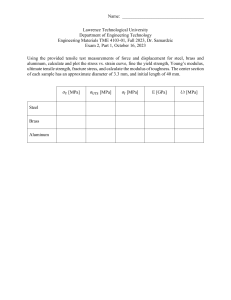

Lab 1 Dr Amal Esawi Omar Magdy Hussein 900211511 Abstract: In this experiment, we performed a static tensile test on three rods made from different materials. The three rods were made from Steel, Aluminum, and Cast Iron. The data presented by the machine was the displacement and the force applied. From these two data provided, stress and strain were calculated to evaluate each material’s strengths. Steel was the strongest material since it had an ultimate tensile strength of 680 MPa. Aluminum was the most ductile material at 18.6%. Cast Iron had the lowest ultimate tensile strength at 220 MPa. Table Of Contents 1. Introduction 2. Materials Used 3. Machine used 4. Procedure 5. Results 6. Analysis 7. Conclusion Introduction: This experiment aimed to determine how different materials would behave when subjected to gradually increasing tension. The different materials that were being used were Steel, Cast Iron, and Aluminum. Tension will cause each material to behave differently based on its atomic structure. Cast Iron is a material known for being brittle; its atomic structure has no capacity for it to slip, so it breaks before it deforms or bends. Aluminum, on the other hand, is known for being very ductile. It is the sixth ductile material on the planet. Its atomic structure allows the individual atoms to slip and slide past each other. This is why ductile materials start to experience necking before they fracture, while brittle materials do not. Necking occurs when the material has passed its elastic limit and into the plastic. Observable deformation starts to occur to the material; its width starts to decrease in size. Brittle materials reach their fracture strength and break. When a tensile material breaks, it experiences a cup and cone fracture. Materials used Machine Used Procedure First, we measured the diameter and the length of each rod. The Aluminum and Cast Iron were 6 mm in diameter, and the steel rod was 5.7 mm in diameter. All three rods had the same length of 32 mm. We attached the aluminum rod first to the machine. The machine's upper and lower arm is tied around the rod. The machine is then activated and starts pulling at a rate of 3 mm/s. A few seconds into the test, we can see Necking talking to the place in the center of the rod before it breaks. The same procedures were applied to the Cast Iron rod. However, since Cast Iron is a brittle material, necking does not develop. It lasted a lot less than Aluminum. For the Steel rod, the same procedures were applied. It also experienced necking since it is a ductile material Results For the aluminum rod, it had a modulus of resistance of 3.35. Its ultimate tensile strength was 360.2 MPa, and its Fracture strength was 300 MPa. It had a ductility of 18.68%. All ductile materials have ductility of over 5%. As you can see, there are instances where the graph fluctuates, which may indicate that, for instance, the clamp may have lost its grip. For the Cast Iron rod, it had a modulus of resistance of 1.13. Its ultimate tensile strength was 220.46 MPa, and its Fracture strength was 220.46 MPa. It had a ductility of 2.025%. All brittle materials have ductility of less than 5%. For the Steel rod, it had a modulus of resistance of 3.33. Its ultimate tensile strength was 680.4 MPa, and its Fracture strength was 508.82 MPa. It had a ductility of 10.94%. All ductile materials have ductility of over 5% Analysis The cross dimensions were used based on the ASTM Standards in Mechanical Testing, which helps ensure that no matter where the test occurs worldwide, it would still give the same result. The actual strain only ever matters if I look at the material’s behavior at the plastic range. Still, most engineers would only consider the elastic region since the material is designed not to exceed it. The diffraction between ductile and brittle materials is that ductile materials gave a warning before they started to break. Necking was seen being formed on the road before it broke. This is because the atomic structure of ductile material has the capacity to slip and slide past each other. However, the atomic structure of brittle materials resists slipping and sliding. This is why it gives no warning before it breaks. Conclusion In the end, we saw that aluminum was the most ductile material out of all of them. This is because atoms can slide past each other. On the other hand, steel is the stroke with the highest ultimate tensile strength. References: https://www.tutorchase.com/answers/ib/chemistry/why-are-metals-malleable-and-ductile https://www.tutorchase.com/answers/ib/chemistry/why-are-metals-malleable-and-ductile