Simulation of a Motor and Cart System

L01

Lauren Hayes

Completed February 15, 2024

Submitted February 15, 2024

1

Summary:

The experiment aimed to replicate the lab's cart system manually using state equations and

Euler’s method in MATLAB. It involved simulating both nonlinear friction and linear

approximations, adjusting step sizes, and varying feedback gain and input amplitudes. Results

were plotted to justify sampling time, analyze system responses to step inputs, and compare

linear and nonlinear simulations. The report included code documentation for transparency. The

experimental setup was based on specified parameters, including Ra, Kt, Kb, and J. Overall, the

study provided insights into system dynamics and the impact of feedback gain and input

amplitude on cart position in the simulated environment.

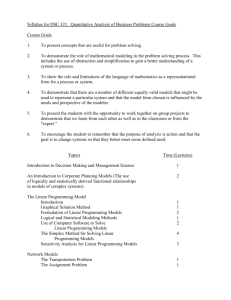

Block Diagram:

Block diagram of the cart system – from the Lab Manual

2

Procedure:

From the block diagram above, the state equations describing the system were generated. The

equations, along with the known parameters, were transferred into a MATLAB script. When

writing the script, one decision to be made was the proper step interval to use (that is, the change

in time, dt). A test and compare method was used. The value of 0.005 was settled upon due to its

delivery of clean results. This value makes sense as Euler’s method will achieve a cleaner

approximation the more values are calculated within a specific time interval.

dt = 0.05

dt = 0.025

dt = 0.005 (chosen)

3

Results:

It was found that once in steady state, linear and nonlinear did not differ in any of the cases.

However, in the time that it took to reach steady state, the linear approximation exhibited a much

faster response, especially in cases II and III. The nonlinear did have a lower percent overshoot,

as can be seen in cases I and II.

A feedback gain of five produced a faster response but with an overshoot, whereas a feedback

gain of two produced no overshoot but a slower response time. The highest feedback gain with

the lowest input magnitude produced the most identical response between the nonlinear and

linear approximations. Only in cases I and II did the nonlinear position ever exceed that of the

linear.

CASE I

4

CASE II

5

CASE III

6

CASE IV

7

Appendix:

%-------------------------------------------------------------------------% This script performs simulations of a linear and a nonlinear system

% subject to different feedback gains and step input magnitudes. It tests

% different sampling times to find an appropriate time step for the

% simulations. The system models a cart with parameters such as moment of

% inertia, voltage constant, resistance, torque constant, and feedback gain.

%-------------------------------------------------------------------------% Parameters:

% - J: Moment of inertia (4 Kg-m^2)

% - kb: Voltage constant (volt/rad/sec)

% - R: Resistance (Ohms)

% - kt: Torque constant (N-m/amp)

% - k0: Feedback gain

%-------------------------------------------------------------------------% Simulation Time:

% - t_start: Start time

% - t_end: End time

% - step_size: Fixed step size for simulation

% - feedback_gains: Feedback gain values to test

% - input_magnitudes: Step input magnitudes to test

%-------------------------------------------------------------------------% Author: Lauren Hayes

% Date: 2/15/2024

%-------------------------------------------------------------------------% Start

close all; % Close all existing figures

clc; % Clear the command window

% Define system parameters

J = 8 * 10^-4; % Moment of inertia (4 Kg-m^2)

kb = 0.1; % Voltage constant (volt/rad/sec)

R = 2; % Resistance (Ohms)

kt = 0.1; % Torque constant (N-m/amp)

k0 = 4; % Feedback gain

% Define simulation time parameters

t_start = 0; % Start time

t_end = 10; % End time

dt = 0.005; % Fixed step size for simulation

% Define feedback gains and input magnitudes

feedback_gains = [5, 2]; % Feedback gain values to test

input_magnitudes = [1, 2]; % Step input magnitudes to test

8

% Loop over different feedback gains

for gain_idx = 1:length(feedback_gains)

k0 = feedback_gains(gain_idx); % Current feedback gain value

% Loop over different step input magnitudes

for input_idx = 1:length(input_magnitudes)

% Reset initial conditions for each simulation

theta = zeros(1, (t_end - t_start) / dt + 1); % Initialize angle array for linear simulation

omega = zeros(1, (t_end - t_start) / dt + 1); % Initialize angular velocity array for linear

simulation

THETA = zeros(1, (t_end - t_start) / dt + 1); % Initialize angle array for nonlinear

simulation

OMEGA = zeros(1, (t_end - t_start) / dt + 1); % Initialize angular velocity array for

nonlinear simulation

% Simulate linear system

for t = 1:length(theta)-1

Vr = 2 * input_magnitudes(input_idx); % Step input for linear simulation

x = 2.53 * (theta(t) / 3); % Calculation for x in linear simulation

Vs = 0.4 * x; % Calculation for Vs in linear simulation

Vi = k0 * (Vr - Vs); % Calculation for Vi in linear simulation

Pa = 2 * Vi; % Calculation for Pa in linear simulation

Va = Pa - kb * (omega(t)); % Calculation for Va in linear simulation

i = Va / R; % Calculation for current in linear simulation

f = omega(t) * 0.01; % Calculation for friction in linear simulation

T = (i * kt) - f; % Calculation for torque in linear simulation

omegaPrime = T / J; % Calculation for angular acceleration in linear simulation

theta(t+1) = theta(t) + dt * omega(t); % Update angle using Euler integration in linear

simulation

omega(t+1) = omega(t) + dt * omegaPrime; % Update angular velocity using Euler

integration in linear simulation

end

% Simulate nonlinear system

for t = 1:length(THETA)-1

VR = 2 * input_magnitudes(input_idx); % Step input for nonlinear simulation

X = 2.53 * (THETA(t) / 3); % Calculation for X in nonlinear simulation

VS = 0.4 * X; % Calculation for VS in nonlinear simulation

VI = k0 * (VR - VS); % Calculation for VI in nonlinear simulation

% Apply condition for PA calculation

if -5 <= VI && VI <= 5

PA = 2 * VI; % Calculation for PA within range in nonlinear simulation

elseif VI < -5

PA = -10; % Calculation for PA when VI is less than -5 in nonlinear simulation

9

else

PA = 10; % Calculation for PA when VI is greater than 5 in nonlinear simulation

end

VA = PA - kb * (OMEGA(t)); % Calculation for VA in nonlinear simulation

I = VA / R; % Calculation for current in nonlinear simulation

% Apply condition for F calculation

if OMEGA(t) < 0

F = OMEGA(t) * 0.008 - 0.02; % Calculation for friction when angular velocity is

negative in nonlinear simulation

elseif OMEGA(t) > 0

F = OMEGA(t) * 0.008 + 0.02; % Calculation for friction when angular velocity is

positive in nonlinear simulation

else

F = 0; % No friction when angular velocity is zero in nonlinear simulation

end

T = (I * kt) - F; % Calculation for torque in nonlinear simulation

OMEGAPrime = T / J; % Calculation for angular acceleration in nonlinear simulation

THETA(t+1) = THETA(t) + dt * OMEGA(t); % Update angle using Euler integration in

nonlinear simulation

OMEGA(t+1) = OMEGA(t) + dt * OMEGAPrime; % Update angular velocity using

Euler integration in nonlinear simulation

end

% Plot results for linear and nonlinear simulations

figure;

plot((0:length(theta)-1) * dt, theta, 'b', 'LineWidth', 2); hold on; % Plot linear simulation

results

plot((0:length(THETA)-1) * dt, THETA, 'r--', 'LineWidth', 2); % Plot nonlinear simulation

results

title(sprintf('Feedback Gain: %d, Input Magnitude: %d', k0,

2*input_magnitudes(input_idx))); % Set plot title

xlabel('Time'); % Set x-axis label

ylabel('Position (cm)'); % Set y-axis label

legend('Linear', 'Nonlinear'); % Set legend

grid on; % Add grid to the plot

end

end

10

11