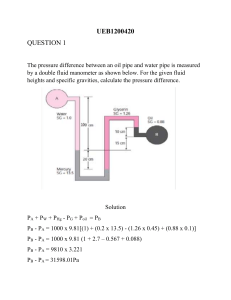

Pressure Drop Analysis in Fluid Flow Apparatus Jermaine Angela B. Prieto, BSChE – 3B Bicol University, jermaineangelabersabe.prieto@bicol-u.edu.ph Abstract Fluid flow mechanics is a crucial aspect of chemical engineering, shaping how liquids and gases move in various processes. This study focuses on understanding how pipes and fittings affect pressure in a fluid flow system. By remodeling a 2006 apparatus with PVC pipes, we aimed to explore how different components impact pressure. Our findings shed light on the importance of smooth flow and minimizing obstacles like bends or narrowings, which can cause pressure to drop. Despite some issues with the apparatus, our experiment highlights the enduring significance of fluid flow mechanics in chemical engineering. The researcher hope to address these challenges to improve efficiency in future studies. Index Terms – fluid mechanics, pressure drop, friction factor INTRODUCTION Fluid Flow Mechanics is a branch of fluid dynamics that deals with the behavior of fluids (liquids and gases) as they move. In chemical engineering, understanding fluid flow mechanics is crucial because it plays a fundamental role in various processes involved in the production, transportation, and transformation of chemicals and materials. Involving fluid statics, or the study of fluids at rest, and fluid dynamics, or the study of fluids in motion, it serves as the fundamental principle in several disciplines in science and engineering. It is also used in the concepts of transport phenomena, equipment design, process optimization, fluid behavior, scale up and process intensification, etc. in chemical engineering. Whether analyzing the flow of liquids through pipelines, the dispersion of gases in reactors, or the behavior of plasmas in advanced processes, a profound understanding of fluid dynamics is indispensable for optimizing efficiency, ensuring safety, and achieving desired outcomes in chemical engineering endeavors. In chemical engineering, the movement of liquids or gases through pipes and ducts is a common practice, especially in heating, cooling, and fluid distribution systems. Typically, fans or pumps compel the fluid to flow through these conduits, creating a defined flow path. A critical aspect of this process is understanding and managing friction, which directly influences pressure drop and head loss within the piping system. Pressure drop serves as a key parameter for determining the power required by pumps to maintain the desired flow rate. In a typical piping setup, various components such as pipes of different diameters, fittings, elbows, valves, and pumps are interconnected to direct and control fluid flow efficiently. By optimizing these elements and managing frictional losses, chemical engineers ensure the smooth and effective operation of fluid distribution networks, contributing to the overall efficiency and performance of chemical processes. In this experiment, the class has remodeled an old fluid flow apparatus, last operated in 2006, to further understand the concepts and mechanisms of fluid flow, pressure drop, and fluid dynamics. In these types of apparatuses, the mostly used pipe types are the circular ones. Compared to noncircular pipes, these can withstand large pressure differences between the inside and the outside without undergoing significant distortion. Noncircular pipes are usually used in applications such as the heating and cooling systems of buildings where the pressure difference is relatively small, the manufacturing and installation costs are lower, and the available space is limited for ductwork. The combined energy dissipation in a pipe system consists of both major and minor losses. Major losses result from frictional energy dissipation, attributed to the viscous nature of the fluid and the surface roughness of the pipe. These losses lead to a pressure drop along the pipe as the pressure is expended to overcome the frictional resistance. The Darcy-Weisbach equation stands as the predominant method for quantifying energy loss in pipe flow. Within this equation, a dimensionless quantity known as the friction factor (f) characterizes the frictional losses within the pipe and it is given by: ∆𝑃𝐿 = 𝑓 2 𝐿 𝜌𝑣𝑎𝑣𝑔 𝐷 (1) 2 2 𝜌𝑣𝑎𝑣𝑔 Where is the dynamic pressure and 𝑓 is the Darcy 2 friction factor. It is also called the Darcy–Weisbach friction factor, named after the Frenchman Henry Darcy (1803–1858) and the German Julius Weisbach (1806–1871), the two engineers who provided the greatest contribution in its development. Minor losses, on the other hand, arise from various factors such as pipe fittings, alterations in flow direction, and modifications in flow area. Given the intricate nature of piping systems and the multitude of fittings employed, the head loss coefficient (K) is empirically determined as a convenient method for swiftly estimating minor head losses. 𝑃 𝑣2 𝛾 2𝑔 [ + + 𝑧] 𝑃 𝑣2 𝛾 2𝑔 =[ + 𝑖𝑛 + 𝑧] 𝑜𝑢𝑡 + ℎ𝐿 (2) Bernoulli’s equation provides a means to assess energy loss within a pipe system, as expressed by Equation (2). Here, 𝑃 𝛾 + 𝑣2 2𝑔 and z represent pressure head, velocity head, and potential head, respectively. The comprehensive head loss, denoted as ℎ𝐿 , encompasses both major and minor losses. Assuming constant diameter through the pipe fitting results in equal inlet and outlet velocities 𝑣𝑖𝑛 = 𝑣𝑜𝑢𝑡 Consequently, when disregarding changes in elevation head, the manometric head difference equates to the static head difference, defined as ∆ℎ through the fitting, as delineated in Equation (3). 𝑃 𝑃 𝛾 𝑖𝑛 𝛾 𝑜𝑢𝑡 [ ] −[ ] = 𝐻1 − 𝐻2 = ∆ℎ (3) 𝐻1 𝑎𝑛𝑑 𝐻2 denote manometer readings pre- and postfitting. The energy loss in a pipe fitting can be quantified as a fraction (K) of the velocity head through the fitting, as represented in Equation (3), where K denotes the loss coefficient and v signifies the mean flow velocity into the fitting. ∆ℎ = 𝐾 𝑣2 2𝑔 (4) Due to the intricate flow dynamics within various fittings, K is typically empirically determined. The head loss coefficient (K) is computed as the ratio of the manometric head difference to the velocity head, elucidated in Equation (4). Notably, in fittings involving alterations in pipe crosssectional area, the difference in velocities cannot be disregarded, leading to an additional change in static pressure. This value assumes a negative value for contractions and a positive value for enlargements. To gauge the pressure difference ∆ℎ pre- and post-gate valve, a pressure gauge directly measures it, subsequently converting it to an equivalent head loss using the conversion ratio: 1 bar= 10.2 m water. The loss coefficient for the gate valve can then be computed using Equation (4). To determine the flow regime through the fitting, the Reynolds number is calculated using Equation (5), where v represents the cross-sectional mean velocity, D denotes the pipe diameter, and \nu stands for the fluid kinematic viscosity. 𝑅𝑒 = 𝑣𝐷 𝑣 (5) Another equation imperative for the computation of flow is the Poiseuille's Law, named after the French physicist Jean Léonard Marie Poiseuille, describes the steady, laminar flow of a Newtonian fluid through a cylindrical pipe or vessel. It relates the flow rate of the fluid to various parameters such as the pressure difference, viscosity of the fluid, length of the pipe, and radius of the pipe. This is given by: 𝑄= 𝜋∆P r4 8𝜇𝐿 (6) Where Q is the volumetric flow rate, ΔP is the pressure difference between the two ends of the pipe, r is the radius of the pipe, μ is the dynamic viscosity of the fluid, and L is the length of the pipe. In this activity, the researchers are to describe how the fluid flows in the apparatus, explain the principles behind the flow, relate the process to its real-life applications (large-scale scenarios), and determine how efficient the apparatus is. METHODOLOGY This section of the paper shows the processes done, and the materials used in the experiment. I. Checking and Preparation of the Apparatus Before conducting the experiment, the researchers made sure to check the equipment first for malfunctions and abnormalities, considering the time it was last used and operated. Since dated back in 2006, the apparatus was expected to have multiple leaks, and malfunctions. To resolve this problem, majority came up with the following proposed solutions: 1. Replace old gauges and buy adhesives and epoxy to stop the leaks 2. Reconstruct the fluid flow apparatus excluding the upper and the lower tanks (using plastic pipes such as the PVC pipes) The first proposed solution was rejected since the pipes were all faulty, the gauges weren’t reading any pressure, and there were still leaks. Therefore, the second proposed solution was used and the apparatus was remodeled. II. Raw Materials Used In this experiment, the materials used to mirror the old model were the following: PVC pipes of sizes 1-in (with length of 142.5in), 1.5-in (L=50-in), 1.75-in (L=70-in), 2-in (L=99.5-in), with 2 pcs 1/2/1 reducer, 6 pcs 1-in elbow reducer, 1/2/1.75 elbow and 1 pc 1.75-in elbow 2 gate valves Pipe adhesives and solvents Epoxy Submersible pump Water III. Installation of Reconstructed apparatus The installation of the remodeled fluid flow apparatus involves a meticulous process, utilizing PVC pipes of varying sizes to ensure optimal performance. Beginning with the foundation, PVC pipes sized at 1-inch, 1.5-inch, 1.75-inch, and 2-inch are selected to facilitate the fluid's journey through the system. To accommodate transitions between different pipe diameters, two pieces of 1/2/1 reducers are integrated strategically along the pipeline. Additionally, six 1-inch elbow reducers are incorporated to facilitate directional changes where necessary, ensuring smooth flow dynamics. Furthermore, precise curvature adjustments are made with a 1/2/1.75 elbow and a singular 1.75-inch elbow, enhancing the efficiency of fluid movement within the apparatus. Each component is meticulously positioned and secured, adhering to industry standards and safety protocols. The result is a meticulously crafted fluid flow apparatus, meticulously designed and installed to optimize performance and reliability in various applications. The apparatus was remodeled without altering both the upper and bottom tanks. There were also gate valves installed before the opening of the last bottom pipe, and after the first gauge. All the gauges were properly sealed to the pipes, making sure that there is no leakage of fluid. Before using the apparatus, it was first washed and cleaned to prevent clogging and more malfunctions. any changes in pressure or flow behavior within the system. Subsequently, the valves were reopened for another 10second interval to resume the flow. The process was repeated once more, with the valves closed for an additional 10-second duration, followed by their reopening for another 10 seconds. Throughout these intervals of opening and closing the valves, data on pressure drop and flow rates were collected and analyzed to understand the effects of pipes and fittings on the overall performance of the system. By employing this experimental methodology, researchers could systematically investigate how different pipe materials and fittings influenced pressure drop and flow characteristics, providing valuable insights for optimizing piping systems in various engineering applications. V. Post-Experiment After completing the experimentation phase to assess the effects of pipes and fittings on pressure drop using the remodeled 2006 apparatus with plastic pipes, some postexperimental procedures were followed. The equipment was drained with water, the area was cleaned, and the submersible pump was removed from the water at the bottom tank. After noticing pressure differences because of the differences in pipe sizes and fittings, the data are now gathered for interpretation, comparison, and analysis. RESULTS AND DISCUSSION FIGURE I RECONSTRUCTED FLUID FLOW APPARATUS Figure 1 shows the remodeled imitation of the original apparatus wherein PVC pipes were used for cost efficiency. IV. This section of the paper explains what happened during, and presents the data acquired from the experiment. Table 1 below shows the readings of the Pressure gauges (in Psi) during the experimentation proper. The pressure gauges read very low pressures and kept fluctuating. TABLE I Experimentation Proper The experimentation process for assessing the effects of pipes and fittings on pressure drop using a remodeled and reconstructed 2006 apparatus involved several steps. Firstly, the apparatus was set up, comprising plastic pipes instead of traditional materials. Two tanks were utilized: an upper tank and a bottom tank. Inside the lower tank, a submersible pump was placed to pressurize the water, which was then propelled upwards to the feed. Once the apparatus was prepared, the experimentation procedure commenced. Initially, the valves were closed for the first 30 seconds to allow the water to start flowing steadily through the system. After this initial period, the valves were opened for a duration of 10 seconds. This allowed for the observation of the pressure drop and flow characteristics during this interval. Following the 10-second open period, the valves were closed again for 20 seconds to momentarily halt the flow of water. This interruption in flow facilitated the examination of PRESSURE READINGS IN EACH GAUGE Pressure Gauge PG1 PG2 PG3 PG4 PG5 PG6 PG7 PG8 PG9 PG10 PG11 PG12 PG13 Pressure Reading (in Psi) 8 8 10 9 10 10 8 10 0 12 10 Interpreting the data obtained from the experiment earlier entails a comprehensive analysis of the pressure readings recorded by the pressure gauge at various key points throughout the fluid flow system. Each pressure gauge (PG1- PG13) represents a specific location within the system where pressure measurements were conducted, providing crucial insights into the pressure distribution and dynamics within the system. The pressure readings, measured in pounds per square inch (Psi), serve as indicators of the pressure conditions at each respective gauge location, shedding light on the performance and behavior of the system under different operational scenarios. Examining the provided data reveals several noteworthy observations: PG2 to PG4 consistently exhibit pressure readings ranging from 8 to 10 Psi, suggesting a relatively stable pressure environment at these points in the system. These consistent readings imply uniform pressure distribution and flow characteristics within this segment of the piping network. PG5 registers a pressure reading of 9 Psi, aligning with the preceding measurements, and indicating continued uniformity in pressure levels along the system. Similarly, PG6 and PG7 record pressure readings of 10 Psi, mirroring the trend of consistent pressure levels observed in earlier measurements. This further corroborates the notion of a well-maintained pressure regime within the system. However, a significant deviation from this trend is observed at PG11, where a pressure reading of 0 Psi is recorded. This abrupt drop in pressure suggests the presence of a flow obstruction, valve closure, or potential fault within the system, warranting further investigation to identify and address the underlying cause. PG12 and PG13 subsequently display pressure readings of 12 Psi and 10 Psi, respectively, indicating a recovery in pressure levels following the observed drop at PG11. This recovery may suggest the resolution of any transient issues or disturbances affecting the system. PG10 records a pressure reading of 10 Psi, consistent with the preceding measurements, reaffirming stable pressure conditions at this location within the system. Notably, PG11 mirrors the anomalous reading observed at PG8, registering a pressure reading of 0 Psi. This recurring occurrence may indicate a persistent issue or fault at this specific point in the system, necessitating thorough troubleshooting and corrective action. In essence, the data garnered from the experiment offers valuable insights into the pressure dynamics and performance of the fluid flow system, highlighting areas of potential concern and prompting further analysis to optimize system operation and reliability. There are factors that affect pressure drop which are; frictional resistance, changes in flow direction, flow reduction or enlargement from fittings, obstruction and blockages, material and roughness. Each of which contribute to pressure drop of the apparatus and in the experiment, not everything was given focus on since the focus were mostly for the repair of the apparatus. Nevertheless, the conducted experiment proved that the outdated model can still work but with lesser efficiency than when it was first used for operation. RECOMMENDATIONS To obtain accurate results, the researchers suggest to follow the following procedures: - Use a pressure gauge that can read the slightest amount of pressure. - Make sure that no leakage shall happen by securing all fittings and pipes were sealed, - Measure the amount of feed and recycle - Calculate the flowrate of the fluid inside the pipes ACKNOWLEDGMENT I would like to express gratitude to our professor, Engr. Junjun Pajara, for letting us explore the use and mechanism of the equipment ourselves. With that, we established teamwork, collaboration, and also independence. Thanks is also given to my family and of course, my friends for helping me with the parts I lacked knowledge about, and the data I failed to take note of. Lastly, to Father Almighty for keeping me sane and guiding me always through this semester. REFERENCES [1] Habib Ahmari, & Shah. (2019, August 14). Experiment #4: Energy Loss in Pipes. Pressbooks.pub; Mavs Open Press. https://uta.pressbooks.pub/appliedfluidmechanics/chapter/experiment 4/ [2] Central States Industrial. Central States Industrial. https://www.csidesigns.com/blog/articles/what-is-pressure-drop-andhow-does-it-affect-your-processing-system (accessed 2024-03-08). [3] FLOW IN PIPES. (n.d.). https://www.kau.edu.sa/Files/0057863/Subjects/Chapter%208.pdf [4]. McGillivray, R. (2022, January 22). Pressure Gauge Calibration. Tameson.com. https://tameson.com/pages/pressure-gauge-calibration CONCLUSION AUTHOR INFORMATION After the experiment, it was concluded that there were flaws on the fluid flow apparatus, making it unable to produce the desired outcomes. Pipes and fittings can significantly impact pressure drop in a fluid flow system due to their geometrical characteristics and flow obstruction properties. Jermaine Angela B. Prieto, 3rd Year Student, Department of Chemical Engineering, Bicol University College of Engineering..