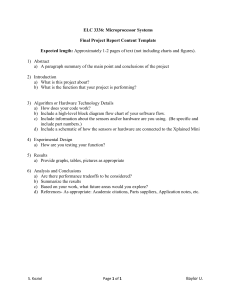

966 JOURNAL OF MICROELECTROMECHANICAL SYSTEMS, VOL. 26, NO. 5, OCTOBER 2017 Thermoresistive Effect for Advanced Thermal Sensors: Fundamentals, Design Considerations, and Applications Toan Dinh, Hoang-Phuong Phan, Afzaal Qamar, Peter Woodfield, Nam-Trung Nguyen, and Dzung Viet Dao Abstract— Microelectromechanical systems sensors have been intensively developed utilizing various physical concepts, such as piezoresistive, piezoelectric, and thermoresistive effects. Among these sensing concepts, the thermoresistive effect is of interest for a wide range of thermal sensors and devices, thanks to its simplicity in implementation and high sensitivity. The effect of temperature on the electrical resistance of some metals and semiconductors has been thoroughly investigated, leading to the significant growth and successful demonstration of thermal-based sensors, such as temperature sensors, convective accelerometers and gyroscopes, and thermal flow sensors. In this paper, we review the fundamentals of the thermoresistive effect in metals and semiconductors. We also discuss the influence of design and fabrication parameters on the thermoresistive sensitivity. This paper includes several desirable features of thermoresistive sensors and recent developments in these sensors are summarized. This review provides insights into how it is affected by various parameters, and useful guidance for industrial designers in terms of high sensitivity and linearity and fast response. [2017-0022] Index Terms— Thermoresistive effect, semiconductor, metal, two-dimensional (2-D) material, thermal sensor, temperature sensor, thermal flow sensor, convective accelerometer, gyroscope. I. I NTRODUCTION F OR MORE than three decades, MEMS (Micro ElectroMechanical Systems) sensors have been developed aiming at high sensitivity, fast response, stability and reproducibility, miniaturization capability and mass production. The working principle of these sensors is based on a variety of physical phenomena such as thermoresistive, piezoresistive, pseudohall, thermoelectric and piezoelectric effects [1], [2]. Among these effects, the thermoresistive effect, which refers to the electrical resistance change with temperature variation, has many advantages in terms of simplicity in design and implementation. Based on this effect, various micro-sized thermal sensors, which can monitor temperature [3], flow [4], [5] and acceleration [6], [7], have been successfully fabricated, thanks to the advancement in MEMS technologies. Manuscript received January 26, 2017; revised April 26, 2017; accepted May 26, 2017. Date of publication June 12, 2017; date of current version September 29, 2017. Subject Editor P. M. Sarro. (Corresponding author: Toan Dinh.) T. Dinh, H.-P. Phan, A. Qamar, D. V. Dao, and N.-T. Nguyen are with the Queensland Micro-Nanotechnology Centre, Griffith University, Nathan, QLD 4111, Australia (e-mail: toan.khac.dinh@gmail.com; toan.dinh@griffithuni.edu.au). P. Woodfield is with the Griffith School of Engineering, Griffith University, Nathan, QLD 4111, Australia. Color versions of one or more of the figures in this paper are available online at http://ieeexplore.ieee.org. Digital Object Identifier 10.1109/JMEMS.2017.2710354 To date, a number of thermal sensing materials have been employed for developing thermal sensors, including metals (e.g. platinum and nickel) and semiconductors (e.g. silicon and polysilicon) [5], [8]. For example, platinum has been used for constructing thermal flow sensors, owing to its linear thermoresistive response, compatibility with microelectronic technologies and relatively high positive temperature coefficient of resistance (TCR) [8]. In addition, semiconductors could also be deployed for thermal sensors, thanks to their wide range of TCR values from positive to high negative. Interestingly, the TCR of semiconductors can be tuned using different doping levels [9] or changing growth parameters [10]. However, the fabrication of these sensors, which requires expensive materials, clean room facilities and specialized wafer processing equipment, has increased their cost, especially for small-scale production [11], [12]. Moreover, the fabrication of thermal flow sensors have involved various solvents and chemicals which are unfriendly for the environment and could lead to contamination issues. In addition, these sensors are unable to work in harsh conditions such as hightemperature and corrosive environments. Therefore, there is a strong demand for investigating alternative novel thermal sensing materials for advanced thermal sensors. Desirable characteristics for these sensors would be (1) low cost and high sensitivity, (2) linear response, stability and sustainability, (3) capability of working in harsh environments such as at high temperatures and (4) flexibility and suitability for a wide range of applications, including the emerging field of wearable applications. The present paper reviews the fundamentals of the themoresistive effect (Figure 1, top-left), and the impact of design and fabrication parameters on its sensitivity (Figure 1, topright). The desirable features for thermoresistive sensors such as sensitivity, linearity and response time are also mentioned (Figure 1, bottom-right). In addition, the applications of this effect for thermal sensors, including temperature sensors, thermal flow sensors and convective accelerometers/gyroscopes, are presented (Figure 1, bottom-left). Finally, current trends and perspectives for the development of the thermoresistive effect and its applications are discussed. This review provides useful design guidance to engineers and researchers who are working on the development of thermal sensors. Following, section 2 revisits the fundamental aspects of thermoresistive effects, including those in semiconductors and metals. Section 3 discusses the impact of design and process 1057-7157 © 2017 IEEE. Personal use is permitted, but republication/redistribution requires IEEE permission. See http://www.ieee.org/publications_standards/publications/rights/index.html for more information. DINH et al.: THERMORESISTIVE EFFECT FOR ADVANCED THERMAL SENSORS 967 Fig. 1. A brief overview of the thermoresistive effect, its design parameters, desirable features and applications. “Materials”: Reproduced from [34] and [36] with permission from the Royal Society of Chemistry and Elsevier. on the performance of thermoresistors. The key parameters are the doping concentration, the material and morphology, the deposition temperature, the grain size and thickness. Section 4 considers the desirable features for thermoresistive sensors, including sensitivity, linearity, time response, power consumption and stability. Finally, section 5 discusses typical applications of the thermoresistive effect such as temperature sensing, flow sensing and acceleration sensing. the temperature difference; T and T0 are the absolute temperature and reference temperature (normally room temperature), respectively. Moreover, the change in the electrical resistance caused by the influence of the change in the surrounding temperature is known as the thermoresistive effect. In addition, the resistance change under the effect of temperature variation is attributed to the geometric effects (αT ) and the change in resistivity (ρ/ρ) [14]: II. F UNDAMENTALS OF T HERMORESISTIVE E FFECT ρ R = − αT R ρ In general, the electrical resistance of a homogeneous bar or film can be expressed in terms of its resistivity and geometry as follows: R=ρ l wt (1) where R and ρ are the electrical resistance and resistivity of the material, respectively; l, w and t are the length, width and thickness of the bar/film, correspondingly. Based on Eq. 1, the resistance change (in the limit of small changes) can be calculated depending on the resistivity change and the dimension changes [13], [14]: ρ l w t R = + − − R ρ l w t (2) The change in each dimension (e.g. length, width and thickness), under a temperature variation, is the same because of the homogeneous property of the material. This depends on the thermal expansion coefficient (TEC, α) of the bar/film as l/l = w/w = t/t = αT , where T = T − T0 is (3) For common metals, while the change in resistivity ranges from 3,900 to 6,800 ppm/K, the geometric effects alone contribute to the TCR less than 30 ppm/K [5], [15]. Therefore, the error in neglecting geometric effects is less than 0.61 % (see Table I). Moreover, for bulk semiconductors, the contribution of geometric effects to the TCR is less than 5 ppm/K and the resistivity change depends upon various parameters such as doping levels, morphologies and temperature ranges. It is important to note that the temperature ranges also influence the TCR of metals. The common value of TCR for bulk semiconductors used for thermal sensing applications is from several thousands to several ten thousands ppm/K [5], [15]. For example, the geometry of silicon (TCR = -6,000 ppm/K [16]) contributes to 2.6 ppm/K, corresponding to an error of 0.04%. Therefore, the geometric effects could be neglected when the structure is employed for temperature sensing purposes. Thus, the TCR is commonly defined as [13], [14]: TCR = ρ 1 R 1 = R T ρ T or T C R = 1 dR R dT (4) 968 JOURNAL OF MICROELECTROMECHANICAL SYSTEMS, VOL. 26, NO. 5, OCTOBER 2017 TABLE I R ESISTIVITY AND TCR OF M ETALS U SED IN T HERMAL -BASED S ENSORS , AND I MPACT OF T HERMAL E XPANSION ON TCR [5], [15], [89] In addition, the resistivity and TCR of thin films also depend upon their thickness. For example, when the thickness of the film shrinks to the nanoscale (e.g. lower than 100 nm), its resistivity increases significantly due to the increase in the number of defects and boundaries in the film [17]. In addition, the absolute TCR of thin-film semiconductors could also increase with decreasing thickness because of the increase in thermionic emission of the trapped carriers in the thin film at elevated temperatures [17]. A high absolute TCR is desired for thermal sensing applications, since a sensor made of a high TCR material commonly performs well, exhibiting corresponding high sensitivity. This section first discusses thermoresistive principles and then reviews the thermoresistive effect in common sensing materials such as metals, silicon and silicon carbide. A. Thermoresistive Effect in Semiconductors This section discusses the thermoresistive effect in silicon, which can be extended to other semiconductors [1], [2]. The thermoresistive effect arises because temperature affects the number of carriers and their mobility in conducting materials. In single crystalline materials, the number of free charge carriers increases with the rise of temperature due to their ability to be excited by thermal energy. This leads to an improvement in electrical conductivity. However, the mobility of the carriers decreases with increasing temperature due to the scattering effect of lattice vibrations. Therefore, when the temperature increases, the resistivity of the semiconductors may decrease (negative temperature coefficient of resistance NTCR), or increase (positive temperature coefficient of resistance - PTCR), depending upon the change in the number of carriers and their mobility. This dependence can be expressed by [1], [2]: 1 = σ = enμe + epμh (5) ρ where σ and e are the conductivity and electron charge, respectively; n and p are the electron concentration and hole concentration; respectively; μe and μh are the corresponding electron mobility and hole mobility. Figure 2 shows three temperature-dependent regions for the resistivity of semiconductors. At sufficiently low temperatures (extrinsic region), more carriers (n ∼ T α ex p(E d /kT ), where E d is the activation (ionization) energy of donors, Fig. 2. Temperature-dependent resistivity in semiconductors. α is a constant and k is the Boltzmann constant, for n-type Si, α = 3/2) would be generated by thermal energy and excited to jump to the conduction band (CB). This is apart from existing carriers, which would always contribute to electrical conductivity. In addition, lattice scattering causes a slight reduction of mobility (μ ∼ T −β , where β is a constant, for extrinsic silicon β = 3/2). The combination of the carrier concentration and mobility can lead to a decrease in electrical resistivity (a negative TCR). Therefore, the electrical resistance R of n-type semiconductors can be expressed in the following form [1], [18]: Ed (6) R = Aex p kT where A is a constant. The decrease in electrical resistivity in the extrinsic region can be determined by a slope of E d /k. However, at a higher temperature range (metal-like region), the free carrier concentration is saturated while the carrier mobility still decreases [19]. This region exhibits a positive TCR. In addition, at the highest temperature range (intrinsic region), a significant number of bonds are being ruptured and the carrier concentration increases. As a result, the temperature-dependent resistance of semiconductors is E commonly described as R = R0 ex p 2kTg , where E g is the energy gap, and the slope of E g /2k defines the decrease of resistivity in this region. For semiconductor temperature sensors, the temperature dependence of electrical resistance is generally used in the DINH et al.: THERMORESISTIVE EFFECT FOR ADVANCED THERMAL SENSORS following form [1], [2], [19]–[21]: 1 1 R = Aex p B − T T0 969 (7) where A is a constant; B is the thermal index, which is used to evaluate the sensitivity of the thermoresistive effect in thermistors, as an alternative parameter to the TCR. B is calculated as E g /2k for semiconductors in the intrinsic region and E d /k for n-type semiconductors in the extrinsic region. The relationship between B and TCR can be written as B = −T C R × T 2 [1], [2], [19]. In the following subsections, we discuss the thermoresistive effect in several different materials for niche applications. 1) Thermoresistive Effect in Silicon and Silicon Nanostructures: It is well-known that Si has been a main-stream material for conventional thermal sensors such as thermal flow sensors and convective accelerometers. The thermoresistive effect in Si has been investigated in terms of temperature dependence of resistivity, carrier concentration and carrier mobility [22]–[30]. For example, the resistivity of in highly doped silicon increases with increasing temperature, due to the dominance of the scattering effect, and then decreases when the temperature is high enough for providing thermal energy to break silicon bonds and generating more carriers. Recent research has focused on the physical effect of Si at nano-scale levels since the carrier mobility of Si nanostructures significantly depends their surface-area-to-volume ratio [31]. Great effort has been made for the development of silicon nanowires (SiNWs) fabricated using bottom-up and top-down approaches [32]–[34]. However, the thermoresistive sensitivity of these SiNWs has been found to be similar to that of bulk and micro-level silicon devices [35], [37], [38]. For example, Wang et al. [35] reported a TCR of SiNWs fabricated by a bottom-up vapor-liquid-solid (VLS) process, which ranges from -3,700 to 120 ppm/K. As these TCR values are relatively low and not of interest for thermal sensing applications, achieving a higher thermoresistive sensitivity and the ability to integrate into nano-systems would be a trend in the development of thermoresistive devices. We used a Focused Ion Beam technique to fabricate SiNWs (Figure 3(a)) by locally amorphizing the single crystal structure, then employed an annealing process to recrystallize the structure for improving the electrical conductivity [36] (Figure 3(b)). This top-down process has resulted in a nanocrystalline structure for the SiNWs (Figure 3); hence a high thermoresistive sensitivity of up to -12,000 ppm/K was observed for the SiNWs (Figure 3(c,d)). However, the thermoresistive properties of Si are significantly degraded at high temperatures. Therefore, alternative materials such as silicon carbide have been investigated, and showed potential for thermal sensors operating in harsh conditions. The following section will discuss the current status of the thermoresistive effect in silicon carbide. 2) Thermoresistive Effect in Silicon Carbide (SiC) for Thermal Sensors Operating in Harsh Environments: Silicon carbide (SiC) is one of the most promising candidates for thermal-based sensors operating in harsh environments, due to its large band gap and superior physical properties [39]–[43]. The thermoresistive effect in SiC Fig. 3. Thermoresistive effect in SiNWs. (a) A 10 μm×0.2 μm× 0.06 μm SiNW fabricated by a Focused Ion Beam method. (b) Nanocyrstalline structure of the SiNW examined by High-Resolution transmission electron microscopy (HRTEM). (c) Relative resistance change of the SiNWs. (d) TCR of the SiNWs. Reproduced from [34] and [36] with permission from the Royal Society of Chemistry and Elsevier. Fig. 4. Thermoresistive effect in SiC. (a) Scanning electron microscopy (SEM) image of the single crystalline 3C-SiC on a glass substrate [48]. (b) TCR of 3C-SiC on glass [48]. (c) Relative resistance change and TCR of a-SiC [54]. (d) Arrhenius plot of thermoresistance in a-SiC [54]. Reproduced from [48] and [54] with permission from the Royal Society of Chemistry. has been investigated in terms of the temperature effect on carrier concentration and its mobility in crystalline SiC [44]–[46]. In p-type 3C-SiC, the hole mobility is limited by acoustic phonon scattering above 300 K and by ionized impurity scattering at temperatures below 250 K [44], [45], following the rule μ H ∼ T −β , where β value ranges from 1.2 to 1.4. In addition, highly doped n-type 3C-SiC has a positive TCR from 400 to 7,200 ppm/K [47]. Up-to-date, most of high quality 3C-SiC has been grown on Si substrate with large area and low cost. However, a large current leakage to the substrate was observed at temperatures above 100 ◦ C [48], indicating that SiC on Si platform is not suitable for thermal sensors at high temperatures. Therefore, SiC films have been transferred on to a glass substrate [48] (Figure 4(a)) to avoid 970 JOURNAL OF MICROELECTROMECHANICAL SYSTEMS, VOL. 26, NO. 5, OCTOBER 2017 the current leakage. The thermoresistive properties of SiC on glass has been investigated with a relatively high temperature coefficient of resistance of up to -5,500 ppm/K [48] (Figure 4(b)). Another advantage of SiC is that its themoresistive properties are not affected by the visible light illumination [49]. In addition, we proved that the thermoresistive effect can tune the sensitivity of SiC material to stress/strain [50]. The hole mobility of other polytypes (6H-SiC and 4H-SiC) was also investigated, and followed the same rule as that of 3C-SiC, but with a stronger dependence on temperature, in which the β value ranges from 2 to 2.6 [51], [52]. The hypothetical reason is that the electron mobility of these polytypes at high temperatures is restricted by intervalley scattering and acoustic phonon scattering. However, the mobility of 3C-SiC is limited by acoustic phonon scattering, and little affected by intervalley scattering, owing to the crystal symmetry of 3C-SiC. These scattering phenomena would affect the temperature-dependent resistivity of n-type and p-type 6H-SiC. For example, Okojie et al. [53] reported a variation of TCR from -3,400 to 5,600 ppm/K, which depends upon the semiconductor type and the doping levels. Recently, the thermoresistive effect in amorphous SiC (a-SiC) has been investigated [54], showing a very large negative TCR of from -16,000 to -4,000 ppm/K (Figure 4(c)). By analyzing the themoresistive properties of a-SiC, the energy characteristics of this system were investigated with two activation thresholds of 150 and 205 meV, corresponding to temperature ranges of 300 to 450 K and 450 to 580 K, respectively (Figure 4(d)). 3) Thermoresistive Effect in Graphite for Low-Cost and Environmentally Friendly Thermal Sensors: As discussed in the previous sections, metals and semiconductors have been employed for conventional thermal sensors. However, these expensive materials have commonly involved complex processes and toxic chemicals. Therefore, there is a strong demand to investigate the low cost and environmentally friendly materials for thermal sensors. Graphite is well-known for this purpose because of its ubiquitousness and relatively high temperature coefficient of resistance (TCR) [55]. The TCR of graphite was observed to be positive [56], which was explained based on the spacing of stacking faults in graphite [57], tunneling conduction, impurity-assisted hopping conduction and a combination of hopping and scattering of carriers by phonons [56]. However, a number of other studies indicated a negative TCR for different types of graphite, which could be attributed to the defects and boundaries in graphite [58]–[60]. A negative TCR of approximately -3000 ppm/K was observed for temperatures of up to 200◦ C and a positive TCR for higher temperatures [61]. Other studies have also reported the thermoresistive effect in graphite at lower temperature ranges [62], [63]. Alternatively, the thermoresistive effect in graphite inks has been reported [64], [65], showing a positive TCR of lower than 2200 ppm/K. However, pencil graphite showed a relatively high negative resistance change from -2,900 to 4,400 ppm/K (Figure 5), which is comparable to that of common temperature sensing materials such as platinum, copper Fig. 5. Thermoresistive effect in graphite [66]. (a) Graphite resistance change as a function of temperature. (b) Temperature coefficient of resistance (TCR) of pencil graphite. Reproduced from [66] with permission from the Royal Society of Chemistry. Fig. 6. Thermoresistive effect in carbon nanotubes [75]. (a) CNT resistance change as a function of temperature. (b) Temperature coefficient of resistance (TCR) of CNT. Reproduced from Ref. [75] with permission from the Royal Society of Chemistry. and nickel [66]–[68], which was explained based on the theory of the boundary between graphite crystallites (referred to Figure 8(b), “C. Material choice and impact of morphologies” section). In this theory, carriers are excited by thermal energy can pass through or pass over the barrier between graphite crystallites, which lead to an increase in the electrical conductivity of graphite. 4) Thermoresistive Effect in Carbon Based Nano-Materials: Recent studies have paid attention to the thermoresistive effect in nano-materials such as carbon nanotubes (CNTs) [69]–[72] and graphene [73], [74]. However, thermoresistive sensitivities of these materials are relatively low (e.g. absolute TCR values are commonly lower than 1250 ppm/K). In addition, the current difficulties in releasing these materials make them challenging to use in Joule heating based thermal sensors. To date, few studies have demonstrated the use of these materials in Joule heating based thermoresistive sensors [75], [76]. Figure 6 shows the thermoresistive effect in CNT yarns with a TCR of approximately 750 ppm/K, which has been used for temperature and flow sensing applications [75]. In some cases, when these materials are mixed with others to make a composite (e.g. epoxy/MWCNT composite, multi-walled carbon nanotubes (MWCNTs)/styrene-b-(ethylene-co-butylene)b-styrene (SEBS) triblock copolymer), their thermoresistive sensitivity can increase and they are potential candidates for highly sensitive temperature sensors [20], [71], [72]. 5) Thermoresistive Effect in Compounds and Other Materials: It is important to note that a giant thermoresistance is desired for thermal sensing applications, and this can be achieved using ceramics and nanocomposites. As such, DINH et al.: THERMORESISTIVE EFFECT FOR ADVANCED THERMAL SENSORS the giant thermoresistance with a temperature coefficient of resistance of up to -6%/K (the thermal index B is from 2000 to 5000 K) was achieved [3], [77]. In the temperature sensing area, it is well-known that ceramic thermistors have been commercially available thanks to their high sensitivity and accuracy and low cost [3]. In contrast to Si-based temperature sensors, oxide semiconductor (ceramic) thermistors have a carrier concentration, which is solely determined by the doping levels; however, the carrier mobility is thermally activated with increasing temperature and the increase in the conductivity is mainly due to hopping of carriers between localized states in the mobility gap. This leads to an extremely large thermoresistive effect in ceramic thermistors. Different giant positive temperature coefficients of resistance have been reported for various nano-composites [78]–[83], in which the conduction mechanism is mainly based on a volume expansion of the composites. This leads to an increase of the distance between conductive nanotubes or nano-particles, or a breakage of conductive pathways. Therefore, a positive temperature coefficient of resistance has been commonly observed for the nano-composites. In some cases, when the electrons in nano-composites are provided enough thermal energy by the increasing temperature, they can tunnel over the separating gaps and the conduction of the composites is thermally activated with a negative TCR [78]. Recently, two-dimensional (2D) materials such as transition metal dichalcogenides (e.g. MoS2 , MoSe2 and WS2 ) have attracted much interest for electronics and sensors, owing to their excellent mechanical, electronic, optoelectronic properties and potential for extremely low power consumption. These materials are constructed based on the arrangement of atomic layers. The electrical conductivity along c-axis (perpendicular to the atomic layers), σ|| , is less than that perpendicular to c-axis (σ⊥ ) and depends upon the number of layers [84]–[86]. When the number of layers decreases to a few (e.g. single layer and bi-layer), the contribution of σ|| is significant. In this case, it has been proven that the tunability of σ|| by electrical field enables high-performance electronics (e.g. transistors) [87]. In addition, the tunability of σ|| by thermal energy (or temperature) can enhance thermoresistive properties of these materials. However, the state-of-the-art results on thermoresistive effects in 2D materials have been limited to bulk forms [84], [85] and few layers at low temperature ranges (<300 K) [87]. Therefore, there are great opportunities to explore the potential of 2D materials for thermoresistive sensors. B. Thermoresistive Effect in Metals In metals, electron concentration in metals is constant (n = const) and contributes to electrical conductivity. There are no more carriers generated as the temperature increases, but the mobility of the existing carriers decreases linearly (μe ∼ T −1 ), due to the scattering effect. As a result, the resistivity or resistance R increases linearly with increasing temperature (ρ ∼ T ) as follows: R = R0 (1 + T C R(T − T0 )) (8) where R0 is the electrical resistance at reference temperature T0 . Therefore, metals commonly show a positive 971 temperature coefficient of resistance (TCR) [5], [15], [88]. Table I shows the TCR of several common metals, which are commonly used for thermal sensing applications [5], [15]. The data from the I indicates positive TCR values ranging from 4000 to 7000 ppm/K and a geometric effect of less than 30 ppm/K. III. I MPACT OF D ESIGN AND P ROCESS ON P ERFORMANCE OF T HERMORESISTORS High-performance thermoresistors are needed to achieve highly sensitive thermal sensors. For example, the sensitivity of thermoresistors strongly depends on the substrates on which these thermoresistors are fabricated. Moreover, doping type and doping level play an important role in determining the sensitivity of semiconducting thermoresistors. The dependence of sensitivity is expanded to the morphology (e.g. crystalline, polycrystalline and amorphous structures) of the thermoresistive materials. In addition, designers should also pay attention to grain size of thermoresistors in choosing deposition temperature and thickness of thermoresistors. A. Substrate Influence For bulk materials, a substrate to support constructing thermoresistive devices is not commonly required. However, for thin film thermoresistive sensors, there is an additional thermal expansion mismatch between the films and their supporting substrates. This effect of substrates on the thermoresistive properties of thin films plays an important role in the accuracy and sensitivity of such devices [14], [15], [90]. There are various studies, which have aimed at evaluating the influence of the substrate on the thermoresistive property of the thin films [14], [15], [90]–[92]. As such, Hall et al. [14] suggested a contribution of 65 ppm/K for thin films supported by glass substrates and a replacement for soft glass of fused quartz can shift the TCR to 36 ppm/K. This effect is quite significant, since the TCR of typical thin films is lower than 100 ppm/K. Similarly, Verma et al. [15], developed a general equation for estimating the impact of thermal strain on the thermoresistive effect in thin films as follows: −2(αl f − αls ) γ (1 − μ f ) + μ f (1 − γ ) (9) = 1 −μf where is the difference between TCR of thin films with and without substrates, αl f and αls are the thermal expansion coefficient of films and substrates, respectively; μ f and γ are the Poisson⣙s ratio of thin films and the strain coefficient of resistivity (G F), respectively. To date, very limited work is available on the impact of semiconducting substrates on the thermoresistive properties [93]. On one hand, the current leakage to the semiconducting substrates at elevated temperatures would make the semiconducting substrates not suitable candidates for thermoresistive sensors at high temperatures [93]. In addition, it is required to isolate the thermoresistive sensing elements from the heater and reduce the power loss to the substrate. Therefore, the thermoresisisive sensors are commonly developed on suspended membranes or insulation substrates such as 972 JOURNAL OF MICROELECTROMECHANICAL SYSTEMS, VOL. 26, NO. 5, OCTOBER 2017 TABLE II A CTIVATION /I ONIZATION E NERGY OF I MPURITIES IN S EMICONDUCTORS [98]–[110] glass, alumina, fused quartz and silicon nitride [14], [94], [95]. In many cases, silicon dioxide (or glass) membranes are preferable as supporting layers for thermoresistive sensors because silicon dioxide has a very low thermal conductivity (e.g. ∼ 1.38 W/(mK)) in comparison with that of silicon nitride (e.g. ∼ 28 W/(mK)) [95]. This is due to the fact that a low thermal conductivity would minimize the conduction heat loss to the substrate. On the other hand, a semiconducting substrate could be also used as an active layer, and the combination of the substrate and the functional layer can create other electronic devices such as diodes [96]. The thermoresistive behavior between these layers has been used for highly sensitive temperature sensors. A detailed review on these devices can be found elsewhere [97]. B. Doping Influence 1) Doping Type: As previously mentioned, the thermoresistive sensitivity depends upon the activation energy (or ionization) energy of dopants. As such, a dopant with high activation energy E d (or E a ) can provide a large temperature coefficient of resistance (T C R = −E d /T 2 ) or a large slope E d /k. The activation energy of donors or acceptors can be calculated using band gap theory [2]. Nitrogen has been commonly used as a donor for Si and SiC while aluminum (Al) and boron (B) have been frequently employed as acceptors. Table II shows the measured ionization energy (E d and E a ) for various impurities in Si and silicon carbide [98]–[110] at room temperature. Doping in semiconductors refers to the introduction a small amount of impurities into the crystal to increase the number of carriers that are excited by thermal energy and contribute to the electrical conductivity [1], [2]. In contrast, the doping in ceramics (a mixture of metal dioxides) refers to the substitution of impurities into chemical sites (e.g. metal or oxygen ions), which leads to changes in the way electrons ’hop’ between ions of the chemical species [3], [111], [112]. 2) Doping Level: There are various studies on the doping dependence of activation energy. It has been reported that activation energy decreases with increasing doping levels [26], [113]–[115]; hence there is a decrease in the thermoresistive sensitivity. Lopatiuk-Tirpak et al. [113] reported a reduction of activation energy of p-type ZnO from 212 to 135 meV with an increase in the doping level from 1.3×1017 to 1.3×1018 cm −3 . The dependence of this activation energy on doping levels is attributed to the formation of the band-tail states, which extend into the forbidden gap and the expansion of the acceptor band. Fig. 7. Impact of doping levels on the thermoresistive effect in semiconductors. (a) Doping dependence of the thermoresistive effect in polysilicon [9]. Reprint with permission from [9]. (b) Doping dependence of the thermoresistive effect in silicon carbide [118]. It was also hypothesized that this dependence is due to the Coulomb interaction between holes in the valence band (VB) and the ionized acceptor states, which leads to the reduction of binding energy. A similar behavior of Si-doped n-typed GaN was reported, exhibiting a reduction of activation energy from 28 to 21 meV with carrier concentrations increasing from 7.25×1017 to 1.6×1019 cm −3 [114]. An activation energy of 40 to 54 meV was reported for SiC [116], also depending on the doping level. The thermoresistive sensitivity of other materials such as silicon and silicon carbide can be controlled by adjusting doping levels [9], [47], [53], [117]. Seto et al. [9] reported a significant improvement in the thermoresistive sensitivity of polysilicon with decreasing doping levels. At low doping points (e.g. ∼ 1016 cm −3 ), the ionization energy is almost half the energy gap value (approximately 0.5 eV) of single crystalline silicon while it reduces to 0.025 eV at a high doping level of 1019 cm −3 (Figure 7(a)). The mechanism of this effect was hypothesized based on a decrease in the barrier height and barrier width with increasing doping levels. The TCR value of silicon was also reported to depend upon doping levels [116]. As such, when decreasing the doping level from 1018 to 1014 cm −3 , the TCR value reduces from approximately 8000 ppm/K to almost 0 ppm/K at room temperature. Furthermore, Shor et al. [47] have reported the doping dependence of 3C-SiC resistivity. At unintentional doping levels, all impurities are ionized below room temperature, and the resistivity increases (T C R ∼ +0.72% /◦ C) with increasing temperatures above room temperature due to the dominant scattering effect. However, at low doping levels, the temperature at which the resistivity reaches a minimum value, is higher (around 200 ◦ C). In the case of degenerately doped 3C-SiC, all impurities are ionized at all DINH et al.: THERMORESISTIVE EFFECT FOR ADVANCED THERMAL SENSORS temperatures, and the scattering effect plays the dominant role, leading to a constant TCR value of 400 ppm/K. Recently, Latha et al. [118] has reported the effect of nitrogen doping on the thermoresistive effect in 3C-SiC (Figure 7(b)), showing an increase in the thermoresistive sensitivity with decreasing doping levels of nitrogen. The change of 6H-SiC resistivity depending on doping levels has been also investigated [53]. For instance, a low doping level (1017 cm −3 ) is fully ionized at 0◦ C, while a high doping level (1019 cm −3 ) has a higher ionization temperature of 500 ◦ C. At the same doping level of 2 × 1019 cm −3 , the p-type 6H-SiC shows a higher absolute TCR in comparison with the n-type. Also with high doping levels, impurity scattering is considered to be the dominant mechanism. C. Material Choice and Impact of Morphologies 1) Material Choice: In general, the use of thermoresistive materials for developing thermal sensors depends upon expected performance and applications. A large thermoresistive effect (i.e. large TCR) is desired for thermoresistive sensors in terms of sensitivity. Nanocomposites and compound materials (mentioned in Section II. A) are potential candidates for this purpose; hence they are commonly employed as sensitive temperature sensors [78]–[83]. However, the disadvantages of these materials are the non-linear and hysteresis characteristics, which require additional circuitry and complex processing of sensor signals for accurate measurements. In addition, these materials have large resistivity; hence they are not suitable for the thermal-based sensors such as thermal flow sensors and convective inertial sensors which involve heating elements. To increase the temperature of the heating elements at low supply voltages, a low resistivity is required, which commonly lies between 10−1 to 10−6 cm [5]. Therefore, highly doped semiconductors (e.g. highly doped single crystalline silicon with resistivity from 10−1 to 10−2 cm) and metals (e.g. platinum nickel with resistivity is from 10−4 to 10−6 cm) are the conventional candidates for these sensors. It is important to note that semiconductors and metals are compatible with conventional MEMS micro-machining technologies, which leads to the commercialization of various thermal-based sensors employing these materials. There is a strong demand to investigate alternative thermoresistive materials which can first satisfy the basic requirements: (1) high thermoresistive sensitivity, (2) low resistivity and 3) compatibility with MEMS machining technologies. The requirements for these alternative materials are also low cost, ease of processing and ability to work in harsh environments including high temperatures, high corrosion and high voltages. Large band gap semiconductors such as silicon carbide are promising candidates for thermal sensors operating in hostile environments thanks to corrosion inertness and superior mechanical and electrical properties [39]–[43], [119], [120], while carbon-based materials such as graphite are a good choice for low cost and rapid prototyping of thermal sensors [64]–[68]. 2) Impact of Morphologies: There are three main morphologies of thermoresistive materials, namely single crystalline, 973 Fig. 8. Transport mechanism in different morphologies. (a) Single crystalline. (b) Polycrystalline. polycrystalline and amorphous configurations. Among these, single crystalline and polycrystalline materials can achieve a reasonable low resistivity (e.g. 0.1 cm for silicon) for heating purposes in various thermal-based sensors such as thermal flow sensors and convective accelerometers. In pure crystalline materials, the generation of carrier concentration and the increase in carrier mobility with increasing temperature play an important role in the behavior of the thermoresistive effect (Figure 8(a)) [1], [2]. For example, in highly doped single crystalline silicon, all impurities are ionized at room temperature, and only scattering is considered at higher temperatures, which leads to a positive temperature coefficient of resistance (e.g. normally lower than 5,000 ppm/K). However, a polycrystalline material is a complex composition of crystallites and the boundaries between them [9], [121], [122]. Therefore, some models have been proposed to explain the resistivity dependence on polycrystalline morphology. As such, Seto [9] hypothesized that boundaries in polycrystalline material can trap carriers, creating a potential barrier φ to impede the movement of carriers through the barrier. Therefore, the boundary resistance plays an dominant role in the thermoresistive effect of polycrystalline material. The boundaries are sensitive to temperature change as both tunnelling and thermionic emission mechanisms can contribute to a decrease in electrical resistance with increasing temperature (Figure 8(b)). When the polycrystalline material is doped at high levels, the barrier is low; hence the thermionic emission mechanism is dominant. The thermoresistive sensitivity was observed to be low in highly doped polycrystalline silicon. The model proposed by Seto [9] has been used to explain the high thermosensitivity of various polycrystalline materials [9], [121], [122]. The temperature-dependent electrical resistance R of poly/nano crystalline structures can be determined by the following equation: φ (10) R = Aex p kT where k is the Boltzmann constant, R is the electrical resistance at temperature T , and A is a constant. In polycrystalline metals, the grain boundary plays a dominant role when the grain size is very small (e.g. much smaller than the electron mean free path) [15]. In this case, the TCR of metal thin films can be much less than the bulk value and it could turn to a negative value if the TCR of bulk material is less than temperature coefficient of bulk mean free path [15], [92]. In ceramics, the role 974 JOURNAL OF MICROELECTROMECHANICAL SYSTEMS, VOL. 26, NO. 5, OCTOBER 2017 of grain boundaries on the thermoresistive properties is still controversial [123]–[125]. As such, it has been reported that the thermoresistive sensitivity of grain boundaries is much higher than that of bulk materials and more sensitive to annealing conditions [123]. However, some other reports have shown that the activation energy of grain boundaries is the same as that of bulk boundaries [124], [125]. Another important morphology of semiconductors is amorphous, which is known for its localized and extended states. Amorphous semiconductors have an energy level between them, named mobility edge. The extended and localized states have a different density of state (DOS), which can be a constant, parabolic or exponent function of temperature depending on the temperature range. In a broad range of temperature T , the conductivity σ of amorphous semiconductors can be expressed in the form: β Ea (11) σ = σ0 ex p − kT where σ0 is the pre-exponential factor, and the power exponent β depends on temperature range. E a denotes the activation energy and k is the Boltzmann constant. Mott et al. [126] developed the concept of variable-range hopping (VRH) for the temperature-dependent conductivity with the assumption of a constant DOS function. The value of β in Eq. 11 was found to be 1/4 for the VRH regime. However, due to the interactions between localized electrons, a Coulomb gap exists in the DOS, which has a parabolic distribution at low temperatures. As a result, β = 1/2 shows the presence of the Coulomb gap [127]. At temperatures high enough (e.g. temperatures close to room temperature), the transport energy moves upward towards the mobility edge. Electron transitions between the de-localized states above the mobility edge and the localized band tail mainly contribute to the conduction of amorphous semiconductors [127]. The temperature dependence of conductivity is observed with β = 1, showing an activation of electrons over the mobility edge [128]. This mechanism has been used for investigating the thermoresistive effect in a-Si and a-Si:H, with TCR values ranging from 20,000 ppm/K to -80,000 ppm/K for a temperature range of 300 to 350 K [129]–[131]. D. Deposition Temperature, Grain Size and Thickness In general, when deposition temperatures (or substrate temperatures) increase, the grain size of thermoresistor films increases and the resistivity decreases. This could tune the thermoresistive sensitivity of the films [10], [132], [133]. For example, it has been reported that an increase in the deposition temperature from 25 to 300 ◦ C can change the TCR of CuNi thin film resistors from negative (-50 ppm/K) to zero and then positive (80 ppm/K) [10]. This could be attributed to the enhancement of amorphization under lower-temperature depositions. It has been found that the crystallinity of the films degrades significantly when the substrate temperature decreases [10], [132]. For instance, Himanshu et al. [134] reported that improvement in crystallinity could be achieved when the deposition temperature increases from 350 to 850 ◦ C; Fig. 9. Influence of substrate temperature on the thermoresistive effect in SiC thin films [134]. Fig. 10. The dependence of thermoresistive effect on thickness of films. (a) Thickness dependence of TCR in platinum [136]. Reprint with permission from [136]. (b) Thickness dependence of TCR in silicon carbide [17]. however, the thermoresistive sensitivity also decreases with a decrease in activation energy from 0.57 to 0.086 eV (Figure 9). In addition, the thermoresistive effect in polycrystalline metal films has been theoretically investigated [15], [91], [92], [135], indicating a dependence of TCR on grain size diameter. As such, the TCR can be small and negative for films with a very small grain size, but it could approach a large positive value (similar to the TCR of bulk material) by using a very large grain size [92]. It has been reported that the thermoresistive sensitivity depends upon the thickness of thin films. For example, the thermoresistivity of platinum nano thin films is lower than that of bulk materials [136]–[138] (Figure 10(a)). However, for semiconductor thin films such as SiC, it has been proven that the thinner the film thickness, the higher the thermoresistive sensitivity (or the higher the TCR) [17], [139]. This phenomenon has been explained based on the free carrier trapping model [140], [141]. As such, thinner films normally have a smaller grain size and have more defects and boundaries, which make a potential barrier to impede the movement of free carriers. Both thermionic and tunnelling currents passing this barrier contribute to the thermosensitivity of the ultrathin films. Figure 10(b) shows the thickness dependence of the TCR of SiC thin films, and indicates a TCR of from -1400 ppm/K to 2200 ppm/K for the film thickness of 16963 to 1530 A, respectively [17]. DINH et al.: THERMORESISTIVE EFFECT FOR ADVANCED THERMAL SENSORS IV. D ESIRABLE F EATURES FOR T HERMAL S ENSORS For effectively realizing the thermoresistive effect for the applications of thermal sensors such as temperature sensors, thermal flow sensors, convective accelerometers and gyroscopes, several important features need to be considered in the design and implementation of thermal-based sensors. These are thermoresistive sensitivity, linearity of response, thermal time response and other features. A. Sensitivity Among the desirable parameters for thermal sensors, sensitivity is one of the most important features because it represents the efficiency of detection or monitoring. As previously mentioned, the temperature coefficient of resistance (TCR) has been commonly used for evaluating the sensitivity of the thermoresistive effect, defined by relative resistance change to the temperature variation. The units of TCR, often found in literature, includes ppm/K (parts-per million per Kelvin) and %/◦ C (percent per Celsius). Moreover, for temperature sensors using ceramic and semiconductor materials, the thermal index B (K), which commonly lies between 1,000 K and 10,000 K, has also been employed as a sensitivity parameter. In addition, giant thermoresistive effect is desired for temperature sensors; hence a ceramic material or a composite/mixture is often deployed since these materials can provide an extremely high TCR of up to 1012 ppm/K [82]. However, these materials might not be suitable for other thermal sensors based on the Joule heating effect, such as thermal flow sensors and inertial sensors. This is due to the fact that these sensors require a low resistivity to reduce the voltage or current supply for heating. Therefore, metals and highly doped semiconductors have been commonly employed to fabricate this type of sensors. However, these materials have some drawbacks in terms of low thermoresistive sensitivity (e.g. lower than 5,000 ppm/K). It is important to note that detecting temperature changes in thermal-based sensors which operate based on Joule heating is quite challenging, since these sensors employ materials with low thermoresistive sensitivity. Therefore, the resistance changes (R/R) in these sensors are commonly converted to a voltage change (V ) by using a Wheatstone bridge, and this voltage change can be amplified using signal amplifiers. Alternatively, a thermoresistive insensitivity or a zero temperature coefficient of resistance (TCR) is desired for the precise control of temperature in heaters and other sensing applications including strain and pressure measurements. Many studies have focused on developing zero-TCR systems with semiconductors and inorganic compounds [117], [118], [140], [142], [143]. For example, controlling doping levels has been proven to be an effective approach to achieve zero-TCR, which is commonly done in the in situ growth process of the semiconductor films [117], [118], [140]. However, a common strategy for achieving zero-TCR in polymers/composites is to mix a negative-TCR material with a positive-TCR material. For example, Chu et al. [142], [143] reported a near zero-TCR of conductive composites consisting of a bi-layer of negative TCR carbon nanotube and positive TCR carbon black, showing 975 less than 2% variation of relative resistance change when the temperature reaches 200 ◦ C. In some cases, the effect of the substrates on the thin films is significant as it can tune the TCR from a negative [66] value to a positive value [144]. B. Linearity Linearity is another desirable parameter for thermal-based sensors, since it is responsible for the accuracy of measurement. Thermal sensors with linear characteristics have various benefits, not only in the accuracy of measurement, but also in terms of simplicity in the design of circuitry and implementation. Most metals show excellent linearity in a wide range of temperatures; hence they have been commonly deployed for fabricating thermal flow sensors, convective accelerometers and gyroscopes. The reason for the linear characteristics of metals is that the number of electrons in metals is constant, while electron mobility is inversely proportional to temperature; hence using equation 5, the resistivity is linearly dependent on temperature. However, the resistance of semiconductors is exponentially dependent on temperature as shown in Eq. 7. Therefore, to realize the design of circuitry and the measurement of signals, Eq. 7 is usually converted to the following form, which presents the linear relationship between ln(R/R0 ) (R and R0 are the electrical resistance at temperature T and T0 , respectively) and 1/T : 1 (12) ln (R/R0 ) = A − B T where A = B/T0 is a constant. Equation 12 has been commonly used for representing the Arrhenius law. From plotting Eq. 12, the sensitivity of the thermoresistive effect B or the activation energy E a = B × k, where k is the Boltzmann constant, can be determined. For example, Figure 7 shows the linear relationship between ln(ρ/ρ0 ) and 1/kT , indicating an activation energy of 0.025 eV to half energy gap of single crystalline silicon. It should be noted that highly doped semiconductors could also achieve a linearity between electrical resistance and temperature, since all impurities have the potential to be ionized at room temperature and the resistance depends upon the scattering mechanism with changing temperature [49]. This behaviour of highly doped semiconductors is similar to that of metals. Therefore, using high doping levels for the Joule heating based sensors could achieve a linear characteristic [16]. C. Thermal Time Response Apart from the sensitivity and the linearity, thermal time response is also considered as a key feature for thermal sensors, as it presents the capability to respond instantaneously to the change in external signals such as temperature, flow and acceleration. Theoretically, the thermal time response of thermoresistive sensors is limited by the thermal time constant τ = Rt h × Ct h , where Rt h and Ct h are the thermal resistance and thermal capacitance of the sensor [145]. Thermal resistance can be calculated as Rt h = L/(A × k), where 976 JOURNAL OF MICROELECTROMECHANICAL SYSTEMS, VOL. 26, NO. 5, OCTOBER 2017 Fig. 11. Response time of thermal flow sensors. (a) The 63.2% response time of a sensor. (b) A thermal time response of 2.5 ms is determined from fitting the equation T = A − B × ex p(−t/τ ) [149]. Reprint with permission from [149]. L, A and k are the length, cross-sectional area and thermal conductivity of the sensor material, respectively. A material with a higher thermal conductivity offers a lower thermal resistance; hence it has a faster thermal time response. For example, 4H-SiC would be preferable to Si for developing thermal sensors with fast thermal time responses because the thermal conductivity of 4H-SiC is much higher than that of Si [146]. Thermal capacitance can be approximated as Ct h = ρt h × V × C H , where ρt h , V and C H are the density, volume and heat capacity of the sensor, respectively. The density of some metals such as platinum (ρt h =21.45 g/cm3 ) is larger than that of semiconductors such as silicon (ρt h =2.33 g/cm3 ) and silicon carbide (ρt h =3.2 g/cm3 ). However, platinum has a much lower heat capacity (C H =125 J/(kgK)) in comparison to silicon (C H =700 J/(kgK)). Therefore, a common strategy to achieve a fast thermal time response is to scale down the thermoresistive elements or choose materials with high thermal conductivity, low density and low heat capability. As such, nano structures (e.g. nanowires and nanobelts) would offer fast time responses which are useful for measuring systems with rapid changes of temperature. Experimentally, the thermal response time is commonly defined as the time needed for the amplitude of the output signal to reach approximately 63.2 % or 90 % of that of a steady-state signal, due to a change of external parameters [94], [147], [148]. Figure 11(a) shows the response time of a thermal flow sensor, which is determined by 63.2 % amplitude of the steady-state signal [147]. The thermal response time could also be determined from the exponential fit for the time dependence of temperature response T = A − B ×ex p(−t/τ ), where A and B are constants; t and τ are the time parameter and the thermal time response, respectively [149]. Figure 11(b) shows the response time of τ =2.5 ms by fitting the response of the sensor [149]. For various MEMS thermal sensors reported in the literature [94], [147]–[149], the thermal response time is within the ms range, corresponding to a the bandwidth of the kHz range. These responses satisfy the practical applications such as measuring human respiration, which requires the monitoring of 12 to 20 breaths per minute, corresponding to a bandwidth of only 0.2 to 0.33 Hz. advantages of micro and nanomachining technologies. For example, a small-in-size heater in thermal flow sensors could be heated up to a high temperature with low power because of its small volume, which can also lead to a faster response of the sensor. For example, Cubukcu et. al. [150] has proven that the sensitivity of the sensor at a constant power consumption is improved by scaling down the size of its structures. Therefore, nanostructures such as nanowires and 2D materials are of interest in terms of low power consumption and fast thermal response. For thermal sensors not requiring a heating element such as temperature sensors, a small size (e.g. length, width and thickness) is of interest as it leads to a faster response to temperature change and a more uniform temperature distribution within the sensor [75]. It is expected that when the size of the thermal sensor is scaled down to lower than a certain value (e.g. 100 nm), the thermoresisitive sensitivity could decrease due to the impact of material morphologies at nanoscales [136]–[138]. However, for thermal flow sensors and inertial sensors which require heaters and thermoresistive sensing elements, a longer (up to 1000 μm) and wider (up to 70 μm) heating elements can result in a larger output signal from the sensor due to the reduced heat conduction to the substrate [149]. However, a long heating element leads to a higher resistance which requires a higher supply voltage. In addition, a wider heating element offers a slower time response. The distance between heating and sensing elements is another important geometrical parameter which can have an even greater effect on the sensitivity and measurement range than the size of the sensor [151]. In some cases, T-shape sensing elements (with two ends free to expand or contract when the temperature changes) can be utilized for lowering the thermally induced stress [152], [153]. With regards to design, themoresistive sensors fabricated on suspending isolation substrates could reduce power loss in comparison to sensors located on thick substrates or semiconducting substrates. To realize the suspended structures, electrodes and thermoresistive elements are commonly patterned first using conventional lithography and surface etching processes; then wet etching of bulk substrates (e.g. silicon) is performed from frontside or backside to release the membrane structures [94], [151]. A number of the thermal flow sensors could operate under sub-mW power consumption (lower than 1 mW) using suspending isolation structures, while these devices can maintain a large measurement range with high resolution and without loosing its fast time response [154], [155]. It is also important to note that a decrease in the supply power leads to a lower sensitivity of such sensors. Therefore, a large thermoresistive effect is desired to achieve a high sensitivity and high resolution of detection at low power consumption [150]. E. Stability and Other Desirable Features D. Low Power Consumption Low power consumption is an obviously desirable feature for not only thermal sensors but also other electronic devices. This can be achieved through miniaturization, taking For practical applications, the repeatability, long-term stability and ability to work in harsh environments without degradation of performance are also desirable features for thermoresistive sensors. Among these features, the DINH et al.: THERMORESISTIVE EFFECT FOR ADVANCED THERMAL SENSORS repeatability and stability are essential for the reliability and accuracy of measurements. These desired characteristics are commonly determined from repeated cycle tests. For example, Shingo Harada et al. [156] observed the consistence of the performance of a flexible thermoresistive temperature sensor after several repeated cycle tests at both the room temperature and an elevated temperature. Thermoresistive structures are typically placed outdoors where the temperature variation, humidity and chemical species are not controlled. This leads to the drift or instability of the sensor signal. For example, when a ceramic thermoresistive element is exposed to atmospheric conditions, its surface chemically adsorbs and dissociates water vapor molecules to form layers of hydroxyl ions, followed by a physical absorption. This results in a change in the electrical conductivity of the themoresistive element [157]. Low porousity thermoresistive materials are desirable for minimizing the impact of humidity on the resistive structures [3], [157]. A signal processing method has been proposed to possibly eliminate the effect of humidity and other factors [158]. In addition, various metals (e.g. aluminum) and semiconductors (e.g. silicon) cannot operate in harsh conditions such as high temperatures. This leads to a strong demand for developing alternative thermoresistive materials, which are able to work in harsh environments. Wide band gap semiconductors have been recently studied with an aim towards high temperature applications, due to their superior electrical and mechanical properties at high temperatures. For example, silicon carbide has demonstrated excellent stability when exposed to 400 ◦ C in air for 2000 hours [159]. V. A PPLICATIONS OF T HERMORESISTIVE E FFECT The insight into the thermoresistive effect described in the previous sections has led to various successful MEMS sensor applications. Among them, thermal flow sensors have been mainly developed using metals (e.g. platinum, gold and nickel) and semiconductors (e.g. silicon and polysilicon). The good conductivity of these materials is required to measure the temperature of the thermoresistors at a low voltage supply. The resistance change of the thermoresistors induced by a flow or a temperature change around the sensor is used to determine characteristics of the flow. Another application of the thermoresistive effect is the detection of acceleration. However, convective accelerometers, commonly employing metals and semiconductors, work based on the movement of the bubbles of heated fluid around them, which leads to an asymmetry of the temperature profile. Therefore, these accelerometers require an enclosed chamber and thermoresistors around them to detect the change of temperature profile. In addition, one of the most important applications of the thermoresistive effect is temperature sensing. Temperature change directly leads to the change in the electrical resistance of thermoresistive materials. A number of materials have been deployed for this purpose, namely metals, semiconductors, nanomaterials and other compounds/mixtures. Temperature sensors could be employed for a wide range of materials because these sensors do not require high conductivity like 977 thermal flow sensors and convective accelerometers which work based on the Joule heating effect. This section will discuss in details the current status of development of thermoresistive sensors such as temperature sensors, thermoresistive flow sensors, convective accelerometers and other advanced thermal sensors based on the thermoresistive effect. A. Temperature Sensors In general, thermocouples, and metal and ceramic thermistors are commonly used as temperature sensors, and are commercially available [3]. Ceramic thermistors, a type of NTCR temperature sensors, have shown various important advantages in terms of high sensitivity, signal-to noise ratios, small size and low cost. The sensitivity of these temperature sensors depends upon the grain size and the composition of the metallic oxides [3]. However, complexity in terms of the chemical composition, the formation of micro-structures and the oxidation processes has led to various difficulties in controlling the processing parameters and the chemical homogeneity. As a result, the process for achieving highly stable and reproducible ceramic thermistors is a significant challenge; hence, costs are raised, limiting their specific applications. The aforementioned difficulties with the ceramic thermistors have resulted in a strong demand to develop simple and single-film semiconductor thermistors, which are stable and reproducible, and avoid the use of chemical mixes [159]–[164]. Efforts have been made to improve these characteristics. For example, SiC thermistors have been developed thanks to their ability to work in harsh environments (e.g. high temperature range) [161]–[164]. The main advantage of SiC thermistors is the fast thermal response and the ability to operate at high temperatures without degrading stability and reproducibility [159]–[164]. In addition, Wasa et al. [159] developed a highly reliable SiC thermistor with no significant ageing after 2000 hours exposed to air at 400 ◦ C. This SiC thermistor was also tested with 10000 cycles at a temperature change rate of 75 ◦ C/second. In comparison to the silicon counterpart, SiC thermistors with their excellent stability under the impacts of the environments such as humidity and erosion, have made them an attractive candidate for temperature sensing in harsh environments [159]–[164]. Metal thermistors have also been developed thanks to their highly linear response to temperature change; hence, they are simple in circuit design and signal measurement [5], [13]. However, relatively low sensitivity limits their applications. In contrast, composite mixture-based thermistors show extremely high sensitivity, which can be several orders larger than that of the ceramic and semiconductor thermistors. These thermistors could be used for human body temperature detection, owing to their flexibility, stretchability and wearability. However, the material cost and the narrow working temperature range are the main disadvantages of these thermistors [81], [82]. The performance and characteristics of the temperature sensors are summarized in Table III. B. Thermal Flow Sensors Thermal flow sensors (i.e. flow sensors which measure the velocity of surrounding fluids and the direction of fluid 978 JOURNAL OF MICROELECTROMECHANICAL SYSTEMS, VOL. 26, NO. 5, OCTOBER 2017 TABLE III C HARACTERISTICS OF T EMPERATURE S ENSORS Fig. 12. Operational concept of thermal sensors and circuitry for measurement of flow signals [175]. (a) Hot-wire/hot-film principle. (b) Calorimetric principle. (c) Time of flight concept. movement) operate based on heat transfer from a heater to the environment [165]. Sensitive thermoresistive elements are commonly employed for the detection of temperature changes, which come from the velocity or direction change of fluids. The working principles of three common thermal flow sensors (e.g. hot-wire/hot-film, calorimetric and time of flight) are shown in Figure 12. The working principle, fabrication and performance of various thermal flow sensors have been extensively reviewed [4], [5]. Table IV summarizes the performance of various thermal flow sensors reported in literature. 1) Hot-Wire and Hot-Film Flow Sensors: In hot-wire and hot-film configurations, a wire/film acts as both a heater and a sensor. The temperature is raised to a steady state via Joule heating and will remain that way until a flow is applied. The cooling effect from the flow reduces the temperature and hence changes the resistance of the heater (Figure 12(a)). This resistance change is usually converted into a voltage change using a Wheatstone bridge [8], [166]–[169]. The equation governing the working principle of hot-wire and hot-film thermal flow sensors is an energy balance between Joule heating and convective cooling as follows: R I 2 = h A (T − Te ) overall boundary area of the heater with the surrounding environment. The thermoresistive effect in metals (e.g. platinum) and semiconductors (e.g. polysilicon) has been commonly employed for developing sensitive thermal flow sensors, since these materials offer high thermoresistivity (high TCRs) and proper resistivity for heating and sensing [8], [11], [169]. For example, platinum has been deployed to fabricate hotfilm flow sensors for measuring air velocity, which showed a high sensitivity of 0.177 mV(m/s)−1/2/mW at a power consumption of 45.1 mW [11]. However, these sensors have some drawbacks in terms of working in harsh environments (e.g. high temperatures and corrosion) due to the degradation of the sensor materials. Therefore, wide band gap semiconductors such as SiC have also been used to develop hot-wire/hotfilm flow sensors. For example, Lyons et al. [149] developed a hot wire bridge thermal flow sensor using 3C-SiC grown on a Si substrate, in which two bridges were fabricated as a heater and a temperature sensor, and arranged in a Wheatstone bridge with two external resistors. The flow sensor showed a fast thermal time response of 3 ms, high sensitivity, high mechanical strength and a good ability to be heated to high temperatures due to the high melting point of SiC. (13) where R, I , T and Te are the resistance of the heater, supply current, temperature of heater and temperature of environment, respectively; h is the heat transfer coefficient and A is the 2) Calorimetric Flow Sensors: Another thermal flow mechanism is calorimetric sensing, which uses the asymmetry of temperature profiles of upstream and downstream temperature sensors when flow is applied (Figure 12(b)). The temperature DINH et al.: THERMORESISTIVE EFFECT FOR ADVANCED THERMAL SENSORS 979 TABLE IV C HARACTERISTICS OF T HERMAL F LOW S ENSORS difference T between the upstream and downstream sensing elements can be defined in the form: T = T e x1 d1 − e x2 d2 (14) where T is the heater temperature; d1 and d2 are distances from the heater to the upstream and downstream resistors. Parameters x 1 and x 2 depend on the surrounding fluid velocity, thermal diffusivity of the fluid and boundary layer thickness. This sensing method is preferable to hot wire and hot film techniques because it is sensitive to small flows and able to detect flow direction due to the presence of the upstream and downstream temperature sensors. In calorimetric sensing, metals and semiconductors have also been commonly used. As such, Cubukcu et al. [150] developed a germanium calorimetric thermal flow sensor with a high sensitivity of 232.77 V/W/(m/s), a fast thermal response of 10 ms and a low power consumption (less than 6 mW). In addition, great effort has been paid to develop calorimetric flow sensors for high-temperature environments using SiC [139]. Lee et al. successfully fabricated a n-poly SiC resistive heater surrounded by one downstream and two upstream temperature sensors on silicon nitride and silicon substrates [173]. This sensor has a sensitivity of 0.73 /sccm and a negative TCR of 1240 ppm/K for both heater and temperature sensors. 3) Time-of-Flight Flow Sensors: In the time of flight thermal sensing method, flow information is tracked by measuring the transition time of a thermal pulse between a heater and a temperature sensor (Figure 12(c)). The transition time is determined based on the flow velocity, thermal conductivity and diffusivity of the fluid [4], [5]. C. Convective Inertial Sensors 1) Convective Accelerometers: The most common mechanical accelerometers utilize a suspended proof mass, which generates displacement with applied accelerations; hence it induces stress/strain that can be measured using piezoresistive elements. However, mechanical accelerometers have some drawbacks such as low shock resistance and a complex fabrication process. Therefore, convective accelerometers without any proof mass have been developed to avoid these drawbacks. The working principle of convective accelerometers was proposed by Weber [176], and then implemented using MEMS technology by Leung et al. [177]. The development of convective accelerometers is based on single-axis (1-D), two-axes (2D) and three-axes (3D) configurations. The working principle of convective accelerometers is shown in Fig. 13(a). Convective accelerometers operate on the movement of a hot bubble of fluid around a heater (a self-heated resistive element by Joule heating), caused by external accelerations. The inertial force, when applied to the mass of the hot bubble, causes asymmetry of the temperature profile around the heater (Figure 13(a)). This temperature difference is detected using two thermoresistive temperature sensors, which are arranged at equal distances from the heater. Convective accelerometers are required for packaging in a hermetic/enclosed chamber to prevent disturbance from external environments. These sensors commonly employ a cavity to thermally insulate the heater from the substrate. This helps lower the power consumption of accelerometers. In the last 20 years, there have been a number of reports on the development of convective accelerometers towards high 980 Fig. 13. JOURNAL OF MICROELECTROMECHANICAL SYSTEMS, VOL. 26, NO. 5, OCTOBER 2017 Convective inertial sensors. (a) Working principle of convective accelerometers [182]. (b) Working principle of thermal gyroscopes [16]. TABLE V T HE P ERFORMANCE OF I NERTIAL S ENSORS sensitivity, fast response and multi-direction detection [6], [12], [152], [153], [176]–[180], [180], [181], [183]–[185]. The performance of various convective accelerometers is summarized in Table V. As high sensitivity is desired for convective accelerometers, the optimization of the design parameters has been intensively investigated. The optimization results reported by Luo et al. [179]–[181] show that an increase in the supply power and cavity sizes can enhance the sensitivity of convective accelerometers. However, the frequency response decreases with increasing cavity size. Surrounding environments with a low viscosity and high thermal diffusivity also contribute to the high sensitivity and fast frequency response of thermal accelerometers. For example Bahari et al. [6] reported that a sensitivity improvement of more than 400 times could be made by changing the filled candidate gases from N2 to C4 H8 . To enable the functionality of multi-direction detection, planar convective accelerometers (2D) have been developed on a plane or thin film, which can be simply fabricated using standard MEMS technologies. However, 3D accelerometers, which are capable of measuring out-of-plane acceleration, have been significantly challenging to fabricate with a requirement of various complex and nonstandard techniques [7]. To date, only Nguyen et al. [12] have reported a monolithic 3-axis thermal convective accelerometer based on the working principle of DINH et al.: THERMORESISTIVE EFFECT FOR ADVANCED THERMAL SENSORS planar accelerometers. However, the z-axis sensitivity of this sensor is relatively low, and it also requires complex additional circuitry for signal processing. 2) Convective Gyroscopes: It is well known that microgyroscopes find applications in the automotive industry such as in anti-skid and stability control (e.g. camera and cell phone stabilization), and anti-roll applications. Gyroscopes can also been found in inertial mouses and displays and other electronic devices. Common mechanical gyroscopes use a proof mass supported by springs as a strain-induced structure, and operate based on the Coriolis effect. As conventional gyroscopes employ moving parts, they are potentially fragile, and have low shock resistance and high levels of vibration noise. Therefore, thermal convective gyroscopes have been proposed by Van et al. [186] (Figure 13(b)). The authors proposed a dual-axis convective micro-gyroscope with high resolution of 0.05 deg/s, high sensitivity of 0.1mV/deg/s and bandwidth of 60 Hz at -3 dB. Since then, there have been a number of reports on the development of convective gyroscopes offering low power-consumption, high sensitivity and multi-direction detection (e.g. three-dimension convective gyroscopes) [16], [186]–[190]. Table V summarizes the recent advances in convective gyroscopes. D. Other Thermoresistive Sensors The thermoresistive effect has been also utilized for chemical composition sensing applications including gas sensors [191]–[194]. For example, in combustion a thermoresistive element can detect the exposure of gases on its active surface, due to the heat rise of combustion [192], [194]. Metal oxides and their compounds are often used for this application because they offer good catalytic properties. Platinum, palladium, and thoria compounds are also excellent catalysts for combustion application. In addition, thermoresistors have been also deployed for the measurement of gas humidity [195]. Furthermore, thermistors which can work in low temperature environments have been used as temperature sensors to detect cryogenic liquid level [196], [197]. Finally, thermoresistors, used as a Pirani gauge heated by a Joule heating current, have been commonly employed for monitoring low pressure ranging from 0.5 to 10−4 torr [198], [199]. VI. C ONCLUSION AND P ERSPECTIVES In the past few decades, the thermoresistive effect in metals and semiconductors has been intensively investigated. The thermoresistive sensitivity of metals has been found to commonly lie between 3,000 to 7,000 ppm/K, while that of silicon ranges from -25,000 ppm/K to 10,000 ppm/K. Giant thermoresistive sensitivity in ceramics and other compounds/mixtures, which can reach up to 1012 ppm/K, has also been achieved. Moreover, the thermoresistive effect in wide band gap semiconductors such as silicon carbide has been examined, showing their potential for operating in high temperature environments. 3C-SiC (β − Si C) and 6H-SiC (α − Si C) have been investigated for their thermoresistive effects, indicating their strong feasibility for thermal sensors. 981 However, lowering the bulk wafer cost of (α−Si C), and growing (β − Si C) thin films in a large area are both necessary for the implementation of thermal sensors. Furthermore, impacts of growth and fabrication parameters on the thermoresistive sensitivity of silicon carbide polytypes would be examined. These parameters include, but not limited to doping levels, thickness of SiC films and type of substrates. The electrical resistivity of single crystalline SiC is potentially useful for sensors employing Joule heating effect. As such, this material can be employed for developing thermal flow sensors and convective accelerometers, which operate in high temperature environments. Thanks to its superior thermal characteristics such as high melting point, SiC could be used in local heaters integrated within SiC systems to heat other structures up to high temperatures, which eliminates the use of external heaters. In addition, SiC grown on Si and subsequently transferred onto glass by Focused Ion Beam (FIB) can avoid current leakage through the SiC/Si junction. However, for large scale production, a bonding technique is recommended to transfer a large-area of SiC on to glass. Therefore, SiC bonded on glass would be a suitable platform for low-cost thermal sensors operating in high-temperature environments. Recently, significant progress has been made in the fabrication and characterization of MEMS thermal sensors, which utilize the thermoresistive effect in many metals such as platinum and semiconductors including silicon and polysilicon. These sensors have shown high sensitivity, linear response and low power consumption, which has led to their commercialization. However, the high cost and the low capability to work in high temperature environments are the current drawbacks. Significant development of high-temperature thermal sensors is expected to be made in the near future, employing large band gap semiconductors such as silicon carbide. While a number of power electronics and circuits have been commercialized, the need for the integration of electronic circuits with thermal sensors, allowing operation at high temperatures, is expected to lead to even more development of high-temperature sensors. For this purpose, alternative thermal sensing materials with their high thermoresistive sensitivity need to be investigated. It is also important to develop proper packaging for thermal sensors because thermal expansion at high temperatures can cause cracking in devices. In addition, the development of thermal sensors could be driven towards miniaturization, a wide range of measurement without signal saturation, large working bandwidth and capability of detecting multi-directions of physical signals. As such, silicon carbide and other wide band gap semiconductor nano-wires are also expected to be utilized in the near future for integration within nanosystems operating at high temperature conditions. One alternative trend in the sustainable development of thermal sensors is to investigate low-cost materials for thermal sensors, which can be processed using cleanroom-free facilities and user-friendly techniques, without using toxic solvents and hazardous chemicals. For example, the thermoresistive effect in pencil graphite has been intensively investigated, and a proof of concept of thermal flow sensors has been successfully demonstrated. This indicates a possible future 982 JOURNAL OF MICROELECTROMECHANICAL SYSTEMS, VOL. 26, NO. 5, OCTOBER 2017 development of graphite-based thermal sensors such as convective accelerometers. Furthermore, future techniques for improving the adhesion of pencil graphite to a substrate, or a covering technique for protection of the graphite sensing layer, are a potential research topic towards commercializing these low cost thermal sensors. ACKNOWLEDGMENT This work was performed in part at the Queensland node of the Australian National Fabrication Facility, a company established under the National Collaborative Research Infrastructure Strategy to provide nano and micro-fabrication facilities for Australia’s researchers. R EFERENCES [1] S. O. Kasap, Principles of Electronic Materials and Devices. New York, NY, USA: McGraw-Hill, 2006. [2] S. M. Sze and K. K. Ng, Physics of Semiconductor Devices. Hoboken, NJ, USA: Wiley, 2006. [3] A. Feteira, “Negative temperature coefficient resistance (NTCR) ceramic thermistors: An industrial perspective,” J. Amer. Ceram. Soc., vol. 92, no. 5, pp. 967–983, 2009. [4] N. T. Nguyen, “Micromachined flow sensors—A review,” Flow Meas. Instrum., vol. 8, no. 1, pp. 7–16, 1997. [5] J. T. Kuo, L. Yu, and E. Meng, “Micromachined thermal flow sensors— A review,” Micromachines, vol. 3, no. 3, pp. 550–573, 2012. [6] J. Bahari, J. D. Jones, and A. M. Leung, “Sensitivity improvement of micromachined convective accelerometers,” J. Microelectromech. Syst., vol. 21, pp. 646–655, Jun. 2012. [7] J. Bahari and A. M. Leung, “Micromachined three-axis thermal accelerometer with a single composite heater,” J. Micromech. Microeng., vol. 21, no. 7, p. 075025, 2011. [8] S. C. C. Bailey et al., “Turbulence measurements using a nanoscale thermal anemometry probe,” J. Fluid Mech., vol. 663, pp. 160–179, Nov. 2010. [9] J. Y. W. Seto, “The electrical properties of polycrystalline silicon films,” J. Appl. Phys., vol. 46, pp. 5247–5254, Sep. 1975. [10] S.-G. Hur, D.-J. Kim, Y. Kang, and S.-G. Yoon, “Effect of the deposition temperature on temperature coefficient of resistance in CuNi thin film resistors,” J. Vac. Sci. Technol. B, Microelectron. Nanometer Struct. Process., Meas., Phenomena, vol. 22, no. 6, pp. 2698–2701, 2004. [11] S.-T. Hung, S.-C. Wong, and W. Fang, “The development and application of microthermal sensors with a mesh-membrane supporting structure,” Sens. Actuators A, Phys., vol. 84, nos. 1–2, pp. 70–75, Aug. 2000. [12] H. B. Nguyen, F. Mailly, L. Latorre, and P. Nouet, “A new monolithic 3-axis thermal convective accelerometer: Principle, design, fabrication and characterization,” Microsyst. Technol., vol. 21, no. 9, pp. 1867–1877, 2015. [13] W. F. Leonard and R. L. Ramey, “Temperature coefficient of resistance in thin metal films,” J. Appl. Phys., vol. 37, no. 9, pp. 3634–3635, 1966. [14] P. M. Hall, “The effect of expansion mismatch on temperature coefficient of resistance of thin films,” Appl. Phys. Lett., vol. 12, no. 6, p. 212, 1968. [15] F. Warkusz, “The size effect and the temperature coefficient of resistance in thin films,” J. Phys. D, Appl. Phys., vol. 11, no. 5, p. 689, 1978. [16] V. T. Dau, D. V. Dao, T. Shiozawa, H. Kumagai, and S. Sugiyama, “Development of a dual-axis thermal convective gas gyroscope,” J. Micromech. Microeng., vol. 16, no. 7, p. 1301, 2006. [17] S. Noh, J. Seo, and E. Lee, “The fabrication by using surface MEMS of 3C-SiC micro-heaters and RTD sensors and their resultant properties,” Trans. Elect. Electron. Mater., vol. 10, no. 4, pp. 131–134, 2009. [18] S. O. Kasap, “Electrical and thermal conduction in solids,” in Principles of Electronic Materials and Devices. New York, NY, USA: McGraw-Hill, 2006, pp. 113–189. [19] M. Prudenziati, A. Taroni, and G. Zanarini, “Semiconductor sensors: I—Thermoresistive devices,” IEEE Trans. Ind. Electron. Control Instrum., vol. IECI-17, no. 6, pp. 407–414, Nov. 1970. [20] C. Yan, J. Wang, and P. S. Lee, “Stretchable graphene thermistor with tunable thermal index,” ACS Nano, vol. 9, no. 2, pp. 2130–2137, 2015. [21] J. L. Cao et al., “Vertical SnSe nanorod arrays: From controlled synthesis and growth mechanism to thermistor and photoresistor,” Nanotechnology, vol. 25, no. 10, p. 105705, 2014. [22] D. Wolpert and P. Ampadu, “Temperature effects in semiconductors,” in Managing Temperature Effects in Nanoscale Adaptive Systems. New York, NY, USA: Springer, 2012, pp. 15–33. [23] B. E. Sernelius, “Temperature-dependent resistivity of heavily doped silicon and germanium,” Phys. Rev. B, Condens. Matter, vol. 41, p. 3060, Feb. 1990. [24] K. Suzuki, N. Miyata, and K. Kawamura, “Resistivity of heavily doped polycrystalline silicon subjected to furnace annealing,” Jpn. J. Appl. Phys., vol. 34, no. 4A, p. 1748, 1995. [25] F. Kerrour, A. Boukabache, and P. Pons, “Modelling of thermal behavior N-doped silicon resistor,” J. Sensor Technol., vol. 2, no. 3, pp. 132–137, 2012. [26] S. S. Li, “The dopant density and temperature dependence of hole mobility and resistivity in boron doped silicon,” Solid-State Electron., vol. 21, no. 9, pp. 1109–1117, 1978. [27] P. Norton and J. Brandt, “Temperature coefficient of resistance for p- and n-type silicon,” Solid-State Electron., vol. 21, no. 7, pp. 969–974, 1978. [28] S. S. Li and W. R. Thurber, “The dopant density and temperature dependence of electron mobility and resistivity in n-type silicon,” SolidState Electron., vol. 20, no. 7, pp. 609–616, 1977. [29] K. Y. Tsao and C. T. Sah, “Temperature dependence of resistivity and hole conductivity mobility in p-type silicon,” Solid-State Electron., vol. 19, no. 11, pp. 949–953, 1976. [30] M. L. Zhang and D. A. Drabold, “Theory of temperature coefficient of resistivity: Application to amorphous Si and Ge,” Europhys. Lett., vol. 98, no. 1, p. 17005, 2012. [31] R. He and P. Yang, “Giant piezoresistance effect in silicon nanowires,” Nature Nanotechnol., vol. 1, pp. 42–46, Oct. 2006. [32] D. Whang, S. Jin, Y. Wu, and C. M. Lieber, “Large-scale hierarchical organization of nanowire arrays for integrated nanosystems,” Nano Lett., vol. 3, no. 9, pp. 1255–1259, 2003. [33] Z. Zhong, D. Wang, Y. Cui, M. W. Bockrath, and C. M. Lieber, “Nanowire crossbar arrays as address decoders for integrated nanosystems,” Science, vol. 302, no. 5649, pp. 1377–1379, 2003. [34] H.-P. Phan et al., “Piezoresistive effect of p-type silicon nanowires fabricated by a top-down process using FIB implantation and wet etching,” RSC Adv., vol. 5, no. 100, pp. 82121–82126, 2015. [35] C.-P. Wang, C.-W. Liu, and C. Gau, “Silicon nanowire temperature sensor and its characteristic,” in Proc. IEEE Int. Conf. Nano/Micro Eng. Mol. Syst. (NEMS), Feb. 2011, pp. 630–633. [36] T. Dinh et al., “High thermosensitivity of silicon nanowires induced by amorphization,” Mater. Lett., vol. 177, pp. 80–84, Aug. 2016. [37] A. Bosseboeuf et al., “Thermal and electromechanical characterization of top-down fabricated p-type silicon nanowires,” Adv. Natural Sci., Nanosci. Nanotechnol., vol. 6, no. 2, p. 025001, 2015. [38] Z. L. Wang, Ed., Nanowires and Nanobelts: Materials, Properties and Devices: Metal and Semiconductor Nanowires, vol. 1. New York, NY, USA: Springer, 2013. [39] J. B. Casady and R. W. Johnson, “Status of silicon carbide (SiC) as a wide-bandgap semiconductor for high-temperature applications: A review,” Solid-State Electron., vol. 39, no. 10, pp. 1409–1422, 1996. [40] H.-P. Phan et al., “The piezoresistive effect in top–down fabricated p-type 3C-SiC nanowires,” IEEE Electron Device Lett., vol. 37, no. 8, pp. 1029–1032, Aug. 2016. [41] V. Cimalla, J. Pezoldt, and O. Ambacher, “Group III nitride and SiC based MEMS and NEMS: Materials properties, technology and applications,” J. Phys. D, Appl. Phys., vol. 40, no. 20, p. 6386, 2007. [42] H.-P. Phan et al., “The effect of strain on the electrical conductance of p-type nanocrystalline silicon carbide thin films,” J. Mater. Chem. C, vol. 3, no. 6, pp. 1172–1176, 2015. [43] D. V. Dao, H.-P. Phan, A. Qamar, and T. Dinh, “Piezoresistive effect of p-type single crystalline 3C–SiC on (111) plane,” RSC Adv., vol. 6, pp. 21302–21307, Feb. 2016. [44] K. Sasaki, E. Sakuma, S. Misawa, S. Yoshida, and S. Gonda, “Hightemperature electrical properties of 3C-SiC epitaxial layers grown by chemical vapor deposition,” Appl. Phys. Lett., vol. 45, no. 1, p. 72, 1984. [45] M. Yamanaka, H. Daimon, E. Sakuma, S. Misawa, and S. Yoshida, “Temperature dependence of electrical properties of n- and p-type 3CSiC,” J. Appl. Phys., vol. 61, no. 2, p. 559, 1987. DINH et al.: THERMORESISTIVE EFFECT FOR ADVANCED THERMAL SENSORS [46] A. Suzuki, A. Uemoto, M. Shigeta, K. Furukawa, and S. Nakajima, “Temperature dependence of electrical properties of non-doped and nitrogen-doped beta-SiC single crystals grown by chemical vapor deposition,” Appl. Phys. Lett., vol. 49, no. 8, p. 450, 1986. [47] J. S. Shor, D. Goldstein, and A. D. Kurtz, “Characterization of n-type β-SiC as a piezoresistor,” IEEE Trans. Electron Devices, vol. 40, no. 6, pp. 1093–1099, Jun. 1993. [48] T. Dinh et al., “Thermoresistive properties of p-type 3C–SiC nanoscale thin films for high-temperature MEMS thermal-based sensors,” RSC Adv., vol. 5, pp. 106083–106086, Dec. 2015. [49] A. R. M. Foisal et al., “3C–SiC on glass: An ideal platform for temperature sensors under visible light illumination,” RSC Adv., vol. 6, pp. 87124–87127, Sep. 2016. [50] H.-P. Phan et al., “Piezoresistive effect in p-type 3C-SiC at high temperatures characterized using Joule heating,” Sci. Rep., vol. 6, Jun. 2016, Art. no. 28499. [51] D. L. Barrett and R. B. Campbell, “Electron mobility measurements in SiC polytypes,” J. Appl. Phys., vol. 38, no. 1, p. 53, 1967. [52] L. Patrick, “Electron mobilities in SiC polytypes,” J. Appl. Phys., vol. 38, no. 1, p. 50, 1967. [53] R. S. Okojie, A. A. Ned, A. D. Kurtz, and W. N. Carr, “Characterization of highly doped n- and p-type 6H-SiC piezoresistors,” IEEE Trans. Electron Devices, vol. 45, no. 4, pp. 785–790, Apr. 1998. [54] T. Dinh et al., “Charge transport and activation energy of amorphous silicon carbide thin film on quartz at elevated temperature,” Appl. Phys. Exp., vol. 8, no. 6, p. 061303, 2015. [55] A. K. Dutta, “Electrical conductivity of single crystals of graphite,” Phys. Rev. B, Condens. Matter, vol. 90, pp. 187–193, Apr. 1953. [56] K. Matsubara, K. Sugihara, and T. Tsuzuku, “Electrical resistance in the c direction of graphite,” Phys. Rev. B, Condens. Matter, vol. 41, p. 969, Jan. 1990. [57] S. Ono, “C-axis resistivity of graphite in connection with stacking faults,” J. Phys. Soc. Jpn., vol. 40, no. 2, pp. 498–504, 1976. [58] D. E. Roberts, “The effect of temperature and magnetization on the resistance of graphite,” Philos. Mag. Ser. 6, vol. 26, no. 151, pp. 158–176, 1913. [59] G. H. Kinchin, “The electrical properties of graphite,” Proc. Roy. Soc. London A, Math., Phys. Eng. Sci., vol. 217, no. 1128, pp. 9–26, 1953. [60] R. A. Buerschaper, “Thermal and electrical conductivity of graphite and carbon at low temperatures,” J. Appl. Phys., vol. 15, no. 5, pp. 452–454, 1944. [61] B. Noyes, Jr., “The variation in the resistance of carbon and graphite with temperature,” Phys. Rev., vol. 24, p. 190, Aug. 1924. [62] A. W. Smith and N. S. Rasor, “Observed dependence of the lowtemperature thermal and electrical conductivity of graphite on temperature, type, neutron irradiation, and bromination,” Phys. Rev., vol. 104, p. 885, Nov. 1956. [63] W. Primak and L. H. Fuchs, “Electrical conductivities of natural graphite crystals,” Phys. Rev., vol. 95, p. 22, Jul. 1954. [64] X. Liu, M. Mwangi, X. Li, M. O’Brien, and G. M. Whitesides, “Paper-based piezoresistive MEMS sensors,” Lab Chip, vol. 11, no. 13, pp. 2189–2196, 2011. [65] A. Bessonov, M. Kirikova, S. Haque, I. Gartseev, and M. J. A. Bailey, “Highly reproducible printable graphite strain gauges for flexible devices,” Sens. Actuators A, Phys., vol. 206, pp. 75–80, Feb. 2014. [66] T. Dinh, H.-P. Phan, D. V. Dao, P. Woodfield, A. Qamar, and N.-T. Nguyen, “Graphite on paper as material for sensitive thermoresistive sensors,” J. Mater. Chem. C, vol. 3, no. 34, pp. 8776–8779, 2015. [67] T. Dinh et al., “Environment-friendly wearable thermal flow sensors for noninvasive respiratory monitoring,” in Proc. IEEE 30th Int. Conf. Micro Electro Mech. Syst. (MEMS), Jan. 2017, pp. 993–996. [68] T. Dinh et al., “Solvent-free fabrication of biodegradable hot-film flow sensor for noninvasive respiratory monitoring,” J. Phys. D, Appl. Phys., vol. 50, no. 21, p. 215401, 2017. [69] A. Di Bartolomeo et al., “Multiwalled carbon nanotube films as smallsized temperature sensors,” J. Appl. Phys., vol. 105, no. 6, p. 064518, 2009. [70] C. L. Kane et al., “Temperature-dependent resistivity of single-wall carbon nanotubes,” Europhys. Lett., vol. 41, no. 6, p. 683, 1998. [71] H. C. Neitzert, L. Vertuccio, and A. Sorrentino, “Epoxy/MWCNT composite as temperature sensor and electrical heating element,” IEEE Trans. Nanotechnol., vol. 10, no. 4, pp. 688–693, Jul. 2011. [72] G. Matzeu, A. Pucci, S. Savi, M. Romanelli, and F. Di Francesco, “A temperature sensor based on a MWCNT/SEBS nanocomposite,” Sens. Actuators A, Phys., vol. 178, pp. 94–99, May 2012. 983 [73] H. Al-Mumen, F. Rao, L. Dong, and W. Li, “Design, fabrication, and characterization of graphene thermistor,” in Proc. 8th IEEE Int. Conf. Nano/Micro Eng. Mol. Syst. (NEMS), Apr. 2013, pp. 1135–1138. [74] P. Sun et al., “Small temperature coefficient of resistivity of graphene/graphene oxide hybrid membranes,” ACS Appl. Mater. Interfaces, vol. 5, no. 19, pp. 9563–9571, 2013. [75] T. Dinh et al., “Environment-friendly carbon nanotube based flexible electronics for noninvasive and wearable healthcare,” J. Mater. Chem. C, vol. 4, no. 42, pp. 10061–10068, 2016. [76] V. T. Dau, C. D. Tran, T. T. Bui, V. D. X. Nguyen, and T. X. Dinh, “Piezo-resistive and thermo-resistance effects of highly-aligned CNT based macrostructures,” RSC Adv., vol. 6, no. 108, pp. 106090–106095, 2016. [77] X. F. Zhou, H. Zhang, H. Yan, C. L. He, M. H. Lu, and R. Y. Hao, “Giant temperature coefficient of resistance in Co-doped ZnO thin films,” Appl. Phys. A, Solids Surf., vol. 114, no. 3, pp. 809–812, 2014. [78] M.-J. Jiang, Z.-M. Dang, and H.-P. Xu, “Significant temperature and pressure sensitivities of electrical properties in chemically modified multiwall carbon nanotube/methylvinyl silicone rubber nanocomposites,” Appl. Phys. Lett., vol. 89, no. 18, p. 182902, 2006. [79] M. B. Heaney, “Resistance-expansion-temperature behavior of a disordered conductor–insulator composite,” Appl. Phys. Lett., vol. 69, pp. 2602–2604, 1996. [80] G. E. Fernandes, J. H. Kim, A. K. Sood, and J. Xu, “Giant temperature coefficient of resistance in carbon nanotube/phase-change polymer nanocomposites,” Adv. Funct. Mater., vol. 23, no. 37, pp. 4678–4683, 2013. [81] Z.-D. Xiang, T. Chen, Z.-M. Li, and X.-C. Bian, “Negative temperature coefficient of resistivity in lightweight conductive carbon nanotube/polymer composites,” Macromol. Mater. Eng., vol. 294, no. 2, pp. 91–95, 2009. [82] K. Ohe and Y. Naito, “A new resistor having an anomalously large positive temperature coefficient,” Jpn. J. Appl. Phys., vol. 10, no. 1, p. 99, 1971. [83] A. Voet, “Temperature effect of electrical resistivity of carbon black filled polymers,” Rubber Chem. Technol., vol. 54, no. 1, pp. 42–50, 1981. [84] S. H. El-Mahalawy and B. L. Evans, “Temperature dependence of the electrical conductivity and Hall coefficient in 2H-MoS2 , MoSe2 , WSe2 , and MoTe2 authors,” Phys. Status Solidi B, vol. 79, no. 2, pp. 713–722, 1977. [85] K.-K. Kam, “Electrical properties of WSe2 , WS2 , MoSe2 , MoS2 , and their use as photoanodes in a semiconductor liquid junction solar cell,” Ph.D. dissertation, Iowa State Univ., Ames, IA, USA, 1982. [86] A. Conan, D. Delaunay, A. Bonnet, A. G. Moustafa, and M. Spiesser, “Temperature dependence of the electrical conductivity and thermoelectric power in MoTe2 single crystals,” Phys. Status Solidi B, vol. 94, no. 1, pp. 279–286, 1979. [87] D. Ovchinnikov, A. Allain, Y.-S. Huang, D. Dumcenco, and A. Kis. (2014). “Electrical transport properties of single-layer WS2 .” [Online]. Available: https://arxiv.org/abs/1408.4906 [88] F. J. Ohkawa, “Temperature dependence of electrical resistivity of metals,” J. Phys. Soc. Jpn., vol. 44, no. 4, pp. 1105–1111, 1978. [89] R. A. Holmwood and R. Glang, “Resistivity and temperature coefficient of pure molybdenum,” J. Chem. Eng. Data, vol. 10, no. 2, pp. 162–163, 1965. [90] B. S. Verma and S. K. Sharma, “Effect of thermal strains on the temperature coefficient of resistance,” Thin Solid Films, vol. 5, no. 4, pp. R44–R46, 1970. [91] F. Warkusz, “Electrical and mechanical properties of thin metal films: Size effects,” Prog. Surf. Sci., vol. 10, no. 3, pp. 287–382, 1980. [92] A. Singh, “Grain-size dependence of temperature coefficient of resistance of polycrystalline metal films,” Proc. IEEE, vol. 61, no. 11, pp. 1653–1654, Nov. 1973. [93] C. Dezauzier et al., “Electrical characterization of SiC for hightemperature thermal-sensor applications,” Sens. Actuators A, Phys., vol. 46, pp. 71–75, Jan./Feb. 1995. [94] F. Mailly et al., “Anemometer with hot platinum thin film,” Sens. Actuators A, Phys., vol. 94, pp. 32–38, Oct. 2001. [95] S. Kim, T. Nam, and S. Park, “Measurement of flow direction and velocity using a micromachined flow sensor,” Sens. Actuators A, Phys., vol. 114, pp. 312–318, Sep. 2004. [96] N. Zhang, C.-M. Lin, D. G. Senesky, and A. P. Pisano, “Temperature sensor based on 4H-silicon carbide pn diode operational from 20 °C to 600 °C,” Appl. Phys. Lett., vol. 104, no. 7, p. 073504, Feb. 2014. 984 JOURNAL OF MICROELECTROMECHANICAL SYSTEMS, VOL. 26, NO. 5, OCTOBER 2017 [97] M. Mansoor, I. Haneef, S. Akhtar, A. De Luca, and F. Udrea, “Silicon diode temperature sensors—A review of applications,” Sens. Actuators A, Phys., vol. 232, pp. 63–74, Aug. 2015. [98] O. Madelung, Semiconductors—Basic Data. Berlin, Germany: Springer, 2012. [99] A. G. Milnes, Deep Impurities in Semiconductors. Hoboken, NJ, USA: Wiley, 1973. [100] E. M. Conwell, “Properties of silicon and germanium: II,” Proc. IRE, vol. 46, no. 6, pp. 1281–1300, Jun. 1958. [101] S. Sze and J. Irvin, “Resistivity, mobility and impurity levels in GaAs, Ge, and Si at 300 K,” Solid-State Electron., vol. 11, no. 6, pp. 599–602, 1968. [102] T. Kimoto et al., “Nitrogen donors and deep levels in high-quality 4H-SiC epilayers grown by chemical vapor deposition,” Appl. Phys. Lett., vol. 67, pp. 2833–2835, Nov. 1995. [103] J. Bluet et al., “Activation of aluminum implanted at high doses in 4H–SiC,” J. Appl. Phys., vol. 88, no. 4, pp. 1971–1977, 2000. [104] Y. Gaoa, S. Soloviev, and T. Sudarshan, “Investigation of boron diffusion in 6H-SiC,” Appl. Phys. Lett., vol. 83, no. 5, p. 905, 2003. [105] W. Gotz et al., “Nitrogen donors in 4H -silicon carbide,” J. Appl. Phys., vol. 73, no. 7, pp. 3332–3338, 1993. [106] W. Hartung, M. Rasp, D. Hofmann, and A. Winnacker, “Analysis of electronic levels in SiC: V, N, Al powders and crystals using thermally stimulated luminescence,” Mater. Sci. Eng., B, vol. 61, pp. 102–106, Jul. 1999. [107] J. Pernot et al., “Free electron density and mobility in highquality 4H–SiC,” Appl. Phys. Lett., vol. 77, pp. 4359–4361, Dec. 2000. [108] H. Iwata and K. M. Itoh, “Donor and acceptor concentration dependence of the electron Hall mobility and the Hall scattering factor in n-type 4H- and 6H-SiC,” J. Appl. Phys., vol. 89, no. 7, pp. 6228–6234, 2001. [109] P. Wellmann, S. Bushevoy, and R. Weingärtner, “Evaluation of ntype doping of 4H-SiC and n-/p-type doping of 6H-SiC using absorption measurements,” Mater. Sci. Eng., B, vol. 80, pp. 352–356, Mar. 2001. [110] H. Matsuura et al., “Dependence of acceptor levels and hole mobility on acceptor density and temperature in Al-doped p-type 4H-SiC epilayers,” J. Appl. Phys., vol. 96, no. 5, pp. 2708–2715, 2004. [111] F. D. Morrison, D. C. Sinclair, and A. R. West, “Doping mechanisms and electrical properties of La-doped BaTiO3 ceramics,” Int. J. Inorganic Mater., vol. 3, pp. 1205–1210, Dec. 2001. [112] M. Li, A. Feteira, D. C. Sinclair, and A. R. West, “Influence of Mn doping on the semiconducting properties of CaCu3 Ti4 O12 ceramics,” Appl. Phys. Lett., vol. 88, no. 23, p. 232903, 2006. [113] O. Lopatiuk-Tirpak et al., “Carrier concentration dependence of acceptor activation energy in p-type ZnO,” Appl. Phys. Lett., vol. 88, no. 20, p. 202110, 2006. [114] M. Kumar, T. N. Bhat, B. Roul, M. K. Rajpalke, A. T. Kalghatgi, and S. B. Krupanidhi, “Carrier concentration dependence of donor activation energy in n-type GaN epilayers grown on Si (1 1 1) by plasmaassisted MBE,” Mater. Res. Bull., vol. 47, pp. 1306–1309, Jun. 2012. [115] G. L. Pearson and J. Bardeen, “Electrical properties of pure silicon and silicon alloys containing boron and phosphorus,” Phys. Rev., vol. 75, p. 865, Mar. 1949. [116] P. Norton and J. Brandt, “Temperature coefficient of resistance for p-and n-type silicon,” Solid-State Electron., vol. 21, pp. 969–974, Jul. 1978. [117] A. Kovalevskii, A. Dolbik, and S. Voitekh, “Effect of doping on the temperature coefficient of resistance of polysilicon films,” Russian Microelectron., vol. 36, pp. 153–158, May 2007. [118] H. Latha, A. Udayakumar, and V. S. Prasad, “Effect of nitrogen doping on the electrical properties of 3C-SiC thin films for high-temperature sensors applications,” Acta Metallurgica Sinica (English Lett.), vol. 27, no. 1, pp. 168–174, 2014. [119] A. Qamar et al., “The effect of device geometry and crystal orientation on the stress-dependent offset voltage of 3C-SiC (100) four terminal devices,” J. Mater. Chem. C, vol. 3, pp. 8804–8809, Mar. 2015. [120] H.-P. Phan et al., “Orientation dependence of the pseudo-Hall effect in p-type 3C-SiC four-terminal devices under mechanical stress,” RSC Adv., vol. 5, no. 69, pp. 56377–56381, 2015. [121] N. C. C. Lu, L. Gerzberg, C.-Y. Lu, and J. D. Meindl, “A conduction model for semiconductor-grain-boundary-semiconductor barriers in polycrystalline-silicon films,” IEEE Trans. Electron Devices, vol. 30, no. 2, pp. 137–149, Feb. 1983. [122] D. M. Kim, A. Khondker, S. Ahmed, and R. R. Shah, “Theory of conduction in polysilicon: Drift-diffusion approach in crystallineamorphous-crystalline semiconductor system—Part I: Small signal theory,” IEEE Trans. Electron Devices, vol. 31, no. 4, pp. 480–493, Apr. 1984. [123] J. T. Irvine, A. Huanosta, R. Valenzuela, and A. R. West, “Electrical properties of polycrystalline nickel zinc ferrites,” J. Amer. Ceram. Soc., vol. 73, no. 3, pp. 729–732, 1990. [124] A. R. Ferreira, C. S. Furtado, and J. M. Perdigao, “Grain-boundary and grain electrical resistances in CoxFe3 -xO4 ,” J. Amer. Ceram. Soc., vol. 75, pp. 1708–1711, Jun. 1992. [125] S. G. Song, Z. Ling, and F. Placido, “Impedance analysis of MnCoCuO NTC ceramic,” Mater. Res. Bull., vol. 40, pp. 1081–1093, Jul. 2005. [126] N. Mott and E. Davis, Electronic Processes in Non-Crystalline Solids. Oxford, U.K.: Clarendon, 1979, p. 465. [127] S. Baranovski, Charge Transport in Disordered Solids With Applications in Electronics, vol. 17. Hoboken, NJ, USA: Wiley, 2006. [128] R. Street, Hydrogenated Amorphous Silicon. Cambridge, U.K.: Cambridge Univ., 1991. [129] M. B. Dutt and V. Mittal, “Investigation of electrical transport properties of as-implanted silicon for making micromachined uncooled bolometric arrays,” J. Appl. Phys., vol. 97, no. 8, p. 083704, 2005. [130] T. A. Abtew, M. Zhang, and D. Drabold, “Ab initio estimate of temperature dependence of electrical conductivity in a model amorphous material: Hydrogenated amorphous silicon,” Phys. Rev. B, Condens. Matter, vol. 76, p. 045212, Jul. 2007. [131] M.-L. Zhang and D. A. Drabold. (2011). “Temperature coefficient of resistivity in amorphous semiconductors.” [Online]. Available: https://arxiv.org/abs/1112.2169 [132] M.-P. Nguyen and S.-G. Yoon, “Effect of deposition temperature on the structural and electrical properties of NiCr thin-film resistors by magnetron cosputtering,” J. Electrochem. Soc., vol. 153, no. 7, pp. G606–G608, 2006. [133] C. C. Lukose, G. Zoppi, and M. Birkett, “Thin film resistive materials: Past, present and future,” in Proc. IOP Conf. Ser., Mater. Sci. Eng., 2016, p. 012003. [134] H. S. Jha and P. Agarwal, “Effects of substrate temperature on structural and electrical properties of cubic silicon carbide films deposited by hot wire chemical vapor deposition technique,” J. Mater. Sci., Mater. Electron., vol. 26, pp. 2844–2850, May 2015. [135] A. Singh, “Film thickness and grain size diameter dependence on temperature coefficient of resistance of thin metal films,” J. Appl. Phys., vol. 45, no. 4, pp. 1908–1909, 1974. [136] F. Lacy, “Using nanometer platinum films as temperature sensors (constraints from experimental, mathematical, and finite-element analysis),” IEEE Sensors J., vol. 9, no. 9, pp. 1111–1117, Sep. 2009. [137] F. Lacy, “Developing a theoretical relationship between electrical resistivity, temperature, and film thickness for conductors,” Nanosc. Res. Lett., vol. 6, p. 1, Dec. 2011. [138] F. Lacy, “Evaluating the resistivity-temperature relationship for RTDs and other conductors,” IEEE Sensors J., vol. 11, no. 5, pp. 1208–1213, May 2011. [139] M. I. Lei, Silicon Carbide High Temperature Thermoelectric Flow Sensor. Cleveland, OH, USA: Case Western Reserve Univ., 2011. [140] M. S. Raman, T. Kifle, E. Bhattacharya, and K. N. Bhat, “Physical model for the resistivity and temperature coefficient of resistivity in heavily doped polysilicon,” IEEE Trans. Electron Devices, vol. 53, no. 8, pp. 1885–1892, Aug. 2006. [141] D. Petkovic and D. Mitic, “Effects of grain-boundary trapping-state energy distribution on the Fermi level position in thin polysilicon films,” in Proc. 20th Int. Conf. Microelectron., 1995, pp. 145–148. [142] K. Chu, S.-C. Lee, S. Lee, D. Kim, C. Moon, and S.-H. Park, “Smart conducting polymer composites having zero temperature coefficient of resistance,” Nanoscale, vol. 7, no. 2, pp. 471–478, 2015. [143] K. Chu and S. H. Park, “Fabrication of a hybrid carbon-based composite for flexible heating element with a zero temperature coefficient of resistance,” IEEE Electron Device Lett., vol. 36, no. 1, pp. 50–52, Jan. 2015. [144] T. Dinh, H.-P. Phan, A. Qamar, N.-T. Nguyen, and D. V. Dao, “Flexible and multifunctional electronics fabricated by a solvent-free and user-friendly method,” RSC Adv., vol. 6, no. 81, pp. 77267–77274, 2016. [145] S. Issa, H. Sturm, and W. Lang, “Modeling of the response time of thermal flow sensors,” Micromachines, vol. 2, pp. 385–393, Oct. 2011. DINH et al.: THERMORESISTIVE EFFECT FOR ADVANCED THERMAL SENSORS [146] M. Mazumder, T. Borca-Tasciuc, S. C. Teehan, E. Stinzianni, H. Efstathiadis, and S. Solovyov, “Temperature dependent thermal conductivity of Si/SiC amorphous multilayer films,” Appl. Phys. Lett., vol. 96, p. 093103, Mar. 2010. [147] C. Sosna, T. Walter, and W. Lang, “Response time of thermal flow sensors with air as fluid,” Sens. Actuators A, Phys., vol. 172, no. 1, pp. 15–20, 2011. [148] T. Neda, K. Nakamura, and T. Takumi, “A polysilicon flow sensor for gas flow meters,” Sens. Actuators A, Phys., vol. 54, nos. 1–3, pp. 626–631, Jun. 1996. [149] C. Lyons, A. Friedberger, W. Welser, G. Müller, G. Krotz, and R. Kassing, “A High-speed mass flow sensor with heated silicon carbide bridges,” in Proc. IEEE 11th Annu. Int. Workshop Micro Electro Mech. Syst. Invest. Micro Struct., Sens., Actuators, Mach. Syst. (MEMS), Jan. 1998, pp. 356–360. [150] A. S. Cubukcu, E. Zernickel, U. Buerklin, and G. A. Urban, “A 2D thermal flow sensor with sub-mW power consumption,” Sens. Actuators A, Phys., vol. 163, no. 2, pp. 449–456, Oct. 2010. [151] N. Sabaté, J. Santander, L. Fonseca, I. Gràcia, and C. Cané, “Multirange silicon micromachined flow sensor,” Sens. Actuators A, Phys., vol. 110, nos. 1–3, pp. 282–288, Feb. 2004. [152] V. T. Dau, D. V. Dao, and S. Sugiyama, “A 2-DOF convective micro accelerometer with a low thermal stress sensing element,” Smart Mater. Struct., vol. 16, no. 6, p. 2308, 2007. [153] D. V. Dao, V. T. Dau, T. Shiozawa, and S. Sugiyama, “Development of a dual-axis convective gyroscope with low thermal-induced stress sensing element,” J. Microelectromech. Syst., vol. 16, no. 4, pp. 950–958, Aug. 2007. [154] J. Van Baar et al., “Micromachined two dimensional resistor arrays for determination of gas parameters,” in Proc. 12th Int. Conf., Solid-State Sens., Actuators Microsyst. TRANSDUCERS, Jun. 2003, pp. 1606–1609. [155] F. Kohl et al., “A micromachined flow sensor for liquid and gaseous fluids,” Sens. Actuators A, Phys., vol. 41, nos. 1–3, pp. 293–299, Apr. 1994. [156] S. Harada, W. Honda, T. Arie, S. Akita, and K. Takei, “Fully printed, highly sensitive multifunctional artificial electronic whisker arrays integrated with strain and temperature sensors,” ACS Nano, vol. 8, no. 4, pp. 3921–3927, 2014. [157] H. Farahani, R. Wagiran, and M. N. Hamidon, “Humidity sensors principle, mechanism, and fabrication technologies: A comprehensive review,” Sensors, vol. 14, no. 5, pp. 7881–7939, 2014. [158] P. Jiang and R. Zhu, “Elimination of drifts in long-duration monitoring for apnea-hypopnea of human respiration,” Sensors, vol. 16, no. 11, p. 1779, 2016. [159] K. Wasa, T. Tohda, Y. Kasahara, and S. Hayakawa, “Highly-reliable temperature sensor using RF-sputtered SiC thin film,” Rev. Sci. Instrum., vol. 50, no. 9, pp. 1084–1088, 1979. [160] E. A. de Vasconcelos, W. Y. Zhang, H. Uchida, and T. Katsube, “Potential of high-purity polycrystalline silicon carbide for thermistor applications,” Jpn. J. Appl. Phys., vol. 37, no. 9A, p. 5078, 1998. [161] T. Nagai, K. Yamamoto, and I. Kobayashi, “Rapid response SiC thinfilm thermistor,” Rev. Sci. Instrum., vol. 55, no. 7, pp. 1163–1165, 1984. [162] T. Nagai and M. Itoh, “SiC thin-film thermistors,” IEEE Trans. Ind. Appl., vol. 26, no. 6, pp. 1139–1143, Nov. 1990. [163] E. A. de Vasconcelos, S. Khan, W. Zhang, H. Uchida, and T. Katsube, “Highly sensitive thermistors based on high-purity polycrystalline cubic silicon carbide,” Sens. Actuators A, Phys., vol. 83, nos. 1–3, pp. 167–171, May 2000. [164] N. Boltovets et al., “A silicon carbide thermistor,” Semicond. Phys., Quantum Electron. Optoelectron., vol. 9, no. 4, pp. 67–70, 2006. [165] A. Vatani, P. L. Woodfield, and D. V. Dao, “A miniaturized transient hot-wire device for measuring thermal conductivity of nonconductive fluids,” Microsyst. Technol., vol. 22, no. 10, pp. 2463–2466, Oct. 2016. [166] R. Ahrens and K. Schlote-Holubek, “A micro flow sensor from a polymer for gases and liquids,” J. Micromech. Microeng., vol. 19, no. 7, p. 074006, 2009. [167] R. J. Adamec and D. V. Thiel, “Self heated thermo-resistive element hot wire anemometer,” IEEE Sensors J., vol. 10, no. 4, pp. 847–848, Apr. 2010. [168] C. Li, P.-M. Wu, J. Han, and C. H. Ahn, “A flexible polymer tube labchip integrated with microsensors for smart microcatheter,” Biomed. Microdevices, vol. 10, no. 5, pp. 671–679, Oct. 2008. 985 [169] G. Soundararajan, M. Rouhanizadeh, H. Yu, L. DeMaio, E. Kim, and T. K. Hsiai, “MEMS shear stress sensors for microcirculation,” Sens. Actuators A, Phys., vol. 118, no. 1, pp. 25–32, Jan. 2005. [170] P. Bruschi, M. Dei, and M. Piotto, “A low-power 2-D wind sensor based on integrated flow meters,” IEEE Sensors J., vol. 9, no. 12, pp. 1688–1696, Dec. 2009. [171] F. Keplinger, J. Kuntner, A. Jachimowicz, and F. Kohl, “Sensitive measurement of flow velocity and flow direction using a circular thermistor array,” in Proc. GMe Workshop, 2006, pp. 133–137. [172] J. Robadey, O. Paul, and H. Baltes, “Two-dimensional integrated gas flow sensors by CMOS IC technology,” J. Micromech. Microeng., vol. 5, no. 3, p. 243, 1995. [173] J.-G. Lee, M. I. Lei, S.-P. Lee, S. Rajgopal, and M. Mehregany, “Micro flow sensor using polycrystalline silicon carbide,” J. Sensor Sci. Technol., vol. 18, no. 2, pp. 147–153, 2009. [174] H. Berthet, J. Jundt, J. Durivault, B. Mercier, and D. Angelescu, “Timeof-flight thermal flowrate sensor for lab-on-chip applications,” Lab Chip, vol. 11, no. 2, pp. 215–223, 2011. [175] E. Meng, P.-Y. Li, and Y.-C. Tai, “A biocompatible Parylene thermal flow sensing array,” Sens. Actuators A, Phys., vol. 144, no. 1, pp. 18–28, May 2008. [176] H. E. Weber, “Accelerometer,” U.S. Patent 2 455 394, Jun. 29, 1943. [177] A. M. Leung, J. Jones, E. Czyzewska, J. Chen, and M. Pascal, “Micromachined accelerometer with no proof mass,” in IEDM Tech. Dig., Dec. 1997, pp. 899–902. [178] A. M. Leung, J. Jones, E. Czyzewska, J. Chen, and B. Woods, “Micromachined accelerometer based on convection heat transfer,” in Proc. IEEE 11th Annu. Int. Workshop Micro Electro Mech. Syst. Invest. Micro Struct., Sens., Actuators, Mach. Syst. (MEMS), Jan. 1998, pp. 627–630. [179] X. Luo, Y. Yang, F. Zheng, Z. X. Li, and Z. Y. Guo, “An optimized micromachined convective accelerometer with no proof mass,” J. Micromech. Microeng., vol. 11, no. 5, p. 504, 2001. [180] X. B. Luo, Z. X. Li, Z. Y. Guo, and Y. J. Yang, “Thermal optimization on micromachined convective accelerometer,” Heat Mass Transf., vol. 38, no. 7, pp. 705–712, Aug. 2002. [181] X. B. Luo, Z. X. Li, Z. Y. Guo, and Y. J. Yang, “Study on linearity of a micromachined convective accelerometer,” Microelectron. Eng., vol. 65, nos. 1–2, pp. 87–101, Jan. 2003. [182] F. Mailly, A. Giani, A. Martinez, R. Bonnot, P. Temple-Boyer, and A. Boyer, “Micromachined thermal accelerometer,” Sens. Actuators A, Phys., vol. 103, no. 3, pp. 359–363, Feb. 2003. [183] S.-H. Tsang, A. H. Ma, K. S. Karim, A. Parameswaran, and A. M. Leung, “Monolithically fabricated polymermems 3-axis thermal accelerometers designed for automated wirebonder assembly,” in Proc. IEEE 21st Int. Conf. Micro Electro Mech. Syst., Jan. 2008, pp. 880–883. [184] S. J. Chen and C. H. Shen, “A novel two-axis CMOS accelerometer based on thermal convection,” IEEE Trans. Instrum. Meas., vol. 57, no. 8, pp. 1572–1577, Aug. 2008. [185] U. Park, D. Kim, J. Kim, I.-K. Moon, and C.-H. Kim, “Development of a complete dual-axis micromachined convective accelerometer with high sensitivity,” in Proc. IEEE Sensors, Oct. 2008, pp. 670–673. [186] D. T. Van, D. V. Dao, H. Kumagai, and S. Sugiyama, “A single-axis thermal convective gas gyroscope,” Sensors Mater., vol. 17, no. 8, pp. 453–463, 2005. [187] V. T. Dau, D. V. Dao, T. Shiozawa, and S. Sugiyama, “Simulation and fabrication of a convective gyroscope,” IEEE Sensors J., vol. 8, no. 9, pp. 1530–1538, Sep. 2008. [188] V. T. Dau, T. X. Dinh, D. V. Dao, and S. Sugiyama, “Design and simulation of a novel 3-DOF MEMS convective gyroscope,” IEEJ Trans. SM, Ints. Elect. Eng. Jpn., vol. 128, no. 5, pp. 219–224, 2008. [189] H. Chang, X. Gong, S. Wang, P. Zhou, and W. Yuan, “On improving the performance of a triaxis vortex convective gyroscope through suspended silicon thermistors,” IEEE Sensors J., vol. 15, no. 2, pp. 946–955, Feb. 2015. [190] R. Zhu, S. Cai, H. Ding, Y. J. Yang, and Y. Su, “A micromachined gas inertial sensor based on thermal expansion,” Sens. Actuators A, Phys., vol. 212, pp. 173–180, Jun. 2014. [191] A. Harley-Trochimczyk, A. Rao, H. Long, A. Zettl, C. Carraro, and R. Maboudian, “Low-power catalytic gas sensing using highly stable silicon carbide microheaters,” J. Micromech. Microeng., vol. 27, no. 4, p. 045003, 2017. [192] C.-H. Han, D.-W. Hong, I.-J. Kim, J. Gwak, S.-D. Han, and K. C. Singh, “Synthesis of Pd or Pt/titanate nanotube and its application to catalytic type hydrogen gas sensor,” Sens. Actuators B, Chem., vol. 128, no. 1, pp. 320–325, Dec. 2007. 986 JOURNAL OF MICROELECTROMECHANICAL SYSTEMS, VOL. 26, NO. 5, OCTOBER 2017 [193] A. Mujahid, P. A. Lieberzeit, and F. L. Dickert, “Solid-state sensors for field measurements of gases and vapors,” in Encyclopedia of Analytical Chemistry. Weinheim, Germany: Wiley, 2014, doi: 10.1002/9780470027318.a0921. [194] R. M. Atkins, “Wet/dry bulb thermistor hygrometer with digital indication,” Instrum. Control Syst., vol. 37, pp. 111–114, Apr. 1964. [195] M. A. Kaganov and T. I. Kaganova, “Direct measurement of the relative humidity of gases,” Instrum. Experim. Techn., vol. 1, pp. 202–204, Sep./Oct. 1962. [196] D. K. Schroder, Semiconductor Materials and Devices Characterization. Hoboken, NJ, USA: Wiley, 2006. [197] J. D. Lewin, “A cryogenic liquid level detector employing thermistors,” J. Sci. Instrum., vol. 10, no. 11, pp. 539–540, 1963. [198] S. Chatterjee, A. K. Halder, K. Sengupta, and H. S. Maiti, “A vacuum gauge using positive temperature coefficient thermistor as the sensor,” Rev. Sci. Instrum., vol. 71, no. 12, pp. 4670–4673, 2000. [199] J. S. Shie, B. C. Chou, and Y. M. Chen, “High performance Pirani vacuum gauge,” J. Vac. Sci. Technol. A, Vac. Surf. Films, vol. 13, no. 6, pp. 2972–2979, 1995. Toan Dinh received the B.Eng. and M.Sc. degrees from the Hanoi University of Science and Technology, Vietnam, in 2009 and 2012, respectively, and the Ph.D. degree from Griffith University, in 2017. He is currently a Research Fellow with the Queensland Micro- and Nanotechnology Center, Griffith University. His research interests include micro/nano-electromechanical systems, physics of semiconductors and sensors for harsh environments, soft robotics, and advanced functional materials for wearable applications. He was a recipient of GUPRS, GUIPRS, and PAS scholarships from Griffith University. Hoang-Phuong Phan received the B.E. and M.E. degrees from the University of Tokyo, Japan, and the Ph.D. degree from Griffith University, Australia. He is currently a Research Fellow with the Queensland Micro and Nanotechnology Center, Griffith University. His main interests focus on silicon carbide MEMS/NEMS for applications in harsh environments. He has also been a Visiting Scholar at the National Institute of Advanced Industrial Science and Technology, Japan, in 2016, and Stanford University, CA, USA, in 2017. He has authored over 50 peer-reviewed journal articles and conference papers, two US patents, and one book, all in micro and nanotechnologies. He was a recipient of the Japanese Government Scholarships (MEXT) for undergraduate and postgraduate studies (2006-2013), and the GUPRS and GUIPRS scholarships from Griffith University for the doctoral course (2013-2016). He received the GU Publication Award, the GGRS-IEIS travel grant, the Springer outstanding theses Award, and the Australian Nanotechnology Network Oversea Fellowship. He was also selected to the Australian delegates to attend the 23rd World Micromachines Summit in Barcelona, Spain, in 2017. He has served as a Reviewer for several journals, including IEEE J OURNAL OF M ICROELECTROMECHANICAL S YSTEMS , Sensors and Actuators A, Micromachines, Material Science and Engineering B, the IEEE S ENSORS J OURNAL, and IEEE E LECTRON D EVICE L ETTERS . Afzaal Qamar received the M.Sc. degree in applied physics from the University of Engineering and Technology, Lahore, in 2004; the M.Phil. degree in physics from the Pakistan Institute of Engineering and Applied Sciences, Islamabad, in 2006, on a national competitive fellowship; and the Ph.D. degree from the Queensland Micro- and Nanotechnology Centre, Griffith University, Australia, on a competitive international scholarship. He served as the Manager Technical for IIIV semiconductors device fabrication at the Institute of Applied Technologies from 2008 to 2014. He also served as a Research Associate at Griffith University. He is currently a Research Fellow with the Department of Electrical Engineering and Computer Science, University of Michigan, USA. His research interests are semiconductor physics, micro/nano devices, thin films, MEMS/NEMS, and piezoresisitve and piezoelectric properties of wide bandgap semiconductors. He has authored over 35 peer-reviewed journal articles on these areas. Peter Woodfield received the Ph.D. degree from Sydney University, in 2001. He is currently a Senior Lecturer with the School of Engineering, Griffith University, Australia. He has extensive experience in the fields of experimental and computational heat transfer, computational fluid dynamics, thermophysical and transport property measurement techniques, jet impingement quench cooling, and inverse heat conduction problems. Nam-Trung Nguyen received the Dipl.Ing., Dr.-Ing., and Dr.-Ing. habilitation degrees from the Chemnitz University of Technology, Germany, in 1993, 1997, and 2004, respectively. In 1998, he was a Post-Doctoral Research Engineer at the University of California at Berkeley, Berkeley, USA. From 1999 to 2013, he was an Associate Professor at Nanyang Technological University, Singapore. Since 2013, he has served as a Professor and the Director of the Queensland Micro- and Nanotechnology Center with Griffith University, Australia. Dzung Viet Dao received the Ph.D. degree in microelectromechanical systems (MEMS) from Ritsumeikan University, Japan, in 2003. He was at Ritsumeikan University as a Post-Doctoral Research Fellow from 2003 to 2006, a Lecturer from 2006 to 2007, and the Chair Professor from 2007 to 2011. In 2011, he joined as a Senior Lecturer with the School of Engineering, Griffith University, where he is currently teaching in Mechatronics and Mechanical Engineering. He is a member of the National Committee on Mechatronics, Engineers Australia. He has authored over 280 papers in scientific journals and conference proceedings, and filed 15 patents. His current research interests include Sensing properties in nanostructures, MEMS sensors and actuators, silicon carbide transducers for harsh environment, and mechatronics.