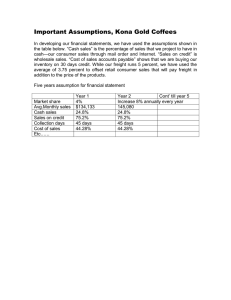

R TM120 ON LY FO RC US TO ME Optimizer Planning in SAP Transportation Management . . PARTICIPANT HANDBOOK INSTRUCTOR-LED TRAINING . Course Version: 16 Course Duration: 2 Day(s) Material Number: 50131927 SAP Copyrights and Trademarks © 2015 SAP SE. All rights reserved. No part of this publication may be reproduced or transmitted in any form or for any purpose without the express permission of SAP SE. The information contained herein may be changed without prior notice. ● Microsoft, Windows, Excel, Outlook, and PowerPoint are registered trademarks of Microsoft Corporation. IBM, DB2, DB2 Universal Database, System i, System i5, System p, System p5, System ME ● R Some software products marketed by SAP SE and its distributors contain proprietary software components of other software vendors. x, System z, System z10, System z9, z10, z9, iSeries, pSeries, xSeries, zSeries, eServer, z/VM, z/OS, i5/OS, S/390, OS/390, OS/400, AS/400, S/390 Parallel Enterprise Server, PowerVM, Power Architecture, POWER6+, POWER6, POWER5+, POWER5, POWER, OpenPower, PowerPC, BatchPipes, BladeCenter, System Storage, GPFS, US TO HACMP, RETAIN, DB2 Connect, RACF, Redbooks, OS/2, Parallel Sysplex, MVS/ESA, AIX, Intelligent Miner, WebSphere, Netfinity, Tivoli and Informix are trademarks or registered trademarks of IBM Corporation. ● Linux is the registered trademark of Linus Torvalds in the U.S. and other countries. ● Adobe, the Adobe logo, Acrobat, PostScript, and Reader are either trademarks or registered trademarks of Adobe Systems Incorporated in the United States and/or other countries. Oracle is a registered trademark of Oracle Corporation ● UNIX, X/Open, OSF/1, and Motif are registered trademarks of the Open Group. ● Citrix, ICA, Program Neighborhood, MetaFrame, WinFrame, VideoFrame, and MultiWin RC ● are trademarks or registered trademarks of Citrix Systems, Inc. HTML, XML, XHTML and W3C are trademarks or registered trademarks of W3C®, World FO ● Wide Web Consortium, Massachusetts Institute of Technology. ● Java is a registered trademark of Sun Microsystems, Inc. ● JavaScript is a registered trademark of Sun Microsystems, Inc., used under license for LY technology invented and implemented by Netscape. ● SAP, R/3, SAP NetWeaver, Duet, PartnerEdge, ByDesign, SAP BusinessObjects Explorer, StreamWork, and other SAP products and services mentioned herein as well as their respective logos are trademarks or registered trademarks of SAP SE in ON Germany and other countries. ● Business Objects and the Business Objects logo, BusinessObjects, Crystal Reports, Crystal Decisions, Web Intelligence, Xcelsius, and other Business Objects products and services mentioned herein as well as their respective logos are trademarks or registered trademarks of Business Objects Software Ltd. Business Objects is an SAP company. ● Sybase and Adaptive Server, iAnywhere, Sybase 365, SQL Anywhere, and other Sybase products and services mentioned herein as well as their respective logos are trademarks or registered trademarks of Sybase, Inc. Sybase is an SAP company. All other product and service names mentioned are the trademarks of their respective companies. Data contained in this document serves informational purposes only. National product specifications may vary. ON LY FO RC US TO ME R These materials are subject to change without notice. These materials are provided by SAP SE and its affiliated companies ("SAP Group") for informational purposes only, without representation or warranty of any kind, and SAP Group shall not be liable for errors or omissions with respect to the materials. The only warranties for SAP Group products and services are those that are set forth in the express warranty statements accompanying such products and services, if any. Nothing herein should be construed as constituting an additional warranty. © Copyright. All rights reserved. iii R ME US TO FO RC LY ON iv © Copyright. All rights reserved. Typographic Conventions American English is the standard used in this handbook. The following typographic conventions are also used. R This information is displayed in the instructor’s presentation ME Demonstration Warning or Caution Hint Facilitated Discussion FO User interface control RC Related or Additional Information US TO Procedure Example text ON LY Window title Example text © Copyright. All rights reserved. v R ME US TO FO RC LY ON vi © Copyright. All rights reserved. Contents xi Course Overview 1 Unit 1: Lesson: Describing Optimizer Planning Lesson: Applying Optimizer Planning Settings Exercise 1: Create Planning Cost Settings Lesson: Identifying Modal Decision Planning Scenarios Exercise 2: Execute Optimization to Determine Means of Transport Exercise 3: Determine Optimizer Run Results Using Planning Costs Exercise 4: Apply Cost Functions to Influence Optimizer Results Lesson: Applying Short-Cut Planning Exercise 5: Maintain Integration Settings for Short-Cut Planning Exercise 6: Maintain Configuration and Execute Short-cut Planning Lesson: Creating Pooled Shipments Exercise 7: Create a Transportation Network to Support Pooled Distribution Exercise 8: Create Pooled Freight Orders ME R 3 6 9 17 19 31 US TO 41 46 49 57 85 86 89 Unit 2: Optimizer Applications Lesson: Creating a Transportation Proposal Exercise 9: Plan a Freight Order Using a Transportation Proposal Lesson: Describing Load Optimization Processes Exercise 10: Create a Vehicle for Load Optimization Exercise 11: Create Freight Units for Load Optimization Exercise 12: Maintain Load Planning Settings Exercise 13: Perform and Analyze Load Planning LY 92 97 103 111 117 FO RC 62 67 75 Optimizer Planning 127 ON 128 133 139 143 Unit 3: Advanced Transportation Network Lesson: Creating Schedules Exercise 14: Create a Carrier Schedule Exercise 15: Generate Departures Lesson: Analyzing the Results of the Path Finder © Copyright. All rights reserved. vii Lesson: Creating Passive Vehicle Resources Exercise 16: Create Passive Vehicle Resources Lesson: Planning Transportation Units with Passive Vehicle Resources Exercise 17: Create Transportation Units Lesson: Planning Transportation Units with the Optimizer Lesson: Planning Transportation with Container Units Exercise 18: Create Container Units 167 179 182 189 197 Unit 5: Lesson: Explaining the Carrier Selection Process Exercise 19: Execute Carrier Selection Lesson: Selecting Carriers Based on Costs and Priorities Exercise 20: Configure Carrier Selection Lesson: Using Allocations Exercise 21: Perform Carrier Selection based on Transportation Allocations Lesson: Using Business Shares Exercise 22: Perform Carrier Selection Based on Business Shares Lesson: Improving Carrier Utilization US TO 198 205 211 217 223 229 236 241 247 254 261 269 275 284 301 Unit 6: Freight Tendering Lesson: Explaining the Tendering Process Exercise 23: Tender a Freight Order Lesson: Configuring the Tendering Plan Exercise 24: Create a Tendering Profile Lesson: Identifying the Tendering Collaboration Scenarios FO 253 Carrier Selection ME 148 153 164 Transportation Unit Planning R Unit 4: RC 147 Unit 7: Lesson: Creating Freight Orders LY 302 Freight Orders in Transportation Management 311 ON 312 319 324 327 334 Unit 8: viii Freight Order Setup Lesson: Configuring Freight Order Types Exercise 25: Create Freight Order Types Lesson: Configuring Freight Order Type Determination Exercise 26: Determine Freight Order Types Lesson: Determining Business Partners © Copyright. All rights reserved. Unit 9: 387 Lesson: Integrating Freight Orders with Shipments Lesson: Creating Shipments from Freight Orders Exercise 27: Create Freight Order-Based Shipments Lesson: Creating Freight Orders from Shipments Lesson: Communicating Freight Orders to Other Companies Unit 10: Lesson: Monitoring Transportation Events Exercise 28: Monitor Freight Order Events Lesson: Configuring SAP Event Management (SAP TM) for Transportation Visibility Lesson: Handling Events in the Collaboration Portal Exercise 29: Monitor Events in the Collaboration Portal ME 388 397 404 414 419 425 Transportation Event Monitoring R 346 350 355 367 380 Freight Order Integration Unit 11: US TO 345 Transportation Execution 426 Lesson: Configuring Freight Order Output 435 Exercise 30: Configure Settings to Enable Printing of Freight Order Documents Lesson: Managing Freight Order Discrepancies Exercise 31: Process a Freight Order with Discrepancies 471 Unit 12: Lesson: Integrating SAP EWM based on Shipments Lesson: Integrating SAP EWM Based on Deliveries Lesson: Integrating SAP EWM for Transit Warehousing Exercise 32: Receive Goods in Transit Warehouse ON LY FO 472 481 489 497 Integration with SAP Extended Warehouse Management RC 444 455 © Copyright. All rights reserved. ix R ME US TO FO RC LY ON x © Copyright. All rights reserved. Course Overview Application Consultant ● Business Process Architect ● Business Process Owner/Team Lead/Power User ON LY FO RC US TO ME ● R TARGET AUDIENCE This course is intended for the following audiences: © Copyright. All rights reserved. xi R ME US TO FO RC LY ON xii © Copyright. All rights reserved. UNIT 1 Optimizer Planning R Lesson 1 3 Lesson 2 6 9 US TO Applying Optimizer Planning Settings Exercise 1: Create Planning Cost Settings ME Describing Optimizer Planning Lesson 3 Identifying Modal Decision Planning Scenarios Exercise 2: Execute Optimization to Determine Means of Transport Exercise 3: Determine Optimizer Run Results Using Planning Costs Exercise 4: Apply Cost Functions to Influence Optimizer Results FO RC Lesson 4 17 19 31 41 Applying Short-Cut Planning Exercise 5: Maintain Integration Settings for Short-Cut Planning Exercise 6: Maintain Configuration and Execute Short-cut Planning 46 49 57 Lesson 5 62 67 75 LY Creating Pooled Shipments Exercise 7: Create a Transportation Network to Support Pooled Distribution Exercise 8: Create Pooled Freight Orders ON UNIT OBJECTIVES ● Describe optimizer planning ● Create planning cost settings ● Execute planning to determine the means of transport ● Execute planning to consolidate deliveries ● Execute planning to enforce minimum shipping requirements ● Describe short-cut planning © Copyright. All rights reserved. 1 Unit 1: Optimizer Planning Maintain integration settings for short-cut planning ● Maintain configuration and execute short-cut planning ● Model the transportation network for pooled shipments ● Create pooled freight orders ON LY FO RC US TO ME R ● 2 © Copyright. All rights reserved. Unit 1 Lesson 1 Describing Optimizer Planning LESSON OBJECTIVES After completing this lesson, you will be able to: Describe optimizer planning ON LY FO RC Route Optimization US TO ● ME R LESSON OVERVIEW This lesson examines how the vehicle scheduling and routing (VSR) optimizer considers routes and locations in transportation planning to minimize costs and operate within constraints. Figure 1: SAP Transportation Management (SAP TM) Document Flow The vehicle scheduling and routing (VSR) optimizer considers routing and the sequence in which resources arrive at certain locations. The VSR optimizer also considers the scheduling of tasks that are running in parallel. It evaluates potential changes to the routing and the © Copyright. All rights reserved. 3 Unit 1: Optimizer Planning effect such changes have on scheduling, helping to avoid the possibility of delayed deliveries and follow-on costs. Mathematical Model FO RC US TO ME R The goal of the optimizer is to assign tasks to vehicles and determine the route and sequence of tasks per vehicle so that all constraints are met and total costs are minimized. The optimizer achieves this goal by evolutionary local search, a population-based meta-heuristic that borrows selection principles from evolutionary algorithms and relies heavily on local optimization. Figure 2: Mathematical Model A more concrete example of the workings of the optimizer is its handling of potential date changes, which it handles by applying each date change to all tasks on the affected resource or dependent tasks on any other resources to derive the most appropriate choice. The consideration of several aspects in parallel is repeated for other variables, such as transshipment locations, and is necessary to create effective plans or to make improvements to existing plans. Costs and Constraints LY The total cost, which the optimizer is designed to minimize, is a weighted sum of the following items: Non-delivery/execution penalty (per freight unit (FU)) ● Earliness and lateness penalty (per FU) ON ● 4 ● Fixed cost (per vehicle or tour) ● Travel-dependent costs (per vehicle), for example, distance and duration. ● Load-dependent costs (per vehicle and tour) ● Sustainability costs such as CO2 emissions (from SAP TM 8.0 by BAdI) © Copyright. All rights reserved. Lesson: Describing Optimizer Planning LESSON SUMMARY You should now be able to: Describe optimizer planning ON LY FO RC US TO ME R ● © Copyright. All rights reserved. 5 Unit 1 Lesson 2 Applying Optimizer Planning Settings ● Create planning cost settings Optimization Costs US TO LESSON OBJECTIVES After completing this lesson, you will be able to: ME R LESSON OVERVIEW In this lesson, we examine the use of optimization costs in the planning process. You learn about the different kinds of planning costs that the vehicle scheduling and routing (VSR) optimizer uses in an optimization run. Fixed costs are calculated once by the system for each capacity used in the VSR optimization run. Capacities include vehicle resources and schedules. For schedules, the fixed costs are incurred per departure. FO RC In addition to fixed costs, other variable costs can be applied. The following are the variable transportation costs per unit for the following dimensions: ● Duration ● Distance ● Transported quantity per distance ● Intermediate stop These costs refer to the use of the dimensions of a capacity, including empty runs, during the VSR optimization run. Duration and Distance Costs LY You can define the costs per duration for each VSR optimization run. You can also define a maximum value and a unit. The unit refers to both the costs and the maximum value. If you do not specify a unit, the system measures duration in seconds. ON You can define the costs per distance for each VSR optimization run. You can also define a maximum value and a unit. The unit refers to both the costs and the maximum value. If you do not specify a unit, the system measures distance in kilometers. You can also specify the cost basis. This determines if the system uses the costs per distance from the costs per distance field in the planning profile or from the transportation lane. Alternatively, you can specify that the system is to take the sum of both values into account. Transported Quantity per Distance and Intermediate Stop Costs You can define the costs per quantity for each VSR optimization run. You must also define a unit. You cannot define a maximum value for the costs per quantity. However, you can specify if the system is to use the costs per quantity from the transportation lane or from the costs per quantity specified in the planning profile. 6 © Copyright. All rights reserved. Lesson: Applying Optimizer Planning Settings US TO ME R For costs per quantity from the transportation lane, you can specify if the system is to calculate the costs in a distance-independent way or if it is to multiply them by the distance. Figure 3: Quantity and Distance RC For costs per quantity from the planning costs, you can specify if the system is to calculate the costs in a distance-independent way per transportation lane or if it is to multiply them by the distance. The system determines the costs per stage if costs are calculated in a distanceindependent way. You are not allowed to define a unit. If multiplying by the distance, the system uses the fixed value that you have defined in the costs per quantity field. You can define the maximum number of intermediate stops and the costs per additional stop. ON LY FO Route-based Versus Destination-based Cost Figure 4: Route-based Versus Destination-based Cost © Copyright. All rights reserved. 7 Unit 1: Optimizer Planning The figure, Route-based Versus Destination-based Cost, illustrates the route-based and destination-based costs as follows: ● Destination-based cost: - Freight order (A → B → C) = Distance (A → B → C) * Cost (A → C) = 300 * 1.5 = $450. - Freight order (A → C → B) = Distance (A → C → B) * Cost (A → B) = 250 * 1.9 = $475. - - R Route-based cost: Freight order (A → B → C) = Distance (A → B) * Cost (A → B) + Distance (B → C) * Cost (B → C) = 200 * 1.9 + 100 * 1.8 = $560. ME ● Freight order (A → C → B) = Distance (A → C) * Cost (A → C) + Distance (C → B) * Cost (C → B) = 150 * 1.5 + 100 * 1.8 = $405. ON LY FO RC US TO Route-based and destination-based distance costs can yield different results. In North America, destination-based distance cost calculation is used frequently, whereas in Europe, route-based distance costs are primarily used. 8 © Copyright. All rights reserved. Unit 1 Exercise 1 Create Planning Cost Settings R Business Example ME ABC Corporation wants to implement SAP TM to support truck-load and less-than-truck-load planning scenarios. Sue, the SAP consultant, needs to create a planning profile to be used during transportation planning. US TO Note: In all exercises, when the values include ##, replace the characters, ##, with the group number that your instructor has assigned to you. This exercise requires you to use sales orders, that are created by the instructor in SAP ERP. In this exercise, you create the planning profile, TM211_PLAN_##, that is required for one or more subsequent exercises on this course. FO RC 1. Create a planning profile by copying planning profile TM200_PLAN to your own profile TM211_PLAN_##. Use the data in the following table: Table 1: Planning Profile Field Value Planning Profile TM211_PLAN_## Description Planning Profile for Group ##. 2. In the Profile Assignments screen area, delete the entry in the Selection Profile for Freight Orders field, and replace the entry in the Capacity Selection Settings field with CAPA-99. LY 3. Create planning cost settings TM211_COST_## with the following values, and assign them to your planning profile TM211_PLAN_##: ON Table 2: Planning Cost Settings Field Value Planning Costs Settings TM211_COST_## Description Planning Cost Setting for Group ## Earliness/Delay Costs Basis Earliness/Delay Costs Defined in Planning Costs Costs for Non-Delivery 999,999,999.00 (if not already defined) © Copyright. All rights reserved. 9 Unit 1: Optimizer Planning Field Value Costs for Earliness per Day 24,00 Costs for Lateness per Day 24,00 Currency USD R 4. In the Means-of-Transport Settings screen area, create two lines for MOT FTL-99 and LTL-99 using the following data: Value Means of Transport FTL-99 Consider Distance Cost from Planning Cost Settings Yes Consider Distance Cost from Transportation Lane No Fixed Costs 1 Means of Transport US TO Field ME Table 3: Means-of-Transport Settings 1 LTL-99 Yes Consider Distance Cost from Transportation Lane No Fixed Costs 1 FO RC Consider Distance Cost from Planning Cost Settings 5. Select the FTL-99 line. This opens two new tabs. Enter the following data in the Means-ofTransport Setting Details tab: Table 4: Means-of-Transport Settings 2 Value Premature Pick-Up 1,0 Delayed Pick-Up 1,0 Premature Delivery 1,0 Delayed Delivery 1,0 Basis for Quantity Costs No Costs Costs per Additional Intermed. Stop 50 Maximum Number of Stops 4 Distance Cost Basis from Lane Route-based Costs per Distance Unit 0,3 ON LY Field 10 © Copyright. All rights reserved. Lesson: Applying Optimizer Planning Settings 6. Select the LTL-99 line. In the Means-of-Transport Setting Details tab, enter the following data: Table 5: Means-of-Transport Settings 3 Value Premature Pick-Up 1,0 Delayed Pick-Up 1,0 Premature Delivery 1,0 Delayed Delivery 1,0 Basis for Quantity Costs Planning Costs: Distance Independent Maximum Number of Stops 1 Distance Cost Basis from Lane Route-based Costs per Quantity 0,01 ME US TO Unit of Measure R Field LB 7. Assign your capacity selection profile and planning cost settings to your planning profile. Use the following data: Table 6: Planning Profile Details Field Value TM211_PLAN_## RC Planning Profile TM211_COST_## ON LY FO Planning Cost Settings © Copyright. All rights reserved. 11 Unit 1 Solution 1 Create Planning Cost Settings R Business Example ME ABC Corporation wants to implement SAP TM to support truck-load and less-than-truck-load planning scenarios. Sue, the SAP consultant, needs to create a planning profile to be used during transportation planning. US TO Note: In all exercises, when the values include ##, replace the characters, ##, with the group number that your instructor has assigned to you. This exercise requires you to use sales orders, that are created by the instructor in SAP ERP. In this exercise, you create the planning profile, TM211_PLAN_##, that is required for one or more subsequent exercises on this course. FO RC 1. Create a planning profile by copying planning profile TM200_PLAN to your own profile TM211_PLAN_##. Use the data in the following table: Table 1: Planning Profile Field Value Planning Profile TM211_PLAN_## Description Planning Profile for Group ##. a) In NWBC, choose Application Administration → Planning → Planning Profiles → Display Planning Profile. LY b) Enter TM200_PLAN, and choose Continue. c) Choose (Copy). ON d) On the Planning Profile tab, in the Planning Profile field, enter the data in the Planning Profile table. 2. In the Profile Assignments screen area, delete the entry in the Selection Profile for Freight Orders field, and replace the entry in the Capacity Selection Settings field with CAPA-99. a) In the Selection Profile for Freight Orders field, delete the entry FOR_3100_00. b) In the Capacity Selection Settings field, replace CAPA_3100_00 with CAPA-99. c) Save your data. 12 © Copyright. All rights reserved. Lesson: Applying Optimizer Planning Settings 3. Create planning cost settings TM211_COST_## with the following values, and assign them to your planning profile TM211_PLAN_##: Table 2: Planning Cost Settings Value Planning Costs Settings TM211_COST_## Description Planning Cost Setting for Group ## Earliness/Delay Costs Basis Earliness/Delay Costs Defined in Planning Costs Costs for Non-Delivery 999,999,999.00 (if not already defined) Costs for Earliness per Day 24,00 Costs for Lateness per Day 24,00 Currency USD US TO ME R Field a) In NWBC, choose Application Administration → Planning → Planning Profile Settings → Planning Costs Settings → Create Planning Costs Settings. b) Enter the data from the Planning Cost Settings table. c) Save your data. RC 4. In the Means-of-Transport Settings screen area, create two lines for MOT FTL-99 and LTL-99 using the following data: Table 3: Means-of-Transport Settings 1 Field FTL-99 Consider Distance Cost from Planning Cost Settings Yes Consider Distance Cost from Transportation Lane No Fixed Costs 1 Means of Transport LTL-99 Consider Distance Cost from Planning Cost Settings Yes Consider Distance Cost from Transportation Lane No Fixed Costs 1 FO Means of Transport LY ON Value a) Choose Edit. b) Enter the data from the Means-of-Transport 1 table. © Copyright. All rights reserved. 13 Unit 1: Optimizer Planning 5. Select the FTL-99 line. This opens two new tabs. Enter the following data in the Means-ofTransport Setting Details tab: Table 4: Means-of-Transport Settings 2 Value Premature Pick-Up 1,0 Delayed Pick-Up 1,0 Premature Delivery 1,0 Delayed Delivery 1,0 Basis for Quantity Costs No Costs Costs per Additional Intermed. Stop 50 Maximum Number of Stops 4 Distance Cost Basis from Lane Route-based Costs per Distance Unit 0,3 US TO ME R Field 6. Select the LTL-99 line. In the Means-of-Transport Setting Details tab, enter the following data: Table 5: Means-of-Transport Settings 3 Field 1,0 FO RC Premature Pick-Up Value 1,0 Premature Delivery 1,0 Delayed Delivery 1,0 Basis for Quantity Costs Planning Costs: Distance Independent Maximum Number of Stops 1 Distance Cost Basis from Lane Route-based Costs per Quantity 0,01 LY Delayed Pick-Up Unit of Measure LB a) Enter the data from the Means-of-Transport Settings 3 table. ON b) Save your data. 7. Assign your capacity selection profile and planning cost settings to your planning profile. Use the following data: Table 6: Planning Profile Details 14 Field Value Planning Profile TM211_PLAN_## © Copyright. All rights reserved. Lesson: Applying Optimizer Planning Settings Field Value Planning Cost Settings TM211_COST_## a) Choose Application Administration → Planning → Planning Profiles → Edit Planning Profile. R b) In the Profile Assignments screen area, enter the data in the Planning Profile Details table. ON LY FO RC US TO ME c) Save your data. © Copyright. All rights reserved. 15 Unit 1: Optimizer Planning LESSON SUMMARY You should now be able to: Create planning cost settings ON LY FO RC US TO ME R ● 16 © Copyright. All rights reserved. Unit 1 Lesson 3 Identifying Modal Decision Planning Scenarios ME R LESSON OVERVIEW In this lesson, we consider the goals of the vehicle scheduling and routing (VSR) optimizer in transportation planning. We look also at the use of costs to influence VSR optimization results, and analyze how constraints and tolerances effect means-of-transport selection. Finally, we examine the use of planning costs to enforce minimum shipping requirements in the VSR optimization run. US TO LESSON OBJECTIVES After completing this lesson, you will be able to: ● Execute planning to determine the means of transport ● Execute planning to consolidate deliveries ● Execute planning to enforce minimum shipping requirements Truck-Load Planning Scenarios RC Freight orders can be created by manual planning or they can be built by the VSR optimizer. Optimizer planning is a key function of SAP Transportation Management (SAP TM) and aims to select the best means of transportation. FO SAP TM decides between shipping an order directly to a customer less than truckload (LTL) scenario or consolidating orders from several customers in a single vehicle full truckload (FTL) scenario. Optimization Execution The goal of the VSR optimizer is freight unit consolidation and the creation of a cost effective and timely route from source to destination. LY VSR Goals and Objectives ● ON ● Goal: Determine a transportation plan that minimizes total costs and satisfies all constraints. Decisions: - Per freight unit: transport or not? - Per transported freight unit: select path through transportation network (stages). - Per selected stage: select capacity or vehicle resource. - Per capacity or vehicle resource: © Copyright. All rights reserved. 17 Unit 1: Optimizer Planning ● ■ Select relative ordering of activities (= routing). ■ Assign start time to each activity (= scheduling). Total costs = sum of: - Penalty costs (non-delivery, earliness, or lateness). - Capacity or vehicle costs (fixed, duration, stops, quantity, and distance). R The total cost is the sum of penalty costs for non delivery, early and late delivery, and vehicle costs for duration, distance, stops, and quantity. FO RC US TO ME Optimizer Constraints Figure 5: Optimizer Constraints The optimizer operates within the constraints defined in the figure, Optimizer Constraints. The optimizer evaluates any changes in routing caused by constraints for their effect on the scheduling and timing. It communicates any change of time or date to all tasks on that resource or to any dependent tasks on any other resource. Considering both aspects in parallel ensures effective planning. LY The optimizer tries to assign freight units to vehicles and determine an effective delivery order for each vehicle so that total transportation costs are minimized. It considers several constraints and takes penalty costs into account as part of the total transportation cost. ON Optimizer Communication When the optimizer starts, the engine communicates with the SAP TM application; the optimizer requires the complete description of the transportation planning scenario to make informed decisions. For each freight unit, the engine decides if it wants to transport it directly or via transshipment locations. 18 © Copyright. All rights reserved. Unit 1 Exercise 2 R Execute Optimization to Determine Means of Transport ME Business Example US TO ABC Corporation wants to implement SAP TM to support truck-load and less-than-truck-load planning scenarios. Sue, the SAP consultant, needs to execute VSR optimization to determine the means of transport required for transportation planning. Note: This exercise requires you to use the data, TM211_PLAN_##, that you created in the exercise “Create Planning Cost Settings”. In this exercise, the system automatically generates sales and freight orders, that are required for one or more subsequent exercises in this course. You also create the item. FU_SEL_3100_##, that is required for one or more subsequent exercises in this course. FO RC 1. In SAP ERP, create several sales orders so that you have data for planning. Note the sales order numbers that you create and use the following data: Table 7: Sales Orders 1 Value Order Type ZT00 Sales Org 3000 Distribution Channel 10 Division 00 LY Field ON Table 8: Sales Orders 2 Field Value Value Value Value Value Value Sold-to Party CUST##-1 6 CUST##-1 7 CUST##-1 8 CUST##-2 5 CUST##-2 6 CUST##-2 8 PO Number TM200_00 TM200_00 TM200_00 TM200_00 TM200_00 TM200_00 Material PRODTM-0 0 PRODTM-0 0 PRODTM-0 0 PRODTM-0 0 PRODTM-0 0 PRODTM-0 0 Quantity 50 50 50 50 50 50 © Copyright. All rights reserved. 19 Unit 1: Optimizer Planning Field Value Value Value Value Value Value Sales Order Number 2. Copy the selection profile FU_SEL_3100_00 to your own selection profile FU_SEL_3100_##. Table 9: Selection Profile ME R 3. Replace the geographical selection attributes FU_GEO_3100_00 with your own geographical attributes FU_GEO_3100_## by replacing the range for destination locations CUST00-01 to CUST00-30 with CUST##-01 to CUST##-03. On the Selection Profile tab, enter the following data: Value Selection Profile FU_SEL_3100_## Description US TO Field FU Selection Profile for Group ## 4. In NWBC, enter the transportation cockpit using the following data: Table 10: Profile Details Field FU_SEL_3100_## FO RC Selection Profile For Freight Units Value Planning Profile TM211_PLAN_## Selection Profiles For Freight Orders FU_SEL_3100_## Layout Standard Layout 5. Create a freight order for the freight unit to CUST##-16 using the optimizer planning function, with all available resources. Analyze the result, but do not save. LY 6. Create a freight order for the freight units to CUST##-17 and CUST##-18 using all available vehicle resources. Use the optimizer planning function with selected entries only. Analyze the result, but do not save. ON 7. Review the details of the freight unit in the Overview tab. Answer the following question before canceling the transaction: How many freight orders are created? 8. Why is one freight order created? 20 © Copyright. All rights reserved. Lesson: Identifying Modal Decision Planning Scenarios 9. Create freight orders for the freight units to CUST##-17 and CUST##-18 using vehicle resource LTL-99. Use the optimizer planning function with selected entries only. Analyze the result, but do not save. 10. Review the details of the freight unit in the Overview screen area. ON LY FO RC US TO ME 12. Why are two freight orders created? R 11. How many freight orders are created? © Copyright. All rights reserved. 21 Unit 1 Solution 2 R Execute Optimization to Determine Means of Transport ME Business Example US TO ABC Corporation wants to implement SAP TM to support truck-load and less-than-truck-load planning scenarios. Sue, the SAP consultant, needs to execute VSR optimization to determine the means of transport required for transportation planning. Note: This exercise requires you to use the data, TM211_PLAN_##, that you created in the exercise “Create Planning Cost Settings”. In this exercise, the system automatically generates sales and freight orders, that are required for one or more subsequent exercises in this course. You also create the item. FU_SEL_3100_##, that is required for one or more subsequent exercises in this course. RC 1. In SAP ERP, create several sales orders so that you have data for planning. Note the sales order numbers that you create and use the following data: Table 7: Sales Orders 1 Field ZT00 FO Order Type Value 3000 Distribution Channel 10 Division 00 LY Sales Org Table 8: Sales Orders 2 Value Value Value Value Value Value Sold-to Party CUST##-1 6 CUST##-1 7 CUST##-1 8 CUST##-2 5 CUST##-2 6 CUST##-2 8 PO Number TM200_00 TM200_00 TM200_00 TM200_00 TM200_00 TM200_00 Material PRODTM-0 0 PRODTM-0 0 PRODTM-0 0 PRODTM-0 0 PRODTM-0 0 PRODTM-0 0 Quantity 50 50 50 50 50 50 ON Field 22 © Copyright. All rights reserved. Lesson: Identifying Modal Decision Planning Scenarios Field Value Value Value Value Value Value Sales Order Number 2. Copy the selection profile FU_SEL_3100_00 to your own selection profile FU_SEL_3100_##. R a) In NWBC, choose Application Administration → Planning → Selection Profiles → Display Selection Profile. ME b) Enter FU_SEL_3100_00 and choose Continue. c) Choose Copy. Table 9: Selection Profile Field US TO 3. Replace the geographical selection attributes FU_GEO_3100_00 with your own geographical attributes FU_GEO_3100_## by replacing the range for destination locations CUST00-01 to CUST00-30 with CUST##-01 to CUST##-03. On the Selection Profile tab, enter the following data: Value Selection Profile Description FU_SEL_3100_## FU Selection Profile for Group ## RC a) In the Selection Profile tab, next to the geographical selection attribute FU_GEO_3100_##, choose Copy. b) Enter the profile name FU_GEO_3100_## and the description Geographical Sel. Attributes for Group ##. FO c) Choose OK. d) On the Geographical Selection Attributes tab, select Destination Locations. e) Replace CUST00–01 with CUST##-01. f) Replace CUST00–30 with CUST##-30. LY g) Save your data. 4. In NWBC, enter the transportation cockpit using the following data: ON Table 10: Profile Details Field Value Selection Profile For Freight Units FU_SEL_3100_## Planning Profile TM211_PLAN_## Selection Profiles For Freight Orders FU_SEL_3100_## Layout Standard Layout © Copyright. All rights reserved. 23 Unit 1: Optimizer Planning a) In NWBC, choose Planning → Planning → Transportation Cockpit. b) Choose New. c) Enter the data from the Profile Details table. d) Save your data. e) Select the row and choose Continue. a) Select the freight unit corresponding to CUST##-16. ME b) Choose Optimizer Planning → Selected Entries with All Resources. R 5. Create a freight order for the freight unit to CUST##-16 using the optimizer planning function, with all available resources. Analyze the result, but do not save. c) In the Freight Orders/Freight Bookings tab, select the new freight order ($0000000). e) Choose Cancel. US TO d) Review the details of the freight unit in the Overview screen area. 6. Create a freight order for the freight units to CUST##-17 and CUST##-18 using all available vehicle resources. Use the optimizer planning function with selected entries only. Analyze the result, but do not save. a) Select the freight units corresponding to CUST##-17 and CUST##-18. b) Choose Optimizer Planning → Selected Entries with All Resources. c) Select the new freight order ($0000000). FO RC 7. Review the details of the freight unit in the Overview tab. Answer the following question before canceling the transaction: How many freight orders are created? One freight order is created. 8. Why is one freight order created? One freight order is created because in the planning cost settings, you defined that the means-of-transport FTL-99 can do a maximum of 4 stops. It is cheaper to do a multi-stop freight order than several freight orders. LY 9. Create freight orders for the freight units to CUST##-17 and CUST##-18 using vehicle resource LTL-99. Use the optimizer planning function with selected entries only. Analyze the result, but do not save. a) Select the freight units corresponding to CUST##-17 and CUST##-18. ON b) Select vehicle resource LTL-99. c) Choose Optimizer Planning → Selected Entries Only. d) Select the new freight order that was generated ($0000000) 10. Review the details of the freight unit in the Overview screen area. 24 © Copyright. All rights reserved. Lesson: Identifying Modal Decision Planning Scenarios 11. How many freight orders are created? Two freight orders are created 12. Why are two freight orders created? ON LY FO RC US TO ME R Two freight orders are created because in the planning cost settings, you defined that the means-of-transport LTL-99 cannot do any additional stops. Therefore, one freight order is created for each customer. © Copyright. All rights reserved. 25 Unit 1: Optimizer Planning Configuration of Planning Cost Settings ● Premature pick-up ● Delayed pick-up ● Premature delivery ● Delayed delivery R The following penalty costs are defined in the planning profile and can be used to control the decisions made by VSR optimization: ME Using Soft Constraints The optimizer calculates additional costs if the transportation plan deviates from the requested pickup and delivery dates. This is done when using soft constraints in the pickup and delivery time window and defining penalty costs in the planning profile. ON LY FO RC Penalty Costs US TO There is a balance in the optimizer process between selecting the cheapest mode of transport and adhering to promised delivery dates and defined pickup dates. For example, the optimizer could decide to ship via an intermodal means of transport even if this means delivering a day late. This is on the condition that savings made by selecting a slower means of transport outweigh the penalty costs for delayed delivery. Figure 6: VSR Optimization and Windows The penalty cost for premature pick-up is incurred when the scheduled pickup time falls between the earliest pickup time (hard constraint) and the allowed premature pickup (soft constraint). 26 © Copyright. All rights reserved. Lesson: Identifying Modal Decision Planning Scenarios The penalty cost for delayed pick-up is incurred when the scheduled pickup time falls between the allowed late pickup time (soft constraint) and the latest pickup time (hard constraint). The penalty cost for premature delivery is incurred when the scheduled delivery time falls between the earliest delivery time (hard constraint) and the allowed premature delivery time (soft constraint). FO RC US TO ME Pickup and Delivery Window Definition R The penalty cost for delayed delivery is incurred when the scheduled delivery time falls between the allowed late delivery time (soft constraint) and the latest delivery time (hard constraint). LY Figure 7: Pick Up and Delivery Windows Defining Pickup and Delivery Windows ON ● ● ● Forwarding orders, SAP ERP-orders, and deliveries work only with single day and time for pick up and delivery. To allow more flexibility for freight consolidation and routing optimization SAP TM Planning uses Time Windows. Combination of pick up and delivery definition and penalty costs controls how the optimizer schedules within the time window. Windows control when goods are to be picked up and delivered. VSR optimization schedules the pickup or delivery exactly in the window defined. If there were no windows, VSR optimization would schedule these dates to minimize the total costs. © Copyright. All rights reserved. 27 Unit 1: Optimizer Planning You can also control the optimization when windows are not taken into account and goods are picked up or delivered too early or too late. Defining Tolerances You can create windows by defining tolerances within which a premature or delayed pickup or delivery is to be allowed. You specify for each tolerance if VSR optimization is to consider it a hard, soft, or hard and soft constraint. Specifying constraints controls if VSR optimization calculates penalty costs when the constraints are not adhered to. ● Maximum earliness ● Maximum delay ● Delay without penalty costs ● Earliness without penalty costs ME R The following tolerances can be defined: ON LY FO RC Hard and Soft Constraints US TO The dates and times defined for the pickup and delivery in the freight unit are the basis for calculating the tolerances. The exact time for the pick-up date or delivery date can be considered. Figure 8: Defining Pick Up and Delivery Windows Conditions are used to set up pickup and delivery windows. The condition is specified in the freight unit type. 28 © Copyright. All rights reserved. Lesson: Identifying Modal Decision Planning Scenarios Window Constraints ● None ● Hard (Acceptable dates) ● Soft (Requested dates ● Hard and soft (Both) ● VSR optimization always adheres to hard constraints. ME ● R VSR optimization takes constraints into account when it assigns freight units to capacities. You can differentiate between hard and soft constraints: You model soft constraints using penalty costs, for example, lateness costs that are part of the total costs. The following are the relevant condition types: For pick up and delivery time window definition: /SCMTMS/TOR_TIMEWIND ● For earliness and lateness cost definition: /SCMTMS/FU_PNLT_COST US TO ● ON LY FO RC Means of Transport Cost Evaluation Figure 9: Means of Transport Costs Using the planning cost settings, the optimizer can determine the best means of transport to use. For example, a break-even analysis between a large truck and a small truck can be modeled with this setting. There is a relation between pickup and delivery penalty time and cost per duration. Depending on business rules, it could be better to delay pickup or deliver early. © Copyright. All rights reserved. 29 Unit 1: Optimizer Planning The maximum distance and durations are useful for deciding on rail or air transport instead of road. The maximum number of stops and costs are useful for reducing the number of visits during a week at customers or suppliers. Figure 10: Stop Off Costs US TO ME R Stop Off Costs ON LY FO RC The figure, Stop Off Costs, shows two stop-offs between locations A and D. Stopover costs are applied to influence the outcome of VSR optimization. The source and target location in a route are not taken into account when calculating the number of stopovers. Maintain the number of stopovers plus one. 30 © Copyright. All rights reserved. Unit 1 Exercise 3 R Determine Optimizer Run Results Using Planning Costs ME Business Example US TO ABC Corporation wants to implement SAP TM to support a truck-load (TL) and less-thantruck-load (LTL) planning scenario. Sue, the SAP consultant, wants to use costs to determine the outcome of optimization runs needed for transportation planning. Note: This exercise requires you to use the planning cost, TM211_COST_##, that you created, and the freight orders that were automatically generated, in the exercise “Execute Optimization to Determine Means of Transport”. In this exercise, the systems automatically generates freight orders that are required for one or more subsequent exercises in this course. RC 1. Analyze the three optimization runs using the Optimization Explanation function to understand why the optimizer creates the results. Identify the optimization runs of the previous exercise. 2. Use the Explanation Tool to view the optimization results. FO 3. What is the total cost in the optimization result for the first run (with freight unit to CUST##-16)? LY 4. Review the settings responsible for this result using the Freight Unit, Resources, and Transportation Network folders. ON 5. What is the gross weight of the freight unit? 6. In the MTR costs folder, what is the fixed cost for LTL-99? © Copyright. All rights reserved. 31 Unit 1: Optimizer Planning 7. In the MTR Costs folder, what is the unit cost for the LTL-99 in the MTR Variable Costs table? R 8. What is the total cost? ME 9. Exit the screen. 10. On the RCCF: Log Display screen, use the Explanation Tool to view the optimization results for the second run (freight units to CUST##-17 and CUST##-18 using FTL-99). US TO 11. What is the total cost in the optimization result for the second run (with freight units to CUST##-17 and CUST##-18 using FTL-99)? 12. Review the settings responsible for this result using the Resources and Transportation Network folders. FO RC 13. In the MTR costs folder, what is the fixed cost for FTL-99? 14. In the MTR costs folder, what is the stop-off cost? LY 15. What is the distance cost for FTL-99? ON 16. In the Solution Details folder, choose Costs. What is the distance in the Determined Distance table? 32 © Copyright. All rights reserved. Lesson: Identifying Modal Decision Planning Scenarios 17. What is the total cost? 18. Exit the screen. R 19. On the RCCF: Log Display screen, use the Explanation Tool to view the optimization results for the third run (freight units to CUST##-17 and CUST##-18 using LTL-99). ME 20. What is the total cost in the optimization result for the third run (with freight units to CUST##-17 and CUST##-18 using LTL-99) US TO 21. Review the settings responsible for this result using the Freight Unit, Resources, and Transportation Network folders. 22. What is the gross weight of the freight unit? RC 23. In the MTR costs folder, what is the fixed cost for LTL-99? FO 24. In the MTR Costs folder, what is the unit cost for the LTL-99 in the MTR Variable Costs table? LY 25. What is the total cost? ON 26. If you select freight units to CUST##17 and CUST##-18, but do not specify the vehicle resource to be used, what is the result? 27. In NWBC, change the fixed costs for LTL-99 to 500 so you can select the other means-oftransport. © Copyright. All rights reserved. 33 Unit 1: Optimizer Planning 28. From your transportation cockpit in NWBC, execute the optimization run using the Optimizer Planning function for all resources to prove that your change worked as desired using freight units corresponding to CUST##-17 and CUST##-18. ON LY FO RC US TO ME 30. In NWBC, revert the fixed costs for LTL-99 to 1. R 29. What is the max utilization of the freight order? 34 © Copyright. All rights reserved. Unit 1 Solution 3 R Determine Optimizer Run Results Using Planning Costs ME Business Example US TO ABC Corporation wants to implement SAP TM to support a truck-load (TL) and less-thantruck-load (LTL) planning scenario. Sue, the SAP consultant, wants to use costs to determine the outcome of optimization runs needed for transportation planning. Note: This exercise requires you to use the planning cost, TM211_COST_##, that you created, and the freight orders that were automatically generated, in the exercise “Execute Optimization to Determine Means of Transport”. In this exercise, the systems automatically generates freight orders that are required for one or more subsequent exercises in this course. RC 1. Analyze the three optimization runs using the Optimization Explanation function to understand why the optimizer creates the results. Identify the optimization runs of the previous exercise. a) In NWBC, enter the transaction code rcc_log and filter by user name. b) On the RCCF: Log Display screen, choose . FO c) In the Define Filter Criteria dialog box, select User Name in the Column Set column and use the arrows to move it to the Filter Criteria column to filter by user name. d) Choose . LY e) Enter your user name for the filter criteria (TM211-##). f) Choose Enter. 2. Use the Explanation Tool to view the optimization results. ON a) Select the earliest row with the optimization run. b) Choose Explanation Tool. c) Open the Solution Details folder. d) Choose Costs and review the Costs table. © Copyright. All rights reserved. 35 Unit 1: Optimizer Planning 3. What is the total cost in the optimization result for the first run (with freight unit to CUST##-16)? The total cost can vary. The fixed cost is 1 and the stop cost is 50. a) Choose Results → Solution Details → Costs. R 4. Review the settings responsible for this result using the Freight Unit, Resources, and Transportation Network folders. The gross weight of the freight unit is 5000 LB. a) Choose Input → Freight Units → Freight Units. US TO 6. In the MTR costs folder, what is the fixed cost for LTL-99? ME 5. What is the gross weight of the freight unit? The fixed cost is defined as 1. You defined the fixed cost in the planning cost settings. a) Choose Resources → MTR Costs → MTR Fix Costs and Penalty Factors. FO RC 7. In the MTR Costs folder, what is the unit cost for the LTL-99 in the MTR Variable Costs table? The unit cost you defined in the planning cost settings is 0.01 per LB. a) Choose Input Resources → MTR Costs → MTR Variable Cost. 8. What is the total cost? The total cost is potentially 1 + 5000 * 0.01 = 1 + 50 = 51. However, with the additional consideration of earliness and lateness, this may vary at different times of the day. 9. Exit the screen. LY 10. On the RCCF: Log Display screen, use the Explanation Tool to view the optimization results for the second run (freight units to CUST##-17 and CUST##-18 using FTL-99). a) Select the first row with the optimization run. ON b) Choose Explanation Tool. c) Choose Result → Solution Details → Costs. d) Review the Costs table. 36 © Copyright. All rights reserved. Lesson: Identifying Modal Decision Planning Scenarios 11. What is the total cost in the optimization result for the second run (with freight units to CUST##-17 and CUST##-18 using FTL-99)? The total cost is 209.66. However, the cost may be different in your system. 12. Review the settings responsible for this result using the Resources and Transportation Network folders. R 13. In the MTR costs folder, what is the fixed cost for FTL-99? ME The fixed cost for FTL-99 is defined as 1. You defined this in the planning cost settings. a) Choose Input → Resources → MTR Costs → MTR Fix Costs and Penalty Factors. 14. In the MTR costs folder, what is the stop-off cost? US TO The stop-off cost is 50. You defined this in the planning cost settings. a) Choose Input → Resources → MTR Costs → MTR Variable Costs. 15. What is the distance cost for FTL-99? 0.3 per km. RC a) Choose Input → Resources → MTR Costs → MTR Variable Costs. 16. In the Solution Details folder, choose Costs. What is the distance in the Determined Distance table? FO The distance is 528.88. However, the distance may be different based on your GIS settings. 17. What is the total cost? LY The total cost is 1 + 50 + 528,88*0,3 = 1 + 50 + 158.66= 209.66 18. Exit the screen. ON 19. On the RCCF: Log Display screen, use the Explanation Tool to view the optimization results for the third run (freight units to CUST##-17 and CUST##-18 using LTL-99). a) Select the first row with the optimization run. b) Choose Explanation Tool. c) Choose Solution Details → Costs. © Copyright. All rights reserved. 37 Unit 1: Optimizer Planning 20. What is the total cost in the optimization result for the third run (with freight units to CUST##-17 and CUST##-18 using LTL-99) The total cost is 248.67. However, with the additional consideration of earliness and lateness, this may vary at different times of the day. 21. Review the settings responsible for this result using the Freight Unit, Resources, and Transportation Network folders. a) Choose Input → Freight Units → Freight Units. US TO 23. In the MTR costs folder, what is the fixed cost for LTL-99? ME The gross weight of the freight unit is 5000 LB. R 22. What is the gross weight of the freight unit? The fixed cost is defined as 1.You defined it in the planning cost settings. a) Choose Resources → MTR Costs → MTR Fix Costs and Penalty Factors. 24. In the MTR Costs folder, what is the unit cost for the LTL-99 in the MTR Variable Costs table? FO RC The unit cost you defined in the planning cost settings is 0.01 per LB. a) Choose Input Resources → MTR Costs → MTR Variable Cost. 25. What is the total cost? The total cost is 2*(1+5000*0,01)+146.66 = 248.67. The majority comes from the delay cost (Result - Solution Details - Cost - Lateness: 146.66). LY 26. If you select freight units to CUST##17 and CUST##-18, but do not specify the vehicle resource to be used, what is the result? Two freight orders using LTL-99 result, because this is the cheaper variant according to the current system setup. ON 27. In NWBC, change the fixed costs for LTL-99 to 500 so you can select the other means-oftransport. a) Choose Application Administration → Planning → Planning Profile Settings → Planning Cost Settings → Edit Planning Costs Settings. b) Planning Costs: TM211_COST_## c) Change the fixed costs for LTL-99 to 500. d) Save your data. 38 © Copyright. All rights reserved. Lesson: Identifying Modal Decision Planning Scenarios 28. From your transportation cockpit in NWBC, execute the optimization run using the Optimizer Planning function for all resources to prove that your change worked as desired using freight units corresponding to CUST##-17 and CUST##-18. a) Choose Optimizer Planning → Selected Entries with all Resources. b) Select the new freight order generated ($0000000). c) Review the details of the freight order in the overview tab. The max utilization of the freight order is 22%. 30. In NWBC, revert the fixed costs for LTL-99 to 1. ME 29. What is the max utilization of the freight order? R d) Accept the result. US TO a) Choose Application Administration → Planning → Planning Profile Settings → Planning Cost Settings → Edit Planning Costs Settings. b) Planning Costs: TM211_COST_## c) Change the fixed costs for LTL-99 to 1. ON LY FO RC d) Save your data. © Copyright. All rights reserved. 39 Unit 1: Optimizer Planning FO RC US TO ME R Cost Function Application Figure 11: Cost Functions The figure, Cost Functions, shows the creation of a cost profile function and how penalty costs are calculated. During optimization, the system avoids transports if a certain load level is not reached. If this minimum load level is not reached, the system does not create a transport. It waits until this level is reached. In the example, there is a penalty of $1500 for a load less than 2000mᵌ. After 2000mᵌ, the penalty cost is reduced from $500 to zero. Additional Linear Loading Costs Additional Linear Loading Costs LY Additional linear loading costs can be applied to increase truck usage. You define two segments for this cost function. For the first segment, you define penalty costs of $1500 and a load of zero cubic meters (mᵌ). Define a gradient of zero. If TRUCK001 leaves the plant with a load of less than 2000mᵌ, the optimizer calculates penalty costs of $1500. ON For the second segment, you define penalty costs of $500 and a load of 2000mᵌ. Define a gradient of one. If TRUCK001 leaves the plant with a load of 2000mᵌ to 2500mᵌ, the optimizer calculates penalty costs between $500 and zero in accordance with the gradient. The penalties decrease in intervals of one unit for each additional cubic meter loaded onto the truck. 40 © Copyright. All rights reserved. Unit 1 Exercise 4 R Apply Cost Functions to Influence Optimizer Results ME Business Example US TO ABC Corporation wants to implement SAP TM to support a truck-load (TL) and less-thantruck-load (LTL) planning scenario. Sue, the SAP consultant, wants to apply cost functions to influence the outcome of VSR optimization needed for transportation planning. Note: This exercise requires you to use the planning cost setting, TM211_COST_##, created in the exercise, Determine Optimizer Run Results Using Planning Costs. RC 1. In NWBC, define a cost function COST_FUNC-##. Define the cost function so that a load cost of 1000 is defined if vehicle resources of means-of-transport FTL-99 are loaded with less than 30000 LB. Define also that a penalty of 1000 applies. This decreases for loads above 30000 LB from 10 at a rate of 0.001. Use the data in the following tables to create cost function settings. Table 11: Segment 1 Field FO Segment Value 1 0 Load Cost 1000 Slope 0 LY Load ON Table 12: Segment 2 Field Value Segment 2 Load 30000 Load Cost 10 Slope -0,001 2. In NWBC, assign your new cost function to your MOT FTL-99 in your cost profile. Use the following data: © Copyright. All rights reserved. 41 Unit 1: Optimizer Planning Table 13: Cost Settings Field Value Planning Cost Settings TM211_COST_## Cost Function COST_FUNC-## Unit of Measure LB R 3. Go to your transportation cockpit and run the Optimizer Planning function on freight units corresponding to CUST##-17 and CUST#-18. ME 4. Accept the result. ON LY FO RC US TO 5. Verify that LTL-99 is again chosen for the two freight orders. Because of the low utilization, the multi-stop freight order using FTL-99 is now too expensive. 42 © Copyright. All rights reserved. Unit 1 Solution 4 R Apply Cost Functions to Influence Optimizer Results ME Business Example US TO ABC Corporation wants to implement SAP TM to support a truck-load (TL) and less-thantruck-load (LTL) planning scenario. Sue, the SAP consultant, wants to apply cost functions to influence the outcome of VSR optimization needed for transportation planning. Note: This exercise requires you to use the planning cost setting, TM211_COST_##, created in the exercise, Determine Optimizer Run Results Using Planning Costs. RC 1. In NWBC, define a cost function COST_FUNC-##. Define the cost function so that a load cost of 1000 is defined if vehicle resources of means-of-transport FTL-99 are loaded with less than 30000 LB. Define also that a penalty of 1000 applies. This decreases for loads above 30000 LB from 10 at a rate of 0.001. Use the data in the following tables to create cost function settings. Table 11: Segment 1 Field FO Segment Value 1 0 Load Cost 1000 Slope 0 LY Load ON Table 12: Segment 2 Field Value Segment 2 Load 30000 Load Cost 10 Slope -0,001 a) In NWBC, choose Application Administration → Planning → Planning Profile Settings → Cost Functions Settings → Create Cost Function Settings. © Copyright. All rights reserved. 43 Unit 1: Optimizer Planning b) Enter your cost function. c) Enter the data in the table, Segment 1. d) Enter the data in the table, Segment 2. e) Save your data. Table 13: Cost Settings Value Planning Cost Settings TM211_COST_## Cost Function COST_FUNC-## Unit of Measure LB US TO ME Field R 2. In NWBC, assign your new cost function to your MOT FTL-99 in your cost profile. Use the following data: a) In NWBC, choose Application Administration → Planning → Planning Profile Settings → Planning Costs Settings → Edit Planning Costs Settings. b) Enter the Planning Cost Setting and choose Continue. c) Select the MOT FTL-99. d) In the Cost Functions tab, enter the data from the table. FO RC e) Save your data. 3. Go to your transportation cockpit and run the Optimizer Planning function on freight units corresponding to CUST##-17 and CUST#-18. a) Choose Planning → Planning → Transportation Cockpit. b) Select your transportation cockpit and choose Continue. c) Select the freight units for CUST##-17 and CUST##-18. d) Choose Optimizer Planning → Selected Entries Only. e) Select the new freight order. LY 4. Accept the result. ON 5. Verify that LTL-99 is again chosen for the two freight orders. Because of the low utilization, the multi-stop freight order using FTL-99 is now too expensive. 44 © Copyright. All rights reserved. Lesson: Identifying Modal Decision Planning Scenarios LESSON SUMMARY You should now be able to: Execute planning to determine the means of transport ● Execute planning to consolidate deliveries ● Execute planning to enforce minimum shipping requirements ON LY FO RC US TO ME R ● © Copyright. All rights reserved. 45 Unit 1 Lesson 4 Applying Short-Cut Planning Finally, we examine and execute short-cut planning. US TO LESSON OBJECTIVES After completing this lesson, you will be able to: ME R LESSON OVERVIEW In this lesson, we examine short-cut planning in SAP Transportation Management (SAP TM). We look also at the maintenance of the transportation requirement types, freight unit building rules, and freight orders for short-cut planning. ● Describe short-cut planning ● Maintain integration settings for short-cut planning ● Maintain configuration and execute short-cut planning ON LY FO RC Short-Cut Planning Processes Figure 12: Automatic Creation of Freight Order 46 © Copyright. All rights reserved. Lesson: Applying Short-Cut Planning Automatic planning allows you to automate the planning process in SAP TM. You can use this process for the following activities: ● Automatic freight order creation ● Automatic carrier selection ● Automatic freight order tendering ● Automatic quotation evaluation and carrier assignment RC US TO ME R Short-Cut Planning Configuration FO Figure 13: Freight Unit Building Rule Freight orders can be created directly for your order-based or delivery-based transportation requirements. This is helpful when large orders already fill up a truck and do not need further consolidation or planning. The Forwarding Order Management (FWM) Business Document LY The system creates a freight order directly when you save an FWM business document (FO, OTR, or DTR) if the following requirements have been met: ON ● ● ● The FWM business document is subcontracted and not consolidated with other FWM business documents. The FWM business document can be delivered in one freight order, meaning there is no pre-carriage or on-carriage. The FWM business document only has one source location and one destination location. Transportation Requirement Types The automatic creation of freight units can be activated in SAP TM configuration for orderbased and delivery-based transportation requirements and forwarding orders. © Copyright. All rights reserved. 47 Unit 1: Optimizer Planning Automatic freight unit building is flagged for the desired OTR and DTR types in the context of automated planning. Freight Unit Building Rules Automatic or direct creation of a freight order is possible via the freight unit building rule. Instead of defining a freight unit type in the freight unit building rule, a freight order type can be specified. R A freight order is then created directly instead of a freight unit. No additional intervention is required by the planner in the transportation cockpit. Freight Orders ON LY FO RC US TO ME Carrier selection can be automatically triggered for a freight order by assigning process controller strategy CARR_SEL as a creation strategy to the freight order type in SAP TM configuration. When doing so, carrier selection is carried out for the freight order upon its creation. The tendering process can also be initiated using process controller strategies. 48 © Copyright. All rights reserved. Unit 1 Exercise 5 R Maintain Integration Settings for Short-Cut Planning ME Business Example ABC Corporation wants to implement SAP TM to support truck-load (TL) and less-than-truckload (LTL) planning scenarios. Sue, the SAP consultant, needs to maintain the integration settings for automatic planning required for transportation management. US TO Sue wants to set up a zero-click scenario for sales orders from customer CUST##-20. To do so, there are four tasks to complete. Note: In this exercise, you create the following items that are required for one or more subsequent exercises in the course: ● FA## ● FUBR-AUTO-## OD## FO RC ● 1. In Customizing for SAP TM, create a freight order type TA## by copying existing freight order type TM00. Assign FTL-99 as the default means-of-transport. Specify CARR_SEL as a creation strategy. Specify CSEL_TM211 as default carrier selection settings and remove the default type flag, the execution organization, the execution group and the last expected event settings. Use the data in the following table: Table 14: Freight Order Type Details Value Screen Area Freight Order Type TA## Freight Order Types Default Type Deselect Freight Order Types Default MTr for Type FTL-99 Default MTr Determination Creation Strategy CARR_SEL Additional Strategies Default Carrier Selection Settings CSEL_TM211 Additional Strategies ON LY Field 2. In NWBC, create a freight unit building rule FUBR-AUTO-## by copying your freight unit building rule FUBR-199. Assign your newly created freight order type TA## as the business document type. © Copyright. All rights reserved. 49 Unit 1: Optimizer Planning 3. In Customizing for SAP TM, create a new OTR-Type OD## by copying your existing OTRtype OTRX. Assign your newly created freight unit building rule FUBR-AUTO-## as the freight unit building rule. ON LY FO RC US TO ME R 4. Display OTR-Type Determination Condition ZOTR_TYPE and ask your instructor to maintain an entry for you that maps sales orders of type ZT00 to customer CUST##-20 for purchase order TM200_00 to your newly created OTR-type OD##. 50 © Copyright. All rights reserved. Unit 1 Solution 5 R Maintain Integration Settings for Short-Cut Planning ME Business Example ABC Corporation wants to implement SAP TM to support truck-load (TL) and less-than-truckload (LTL) planning scenarios. Sue, the SAP consultant, needs to maintain the integration settings for automatic planning required for transportation management. US TO Sue wants to set up a zero-click scenario for sales orders from customer CUST##-20. To do so, there are four tasks to complete. Note: In this exercise, you create the following items that are required for one or more subsequent exercises in the course: ● FA## ● FUBR-AUTO-## OD## FO RC ● 1. In Customizing for SAP TM, create a freight order type TA## by copying existing freight order type TM00. Assign FTL-99 as the default means-of-transport. Specify CARR_SEL as a creation strategy. Specify CSEL_TM211 as default carrier selection settings and remove the default type flag, the execution organization, the execution group and the last expected event settings. Use the data in the following table: Table 14: Freight Order Type Details Value Screen Area Freight Order Type TA## Freight Order Types Default Type Deselect Freight Order Types Default MTr for Type FTL-99 Default MTr Determination Creation Strategy CARR_SEL Additional Strategies Default Carrier Selection Settings CSEL_TM211 Additional Strategies ON LY Field a) In Customizing for SAP TM, choose SAP Transportation Management → Transportation Management → Freight Order Management → Freight Order → Define Freight Order Types. © Copyright. All rights reserved. 51 Unit 1: Optimizer Planning b) Choose Execute. c) Select freight order type TM00. d) Choose Copy As and enter the data in the table provided. ME R Note: Before you enter a value in the Default MTr for Type field, remove the default value in the Transportation Mode field. After you enter the value in the Default MTr for Type field, in the Transportation Mode field, enter 01. e) In the Organizational Unit Determination screen area, delete the entries in the Execution Org. and Execution Group fields. f) In the Execution Settings screen area, delete the entry in the Last Exp. Event field. US TO g) Press Enter on your keyboard and save your data. 2. In NWBC, create a freight unit building rule FUBR-AUTO-## by copying your freight unit building rule FUBR-199. Assign your newly created freight order type TA## as the business document type. a) Choose Application Administration → Planning → Overview Settings. b) From the Active Queries list, select All Freight Unit Building Rules. Copy. FO RC c) Select your freight unit building rule FUBR-199 and choose d) Enter the freight unit building rule FUBR-AUTO-##. e) Document Type: TA##. f) Press Enter on your keyboard and save your data. 3. In Customizing for SAP TM, create a new OTR-Type OD## by copying your existing OTRtype OTRX. Assign your newly created freight unit building rule FUBR-AUTO-## as the freight unit building rule. LY a) In Customizing for SAP TM, choose SAP Transportation Management → Transportation Management → Integration → ERP Logistics Integration → OrderBased Transportation Requirement → Define Order-Based Transportation Requirement Types. b) Select your freight order type OTRX. Copy As. ON c) Choose d) Enter the OTR type OD## e) Enter the freight unit building rule FUBR-AUTO-##. f) Press Enter on your keyboard and save your data. 4. Display OTR-Type Determination Condition ZOTR_TYPE and ask your instructor to maintain an entry for you that maps sales orders of type ZT00 to customer CUST##-20 for purchase order TM200_00 to your newly created OTR-type OD##. 52 © Copyright. All rights reserved. Lesson: Applying Short-Cut Planning a) In NWBC, choose Application Administration → General Settings → Conditions → Display Condition. b) Enter the condition ZOTR_TYPE and continue. ON LY FO RC US TO ME R c) Ask your instructor now to maintain the condition. © Copyright. All rights reserved. 53 Unit 1: Optimizer Planning Carrier Profile Carriers are business partners that are assigned the business partner role Carrier. You characterize the transportation capabilities of a carrier with the carrier profile. This object stores information that is used in a similar constellation for multiple carriers. You create only one profile for each carrier. ● Transportation lane and carrier-specific parameters ● Product freight groups ● Transportation groups ● Equipment groups and equipment types ● Fixed transportation costs ● Dimension costs ME Freight code sets US TO ● R You can store the following objects in a carrier profile: You use the carrier profile when selecting a carrier. In SAP TM, to define the carrier profile, choose Master Data → General → Define Carrier Profile. Carrier Selection Settings FO RC Definition of settings can be done in the carrier selection settings or in the transportation lane. ● Carrier selection settings ● Determination of costs ● Transportation charge interpretation ● Business share usage ● Transportation allocation usage ● Incompatibility usage LY The carrier selection settings are part of the planning profile settings and are required to launch a carrier selection run. Carrier selection settings can be retrieved from the freight order type as default carrier selection settings or via a condition maintained in the freight order type customizing. ON Specify in the carrier selection settings that automatic tendering is to start after the carrier selection run. Tendering Profile The tendering profile is used to define a tendering plan. It contains basic tendering data and is a prerequisite for automatic tendering. You can use a tendering profile when you manually create a tendering plan. Within the profile, you can define multi-step tendering in a tendering plan. This allows a company to mix tendering types. Profile Definitions 54 © Copyright. All rights reserved. Lesson: Applying Short-Cut Planning Within the tendering profile, you can define multiple variants such as direct, peer-to-peer, and broadcast tendering. You can also decide if the rule based tendering is fully automatic or semi-automatic. The tendering profile also allows you to define the medium of tendering communication. It can be web-based, e-mail, SMS, or B2B oriented. You can identify a multi-currency setting, event monitoring, and exception based management. ME Automatic Planning Execution R You can classify a fully configurable process, request for quotation (RFQ) publishing, and authorization-based RFQ processing and data visibility. Automatic planning allows you to automate the planning process in SAP TM. You can use this process for: Automatic freight order creation ● Automatic carrier selection ● Automatic freight order tendering ● Automatic quotation evaluation and carrier assignment US TO ● ON LY FO RC When a sales order is created in SAP ERP, it is transferred to SAP TM where an order-based transportation requirement is created. If all planning steps are automated in SAP TM, no additional user intervention is needed; a freight order is automatically created and tendered to a carrier. © Copyright. All rights reserved. 55 ON LY FO RC US TO ME R Unit 1: Optimizer Planning 56 © Copyright. All rights reserved. Unit 1 Exercise 6 R Maintain Configuration and Execute Short-cut Planning ME Business Example Sue, the SAP consultant needs to execute the zero click scenario. US TO Note: This exercise requires you to use the order-based transportation requirement, OD##, created in the exercise “Maintain Integration Settings for Short-Cut Planning”. 1. In SAP ERP, create a sales order. From the SAP Easy Access screen, enter transaction code VA01 to start creating the order. Use the following data: Field Value Order Type 3000 RC Sales Organization ZT00 Distribution Channel 10 Division 00 FO Sold-to party CUST##-20 TM200_00 Material PRODTM-00 Quantity 50 LY PO Number 2. In NWBC, check the document flow of the resultant OTR. ON 3. In the Document Flow tab, is a successor business document created? 4. What type of document is the successor business document? © Copyright. All rights reserved. 57 Unit 1: Optimizer Planning 5. Navigate into the successor business document and review the details in the General Data tab. 6. Can you explain why a freight order of type TA## is the successor document? 9. Is a carrier ranking created? US TO 8. In the Subcontracting tab, has a carrier been selected? ME R 7. In the General Data tab, which means of transport is used in this business document? ON LY FO RC 10. Can you explain why a carrier ranking is created? 58 © Copyright. All rights reserved. Unit 1 Solution 6 R Maintain Configuration and Execute Short-cut Planning ME Business Example Sue, the SAP consultant needs to execute the zero click scenario. US TO Note: This exercise requires you to use the order-based transportation requirement, OD##, created in the exercise “Maintain Integration Settings for Short-Cut Planning”. 1. In SAP ERP, create a sales order. From the SAP Easy Access screen, enter transaction code VA01 to start creating the order. Use the following data: Field Value Order Type 3000 RC Sales Organization ZT00 Distribution Channel 10 Division 00 FO Sold-to party CUST##-20 TM200_00 Material PRODTM-00 Quantity 50 LY PO Number 2. In NWBC, check the document flow of the resultant OTR. ON a) Choose ERP Logistics Integration → Worklist → Overview Transportation Requirements. b) In the Document column, select the OTR created in Step 1. 3. In the Document Flow tab, is a successor business document created? Yes, a successor business document is created. © Copyright. All rights reserved. 59 Unit 1: Optimizer Planning 4. What type of document is the successor business document? The successor business document is a freight order of type TA##. 5. Navigate into the successor business document and review the details in the General Data tab. 6. Can you explain why a freight order of type TA## is the successor document? ME R Yes. The sales order of type ZT00 for CUST##-20 was mapped onto an OTR-type OD##. Customizing this OTR type included a freight unit building rule FBR-AUTO-## that created business documents of type TA##. 7. In the General Data tab, which means of transport is used in this business document? Means of transport FTL-99 is used in this business document. US TO 8. In the Subcontracting tab, has a carrier been selected? No carrier has been selected until now. 9. Is a carrier ranking created? Yes, a carrier ranking is created. FO RC a) In the freight order, choose Subcontracting → Carrier Ranking. 10. Can you explain why a carrier ranking is created? ON LY Yes. In the freight order type, customizing creation strategy CARR_SEL is defined, which initiates carrier selection on creation of the freight order. Carrier selection setting CSEL_TM211 is used in this process which is defined as a default carrier selection setting in the customizing of freight order type TA##. These carrier selection settings only create a carrier ranking, but do not award a result. 60 © Copyright. All rights reserved. Lesson: Applying Short-Cut Planning LESSON SUMMARY You should now be able to: Describe short-cut planning ● Maintain integration settings for short-cut planning ● Maintain configuration and execute short-cut planning ON LY FO RC US TO ME R ● © Copyright. All rights reserved. 61 Unit 1 Lesson 5 Creating Pooled Shipments ME R LESSON OVERVIEW In this lesson, you examine the process of modeling the transportation network for pooled distribution. You learn about the purpose and definition of a transshipment location. You then consider the use of the transportation network for pooled distribution to generate pooled shipments. US TO Finally, you identify the requirement for a pooled shipment in multiple freight orders and execute planning for pooled distribution. LESSON OBJECTIVES After completing this lesson, you will be able to: ● Model the transportation network for pooled shipments ● Create pooled freight orders ON LY FO RC Pooled Distribution Figure 14: Pool Distribution 62 © Copyright. All rights reserved. Lesson: Creating Pooled Shipments In the pooled distribution process, the SAP Transportation Management (SAP TM) system determines whether it is more cost-effective to deliver freight directly to the customer via truckload or using a pool location to consolidate freight. The second option is cheaper yet more time-consuming. VSR Optimization in Pooled Distribution R In the pool distribution process, a shipper wants to send goods from a shipping point to customers using pool or hub locations for consolidation. For planning, sales orders are created in the SAP ERP system and then transferred as order-based transportation requests into the SAP TM system. ME The VSR optimizer determines whether it is more cost-effective and less time-consuming to deliver freight to customers via less than truckload (LTL) directly with no consolidation allowed or to a pool location for consolidation. From there, freight can be delivered to customers via full truck load (FTL) with multiple stop offs. FO RC US TO Transshipment Locations Figure 15: Transshipment Locations LY A transshipment location is used for unloading goods from one vehicle resource and loading it onto another vehicle resource during the transportation process. Transshipment locations are used when different means of transport or different carriers have to be used in the transportation process. You can also use transshipment locations when consolidating or deconsolidating goods to be transported. Definition of a Transshipment Location ON A transshipment location is defined by assigning a location to either another location or to a transportation zone. When you assign a transshipment location to a transportation zone, it can be used as a transshipment location by all locations that are part of that transportation zone. If you define a transshipment location and want to use it in your transportation processes, you must define transportation lanes that take the transshipment location into consideration. © Copyright. All rights reserved. 63 Unit 1: Optimizer Planning FO RC US TO ME R Rough Planning Figure 16: Rough Planning Rough Planning Business Rationale ● ● For pre- and on-carriages, rough planning is sufficient. For pre- and on-carriages, neither transportation lanes, vehicles, or schedules are required, thus reducing the effort for master data maintenance. ON LY For many business processes, it is not important to plan complete end-to-end transportation in detail. For example, it may be important to find the right flights, but if the airport can be reached within a predefined time interval, the planning for this stage of the journey does not need to be planned with the same precision. The assignment of transshipment locations to transportation zones (entry or exit point into a transportation network) allows planners to specify a duration that can be used for rough planning. This means that a detailed transportation network (transportation lanes, for example) is not required for pre or oncarriage. Transshipment locations are defined only as entry and exit points in the network. If entry and exit points are connected indirectly via schedules or freight bookings, the transshipment points for these do not have to be defined as transshipment locations (from SAP TM 9.0). If stages are maintained (via transportation proposal or manually) constraints resulting from stage information can be considered or respected. 64 © Copyright. All rights reserved. Lesson: Creating Pooled Shipments US TO ME R Transportation Lanes RC Figure 17: Transportation Lanes FO A transportation lane represents a relationship between two locations, two transportation zones, or a combination of locations and zones. It connects two locations or all locations within the zones for a specific means of transport. You use this business object when planning distribution and procurement between different locations. A transportation lane is defined by a source location or zone, a destination location or zone, and a means of transport. You can assign carriers to the transportation lane. A transportation lane points only in one direction. To model the reverse direction, you need to create another transportation lane. LY Editing a Transportation Lane You can change or display transportation lanes that you have defined in SAP TM by choosing Master Data → Transportation Network → Define Transportation Lane. ON You can also view and edit multiple transportation lanes on the Mass Maint. (Display/Change) tab. Transportation lanes are used in transportation processes such as dispatching or subcontracting. The origin and destination locations, carrier, and means of transport are assigned to the transportation lane. © Copyright. All rights reserved. 65 ON LY FO RC US TO ME R Unit 1: Optimizer Planning 66 © Copyright. All rights reserved. Unit 1 Exercise 7 R Create a Transportation Network to Support Pooled Distribution ME Business Example US TO ABC Corporation wants to implement SAP TM to support truck-load and less-than-truck-load planning scenarios. Sue, the SAP consultant, needs to create a transportation network to support pooled distribution. Note: In this exercise, you create the following items that are required for one or more subsequent exercises in the course: ATLANTA-## ● POOL-## ● RESOURCE POOL-## FO RC ● 1. In NWBC, model a pool distribution scenario for customer CUST##-22 via a hub in Atlanta. For this purpose, create a hub called ATLANTA-## and assign the customer to this hub. Use the data in the following table: Table 15: Hub Details Value Location ATLANTA-## Location Type 1140 Description Atlanta Hub Country US Region GA City Atlanta ON LY Field 2. Assign the transshipment location. Use the data in the following table: Table 16: Transshipment Location Details Field Value Location CUST##-22 © Copyright. All rights reserved. 67 Unit 1: Optimizer Planning Field Value Transshipment Location ATLANTA-## 3. A dedicated fleet is used for transportation from your shipping point SP3100 to your pool point ATLANTA-##. In Customizing for SAP TM, create a means-of-transport POOL-## and resource POOL-## by copying your means-of-transport FTL-99 and resource FTL-99. R 4. In NWBC, define your new resource POOL-##. Change the means of transport from FTL-99 to POOL-## in the General Data tab. Table 17: New Resource Details Value Resource FTL-99 Resource POOL-## Short Description Pool Resource for Group ## US TO ME Field 5. The new means of transport now needs to be registered in the transportation network. In NWBC, create a transportation lane from SP3100 to your pool point ATLANTA-##. Use the data in the following table to generate the proposal: Table 18: Transportation Lane Proposal Details Field Value SP3100 RC Start Location Dest. Location ATLANTA-## Means of Transport POOL-## Start Date Beginning of current year FO End Date 31.12.9999 Select Priority/Costs Priority Cost Origin Internal Costs LY Relevant to Carrier Sel. 6. Assign carriers CAR##-01 and CAR##-02 to your new means of transport. Use the data in the following tables: ON Table 19: Carrier for Means of Transport Data 68 Field Value BP Number CAR##-01 Transportation cost 0,45 KM Priority 1 Consider carrier for P2P Tendering Select © Copyright. All rights reserved. Lesson: Creating Pooled Shipments Field Value Carrier Priority for P2P Tendering 1 Value BP Number CAR##-02 Transportation cost 0,55 KM Priority 2 Consider carrier for P2P Tendering Select the checkbox Carrier Priority for P2P Tendering 2 ON LY FO RC US TO ME Field R Table 20: Carrier for Means of Transport Data (2) © Copyright. All rights reserved. 69 Unit 1 Solution 7 R Create a Transportation Network to Support Pooled Distribution ME Business Example US TO ABC Corporation wants to implement SAP TM to support truck-load and less-than-truck-load planning scenarios. Sue, the SAP consultant, needs to create a transportation network to support pooled distribution. Note: In this exercise, you create the following items that are required for one or more subsequent exercises in the course: ATLANTA-## ● POOL-## ● RESOURCE POOL-## FO RC ● 1. In NWBC, model a pool distribution scenario for customer CUST##-22 via a hub in Atlanta. For this purpose, create a hub called ATLANTA-## and assign the customer to this hub. Use the data in the following table: Table 15: Hub Details Value Location ATLANTA-## Location Type 1140 Description Atlanta Hub Country US Region GA City Atlanta ON LY Field a) Choose Master Data → Transportation Network → Locations → Define Location, and enter the data in the table provided. b) Choose Create. c) In the Address tab, assign the country and region. d) Save your data and exit the screen. 70 © Copyright. All rights reserved. Lesson: Creating Pooled Shipments 2. Assign the transshipment location. Use the data in the following table: Table 16: Transshipment Location Details Field Value Location CUST##-22 Transshipment Location ATLANTA-## R a) Choose Master Data → Transportation Network → Locations → Assign Transshipment Location. ME b) Select the Locations radio button, and enter the data in the table provided. c) Choose Create / Update Assignments. US TO 3. A dedicated fleet is used for transportation from your shipping point SP3100 to your pool point ATLANTA-##. In Customizing for SAP TM, create a means-of-transport POOL-## and resource POOL-## by copying your means-of-transport FTL-99 and resource FTL-99. a) Choose SAP Transportation Management → Transportation Management → Master Data → Resource → Define Means of Transport. b) Select your Means of Transport FTL-99. c) Choose Copy As. d) Enter the means-of-transport POOL-##. FO RC e) Press ENTER on your keyboard to continue through the warning message. f) Save your data and exit Customizing. 4. In NWBC, define your new resource POOL-##. Change the means of transport from FTL-99 to POOL-## in the General Data tab. Table 17: New Resource Details Value Resource FTL-99 Resource POOL-## Short Description Pool Resource for Group ## LY Field ON a) Choose Master Data → Resources → Define Resource. b) Enter the resource FTL-99 and choose Change Resource. c) Select your resource FTL-99 and choose Copy Resources. d) In the Copy Resources dialog box, in the To screen area, enter the resource and description from the table. e) Choose Copy. f) Select the resource POOL-##. © Copyright. All rights reserved. 71 Unit 1: Optimizer Planning g) In the General Data tab, change the Means of Transport from FTL-99 to POOL-##. h) Save your data. 5. The new means of transport now needs to be registered in the transportation network. In NWBC, create a transportation lane from SP3100 to your pool point ATLANTA-##. Use the data in the following table to generate the proposal: Table 18: Transportation Lane Proposal Details Value Start Location SP3100 Dest. Location ATLANTA-## Means of Transport POOL-## Start Date Beginning of current year End Date 31.12.9999 Priority/Costs ME US TO Relevant to Carrier Sel. R Field Select Priority Cost Origin Internal Costs a) Choose Master Data → Transportation Network → Transportation Lanes → Define Transportation Lane. c) Choose RC b) Enter the start and destination location. Create. d) In the Means of Transport screen area, choose Create. FO e) Enter the data from the Transportation Lane Proposal Details table. f) Choose Generate Proposal. g) Choose Copy and Close, to accept the data. LY h) Save your data. 6. Assign carriers CAR##-01 and CAR##-02 to your new means of transport. Use the data in the following tables: Table 19: Carrier for Means of Transport Data Value BP Number CAR##-01 Transportation cost 0,45 KM Priority 1 Consider carrier for P2P Tendering Select ON Field 72 © Copyright. All rights reserved. Lesson: Creating Pooled Shipments Field Value Carrier Priority for P2P Tendering 1 Value BP Number CAR##-02 Transportation cost 0,55 KM Priority 2 Consider carrier for P2P Tendering Select the checkbox Carrier Priority for P2P Tendering 2 ME Field R Table 20: Carrier for Means of Transport Data (2) US TO a) In the Carrier for Means of Transport screen area, select your MoT and choose Create. b) Enter the data from the Carrier for Means of Transport table. c) Choose Copy and Close, to accept the MoT data. d) Select your MoT repeat steps a-c using the data for CAR##-02. ON LY FO RC e) Save your data. © Copyright. All rights reserved. 73 Unit 1: Optimizer Planning Multi-Stage Transportation The VSR optimizer evaluates the various possibilities for transporting the selected freight units. It then opts for pooled distribution whenever it is cost-effective to do so. In a standard pooled distribution process, the VSR optimizer creates one freight order to transport the cargo to the transshipment location. It then creates a second freight order to transport the cargo out of the transshipment location. ON LY FO RC US TO ME R Other scenarios are also possible. Multiple freight orders allow splitting up of resource assignment, carrier assignment, and other downstream planning and execution activities. 74 © Copyright. All rights reserved. Unit 1 Exercise 8 Create Pooled Freight Orders R Business Example ME Sue, the SAP consultant, now wants to verify that using the pool point is a valid option in the transportation network. Sue needs to include the newly created means of transport in the planning configuration. US TO Note: This exercise requires you to use the means of transport, POOL-##, that your created in the exercise Create a Transportation Network to Support Pooled Distribution. 1. In NWBC, create a new capacity selection setting, CAPA-POOL-##, by copying your capacity selection settings CAPA-99. Replace LTL-99 with POOL-##. RC 2. In NWBC, create a new planning cost setting COST-POOL-## by copying your existing planning cost settings TM211–COST-##. Replace LTL-99 with POOL-##. Adjust the fixed cost for POOL-## to 1. Remove the cost function and unit of measure from means of transport FTL-99. 3. In NWBC, create a new planning profile PLAN-POOL-## by copying your existing planning profile TM211–PLAN-##. Replace planning cost settings and capacity selection settings with COST-POOL-## and CAPA-POOL-## respectively. FO 4. Create a sales order for CUST##-22 using the following data: Table 21: Sales Order Value Order Type ZT00 Sales Organization 3000 Distribution Channel 10 Division 00 Sold-to CUST##-22 PO Number TM200_00 Material PRODTM-00 Quantity 50 ON LY Field © Copyright. All rights reserved. 75 Unit 1: Optimizer Planning 5. In NWBC, start the transportation cockpit from the OTR worklist by selecting the OTR created in the previous step, and the selection planning profile PLAN-POOL-##. In the transportation cockpit, create a transportation proposal for the selected freight unit. ON LY FO RC US TO ME R 6. How many options are created? 76 © Copyright. All rights reserved. Unit 1 Solution 8 Create Pooled Freight Orders R Business Example ME Sue, the SAP consultant, now wants to verify that using the pool point is a valid option in the transportation network. Sue needs to include the newly created means of transport in the planning configuration. US TO Note: This exercise requires you to use the means of transport, POOL-##, that your created in the exercise Create a Transportation Network to Support Pooled Distribution. 1. In NWBC, create a new capacity selection setting, CAPA-POOL-##, by copying your capacity selection settings CAPA-99. Replace LTL-99 with POOL-##. a) Choose Application Administration → Planning → Overview Settings. RC b) On the Active Queries screen area, choose All Capacity Selection Settings. c) Select CAPA-99. d) Choose Copy. e) In the Capacity Selection Settings field, enter CAPA-POOL-##. FO f) Replace LTL-99 with POOL-##. g) Save your data. LY 2. In NWBC, create a new planning cost setting COST-POOL-## by copying your existing planning cost settings TM211–COST-##. Replace LTL-99 with POOL-##. Adjust the fixed cost for POOL-## to 1. Remove the cost function and unit of measure from means of transport FTL-99. a) Choose Application Administration → Planning → Overview Settings. ON b) From the Active Queries screen area, choose All Planning Costs Settings. c) Select TM211_COST_##. d) Choose Copy. e) In the Planning Cost Settings field, enter COST-POOL-##. f) Replace LTL-99 with POOL-## and adjust the fixed cost for POOL-##. g) Select FTL-99. © Copyright. All rights reserved. 77 Unit 1: Optimizer Planning This opens two new tabs. h) On the Cost Functions tab page, delete the Cost Function and Unit of Measure. i) Save your data. 3. In NWBC, create a new planning profile PLAN-POOL-## by copying your existing planning profile TM211–PLAN-##. Replace planning cost settings and capacity selection settings with COST-POOL-## and CAPA-POOL-## respectively. b) On the Active Queries screen area, choose All Planning Profiles. d) Choose ME c) Select TM211_PLAN_##. R a) Choose Application Administration → Planning → Overview Settings. Copy. e) On the Planning Profile tab page, enter PLAN-POOL-##. g) Save your data. US TO f) In the Profile Assignments screen area, replace the Capacity Selection Settings and Planning Cost Settings. 4. Create a sales order for CUST##-22 using the following data: Table 21: Sales Order Field Value Order Type RC ZT00 Sales Organization 3000 Distribution Channel 10 Division 00 FO Sold-to CUST##-22 TM200_00 Material PRODTM-00 Quantity 50 LY PO Number a) In SAP ERP, enter transaction code VA01. b) Enter the data from the table. ON c) Save your new sales order and record the number. 5. In NWBC, start the transportation cockpit from the OTR worklist by selecting the OTR created in the previous step, and the selection planning profile PLAN-POOL-##. In the transportation cockpit, create a transportation proposal for the selected freight unit. a) Choose ERP Logistics Integration → Worklist → Overview Transportation Requirements. b) Select the row corresponding to the sales order number created in Step 4. 78 © Copyright. All rights reserved. Lesson: Creating Pooled Shipments c) Choose Start Transportation Cockpit. d) In the Profile and Layout Sets screen, choose New. e) In the new row, enter the planning profile PLAN-POOL-##. If the profile and layout sets screen is not shown, choose Change Profile Selection screen to go to the Profile and Layout Sets screen. f) Save your data. i) Choose Transportation Proposals. 6. How many options are created? ME h) Select the freight unit corresponding to CUST##-22. R g) Select the newly created row and choose Continue. ON LY FO RC US TO Three options are shown with different costs. Option 1: SP3100 to ATLANTA-## using POOL-## and continuing to CUST##-22 using FTL-99. Option 2: SP3100 to ATLANTA-## using FTL-99 and continuing to CUST##-22 using FTL-99. Option 3: SP3100 direct to CUST##-22 using FTL-99. © Copyright. All rights reserved. 79 Unit 1: Optimizer Planning LESSON SUMMARY You should now be able to: Model the transportation network for pooled shipments ● Create pooled freight orders ON LY FO RC US TO ME R ● 80 © Copyright. All rights reserved. Unit 1 Learning Assessment A Vehicle capacity X B Driver experience X C Handling resources X D Depot location US TO X ME Choose the correct answer. R 1. Which of the following items is not a constraint considered by the VSR optimizer? 2. Using the planning cost settings, the optimizer can determine the best means of transport to use. Determine whether this statement is true or false. True X False RC X FO 3. The SAP TM system creates a freight order directly via the freight unit building rule when you save an FWM business document if the FWM business document only has one source location and one destination location, if the FWM business document is subcontracted and not consolidated with other FWM business documents, and if the FWM business document can be delivered in one freight order, meaning there is no pre-carriage or oncarriage. Determine whether this statement is true or false. True X False ON LY X © Copyright. All rights reserved. 81 Unit 1: Learning Assessment 4. To create carrier selection profiles in SAP TM, what is the correct menu path to choose? Choose the correct answer. A Planning → Selection Profiles → Create Selection Profile X B Planning → Planning Profiles → Create Planning Profile X C Planning → Planning Profile Settings → Carrier Selection Settings → Create Carrier Selection Settings X D Planning → Capacity Selection Settings → Create Capacity Selection Settings ME R X 5. Any freight order with more than one stage must visit at least one transshipment location. X True X False US TO Determine whether this statement is true or false. 6. A transshipment location allows you to change the means-of-transport. Determine whether this statement is true or false. True X False ON LY FO RC X 82 © Copyright. All rights reserved. Unit 1 Learning Assessment - Answers A Vehicle capacity X B Driver experience X C Handling resources X D Depot location US TO X ME Choose the correct answer. R 1. Which of the following items is not a constraint considered by the VSR optimizer? 2. Using the planning cost settings, the optimizer can determine the best means of transport to use. Determine whether this statement is true or false. True X False RC X FO 3. The SAP TM system creates a freight order directly via the freight unit building rule when you save an FWM business document if the FWM business document only has one source location and one destination location, if the FWM business document is subcontracted and not consolidated with other FWM business documents, and if the FWM business document can be delivered in one freight order, meaning there is no pre-carriage or oncarriage. LY Determine whether this statement is true or false. True X False ON X © Copyright. All rights reserved. 83 Unit 1: Learning Assessment - Answers 4. To create carrier selection profiles in SAP TM, what is the correct menu path to choose? Choose the correct answer. A Planning → Selection Profiles → Create Selection Profile X B Planning → Planning Profiles → Create Planning Profile X C Planning → Planning Profile Settings → Carrier Selection Settings → Create Carrier Selection Settings X D Planning → Capacity Selection Settings → Create Capacity Selection Settings ME R X 5. Any freight order with more than one stage must visit at least one transshipment location. X True X False US TO Determine whether this statement is true or false. 6. A transshipment location allows you to change the means-of-transport. Determine whether this statement is true or false. True FO RC X False ON LY X 84 © Copyright. All rights reserved. Optimizer Applications Lesson 1 86 89 ME Creating a Transportation Proposal Exercise 9: Plan a Freight Order Using a Transportation Proposal R UNIT 2 Lesson 2 FO RC UNIT OBJECTIVES 92 97 103 111 117 US TO Describing Load Optimization Processes Exercise 10: Create a Vehicle for Load Optimization Exercise 11: Create Freight Units for Load Optimization Exercise 12: Maintain Load Planning Settings Exercise 13: Perform and Analyze Load Planning Plan freight orders using transportation proposals ● Create a vehicle for load optimization ● Create freight units for load optimization ● Maintain load planning settings ● Perform load planning ON LY ● © Copyright. All rights reserved. 85 Unit 2 Lesson 1 Creating a Transportation Proposal LESSON OBJECTIVES After completing this lesson, you will be able to: Plan freight orders using transportation proposals Transportation Proposals US TO ● ME R LESSON OVERVIEW This lesson provides an overview of the transportation proposal functionality offered by SAP Transportation Management (SAP TM). A transportation proposal defines how a freight unit can be transported through a transportation network (which is defined by locations, transshipment locations, transportation zones, transportation lanes, vehicle resources, schedules, and bookings). For a given transportation demand (freight unit), the system determines a set of alternative transportation proposals. The transportation proposal functionality serves the following purposes: To create the stages upfront, for example, to choose the option of ocean transport, because the customer has placed their order well in advance and this is the cheapest choice. In this use case, no freight orders are created based on the proposal result, but only the stage information is stored. This allows the task of planning the different stages to be assigned to different planners and to be completed at different times. ON LY ● To help the user identify the different transportation options for a freight unit. In a complex network, in which end-to-end transportation requires several stages, transportation proposals are an easy way to make the different options transparent. Transportation proposals can differ in relation to routing, means of transport, and time required. Each of these variables can increase or reduce costs, and the proposals thus provide the planner responsible with the necessary information to make an appropriate choice. FO RC ● Figure 18: Visualization Of Transportation Proposals 86 © Copyright. All rights reserved. Lesson: Creating a Transportation Proposal Entry Points for Transportation Proposal Determination The entry points for transportation proposal determination are as follows: ● Forwarding Order → Stages → Actual Route → Define Route ● Transportation Cockpit → Select Freight Unit(s) → Transportation Proposal Layout of the Transportation Proposal Result ● Route variation ● Carrier variation ● Departure date variation ● Time relevance ● Cost variance US TO Transportation Proposal: User-Defined Preferences ME R The layout of the transportation proposal result screen can be flexibly configured, similar to the transportation cockpit layout. The results can be displayed in a table format or visualized on a map. If the transportation proposal has been carried out for several freight units (because these compete for the same capacity, for example), the solution is always for a valid combination of assignments. In the table-based layout, each stage is shown in a separate line. In complex networks, there could be millions of routing options for a given transport, with only minor differences between them. Depending on the objective of the planner, results can be presented according to defined criteria. ON LY FO RC Preferences can be weighed against each other on the basis of relevance: none, low, medium, or high. Figure 19: Transportation Proposal User Interface Features of the Transportation Proposal The features of the transportation proposal are as follows: © Copyright. All rights reserved. 87 Unit 2: Optimizer Applications ● ● ● Implicit definition of transshipment locations by schedules and freight bookings (simplified definition of transportation network) Mode of transport constraints on freight unit and freight unit stage level Fast determination of transportation proposals, yielding more alternatives according to predefined variation criteria (for example, route, carrier, and departure date), and trade-off between time and cost (controlled variation according to pre-defined criteria) Consideration of preferences for locations, carrier, mode of transport, dates, and times. ● Display of multiple solutions on the result map Rough planning (detailed planning on the main leg and rough planning for pre leg and subsequent leg, based on rough definition of transportation durations) ON LY FO RC US TO ME ● R ● 88 © Copyright. All rights reserved. Unit 2 Exercise 9 R Plan a Freight Order Using a Transportation Proposal ME Business Example As a transportation planner, you need to be able to generate transportation proposals so that you can make an informed choice on all transportation options available. US TO 1. Create a transportation proposal for the sales order to customer CUST##-26. Enter the transportation cockpit with the freight unit selection profile FU_SEL_3100_## and planning profile TM211_PLAN_##. 2. How many different transportation proposals are presented? 3. Choose Expand All to show the different carrier options and costs. ON LY FO RC 4. How many carriers are proposed as possible carriers? What is the difference between them, and why are these carriers proposed? © Copyright. All rights reserved. 89 Unit 2 Solution 9 R Plan a Freight Order Using a Transportation Proposal ME Business Example As a transportation planner, you need to be able to generate transportation proposals so that you can make an informed choice on all transportation options available. US TO 1. Create a transportation proposal for the sales order to customer CUST##-26. Enter the transportation cockpit with the freight unit selection profile FU_SEL_3100_## and planning profile TM211_PLAN_##. a) In NWBC, choose Planning → Planning → Transportation Cockpit. b) In the Profile and Layout Sets selection screen, select the profile with the selection profile (FUs) FU_SEL_3100_## and planning profile TM211_PLAN_##, then choose Continue. c) In the transportation cockpit, locate the freight unit for the sales order to CUST##–28. FO RC d) Select the row for this freight unit and choose Transportation Proposals. 2. How many different transportation proposals are presented? The system offers two options - one using FTL-99, the other using LTL-99. 3. Choose Expand All to show the different carrier options and costs. 4. How many carriers are proposed as possible carriers? What is the difference between them, and why are these carriers proposed? ON LY Four carriers are proposed. The difference between them is the means of transport (MTr) - two carriers are proposed for each of the two MTrs. This leads to different transportation durations between the two proposals. These carriers are proposed because of the transportation network setup. Customer CUST##-26 belongs to transportation zone USMOUNTAIN and US-99. In the transportation lane that runs between SP3100 (the source location) and US-MOUNTAIN, LTL-99 is defined. On the intra zone transportation lane for US-99, FTL-99 is defined. 90 © Copyright. All rights reserved. Lesson: Creating a Transportation Proposal LESSON SUMMARY You should now be able to: Plan freight orders using transportation proposals ON LY FO RC US TO ME R ● © Copyright. All rights reserved. 91 Unit 2 Lesson 2 Describing Load Optimization Processes ME R LESSON OVERVIEW This lesson examines the necessary maintenance of capacity master data for load maintenance. You learn about freight unit creation for load optimization, and you can create a vehicle for load optimization. You look at freight unit dimensions and can practise creating freight units for load optimization. US TO LESSON OBJECTIVES After completing this lesson, you will be able to: Create a vehicle for load optimization ● Create freight units for load optimization ● Maintain load planning settings ● Perform load planning FO RC ● Load Optimization During truck planning, rules are applied to fulfill legal restrictions. For example, certain axle loads may not be exceeded. In addition, a certain loading sequence of the goods to be transported optimizes the transportation plan. Load planning concerns the loading of goods to be transported in an optimized manner into a transportation unit, be it be a truck, trailer, or container resource. You can plan the loading space of box trucks, trailers, semi-trailers, and containers in the transportation cockpit or directly in one of the following business documents: Road freight order ● Trailer unit ● Container unit LY ● ON Planning is carried out at the level of business document items. Load planning returns an approximate calculation of how the available loading space can be optimally used, taking into account the maximum axle loads and the maximum weight of a vehicle resource. The calculation is based on the master data that you enter for the resource. In automatic load planning, also known as load optimization, the load optimizer creates a load plan for your business document. It considers capacity restrictions in terms of the height, width, weight, and length of the loading space. For vehicle resources with two axle groups, it also considers the maximum axle load. 92 © Copyright. All rights reserved. Lesson: Describing Load Optimization Processes RC Figure 20: Vehicle Capacity US TO ME R Vehicle Capacity Vehicle Capacity Attributes ● VSR: One-dimensional, for example, volume or mass. Up to eight dimensions. FO - - VSO: - Three-dimensional, for example, pallet or box size. - Visual representation. LY ● ● Vehicle capacity is maintained in vehicle resource master data. ON In vehicle scheduling and routing (VSR) planning, SAP Transportation Management (SAP TM) considers the resource capacities of weight and volume. However, the new load planning function requires much more information on master data level. Not only are weight and volume limitations considered more precisely, but weight distribution of axles is also planned. This is required to fulfill legal restrictions when creating a load plan. Within the resource master data, on the Physical Properties tab, there are additional capacity and resource configuration fields to maintain. You can specify attributes regarding dimension, weight, and type of resource. One specific attribute is the definition of axle groups. From SAP TM 9.1, a resource viewer (master data transaction) is offered to display the resource configuration. © Copyright. All rights reserved. 93 Unit 2: Optimizer Applications US TO ME R Vehicle Types RC Figure 21: Vehicle Types Example 1: Box Truck The table, Box Truck, provides a detailed explanation of the elements of the figure, Vehicle Types Example 1: Box Truck: FO Table 22: Box Truck Name in the Master Data Description a1 Axle Group Distance 1 Distance between axle group 1 and the front of the box truck c Cargo body distance Distance between the start of the loading space and the front of the box truck a2 Axle Group Distance 2 Distance between axle group 2 and the front of the box truck d Connector Distance Distance between the trailer coupling of the box truck and the front of the vehicle s2 Distance Between Axles Distance within axle group 2 h Interior Height Height of the loading space ON LY Measurement in Figure 94 © Copyright. All rights reserved. Lesson: Describing Load Optimization Processes Measurement in Figure Name in the Master Data Description l Interior Length Length of the loading space US TO ME R Vehicle Types Example 2: Semi-Trailer FO RC Figure 22: Vehicle Types Example 2: Semi-Trailer The table, Semi-Trailer, provides a detailed explanation of the elements of the figure, Vehicle Types Example 2: Semi-Trailer: Table 23: Semi-Trailer Name in the Master Data Description a1 Axle Group Distance 1 Distance between axle group 1 and the front of the trailer s1 Distance Between Axles Distance within axle group 1 k King Pin Distance Distance between the king pin and the front of the trailer h Interior Height Height of the loading space l Interior Length Length of the loading space p Split Deck Position Position in the trailer at which you have added the split deck ON LY Measurement in Figure © Copyright. All rights reserved. 95 ON LY FO RC US TO ME R Unit 2: Optimizer Applications 96 © Copyright. All rights reserved. Unit 2 Exercise 10 Create a Vehicle for Load Optimization R Business Example ME As a transportation planner, you need to generate load plans that adhere to defined load planning rules. You are tasked to demonstrate that process and create corresponding master data. US TO Note: In this exercise you create the resource, FTL-##, that is required for one or more subsequent exercises in this course. 1. Create a vehicle resource FTL-## by copying the vehicle resource FTL-99. Maintain the following dimensions: Table 24: Phys. Properties Data Field 12000 FO RC Max Gross Weight Value KG Max Length 10 Max Width 2,5 Max Height 3 UoM M Number of Axles 3 First Axle Group — Axle Type 1–Single Axle ON LY UoM First Axle Group — Axle Group Distance 8 First Axle Group — UoM M First Axle Group — Max Weight on Group 5000 First Axle Group — UoM KG Second Axle Group — Axle Type 2 — Tandem Axle Second Axle Group — Axle Group Distance 2 Second Axle Group — Distance between Axles 1,5 Second Axle Group — UoM M © Copyright. All rights reserved. 97 Unit 2: Optimizer Applications Field Value Second Axe Group — Max Weight on Group 8000 Second Axle Group — UoM KG Payload weight 12000 UoM KG Internal Length 10 Internal Width 2,5 Internal Height 3 UoM Table 26: Copy Resources Field Resource M Value FTL-## Load Planning Group ## FO RC Short Description ME Value US TO Field R Table 25: Capacity Data 2. In the Resource Viewer, check your resource by verifying that the data entered in Step 1 is maintained in the Resource Configurator screen area. Review the 3D model also. ON LY 3. Examine how the 3D model changes if you enter a split deck at a position of 1,5 in the Resource Configurator screen area. 98 © Copyright. All rights reserved. Unit 2 Solution 10 Create a Vehicle for Load Optimization R Business Example ME As a transportation planner, you need to generate load plans that adhere to defined load planning rules. You are tasked to demonstrate that process and create corresponding master data. US TO Note: In this exercise you create the resource, FTL-##, that is required for one or more subsequent exercises in this course. 1. Create a vehicle resource FTL-## by copying the vehicle resource FTL-99. Maintain the following dimensions: Table 24: Phys. Properties Data Field 12000 FO RC Max Gross Weight Value KG Max Length 10 Max Width 2,5 Max Height 3 UoM M Number of Axles 3 First Axle Group — Axle Type 1–Single Axle ON LY UoM First Axle Group — Axle Group Distance 8 First Axle Group — UoM M First Axle Group — Max Weight on Group 5000 First Axle Group — UoM KG Second Axle Group — Axle Type 2 — Tandem Axle Second Axle Group — Axle Group Distance 2 Second Axle Group — Distance between Axles 1,5 Second Axle Group — UoM M © Copyright. All rights reserved. 99 Unit 2: Optimizer Applications Field Value Second Axe Group — Max Weight on Group 8000 Second Axle Group — UoM KG Payload weight 12000 UoM KG Internal Length 10 Internal Width 2,5 Internal Height 3 UoM ME Value US TO Field R Table 25: Capacity Data M Table 26: Copy Resources Field Value Resource FTL-## Load Planning Group ## FO RC Short Description a) In NWBC, choose Master Data → Resources → Define Resource. b) Enter the resource FTL-99 and choose Enter. c) Select the resource FTL-99 and choose Copy Resources. d) On the Copy Resources dialog box, in the To screen area, enter the resource FTL-##. Use the data in the Copy Resources table provided. e) Choose Copy Object. LY f) Choose the row containing the new resource FTL-##. g) In the Phys. Properties tab, enter the data from the Phys. Properties Data table in the step. ON h) In the Capacity tab, enter the data from the Capacity Data table in the step. i) Save your data. 2. In the Resource Viewer, check your resource by verifying that the data entered in Step 1 is maintained in the Resource Configurator screen area. Review the 3D model also. a) In NWBC, choose Master Data → Resources → Resource Viewer. b) In the Search Criteria screen area, search for your resource by entering FTL-## as the search criteria for the vehicle resource. 100 © Copyright. All rights reserved. Lesson: Describing Load Optimization Processes c) Choose Search. d) In the Resources screen area, select your resource FTL-##. e) Close all screen areas except for the Resource Configurator screen area. f) Check that the values for the interior dimensions (length, height, width) and the data for the axle groups is maintained. g) Hide the Resource Configurator screen area and open the 3D model. R 3. Examine how the 3D model changes if you enter a split deck at a position of 1,5 in the Resource Configurator screen area. ME a) In the Resource Configurator screen area, enter a value of 1,5 in the Split Deck Position field and press Enter on your keyboard. b) Close the Resource Configurator screen area, and open the 3D Model screen area. ON LY FO RC US TO c) In the 3D Model screen area, open the context menu and choose Switch View → Right. © Copyright. All rights reserved. 101 Unit 2: Optimizer Applications Freight Unit Dimensions Dimensions of individual packages are determined from the business document items; that is, freight unit items are the basis for load planning and load optimization in the transportation cockpit. ● Height ● Width ● Gross weight ME Length ON LY FO RC US TO ● R The following are relevant dimensions: 102 © Copyright. All rights reserved. Unit 2 Exercise 11 Create Freight Units for Load Optimization R Business Example ME ABC Corporation wants to implement SAP TM to support truck-load and less-than-truck-load planning scenarios. Sue, the SAP consultant, needs to create freight units for load optimization to support this. US TO Note: You must complete the exercise, Create a Vehicle for Load Optimization, before attempting this exercise. This exercise requires you to use the data, FTL-##, that you created in the exercise “Create a Vehicle for Load Optimization”. In this exercise, the system automatically generates a forwarding order and freight unit that are required for one or more subsequent exercises in the course. FO RC 1. Create a forwarding order using forwarding order type FWOX and movement type T2C. The order is from SP3100 (source location, shipper, ordering party) to CUST##-25 (destination location, consignee). The pick up date is Tuesday of next week, and the delivery date is Friday of next week. Create the following six items in the forwarding order: Table 27: Order Items Value Value Value Value Value Value Item 10 20 30 40 50 60 Item Type PRD PRD PRD PRD PRD PRD Gross Weight 2000 500 100 2000 500 100 Gross Weight UoM KG KG KG KG KG KG Length 5 3 1 5 3 1 Width 1 1 1 1 1 1 Height 1 1,4 2 1 1,4 2,5 UoM M M M M M M ON LY Field © Copyright. All rights reserved. 103 Unit 2: Optimizer Applications Table 28: Order Details Value Screen Area Ordering Party SP3100 Business Partner Shipper SP3100 Business Partner Consignee CUST##-25 Business Partner Movement Type T2C General Terms Source Location SP3100 Source Pick-up-Date Tuesday of next week Source Destination Location CUST##=25 Delivery Date Friday of next week ME R Field Destination Destination US TO 2. Verify that a freight unit is created automatically for your forwarding order. 3. Verify that the dimension information (length, width, height) is carried over into the unit items. ON LY FO RC 4. Record your freight unit number. 104 © Copyright. All rights reserved. Unit 2 Solution 11 Create Freight Units for Load Optimization R Business Example ME ABC Corporation wants to implement SAP TM to support truck-load and less-than-truck-load planning scenarios. Sue, the SAP consultant, needs to create freight units for load optimization to support this. US TO Note: You must complete the exercise, Create a Vehicle for Load Optimization, before attempting this exercise. This exercise requires you to use the data, FTL-##, that you created in the exercise “Create a Vehicle for Load Optimization”. In this exercise, the system automatically generates a forwarding order and freight unit that are required for one or more subsequent exercises in the course. FO RC 1. Create a forwarding order using forwarding order type FWOX and movement type T2C. The order is from SP3100 (source location, shipper, ordering party) to CUST##-25 (destination location, consignee). The pick up date is Tuesday of next week, and the delivery date is Friday of next week. Create the following six items in the forwarding order: Table 27: Order Items Value Value Value Value Value Value Item 10 20 30 40 50 60 Item Type PRD PRD PRD PRD PRD PRD Gross Weight 2000 500 100 2000 500 100 Gross Weight UoM KG KG KG KG KG KG Length 5 3 1 5 3 1 Width 1 1 1 1 1 1 Height 1 1,4 2 1 1,4 2,5 UoM M M M M M M ON LY Field © Copyright. All rights reserved. 105 Unit 2: Optimizer Applications Table 28: Order Details Value Screen Area Ordering Party SP3100 Business Partner Shipper SP3100 Business Partner Consignee CUST##-25 Business Partner Movement Type T2C General Terms Source Location SP3100 Source Pick-up-Date Tuesday of next week Source Destination Location CUST##=25 Delivery Date Friday of next week ME R Field Destination Destination US TO a) In NWBC, choose Forwarding Order Management → Forwarding Order → Create Forwarding Order. b) Enter FWOX in the Forwarding Order Type field. c) Choose Continue. d) Enter the data in the Order Details table. e) In the Items table, choose Insert → Product. FO RC f) Enter the data from the table, repeating Substep e each time you want to create a new row. g) Save your data and record your forwarding order number. 2. Verify that a freight unit is created automatically for your forwarding order. a) In NWBC, choose Forwarding Order Management → Forwarding Order → Display Forwarding Order. ON LY b) Select the Document Flow tab. 106 © Copyright. All rights reserved. Lesson: Describing Load Optimization Processes Note: If more than one freight unit is created, cancel the existing freight units. a) Choose the freight unit with the lowest number. b) Choose Edit. d) In the warning message that appears, choose OK. e) Save your data. R c) Choose Cancel Document. ME f) Repeat Steps a-e for any additional freight units that have been created. US TO g) Return to the forwarding order and choose Refresh. c) One freight unit is created for the forwarding order. 3. Verify that the dimension information (length, width, height) is carried over into the unit items. a) In the Document Flow tab of the forwarding order, choose the Business Document number to navigate into the freight unit. b) Select an item in the Item screen area. RC c) On the General Data tab, verify that the values for length, width, and height are maintained. 4. Record your freight unit number. ON LY FO The freight unit number varies. © Copyright. All rights reserved. 107 Unit 2: Optimizer Applications Load Planning Settings Load planning settings define a process controller strategy. This strategy defines a sequence of methods to be executed for the load planning and enables a flexible combination of standard and custom logic. With the strategy, it is possible to define a set of rules to be applied when optimizing the load. The rules can be given a priority, deactivated to test the planning with a different rule set, and adjusted with certain attributes. R Load Planning Settings Definition Load planning strategy ● Load optimization runtime ● Load planning rules (including their priorities and parameters) ME ● Load Planning Rules US TO Load planning settings are assigned in the planning profile. By assigning a planning profile in the freight order type, different load planning settings can be used for different freight order types. In automatic load planning, you can define rules to be considered by the system during a load optimization run. You can choose between the following types of rules: Rules that apply to automatic planning for all resource types ● Rules that apply only to the automatic load planning of box trucks ● Rules that apply only to the automatic planning of trailers and semi-trailers ● FO RC ● Rules that apply only to the automatic load planning of the upper decks of double-deck trailers You can define different rules for the lower and upper deck of double-deck trailers. The combination of stack, row, and line indicates the exact position of each package loaded onto the resource. Packages loaded on top of each other form a stack. Packages loaded next to each other from left to right form a row. The first row of a deck is always placed towards the start of the loading space. Packages loaded one behind the other from front to back form a line. The first line of a deck is always on the left side of the deck in the direction of travel. LY Rules for Load Planning Stack height ascending in driving direction ● Stack height descending in driving direction ● Maximum height difference of adjacent stacks ON ● 108 ● Maximum height difference of stacks within a row ● Maximum height difference of stacks within a line ● Penalty for packages that cannot be loaded based on weight ● Penalty for packages that cannot be loaded based on weight multiplied by volume ● Packages with high density must be at the bottom of the stack ● Packages can be positioned anywhere in the stack regardless of weight and density © Copyright. All rights reserved. Lesson: Describing Load Optimization Processes US TO ME R Features of Load Planning Rules Figure 23: Load Planning Rules Example: Loading Pattern Load planning rules are characterized by the following features: Loading pattern ● Orientation ON LY FO RC ● © Copyright. All rights reserved. 109 ON LY FO RC US TO ME R Unit 2: Optimizer Applications 110 © Copyright. All rights reserved. Unit 2 Exercise 12 Maintain Load Planning Settings R Business Example ME ABC Corporation wants to implement SAP TM to support its truck-load and less-than-truckload planning scenarios. Sue, the SAP consultant, needs to maintain load planning settings to do this. Item US TO Note: This exercise requires you to use the items, created in previous tasks, as follows: Created in the Task Freight Unit [NUMBER] Create Freight Units for Load Optimization TM211_PLAN_## Create Planning Cost Settings FO RC In this exercise, you create the following items, that are required for one or more subsequent exercises in the course: ● LOAD_PLAN_## ● CAPA_LOAD_## ● LOAD_PLAN_LAYOUT_## 1. Create load planning settings LOAD_PLAN_##. Assign the load planning rule 1000 (stack height ascending in driving direction) with priority 1 (high) to your load planning settings LOAD_PLAN_##. Use the data in the following table: ON LY Table 29: Load Planning Settings Field Value Load Planning Settings LOAD_PLAN_## Description Load Planning Settings for Group ## Load Planning Strategy ALP_DEF Runtime 10 2. Assign your load planning settings LOAD_PLAN_## to your planning profile TM211_PLAN_##. Change the capacity selection by copying capacity selection settings © Copyright. All rights reserved. 111 Unit 2: Optimizer Applications CAPA-99 to your own settings CAPA_LOAD_## and add vehicle resource FTL-## to your selection of vehicle resources. Use the data in the following tables: Table 30: Capacity Selection Settings 1 Value Profile CAPA_LOAD_## Description Capacity Selection for Load Planning ## Table 31: Capacity Selection Settings 2 ME R Field Value Attributes for Vehicle Resource Selection VEHICLERES_ID Sign Inclusive Option Value US TO Field = FTL-## ON LY FO RC 3. Create a transportation cockpit layout with load planning enabled. 112 © Copyright. All rights reserved. Unit 2 Solution 12 Maintain Load Planning Settings R Business Example ME ABC Corporation wants to implement SAP TM to support its truck-load and less-than-truckload planning scenarios. Sue, the SAP consultant, needs to maintain load planning settings to do this. Item US TO Note: This exercise requires you to use the items, created in previous tasks, as follows: Created in the Task Freight Unit [NUMBER] Create Freight Units for Load Optimization TM211_PLAN_## Create Planning Cost Settings FO RC In this exercise, you create the following items, that are required for one or more subsequent exercises in the course: ● LOAD_PLAN_## ● CAPA_LOAD_## ● LOAD_PLAN_LAYOUT_## 1. Create load planning settings LOAD_PLAN_##. Assign the load planning rule 1000 (stack height ascending in driving direction) with priority 1 (high) to your load planning settings LOAD_PLAN_##. Use the data in the following table: ON LY Table 29: Load Planning Settings Field Value Load Planning Settings LOAD_PLAN_## Description Load Planning Settings for Group ## Load Planning Strategy ALP_DEF Runtime 10 a) In NWBC, choose Application Administration → Planning → Planning Profile Settings → Load Planning Settings → Create Load Planning Settings. © Copyright. All rights reserved. 113 Unit 2: Optimizer Applications b) Enter the data in the Load Planning Settings table. c) In the Load Planning Rules screen area, choose Insert. d) In the Load Planning Rule field, enter 1000. e) Save your data. R 2. Assign your load planning settings LOAD_PLAN_## to your planning profile TM211_PLAN_##. Change the capacity selection by copying capacity selection settings CAPA-99 to your own settings CAPA_LOAD_## and add vehicle resource FTL-## to your selection of vehicle resources. Use the data in the following tables: ME Table 30: Capacity Selection Settings 1 Value Profile CAPA_LOAD_## Description Capacity Selection for Load Planning ## US TO Field Table 31: Capacity Selection Settings 2 Field Value Attributes for Vehicle Resource Selection VEHICLERES_ID Sign Inclusive = FO RC Option Value FTL-## a) In NWBC, choose Application Administration → Planning → Planning Profiles → Edit Planning Profile. b) In the Planning Profile field, enter TM211_PLAN_## and choose Continue. c) On the Planning Profile tab, in the Profile Assignments screen area, in the Load Planning Settings field, enter LOAD_PLAN_##. LY d) Save your data. e) Choose Edit. f) Beside the Capacity Selection Settings field, choose New. ON g) Enter the data in the Capacity Selection Settings 1 table. h) Choose OK. i) Select the Capacity Selection Settings tab. j) Enter a new line in the table using the data in the Capacity Selection Settings 2 table. k) Save your data. 3. Create a transportation cockpit layout with load planning enabled. 114 © Copyright. All rights reserved. Lesson: Describing Load Optimization Processes a) Choose Application Administration → Planning → General Settings → Page Layouts → Page Layouts for Transportation Cockpit. To make the required changes to the layout, use the data in the following table: Table 32: Page Layout Details Positions of Screen Area Width Additional Info Requirements Area Top left 100% n/a Resources Area Middle left 50% Orders Area Middle right 50% R Field Select the Freight Orders / Freight Bookings row US TO ● ● Bottom left FO RC Order Details Area In the Display column, select all checkboxes ME ● 100% ● In the Details of Freight Orders / Freight Bookings screen area, select the Load Planning checkboxes In the Display column, select the Utilization and Load Plan checkboxes b) Choose New. c) In the Page Layout field, enter LOAD_PLAN_LAYOUT_##. LY d) In the Visibility Pushbutton screen area, leave all the selected checkboxes and also select the Explanation — Load Planning checkbox. e) Below the Visibility Pushbutton screen area, there are a number of tabs. Use the data in the Page Layout Details table to make the required changes. ON f) Save your data. © Copyright. All rights reserved. 115 Unit 2: Optimizer Applications Transportation Cockpit The transportation cockpit layout can be enhanced to perform the following activities: Initiate load planning (Orders screen area). ● Initiate load planning (Transportation Unit screen area). ● Visualize and analyze load planing (Order Details screen area). ● Explain the load planning result (Visibility button). R ● ME Load Planning The load plan is the result of load planning. It provides you with an overview of how the loading space available for transporting a business document is used currently. US TO In both the transportation cockpit and in the business document, you can display the complete load plan as a 3D load plan or a table load plan of business document items. In the 3D load plan, you can show or hide individual objects as well as entire rows, columns, or stacks and fill them with different colors. Furthermore, you can show and hide gridlines in your decks in the 3D load plan. If items cannot be loaded, the load plan includes information on the loading sequence and the exact position on the vehicle. In addition to the load plan, a load distribution is available for each axle and the complete vehicle. This document proves that the load plan fulfills legal requirements. An additional tab holds statistical indicators such as the used volume and area. The Load Plan FO RC The load plan contains the following information about the business document item: Resource ● Item in the resource ● Loading sequence ● Row, stack, and level in the loading space ● Gross weight ● Height, width, and length ● Stackability LY ● Load Plan Analysis The following is the load distribution and statistical data based on the current load plan: Number of loaded business document items ● Used area on the lower deck of your double-deck trailer ● Utilization of the loading volume in percent ● Used area on the upper deck of your double-deck trailer ● Maximum weight for each axle group compared to the current weight for each axle group ● Maximum trailing load compared to the current trailing load ON ● 116 © Copyright. All rights reserved. Unit 2 Exercise 13 Perform and Analyze Load Planning R Business Example ME ABC Corporation wants to implement SAP TM to support its truck-load and less-than-truckload planning scenarios. Sue, the SAP consultant, needs to perform and analyze load planning to support this implementation. US TO Note: In this exercise you are required to use the planning profile, TM211_PLAN_##, that you created in the exercise “Maintain Load Planning Settings”. 1. In the transportation cockpit, create a freight order from SP3100 to CUST##–25 using vehicle resource FTL-##. Manually drag the freight unit that you created in the exercise Create Freight Units for Load Optimization to your vehicle resource. Use the following profiles to enter the transportation cockpit: Field Value FU_SEL_3100_## RC Selection Profile (FUs) FU_SEL_3100_## Planning Profile TM211_PLAN_## Transportation Cockpit Layout LOAD_PLAN_LAYOUT_## FO Selection Profile (FOs) 2. Execute load planning for the newly created freight order. LY 3. How many items are loaded? ON 4. Review the load plan. What is the execution status at the source location SP3100? 5. Review the load distribution. What is the total utilization? © Copyright. All rights reserved. 117 Unit 2: Optimizer Applications 6. What is the utilization of axle group 1 and axle group 2? R 7. What is the floor size of the cargo body? How much floor space is used? ON LY FO RC US TO ME 8. What is the volume of the truck and how much of the volume has been used? 118 © Copyright. All rights reserved. Unit 2 Solution 13 Perform and Analyze Load Planning R Business Example ME ABC Corporation wants to implement SAP TM to support its truck-load and less-than-truckload planning scenarios. Sue, the SAP consultant, needs to perform and analyze load planning to support this implementation. US TO Note: In this exercise you are required to use the planning profile, TM211_PLAN_##, that you created in the exercise “Maintain Load Planning Settings”. 1. In the transportation cockpit, create a freight order from SP3100 to CUST##–25 using vehicle resource FTL-##. Manually drag the freight unit that you created in the exercise Create Freight Units for Load Optimization to your vehicle resource. Use the following profiles to enter the transportation cockpit: Field Value FU_SEL_3100_## RC Selection Profile (FUs) FU_SEL_3100_## Planning Profile TM211_PLAN_## Transportation Cockpit Layout LOAD_PLAN_LAYOUT_## FO Selection Profile (FOs) a) In NWBC, choose Planning → Planning → Transportation Cockpit. b) Choose New and enter the data from the table. LY c) Save your data. d) Select the newly created line and choose Continue. ON e) In the transportation cockpit, select the freight unit to CUST##–25. f) Drag the freight unit to the vehicle resource FTL-##. A new freight order is created in the Freight Orders / Freight Bookings screen area. You can identify the order by the $ symbol in the Document column. g) Save your data. 2. Execute load planning for the newly created freight order. a) Select the freight order in the Freight Orders / Freight Bookings screen area. b) In the Freight Orders / Freight Bookings screen area, choose Load Planning. c) Save your data. © Copyright. All rights reserved. 119 Unit 2: Optimizer Applications 3. How many items are loaded? 6 of 6 items are loaded. 4. Review the load plan. What is the execution status at the source location SP3100? The execution status is either Load Plan Up-to-Date or Not Loaded. R a) Select the freight order in the Freight Orders / Freight Bookings screen area. 5. Review the load distribution. What is the total utilization? US TO The total utilization is 43%. ME b) In the Overview tab, in the Execution Status column, the execution status is displayed. a) Select the freight order in the Freight Orders / Freight Bookings screen area. b) Select the Load Plan tab, and then select the Load Distribution tab to view the required data. 6. What is the utilization of axle group 1 and axle group 2? FO RC The utilization of axle group 1 is 60% and the utilization of axle group 2 is 7%. a) Select the freight order in the Freight Orders / Freight Bookings screen area. b) Select the Load Plan tab, and then select the Load Distribution tab to view the required data. 7. What is the floor size of the cargo body? How much floor space is used? The floor size of the cargo body is 25m² and the used floor of the cargo body is 10m² (40%). LY a) Select the freight order in the Freight Orders / Freight Bookings screen area. b) Select the Load Plan tab, and then select the Statistics tab to view the required data. 8. What is the volume of the truck and how much of the volume has been used? ON The volume of the truck is 75m³ and 22,9m³ has been used. a) Select the freight order in the Freight Orders / Freight Bookings screen area. b) Select the Load Plan tab, and then select the Statistics tab to view the required data. 120 © Copyright. All rights reserved. Lesson: Describing Load Optimization Processes LESSON SUMMARY You should now be able to: Create a vehicle for load optimization ● Create freight units for load optimization ● Maintain load planning settings ● Perform load planning ON LY FO RC US TO ME R ● © Copyright. All rights reserved. 121 ON LY FO RC US TO ME R Unit 2: Optimizer Applications 122 © Copyright. All rights reserved. Unit 2 Learning Assessment R 1. Why is rough planning sometimes sufficient for pre- and on-carriage? ME Choose the correct answer. A Main carriage is the only portion of a transportation route that ever requires planning. X B Pre-carriage and on-carriage are planned by the shipper and the customer respectively, no detailed plans are required. X C A carrier or LSP may be extremely familiar with the routes for pre-carriage, for example from a warehouse to an airport. The same degree of planning is therefore not required for each individual shipment. X D Pre-carriage and on-carriage must always be planned with the same degree of detail as the main carriage. US TO X 2. Which of the following can be expressed as preferences for a transportation proposal? RC Choose the correct answers. A Route variation X B Departure date variation FO X X C Driver preference X D Incompatibilities 3. Which of the following load planning rules are available in SAP TM 9.1? ON LY Choose the correct answers. X A Stack height ascending in driving direction X B Packages with high density must be on top of the stack X C Maximum height difference of packages in one row X D U.S. Federal Bridge Formula X E Truck: Load all packages with the same loading formula © Copyright. All rights reserved. 123 Unit 2: Learning Assessment 4. Load planning considers the business document items to determine the dimensions of the individual packages. X True X False 5. For which of the following documents can you execute load planning? A Freight order X B Transportation unit X C Forwarding order X D Handling resource US TO X ME Choose the correct answers. R Determine whether this statement is true or false. 6. Load optimization can consider only one planning rule. Determine whether this statement is true or false. True X False ON LY FO RC X 124 © Copyright. All rights reserved. Unit 2 Learning Assessment - Answers R 1. Why is rough planning sometimes sufficient for pre- and on-carriage? ME Choose the correct answer. A Main carriage is the only portion of a transportation route that ever requires planning. X B Pre-carriage and on-carriage are planned by the shipper and the customer respectively, no detailed plans are required. X C A carrier or LSP may be extremely familiar with the routes for pre-carriage, for example from a warehouse to an airport. The same degree of planning is therefore not required for each individual shipment. X D Pre-carriage and on-carriage must always be planned with the same degree of detail as the main carriage. US TO X RC 2. Which of the following can be expressed as preferences for a transportation proposal? Choose the correct answers. A Route variation X B Departure date variation FO X X C Driver preference X D Incompatibilities LY 3. Which of the following load planning rules are available in SAP TM 9.1? ON Choose the correct answers. X A Stack height ascending in driving direction X B Packages with high density must be on top of the stack X C Maximum height difference of packages in one row X D U.S. Federal Bridge Formula X E Truck: Load all packages with the same loading formula © Copyright. All rights reserved. 125 Unit 2: Learning Assessment - Answers 4. Load planning considers the business document items to determine the dimensions of the individual packages. X True X False 5. For which of the following documents can you execute load planning? A Freight order X B Transportation unit X C Forwarding order X D Handling resource US TO X ME Choose the correct answers. R Determine whether this statement is true or false. 6. Load optimization can consider only one planning rule. Determine whether this statement is true or false. True FO RC X False ON LY X 126 © Copyright. All rights reserved. Lesson 1 Creating Schedules Exercise 14: Create a Carrier Schedule Exercise 15: Generate Departures Lesson 2 UNIT OBJECTIVES 128 133 139 143 US TO Analyzing the Results of the Path Finder R Advanced Transportation Network ME UNIT 3 Create carrier schedules ● Generate departures ● Use the Path Finder to analyze results ON LY FO RC ● © Copyright. All rights reserved. 127 Unit 3 Lesson 1 Creating Schedules ● Create carrier schedules ● Generate departures ON LY FO RC Carrier Schedules US TO LESSON OBJECTIVES After completing this lesson, you will be able to: ME R LESSON OVERVIEW In this lesson, you learn about carrier schedules, schedule types, and schedule capacities. You create a carrier schedule before you examine and generate departures. Figure 24: Sailing Schedule with Gateway (CFS) When shipping products via air or ocean, consider that your partners are typically renting space at a port facility. This facility is used by many parties, and so options for moving product may be limited. While the road-based scenario can make use of a variety of transportation lanes due to the flexibility of the carriers, ocean and air carriers often face more competition and more 128 © Copyright. All rights reserved. Lesson: Creating Schedules regulation. This limits the flexibility for departures and arrivals. From a transportation planning perspective, the implication is that you may need a more structured and predictable plan for scheduling purposes. With SAP Transportation Management (SAP TM), your organization can take advantage of different types of schedules to model specific departure and arrival rules suited to air and ocean shipping. Carrier Schedules for Actual Transportation ME R Carrier schedules represent the actual transportation executed by the schedule vehicle, be it by plane, vessel, train, or truck. Usually, these schedules involve stopping at locations such as ports and airports that are used commonly and shared by many different carriers. Flights for air transportation and vessel voyages for ocean are examples of carrier schedules. Carrier schedules can also be truck schedules. Location and time information are relevant to a schedule. For example, the planner asks the following questions: When and from where does the plane depart? ● When do you have to be there to board it? ● When will it arrive? ● Which carrier is responsible for the transportation? ● What can be transported? US TO ● RC Carrier schedules do not just have a start and end destination; they can have multiple stops, which is common for air transportation. Carrier schedules can be executed by different carriers on different stages using a connection schedule. It is possible to use a multi-stop carrier schedule in any sequential location combination, so it is not required to start at the first and leave at the last location. FO Schedules can be created manually in SAP TM and uploaded from an external source. You can also upload schedules from an external data source to SAP TM by calling function module /SCMTMS/BAPI_SCHEDULE_SAVEMULT. This function is available for the sea, air, and road transportation modes. Alternatively, you can upload schedules for the air transportation mode in a spreadsheet or CSV format to SAP TM by executing report / SCMTMS/SCH_UPLOAD. For more information, see the system documentation. ON LY You can delete schedules created manually and uploaded by calling function module / SCMTMS/BAPI_SCHEDULE_DELMULTI or by executing report /SCMTMS/SCH_DELETION. © Copyright. All rights reserved. 129 Unit 3: Advanced Transportation Network FO RC US TO ME R Schedule Types Figure 25: Overview of Schedules SAP TM allows businesses to create different schedule types to handle the multiple shipping scenarios they may encounter. Schedules can be maintained for each business partner or carrier, and can identify different loading and unloading points, such as ports and airports. If you have reappearing transportation traffic in your transportation network scenario, you can use the schedules functionality. A combination of transportation mode, gateway customer fact sheets (CFS), direct, and reference fields define the type of schedule. LY A gateway schedule includes two gateway locations. In ocean scenarios, the locations could be the CFS-locations. In air scenarios, they can be the gateway locations. Gateway Schedules: Subcategories The following are the subcategories in gateway schedules: Direct ON ● The schedule goes from A to B without changing the mode of transport. For example, GW Nurnberg to GW Hamburg via truck. ● Indirect The schedule goes from A to B but the mode of transport changes. For example, GW Hamburg to GW Cape Town via truck and ocean. Air and Ocean Scenarios: Subcategories The following are the subcategories in ocean and air scenarios: 130 © Copyright. All rights reserved. Lesson: Creating Schedules ● Sailing schedules with vessel information ● Master flight schedules with aircraft information Carrier schedules describe a sequence of transportation stops where the start location and the target stop are not gateways. A gateway is a transportation hub where freight is consolidated and deconsolidated. Carrier Schedules ● Ocean Carrier Schedule ● ME R Use the ocean carrier schedule to define a standard sequence of transportation stops that are served by a ship. By specifying departure rules, you can generate voyages automatically. Carrier Flight Schedule ● Road Schedule US TO Use the carrier flight schedule to define a standard sequence of transportation stops that are served by a plane. By specifying departure rules, you can generate flights automatically. Use the road schedule to define a standard sequence of transportation stops that are served by a truck. Schedule Capacities In the schedule type, you can define if the schedule should have the following items assigned to it: Limited capacities ● Transportation costs ON LY FO RC ● © Copyright. All rights reserved. 131 ON LY FO RC US TO ME R Unit 3: Advanced Transportation Network 132 © Copyright. All rights reserved. Unit 3 Exercise 14 Create a Carrier Schedule R Business Example ME ABC Corporation wants to implement SAP TM to support its planning scenarios. Sue, the SAP consultant, needs to create a carrier schedule to support this implementation. US TO Note: In this exercise, you create the carrier schedules that are required for one or more subsequent exercises in this course. 1. Create a new carrier schedule using schedule type 2000 for carrier CAR##-04 with shipping type 2. The schedule should be valid for the current month and the following two months. Maintain the following port sequence: Table 33: Port Sequence 10 20 30 Cargo CutOff (Days) Transit Dura- Days to tion (Days) Availability PORT-HMBG 1 1 PORT-RTDM 1 20 1 PORT-SHNG 1 20 1 PORT-NWRK FO 40 Location RC Sequence Availability Time 12:00 1 Table 34: Schedule Details Value Description Schedule for Group ## Valid from Beginning of current month Valid to The end of the month after next month Shipping Type 2 Carrier CAR##-04 ON LY Field 2. Record your schedule number. © Copyright. All rights reserved. 133 Unit 3: Advanced Transportation Network 3. What is the meaning of the value in the Cargo Cut-Off (offset in days) field? ON LY FO RC US TO ME R 4. What is the meaning of the value in the Days to Availability field? 134 © Copyright. All rights reserved. Unit 3 Solution 14 Create a Carrier Schedule R Business Example ME ABC Corporation wants to implement SAP TM to support its planning scenarios. Sue, the SAP consultant, needs to create a carrier schedule to support this implementation. US TO Note: In this exercise, you create the carrier schedules that are required for one or more subsequent exercises in this course. 1. Create a new carrier schedule using schedule type 2000 for carrier CAR##-04 with shipping type 2. The schedule should be valid for the current month and the following two months. Maintain the following port sequence: Table 33: Port Sequence 10 20 30 Cargo CutOff (Days) Transit Dura- Days to tion (Days) Availability PORT-HMBG 1 1 PORT-RTDM 1 20 1 PORT-SHNG 1 20 1 PORT-NWRK FO 40 Location RC Sequence Availability Time 12:00 1 Table 34: Schedule Details Value Description Schedule for Group ## Valid from Beginning of current month Valid to The end of the month after next month Shipping Type 2 Carrier CAR##-04 ON LY Field a) In NWBC, choose Master Data → Transportation Network → Schedule → Create Schedule. b) Enter 2000 in the Schedule Type field. © Copyright. All rights reserved. 135 Unit 3: Advanced Transportation Network c) Choose Continue. d) Enter the data in the Schedule Details table. e) In the Standard Port Sequence screen area, choose Create. f) Insert the data from the table for sequence 10. g) Choose Create and repeat step f for sequences 20, 30, and 40. h) Save your data. This varies. US TO 2. Record your schedule number. ME R Note: When you are creating new sequences, if the fields are not editable, choose Create to insert a new line. The fields in the previous line then become editable. 3. What is the meaning of the value in the Cargo Cut-Off (offset in days) field? This is the time that the cargo needs to arrive at the port prior to the departure of the vessel. FO RC 4. What is the meaning of the value in the Days to Availability field? ON LY This is the time that the cargo arrives after the vessel reaches the port. 136 © Copyright. All rights reserved. Lesson: Creating Schedules Departure Calendar By specifying departure rules in carrier schedules, you can generate voyages, flights, and departures automatically. The system calculates the arrival and departure dates and times at each transportation stop in the sequence, taking into account the transit duration, cut-off times, and availability of the goods for each stop. You can then modify each generated voyage individually. Transit duration ● Length of stay ● Cargo cut-off time ● Availability time ME ● R You can define the following durations and times for each stop: US TO You can generate concrete departures from your departure rule and adjust them individually for each departure if required. You can define departure rules at schedule or transportation stage level for carrier schedules and gateway schedules. You can also apply departure rules from a referenced carrier schedule to a gateway schedule. Automatic Calculation of Times RC In the Departure Rules screen area of your schedule, if you select the Auto Fill Times checkbox and specify particular times for various transportation stages, the system calculates the missing times for the various transportation stages of the departure rule automatically. It also takes the different time zones of each of the locations into account. FO In carrier schedules, for example, the system uses the arrival time at the destination location of the first transportation stage and the length of stay at the destination location of the first destination stage to calculate the departure time at the source location of the second transportation stage. Departures Possible Alterations to Departures (Voyages, Flights, Trips) The following alterations can be made to departures: Created ● Changed ● Deleted LY ● ON Changes to Each Departure Changes can be made to each departure in the following areas: ● The location sequence ● Dates and times © Copyright. All rights reserved. 137 ON LY FO RC US TO ME R Unit 3: Advanced Transportation Network 138 © Copyright. All rights reserved. Unit 3 Exercise 15 Generate Departures R Business Example ME ABC Corporation wants to implement SAP TM to support its planning scenarios. Sue, the SAP consultant, needs to generate departures to support this implementation. US TO Note: This exercise requires you to use the carrier schedules, that you created in the exercise “Create a Carrier Schedule”. 1. Create voyages from today until the end of the next month for the schedule that you created in the previous exercise. The vessels should leave PORT-HMBG on each Tuesday. Create a corresponding rule and generate voyages based on this rule. Use the information in the following table: Table 35: Voyage Details Value RC Field Start Date Today’s date End Date The end of next month FO 2. How many voyages are created? 3. In the third voyage, replace the stop at PORT-RTDM with a stop in PORT-DOVR. ON LY 4. In the fourth voyage, remove the stop in PORT-SHNG and change the transit duration from PORT-RTDM to PORT-NWRK to 12 days. © Copyright. All rights reserved. 139 Unit 3 Solution 15 Generate Departures R Business Example ME ABC Corporation wants to implement SAP TM to support its planning scenarios. Sue, the SAP consultant, needs to generate departures to support this implementation. US TO Note: This exercise requires you to use the carrier schedules, that you created in the exercise “Create a Carrier Schedule”. 1. Create voyages from today until the end of the next month for the schedule that you created in the previous exercise. The vessels should leave PORT-HMBG on each Tuesday. Create a corresponding rule and generate voyages based on this rule. Use the information in the following table: Table 35: Voyage Details Start Date End Date Value RC Field Today’s date The end of next month FO a) In NWBC, choose Master Data → Transportation Network → Overview Transportation Network. b) Choose All Schedules. c) Select the schedule that you created in the previous exercise. LY d) In the Voyages screen area, choose Create. e) In the row containing the PORT-HMBG to PORT-RTDM, select the checkbox for Tuesday. f) Select the row containing rule 1, PORT-HMBG to PORT-NWRK. ON g) Choose Generate Voyages → For Specific Time Period. h) In the dialog box, enter the data in the table provided. i) Choose Generate Voyages. j) Save your data. 140 © Copyright. All rights reserved. Lesson: Creating Schedules 2. How many voyages are created? This varies. a) In the Voyages screen area, in the Voyages tab, the required data is displayed. 3. In the third voyage, replace the stop at PORT-RTDM with a stop in PORT-DOVR. a) In the Voyages screen area, in the Voyages tab, select the third voyage. R b) Choose Edit. ME c) In the Actual Port Sequence screen area, replace PORT-RTDM with PORT-DOVR. d) Save your data. 4. In the fourth voyage, remove the stop in PORT-SHNG and change the transit duration from PORT-RTDM to PORT-NWRK to 12 days. b) Choose Edit. US TO a) In the Voyages screen area, in the Voyages tab, select the fourth voyage. c) Select the row to PORT-SHNG. d) Choose Delete. e) Change the transit duration from 20 to 12. ON LY FO RC f) Save your data. © Copyright. All rights reserved. 141 Unit 3: Advanced Transportation Network LESSON SUMMARY You should now be able to: Create carrier schedules ● Generate departures ON LY FO RC US TO ME R ● 142 © Copyright. All rights reserved. Unit 3 Lesson 2 Analyzing the Results of the Path Finder LESSON OBJECTIVES After completing this lesson, you will be able to: Use the Path Finder to analyze results US TO ● ME R LESSON OVERVIEW In this lesson, you examine transportation network complexity and consider the use and benefits of the path finder in transportation planning. Transportation Network Complexity Scenario building can be time consuming. Scenario validation, especially for transportation optimization, is even more time consuming. The planner needs to establish if all elements of the transportation network are maintained correctly to enable the optimizer to find a valid solution. RC You can use the path finder function to search for legs in your transportation network and take the following considerations into account during the process: Locations ● Transshipment locations ● Transportation lanes ● Schedules FO ● ● Transportation zones LY The path finder enables you to easily determine whether a connection exists between two locations and, therefore, whether you have correctly configured your master data. However, the path finder does not take incompatibilities into consideration. Path Finder Execution You can execute the path finder and check the result in either the transportation network cockpit or on the transportation proposals user interface. ON ● ● Transportation Network Cockpit When you open the context menu for a location in the transportation network cockpit, you can choose Find Path To Location and enter a destination in the displayed dialog box. The system then calculates all of the available connections in the transportation network and displays them on the map. The color of the connections indicates whether a valid transportation lane or schedule exists. Transportation Proposals © Copyright. All rights reserved. 143 Unit 3: Advanced Transportation Network When you call the user interface for transportation proposals, you can choose the appropriate button to show or hide the available connections on the map. As in the transportation network cockpit, the color of the connections indicates whether a valid transportation lane or schedule exists. ● Explanation Tool R When you select one or more freight units, you can choose Show Network Path to analyze the underlying transportation network that is taken into account when planning the selected freight units. Path Finder Report Source location - Destination location Options - Determine path - Determine connections Restrictions - Outbound, inbound, or implicit hub - Transportation mode - Means of transport FO RC ● - ME ● Requests US TO ● Path Finder Report: /SCMTMS/FIND_TN_PATH The required input for the tool is a start and a destination location. Using assigned transshipment locations and existing connections (transportation lanes, schedules, and booking), the path finder tries to find all paths. The result indicates if there is a valid connection or not (all existing are listed) for each stage of a path. It is thus easy to find out if you have assigned a transshipment location, but if it cannot be reached from your start location. LY The report has some limitations. For example, it is not possible to search within a certain timeframe and respect the validity of the connections. Also, transportation mode and meansof-transport filters are not available and incompatibilities are not considered. LESSON SUMMARY You should now be able to: Use the Path Finder to analyze results ON ● 144 © Copyright. All rights reserved. Unit 3 1. Carrier schedules can reference a corresponding schedule. X True X False ME Determine whether this statement is true or false. R Learning Assessment US TO 2. What is the minimum number of locations required to define a carrier schedule? X A 1 X B 2 X C 3 X D 4 RC Choose the correct answer. 3. The path finder can be used to visualize proposals. Determine whether this statement is true or false. True X False ON LY FO X © Copyright. All rights reserved. 145 Unit 3 1. Carrier schedules can reference a corresponding schedule. X True X False ME Determine whether this statement is true or false. R Learning Assessment - Answers Choose the correct answer. A 1 X B 2 X C 3 X D 4 FO RC X US TO 2. What is the minimum number of locations required to define a carrier schedule? 3. The path finder can be used to visualize proposals. Determine whether this statement is true or false. True X False ON LY X 146 © Copyright. All rights reserved. UNIT 4 Transportation Unit Planning Lesson 2 164 167 US TO Planning Transportation Units with Passive Vehicle Resources Exercise 17: Create Transportation Units 148 153 ME Creating Passive Vehicle Resources Exercise 16: Create Passive Vehicle Resources R Lesson 1 Lesson 3 Planning Transportation Units with the Optimizer Lesson 4 179 182 189 RC Planning Transportation with Container Units Exercise 18: Create Container Units FO UNIT OBJECTIVES Create passive vehicle resources ● Analyze transportation units ● Create transportation units LY ● Outline transportation unit planning ● Apply optimizer settings to passive vehicle resources ● Create container units ON ● © Copyright. All rights reserved. 147 Unit 4 Lesson 1 Creating Passive Vehicle Resources LESSON OBJECTIVES After completing this lesson, you will be able to: Create passive vehicle resources ● Analyze transportation units Means of Transport US TO ● ME R LESSON OVERVIEW In this lesson, you learn about passive vehicle resources and their creation in SAP Transportation Management (SAP TM). You then examine transportation units and learn how to analyze rail units. ON LY FO RC The figure, Transportation Resources: Mode of Transport and Means of Transport, provides information about the means of transport in SAP TM. Figure 26: Transportation Resources: Mode of Transport and Means of Transport 148 © Copyright. All rights reserved. Lesson: Creating Passive Vehicle Resources Transportation Resources ● ● ● Mode of Transport (MoT): For example, road or sea. Means of Transport (MTr): For example, railcar, truck, refrigerated truck, less than truckload (LTL), full truckload (FTL), barge, and vessel. Vehicles and resources: For example, maintenance of capacities and depot locations for individual vehicles. RC Figure 27: Vehicle Resources US TO ME R Passive Vehicle Resources Depending on the means of transport, a vehicle resource can be modeled with or without capacity and may be active or passive, as follows: ● Active FO The vehicle resource can move by itself. ● Passive The vehicle resource must be pulled by another resource. LY MTr combinations can be used to model truck and trailer combinations. Vehicle Types ON ● ● ● You can define your vehicle resources, such as railcars and trailers, as resources with the necessary details in the master data. Alternatively, you can also define a vehicle group and type for railcars and trailers that contains only general information about these vehicles. You can define a vehicle type and group in the freight unit building rule. This means that the rule can be used to create a container, railcar, or transportation unit depending on the equipment or vehicle group category. Vehicle Group and Vehicle Type The vehicle and vehicle group types specify attributes such as the physical properties of a certain kind of vehicle. When you have created a vehicle type you can do the following: © Copyright. All rights reserved. 149 Unit 4: Transportation Unit Planning ● ● Use the type as a template to create vehicle resources, copying the attributes of the type to the new resource. Request a special type of vehicle resource in a forwarding order or in a booking order. This is similar to the function already available for container groups and types. Parameters for Vehicle Resources You can define, among others, the following parameters for vehicle resources: Passive Means of Transport R ● ● Vehicle Combination ME You can define vehicle resources that cannot move by themselves. In Customizing, select the Passive Means of Transport checkbox for the means of transport that is assigned to the vehicle resource. You can combine means of transport to create vehicle combinations. LY FO RC US TO Means-of-Transport Combinations ON Figure 28: Compartments and Trailers A means of transport combination is an instance of a particular means of transport, or a group of identical instances of means of transport, that can provide transportation services. You use this business object to map the capacity and availability of vehicles that you want to use for transportation. MTr combinations have the following attributes: ● 150 They can be used to model a truck and trailer combination. © Copyright. All rights reserved. Lesson: Creating Passive Vehicle Resources ● ● ● You specify capacities (several units of measure (UoM)): Maximum capacities of the combination. Additional (freely definable) attributes can be used for compatibilities and incompatibilities, based on a customizable attribute definition (code + text). Coupling or uncoupling durations are defined per passive MTr. ON LY FO RC US TO ME R ● You can specify the number of the objects of each MTr within the combination. For example, one truck and two trailers. © Copyright. All rights reserved. 151 ON LY FO RC US TO ME R Unit 4: Transportation Unit Planning 152 © Copyright. All rights reserved. Unit 4 Exercise 16 Create Passive Vehicle Resources R Business Example ME ABC Corporation wants to implement SAP TM to support its planning scenarios. Sue, the SAP consultant, needs to create passive vehicle resources to support this implementation. ● TRAIL_## ● COMBI-## US TO Note: In this exercise, you create the following items that are required for one or more subsequent exercises in the course: 1. Create a means-of-transport TRAIL-## representing your trailers. It should be your own means-of-transport. Use the data from the following table: FO RC Table 36: Means of Transport Details Value Means-of-Transport TRAIL-## Description Trailer for Group ## Standard Code 031 Transportation Mode 01 – Road Resource Class Trailer Passive Select checkbox Your Own MTr Selection checkbox LY Field ON 2. Create a means-of-transport combination COMBI-## by allowing one trailer of means-oftransport TRAIL-## to be coupled to one means-of-transport FTL-99. Define the total capacity of the combination to be 65000 LB. Use the information in the following table: Table 37: Transport MTR Combination MTR Number COMBI-## FTL-99 1 COMBI-## TRAIL-## 1 © Copyright. All rights reserved. 153 Unit 4: Transportation Unit Planning Table 38: Order MU Capacity LB 65000 Table 39: Coupling Details R 3. Define the coupling and uncoupling duration for your trailer TRAIL-## so that it is 5 minutes each. Use the data in the following table: Coupling Duration Uncoupling Duration TRAIL-## 0:05 0:05 ME MTR US TO 4. Create a vehicle resource TRAIL-## representing your trailer. The trailer should have a 35000 LB capacity and be created in the time zone CST with depot location SP3100. Use the data from the following table: Table 40: Vehicle Resource Details Field Value Resource Class Means-of-Transport Location Trailer TRAIL-## SP3100 Time Zone RC CST Factory Calendar US Continuous Dimension Mass Capacity 35000 LB ON LY FO Unit 154 © Copyright. All rights reserved. Unit 4 Solution 16 Create Passive Vehicle Resources R Business Example ME ABC Corporation wants to implement SAP TM to support its planning scenarios. Sue, the SAP consultant, needs to create passive vehicle resources to support this implementation. ● TRAIL_## ● COMBI-## US TO Note: In this exercise, you create the following items that are required for one or more subsequent exercises in the course: 1. Create a means-of-transport TRAIL-## representing your trailers. It should be your own means-of-transport. Use the data from the following table: FO RC Table 36: Means of Transport Details Value Means-of-Transport TRAIL-## Description Trailer for Group ## Standard Code 031 Transportation Mode 01 – Road Resource Class Trailer Passive Select checkbox Your Own MTr Selection checkbox ON LY Field a) In Customizing for SAP TM, choose SAP Transportation Management → Transportation Management → Master Data → Resources → Define Means-ofTransport. b) Choose New Entries. c) Enter the data in the Means of Transport table. d) Choose Save and press Enter on your keyboard to continue through the warning. 2. Create a means-of-transport combination COMBI-## by allowing one trailer of means-oftransport TRAIL-## to be coupled to one means-of-transport FTL-99. Define the total capacity of the combination to be 65000 LB. Use the information in the following table: © Copyright. All rights reserved. 155 Unit 4: Transportation Unit Planning Table 37: Transport MTR Combination MTR Number COMBI-## FTL-99 1 COMBI-## TRAIL-## 1 Capacity LB 65000 ME MU R Table 38: Order b) Choose New Entries. US TO a) In Customizing for SAP TM, choose SAP Transportation Management → Transportation Management → Master Data → Resources → Define Means-ofTransport Combination. c) Enter the data in the Transport table. d) Select one of the rows and, from the navigation pane, choose Capacity. e) Choose New Entries. f) Enter the data in the Order table. FO RC g) Save your data. 3. Define the coupling and uncoupling duration for your trailer TRAIL-## so that it is 5 minutes each. Use the data in the following table: Table 39: Coupling Details MTR Coupling Duration Uncoupling Duration TRAIL-## 0:05 0:05 LY a) In Customizing for SAP TM, choose SAP Transportation Management → Transportation Management → Master Data → Resources → Define Coupling / Uncoupling Duration. b) Choose New Entries. c) Enter the data in the Coupling Details table. ON d) Save your data. 4. Create a vehicle resource TRAIL-## representing your trailer. The trailer should have a 35000 LB capacity and be created in the time zone CST with depot location SP3100. Use the data from the following table: Table 40: Vehicle Resource Details 156 Field Value Resource Class Trailer © Copyright. All rights reserved. Lesson: Creating Passive Vehicle Resources Value Means-of-Transport TRAIL-## Location SP3100 Time Zone CST Factory Calendar US Continuous Dimension Mass Capacity 35000 Unit LB ME R Field a) In NWBC, choose Master Data → Resources → Define Resources. b) Enter TRAIL-## in the Resources field. US TO c) Choose Create Resources. d) Enter the data provided in the table. ON LY FO RC e) Save your data. © Copyright. All rights reserved. 157 Unit 4: Transportation Unit Planning Transportation Units Table 41: Transportation Unit (TU) Freight Unit Transportation Unit Freight Order Represents demand + + - Default route to define stages + + - Provides capacity - + + Different quantities per stage - + + Cargo management - + Subcontracting - - ME R Feature + US TO + Using the transportation unit business document, you can depict transport requirements or capacity, for example: ● A trailer and its load ● The capacity of a railcar or several railcars that are transported together ● A container and its load RC You use the transportation unit to consolidate freight units. You can then plan the transportation unit as a unit for several transportation stages. That is, you can assign it to one or more freight orders. ON LY FO Within the transportation unit type, you configure the most important settings for the transportation unit. For example, you use the transportation unit category to indicate whether you want to create the transportation unit type for a trailer, a railcar, or a container. When you then create the related business document, such as a trailer unit, for example, the system offers you only the relevant transportation units. 158 © Copyright. All rights reserved. Lesson: Creating Passive Vehicle Resources US TO ME R Document Structure with Transportation Units Figure 29: Document Structure with Transportation Unit Document Structure with Transportation Units: An Explanation FO RC Table 42: Document Structure with Transportation Units: An Explanation The following table provides explanatory information about the figure, Document Structure with Transportation Units. Structure Trailer TU 1 ● Contains FU 1 and FU 2 ● Defines own stages Mover FO 1 ● Covers 1 TU stage Mover FO 2 ● Covers 2 TU stages ON LY Transportation Order © Copyright. All rights reserved. 159 Unit 4: Transportation Unit Planning Figure 30: Trailer Units US TO ME R Trailer Units TU is a new document or object in SAP TM. FO RC The planning features for tractor and trailer resources are in the Transportation Cockpit. The TU was introduced in SAP TM 9.0. A TU is a document that represents a trailer, such as a passive vehicle resource. The trailer document is used for certain logistical activities, such as a trailer swap scenario where the same physical trailer is used to transport goods with multiple tractors, or a scenario where the trailer is loaded first and then it is routed through a network of trailer exchange locations. The trailer document represents both of the following: A capacity that can be used to transport freight units A transportation demand that requires a freight order to be moved LY ● ● The Trailer Unit ON The logistical processing of transports with trailers comprises of trailer units. You require a trailer unit if a trailer is moved by more than one tractor. In the transportation unit type, you configure the most important settings for the trailer units. You cannot perform subcontracting for trailer units. Trailer units contain the following information: ● General Data (such as locations and dates) You can enter one-time locations at stage level. The system stores these new locations and adjusts stages in the document. It also adjusts the locations in the assigned execution documents. 160 © Copyright. All rights reserved. Lesson: Creating Passive Vehicle Resources ● Transportation Stages On the Stages tab, you can see the following information: Assignment of the trailer to one or more tractors - The route the trailer takes - Transportation stage types Freight Quantities and weights - Goods information - Dangerous goods information - Seal information - Information about foreign trade Overview US TO ● - ME On the Freight tab, you can see the following information: R ● - The Overview tab is an integrated view of the Stages and Freight tabs. It contains the following information: Assignment of the trailer to one or more tractors - The route the trailer takes - The maximum utilization as well as planned departure and arrival times RC - Trailer units also contain the following information: ● Execution information, such as, actual departure times. ● Document dependencies and predecessor and successor documents (document flow). Status information and blocking information. FO ● Rail Car Units A railcar unit makes up the logistic processing of transports with railcars. It describes the assignment of cargo to a railcar. ON LY A railcar unit can comprise of one or more railcars. If a customer orders a full carload and you have already defined the railcar items in the forwarding order, the system can create a railcar unit instead of a freight unit during freight unit building. The relevant item in the forwarding order must be a passive vehicle resource type and you must have entered a transportation unit in the freight unit building rule. If you have not already created the railcar items in the forwarding order, you can use the railcar unit as a consolidation document. This means that the freight unit is created based on a product item. You then assign this product freight unit to the railcar unit. Alternatively, you can assign the freight unit directly to a railcar that you have created in the rail freight order. A railcar unit must be assigned to a rail freight order before you can carry out the follow-on processes. You can assign the individual stages for the railcar unit to one or more rail freight orders. You cannot subcontract railcar units. The railcar unit is used only for logistical purposes and for the assignment of different subcontracting documents. © Copyright. All rights reserved. 161 Unit 4: Transportation Unit Planning Within the transportation unit type, you configure the most important settings for the railcar unit. Railcar units contain the same information as trailer units. The following points are variances: Source location and destination location (rail) - Number of railcars - Number of assigned rail freight orders Resources and Equipment R - - Position of a railcar in the train - Equipment group and type - Railcar details such as whether the railcar belongs to the shipper or the carrier Information about seals. The handling execution status and the cargo execution behave in the same way as for rail freight orders. ON LY FO RC - ME ● General Data US TO ● 162 © Copyright. All rights reserved. Lesson: Creating Passive Vehicle Resources LESSON SUMMARY You should now be able to: Create passive vehicle resources ● Analyze transportation units ON LY FO RC US TO ME R ● © Copyright. All rights reserved. 163 Unit 4 Lesson 2 R Planning Transportation Units with Passive Vehicle Resources US TO LESSON OBJECTIVES After completing this lesson, you will be able to: ME LESSON OVERVIEW In this lesson, you learn about the manual creation of transportation units. You practise creating a transportation unit with a passive vehicle resource, and then examine freight orders with transportation units. ● Create transportation units ● Outline transportation unit planning Manual Creation of Transportation Units Transportation Unit Creation Options for manual creation: - - ● FO RC ● In the transportation cockpit Via a separate transaction in freight order management Options for automatic creation: - - Via freight unit building rules Via the VSR optimizer Transportation units can be created via the following options: Manual creation in the transportation cockpit LY ● You create a trailer unit by assigning existing transportation stages (that is, freight units) to a trailer (document or resource). Manual creation on the user interface for creating trailer units ON ● You create the trailer unit and enter the items via Freight Order Management → Road → Trailer Unit → Create Trailer Unit. ● Automatic creation from a transportation requirement (OTR, DTR, FWO) If, instead of creating freight units, you want to create trailer units automatically from your forwarding order (FWO), enter a transportation unit type in the freight unit building rule. This function is also available for order-based requirements (OTR) and delivery-based transportation requirements (DTR). 164 © Copyright. All rights reserved. Lesson: Planning Transportation Units with Passive Vehicle Resources RC US TO ME R Transportation Unit Planning Figure 31: Transportation Unit Planning ON LY FO The figure, Transportation Unit Planning, examines transportation unit planning processes in SAP TM. © Copyright. All rights reserved. 165 ON LY FO RC US TO ME R Unit 4: Transportation Unit Planning 166 © Copyright. All rights reserved. Unit 4 Exercise 17 Create Transportation Units R Business Example ME ABC Corporation wants to implement SAP TM to support their planning scenarios. Sue, the SAP consultant, must create transportation units to support the implementation. US TO Note: This exercise requires you to use items, created in the exercise, Create Passive Vehicle Resources, as follows: ● TRAIL-## ● COMBI-## ● TM211_PLAN_## RC 1. Create a document type TU## for your trailer units by copying the existing trailer unit type TUKT. Deselect the Default Type checkbox. 2. Change the planning profile TM211_PLAN_## so that only vehicle resources MOVER-99 and TRAIL-## are selected (via capacity selection settings COMBI_##), and the default type TU## is chosen for trailer documents. Use the information in the following tables: FO Table 43: Planning Profile Value Profile COMBI_## Description Capacity Selection for Truck & Trailer ## LY Field ON Table 44: Planning Assignments Line Field Value 1 Attributes for Vehicle Resource Selection VEHICLERES_ID Sign Inclusive Option = Lower Limit MOVER-99 Attributes for Vehicle Resource Selection VEHICLERES_ID 2 © Copyright. All rights reserved. 167 Unit 4: Transportation Unit Planning Line Field Value Sign Inclusive Option = Lower Limit TRAIL-## Table 45: Forwarding Order Details Value Ordering Party SP3100 Shipper Consignee Movement Type Source Location Pick-up Date SP3100 CUST##-28 T2C SP3100 Tuesday of next week CUST##-28 FO RC Destination Location US TO Field ME R 3. Create a forwarding order using forwarding order type FWOX and movement type T2C. The forwarding order is from SP3100 (source location, shipper, ordering party) to CUST##-28 (destination location and consignee).The pick-up date is Tuesday of next week, and the delivery date is Friday of next week. Use the following data to add an item to the forwarding order: Delivery Date Friday of next week Table 46: Item Details Value Item 10 Item Type PRD Gross Weight 20000 Gross Weight UoM LB LY Field ON 4. Change your transportation cockpit layout LOAD_PLAN_LAYOUT_## so that requirements and resources are displayed at the top of the screen, transportation units and freight orders are in the middle of the screen, and the freight order details are at the bottom of the screen. Use the information in the following table to make the changes: Table 47: Cockpit Layout Details 168 Tab Position of Screen Area Width Requirements Area Top Left 50% Resources Area Top Right 50% Additional Changes © Copyright. All rights reserved. Lesson: Planning Transportation Units with Passive Vehicle Resources Width Additional Changes Transportation Units Middle Left Area 50% In the Content of Transportation Units Area table, in the Trailer Unit Hierarchy and Container Unit row, in the Display column, select the checkbox. Orders Area Middle Right 50% Order Details Area Bottom Left R Position of Screen Area In the Content of Orders Area table, in the Freight Orders/ Freight Bookings row, in the Display column, select the checkbox. US TO ME Tab 100% RC 5. Create a trailer document from SP3100 to CUST##-28 using vehicle resource TRAIL-##. Manually drag the freight unit created in the previous step to your trailer in the transportation cockpit. Use planning profile TM211_PLAN_## and selection Profile FU_SEL_3100_## and transportation cockpit layout LOAD_PLAN_LAYOUT_## to enter the transportation cockpit. Use the data in the following table: Table 48: Planning Profile Data Field Value FU_SEL_3100_## Selection Profile for Freight Orders FU_SEL_3100_## FO Selection Profile for Freight Units Planning Profile TM211_PLAN_## Transportation Cockpit Layout LOAD_PLAN_LAYOUT_## LY 6. Is a trailer document created? ON 7. Create a freight order by dragging the newly created trailer document to your vehicle resource MOVER-99. 8. Is a freight order created? Record the freight order number. © Copyright. All rights reserved. 169 Unit 4: Transportation Unit Planning ON LY FO RC US TO ME R 9. Is the trailer document changed? 170 © Copyright. All rights reserved. Unit 4 Solution 17 Create Transportation Units R Business Example ME ABC Corporation wants to implement SAP TM to support their planning scenarios. Sue, the SAP consultant, must create transportation units to support the implementation. US TO Note: This exercise requires you to use items, created in the exercise, Create Passive Vehicle Resources, as follows: ● TRAIL-## ● COMBI-## ● TM211_PLAN_## FO RC 1. Create a document type TU## for your trailer units by copying the existing trailer unit type TUKT. Deselect the Default Type checkbox. a) In Customizing for SAP TM , choose SAP Transportation Management → Transportation Management → Freight Order Management → Transportation Unit → Define Transportation Unit Types. b) Select the document type TUKT. c) Choose Copy As. d) Enter TU## in the Transportation Unit Type field. e) Deselect the Default Type checkbox. LY f) Press Enter on your keyboard, and choose Save. ON 2. Change the planning profile TM211_PLAN_## so that only vehicle resources MOVER-99 and TRAIL-## are selected (via capacity selection settings COMBI_##), and the default type TU## is chosen for trailer documents. Use the information in the following tables: Table 43: Planning Profile Field Value Profile COMBI_## Description Capacity Selection for Truck & Trailer ## © Copyright. All rights reserved. 171 Unit 4: Transportation Unit Planning Table 44: Planning Assignments Field Value 1 Attributes for Vehicle Resource Selection VEHICLERES_ID Sign Inclusive Option = Lower Limit MOVER-99 Attributes for Vehicle Resource Selection VEHICLERES_ID Sign ME 2 R Line Inclusive Option = Lower Limit US TO TRAIL-## a) In NWBC, choose Application Administration → Planning → Planning Profiles → Edit Planning Profiles. b) Enter TM211_PLAN_## in the Planning Profile field. c) Choose Continue. FO RC d) In the Planning Profile tab, in the Business Document Type screen area, enter TU## in the Default Type for Trailer Unit field. e) In the Planning Profile tab, in the Profile Assignments screen area, beside the Capacity Selection Settings field, choose Copy. f) In the Enter New Settings ID dialog box, enter the data in the Planning Profile table. g) Choose OK. h) Select the Capacity Selection Settings tab. i) Delete the existing lines by selecting each line and choosing Delete. j) Enter the data in the Planning Assignments table. LY k) Save your data. ON 3. Create a forwarding order using forwarding order type FWOX and movement type T2C. The forwarding order is from SP3100 (source location, shipper, ordering party) to CUST##-28 (destination location and consignee).The pick-up date is Tuesday of next week, and the delivery date is Friday of next week. Use the following data to add an item to the forwarding order: Table 45: Forwarding Order Details 172 Field Value Ordering Party SP3100 Shipper SP3100 © Copyright. All rights reserved. Lesson: Planning Transportation Units with Passive Vehicle Resources Value Consignee CUST##-28 Movement Type T2C Source Location SP3100 Pick-up Date Tuesday of next week Destination Location CUST##-28 Delivery Date Friday of next week Value Item 10 Item Type Gross Weight Gross Weight UoM US TO Field ME Table 46: Item Details R Field PRD 20000 LB a) In NWBC, choose Forwarding Order Management → Forwarding Order → Create Forwarding Order. RC b) In the Forwarding Order Type field, enter FWOX. c) Choose Continue. d) Enter the data in the Forwarding Order Details table. e) In the Items screen area, choose Insert → Product. FO f) Enter the values from the Item Details table. g) Save your data. LY 4. Change your transportation cockpit layout LOAD_PLAN_LAYOUT_## so that requirements and resources are displayed at the top of the screen, transportation units and freight orders are in the middle of the screen, and the freight order details are at the bottom of the screen. Use the information in the following table to make the changes: ON Table 47: Cockpit Layout Details Tab Position of Screen Area Width Requirements Area Top Left 50% Resources Area Top Right 50% © Copyright. All rights reserved. Additional Changes 173 Unit 4: Transportation Unit Planning Width Additional Changes Transportation Units Middle Left Area 50% In the Content of Transportation Units Area table, in the Trailer Unit Hierarchy and Container Unit row, in the Display column, select the checkbox. Orders Area Middle Right 50% In the Content of Orders Area table, in the Freight Orders/ Freight Bookings row, in the Display column, select the checkbox. Order Details Area Bottom Left R Position of Screen Area US TO ME Tab 100% a) In NWBC, choose Application Administration → Planning → General Settings → Page Layouts → Page Layouts for Transportation Cockpit. b) Select the page layout LOAD_PLAN_LAYOUT_##. FO RC c) In the bottom half of the screen, make the changes detailed in the Cockpit Layout Details table. d) Save your data. 5. Create a trailer document from SP3100 to CUST##-28 using vehicle resource TRAIL-##. Manually drag the freight unit created in the previous step to your trailer in the transportation cockpit. Use planning profile TM211_PLAN_## and selection Profile FU_SEL_3100_## and transportation cockpit layout LOAD_PLAN_LAYOUT_## to enter the transportation cockpit. Use the data in the following table: Table 48: Planning Profile Data LY Field Value FU_SEL_3100_## Selection Profile for Freight Orders FU_SEL_3100_## Planning Profile TM211_PLAN_## ON Selection Profile for Freight Units Transportation Cockpit Layout LOAD_PLAN_LAYOUT_## a) In NWBC, choose Planning → Planning → Transportation Cockpit. b) Choose New. c) Create a new profile using the data in the Planning Profile Data table. d) Save your data. 174 © Copyright. All rights reserved. Lesson: Planning Transportation Units with Passive Vehicle Resources e) Select the new line and choose Continue. f) Select the freight unit that is created based on the forwarding order. g) Select the Trailers tab in the resources screen area to display your trailer TRAIL-##. h) Drag the freight unit to the trailer TRAIL-## and drop the freight unit on the trailer TRAIL-##. i) A new trailer document appears in the Trailer Unit Hierarchy screen area. R You can identify it by the $ sign in front of the number. 6. Is a trailer document created? ME j) Save your data. Yes a trailer document is created. The number varies. US TO a) Select the Trailer Unit Hierarchy screen area to view the required information. 7. Create a freight order by dragging the newly created trailer document to your vehicle resource MOVER-99. a) Select the Trucks tab in the resources screen area to show your vehicle resource MOVER-99. b) Drag the trailer document to vehicle resource MOVER-99 and drop it onto the vehicle resource. RC c) Save your data. 8. Is a freight order created? Record the freight order number. FO Yes, a freight order is created. The number varies. a) The required data is visible in the Freight Orders /Freight Bookings screen area. 9. Is the trailer document changed? ON LY Yes. In addition to loading and unloading activities, the trailer document now includes coupling and uncoupling activities in the trailer hierarchy. © Copyright. All rights reserved. 175 Unit 4: Transportation Unit Planning Freight Orders with Transportation Units FO RC US TO ME R The figure, Freight Orders with Transportation Units, provides information about freight orders with transportation units in SAP TM. Figure 32: Freight Orders with Transportation Units Train Composition Rail freight orders make up the logistical processing of transports with trains. A rail freight order can model a train with one or more locomotives and one or more railcars. You can execute rail freight orders or award them as a subcontract. A rail freight order includes the following items: ● Locomotives (Vehicle Resources) LY If a train has several locomotives, you can model them using multi-items. During planning, the system considers only the main locomotive that you have specified at header level. The other locomotives are not taken into account during scheduling or when considering incompatibilities. ● Railcars (Passive Vehicle Resources) ON Railcar items can either result from the assigned railcar units or be created directly in the rail freight order. The latter is true in less complex scenarios. ● Cargo You assign cargo items to your railcars. Rail Freight Order Structure General Data ● 176 © Copyright. All rights reserved. Lesson: Planning Transportation Units with Passive Vehicle Resources - - Number of railcars. The actual number of railcars is displayed here. If you have agreed scale prices with your carrier, you can enter the number of railcars for the respective scale as the rating value once you have confirmed this with the carrier. The system then calculates the tariff based on this amount instead of the actual value. When doing so, it considers the calculation basis and rate table that you have defined. Indicates if there are multiple executing carriers Items - Position of a railcar in the train - Equipment group and type - Railcar details, such as whether the railcar belongs to the shipper or the carrier ME ● Source location and destination location (rail) R - ON LY FO RC US TO The Items tab page replaces the Cargo and Equipment tab pages. You can personalize your user interface so that the system displays the old tab pages. © Copyright. All rights reserved. 177 Unit 4: Transportation Unit Planning LESSON SUMMARY You should now be able to: Create transportation units ● Outline transportation unit planning ON LY FO RC US TO ME R ● 178 © Copyright. All rights reserved. Unit 4 Lesson 3 R Planning Transportation Units with the Optimizer ● US TO LESSON OBJECTIVES After completing this lesson, you will be able to: ME LESSON OVERVIEW This lesson examines the planning profiles and settings required to execute the optimizer in SAP Transportation Management (SAP TM). Apply optimizer settings to passive vehicle resources Planning Profiles Planning profiles are used to influence and control the outcome of the optimizer. A planning profile must be specified for an optimizer run and takes into account the various settings of the profile. These settings control different steps of the optimization process. There are several sub-profiles which must be created for use in the planning profile. RC There are a number of planning profile assignments, as follows: Selection profile for transportation units ● Selection profile for freight orders ● Selection profile for freight bookings FO ● Capacity selection settings ● Optimizer settings ● Load planning settings ● Planning cost settings ● Incompatibility settings ● Carrier selection settings LY ● ON Capacity Selection Settings ● Vehicle resources ● Container resources ● Schedules © Copyright. All rights reserved. 179 Unit 4: Transportation Unit Planning FO RC Figure 33: Incompatibility Settings US TO ME R Incompatibility Settings The figure, Incompatibility Settings, provides information about incompatibility settings in SAP TM. ON LY Automatic Planning Figure 34: Optimizer Constraints 180 © Copyright. All rights reserved. Lesson: Planning Transportation Units with the Optimizer The vehicle scheduling and routing (VSR) optimizer can create trailer documents as a result of considering all constraints. LESSON SUMMARY You should now be able to: Apply optimizer settings to passive vehicle resources ON LY FO RC US TO ME R ● © Copyright. All rights reserved. 181 Unit 4 Lesson 4 Planning Transportation with Container Units LESSON OBJECTIVES After completing this lesson, you will be able to: Create container units ON LY FO RC Equipment Types US TO ● ME R LESSON OVERVIEW In this lesson, you learn about freight unit creation using equipment types. You examine container consolidation and container unit planning in the transportation planning process. Figure 35: Equipment Types Equipment types are the most integral part of the entire shipping industry. These shipping containers store the various products that need to be shipped from one part of the world to another. 182 © Copyright. All rights reserved. Lesson: Planning Transportation with Container Units Depending on the type of products that are shipped or the special services needed for them, equipment types may vary in dimension, structure, materials, or construction. Various types of shipping containers are used to meet the diverse requirements of the cargo shipping world. The following are some of the most common types of shipping containers in use today: Dry storage containers ● Flat rack containers ● Open-top containers ● Tunnel containers ● Open-side containers ● Double-door containers ● Refrigerated containers ● Insulated and Thermal containers US TO ME R ● Resources and Equipment Types RC In SAP TM, a resource can be linked to a piece of equipment. Equipment types determine the type of truck or equipment that is requested to carry out the shipping. When your business requires specific types of containers or equipment, you can include this factor in your business process. With SAP TM, you can define equipment groups and specify different types of shipping containers. For example, in the air industry, the term Universal Loading Device is used to describe the type of container that is appropriate depending on the type of plane that is used. In the ocean and road industry, it is the type of container or trailer that is required based on the weight or dimension of the items being shipped. In SAP TM you can define equipment groups as well as equipment types. Within an equipment group, you define different types of equipment that have various limitations based on weight, volume, or temperature. FO Equipment groups are specific to a transportation mode. Depending on the assigned transportation mode, you can enter values for ocean-specific or land-specific containers, or for air-specific unit load devices (ULDs). Transportation Unit Resource LY An instance of a particular transportation unit, such as a container, you can use the transportation unit resource to map the capacity and availability that you want to use for transportation. ON You can choose up to eight dimensions and units of measurement to describe the capacity. Note that the mass and volume are predefined by default. Planning can only take the transportation unit resource capacity into account if these correspond to the dimensions and units of measurement that you define in a freight unit building rule. The equipment, and equipment group types, specify attributes such as the physical properties of a certain kind of transportation unit resource. By creating a transportation unit resource, you can do the following: ● ● Use the type as a template to create transportation unit resources, copying the attributes of the type to a new resource. Request a special type of transportation unit resource in a forwarding order or in a booking order. © Copyright. All rights reserved. 183 Unit 4: Transportation Unit Planning Transportation Unit Resource Master data object to represent individual containers ● Can be created with reference to equipment group type ● Parameters for transportation unit resource resources include the following: - Minimum number of seals - Physical properties - Downtimes - Grouping attributes - Alternative names Container Units ME Capacity US TO - R ● You can use equipment groups and types when creating forwarding orders or forwarding quotation items of the container category. Data that relates to the physical properties of the container is then available in the forwarding order and subsequent business documents for the planner. In addition, after you have entered the equipment group, the equipment type, and the number of containers in the forwarding order, the system calculates the tare weight and the capacity of the container in the twenty-foot equivalent unit (TEU), based on settings applied in Customizing. FO RC A container unit models the logistical handling of the transportation of one or several containers. Each of these containers can contain several freight units. A container unit must be assigned to a freight document before you can carry out the followon process. You assign the individual stages for the container unit to one or more freight documents. You cannot subcontract container units. The container unit is used only for logistical purposes and for the assignment of different subcontracting documents. Within the transportation unit type, you configure the most important settings for the container unit. Container units contain the same information as trailer units. Container Unit Attributes General Data - Source location and destination location - Number of containers - Number of assigned freight documents ON LY ● - ● ● 184 Information about whether container provisioning and return is required Freight and Container Details - Transportation unit resource - Equipment group and equipment type - Information about whether the container is owned by the shipper Equipment © Copyright. All rights reserved. Lesson: Planning Transportation with Container Units - Seal information - Document references Transportation Unit Creation Using Equipment Types R If a customer orders a full container and you have already defined the container items in the forwarding order, the system can create a container unit instead of a freight unit during freight unit building. The relevant item in the forwarding order must be of Passive Vehicle Resource type, and you must have entered a transportation unit in the freight unit building rule. LY FO RC US TO ME If you have not already created the container items in the forwarding order, you can use the container unit as a consolidation document. This means that a freight unit is created based on a product item. You must assign this product freight unit to a container unit. Alternatively, you can assign the freight unit directly to a container that you have created in the freight document. Figure 36: Transportation Unit Creation Using Equipment Types ON You can also use freight unit building rules to take into account equipment groups and equipment types as well as the physical properties of your equipment when creating transportation units (TUs). During freight unit building, the system consolidates the business document items into containers and displays them as transportation units. For these TUs, the system copies the physical properties as well as the equipment group that you defined in Customizing. SAP TM only considers equipment for the business document of Package and Product Item (schedule line) types. The system determines a freight unit building rule for these types of item, and you have specified in this freight unit building rule that the system is to copy the equipment from the business document item, an error message appears and the creation of the freight units or transportation units is cancelled. © Copyright. All rights reserved. 185 Unit 4: Transportation Unit Planning For example, You have forwarding order with the following two items: ● Item 10: Ten pallets at 10,000 kilograms each ● Item 20: Nine pallets at 9,000 kilograms each If you use the equipment type CNT_Example in the freight unit building rule, SAP TM creates the following item: Item 10: One container, CNT_EXAMPLE, gross weight: 22,000 kilograms, Tare weight: 3,000 kilograms R ● Incompatibilities for Container Units ● ● ● Container unit — Vehicle resource: A container unit is not allowed on a vehicle resource, for example, an equipment type is not allowed on a certain truck type. Container unit — Transshipment location: A container unit is not allowed to be routed via a transshipment location, for example, because of storage constraints. Container unit — Freight booking: A container unit containing hazardous goods cannot be booked on some freight bookings. Container unit — Schedule: A container unit containing hazardous goods cannot be booked on some schedules. FO RC ● Container unit — Container unit (vehicle level): Two container units are not allowed on the same level. US TO ● ME This item has two sub-items that correspond to the items of the forwarding order. Manual Planning of Container Units In the Transportation cockpit, you can plan and reassign container units by busing drag and drop. Alternatively, you can reassign by selecting the relevant rows and choosing Reassignment. Table 49: Manual Planning — Container Units Target (drop) Action CU stage FO (railcar unit, trailer unit) Assign CU stage to FO (railcar unit, trailer unit) and add missing locations of FO (railcar unit, trailer unit) Location in FO (railcar unit, trailer unit) Assign CU stage to FO (railcar unit, trailer unit) and add missing locations at position of drop location of FO (railcar unit, trailer unit) CU stage Compartment in FO Assign CU stage to compartment of FO and add missing location to FO CU stage FB Assign CU stage to FB and Add missing locations t CU LY Source (drag) ON CU stage 186 © Copyright. All rights reserved. Lesson: Planning Transportation with Container Units In the layout settings for the Transportation cockpit, you defined a layout for which you have selected the Reassignment checkbox on the Orders Area or Transportation Units Area tab pages. Alternatively, you can select the Reassignment checkbox on the Hierarchies Area tab page. You select the layout that you have defined in the layout settings for the Transportation cockpit. In the Freight Orders/Freight Bookings screen area, you choose Dual View. You can now execute your reassignment activities. In Customizing, make relevant settings to configure your standard layout for reassignment in the layout settings for the transportation cockpit. ● ● ME ● TUCNT for location-based reassignment of container units with the associated freight units TUCLD for location-based reassignment of container units with the associated freight documents TUCNS for reassignment of container units with the associated freight units based on the freight unit stage US TO ● R The following hierarchy types are predefined for use with container units: TUCSD for reassignment of container units with the associated freight documents based on the freight unit stage In addition, you can define your own hierarchy types. Container Triangulation FO RC Container triangulation can be used to save on transportation charges by combining a request for empty provisioning, and a request for empty return. For example, you have to organize the pickup and delivery of an empty container that is no longer required from a consignee, and organize the subsequent transportation of this empty container to the container yard. You have to organize the pickup of a second container of the same type from the container yard and the provisioning of this empty container to another customer. By combining both requests into one order, you have the first empty container transported directly to the second customer. ON LY Note: Triangulation is supported for container units and railcar units only. Triangulation is not supported for trailer units. © Copyright. All rights reserved. 187 Figure 37: Container Triangulation US TO ME R Unit 4: Transportation Unit Planning FO RC Triangulation and Transportation Units There are at least two transportation units, one for the empty provisioning and one for the empty return (movement category Empty Return and Empty Provisioning). The two transportation units must have the same equipment type. The transportation unit for the empty provisioning must be unplanned. LY You can combine a transportation unit for the empty provisioning (empty provisioning TU) and a transportation unit for the empty return (empty return TU) in a single transportation unit (triangulation transportation unit). From a technical point of view, the system keeps the empty return TU and deletes the empty provisioning TU. The new triangulation transportation unit (triangulation TU) now refers to two forwarding orders and is assigned the movement category Triangulation. As with any other transportation unit you can plan this transportation unit on a freight order. When you revoke triangulation, the system dissolves the triangulation TU into the two original transportation units. Triangulation is supported for unplanned transportation units only. ON To perform triangulation, select a container unit or a railcar unit in the personal object worklist for container units or railcar units, and choose Triangulation → Create Triangulation. If you have selected the option for a container unit or railcar unit for the provisioning, the system automatically proposes only container units or railcar units for the return, and vice versa. You can also perform triangulation by selecting two container units, or two railcar units, (one for the provisioning and one for the return), choose Triangulation → Create Triangulation. 188 © Copyright. All rights reserved. Unit 4 Exercise 18 Create Container Units R Business Example ME ABC Corporation wants to implement SAP TM to support their planning scenarios. Sue, the SAP consultant, must create a container unit and plan it on a truck transport. Item US TO Note: This exercise requires you to use the data, created in a previous exercise as follows: Created in the Exercise FU_SEL_3100_## Execute Optimization to Determine Means of Transport TM211_PLAN_## Create Transportation Units RC 1. Create a transportation unit resource CONTAINER-## for a 40ft container. Use equipment group CN and equipment type 42GP as a template. Use the information in the following table: Table 50: Transportation Unit Resource Details Field Value CN Equipment Type 42GP Time Zone CST Factory Calendar US LY FO Equipment Group 2. Assign one of your unplanned freight units to your container CONTAINER-## manually using drag & drop in the transportation cockpit to create a container unit. ON 3. Use the optimizer to assign the container unit to your vehicle resource FTL-##. 4. Examine the freight order created in the previous step. © Copyright. All rights reserved. 189 Unit 4 Solution 18 Create Container Units R Business Example ME ABC Corporation wants to implement SAP TM to support their planning scenarios. Sue, the SAP consultant, must create a container unit and plan it on a truck transport. Item FU_SEL_3100_## TM211_PLAN_## US TO Note: This exercise requires you to use the data, created in a previous exercise as follows: Created in the Exercise Execute Optimization to Determine Means of Transport Create Transportation Units FO RC 1. Create a transportation unit resource CONTAINER-## for a 40ft container. Use equipment group CN and equipment type 42GP as a template. Use the information in the following table: Table 50: Transportation Unit Resource Details Value Equipment Group CN Equipment Type 42GP Time Zone CST Factory Calendar US LY Field a) In NWBC, go to Master Data → Resources → Define Resources. ON b) In the Resource field, enter CONTAINER-##. c) Choose Create Resources. d) Open the Transportation Unit tab page. e) Enter the data in the table provided. f) Choose Copy Equipment/Type Data. g) Choose Save. 190 © Copyright. All rights reserved. Lesson: Planning Transportation with Container Units 2. Assign one of your unplanned freight units to your container CONTAINER-## manually using drag & drop in the transportation cockpit to create a container unit. a) In NWBC, go to Planning → Planning → Transportation Cockpit. b) Select the line with the selection profile for FU FU_SEL_3100_##, planning profile TM211_PLAN_##, and transportation cockpit layout LOAD_PLAN_LAYOUT_##. c) Choose Continue. R d) In the upper right screen area, open the Container tab page. e) Choose Insert. ME f) Enter CONTAINER-##, and choose Ok. g) Drag an unplanned freight unit from the freight units stages area, and drop it on your container CONTAINER-##. h) In the middle left screen area, open the Container Unit tab page. US TO i) To create the container unit, choose Save. 3. Use the optimizer to assign the container unit to your vehicle resource FTL-##. a) In the upper right screen area, open the Truck tab page. b) Choose Insert. c) Enter FLT-##, and choose OK. d) Select the line with FTL-## in the upper right screen area. RC e) Select the container unit created in the previous step in the middle left screen area. f) Choose Optimizer Planning → Selected Entries Only. g) Choose Accept. FO h) Choose Save. 4. Examine the freight order created in the previous step. a) In the middle left screen area, select the freight order created in the previous step. ON LY b) In the bottom screen area, on the Overview tab page, expand the freight order to see the freight units in the container and the container on the truck. © Copyright. All rights reserved. 191 Unit 4: Transportation Unit Planning LESSON SUMMARY You should now be able to: Create container units ON LY FO RC US TO ME R ● 192 © Copyright. All rights reserved. Unit 4 Learning Assessment R 1. Which of the following are the allowed transportation unit categories? A Container X B Railcar X C Trailer X D Vehicle resource US TO X ME Choose the correct answers. 2. How can you create transportation unit documents? Choose the correct answers. A Manually, using a separate transaction X B Automatically, using the VSR optimizer X C Via drag-and-drop in the transportation cockpit X D Via drag-and-drop in a freight unit worklist RC X FO 3. Is there any limitation related to the number of active and passive vehicle resources in a truck and trailer scenario? Choose the correct answer. A Active vehicle resources: Exactly one; Passive vehicle resources: No limit ON LY X X B Active vehicle resources: No limit; Passive vehicle resources: No limit X C Active vehicle resources: At least one; Passive vehicle resources: As specified in means-of-transport customizing X D Active vehicle resources: Exactly one; Passive vehicle resources: As specified in means-of-transport customizing © Copyright. All rights reserved. 193 Unit 4: Learning Assessment 4. Is there any limitation related to the number of active and passive vehicle resources in a rail scenario? Choose the correct answer. A Train: At least one; Railcars: No limit X B Train: No limit; Railcars: As specified in means-of-transport customizing X C Train: Exactly one; Railcars: No limit X D Train: At least one; Railcars: As specified in means-of-transport customizing ME R X 5. In which transportation modes can you use container units? A Rail X B Road X C Sea X D Air X E Pipeline ON LY FO RC X US TO Choose the correct answers. 194 © Copyright. All rights reserved. Unit 4 Learning Assessment - Answers R 1. Which of the following are the allowed transportation unit categories? A Container X B Railcar X C Trailer X D Vehicle resource US TO X ME Choose the correct answers. 2. How can you create transportation unit documents? Choose the correct answers. A Manually, using a separate transaction X B Automatically, using the VSR optimizer X C Via drag-and-drop in the transportation cockpit X D Via drag-and-drop in a freight unit worklist FO RC X 3. Is there any limitation related to the number of active and passive vehicle resources in a truck and trailer scenario? Choose the correct answer. A Active vehicle resources: Exactly one; Passive vehicle resources: No limit X B Active vehicle resources: No limit; Passive vehicle resources: No limit X C Active vehicle resources: At least one; Passive vehicle resources: As specified in means-of-transport customizing X D Active vehicle resources: Exactly one; Passive vehicle resources: As specified in means-of-transport customizing ON LY X © Copyright. All rights reserved. 195 Unit 4: Learning Assessment - Answers 4. Is there any limitation related to the number of active and passive vehicle resources in a rail scenario? Choose the correct answer. A Train: At least one; Railcars: No limit X B Train: No limit; Railcars: As specified in means-of-transport customizing X C Train: Exactly one; Railcars: No limit X D Train: At least one; Railcars: As specified in means-of-transport customizing ME R X 5. In which transportation modes can you use container units? A Rail X B Road X C Sea X D Air X E Pipeline ON LY FO RC X US TO Choose the correct answers. 196 © Copyright. All rights reserved. UNIT 5 Carrier Selection Lesson 2 211 217 US TO Selecting Carriers Based on Costs and Priorities Exercise 20: Configure Carrier Selection 198 205 ME Explaining the Carrier Selection Process Exercise 19: Execute Carrier Selection R Lesson 1 Lesson 3 Using Allocations Exercise 21: Perform Carrier Selection based on Transportation Allocations Lesson 4 223 229 236 241 RC Using Business Shares Exercise 22: Perform Carrier Selection Based on Business Shares Lesson 5 247 FO Improving Carrier Utilization LY UNIT OBJECTIVES Execute carrier selection ● Define carrier costs ● Configure carrier selection ON ● ● Consider allocations ● Perform carrier selection based on business shares ● Explain continuous moves © Copyright. All rights reserved. 197 Unit 5 Lesson 1 LESSON OBJECTIVES After completing this lesson, you will be able to: Execute carrier selection ON LY FO RC Carrier Selection Process US TO ● ME LESSON OVERVIEW In this lesson, you will execute carrier selection. R Explaining the Carrier Selection Process Figure 38: Document Flow – Subcontracting Carrier selection is used to determine the right combination of carrier and carrier assignments based on cost, incompatibilities, priority, and business share goals. With carrier selection, you can assign a suitable carrier to freight orders or freight bookings manually or automatically. Carrier Selection can be started from the following: 198 © Copyright. All rights reserved. Lesson: Explaining the Carrier Selection Process ● Freight order or freight booking UI ● Transportation Cockpit (FOR/FB List) ● Running freight optimization report /SCMTMS/BACKGRD_PLN ● Running carrier selection report /SCMTMS/VSR_OPT_BGD in batch or online mode US TO ME R Ultimately, the carrier is assigned to the freight order. RC Figure 39: Carrier Selection Process Flow Once a freight order has been built, a shipper will need to choose (and communicate with) the business partner responsible for moving the product. We will refer to this as carrier selection. FO Carrier selection is used to assign a suitable carrier to your subcontractable business documents (for example, freight orders), either manually or automatically. The aim is to find a carrier with the lowest costs under consideration of the defined constraints. ON LY In manual carrier selection, you manually assign the required carrier to your business documents. If you have configured a check against transportation allocations, the system takes this into account and checks transportation capacities (transportation allocations) that you have defined for the individual carriers. If, during the allocation, the system finds relevant transportation allocations without capacity or that certain rules are violated by the allocation, warning messages appear. A separate optimization is available for automatic carrier selection. It takes selected optimization options into account when determining the most cost-effective carrier for all business documents that you have selected. If none of the carriers are available, the system does not assign any carrier to the relevant business documents. © Copyright. All rights reserved. 199 Figure 40: Carrier Availability US TO ME R Unit 5: Carrier Selection Based on the carrier availability, the lanes are maintained in SAP Transport Management (SAP TM) specific to means of transport. FO RC A carrier can be available for a lane, but may be incompatible for a specific customer who could exist on that lane. Similarly, a carrier can be incompatible with the order characteristics if, for example, an order contains hazardous items but the carrier does not have any experience in handling such items. A carrier may be maintained on a lane, but could have met the allocation requirements for the period and, for this reason, is not considered during carrier selection. The allocation requirements can be specific to a means of transport or zone hierarchy. Carrier availability can also be influenced by the purchasing organization the carrier is associated with in the freight agreement. Thus, the carrier may be available only for a specific purchasing organization within a company. This is based on the purchase organization definition in SAP TM, as defined by the individual client requirement. LY You can define different carriers on an inbound or outbound lane. Every lane has a validity period, and the lane-level validity applies to the carriers associated with that lane, which is specific to the means of transport. A carrier availability can be turned on and off for a specific lane by updating the validity. Carrier Selection Strategies ON Strategy Options During planning in SAP TM, strategies are defined which are optimization options for carrier selection. The system takes these strategies into account during the automatic carrier selection process. You define strategies either in the transportation lane or in carrier selection settings. Initially, the system considers the appropriate transportation lane for each freight order. This allows it to consider different settings in one run. Taking strategies and settings into consideration, the optimizer then creates a carrier ranking list containing the different carrier options. The strategy options supported are as follows: 200 © Copyright. All rights reserved. Lesson: Explaining the Carrier Selection Process Cost and Priority ● Business Share ● Transportation Allocation ● Continuous Move US TO ME R ● Figure 41: Carrier Selection Strategies As well as manually assigning a carrier to a freight order, you can also use automatic carrier selection and influence it by different strategies and settings, as follows: RC Cost and Priority - the cost from either transportation charge management or planning costs can be used to determine the carrier. The best carrier can be based on the following: - Cost * Priority - Cost + Priority - Priority if no cost is to be used FO ● - ● Business shares – if a fixed percentage of freight business is to be allocated to a certain carrier, then the business shares can be used. Transportation Allocation – if there is either a minimum or a maximum restriction that regulates how much business you are doing with a certain carrier in a certain region for a certain means of transport. LY ● Cost only ON ● Continuous Moves – combine freight documents for subcontracting to achieve lower rates. Carrier Selection Strategies The following strategies can be used for carrier selection: ● Cost: All carriers that meet the criteria (based on valid lane, incompatibilities, business share, and allocation) are selected and ranked in ascending order of the total cost calculated based on TCM (freight agreement, calculation sheet, rate table/scale required for the O/D pair, means of transport combination). Internal cost is maintained on the lane © Copyright. All rights reserved. 201 Unit 5: Carrier Selection or on the planning profile. Alternatively, the system can also be set up to assign the lowest cost carrier to the FOR based on the settings in the carrier selection profile. ● R Cost + priority: The carriers are ranked in ascending order of their TCM/lane cost and the priority assigned on the lane. The lowest-cost carrier is selected for automatic assignment. However, for tendering, all the carriers in the ranking list are relevant (peer-to-peer/ broadcast) based on the specific flag maintained at carrier level in the lane. ME ● Priority: The business decides the preferred carriers for specific lanes and assigns a priority ranking to each carrier per lane. Based on the lane settings or carrier selection profile settings, the carriers that meet the criteria mentioned are selected and ranked in descending order of their lane priorities. The highest-priority ranking (for example, 1 to 10, with 1 being the highest priority) is picked up as the number 1 carrier in the ranking list. The priority 1 carrier can then be assigned directly to the FOR based on the carrier selection settings. Cost * priority: The carriers are ranked in ascending order of their TCM/lane cost * the priority assigned on the lane. The lowest-cost carrier is selected for automatic assignment. However, for tendering, all the carriers in the ranking list are relevant (peer-to-peer/ broadcast), based on the specific flag maintained at the carrier level in the lane. Carrier Selection Ranking US TO ● ON LY FO RC When using automatic carrier selection, the system will create a carrier ranking list of the relevant carriers for a particular freight order or freight booking. For each relevant carrier, users can see a variety of information that influenced the selection process. This could include the means of transport cost, delivery performance ratings, and others. After automatic carrier selection has been performed, the ranking list will be visible in the freight order. Figure 42: Carrier Ranking List 202 © Copyright. All rights reserved. Lesson: Explaining the Carrier Selection Process US TO ME R Carrier Selection Result Figure 43: Carrier Selection Result (Ranking List) ON LY FO RC Based on the settings maintained earlier, when we perform carrier selection, the system determines the least costly carriers and ranks them from lowest to highest cost, or from lowest to highest priority. This ranking is then considered for tendering. It can, however, be manually switched in the freight order. Additions and deletions are also possible. © Copyright. All rights reserved. 203 ON LY FO RC US TO ME R Unit 5: Carrier Selection 204 © Copyright. All rights reserved. Unit 5 Exercise 19 Execute Carrier Selection R Business Example ME You want to set up SAP TM so that carriers are selected automatically for a certain lane, based on cost and priorities. The costs will be calculated using transportation charge management. Note that, in this exercise, when the values include ##, replace the characters with the number assigned to you by your instructor. US TO Create a Sales Order In this task, you will create a sales order, which will later be planned using optimizer. 1. In SAP ERP, create a sales order using the following data: Field Value Order Type Sales Organization Division 3000 10 RC Distribution Channel ZT00 00 TM_CUST_00 PO Number TM300-GRP##-1.1 Material PRODTM-00 Order Quantity 300 FO Sold-To Party LY Plan OTR and Verify Carrier Selection In this task, you plan the OTR and verify that the selected carrier in the freight order is the one with the lowest price based on the cost * priority strategy. ON 1. Plan the OTR with the vehicle resource C_00_TRUCK_01, using the following profiles: Field Value Planning Profile GRP##_CARRIER_SELECTION Selection Profile (FOs) GRP##_NA_FO_SEL_PROF Transportation Cockpit Layout Standard Layout Layout for Planning Results Screen Standard Layout Description Carrier Selection COST AND PRIORITY © Copyright. All rights reserved. 205 Unit 5: Carrier Selection ON LY FO RC US TO ME R 2. Open the freight order and calculate the charges. Verify that the charges are the same as the proposed amount. 206 © Copyright. All rights reserved. Unit 5 Solution 19 Execute Carrier Selection R Business Example ME You want to set up SAP TM so that carriers are selected automatically for a certain lane, based on cost and priorities. The costs will be calculated using transportation charge management. Note that, in this exercise, when the values include ##, replace the characters with the number assigned to you by your instructor. US TO Create a Sales Order In this task, you will create a sales order, which will later be planned using optimizer. 1. In SAP ERP, create a sales order using the following data: Field Value Order Type Sales Organization Division 3000 10 RC Distribution Channel ZT00 00 TM_CUST_00 PO Number TM300-GRP##-1.1 Material PRODTM-00 Order Quantity 300 FO Sold-To Party LY a) In SAP ERP, on the Easy Access screen, in the Command field, enter transaction code VA01 and press Enter. ON b) In the Create Sales Order: Initial Screen, enter the following data: Field Value Order Type ZT00 Sales Organization 3000 Distribution Channel 10 Division 00 c) Choose Enter. © Copyright. All rights reserved. 207 Unit 5: Carrier Selection d) On the Create TM100 Standard Order: Overview screen, enter the following information: Field Value Sold-To Party TM_CUST_00 PO Number TM300-GRP##-1.1 Value Material PRODTM-00 Order Quantity 300 f) Choose Save and note the sales order number. ME Field R e) In the All items table, enter the following information: US TO Plan OTR and Verify Carrier Selection In this task, you plan the OTR and verify that the selected carrier in the freight order is the one with the lowest price based on the cost * priority strategy. 1. Plan the OTR with the vehicle resource C_00_TRUCK_01, using the following profiles: Field Planning Profile Selection Profile (FOs) Value GRP##_CARRIER_SELECTION GRP##_NA_FO_SEL_PROF Standard Layout Layout for Planning Results Screen Standard Layout Description Carrier Selection COST AND PRIORITY FO RC Transportation Cockpit Layout a) In SAP TM, in the NetWeaver Business Client, choose ERP Logistics Integration → Overview Transportation Requirements. LY b) Select the OTR based on the sales order that you created in the task Create a Sales Order. c) Choose Start Transportation Cockpit. d) On the Transportation Cockpit: Profile and Layout Sets screen, check for a row with the same profiles and layout settings as in the table. If it exists already, skip to step (h). ON e) If the profile row does not yet exist as shown in the table, choose New. f) Enter the data provided in the table. g) Choose Save. h) Select the row corresponding to the entries in the table and choose Continue. i) In the Freight Unit screen area, select the freight unit. 208 © Copyright. All rights reserved. Lesson: Explaining the Carrier Selection Process j) In the Vehicles screen area, select the vehicle resource C_00_TRUCK_01. k) With both the freight unit and the vehicle resource selected, choose Optimizer Planning → Selected Entries Only. l) On the Freight Orders/Freight Bookings screen area, select the freight order that has just been created. R m) On the Freight Orders/Freight Bookings screen area, on top right, choose Maximize. Scroll to the right and review the carrier assignment as a result of carrier selection, which was executed as part of optimizer planning. On top right, choose Restore. ME n) On the Carrier Ranking tab, select the carrier with the lowest amount. It will be at the top of the list. Verify that this is the carrier that was assigned to the freight order automatically. p) Choose Accept. q) Choose Save. US TO o) Verify that no charges were calculated for two carriers, and that these carriers have been ranked at the end of the list. 2. Open the freight order and calculate the charges. Verify that the charges are the same as the proposed amount. a) In the Transportation Cockpit, in the Freight Order/Freight Booking screen area, open the freight order. RC b) On the General Data tab, verify that the Carrier field displays carrier selected in the previous step. c) Open the Statuses tab, and verify that the Subcontracting Status is Carrier Assigned. d) Open the Subcontracting tab. FO e) On the Subcontracting tab, open the Carrier Ranking tab. f) Note the amount for the carrier. g) Open the Charges tab and choose Edit. h) Choose Charges/Settlement → Calculate Charges. LY i) Note the charges in the Final Amount column. It should be the same as the amount proposed by the carrier selection strategy. ON j) Choose Save. k) Close the freight order window. l) Close the Transportation Cockpit window. © Copyright. All rights reserved. Note: During the next demonstrations and exercises, we will look at the settings that led to this result. 209 Unit 5: Carrier Selection LESSON SUMMARY You should now be able to: Execute carrier selection ON LY FO RC US TO ME R ● 210 © Copyright. All rights reserved. Unit 5 Lesson 2 R Selecting Carriers Based on Costs and Priorities LESSON OBJECTIVES After completing this lesson, you will be able to: Define carrier costs ● Configure carrier selection US TO ● ME LESSON OVERVIEW In this lesson, you will define carrier costs and configure carrier selection. ON LY FO RC Prerequisites for Carrier Selection Figure 44: Influences To Carrier Selection There are a number of factors that influence carrier selection, including the following: ● Master data ● Planning Profile ● Lane settings ● Incompatibilities © Copyright. All rights reserved. 211 Unit 5: Carrier Selection Master data ● ● ● Define available carriers in the transportation lane Create allocation or business shares data if they are to be used during carrier selection Carriers either CIFed from SAP ERP or created in SAP TM R Note: Only CIFed carriers can be used for settlement of cost back to SAP ERP ME Planning Profile Selection profile for carrier selection defining how the freight orders will be selected ● Planning Strategy setting ● Carrier Selection settings Lane Settings ● ● US TO ● The lane settings identifies if cost will be considered, and if so, the origin of the costs. It can also specify the settings for business shares and allocation. If costs and priority will be used, the priority assigned to carriers can be specified here as well FO RC Incompatibilities ● You can create incompatibilities such as carrier with product groups or carrier with vehicles, and so on. Carrier Selection Master Data The following master data is required before performing carrier selection: ● The prerequisite to lane creation is the setup of locations and zones, which can be manually created in SAP TM, or created when the shipping points customers, and vendor are CIFed from SAP ERP to SAP TM. LY ● Transportation lane has to be set up between two zones or location pairs, specific to a means of transport. The validity period is defined per lane, and carriers are assigned to the lane created. The carrier is CIFed from SAP ERP or can also be locally maintained in TM, depending on the scenario. ON ● Costs and Priorities in Carrier Selection In carrying out carrier selection, the system can put more weight on priorities or costs. In terms of priority, the system can determine the most favorable carrier based on the priorities you have defined. In effect, this means that the system chooses the carrier with the highest priority, while taking into account the various restrictions that may be in place. Alternatively, the system can determine the carrier on the basis of lowest total cost. Costs in this case can refer to internal costs or to charges calculated in charge management (we will look at this option in a separate lesson). 212 © Copyright. All rights reserved. Lesson: Selecting Carriers Based on Costs and Priorities Internal Costs Internal costs draw on transportation costs and carrier costs as defined for your carriers. For example, you may have defined a transportation cost per business document (freight order, for example), or you could have defined a transportation cost per unit of weight or volume. Carrier costs are typically defined per unit of distance (kilometers or miles). You define internal costs in the transportation lane or in the carrier profile. FO RC US TO Settings - Transportation Lane ME R Note: When we speak of internal costs here, we are not speaking of real world costs. Internal costs are used for weighting only, as part of the carrier selection process. LY Figure 45: Settings - Transportation Lane To carry out carrier selection based upon cost and priority, you must maintain the appropriate setting on the lane as follows: ON ● Strategy must have Relevance to Carrier Selection selected ● In the Priority/Costs field, specify the cost or priority setting ● Define Cost Origin Note: For distance-based lane rating, if the fixed flag is maintained on the lane, the distance is picked up from the lane. Otherwise, the distance will be recalculated during optimization. © Copyright. All rights reserved. 213 Unit 5: Carrier Selection US TO ME R Settings - Lane / Means of Transport FO RC Figure 46: Settings - Lane / Means of Transport On the transportation lane, for each carrier you can maintain internal costs in case the cost origin is set to internal cost. If priorities are used as part of the strategy, a priority per carrier can be maintained here as well You have to maintain the tendering type relevance for a specific carrier at transportation line level. Thus if the carrier is relevant to peer-to-peer tendering for the lane SP3100 - > USCUST-01, the peer-to-peer flag must be checked and the required priority maintained in the lane. A similar setup is required for broadcast. LY To Define Carrier Costs 1. In NWBC, choose the Master Data folder and then choose Transportation Network → Transportation Lanes → Define Transportation Lane. ON 2. Under Transp. Lane Maintenance, enter transportation lane values in the following fields according to your requirements: ● Start Location/Zone ● Dest. Loc./Zone 3. Choose Change. 4. Note that carriers are assigned to a specific means of transport (MTr), and each carrier can have a different cost per KM or mile. 214 © Copyright. All rights reserved. Lesson: Selecting Carriers Based on Costs and Priorities 5. Display details for a means of transport by double-clicking the means of transport in the MTr column. 6. Note the carriers assigned to this MTr in the bottom left screen area. 7. Note the Unit column and that carrier costs can be defined per kilometer or mile unit. 8. Define the costs appropriately in the adjacent Carrier Costs column. ME FO RC US TO Carrier Selection Settings R 9. Transportation costs can also be defined, and may use other units such as weight or volume. Figure 47: SAP TM Carrier Selection - Settings / Planning Profile ON LY Carrier selection settings are included in optimization. Although some of the same settings are available in the carrier settings on the transportation lane, these settings override settings maintained directly on the lane. The settings in this profile are based on strategies such as lowest cost, business share, and priority. It considers continuous move options and equipment allocations and can tender automatically based on the tendering strategy. The profile also contains more enhanced settings, such as the ability to automatically perform carrier selection after vehicle scheduling and routing. In the direct shipment options (DSO), carrier selection can be enabled at time of freight unit building by using the carrier selection settings (additional setup is required to enable the DSO functionality). The profile also allows carrier selection in the freight order, which then uses this information for tendering. Critical Carrier Selection Settings ● Incompatibilities between order and carrier, or customer and carrier, can also be maintained in the carrier selection settings. © Copyright. All rights reserved. 215 Unit 5: Carrier Selection ● ● The system can be set up to use allocations, business share, and strategy for carrier selection and for the determination of cost origin in two different ways: maintained on the lane or maintained in the carrier selection settings. The carrier selection settings have priority over the settings maintained on the lane. You can also define if you want to stop at carrier ranking or continue with tendering. If so, the system will prompt you to maintain the tendering manager and tendering profile. The tendering profile contains the tendering type (peer-to-peer or broadcast). ● ● ME ● Maintain incompatibilities and associate these to the carrier selection settings. These incompatibilities could be order versus carrier, or customer versus carrier incompatibility. Transportation charge interpretation tells the system what to do when no charges are found for a carrier. Action after carrier selection alerts the system for the next action, based on the list above. If automatic tendering is selected, you need to maintain the tendering manager and the tender profile. US TO ● R Other Carrier Selection Settings Manual assignments can be considered final, or can be changed based on the settings maintained in the Advanced Settings tab. To Create Carrier Selection Settings FO RC 1. In NWBC, choose the Application Administration folder and then choose Planning → Planning Profile Settings → Carrier Selection Settings → Create Carrier Selection Settings. 2. Make your settings as required under General Data, Other Settings, and Advanced Settings. Required fields are marked with a red asterisk. Depending on your requirements, the most important fields are typically as follows: Incompatibility Settings ● Allocation Usage ● BS Usage (Business Share) ● Strategy LY ● Carrier Cost Origin ON ● 216 Note: The settings maintained here take precedence over those maintained for a transportation lane. For example, settings in relation to strategy and carrier cost origin can be made for both carrier selection settings and transportation lane settings, but those made here have priority. © Copyright. All rights reserved. Unit 5 Exercise 20 Configure Carrier Selection R Business Example ME You want to set up SAP TM so that carriers are selected automatically for a certain lane, based on cost and priorities. The costs will be calculated using transportation charge management. Note that, in this exercise, when the values include ##, replace the characters with the number assigned to you by your instructor. US TO Prepare Master Data for Carrier Selection Based on Cost and Priority In this task, you verify the carrier selection related settings for a transportation lane. The lane must be relevant for carrier selection with the appropriate cost origin and strategy defined. 1. Verify the carrier selection settings in the transportation lane and means of transport using the following data: Field Value Start Location/Zone SP3100 CTM_96161 Means of Transport TM_FB45 Relevant to Carrier Selection Selected Priority/Costs Costs * Priority Cost Origin Costs calculated by component TCM FO RC Destination Location/Zone 2. Verify the priority of the carriers assigned to the Means of Transport TM_FB45 as follows: Means of Trans- Start date port End data Priority CARR-00-01 TM_FB45 01.01.2013 31.12.9999 1 CARR-00-02 TM_FB45 01.01.2013 31.12.9999 2 CARR-00-03 TM_FB45 01.01.2013 31.12.9999 3 CARR-00-04 TM_FB45 01.01.2013 31.12.9999 9 ON LY Business Partner Configure Planning Profiles In this task, you will verify the planning profile, and its subordinate profiles, with settings relevant for carrier selection using Cost * Priority. 1. Display planning profile GRP##_CARRIER_SELECTION. 2. Verify the following optimizer settings: © Copyright. All rights reserved. 217 Unit 5: Carrier Selection Field Value Planning Strategy VSR_1Step Planning Strategy for Transp. Prop. VSR_1Step ME R 3. Explain how the planning strategy VSR_1STEP affects carrier selection. 4. Verify that the carrier selection settings match the following data: Value Check Incompatibilities Selected Incompatibility Settings C_NA_INCOMPAT_CARR_CUST_INCOMPAT Strategy Carrier Cost Origin Planning Strategy Optimizer Runtime Costs*Priority Use Transportation Charges from TCM TSPS_DEF 10 Keep FO RC Action for Manual Ranking US TO Field Accept Carrier with Charges of Zero as C. with Highest Costs Common Currency USD Action After Carrier Selection Run Assign Best Carrier Continuous Move Do Not Create Continuous Move Continuous Move Information Selected ON LY Transportation Charge Interpretation 218 © Copyright. All rights reserved. Unit 5 Solution 20 Configure Carrier Selection R Business Example ME You want to set up SAP TM so that carriers are selected automatically for a certain lane, based on cost and priorities. The costs will be calculated using transportation charge management. Note that, in this exercise, when the values include ##, replace the characters with the number assigned to you by your instructor. US TO Prepare Master Data for Carrier Selection Based on Cost and Priority In this task, you verify the carrier selection related settings for a transportation lane. The lane must be relevant for carrier selection with the appropriate cost origin and strategy defined. 1. Verify the carrier selection settings in the transportation lane and means of transport using the following data: Field Value Start Location/Zone SP3100 CTM_96161 Means of Transport TM_FB45 Relevant to Carrier Selection Selected Priority/Costs Costs * Priority Cost Origin Costs calculated by component TCM FO RC Destination Location/Zone a) In SAP TM, in the NetWeaver Business Client, choose Master Data → Transportation Network → Transportation Lanes → Define Transportation Lanes. ON LY b) In the Define Transportation Lanes for Carrier Selection screen, enter the following data: Field Value Start Location/Zone SP3100 Destination Location/Zone CTM_96161 c) Press Enter and choose Display. d) On the Display SP3100 -> CTM_96161 screen, double-click the Means of Transport TM_FB45. A panel displays showing the details of the Means of Transport. © Copyright. All rights reserved. 219 Unit 5: Carrier Selection e) On the Strategy screen area of the panel, verify the following data: Value Relevant to Carrier Selection Selected Priority/Costs Costs * Priority Cost Origin Costs calculated by component TCM f) Choose R Field (Copy and Close). ME 2. Verify the priority of the carriers assigned to the Means of Transport TM_FB45 as follows: Means of Trans- Start date port End data Priority CARR-00-01 TM_FB45 01.01.2013 31.12.9999 1 CARR-00-02 TM_FB45 01.01.2013 31.12.9999 2 CARR-00-03 TM_FB45 01.01.2013 31.12.9999 3 CARR-00-04 TM_FB45 01.01.2013 31.12.9999 9 US TO Business Partner a) In the Carrier for Means of Trans. TM_FB45 screen area, verify the data in the table. b) Close the window. FO RC Configure Planning Profiles In this task, you will verify the planning profile, and its subordinate profiles, with settings relevant for carrier selection using Cost * Priority. 1. Display planning profile GRP##_CARRIER_SELECTION. a) In the NetWeaver Business Client, choose Application Administration → Planning → Planning Profiles → Display Planning Profiles. b) Enter the planing profile and choose Continue. 2. Verify the following optimizer settings: Value Planning Strategy VSR_1Step Planning Strategy for Transp. Prop. VSR_1Step LY Field ON a) On the Optimizer Settings tab, verify that the Planning Strategy is VSR_1STEP. 3. Explain how the planning strategy VSR_1STEP affects carrier selection. The VSR_1STEP planning strategy performs carrier selection during planning and is th the reason why carrier selection was automatically executed during optimizer planning in the previous exercise. 4. Verify that the carrier selection settings match the following data: 220 © Copyright. All rights reserved. Lesson: Selecting Carriers Based on Costs and Priorities Value Check Incompatibilities Selected Incompatibility Settings C_NA_INCOMPAT_CARR_CUST_INCOMPAT Strategy Costs*Priority Carrier Cost Origin Use Transportation Charges from TCM Planning Strategy TSPS_DEF Optimizer Runtime 10 Action for Manual Ranking Keep Transportation Charge Interpretation Accept Carrier with Charges of Zero as C. with Highest Costs Common Currency USD US TO ME R Field Action After Carrier Selection Run Assign Best Carrier Continuous Move Do Not Create Continuous Move Continuous Move Information Selected a) On the Carrier Selection Settings tab, verify the data in the table. ON LY FO RC b) Close the window. © Copyright. All rights reserved. 221 Unit 5: Carrier Selection LESSON SUMMARY You should now be able to: Define carrier costs ● Configure carrier selection ON LY FO RC US TO ME R ● 222 © Copyright. All rights reserved. Unit 5 Lesson 3 Using Allocations LESSON OBJECTIVES After completing this lesson, you will be able to: Consider allocations US TO ● ME R LESSON OVERVIEW In this lesson, you will perform carrier selection based on transportation allocations. Transportation Allocations LY FO RC Transportation allocations allow companies to assign defined quantities of capacity to certain business partners. This includes set minimum or maximum capacity restrictions that regulate how much business is allowed with a certain carrier in a certain region for a certain means of transport. A separate business object is used to model these allocations. ON Figure 48: Transportation Allocation © Copyright. All rights reserved. 223 Unit 5: Carrier Selection US TO ME R Transportation Allocations Figure 49: Transportation Allocations Often, firm relationships exist with carriers in the form of contracts. These contracts can guarantee that an amount of business is allocated to a carrier, which if not met, results in penalties. SAP TM has the tools to track these relationships or, alternatively, divide up business between different carriers. ● ● A carrier commits to at least 25 shipments or truckloads from Nashville each day. However, for business reasons, the availability changes each day. A carrier normally provides two trucks per day from Dayton, Ohio. For business reasons, the carrier is able to offer, on Tuesday and Friday only, five trucks to the shipper. A carrier can include additional capacity to the existing number of shipments by truck. For example, a carrier could add five additional trucks during the week between Tuesday and Thursday. ON LY ● FO RC The following are examples of transport allocations: 224 © Copyright. All rights reserved. Lesson: Using Allocations US TO ME R Transportation Allocation Characteristics Figure 50: Transport Allocations In Carrier Selection Transportation Allocation Characteristics Carrier capacity can be defined for any geographical level in arbitrary dimension. When defining the allocation, the trade lane can be specified as follows: Along From FO Within RC ● Both source location/zone and destination location/zone can be specified Source location/zone only Using zone hierarchy Destination location/zone only Inbound Destination zone is specified Outbound Source zone is specified LY To ● Extended carrier selection optimizer interface ON - ● - During carrier selection either using optimizer or manual planning, the allocation can be checked During tendering, the allocation can be checked Carrier capacity and utilization can be extracted to SAP NetWeaver © Copyright. All rights reserved. 225 Unit 5: Carrier Selection US TO ME R Extended Scope of Transportation Allocation Figure 51: Extended Scope of Transportation Allocations FO RC In SAP TM, you can define a connection between allocations and the freight agreement for a specific carrier. Only when a single trade lane has been defined for an agreement item, can an allocation from the item of the single party freight agreement be created. The type of allocation created is defined in the Agreement Type Customizing activity. If the carrier or trade lane in the agreement is changed, the user receives a message in an alert box stating that the allocation is no longer relevant. Other Transportation Allocation Features Transportation allocation types can be defined in Customizing. ● ● ● Bucket quantities are extended - multiple dimensions for the same bucket can be specified. Handling code support. LY ● Transportation allocation supports air freight capacity check and the integration of schedules. Further optional attributes can be specified. ● Transportation mode/user-specific user interface capability. ON Trade Lanes 226 © Copyright. All rights reserved. Figure 52: Trade Lanes US TO ME R Lesson: Using Allocations A trade lane is an abstract representation of transport classification. A trade lane instance does not represent a connection between any transportation network nodes (zone/location, and so on), it is a context independent classification of any transportation-related activities. RC Trade Lanes may build up a hierarchy, that is, more generic trade lanes imply more specific trade lanes (for example: “Within Germany using means of transport Truck” implies “Along from Frankfurt to Hamburg using means of transport Chilled Truck” and “Within Bavaria using means of transport Truck for liquids”). ON LY FO Trade lanes may overlap each other (for example, “From Germany using Airplane” and “Within Europe using Airplane”). Trade lane hierarchies include transportation zone hierarchy (for example: “From Germany“ implies “From Bavaria”, which implies“From Plant_Munich”), means of transport hierarchy (for example: “Within Germany with Mtr Truck” implies “Within Germany with Mtr Chilled_Truck”) and means of transport – mode of transport relations (for example: “Within Germany with Mode of Transport Road” implies “Within Germany with Mtr Chilled_truck”). © Copyright. All rights reserved. 227 ON LY FO RC US TO ME R Unit 5: Carrier Selection 228 © Copyright. All rights reserved. Unit 5 Exercise 21 R Perform Carrier Selection based on Transportation Allocations ME Business Example You want to define a transportation allocation for a new carrier. Before configuring the settings, you would like to review the settings for the same scenario for an existing allocation. Prepare the Lane to Use Transportation Allocation Field US TO 1. Verify the carrier selection settings in the transportation lane and means of transport using the following data: Value Start Location/Zone SP3100 Destination Location/Zone CTM_96161 Means of Transport TM_FB48 Selected RC Relevant to Carrier Selection Costs Cost Origin Costs calculated by Component TCM Use Trp. Allocations Selected Planning Period Day FO Priority/Costs Configure Planning Profiles 1. Display planning profile GRP00_TM120_CARSEL_TAL. ON LY 2. Verify the following optimizer settings: Field Value Planning Strategy VSR_1Step Planning Strategy for Transp. Prop. VSR_1Step 3. Verify the following carrier selection settings: Field Value Type of Carrier Selection Settings General Carrier Selection Allocation Usage Use Transportation Allocations BS Usage Do Not Use Business Shares © Copyright. All rights reserved. 229 Unit 5: Carrier Selection Field Value Strategy Costs Carrier Cost Origin Use Transportation Charges from TCM Configure the Allocation Type TAL Type ZTM Period Daily Full Calendar Units Selected Number Range 01 Use Carrier Selection ME Value US TO Field R 1. Verify that the transportation allocation type is configured for carrier selection using the following data: Selected Carrier Selection Unit of Measurement EA Update Quantity Automatically Selected TAL BW Relevance Not selected FO RC Set up Allocations for Carrier In this task, you display the worklist for transportation allocations and view the details of the current allocation. 1. Display the most recent transportation allocation for the carrier CAR00-02 and means of transport TM_FB48. 2. Record the values for the following fields of the allocation: Field Value Allocation Type Carrier LY Orientation Source Type Source ON Destination Type Destination Means of Transport Maximum Pieces per Bucket 230 © Copyright. All rights reserved. Unit 5 Solution 21 R Perform Carrier Selection based on Transportation Allocations ME Business Example You want to define a transportation allocation for a new carrier. Before configuring the settings, you would like to review the settings for the same scenario for an existing allocation. Prepare the Lane to Use Transportation Allocation Field US TO 1. Verify the carrier selection settings in the transportation lane and means of transport using the following data: Value Start Location/Zone SP3100 Destination Location/Zone CTM_96161 Means of Transport TM_FB48 Selected RC Relevant to Carrier Selection Costs Cost Origin Costs calculated by Component TCM Use Trp. Allocations Selected Planning Period Day FO Priority/Costs a) In SAP TM, in the NetWeaver Business Client, choose Master Data → Transportation Network → Transportation Lanes → Define Transportation Lanes. ON LY b) In the Define Transportation Lanes for Carrier Selection screen, enter the following data: Field Value Start Location/Zone SP3100 Destination Location/Zone CTM_96161 c) Press ENTER and then choose Display. d) On the Display SP3100 -> CTM_96161 screen, double-click the Means of Transport TM_FB48. A panel displays showing the details of the Means of Transport. © Copyright. All rights reserved. 231 Unit 5: Carrier Selection e) In the Strategy area of the panel, verify the following data: Value Relevant to Carrier Selection Selected Priority/Costs Costs Cost Origin Costs calculated by component TCM R Field Field Value Use Trp. Allocations Selected Planning Period Day (Copy and Close). Configure Planning Profiles US TO g) Choose ME f) In the Transportation Allocation screen area of the panel, verify the following data: 1. Display planning profile GRP00_TM120_CARSEL_TAL. a) In the NetWeaver Business Client, choose Application Administration → Planning → Planning Profiles → Display Planning Profiles. b) Enter the planing profile and choose Continue. FO RC 2. Verify the following optimizer settings: Field Value Planning Strategy VSR_1Step Planning Strategy for Transp. Prop. VSR_1Step a) On the Optimizer Settings tab, verify that the Planning Strategy is VSR_1STEP. 3. Verify the following carrier selection settings: Value Type of Carrier Selection Settings General Carrier Selection Allocation Usage Use Transportation Allocations BS Usage Do Not Use Business Shares Strategy Costs Carrier Cost Origin Use Transportation Charges from TCM ON LY Field a) On the Carrier Selection Settings tab, verify the data in the table. b) Close the window. Configure the Allocation Type 232 © Copyright. All rights reserved. Lesson: Using Allocations Value TAL Type ZTM Period Daily Full Calendar Units Selected Number Range 01 Use Carrier Selection Selected Carrier Selection Unit of Measurement EA Update Quantity Automatically Selected TAL BW Relevance Not selected US TO ME Field R 1. Verify that the transportation allocation type is configured for carrier selection using the following data: a) In SAP TM, in Customizing for SAP Transportation Management, choose SAP Transportation Management → Transportation Management → Planning → General Settings → Define Transportation Allocation Types. b) Verify the settings and exit the function. Set up Allocations for Carrier In this task, you display the worklist for transportation allocations and view the details of the current allocation. FO RC 1. Display the most recent transportation allocation for the carrier CAR00-02 and means of transport TM_FB48. a) In SAP TM, in the NetWeaver Business Client, choose Planning → Worklist → >Overview Planning. b) Choose the active query Transportation Allocations and refresh the query. c) If the Quick Criteria Maintenance screen area is not already displayed, choose Show Quick Criteria Maintenance. d) Search for transportation allocations for means of transport TM_FB48 for carrier CAR00-02 by entering these values in the search criteria. LY e) Choose Apply. f) Choose Hide Quick Criteria Maintenance. ON 2. Record the values for the following fields of the allocation: Field Value Allocation Type Carrier Orientation Source Type Source © Copyright. All rights reserved. 233 Unit 5: Carrier Selection Field Value Destination Type Destination Means of Transport a) In the worklist, select the row for allocations and choose Display. The values are as follows: ME b) Record the values and close the window. Value Allocation Type ZTM Carrier CAR00-02 Source Type Source Destination Type Destination Along Location SP3100 Zone CTM_96161 TM_FB48 FO RC Means of Transport US TO Field Orientation R Maximum Pieces per Bucket Maximum Pieces Per Bucket 4 c) Review that, according to the planning period, daily buckets were created for the validity period. d) Review that minimum and maximum values can be maintained for different dimensions or unit of measures. ON LY e) Review that the current (actual) values will be displayed if the freight orders are subcontracted to the carrier during the validity period of the transportation allocation. 234 © Copyright. All rights reserved. Lesson: Using Allocations LESSON SUMMARY You should now be able to: Consider allocations ON LY FO RC US TO ME R ● © Copyright. All rights reserved. 235 Unit 5 Lesson 4 LESSON OBJECTIVES After completing this lesson, you will be able to: Perform carrier selection based on business shares Business Shares US TO ● ME LESSON OVERVIEW In this lesson, you will perform carrier selection based on business shares. R Using Business Shares FO RC Selecting Carriers Based on Business Share Figure 53: Selecting Carriers Based on Business Shares Objectives of Business Shares Assign defined percentages to certain business partners ● Support negotiation of freight agreements ● Avoid dependency on a single vendor ● Consider the capacity of a carrier for a certain relation/route/geography LY ● ON Like transportation allocations, business shares make use of trade lanes. 236 © Copyright. All rights reserved. Lesson: Using Business Shares US TO ME R Business Share (Example) Figure 54: Selecting Carriers Based on BS and Transportation Allocation RC When defining the business share context, you create the business share buckets. The percentage of business share a carrier can have for these individual buckets is the actual business share a carrier is allowed to have. There are different types of bucket available during business share creation. They are yearly, quarterly, monthly, weekly, and daily. Example One ON LY FO Carrier A can have a weekly bucket of 75% of the business share on the lane between Hamburg and Frankfurt between the validity periods March 1 2015 to 31 May 2015. In the same context, Carrier B can have a weekly bucket of 25% defined. © Copyright. All rights reserved. 237 US TO ME R Unit 5: Carrier Selection Figure 55: Business Share Tolerances and Penalty Costs FO RC Tolerances and penalty costs can be defined for business shares. As long as business shares are within the tolerance limits, the cost calculations during carrier ranking are not affected. Tolerances are always defined in percentages (%). If the total business share of the carrier exceeds the defined tolerances, either shortfall or over, a penalty applies. The shortage penalty costs are added to all carriers, other than the one selected. The excess penalty costs are added to the carrier under consideration. Penalties are maintained as numeric values in the business share. This number is multiplied by the deviation percentage to arrive at the penalty cost. It only makes sense to use business shares if you have defined penalty costs. It is recommended to also always define tolerances to give the optimizer a certain amount of leeway. Example Two ON LY There is a penalty of 1000 defined in the business share. An excess tolerance of 10% is also defined. During business share calculation, if the excess is 12%, the excess liable for penalty is 2%. This 2 is multiplied by 1000 to arrive at the total excess penalty costs of 2000. 238 © Copyright. All rights reserved. Lesson: Using Business Shares Note: When calculating the total costs for a carrier, if you are working with TCM costs, there will be a currency assigned to the costs. To assign a currency to business share penalty costs, go to: Carrier Selection Settings -> Advanced Settings -> Common Currency . R For example, if you are working with carriers from multiple geographic locations with multiple currencies to arrive at the correct ranking, the system uses the common currency (maintained in the Carrier Selection Settings ) for all its calculations. The currency displayed in the carrier ranking list is always the local currency of the carrier (maintained in the freight agreement). ME All FORs in the business share context are selected for the business share penalty calculations, though these FORs are not selected during the planning run. US TO For example, assume in a business share context there are two carriers, A and B. There are no tolerances defined. Carrier A is awarded a 60% business share and Carrier B a 40% business share. There are already 10 freight orders awarded, of which Carrier A is assigned six and Carrier B is assigned four. Now let us perform carrier selection for the eleventh FOR. If Carrier B is assigned this FOR, Carrier A will have a shortfall of business share, and the penalty cost for the shortfall will be charged to Carrier B, on top of the usual costs determined during carrier selection. ON LY FO RC If Carrier A is assigned the eleventh FOR, Carrier B will have a shortfall of business share, and the penalty cost will be charged to carrier A, on top of the usual costs determined during carrier selection. Both options are evaluated by the system and the ranking done accordingly. © Copyright. All rights reserved. 239 ON LY FO RC US TO ME R Unit 5: Carrier Selection 240 © Copyright. All rights reserved. Unit 5 Exercise 22 R Perform Carrier Selection Based on Business Shares ME Business Example You want to define carrier selection for a new lane based on business share. Before configuring the settings, you would like to review the settings for the same scenario for an existing lane. US TO Note that, in this exercise, when the values include ##, replace the characters with the number assigned to you by your instructor. Prepare Master Data for Carrier Selection Based on Business Share In this task, you will define the settings for the transportation lane to perform carrier selection based on business share. 1. Verify the carrier selection settings in the transportation lane and means of transport using the following data: Field FO RC Start Location/Zone Value SP3100 CTM_96161 Means of Transport TM_FB53 Relevant to Carrier Selection Selected Priority/Costs Costs Cost Origin Costs calculated by Component TCM Use Business Share Selected LY Destination Location/Zone Configure Planning Profiles In this task, you will review the settings in the planning profile relevant to carrier selection. ON 1. Verify the carrier selection settings in planning profile GRP##_CARR_SEL_BS. Field Value BS Usage Always Use Business Shares View Business Share Details In this task, you will display the worklist for business shares and view the details for a business share. 1. Display the Business Share worklist for means of transport TM_FB53 for the year 2013. © Copyright. All rights reserved. 241 Unit 5: Carrier Selection 2. Display a particular business share for 2013 for means of transport TM_FB53. 3. List each carrier and respective target business share. R CAR00-01: ME CAR00-02: US TO 4. What steps would allow you to display or change multiple business share records within the same screen? 5. Review that the current (actual) share is displayed when freight orders are subcontracted to the carrier during the selected timeframe. FO RC 6. Review that penalty costs can be maintained separately for shortfall and exceeding the target share. These costs will be considered when building the carrier ranking list. ON LY 7. Review that negative and positive tolerances can be defined separately to define a corridor around the target share in which no penalty costs will be applied. 242 © Copyright. All rights reserved. Unit 5 Solution 22 R Perform Carrier Selection Based on Business Shares ME Business Example You want to define carrier selection for a new lane based on business share. Before configuring the settings, you would like to review the settings for the same scenario for an existing lane. US TO Note that, in this exercise, when the values include ##, replace the characters with the number assigned to you by your instructor. Prepare Master Data for Carrier Selection Based on Business Share In this task, you will define the settings for the transportation lane to perform carrier selection based on business share. 1. Verify the carrier selection settings in the transportation lane and means of transport using the following data: Field FO RC Start Location/Zone Value SP3100 CTM_96161 Means of Transport TM_FB53 Relevant to Carrier Selection Selected Priority/Costs Costs Cost Origin Costs calculated by Component TCM Use Business Share Selected LY Destination Location/Zone ON a) In SAP TM, in the NetWeaver Business Client, choose Master Data → Transportation Network → Transportation Lanes → Define Transportation Lanes. b) In the Define Transportation Lanes for Carrier Selection screen, enter the following data: Field Value Start Location/Zone SP3100 Destination Location/Zone CTM_96161 c) Choose Enter then choose Display . © Copyright. All rights reserved. 243 Unit 5: Carrier Selection d) In the Display SP3100 -> CTM_96161 screen, double-click the row corresponding to TM_FB53. A new Means of Transport panel appears. Field Value Relevant to Carrier Selection Selected Field Value Use Business Share Selected (Copy and Close ). h) Close the window. US TO g) Choose ME f) In the Share of Business area of the panel, verify the following data: R e) In the Strategy area of the panel, verify the following data: Configure Planning Profiles In this task, you will review the settings in the planning profile relevant to carrier selection. 1. Verify the carrier selection settings in planning profile GRP##_CARR_SEL_BS. Field Always Use Business Shares FO RC BS Usage Value a) In the NetWeaver Business Client, choose Application Administration → Planning → Planning Profiles → Display Planning Profiles. b) On the Display Planning Profile screen, enter the profile then click Continue . c) Open the Carrier Selection Settings tab. d) Verify the fields for the table. e) Close the window. LY View Business Share Details In this task, you will display the worklist for business shares and view the details for a business share. 1. Display the Business Share worklist for means of transport TM_FB53 for the year 2013. ON a) In SAP TM, in the NetWeaver Business Client, choose Planning → Worklist → Overview Planning. b) Choose the active query Business Shares and refresh the query c) Choose Show Quick Criteria Maintenance if the Quick Criteria Maintenance is not already displayed. d) Search for business shares for means of transport TM_FB53 for 2013 by entering TM_FB53 in the Means of Transport field, and a range of 01.01.2013 31.12.2013 in the Validity Start Time field. 244 © Copyright. All rights reserved. Lesson: Using Business Shares e) Choose Apply. f) Choose Hide Quick Criteria Maintenance . 2. Display a particular business share for 2013 for means of transport TM_FB53. a) In the worklist table, select the row for a period of your choice. b) Choose Display. R 3. List each carrier and respective target business share. ME CAR00-01: 50.0 US TO CAR00-02: 50.0 4. What steps would allow you to display or change multiple business share records within the same screen? RC From the worklist, select the rows you want to view or change, then click Display or Edit . The next screen will show all the business shares selected in the worklist. If you are in Edit mode, you can update the carrier targets, penalties, tolerances, recalculate the booked quantity, and insert carriers. 5. Review that the current (actual) share is displayed when freight orders are subcontracted to the carrier during the selected timeframe. FO 6. Review that penalty costs can be maintained separately for shortfall and exceeding the target share. These costs will be considered when building the carrier ranking list. ON LY 7. Review that negative and positive tolerances can be defined separately to define a corridor around the target share in which no penalty costs will be applied. © Copyright. All rights reserved. 245 Unit 5: Carrier Selection LESSON SUMMARY You should now be able to: Perform carrier selection based on business shares ON LY FO RC US TO ME R ● 246 © Copyright. All rights reserved. Unit 5 Lesson 5 Improving Carrier Utilization LESSON OBJECTIVES After completing this lesson, you will be able to: Explain continuous moves Continuous Moves US TO ● ME R LESSON OVERVIEW In this lesson, you will improve carrier utilization with continuous moves. Continuous move scenarios can identify opportunities to avoid empty runs or utilize capacity more effectively. As part of automatic carrier selection, the system tries to combine freight orders by forming continuous moves. The aim is to reduce the costs of subcontracting by assigning additional freight orders to the same carrier. If the carrier is providing a special discount for continuous move or round-trip move, the discount percentage can be maintained at carrier level in the lane. Optimizer will pick this additional discount during carrier selection for the continuous move or round-trip lane. ON LY FO RC The system takes into account continuous moves during automatic carrier selection only. Figure 56: SAP TM Carrier Selection: Continuous Move - Scenario Overview As part of the automatic carrier selection, the system tries to combine freight order by forming continuous moves. A continuous move is when the transportation service provider (TSP) agrees to take on a completely new shipment straight after the completion of a freight order. The aim is to reduce the costs of the by assigning additional freight orders to a carrier. © Copyright. All rights reserved. 247 Unit 5: Carrier Selection Types of Continuous Moves The following types of continuous move are available: ● Simple continuous move The carrier accepts one or more additional business documents and, after executing the first business document, directly executes the following business documents one after the other. Round trip R ● ME A round trip is a simple continuous move for which the source location of the first business document and the destination location of the second business document are identical. A round trip can only consist of exactly two business documents, the system cannot take into account complex round trips where multiple source locations (pickup) or destination locations (delivery) are served. ● ● ● US TO The system can combine two or more business documents in a continuous move if the following conditions are met: The relevant carrier is available for both business documents. The arrival date/time of the first business document lies in the departure window of the second business document. The departure date/time of the second business document lies in the arrival window of the first business document. FO RC Furthermore, the distance between the destination location of the first business document and the source location of the second business document must not exceed the smaller maximum distance that you have defined for the carrier in the transportation lanes. Cost Calculation for Continuous Moves The system first determines the costs per business document (for example, freight order). Here it considers the strategy and origin of the carrier costs that you defined in the carrier selection settings. The system then determines the discount per business document. When doing so, it takes into account the settings that you have made in the transportation lane for the carrier and the means of transport. The system deducts this discount from the costs determined previously for each business document. ON LY If you specified in the carrier selection settings that the system is to perform a recalculation of costs from charge management for continuous moves, the system considers the discounts for continuous moves for the business documents from charge management in the recalculation, however, only for the carriers that offer continuous moves. The system saves the result in the ranking list. LESSON SUMMARY You should now be able to: ● 248 Explain continuous moves © Copyright. All rights reserved. Unit 5 Learning Assessment R 1. Which of the following statements about carrier selection are correct? ME Choose the correct answers. A Carrier selection based on business share means that a fixed percentage of business is allocation to a certain carrier. X B Carrier selection based on transportation allocations is maintained on the transportation lane level. X C Carrier selection based on transportation allocations means that there is either a minimum or maximum restriction that regulates how much business you do with a certain carrier in a certain region for a certain means of transport. X D Available carriers are defined in the transportation lane. US TO X 2. Which of the following factors influence carrier selection? RC Choose the correct answers. A Master data X B Planning profile X C Lane Settings X D Freight order type X E Incompatibilities FO X LY 3. Incompatibilities between order and carrier, or customer and carrier, can also be maintained in the carrier selection settings. ON Determine whether this statement is true or false. X True X False © Copyright. All rights reserved. 249 Unit 5: Learning Assessment 4. When defining transportation allocations, a trade lane can be specified. Determine whether this statement is true or false. X True X False R 5. Based on what you have learned about business share in transportation planning, which of the following statements is true? ME Choose the correct answer. A Business share is an in-built mechanism in SAP TM for ensuring all carriers in a region have sufficient business. X B Business share buckets provide a means of numerous shippers pooling together to create merged (shared) freight orders. X C Business share settings define the percentage of business to be allocated to various carriers. Costs are incurred for non-adherence and the system takes these into account during optimization. X D A company may have working formalised relationships with a number of carriers. Business share allocation ensures that all carriers receive the same amouont of business from the comapany. US TO X FO RC 6. What are the aims of continuous moves? Choose the correct answers. A To reduce the costs of the freight order. X B To utilize capacity more effectively. X C To reduce the costs of subcontracting. X D To ensure the lowest-cost carrier is always assigned. ON LY X 250 © Copyright. All rights reserved. Unit 5 Learning Assessment - Answers R 1. Which of the following statements about carrier selection are correct? ME Choose the correct answers. A Carrier selection based on business share means that a fixed percentage of business is allocation to a certain carrier. X B Carrier selection based on transportation allocations is maintained on the transportation lane level. X C Carrier selection based on transportation allocations means that there is either a minimum or maximum restriction that regulates how much business you do with a certain carrier in a certain region for a certain means of transport. X D Available carriers are defined in the transportation lane. US TO X 2. Which of the following factors influence carrier selection? RC Choose the correct answers. A Master data X B Planning profile X C Lane Settings X D Freight order type X E Incompatibilities LY FO X 3. Incompatibilities between order and carrier, or customer and carrier, can also be maintained in the carrier selection settings. ON Determine whether this statement is true or false. X True X False © Copyright. All rights reserved. 251 Unit 5: Learning Assessment - Answers 4. When defining transportation allocations, a trade lane can be specified. Determine whether this statement is true or false. X True X False R 5. Based on what you have learned about business share in transportation planning, which of the following statements is true? ME Choose the correct answer. A Business share is an in-built mechanism in SAP TM for ensuring all carriers in a region have sufficient business. X B Business share buckets provide a means of numerous shippers pooling together to create merged (shared) freight orders. X C Business share settings define the percentage of business to be allocated to various carriers. Costs are incurred for non-adherence and the system takes these into account during optimization. X D A company may have working formalised relationships with a number of carriers. Business share allocation ensures that all carriers receive the same amouont of business from the comapany. FO RC US TO X 6. What are the aims of continuous moves? Choose the correct answers. A To reduce the costs of the freight order. X B To utilize capacity more effectively. X C To reduce the costs of subcontracting. X D To ensure the lowest-cost carrier is always assigned. ON LY X 252 © Copyright. All rights reserved. Lesson 1 Explaining the Tendering Process Exercise 23: Tender a Freight Order Lesson 2 254 261 269 275 US TO Configuring the Tendering Plan Exercise 24: Create a Tendering Profile R Freight Tendering ME UNIT 6 Lesson 3 284 RC Identifying the Tendering Collaboration Scenarios UNIT OBJECTIVES Explain tendering types ● Explain the tendering process in SAP TM ● Tender a freight order FO ● Configure the settings to enable order tendering ● Determine communication methods with carriers ● Collaborate using the SAP TM collaboration portal ON LY ● © Copyright. All rights reserved. 253 Unit 6 Lesson 1 Explaining the Tendering Process LESSON OBJECTIVES After completing this lesson, you will be able to: Explain tendering types ● Explain the tendering process in SAP TM ● Tender a freight order LY FO RC Order Tendering US TO ● ME R LESSON OVERVIEW In this lesson, you will tender a freight order using different tendering processes. Figure 57: Subcontracting: Tendering - Context Process Flow ON Once carrier selection has taken place, communication with the selected carrier needs to be initiated. This process is referred to as order tendering. Different tendering processes can be deployed depending upon the technology used by the carrier. You use this process to tender (offer) a freight order to one or more potential transportation service providers (TSPs). Tendering is a bidding process, in which you request one or multiple TSPs to submit a quote for a transportation service that is defined in a freight order. You can select the TSP that you want to execute the transportation service by evaluating the quotes. The main characteristics of the tendering process are flexible configuration and the reduction of required manual interaction to support ease of use and lower total cost of ownership (TCO). 254 © Copyright. All rights reserved. Lesson: Explaining the Tendering Process Figure 58: Order Tendering Process ME R Order Tendering Process The figure Order Tendering Process shows an example of the freight order tendering process. Tendering Types Peer-to-Peer Tendering ● Broadcast Tendering RC ● US TO In general, there are two types of tendering, as follows: Long-term tendering is where contracts are negotiated for a longer period, for example, a year. Long term tendering is a process that is covered in Strategic Freight Management, which we will look at in the Managing Freight Contracts lesson. Short term tendering is where tendering is executed based on specific orders. This is known as order tendering. SAP TM supports the following short term tendering scenarios: The strategies for each are determined in tendering profiles in SAP TM. Parties and Roles in the Tendering Process FO At least two parties are involved in the tendering process - a customer who wants to subcontract a transportation service that is defined in a freight order, and a supplier (subcontractor) or TSP, who potentially carries out the transportation service. There are two roles on the customer side of the tendering process. The first is a transportation dispatcher, who is responsible for the transportation service, that is, the freight order. The second is the tendering manager, who is responsible for configuring and executing the tendering process and acquiring an acceptable quote from a TSP to perform the transportation service. LY Manual and Automatic Tendering ON When a transportation dispatcher initiates the tendering process, they have two options: manual process configuration or automatic tendering. If they want to tender only a single freight order, the transportation dispatcher can choose between the two options. If they initiate a tendering process using manual configuration, the tendering manager must configure and start the tendering process manually. If the transportation dispatcher wants to tender more than one freight order, they must initiate automatic tendering and use the automatic tendering configuration in the system. © Copyright. All rights reserved. 255 Unit 6: Freight Tendering Figure 59: Peer to Peer Tendering US TO ME R Peer-to-Peer Tendering FO RC Peer-to-peer tendering is a process whereby freight orders are tendered sequentially or “offered” to preselected carriers or transportation service providers (TSPs). Peer-to-peer tendering involves the sequential sending of freight requests for quotation (freight RFQs) to each proposed carrier. The system waits until the carrier sends a freight quotation (FQ) or until the maximum response time has passed. If the TSP does not send a quote within the maximum response time, the peer-to-peer tendering process continues, and the system sends a request for quote to the next TSP. If peer-to-peer tendering ends without an acceptable quote, the tendering process continues with the next tendering process step that you have configured. If the TSP sends a quote before the maximum response time has elapsed, the system evaluates the quote and can either accept or reject it. In the case of rejection, a new RFQ is sent out. The process continues until at least one acceptable FQ has been received. The system awards this a Quotation Acceptable evaluation result and the process ends successfully. There are two types of peer-to-peer tendering: response required and no response required. Broadcast Tendering ON LY Broadcast tendering is a tender process whereby freight orders are simultaneously tendered (offered) to preselected TSPs. All TSPs have to respond within a given maximum response time. There are two types of broadcast tendering: best offer and first acceptable offer. Depending on which one of these is being used, either the first acceptable quote wins or, after the maximum response time, the system evaluates all the acceptable quotes and selects the TSP that has submitted the quote with the lowest price. If broadcast tendering ends without an acceptable quote, the tendering process continues with the next tendering process step that you have configured. 256 © Copyright. All rights reserved. US TO ME R Lesson: Explaining the Tendering Process Figure 60: Broadcast Tendering Tender Types Available in SAP TM ● ● ● Peer–to– Peer Tendering – Response Required: If a Carrier does not respond in a given amount of time, it is automatically considered a rejection. Peer–to– Peer Tendering – No Response Required: If a Carrier does not respond in a given amount of time, it is automatically considered an acceptance. RC ● Broadcast Tendering – Best Offer: Out of all responses within the given timeframe, the best offer (that is, lowest) is accepted. Broadcast Tendering – First Acceptable Offer: The first response is accepted FO A typical setup is a two-step tendering process. The first step is enabled for Peer-to-Peer Tendering with a max response time of 30 minutes per carrier. If no response is received from any of the carriers then the second step is started. The second step is broadcast tendering, where all carriers will receive the tender request and the tender will be awarded to the carrier who responds first or offers the best price. LY RFQ-Based Tendering Process Available Tendering Processes ON The following tendering processes are available, based on the settings maintained in the tendering profile: ● RFQ-based, award manually ● RFQ-based, award automatically ● Direct tendering, send freight order directly © Copyright. All rights reserved. 257 US TO ME R Unit 6: Freight Tendering Figure 61: Process: RFQ-based Tendering FO RC This process is common in European regions where you send an RFQ to the carrier, and the carrier then quotes their price for the tender in the form of a freight quotation. ON LY You either accept or reject the freight quote manually or automatically, based on the parameters set in the tendering profile. Acceptance is then sent to the awarded carrier. 258 © Copyright. All rights reserved. Lesson: Explaining the Tendering Process US TO ME R Direct Tendering Process RC Figure 62: Process: Direct Tendering You can use a direct tendering process to send a freight order (FO) directly to a specified carrier without creating a freight RFQ. Carriers can confirm or reject the FOs. FO If a carrier does not respond within a certain period of time, the tender can be considered as accepted automatically. If required, confirmation can be sent as an e-mail to the confirmed carrier. Direct and RFQ tendering are separate tendering processes, but can be combined if required. LY Facilitated Discussion: Carrier Tendering Criteria Freight Order Tendering ON A tendering process starts if you or the system determine more than one possible carrier. This tendering process can use a mixture of different modes of tendering (peer-to-peer or broadcast tendering). You can define a timeout in the system, so that it either tenders the freight order to another carrier or switches from one tendering type to the next. The tendering process results in one carrier being selected to execute the freight order. Carriers can accept or decline these freight RFQs and change data, such as the price, when they return the freight quotations. You can then automatically accept the tendering and send the freight order back to the awarded carrier. © Copyright. All rights reserved. 259 ON LY FO RC US TO ME R Unit 6: Freight Tendering 260 © Copyright. All rights reserved. Unit 6 Exercise 23 Tender a Freight Order R Business Example ME A large consumer electronics manufacturer has a core carrier program in place. Dedicated carriers handle most of the freight. As part of the SAP TM implementation, the logistics transportation manager would like to be able to tender the freight to core carriers first. During December, in case the core carriers are unable to meet the demands, the plan is to broadcast the freight to other carriers. US TO Note that, in this exercise, when the values include ##, replace the characters with the number assigned to you by your instructor. 1. In SAP ERP, create a sales order using the following data: Field Order Type Sales Organization Distribution Channel ZT00 3000 10 00 FO RC Division Value Sold-To Party TM_CUST_00 PO Number TM300-GRP##-2.1 Material PRODTM-00 Order Quantity 300 2. Plan the OTR using the following profiles: ON LY Field Value Planning Profile GRP##-NA-FU-PLAN-PROF Transportation Cockpit Layout Standard Layout Layout for Planning Results Screen Standard Layout Description Planning without carrier selection 3. Create a ranking list with the following data: © Copyright. All rights reserved. 261 Unit 6: Freight Tendering Table 51: Carrier Ranking tab, for peer-to-peer tendering relevance Field Value Carrier CAR00-01 Values Carrier CAR00-02 Carrier CAR00-03 Carrier CAR00-04 4. Perform tendering using the TM120_00_TEND_PROFILE. ME Field R Table 52: Carrier Ranking tab, for broadcast tendering relevance US TO 5. Perform “Reject / Accept RFQ” . Reject the first tender (peer to peer) due to no time . Accept the tendering broadcast for all carriers. 6. In the SAP TM system, the RFQ is awarded. Note the carrier that was selected. ON LY FO RC Note: The tendering responses are evaluated by a background report that runs every 5 minutes on this system. Therefore, it might take up to 5 minutes for your freight order to be updated. Please keep refreshing the freight order until you see the described results. 262 © Copyright. All rights reserved. Unit 6 Solution 23 Tender a Freight Order R Business Example ME A large consumer electronics manufacturer has a core carrier program in place. Dedicated carriers handle most of the freight. As part of the SAP TM implementation, the logistics transportation manager would like to be able to tender the freight to core carriers first. During December, in case the core carriers are unable to meet the demands, the plan is to broadcast the freight to other carriers. US TO Note that, in this exercise, when the values include ##, replace the characters with the number assigned to you by your instructor. 1. In SAP ERP, create a sales order using the following data: Field Order Type Sales Organization Distribution Channel ZT00 3000 10 00 FO RC Division Value Sold-To Party TM_CUST_00 PO Number TM300-GRP##-2.1 Material PRODTM-00 Order Quantity 300 a) In SAP ERP, on the Easy Access screen, in the Command field, enter transaction VA01 and choose Enter . ON LY b) In the Create Sales Order: Initial Screen , enter the following data: Field Value Order Type ZT00 Sales Organization 3000 Distribution Channel 10 Division 00 c) Choose Enter. d) In the Create TM100 Standard Order: Overview screen, enter the following information: © Copyright. All rights reserved. 263 Unit 6: Freight Tendering Field Value Sold-To Party TM_CUST_00 PO Number TM300-GRP##-2.1 Value Material PRODTM-00 Order Quantity 300 f) Choose Save and note the sales order number. 2. Plan the OTR using the following profiles: Planning Profile Value US TO Field ME Field R e) In the All items table, enter the following information: GRP##-NA-FU-PLAN-PROF Transportation Cockpit Layout Standard Layout Layout for Planning Results Screen Standard Layout Description Planning without carrier selection FO RC a) In SAP TM, in the NetWeaver Business Client, choose ERP Logistics Integration → Overview Transportation Requirements. b) Select the OTR based on the sales order that you created in step 1. c) Choose Start Transportation Cockpit . d) On the Transportation Cockpit: Profile and Layout Sets screen, check for a row with the same profiles and layout settings as in the table. If it exists, already, skip to step (h). If the Profile and Layout Sets screen is not displayed, choose Change Profile Selection → Profile Selection Screen. e) If the profile row does not yet exist as shown in the table, choose New. LY f) Enter the data in the table. g) Choose Save. ON h) Select the row corresponding to the entries in the table and choose Continue. i) In the Freight Unit screen area, select the freight unit. j) Choose Optimizer Planning → Selected Entries with All Resources. k) In the Freight Orders/Freight Bookings screen area, select the freight order that has just been created. l) Choose Accept. m) Choose Save. 264 © Copyright. All rights reserved. Lesson: Explaining the Tendering Process 3. Create a ranking list with the following data: Table 51: Carrier Ranking tab, for peer-to-peer tendering relevance Field Value Carrier CAR00-01 Values Carrier CAR00-02 Carrier CAR00-03 Carrier CAR00-04 ME Field R Table 52: Carrier Ranking tab, for broadcast tendering relevance US TO a) In the Transportation Cockpit , in the Freight Order/Freight Booking screen area, open the freight order. b) Choose the Subcontracting tab and choose Edit. c) In the Subcontracting Data screen area, choose the Carrier Ranking tab. d) To insert the carrier for peer-to-peer tendering, choose Insert Carrier. RC e) For carrier CAR00-01, for peer-to-peer relevance, select the Peer-to-Peer Tendering Relevance checkbox. Note: Ensure the Broadcast Tendering Relevance checkbox is not selected. FO f) To insert the carriers for broadcast tendering, choose Insert Carrier. LY g) For carriers, CAR00-02, CAR00-03 and CAR00-04, for broadcast relevance, select the Broadcast Tendering Relevance checkbox. Note: Ensure the Peer-to-Peer Tendering Relevance checkbox is not selected. h) Save and choose Edit. ON 4. Perform tendering using the TM120_00_TEND_PROFILE. a) Choose Subcontracting -> Automatic Tendering . b) In the Tendering dialog box, enter TM120_00_TEND_PROFILE in the Tendering Profile field. Choose OK. c) On the Subcontracting tab, choose the Tendering Overview tab and review the two tendering steps that have been created. d) Save your entries. © Copyright. All rights reserved. 265 Unit 6: Freight Tendering Note: An RFQ for your freight order has been created. Make a note of your RFQ number:_________________________ R Caution: Leave the freight order screen open. You need it in the next exercise step. ME 5. Perform “Reject / Accept RFQ” . Reject the first tender (peer to peer) due to no time . Accept the tendering broadcast for all carriers. a) In NWBC for SAP TM, on the Freight Order Management tab, choose Road -> Overview Tendering. US TO b) In the Active Queries screen area, for Freight RFQs , choose Open and refresh the query. c) Now reject the RFQ for Carrier 01. Select the row of your Freight RFQ. Choose Create Freight Quotation -> Reject (no time). d) In the Reject Request for Quotation dialog box, choose OK . FO RC e) In the freight order, choose Refresh. On the Subcontracting tab, choose the Tendering Overview tab. The new status in the tendering plan is Closed for the RFQ for Carrier 01. Step 2 of your tendering plan has been started automatically. Note: The tendering responses are evaluated by a background report that runs every 5 minutes on this system. Therefore, it might take up to 5 minutes for your freight order to be updated. Please keep refreshing the freight order until you see the described results. f) Three new RFQs are now shown. You can see them by expanding the first column. Make note of the new RFQ numbers. LY Caution: Leave the freight order screen open. You need it in the next exercise step. ON g) To accept the broadcast tendering for Carriers 02 - 04, go back to the Overview Tendering worklist. h) In the Active Queries screen area, for Freight RFQs , choose Open . i) Choose Refresh. j) Select the three newly shown RFQs (for carriers CAR00-02, CAR00-03, CAR00-04). k) Choose Create Freight Quotation → Accept. l) In the Accept without Changes dialog box, choose OK . 266 © Copyright. All rights reserved. Lesson: Explaining the Tendering Process 6. In the SAP TM system, the RFQ is awarded. Note the carrier that was selected. Note: The tendering responses are evaluated by a background report that runs every 5 minutes on this system. Therefore, it might take up to 5 minutes for your freight order to be updated. Please keep refreshing the freight order until you see the described results. R a) Go to the freight order. On the Subcontracting tab, choose the Tendering Overview tab. ON LY FO RC US TO ME b) Choose Refresh. Note the carrier that was awarded the tender and assigned to the freight order. © Copyright. All rights reserved. 267 Unit 6: Freight Tendering LESSON SUMMARY You should now be able to: Explain tendering types ● Explain the tendering process in SAP TM ● Tender a freight order ON LY FO RC US TO ME R ● 268 © Copyright. All rights reserved. Unit 6 Lesson 2 LESSON OBJECTIVES After completing this lesson, you will be able to: Configure the settings to enable order tendering US TO ● ME LESSON OVERVIEW In this lesson, you will configure the settings to enable order tendering. R Configuring the Tendering Plan FO RC Configuration Settings for Tendering Figure 63: General Settings for Tendering LY The standard settings for tendering are defined in the Define General Settings for Tendering Customizing activity. You can also specify the tendering communication and process settings that you can use in the Define Freight Order Types Customizing activity. ON In Customizing for SAP Transportation Management, choose SAP Transportation Management → Transportation Management → Freight Order Management → Tendering → Define General Settings for Tendering. In the 01 - Visibility Settings view, you can select the settings that determine the visibility level of a price limit, submitted price, and stop dates in a tendering process. In the 02 - Rejection Reason Codes view, you can define reason code identifiers (IDs) and descriptions to classify the reasons for rejecting freight request for quotations (freight RFQs). © Copyright. All rights reserved. 269 Unit 6: Freight Tendering US TO ME R E-Mail and SMS Content Settings FO RC Figure 64: Tendering Profile: E-Mail and SMS In the 03 - E-mail and SMS Content view, you can define the following settings: Documents for Notifications You can specify the names of the documents that the system uses to create e-mails. You can specify separate documents for the e-mail subject field, the e-mail body text, and SMS text content. You can also specify additional information that the system adds to other e-mail body text or SMS text. The system uses the e-mail or SMS type to determine where it adds the additional text. You must define the documents that you use in this view as General text documents in transaction SE61. Triggering Notifications at Process Events LY You can specify that the system sends an e-mail or an SMS message to a carrier when an event occurs in the tendering process. Events include sending a freight RFQ to a carrier and awarding a freight quotation (FQ). Bundling Notifications ON You can schedule the sending of e-mails and SMS messages in a batch report. With this, the contact person for the carrier receives e-mails or SMS messages only when the batch report runs in your system. The e-mails or SMS messages contain information about all the new events that have taken place since the last bundle of e-mails or SMS messages were sent. This means that the carrier does not receive 10 separate e-mails for new freight RFQs, but one e-mail containing the information on all 10 new freight RFQs. Process Settings In the 04 - Process Settings view, you can specify the following process settings for tendering: 270 © Copyright. All rights reserved. Lesson: Configuring the Tendering Plan Default tendering manager ● Visibility settings ● Tendering profile ● Carrier selection settings ● Maximum response duration ● Considering the calling hours of a business partner R ● ME You can use the process and communication settings that you define in the Define Freight Order Types Customizing activity to specify the tendering settings for each freight order type. The following are the settings in the freight order type that the system uses to determine the Customizing settings for tendering: Default, where the system uses the system default settings ● Freight order type, where the system uses the type of freight order ● Conditions, where the system uses the runtime characteristics of a freight order Communication Settings US TO ● In the 05 - Communication Settings view, you can specify the following communication settings for tendering: ● ● Use EDI messages to communicate with carriers Send particular types of e-mails to carriers. (Types include e-mails for freight RFQs, FQ cancelations, and FQ awards) Send freight RFQs as e-mails or SMS messages ON LY FO ● Send alerts to tendering managers whether or not the managers have subscribed to a tendering alert category RC ● © Copyright. All rights reserved. 271 Unit 6: Freight Tendering US TO ME R Carrier-Specific Communication Settings Figure 65: Tendering Profile: Carrier Communication and Defaults In the 06 - Carrier -Specific Communication Settings view, you can define communication settings for a particular carrier that are different from the general communication settings defined in the 05 - Communication Settings view. ● ● FO RC This includes the following settings: Send EDI messages to this carrier and not to other carriers Send particular types of e-mails and SMS messages to this carrier and not to other carriers In the 07 - Default Settings view, you must specify one default set of process settings and one default set of communication settings for your tendering processes. The system uses these settings if it cannot determine specific settings based on the freight order type. You can also enable the system to create change documents to record the changes you make to the tendering profiles that you edit. ON LY Tendering Profiles Figure 66: Tendering Profile Setup The tendering profile contains basic tendering data and is a prerequisite for automatic tendering. You can use a tendering profile when you manually create a tendering plan. Within the profile, you can define multi-step tendering. This allows a company to mix tendering 272 © Copyright. All rights reserved. Lesson: Configuring the Tendering Plan types. For example, you can first use peer-to-peer tendering, and if this is unsuccessful you can use broadcast tendering. US TO ME R Tendering Profile Details Figure 67: Tendering Profile Details RC To create a new tendering profile, in SAP TM, in the NetWeaver Business Client, on the Application Administration tab, choose Tendering → Tendering Profiles → Create Tendering Profile. The tendering profile is set up according to business requirements. Parts of the Tendering Profile FO The following are the main parts of a tendering profile: Tendering step You can specify one or more tendering steps Tendering type The following are the tendering types: Peer-to-Peer Tendering — Response Required ● Peer-to-Peer Tendering — No Response Required ● Broadcast Tendering — Best Offer ● Broadcast Tendering — First Acceptable Offer ON LY ● Tendering process mode The following are the tendering process modes: ● Freight RFQ Based, Award Manually ● Freight RFQ Based, Award Automatically ● Direct Tendering, Send Freight Order Directly © Copyright. All rights reserved. 273 Unit 6: Freight Tendering Carrier/Carrier Assignment Method The assignment of a carrier is optional in a tendering profile. When you use a profile to create a new tendering plan, the system can retrieve a carrier according to the carrier assignment strategy. The following are the standard carrier assignment strategies: Get Carriers from Ranking List ● Get Carriers from the Transportation Lane Master Data ● Get Assigned Carrier from Freight Order ● Assign Carriers Manually You can set a relative price limit for each tendering step. Maximum response duration ME Relative price limit R ● Manual evaluation US TO This is the longest period of time within which a carrier must respond This requires the tendering manager to manually evaluate each freight quotation (FQ). Carrier-specific freight agreement (FA) ON LY FO RC Visibility settings 274 © Copyright. All rights reserved. Unit 6 Exercise 24 Create a Tendering Profile R Business Example ME A large TV plasma manufacturer has a core carrier program in place. Dedicated carriers handle most of the freight. As part of the SAP TM implementation, the logistics transportation manager would like to be able to tender the freight to core carriers first. During December, in case the core carriers are unable to meet the demands, the plan is to broadcast the freight to other carriers. US TO To do this, you must: 1. In Customizing for SAP TM, create a visibility setting as outlined in Task 1. 2. In SAP TM, in the NetWeaver Business Client, create a 2-step tendering profile as outlined in Task 2. Note that, in this exercise, when the values include ##, replace the characters with the number assigned to you by your instructor. RC Create a Visibility Setting Before a tendering profile can be created, you have to create the visibility setting in Customizing. 1. In Customizing for SAP TM, create the visibility settings with the following data: Field Value Visibility Settings FO TM300_##_VIS TM300 Group ## visibility settings Stop Dates Visib. Editable, for information only Price Limit Not Relevant LY Vis. Stngs Desc. Subm. Price Visib Hidden Lowest Price Hidden ON Create a 2-Step Tendering Profile In SAP TM, in the NetWeaver Business Client, create a 2-step tendering profile. Tendering type Tendering process Carrier assignment method Visibility Settings Freight RFQ-Based, Award Automatically Get Carriers from Ranking list TM300_##_VIS Step 1 Peer-2-Peer Tendering – Response Required © Copyright. All rights reserved. 275 Unit 6: Freight Tendering Tendering type Tendering process Carrier assignment method Visibility Settings Freight RFQ-Based, Award Automatically Get Carriers from Ranking list TM300_##_VIS Step 2 Broadcast Tendering – First acceptable offer Field Description Tendering Type Determines how ten- Peer-to-Peer dering is carried out Tendering, Response Required Tendering Process Tendering process mode -Freight RFQBased, Award Automatically Carrier Carrier Blank -- Freight RFQ Sequence Number Freight RFQ sequence number Blank -- Carrier Assignment Method Determines how car- Get Carriers riers are assigned to from Ranking the freight order List A ranking list is provided from which carriers are selected Carrier-Specific Freight Agreement Carrier-specific freight agreement -- Maximum Response Duration Maximum time with- 00:05 in which the carrier must respond to an RFQ FO RC LY ON 276 Description Tender is sent to one carrier and a confirmation is required from this carrier US TO Value ME 2. Enter your data for Step 1 based on the following data: R 1. In SAP TM, in the NetWeaver Business Client, create a new two-step tendering profile, TM300_##_TEND_PROFILE. Deselect checkbox The RFQ is confirmed in the freight order when the program that checks the responses is executed. If you want to run this report manually, on the SAP Easy Access screen, choose Application Administration -> Background Reports -> Background Processing of Tendering . © Copyright. All rights reserved. Lesson: Configuring the Tendering Plan Description Value Description Visibility Settings Defines the visibility setting for RFQ, that is, whether prices are displayed, whether the carrier can change the prices, and so on TM300_##_VIS -- 3. Enter your data for Step 2 based on the following data: Description Tendering Type Determines how ten- Broadcast TenTender is sent to all dering is carried out dering – First carriers Acceptable Offer Tendering Process Tendering process mode Freight RFQBased, Award Automatically Carrier Carrier Blank Freight RFQ Sequence Number Freight RFQ sequence number Blank Carrier Assignment Method Determines how car- Get Carriers riers are assigned to from Ranking the freight order List RC Carrier-specific freight agreement Maximum Response Duration Maximum time with- 00:05 in which the carrier must respond to an RFQ ON LY FO Carrier-Specific Freight Agreement © Copyright. All rights reserved. Description ME Field US TO Value R Field A ranking list is provided from which carriers are selected Not selected The RFQ is confirmed in the freight order when the program that checks the responses is executed. If you want to run this report manually, on the SAP Easy Access screen, choose Application Administration -> Background Reports -> Background Processing of Tendering . 277 Unit 6: Freight Tendering Description Value Description Visibility Settings Defines the visibility setting for RFQ, that is, whether prices are displayed, whether the carrier can change the prices, and so on TM300_##_VIS ON LY FO RC US TO ME R Field 278 © Copyright. All rights reserved. Unit 6 Solution 24 Create a Tendering Profile R Business Example ME A large TV plasma manufacturer has a core carrier program in place. Dedicated carriers handle most of the freight. As part of the SAP TM implementation, the logistics transportation manager would like to be able to tender the freight to core carriers first. During December, in case the core carriers are unable to meet the demands, the plan is to broadcast the freight to other carriers. US TO To do this, you must: 1. In Customizing for SAP TM, create a visibility setting as outlined in Task 1. 2. In SAP TM, in the NetWeaver Business Client, create a 2-step tendering profile as outlined in Task 2. Note that, in this exercise, when the values include ##, replace the characters with the number assigned to you by your instructor. FO RC Create a Visibility Setting Before a tendering profile can be created, you have to create the visibility setting in Customizing. 1. In Customizing for SAP TM, create the visibility settings with the following data: Value Visibility Settings TM300_##_VIS Vis. Stngs Desc. TM300 Group ## visibility settings Stop Dates Visib. Editable, for information only Price Limit Not Relevant ON LY Field Subm. Price Visib Hidden Lowest Price Hidden a) In SAP TM, in Customizing for SAP Transportation Management, choose SAP Transportation Management → Transportation Management → Freight Order Management → Tendering → Define General Settings for Tendering. b) Choose 01 - Visibility Settings. c) To create a new profile, choose New Entries. Enter the data from the table in this step. d) Save your entries and exit Customizing. Create a 2-Step Tendering Profile In SAP TM, in the NetWeaver Business Client, create a 2-step tendering profile. © Copyright. All rights reserved. 279 Unit 6: Freight Tendering Tendering type Tendering process Carrier assignment method Visibility Settings Freight RFQ-Based, Award Automatically Get Carriers from Ranking list TM300_##_VIS Freight RFQ-Based, Award Automatically Get Carriers from Ranking list TM300_##_VIS Step 1 Peer-2-Peer Tendering – Response Required ME Broadcast Tendering – First acceptable offer R Step 2 1. In SAP TM, in the NetWeaver Business Client, create a new two-step tendering profile, TM300_##_TEND_PROFILE. US TO a) In SAP TM, in the NetWeaver Business Client, on the Application Administration tab, choose Tendering → Tendering Profiles → Create Tendering Profile. b) In the Tendering Profile field, enter TM300_##_TEND_PROFILE. c) In the Tendering Profile Description field, enter TM300 Group ## Tendering Profile. d) Proceed with the next exercise step without saving. 2. Enter your data for Step 1 based on the following data: Description Value Description Tendering Type Determines how ten- Peer-to-Peer dering is carried out Tendering, Response Required Tendering Process Tendering process mode -Freight RFQBased, Award Automatically Carrier Carrier Blank -- Freight RFQ Sequence Number Freight RFQ sequence number Blank -- Carrier Assignment Method Determines how car- Get Carriers riers are assigned to from Ranking the freight order List A ranking list is provided from which carriers are selected Carrier-specific freight agreement -- ON LY FO RC Field Carrier-Specific Freight Agreement 280 Deselect checkbox Tender is sent to one carrier and a confirmation is required from this carrier © Copyright. All rights reserved. Lesson: Configuring the Tendering Plan Description Value Maximum Response Duration Maximum time with- 00:05 in which the carrier must respond to an RFQ Visibility Settings Defines the visibility setting for RFQ, that is, whether prices are displayed, whether the carrier can change the prices, and so on Description The RFQ is confirmed in the freight order when the program that checks the responses is executed. If you want to run this report manually, on the SAP Easy Access screen, choose Application Administration -> Background Reports -> Background Processing of Tendering . -- US TO TM300_##_VIS FO RC a) Choose Insert Step. ME R Field b) Enter the data provided in the table. c) Proceed with the next exercise step without saving. 3. Enter your data for Step 2 based on the following data: Description Tendering Type Determines how ten- Broadcast TenTender is sent to all dering is carried out dering – First carriers Acceptable Offer Tendering Process Tendering process mode Freight RFQBased, Award Automatically Carrier Carrier Blank Freight RFQ Sequence Number Freight RFQ sequence number Blank Carrier Assignment Method Determines how car- Get Carriers riers are assigned to from Ranking List the freight order Carrier-Specific Freight Agreement Carrier-specific freight agreement ON LY Field © Copyright. All rights reserved. Value Description A ranking list is provided from which carriers are selected Not selected 281 Unit 6: Freight Tendering Description Value Maximum Response Duration Maximum time with- 00:05 in which the carrier must respond to an RFQ Visibility Settings Defines the visibility setting for RFQ, that is, whether prices are displayed, whether the carrier can change the prices, and so on Description The RFQ is confirmed in the freight order when the program that checks the responses is executed. If you want to run this report manually, on the SAP Easy Access screen, choose Application Administration -> Background Reports -> Background Processing of Tendering . US TO TM300_##_VIS FO RC a) Choose Insert Step. ME R Field b) Enter the data provided in the table. c) Save your entries. ON LY d) Exit the function. 282 © Copyright. All rights reserved. Lesson: Configuring the Tendering Plan LESSON SUMMARY You should now be able to: Configure the settings to enable order tendering ON LY FO RC US TO ME R ● © Copyright. All rights reserved. 283 Unit 6 Lesson 3 R Identifying the Tendering Collaboration Scenarios US TO LESSON OBJECTIVES After completing this lesson, you will be able to: ME LESSON OVERVIEW In this lesson, you will look at different tendering collaboration scenarios and ways to communicate with carriers. ● Determine communication methods with carriers ● Collaborate using the SAP TM collaboration portal Tendering Communication Methods FO RC As part of the tendering process, it is important to review the communication methods that support the tendering scenarios. For carriers who may not be able to support EDI (electronic data interchange) scenarios, SAP has developed a Web-based collaboration portal to improve communication. This requires subcontractors to log on to SAP TM using the Web in order to process a freight order. On a periodic basis, each subcontractor views their RFQs (modeled as tendering requests) and submits quotations (modeled as tendering responses). Each subcontractor is provided with their own user IDs and passwords, as well as the relevant authorization to restrict visibility to only the loads that have been tendered to them. Additional methods are supported, such as receiving RFQs by e-mail and SMS and submitting quotations by e-mail without the need to access an SAP TM system at all. In this case, an RFQ is sent to a carrier by e-mail or SMS message. The carrier responds to the e-mail using a regular e-mail client on a PC or a mobile device. The e-mail is then converted (using PI) into a quotation. Carriers can accept RFQs directly, reject them with a specified reason, or accept them with changes. ON LY Mobile tendering using a smartphone app is also supported and allows a mobile device to receive new RFQs, respond to RFQs, and include changes to dates and prices. Users can check addresses and routes on a map, e-mail or phone the contact person, create a calendar entry for awarded tenders, and check other appointments in the calendar. 284 © Copyright. All rights reserved. US TO ME R Lesson: Identifying the Tendering Collaboration Scenarios Figure 68: Tendering Communication Methods Advanced Communication If a subcontractor is more technically advanced, B2B communication can be used. FO RC In this situation, a copy of the freight order is created for the carrier (the tendering manager or system administrator can control what is included in the copy that is visible to the carrier). The copy is persisted in the system to retain what was communicated to the carrier. A freight request for quotation (tendering request) is sent via PI and received as a forwarding quotation in the supplier’s SAP TM system. The carrier can accept the order directly or, if the first carrier rejects the order, the freight order will be sent to the next carrier. Finally, a quotation confirmation is sent back to the customer and is converted into a quotation (tendering response) in the customer’s SAP TM system. The Change Controller allows you to react to changes in the FO, for example, by stopping tendering when there are major changes in the FO. ON LY Tendering via B2B Messages Figure 69: Connection of RFQ-based Tendering and Forwarding Quotation via B2B Messages © Copyright. All rights reserved. 285 Unit 6: Freight Tendering In RFQ-based tendering via business-to-business (B2B) messages, a freight request for quotation (modeled as a “tendering request”) is received by the supplier's TM system as a forwarding quotation. The quotation confirmation is sent back to the customer and is converted into a quotation (“tendering response”) in the customer’s TM system. US TO ME R Direct Tendering via B2B Messages Figure 70: Connection of Direct Tendering and Forwarding Order via B2B Messages FO RC In direct tendering via B2B messages, the freight order is sent directly to the carrier, where is it received as a forwarding order. The carrier can accept the order directly. If the carrier rejects the order, the freight order will be sent to the next carrier. ON LY Tendering via Email and SMS Figure 71: Tendering via E-mail and SMS In the Tendering via E-mail and SMS scenario, an RFQ (modeled as a "tendering request") is sent to a carrier by e-mail or SMS. The carrier responds to the e-mail using a regular e-mail client on a PC or a mobile device and sends it back to the ordering party. The e-mail is then converted into a quotation (modeled as a "tendering response"). 286 © Copyright. All rights reserved. Lesson: Identifying the Tendering Collaboration Scenarios You can define communication settings for a particular carrier that are different from the general communication settings. Mobile Tendering RC US TO ME R Freight RFQs can easily be integrated with carriers who cannot implement a complex B2B integration. Mobile tendering allows a mobile device to receive new RFQs, respond to RFQs, and include changes to dates and prices. Users can check addresses and routes on the map, e-mail or phone the contact person, create a calendar entry for awarded tenders, and check other appointments in the calendar. Figure 72: Mobile Tendering To Tender with a Mobile App FO 1. Download the SAP Transport Tendering app from the Apple App Store. 2. Open the app and follow the instructions to complete the installation. To run the app on real data, you need to connect to your company's SAP server by entering the server address. ON LY 3. Requests are grouped under four headings, as follows: ● Open ● Quoted ● Completed ● All 4. Choose any of the headings to view details of requests in that category. 5. Use the app as appropriate to accept or reject quotes. © Copyright. All rights reserved. 287 Unit 6: Freight Tendering US TO ME R SAP TM Collaboration Portal Figure 73: SAP TM Collaboration Portal The SAP Transportation Management collaboration portal for carriers (SAP TM Collaboration Portal) supports collaborative business processes. FO RC As a carrier working with several shippers that use the SAP TM collaboration portal, you have separate access to each of your shippers. In each case, you can work with one shipper only. The shipper can provide you with access to the following areas in the SAP TM collaboration portal: ● In the Freight Settlement area, you can enter differences in logistical item quantities, charge amounts in a freight order, and create a freight settlement dispute case against the shipper. LY ● In the Freight Order Management area, you can take part in a tendering process started by a shipper. You can view your shipper's freight requests for quotation, and submit freight quotations to the shipper. You can accept, change, or reject the shipper's freight requests for quotation. You can report planned and unexpected events for a freight order as well as enter quantity deviations. In the Freight Agreement Management area, you can respond to your shipper's freight agreement RFQs with your rates for the transportation services. ON ● Note: In this training course we focus on the tendering functionality. Other Collaboration Portal functionalities are covered in other TM training courses. The following browsers are supported: ● 288 Windows © Copyright. All rights reserved. Lesson: Identifying the Tendering Collaboration Scenarios ● - Internet Explorer 9 and upwards, including IE10 - Firefox 24 (Firefox Extended Support Release - ESR) and latest version - Chrome (latest version) MAC OS X - Safari 5.1 and upwards FO RC US TO ME R SAP TM Collaboration Portal - Topics Overview Figure 74: SAP TM Collaboration Portal - Topics Overview The main benefits of the SAP TM Collaboration Portal are: Small and mid-size carriers do not need to have SAP TM installed LY ● ● ON ● ● ● Full browser based solution means that carrier even does not need to have access to shipper’s network (that is connection via VPN, and so on) All common browsers are supported (Internet Explorer 9, Mozilla Firefox, Safari, Google Chrome) Carrier does not have to install anything, but just log in into the collaboration portal with the access (login and password) provided by the shipper as SAP TM collaboration portal owner/host Carrier can see only request for quotations (RFQ) assigned to it and his transmitted quotations © Copyright. All rights reserved. 289 Unit 6: Freight Tendering ● User settings in the portal are stored and available after re-logon to increase the usability of the portal by the carrier As a carrier, you enter the SAP Transportation Management collaboration portal through the Home screen. This screen displays a worklist with the key performance indicators (KPIs) for the available areas in the form of tiles. From the tiles, you can navigate to the individual areas to continue your work. You can see only the areas that are relevant for you. ● Pending freight quotations: the number of freight quotations that you have submitted to the shipper and for which a decision about the award is pending Open freight orders for execution: the number of open freight orders for which you still have to report at least one event US TO ● Open freight RFQs: the number of freight RFQs to which you can respond with a freight quotation ME ● R The following KPIs are available for Freight Order Management: ON LY FO RC SAP TM Collaboration Portal - Process Overview Figure 75: SAP TM Collaboration Portal - Process Overview As a carrier, you can display the freight requests for quotation (RFQs) that you have received from a shipper. You can also display the freight quotations that you submitted to your shipper for a specific freight RFQ. If you do not make any changes you can accept one or more freight RFQs. If you make changes you can accept only one freight RFQ. You can reject one or more freight RFQs and provide a reason for rejection. Furthermore, you can display the details about the tendered freight order, such as item details, location information, and business partner. 290 © Copyright. All rights reserved. Lesson: Identifying the Tendering Collaboration Scenarios The business process of tendering in the Freight Order Management area in the SAP Transportation Management collaboration portal corresponds to the tendering process in the standard SAP TM system. RC US TO ME R Technical Architecture of the SAP TM Collaboration Portal Figure 76: Freight Requests for Quotation (RFQs) FO On the Freight Requests for Quotation screen, you can view all freight requests for quotation that you have received from a specific shipper. You can display open and closed freight RFQs. From the toolbar, you can apply the quick filter to filter freight RFQs by their status (open, closed, all). In the table view, you can apply a filter to those fields that support the filter function by entering a filter value in accordance with the SAP UI5 standard. You can show or hide individual columns and change their sequence by using drag and drop. LY You can find freight RFQs using the search field in the toolbar. The system returns all freight RFQs that contain the search term in a field (fuzzy search) irrespective of whether the field is shown or hidden. ON If a field can be sorted, you can display the contents of the individual columns in ascending or descending order. © Copyright. All rights reserved. 291 Unit 6: Freight Tendering FO RC Figure 77: RFQs Details US TO ME R RFQs Details On the Freight Requests for Quotation screen, you have the following options: ● ● ● ● You can accept one or more freight RFQs at the same time. You can reject one or more freight RFQs at the same time and specify a reason for rejection. You can accept a freight RFQ with changes. You can view the stop sequence and the tendering details (cargo information, locations, and business partners). You can display the source location and destination location of a freight RFQ on a map. ● You can view the lowest suggested price submitted by another carrier. ● You can export the content of a freight RFQ from the table view to a Microsoft Excel file. ON LY ● 292 © Copyright. All rights reserved. Lesson: Identifying the Tendering Collaboration Scenarios US TO ME R Accept RFQ with Changes RC Figure 78: Accept RFQ with Changes The stop sequence view enables you to see which cargo items were loaded and unloaded at each stop. FO For each stop in the stop sequence, you can view the expected arrival and departure times, as well as the gross weight and volume of the truck once the loading or unloading operation has been completed at a specific location. You can also view the weight, volume, quantity, and dimensions for each separate cargo item, and see whether the item is classified as dangerous goods. You can also see whether each cargo item is to be loaded or unloaded at the specific location. LY On the Freight Requests for Quotation screen, the table view and detail view show the calculated gross weight and volume for the entire freight order. You can view the calculated quantity in the table view only. ON When your shipper sends a freight request for quotation (RFQ), you can accept it without making any changes, accept it with changes, or reject it. Accepting Freight RFQ Without Changes If you are in agreement with the freight RFQ, you can accept it without making any changes. Accepting Freight RFQ with Changes Depending on the tendering settings, you can use the following functions: ● If you want to accept a freight RFQ with changes, you can change the price and dates. You can suggest your own price in relation to the price limit of the shipper. You can change © Copyright. All rights reserved. 293 Unit 6: Freight Tendering both the amount and the currency. Your suggested price appears on the freight quotation as the submitted price. ● You can overwrite dates (start and end date) requested by the shipper. These appear on the freight quotation as the submitted dates. Acceptable dates are fixed limits defined by the shipper and are used to delimit the requested dates. You cannot change the acceptable dates. If you reject several freight RFQs at the same time, each one is assigned the same rejection reason. ME ● R Rejecting a Freight RFQ ● If you reject a freight RFQ, you can specify a rejection reason. LY FO RC US TO Freight Quotations Figure 79: Freight Quotations ON You can display all of the freight quotations that you have sent to a shipper. If you want to display information about a specific freight quotation in the detail view, you must select a single row. If you have accepted a freight RFQ with changes, your suggested price is shown on the freight quotation as the submitted price. On the Freight Request for Quotation screen, the system always displays the information from the freight RFQ most recently submitted. You can display the source location and destination location of a freight quotation on a map. You can view the lowest suggested price submitted by another carrier. You can export the content of a freight quotation from the table view to a Microsoft Excel file. 294 © Copyright. All rights reserved. Lesson: Identifying the Tendering Collaboration Scenarios Facilitated Discussion: SAP TM Collaboration Criteria List the ways your organization can use the different collaboration methods during tendering. LESSON SUMMARY You should now be able to: Determine communication methods with carriers ● Collaborate using the SAP TM collaboration portal ON LY FO RC US TO ME R ● © Copyright. All rights reserved. 295 ON LY FO RC US TO ME R Unit 6: Freight Tendering 296 © Copyright. All rights reserved. Unit 6 Learning Assessment True X False ME X US TO Determine whether this statement is true or false. R 1. Broadcast tendering refers to a process whereby all quotations received (in response to an RFQ) are broadcast to all carriers in an effort to improve transparency. 2. During the tendering process, a shipper sends a freight order directly to a specific carrier without creating a freight RFQ. What tendering process is the shipper using? Choose the correct answer. A Direct tendering X B Broadcast tendering X C Best offer tendering X D First response tendering RC X 3. Which of the following statements about freight order tendering are correct? FO Choose the correct answers. A During the tendering process, only one tendering mode can be used. X B During the tendering process, carriers can update prices when the return freight quotations. ON LY X X C The tendering process results in one carrier being selected to execute the freight order. X D The tendering process starts if you or the system determine more than one possible carrier. © Copyright. All rights reserved. 297 Unit 6: Learning Assessment 4. In the standard settings for tendering, which settings control the information from a freight RFQ that can be seen and edited by a carrier? A Visibility Settings X B Carrier -Specific Communication Settings X C E-mail and SMS Content Setting X D E-mail and SMS Content Setting ME X R Choose the correct answer. 5. When does the system use the settings defined in the Default Settings view? Choose the correct answer. A When the system cannot determine a freight order type specific settings. X B When the system is performing automatic tendering. X C When carrier does not have its own SAP TM system. X D When the system receives a freight RFQ rejection from a carrier. US TO X 6. A carrier does not have an SAP Transportation Management (SAP TM) system. What tendering scenario can be used between the carrier and the shipper? FO RC Choose the correct answer. X A Tendering via E-mail X B Tendering via SMS X C Tendering via B2B messages X D Tendering via Collaboration Portal 7. To use the Collaboration Portal, a carrier must have SAP TM installed. LY Determine whether this statement is true or false. True X False ON X 298 © Copyright. All rights reserved. Unit 6 Learning Assessment - Answers True X False ME X US TO Determine whether this statement is true or false. R 1. Broadcast tendering refers to a process whereby all quotations received (in response to an RFQ) are broadcast to all carriers in an effort to improve transparency. 2. During the tendering process, a shipper sends a freight order directly to a specific carrier without creating a freight RFQ. What tendering process is the shipper using? Choose the correct answer. A Direct tendering X B Broadcast tendering X C Best offer tendering X D First response tendering RC X FO 3. Which of the following statements about freight order tendering are correct? Choose the correct answers. A During the tendering process, only one tendering mode can be used. X B During the tendering process, carriers can update prices when the return freight quotations. ON LY X X C The tendering process results in one carrier being selected to execute the freight order. X D The tendering process starts if you or the system determine more than one possible carrier. © Copyright. All rights reserved. 299 Unit 6: Learning Assessment - Answers 4. In the standard settings for tendering, which settings control the information from a freight RFQ that can be seen and edited by a carrier? A Visibility Settings X B Carrier -Specific Communication Settings X C E-mail and SMS Content Setting X D E-mail and SMS Content Setting ME X R Choose the correct answer. 5. When does the system use the settings defined in the Default Settings view? Choose the correct answer. A When the system cannot determine a freight order type specific settings. X B When the system is performing automatic tendering. X C When carrier does not have its own SAP TM system. X D When the system receives a freight RFQ rejection from a carrier. US TO X FO RC 6. A carrier does not have an SAP Transportation Management (SAP TM) system. What tendering scenario can be used between the carrier and the shipper? Choose the correct answer. X A Tendering via E-mail X B Tendering via SMS X C Tendering via B2B messages X D Tendering via Collaboration Portal LY 7. To use the Collaboration Portal, a carrier must have SAP TM installed. Determine whether this statement is true or false. ON X X 300 True False © Copyright. All rights reserved. UNIT 7 Freight Orders in Transportation Management R Lesson 1 List the methods of creating freight orders in SAP TM ON LY FO RC ● US TO UNIT OBJECTIVES 302 ME Creating Freight Orders © Copyright. All rights reserved. 301 Unit 7 Lesson 1 Creating Freight Orders LESSON OBJECTIVES After completing this lesson, you will be able to: List the methods of creating freight orders in SAP TM US TO ● ME R LESSON OVERVIEW In this lesson, you learn the different methods of creating freight orders in SAP TM. ON LY FO RC Role of Freight Orders in Transportation Figure 80: SAP TM Document Flow Depending on the scenario in which SAP TM is used, different types of transportation requests can be created in SAP TM to start the transportation process. These requests can include forwarding orders (FWO), order-based transportation requirements (OTR), and delivery-based transportation requirements (DTR). Upon receiving the requests, freight units are created to become the basic element for planning the movement through the network. The freight unit is a logical transport unit used 302 © Copyright. All rights reserved. Lesson: Creating Freight Orders in planning. This transportation unit can be a pallet or container, but it can also be two pallets that need to be transported together, for example, for customs reasons. Freight orders record the manual or system-generated transportation planning (intermodal) activities. These freight orders are the result of planning and the consolidation of freight units on a vehicle-booked capacity or scheduled means of transport. Once freight orders are created, the carrier's short-term tendering works with additional business documents, Requests for Quotation (RFQs). Once this has been completed, transport order execution can be triggered and follow-on settlement processing can begin. FO RC US TO Freight Orders and Freight Bookings ME R Freight Orders and Freight Bookings are both the result of transportation planning and the freight document for execution. Different follow-up processes can be triggered based on Freight Orders, including subcontracting (carrier selection, tendering), charge calculation, ERP delivery and shipment creation, and tracking and tracing. LY Figure 81: Freight Orders / Freight Bookings Freight orders/bookings contain the following: ON ● Planning information, for example, planned means of transport and stages, routing, planned pickup and delivery dates, durations and distances ● Document dependencies, as well as predecessor and successor documents ● Transportation charges and cost distribution ● ● Cargo information: quantities and weights, goods information; corresponding freight orders; pick-up and delivery freight orders Execution information © Copyright. All rights reserved. 303 Unit 7: Freight Orders in Transportation Management ● Business partner information ● Output management ● Customs-relevant information ● Status information and blocking information ● Subcontracting FO RC US TO ME R Integration of Freight Orders / Booking to other Applications or Components Figure 82: Integration of Freight Orders / Booking to other Applications or Components In a freight order, execution is planned by a carrier or the shipper. The freight order contains the following: The plan for the logistical processing, for example, when and onto which vehicle freight units are to be loaded LY ● ● Planned departure times for the vehicles ● Execution data, and so on ON Above all, freight orders are used for land transportation. You can perform carrier selection for freight orders. You can then either subcontract freight orders directly to a carrier, or you can first perform tendering. Change controllers can be used to define how the system reacts to changes. On the other hand, in freight booking the execution is planned by a carrier, such as a ship owner. The freight booking contains the plan for the logistical processing, such as the fixed departure times of the ship. A freight booking is used to reserve freight space on a ship or in an airplane or can be created during transportation planning. The freight booking is also the document for the actual execution. 304 © Copyright. All rights reserved. Lesson: Creating Freight Orders RC US TO ME R Freight Order Creation Methods Figure 83: Creating Freight Orders You have the following four options of creating freight orders (FOs): 1. Manual Creation FO 2. Creation from Transportation Planning 3. Direct Creation from a Business Document in Forwarding Order Management (FWM) 4. Creation by Copying LY Manual Creation Manual creation is generally used when you already know the most important transportation data, such as source location, destination location, and business partner, because you regularly transport goods for a certain customer using a certain carrier. ON To manually create a freight order, you require the following information: general data for the freight order (shipper, consignee, carrier, resource, locations, dates and times, schedules, and terms of payment), information about any additional intermediate stops, the items involved (add freight units to the freight order or enter the items directly on the freight order), and information about the charges involved (as calculated, or configure the system to calculate charges). Once the required information has been entered, you can check the consistency and save the freight order. The freight order can then be sent over to the carrier and confirmed or rejected on behalf of the carrier. Necessary documents can be printed, and a freight settlement document created after the execution. © Copyright. All rights reserved. 305 Unit 7: Freight Orders in Transportation Management A possible variant of this process is that you simply enter the general data. You then call the transportation cockpit and assign freight units to your freight order. You then perform all additional planning steps in the transportation cockpit: for example, you can have the system calculate the transportation charges and you perform carrier selection or tendering. Creation from Transportation Planning Many companies responsible for shipping large volumes of products can use the optimizer planning in SAP TM. This gives planners a high-level perspective of their transportation demands. You can perform planning either manually or automatically. ME R In planning, freight orders are created based on business documents, such as forwarding orders. To do this, freight units are first created from the inbound business documents. Capacities are then assigned to these freight units. Various constraints are taken into account, such as requested delivery dates. Freight orders are the result of the planning. US TO Vehicle Scheduling and Routing (VSR) optimization is used to generate optimized freight orders. This generation is based, on the one hand, on minimization of the defined costs (for example, vehicle costs and distance-dependent vehicle costs). It also considers the selected constraints (for example, windows for delivery and incompatibilities). VSR optimization can be scheduled in the background. The optimizer evaluates all options for consolidation and all possible ways through the transportation network to obtain an optimal plan based on the cost settings made in the Planning Cost Settings area of the planning profile. Direct Creation from a Business Document in Forwarding Order Management (FWM) FO RC Freight orders can also be created directly from a business document in forwarding order management (FWM business documents). It is possible to create a freight order directly for a forwarding order stage from within the forwarding order screen. The system creates a freight order directly when you save an FWM business document (forwarding order, order-based or delivery-based transportation requirement) if the following requirements have been met: ● The FWM business document can be delivered in one freight order, meaning there is no pre-carriage or on-carriage. LY ● The FWM business document is subcontracted and not consolidated with other FWM business documents. ● The FWM business document only has one source location and one destination location. The various options by which freight orders can be created directly are the following: FWM business document type determines the freight order creation. ● FWM business document stage type determines the freight order creation. ● FWM business document attributes determine the freight order creation. ON ● Creation by Copying You can create a freight order by copying an existing one (a reference document). The system copies the header data and the logistical data. However, it does not copy references to freight units and execution information. 306 © Copyright. All rights reserved. Lesson: Creating Freight Orders Other Creation Methods There are also other methods for freight order creation, such as creation via Web Service, creation from ERP shipment, bill of lading creation, creation of pick-up and delivery freight order from booking, and creation from a customer pick-up or self-delivery stage. LESSON SUMMARY You should now be able to: List the methods of creating freight orders in SAP TM ON LY FO RC US TO ME R ● © Copyright. All rights reserved. 307 ON LY FO RC US TO ME R Unit 7: Freight Orders in Transportation Management 308 © Copyright. All rights reserved. Unit 7 Learning Assessment ME Choose the correct answer. R 1. Which method of freight order creation is best suited for companies who are shipping large volumes of products? A Manual Creation X B Creation from Transportation Planning X C Direct Creation from a Business Document in Forwarding Order Management (FWM) X D Creation by Copying ON LY FO RC US TO X © Copyright. All rights reserved. 309 Unit 7 Learning Assessment - Answers Choose the correct answer. ME R 1. Which method of freight order creation is best suited for companies who are shipping large volumes of products? A Manual Creation X B Creation from Transportation Planning X C Direct Creation from a Business Document in Forwarding Order Management (FWM) X D Creation by Copying ON LY FO RC US TO X 310 © Copyright. All rights reserved. UNIT 8 Freight Order Setup Lesson 2 Lesson 3 334 RC Determining Business Partners 324 327 US TO Configuring Freight Order Type Determination Exercise 26: Determine Freight Order Types 312 319 ME Configuring Freight Order Types Exercise 25: Create Freight Order Types R Lesson 1 UNIT OBJECTIVES Use freight order types ● Determine organizational units in freight orders automatically ● Create freight order types FO ● Set up freight order type determination based on the appropriate usage ● Identify the business partner roles assigned to freight orders ● Determine business partners in freight orders ON LY ● © Copyright. All rights reserved. 311 Unit 8 Lesson 1 Configuring Freight Order Types LESSON OBJECTIVES After completing this lesson, you will be able to: ME R LESSON OVERVIEW In this lesson, you learn how create, configure and use freight order types. You also learn how to determine organizational units in freight orders automatically. Use freight order types ● Determine organizational units in freight orders automatically ● Create freight order types ON LY FO RC Freight Order Types US TO ● Figure 84: Freight Order Types A freight order type defines parameters that influence how the system processes the freight order. When manually creating a freight order, the user has to select a freight order type. Freight Order Type Settings Here are some of the settings that can be configured in the freight order type: 312 © Copyright. All rights reserved. Lesson: Configuring Freight Order Types Basic Settings Enabling charges and settlement ● Determining shipper and consignee ● Specifying if a freight order can be subcontracted ● Defining whether a freight order is to be deleted or only canceled ● Specifying if the freight order is to be used for customer self-delivery or pickup R ● Execution Settings ● ME ● Define whether the system is to perform the execution steps within SAP Transportation Management. Specify additional conditions that need to be fulfilled so that the status Ready for Execution can be set. Define the settings for integration with SAP Event Management. Tendering Settings ● US TO ● You can define process and communication settings or define a condition to determine these settings. Organizational Unit Determination ● You can define how the system determines the purchasing organization and the execution organization. ● RC Change Controller Settings You can define settings for the change controller, for example, a default change strategy and a condition for change strategy determination. Service Level Determination If you have not defined a condition or you have defined one and the system cannot determine a result, the system uses the default service level. FO ● Default Means of Transport Determination If you have not defined a condition or you have defined one and the system cannot determine a result, the system uses the default means of transport. LY ● Output Settings ● You can define an output profile and a text schema, for example. ON Additional Settings ● Dangerous goods profile ● Default FSD Type, internal settlement document type ● Carrier selection settings ● Enable compliance checks © Copyright. All rights reserved. 313 Unit 8: Freight Order Setup ● Partner determination profile ● Number range for house bill of ladings In the freight order type, you can specify if a freight order is to be used for customer selfdelivery or pick-up. Freight Order Type Customizing FO RC US TO ME R The freight order type determines how a freight order is processed in SAP TM. There are some basic settings allowing for flexible customization options. Figure 85: Freight Order Type Customizing ON LY Freight Order Type Figure 86: Freight Order Type 314 © Copyright. All rights reserved. Lesson: Configuring Freight Order Types The figure, Freight Order Type, shows a system view of some of the options related to customizing freight order types. US TO ME R Usage of Different Types of Freight Orders and Freight Bookings RC Figure 87: Freight Order/Booking Types in the Document Flow The figure gives an overview of how different types of freight orders and freight bookings can be used in a transportation scenario and the document flow. FO The freight orders for pick-up and delivery represent the freight documents for the initial or final phase of the main carriage respectively. Such transfer orders can be created out of the freight booking document. To Use Freight Order Types 1. In SAP TM, In the NetWeaver Business Client, choose Freight Order Management. LY 2. Choose Road → Overview Freight Orders. 3. In the Active Queries area, choose the All query. 4. In the Document Type column, note the freight order type. ON 5. In the Document column, click the hyperlink to open a freight order. 6. Open the General Data tab. 7. In the Document Type field, note the freight order type. 8. Close the freight order document. © Copyright. All rights reserved. 315 Unit 8: Freight Order Setup US TO ME R Freight Order Organizational Unit Determination Figure 88: Determination of Organizations in Freight Documents It is possible to configure the automatic determination of the purchasing/execution organizations in the freight documents. FO RC Automatic determination can be customized in the freight order or freight booking document types in the following ways: with a default organization assignment, based on the user assignment, and by specifying an organization determination condition of type /SCMTMS/ TOR_ORGUNIT. Organizational Unit Conditions for Freight Orders The system first checks the Condition field. If you have not entered a condition, or if the condition does not return a result, the system checks whether the Consider Organization Unit of User checkbox is selected, and whether the user is assigned to a purchasing organization and an execution organization. If the checkbox is not selected or the user is not assigned to a purchasing organization and an execution organization, the system uses the data maintained in the Default Org Unit area. To View Organizational Units in the Freight Order LY 1. In SAP TM, in the NetWeaver Business Client, choose Freight Order Management. 2. Choose Road → Edit Road Freight Order. 3. In the Freight Order field, enter the freight order number and choose Continue. ON 4. Open the General Data tab. 5. Scroll to the Organizational Data section. 6. In the Purchasing Organization field, the purchasing organization is specified. 7. In the Purchasing Group field, the purchasing group is specified. 8. In the Planning and Execution Organization field, the planning and execution organization is specified. 9. In the Planning and Execution Group field, the planning and execution group is specified. 316 © Copyright. All rights reserved. Lesson: Configuring Freight Order Types 10. Close the freight order document. Freight Order Type Creation ON LY FO RC US TO ME R The freight order type, freight booking type, freight unit type, transportation unit type, and service order type need to be unique across these five business document categories. For example, you cannot create a freight unit type 0003 and a freight order type 0003. © Copyright. All rights reserved. 317 ON LY FO RC US TO ME R Unit 8: Freight Order Setup 318 © Copyright. All rights reserved. Unit 8 Exercise 25 Create Freight Order Types R Business Example ME The freight order type defines the most important settings for the freight order. In this exercise, you can practice creating freight order types. Note that, in this exercise, when the values include ##, replace the characters with the number assigned to you by your instructor. US TO 1. In Customizing for SAP Transportation Management, open the screen where you define freight order types. 2. Create a freight order type using the following data and configure the settings based on the business requirements: Field Freight Order Type Value TO## TM310 Group ## Freight Order Sequence Type of Stops Defined and Linear FO RC Freight Order Description Default Change Strategy DEF_CHACO Output Profile /SCMTMS/TOR Add. Output Profile /SCMTMS/TOR_PRINT_ROAD Purchasing Org. 50000808 Business requirements: External carriers could be assigned to the freight order. ● The shipper and consignee are based on predecessor documents. ● The user can delete the freight order if necessary. ● The user can calculate the transportation charges in the freight orders. ● The freight orders are to be settled. ON LY ● ● The freight order numbers should be numbers between 6100000000 and 6199999999. ● The freight order number should be determined when saving. ● The units of measure in the freight order should default to US Pound and Cubic Foot. © Copyright. All rights reserved. 319 Unit 8: Freight Order Setup ● The Default FSD Type should be set to Default Freight Settlement Document (0001). ON LY FO RC US TO ME R ● The transportation mode for the freight orders should default to road. 320 © Copyright. All rights reserved. Unit 8 Solution 25 Create Freight Order Types R Business Example ME The freight order type defines the most important settings for the freight order. In this exercise, you can practice creating freight order types. Note that, in this exercise, when the values include ##, replace the characters with the number assigned to you by your instructor. US TO 1. In Customizing for SAP Transportation Management, open the screen where you define freight order types. a) In Customizing for SAP Transportation Management, choose SAP Transportation Management → Transportation Management → Freight Order Management → Freight Order → Define Freight Order Types. 2. Create a freight order type using the following data and configure the settings based on the business requirements: Field Value TO## RC Freight Order Type TM310 Group ## Freight Order Sequence Type of Stops Defined and Linear Default Change Strategy DEF_CHACO Output Profile /SCMTMS/TOR Add. Output Profile /SCMTMS/TOR_PRINT_ROAD Purchasing Org. 50000808 FO Freight Order Description ON LY Business requirements: ● External carriers could be assigned to the freight order. ● The shipper and consignee are based on predecessor documents. ● The user can delete the freight order if necessary. ● The user can calculate the transportation charges in the freight orders. ● The freight orders are to be settled. ● The freight order numbers should be numbers between 6100000000 and 6199999999. © Copyright. All rights reserved. 321 Unit 8: Freight Order Setup ● The freight order number should be determined when saving. ● The units of measure in the freight order should default to US Pound and Cubic Foot. ● The transportation mode for the freight orders should default to road. ● The Default FSD Type should be set to Default Freight Settlement Document (0001). a) Choose New Entries. R b) Enter the data provided in the table. Value Freight Order Type TO## Freight Order Description TM310 Group ## Freight Order Enable Settlement Selected Default FSD Type Default Freight Settlement Document (0001) US TO ME Field Relevant for Subcontracting Shipper/Consignee Determination Determination based on Predecessor Documents Freight Order Can be Deleted Selected Sequence Type of Stops Defined and Linear FO RC Freight Order Can be Subcontracted Draw number when saving document Number Range Interval FO Default Unit of Measure for Weigh US pound (LB) Default Unit of Measure for Volume Cubic foot (FT3) Enable Charge Calculation Selected Default Change Strategy DEF_CHACO Transportation Mode 01(Road) LY Time for Drawing /SCMTMS/TOR Add. Output Profile /SCMTMS/TOR_PRINT_ROAD Purchasing Org. 50000808 ON Output Profile c) Save and exit the function. 322 © Copyright. All rights reserved. Lesson: Configuring Freight Order Types LESSON SUMMARY You should now be able to: Use freight order types ● Determine organizational units in freight orders automatically ● Create freight order types ON LY FO RC US TO ME R ● © Copyright. All rights reserved. 323 Unit 8 Lesson 2 Configuring Freight Order Type Determination LESSON OBJECTIVES After completing this lesson, you will be able to: Set up freight order type determination based on the appropriate usage US TO ● ME R LESSON OVERVIEW In this lesson, you learn how to set up and configure freight order type determination based on the appropriate usage. FO RC Freight Order Type Determination Figure 89: Freight Order Type Determination It is possible to assign a freight order type to the following: Forwarding order stage types ● Freight unit types (direct shipment options) ● Freight unit building rules (short-cut planning) ● Freight booking types (to create pickup and delivery transfer orders) ● Planning profiles LY ● ON Freight Order Determination The system determines freight order types in one of the following ways: ● ● 324 If freight orders are created during planning and the freight order type is configured in the Business Document Type area of the planning profile, then the system determines the freight order type according to your settings. If freight orders are created from forwarding order stages, the system determines the freight order type based on the Customizing activity Define Default Freight Document Types for Stages. © Copyright. All rights reserved. Lesson: Configuring Freight Order Type Determination ● ● If freight units are converted into freight orders when direct shipment options (DSO) are determined, the system uses the freight order type that you specified for DSO in the freight unit type. If the system cannot identify the freight order type, then it uses the default freight order type that is defined in the Customizing activity. US TO ME R Business Rule Framework (BRF) and Conditions Figure 90: FO Type Determination Based on BRF and Conditions The business rule framework (BRF) and conditions can be used for determining freight order types, based on various business rules or needs. For determining freight order types based on BRF and conditions, set up the freight order type Determination Condition /SCMTMS/TOR_TYPE. This condition can be assigned to the freight unit type (for direct shipment options) or the planning profile. ON LY FO RC During the creation of the freight order, the system evaluates the BRF and condition, and then identifies the freight order type based on the available data. © Copyright. All rights reserved. 325 ON LY FO RC US TO ME R Unit 8: Freight Order Setup 326 © Copyright. All rights reserved. Unit 8 Exercise 26 Determine Freight Order Types R Business Example ME There are a number of ways to determine freight order types automatically. In this exercise, you will practice the various methods. Note that, in this exercise, when the values include ##, replace the characters with the number assigned to you by your instructor. US TO 1. Determine if there is a freight order type (for direct shipment) associated with the freight unit type EPFU. 2. When is a freight order type directly specified in a freight unit building rule? FO RC 3. Determine how the freight order type is determined when planning with the GRP##-NAFU-PLAN-PROF planning profile. 4. Identify the freight order type that is determined when planning road freight orders using the GRP##-NA-FU-PLAN-PROF planning profile. 5. Navigate to where you can assign the freight order type for delivery or pickup to the freight booking type FB##. 6. In SAP ERP, create a new sales order using the data provided in the following table: Value Order Type ZT00 Sales Org. 3000 Distribution Channel 10 Division 00 Sold-to Party CUST00-25 PO Number TM310-GRP##-2.2 Material PRODTM-00 Quantity 20 Unit of Measurement Box ON LY Field 7. Navigate to Overview Transportation Requirements. © Copyright. All rights reserved. 327 Unit 8: Freight Order Setup 8. In the worklist, select the OTR for your sales order and start the Transportation Cockpit. 9. In the Transportation Cockpit: Profile and Layout sets screen, create an entry using the data provided in the following table: R Note: If the screen is not displayed, choose Change Profile Selection → Profile Selection Screen. Value Planning Profile GRP##-NA-FU-PLAN-PROF Transportation Cockpit Layout Standard Layout for Planning Result Screen Standard Description TM310 Group ## Profile and Layout Set US TO ME Field 10. In SAP TM, plan the newly created sales order with vehicle resource US-FTL-01. 11. What is the freight order type of the freight order what was just created? ON LY FO RC 12. In this scenario, how was the freight order type determined? 328 © Copyright. All rights reserved. Unit 8 Solution 26 Determine Freight Order Types R Business Example ME There are a number of ways to determine freight order types automatically. In this exercise, you will practice the various methods. Note that, in this exercise, when the values include ##, replace the characters with the number assigned to you by your instructor. US TO 1. Determine if there is a freight order type (for direct shipment) associated with the freight unit type EPFU. a) In SAP TM, in Customizing for SAP Transportation Management, choose SAP Transportation Management → Transportation Management → Planning → Freight Unit → Define Freight Unit Types. b) In the list, select the freight unit type. c) Choose (Details). RC d) In the Direct Shipment Options section, in the Freight Order Type field, note any freight order type specified. Yes. Freight order type EPFO has been specified. FO 2. When is a freight order type directly specified in a freight unit building rule? A A freight order type is directly specified in the freight unit building rule to configure a shortcut planning scenario. LY 3. Determine how the freight order type is determined when planning with the GRP##-NAFU-PLAN-PROF planning profile. ON a) In SAP TM, in the NetWeaver Business Client, choose Application Administration → Planning → Planning Profiles → Display Planning Profile. b) Enter the profile and choose Continue. c) In the Planning Profile , select the Planning Profile tab. d) In the Business Document Type section, look in the Type Determination Rule field. © Copyright. All rights reserved. 329 Unit 8: Freight Order Setup The freight order type is determined as Defined per Category in the Planning Profile. 4. Identify the freight order type that is determined when planning road freight orders using the GRP##-NA-FU-PLAN-PROF planning profile. a) In the Business Document Type section, look in the Default Type for Road FO field. R T0##. ME 5. Navigate to where you can assign the freight order type for delivery or pickup to the freight booking type FB##. a) In Customizing for SAP Transportation Management, choose SAP Transportation Management → Transportation Management → Freight Order Management → Freight Booking → Define Freight Booking Type. US TO b) Select the freight booking type. c) To view the details of the freight booking type, choose (Details). d) In the Additional Settings section: ● In the Default FO Type for Delivery field, you can specify the freight order type for delivery. FO RC ● In the Default FO Type for Pick-Up field, you can specify the freight order type for pick-up. 6. In SAP ERP, create a new sales order using the data provided in the following table: Value Order Type ZT00 Sales Org. 3000 Distribution Channel 10 Division 00 Sold-to Party CUST00-25 PO Number TM310-GRP##-2.2 Material PRODTM-00 Quantity 20 Unit of Measurement Box ON LY Field a) In SAP ERP, in the Command field, enter transaction code VA01 and press Enter. (Alternatively, in SAP ERP, on the SAP Easy Access screen, choose Logistics → Sales and Distribution → Sales → Order → Create). b) In the Order Type field, enter ZT00. 330 © Copyright. All rights reserved. Lesson: Configuring Freight Order Type Determination c) In the Sales Organization field, enter 3000. d) In the Distribution Channel field, enter 10. e) In the Division field, enter 00. f) Choose Enter. g) In the Sold-to Party field, enter CUST00-25. R h) In the PO Number field, enter TM310-GRP##-2.2. j) In the Quantity field, enter 20 . k) In the Unit of Measurement field, enter BOX . ME i) In the Material filed, enter PRODTM-00. l) Save and note the sales order number. You will need this number in the next step. US TO 7. Navigate to Overview Transportation Requirements. a) In SAP TM, in the NetWeaver Business Client, choose ERP Logistics Integration → Worklist → Overview Transportation Requirements . 8. In the worklist, select the OTR for your sales order and start the Transportation Cockpit. a) Based on the sales order number in the Original Order column, select the row corresponding to your sales order number. b) Choose Start Transportation Cockpit. RC 9. In the Transportation Cockpit: Profile and Layout sets screen, create an entry using the data provided in the following table: FO Note: If the screen is not displayed, choose Change Profile Selection → Profile Selection Screen. Value Planning Profile GRP##-NA-FU-PLAN-PROF Transportation Cockpit Layout Standard ON LY Field Layout for Planning Result Screen Standard Description TM310 Group ## Profile and Layout Set a) In the SAP Transportation Cockpit: Profile and layout set screen, enter the data provided in the table. b) Choose Save. c) Select the entry, and choose Continue. You will now see the Transportation Cockpit: Standard Layout. There are 4 quadrants on this screen: © Copyright. All rights reserved. 331 Unit 8: Freight Order Setup Top Left = Freight Units Bottom Left = Vehicle tab /Trailers tab /Schedule tab Top Right = Freight Order/Freight Booking Bottom Right = Overview/Stages/Carrier Ranking/Allocation/Charge 10. In SAP TM, plan the newly created sales order with vehicle resource US-FTL-01. a) Choose the freight unit. b) On the Vehicle tab, select the vehicle resource US-FTL-01. R c) Choose Optimizer Planning → Selected Entries Only. e) Note the freight order number. ME d) Accept the proposal and choose Save. 11. What is the freight order type of the freight order what was just created? US TO a) In the Freight Orders/Freight Bookings area, click the link in the Document column to open your newly created freight order. b) Open the General Data tab, and look in the Document Type field. T0##. FO RC 12. In this scenario, how was the freight order type determined? ON LY The freight order type was determined by the planning profile settings. 332 © Copyright. All rights reserved. Lesson: Configuring Freight Order Type Determination LESSON SUMMARY You should now be able to: Set up freight order type determination based on the appropriate usage ON LY FO RC US TO ME R ● © Copyright. All rights reserved. 333 Unit 8 Lesson 3 Determining Business Partners LESSON OBJECTIVES After completing this lesson, you will be able to: ME R LESSON OVERVIEW In this lesson, you learn how to identify the business partner roles assigned to freight orders. You will also learn how to determine business partners in freight orders. Identify the business partner roles assigned to freight orders ● Determine business partners in freight orders US TO ● FO RC Freight Order Business Partners LY Figure 91: Freight Orders Default Business Partners By default, there are a number of party roles specified in a freight order, such as a carrier, executing carrier, shipper, consignee, and communication party. ON In addition, other party roles can be either manually added or automatically determined by the system. 334 © Copyright. All rights reserved. Lesson: Determining Business Partners US TO ME R Business Partner Roles Assignment Figure 92: Business Partners In Freight Orders It is possible to maintain different party roles within the freight order business document. From a business perspective, there are a number of relevant and required party roles, such as a carrier, shipper, or consignee. RC Carrier Information Maintenance Carrier information can be maintained in the following ways: Entered manually ● Determined based on the carrier selection process FO ● ● Determined based on the tendering process ● Copied over into the freight document when selecting a schedule ● Determined from Partner Determination functionality LY The shipper and consignee information is primarily required when a house bill of lading is generated for the business document. A house bill of lading serves as a receipt to the shipper for the goods that are being shipped. Shipper and Consignee Maintenance ON Shipper and consignee information can be maintained in the following ways: ● ● ● Entered manually Determined from the predecessor business document (related forwarding order, OTR or DTR) Determined using the Partner Determination functionality © Copyright. All rights reserved. 335 Unit 8: Freight Order Setup US TO ME R Business Partner Determination Figure 93: Business Partner Determination FO RC Based on various factors, the business partners relevant for a business process can vary. Factors affecting the business partners and the partner roles can be, for example, shipment type, traffic direction, mode of transportation, and so on. In addition, sometimes certain control mechanisms need to be in place, which influence how and when it is possible to modify business partners. For this purpose, partner determination procedures can be used. Partner determination procedures are sets of rules for how the system works with business partners during a business process. It brings together partner functions, and also includes additional information on the behavior of the business partners. Automatic determination of the relevant business partners results in a more efficient system and also reduces the chance of manual errors. Configuring a Partner Determination Procedure ON LY It is possible to define a partner determination procedure and assign it to different document categories at a document-type level. Then, when you create documents of that type, the system works with the partners involved according to the rules specified in the procedure. Therefore, the system can automatically handle partners for an internet sales transaction differently than it handles a business activity, for example, without end users concerning themselves with these differences. The settings in the procedure apply both to partners determined automatically and those entered manually. The steps involved in configuring a partner determination procedure are the following: 1. Set up the relevant and required party roles in the system. 2. Define partner determination profiles and assign required settings to the party role (for example mandatory, or optional) and specify the logic for determining the party role value (for example, reference another party role, determined from BAdI). 3. Assign the partner determination profile in the freight order/freight booking document type in Customizing. 336 © Copyright. All rights reserved. Lesson: Determining Business Partners The partner determination profile influences the following: ● The party roles available in a business document. ● The level of control the user has in entering the party role. ● Depending on the settings you define in Customizing, whether you change or delete a party role, or add one from a list of available party roles. You can also specify settings that prevent specific party roles from being changed or deleted. How the system determines business partners for the party roles. Business Partner Determination: Relationships R ● Party role and source party role ME The system uses one of the following relationships, which you specify in Customizing, to determine a business partner: US TO A party role can be specified as the source party role for a particular party role. In the application, a business partner is entered in the field that is specified as the source party role, and the system automatically copies the business partner to the associated party role. For example, in Customizing, you specify the party role as Invoicing Party, the source type as Party Role, and the source role as Carrier. In the application when the carrier is maintained as ABC, the system assigns ABC as the business partner for the invoicing party. Party role and the source party role in business partner master data (relationship) RC The system uses the relationship between organizations and business partners in the Customer Partner Determination and Vendor Partner Determination tabs in the BP (Maintain Business Partner) transaction to determine a business partner in a business document. FO For example, take a logistics service provider (LSP), which has a business with a business partner APP_1. In the BP (Maintain Business Partner) transaction of APP_1 with partner function Sold-to Party, maintain on the Customer Partner Determination tab of the BP transaction for APP_1, and create a relationship between sales organization 561234 and the business partner APP_INV (APP_INV fulfills the role of invoicing party for APP_1). In the profile Customizing, specify the party role as Invoicing Party, the source type as BP Relationship, and the source role as Ordering Party. LY In a forwarding order, you specify the organization as 561234 on the General Data tab and the ordering party as APP_1 on the Business Partner tab. The system checks the business partner master data for APP_1. On the Customer Partner Determination tab, it finds that APP_1 uses APP_INV as the invoicing party for organization 561234. It assigns APP_INV as the business partner for the invoicing party. ON BAdI There is also an option to determine business partners based on BAdIs. If business partners are determined based on special business rules or conditions, then the BAdI can be implemented and pointed to the relevant party role. To Configure Business Partner Determination Note that, in this procedure, when the values include ##, replace the characters with the number assigned to you by your instructor © Copyright. All rights reserved. 337 Unit 8: Freight Order Setup 1. To view the standard party roles available in the SAP TM. a) In SAP TM, in Customizing for SAP Transportation Management, choose SAP Transportation Management → Transportation Management → Master Data → Business Partners → Define Party Roles. b) Go back. 2. To configure the business partner determination profile. R a) In SAP TM, in Customizing for SAP Transportation Management, choose SAP Transportation Management → Transportation Management → Master Data → Business Partners → Define Partner Determination Profiles. c) In the Part. Det. Prof. column, enter PP##. ME b) On the Change View "Define Partner Determination Profile": Overview screen, choose New Entries. d) In the Description column, enter GRP## - Partner Determination Profile. US TO e) Press Enter. f) Select the new entry. g) In the Dialog Structure, double-click Assign Party Roles. h) Choose New Entries. i) Enter the following data: Edit Level 1 Ordering 1 Party 6 Shipper Srce Type Srce Role Not Mod. Mandato- Party ry Role -- Selected 2 Mandato- Party ry Role -- Selected 5 Consign- 3 ee Optional Party Role -- Selected 12 Carrier 4 Mandato- Party ry Role -- Selected 10 Bill-to Party 5 Choose from List 6 -- 203 Notify Party 6 Optional Party Role 12 -- TM001 Additional Notify Party 7 Optional Party Role 5 – ON LY FO RC Party Role Party Role Sequence Desc. Party Role j) Save and exit the function. 3. To assign the business partner profile to a freight order type. 338 © Copyright. All rights reserved. Lesson: Determining Business Partners a) In SAP TM, in Customizing for SAP Transportation Management, choose SAP Transportation Management → Transportation Management → Freight Order Management → Define Freight Order Types. b) Select and open freight order type T0##. c) In the Additional Settings section, in the Partner Determination Profile field select GRP## - Partner Determination Profile. LESSON SUMMARY You should now be able to: ME R d) Save and exit the function. Identify the business partner roles assigned to freight orders ● Determine business partners in freight orders ON LY FO RC US TO ● © Copyright. All rights reserved. 339 ON LY FO RC US TO ME R Unit 8: Freight Order Setup 340 © Copyright. All rights reserved. Unit 8 Learning Assessment True X False US TO X ME Determine whether this statement is true or false. R 1. A freight order type defines the parameters that influence how the system processes a freight order. 2. When automatically determining organizational units in freight orders, which of the following does the system check first? Choose the correct answer. A Whether the user is assigned to a purchasing organization X B Whether the Consider Organization Unit of User checkbox is selected X C Whether there is a condition in the Condition field X D Whether the user is assigned to an execution organization RC X 3. Which of the following statements about organizational units are correct? FO Choose the correct answers. A Organizational units are used to represent the organizational structure of a company. X B Organizational units are used to allocate revenue and costs to different groups within a company. ON LY X X C Organizational units in SAP TM are determined by organizational units in SAP ERP. X D Organizational units can be determined automatically based on predefined conditions. © Copyright. All rights reserved. 341 Unit 8: Learning Assessment 4. If the system is unable to determine a freight order type, the default freight order type specified in the customizing activity is chosen. Determine whether this statement is true or false. X True X False R 5. Which of the following party roles are specified by default in a freight order? ME Choose the correct answers. A Carrier X B Shipper X C Consignee X D Communication party X E Purchasing organization US TO X 6. The partner determination profile influences how the system determines business partners for party roles. Determine whether this statement is true or false. True X False ON LY FO RC X 342 © Copyright. All rights reserved. Unit 8 Learning Assessment - Answers X True X False ME Determine whether this statement is true or false. R 1. A freight order type defines the parameters that influence how the system processes a freight order. US TO That is correct. A freight order type defines the parameters that influence how the system processes a freight order. 2. When automatically determining organizational units in freight orders, which of the following does the system check first? Choose the correct answer. A Whether the user is assigned to a purchasing organization X B Whether the Consider Organization Unit of User checkbox is selected X C Whether there is a condition in the Condition field X D Whether the user is assigned to an execution organization FO RC X 3. Which of the following statements about organizational units are correct? Choose the correct answers. A Organizational units are used to represent the organizational structure of a company. ON LY X X B Organizational units are used to allocate revenue and costs to different groups within a company. X C Organizational units in SAP TM are determined by organizational units in SAP ERP. X D Organizational units can be determined automatically based on predefined conditions. © Copyright. All rights reserved. 343 Unit 8: Learning Assessment - Answers 4. If the system is unable to determine a freight order type, the default freight order type specified in the customizing activity is chosen. Determine whether this statement is true or false. X True X False R 5. Which of the following party roles are specified by default in a freight order? ME Choose the correct answers. A Carrier X B Shipper X C Consignee X D Communication party X E Purchasing organization US TO X 6. The partner determination profile influences how the system determines business partners for party roles. FO RC Determine whether this statement is true or false. True X False ON LY X 344 © Copyright. All rights reserved. UNIT 9 Freight Order Integration R Lesson 1 Lesson 2 350 355 US TO Creating Shipments from Freight Orders Exercise 27: Create Freight Order-Based Shipments 346 ME Integrating Freight Orders with Shipments Lesson 3 Creating Freight Orders from Shipments Lesson 4 367 380 RC Communicating Freight Orders to Other Companies UNIT OBJECTIVES Describe the integration scenarios between freight orders and shipments FO ● Explain the business scenarios for freight order-based shipments ● Configure the settings to enable freight order-based shipments ● Create shipment-based freight orders ● Configure settings to enable shipment-based freight orders ● Explain the business scenarios for business-to-business communication ON LY ● © Copyright. All rights reserved. 345 Unit 9 Lesson 1 Integrating Freight Orders with Shipments LESSON OBJECTIVES After completing this lesson, you will be able to: Describe the integration scenarios between freight orders and shipments US TO ● ME R LESSON OVERVIEW In this lesson, you learn about the integration scenarios between freight orders and shipments. LY FO RC Shipment Integration Scenarios ON Figure 94: Freight Order - Shipments Integration Note: The terms inbound and outbound , in the context of SAP ERP shipment integration, are from the perspective of SAP TM. The shipment integration process is typically used when customers have multiple systems. SAP Enterprise Resource Planning (SAP ERP) performs tasks such as the purchasing of material from external and internal suppliers, the storage of material in plant warehouses, and the shipping of these materials to customers. Transport to and from the warehouse can be managed by a transport module or transport system. 346 © Copyright. All rights reserved. Lesson: Integrating Freight Orders with Shipments Transport planning is performed in an external system - SAP Transportation Management (SAP TM). SAP TM can be used to perform certain functions of the transportation process (such as planning, tendering, and charge calculation). However, transportation management as a whole is performed in SAP ERP. Shipment Scenarios There are two possible variations of this business scenario: ● Shipment integration outbound Shipment integration inbound US TO ● ME R In this scenario, SAP ERP has deliveries (inbound or outbound), which contain the necessary information for the fulfillment of the orders. The deliveries are transmitted to SAP TM, where they become delivery based transport requests (DTR). Planning is performed in SAP TM resulting in freight orders. These freight orders are then sent back to SAP ERP, where they become SAP ERP shipments so the execution can proceed. In this scenario, the transportation planning is performed in SAP TM and the SAP ERP shipment is used only for execution. In this scenario, sales orders created in SAP ERP result in deliveries that are relevant for transportation. A shipment is created for the deliveries. When the shipment is ready for tendering, indicated by its status, and saved, the shipment is sent to SAP TM and a freight order is created. Tendering is then carried out in SAP TM. The tendering result is sent back to SAP ERP and the shipment is updated with the proper forwarding agent. RC Both of these scenarios are used by customers who have already implemented and are using SAP LE-TRA, the transportation component of SAP ERP, and have invested in enhancements development and want to protect these investments. In such cases, they use SAP TM only for specific purposes. The terms inbound and outbound, in the context of SAP ERP shipment integration, are from the perspective of SAP TM. FO There is a 1:1 relation between the SAP ERP shipment document and the SAP TM freight order. LY Hint: It is also possible to use SAP Extended Warehouse Management (SAP EWM) for the purpose of execution. SAP EWM integration is covered in a different enablement. ON Enhancements for Shipment Integration Figure 95: Enhancements for Shipment Integration © Copyright. All rights reserved. 347 Unit 9: Freight Order Integration There are many Business Add-Ins (BAdIs) available, which customers can use to the extend the standard functionality of SAP TM to match their business processes. BAdIs for Outbound Integration ● BAdI for TransportationOrderSCMExecutionRequest_Out You can use this BAdI to change or extend the data transferred through the service interface TransportationOrderSCMExecutionRequest_Out. ● BAdI for TransportationOrderSCMExecutionCancellationReq_Out BAdI for TransportationOrderSCMExecutionConfirmation_In ME ● R You can use this BAdI to change or extend the data transferred through the service interface TransportationOrderSCMExecutionCancellationRequest_Out. You can use this BAdI to change or extend the data transferred through the service interface TransportationOrderSCMExecutionConfirmation_In. ● BAdI for TranspOrderSCMExecutionStatusNotification_In ● US TO You can use this BAdI to change or extend the data transferred through the service interface TransportationOrderSCMExecutionStatusNotification_In. BAdI for TranspOrderSCMExecDeliveryAssignmentChngdNotif_In You can use this BAdI to change or extend the data transferred through the service interface TransportationOrderSCMExecutionDeliveryAssignmentChangedNotification_In. ● BAdI for TranspOrderSCMExecutionItmPckgAssgnmtChngdNotif_In FO RC You can use this BAdI to change or extend the data transferred through the service interface TransportationOrderSCMExecutionItmPckgAssgnmtChangedNotification_In. BAdIs for Inbound Integration ● BAdI for TransportationOrderSCMRequest_In You can use this BAdI to change or extend the data transferred through the service interface TransportationOrderSCMRequest_In. This BAdI contains the method CHANGE_MODIFICATION. You can use this method to handle new fields within the inbound service interface TransportationOrderSCMRequest_In. For example, if you extend a business object in the sending system, you can use this method to extend the inbound service interface. You can then map the new fields to existing or new fields in the transportation order business object. BAdI for TransportationOrderSCMCancellationRequest_In LY ● You can use this BAdI to change or extend the data transferred through the service interface TransportationOrderSCMCancellationRequest_In. BAdI for TranspOrderSCMTenderingResultNotification_Out ON ● You can use this BAdI to change or extend the data transferred through the service interface TransportationOrderSCMTenderingResultNotification_Out. In Customizing for SAP Transportation Management, you can access the BAdIs by choosing SAP Transportation Management → Transportation Management → Business Add-Ins (BAdIs) for Transportation Management → Integration → Enterprise Services → ERP Logistics Integration → ERP Shipment Integration . Facilitated Discussion: Integration Scenarios 348 © Copyright. All rights reserved. Lesson: Integrating Freight Orders with Shipments LESSON SUMMARY You should now be able to: Describe the integration scenarios between freight orders and shipments ON LY FO RC US TO ME R ● © Copyright. All rights reserved. 349 Unit 9 Lesson 2 Creating Shipments from Freight Orders LESSON OBJECTIVES After completing this lesson, you will be able to: ME R LESSON OVERVIEW In this lesson, you learn about freight order-based shipment scenario and how to configure the settings to enable freight order-based shipments. Explain the business scenarios for freight order-based shipments ● Configure the settings to enable freight order-based shipments US TO ● ON LY FO RC Freight Order-based Shipments Scenarios Figure 96: Creating Shipments from Freight Orders In this scenario, you carry out transportation planning in SAP Transportation Management (SAP TM) for transportation activities that are based on deliveries received from SAP ERP. You can then carry out transportation execution in SAP ERP for the freight orders that were created during transportation planning. 350 © Copyright. All rights reserved. Lesson: Creating Shipments from Freight Orders Note the following: SAP TM creates a delivery-based transportation requirement (DTR) for each delivery received from SAP ERP. There is always a one-to-one relationship between an ERP delivery and a DTR. ● SAP ERP creates an ERP shipment for each freight order received from SAP TM. There is an n-to-one relationship between DTRs and a freight order; and, therefore, between the ERP deliveries that were originally sent to SAP TM and the ERP shipment that SAP ERP creates based on a freight order. R ● Outbound integration of shipment processing enables you to do the following: Transfer freight orders from SAP TM to SAP ERP and create shipments in SAP ERP based on the freight orders. ME ● Update a freight-order-based shipment in SAP ERP if the relevant freight order is changed in SAP TM and the changes are transferred to SAP ERP. ● Delete a freight-order-based shipment in SAP ERP if the relevant freight order is deleted in SAP TM. US TO ● Send a confirmation from SAP ERP to SAP TM when a shipment is created in SAP ERP based on a freight order in SAP TM. ● Update the execution status of a freight order in SAP TM based on the overall status of the corresponding shipment in SAP ERP using a status notification. ● Update a freight order in SAP TM based on a notification about changes to deliveries assigned to a shipment in SAP ERP. RC ● Update a freight order in SAP TM based on a notification about changed item and handling unit assignments to container handling units of a shipment in SAP ERP. ● When the freight order is updated, the related shipment document is updated automatically. LY FO Note: The outbound integration scenario can also be used when the execution is performed in SAP EWM (instead of SAP ERP). In this case the EWM system needs the packaging material information for planning purposes. The necessary information for creating handling units must be sent from SAP TM to SAP ERP and is essential for scenarios where an EWM system is used to pick/pack/load. Process ON 1. You send ERP deliveries to SAP TM, and the SAP TM system creates delivery-based transportation requirements (DTRs) for the deliveries. 2. You plan the transportation process in SAP TM based on the DTRs. During planning, you create freight orders. 3. You carry out tendering for the freight orders in SAP TM (optional). 4. You send the freight orders to SAP ERP to carry out transportation execution. 5. SAP ERP creates a shipment for each freight order. © Copyright. All rights reserved. 351 US TO ME R Unit 9: Freight Order Integration Figure 97: Freight Order Based Shipment Creation In a freight order-based shipment, the freight order can be created using SAP TM. The freight order creation can be based upon sales orders sent to SAP TM as Order Transportation requests (OTRs). FO RC The delivery may be created via the delivery proposal process in SAP TM. The delivery proposal can be triggered using a batch job or online in the POWL of the Order Transportation Request or in the Transportation Cockpit. When the delivery is created in SAP ERP, the TRDO output is created. The output triggers the Delivery Transportation Request (DTR) to be created in SAP TM. ON LY Once the DTR is created in SAP TM, the freight order is automatically enabled for shipment creation. 352 © Copyright. All rights reserved. Lesson: Creating Shipments from Freight Orders Figure 98: Shipment Creation US TO ME R Shipment Creation The shipment can be triggered from SAP TM fright order using the following processes: ● Batch job Process Freight Orders (/SCMTMS/TOR_FO_PROC). When you use this report, you can select freight orders using a selection profile or by specifying selection criteria explicitly. RC ● In the freight order UI, you can choose to trigger the shipment directly. Note that you do not have to be in Change mode to trigger this process. ON LY FO Freight Order Shipment Integration Figure 99: FreightOrderShipmentIntegration_image.pptx © Copyright. All rights reserved. 353 Unit 9: Freight Order Integration When integrating the SAP TM freight order with SAP ERP shipment, configure the following settings: ● In SAP ERP, determine output condition types for confirmation and status notification ● Determine partner profile for message type SHPMNT05 with the following message codes: - CNF – to process confirmation message. This message updates the shipment number reference in the TOR Root STA – to process the status change messages from SAP ERP - UPD – to update the SAP ERP with the changes from SAP TM ME - Generate output condition records from SAP ERP for confirmation and status changes ON LY FO RC US TO ● CRE – to create the SAP ERP shipment the first time R - 354 © Copyright. All rights reserved. Unit 9 Exercise 27 Create Freight Order-Based Shipments R Business Example ME You are a logistics specialist assigned to the SAP TM implementation team. As part of your role, you will set up the integration between SAP TM and SAP ERP so shipments are created in SAP ERP based on the planning results in SAP TM. This exercise will help you understand the integration process and the settings required to perform this function. US TO Note that, in this exercise, when the values include ##, replace the characters with the number assigned to you by your instructor. Create Sales Orders in SAP ERP 1. In SAP ERP, create two sales orders with one item each using the data in the table. Field Value Order type Sales Organization Division Product 3000 10 RC Distribution Channel ZT00 00 PRODTM-00 FO Quantity 20 Create the sales orders using the data in the table. Sold-to Party PO Number Sales Order 1 CUST00-25 TM310-GRP##-3.2-25 Sales Order 2 CUST00-26 TM310-GRP##-3.2-26 LY Sales Order Execute Transportation Planning to Create a Freight Order The sales orders have been transferred to SAP TM. In this task, you will plan the sales order. ON 1. Navigate to Overview Transportation Requirements. 2. In the worklist, select your OTRs and start the Transportation Cockpit. 3. On the Transportation Cockpit: Profile and Layout sets screen, choose an entry using the data in the table. © Copyright. All rights reserved. 355 Unit 9: Freight Order Integration Note: If the screen is not displayed, choose Change Profile Selection → Profile Selection Screen. Value Planning Profile GRP##-NA-FU-PLAN-PROF Transportation Cockpit Layout Standard Layout for Planning Result Screen Standard Description TM310 Group ## Profile and Layout Set ME R Field US TO 4. In SAP TM, use Optimizer Planning to create the freight order. Create and Send Delivery Proposals After having planned the sales orders in SAP TM, we will create delivery proposals in SAP TM and send the delivery proposals to SAP ERP to create deliveries based on the results of transportation planning. 1. Trigger delivery creation in SAP ERP from SAP TM. RC Create the ERP Shipment from the TM Freight Order After creating deliveries in SAP ERP, we now create a shipment in SAP ERP from SAP TM based on the freight order. 1. In SAP TM, trigger shipment creation from the freight order. 2. In SAP ERP, view the ERP shipment that was created in the previous step. Assign a carrier to the Freight Order and update the Shipment FO 1. In SAP TM, assign the carrier to the freight order and then send to SAP ERP. ON LY 2. In SAP ERP, view the ERP shipment again and verify that the carrier has been updated in the shipment. 356 © Copyright. All rights reserved. Unit 9 Solution 27 Create Freight Order-Based Shipments R Business Example ME You are a logistics specialist assigned to the SAP TM implementation team. As part of your role, you will set up the integration between SAP TM and SAP ERP so shipments are created in SAP ERP based on the planning results in SAP TM. This exercise will help you understand the integration process and the settings required to perform this function. US TO Note that, in this exercise, when the values include ##, replace the characters with the number assigned to you by your instructor. Create Sales Orders in SAP ERP 1. In SAP ERP, create two sales orders with one item each using the data in the table. Field Order type Sales Organization ZT00 3000 10 FO RC Distribution Channel Value Division 00 Product PRODTM-00 Quantity 20 Create the sales orders using the data in the table. Sold-to Party PO Number Sales Order 1 CUST00-25 TM310-GRP##-3.2-25 Sales Order 2 CUST00-26 TM310-GRP##-3.2-26 LY Sales Order a) In SAP ERP, in the Command field, enter transaction code VA01 and press Enter. ON b) Enter the data provided in the following table: Field Value Order type ZT00 Sales Organization 3000 Distribution Channel 10 © Copyright. All rights reserved. 357 Unit 9: Freight Order Integration Field Value Division 00 c) Press Enter. The Create TM100 Standard Order: Overview screen opens. d) In the Create TM100 Standard Order: Overview screen, enter the following data (all other fields must be left as default): Value Sold-to Party CUST00-25 PO Number TM310-GRP##-3.2-25 Order Quantity PRODTM-00 US TO Material ME e) In the All Items section, enter the following data: R Field 20 f) Save the sales order and record your sales order number. g) Repeat steps d to f to create the second sale orders using the data in the table. Sold-to Party PO Number Product Quantity Sales Order 2 CUST00-26 TM310PRODTM-00 GRP##-3.2-26 20 RC Sales Order Execute Transportation Planning to Create a Freight Order The sales orders have been transferred to SAP TM. In this task, you will plan the sales order. FO 1. Navigate to Overview Transportation Requirements. a) In SAP TM, choose ERP Logistics Integration. b) Choose Overview Transportation Requirements. 2. In the worklist, select your OTRs and start the Transportation Cockpit. LY a) Based on the sales order numbers in the Original Order column, select the rows corresponding to your sales order numbers. b) Choose Start Transportation Cockpit. ON 3. On the Transportation Cockpit: Profile and Layout sets screen, choose an entry using the data in the table. 358 Note: If the screen is not displayed, choose Change Profile Selection → Profile Selection Screen. Field Value Planning Profile GRP##-NA-FU-PLAN-PROF © Copyright. All rights reserved. Lesson: Creating Shipments from Freight Orders Field Value Transportation Cockpit Layout Standard Layout for Planning Result Screen Standard Description TM310 Group ## Profile and Layout Set R a) On the SAP Transportation Cockpit: Profile and layout sets screen, enter the data provided in the table. ME b) Choose Save. c) Select the entry, and choose Continue. You will now see the Transportation Cockpit: Standard Layout. There are 4 quadrants on this screen, as follows: US TO Top Left = Freight Units Bottom Left = Vehicle tab /Trailers tab /Schedule tab Top Right = Freight Order/Freight Booking Bottom Right = Overview/Stages/Carrier Ranking/Allocation/Charge 4. In SAP TM, use Optimizer Planning to create the freight order. a) In the Transportation Cockpit, in the Freight Unit quadrant, select the two freight units. b) In the Vehicles quadrant, select Resource US-FTL-01. RC c) Choose Optimizer Planning → Selected Entries Only. d) Choose Accept. e) Choose Save. FO f) Note the freight order created. Create and Send Delivery Proposals After having planned the sales orders in SAP TM, we will create delivery proposals in SAP TM and send the delivery proposals to SAP ERP to create deliveries based on the results of transportation planning. LY 1. Trigger delivery creation in SAP ERP from SAP TM. ON a) On the Transportation Cockpit main screen, select the newly created freight order and then choose Create Delivery Proposals in the main toolbar. b) In the Transportation Cockpit: Delivery Proposal Overview screen, review the two delivery proposals. Why have two proposals been created for the one freight order? Because two different customer locations are shipped to. c) On the Transportation Cockpit: Delivery Proposal Overview screen, click Send Delivery Proposal to ERP. © Copyright. All rights reserved. 359 Unit 9: Freight Order Integration d) Choose Back to return to the Transportation Cockpit main screen. e) In the Freight Unit Stages area, scroll to the right to review the numbers in the Requirement Document column. These are the numbers of the documents, on which the freight units are based. After choosing Refresh, the numbers should change - the old OTR numbers (starting with 110...) are replaced by the DTR numbers (starting with 119...) after the deliveries have been created in SAP ERP and have been transferred to SAP TM. ME R Hint: You may need to wait for a few minutes before the numbers change. Choose Refresh a few times. US TO Create the ERP Shipment from the TM Freight Order After creating deliveries in SAP ERP, we now create a shipment in SAP ERP from SAP TM based on the freight order. 1. In SAP TM, trigger shipment creation from the freight order. a) Navigate to the Freight Orders / Freight Booking quadrant and select the freight order that was created. b) Open the freight order and choose Edit. c) Choose Follow Up → Create/Update ERP Shipment. d) In the Warning dialog box, choose OK. FO RC e) Navigate to the Statuses tab and review the Transmission-to-ERP Status. The transmission starts and the transmission date and time is entered. f) Refresh the freight order until the Transmission-to-ERP Status changes to Transmission Successful. g) On the Document Flow tab, review that the ERP Shipment has been added as a successor business document of the freight order. Leave the freight order screen open (in Display mode). 2. In SAP ERP, view the ERP shipment that was created in the previous step. a) In SAP ERP, in the Command field, enter transaction code VT03N and press Enter. LY b) In the Shipment Number field, enter the freight order number and press Enter. c) Review the shipment including the overall status, the Forwarding Agent, the shipping type, and the planning dates. ON d) Go to the Stages tab and review the stages. e) Double-click the stages to review the stage details like the duration, distances, and the deliveries in stage. Assign a carrier to the Freight Order and update the Shipment 1. In SAP TM, assign the carrier to the freight order and then send to SAP ERP. a) In SAP TM, go back to the freight order screen and choose Edit. 360 © Copyright. All rights reserved. Lesson: Creating Shipments from Freight Orders b) On the General Data tab, in the Carrier field, enter US-CAR-03. c) Click Follow Up → Create/Update ERP Shipment. d) In the Warning dialog box, select OK. e) On the Statuses tab, review the new status Re-transmitted After Changes in TM and the updated transmission date/time. R 2. In SAP ERP, view the ERP shipment again and verify that the carrier has been updated in the shipment. a) In SAP ERP, in the Command field, enter transaction code VT03N and press Enter. c) Open the Processing tab. ME b) In the Shipment Number field, enter the freight order number and press Enter. d) In the FwdAgent field, the carrier should be specified. Verify that it has been updated. ON LY FO RC US TO Hint: It may take a few minutes for the carrier to appear in the shipment. © Copyright. All rights reserved. 361 Unit 9: Freight Order Integration US TO ME R Freight Order-Based Shipment Settings FO RC Figure 100: Outbound Shipment Integration - Settings Settings and Prerequisites in SAP ERP ● ● Adopt route and determine legs -these settings prevent the system from carrying out additional calculations related to transportation stages when it creates a shipment. Data about stages is taken from the IDoc. Maintain transportation planning point ‘1000’ - SAP TM does not use transportation planning points. Transportation planning point 1000 is, therefore, transferred by default to SAP ERP. If you require other transportation planning points that are stored with the SAP ERP shipment, implement BAdI BADI_LE_SHIPMENT to determine and save the correct transportation planning point for the shipment. LY ● Set up an external number range that matches the freight order (FO) number range. Ensure that the delivery types are relevant for transportation planning ● Set up shipment types ON ● 362 Note: If you also want to integrate SAP Extended Warehouse Management (SAP EWM), set up an external number range with the same interval for transportation units (TUs) in SAP EWM. This ensures that, in the context of outbound shipment integration, a freight order in SAP TM has the same number as the corresponding shipment in SAP ERP and transportation unit in SAP EWM. For more information, see the respective scenario configuration guides. © Copyright. All rights reserved. Lesson: Creating Shipments from Freight Orders ● Assign an output profile to the FO types. ● Choose the correct Document Creation Relevance field: - Shipment creation in SAP ERP - Shipment creation with HUs for vehicles and containers - Shipment creation with HUs for vehicles only - Shipment creation with HUs for containers only Each DTR should contain all items from the corresponding delivery. ● The FO are based on DTRs only. ME ● R Settings and Prerequisites in SAP TM US TO The FO should contain all freight units (FUs) from each related DTR (no subsequent delivery split in SAP ERP). ● The FO must contain FUs that are derived from either exclusively inbound deliveries or exclusively outbound deliveries. ● The FO contains FUs that are related to deliveries from the same ERP system. ● The FO should be In Process and not have one of the following statuses: Blocked for execution, Blocked for planning or Marked for deletion. ● Packaging Information RC If you want the shipments in SAP ERP to contain packaging information in the form of handling units, specify that packaging information is to be sent to SAP ERP along with the other freight order data. Packaging information is required if you want to send the shipments from SAP ERP to SAP EWM to carry out warehouse planning and execution. FO If you select shipment creation with handling units, configure the required settings for vehicle resources or containers, as follows: To enable SAP ERP to generate a handling unit for a vehicle resource, assign a packaging material in the resource master data. In SAP NWBC, choose Master Data → Resources → Define Resource . You specify the packaging material on the Transport tab. LY ● To enable SAP ERP to generate a handling unit for a container, assign a packaging material to the container's equipment type and group. This can be done in Customizing for transportation management under Master Data → Resources → Define Equipment Groups and Equipment Types → Equipment Type. ON ● To Configure Settings Freight Order-based Shipments 1. Enable Freight Order types for ERP Shipment Integration Outbound. a) In SAP TM, in Customizing for SAP Transportation Management, choose SAP Transportation Management → Transportation Management → Freight Order Management → Freight Order → Define Freight Order Types. © Copyright. All rights reserved. 363 Unit 9: Freight Order Integration b) Select the row for the freight order type and choose (Details). c) Check if the Number Range Interval is an internal number range. In the field, press F4 and make a note of the From number and the To number. d) In the Additional Settings section, in the Document Creation Relevance field, enter Shipment Creation in SAP ERP, or Shipment Creation with HUs for Vehicles and Containers or Shipment Creation with HUs for Containers Only or Shipment Creation with HUs for Vehicles Only. R e) Save and exit the function. ME 2. Create shipment type in SAP ERP for ERP Shipment Integration Outbound. a) In SAP ERP, in Customizing for Logistics Execution, choose Logistics Execution → Transportation → Shipments → Define Number Ranges for Shipments. b) Choose Change intervals. US TO c) If required, define a new external number range for the freight order using the same number range that was used in the ERP shipment. d) Click Save and exit the function. e) In Customizing, choose Define Shipment Types. f) Choose New Entries. g) Create a new shipment type T0##, with the following details: Value RC Field T0## Description GRP## Ship. Int. Outbound NR int. assgnt 01 No. range ext. FO ShpmtComplType Loaded Outbound Shipment Shipping Type 01 (Truck) Service Level Load Process Control Individual shipment using one mode of transport Leg Indicator Direct Leg Adopt route Do not adopt stages Determine legs Blank. No legs to be determined GR-RelevanceInd Normal Pick check Shipment completion only for full picking Weight unit LB ON LY FO Shipment Type 364 © Copyright. All rights reserved. Lesson: Creating Shipments from Freight Orders Field Value Volume unit CDM h) Save and exit the function. 3. Maintaining transportation planning points. R a) In SAP ERP, in Customizing for Enterprise Structure, choose Definition → Logistics Execution → Maintain Transportation Planning Point. b) Create transportation planning point 1000 by copying the existing transportation planning point 0001 to be used for SAP TM integration. US TO ME SAP TM does not use transportation planning points. Transportation planning point 1000 is, therefore, transferred by default to SAP ERP. If you require other transportation planning points that are stored with the SAP ERP shipment, implement BAdI BADI_LE_SHIPMENT to determine and save the correct transportation planning point for the shipment. c) In SAP ERP, in Customizing for Enterprise Structure, choose Definition → Logistics Execution → Maintain Transportation Planning Point for External Systems. An entry for the transportation planning point defined above should exist. 4. Maintain the output control settings. a) Configure output control settings to send shipments from SAP ERP to SAP TM in the context of SAP TM Outbound Shipment Integration. RC This involves Customizing activities for maintaining field catalogs, condition tables, access sequences, condition types, and schemas. For detailed information, refer to the integration guide Basic Settings and Integration for SAP ERP. 5. Configure inbound and outbound processing. ON LY FO Configure the settings for inbound communication to SAP ERP (inbound IDocs) and outbound communication from SAP ERP (outbound IDocs). For detailed information, refer to the integration guide Basic Settings and Integration for SAP ERP. © Copyright. All rights reserved. 365 Unit 9: Freight Order Integration LESSON SUMMARY You should now be able to: Explain the business scenarios for freight order-based shipments ● Configure the settings to enable freight order-based shipments ON LY FO RC US TO ME R ● 366 © Copyright. All rights reserved. Unit 9 Lesson 3 Creating Freight Orders from Shipments LESSON OBJECTIVES After completing this lesson, you will be able to: ME R LESSON OVERVIEW In this lesson, you learn about shipment-based freight order scenarios and how to configure the settings to enable shipment-based freight orders. Create shipment-based freight orders ● Configure settings to enable shipment-based freight orders US TO ● ON LY FO RC Shipment-Based Freight Order Scenarios Figure 101: Inbound Shipment Integration In the shipment-based freight order scenario, the transportation planning functions are carried out in SAP ERP or a third party logistics system and not in SAP TM. SAP ERP shipments are created as a result of this process. The SAP ERP shipment is then integrated with SAP TM for one or more of the following scenarios: © Copyright. All rights reserved. 367 Unit 9: Freight Order Integration ● To perform tendering functions ● For freight costing and rating purposes To carry out the inbound shipment integration, do the following: ● ME ● The shipment to be integrated to SAP TM must have the output created. The output should be set up to create IDOC of type SHPMNT05. SAP Integration system , SAP PI must be setup to process and map the SHPMNT05 to the appropriate message for SAP TM. Customizing must be established in both SAP ERP and SAP TM. US TO ● R Note: There is a one-to-one relationship between an SAP ERP shipment and an SAP TM freight order. An SAP TM freight order must be synchronized with an SAP ERP shipment if it is used for freight costing purposes. The interface shown in the figure, is based on services (inbound and outbound) in SAP TM and IDocs in SAP ERP. PIs are connected to an XI system integration process. These services and IDocs are not covered in this training. LY FO RC Inbound Shipment Integration Message Flow ON Figure 102: Inbound Shipment Integration Message Flow The figure, Inbound Shipment Integration Message Flow, shows the message flow between SAP ERP and SAP TM. When a shipment's tendering status is New Offer from the Carrier, the process is triggered. An output generates IDoc SHMPNT05, which is mapped to an SOA message TransportationOrderSCMRequest_In. In SAP TM, during the inbound proxy processing, a freight order is created. You can choose to trigger carrier selection from SAP TM. To do so, specify the means of transport for the freight order and set up the appropriate transportation lane. Once these settings are in place, you can trigger the tendering process if the freight order is set up as 368 © Copyright. All rights reserved. Lesson: Creating Freight Orders from Shipments Relevant for Subcontracting. The tendering result can be passed to an SAP ERP shipment using the message TransportationOrderSCMTenderingResultNotification_Out, which can be mapped to SHPMNT.SHPMNT05. If you have found and accepted a carrier, the enterprise service sends the following data: Carrier ● Price ● Confirmed dates and times ● Tendering status R ● ME If you have not found a carrier, the enterprise service sends the corresponding tendering status. US TO If the SAP ERP shipment document already contains a carrier, the carrier information is sent to SAP TM. Ensure that the carrier partner is CIFed from SAP ERP to SAP TM. Once SAP TM receives the shipment, a freight order is created and the tendering process can be carried out. During tendering, the carrier can submit a quotation to SAP TM. The price in this quotation can be passed back to SAP ERP and stored in the shipment document. LY FO RC Freight Costing and Cost Distribution Figure 103: Freight Costing and Cost Distribution ON To integrate SAP ERP shipments into SAP TM for freight costing and cost distribution purposes, create the necessary transportation charge management (TCM) master data, such as agreements and rate tables; and configure the system for cost distribution and settlement functions. To Create Shipment-Based Freight Orders 1. In SAP ERP, create a sales order using the data in the table. © Copyright. All rights reserved. 369 Unit 9: Freight Order Integration Value Order Type ZT00 Sales Organization 3000 Distribution Channel 10 Division 00 Sold-to-Party CUST00-25 PO Number TM310-GRP00-3.3 Product PRODTM-00 Quantity 20 UoM BOX US TO ME Field R Table 53: Sale Order Data a) In SAP ERP, in the Command field, enter transaction code VA01 and press Enter. b) Enter the data provided in the table. Field Order Type Sales Organization ZT00 3000 10 FO RC Distribution Channel Value Division 00 c) Press Enter. d) In the Create TM100 Standard Order: Overview screen, enter the following data: (All other fields must be left with default values.) Value Sold-to Party CUST00-25 PO Number TM310-GRP00-3.3 LY Field ON e) On the All Items section, enter the following data: Product Quantity UoM PRODTM-00 20 BOX f) Take note of the delivery date. g) Choose Save. h) Record the sales order number. 2. Create deliveries for the sales order. 370 © Copyright. All rights reserved. Lesson: Creating Freight Orders from Shipments a) In SAP ERP, on the SAP Easy Access screen, in the Command field, enter transaction code VL01N and press Enter. b) In the Create Outbound Delivery with Order Reference screen, in the Shipping Point field, enter 3100. c) In the Order field, enter the sales order number. d) In the Selection Date field, enter the delivery date of the sales order and press Enter. f) Record the deliver number. Value Transport. Planning Point 3000 Shipment Type T100 US TO Field ME 3. Create a shipment for the delivery using the data in the table. R e) Click Save. a) In SAP ERP, on the SAP Easy Access screen, in the Command field, enter transaction code VT01N and press Enter. b) Enter the data from the table. c) Choose Select Deliveries. RC d) In the dialog box, in the W. ref. to area, in the Outbound Delivery field, enter the delivery number in the first field. e) Choose Execute. f) Save the shipment and note the shipment number. g) Exit the function. FO 4. Send the shipment to SAP TM for tendering. a) In the Command field, enter transaction code VT02N and press Enter. b) Enter the shipment number and press Enter. LY c) On the Processing tab, in the Forwarding Agent field, enter CARR-00-01. d) In the Stages tab, click Leg determination. ON e) Click Continue to accept the proposal. f) On the Stages tab, scroll to the right and enter the Planned Shipment Start and Planned Shipment End Date according to the delivery dates. g) Open the Tender tab. h) In the Tender status field, choose New Offer from Shipper. i) Save the shipment. 5. In SAP TM, view the freight order created from the shipment. © Copyright. All rights reserved. 371 Unit 9: Freight Order Integration a) In SAP TM, in the NetWeaver Business Client, choose Freight Order Management → Road → Overview Road Freight Orders. b) Select the query All Created from ERP Shipment. c) Choose Refresh. d) In the query list, use the ERP Shipment column, and locate the shipment number. e) The freight order number, is in the Document column on the same row. R 6. Open the freight order. a) In the query list, select the row for the freight order. ME b) Choose Edit. c) Open the General Data tab. d) In the Document Type field, you will see the freight order type. US TO e) In the Carrier field, you see that the carrier information has been carried over from the shipment. f) Open the Document Flow tab. Here you will see the predecessor documents. 7. Send the freight order for tendering. a) In the freight order, choose Subcontracting → Automatic Tendering. b) In the dialog box, enter the following data: Value FO RC Field Tendering Manager Your User ID Tendering Profile TM310-BROADCAST-1STEP c) Save the freight order. d) Open the Subcontracting tab, and open the Tendering Overview tab. e) Note the RFQ numbers created for carriers CARR-00-01 and CARR-00-02. 8. Accept and award the tender to CARR-00-02. LY a) In SAP TM, in the NetWeaver Business Client, choose Freight Order Management → Road → Overview Tendering. b) In the Freight RFQs query section, select Open. ON c) Click Refresh. d) Select the RFQ corresponding to carrier CARR-00-01. e) Choose Create Freight Quotation → Reject (other). f) In the dialog box, click OK. g) Select the RFQ corresponding to carrier CARR-00-02. h) Choose Create Freight Quotation → Accept. 372 © Copyright. All rights reserved. Lesson: Creating Freight Orders from Shipments i) In the dialog box, choose OK. j) Open or refresh the freight order. k) Open the Subcontracting tab. l) In the Tendering Overview tab, select the RFQ for CARR-00-02. R m) Look at the Award Status, it has changed to Awarded. Look at the Carrier field, carrier CARR-00-02 has been assigned to the freight order now. ME Note: The quotations are evaluated by a background report which is scheduled to run every five minutes on this system. Therefore, it might take up to five minutes until the quotation is awarded and the new carrier is assigned. US TO n) Review the changed carrier in the SAP ERP shipment. Shipment-Based Freight Order Settings Configuring Inbound Shipment Integration Settings in SAP TM Assign Freight Order Types to ERP Shipment Types ● Maintain suitable output profile for the freight order ● Specify Freight Order Type as Relevant for Sub-Contracting ● RC ● Specify Document Creation Relevance for Freight Order Type as Freight Order Created from SAP ERP Shipment. Configuring Inbound Shipment Integration Settings in SAP ERP Set necessary delivery types as relevant for transportation FO ● ● Associate the necessary output type to the shipment type ● Maintain condition types for service agents LY Configuring Inbound Shipment Integration Settings in SAP NetWeaver XI Set up the inbound integration scenario TM_ERPShipmentIntegration_In ON ● © Copyright. All rights reserved. 373 US TO Figure 104: Configuration for Multiple Processing ME R Unit 9: Freight Order Integration You can configure the SAP ERP shipment output for multiple processing so that critical changes are transferred to SAP TM. This is especially important when using SAP TM for freight costing and cost distribution purposes. To do this, set up a partner profile with consideration to the following settings: ● Message Code FO RC 1. CRE/UPD for triggering creation or update of TM freight order 2. TND to receive tendering result notifications from SAP TM 3. CNC for triggering cancelations in SAP TM ● Process Code 1. SD11 for all scenarios To trigger the cancellation of freight orders after the shipment is canceled or deleted, activate SHIPPL.TPSSHP01. Depending upon your scenario, there are 2 variants for canceling the freight order. LY Variant 1 If you reset the tender status in shipments to CN and you want to delete shipments in ERP, use this variant. Depending on the type of freight order, this will either delete the freight order in SAP TM, or its status will be changed to Canceled . ON To configure this variant, proceed as follows: 1. Create a Business Add-In (BAdI) implementation for the BAdI BADI_LE_SHIPMENT in the method BEFORE_UPDATE. For this, use the source code that is described in the manual correction instructions 936359. When you delete the shipment or change its tender status to CN, the IDoc TPSSHT01 is created with the output type SHIPPL in the method. 2. Create a new database table to be able to determine the logical system for the IDoc TPSSHT01. Open transaction SE11 and create a new database table with the following fields: 374 © Copyright. All rights reserved. Lesson: Creating Freight Orders from Shipments Key Initial value Data element Short description MANDT X X MANDT Client TPLST X X TPLST Transportation planning point SHTYP X X SHTYP Shipment type VTPARN EDI_VTPARN Partner number VTPART EDI_VTPART R Field ME Partner type 3. Modify the function module IDOC_OUTPUT_SHIPPL that is called in the BAdI implementation as described in the manual correction instructions 1298598. Variant 2 US TO Use this variant if you only want to reset the tender status in the shipment to CN. Shipments are never deleted in SAP ERP in your process. Depending on the type of the freight order, this mean that, in SAP TM, the freight order deleted or the status is changed to canceled. With this output type, an IDoc is created with the basic type SHPMNT05 and the message variant CNC. This IDoc is used in SAP PI for a web service that deletes or cancels a freight order in SAP TM. You can create the output type, for example ZTND, using the settings listed below. Table 54: Output Configuration: General Data Value RC Field ZTND Access Sequence (on the General tab) Z001 Access to Conditions (on the General tab) Selected FO Output Type Selected Dispatch Time (on the Default Values tab) Send Immediately (4) Transmission Medium (on the Default Values tab) EDI (6) Partner Function (on the Default Values tab) SP LY Multiple Issuing (on the General tab) Table 55: Output Configuration: Processing Routines Value Program RSNATED From Routine EDI_PROCESSING ON Field Table 56: Output Configuration: Partner Functions Open the Partner Functions folder and create a new entry with the following data: © Copyright. All rights reserved. 375 Unit 9: Freight Order Integration Field Value Medium EDI (6) Function SP Name Forwarding Agent Table 57: Output Procedure: General Data ME In the Control Data folder, create a new entry with the following data: R Variant 2 Output Procedure Value Step Numerical value Counter Numerical value Output type ZTND (TNDR) US TO Field Requirement 52 In Customizing for Logistics Execution, choose Logistics Execution → Transportation → Basic Transportation Functions → Output Control → Maintain Output Determination for Shipments → Maintain Output Types. You can customize your access sequence according to your business requirements. RC After the output type has been successfully created, assign it to the output determination procedure. In Customizing for Logistics Execution, choose Logistics Execution → Transportation → Basic Transportation Functions → Output Control → Maintain Output Determination for Shipments → Maintain Output Determination Procedure. FO To send the updates to SAP TM, create another output type, for example ZUPD. To prevent the message from being generated if the tender status has not changed, create a requirement. There is an example for a requirement in the manual correction instruction in SAP OSS note 1298755. LY To Configure Settings for Shipment-Based Freight Orders Note that, in this procedure, when the values include ##, replace the characters with the number assigned to you by your instructor ON 1. In SAP ERP, in Customizing for Logistics Execution create a shipment type for ERP Shipment Integration Inbound with the following information: 376 Field Value Shipment type T1## Description GRP## ShipInt Inbnd NR int. assgnt 01 ShpmtComplType Loaded Outbound Shipment Shipping Type 01 (Truck) © Copyright. All rights reserved. Lesson: Creating Freight Orders from Shipments Value Service Level Load ProcessControl Individual shipment using one mode of transport Leg Indicator Direct Leg Adopt Route Adopt All stages Determine Legs Legs determined according to departure point & itinerary GR- RelevanceInd Normal Pick check Shipment completion only for full picking Weight Unit LB Copy Routine ME US TO Volume Unit R Field CDM 7 (Service Agent/Route) a) In Customizing for Logistics Execution, choose Logistics Execution → Transportation → Shipments → Define Shipment Types. b) Choose New Entries. RC c) Enter the data provided in the table. d) Save the shipment type. 2. Assign the output determination procedure for shipment type using the following data: Field Value T1## Output Determination Procedure ZSHIP1 FO Shipment Type LY a) In Customizing for Logistics Execution, choose Logistics Execution → Transportation → Basic Transportation Functions → Output Control → Maintain Output Determination for Shipments → Assign Output Determination Procedure. b) Navigate to your shipment type T1##. ON c) Save the assignment. 3. Assign the text determination procedure for shipment type using the following data: Field Value Shipment Type T1## Text Determination Procedure 03 © Copyright. All rights reserved. 377 Unit 9: Freight Order Integration a) In Customizing for Logistics Execution, choose Logistics Execution → Transportation → Basic Transportation Functions → Text Control → Define and Assign Text Determination Procedure. b) Choose Shipment → Header. c) Choose Change. d) In the Dialog Structure, double-click Text Procedure Assignment. R e) Navigate to your shipment type and assign the text determination procedure as shown in the table. ME f) Save the assignment. 4. Create condition records for shipments with the following data: Shipment Carrier Type TNDR T1## TNCN ZSHP Function Partner Medium Date Language CARR-00 LS -01 XI_00_8 00 6 4 EN T1## CARR-00 LS -01 XI_00_8 00 6 4 EN T1## CARR-00 LS -01 XI_00_8 00 6 4 EN US TO Output Type RC a) In SAP ERP, in the Command field, enter transaction code VV71 and press Enter. b) Create condition records using the data in the table. c) Save the condition records. Field Value Freight Order Type T1## Reference Freight Order Type T100 Description TM120 ## For Inbound Integration LY FO 5. Create a freight order type for Inbound ERP Integration by copying an existing freight order type. Use the following data: Default Type for ERP Shipment Integration Blank ON a) In Customizing for SAP Transportation Management, choose SAP Transportation Management → Transportation Management → Freight Order Management → Freight Order → Define Freight Order Types. b) Choose the row for T100. c) Choose (Copy As). d) Update the Freight Order Type , Description and the Default Type for EPR Shipment Integration fields with the data in the table. 378 © Copyright. All rights reserved. Lesson: Creating Freight Orders from Shipments Caution: Do not change any other settings in the new freight order type but take over the settings from freight order type T100. e) Choose Copy. f) Save the freight order type. Value ERP Shipment Type T1## Freight Order Type T1## ME Field R 6. Map ERP shipment types to TM freight order types with the following data: US TO a) In Customizing for SAP Transportation Management, choose SAP Transportation Management → Transportation Management → Integration → ERP Logistics Integration → Shipment Integration → Assign Freight Order Types to ERP Shipment Types. b) Create a new entry using the data provided in the table. c) Save the mapping. FO RC LESSON SUMMARY You should now be able to: Create shipment-based freight orders ● Configure settings to enable shipment-based freight orders ON LY ● © Copyright. All rights reserved. 379 Unit 9 Lesson 4 R Communicating Freight Orders to Other Companies ● US TO LESSON OBJECTIVES After completing this lesson, you will be able to: ME LESSON OVERVIEW In this lesson, you learn about the different business scenarios for business-to-business communication. Explain the business scenarios for business-to-business communication FO RC Freight Order Communication LY Figure 105: SAP TM Usage with Shippers and LSPs ON When looking at shippers that use SAP TM, we talk about ERP logistics integration and planning that creates freight orders. When looking at LSP business in SAP TM, we talk about forwarding orders from customers. We can now put the perspectives of the shipper and the LSP together; a shipper using SAP TM communicates with an LSP using SAP TM. In this case, the shipper creates freight orders and sends them to the carrier assigned to the freight order. In the shipper‘s TM system, an XML message is created and sent to the middleware system that takes care of routing the message to the right business partner. In the LSP‘s TM system, when the shipper‘s XML message is received, a forwarding order is created based on the information in the shipper‘s freight order. If the LSP confirms the forwarding order, this confirmation is sent back to the shipper and the freight order is updated. 380 © Copyright. All rights reserved. Lesson: Communicating Freight Orders to Other Companies US TO Figure 106: Sending Freight Orders to Carriers ME R Freight Order Sending The freight order can be sent from the freight order UI as the figure shows. Choose Send to Carrier; the follow up activity depends on the technical setup of the system landscape. The SAP TM system creates an XML message with all information about the freight order and sends it to the assigned middleware. RC When the LSP sends a confirmation outside of the system (that is via E-mail, telephone, or fax), the confirmation can be entered in the freight order manually by choosing Set to confirmed by carrier. When the LSP sends a confirmation electronically, the confirmation is logged in the freight order automatically. FO Note: In case of tendering processes, the freight RFQ of the shipper is again sent to the LSP‘s TM system, where a forwarding quotation is created. When the forwarding quotation is processed and responded to by the LSP, it is sent back to the shipper where the freight RFQ is updated. LY LESSON SUMMARY You should now be able to: Explain the business scenarios for business-to-business communication ON ● © Copyright. All rights reserved. 381 ON LY FO RC US TO ME R Unit 9: Freight Order Integration 382 © Copyright. All rights reserved. Unit 9 Learning Assessment ME Choose the correct answer. R 1. Which of the following statements is an example of the shipment outbound scenario? A When transportation activities based on deliveries transferred from SAP ERP are planned in SAP TM. X B When transportation activities based on deliveries that are transferred from SAP ERP are booked in SAP TM. X C When transportation activities are booked and planned in SAP ERP. X D When transportation activities are booked and planned in SAP ERP. US TO X 2. Inbound integration of shipment processing enables you to do which of the following tasks? RC Choose the correct answers. A Transfer shipments from SAP ERP to SAP TM and create freight orders in SAP TM based on the shipments. X B Update shipment-based freight orders in SAP TM if the relevant shipment in SAP ERP changes or if a delivery within the shipment changes. FO X C Transfer the tendering result for a freight order from SAP TM to the shipment in SAP ERP. X D Cancel freight orders in SAP TM if the relevant shipment in SAP ERP is deleted or the tendering status is reset. LY X E Create shipments in SAP ERP based on the freight orders transferred from SAP TM to SAP ERP. ON X © Copyright. All rights reserved. 383 Unit 9: Learning Assessment 3. In the outbound integration scenario, identify the order in which the following tasks are performed. Arrange these steps into the correct sequence. 0 Send ERP deliveries to SAP TM. 0 Plan the transportation process in SAP TM. 0 Shipments created in SAP ERP. 0 Transport execution in SAP ERP. ME 0 Send the freight orders to SAP ERP. R 0 Tender the freight orders in SAP TM. Choose the correct answers. US TO 4. For freight order-based shipments, which of the following settings must be maintained in SAP ERP? A Set up an external number range object that matches the freight order number range. X B Adopt route and determine legs. X C Maintain transportation planning point ‘1000’. FO RC X D Ensure that the delivery types are relevant for transportation execution. X E Set up shipment types. ON LY X 384 © Copyright. All rights reserved. Unit 9 Learning Assessment - Answers ME Choose the correct answer. R 1. Which of the following statements is an example of the shipment outbound scenario? A When transportation activities based on deliveries transferred from SAP ERP are planned in SAP TM. X B When transportation activities based on deliveries that are transferred from SAP ERP are booked in SAP TM. X C When transportation activities are booked and planned in SAP ERP. X D When transportation activities are booked and planned in SAP ERP. US TO X That is correct. A shipment outbound scenario is when transportation activities based on deliveries transferred from SAP ERP are planned in SAP TM. RC 2. Inbound integration of shipment processing enables you to do which of the following tasks? Choose the correct answers. A Transfer shipments from SAP ERP to SAP TM and create freight orders in SAP TM based on the shipments. X B Update shipment-based freight orders in SAP TM if the relevant shipment in SAP ERP changes or if a delivery within the shipment changes. X C Transfer the tendering result for a freight order from SAP TM to the shipment in SAP ERP. X D Cancel freight orders in SAP TM if the relevant shipment in SAP ERP is deleted or the tendering status is reset. X E Create shipments in SAP ERP based on the freight orders transferred from SAP TM to SAP ERP. ON LY FO X © Copyright. All rights reserved. 385 Unit 9: Learning Assessment - Answers 3. In the outbound integration scenario, identify the order in which the following tasks are performed. Arrange these steps into the correct sequence. 1 Send ERP deliveries to SAP TM. 2 Plan the transportation process in SAP TM. 5 Shipments created in SAP ERP. 6 Transport execution in SAP ERP. ME 4 Send the freight orders to SAP ERP. R 3 Tender the freight orders in SAP TM. Choose the correct answers. US TO 4. For freight order-based shipments, which of the following settings must be maintained in SAP ERP? A Set up an external number range object that matches the freight order number range. X B Adopt route and determine legs. X C Maintain transportation planning point ‘1000’. X D Ensure that the delivery types are relevant for transportation execution. X E Set up shipment types. ON LY FO RC X 386 © Copyright. All rights reserved. UNIT 10 Transportation Event Monitoring Lesson 2 388 397 ME Monitoring Transportation Events Exercise 28: Monitor Freight Order Events R Lesson 1 404 US TO Configuring SAP Event Management (SAP TM) for Transportation Visibility Lesson 3 414 419 RC Handling Events in the Collaboration Portal Exercise 29: Monitor Events in the Collaboration Portal UNIT OBJECTIVES Monitor transportation events with SAP Event Management ● Configure settings to enable transportation event visibility ● Handle events in the Collaboration Portal ON LY FO ● © Copyright. All rights reserved. 387 Unit 10 Lesson 1 Monitoring Transportation Events LESSON OBJECTIVES After completing this lesson, you will be able to: Monitor transportation events with SAP Event Management Event Management US TO ● ME R LESSON OVERVIEW In this lesson, you learn how to monitor transportation events with SAP Event Management. LY FO RC Nowadays, supply chains are global and complex. End-to-end supply chain visibility is one of the key factors in efficient supply chain operation and control. SAP Event Management is the only application needed to provide this visibility, because it is available to all partners, including customers. SAP Event Management can also work with multiple SAP and non-SAP applications. ON Figure 107: Visibility Across Business Partners And IT Environments As companies expand their suite of IT products to handle more complex scenarios, they often have to add systems to their enterprise resource planning environment. This makes it difficult for business users and management to gain a complete view of end-to-end processes and to monitor potential service issues. Therefore, it is imperative to have a tool that can incorporate information from several systems and provide insight into the progress of order fulfillment. SAP Event Management makes processes, assets, and performance visible across the entire supply chain. Extensive tracking and tracing functions allow process monitoring, automated exception resolution, proactive alerting, as well as extensive reporting in a single solution. 388 © Copyright. All rights reserved. Lesson: Monitoring Transportation Events Event Management in SAP Transport Management (TM) R The event management system is designed to work with several SAP Enterprise Resource Planning (SAP ERP) instances, if necessary. It can communicate with SAP Customer Relationship Management (SAP CRM), where sales orders may be received, and this communication is processed back to the customer to support order fulfillment. SAP Advanced Planning and Optimization (SAP APO) may be responsible for creating the replenishment plan. SAP ERP or SAP Manufacturing Execution (SAP ME) may be responsible for communication and tracking progress on the shop floor. SAP Extended Warehouse Management (SAP EWM) can be responsible for the picking and packing as part of the logistics execution. ME SAP Event Management offers visibility processes to monitor transportation execution in connection with SAP Transport Management (SAP TM). The transportation execution visibility processes enable users in roles such as transportation dispatcher, shipper, or ordering party, to track and monitor planned events, or to report an actual event. Tracking and tracing is provided for the following business document types in SAP TM: Freight unit ● Freight order ● Freight booking ● Transportation unit ● Resource ● Instruction execution for standard operating procedures US TO ● RC In each case, the goal is to manage by exception, reduce time to action, and spend less time fire-fighting. ON LY FO Event Management Process Figure 108: Related Events - SAP Event Management The four cornerstones of SAP Event Management are monitor, notify, analyze, and adjust. They contribute to providing an adaptive solution. The monitoring process collects data from the various source systems. Notifications can be set up to be triggered, with alerts sent to the © Copyright. All rights reserved. 389 Unit 10: Transportation Event Monitoring parties responsible if a process deviates from its anticipated course. Based on the alerts, the appropriate parties can then simulate adjustments and make any necessary changes. Finally, in relation to analytics, SAP Event Management can be tied into the SAP Business Warehouse (SAP BW) environment to support transportation management reviews. US TO ME R Event Types Figure 109: Monitoring Types Of Events ● FO RC SAP Event Management can process several different types of events. Within a given process, you have events that you expect to happen, and events that actually happen. Typically, you want to compare the actual event with what you expected, as follows: Regular Event The first type of event is an event that you expect to happen within a particular time frame, and it happens as expected. This is a regular event. ● Overdue Event LY This is an event that you expect to happen within a particular time frame, and it happens outside the expected time frame. An overdue event can cause a subsequent event to be rescheduled, or it could just be recorded as an overdue event. ● Unexpected Event ON The third type of event is one that is unexpected. This could be a truck that breaking down or a malfunction in a piece of equipment; something that could potentially have an effect on subsequent events, causing something to be rescheduled or another action to be taken. An unexpected event could trigger an alert or another type of notification. ● Unreported Event In this case, you expect an event to occur within a particular time frame, but it is not reported. It is possible that something still needs to happen following this event, so you could set a time limit that sends a message or triggers something to happen when the event is unreported for a certain time period. 390 © Copyright. All rights reserved. Lesson: Monitoring Transportation Events Event Management Tool Features Event Management monitoring tools provide the following: 1. Expected events are coming from the application system, in this case SAP TM. The expected events are the activities planned in SAP TM planning. 2. The reported events are the events that are reported from the real-world operations. R 3. Based on received events from operations or unreported events, the rules in SAP Event Management are triggered to respond to real-world activities happening in operations or execution. US TO ME 4. Using SAP TM screens or the SAP Event Management Web front-end, expected and real events are made visible to user and target groups, such as (internal) customers, planners, and people in operations. This visibility is given from a transport order, or on the demandside by way of freight unit tracking, tracing, and monitoring and, for the operations-side, by way of freight orders and bookings tracking, tracing and monitoring. SAP Event Management can point out critical situations within your supply chain in good time by comparing expected events with the actual events, and can then, for example, actively notify those persons involved. An expected event is an event that can be defined before the corresponding business process has begun and that describes the normal flow of the business process. In the context of SAP TM integration, expected events are activities planned in SAP TM. Expected events include the following: Cargo receipt ● Onboard confirmation ● Proof of delivery RC ● FO The expected events are compared to actual events (also known as reported events). Reported events include the following: Unloading truck ● Late departure ● Accident ● No POD sent LY ● Transportation Execution Visibility Process ON The transportation execution visibility process enables users and target groups, such as (internal) customers, planners, and people in operations, to monitor events or to report an actual event by way of SAP TM screens or the SAP Event Management web interface. SAP Event Management offers visibility processes to monitor transportation execution in connection with SAP TM. Tracking and tracing is provided for the following business document types in SAP TM: ● Freight units ● Freight orders © Copyright. All rights reserved. 391 Unit 10: Transportation Event Monitoring ● Freight bookings ● Transportation unit ● Resources ● Instruction execution for standard operating procedures Visibility Processes for Transportation Monitoring ME R Transportation operations is an area in which transparency is crucial, especially in those cases where lengthy transportation times have to be considered, such as when shipping overseas. To ensure customer satisfaction, it is more important than ever to keep full control of events, even if parts of the business process may run outside the sphere of influence of your company. FO RC US TO Visibility processes for transportation management offer preconfigured, out-of-the box content for transportation operations, supporting you in tracking relevant activities within and beyond the confines of your company. You can monitor different processes and business documents, such as freight units, freight orders, and freight bookings. Depending on your role, you can choose different layouts for the user interface, such as shipper and consignee, which result in a comprehensive and easy to understand view of transportation operations. LY Figure 110: Visibility for Transportation Execution ON The figure, Visibility for Transportation Execution, depicts a realistic scenario in which SAP TM and SAP Event Management can be integrated to monitor an end-to-end international order. In the first step of the process, the order is created in SAP ERP and sent to SAP TM. At this point, a freight unit is created and scheduling can begin. SAP TM provides the basis for tracking and tracing in SAP EM. In SAP TM, freight units, orders and bookings create the event handlers, and the planned activities in SAP TM are the expected events that SAP EM monitors. For real-world awareness and proactive monitoring, SAP TM relies on SAP EM. Actual events that occur during execution are reported in SAP EM. The reporting of events can happen in SAP TM and be sent to SAP EM, or happened in SAP EM and be sent to SAP TM. 392 © Copyright. All rights reserved. Lesson: Monitoring Transportation Events US TO ME R Visibility Processes for Transportation and Event Management — Process Flow Figure 111: Visibility Processes for Transportation and Event Management — Process Flow Alerts RC The figure, Visibility Processes for Transportation and Event Management - Process Flow, shows a typical scenario in which the SAP EM and SAP TM systems are updated to reflect accurately the real world progress of a freight order. FO During the loading process, SAP ERP or SAP EWM may send a signal (notification) that there is a delay in the loading process. This can trigger an alert. The transportation planner may have to adjust the schedule to ensure that the container makes it to the ship on time. Once the ship has left the departure port, GPS updates may indicate that the ship has not reached its midway point. This could be due to weather or mechanical issues. The customer service agent can be notified and can contact the customer to inform them of anticipated delays. ON LY Due to the alert system, the planning team does not have to watch over every order. They can spend most of their time managing exceptions. © Copyright. All rights reserved. 393 Unit 10: Transportation Event Monitoring FO RC US TO ME R Standard Content For Transportation Monitoring Figure 112: Event Management Content for SAP TM The figure, Event Management Content for SAP TM, shows both expected and unexpected events. The expected events are planned activities in SAP TM. For example, when loading begins for a freight unit, SAP TM reports to SAP EM that this event has occurred. Unexpected events are events that are not planned, for example delays, damaged packaging material, and cancellations. Unexpected events can also be reported from SAP TM. ON LY Mobile Tracking and Tracing Figure 113: SAP TM Mobile Solutions SAP TM Notifier is an app that provides event report functionality to Android-based mobile devices. It enables you to display a list of open and assigned freight orders along with their 394 © Copyright. All rights reserved. Lesson: Monitoring Transportation Events details, for example, the stops for a freight order and freight units that are assigned to the stops. You can also report the delivery status. Additional features include the ability to display the map indicating the exact location of the freight order or freight unit in real-time (from the latest reported events). Each stop has a list of predefined events that you can use to report the status of your delivery, for example, start loading or finish loading. In addition to the predefined events, you can send a delay notification for an event. RC US TO ME R SAP TM Notifier Figure 114: SAP Transport Tracker FO With the SAP TM Notifier app, you can display freight order details and report the status of your delivery using predefined events on your mobile device. Mobile devices provide planning information for the driver, and execution information back to the planner from the driver. Mobile tracking enables users by being able to do the following: Display open freight orders that are valid within a certain time frame ● Display details of a freight order ● Display details of a stop LY ● Display freight units for a stop ● Display events for a stop ● Display information about a freight order on a map ● Confirm an event for a stop after completing the corresponding activity ● Report a delay for an event ON ● Use Case for SAP TM Notifier App 1. Gather the relevant freight orders. 2. Review the tour data. © Copyright. All rights reserved. 395 Unit 10: Transportation Event Monitoring 3. Show data on the map. 4. Report potential problems or delays. 5. Execute part of the freight order or the whole freight order and report back the execution. The technical requirements for the SAP TM Notifier App are as follows: SAP Transportation Management Release 8.0 ● SAP Event Management Release 7.1, Enhancement Package 1, SP05 ● SAP NetWeaver Release 7.02 ● SAP NetWeaver Gateway 2.0 Support Package 2 ● Sybase Unwired Platform 2.1 ON LY FO RC US TO ME R ● 396 © Copyright. All rights reserved. Unit 10 Exercise 28 Monitor Freight Order Events R Business Example ME Verify that your freight order is relevant for SAP Event Management tracking. Use freight order type T0##. Note that, in this exercise, when the values include ##, replace the characters with the number assigned to you by your instructor. Field US TO 1. In Customizing for SAP TM, verify that your freight order is relevant for SAP Event Management tracking. Use freight order type T0##. Ensure that the following parameters are set: Value Execution Tracking Relevance Execution Tracking with External Event Management Immediate Processing Selected Selected Severe Execution Checks Not selected Application Object Type ODT30_TO (Tour in Transportation Execution Visibility Process (New)) Last Exp. Event UNLOAD_END FO RC Propagate Execution Info (Last Expected Event for Execution of a Document) LY Create a Sales Order Create a sales order in the SAP ERP system. ON 1. In SAP ERP, create a sales order with the following data: Field Value Order Type ZT00 Sales Organization 3000 Distribution Channel 10 Division 00 Sold-to Party CUST00-25 PO Number TM320–GRP##-1.1 © Copyright. All rights reserved. 397 Unit 10: Transportation Event Monitoring Field Value Material PRODTM-00 Order Quantity 30 Make a note of the order number. Create a Freight Order R 1. In NWBC, in the worklist, select your OTR and open the transportation cockpit. ME 2. Update the SAP Transportation Cockpit: Profile and Layout Sets using the following data: Value Planning Profile GRP##-NA-FU-PLAN-PROF Transportation Cockpit Layout Standard Layout for Planning Result Screen Standard Description GRP## Profile and Layout Set Default Set US TO Field Selected 3. Plan the freight order with carrier US-CAR-01, using Optimizer Planning. 4. In the freight order, determine all the planned events. FO RC 5. In the freight order, where can you find the planned departure and arrival dates? Record Expected Events and Event Exceptions in SAP TM In this task, you report an expected event and create an unexpected event in SAP TM. 1. In NWBC, change your freight order by reporting Proof of Pickup. LY 2. In NWBC, change your freight order by adding an unexpected event with the following details: User action or value Event Delay Event Reason Snowstorm Actual Event Date Today's date ON Field 398 © Copyright. All rights reserved. Unit 10 Solution 28 Monitor Freight Order Events R Business Example ME Verify that your freight order is relevant for SAP Event Management tracking. Use freight order type T0##. Note that, in this exercise, when the values include ##, replace the characters with the number assigned to you by your instructor. Field US TO 1. In Customizing for SAP TM, verify that your freight order is relevant for SAP Event Management tracking. Use freight order type T0##. Ensure that the following parameters are set: Value Execution Tracking Relevance Execution Tracking with External Event Management Immediate Processing Selected Selected Severe Execution Checks Not selected Application Object Type ODT30_TO (Tour in Transportation Execution Visibility Process (New)) Last Exp. Event UNLOAD_END FO RC Propagate Execution Info (Last Expected Event for Execution of a Document) LY a) In Customizing for SAP Transportation Management, choose SAP Transportation Management → Transportation Management → Freight Order Management → Freight Order → Define Freight Order Types. ON b) Make sure that you are in the display mode. To switch to the display mode on the Change View Freight Order Types: Details screen, choose Change → Display. c) Select the freight order type and choose (Details). d) On the Display View Freight Order Types: Details screen, in the Execution Settings screen area, verify that the settings are as shown in the table. e) Exit the function. Create a Sales Order Create a sales order in the SAP ERP system. © Copyright. All rights reserved. 399 Unit 10: Transportation Event Monitoring Value Order Type ZT00 Sales Organization 3000 Distribution Channel 10 Division 00 Sold-to Party CUST00-25 PO Number TM320–GRP##-1.1 Material PRODTM-00 Order Quantity 30 US TO Make a note of the order number. ME Field R 1. In SAP ERP, create a sales order with the following data: a) In SAP ERP, on the SAP Easy Access screen, choose Logistics → Sales and Distribution → Sales → Order → Create (VA01). b) On the Create Sales Order: Initial Screen, enter the following data: Field Order Type Sales Organization ZT00 3000 10 FO RC Distribution Channel Value Division 00 c) Choose Enter. d) On the Create TM100 Standard Order: Overview screen, enter the following data: Value Sold-to Party CUST00-25 PO Number TM320–GRP##-1.1 LY Field Material PRODTM-00 Order Quantity 30 ON e) Choose Save. f) Make a note of the order number: __________________________ Create a Freight Order 1. In NWBC, in the worklist, select your OTR and open the transportation cockpit. a) In NWBC, choose ERP Logistics Integration → Worklist → Overview Transportation Requirements. 400 © Copyright. All rights reserved. Lesson: Monitoring Transportation Events b) Choose Refresh. c) In the Order-Based Transportation Requirements - All screen area, select your sales order, and choose Start Transportation Cockpit. 2. Update the SAP Transportation Cockpit: Profile and Layout Sets using the following data: Value Planning Profile GRP##-NA-FU-PLAN-PROF Transportation Cockpit Layout Standard Layout for Planning Result Screen Standard Description GRP## Profile and Layout Set Default Set Selected ME R Field US TO a) On the Transportation Cockpit: Profile and Layout Sets screen, choose New. b) Enter the data provided in the table (or select your Profile and Layout Set if you have already created one). c) Choose Save. d) Choose Continue. e) Select the new row and choose Continue. 3. Plan the freight order with carrier US-CAR-01, using Optimizer Planning. RC a) In the Freight Unit Stages screen area, select the freight unit. b) Choose Optimizer Planning → Selected Entries with All Resources. c) Note the freight order number. FO d) Select the new freight order and choose Carrier Selection → Manual. e) In the Assign Carrier Manually dialog box, enter US-CAR-01 and choose OK. f) Choose Accept. g) Choose Save. LY 4. In the freight order, determine all the planned events. a) In the Freight Orders/Freight Bookings screen area, choose the freight order document number. ON b) Open the Execution tab and review the expected results. c) For each event, note the Planned Date and Location. 5. In the freight order, where can you find the planned departure and arrival dates? Open the Stages tab and you will see the planned departure and arrival dates and times for that stage. © Copyright. All rights reserved. 401 Unit 10: Transportation Event Monitoring a) Open the Stages tab. b) Select a stage and in the Stages table, you can see the relevant information. c) On the Stages tab, select the stage in the table. This opens new tabs. d) View the required information on the Dates/Times tab. Note that the planned dates that are taken over into the expected events. R e) Stay on the Freight Order screen. ME Record Expected Events and Event Exceptions in SAP TM In this task, you report an expected event and create an unexpected event in SAP TM. 1. In NWBC, change your freight order by reporting Proof of Pickup. a) In your freight order, on the Execution tab, choose Edit. US TO b) Select the Proof of Pickup event row. c) On the Execution tab, below the table of events, in the Actual Event Date field, ensure that you can enter a date. Do not enter a date here. d) In the table of events, choose Report Event. e) Check that the status is changed for the proof of pickup event and that the current date and time is the actual event date. RC f) In the Proof of Pickup row, check that in the Source of Exec. Information column, it is Reported Directly for this Document. g) Save your data and stay on this screen. 2. In NWBC, change your freight order by adding an unexpected event with the following details: Field FO Event User action or value Delay Event Reason Snowstorm Actual Event Date Today's date LY a) In your freight order, on the Execution tab, choose Edit. b) Choose Insert Event. ON c) On the Execution tab, enter the data provided in the table. d) Choose Save. e) Note that the unexpected event has appeared in the event list on the Execution tab. f) Close the window. 402 © Copyright. All rights reserved. Lesson: Monitoring Transportation Events LESSON SUMMARY You should now be able to: Monitor transportation events with SAP Event Management ON LY FO RC US TO ME R ● © Copyright. All rights reserved. 403 Unit 10 Lesson 2 R Configuring SAP Event Management (SAP TM) for Transportation Visibility ● US TO LESSON OBJECTIVES After completing this lesson, you will be able to: ME LESSON OVERVIEW In this lesson, you learn how to configure the settings to enable visibility to transportation events with SAP EM. Configure settings to enable transportation event visibility ON LY FO RC Event Creation Architecture Landscape Figure 115: Creating Events: Architectural Landscape In SAP TM, an application interface (AI) to SAP Event Management (SAP EM) configuration is required so that data is transferred from the SAP TM to SAP EM. Examples of configuration objects include function modules (codes) and extractors required to interface the data between the two systems. SAP TM must be configured so that programs (or extractors) can extract data (for example, expected events) from SAP TM and send the data via the application interface to SAP EM. 404 © Copyright. All rights reserved. Lesson: Configuring SAP Event Management (SAP TM) for Transportation Visibility Note: This configuration is not part of this course. To use the SAP EM features, configuration is also required in SAP EM. This may include visibility settings using the Web UI or SAP GUI. Additionally, roles and role assignment to users should be set up to enable access to visibility scenarios. R In SAP EM, Business Application Programming Interface (BAPIs) are used to integrate with SAP TM and other non-SAP systems, via SAP Process Integration (SAP PI) or other methods. ME The BAPIs are as follows: ● /SAPTRX/BAPI_EH_POST - for creation of event handlers ● /SAPTRX/BAPI_EH_ADDEVENTMSG_02 - for reporting events Integration Tools between SAP TM and SAP EM US TO Non-TM systems use IDoc and Web Services to integrate into SAP EM. SAP TM is different from other SAP solutions (for example, SAP ERP) in the way that it interfaces with the application interface. In SAP ERP, this interface is triggered by BAdIs when a business document is saved. SAP TM uses the Post-Processing Framework (PPF) for this. The PPF is also used for printing and interfaces to SAP ERP and SAP Global Trade Services (SAP GTS). Therefore, before the integration can start, you need to check if this EM Interface is enabled in the PPF. ON LY FO RC In Customizing for Cross- Application Components, choose Reusable Objects and Functions for BOPF Environment → PPF Adapter for Output Management → Maintain Output Management Adapter Settings. © Copyright. All rights reserved. 405 Unit 10: Transportation Event Monitoring US TO ME R Event Types and Event Handler Configuration Settings FO RC Figure 116: Creating Event Handlers and Expected Events in TM In the integration between SAP TM and SAP EM, two different interfaces and functions are used, as follows: 1. Creation and update of the Event Handler with all expected events and other critical fields such as parameter and tracking IDs. 2. Sending or reporting of events from the SAP TM system, for example, loading or unloading events from freight unit or freight order. LY To be able to create event handlers in SAP TM, you must configure the application object types (AOTs). From the AOTs, the extractors are created. These extractors send the data to SAP EM and create SAP EM event handlers. Content of Application Object Types Application Object Types contain the following: Expected events, with planned dates and times ON ● ● ● Tracking IDs that uniquely identify the trackable object or business document, for example, a freight order Information and system parameters that contain information about the object Content of Extractors The extractors contain the following: 406 © Copyright. All rights reserved. Lesson: Configuring SAP Event Management (SAP TM) for Transportation Visibility ● A freight order ● A freight booking ● A freight unit ● A transportation unit ● Other objects R Event Handlers and Reporting Events in SAP EM ME An event handler represents a business document (for example, freight order, freight unit, or transportation unit) or a business process (for example, within a Transportation Execution) that is relevant to tracking or monitoring functions. SAP EM creates an event handler for each object. The event handler contains all of the information necessary to track this application object. It contains this information in a form that is independent of its origin, so that SAP EM can map and track business processes in a uniform way. ON LY FO RC US TO The event handler information makes it possible to enable the monitoring of events that are reported to SAP EM for an application object, and to check if the actual events occur in line with the expected events. In SAP TM, event types are used to send or report events to SAP EM. Figure 117: Reporting Events in SAP EM Events When events are reported, SAP EM uses the tracking ID that is provided in the event message to find the corresponding event handler. Basic Fields in an Event An event contains the following basic fields: © Copyright. All rights reserved. 407 ● Date ● Time ● Time zone ● Tracking ID ● Tracking code ● Event code R Unit 10: Transportation Event Monitoring FO RC US TO Visibility Process Configuration ME All of these fields are configured or coded in the event types. Figure 118: SAP-Delivered Visibility Processes LY To monitor SAP TM Execution events, you can use the visibility scenarios from the freight order, freight booking, resource, or freight unit in the standard. This means that the application object types (AOTs) and the event type configuration are already available and only need to be activated. You also need to assign the application (in this case, SAP TM) to the SAP EM system. ON Visibility Scenario Prerequisites To use the visibility scenarios for transportation execution in SAP EM, you will need to ensure that the following prerequisites are fulfilled: 1. An RFC destination between SAP TM and SAP EM in transaction SM59 is created. 2. All services below default_host/sap/bc/webdynpro/saptrx/ in transaction SICF for the SAP EM Web interface to work. 3. Business function SCM_EM_TMCONTENT01 is activated in SAP EM. 408 © Copyright. All rights reserved. Lesson: Configuring SAP Event Management (SAP TM) for Transportation Visibility Configuration in SAP TM Once the prerequisites are fulfilled, you can perform the following configuration in SAP TM: 1. Define SAP EM. 2. Define used business process types, application object types, and event type. a. Assign SAP EM to the application object types. c. Assign SAP EM to all required events types. R b. Mark the event management relevance for the application object. 3. Activate the application object types. Configuration in SAP EM US TO Perform the following steps in SAP EM: ME d. Mark the event management relevance for all required events types. 1. Define an application system. 2. Assign a parameter profile to the mapping area. 3. Assign user profiles to users or a role. RC Hint: When you use SAP Event Management for the first time, all Web interface fields are not yet compiled. To avoid problems in the Web interface, open the configuration transaction Configure Fields for User Profiles once. ON LY FO Settings in SAP Transportation Management Figure 119: Configuration in SAP TM Define the System Configuration The RFC connection to the SAP Event Management system and the definition of the logical system serve as base definitions for connecting to SAP EM. In SAP TM, define the system configuration as follows: © Copyright. All rights reserved. 409 Unit 10: Transportation Event Monitoring 1. Define Logical System for SAP Event Management. In Customizing for Integration with Other SAP Components, choose Event Management Interface → Define System Configuration → Define Logical System. 2. Define RFC Destination to SAP Event Management. In Customizing for Integration with Other SAP Components, choose Event Management Interface → Define System Configuration → Define RFC Connection to SAP EM. 3. Define SAP Event Management System. ME Define the Application Object Type R In Customizing for Integration with Other SAP Components, choose Event Management Interface → Define System Configuration → Define RFC Connection to SAP EM. Define the Event Type US TO SAP delivers a predefined application object type with the relevant functions and extractors. The application object type determines the SAP EM relevance of objects and processes in SAP TM. To define the application object type, in Customizing for Integration with Other SAP Components, choose Event Management Interface → Define Application Interface → Define Used Bus. Proc. Types, Appl. Obj. Types, and Evt Types. SAP delivers a predefined event type with the relevant functions and extractors. The event type determines whether the change to an SAP TM object requires an event to be sent to the relevant event handler in SAP EM. To define the event type, in Customizing for Integration with Other SAP Components, choose Event Management Interface → Define Application Interface → Define Used Bus. Proc. Types, Appl. Obj. Types, and Evt Types. FO RC Set Freight Unit Types and Freight Order Types for SAP EM Integration To track the execution status of a freight order or freight unit, the Execution Tracking Relevance field in the freight order type and in the freight unit type must be set to Execution Tracking with External Event Management. You can define the freight order in Customizing for SAP Transportation Management. Choose Transportation Management → Freight Order Management → Freight Order → Define Freight Order Types. You can define the freight unit in Customizing for SAP Transportation Management. Choose Transportation Management → Planning → Freight Unit → Define Freight Unit Types. ON LY Settings in SAP Event Management Figure 120: Configuration in SAP EM The remote function call RFC connection to the SAP Event Management system and the definition of the logical system serve as base definitions for connecting to SAP EM. 410 © Copyright. All rights reserved. Lesson: Configuring SAP Event Management (SAP TM) for Transportation Visibility Parameter Mapping The mapping profile is used to unify parameters when data is coming from SAP TM and to determine event handler types. To define the parameter mapping, in Customizing for Event Management, choose Event Management → Event Handlers and Event Handler Data → Parameters → Define Parameter Mapping. To Configure Integration Between Freight Orders and Event Management R 1. View the Event Manager Definition for the SAP TM logical system ZMTCLNT800. b) In the Information dialog box, choose Continue. ME a) In Customizing for SAP TM, choose Integration with Other SAP Components → Event Management Interface → Define Application Interface → Define SAP EM. c) In the Display View “SAP Event Manager Definitions”: Overview screen, look for the row with ZMTCLNT800 in the Dest. field. Field Event Manager EM Log. System SAP EM Version Local Value Name or identification of an Event Manager The logical System ID of Event Manager SAP Event Manager release used Do not select the checkbox Enter the standard name of an RFC destination. If the receiver is an SAP system, the name of the instance in the SAP system is displayed. (For example ZMTCLNT800) RC Dest. US TO d) Here you will see the various event manager definitions. FO Sync. Select checkbox if the communication to the Event Manager occurs synchronously for all BAPIs. Deselect this checkbox to improve performance. Select this checkbox for test purposes only. In a productive environment, it is recommended that you use asynchronous communication. LY e) Exit the function. ON 2. View the business process type settings in SAP TM. a) In Customizing for SAP TM, choose Integration with Other SAP Components → Event Management Interface → Define Application Interface → Define Used Bus. Proc. Types, Appl. Obj. Types, and Evt Types. b) On the Change View “Define Used Business Process Types”: Overview screen, select the row for a business process type (for example, TMS_TOR). c) In the Dialog Structure screen area, choose Define Application Object Types. d) On the Change View “Define Application Object Types”: Overview screen, select an application object type (for example, ODT30_T0). © Copyright. All rights reserved. 411 Unit 10: Transportation Event Monitoring e) Choose (Details). f) On the Change View “Define Application Object Types”: Details screen, in the Event Manager field, ensure that the name of the Event Manager is entered (for example, EM_TM_800). g) Ensure that the EM Relevance of Appl. Obj. checkbox is checked. 3. View the event types. R a) In the Dialog Structure, choose Define Event Types. c) Choose ME b) In the Change View “Define Event Types”: Overview screen, select an event type (for example, ODT_20_Scheduled). (Details). US TO d) In the Change View “Define Event Types”: Details screen, on the General Data tab, in the Event Manager field, ensure that the Event Manager name is entered (for example, EM_TM_800). e) Ensure that the EM Relevance of Appl. Obj. checkbox is selected. f) Return to Customizing. 4. Enable event management tracking in SAP TM for freight order. a) In Customizing for SAP TM, choose SAP Transportation Management → Transportation Management → Freight Order Management → Freight Order → Define Freight Order Types. FO RC b) Choose a freight order type. c) Choose (Details). d) On the Change View “Freight Order Types”: Details screen, in the Execution Settings screen area, in the Execution Track Relev. field, choose Execution Tracking with External Event Management. e) If you select the Immediate Processing checkbox, the life cycle status is automatically set to In Process when a freight order is created. LY f) The Propagate Execution Info setting indicates whether an event that is reported for a freight order is to be propagated to the predecessor freight units. g) If severe execution checks are activated, the system only allows you to perform cargo management related activities on the freight order interface if the handling execution status of the related items is set to a value that allows such activities. ON h) In the Event Management Settings section, in the Application Object Type field, select an application object type for freight orders (for example, ODT30_T0). i) In the Last Exp. Event field, select the last expected event, for example, POD (Proof of Delivery). If this event is reported from the destination stop of a freight order, the freight order is finished from an execution perspective and the system changes the execution status of the freight order to Executed. j) Save and exit the function. 5. Enable settings for event tracking in SAP EM. 412 © Copyright. All rights reserved. Lesson: Configuring SAP Event Management (SAP TM) for Transportation Visibility a) In Customizing for SAP TM, choose Event Management → General Settings in SAP Event Management → Define Application System. b) In the Information dialog box, choose Continue. c) On the Display View "Application System Definition": Overview, screen in the logical System field, enter the name of the system that is integrated with SAP EM (for example, TM_00_800). 6. Enable Settings for the event handlers in SAP EM system. R d) Save and exit the function. ME a) In Customizing for SAP TM, choose Event Management → Event Handlers and Event Handler Data. LESSON SUMMARY You should now be able to: Configure settings to enable transportation event visibility ON LY FO RC ● US TO b) Maintain additional settings for Event Handlers, Expected Events, and Parameters. For more information, refer to the guide Integration of SAP TM and SAP Event Management. © Copyright. All rights reserved. 413 Unit 10 Lesson 3 Handling Events in the Collaboration Portal LESSON OBJECTIVES After completing this lesson, you will be able to: Handle events in the Collaboration Portal US TO ● ME R LESSON OVERVIEW In this lesson, you learn how to monitor and handle events in the Collaboration Portal. LY FO RC Event Handling in the Collaboration Portal ON Figure 121: SAP TM Collaboration Portal The SAP Transportation Management collaboration portal for carriers (SAP TM Collaboration Portal) supports collaborative business processes. As a carrier working with several shippers that use the SAP TM collaboration portal, you have separate access to each of your shippers. In each case, you can work only with this one shipper. The main benefits of the SAP TM Collaboration Portal are as follows: 414 © Copyright. All rights reserved. Lesson: Handling Events in the Collaboration Portal ● ● ● ● The SAP TM Collaboration Portal is a full browser-based solution, which means that the carrier does not need access to shipper’s network (for example, a VPN connection). All common browsers are supported (Internet Explorer 9, Mozilla Firefox, Safari, Google Chrome). The carrier does not have to install anything, but just log in into the collaboration portal with the access (logon and password) provided by the shipper as SAP TM Collaboration Portal owner or host. R ● Small and mid size carriers do not need to have SAP TM installed. The carrier can see only request for quotations (RFQ) assigned to it, and the transmitted quotations. ME ● To increase the usability of the portal by the carrier, user settings in the portal are stored and are available after logging on again. LY FO RC US TO Event Notification and Handling Figure 122: Event Notification and Handling ON Since the introduction of the Collaboration Portal, new functionality has been added to the portal. One of the newer functionalities in the area of freight order management is event notification and handling. It enables carriers to report expected (planned) and unexpected events related to a freight order or the stops of a freight order, to the shipper. © Copyright. All rights reserved. 415 Unit 10: Transportation Event Monitoring FO RC US TO ME R Freight Orders for Execution Figure 123: Freight Orders for Execution Carriers enter the SAP Transportation Management Collaboration Portal on the Home screen. This screen displays a worklist with the key performance indicators (KPIs) for the available areas in the form of tiles. From the tiles, shippers can navigate to the individual areas to continue their work. The area of freight order management has been enhanced with a tile for Event Handling. The tile displays the open freight orders for execution, for which events still have to be reported, if necessary. LY The Freight Orders for Execution subscreen gives an overview of all of the freight orders assigned to the carrier. The list can be filtered by the freight order status, and the individual freight order for which an event should be reported can be selected. The locations where the events occur can be displayed on a map, or the sequence of locations can be displayed in a numbered list. ON The list supports sorting, searching for freight orders, and filtering. You can apply a quick filter in the toolbar to filter the freight orders by the status of the event confirmation to show only open freight orders (Open), freight orders for which all the planned events have already been reported (Closed), or freight orders that have been canceled by the shipper (Canceled). The next planned (Open) event is displayed for each freight order, together with the affected locations and the date and time. By selecting a single row in the list, the next open event can be directly reported. 416 © Copyright. All rights reserved. Lesson: Handling Events in the Collaboration Portal Figure 124: Reporting Events US TO ME R Reporting Events RC The Freight Order Details screen displays all of the execution related information. There is a subscreen for entering tracking related information. On this screen, the carrier can enter actual event data, such as reporting expected events, including comments, or add additional events. FO On this subscreen, as well as the next planned event, the carrier can also report all open events, such as Arrival, Loading Begin (for an expected event), or Delay (for an unexpected event). The carrier can enter the date and time, a comment, and a reason for each event. It is possible to report multiple events at the same time. The carrier can also upload attachments and add notes to the freight order. Note that the system displays planned events only if an integration with SAP Event Management is set up in the back-end SAP TM system. ON LY The carrier can report unplanned events that affect an individual location (Location Events) or the transportation as a whole, for example a delay (Tour Events). © Copyright. All rights reserved. 417 Unit 10: Transportation Event Monitoring ME R Quantity Discrepancies US TO Figure 125: Quantity Discrepancies ON LY FO RC In addition to event notification and handling, there is also a subscreen for entering all cargorelated information. This screen enables the carrier to enter actual quantities on particular stops. If there is a discrepancy between the quantity given in the freight order and the actual quantity, this discrepancy can be reported by entering the actual quantity. 418 © Copyright. All rights reserved. Unit 10 Exercise 29 Monitor Events in the Collaboration Portal R 1. Open the Collaboration Portal. Use the following credentials to logon: User: US_CARR01 US TO Password: carrier01 ME Use the URL https://wdflbmt2290.wdf.sap.corp:51681/sap/bc/ui5_ui5/tmui/ coll_portal/ 2. Display all open freight orders for execution. 3. Open the freight order that you created for monitoring. 4. Review the events that have been reported so far. 5. Report Arrival at Destination with the current date and time. ON LY FO RC 6. Review the updated events in NWBC. © Copyright. All rights reserved. 419 Unit 10 Solution 29 Monitor Events in the Collaboration Portal R 1. Open the Collaboration Portal. Use the following credentials to logon: User: US_CARR01 US TO Password: carrier01 ME Use the URL https://wdflbmt2290.wdf.sap.corp:51681/sap/bc/ui5_ui5/tmui/ coll_portal/ a) Open the Collaboration Portal using the URL provided. b) Logon to the Collaboration Portal using the credentials provided. 2. Display all open freight orders for execution. a) Choose the Event Handling → Freight Orders for Execution tile. 3. Open the freight order that you created for monitoring. FO RC a) In the list of Open freight orders, find the freight order that you created for monitoring, and, to open it, click the link with the freight order ID. 4. Review the events that have been reported so far. a) On the Events tab, review the events that have already been reported for the shipping point in Chicago. b) On the Events tab, review the events that have already been reported for the tour. 5. Report Arrival at Destination with the current date and time. a) In the area of the destination location in Denver, in the Reported Date/Time column, enter today’s date and the current time. LY b) Above the table, choose Update Events. 6. Review the updated events in NWBC. a) Return to your freight order screen in NWBC and choose Refresh. ON b) Review the event Arrival at Destination. 420 © Copyright. All rights reserved. Lesson: Handling Events in the Collaboration Portal LESSON SUMMARY You should now be able to: Handle events in the Collaboration Portal ON LY FO RC US TO ME R ● © Copyright. All rights reserved. 421 ON LY FO RC US TO ME R Unit 10: Transportation Event Monitoring 422 © Copyright. All rights reserved. Unit 10 Learning Assessment A Freight unit X B Transportation unit X C Resource X D Shipment US TO X ME Choose the correct answers. R 1. In which of the following business document types is SAP TM tracking and tracing provided? 2. When configuring the transportation execution visibility process, which of the following settings must be configured in SAP EM? Choose the correct answers. A Define an application system X B Assign a parameter profile to the mapping area X C Assign user profiles to users or a role X D Assign SAP EM to all required events types ON LY FO RC X © Copyright. All rights reserved. 423 Unit 10 Learning Assessment - Answers R 1. In which of the following business document types is SAP TM tracking and tracing provided? A Freight unit X B Transportation unit X C Resource X D Shipment US TO X ME Choose the correct answers. 2. When configuring the transportation execution visibility process, which of the following settings must be configured in SAP EM? Choose the correct answers. A Define an application system X B Assign a parameter profile to the mapping area X C Assign user profiles to users or a role X D Assign SAP EM to all required events types ON LY FO RC X 424 © Copyright. All rights reserved. UNIT 11 Transportation Execution R Lesson 1 426 435 ME Configuring Freight Order Output Exercise 30: Configure Settings to Enable Printing of Freight Order Documents Lesson 2 UNIT OBJECTIVES 444 455 US TO Managing Freight Order Discrepancies Exercise 31: Process a Freight Order with Discrepancies Configure settings to enable the printing of documents in the freight order ● Process different types of discrepancies in SAP TM ON LY FO RC ● © Copyright. All rights reserved. 425 Unit 11 Lesson 1 Configuring Freight Order Output LESSON OBJECTIVES After completing this lesson, you will be able to: Configure settings to enable the printing of documents in the freight order US TO ● ME R LESSON OVERVIEW In this lesson, you learn how to integrate SAP Extended Warehouse Management (SAP EWM) transportation execution directly into SAP Transportation Management. FO RC Output Management: Integration LY Figure 126: Output Management Overview ON Whether managing requests, planning, subcontracting, executing, or settling, each of the users and managers involved needs to be notified when a task is required or a report on recent activity is made. Users need to view the results of business process activities and generate automated outputs in response to various business events. SAP TM output management is an important requirement for keeping your business processes flowing and synchronized. Output management automates the output of business documents, such as printouts, in response to certain business events. Output management enables you to perform application-specific tasks such as uploading data to a business intelligence (BI) system and sending events to SAP Event Management. The solution enables you to set up outputs easily. It supports both automated back-end and manual front-end outputs. You can also use a comprehensive output history to check and monitor all the outputs that have been triggered for a business document. Output management also supports the ArchiveLink, preview, and log display capabilities. 426 © Copyright. All rights reserved. Lesson: Configuring Freight Order Output Output Management Communication Output management provides you with the following external communication: ● Printouts ● Faxes ● E-mails R Communication Types Application-to-application (A2A) communication ● Business-to-business (B2B) communication ● SAP NetWeaver alert posting ● Workflow task actioning LY FO RC US TO ● ME Output management also provides you with methods to action the following types of communication: Figure 127: Examples of Output ON The figure, Examples of Output, depicts a possible example of output management using SAP TM in a logistics service provider (LSP) scenario. Once a customer places a transportation request with a freight forwarder, a forwarding order is created. The confirmed forwarding order documents can be printed or sent to the customer by e-mail. If necessary, this can trigger a workflow process to seek management approval. This could be the case if you wanted to ship a product to a country that may be subject to government sanctions - the legal department would therefore need to review it before it ships. Once planning is complete, the freight forwarder can tender the shipment to a carrier via B2B or other means. This could include a request for quote, particularly if this type of job has not been contracted before, or if costs have undergone significant change due to economic conditions. The carrier can reply using conventional or electronic means, depending on the technology available to them. Once the order has been shipped in SAP TM, the settlement documents can trigger the generation © Copyright. All rights reserved. 427 Unit 11: Transportation Execution of freight invoices, and (if the costs that were agreed are relevant) the invoice verification process can be activated. FO RC US TO ME R Output Management UI Actions Figure 128: Output Management UI There are several actions that can be performed from the output management UI of the business documents. Manual Generate Actions The following options are available as manual generate actions: Generating actions, including scheduling conditions checks ● Generating a list of actions LY ● ● Generating actions, skipping schedule condition checks ● Configuring actions that can skip schedule conditions ON Manual Executing Actions The following options are available as manual executing actions: 428 ● Executing actions, including conditions checks (explicit save required) ● Executing and saving ● Executing actions, skipping start conditions ● Configuring actions that can skip the start conditions © Copyright. All rights reserved. Lesson: Configuring Freight Order Output E-mail Subject and Note Templates The following e-mail subject and note templates are available: ● E-Mail subject is defaulted to the action name. ● E-Mail note is defaulted, based on customizing Change Output Parameters Choose relevant communication medium ● Modify ● Printer ● Number of print copies ● Languages ● Recipients US TO Attachment Options ME ● R The following change output parameters are available: The following options for attachments are possible: ● ● ● Attaching files in the output management UI Predetermining the attachments using a BAdI or configuring in Post Processing Framework (PPF) Customizing RC ● Uploading the attachments into the attachments folder of the leading business document Sending the attachments to all the e-mail recipients, along with leading business document FO Output Management: PPF Settings ON LY The post processing framework (PPF) provides SAP applications with a uniform interface for the condition-dependent generation of actions (for example, printing delivery notes, faxing order confirmations, or triggering approval procedures). The actions are generated if specific conditions are fulfilled for an application document, for example a specific status is set (approval by some person) or a specific date has been reached (two weeks before end of contract). The actions are then processed either directly, in a scheduled report later, or can be deferred via queued remote function call (qRFC). © Copyright. All rights reserved. 429 ME R Unit 11: Transportation Execution US TO Figure 129: Post Processing Framework Schematic The PPF is part of the SAP NetWeaver Application Server and can be used by applications. It is the successor to message control and offers a wider range of functions, simpler connection to the applications, and greater flexibility. The PPF provides tools for scheduling, starting, and monitoring actions. Actions can be determined, generated, and processed either automatically or with user interaction. With the PPF, you can evaluate modifiable conditions for determining actions. The application can be used to select the determination technology with which the conditions are evaluated or use its own determination technology. RC Processing types are provided by the PPF to execute various actions, as follows: ● Printing, sending e-mails, and faxing with Smart Forms ● Starting a workflow ● Starting a Business Add-In FO The processing types can be adopted by the application, adapted to meet the requirements of the application, or replaced with the processing types of the application. The PPF also provides tools for the administration of actions. It has an action overview with status display, determination logs, and processing logs. The overview can be included in the application as a subscreen. LY The PPF triggers the main outbound communication and integration steps such as PI outbound messaging, integration to SAP Event Management, BI, and workflow. In addition, printing is triggered via PPF and handled by Adobe Document Services (ADS). ON Post Processing Framework (PPF) Configurations ● Maintain application, action profile, action definition, and processing type Table 58: Processing Type 430 Method call For triggering outputs such as B2B/A2A and so on, or to trigger any application-specific tasks External communication For print, fax, and e-mail © Copyright. All rights reserved. Lesson: Configuring Freight Order Output Trigger alert For triggering an alert Workflow For triggering a workflow ● Create conditions for the action definition: start condition and schedule conditions ● Create processing details R An action definition is metadata or a skeleton of a business task and has to be maintained with its individual configuration. While defining an action, it is possible to specify the type of action (external, workflow, method call, or alert). ME The processing details are taken from the action definition and can be modified. For example, the recipients (e-mail or fax) for external communication can be set. A valid printer has to be set with the PPF conditions for actions, which result in printing. Schedule condition US TO To trigger PPF actions, start and schedule conditions need to be configured according to business needs or rules, as follows: The schedule condition decides whether an action should be scheduled for processing. An action is therefore only generated if the schedule condition is met. The filter value is specified in the Schedule condition field. The standard value /BOFU/ EVAL_SCHEDULE_CONDITION ensures that the method in the agent class is invoked. Start condition RC The start condition is checked before the action is executed. The action is only executed when the start condition has been fulfilled. The filter value is specified in the Start condition field. The standard value /BOFU/ EVAL_START_CONDITION ensures that the method in the agent class is invoked. ON LY FO Output Management: Adapter Settings Figure 130: Output Management Integration with SAP TM Output management automates the output of business documents such as printouts, in response to certain business events. This output management adapter helps you to integrate output management functionality with application business objects (BOs) that are implemented in a business object processing framework (BOPF). © Copyright. All rights reserved. 431 Unit 11: Transportation Execution Output Management Adapter The output management adapter uses PPF to generate and process outputs. Depending on how you configure PPF, it generates output actions for particular application data records. The system then processes these actions and sends the output data. US TO ME R All of the relevant action-level outputs are hard wired to the corresponding methods in the agent class that is specified in the output management adapter customizing. This enables easy implementation at the customer end. Figure 131: Configuration - Output Management Adapter Settings FO RC Action Profiles When associating an agent class to a BO, it is possible to assign an action profile; assign actions to the action profile, and specify whether the action is critical or uncritical. Critical outputs must be completed within the logical unit of work (LUW), such as business-tobusiness (B2B) method calls or workflows. ON LY Non-critical outputs fall into the category of communication methods, such as print, e-mail, and fax. 432 © Copyright. All rights reserved. US TO ME R Lesson: Configuring Freight Order Output Figure 132: Output Management Agent Classes Any BOPF application implementing output management should create a class for handling the actions according to business needs. This class should be created with /BOFU/ CL_PPF_SERV_FOR_BO as the super class. ON LY FO RC The agent classes can be assigned to the BO node using the O/P adapter settings. © Copyright. All rights reserved. 433 ON LY FO RC US TO ME R Unit 11: Transportation Execution 434 © Copyright. All rights reserved. Unit 11 Exercise 30 R Configure Settings to Enable Printing of Freight Order Documents ME Business Example The system must be configured before freight order documents can be printed. You are an SAP consultant working with your client ABC Shipping. You have been asked to configure the system so the company can print freight order documents. In this exercise, you can practice configuring the settings. RC 2. What is an action profile? US TO 1. In SAP TM, what framework is used for any form of communication? FO 3. What is an action definition? LY 4. Identify the four main processing types supported in post processing framework. ON 5. Identify the standard action profile for printing freight documents for road freight. 6. Locate the action definitions defined within action profile /SCMTMS/TOR_PRINT_ROAD. 7. Determine whether the action definition for /SCMTMS/PRINT_MAN is active or inactive. 8. Explore the action definition settings for the action definition /SCMTMS/PRINT_MAN. © Copyright. All rights reserved. 435 Unit 11: Transportation Execution 9. What is the significance of setting the processing time to Processing using the selection report? ME 11. Identify the processing types defined for /SCMTMS/PRINT_MAN. R 10. What is meant by the Changeable in Dialog setting? US TO 12. Locate the form name for processing type external communication for /SCMTMS/ PRINT_MAN. FO RC 13. Identify the form type of the /SCMTMS/FP_MANIFEST form. 14. Locate where the archiving for documents can be enabled. 15. What is the difference between start conditions and schedule conditions? LY 16. Identify the schedule condition maintained for /SCMTMS/PRINT_MAN. ON 17. Locate where a default printer for this action is defined. 18. What is the function of an agent class? 436 © Copyright. All rights reserved. Lesson: Configuring Freight Order Output 19. Identify the agent class associated with the printing TOR objects. R 20. Identify the action profiles associated with the /SCMTMS/TOR_PRINTING output agent. ME 21. Identify whether actions relating to the printing of documents for road are enabled. US TO 22. Identify whether it is possible to skip the schedule condition checks for /SCMTMS/ PRINT_MAN. RC 23. Identify whether it is possible to skip the start condition checks for the action /SCMTMS/ PRINT_MAN. ON LY FO 24. Identify the output types associated with the freight order type T0##. © Copyright. All rights reserved. 437 Unit 11 Solution 30 R Configure Settings to Enable Printing of Freight Order Documents ME Business Example The system must be configured before freight order documents can be printed. You are an SAP consultant working with your client ABC Shipping. You have been asked to configure the system so the company can print freight order documents. In this exercise, you can practice configuring the settings. US TO 1. In SAP TM, what framework is used for any form of communication? Output management based on post processing framework. 2. What is an action profile? An action profile is used to group action definitions that belong together. For example, an action profile can be used to group all actions related to freight orders for road. FO RC 3. What is an action definition? An action definition is the basic structure for an action. It defines characteristics of the action such as the time of trigger and whether it can be executed from the UI. 4. Identify the four main processing types supported in post processing framework. External communication, Method Call, Alert, and Workflow. LY 5. Identify the standard action profile for printing freight documents for road freight. /SCMTMS/TOR_PRINT_ROAD is the standard action profile for actions related to printing freight documents for road freight. ON a) In Customizing for SAP TM, choose Cross-Application Components → Processes and Tools for Enterprise Applications → Reusable Objects and Functions for BOPF Environment → PPF Adapter for Output Management → Maintain PPF Settings. b) Select the application /SCMTMS/TRANSPORTATION. c) Choose Define Action Profile and Actions. d) Check the list for an action profile with the description Actions for Print Documents Road Freight. 438 © Copyright. All rights reserved. Lesson: Configuring Freight Order Output 6. Locate the action definitions defined within action profile /SCMTMS/TOR_PRINT_ROAD. a) In the Action Profile table, choose the action profile /SCMTMS/TOR_PRINT_ROAD. b) In the Dialog Structure screen area, choose Action Definition. 7. Determine whether the action definition for /SCMTMS/PRINT_MAN is active or inactive. The action definition is active because the Inactive checkbox is not selected. R a) In the /SCMTMS/PRINT_MAN row, look at the Inactive checkbox. If the checkbox is selected, the action definition is inactive. ME 8. Explore the action definition settings for the action definition /SCMTMS/PRINT_MAN. a) In the list of action definitions, double-click /SCMTMS/PRINT_MAN. b) View the various settings for the action definition. US TO 9. What is the significance of setting the processing time to Processing using the selection report? This means that the action is only scheduled when generated. The action can be further processed using a selection report or explicitly by a user from the corresponding business document. 10. What is meant by the Changeable in Dialog setting? RC If the Changeable in Dialog checkbox is not selected, actions triggered by the action definition can no longer be manually changed after automatic determination. 11. Identify the processing types defined for /SCMTMS/PRINT_MAN. FO The external communication processing type is defined. a) In the Dialog Structure, choose Processing Types. b) Note the defined processing type. LY 12. Locate the form name for processing type external communication for /SCMTMS/ PRINT_MAN. ON The form name is /SCMTMS/FP_MANIFEST. a) On the Display View “Processing Types” Overview screen, select the Document tab. b) Look in the Form Name field. 13. Identify the form type of the /SCMTMS/FP_MANIFEST form. PDF-Based Forms. © Copyright. All rights reserved. 439 Unit 11: Transportation Execution a) Look in the Form Type field. 14. Locate where the archiving for documents can be enabled. a) Select the Archiving tab. b) Look in the Archive Mode field. 15. What is the difference between start conditions and schedule conditions? ME 16. Identify the schedule condition maintained for /SCMTMS/PRINT_MAN. R Schedule conditions specify when actions are scheduled or generated for processing. Start conditions specify when actions are triggered or processed. The /BOFU/EVAL_SCHEDULE_CONDITION schedule condition is maintained. US TO a) Exit the Define Action Profile and Actions function. b) On the Display View “PPF: Applications in Customizing”: Overview screen, select / SCMTMS/TRANSPORTATION. c) Choose Condition Configuration (Transportable Conditions). d) In the Scheduling of Actions column, in theAction Profiles folder, choose Actions for Print Documents Road Freight. (Technical Names) to view the technical names of the action profiles. FO RC e) Choose f) In the Actions for Print Documents Road Freight table, select the /SCMTMS/ PRINT_MAN action definition. g) Open the Schedule Condition tab. 17. Locate where a default printer for this action is defined. a) Open the Processing Details tab. b) Open the Printer tab. 18. What is the function of an agent class? LY An agent class can be used to capture business logic for processing or generating actions. 19. Identify the agent class associated with the printing TOR objects. ON The agent class is /SCMTMS/CL_PPF_SERV_FOR_TOR. a) In Customizing for SAP TM, choose Cross-Application Components → Processes and Tools for Enterprise Applications → Reusable Objects and Functions for BOPF Environment → PPF Adapter for Output Management → Maintain Output Management Adapter Settings. b) In the Output Agent column, locate /SCMTMS/TOR_PRINTING. c) Look in the Agent Class for BO Node column. 440 © Copyright. All rights reserved. Lesson: Configuring Freight Order Output 20. Identify the action profiles associated with the /SCMTMS/TOR_PRINTING output agent. /SCMTMS/TOR_CREATE_FWSD, /SCMTMS/TOR_PRINT_AIR, /SCMTMS/ TOR_PRINT_ROAD, /SCMTMS/TOR_PRINT_SEA, /SCMTMS/TOR_PRINT_AIR_FU and / SCMTMS/TOR_PRINT_PARCEL_ROOT. b) In the Dialog Structure, choose Assign PPF Profiles. R a) Select the entry corresponding to the /SCMTMS/TOR_PRINTING output agent. ME 21. Identify whether actions relating to the printing of documents for road are enabled. Yes, actions related to printing of documents for road are enabled. a) Choose action profile /SCMTMS/TOR_PRINT_ROAD. US TO b) Look at the Enable checkbox. 22. Identify whether it is possible to skip the schedule condition checks for /SCMTMS/ PRINT_MAN. No. The Can Gnrt. W/o Check (Can Generate Without Check) checkbox is unselected, therefore it is not possible to skip the schedule condition checks. RC a) In the Dialog Structure, choose Action Settings. b) Select the action /SCMTMS/PRINT_MAN. c) Choose (Details) to view the details of the action. FO d) Look at the Can Gnrt. W/o Check (Can Generate Without Check) checkbox. 23. Identify whether it is possible to skip the start condition checks for the action /SCMTMS/ PRINT_MAN. LY No. The Can Execute Without Condition Check checkbox is unselected, therefore it is not possible to skip the start condition checks. a) In the Dialog Structure, choose Processing Type Settings. ON b) Look at the Can Execute Without Condition Check checkbox. 24. Identify the output types associated with the freight order type T0##. /SCMTMS/TOR and /SCMTMS/TOR_PRINT_ROAD are the output types associated with the freight order type T0##. © Copyright. All rights reserved. 441 Unit 11: Transportation Execution a) In Customizing for SAP TM, choose SAP Transportation Management → Transportation Management → Freight Order Management → Freight Order → Define Freight Order Types. b) Select the freight order type and choose (Details) to view the details. ON LY FO RC US TO ME R c) In the Output Options section, check the maintained output profiles. 442 © Copyright. All rights reserved. Lesson: Configuring Freight Order Output LESSON SUMMARY You should now be able to: Configure settings to enable the printing of documents in the freight order ON LY FO RC US TO ME R ● © Copyright. All rights reserved. 443 Unit 11 Lesson 2 Managing Freight Order Discrepancies LESSON OBJECTIVES After completing this lesson, you will be able to: Process different types of discrepancies in SAP TM FO RC Freight Order Discrepancies US TO ● ME R LESSON OVERVIEW In this lesson, you learn how to process different types of discrepancies in SAP TM. LY Figure 133: Freight Order Discrepancies Overview ON In the context of transportation management, a discrepancy can be described as a deviation from what is expected and what is actually received. A discrepancy could be in the quantity of goods received or it could be damaged packaging or missing documents. In SAP TM there are two categories of discrepancies, which are Quantity and General. To have more precise differentiation of discrepancies, subcategories have been defined. Quantity Discrepancies 444 ● Missing cargo (pieces) ● Unexpected cargo (pieces) © Copyright. All rights reserved. Lesson: Managing Freight Order Discrepancies ● More weight or volume than expected ● Less weight or volume than expected General Discrepancies Damaged cargo ● Dangerous goods ● Overdimensional cargo ● High-value cargo ● Stackable cargo ● Different equipment or packaging type ● Bonded goods ● To be clarified ME US TO Blocks R ● When a discrepancy is reported in an FO, FB, or TU document, the system automatically blocks the subsequent stages of the transport when reported discrepancies are not yet resolved. For freight units, further planning and execution are blocked. RC For freight orders, freight bookings, and transportation units, execution and invoicing blocks are set. In SAP TM, you can select a checkbox in the freight order, freight booking document, or transportation unit that prevents the system from setting a block. FO If there are unresolved discrepancies in a document, it is not possible to set the freight execution status to Freight Ready for (Un-) Loading. Moreover, a block on an unresolved discrepancy implies that no goods receipt may take place; therefore, you cannot set the cargo receipt status. Discrepancies Between Planned Quantities and Actual Quantities LY Quantities requested by the ordering party to be transported are entered in the forwarding order. When the actual quantities are reported, there can be discrepancies between it and the requested quantities. Such deviations are referred to as “quantity discrepancies”. They can be reported in the freight order (for example, FO for delivery), in the freight booking document, or in the transportation unit. ON When a quantity discrepancy is entered in the FO, FB, or TU, the discrepancy is reflected in the FU as well automatically. In SAP TM, you can define a tolerance range for reported quantity discrepancies. You can enter the following tolerance limits in percent: ● ● Lower tolerance - This limit is used if the actual quantity is less than the planned quantity Upper tolerance - This limit is used if the actual quantity is greater than the planned quantity If the reported quantity discrepancy is within this predefined tolerance range, the system does not set any blocks. © Copyright. All rights reserved. 445 Unit 11: Transportation Execution US TO ME R For example, the tolerance range has an upper and lower tolerance limit of 10%. If the expected quantity is 40 boxes and the actual quantity is between 36 to 44 boxes, no block set by the system. However if the actual quantity is <36 or >44 then a block is set. Figure 134: Quantity Discrepancies and Tolerance Ranges ON LY FO RC General Discrepancies Figure 135: General Discrepancies 446 © Copyright. All rights reserved. Lesson: Managing Freight Order Discrepancies Not all discrepancies in shipments are related to quantities. For example, you can enter discrepancies in the following situations: ● Documents are missing for an item ● There is a dangerous goods item not designated as such ● Packaging of an item is damaged Discrepancy type ● Discrepancy date ● Notes (optional) ● Attachments (optional) US TO ● ME You enter a discrepancy by making entries including the following: R You enter discrepancies on the Discrepancies tab of the individual freight order item or freight booking item. LY FO RC Prerequisites to Discrepancy Handling ON Figure 136: Prerequisites / Customizing Before you can handle any discrepancies in SAP TM, you define the discrepancy types in Customizing. In SAP TM, in Customizing for SAP Transportation Management, choose SAP Transportation Management → Transportation Management → Freight Order Management → Define Discrepancy Profile. In this Customizing activity, you can define discrepancy types and associate them with predefined events and discrepancy subcategories. Further, among the discrepancy types associated with the same event, you must select one discrepancy type as the default discrepancy type. You can also define lower or upper discrepancy tolerances. © Copyright. All rights reserved. 447 Unit 11: Transportation Execution You can define discrepancy profiles. If you do so, you can assign discrepancy types with different stop categories to them. You can assign discrepancy profiles to freight order types, freight booking types, and transportation unit types. Methods of Entering Discrepancies The following options are available when reporting discrepancies: ● R ● Report other discrepancies in Items tab of FO, FB, or TU and enter detailed information in the Discrepancies tab of the item details. Add any necessary attachments to a reported discrepancy within the Attachments column on the Discrepancies tab of the item details. ME ● Report quantity discrepancies in Items tab of FO, FB, or TU and actual values in the Quantities tab of the item details. Add any necessary notes to a reported discrepancy within either the Note or the Notes column on the Discrepancies tab of the item details. US TO ● Note: It is possible to do the following: Report multiple discrepancies for the same item ● Enter the same discrepancy for several items ● Remove a discrepancy that has been added by mistake ON LY FO RC ● Figure 137: Freight Unit Unassignment 448 © Copyright. All rights reserved. Lesson: Managing Freight Order Discrepancies It is possible to unassign FUs for which discrepancies have been reported. FUs can be unassigned from a FO, FB, or TU in the FO/FB/TU screen or in the transportation cockpit. While the discrepancy and the block or blocks still exist on the freight unit level, they are removed in the FB, FO, or TU. This means that the cargo (without the goods of the unassigned FU) is can proceed with further processing. RC US TO ME R Status Changes Figure 138: Status Change The system automatically copies information related to discrepancies and statuses between the documents involved. FO Discrepancies entered in the freight order are automatically copied to the freight booking and freight unit. The resolution of discrepancies in the freight booking also appear in the freight unit and freight order. ON LY Changes of the Cargo Execution Status in the freight order for delivery are visible in the freight booking. Note: It is not possible to set the cargo execution status to Ready for Unloading as long as discrepancies are unresolved. Resolving Discrepancies During execution, discrepancies can be determined between the actual quantities and the quantities that have been ordered by the customer. Furthermore, exceptions can occur, such as missing or damaged cargo. This data can be sent from SAP EWM to SAP TM, and either copied into the freight order or freight booking automatically, or entered into the freight order or freight booking manually. © Copyright. All rights reserved. 449 Unit 11: Transportation Execution The customer service agent or transportation planner must decide with the ordering party how to proceed with the discrepancies. Depending on this decision, the customer service agent can adjust the ordered data to the actual data, or can plan the subsequent delivery of missing cargo. To support the exception handling process, the following functions of SAP TM have been added or enhanced: Discrepancy profile with the option to define discrepancy subcategories ● Personal object worklist (POWL) for discrepancies ● Copy of actual data from freight document to ordered data of forwarding order ● Change of forwarding order data after execution has started ● Assignment of local freight document items to forwarding orders and freight units ● Manual freight unit split after execution has started ● Manual corrections of items, for example, after transfer of data from SAP EWM ME US TO FO RC New Worklist for Discrepancies R ● Figure 139: Discrepancy Worklist LY Before SAP TM 9.3, it was possible to find Forwarding Orders with discrepancies, but the result list was based on the document level instead discrepancies level. With SAP TM 9.3 a central worklist or POWL has been provided to list all discrepancies with details. ON The POWL can be found in the area of Forwarding Order Management. You can display discrepancies with all relevant data. You can resolve discrepancies directly and access the related documents such as forwarding orders and freight orders. The POWL includes options for resolving missing cargo discrepancies with and without keeping the freight units that have been created automatically by the system. It includes an option to resolve discrepancies with unexpected cargo and assign the local freight order items to forwarding order and freight unit items. The same UI options for resolving discrepancies have also been added to the Discrepancy tab of the item details (for forwarding orders and freight documents). 450 © Copyright. All rights reserved. Lesson: Managing Freight Order Discrepancies You can resolve discrepancies as follows: ● ● ● ● If you want to split the freight units for missing cargo and delete the split items, choose Resolve → Resolve Missing Cargo (Delete FU Item). If you have received unexpected cargo that does not have an item and is not assigned to a freight unit in the forwarding order, choose Resolve → Resolve Unexpected Cargo (Assign FWO Item). R ● If you split the freight units for missing cargo and keep the split items but want to remove them from the freight order, choose Resolve → Resolve Missing Cargo (Retain FU Item). If you have received unexpected cargo, and this already has an item and is assigned to a freight unit in the forwarding order, choose Resolve → Resolve Discrepancy. ME ● If you want to resolve a discrepancy, choose Resolve. If you have resolved a discrepancy by mistake and want to undo this, choose Undo Resolve. If you have entered a discrepancy by mistake, choose Delete. US TO ● Conditions for Using the Resolve and Undo Resolve Buttons You can use the actions associated with the Resolve button for specific discrepancy types only. The following conditions apply: ● Resolve discrepancy ● RC This action is permitted for all discrepancy types, except for discrepancies with the subcategory Missing Cargo. You cannot execute the Resolve action for this subcategory if the Quantity Update column in the Customizing activity Define Discrepancy Profile has the value Split Predecessor Document. Resolve missing cargo (retain FU item) FO You can execute this action for discrepancies with the subcategory Missing Cargo, only if the Quantity Update column in the Customizing activity Define Discrepancy Profile has the value Split Predecessor Document. ● Resolve missing cargo (delete FU item) LY You can execute this action for discrepancies with the subcategory Missing Cargo, only if the Quantity Update column in the Customizing activity Define Discrepancy Profile has the value Split Predecessor Document. ● Resolve unexpected cargo (assign FWO item) You can execute this action only for discrepancies with the subcategory Unexpected Cargo. ON You can use the action associated with the Undo Resolve button for specific discrepancy types only. The following conditions apply: ● ● The discrepancy must have the status Resolved. The discrepancy must not have the subcategory Missing Cargo. If the discrepancy does have the subcategory Missing Cargo, the action Undo Resolve can be executed only if the Quantity Update column in the Customizing activity Define Discrepancy Profile does not have the value Split Predecessor Document. © Copyright. All rights reserved. 451 Unit 11: Transportation Execution FO RC US TO ME R Resolving Discrepancies in the Forwarding Order Figure 140: Resolving Discrepancies in the Forwarding Order To resolve discrepancies and handle exceptions, corresponding actions have been developed and added to the POWL. However the actions may be also used in a forwarding order (FWO) screen. LY In a forwarding order, you enter the quantities and attributes requested by the ordering party for the items to be transported. When the actual quantities are reported, there can be discrepancies between them and the requested quantities. You can enter these quantity discrepancies in the freight document, just as you enter other discrepancies, such as packaging damage or missing documents. These discrepancies are then also displayed in the forwarding order. ON Using the displayed data, you can check discrepancies and, for example, clarify, after discussion with the ordering party, whether the discrepancies are acceptable. Then, for further planning, you can set discrepancies to resolved, or block stages of the forwarding order that were not yet executed. In addition, you can search for forwarding orders that contain discrepancies. You can also display discrepancies in your personal object worklist for discrepancies. 452 © Copyright. All rights reserved. Lesson: Managing Freight Order Discrepancies RC US TO ME R Copy Actual Data Figure 141: Copy Actual Data FO You can copy actual data that has been reported by SAP EWM, or entered in the freight document manually, to the ordered data of the forwarding order. The system displays, in the details of the forwarding order item, whether discrepancies exist, and whether actual data differs from ordered data. LY You can change most of the ordered data, even if execution has already started (cargo receipt status is On Hand). However, the changes are then no longer propagated to follow-up documents, such as freight units and freight orders. If a settlement document already exists, you must cancel the settlement document first, then change the data, and, finally, create a new settlement document. On the item detail screen of the forwarding order UI, you can see whether actual data differs from ordered data. In the item table you have the option to copy actual quantities and attributes to the ordered data of a forwarding order item. ON A new status in the item details (Item Processing Status) indicates whether actual data has already been copied to ordered data. Furthermore, it shows whether the item is statistical, which means that it has no freight units anymore. In this case, the system has deleted the freight units of the forwarding order item after you have solved a discrepancy and copied actual data to the ordered data (because the quantity of the item was zero). © Copyright. All rights reserved. 453 ON LY FO RC US TO ME R Unit 11: Transportation Execution 454 © Copyright. All rights reserved. Unit 11 Exercise 31 Process a Freight Order with Discrepancies R Business Example ME A distribution company wants to control what happens when discrepancies are identified in freight orders and shipments. Note that, in this exercise, when the values include ##, replace the characters with the number assigned to you by your instructor. Field Discrepancy Type US TO 1. In Customizing for SAP TM, create a general discrepancy type with the following information: Value D##0 Discrepancy Type Description GRP## General Discrepancy Text Type D0000 Associated Event Selected FO RC No Block GEN_DISCRP Discr. Subcategory Damaged Cargo 2. Create a quantity discrepancy type with the following data: Value Discrepancy Type D##1 Discrepancy Type Description GRP## Quantity Discrepancy Text Type D0001 Associated Event REPORT_QUANTITY Discr. Subcategory Missing Cargo Lower Tolerance 10 Upper Tolerance 10 ON LY Field 3. Create a Discrepancy Profile with the following data and assign your Discrepancy Types to the Discrepancy Profile: Field Value Discr. Prf. DISCPRF## © Copyright. All rights reserved. 455 Unit 11: Transportation Execution Value Discrepancy Profile Description Discrepancy Profile Group ## Field Value Discr. Type D##0 Stop Cat. Relevance Inbound and Outbound Stop Discr. Type D##1 Stop Cat. Relevance Inbound and Outbound Stop ME R Field 4. Assign your discrepancy profile to your freight order type, using the following data: Value Freight Order Type T0## Discrepancy Profile 5. Create a forwarding order. Field US TO Field DISCPRF## Value Forwarding Order Type 01– Road RC Transportation Mode T0## 17– Less-Than-Truckload Movement Type T2C (TM200–Direct) Sales Organization 50001426 Ordering Party EU-CUST-01 FO Shipping Type EU-CUST-01 Consignee EU-CUST-08 Pick-up Date Next Monday Delivery Date One day after pick-up Item Type PRD Product PRODTM-00 Quantity 20 Quantity Unit of Measurement CRT Gross weight 1000 Gross weight UOM LB ON LY Shipper 456 © Copyright. All rights reserved. Lesson: Managing Freight Order Discrepancies Value Item Type PRD Product PRODTM-00 Quantity 20 Quantity Unit of Measurement CRT Gross weight 1000 Gross weight UOM LB ME 6. Create a freight order for your forwarding order. R Field 7. There are 20 cartons in the freight order you just created. During loading, the driver reported that only 19 were loaded. In the freight order, report a discrepancy for 1 carton. Value Quantity US TO Field 19 Gross Weight 430kg RC 8. What date was the quantity discrepancy reported? FO 9. Is the quantity discrepancy within tolerance limits? 10. Is the freight order blocked? ON LY Note: You can also see this on the Statuses tab, in the Blocking Information screen area. 11. Update the actual quantities to 15 cartons. Use the following information: Field Value Quantity 15 © Copyright. All rights reserved. 457 Unit 11: Transportation Execution Field Value Gross Weight 340kg R 12. Is the quantity discrepancy within tolerance limits? ME 13. Is there a block on the freight order? Why? 14. Report a general discrepancy for the freight order and enter a reason for the discrepancy. US TO 15. Determine if there is a planning block on the freight order. What is the reason for this? FO RC 16. Determine whether there is an invoicing block on the freight order. 17. Determine whether there is an execution block on the freight order. What is the reason for this? LY 18. Determine the status of the freight unit related Item 10 of the freight order. ON 19. Identify the reasons for the block on the freight unit. 20. Resolve the discrepancy in the freight order. 21. Is there a block on the freight order? 458 © Copyright. All rights reserved. Lesson: Managing Freight Order Discrepancies ON LY FO RC US TO ME R 22. Determine the status of the freight unit for the Item 10 after the discrepancy has been resolved © Copyright. All rights reserved. 459 Unit 11 Solution 31 Process a Freight Order with Discrepancies R Business Example ME A distribution company wants to control what happens when discrepancies are identified in freight orders and shipments. Note that, in this exercise, when the values include ##, replace the characters with the number assigned to you by your instructor. Field Discrepancy Type US TO 1. In Customizing for SAP TM, create a general discrepancy type with the following information: Value D##0 Discrepancy Type Description GRP## General Discrepancy Text Type D0000 Associated Event Selected FO RC No Block GEN_DISCRP Discr. Subcategory Damaged Cargo a) In Customizing for SAP TM, choose SAP Transportation Management → Transportation Management → Freight Order Management → Define Discrepancy Profile. b) In the Discrepancy Types dialog box, choose New Entries. c) Enter the data provided in the table. LY d) Press Enter on your keyboard. e) If a warning message concerning the namespace is displayed, press Enter again. f) Save the discrepancy type and go back. ON 2. Create a quantity discrepancy type with the following data: 460 Field Value Discrepancy Type D##1 Discrepancy Type Description GRP## Quantity Discrepancy Text Type D0001 Associated Event REPORT_QUANTITY Discr. Subcategory Missing Cargo © Copyright. All rights reserved. Lesson: Managing Freight Order Discrepancies Field Value Lower Tolerance 10 Upper Tolerance 10 a) In the Change View "Discrepancy Types": Overview screen, choose New Entries. b) Enter the data provided in the table. R c) Press Enter on your keyboard. ME d) If a warning message concerning the namespace is displayed, press Enter again. e) Save the discrepancy type and stay in the function. 3. Create a Discrepancy Profile with the following data and assign your Discrepancy Types to the Discrepancy Profile: Value Discr. Prf. US TO Field DISCPRF## Discrepancy Profile Description Discrepancy Profile Group ## Field Value Discr. Type Inbound and Outbound Stop RC Stop Cat. Relevance D##0 Discr. Type D##1 Stop Cat. Relevance Inbound and Outbound Stop FO a) Select Discrepancy Profiles and choose New Entries. b) Enter the data provided in the first table. c) Select the line with the new entry and, from the dialog structure, choose Assign Discrepancy Types to Profile. LY d) Choose New Entries and enter the data provided in the second table. e) Save and leave the customizing activity. ON 4. Assign your discrepancy profile to your freight order type, using the following data: Field Value Freight Order Type T0## Discrepancy Profile DISCPRF## a) In the SAP Customizing Implementation Guide (SPRO), choose SAP Transportation Management → Transportation Management → Freight Order Management → Freight Order → Define Freight Order Type. © Copyright. All rights reserved. 461 Unit 11: Transportation Execution b) Select Freight Order Type T0## and choose Details. c) In Execution Settings, enter DISCPRF## as your Discrepancy Profile. d) Save and leave the customizing activity. Value Forwarding Order Type T0## Transportation Mode 01– Road Shipping Type 17– Less-Than-Truckload Movement Type T2C (TM200–Direct) Sales Organization 50001426 Ordering Party EU-CUST-01 Shipper EU-CUST-01 Pick-up Date Delivery Date Item Type Product EU-CUST-08 Next Monday One day after pick-up PRD PRODTM-00 20 FO RC Quantity US TO Consignee ME Field R 5. Create a forwarding order. CRT Gross weight 1000 Gross weight UOM LB Field Value Item Type PRD Product PRODTM-00 LY Quantity Unit of Measurement 20 Quantity Unit of Measurement CRT Gross weight 1000 ON Quantity Gross weight UOM LB a) In NWBC, choose Forwarding Order Management → Forwarding Order → Create Forwarding Order. b) Enter the data provided in the first table. c) Choose Continue. 462 © Copyright. All rights reserved. Lesson: Managing Freight Order Discrepancies d) In the top right of the screen, in the Page field, choose Fast Order Entry (Land). e) Enter the data provided in the first table. f) In the Items table, choose Insert → Product. g) Enter the product information provided in the second table. h) Choose Save. 6. Create a freight order for your forwarding order. c) Choose Freight Document → Create. ME b) On the Actual Route tab, select the main stage. R a) In the top right of the screen, to display all data, in the Page field, choose Forwarding Order. e) Choose Save. US TO d) In the Stages table, in the Document column, note the freight order number (you may need to scroll to see the Document column). 7. There are 20 cartons in the freight order you just created. During loading, the driver reported that only 19 were loaded. In the freight order, report a discrepancy for 1 carton. Field Value Quantity 430kg RC Gross Weight 19 a) In the forwarding order, on the Stages tab, choose the link in the document column to open the freight order. b) Choose the Items tab. FO c) Choose Edit. d) Choose the Product 10 PRODTM-00 row. e) Choose the Quantities tab. f) On the Actual Quantities screen area, enter the data provided in the table. LY g) Save your changes. ON 8. What date was the quantity discrepancy reported? Today’s date. a) Choose the Product 10 PRODTM-00 row. b) Open the Discrepancies tab to see the date that the discrepancy was reported. 9. Is the quantity discrepancy within tolerance limits? © Copyright. All rights reserved. 463 Unit 11: Transportation Execution Yes. a) On the Discrepancies tab, locate the Within Tolerance field. b) The Within Tolerance checkbox is selected, so the discrepancy is within the tolerance limits. R 10. Is the freight order blocked? No. US TO ME Note: You can also see this on the Statuses tab, in the Blocking Information screen area. a) On the Discrepancies tab, locate the No Block field. b) The No Block checkbox is selected, so the freight order is not blocked. 11. Update the actual quantities to 15 cartons. Use the following information: Field 15 FO RC Quantity Value Gross Weight 340kg a) In the Actual Quantities screen area, enter the data provided in the table. 12. Is the quantity discrepancy within tolerance limits? No. LY a) On the Discrepancies tab, locate the Within Tolerance field. b) The Within Tolerance checkbox is selected, so that the discrepancy is not within the tolerance limits. ON 13. Is there a block on the freight order? Why? Yes. The quantity discrepancy type permits a ± 10% deviation from the planned quantity without a block. The order quantity is 20 pieces, so the permissible deviation is ± 2. Actual quantities greater than 18 and less than 22 are within the tolerance limits and, therefore, the document will be blocked. a) On the Discrepancies tab, locate the No Block field. 464 © Copyright. All rights reserved. Lesson: Managing Freight Order Discrepancies b) The No Block checkbox is selected, so the freight order is blocked. Note: You can also see this on the Statuses tab, in the Blocking Information screen area. 14. Report a general discrepancy for the freight order and enter a reason for the discrepancy. R a) Choose the Discrepancies tab. b) Choose Insert and enter discrepancy type D##0. d) In the Notes column, choose New. ME c) In the Note column, enter a description of the discrepancy: One carton is damaged. US TO e) In the Notes dialog box, verify that your note is displayed. f) In the dialog box, choose Insert. g) In the new row, in the Text Type field, select GRP00 -Header Note. h) Click in the text box, and enter the following text: Contact shipper for instructions. i) To close the dialog box, choose Close. j) Save the freight order. RC 15. Determine if there is a planning block on the freight order. What is the reason for this? FO No, there is no planning block on the freight order. Discrepancies do not affect the planning. a) In the freight order, choose the Statuses tab. b) Under Blocking Information, look in the Planning Block field. LY 16. Determine whether there is an invoicing block on the freight order. ON Yes, there is an invoicing block on the freight order. Invoicing can only be performed if there are no discrepancies, or if reported discrepancies have been resolved. a) In the freight order, on the Statuses tab, check the Invoicing Block field. 17. Determine whether there is an execution block on the freight order. What is the reason for this? Yes, there is an execution block on the freight order. Execution can only be performed if there are no discrepancies, or if reported discrepancies have been resolved. © Copyright. All rights reserved. 465 Unit 11: Transportation Execution a) In the freight order, on the Statuses tab, select the Execution Block checkbox. b) To view the reason for the block, choose Details. 18. Determine the status of the freight unit related Item 10 of the freight order. There is a red light next to the freight unit. The red light means that the freight unit is blocked. R a) In the freight order, choose the Document Flow tab. 19. Identify the reasons for the block on the freight unit. ME b) In the Document Hierarchy column, check the status (stop light) icon next to the freight unit number. US TO There is a planning and execution block, because a discrepancy was reported for the freight unit item in the freight order. Choose Details to find out more information about the blocks. a) To open the freight unit, in the Document Flow tab, choose the freight unit number. b) In the freight unit, choose the Statuses tab. 20. Resolve the discrepancy in the freight order. FO RC a) Choose the Items tab. b) Choose the Product 10 PRODTM-00 row. c) On the Discrepancies tab, select Quantity Discrepancy and choose Resolve → Resolve Discrepancy. d) Save your changes. 21. Is there a block on the freight order? No. The block was removed when the discrepancy was resolved. LY a) Choose the Statuses tab. b) Check the Block status. ON 22. Determine the status of the freight unit for the Item 10 after the discrepancy has been resolved There is no block on the freight unit. a) In the freight order, choose the Document Flow tab. b) Check the status of the freight unit. 466 © Copyright. All rights reserved. Lesson: Managing Freight Order Discrepancies LESSON SUMMARY You should now be able to: Process different types of discrepancies in SAP TM ON LY FO RC US TO ME R ● © Copyright. All rights reserved. 467 ON LY FO RC US TO ME R Unit 11: Transportation Execution 468 © Copyright. All rights reserved. Unit 11 Learning Assessment True X False ME X US TO Determine whether this statement is true or false. R 1. Output management automates the output of business documents, such as printouts, in response to certain business events. 2. When a discrepancy is reported in a freight order document, what blocks are applied to the freight order? Choose the correct answers. A Planning block X B Execution block X C Invoicing block X D Delivery block RC X FO 3. The planned weight of a delivery is 100 kg but the actual weight is 125 kg. A quantity discrepancy exists. The upper and lower tolerance range is +/-20%. Which of the following statements about the quantity discrepancy are correct? Choose the correct answer. A The actual quantity exceeds the upper tolerance limit by 5%. X B The actual quantity exceeds the upper tolerance limit by 10%. X C The actual quantity exceeds the lower tolerance limit by 5%. X D The actual quantity exceeds the lower tolerance limit by 10%. X E The actual quantity is within the tolerance range. ON LY X © Copyright. All rights reserved. 469 Unit 11 Learning Assessment - Answers True X False ME X US TO Determine whether this statement is true or false. R 1. Output management automates the output of business documents, such as printouts, in response to certain business events. 2. When a discrepancy is reported in a freight order document, what blocks are applied to the freight order? Choose the correct answers. A Planning block X B Execution block X C Invoicing block X D Delivery block FO RC X 3. The planned weight of a delivery is 100 kg but the actual weight is 125 kg. A quantity discrepancy exists. The upper and lower tolerance range is +/-20%. Which of the following statements about the quantity discrepancy are correct? Choose the correct answer. A The actual quantity exceeds the upper tolerance limit by 5%. LY X B The actual quantity exceeds the upper tolerance limit by 10%. X C The actual quantity exceeds the lower tolerance limit by 5%. X D The actual quantity exceeds the lower tolerance limit by 10%. X E The actual quantity is within the tolerance range. ON X 470 © Copyright. All rights reserved. UNIT 12 Integration with SAP Extended Warehouse Management R Lesson 1 Lesson 2 Lesson 3 481 US TO Integrating SAP EWM Based on Deliveries 472 ME Integrating SAP EWM based on Shipments Integrating SAP EWM for Transit Warehousing Exercise 32: Receive Goods in Transit Warehouse RC UNIT OBJECTIVES 489 497 Execute the freight order-based shipment by using SAP EWM ● Configure settings to enable warehouse integration based on shipments ● Directly integrate SAP TM into SAP EWM ● Configure settings to enable warehouse integration based on deliveries ● Integrate SAP TM into SAP EWM in a Logistic Service Provider scenario ● Configure settings to enable transit warehouse integration ON LY FO ● © Copyright. All rights reserved. 471 Unit 12 Lesson 1 Integrating SAP EWM based on Shipments LESSON OBJECTIVES After completing this lesson, you will be able to: ME R LESSON OVERVIEW In this lesson, we examine the integration of SAP Enterprise Resource Planning (SAP ERP) sales orders and outbound deliveries with SAP transportation planning and SAP Extended Warehouse Management (SAP EWM) warehouse planning and execution. Execute the freight order-based shipment by using SAP EWM ● Configure settings to enable warehouse integration based on shipments US TO ● ON LY FO RC Integration Scenarios for SAP EWM Based on Shipments Figure 142: SAPTM-SAP ERP—SAP EWM Integration The integration of SAP TM into the SAP EWM application enables you to integrate SAP TM transportation planning with SAP ERP delivery and shipment processing and SAP EWM warehouse planning and execution. In a first integration, based on release SAP TM 9.0, SAP TM was integrated into SAP EWM via SAP ERP. In this scenario, data is not sent directly between SAP TM and SAP EWM. 472 © Copyright. All rights reserved. Lesson: Integrating SAP EWM based on Shipments In this process, you plan the transportation in SAP TM based on sales orders created in SAP ERP. SAP TM proposes and creates deliveries based on dates and quantities according to transportation planning results, taking into account transportation constraints, such as resource availability and transportation durations. The SAP TM system sends delivery proposals to SAP ERP, which creates the deliveries and forwards them to SAP TM and to SAP EWM for further processing. As a result of the transportation planning in SAP TM, a freight order is created in SAP TM. The creation of a freight order results in the creation of a shipment in SAP ERP and of a transportation unit (TU) in SAP EWM. ME R In the warehouse you pick the goods by waves directly into shipping handling units (HUs), for example, pallets. You then stage the shipping HUs and load them into a truck before posting the goods issue. As a result of the goods issue, the deliveries are updated in SAP ERP for later billing and the freight order in SAP TM is updated for a later freight cost settlement. Main Outbound Integration Scenarios Supported with SAP TM-ERP-EWM Integration 1. Outbound process with order-based transportation planning in SAP TM US TO 2. Outbound process with delivery-based transportation planning in SAP TM 3. Outbound process with transportation planning in SAP EWM ON LY FO RC 4. Deletion of transportation planning Figure 143: Order Based Transportation Planning in SAP TM An order-based SAP EWM integration scenario starts with the creation of a sales order. A sales order in SAP ERP creates an order-based transportation request (OTR) and associated freight units in SAP TM. When the freight units (FUs) are planned, freight orders are created. Based on this freight order, outbound deliveries are created in SAP ERP by using the functionality of delivery proposals. © Copyright. All rights reserved. 473 Unit 12: Integration with SAP Extended Warehouse Management Outbound deliveries are created in SAP ERP. The outbound delivery is sent to SAP EWM as an outbound delivery request where an outbound delivery order is created. At the same time it is also sent to SAP TM where a delivery based transportation request (DTR) is created, which consumes the OTR created earlier. The status of the OTR will change to Fully Consumed. The FUs are updated and transferred to SAP ERP where a shipment is created. The shipment is assigned the outbound deliveries. The shipment creates a transportation unit in SAP EWM. ME R Note: Now, the freight order and the assigned freight units in SAP TM, the SAP ERP shipment and the assigned outbound deliveries, the transportation unit and the assigned outbound delivery order in SAP EWM are synchronized. The delivery is picked, packed, staged, and loaded in SAP EWM. A goods issue is triggered in SAP EWM. The goods issue and checkout of the transportation unit result in an update in SAP ERP. The delivery update means that information about the actual weights. quantities, and packing is sent from SAP EWM to SAP ERP. The DTR is updated in SAP TM. US TO When the shipment status is updated, the freight order status is updated to In Execution. The freight order is executed in SAP TM. Once the execution is complete, the status of the SAP ERP shipment is updated. The final step in the process is charge calculation and settlement in SAP TM. ON LY FO RC Delivery Based Transportation Planning in SAP TM Figure 144: Delivery Based Transportation Planning in SAP TM The delivery-based transportation planning process starts with a sales order. The sales order is not sent through transportation management system, but deliveries are created in SAP 474 © Copyright. All rights reserved. Lesson: Integrating SAP EWM based on Shipments ERP. The deliveries are sent to both SAP TM and SAP EWM. The remainder of the process is the same as order-based process. RC US TO ME R Transportation Planning in SAP EWM Figure 145: Transportation Planning in SAP EWM FO In the SAP EWM-driven scenario, also known as SAP EWM-based transportation planning, the transportation planning starts in SAP ERP system with the creation of the sales order and the creation of outbound deliveries. The outbound deliveries are sent to SAP EWM, but not to SAP TM. The SAP EWM system performs transportation planning by creating the transportation unit by itself and assigning the units to it. A goods issue is triggered once the TU is picked, packed, staged, and loaded. ON LY After the transportation unit is checked out, the delivery is updated and a shipment created in SAP ERP. The shipment is sent to SAP TM where a freight order is created enabling SAP TM to perform charge calculation and settlement. © Copyright. All rights reserved. 475 Unit 12: Integration with SAP Extended Warehouse Management US TO ME R Deletion of Transportation Planning in SAP EWM FO RC Figure 146: Deletion of Transportation Planning in SAP EWM Sometimes, a transportation unit (TU) in SAP EWM cannot be executed as planned. In such circumstances, the TU is deleted, thus deleting the shipment and, depending on how the freight order is configured in SAP TM, either deleting or canceling the freight order. ON LY The deletion or cancellation of a freight order enables SAP TM to perform the planning and start the process again. This process is called deletion of transportation planning. 476 © Copyright. All rights reserved. Lesson: Integrating SAP EWM based on Shipments US TO ME R Integration Settings for SAP EWM Based on Shipments Figure 147: Configure Settings to Enable Integration Between SAP EWM and SAP TM When goods of several outbound delivery documents are to be transported together, transportation planning in TM is based on SAP ERP sales orders or deliveries. SAP TM then creates shipments in SAP ERP, which are sent to SAP EWM. SAP ERP creates the required handling units, using container as the packaging material. FO RC SAP EWM converts handling units (HUs) in SAP ERP shipments into a vehicle or transportation unit and a planned shipping and receiving activity in SAP EWM. A transportation unit is the smallest loadable unit of a vehicle that is used to transport goods. Transportation units are mapped to handling units (HUs) and packaging materials can be assigned. By linking the packaging materials to a means of transport, the construction rules for the vehicles can be specified (for example, order of arrangement of transportation unit, and so on). After the warehouse execution, the transport information is sent via SAP ERP to SAP TM, where transport execution and freight settlement occurs. LY For the order-based and delivery-based SAP EWM integration scenarios, SAP TM is configured to send the relevant packaging information for the creation of handling units in SAP ERP. Configuration of SAP TM Tasks SAP TM must be configured to perform the following tasks: Assigning packaging materials to container equipment types. ● Assigning packaging material to vehicles resources. ON ● ● Assigning appropriate document creation relevance in the freight order used for shipment integration. It is possible to send either the container packaging information or the vehicle resource information or both. © Copyright. All rights reserved. 477 Unit 12: Integration with SAP Extended Warehouse Management Supported Shipment Relevance in SAP TM The shipment relevance supported in SAP TM are the following: ● Shipment creation with HUs for Vehicles Only Generates a handling unit for an SAP TM vehicle resource in SAP ERP. ● Shipment creation with HUs for Containers Only Generates a handling unit for an SAP TM container in SAP ERP. Shipment creation with HUs for Vehicles and Containers R ● ME Generates a handling for both vehicle resource and container information to SAP ERP. To Configure Settings to Enable Integration Between SAP EWM and SAP TM 1. View the main customizing settings in the SAP EWM. US TO a) In SAP TM, in Customizing for SCM Extended Warehouse Management, choose Extended Warehouse Management → Goods issue Process → Transportation Management in EWM → Shipments → Define Shipment Type. b) Select and open each of the following: PTRQ, FTRQ, and BOLD. c) Go back. d) In Customizing settings, choose Shipments → Maintaining Settings for Determining Shipment Types. FO RC Here, only the determination of BOLD from FTRQ is maintained. e) In Customizing for SCM Extended Warehouse Management, choose Extended Warehouse Management → Goods issue Process → Transportation Management in EWM → Freight Documents → Define Freight Document Type. There is just one freight document type created, FRD. f) In Customizing for SCM Extended Warehouse Management, choose Extended Warehouse Management → Goods issue Process → Transportation Management in EWM → Freight Documents → Define Maintain Settings for Determining Freight Document Types. LY This setting is only required if you use an external transport planning system in connection with SAP TM. 2. Activate transportation management in SAP EWM. ON a) In Customizing for SCM Extended Warehouse Management, choose Extended Warehouse Management → Goods issue Process → Transportation Management in EWM → Basics → Activate Transportation Management. b) Check the Log Output as List checkbox. c) Choose Execute. For most objects the system will note that the objects do not need to be generated or activated, because they are already in use. 3. Define packaging material types in SAP TM. 478 © Copyright. All rights reserved. Lesson: Integrating SAP EWM based on Shipments a) In SAP TM, in Customizing for SAP Transportation Management, choose SCM Basis → Pack → Handling Units → Define Packaging Material Types. b) If required, define a new packing material type using the following data: Value PkMtT Enter a unique ID Description Packaging Material PMCat Means of Transport, Transport Element, Transport Unit R Field ME 4. Specify a packaging material for container equipment group and equipment type. a) In SAP TM, in Customizing for SAP Transportation Management, choose Transportation Management → Master Data → Resources → Define Equipment Groups and Equipment Types. US TO b) In the Dialog Structure, choose Transportation Unit Groups. c) Select the equipment group for containers (or maintain if required.) d) In the Dialog Structure, choose Equipment Type (or create a new equipment type.) e) Select an equipment type and choose (Display). f) In the Packaging Matl. field, specify the appropriate packaging material. RC g) Save and exit the function. 5. Specify the packaging material for the vehicle resource. a) On the SAP Easy Access screen, in the Menu, choose Menu → SAP Menu. FO b) In the SAP Menu, choose SAP Transportation Management → Transportation Management → Master Data → Resource → Resource c) In the Resource field, enter the vehicle resource (for example, TM_TRUCK). d) Choose (Display Resources). (Display<->Change). LY e) In the Display Resources: Header Data screen, choose f) Open the Transportation tab. g) In the Pack. Material field, enter specify the packaging material. ON h) Save and exit the function. 6. Configure a freight order to transfer packaging information to SAP ERP. a) In SAP TM, in Customizing for SAP Transportation Management, choose SAP Transportation Management → Transportation Management → Freight order Management → Freight Order → Define Freight Order Types. b) Select the freight order type that is to be used for integration with SAP EWM. c) Choose © Copyright. All rights reserved. (Details). 479 Unit 12: Integration with SAP Extended Warehouse Management d) In the Document Creation Relevance field, choose one of the following: ● ● Shipment Creation with HUs for Vehicles Only – Choose this option to generate a handling unit for an SAP TM vehicle resource in SAP ERP. Shipment Creation with HUs for Containers Only – Choose this option to generate a handling unit for an SAP TM container in SAP ERP. Shipment Creation with HUs for Vehicles and Containers – Choose this option to generate a handling unit for both vehicle resource and container information in SAP ERP. R ● ME e) Save and exit the function. LESSON SUMMARY You should now be able to: Execute the freight order-based shipment by using SAP EWM ● Configure settings to enable warehouse integration based on shipments ON LY FO RC US TO ● 480 © Copyright. All rights reserved. Unit 12 Lesson 2 Integrating SAP EWM Based on Deliveries LESSON OBJECTIVES After completing this lesson, you will be able to: ME R LESSON OVERVIEW In this lesson, you learn how to integrate SAP Extended Warehouse Management (SAP EWM) transportation execution directly into SAP Transportation Management (SAP TM). Directly integrate SAP TM into SAP EWM ● Configure settings to enable warehouse integration based on deliveries US TO ● LY FO RC Integration Scenarios for Direct Integration ON Figure 148: History of TM-EWM Integration Since release 9.1, a direct integration between SAP TM and SAP EWM is available, and SAP ERP shipments are no longer required for integration. Communication is now carried out between SAP TM and SAP EWM directly, via services. © Copyright. All rights reserved. 481 Unit 12: Integration with SAP Extended Warehouse Management US TO ME R Process Flow in System Landscape Outbound Process Figure 149: Process Flow in System Landscape Outbound Process This system setup enables end-to-end integrated transportation planning, warehouse execution, and freight settlement by way of a direct interface between SAP TM and SAP EWM. FO RC SAP TM and SAP EWM are part of the supply chain execution platform. Customer orders and delivery orders are generated in SAP ERP. The transportation planning occurs in the SAP TM. The result of the planning is a freight order. This freight order is transferred to SAP EWM directly. SAP EWM is responsible for operations such as picking, packing, and staging from the warehouse. The goods are loaded onto the truck. Once loading is complete, the transport is ready for execution and sent back to SAP TM. In SAP TM, the execution is processed. After successful execution, the freight order is settled in SAP TM. Integrate Best-in-Class Applications ON LY The SAP EWM-SAP TM integration allows a tight integration of master data and Customizing between two systems. The communication occurs by way of the exchange infrastructure (XI). With the update to 9.1, the views for Customizing have not changed, so administrators can still use the same screens. Existing integration features of the release 9.0. are still available in SAP TM 9.1. 482 Note: Besides freight orders, direct integration with SAP EWM is also supported for freight bookings and transportation units. © Copyright. All rights reserved. US TO ME R Lesson: Integrating SAP EWM Based on Deliveries Figure 150: Integrate Best-in-Class Applications FO RC When you plan to send goods from several outbound delivery documents with the same transport, transportation planning in SAP TM is based on SAP ERP sales orders or deliveries. SAP TM sends the transportation planning results to SAP EWM. The information from SAP TM is mapped into corresponding TU or vehicle activities. Building rules are not used in SAP EWM. After the warehouse execution, the transport information is communicated from SAP EWM to SAP TM to carry out transport execution and freight settlement in SAP TM. The communication back to SAP TM is triggered on goods issue of the TU, and contains information about what is loaded on the TUs that are posted goods issue. ON LY Note: Delivery-based outbound transportation planning in SAP TM is also supported for outbound deliveries created in SAP EWM (DirODO). SAP EWM Customizing enables the setting of a TM-relevant transportation planning types and therefore the assignment of such deliveries to TUs created from SAP TM. © Copyright. All rights reserved. 483 Unit 12: Integration with SAP Extended Warehouse Management FO RC US TO ME R Main Process Steps of Order-Based Outbound Transportation Planning Figure 151: Outbound Process The main process steps of order-cased outbound transportation planning are as follows: 1. SAP TM receives sales orders or deliveries from SAP ERP and creates corresponding transportation requirements and freight units. 2. Based on transportation requirements, transportation is planned, freight orders are created in SAP TM. LY 3. When transportation planning is based on sales orders, SAP TM creates deliveries in SAP ERP. 4. SAP ERP distributes outbound deliveries to SAP EWM and SAP EWM generates corresponding warehouse requests of the type outbound delivery order automatically. ON 5. Based on the freight order information, a message is sent from SAP TM to SAP EWM directly, where a vehicle or a TU and a planned shipping and receiving activity is created automatically, and the outbound delivery orders are assigned to the TU activity. 6. Perform the warehouse activities related to the outbound delivery orders such as picking, packing, staging, and loading the goods. Note that all warehouse activities except loading can be performed before arrival of the TU to the door. 7. Execute the action Arrival at Checkpoint for the vehicle or the TU. The system changes the status of the shipping and receiving activity automatically from Planned to Active. 8. Assign a door to the vehicle or the TU. 484 © Copyright. All rights reserved. Lesson: Integrating SAP EWM Based on Deliveries 9. If yard management is active, move the vehicle or the TU from the yard to the assigned door. If yard management is not active, execute the action Arrival at Door for the TU. 10. Perform the warehouse activities such as loading the goods, posting the goods issue, and printing the transportation documents. R 11. With the goods issue posting in SAP EWM, the delivery information is transferred to SAP ERP, where the deliveries are updated automatically with the execution data. The information is forwarded from SAP ERP to SAP TM, where the corresponding deliverybased transportation requirement (DTR) is updated automatically. ME 12. With the goods issue posting in SAP EWM, the transport-relevant information is sent from SAP EWM to SAP TM automatically, where the freight order is updated with the execution and status data (for example, the stop of the freight order is set to Departed; loaded items are set to Loaded). US TO 13. If yard management is active, move the vehicle or the TU from the door to the yard. If yard management is not active, execute the action Departure from Door for the vehicle or the TU. 14. Execute the action Departure from Checkpoint for the vehicle or the TU. SAP EWM automatically changes the status of the shipping and receiving activity from Active to Completed. 15. Set the execution status of the SAP TM freight order to Completed if this was not set automatically in the previous step. 16. Carry out the freight settlement In SAP TM. The freight settlement document in SAP TM is the basis for the invoice verification and settlement in SAP ERP. RC Inbound Process In delivery-based planning, the deliveries are already created in SAP ERP based on the sales orders. ON LY FO The communication between SAP TM and SAP EWM is the same for delivery-based planning as for order-based transportation planning. © Copyright. All rights reserved. 485 Figure 152: Inbound Process US TO ME R Unit 12: Integration with SAP Extended Warehouse Management FO RC As in the delivery-based outbound transportation planning, a transport planner plans inbound deliveries in SAP TM and sends a message for warehouse execution to SAP EWM. The creation of TUs or Vehicles with their assignments to the inbound deliveries is also automatic. The unloading of the transportation unit should be sent from SAP EWM to SAP TM to update the freight order. This communication step is new compared to release 9.0. SAP EWM and SAP TM Integration Settings SAP TM must be configured to perform the following tasks: Assign packaging materials to container equipment types. ● Assign packaging material to vehicles resources. ● Assign appropriate document creation relevance in the freight order type. LY ● ON Set the relevance to Transportation Activity Creation in SAP EWM. To Configure Settings in SAP TM 1. Define a packaging material type in SAP TM. a) In Customizing for SAP TM, choose SAP Transportation Management → Transportation Management → SCM Basis → Pack → Handling Units → Define Packaging Material Types. b) Create an entry with Packaging Material Category A (Means of Transport). 2. Define a means of transport in SAP TM. 486 © Copyright. All rights reserved. Lesson: Integrating SAP EWM Based on Deliveries a) In Customizing for SAP TM, choose SAP Transportation Management → Transportation Management → Master Data → Resources → Define Means of Transport. b) Create an entry with the transportation mode Road. c) Select the Multiresource checkbox. 3. Define vehicle resources in SAP TM. R a) In NWBC, choose Master Data → Resources → Define Resources. b) Choose Create Resources. 4. Define package type codes in SAP TM. ME c) On the Vehicle tab, enter the resource data including the means of transport that you created in Step 2. b) Create an entry. US TO a) In Customizing for SAP TM, choose SAP Transportation Management → Forwarding Order Management → Define Package Type Codes. 5. Define equipment groups and equipment types in SAP TM. a) In Customizing for SAP TM, choose SAP Transportation Management → Transportation Management → Master Data → Resources → Define Equipment Groups and Equipment Types. b) In the Dialog Structure screen area, choose Transportation Unit Groups. RC c) Select the equipment group CN with the description Container and the resource class Container. d) In the Dialog Structure screen area, choose Transportation Mode Assignment. e) Select transportation mode category 1, Road. FO f) In the Dialog Structure screen area, choose Transportation Unit Type and create a new entry. 6. Define freight order types for SAP EWM integration. LY a) In Customizing for SAP TM, choose SAP Transportation Management → Transportation Management → Freight Order Management → Freight Order → Define Freight Order Types. b) Create a freight order type. ON c) In the Additional Settings screen area, in the Document Creation Relevance field, enter E (Transportation Activity Creation in SAP EWM). d) In the Output Options screen area, in the Output Profile field, enter /SCMTMS/TOR. To Configure Settings in SAP EWM 1. Check the packaging material type in SAP EWM. © Copyright. All rights reserved. 487 Unit 12: Integration with SAP Extended Warehouse Management a) In Customizing for SAP TM, choose SCM Extended Warehouse Management → Extended Warehouse Management → Cross-Process Settings → Handling Units → Basics → Define Packaging Material Types. b) Check that an entry corresponding to the packaging material type in SAP TM exists. 2. Configure the means of transport in SAP EWM. a) In Customizing for SAP TM, choose SAP Transportation Management → SCM Basis → Master Data → Transportation Lane → Maintain Means of Transport. R b) Check that an entry corresponding to the means of transport in SAP TM exists. ME c) In Customizing for SAP TM, choose SCM Extended Warehouse Management → Extended Warehouse Management → Cross-Process Settings → Shipping and Receiving → General Settings → Define Control Parameters for Forming Vehicles / Transportation Units. US TO d) Check that entries exist for TU (Transportation Unit) with action profile /SCWM/TU and for VEH (Vehicle) with action profile /SCWM/VEH. 3. Define the link between packaging material and MTR in SAP EWM. a) In SAP TM, on the SAP Easy Access screen, choose SAP Extended Warehouse Management → Extended Warehouse Management → Settings → Shipping and Receiving → Link Between Packaging Material (TU) and Means of Transport. b) Check that an entry exists that links the means of transport to the packaging material. FO RC LESSON SUMMARY You should now be able to: Directly integrate SAP TM into SAP EWM ● Configure settings to enable warehouse integration based on deliveries ON LY ● 488 © Copyright. All rights reserved. Unit 12 Lesson 3 Integrating SAP EWM for Transit Warehousing LESSON OBJECTIVES After completing this lesson, you will be able to: ME R LESSON OVERVIEW In this lesson, you learn how to integrate SAP TM into SAP EWM in a Logistic Service Provider scenario. You also learn how to configure settings to enable transit warehouse integration. Integrate SAP TM into SAP EWM in a Logistic Service Provider scenario ● Configure settings to enable transit warehouse integration LY FO RC Transit Warehousing US TO ● Figure 153: Direct SAP TM-SAP EWM Integration for Logistic Service Providers ON With release 9.3, the integration of SAP Transportation Management (SAP TM) and SAP Extended Warehouse Management (SAP EWM) has been further enhanced, and the integration is now possible without an SAP ERP system. While with 9.1 integration was achieved directly between SAP TM and SAP EWM, the integration was still based on SAP ERP deliveries. This scenario, therefore, supported only shippers that use SAP ERP logistics integration in SAP TM. Transit Warehousing now supports direct SAP TM – SAP EWM integration, without predecessor documents in SAP ERP. Instead, the process can be based on forwarding orders (FWOs) and, therefore, supports Logistic Service Providers. You perform transportation planning in SAP TM, and then send your freight documents and transportation units to SAP © Copyright. All rights reserved. 489 Unit 12: Integration with SAP Extended Warehouse Management EWM. In SAP EWM, you then execute the warehouse tasks, such as picking, packing, staging, and loading or unloading. You execute the settlement in SAP TM. US TO ME R Integrated Planning and Execution Figure 154: Integrated Planning and Execution FO RC Transit Warehousing enables a seamless integration of the planned (system-based) flow of goods in SAP TM and the physical (system-based) flow of goods in SAP EWM across the entire transportation chain. By integrating the two systems, you gain transparency on warehouse data in SAP TM, for example, whether a truck has been loaded or unloaded in SAP EWM, and whether discrepancies exist, for example, quantity discrepancies. In this process, you can temporarily store the cargo in transit warehouses, regional hubs, gateways (air freight) or container freight stations (ocean freight) until it is shipped to the next location. You can also organize the cargo across the entire transportation chain and gain transparency with regard to the specific warehouse data. The process of handling cargo at one location can be repeated at several locations. ON LY In SAP EWM, processing is based on business documents that are created via the loading and unloading instructions from SAP TM. In addition, the warehouse layout is configured in accordance with the requirements of transit warehousing. For example, special warehouse types are available and a product master is no longer required. The handling of the cargo is carried out on package level instead of product level. 490 © Copyright. All rights reserved. Lesson: Integrating SAP EWM for Transit Warehousing US TO ME R Process and Document Overview RC Figure 155: Process and Document Overview In this process example shown in the figure, Process and Document Overview, there are several FWOs from different shippers to different consignees. ON LY FO The ocean or air main leg is covered by a freight booking (FB). The pickup, drayage, and delivery legs are covered by separate freight orders (FOs). In between, goods are shipped through a transit warehouse, gateway, or container freight station (CFS), where they are unloaded from the vehicle resource and loaded to the next vehicle resource. © Copyright. All rights reserved. 491 Unit 12: Integration with SAP Extended Warehouse Management Figure 156: Integrated Process US TO ME R Integrated Process FO RC The example process shown in the figure, Integrated Process, is supported by integrating SAP TM with SAP EWM using the transit warehousing scenario. The first relevant integration point is the unloading of goods at the transit warehouse TW Tokyo after the pick-up stage. The pick-up location in Tokyo is managed by the shipper. At the same transit warehouse TW Tokyo, the goods are loaded onto the next truck for the feeding pre-carriage leg. Both the inbound (unloading) and the outbound (loading) process are supported. In the following stages of the transportation chain, further transit warehouses and gateways are passed through in the same manner. ON LY The last integration point is the loading of goods at TW San Diego for the delivery leg. The delivery location in Tucson is managed by the consignee. 492 © Copyright. All rights reserved. Lesson: Integrating SAP EWM for Transit Warehousing RC Figure 157: Process Flow US TO ME R Process Flow In an inbound scenario, the processes Receive from shipper, Receive from other transit warehouse and Receive from airport/seaport (drayage) are supported. The customer service agent creates a forwarding order in SAP TM. FO The transportation planner creates an actual route manually or has the system determine this route. The actual route contains one or more locations that are relevant for transit warehousing. A location is relevant for transit warehousing if you have entered a warehouse number and a logical system (SAP EWM system) in the location master data. ON LY From the forwarding order, the transportation planner creates a freight order for picking up the goods at the shipper and transporting them to the transit warehouse. Afterwards, the transportation planner sets the execution status of the freight order to Ready for Transportation Execution, which means that the transportation activities can start. Finally, the transportation planner sets the cargo execution status of the freight order for the transit warehouse to Cargo Ready for Unloading. The system sends an unloading instruction to SAP EWM. On receipt of the message, SAP EWM generates a transportation unit and the corresponding handling units and an inbound delivery. On arrival of the truck on the yard, the warehouse staff log the arrival of the truck and assign it to a door. SAP EWM sends a notification to SAP TM. On receiving the message, the freight document is updated with the information about the arrival of the truck. The warehouse staff unload the truck and posts goods receipt. When the freight is fully received, SAP EWM sends an unloading report to SAP TM. On receiving the message, the freight order and the freight units are updated with the information about the received cargo. © Copyright. All rights reserved. 493 Unit 12: Integration with SAP Extended Warehouse Management In case of exceptions, exception handling is processed. The SAP EWM transmission status on SAP TM freight documents provides information about the status of the message exchange. In SAP EWM, new UIs for inbound handling were implemented, for Freight Order Inbound, Unloading Preparation, and Stock List. These new UIs display SAP EWM information for the underlying SAP TM freight documents. It is possible to navigate directly to the SAP TM documents. R In addition, new RF-transactions were implemented for receiving and putaway. Process Flow in Outbound Scenario ME In an outbound scenario, the processes Deliver to consignee, Send to other transit warehouse and Send to airport/seaport (drayage) are supported. US TO In SAP TM, a forwarding order is created and planned as described in the inbound scenario. Afterwards, an unloading list is created based on a freight document. The transportation planner sets the execution status of the freight document to Ready for execution, that is, the transportation activities can begin. The transportation planner sets the cargo execution status of the freight document to the transit warehouse on cargo ready for loading. The system sends a loading instruction to SAP EWM. On receipt of the message, SAP EWM generates a transportation unit and an outbound delivery order and assigns the corresponding handling units to the outbound delivery order. On arrival of the truck on the yard, the warehouse staff log the arrival of the truck and assign it to a door. SAP EWM sends a notification to SAP TM. On receiving the message, the freight document is updated with the information about the arrival of the truck. FO RC The warehouse staff take the handling units to the staging area. The warehouse staff load the truck. SAP EWM sends a loading report to SAP TM. On receiving the message, the freight order and the freight units are updated with the information about the loaded cargo. The warehouse staff log the departure of the truck and post goods issue. SAP EWM sends another message to SAP TM. On receiving the message, the freight order is updated in SAP TM. In case of exceptions, exception handling is processed. The SAP EWM transmission status on SAP TM freight documents provides information about the status of the message exchange. LY In SAP EWM, new UIs for outbound handling were implemented, for Freight Order Outbound and Loading Preparation. These new UIs display SAP EWM information for the underlying SAP TM freight documents. It is possible to navigate directly to the SAP TM documents. ON In addition, new RF-transactions for were implemented for packing and loading. 494 © Copyright. All rights reserved. Lesson: Integrating SAP EWM for Transit Warehousing US TO ME R Integration Highlights Figure 158: Integration Highlights The direct integration of SAP TM into SAP EWM was enhanced with many features, which enhance the existing integration scenario for shippers. Some of the new features are as follows: RC Multi-Document Handling Transit warehousing supports planning and execution with trailers. The data that is returned from SAP EWM is reported back to all the related business documents across multiple levels, that is, not only to the freight order but also to one or more trailer units and freight units. FO Truck & Trailer Transit warehousing supports planning and execution with trailers. The data that is returned from SAP EWM is reported back to all the related business documents across multiple levels, that is, not only to the freight order but also to one or more trailer units and freight units. LY Prerequisites for Truck & Trailer ON In the resource master data you have defined an active vehicle resource for your truck and a passive vehicle resource for your trailer. You have maintained the necessary settings in the customizing for your transportation unit type. The trailer must have been coupled to the truck before the execution of warehouse tasks. Multiple (Delta) Updates As a new feature, it is now also possible to transfer multiple updates. It is possible to receive a new (delta) Loading/Unloading Report in SAP TM from SAP EWM. The Loading/Unloading Report contains only new or updated information of the already loaded or unloaded handling units. Enhanced Discrepancy Handling © Copyright. All rights reserved. 495 Unit 12: Integration with SAP Extended Warehouse Management It is possible to react to discrepancies reported from SAP EWM with different actions, which are supported from a POWL. Support of late FU Splits (in Execution) It is possible to react to warehouse confirmations with FU splits, even when execution has already started. Backward Propagation Support of SAP EWM Handling Units across Freight Units R Confirmation data from SAP EWM can be propagated backwards to predecessor documents. ME It is possible to process SAP EWM handling units that include items of several freight units (Cross FU-Handling). Cross-System Document Flow US TO The document flow of the freight order, freight booking, or trailer unit was enhanced with SAP EWM entries. It is possible to navigate directly to the corresponding SAP EWM transaction from the SAP TM document flow. Search Documents by Handling Unit ID ON LY FO RC It is possible to search for freight documents using the SAP EWM HU ID. 496 © Copyright. All rights reserved. Unit 12 Exercise 32 Receive Goods in Transit Warehouse R Business Example ME A freight forwarder wants to plan orders for international transport via air and is responsible for the entire transportation chain. In the exercise, you plan the first stage of the transport (pick-up from customer) in SAP TM and integrate into SAP EWM to receive the goods in the first transit warehouse. Create a Forwarding Order US TO 1. In SAP NetWeaver Business Client (NWBC), create a forwarding order using the data provided in the following tables. Use the forwarding order type AF01. On the General Data tab, enter the following data: Field Value Sales Organization Incoterm EXW RC Incoterm Location OAF-FWH-05 (FH Tokyo) Movement Type DD Use the following data for the new package: Field AF03 Package Type PAL Quantity 3 Quantity UoM EA FO Item Type LY ON Value Gross Weight 800 Gross Weight UoM kg Gross Volume 3 Gross Volume UoM M3 Net Weight 680 Net Weight UoM kg On the Package Details tab, enter the following data: Field Value Item Description Clothing © Copyright. All rights reserved. 497 Unit 12: Integration with SAP Extended Warehouse Management Value Length 1,5 Width 2 Height 1 Unit of Measure M Goods Value 4.050.000 JPY R Field Value Ordering Party OAF-CU-01 Shipper OAF-CU-01 Consignee OAF-CO-01 Collect Agreement Party Import Organization US TO Filed ME On the Business Partner tab, enter the following data: OAF-FWH-21 AF-FWH-20 On the Location and Date/Times tab, enter the following data: Field Source Location OAF-CU-01 OAF-CO-01 FO RC Destination Location Value Pick-Up Date <Today> + 1 day Delivery Date <Today> + 4 days 2. Write down the number of your forwarding order. LY Plan Customer Pick-up In SAP NWBC, plan the pickup of the goods from the customer. 1. Open your forwarding order in the Transportation Cockpit, using the following settings: Value Planning Profile AF-PLAN-PROF-PRE Transportation Cockpit Layout EKT 93 TH ON Field 2. Apply the default route to your freight unit. 3. Create a freight order for the first stage using Create Freight Document. 4. Save and write down the number of your freight order. Send Unloading Instructions to SAP EWM 498 © Copyright. All rights reserved. Lesson: Integrating SAP EWM for Transit Warehousing 1. Open your freight order and review the items. 2. Review the Execution Status, the Logistical Execution Status, and the Transmission-toEWM Status. 3. Record that your freight order is ready for transportation execution. Review the status changes. 4. Record the departure of your freight order from the customer pick-up location and save. Review the status changes. 7. Review the document flow of your freight order. ME 6. Review the new status of your freight order. R 5. Record that the cargo of your freight order is ready for unloading at the first transit warehouse and save. Review the status changes. 8. Make sure that the freight order is displayed in display mode. US TO Inbound Processing in SAP EWM (Receiving at Warehouse) The truck arrives at the warehouse. The arrival needs to be registered, then the truck is moved to a door, and the HUs are received. 1. Review the SAP EWM freight order, the TU, and the HUs that were created in SAP EWM. RC 2. How many TUs were created? What are their IDs? FO 3. How many HUs were created? What are their IDs? 4. Record the arrival of the truck at the checkpoint. 5. Review the status changes on your freight order in SAP TM. 6. In SAP EWM, record the arrival of the truck at the door, using door DO##. LY 7. Record the receiving of the HUs. 8. Review the status changes on your freight order in SAP TM. 9. Review the items of your SAP TM freight order. ON 10. In SAP EWM, record the departure of the truck from the checkpoint. 11. Review the events on your SAP TM freight order. Monitor Handling Units 1. In SAP EWM, monitor the HUs for your forwarding order using the Handling-Unit Stock List. © Copyright. All rights reserved. 499 Unit 12 Solution 32 Receive Goods in Transit Warehouse R Business Example ME A freight forwarder wants to plan orders for international transport via air and is responsible for the entire transportation chain. In the exercise, you plan the first stage of the transport (pick-up from customer) in SAP TM and integrate into SAP EWM to receive the goods in the first transit warehouse. Create a Forwarding Order US TO 1. In SAP NetWeaver Business Client (NWBC), create a forwarding order using the data provided in the following tables. Use the forwarding order type AF01. On the General Data tab, enter the following data: Field Sales Organization Incoterm OAF-FWH-05 (FH Tokyo) EXW FO RC Incoterm Location Value Movement Type DD Use the following data for the new package: Value Item Type AF03 Package Type PAL Quantity 3 Quantity UoM EA LY Field 800 Gross Weight UoM kg Gross Volume 3 Gross Volume UoM M3 Net Weight 680 Net Weight UoM kg ON Gross Weight On the Package Details tab, enter the following data: 500 Field Value Item Description Clothing © Copyright. All rights reserved. Field Value Length 1,5 Width 2 Height 1 Unit of Measure M Goods Value 4.050.000 JPY On the Business Partner tab, enter the following data: Value Ordering Party OAF-CU-01 Shipper OAF-CU-01 Consignee OAF-CO-01 Import Organization US TO Collect Agreement Party ME Filed R Lesson: Integrating SAP EWM for Transit Warehousing OAF-FWH-21 AF-FWH-20 On the Location and Date/Times tab, enter the following data: Field Value Source Location OAF-CO-01 RC Destination Location OAF-CU-01 Pick-Up Date <Today> + 1 day Delivery Date <Today> + 4 days FO a) In SAP NWBC, choose Forwarding Order Management → Forwarding Order → Create Forwarding Order. b) Enter air forwarding order type AF01 and choose Continue. LY c) Choose the General Data tab, and enter the data provided in the table for the General Data tab. d) In the Items area, insert a new package and enter the data provided in the table for the new package. ON e) Select the item and enter the data provided for the Package Details tab. f) Choose the Business Partner tab, and enter the data provided in the table for the Business Partner tab. g) Choose the Location and Dates/Times tab, and enter the data provided in the table for the Location and Dates/Times tabs. h) Choose Save. © Copyright. All rights reserved. 501 Unit 12: Integration with SAP Extended Warehouse Management 2. Write down the number of your forwarding order. Plan Customer Pick-up In SAP NWBC, plan the pickup of the goods from the customer. Value Planning Profile AF-PLAN-PROF-PRE Transportation Cockpit Layout EKT 93 TH ME Field R 1. Open your forwarding order in the Transportation Cockpit, using the following settings: a) On the Forwarding Order screen, choose Follow-Up → Start Transportation Cockpit. US TO b) If the system takes you directly to the transportation cockpit main screen, choose Change Profile Selection → Profile Selection Screen. c) To add a new line to the profile and layout set table, choose New. d) Enter the data provided in the table. e) Choose Save. f) Select the new line and choose Continue. 2. Apply the default route to your freight unit. FO RC a) In the main screen of the transportation cockpit, in the Freight Unit Stages area, select your freight unit and choose Apply Default Route. The journey from the customer to the consignee will be broken down into several transportation stages (only the export stages will be shown in the transportation cockpit). 3. Create a freight order for the first stage using Create Freight Document. a) Select the stage from the customer location (OAF-CU-01) and choose Create Freight Document. A freight order is created and displayed in the Freight Orders/Freight Bookings area of the transportation cockpit. LY 4. Save and write down the number of your freight order. a) Choose Save. ON b) Write down the number of your freight order. Send Unloading Instructions to SAP EWM 1. Open your freight order and review the items. a) To open your freight order, choose the ID in the Freight Orders/Freight Bookings area of the transportation cockpit. b) Choose the Items tab. 502 © Copyright. All rights reserved. Lesson: Integrating SAP EWM for Transit Warehousing c) Verify that there is one package item Clothing with a quantity of 3 EA. 2. Review the Execution Status, the Logistical Execution Status, and the Transmission-toEWM Status. a) Choose the Statuses tab. The Execution status is Not Started. The Logistical Execution status is Not Loaded. The Transmission-to-EWM status is Not Sent. a) Choose Edit. ME R 3. Record that your freight order is ready for transportation execution. Review the status changes. b) From the Set Status dropdown list choose Set to Ready for Transportation Execution. c) Review the status changes. US TO 4. Record the departure of your freight order from the customer pick-up location and save. Review the status changes. a) From the Set Status dropdown list choose Set to Departed. b) Review the status changes. c) Choose Save. 5. Record that the cargo of your freight order is ready for unloading at the first transit warehouse and save. Review the status changes. RC a) From the Set Item Status dropdown list choose Set to Cargo Ready for Unloading. b) Review the status changes. c) Choose Save. The unloading instructions are now sent to SAP EWM. FO 6. Review the new status of your freight order. a) Verify that the Execution status has changed to In Execution. b) Verify that the Logistical Execution status has changed to Cargo Ready for Unloading. c) Verify that the Transmission-to-EWM status has changed to Sent. LY 7. Review the document flow of your freight order. a) Choose the Document Flow tab. ON b) Verify that there is a new entry, EWM Freight Order with the same ID as your SAP TM freight order. 8. Make sure that the freight order is displayed in display mode. Inbound Processing in SAP EWM (Receiving at Warehouse) The truck arrives at the warehouse. The arrival needs to be registered, then the truck is moved to a door, and the HUs are received. 1. Review the SAP EWM freight order, the TU, and the HUs that were created in SAP EWM. a) In SAP NWBC, choose Extended Warehouse Management → Transit Warehousing → Process Freight Orders. © Copyright. All rights reserved. 503 Unit 12: Integration with SAP Extended Warehouse Management b) When asked for a warehouse number, enter JPTY and choose OK. c) From the active queries, choose Inbound → Freight Orders for Processing. d) If no freight orders are shown, choose Refresh. e) Identify your freight order number created previously and click the document number. The EWM inbound freight order is opened in a new window. R f) Review the header data, including the parties, transportation data, dates, statuses, and progress. ME 2. How many TUs were created? What are their IDs? One TU was created. It has the same ID as your freight order. Three HUs were created. a) Write down their IDs. US TO 3. How many HUs were created? What are their IDs? 4. Record the arrival of the truck at the checkpoint. a) Choose Arrival at Checkpoint. FO RC b) Verify that the TU status changes to Arrival. 5. Review the status changes on your freight order in SAP TM. a) Go back to your TM freight order screen and choose Refresh. b) Verify that the Logistical Execution status has changed to Arrived. c) Verify that the Transmission-to-EWM status has changed to Partially Received. 6. In SAP EWM, record the arrival of the truck at the door, using door DO##. a) Go back to your SAP TM freight order screen. LY b) On the TUs/TU Containers tab, select the row of the TU and choose Arrival at Door. c) In the pop-up, select the line with door DO##. d) Verify that the TU status has changed to At Door. ON 7. Record the receiving of the HUs. a) On the HUs/HU Containers tab, select all HU lines and choose Receive HU. b) Verify that the HU status has changed to Received. c) Verify that the TU status has changed to Receiving. d) Verify that the progress on header level changes to 100%. e) Choose Receiving Completed for the TU. f) Verify that the TU status has changed to Receiving Completed. 504 © Copyright. All rights reserved. Lesson: Integrating SAP EWM for Transit Warehousing 8. Review the status changes on your freight order in SAP TM. a) Go back to your SAP TM freight order screen and choose Refresh. b) Verify that the Logistical Execution status has changed to Unloaded. c) Verify that the Transmission-to-EWM status has changed to Received. 9. Review the items of your SAP TM freight order. a) On the Items tab, choose Refresh. R b) Verify that, below the package item Clothing, there are now three new package items with the actual HU IDs. a) Go back to your SAP EWM freight order screen. b) Choose Departure from Checkpoint. ME 10. In SAP EWM, record the departure of the truck from the checkpoint. US TO c) Verify that the TU status has changed to Departure. 11. Review the events on your SAP TM freight order. a) Go back to your SAP TM freight order screen. b) On the Execution tab, choose Refresh. c) Review the reported events. Monitor Handling Units RC 1. In SAP EWM, monitor the HUs for your forwarding order using the Handling-Unit Stock List. a) In SAP NWBC, navigate to Extended Warehouse Management → Transit Warehouse → Handling-Unit Stock List. b) When asked for a warehouse number, enter JPTY and choose OK. FO c) For the selection criterion Forwarding Order Number, enter the number of your forwarding order and choose Search. ON LY d) Review the handling units in the list. © Copyright. All rights reserved. 505 Unit 12: Integration with SAP Extended Warehouse Management US TO ME R Transit Warehouse Integration Setup FO RC Figure 159: SAP TM Customizing Settings Define SAP EWM Integration Profile The SAP EWM integration profile is defined in the customizing activity SAP Transportation Management → Transportation Management → Integration → Integration with SAP Extended Warehouse Management → Define EWM Integration Profile. You can define a profile for the direct integration with SAP EWM or an external warehouse management system. In the integration profile, you can define the following: Whether loading and unloading instructions are to be sent manually or automatically. ● Whether loading and unloading instructions are to be sent once or multiple times. LY ● ● Whether related transportation units are to be marked as relevant for loading or unloading when sending loading and unloading instructions. The options available for defining the SAP EWM integration profile can be defined as follows: ON 1) Sending of (Un)Loading Instructions The sending of loading or unloading instructions defines how loading and unloading instructions are sent to SAP EWM or an external warehouse management system. The loading and unloading instructions can either be sent manually or automatically, as follows: ● 506 Manual sending © Copyright. All rights reserved. Lesson: Integrating SAP EWM for Transit Warehousing For manual sending, send the loading and unloading instructions manually by selecting Send Loading/Unloading Instruction under Follow Up in your freight document or transportation unit. ● Automatic sending For automatic sending, if there is a status change, for example, when the freight order is set to Cargo Ready for Loading/Unloading, loading and unloading instructions are sent by the system automatically. R Selecting Automatic and Manual Sending of (Un)Loading Instructions allows you to send loading and unloading instructions either manually or automatically in your freight document or transportation unit. 2) Delta Handling of (Un)Loading Instructions ME ● US TO Delta handling defines whether loading and unloading instructions for one warehouse location are to be sent only once or multiple times. If Send (Un)Loading Instructions Once and Lock Document is selected, the freight document or transportation unit can no longer be edited after the loading and unloading instructions have been sent. Editing is only possible after the notification message from SAP EWM has been received. Note that, for the delivery-based integration of SAP TM with SAP EWM, the loading and unloading instructions can only be sent once per warehouse location. 3) Include Related Transp. Units in (Un)Loading Instructions If a freight document contains assigned transportation units (TUs), there are two options: Include Related TUs in (Un)Loading Instructions RC ● When the freight document items are sent to SAP EWM as loading or unloading instructions, the system also marks the freight document items that are related to the assigned transportation unit as relevant for loading or unloading. ● Exclude Related TUs from (Un)Loading Instructions FO When the freight document items are sent to SAP EWM as loading or unloading instructions, the system does not mark the freight document items that are related to the assigned transportation unit as relevant for loading or unloading. Note that this applies also if you send a transportation unit that contains assigned transportation units to SAP EWM. LY For example, you have created a trailer unit and a freight order and have assigned the trailer unit to the freight order. Then you have triggered the sending of the loading instruction for the freight order. ON If you select Include Related TUs in (Un)Loading Instructions, the loading instruction for the items that are related to the trailer unit specifies that those items are relevant for loading. If you select Exclude Us from (Un)Loading Instructions, the loading instruction for the items that are related to the trailer unit specifies that those items are not relevant for loading. Note that, currently SAP EWM integration of TUs is only supported as part of a freight document; TUs cannot be integrated into SAP EWM separately. Therefore the option Include Related TUs in (Un)Loading Instructions is the only way to integrate TUs into SAP EWM, making the option Exclude Related TUs from (Un)Loading Instructions redundant until standalone integration of TUs into SAP EWM is supported. © Copyright. All rights reserved. 507 Unit 12: Integration with SAP Extended Warehouse Management Define Discrepancy Profile In this Customizing activity, you can define discrepancy types and associate them with predefined events and discrepancy subcategories. Furthermore, among the discrepancy types associated with the same event, you must select one discrepancy type as the default discrepancy type. You can also define upper or lower discrepancy tolerances. You can define discrepancy profiles. If you do so, you can assign discrepancy types with different stop categories to them. ME R In a discrepancy profile, you can assign only one discrepancy type for each discrepancy subcategory and stop category. You can use the stop category to define different behavior for inbound and outbound stops for a discrepancy subcategory of a discrepancy profile. Define Freight Order Types / Freight Booking Types / Transportation Unit Types US TO In the customizing activity SAP Transportation Management → Transportation Management → Freight Order Management → Freight Order / Freight Booking / Transportation Unit → Define Freight Order Types / Freight Booking Types / Transportation Unit Types, the freight document type has to be set up for integration. The integration comprises the following settings: 1. Assignment of SAP EWM Integration Profile 2. Assignment of Discrepancy Profile The following applies to the assignment of discrepancy profiles to document types: If there is no discrepancy profile assigned to the document type and there are no discrepancy profiles in the system because you have not used them so far (compatibility mode), the system creates the discrepancies according to the existing discrepancy types. FO RC ● ● ● If there is no discrepancy profile assigned to the document type and there are discrepancy profiles in the system, but they do not apply to the current document type, the system does not create discrepancies for this document type. If there is a discrepancy profile assigned to the document type, only discrepancies for the types assigned to the discrepancy profile are created. 3. Assignment of Output Profile LY The output profile has to include the messages for transit warehouse integration, for example, output profile /SCMTMS/TOR. 4. Set Document Creation Relevance ON Specifies whether a business document can be created either in SAP ERP or SAP EWM. This field is used both for integration with SAP ERP and with SAP EWM. You can specify for your freight orders and trailers (transportation unit type) whether transportation activities can be created in SAP EWM based on the SAP TM execution document. If you have selected the Transportation Activity Creation in SAP EWM option, the system sends a loading or unloading instruction when you select the Set to Cargo Ready for Loading or Set to Cargo Ready for Unloading action in the execution document. In SAP EWM, the system automatically creates transportation activities. 508 © Copyright. All rights reserved. Lesson: Integrating SAP EWM for Transit Warehousing If you have not selected the Transportation Activity Creation in SAP EWM option, you have to trigger the sending of the loading or unloading instruction manually in the execution document. Note that, once the loading or unloading instruction is sent, you cannot cancel the execution document in SAP TM. RC US TO ME R Master Data Setup Figure 160: Master Data Setup FO To transfer electronic data interchange (EDI) messages between SAP TM and SAP EWM, the target system and the warehouse number in the target system must be known. Therefore the location master in SAP TM was enhanced with the logical system of the SAP EWM instance and the warehouse number to determine the respective receiving SAP EWM system when transferring EDI messages from SAP TM to SAP EWM. A location is only relevant for transit warehousing if you have specified a warehouse number and a logical system (SAP EWM) system in the location master. ON LY SAP EWM stores the shipper of an inbound delivery and the consignee of an outbound delivery as business partners (and not as locations). This means that, for all transports between freight forwarder locations (hubs or gateways), the sending hubs (for inbound transports), and the receiving hubs (for outbound transports) must be available as business partners in SAP EWM. For all freight forwarder locations (hubs or gateways) an organization with a business partner, which is maintained in the location master, usually exists, which means that it is possible to distribute these business partners from SAP TM to SAP EWM. © Copyright. All rights reserved. 509 Unit 12: Integration with SAP Extended Warehouse Management LESSON SUMMARY You should now be able to: Integrate SAP TM into SAP EWM in a Logistic Service Provider scenario ● Configure settings to enable transit warehouse integration ON LY FO RC US TO ME R ● 510 © Copyright. All rights reserved. Unit 12 Learning Assessment A Staging X B Settlement X C Transportation planning X D Picking US TO X ME Choose the correct answers. R 1. When integrating SAP TM with SAP EWM, which operations are carried out in SAP EWM? 2. SAP TM must be configured to assign packaging materials to container equipment type. Determine whether this statement is true or false. True X False ON LY FO RC X © Copyright. All rights reserved. 511 Unit 12 Learning Assessment - Answers Choose the correct answers. A Staging X B Settlement X C Transportation planning X D Picking US TO X ME R 1. When integrating SAP TM with SAP EWM, which operations are carried out in SAP EWM? 2. SAP TM must be configured to assign packaging materials to container equipment type. Determine whether this statement is true or false. True X False ON LY FO RC X 512 © Copyright. All rights reserved.