Plate Fin Heat Exchanger Characteristics: Heat Transfer & Friction

advertisement

ELSEVIER

PII: S0140-7007(96)00021-7

Int J. ReJ?ig. Vol. 19, No. 4, pp. 223-230, 1996

Copyright @ 1996 Elsevier Science Ltd and IIR

Printed in Great Britain. All rights reserved

0140-7007/96/$15.00 + 00

Sensible heat and friction characteristics of plate fin-and-tube heat

exchangers having plane fins

Chi-Chuan Wang and Yu-Juei Chang

E n e r g y a n d R e s o u r c e s L a b o r a t o r i e s , I n d u s t r i a l T e c h n o l o g y R e s e a r c h Institute,

Hsinchu, Taiwan, ROC

Yi-Chung Hsieh and Yur-Tsai Lin

D e p a r t m e n t o f M e c h a n i c a l Engineering, Y u a n - Z e Institute o f T e c h n o l o g y ,

Taiwan, ROC

Received 10 October 1995; revised 14 March 1996

In the present study, 15 samples of plate fin heat exchangers with different geometrical parameters, including

the number of tube rows, fin spacing and fin thickness are tested and compared in an induced flow open wind

tunnel. Results are presented in the form of friction factor and Colburn j-factor against Reynolds number

based on the tube collar diameter in the range of 300 to 7500. Comparisons with the existing plate fin

correlation are also reported. It is found that the fin spacing does not affect the heat-transfer coefficient. The

number of tube rows has negligible effect on the friction factor, and the fin thickness does not affect the heattransfer or friction characteristics.

(Keywords: heat transfer; pressure loss; battery; tube; fin; air; measurement; Reynolds)

Copyright ~) 1996 Elsevier Science Ltd and IIR

Transfert de chaleur sensible et caract6ristiques de frottement pour

6changeurs de chaleur plaque-ailettes, pourvus d'ailettes planes

Dans /'article, les auteurs essaient et comparent, dans un tunnel aOrodynamique ouvert it ~coulement./brcO.

quinze Ochantillons d'Ochangeurs de chaleur it plaque-ailettes, en en modifiant les parambtres g~omOtriques, h

savoir: le nombre de rang~es de tubes, l'espacement des ailettes et leur ~paisseur. Ils pr~sentent les rOsultats sous

jorme du facteur de frottement et du facteur j de Co~burn, compar& au hombre de Reynolds" fondd sur de

diambtre circulaire du tube, dans la plage de 300 h 7500. Ils rapportent Ogalement des comparaisons avecla

correlation existante des plaques-ailettes, lls d~duisent que l'espacement des ailettes n 'a aucune incidence sur le

coefficient de transfert de chaleur. Le nombre de rang~es de tubes a un effet ndgligeable sur le facteur de

j?ottement, et l'(paisseur des ailettes n'effecte ni le transfert de chaleur ni les caract~ristiques de frottement.

(Mot cl+s: Transfert de chaleur; perte de pression: batterie; tube; ailette: air: mesure: Reynolds)

Copyright (~! 1996 Elsevier Science Ltd and IIR

The plate fin-and-tube heat exchangers, consisting of

mechanically or hydraulically expanded round tubes in a

block of parallel continuous fins, are widely used in

industry and particularly in the heating, air-conditioning

and refrigeration industries. The complex airflow pattern

across the fin-and-tube surface makes the theoretical

prediction of heat-transfer coefficients very difficult, and

therefore most publications are related to experimental

works. The most systematic study was carried out by

Rich 1'2, who investigated a total of 14 coils, in which the

fin spacing was varied from H I D e = 0.084 to 0.64. He

concluded that the heat-transfer coefficient was essentially independent of the fin spacing. He further

concluded that the pressure drop per row is independent

of the number of tube rows.

McQuiston 3 stated that the j-factor could be correlated by applying a correction 'finning factor', defined as

Ao/Ato , to the Reynolds number. A strong dependence of

heat-transfer coefficients on the finning factor was

observed. McQuiston 3 showed an ( A o / A t o ) - 015 dependence in his plate-fin data. Kayansayan 4 indicated that

the j-factor is proportional t o (Ao/Ato) -0362. Based on

the previously published data, Gray and Webb 5 proposed a correlation for the existing experimental data.

The RMS error of the resulting correlation is 7.3% for

heat-transfer coefficients and 7.8% for friction factors.

Numerous studies have been devoted to plate fin-andtube heat exchangers. However, most of the previously

published data are for large tube diameter (e.g.

Do = 12.7 and 15.8mm). Kayansayan 4 presented six

experimental data sets for a 9.52-mm-tube. However, the

heat exchangers he tested were all four-row coils. Kays

and London 6 have published few data for tube diameter

of the order 10 mm. To date, there is no systematic study

223

224

C.-C. Wang et al.

Nomenclature

Area (m 2)

Total surface area (m 2)

External tube surface area (m 2)

Heat capacity rate (W K -1)

Specific heat at constant pressure

(Jkg -1K -l)

D~

Fin collar outside diameter (m)

Inside tube diameter (m)

Di

Tube outside diameter (m)

Do

Friction factor

f

G~

Mass flux of the air based on the

minimum flow area (kg m 2 s)

H

Fin spacing (m)

h

Heat-transfer coefficient

( W m -2 K -l)

j = N u / R e P r 1/3

the Colburn factor

Thermal conductivity

k

(Wm -1 K -1)

Abrupt contraction pressure-loss

Kc

coefficient

Abrupt expansion pressure-loss

ICe

coefficient

Depth of the heat exchanger in

L

airflow direction (m)

Number of tube row

N

Mass flow rate (kgs -1)

rn

N T U = U A / Cmin Number of transfer unit

Nusselt number

Nu = hDc/k

AP

Pressure drop (Pa)

Fin pitch (m)

rp

Longitudinal tube pitch (m)

Pl

Prandtl number

Pr

Transverse tube pitch (m)

l?.t

Q

Heat-transfer rate (W)

A

Ao

Ato

C

¢p

Qmax = Cmin(Twater,in-Tair,in)

The maximum possible heat

transfer rate (W)

rc

Tube outside radius, including

collar thickness (m)

Re = p V D / #

Reynolds number

to the air side performance of the plane fin heat

exchangers having a nominal tube diameter of

9.52 mm. As is well-known, coils having a tube diameter

of 9.52mm are very popular in recent HVAC&R

applications. As a result, the objective of the present

study is to provide more experimental data on plate finand-tube heat exchangers having a 9.52-mm tube

diameter. In addition, the effect of fin spacing, the

number of tube rows and fin thickness on the heattransfer and friction characteristics are also investigated.

Experimental apparatus

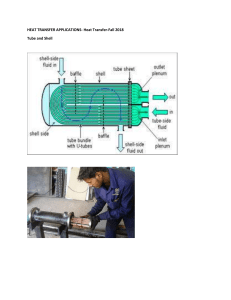

Experiments were conducted in a forced draft wind

tunnel as described in Figure 1. The airflow was driven by

a 5.6 kW centrifugal fan with an inverter. To avoid and

minimize the effect of flow maldistribution, an air

straightener-equalizer and a mixer were provided. The

inlet and the exit temperature across the sample coil were

Req

r

T

t

U

Equivalent radius for ciruclar fin (m)

Tube inside radius (m)

Temperature (°C)

Fin thickness (m)

Overall heat-transfer coefficient

(Wm -2 K -l)

/

X L = V(Pt/2)2 + p2t/2

geometric parameter (m)

geometric parameter (m)

XM = Pt/2

Greek letters

6

e = Qave/Qmax

q

q0

#

Thickness of the tube wall (m)

Heat exchanger effectiveness

Finn efficiency

Surface effectiveness

Dynamic viscosity of fluid

(kgm -1 s-1)

Density (kg m -3)

Contraction ratio of crosssectional area

Subscripts

1

2

air

ave

b

i

in

f

m

min

max

o

out

water

w

air side inlet

air side outlet

air side

average value

base surface

tube side

inlet

fin surface

mean value

minimum value

maximum value

total surface

outlet

water side

wall of the tube

measured by two T-type thermocouple meshes. The inlet

measuring mesh consisted of 8 thermocouples, while the

outlet mesh contained 16 thermocouples. The sensor

locations inside the rectangular duct were established by

following ASHRAE 7 recommendations• The thermocouple data were individually recorded and then

averaged. During the isothermal test, the variance of

these thermocouples were within +0.2°C. All the

thermocouples were pre-calibrated by a high-resolution

(0.01°C) quartz thermometer. The calibrated uncertainties of the thermocouples, as depicted in Table 1, were

within +0.1°C. The pressure drop of the test coil was

detected by a precision differential pressure transducer,

reading to 0.1 Pa. The airflow measuring station, a

multiple nozzle code test, was designed on the basis of

the ASHRAE 41.2 standard s. The geometric parameters

of the tested coils are illustrated in Table 2. The working

medium on the tube side was hot water. The inlet

temperature was controlled by a thermostat reservoir

Characteristics of heat exchangers

®@

©

I;i

® ®G 9 ,&_? ®

i-

___>

lh)l

q

Water

;,

I

i',',

w,

w,

i',',

<

I ]r ----j

.

Rt~N('I 'v ()ll

rvoiv ~

.

.

.

.

n~,]1,~ ~

I

l

I

I

........

.

.

.

.

.

.

"=---'l

....

I)rld

'"

I Rccordcr

k

.

J

Q

@

L I

I;;

i:p

I

l ')'-~

0 ,~ 0

l i-

f

.j

iII

,,,,,

225

•

•

~(Oml)U t

L 7 .....

• . . . . . . .

|

~-J

"--

III

Ill

,

tj

f I

@

III

©

9 code

1 inlel

honey cone straight(met

:~ d c v c h q ) i n g

seclion

4 'I'/C i n l e t , l c m t ) e r a t . u r e

ill(,aHIll'illg

st al.ion

,-) t)l,(~,..;slli,(~ t a l ) ( i n h H

)

6 lest unit

7 pressul'c lap(outlet)

[+ T / C o u l l e t t e m p e r a t u r e

tll(+aSlll'illg s l a t i o n

t e s t e r for lllf!a~lll'OlllUll[

flow l ' a l e

selling means

nozzle pr(rssurc Iap(inlel)

nozzle pressure

tap(outlel)

m u l t i t ) l e llozzl(~s p l a l e

s e l l i n g nteans

variable exhausl

fan system

discharge

waler putnp

of

10

11

12

13

14

15

16

17

aiF

Figure 1 Schematic of experimental set-up

Figure 1 Scheme de l'installation exp&imentale

Table 1

Summary of estimated uncertainties

Tableau 1 Dimensionsg~om~triques de plusieurs ~chantillons d'&hangeurs de chaleur h plaque-ailettes

Primary measurements

Derived quantities

Parameter

Uncertainty

Parameter

'}/air

?ilwate r

0.3 1%

0.5 %

0.5%

0.05"C

0. I C

0.05~C

Reoc

Rei

Ap

Twater

Tair

T

f

qwater

qair

j

Uncertainty (%)

ReDs = 600

Uncertainty 1%)

+1.0

+0.73

+17.7

:t:2.95

4-3.5

+9.4

±0.47

+0.73

+1.3

+0.89

± 1.6

-]=3.9

ReDs = 7000

Table 2 Geometric dimensions of the sample plate fin-and-tube heat exchangers

Tableau 2 R#sum#des erreurs estim&s

No.

Fin thickness (ram)

Fin pitch (mm)

Dc (mm)

Pt (mm)

& (ram)

Row No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

0.13

0.13

0.13

0.13

0.13

0.13

0.13

0.13

0.13

0.2

0.2

0.2

0.2

0.2

0.2

1.82

2.24

3.20

2.03

2.23

3.00

1.85

2.21

3.16

1.77

3.21

1.77

3.17

1.74

3.16

10.23

10.23

10.23

10.23

10.23

10.23

10.23

10.23

10.23

10.23

10.23

10.23

10.23

10.23

10.23

25.4

25.4

25.4

25.4

25.4

25.4

25.4

25.4

25.4

25.4

25.4

25.4

25.4

25.4

25.4

22

22

22

22

22

22

22

22

22

22

22

22

22

22

22

2

2

2

4

4

4

6

6

6

2

2

4

4

6

6

Notes: tube wall thickness after expansion: 0.336 mm; the test samples are all staggered layout

having an adjustable heat capacity up to 80 kW. Both the

inlet and outlet temperatures were measured by two precalibrated RTDs (Pt-100 f~) which have an accuracy of

0.1°C. The water volumetric flowrate was detected by a

magnetic flow meter with 0.0021s -z resolution. All the

data signals were collected and converted by a data

acquisition system (a hybrid recorder). The data

acquisition system then transmitted the converted signals

through a GPIB interface to the host computer for

further operation. During the experiments, the water

inlet temperature was held constant at 60.0 + 0.1 °C. The

air frontal velocities ranged from 0.3 to 6 . 2 m s -1.

C.-C. Wang et al.

226

Generally, the energy balance between air side and tube

side was within 2%. In all cases, the water side resistance

(evaluated as 1/hiAi) was less than 12% of the overall

resistance in all cases, and the wall resistance (evaluated

as 6w/kwAw) was negligible. The dominant thermal

resistance was always on the air side. Uncertainties in

the reported experimental values of the Colburnj-factor

and friction factor f were estimated by the method

suggested by Moffat 9. The maximum uncertainties are

tabulated in Table 1. The highest uncertainties were

associated with the lowest Reynolds number.

Analysis

In the analysis, to provide the heat transfer characteristics of the tested coils, the e-NTU method is used to

determine the UA term of the heat exchanger. The UA

product was calculated using the e-NTU method for the

unmixed-unmixed cross-flow configuration. Correspondingly, the appropriate e-NTU relationship l° is

= 1 - e x p [ N T U ° 2 2 / C * { e x p ( - C * N T U °78) - 1}]

(1)

Cmin

Cmax

~b/airCp,air

r/'twaterCp,water

-

0ave

Qmax

.

1

-- - -

1

rlohoA o

+

¢5w

~

+ -

1

hiA i

(5)

(6)

where

f = (l.581n(ReD~) - 3.28) -2

(7)

where Re i = p VDi/iz. The finned surface effectiveness,

~0, is defined as the ratio of the actual heat transfer to the

heat-transfer rate occurring when both fin and base are

at the same base temperature. This term may be written

in terms of the fin efficiency ~, fin surface area Af and

total surface area A0 as

r/0 = 1 - A f ( 1 -~7)

A0

(8)

where A0 = Af + A b and Af, A b are the areas of the fin

and base, respectively. In the present investigation, the

estimation of fin efficiency, ~7, is calculated using the

Schmidt 12 approximation for the staggered plate-fin

geometry. The fin efficiency is expressed as

-

tanh(mr0)

mrO

Req = 1.27 XM

r

r

XL --0.3

(12)

With Equations (9)-(12), an iterative process is needed

to obtain the air side heat-transfer coefficient h0 and the

surface effectiveness r/0. The heat-transfer characteristics

of the heat exchanger are presented in the following nondimensional groups:

Nu = hoDc/k

(13)

ReDo = pVmaxDc/#

(14)

j = Nu/(ReocPfl/3)

AcPm [2R1AP

The tube-side heat-transfer coefficient, hi, is evaluated

from the Gnielinski ll semi-empirical correlation:

(k)

( R e i - lOOO)Pr(fi/2)

hi = ~ i 1 + 1 2 . 7 x / - ~ ( P r 2/3 - 1)

(11)

(15)

f -Ao

where the total heat transfer rate, Qave, is the arithmetic

average of the air side and the water side heat-transfer

rates. The overall heat-transfer resistance is evaluated

from the following relationship:

UA

~=(~9-)[l+0.351n(Req/r)]

(4)

rr/waterCp,water(Tin,water- Tin,air)

N T U =- UA/Crnin

(10)

(3)

(2)

Oave

-

2~°

m--v

All the fluid properties are evaluated at the average

values of the inlet and outlet temperatures.

The core friction of the heat exchanger is calculated

from the pressure drop equation described by Kays and

London 6, which includes the entrance and exit pressure

loss coefficients Kc and Ke. The relation for the nondimensional friction f a c t o r f in terms of pressure drop is:

where

c * _= - - -

where

(9)

Pl [ Gc2

2(P_21 _ )

(Kc -[- 1 -- 0 "2) --

\P2

1

/16/

where A 0 and Ac stand for the total heat-transfer area

and the flow cross-sectional area, respectively, and 0- is

the ratio of the minimum flow area to frontal area.

Results and discussion

The experimentally determined values of the Colburn jfactor and friction f a c t o r f for the 15 test samples plotted

against Reynolds number (ReDo) are displayed in Figure

2. The characteristic dimension of the Reynolds number,

ReDc, is the tube outside diameter including collar

thickness. As expected, the friction factor decreases

with the increase of Reynolds number for all test

samples. The j-factors, for samples 7 and 14, show a

maximum for the Reynolds number is less than 2000.

The experimental data of Rich 2 also reveals this kind of

phenomenon. A private discussion between Webb and

Rich 5 had attributed this unexpected phenomenon to the

experimental error at low airflow rates. Gray and Webb 5

therefore, had neglected the experimental data for

ReL < 5000 (corresponds to ReDo = 2750) in correlating

the data of Rich 12

' . Since the present experiments were

carried out carefully with the standard nozzles operated

following the ASHRAE standard 8 recommendation

(nozzle velocities are between 15 and 70ms-l). The

energy balance between air side and tube side is less than

3% throughout the experiments, and good experimental

repeatabilities are achieved at low velocities. Consequently, the maximum of the Coburn j-factors for

samples 7 and 14 may not be due to experimental

Characteristics of heat exchangers

227

0

10

0

10

q~)-#1

"--~"-:#2

-A-:N3

"~-:#4

-~-:#5

"O-:#6

-~-:#7

~:#8

4~:#9

-'~P'-#10

,

-'~:#11

--B--:#I2

-C--:#13

-{-]-:#14

--.~--#15

~ , i,,,

I

E

,

, , ~ ,i

I

i

I

-¢¢-:#10, H = 1 . 5 7 mm, R o w = 2

--t9--:#12, H = 1 . 5 7 mm, R o w = 4

-[]-:#14. H = 1 , 5 4 mm, R o w = 6

f

f

-1

10

-1

10

-2

10

9

10"

I

I

I IIIII

I

I

I

10

4

10

ReDc

Figure 2

j a n d f f o r the tested s a m p l e s

Figure 2

j e t f pour les ~chantillons essayks

mm

I

I

I I I I

3

10

t=0.2

uncertainty. Note that samples 7 and 14 are of six-row

configuration and smallest fin spacing. The possible

explanation for this unusual phenomenon are twofold.

Firstly, as illustrated by Rich l, the standing vortices

form behind a cylinder in cross-flow at low Reynolds

number and the eddies breaks away from the cylinder

and move downstream at higher Reynolds number. The

size of the standing vortices is likely to increase with the

number of tube rows, and eventually a detectable decay

of the heat-transfer coefficient is found. Secondly, the

flow visualization experiments conducted by Chen and

Ren ~3 indicate that the smaller fin spacing is responsible

for reducing the vortex. As a result, the airflow pass

through the heat exchanger is somewhat like channel

flow and the exponent dependence in the Reynolds

number is changed. Note that for channel flow, the

Reynolds number dependence is Re -°z, whereas for pure

tube bank flow, the Reynolds number dependence is

Re -°'4. Combining these two effects, the 'maximum

phenomenon' is expected to form at low air velocities

especially for heat exchangers with larger number of tube

rows and smaller fin spacing. Similar results were also

shown in the automotive multilouver fin surface as

reported by Davenport TM and Achaichia and Cowel115.

Webb and Trauger r6 found that some of the air streams

bypass the louvers at low Reynolds number and act as

'duct flow' between the fin channels so that a lower jfactor will be obtained. Achaichia and Cowel115 identified the flow pattern as 'fin directed flow' for the low

Reynolds number region and 'louver directed flow' for

high Reynolds number region.

Figure 3 illustrates the effect of the number of tube

rows on the heat-transfer and friction characteristics.

The number of tube rows are 2, 4 and 6, respectively. The

fin spacing is approximately 1.57 mm. As can be seen, the

Colburn j-factors decrease with the increase of the

I

i I III]

I I I i

3

10

10

4

10

ReD c

F i g u r e 3 Effect o f the n u m b e r o f t u b e r o w o n the h e a t - t r a n s f e r a n d

friction characteristics

F i g u r e 3 Effet du nombre de rangOes de tubes sur le transfert de chaleur

et lefrottement

number of tube rows for Reynolds number less than

2000. However, the effect of the number of tube rows

diminishes as Reynolds number increases over 2000.

This phenomenon is very similar to the plate fin data as

shown by Rich 2 and Senshimo and Fujii 17. Figure 5

shows also that there is no detectable variation of the

heat-transfer coefficients with increasing row number for

Reo~ > 2000. This is due to the downstream turbulence

eddies shed from the tubes that cause good mixing in the

downstream fin region. As they Reynolds number

decreases, the downstream turbulence tends to diminish

and the vortices behind the tube cylinder are expected to

form. As a result, the number of tube rows shows a

significant effect on the heat-transfer characteristics for

ReD~ < 2000. Figure 3 also indicates that the friction

factors are independent of the number of tube rows.

Again, this phenomenon is very similar to other plate finand-tube heat exchangers as shown by Rich 2, the louver

fin geometry for Chang et al. 18, the wavy fin configuration of Wang et al. 19 and the convex-louver fin geometry

of Wang et al. 2°.

Figure 4 illustrates the effect of the fin thickness on the

thermal-hydraulic characteristics of the plate fin-andtube heat exchangers. The effect of fin thickness on the

thermal-hydraulic characteristics of the plate fin-andtube heat exchanger have not been investigated before.

Gray and Webb 5 argued that the fin thickness should not

affect the thermal-hydraulic characteristics of the plate

fin-and-tube heat exchangers. They explained that the fin

thickness affects only the airflow velocity in the heat

exchanger, which is accounted for by the Reynolds

number. In addition, the friction correlation excludes the

entrance and exit losses. As a result, it is likely that the fin

C.- C. Wang et a l.

228

0

0

10

i

r

p

i

i

i

~J

10

r

I

"0-:#9, H=3.03 mm, Row= 6, t=0.13 mm

-0-:#4. H= 1.90 mm

--A--:#15, H=2.96 mm. Row= 6, t=0.2 mm

t1-:#5, H=210 mm

-&-:#3. H=3.07 ram, Row

-Q-:#6, H=2.87 mm

2, t=0.13 mm

R o w = 4, t = 0 . 1 3 m m

--$-:#11, H=3.01 ram, Row= 2, t=0.2 mm

f

f

10-1

10

10 .2

10

-2

I

i

i

I I IIII

I

I

I

I I II

I

3

10

4

10

I

10

10

Figure 4 Effectof fin thickness on the heat-transfer and friction

characteristics

Figure4 Effet de l'~paisseur des ailettes sur le transfert de chaleur et le

Figure 5

istics

frottement

froltement

thickness may not effect the thermal-hydraulic characteristics of the plate fin-and-tube heat exchanger.

However, the heat transfer correlation for the

individually finned and tube heat exchanger as proposed

by Briggs and Young 21 is

(17)

TM

As seen, the fin thickness shows a slight effect on the

transfer coefficients. Rabas et al. 22 developed more

accurate j and f correlations for low fin height and

small fin spacings. The correlation also indicates that the

j are related to the fin thickness, and is given by

1.12

j=O.292Ren(~o)

.

(L.

(---He)°26\ H /

I

i

I I I r i

3

10

4

10

ReDc

ReDc

j=O.134Re-°'319(H)°2(H)

I I I I II]

2

0.67 ( d e

.~ 0.47 ( @ )

0.77

\Doj

(18)

where n = -0.415 + 0.0346 de/s.

The effect of fin thickness on the thermal-hydraulic

characteristics is generally small for individual fin

geometry. For the present continuous fin-and-tube

configuration, as depicted in Figure 4, the effect of fin

thickness on both the friction factor and the Coburn jfactor are negligible. The correlation form of Equation

(17) was used for the present data. It was found that the

exponent dependence of fin thickness is smaller than that

of Equation (17).

Figure 5 depicts the effect of fin spacing on the heattransfer and friction factors. Rich l concluded that the

heat-transfer coefficients are essentially independent of

fin spacing. In the analysis by Elmahdy and Biggs23, the

heat-transfer coefficient increased with fin spacing. On

Effect of fin spacing

on heat-transfer

and friction character-

Figure 5 Effet du pas des ailettes sur le transfert de chaleur et le

the contrary, the experimental results of McQuiston and

Tree 24 showed a decrease in heat-transfer coefficient with

decreasing fin spacing. Using an oil-lampblack visualization technique, Chen and Ren 13 studied the airflow

pattern for a two-row plate fin-and-tube heat exchanger.

They concluded that the vortices behind the tube do not

effect the heat-transfer coefficient for ReDo < 7000 when

H / D c < 0.33, and the fin spacing does not affect the

heat-transfer coefficient for H / D c > 0.33. The present

three samples are of four-row configuration and their

corresponding H / D c values are 0.186, 0.205 and 0.281,

respectively. Since the Reynolds number of most of the

experimental data are less than 7000, it is seen that the

heat-transfer coefficient is nearly independent of the fin

spacing. The data here are consistent with the data of

Rich 1 and the criteria proposed by Chen and Ren 13 .

Figure 6 compares the ability_ of the correlations by

McQuiston 3, Gray and Webb 5 and Kayansayan4 to

predict the j and f data for two-, four- and six-row

configurations. The McQuiston 3 correlation considerably overpredicts the friction factors and yields an

unacceptable overprediction of the j-factors for Reynolds number less than 1000. Good agreements of jfactors with the Gray and Webb 5 correlation are

generally reported, and the deviations between the

predictions of the Gray and Webb 5 correlation and the

present experimental data are generally within

+ 2 0 / - 8%. The deviation between the prediction of

the Gray and Webb 5 correlation and the present data

increases with decrease in Reynolds number. This is

probably due to the data bank of the Gray and Webb 5

correlation usually having a Reynolds number higher

than 2500. The predictions of the friction factors of the

plate fin data by the Gray and Webb 5 correlation are

Characteristics of heat exchangers

0

10

--.

•-, 10

10

i

i

i i E i ii I

--A-:#15, H = 2 . 9 6 mrn, R o w = 6

..... :McQuistion Correlation for #15

- - -:Gra y & Webb (1986) Correlation for #15

-C--:#13, H = 2 . 9 7 ram, R o w = 4

- - :McQuiston Correlation for #13

i - - : G r a y & Webb Correlation for #13

-e'4r-:#11, H = 3 . 0 1 mm, R o w = 2

[

:McQuiston Correlation for #11

/ "- - :Gray & Webb Correlation tor #11

-l

229

1

-B--:#12, H = 1 . 5 7 ram

..... :Gray & Webb (1986) Correlation for Sample#12

:McQuistion Correlation for #12

:Kayansayan Correlation for #12

-C---:#13, H = 2 . 9 7 rnm

- - :Gray & W e b b (1986) Correlation for Sample# 13

- - :McQuistion Correlation for # 13

- - - : K a y a n s a y a n Correlation for #13

- ~ - : K a y a n s a y a n 07, H = 2 . 2 0

-M-- :Kayansayan #8, H = 3.20

--6--:Kayansayan #9, H = 2 . 5 0

f

~'~

.~" -.~..,~

-2

10

10-~

t=0.2

mm

i

I

/

\Kayansayan Correlation for #15,#13,#11

I

i I i IlL

I

i

i

i i I I

3

10

Row=4,

i

4

10

ReDc

10

t=0.20

10

mm

I Iiiiii

~

~

3

111

t

4

10

10

i t Jt

5

10

ReDc

Figure 6 Comparisonofj andf betweentypicaltest sampleswith the

McQuiston-, Gray and Webb5 and Kayansayan4 correlations

Figure 6 Comparaisonde j et f, de plusieurs dchantillons types avec la

corrOlation de McQuiston. Gray et Webb et Kayansayan

Figure 7 Comparison of j values between test samples with

Kayansayan4 and the present experimental data with identical tube

of row, Pt, PI and fin thickness

Figure 7 Comparaisondes valeurs de j, de plusieurs &:hantillons types,

avec la corrOlation de Kayansayan et les donnOesexp&imentales aetuelles

tubes, P, P~et 6paisseur des ailettes identiques

approximately + 3 0 / - 15% compared to the present

data. The deviations here may be attributed to the data

bank used for their correlation being generally for larger

tube diameters. In addition, the prediction of friction

factors by the Gray and Webb 5 correlation are generally

linear (in a logarithmic scale plot). However, as is

known, the friction factors are usually4 nonlinear in a

logarithmic scale plot. The Kayansayan correlation for

j-factors considerably underpredicts the experimental

data, especially in low Reynolds number regions.

Figure 7 comp4ares the present j-factor data with that

of Kayansayan for identical transverse pitch, longitudinal pitch, tube diameter, number of tube rows and

fin thickness. Although the present data show a

negligible effect of fin spacing, the Kayansayan 4 data

are quite scattered. The present data show 5-25% higher

heat-transfer coefficients than those of Kayansayan4.

The Kayansayan correlation typically predicts lower jfactors than those of others.

It is obvious from the curves shown in Figure 2 that no

single curve can be expected to describe the complex

behaviors for both j- and f-factors. In addition, the

maximum phenomenon for samples 7 and 14 make the

problem even more complicated. As a result, using a

multiple linear regression technique in a practical range

of experimental data (800 < ReD~ < 7500), the appropriate correlation form o f j a n d f for the present data are

/

(Fp-~ -0.212

, \-0.0449

N 0.0897\DccJ

j = 0.394ReD°392~c)~

/

~, \ - 0 . 1 0 4

f=l'Og9ReD°4181~c)"

(

(19)

)-0.197

N-°°935 DccFP

(20)

As shown in Figure 8, Equation (19) can describe 97%

of the experimental data within 10% and Equation (20)

can describe 88% of the experimental data within 10%.

The RMS error of the resulting correlation is 4.1% for

heat-transfer coefficients, and 6.5% for friction factors.

Conclusions

Experiments on the heat-transfer and pressure drop

characteristics of plate fin-and-tube heat exchangers

were carried out for Dc = 10.23mm. In the present

study, 15 samples of plate fin-and-tube heat exchangers

with different geometrical parameters, including row

number, fin thickness and fin spacing. On the basis of

previous discussions, the following conclusions are

made:

1. The maximum phenomena of Colburn j-factor at

low Reynolds numbers occur for plate fin-and-tube

heat exchanger at larger number of tube row and

smaller fin spacing.

2. The experimental data indicate that the number of

tube rows does not affect the friction factors. A

significant reduction of the heat-transfer coefficients

is found for Reynolds number less than 2000 for the

six-row coil, and the effect of the number of tube row

diminishes for 2000 < Reoc < 7500.

3. Fin thickness has negligible effect on both heattransfer and friction characteristics of plate fin-andtube heat exchangers.

4. Fin spacing has negligible affect on the heat-transfer

C.-C. Wang et al.

230

0.1

/

information

appreciated.

/

f r o m Prof.

Ralph

Webb

are very m u c h

(f)

0.08

References

0.06

1

2

0.04

/

0.02

0.02

0.04

0.06

Correlation ( f )

i

0.08

3

4

5

O. 1

6

7

8

0.03

. . . .

I

. . . .

I

. . . .

9

10

()

11

£/A o

q

12

13

14

~0.01

15

16

•

0

F

5

0

0.01

0.02

Correlation ( j )

J

i

17

0.03

Figure 8 Comparison of the experimental data and the present

correlations: (a) friction factor, f ; (b)j-factors

Figure 8 Comparaison des donn~es exp&imentales et des correlations

aetuelles. (a) facteur de frottement, f. et (b) facteurs j

18

19

20

characteristics of plate fin-and-tube heat exchangers

at t h e p r e s e n t test r a n g e .

Acknowledgements

T h e a u t h o r s w o u l d like to e x p r e s s t h e i r g r a t i t u d e for

the E n e r g y R & D

foundation

f u n d i n g f r o m the

E n e r g y C o m m i s s i o n o f the M i n i s t r y o f E c o n o m i c

Affairs, T a i w a n , w h i c h p r o v i d e d f i n a n c i a l s u p p o r t

f o r the p r e s e n t study. V a l u a b l e s u g g e s t i o n s a n d

21

22

23

24

Rich, D. G. The effect of fin spacing on the heat transfer and friction performance of multi-row, plate fin-and-tube heat exchangers ASHRAE Trans (1973) 79(2) 137 145

Rich, D. G. The effect of the number of tube rows on heat transfer performance of smooth plate fin-and-tube heat ASHRAE

Trans (1975) 81(1) 307-317

McQuiston, F. C. Correlation of heat, mass and momentum

transport coefficients for plate fin-and-tube heat transfer surfaces with staggered tubes A SHRAE Trans (1978) 84(1) 294 309

Kayansayan, N. Heat transfer characterization of flat plain fins

and round tube heat exchangers Exper Thermal Fluid Sci

(1993) 6 263 272

Gray, D. L., Webb, R. L. Heat transfer and friction correlations

for plate finned-tube heat exchangers having plain fins Proc 8th

Heat Transfer ConJ (1986) 2745 2750

Kays, W. M., London, A. L. Compact Heat Exchangers 3rd ed

McGraw-Hill (1984)

ASHRAE Handbook Fundamental S1 Edition (1993) Ch. 13. 14

15

ASHRAE ASHRAE Standard 41.2-1987 Standard Methods[or

Laborato O' Air-flow Measurement (1987)

Moffat, R. J. Describing the uncertainties in experimental results

Exp Thermal Fluid Sci (1988) 1 3 17

McQuiston, F. C., Parker, J. D. Heating, Ventillating. and Airconditioning 4th ed. John Wiley, New York (1994) Ch. 14, 57l

Gnielinski, V. New equation for heat and mass transfer in turbulent pipe and channel flow Int Chem Engng (1976) 16 359 368

Schmidt, Th. E. Heat transfer calculations for extended surfaces

Refrig Eng (1949) April 351 357

Chen, Z. Q., Ren, J. X. Effect of fin spacing on the heat transfer

and pressure drop of a two-row plate fin and tube heat exchanger Int J Refrig (1988) 11 456-360

Davenport, C. J. Correlation for heat transfer and flow friction

characteristics of louvered fin AIChE Syrup Set (1983) 79(25)

19-27

Achaiehia, A., CoweU, T. A. Heat transfer and pressure drop

characteristics of flat tube and louvered plate fin surfaces Exp

Thermal Fluid Sci (1988) 1 147 157

Webb, R. L., Trauger, P. Flow structure in the louvered fin heat

exchanger geometry Exp Thermal Fluid Sci (1991) 4 205 217

Seshimo, Y., Fujii, M. An experimental study of the performance

of plate fin and tube heat exchangers at low Reynolds number

3rd ASME/JSME Thermal Engineering Joint Con/( 1991 ) 4

449-454

Chang, W. R., Wang, C. C., Tsi, W. C., Shya, R. J. Air-side performance of louver fin heat exchanger 4th ASME..rJSME Thermal Engineering Joint Conf (1995) 4 467 472

Wang, C. C., Fu, W. L., Chang, C. T. Heat transfer and friction

characteristics of typical wavy fin-and-tube heat exchangers Exp

Thermal Fluid Sci (1996) accepted for publication

Wang, C. C., Chen, P. Y., Jang, J. Y. Heat transfer and friction

characteristics of convex-louver fin-and-tube heat exchangers

Exp Heat Tran~br (1996) accepted for publication

Briggs, D. E., Young, E. H. Convective heat transfer and pressure drop of air flowing across triangular pitch banks of finned

tubes Chem Eng Prog Syrup Ser (1963) 59(41) 1 10

Rabas, T. J,, Eekels, P. W., Sabatino, R. A. The effect of fin density on the heat transfer and pressure drop performance of low

finned tube banks Chem Eng Commun (1981) 10(1) 127 147

Elmahdy, P. E., Biggs, P. E. Finned tube heat exchangers:

correlation of dry surface data ASHRAE Trans (1979) 85(2)

262 273

McQuiston, F. C., Tree, D. R. Heat transfer and friction data for

two fin-tube surfaces J Heat Tran~ffbr (1971) 93 249 250