges are small sheets of metal foil cut in a zigzag

pattern. They are only a few microns thick so they are mounted on a backing sheet, for mechanical stability

and electrical insulation. Gauges are bonded to the surface of the structural part under examination. The

strain gauge stretches and compresses with the surface of the part that they are stuck to. To give a direct

reading of strain, the reading from a strain gauge is multiplied by a constant called the

gauge factor. This compensates for the slight differences in manufacture between each batch of gauges.

The gauge factor usually varies between 1.8 and 2.2. TecQuipment set the gauge factor into the electronic

circuits of the SMl 007, so you do not need to allow for it in your readings. There are six strain gauges on

the cylinder, arranged at various angles to allow the study of how the strain varies at different angles to the

axis (see Figure 5). The strain display on the front of the equipment shows the readings from each strain

gauge in ).1£ (microstrain). The display shows only four readings at a time, so you must use the 'Scroll

Readings' button to scroll up and down to see all six values. Note that

a negative reading is a compressive strain and a positive reading is a tensile strain.

Versatile Data Acquisition System (VDAS)

Figure 6 The VDAS Hardware and Software

3

Technical Details:

Notation:

This section only gives the basic information needed to do the

experiments. For full theory, refer to the textbooks

Noise Levels: The noise levels recorded at this

apparatus are less than 70 dB (A).

* Strain is a ratio of dimensions and has no units. The Thin

Cylinder display shows a traditional unit, the

‘µ€' (micro-strain) which is the strain value x 10-6.

Useful Equations

4

Theory:

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

SECTION 2: EXPERIMENTS

Experiment 1: Deflection of a Cantilever

Remove any clamps and knife edges from the

backboard. Set up one of the cantilevers as shown in

Figure 3.

Slide the digital dial test indicator to the position on

the beam shown in Figure 3, and lock it using the

thumb nut at the rear. Slide a knife-edge hanger to the

position shown.

Tap the frame lightly and zero the digital dial test

indicator using the 'origin' button.

Apply masses to the knife-edge hanger in the

increments shown in Table 1. Tap the frame lightly each

time you add the masses. Record the digital dial test

indicator reading for each increment of mass.

Repeat the procedure for the other two materials and

fill in a new table.

In this experiment, we will examine the deflection of a

cantilever subjected to an increasing point load. We will

repeat this for three different materials to see if their

deflection properties vary.

m

I:

2

I

Material

Width

b: d:

Depth

4

Nm

mm

mm

Evalue:

w

Mass

Figure 3 Cantilever set-up

schematic

0 and (g)

Actual

deflection

Theoretical

deflection

(mm)

(mm)

100

200

400

300

500

You may find the following table useful in converting

the masses used in the experiments to loads.

Mass (Grams)

0.98

2.94

4.90

3.92

1.96 (Newtons)

Load

Table 1 Results for Experiment 1 (beam 1)

Table 1 Grams to Newtons conversion table

I:

m

I

-2

Material

Width

Depthb:d:

4

Nm

mm

mm

Evalue:

As well as the information given on the backboard you

will need the following formula:

Deflection

WL3

3E1

Mass

0

(g)

Actual

deflection

Theoretical

deflection

(mm)

(mm)

100

400

300

200

500

where:

W=Load (N)

L = Distance from support to position of loading

(m);

E = Young's modulus for cantilever material (Nm-2);

= Second moment of area of the cantilever (m\

1

Using a vernier gauge, measure the width and depth of

the aluminium, brass and steel test beams. Record the

values next to the results tables for each material and

use them to calculate the second moment of area, 1.

Table 2 Results for Experiment

Page 3

1 (beam 2)

TecQuipment

m

Deflections

of Beams and Cantilevers:

I

4 -2

mm

Width b:

NmMaterialDepth

d:

mm

value:

Mass

Actual(mm)

deflection

Theoretical

(mm)

deflection

100

400

300

200

500

Table 3 Results for Experiment

Student Guide

On the same axis, plot a graph of Deflection versus

Mass for all three beams. Comment on the relationship

between the mass and the beam deflection. Is there a

relationship between the gradient of the line for each

graph and the modulus of the material?

Calculate the theoretical deflection for each beam

and add the results to your table and the graph. Does the

equation accurately predict the behaviour of the beam?

Why is it a good idea to tap the frame each time we

take a reading from the digital dial test indicator?

Name at least three practical applications of a

cantilever structure.

1 (beam 3)

Page 4

TecQuipment

Deflections

of Beams and Cantilevers:

Student

Guide

Experiment 2: Deflection of a Simply Supported Beam

In this experiment, we will examine the deflection of am

I:

simply supported

beam subjected to an increasing point

load. We will also vary the beam length by changing the

distance between the supports. This means we can find

out the relationship between the deflection and the

(g)

0

length ofthe beam.

As well as the information given on the backboard

you will need the following formula:

Maximum deflection =

4

Mass

mm

mm

Nm-2

Evalue: Depth

Widthd: b:

Actual(mm)

deflection

Theoretical

(mm)

deflection

100

200

300

500

400

WL3

48E1

where:

W= Load (N);

L = Distance from support to support (m);

E = Young's modulus for cantilever material (Nm-2);

1 = Second moment of area of the cantilever (m\

Table 4 Results for Experiment 2 (fixed beam

length variable load)

Part 2

Part 1

Using a vernier gauge, measure the width and depth of

the aluminium test beam. Record the values next to the

results table and use them to calculate the second

moment of area, 1.

Remove any clamps from the backboard. Setting

length between supports I to 400 mm, set up the beam

as shown in Figure 4.

Set up the beam with the length I at 200 mm. Ensure the

digital dial test indicator and load hanger are still central

to the beam, as shown in Figure 5.

r'o2rl

r--A

f-H.~

mm-I

f-o--200 mm-r---200

1= 400

tw

DDA

mm---"

A

Figure 4 Simply supported beam set-up and

schematic (fixed beam with variable load)

Slide the digital dial test indicator into position on the

beam and lock it using the thumb nut at the rear. Slide a

knife-edge hanger to the position shown.

Tap the frame lightly and zero the digital dial test

indicator using the 'origin' button.

Apply masses to the knife-edge hanger in the

increments shown in the results table. Tap the frame

lightly each time, and record the digital dial test

indicator reading for each increment of mass.

I

w

ADD

Figure 5 Simply supported beam set-up and

schematic (fixed beam load with variable length)

Lightly tap the frame and zero the digital dial test

indicator using the 'origin' button. Apply a 500 g mass

and record the deflection in Table 5. Repeat the

procedure for each increment of beam length.

From Table 4 plot a graph of Deflection versus

Applied Mass for a simply supported beam. Comment

on the your graph. Inspect the ruling equation of the

beam. What is the relationship between the deflection

and the beam length? Test your assumption by filling in

the empty column of Table 5 with the correct variable.

Plot a graph.

Page 5

TecQuipment

Length (mm)

Deflections of Beams and Cantilevers: Student Guide

Name at least one example where this type of bending is

desirable and one where it is undesirable.

Deflection (mm)

380

320

260

560

500

440

Table 5 Results for Experiment 2 (fixed beam load

variable length)

Page 6

INDIAN INSTITUTE OF TECHNOLOGY, GUWAHATI

DEPARTMENT OF MECHANICAL ENGINEERING

LABORATORY SHEET

NAME:

ROLL No.:

DATE OF EXPERIMENT:

Gr.No. :

DATE OF SUBMISSION:

EXPERIMENT: HARDNESS TEST

OBJECTIVE: To determine the hardness of a given set of specimens by (i) Brinell

(ii) Vickers and (iii) Rockwell hardness testing machines.

APPARATUS:

1. Brinell hardness testing machine, 5mm and 10mm diameter steel ball

indentors, microscope.

2. Vickers hardness testing machine, diamond pyramid indentor, microscope.

3. Rockwell machine, loads and indentors: 1/16 inch diameter steel ball indentor and

diamond indentor 120o cone angle.

THEORY AND PROCEDURE:

Hardness of a material has been defined in various ways as the resistant of it’s surface to

plastic deformation, cutting, wear, scratching, abrasion, indentation or energy absorption

under impact. Hardness depends on crystal structure, dislocations, atomic bonds etc.

Indentation Hardness Test is one of the most frequently used non destructive tests for

quality control of machine parts or structural members to ensure that the specific piece

does have the material property used in design. It is a quick and inexpensive test and

information about yield stress. It is presumed that if the hardness is within certain bounds

then so are the other properties.

In Indentation Hardness Test, a pyramid, cone or ball is pressed into a flat surface by

gradual application of a load to produce a permanent indentation. Restraint of the

1

surrounding undeformed material means that most of the applied load merely developed

hydrostatic compressive stress which does not cause the metal to deform plastically. For

plain carbon and low steel alloy steels, the ultimate tensile strength (in Mpa) can be

estimated by multiplying BHN by 3.45. For other materials, relationship will be different

and may exhibit too much variation to be dependable. The most common indentation

hardness test are:

Brinell test: A 5mm or 10mm diameter (D) hardened steel or tungsten carbide sphere is

pressed into the flat surface of a test specimen under a load P of 250 Kgf, 500 Kgf,

700Kgf, 1000Kgf or 3000Kgf. The load is removed automatically after appliction or

preset time and diameter d of the indentation is measured by a microscope. Brinell

hardness number BHN is defined in Kgf/ mm2 as force per unit surface area Ac

P

2P

BHN=

(1)

=

Ac πD D − D 2 − d 2

[

]

P= 3000Kgf and 10mm steel indentor are used in a standard test. If a material is soft, load

(250 to 3000 kgf) and diameter D of ball should be adjusted to keep

d

within 0.3 to 0.5.

D

For BHN > 500Kgf/ mm2 , Tungsten cabide ball should be used. Nearest edge of the

specimen should be at a distance > 2.5d and thickness of specimen be > 5d to avoid

spurious side and bottom effects. The spherical indentor, unlike conical and pyramidal

indentors, does not provide geometrical similitude for indentations of different size d.

The BHN of a given material is not constant for all values of

d

D

due to the varying

inclination at the top of a spherical sector.

Vickers test: A diamond pyramid with a square base and a angle of 136o±0.5 between

2

opposite faces is used as an indentor. The Vickers Hardness value is defined by

V=

P 1.854 P

=

Kgf/mm2

2

Ac

dm

(2)

where dm is the mean diagonal of the square indentation.

Rockwell Test: A hard steel spherical ball of diameter 1.588mm (1/16 in) or a diamond

conical indentor (120o angle) is forced into the surface and the depth of indentation is

read on a electronic display. A minor load is applied to provide a firm contact with the

surface till display shows ‘SET’. The major (total) load is then automatically applied for

a preset time. To eliminate elastic effects the net change in penetration ∆ mm is measured

automatically after returning the load to minor value. The Rockwell hardness number

defined by the following equation, can be read directly from the electronic display:

R = C1- C2 ∆

(3)

Various scales use different indentors, loads, C1 and C2. The most common are the

Rockwell C (cone) 20-70 RC and Rockwell B (ball) 30-100 RB scales, used or hard

(or RB > 100) and soft metals respectively:

Table 1

Scale

Indentor

RB

1/16’’ or

1.588mm

Hard steel ball

Diamond

cone 120o

RC

Minor

(Preload)

Kgf

10

10

Major

(Total load) Kgf

Relation to Brinell

hardness BHN

100

RB= 130-500 ∆

RB ≅ 134-6700/BHN

150

RC= 100-500 ∆

RC ≅ 115-1500/√BHN

3

OBSERVATION AND CALCULATION

The captioned sketches of the three machines are given in Fig. 1, 2 and 3.

1.BHN:

Flat polished specimen.

Dia. of indentor D =

mm

The diameter d of the indentation for different loads P is tabulated in table 2 and BHN

computed by (1): The BHN vs load P is plotted in fig 4.

P kgf

d mm

BHN kgf/ mm2

P kgf

d mm

BHN kgf/ mm2

P kgf

d mm

BHN kgf/ mm2

If d/ D for P = 3000 kgf is in the range 0.3 to 0.5, then P1= 3000 kgf, else from table 2

choose a load P1 for which d/ D ≅ 0.4 and take three indentations corresponding to this

load :

P1=

kgf

mean d =

mm

kgf/ mm2

BHN for material ( from P1 and d ) =

Approx. ultimate tensile strength σu = 3.45 X BHN =

4

Mpa

2. Vickers: The observations for various materials are tabulated in Table 3

Table 3

Material to be

tested

Load : kgf

Diagonal dimension of

indentation

d1

d2

VHN

Mean

VHN

Mean

dm

3. Rockwell: The observations for various specimens are tabulated in Table 4.

Table 4

Specimen

Scale

Indentor

Rockwell hardness

(2)

(3)

(4)

(5)

(1)

5

Average

Write discussion and sources of errors:

EXERCISE : ( T o be submitted with the report )

1.Thickness of a strip is reduced in a cold rolling operation. How the hardness of the strip

is compared with its hardness before rolling and why ?

2. Why are hardness testing s used so frequently ?

3. Define BHN, Vickers diamond hardness number and Rockwell hardness numbers.

4. Why is it necessary to stipulate different loads P for finding BHN of two different class

of materials, say brass and steel ?

5. List the main advantages of Vickers diamond test over Brinell test.

6. Find Vickers diamond hardness number of Al if diagonal lengths of impression for

indenting load of 2.5 kgf are 0.363mm and 0.361mm. What size diamond impression

would be made in the same material under indenting load of 5 Kgf ?

7. What is the need and role of minor load in Rockwell test in contrast to the other

hardness tests ?

8. Why is the reading in the Rockwell test taken after removal of major load but when the

minor load is still acting?

9. What is wrong with the test result “Rockwell hardness of steel is 64”?

10. In a Brinell test on annealed Cu with 5 mm dia. ball, the reading of d are 2.2, 2.7 and

3.1 mm for loads of 125, 250 and 350 kgf. Find BHN. What would be the diameter of

impression for a load of 300 kgf?

6

INDIAN INSTITUTE OF TECHNOLOGY, GUWAHATI

DEPARTMENT OF MECHANICAL ENGINEERING

LABORATORY SHEET

NAME:

ROLL No.:

DATE OF EXPERIMENT:

Gr.No. :

DATE OF SUBMISSION:

EXPERIMENT: IZOD AND CHARPY IMPACT TEST

Objective; To study the toughness or energy absorbing properties of various materials

under two types of impact tests i.e. Izod and Charpy impact tests.

Theory and background: So far we have learned about quasi-static tests on materials

wherein load is so slowly applied that the inertia is ignored. Under dynamic test the rate

of application of the load is many times faster than in the quasi-static cases. The behavior

of the material may change substantially under these conditions of loading especially in

the presence of stress concentrations around notches and at low temperatures, i.e. a

ductile material (under static loading) may become brittle.

(A) Fracture: Fracture is the separation of body under stress into two or more parts.

The fracture is considered brittle if the microcracks propagate rapidly with

minimum absorption of energy and negligible plastic deformation. In single

crystals brittle fracture accompanies cleavage along the weakest crystal plane. In

polycrystalline materials the fracture surface is granulated and rough in

appearance. According to Griffith, failure in brittle materials is caused by crack

propagation due to stress concentration at the tips of existing microcracks.

Ductile fracture occurs after considerable plastic deformation, accompanied by

slipping at intergranular boundaries. Such fracture begins with the formation of

voids in the materials, generally at non-metallic inclusions. Under continually

increasing loads these voids propagates to the surface and causes failure.

(B) IMPACT TESTING: The ordinary static testing is not satisfactory when we

want to determine the suitability of a material to resist sudden shock or impact.

Machines have been designed in which a specimen receives a simple shock and

the energy absorbed by the specimen is taken as the measure of the resistance of

the material to impact, or its dynamic toughness. The impact used in our

laboratory has the provision of carrying out two impact tests (i.e.Izod and

Charpy) by changing the support attachment and striker head. It has a swinging

pendulum with a fixed weight, with different starting positions for the two tests,

giving different initial potential energies.

1

(B1) IZOD TEST (Bending of a notched cantilever) : This test uses a 10mm x 10mm

Cantilever test piece of total length 75mm. A “V” notch is provided at 28mm

from one end, the depth of the notch is 2mm, its angle is 45o and its root radius is

0.25mm. The specimen is fixed vertically at the base; the cantilever portion above the

notch is 28mm long. The hammer strikes near the top of the specimen(6mm from tip)

and then moves further after the fracture of the specimen. The difference of the

potential energy between the initial and final positions of the hammer gives the

energy absorbed in the impact. A rotating pointer on the scale records this difference

directly.

(B2) CHARPY TEST: (Bending of a simply supported beam): The specimen used

for Charpy test, like the Izod test is 10mm x 10mm in section and has a 2mm wide,

5mm deep U-shaped notch. The length of the specimen is 55mm and notch is at its

center. The beam is supported horizontally by two standard supports and hammer

strikes it at the center from the notch less side. Thus tensile stresses at the notch tend

to open the notch and cause failure.

TEST DETAILS:

1. Temperature is a very important factor in the measurement of toughness. Most

materials show loss of toughness with the fall off room temperature. Reduced

temperature in many metals and polymers can lead to increase in yield stress

relative to fracture stress in tension. Hence the metal fractures like a brittle

material instead of like a ductile material. There are generally three regions. At

low temperature the materials give brittle fracture with little change in toughness

with temperature. This is low toughness low temperature region. Then there is a

transition range with rapid increase in toughness with temperature and finally we

have the high toughness high temperature region, showing little change in

toughness with temperature. The change from ductile yielding to brittle structure

can be quite abrupt and is referred to as the ductile-brittle transition temperature.

Conduct Charpy test for some material at room temperature and after cooling the

specimen to 0oC.

2. Brittle fracture and ductile fracture have characteristic appearances and can be

easily recognized.

3. Large value of stress concentration in marginally ductile material, particularly

notch-type concentrations can lead to brittle failure. The high rate of strain can

cause yield stress σy and the stress concentration can introduce hydrostatic

tension, reducing fracture stress σf in tension. Both effects promote brittle

behavior. Materials that are sensitive to this effect are called notch sensitive.

4

Accuracy of the notch is also an important factor. Small changes in the shape,root

radius and finish of the notch may create large difference in the test results.

5

Positioning of the specimen in the machine is important but is generally done by

a template.

2

OBSERVATIONS AND CALCULATIONS:

CHARPY1 and CHARPY2 refer to specimen at room temperature ,CHARPY3

refer to specimen at ice cooled and heated at100 oC respectively.

SPECIFICATION

Temp.

Material

Length

Breadth

Diagonal

Notch position

Notch angle

Root radius

Initial energy of

hammer

Final energy of

hammer

Energy absorbed

Type of fracture.

IZOD

Room

CHARPY1

Room(H)

CHARPY2

Room(A)

CHARPY3

……oC (A)

NOTCH IMPACT TESTS: Notch impact tests are used as quality

control/acceptance checks. These are relatively simple and are easy and rapid to

conduct. A fast moving hammer strikes a test specimen containing a milled notch,

and the energy absorbed in fracturing the test piece is measured. The ductilebrittle transition temperature is considerably higher for impact loading conditions

than for slow strain rate conditions. It is comparatively easy to determine the

transition temperature range under impact loading conditions, as there is a very

large difference between the energy required to cause ductile and brittle fractures

in this type of test. Another major use of notch impact test is to find whether heat

treatments have been carried out successfully.

DISCUSSION OF RESULT AND SOURCES OF ERROR:

EXERCISE

1. Which parameter of the notch geometry is most important factor influencing the

notch impact values?

2. Define clearly ductile and brittle fractures?

3. What are the main reasons for using notch impact test?

4. What is the major advantage of Charpy test over Izod test?

5. What is the basic difference between Izod and Charpy test?

3

1.00R±.07

1

10 +.1

-0

55 +.6

-0

Root Radius 1.00±.07

5

5

10 +.11

-.11

2

5

Specimen for Charpy Impact Test

Enlarged section of 'U' notch of

square specimen

Included angle 45°

Root Radius

0.25mm

10

10

8

10

22

28

Enlarged section of "V" notch of square

specimen

75

Specimen for Izod Impact Test

(Material: MS)

All dimensions are in mm.

4

INDIAN INSTITUTE OF TECHNOLOGY, GUWAHATI

DEPARTMENT OF MECHANICAL ENGINEERING

LABORATORY SHEET

NAME:

ROLL No.:

DATE OF EXPERIMENT:

Gr. No.:

DATE OF SUBMISSION:

PHOTOELASTICITY

1. Objectives

The objectives of this experiment are

1. To introduce a very fundamental and most important experimental technique to view the principal stress

components and directions of principal stresses– the photoelastic method

2. To use the photoelastic technique for the direct measurement of principal stresses for the plane stress

condition at any given point in the sample.

3. To view the map of principal directions at any given point in the sample.

2. Introduction

Photoelasticity is an experimental technique for stress analysis that is particularly useful for members having

complicated geometry, complicated loading conditions, or both. For such cases, analytical methods (that is,

strictly mathematical methods) may be cumbersome or impossible, and analysis by an experimental approach

maybe more appropriate. The name photoelasticity reflects the nature of this experimental method: photo

implies the use of light rays and optical techniques, while elasticity depicts the study of stresses and

deformations in elastic bodies.

The essential feature of this method is that one can visualize the distribution of principal stresses and

their directions at all infinite number of points of the sample under study. Moreover, this technique provides

quantitative evidence of highly stressed areas at which most of the failures usually originates. On the other hand,

often equally important, it also shows the areas of low stress level where structural material is utilized

inefficiently. This technique has been widely used to aid in development of correct analytical methods for

complex stress analysis problems.

3. The Polariscope

The most common equipment for photoelastic studies of engineering components is the polariscope. Polariscope

utilizes the properties of polarized light. There are two basic types of polariscopes, plane polariscopes and

circular polariscopes. The polariscope used for this laboratory can be configured as either. However we use

circular polariscope for laboratory work.

4. Photoelastic behavior

The photoelastic method is based upon a unique property of some transparent materials, in particular, certain

plastics. This property is known as birefringent property. Consider a model of some structural part made from a

photoelastic (birefringent) material. When the model is stressed and a ray of light enters the sample two

phenomena takes place due to change in optical properties of the sample

[1]

At each point of the stressed body the light wave is resolved into two mutually perpendicular

components lying in the planes of the principal stresses occurring at that point.

1

[2]

The linear velocity of each of the components of the light wave is retarded through the stresses

specimen in direct proportion to the difference in the principal stresses.

These facts are the basis of the photoelastic method stress analysis. This phenomenon is called double refraction

or birefringence, and is the same as exhibited by certain optical crystals — but in photoelasticity the double

refraction is artificial, being controlled by the state of stress or strain at each point in the body.

4. Isoclinic and Isochromatic lines

Once the state of the stress at each point of a stressed body is available, many visual interpretations of the

various aspects of the available data can be made. For example, the points of algebraically equal principal

stresses regardless of their sense, when connected, provide a map of stress contours. Thus any point lying on a

stress contour has a principal stress of the same algebraic magnitude. Similarly, the points at which the

directions of the minimum principal stresses form a constant angle with the x axis may be connected. This

means that the direction of the maximum principal stresses through the same points also forms a constant angle

with the x axis. The line so connected is a locus of points along which the principal stresses have parallel

directions. Such line is called an isoclinic line. Similarly a line that is a locus of points along which the

difference in principal stresses (σ 1 − σ 2 ) remains constant is called an isochromatic line. Basically we can

visualize the isoclinic lines and isochromatic lines of a stressed member using polariscope.

5. Photoelasticity terminologies

a. White light: Light from a source that emits a continuous spectrum with nearly equal energy for every

b.

wavelength.

Monochromatic light: Light of a single wavelength such as light emitted by sodium vapor lamps.

c.

Plane Polarized light: Light that is restricted to vibrate in a single plane

d.

Plane Polarizer: Optical element that generates polarized light along its axis of polarization. Light

waves perpendicular to axis of the polarization are absorbed.

e.

Analyzer: It is also a plane polarizer except that it is near the user or analyst and hence its name. The

Polariscope consists of a polarizer at the source of light and another polarizer at the user or analyst side.

f.

The one that is at the light source is termed as polarizer and the other one is termed as analyzer.

Quarter-wave plate: A wave plate is an optical element which has the ability to resolve a light vector

into two orthogonal components and to transmit the components with different velocities. Specifically

if the phase lag is by an amount of one quarter of the wave length then the wave plate is termed as

quarter wave plate. Quarter wave plates are employed in polariscopes in order to condition the light.

6. Circular polariscope

The setup of the circular polariscope is illustrated in Fig. 1. Figure 2 shows a schematic diagram of the circular

polariscope. The circular polariscope contains four optical elements. The first element following the light source

is the polarizer. It converts the ordinary light into plane-polarize light. The second element is a quarter wave

plate set an angle 450 to the plane polarization. This quarter wave plate converts the plane polarized light into

circularly polarized light and hence the name circular polariscope. The second quarter wave plate is set with its

fast axis parallel to the slow axis of the first quarter wave plate. The purpose of this element is to convert the

circularly polarized light into plane polarized light vibrating in the vertical plane. The last element is the

analyzer (another polarizer) with its axis of polarization horizontal (opposite to the axis of polarizer see Fig. 2)

and its purpose is to extinguish the light.

As a result of photoelastic effect the light exits the stressed sample with two light vectors E1 and E2

parallel to the directions of principal directions at that point with a phase shift. These rays finally passes through

2

the analyzer (after crossing quarter wave plate) which allows only the components of light parallel to the axis of

polarization and thus permit them to come to optical interference. Due to photoelastic effect one of the rays of

E1 and E2 is retarded relative to other by an amount directly proportional to the principal stress difference at that

point. If the relative retardation N is 0, 1, 2, 3,... cycles, the waves reinforce each other, and the combined effect

is a large light intensity. If the phase difference N is 1/2, 3/2, 5/2, 7/2,... cycles, the amplitude of the two

interfering waves is everywhere equal and opposite; destructive interference ensues, and the light intensity

diminishes to zero (extinction)

Fig. 1 Basic set-up of circular polariscope

Fig. 2. Schematic diagram of the circular polariscope.

Intermediate intensities are developed for intermediate values of N. Thus, a photoelastic pattern of dark and light

bands, such as shown in Fig. 3 (typical), is formed as follows: the locus of points at which N = 0 forms a dark

band: the locus of points at which N = 1/2 forms an adjacent light band; another dark band is formed by rays

traversing the photoelastic material at points where N = 1; and successive dark and light bands are formed for

increasing values of N. In the nomenclature of optical interference, these bands are called fringes. These fringes

which are formed due to interference of two different velocity waves are known as isochromatic fringes. Thus

Fig. 3 shows the locus of points along which the difference between the two principal stresses remains constant.

It should be noted that if the bands corresponding to N = 0, 1, 2, etc., are dark then band corresponding to

N=1/2, 2/3 etc must be light. This arrangement is called as dark field arrangement.

3

Fig.3 A typical isochromatic fringes

7. Analysis of Isochromatic fringe pattern

Let us view a plane-stress model in a circular polariscope. A pattern of dark and light bands (Fig. 6) forms in the

viewing screen when external forces or loads are applied to the model, and the number of these bands increases

in proportion to the external forces.

Fig.6 Formation of isochromatic patterns for increasing loads.

The isochromatic pattern is related to the stress system by the stress-optic law. Namely

σ1 − σ 2 =

f

N

t

(1)

where f is the stress-optical coefficient (Kg/cm), a constant that depends upon the model material and the

wavelength of light employed, t(cm) is the model thickness, and N is the relative retardation of rays forming the

pattern. The term N is also known as isochromatic fringe order. The fringe order, N, is defined as the number of

cycles of relative retardation between two components of a light beam passing through the stressed model.

Equation (1) states that the relative retardation, N, at each point in the model is directly proportional to the

difference of principal stresses σ 1 − σ 2 at the point. Thus isochromatics are locus of points at which σ 1 − σ 2

are constant. However we also know that the difference σ 1 − σ 2 is equals to two times the maximum shear

stress at that point

σ 1 − σ 2 = 2τ max =

f

N

t

Thus isochromatics are also locus of constant maximum shear stress points on the stressed model.

4

(2)

8. Difference between plane and circular polariscope.

Quarter wave plates are absent in plane polariscope. You can see only isochromatic patterns in circular

polariscope. Plane polariscope provides both isochromatic and isoclinic lines such that it is difficult to

distinguish them. Therefore, generally plane polariscope set up is used to determine the principal stress

directions at different points in the stressed sample. In order to find the magnitude of principal stresses circular

polariscope is used. Both the set-ups can be obtained using the present polariscope.

9. Monochromatic light and white light source

One can use either monochromatic or white light for viewing the isochromatics/isoclinics. Monochromatic light

produces dark and light bands a single color. It is very easy to distinguish dark and light bands (and hence

determination of fringe order N) of a single color and hence monochromatic light is generally employed in

photoelastic studies. Since the white light contains wavelengths of entire spectrum, isochromatic fringe patterns

appear in different colors. It is relatively difficult to estimate the fringe order from the colored isochromatic

fringe patterns. With white light, isoclinics appear in black color.

10. Experimental procedure

Fig. 7 A simply supported beam

In order to understand the principles of photoelastic method the following laboratory experiment will be

conducted

1.

A simply supported beam subjected to two concentrated forces placed at equal distance from the

supports as shown in Fig. 7.

2.

The direction and magnitude of principal stresses at any point within the beam can be computed if the

applied loads and cross-sectional properties are known.

3.

4.

Turn-on the monochromatic light switch and wait for 20 minutes

Adjust, analyzer and two quarter-wave plates to form a circular polariscope

5.

6.

Keep the specimen at the center of the loading frame

With no load observed the beam. No isochromatics can be identified as the difference between

principal stresses is zero everywhere.

7.

Place 1, 2 and 2 Kg of weight in the weighing pan in order. Observe formation of fringes with

increasing load. You will also see some dark fringes at the supports and loading points.

8.

Add 5 Kg of weight in the weighing pan and observe the formation more isochromatic fringes with

N=0 fringe at the center of the beam i.e., neutral axis.

9.

Determine the fringe order of the dark fringe at the sample point 1 on the beam (a red mark is placed on

the beam sample). This fringe order corresponds to 6 Kg weight in the weighing pan.

5

10. Add 6 more Kg of weight gently to the existing weights. Observe the formation of more number of

fringes on both tensile and compressive side. However you can see always a fringe at neutral axis

which represent N=0 fringe.

11. Determine the fringe order of the dark fringe at the two sampling points 1 and 2 on the beam. These

fringe orders correspond to 13 Kg weight in the weighing pan.

12. Obtain the stress-optical coefficient, thickness, dimensions of the beam and dimensions of the lever (to

which weighing pan is attached).

13. Calculate the experimental values of principal stresses at the sampling points 1 for the loads

corresponding to 6 Kg and at sampling points 1 and 2 corresponding to 13 Kg. Note that the weights in

the weighing pan are not equal to the applied forces Ps on the simply supported beam (Fig. 7).

14. Calculate using elementary beam theory the principal stresses at the sampling points 1 and 2 for

different loads and compare with experimentally obtained values.

15. Turn the quarter-wave plates for plane polariscope set up. Switch off monochromatic light and wait for

10 minutes. Switch of the fan. Turn on the white light. You can see now the colored isochromatic

fringe pattern due to the white light and isoclinic lines simultaneously. Turn the front knob to see the

changing isoclinics.

16. Prepare the following tables of results

17. All neat and systematic calculations for filling up the following tables must be attached with this

manual.

Table 1: Properties of simply supported beam

t (cm)

h (cm)

I (cm4)

L1 (cm)

L2(cm)

P value for 6 Kg in weighing pan

P value for 13 Kg

Distance from the neutral axis of

Sampling point 1 (y1)

Distance

from

neutral

axis

of

f ( Kg / cm)

of

Sampling point 2 (y2)

Optical

constant

stressed sample

6

Table 2: Fringe orders at the sampling points for different loads

Sampling Point

Fringe order N at

5 Kg

13 Kg

1

2

----------------

Table 3. Comparison of theoretical and experimental results

Sampling

5 Kg

13 Kg

Point

Theoretical Experimental Theoretical Experimental

results

results

results

results

σ1

σ1

σ1

σ1

( Kg / cm 2 )

( Kg / cm 2 )

( Kg / cm 2 )

( Kg / cm 2 )

--------

---------

1

2

7

INDIAN INSTITUTE OF TECHNOLOGY, GUWAHATI

DEPARTMENT OF MECHANICAL ENGINEERING

LABORATORY SHEET

NAME :

ROLL NO :

GROUP NO :

DATE OF EXPERIMENT:

DATE OF SUBMISSION:

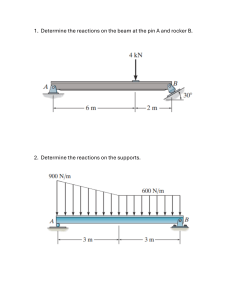

EXPERIMENT: Bending stress in a beam experiment in the structures frame

SECTION 1.0 INTRODUCTION AND DESCRIPTION

Introduction

This guide describes how to set up and perform Bending Stress in a Beam experiments. The equipment

clearly demonstrates the principles involved and gives practical support to your studies.

Description

Figure 1 shows the Bending Stress in a Beam experiment. It consists of an inverted aluminium T- beam,

with strain gauges fixed on the section (the front panel shows the exact positions).

The panel assembly and Load Cell apply load to the top of the beam at two positions each side of the strain

gauges. Loading the beam in this way (rather than loading the beam at just one point) has two main

advantages: It allows a gauge to be placed on the top of the beam. The constant bending moment area it

creates gives better strain gauge performance and avoids stress concentration close to the gauge positions.

Strain gauges are sensors that experience a change in electrical resistance when stretched or compressed.

Strain gauges are made from a metal foil formed in a zigzag pattern. They are only a few microns thick so

they are mounted on a backing sheet. The backing sheet electrically insulates the zigzag element and

supports it so it does not collapse when handled.

1

The T-beam has strain gauges bonded to it. These stretch and compress the same amount as the beam, so

measure strain in the beam. If you look carefully at the equipment you will notice there is another set of

strain gauges. These are called dummy gauges. The dummy gauges, and how the way they are connected in

the electrical circuit, help reduce inaccurate readings caused by temperature changes and thermal

expansion. The Digital Strain Display converts the change in electrical resistance of the strain gauges to

show it as displacement (strain). It shows all the strains sensed by the strain gauges, reading in micro strain.

Look at the reference information on the unit. It is useful and you may need it to complete the experiments

in this guide.

How to Set up the Equipment

The Bending Stress in a Beam experiment fits into a Test Frame. Figure 2 shows the Bending Stress in a

Beam experiment in the Frame. Before setting up and using the equipment, always: Visually inspect all

parts, including electrical leads, for damage or wear. Check electrical connections are correct and secure.

Check all components are secure and fastenings are sufficiently tight. Position the Test Frame safely. Make

sure it is on a solid, level surface, is steady, and easily accessible. Never apply excessive loads to any part

of the equipment.

The following instructions may already have been completed for you.

I. Place an assembled Test Frame (refer to the separate instructions supplied with the Test Frame if

necessary) on a Work bench. Make sure the 'window' of the Test Frame is easily accessible.

2. There are two securing nuts in each of the side members of the frame (on the inner track). Move one

securing nut from each side to the outer track (see STR 1 instruction sheet). Slide them to about the

positions shown in Figure 2. Fix the two supports on to the frame in the same position.

3. Slide two nuts into position to hold the load cell. Fix the load cell leaving the screws slightly loose.

4. Lift the beam into position and level the ends of the beam with the frame.

5. Position the load cell so the hole in the fork reaches the hole of the loading position, and it is vertical.

Tighten the load cell using the 6 mm A/F hexagonal key. Secure the fork using a pin.

6. Make sure the Digital Force Display is 'on'. Connect the mini DIN lead from 'Force Input l' on the

Digital Force Display to the socket marked' Force Output' on the left-hand side of the load cell.

7. With no load on the load cell (the pin should turn), use the control on the front of the load cell to set the

reading to around zero.

8. Make sure the Digital Strain Display is 'on' and set to gauge configuration I . Matching the number on

the lead to the number on the socket, connect the strain gauges to the strain display. Leave the gauges for

five minutes to warm up and reach a steady state.

2

3

SECTION 2.0 EXPERIMENTS

Ensure the beam and Load Cell are properly aligned. Turn the thumbwheel on the Load Cell to apply a

positive (downward) preload to the beam of about 100 N. Zero the Load Cell using the control. Take the

nine zero strain readings by choosing the number with the selector switch. Fill in Table I with the zero

force values. Increase the load to 100 N and note all nine of the strain

st

readings.

dings. Repeat the procedure in

100 N increments to 500 N. Finally; gradually release the load and preload.

Correct the strain reading values for zero (be careful with your signs!) and convert the load to a bending

moment then fill in Table 2.

From your results, plot a graph of strain against bending moment for all nine gauges (on the same graph).

4

What is the relationship between the bending moment and the strain at the various positions?

What do you notice about the strain gauge readings on opposite

opposite sides ofthe section? Should they be

identical?

If the readings are not identical, give two reasons why.

TABLE 1:

TABLE 2:

5

TABLE 3:

Calculate the average strains from the pairs of gauges and enter your results in Table 3 (disregard the zero

values).Carefully measures the actual strain gauge positions and enter the values into Table 3.

Plot the strain against the relative vertical position of the strain gauge pairs on the same graph for each

value of bending moment. Take the top of the beam as the datum.

Calculate the second moment of area and position of the neutral axis for the section (use a Vernier Caliper

to measure the exact size of the section) and add the position of the neutral axis to the plot.

• What is the value of strain at the neutral axis?

• Calculate the maximum stress in the section by turning the strains into stress values (at the maximum

load).Compare this to the theoretical value.

• Does the bending equation accurately predict the stress in the beam?

6