INTERIOR DESIGN LECTURE NOTES - SYSTEMS AND MATERIALS

advertisement

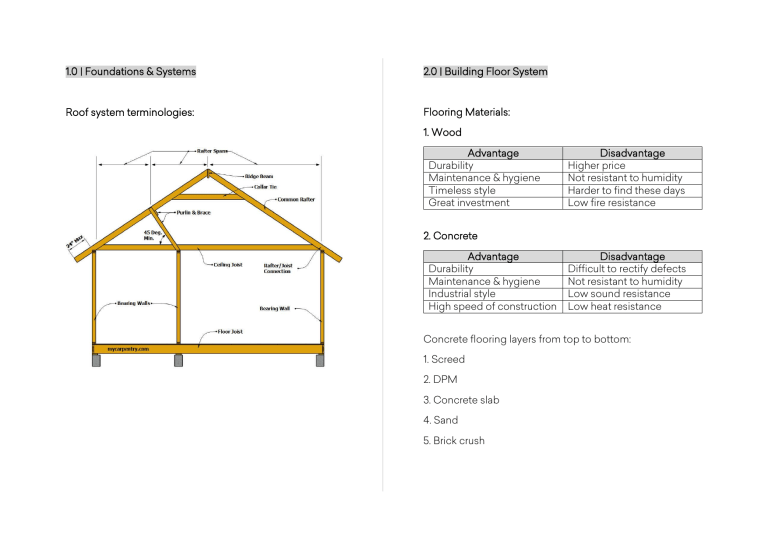

1.0 | Foundations & Systems 2.0 | Building Floor System Roof system terminologies: Flooring Materials: 1. Wood Advantage Durability Maintenance & hygiene Timeless style Great investment Disadvantage Higher price Not resistant to humidity Harder to find these days Low fire resistance 2. Concrete Advantage Durability Maintenance & hygiene Industrial style High speed of construction Disadvantage Difficult to rectify defects Not resistant to humidity Low sound resistance Low heat resistance Concrete flooring layers from top to bottom: 1. Screed 2. DPM 3. Concrete slab 4. Sand 5. Brick crush 4.0 | Doors & Windows Door ironmongeries: 1. Door knob/handles/door pull (Door details 1 & 5) 2. Door hinges (Door details 1 & 5) 3. Door lock (Door details 1 & 5) 4. Peep holes 5. Door stopper 6. Door chain 7. Floor spring (at the bottom) or door closer (at the top of the door) In order to assist the opening and closing of particularly heavy doors and high wind climate. Singapore Important Instances 5.0 | Metals 2. Corten steel thick layer of rust Ferrous metal: 1. Cast Iron Advantage Tough under severe conditions Tough in compression - Disadvantage Rusting Graphitization Coating failure Heavy Expensive 2. Wrought iron Advantage Excellent weldability Tough Disadvantage Cannot be hardened by heating Labor intensive in manufacturing process 2. (Stainless) steel Advantage High strength Sustainable Aesthetic appeal, can be plated with color Value for money Disadvantage Rusting Gets heated quickly Susceptible to scratching, fingerprints, and smudges - Advantage Economic Long lasting Recyclable Disadvantage - 5.0 | Metals 7.0 | Timber Non-ferrous metal: Raw timber: 1. Brass 3. Types of lumber cuts Advantage Soft, easily drilled Corrosion resistant Malleable Disadvantage Difficult to handle Expensive Changing color 2. Common metal finishes Types Plain Quarter Rift Crown/live Waste/cost Minimum Medium Maximum - Stability Minimum Maximum Medium - 7.0 | Timber 7.0 | Timber 2. Asian timber less cost based from location 4. Types of manufactured timber cheap & easily a. Indoor - Jelutong - Meranti - Ramin b. Outdoor anti termite, does not absorb heat much manufactured a. Plywood thickness: 3, 6, 9, 12, 15, 18, 24 mm dimension: 2440 x 1220 mm - Block plywood made out of ice cream layers - Rosewood - Nyatoh - Kapur - Balau - Chengai - Teak not good with water, need to be dried properly first - Cheap backing for veneer - Requires secondary finishing - Can be used for door carcass 18 mm thickness b. MDF (Medium Density Fiberboard) - Often used in a non-local context thickness: 3, 6, 9, 12, 15, 18, 24 mm - Trend in cabinetry dimension: 2440 x 1220 mm - Can be used for acoustic purposes reduce echo - Compressed fine-wood/saw dust with a binder (glue) - Requires secondary finishing Advantage Cheap Consistent in size. And strength Good with spray paint c. Reconstitute Engineered Wood Disadvantage Easily expand - thickness: 6, 9, 12, 15, 18, 24 mm dimension: 2440 x 1220 mm - Plywood with real solid wood or 3 mm thick veneer layer - Excellent holding strength c. Particle/chip board (Low Density Fiberboard) - Engineered internal core does not warp thickness: 3, 9, 12, 15, 18 mm - Readily used for timber flooring dimension: 2440 x 1220 mm - Good for speaker d. Marine plywood - Weaker than MDF, but similar characteristics thickness: 6, 9, 12, 15, 18, 24 mm - Often used in a non-local context dimension: 2440 x 1220 mm - Requires secondary finishing - Water resistant, can resist impact, superior surface finish - For boats, docks, bathrooms, and caravans d. OSB (Oriented Strand Board) thickness: 6, 9, 12, 15, 18, 24 mm dimension: 2440 x 1220 mm - Requires secondary finishing d. Honeycomb 7.0 | Timber thickness: 10, 20, 25, 30, 40, 50, 60 mm dimension: 2440 x 1220 mm 5. Type of finishes - High stiffness yet lightweight a. Stain color - Great holding strength - Can age to a darker color, especially under the sun - For doors: cabinetry door and interior door panel - Can stain to a darker color, but not lighter from the wood b. PU (Polyurethane) finish - Percentage of gloss matte, satin, semi-gloss, high-gloss - Easily scratched 3. Types of pore finishes Open pore finish is a type of finish that allows oil and other contaminants to seep through the pores and collect on the surface of the wood. Closed pore finish, on the other hand, is a type of finish that has smaller pores that prevent the accumulation of oil and other contaminants. 7.0 | Timber 8.0 | Glass & Plastics 1. Raw timber forms 4. Thermoplastic types a. Panels a. Acrylic Thickness: 24, 50, 75 mm - Seamless Width: 300 mm - Different shine than glass Length: too long equals logistic issues - Thermoform b. Battens - Easily scratches 24 x 24, 50 x 50, 50 x 75, 22 x 22, 42 x 22, 75 x 75 mm b. Polycarbonates - Requires secondary finish - Glass-like surface and Clarity - Used for furniture, roofs, finger joints timber used as internal support - Strong and stiff more robust to impact c. Veneer Thickness 1.3-2 mm Dimension 1220 x 2440 mm - Unlike solid wood, just the seamless timber skin - Applied to plywood and finished c. PVC - Rigid and flexible - Cost effective - Durable - Easily maintained d. ABS - For FDM 3D Printing 5. Thermosetting types 8.0 | Glass & Plastics a. Epoxy resin b. HPL 2. Types of archictetural glass further in paper c. Polyurethane a. Annealed glass next page d. DF - Processed to reduce cracking in temperature change - Heat resistant - Dangerously break into large pieces - Waterproof - Raw material can be recycled - Brittle - Stand stress than tempered glass edges - For bathroom and lamination b. Heat strengthened glass (safety glass) 2-25 mm - Semi-tempered glass, not as high as temperature method - Remains in the frame when breaks, does not fall - Can’t be drilled, chamfered, or make bolt openings after heated c. Tempered glass (safety glass) - Good for harsh conditions - 4-6x stronger than annealed glass - Resistance for thermal and impact - Wind pressure - Safe break pieces - Weak edge - For windows, escalator side panels, wall cladding, furniture showcase, shop frontage, glass facades, and structural glass. d. Spandrel glass - Opaque to hide vent, wires, and slabs e. Low iron glass - Not green-ish, optimal clarity f. Slip resistance glass 4.25 mm - Treated to increase friction, anti-slip in wet conditions g. One way mirror - See-through from the darker side h. Back painted glass i. Crystal - High PbO 30%> content j. Smart glass/film k. Chemically strengthened glass - Can go as this as 1 mm (phone screen protector) - 5-6x stronger than annealed glass 3. Glass fastener - Clamp - Spider clamp (4 sides) - Accessories rubber gasket + u-channel 8.0 | Glass & Plastics 10.0 | Fabric, Leather and Rubber 1. History 1. Fabric types - Sheet glass <1920 - Plate glass very even & flat for undistorted vision 1920 - Float glass eliminate grinding & polishing 1960 2. Synthetic Fiber check paper for natural fiber a. Polyester & nylon check paper b. Solution dyed fabric check paper 10.0 | Fabric, Leather and Rubber 10.0 | Fabric, Leather and Rubber 1. Soft Covering 2. Wallcovering c. PVC Leather Vinyl (easily cleaned), paper, and fabric PVC, plastic coated material - Could create instant change to the room ambiance - The affordable alternative to real leather - Wide range of pricing - Durable and long-lasting - Relatively easy to maintain - Anti-scratch - Customizable pattern, ‘strike off’ as a test sample - Anti-peel - Non-breathable sticky and sweaty to sit 3. Carpet Carpet tiles: offices and commercial project Carpet wall: office, hotel, and commercial project - Comes in wide range of color - High quality ones are easily maintained, anti-absorbent to spillage. 9.0 | Stone - It is high resistance to chemical erosion for making tanks to store highly caustic materials b. Marble 2 points see paper - Re-crystalized, hard, compact fine to very fine-grained metamorphosed rocks capable of taking shiny polish. - Exceptionally hard and durable - Resistant to freeze-thaw cycles c. Limestone 20 mm, 1 point see paper - Hard, dense and durable - Affected by acids - Slightly soluble in water, soft stone - Course texture 1. Natural Stone - Earthy tones a. Granite - The hardest building stone for excellent wear, durable for interior and exterior applications - Granite is highly stable thermally, no changes - Impervious to weathering from temperature or air borne chemicals d. Sandstone 3 points see paper - Relatively absorptive for interior applications - If left unpolished or textured, creates a soft matte surface - May need to impregnate sealers if required d. Travertine 2 point see paper - The stone is characterized by pitted holes and trough in its surface - Has many void holes that are filled with grout, honed, polished to uniform like other marbles. - Application for floors, walls, countertops, exterior cladding and pavement - Ceramic tiles are generally tough, certain dark, pigment – rich colors. - Tiles can be flat or embossed with a pattern - Hard wearing, easy to clean, stain and heat resistant, waterproof b. Homogenous Tiles 150 x 150, 300 x 300, 300 x 600, 600 x 600, 1200 x 2400 mm e. Slate 2 point see paper - Thin and brittle - Unless honed smooth, it has a distinct cleft pattern - Heat resistant and less absorbent than granite - Course texture - Dark grey tones 2. Artificial stone hard wearing material, does not burn, easily stain, heat-resistant, waterproof, cheap, and easy installation. a. Ceramic 150 x 150, 300 x 300, 300 x 600, 600 x 600, 1200 x 2400 mm - Made of clay, silica, fluxes, colorings and other was materials to give an impermeable and vitreous enamel surface. A type of porcelain tile: porcelain & ceramic. Porcelain is denser and less porous than the latter, durable and suitable interior and outdoor use. c. Mosaic tiles 10 x 10, 25 x 25, 30 x 30, 50 x 50 mm - Small pieces of tiles that are held together in a sheet. Made out of glass, metal, stone, real pebbles, porcelain, etc. - The sheet comes in 300 x 300 mm 9.0 | Stone 1. Tiling method a. Mortar - Apply mortar to surface d. Glass tiles - Perform well in high moisture area - Apply adhesive to the back of the tile to mount it on top of the mortar layer - Reflects sunlight at outdoor b. Grouting - Attach in a mesh backing sheet for quicker laying - Consists of water, cement and sand which comes in various colors and texture e. Quartz W 1435 x L 3048 x T 20 mm - 93% quartz (one of nature’s hardest material) and highquality polymer resins and pigments. - Durable, anti-bacterial, can mimic any material, less maintenance, non-porous, anti-staining f. Sintered stone 3 & 6 mm - Blend of man-made processes with natural materials - Resistant to chemicals, abrasion, scratching, impact, and thermal shock - To fill up joints, cracks in tiles or masonry 9.0 | Stone - Can be reinforced with glass fibers and non-steel. Some structure have been using “plastic” fiber reinforcement which can be as strong as metal as it resists corrosion 2. Concrete facts - Is a replica of natural stone: cement, water and aggregates - Chemical mixtures added to achieve a certain goal. Commonly accelerating admixtures, retarding admixtures, fly, ash, air, entertaining admixtures and water reducing admixtures. b. Pre-cast concrete - Consists of water, cement and sand which comes in various colors and texture - To fill up joints, cracks in tiles or masonry - Fireproof, durable, and low maintenance material - Sound proof and superior strength and safety - Potential green material due to fly ash aggregate - Further refinement and longer span than reinforced concrete - Means that the concrete is pulled or tensioned before it has to support the service loads 3. Concrete types a. Reinforced concrete - Apply mortar to surface - Apply adhesive to the back of the tile to mount it on top of the mortar layer - Development that makes it flexible and strong due to its combination with metal bars and mesh - Used for slabs, walls, beams, columns, foundation, frames and more - Allows to build more longer and elegant designs - Pre-stressing can reduce the size of a beam required to perform a specific task c. Pre-stressed concrete - Consists of water, cement and sand which comes in various colors and texture -Pre-tensioned: the steel is pulled before the concrete is poured - Post-tensioned: the concrete is poured and then the tension applied. Steel cables inside plastic ducts or sleeves are positioned in the forms before the concrete place. Afterwards, once the concrete has set, the cables are pulled tight and anchored against the outer edge of the concrete.