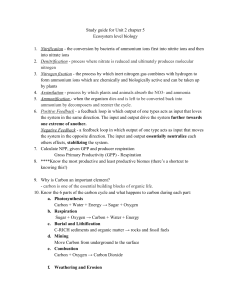

Ammonia & Sulfuric Acid Production: Haber & Contact Processes

advertisement

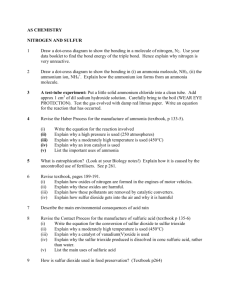

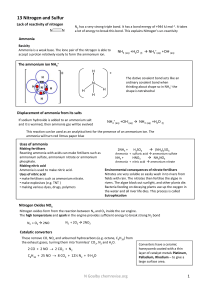

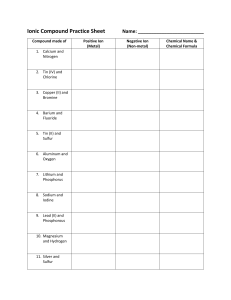

11/1/23 Manufacture of ammonia The Haber Process is used to manufacture ammonia, which is used to produce nitrogen-based fertilisers. The raw materials for the Haber process are nitrogen and hydrogen: 1. Nitrogen is obtained from the air and 2. hydrogen may be obtained from natural gas/hydrocarbons or steam • • • • • Stage 1: The gases are pumped into the compressor through pipes. Stage 2: The gases are compressed to about 200 atmospheres inside the compressor. Stage 3: The pressurized gases are pumped into a tank containing layers of catalytic iron beads at a temperature of 450°C. Some of the hydrogen and nitrogen react to form ammonia: N2(g) + 3H2(g) ⇌ 2NH3(g) Stage 4: Unreacted H2 and N2 and product ammonia pass into a cooling tank. The ammonia is liquefied and removed to pressurised storage vessels. Stage 5: the unreacted H2 and N2 gases are recycled back into the system and start over again. 26 Manufacture of ammonia 27 1 11/1/23 Manufacture of ammonia Since the reaction between nitrogen and hydrogen is reversible, there are some conditions which must be strictly maintained to make the process efficient. The conditions are: 1. Temperature 2. Pressure 28 Manufacture of ammonia Temperature: 450ºC • A higher temperature would favour the reverse reaction as it is endothermic (takes in heat) so a higher yield of reactants would be made. • If a lower temperature is used it favours the forward reaction as it is exothermic (releases heat) so a higher yield of products will be made. • However at a lower temperature the rate of reaction is very slow. • So 450ºC is a compromise temperature between having a lower yield of products but being made more quickly. 29 2 11/1/23 Manufacture of ammonia Pressure: 200 atm (20000 kPa) • A lower pressure would favour the reverse reaction as there are more molecules on the reactant side (4 molecules of gaseous reactants) so a higher yield of reactants will be made. • A higher pressure would favour the forward reaction as there are less molecules on the product side (2 molecules of gaseous products) so a higher yield of products will be made. • However high pressures can be dangerous and very expensive equipment is needed. • So 200 atm is a compromise pressure between a lower yield of products being made safely and economically. N2(g) + 3H2(g) ⇌ 2NH3(g) 30 Manufacture of ammonia 31 3 11/1/23 Sulfur dioxide: source Sulfur dioxide • Sulfur dioxide can be made by the direct combination of sulfur with oxygen (burning) and by roasting (heating) sulfur ores in air. • This is the method used in the first stage of the manufacture of sulfuric acid: S + O2 → SO2 32 Manufacturing of sulfuric acid Sulfuric acid is synthesised by the Contact process which uses sulfur and oxygen from air and is done in three distinct stages. Stage 1 • The first stage is the oxidation of sulfur: S + O2 → SO2 Stage 2 • The main stage is the oxidation of sulfur dioxide to sulfur trioxide using a V2O5 (Vanadium (v) oxide) catalyst: 2SO2 + O2 ⇌2SO3 • The conditions for the main stage of production of sulfur trioxide need to be considered: 33 4 11/1/23 Manufacturing of sulfuric acid Conditions during Stage 2 Temperature: 450ºC • • • The reaction is exothermic, so increasing the temperature shifts the position of equilibrium to the left in the direction of the reactants. Therefore the higher the temperature, the lower the yield of sulfur trioxide. The optimum temperature is a compromise between a higher rate of reaction at a higher temperature and a lower equilibrium yield at a higher temperature. Pressure: 2 atm (200 kPa) • • • An increase in pressure shifts the position of equilibrium to the right in the direction of a smaller number of gaseous molecules. However the position of equilibrium lies far to the right (the equilibrium mixture contains about 96% sulfur trioxide). So the reaction is carried out at just above atmospheric pressure because: – a) it is not worth spending the extra energy or money required to produce high pressures. – b) a higher pressure would increase the problems of dealing with the corrosive mixture of gases. 34 Stage 3 • Manufacturing of sulfuric acid Once stage 2 is completed, the sulfur trioxide is absorbed into a solution of 98% sulphuric acid to produce a thick liquid called oleum: SO3 + H2SO4 → H2S2O7 • • It is not absorbed into water because a fine mist of sulfuric acid would be produced and this would be difficult to condense and is also highly dangerous. Oleum is added to water to form concentrated sulfuric acid: H2S2O7 + H2O → 2H2SO4 35 5 11/1/23 Uses of sulfuric acid Dilute • Used as a catalyst in many organic reactions. • Also used as to clean the surface of metals. Concentrated • Used in car batteries, making phosphate fertilisers, soaps and detergents. • It is also used to make acid drain cleaners and in the production of paints and dyes. • Dehydrating agent, very good at removing water from other substances 36 Ammonium nitrate and other fertilisers • Ammonium nitrate is the most important of the nitrogenous fertilisers. It contains 35% by mass of nitrogen. It is produced when ammonia solution reacts with nitric acid: NH3(aq) + HNO3(aq) è NH4NO3(aq) • Ammonium nitrate is soluble in water, as are all other ammonium salts, for example ammonium sulphate, (NH4)2SO4. this solubility is important because plants need soluble nitrogen compounds that they can take up through their roots. 37 6 11/1/23 Ammonium nitrate and other fertilisers A modern fertiliser factory produces two main types of product: • Straight N fertilisers are solid nitrogen-containing fertilisers sold in pellet form, for example ammonium nitrate (NH4NO3), ammonium sulphate ((NH4)2SO4) and urea (CO(NH2)2). • NPK Fertilisers 1. These fertilisers contain nitrogen, potassium and phosphorus. 2. Nitrogen promotes healthy leaves, potassium promotes growth and healthy fruit and flowers and phosphorus promotes healthy roots. 3. NPK compounds fertiliser are a mixture of the following water-soluble ions: – Ammonium ions, NH4+ and nitrate ions, NO3–, are sources of soluble nitrogen. – Phosphate ions, PO43- (along with ammonium ions, NH4+) are a source of soluble phosphorus. – Most common potassium compounds (mainly KCl) dissolve in water to produce potassium ions, K+. 38 Ammonium nitrate and other fertilisers Different plants need different combinations of nitrogen (N), phosphorus (P) and potassium (K), which is why NPK fertilisers are produced. For example, • fruits like apple and tomatoes need a lot of potassium, whereas • leafy vegetables like cabbage need a lot of nitrogen and • root crops like carrots need a lot of phosphorus 39 7 11/1/23 Compound fertilizer • Ammonium salts tend to make the soil slightly acidic. To overcome this, they can be mixed with chalk (calcium carbonate), which will neutralise this effect. Calcium ammonium nitrate (CAN), also known as nitrochalk, is an example of a compound fertilizer. • A fertilizer such as an NPK fertilizer or nitrochalk that contains more than one compound to provide essentials to the soil are called compound fertilizer. 40 8