Managing Products & Services: Operations Management

advertisement

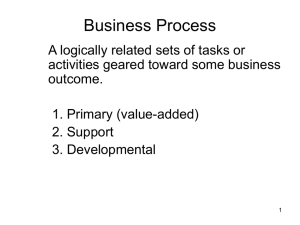

First Topic Assigned Managing Products and Services Group Members: Abpi JR. Jojitnur G. Biruar, Ullysses Al Mohaimen B. Delos Reyes, Angelo Gabriel C. Imam, Datu Shajod A. Jazmines, Anton David B. Masukat, Aljames Carl B. Sangcupan, Caezzar Yazzer L. Tanto, Norhassan M. Organization ❖ Organizations are designed primarily to fi produce products or services. To survive and grow, the operations function must be carried out in the most economical manner possible. As most companies aim for pro tability, all activities, including operations, must contribute to achieving such objectives. Operation fi Refers to any process that accepts inputs and uses resources to change those inputs in useful ways. The transformation process converts the inputs into nal goods and services. Examples of Final Goods and Services Services for the construction of ports, high-rise buildings, roads, bridges, etc., produced by construction rms. ❖ Electrical products like transformers, circuit breakers, switch gears, power capacitors, etc., produced by electrical manufacturing rms. fi ❖ fi Industrial chemicals like methylene chloride, borax powder, phosphoric acid, etc., produced by chemical manufacturing rms. fi ❖ Electronic products like oscilloscope, microwave test systems, transistors, cable testers, etc., produced by electronics manufacturing rms. ❖ Mechanical devices like forklifts, trucks, loaders, etc., produced by manufacturing rms. ❖ Engineering consultancy services for construction management, supervision, project management services, etc., produced by engineering consultancy rms. fi ❖ fi fi Examples of Final Goods and Services fi fi fi Operations Management Is accurately de ned by Aldag and Stearns as "the process of planning, organizing, and controlling operations to reach objectives ef ciently and effectively." Ef ciency relates to the cost of doing something or resource utilization, while effectiveness refers to goal accomplishment. Efficiency ❖ Is related to the cost of doing something or fi resource utilization. When a person performs a job at a lower cost than another, they are more ef cient. Effectiveness refers to goal accomplishment. If one can reach objectives, like producing 10,000 units in a month, they are considered effective. fi fi Operations management must be performed in coordination with other functions like marketing and nance. Although speci c activities of operations divisions differ, the basic function remains the same: to produce products or services. Operations and the Engineer Manager fi The engineer manager, at any management level, is expected to produce output. As a manufacturing engineer, their function is to determine and de ne the equipment, tools, and processes required to ef ciently convert the design of the desired product into reality. In a construction rm, the engineer in charge of operations is responsible for the actual construction of bridges or roads, using the least expensive and easiest methods. The engineer, as an operations manager, must contribute to the production of quality goods or services and cost reduction in their department. fi fi ❖ The typical operations manager has several years of experience in the operations division and possesses an academic background in engineering. Managing Service Processes Managing Service Processes Flowcharting: A visual representation technique using symbols and diagrams to illustrate the sequence of steps and interactions in a service process. ❖ Service Blueprint: A diagram showing how the service elements are connected and related to each other. ❖ Identify Failure: A good blueprint will highlight the risks that go with the service provided. ❖ Failure Proo ng: Identifying and analyzing the possible failures will help in doing corrective actions before everything could go wrong. fi ❖ Managing Service Processes ❖ Setting Service Targets: Standards that align with the customer’s expectations should be set by the service providers to have a satisfactory service. ❖ Service Process Redesign: The service features should be able to keep up with the changes in technology. ❖ Managing Customers Effectively: This is a way to enhance customer performance and reduce customer-induces failures. Types of Transformation Process Types of Transformation Process Manufacturing Processes A. Job shop B. Batch ow C. Worker-paced line ow D. Machine-paced line ow E. Batch/continuous ow hybrid F. Continuous ow fl fl fl fl fl Manufacturing processes involve making products by hand or with machinery. Manufacturing Processes ❖ Batch ow processes manufacture lots of generally own-designed products. It offers exibility in producing low or high volumes, with not all procedures performed on all products. Examples include wineries, scrap-metal reduction plants, and road-repair contractors. fl A job shop's production is based on sales orders for various small lots. Job shops are useful for manufacturing small lots needed by many companies. fl ❖ Manufacturing Processes fi A machine-paced assembly line produces standard products with machines playing a signi cant role. Examples include automobile manufacturers like General Motors and Ford Motors. Characteristics include a clear, rigid process pattern, specialized equipment, line ow layout, capital equipment as a bigger cost item than labor, large operation size, and machine-paced processes. fl ❖ fl A worker-paced assembly line is arranged to process large volumes of standardized products or services. Examples include food marts like McDonald's and Shakeys. Characteristics include standardized products, a clear process pattern, specialized equipment, variable operation size, worker-paced processes, line ow layout, and labor as a signi cant cost item. fi ❖ Manufacturing Processes fl Continuous ow processing is characterized by the rapid rate at which items move through the system. It is suitable for producing highly standardized products like calculators, typewriters, automobiles, televisions, cellular phones, etc. Characteristics include an economy of scale in production, a clear and rigid process, the use of specialized equipment, line ow layout, highly capitalintensive operations, very large operation size, and fast processing. fl ❖ fl Batch/Continuous Flow Hybrid combines batch and continuous ow methods. Two distinct layouts are used, one for batch and one for continuous ow. Examples include breweries, gelatin producers, and tobacco manufacturers. fl ❖ Types of Transformation Process Service Processes A. Service factory B. Service shop C. Mass service D. Professional service Service processes involve providing services to individuals either by hand or with machinery. Service Processes Service Factory: A service factory offers a limited mix of services, resulting in some economies of scale. This allows the company to compete in terms of price and service production. ❖ Service Shop: A service shop provides a diverse mix of services. The layout used is similar to job shops or xed positions and is adaptable to various requirements. ❖ Mass Service: A mass service company provides services to a large number of people simultaneously. A unique processing method is necessary to satisfy this requirement, offering a limited mix of services. fi ❖ Service Processes fi Professional Services: Professional services provide specialized services to other rms or individuals. Examples include engineering or management consulting services, design services, advertising agencies, accounting services, legal services, data processing services, and health services. Professional service rms offer a diverse mix of services, have lower capital equipment utilization compared to service factories and service shops, use a loose process pattern, and have a process layout identical to a job shop. fi ❖ Service Processes They often face delivery problems due to non-uniform demand, and strategies to address this include staggered work-shift schedules, hiring part-time staff, providing customers with the opportunity to select the level of service, installing auxiliary capacity or hiring subcontractors, using multi-skilled oating staff, and installing customer self-service. fl ❖ Important Parts of Productive System Important Parts of Productive System Product Design: Customers expect products to perform according to assigned functions. Good product design assures this. Product design refers to the process of creating a set of product speci cations appropriate to the demands of the situation. ❖ Production Planning and Scheduling: Production planning involves forecasting future sales, translating forecasts into demand for various production facilities, and arranging procurement. It is crucial for capacity decisions, reducing opportunities for wastages. fi ❖ ❖ Purchasing and Materials Management: Firms need to purchase supplies and materials ef ciently for production activities. Proper management of purchasing and materials is essential, especially in high-volume production rms. ❖ Inventory Control: Inventory control establishes and maintains appropriate levels of reserve stocks of goods. Balancing reserve levels is critical to avoid high storage costs and related risks. fi fi Important Parts of Productive System ❖ Quality Control: Quality control measures products or services against standards set by the company. Maintaining standard requirements facilitates production and keeps customers satis ed. Poor quality control leads to customer complaints, returned merchandise, expensive lawsuits, and signi cant promotional expenditures. fi Work-Flow Layout: Work- ow layout determines the physical arrangement of the production system, minimizing investment, production time, utilizing existing space effectively, ensuring employee convenience, safety, and comfort, maintaining exibility, minimizing material handling costs, reducing variation in types of material-handling equipment, facilitating the manufacturing or service process, and organizational structure. fl ❖ fi fl Important Parts of Productive System fi fi SUMMARY Organizations aim for economical operations. Operations, transforming inputs into goods and services, demand ef cient management for pro tability. Key Points ❖ Operations: Any process changing inputs into goods/services. Operations Management: Involves planning, organizing, and controlling to reach objectives ef ciently. ❖ Ef ciency vs. Effectiveness: Ef ciency relates to cost/resource utilization, effectiveness to goal accomplishment. ❖ Engineer Manager's Role: Producing quality goods/services, reducing costs. fi ❖ fi fi Examples: Industrial chemicals, construction services, electrical/electronic products, mechanical devices, engineering consultancy. A. Service factory B. Service shop C. Mass service D. Professional service fl A. Job shop B. Batch ow C. Worker-paced line ow D. Machine-paced line ow E. Batch/continuous ow hybrid F. Continuous ow fl Service Processes fl Manufacturing Processes fl fl Types of Transformation Process Important Components Product Design: Ensures products meet functional expectations. ❖ Production Planning: Forecasting sales, arranging production facilities. ❖ Purchasing and Materials Management: Ef ciently managing supplies/materials. fi ❖ Important Components ❖ Inventory Control: Balancing stock levels for cost-effectiveness. ❖ Work-Flow Layout: Organizing the physical arrangement for ef ciency. ❖ Quality Control: Measuring against company standards to ensure customer satisfaction. fi fi Conclusion: Ef ciently managing these components ensures cost-effective operations and customer satisfaction.