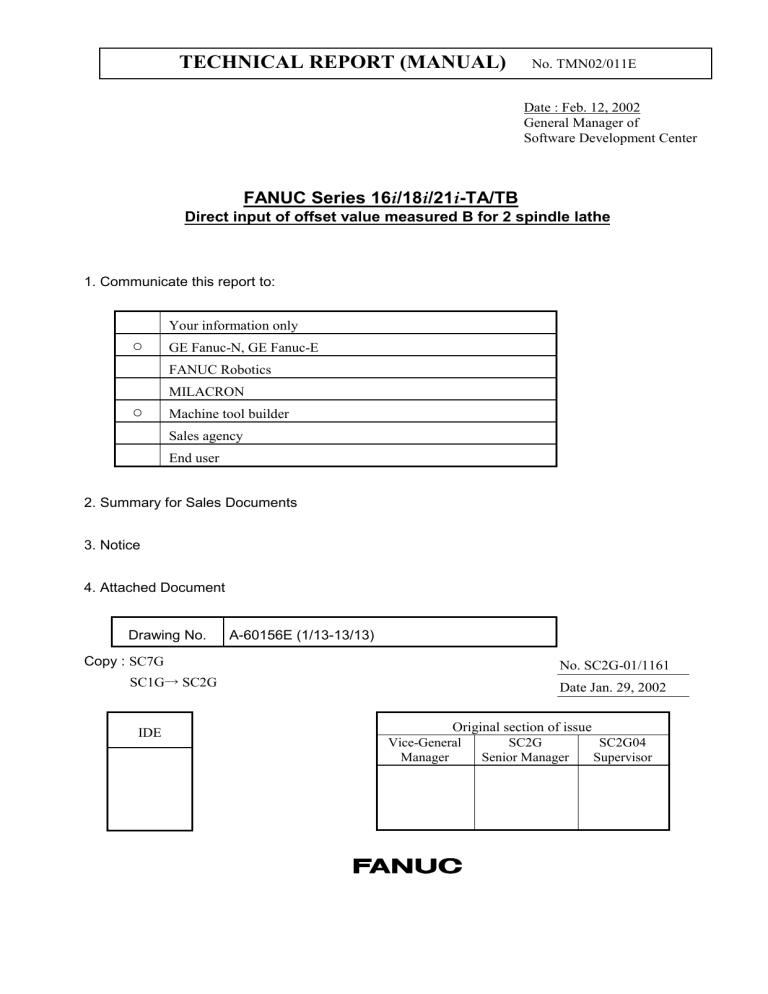

TECHNICAL REPORT (MANUAL) No. TMN02/011E Date : Feb. 12, 2002 General Manager of Software Development Center FANUC Series 16i/18i/21i-TA/TB Direct input of offset value measured B for 2 spindle lathe 1. Communicate this report to: Your information only ○ GE Fanuc-N, GE Fanuc-E FANUC Robotics MILACRON ○ Machine tool builder Sales agency End user 2. Summary for Sales Documents 3. Notice 4. Attached Document Drawing No. Copy : SC7G SC1G SC2G IDE A-60156E (1/13-13/13) No. SC2G-01/1161 Date Jan. 29, 2002 Original section of issue Vice-General SC2G SC2G04 Manager Senior Manager Supervisor FANUC Series 16i /18i /21i – TA/TB Direct input of offset value measured B for 2 spindle lathe Contents 1. Outline.................................................................................................................................... 2 2. Touch Sensor ........................................................................................................................ 2 3. Setting of Tool Offset Value .................................................................................................. 3 4. Setting of Z-axis Work Origin Offset (G54∼G59) .................................................................. 6 5. Signal ..................................................................................................................................... 8 6. Parameter ............................................................................................................................ 11 FANUC Series 16i /18i /21i – TA/TB Title Draw No. Edit Date Date Design Jan.31.02 Description Desig. Desig. Apprv. Apprv. Direct input of offset value measured B for 2 spindle lathe A-60156E Sheet 1/13 1. Outline In 2 spindle lathe which has the back spindle, each spindle has the workpiece coordinate system for itself. By using this function, it is available to set automatically the tool offset and the Z-axis workpiece origin offset corresponding to each work coordinate system with the touch sensor. This function is the additional option. This function needs the following functions. − Direct input of offset value measured B (−J933) − Workpiece Coordinate System (−J894) 2. Touch Sensor This touch sensor makes contact in two directions in each axis, and outputs four signals when it detects a tool contact. The contact faces are selected according to the tool nose figures to be measured. a) +MIT1: Contact to X-axis (+) contact face (Contact in X + direction) b) −MIT1: Contact to X-axis (−) contact face (Contact in X – direction) c) +MIT2: Contact to Z-axis (+) contact face (Contact in Z + direction) d) −MIT2: Contact to Z-axis (−) contact face (Contact in Z – direction) X axis (−) contact face (−MIT1) Z axis (+) contact face (+MIT2) +X +Z Z axis (−) contact face (−MIT2) X axis (+) contact face (+MIT1) FANUC Series 16i /18i /21i – TA/TB Title Draw No. Edit Date Date Design Jan.31.02 Description Desig. Desig. Apprv. Apprv. Direct input of offset value measured B for 2 spindle lathe A-60156E Sheet 2/13 3. Setting of Tool Offset Value Determine a specific point on the machine tool as the measuring reference position. In advance, set the distance from this point to the measuring position (contact face of the touch sensor) as a reference value, using parameter No. 5015 to 5018 and No. 5056 to 5059. Select the tool whose offset value is to be measured, and bring it to touch the sensor, receiving a contact detection signal (tool compensation value write signal). The mechanical coordinate value is the distance from the tool nose position of the measuring tool at the mechanical reference (home) position to the measuring position; set the difference between this value and the reference value (parameter setting) into the tool offset value memory as the tool geometry offset value. The corresponding tool wear offset value becomes 0. (Tool offset value to be set) = (Mechanical coordinate value when tool compensation value write signal has become “1”) – (Reference value (parameter value) corresponding to the tool compensation value write signal) The tool offset numbers are divided into two parts for spindle 1 and spindle 2 by the parameter No. 5053 are used. Example ) Tool offset number For spindle 1 For spindle 2 Value of the parameter No. 5053 When setting = 8 When setting = 10 1∼8 1∼10 9∼16 11∼16 Note In case the value of the parameter No. 5053 is 0 or more than the maximum tool offset number, the tool offset numbers are divided into to parts as follows. Tool offset pairs For spindle 1 For spindle 2 Tool offset pairs For spindle 1 For spindle 2 16 1∼8 9∼16 400 1∼200 201∼400 32 1∼16 17∼32 999 1∼449 450∼999 64 1∼32 33∼64 99 1∼49 50∼99 FANUC Series 16i /18i /21i – TA/TB Title Draw No. Edit Date Date Design Jan.31.02 Description Desig. Desig. Apprv. Apprv. Direct input of offset value measured B for 2 spindle lathe A-60156E Sheet 3/13 The tool offset number can be selected by the parameter No. 5005#5 (QNI) manually or automatically. •QNI=0 (Manual selection) Set the cursor to the desired tool compensation number by operating the MDI (such as page and cursor keys). •QNI=1 (Automatic selection) In the offset write mode, the cursor is set to the desired tool compensation number, using the tool compensation number input signal. For spindle 1, the cursor is set to a tool compensation number selected by the input signal. For spindle 2, the cursor is set to the sum of the value specified in parameter No. 5053 and the tool compensation number selected by the input signal. In this case, the MDI cannot be used to change the cursor position on the offset screen. Note If the tool compensation number specified by the tool compensation number input signal is out of range, the last tool compensation amount memory number for each spindle is set up. FANUC Series 16i /18i /21i – TA/TB Title Draw No. Edit Date Date Design Jan.31.02 Description Desig. Desig. Apprv. Apprv. Direct input of offset value measured B for 2 spindle lathe A-60156E Sheet 4/13 • Basic Procedure to Set Tool Offset Value The tool offset value is automatically set to the tool offset memory by the following operation. The distance between the measured reference position, which is the tool nose position of the standard tool or the imaginary position , and the tool nose position of the actual used tool is set as the tool offset value. (1) Select the spindle measuring the tool offset by the measured spindle select signal (G040.5) (2) Execute manual reference position return. By executing manual reference position return, a machine coordinate system is established. The tool offset value is computed on the machine coordinate system. (3) Select manual handle mode or manual continuous feed mode and set the tool compensation value write mode select signal GOQSM to “1”. The CRT display is automatically changed to the tool offset screen (geometry), and the “OFST” indicator starts blinking in the status indication area in the bottom of the screen, which informs that the tool compensation value writing mode is ready. Then the measured spindle check signal S1MES (F062.3) or S2MES (F062.3) is set to “1”. Note After that, the measured spindle select signal S2TLS (G040.5) cannot be changed until the tool compensation value write mode select signal GOQSM (G039.7) is changed to “0”. (4) (5) Select a tool to be measured. Move the cursor to the desired offset number by manual or automatic operation. (6) Near the tool to the sensor by manual operation. (7) Place the tool edge to a contacting surface of the sensor by manual handle feed. Bring the tool edge in contact with the sensor. This causes the tool compensation value writing signals (+MIT1, –MIT1, +MIT2 or – MIT2) to input to CNC. The tool compensation value writing signal is set to “1”, and the : i) The axis is interlocked in this direction and its feeding is stopped. ii) The tool offset value extracted by the tool offset memory (tool geometry offset value) which corresponds to the offset number shown by the cursor is set up. (8) For both X-axis and Z-axis, their offset value are set by the operations (5) and (6). The offset value is set to X-axis or Z-axis coinciding with the cursor. (9) Repeat operations (4) to (8) for all necessary tools. (10) Set the tool compensation value writing mode signal GOQSM to “0”. i) The writing mode is canceled and the blinking “OFST” indicator light. ii) The measured spindle check signal S1MES (F062.3) or S2MES (F062.4) is set to “0”. FANUC Series 16i /18i /21i – TA/TB Title Draw No. Edit Date Date Design Jan.31.02 Description Desig. Desig. Apprv. Apprv. Direct input of offset value measured B for 2 spindle lathe A-60156E Sheet 5/13 4. Setting of Z-axis Work Origin Offset (G54∼ ∼G59) In 2 spindle lathe which has the back spindle, each spindle has the workpiece coordinate system for itself. By assigning any G code from G54 to G59 for each workpiece coordinate system, this function set Z-axis work origin offset of them automatically. [Z-axis work origin offset] = − ([Z-axis tool geometry offset] − [Z-axis machine coordinate value]) Any G code from G54 to G59 can be selected manually or automatically by the parameter No. 5051#1(WNI). •WNI=0 (Manual selection) Set the cursor to the desired workpiece coordinate system G54 to G59 by operating the MDI (such as page and cursor keys). Note You cannot set the value to the external workpiece origin offset (EXT). When the cursor coincides with the external workpiece origin offset (EXT), the warning “ ”Write inhibited” occurs in setting the work origin offset value write signal to 1. •WNI=1 (Automatic selection) Set the parameter No. 5054 and No.5055 in advance to the G code number of the workpiece coordinate system corresponding with them. CNC select the workpiece coordinate system automatically by their parameters in the workpiece origin offset write mode. NOTE If the value set in this parameter is 0, or if the value falls outside the valid data range, 54 is assumed for the workpiece coordinate system memory for spindle 1, while 57 is assumed for the workpiece coordinate system memory for spindle 2. The tool offset number used for measurement is selected manually or automatically by the setting of the parameter No.5005#5. (QNI). •QNI=0 (Manual selection) Specify the desired tool compensation number in parameter No. 5020. •QNI=1 (Automatic selection) The cursor is set to the desired tool compensation number, using the tool compensation number input signal. For spindle 1, the cursor is set to a tool compensation number selected by the input signal. For spindle 2, the cursor is set to the sum of the value specified in parameter No. 5053 and the tool compensation number selected by the input signal is used. FANUC Series 16i /18i /21i – TA/TB Title Draw No. Edit Date Date Design Jan.31.02 Description Desig. Desig. Apprv. Apprv. Direct input of offset value measured B for 2 spindle lathe A-60156E Sheet 6/13 • Basic Procedure to Set Z-axis workpiece origin offset Value The Z-axis workpiece origin offset value is automatically set by the following operation. This has to be performed after measurement of the tool geometry offset value. (1) Select the spindle measuring the tool offset by the measured spindle select signal (G040.5) (2) Execute manual reference position return. By executing manual reference position return, a machine coordinate system is established. The Z-axis work piece coordinate offset value is computed on the machine coordinate system. (3) Set the workpiece origin offset value write mode select signal WOQSM (G039.6) to “1”. The CRT display is automatically changed to the work coordinate system setting screen, and the “OFST” indicator starts blinking in the status indication area in the bottom of the screen, which informs that the workpiece origin offset value write mode is ready. Then the measured spindle check signal S1MES (F062.3) or S2MES (F062.3) is set to “1”. Note After that, the measured spindle select signal S2TLS (G040.5) cannot be changed until the workpiece origin offset value write mode select signal WOQSM (G039.6) is changed to “0”. (4) (5) (6) (7) (8) (9) Select a tool to be measured. Check tool offset numbers. The tool offset number corresponding to the tool required for measurement, shall be set in the parameter (No.5020) in advance. The tool offset number can also be set automatically by setting the tool offset number input signal (with parameter No.5005#5(QNI)=1). Near the tool to an end face of the workpiece. Place the tool edge to the end face (sensor) of the workpiece using manual operation. When the tool edge contacts the end face of the workpiece, input the workpiece origin offset write signal WOSET (G040#7). The Z–axis the workpiece origin offset is automatically set. Release the tool. Set the workpiece origin offset value write mode signal WOQSM (G39.6) to “0”. i) The writing mode is canceled and the blinking “WSFT” indicator light. ii) The measured spindle check signal S1MES (F062.3) or S2MES (F062.4) is set to “0”. FANUC Series 16i /18i /21i – TA/TB Title Draw No. Edit Date Date Design Jan.31.02 Description Desig. Desig. Apprv. Apprv. Direct input of offset value measured B for 2 spindle lathe A-60156E Sheet 7/13 5. Signal Tool offset write mode select Signal GOQSM<G039#7> [Classification] [Function] [Operation] Input signal The mode for writing tool compensation is selected. When this signal is turned “1” in a manual operation mode, the mode for writing tool compensation is selected. The control unit then automatically switches the screen displayed on the CRT to the tool geometry compensation screen and blinks the “OFST” status display in the bottom of the screen to notify that the mode has been changed to the mode for writing tool compensation. Tool offset write signal #1 #1 #1 #1 +MIT1 , −MIT1 , +MIT2 , −MIT2 <X004#2, #3, #4, #5> (Path1) #2 #2 #2 #2 +MIT1 , −MIT1 , +MIT2 , −MIT2 <X013#2, #3, #4, #5> (Path2) #3 #3 #3 #3 +MIT1 , −MIT1 , +MIT2 , −MIT2 <X011#2, #3, #4, #5> (Path3) [Classification] [Function] [Operation] Input signal Each of these signals inhibits the tool from being fed along the corresponding axis during manual operation. When signal GOQSM for selecting the mode for writing tool compensation is set to “1”, the manual feed is inhibited and also the tool geometry compensation along the axis is automatically calculated and the result is set in tool compensation memory. When these signals are turned “1”, the control unit operates as follows: • Inhibits tools from being fed along the corresponding axis during manual operation. +MIT1: Inhibits the tool from being manually fed in the positive direction along the X-axis. –MIT1 : Inhibits the tool from being manually fed in the negative direction along the X-axis. +MIT2 : Inhibits the tool from being manually fed in the positive direction along the Z-axis. –MIT2 : Inhibits the tool from being manually fed in the negative direction along the Z-axis. • When signal GOQSM for selecting the mode for writing tool compensation is turned “1”, the manual feed interlock signal also automatically calculates the tool geometry compensation for the tool compensation number pointed to by the cursor and sets the result in tool compensation memory. Note This signal is used as the manual feed interlock signal in each axis direction. FANUC Series 16i /18i /21i – TA/TB Title Draw No. Edit Date Date Design Jan.31.02 Description Desig. Desig. Apprv. Apprv. Direct input of offset value measured B for 2 spindle lathe A-60156E Sheet 8/13 Tool offset number select signals OFN0∼ ∼OFN5<G039#0∼ ∼#5> OFN6∼ ∼OFN9<G040#0∼ ∼#3> [Classification] [Function] [Operation] Input signal Selects the tool offset number. When the mode for writing tool compensation is selected, the cursor is automatically positioned on the tool geometry compensation number selected by these signals. A tool offset number is specified by 10–bit binary number. Number 0 to 998 corresponds to the compensation number 1 to 999. Note This signal is available only when the parameter No.5005#5 (QNI) =1. Work origin offset write mode select signal WOQSM<G039#6> [Classification] [Function] [Operation] Input signal Select the mode for writing the work origin offset. When this signal is turned “1” in a manual operation mode, the mode for writing the work origin offset is selected. The control unit then automatically switches the screen displayed on the CRT to the tool geometry compensation screen and blinks the “WSFT” status display in the bottom of the screen to notify that the mode has been changed to the mode for writing the work origin offset. Work origin offset write signal WOSET<G040#7> [Classification] [Function] [Operation] Input signal Automatically calculates and sets the work origin offset amount for the workpiece coordinate system. When this signal turns to “1” in the mode for the work origin offset for the workpiece coordinate system, it triggers automatic calculation and setting of the Z-axis work origin offset amount for the workpiece coordinate system. Measured spindle select signal S2TLS <G040#5> [Classification] [Function] [Operation] Input signal The spindle measuring the tool offset amount and Z-axis work origin offset amount is selected. When this signal turns to “1” in the mode for the work origin offset for the workpiece coordinate system, it triggers automatic calculation and setting of the Z-axis work origin offset amount for the workpiece coordinate system. FANUC Series 16i /18i /21i – TA/TB Title Draw No. Edit Date Date Design Jan.31.02 Description Desig. Desig. Apprv. Apprv. Direct input of offset value measured B for 2 spindle lathe A-60156E Sheet 9/13 Measured spindle check signal 1 S1MES <F062#3> Measured spindle check signal 2 S2MES <F062#4> [Classification] [Function] [Output condition] Output signal The spindle under measurement is specified. These signals check which head is being measured in the tool offset write mode or the workpiece origin offset write mode according to the S2TLS (spindle measurement select) signal. If spindle 1 is selected, S1MES = 1 and S2MES = 0. If spindle 2 is selected, S1MES = 0 and S2MES = 1. Signal address #7 #6 #5 #4 #1 #3 #1 #2 #1 #1 X004 -MIT2 +MIT2 -MIT1 +MIT1 X011 -MIT2#3 +MIT2#3 -MIT1#3 +MIT1#3 X013 -MIT2#2 +MIT2#2 -MIT1#2 +MIT1#2 #7 #5 #4 #3 #2 #1 #0 G039 GOQSM WOSQM OFN5 OFN4 OFN3 OFN2 OFN1 OFN0 G040 WOSET S2TLS OFN9 OFN8 OFN7 OFN6 #4 #3 #2 #1 #0 S2MES S1MES #7 #6 #0 #1 #6 F062 #5 FANUC Series 16i /18i /21i – TA/TB Title Draw No. Edit Date Date Design Jan.31.02 Description Desig. Desig. Apprv. Apprv. Direct input of offset value measured B for 2 spindle lathe A-60156E Sheet 10/13 6. Parameter #7 #6 5005 [Data type] type] QNI #5 #4 #3 #2 #7 WHI 5020 [Data type] type] [Valid data range] 5015 5016 5017 5018 #0 Bit In Direct input of offset value measured B or this function 0 Not automatically select the tool offset number 1:Automatically selects a tool offset number #6 #5 #4 #3 #2 5051 [Data type] type] DSN #1 QNI #1 #0 WNI DSN Bit When this function is used: 0 : One touch sensor is used for both main spindle 1 and main spindle 2. 1 : Two touch sensors are used for both main spindle 1 and main spindle 2. When a workpiece reference point offset value is set in workpiece coordinate system memory with the tool setter function for 1–turret, 2–spindle lathes: 0 : The value is set at the current cursor position. 1 : A memory is automatically selected. (The workpiece coordinate system memory set in parameter No.5054 or No.5055 is selected.) Tool offset number used for the input of tool offset value measured B Byte 1 to the number of tools to be compensated. Set the tool offset number used for the input of tool offset value measured B function or this function (i.e. when workpiece coordinate system shift value is set). This parameter is valid when the tool offset number is not selected automatically (Parameter No.5005#5(QNI)=0). Distance (X1P) between reference position and X axis + contact surface on the touch sensor 1 Distance (X1M) between reference position and X axis - contact surface on the touch sensor 1 Distance (Z1P) between reference position and Z axis + contact surface on the touch sensor 1 Distance (Z1M) between reference position and Z axis - contact surface on the touch sensor 1 FANUC Series 16i /18i /21i – TA/TB Title Draw No. Edit Date Date Design Jan.31.02 Description Desig. Desig. Apprv. Apprv. Direct input of offset value measured B for 2 spindle lathe A-60156E Sheet 11/13 Distance (X2P) between reference position and X axis + contact surface 5056 on the touch sensor 2 Distance (X2M) between reference position and X axis - contact surface 5057 on the touch sensor 2 Distance (Z2P) between reference position and Z axis + contact surface 5058 on the touch sensor 2 Distance (Z2M) between reference position and Z axis - contact surface 5059 on the touch sensor 2 [Data type] [Unit of data] 2–word Increment system Millimeter machine Inch machine IS-B 0.001 0.0001 IS-C 0.0001 0.00001 Unit mm inch [Valid data range] −99999999∼99999999 They set the distance (with sign) between the measurement reference position and sensor contact surface. For an axis under diameter programming, set it by a diameter value. Measurement reference position X1M X2M X2-axis -(contact surface) X1-axis -(contact surface) X1P Z1-axis -(contact surface) Z1M Z1-axis +(contact surface) Touch sensor 1 X-axis +(contact surface) Z2-axis +(contact surface) Z2P Z2-axis -(contact surface) X2-axis +(contact surface) Z2M Z1P X2P Touch sensor 2 NOTE These parameters are enabled when the DSN parameter (parameter No.5051#0) is set to 1. FANUC Series 16i /18i /21i – TA/TB Title Draw No. Edit Date Date Design Jan.31.02 Description Desig. Desig. Apprv. Apprv. Direct input of offset value measured B for 2 spindle lathe A-60156E Sheet 12/13 5053 [Data type] [Unit of data] [Valid data range] Bias for tool offset numbers for measured tool offset value setting Byte Number 1 to maximum tool offset count When this function is used, this parameter allocates tool offset numbers for measured tool offset measurement values to spindle 1 and spindle 2. Example: When the tool offset count is 16 pairs Tool offset number When setting = 8 When setting = 10 1∼8 1∼10 9∼16 11∼16 For spindle 1 For spindle 2 NOTE If 0 is set for this parameter, or if the maximum tool offset count is exceeded, the following is assumed: 5054 5055 [Data type] [Unit of data] [Valid data range] For spindle 1 For spindle 2 16 1∼8 9∼16 Tool offset number 32 64 1∼16 1∼32 17∼32 33∼64 For spindle 1 For spindle 2 400 1∼200 201∼400 Tool offset number 999 1∼449 450∼999 99 1∼49 50∼99 G code of workpiece coordinate system selected for spindle 1 G code of workpiece coordinate system selected for spindle 2 Byte Number 54 to 59 When the parameter No.5051 (WNI) is set to 1, in each of these parameters, a workpiece coordinate system from G54 to G59 for workpiece reference point offset value setting. NOTE If the value set in this parameter is 0, or if the value falls outside the valid data range, 54 is assumed for the workpiece coordinate system memory for spindle 1, while 57 is assumed for the workpiece coordinate system memory for spindle 2. FANUC Series 16i /18i /21i – TA/TB Title Draw No. Edit Date Date Design Jan.31.02 Description Desig. Desig. Apprv. Apprv. Direct input of offset value measured B for 2 spindle lathe A-60156E Sheet 13/13