molecules

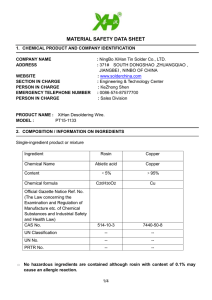

Review

Advances in Rosin-Based Chemicals: The Latest

Recipes, Applications and Future Trends

Szymon Kugler 1, * , Paula Ossowicz 1 , Kornelia Malarczyk-Matusiak 1

and Ewa Wierzbicka 2

1

2

*

Faculty of Chemical Engineering, West Pomeranian University of Technology in Szczecin, Pulaskiego 10,

70-322 Szczecin, Poland; paula.ossowicz@zut.edu.pl (P.O.); kornelia.malarczyk@zut.edu.pl (K.M.-M.)

Industrial Chemistry Research Institute, Rydygiera 8, 01-793 Warsaw, Poland; ewa.wierzbicka@ichp.pl

Correspondence: skugler@zut.edu.pl

Received: 22 March 2019; Accepted: 23 April 2019; Published: 26 April 2019

Abstract: A comprehensive review of the publications about rosin-based chemicals has been compiled.

Rosin, or colophony, is a natural, abundant, cheap and non-toxic raw material which can be easily

modified to obtain numerous useful products, which makes it an excellent subject of innovative

research, attracting growing interest in recent years. The last extensive review in this research area

was published in 2008, so the current article contains the most promising, repeatable achievements in

synthesis of rosin-derived chemicals, published in scientific literature from 2008 to 2018. The first

part of the review includes low/medium molecule weight compounds: Especially intermediates,

resins, monomers, curing agents, surfactants, medications and biocides. The second part is about

macromolecules: mainly elastomers, polymers for biomedical applications, coatings, adhesives,

surfactants, sorbents, organosilicons and polysaccharides. In conclusion, a critical evaluation of

the publications in terms of data completeness has been carried out with an indication of the most

promising directions of rosin-based chemicals development.

Keywords: rosin; curing agent; resin; surfactant; biocide; medicine; polymer

1. Introduction

The natural origin, low price, abundance and chemical modification potential of rosin make it a

valuable raw material in numerous applications [1–14]. Besides the mentioned advantages, rosin is

also safe for living organisms [15]. Its derivatives are claimed as non-toxic as well, despite their

allergenicity [16,17]. This unique set of beneficial properties of rosin determines it as an attractive

subject of innovative research characterized by a considerably growing interest in recent decades,

as can be seen in Figure 1.

Unfortunately, the awareness of the possibility of using rosin as a raw material for obtaining

valuable chemicals is generally unsatisfactory. There is a burning need to bring this topic to the

attention of a larger group of scientists. Furthermore, the growing number of publications causes

difficulties in keeping up with the latest research, as well as in selection of more promising discoveries.

Sadly, the last comprehensive review document dedicated exclusively to rosin and its modifications

was published in 2008 [1]. Since then, only fragmentary information on rosin has appeared in review

articles on bio-based polymers and resin systems [2–21], as well as in reviews on rosin derivatives in

catalysis [12], controlled drug-delivery systems [13] and small-molecule compounds [14].

In view of these facts, publication of a wide, comprehensive and critical review of achievements

since 2008 is an important solution to solve the problem of a severe lack of current review literature in

this field. The growing number of publications is not the only obstacle in creating a literature review

on rosin. No less important challenge is to collect information from existing literature. Quite often

Molecules 2019, 24, 1651; doi:10.3390/molecules24091651

www.mdpi.com/journal/molecules

Molecules 2019, 24, 1651

Molecules 2019, 24, x FOR PEER REVIEW

2 of 52

2 of 51

articles do not contain full information about a particular reaction, but refer to earlier articles, which,

not contain

information

particular

reaction,online,

but refer

earlier

in turn,often

mayarticles

refer todoeven

earlierfull

articles,

whichabout

mayanot

be available

ortomay

notarticles,

be in English.

which, in turn, may refer to even earlier articles, which may not be available online, or may not be in

The current article is a direct answer to the aforementioned issues. Its aims are: (I) to provide

English.

a precise review of the scientific literature from 2008 to 2018, (II) select promising studies with clear

The current article is a direct answer to the aforementioned issues. Its aims are: (I) to provide a

practicalprecise

application

and

an overall

assessment

in with

orderclear

to identify

review of

the(III)

scientific

literature

from 2008 of

to the

2018,reviewed

(II) select achievements

promising studies

the most

perspective

development

directions

of rosin-based

chemicals.

The review

is identify

presented in a

practical

application

and (III) an overall

assessment

of the reviewed

achievements

in order to

thepleasant-to-browse

most perspective development

directionswith

of rosin-based

Thereaction

review is schemes.

presented in

a article

modern,

form, illustrated

patientlychemicals.

completed

The

modern,

pleasant-to-browse

form,

illustrated

with

patiently

completed

reaction

schemes.

The

article

provides concise, but exhaustive information on the achievements in preparation of rosin-derived

provides concise, but exhaustive information on the achievements in preparation of rosin-derived

chemicals in the last decade. Its main idea is to inspire and encourage the world of science to actively

chemicals in the last decade. Its main idea is to inspire and encourage the world of science to actively

take interest

in rosin and the possibilities of its modification.

take interest in rosin and the possibilities of its modification.

Figure

1. Number

of scientific

articlesand

andpatent

patent documents

containing

the keyword

“rosin”“rosin”

in the in the

Figure 1.

Number

of scientific

articles

documents

containing

the keyword

years 1990-2017.

years 1990–2017.

Basic Information

about

Rosin

2. Basic2.Information

about

Rosin

or colophony, is a solid and brittle mixture of non-volatile conifer tree resin components.

Rosin, Rosin,

or colophony,

is a solid and brittle mixture of non-volatile conifer tree resin components.

It can display colors ranging from almost colorless, through shades of yellow and brown to black.

It can display colors ranging from almost colorless, through shades of yellow and brown to black.

Depending on the origin, two industrially important types of rosin can be distinguished, i.e. gum

Depending

two

industrially

ofremaining

rosin canafter

be distinguished,

i.e.,

gum rosin

rosinon

andthe

tallorigin,

oil rosin.

Gum

rosin is theimportant

non-volatiletypes

residue

distillation of tree

resin

and tallobtained

oil rosin.byGum

rosin

is thetrees.

non-volatile

residue

remaining

after pulping

distillation

treeprocess.

resin obtained

tapping

of living

Tall oil rosin

is a by-product

of wood

in theofkraft

Gumofrosin

accounts

of world

rosin production,

whereas

tall in

oil the

rosin

is ca.process.

35%. In the

by tapping

living

trees. for

Tallca.oil60%

rosin

is a by-product

of wood

pulping

kraft

Gum rosin

past,

rosin

was

widely

obtained

from

the

solvent

extraction

of

harvested

wood

as

so-called

wood

accounts for ca. 60% of world rosin production, whereas tall oil rosin is ca. 35%. In the past, rosin was

rosin, but nowadays, this technology is of little importance [1,22]. The price of rosin in the first half

widely obtained from the solvent extraction of harvested wood as so-called wood rosin, but nowadays,

of 2018 ranged from 300 to 2750 USD/ton depending on its origin, supplier and color. Annual world

this technology

is of little importance [1,22]. The price of rosin in the first half of 2018 ranged from 300

production of rosin is ca. 1.2 million tons and has remained stable in the last decades [1,2,22].

to 2750 USD/ton

depending

ongeneral

its origin,

supplier

and color.

Annual

production

rosin is ca.

Resin acids,

with the

formula

C19H29COOH,

constitute

up world

to 95 wt.%

of rosin, of

while

1.2 million

tons

and has remained

in the

[1,2,22].

neutral

compounds

are present stable

in amounts

of alast

fewdecades

percent. A

number of resin acids based on a few

diterpene

wereformula

identifiedCso

far29[1].

The most

abundant

acids

are of

built

on while

Resin

acids,carbon

with skeletons

the general

COOH,

constitute

upresin

to 95

wt.%

rosin,

19 H

abietane

and

pimarane

skeletons.

Their

structural

formulas

are

shown

in

Figure

1.

It

should

neutral compounds are present in amounts of a few percent. A number of resin acids basedbeon a few

emphasized, that abietane-structured acids are characterized by conjugated double bond systems,

diterpene carbon skeletons were identified so far [1]. The most abundant resin acids are built on abietane

which makes them particularly susceptible to chemical modifications. It is noteworthy, that abietaneand pimarane

skeletons.

Their structural

aretoshown

in Figure

2. It should

be emphasized,

structured

acids isomerize

at elevated formulas

temperature

afford readily

reactive

levopimaric

acid,

that abietane-structured

areother

characterized

by conjugated

systems,

according to Scheme acids

1. On the

hand, pimarane-type

acids do double

not have bond

conjugated

doublewhich

bond makes

systems, which

limits their

chemical modifications.

processability. The

chemical

of rosin acids

them particularly

susceptible

to chemical

It isdetailed

noteworthy,

thatcomposition

abietane-structured

depends

on

its

type

(gum,

tall

oil

or

wood),

thermal

history,

species

of

tree

and

geographical

isomerize at elevated temperature to afford readily reactive levopimaric acid, accordingorigin

to Scheme 1.

Compositions of gum rosin from various sources are presented in Table 1, where it can be

On the [23,24].

other hand,

pimarane-type acids do not have conjugated double bond systems, which limits

their chemical processability. The detailed chemical composition of rosin depends on its type (gum,

tall oil or wood), thermal history, species of tree and geographical origin [23,24]. Compositions of gum

rosin from various sources are presented in Table 1, where it can be seen that the content of abietanetype acids may vary between 64 and 87 wt.%. Such detailed composition of a rosin can be determined,

e.g., by the capillary electrophoresis method [25].

Molecules 2019, 24, x FOR PEER REVIEW

3 of 51

Molecules

1651

3 of 52

seen2019,

that24,the

content of abietane- type acids may vary between 64 and 87 wt.%. Such detailed

composition of a rosin can be determined, eg. by the capillary electrophoresis method [25].

COOH

COOH

COOH

A) Abietic acid

B) Levopimaric acid

C) Palustric acid

COOH

D) Neoabietic acid

Molecules 2019, 24, x FOR PEER REVIEW

4 of 51

included in the schemes. There are situations where some data simply has not been reported by

original authors, eg. product morphology or yield. Such missing data could not be presented in this

review. What

does the above mean?

The more data provided,

the more advancedCOOH

the research on a

COOH

COOH

COOH

compound, and the more reliable the recipe. The lack of data should indicate that the research on a

E) Dehydroabietic

H) Pimaric acid

F) Sandaracopimaric

G) Isopimaric acid

certain

rosin derivative is probably

at an early, basic stage. It has to be underlined that reaction

acid

acid

schemes do not take into account advanced stereochemistry. Finally, almost all reactions were

Figure

1. Structural

thenitrogen

most common

abietane-structured

(A–E)

and

Figure

2. Structural

of theofmost

common

abietane-structured

(A–E)

and pimarane-structured

conducted

under

an formulas

inertformulas

atmosphere:

or

argon,

so reaction

schemes

do

notpimaraneinclude this

structured

(F–H) resin acids.

information.

(F–H)

resin acids.

Table 1. Composition of resin acids in gum rosin from different sources [23].

Species

Origin

Pinus massoniana

Pinus elliotti

NH2

Pinus merkusii

Pinus sylvestris

DehydroPinus halepensis

abietylamine

China

Brazil

Indonesia

Russia

NH3 Greece

>150°C France

Portugal

Pinus pinaster

Spain

O

Cl

P

USA

Cl

Cl

HOOC

Abietane-type Acids Content (wt.%)

Other Acids

HOOCPalustric/Levopimaric Neoabietic Dehydroabietic

(wt.%)

Abietic

Rosin

39

25

16

7

13

37

15

16

5

27

28

27

5

4

36

35

23

15

10

17

HOOC

45

23

13

5

14

Abietic acid

35 Ni

20 180°C

15

9

21

200°C

3h

34

21

19

9

17

26

22

27

6

19

O

O

14

39

18

4

25 O

HOOC

Levopimaric acid

Dehydroabietic acid

O

O

OH for making films, coatings and

In recent studies

unmodified rosin was used

adhesives [26–42],

65°C/3h

O

biomedical applications [43–55], or in mining, metallurgy and construction [56–58] and for filler

230°C, 3h

O

pTSA

COOH

purposes [59–64]. However, chemical modification

of rosin gives many-fold

greater possibilities of

in CH3COOH

using

of this12h

article.

O=C this raw material, which are described in the next, main section 120°C,

in CHCl3

HOOC

Cl

chloride

3.Dehydroabietyl

Rosin-based Chemicals

(yield 93%)

HOOC

Acrylpimaric acid

yield: 73- 93%

Maleopimaric acid

yield: 92%

3.1. General Comments

on the

Whole Review

Scheme

Synthesis

of essential

essential rosin-based

Scheme

1.1.Synthesis

of

rosin-basedsubstrates/intermediates.

substrates/intermediates.

The review contains short, but exhaustive descriptions of rosin-derived compound syntheses

Table 1. Composition

of resin acids in gum rosin from different sources [23].

3.2.

Small and

Moleculeliterature

Compounds

published

in Medium

the scientific

from the JCR list since 2008. It does not include older

achievements

in the

field ofrosin-derived

rosin, that were

widely described

in

previous

reviewwith

literature

and

Abietane-type

Acids

Content

(wt.%)

This section

describes

small/medium

molecule

compounds

strictly[1,65]

defined

Other

Acids

Species

Origin

commercialized

It includes

preparations

of

completely

new

chemicals,

as

well

as

new

ways

(wt.%)

structures

that do[66–80].

not contain

the

repeated

units

typical

for

macromolecules.

Abietic

Palustric/Levopimaric Neoabietic

Dehydroabietic

to synthesize already

known compounds.

Only

products with

declared or7 obvious practical

Pinus massoniana

China

39

25

16

13

applications

into two 16sections according

to the general

3.2.1.

PinusIntermediates

elliotti have been

Brazilchosen. The

37 review is divided

15

5

27

Pinus merkusii

Indonesia

28 compounds,27

5 is divided according

4

36

molecular

structure

of the prepared

while each section

to practical

are the products

of simple 23

rosin modifications,

which are10necessary for17the

PinusIntermediates

sylvestris

35

15

application

and theRussia

structure similarity

of the compounds. The collected

data are given in the article

Pinus halepensis

45

5 described ways

14

preparation

of manyGreece

new compounds.

They can 23

be synthesized in13very simple, well

text and in schemes.

The following

name, product

France

35 information20are presented in

15the text: product

9

21

with high yields. The

sustainability

of these processes is high: They

usually use

a biobased main

Portugal

21

19 applications.9 On the other hand,

17

morphology,

substrates

name(s), 34

separation techniques

and practical

Pinus pinaster

substrate

(rosin) in solvent-free

processes.

Some drawback

can be 27

the separation processes,

that19

may

Spain

26

22

6

data such as reaction scheme, catalyst use, reaction media, temperature, pressure, time and yield are

14 high viscosity,

39 m.p. and stickiness

18

4

not always be easy, USA

because of the

of products.

In view of25the

above, rosin-based intermediates have very high commercialization potential and some of them are

commercially available in certain regions of the world.

In recent studies unmodified rosin was used for making films, coatings and adhesives [26–42],

Maleopimaric acid is an off-white solid (m.p. 223 °C). It can be prepared from abietic acid and

biomedical applications [43–55], or in mining, metallurgy and construction [56–58] and for filler

maleic anhydride via a Diels-Alder reaction according to Scheme 1 [81], followed by recrystallization

[82]. Maleopimaric acid is one of the crucial products in rosin chemistry. It can be used directly as an

epoxy resin hardener, but its applications are much wider. They include preparation of epoxy resins

[83,84], acrylic resins [85–87], allyl resins [88–90], polyols [91], bio-based curing agents for synthetic

epoxy resins [92–98] or bio-based ones [99], surfactants [100–103], intermediates [104,105],

biologically active compounds [105–108], polyurethanes [109-112], chemicals for NMR techniques

[113] and photolitography [114], sorbents [115], organosilicon compounds [116], printing inks [117]

Molecules 2019, 24, 1651

4 of 52

purposes [59–64]. However, chemical modification of rosin gives many-fold greater possibilities of

using this raw material, which are described in the next, main section of this article.

3. Rosin-based Chemicals

3.1. General Comments on the Whole Review

The review contains short, but exhaustive descriptions of rosin-derived compound syntheses

published in the scientific literature from the JCR list since 2008. It does not include older

achievements in the field of rosin, that were widely described in previous review literature [1,65] and

commercialized [66–80]. It includes preparations of completely new chemicals, as well as new ways to

synthesize already known compounds. Only products with declared or obvious practical applications

have been chosen. The review is divided into two sections according to the general molecular structure

of the prepared compounds, while each section is divided according to practical application and the

structure similarity of the compounds. The collected data are given in the article text and in schemes.

The following information are presented in the text: product name, product morphology, substrates

name(s), separation techniques and practical applications. On the other hand, data such as reaction

scheme, catalyst use, reaction media, temperature, pressure, time and yield are included in the schemes.

There are situations where some data simply has not been reported by original authors, e.g., product

morphology or yield. Such missing data could not be presented in this review. What does the above

mean? The more data provided, the more advanced the research on a compound, and the more reliable

the recipe. The lack of data should indicate that the research on a certain rosin derivative is probably at

an early, basic stage. It has to be underlined that reaction schemes do not take into account advanced

stereochemistry. Finally, almost all reactions were conducted under an inert atmosphere: nitrogen or

argon, so reaction schemes do not include this information.

3.2. Small and Medium Molecule Compounds

This section describes rosin-derived small/medium molecule compounds with strictly defined

structures that do not contain the repeated units typical for macromolecules.

3.2.1. Intermediates

Intermediates are the products of simple rosin modifications, which are necessary for the

preparation of many new compounds. They can be synthesized in very simple, well described ways

with high yields. The sustainability of these processes is high: They usually use a biobased main

substrate (rosin) in solvent-free processes. Some drawback can be the separation processes, that may

not always be easy, because of the high viscosity, m.p. and stickiness of products. In view of the

above, rosin-based intermediates have very high commercialization potential and some of them are

commercially available in certain regions of the world.

Maleopimaric acid is an off-white solid (m.p. 223 ◦ C). It can be prepared from abietic acid and

maleic anhydride via a Diels-Alder reaction according to Scheme 1 [81], followed by recrystallization [82].

Maleopimaric acid is one of the crucial products in rosin chemistry. It can be used directly as an

epoxy resin hardener, but its applications are much wider. They include preparation of epoxy

resins [83,84], acrylic resins [85–87], allyl resins [88–90], polyols [91], bio-based curing agents for

synthetic epoxy resins [92–98] or bio-based ones [99], surfactants [100–103], intermediates [104,105],

biologically active compounds [105–108], polyurethanes [109–112], chemicals for NMR techniques [113]

and photolitography [114], sorbents [115], organosilicon compounds [116], printing inks [117] and

for the hydrophobization of wood surfaces [118–120]. It is noteworthy that the main degradation

products of maleopimaric acid are water, carbon dioxide, formamide and also aliphatic and aromatic

derivatives [121]. It is worth noting that fumaropimaric acid is an isomer of hydrated maleopimaric

acid, which can be synthesized in a similar way [122], but its importance to rosin chemistry is much

smaller: it can be used in synthesis of triglycidyl epoxy resin [122] and water-borne polyurethanes [109].

Molecules 2019, 24, x FOR PEER REVIEW

5 of 51

derivatives [121]. It is worth noting that fumaropimaric acid is an isomer of hydrated maleopimaric

acid, which

be synthesized in a similar way [122], but its importance to rosin chemistry is much

Molecules

2019, can

24, 1651

5 of 52

smaller: it can be used in synthesis of triglycidyl epoxy resin [122] and water-borne polyurethanes

[109].

◦ C). It can be prepared from abietic acid and acrylic

Acrylpimaric

off-white

solid

(m.p.

220220

Acrylpimaricacid

acidisisanan

off-white

solid

(m.p.

°C). It can be prepared from abietic acid and

acid

according

to Scheme

1, followed

by precipitation,

filtration,filtration,

washing washing

and recrystallization

[123,124].

acrylic

acid according

to Scheme

1, followed

by precipitation,

and recrystallization

It

is noteworthy

that neat that

rosinneat

canrosin

be acrylated

as well [125].

an important

material

in rosin

[123,124].

It is noteworthy

can be acrylated

as wellAs

[125].

As an important

material

in

chemistry,

acrylpimaric

acid

can

be

used

for

preparation

of

diallyl

acrylpimarate

[123],

polyesters

of

rosin chemistry, acrylpimaric acid can be used for preparation of diallyl acrylpimarate [123],

acrylated

and polyethylene

glycols

[125], epoxy

resins[125],

[126,127],

acrylpimaryl

dichloride

[128,129],

polyestersrosin

of acrylated

rosin and

polyethylene

glycols

epoxy

resins [126,127],

acrylpimaryl

acrylpimaric

acid amides

[130], cyclic

diamide

ammonium

salts [132–136],

calcium

dichloride [128,129],

acrylpimaric

acid

amides[131],

[130],quaternary

cyclic diamide

[131], quaternary

ammonium

and

zinc

salts

[137]

as

well

as

polyesters

[138].

Moreover,

it

can

be

used

directly

as

an

epoxy

salts [132–136], calcium and zinc salts [137] as well as polyesters [138]. Moreover, it can becuring

used

agent

[139].

directly as an epoxy curing agent [139].

Another

is aa viscous,

viscous,

Another important

important compound

compound in

in this

this subsection

subsection is

is dehydroabietyl

dehydroabietyl chloride.

chloride. ItIt is

yellow,

oily

liquid

[140,141].

It

can

be

prepared

using:

(i)

oxalyl

chloride

according

to

Scheme

1

yellow, oily liquid [140,141]. It can be prepared using: (i) oxalyl chloride according to Scheme 1 prior

prior

to evaporation

of unnecessary

substances

[142],

phosphorustrichloride

trichlorideinin chloroform

chloroform (yield

to evaporation

of unnecessary

substances

[142],

(ii)(ii)

phosphorus

(yield

92.5%)

[140]

or

(iii)

thionyl

chloride

in

presence

of

4-dimethylaminopyridine

[143].

It can

used

92.5%) [140] or (iii) thionyl chloride in presence of 4-dimethylaminopyridine [143]. It can

bebe

used

as

as

a

substrate

for

the

synthesis

of

macroinitiators

for

atom

transfer

radical

polymerization

(ATRP)

a substrate for the synthesis of macroinitiators for atom transfer radical polymerization (ATRP)

reactions

[142], rosin

rosinphosphate

phosphateesters

esters

[140],

N-hydroxyethylacrylamide

ester

of dehydroabietic

reactions [142],

[140],

N-hydroxyethylacrylamide

ester

of dehydroabietic

acid

acid

[144],

dehydroabietic

ethyl

methacrylate

[145,146],

dehydroabietic

propargyl

ester [147]

[144], dehydroabietic ethyl methacrylate [145,146], dehydroabietic propargyl ester

[147]

dehydroabietic

hexylacrylate

acrylate

[148],

as well

as intermediates

other intermediates

in synthesis

various

dehydroabietic hexyl

[148],

as well

as other

in synthesis

of various of

surfactants

surfactants

[143,149]

and

medicines

[141,150,151].

[143,149] and medicines [141,150,151].

◦ C). It is commercially

Dehydroabietylamine,

also known

known as

44.5 °C).

Dehydroabietylamine, also

as leelamine,

leelamine, is

is aa solid

solid (m.p.

(m.p. 44.5

It is commercially

available.

Its

application

in

antitumor

therapies

was

investigated

in

recent

years

[152–155].

Moreover,

available. Its application in antitumor therapies was investigated in recent years [152–155]. Moreover,

it

can

be

a

substrate

for

preparation

of

epoxy

resin

[156],

bio-based

benzoxazines

[157],

quaternary

it can be a substrate for preparation of epoxy resin [156], bio-based benzoxazines [157], quaternary

ammonium

surfactants [158,159],

[158,159], acrylic

acrylicmonomers:

monomers:glycidyl

glycidyl

methacrylate

monomer

[160]

or

ammonium surfactants

methacrylate

monomer

[160]

or NN-dehydroabietic

acrylamide

[161].

dehydroabietic acrylamide [161].

3.2.2. Resins and Monomers

3.2.2. Resins and Monomers

Rosin-based resins and monomers are compounds which contain epoxy, acrylic, allyl, hydroxyl or

Rosin-based resins and monomers are compounds which contain epoxy, acrylic, allyl, hydroxyl

oxazine reactive groups, that enable cross-linking, polymerization or building in the polymer matrix.

or oxazine reactive groups, that enable cross-linking, polymerization or building in the polymer

Their preparations are usually well described and easy to perform. The syntheses are similar to

matrix. Their preparations are usually well described and easy to perform. The syntheses are similar

conventional resins/monomers preparations, however the necessity of using organic solvents in several

to conventional resins/monomers preparations, however the necessity of using organic solvents in

reactions is a disadvantage in the context of Green Chemistry rules. The high modification potential

several reactions is a disadvantage in the context of Green Chemistry rules. The high modification

of rosin derivatives allows one to prepare resins and monomers showing diverse and designable

potential of rosin derivatives allows one to prepare resins and monomers showing diverse and

properties. They can exhibit adjustable glass transition temperatures, low volume shrinkage, as well as

designable properties. They can exhibit adjustable glass transition temperatures, low volume

improve elastic modulus, Young’s modulus, shape-memory, flame retardancy, corrosion protection

shrinkage, as well as improve elastic modulus, Young's modulus, shape-memory, flame retardancy,

features of final casts/polymers in comparison with petroleum-based compounds. Therefore, the best

corrosion protection features of final casts/polymers in comparison with petroleum-based

described recipes show high commercialization potential in the segment of resins, adhesives and

compounds. Therefore, the best described recipes show high commercialization potential in the

paints, but in most cases, additional applied research should be performed to increase their technology

segment of resins, adhesives and paints, but in most cases, additional applied research should be

readiness level (TRL).

performed to increase their technology readiness level (TRL).

Triglycidyl ester of maleopimaric acid is a beige, viscous liquid. It can be prepared from

Triglycidyl ester of maleopimaric acid is a beige, viscous liquid. It can be prepared from

maleopimaric acid, epichlorohydrin and sodium hydroxide according to Scheme 2, followed by

maleopimaric acid, epichlorohydrin and sodium hydroxide according to Scheme 2, followed by

filtration, washing and evaporation [83]. It can be used in liquid epoxy resins [83], non-cytotoxic

filtration, washing and evaporation [83]. It can be used in liquid epoxy resins [83], non-cytotoxic biobio-based epoxypolyurethanes [162] as well as synthesis of rosin-based cyclic carbonates [132]. Similar

based epoxypolyurethanes [162] as well as synthesis of rosin-based cyclic carbonates [132]. Similar

liquid resin can be synthesized from fumaropimaric acid [122].

liquid resin can be synthesized from fumaropimaric acid [122].

O

Maleopimaric

acid

1.

O

O

COOH

Cl

O

O

O

2. NaOH

O

O

TBA Br

in H2O

70-130°C, 10h

O

COO

O

O

Scheme 2. Synthesis of triglycidyl ester of maleopimaric acid.

Maleopimaric acid

triglycidyl ester

yield: 75%

Molecules

2019,

24,

xx FOR

PEER

REVIEW

Molecules

2019,

24,24,

FOR

PEER

REVIEW

Molecules

2019,

x FOR

PEER

REVIEW

Molecules 2019, 24, 1651

66 of

51

6of of5151

6 of 52

Scheme

2.

Synthesis

of

triglycidyl

ester

of

maleopimaric

acid.

Scheme

2. 2.

Synthesis

ofof

triglycidyl

ester

ofof

maleopimaric

acid.

Scheme

Synthesis

triglycidyl

ester

maleopimaric

acid.

yellowish

liquid.

Diglycidyl

can

bebeprepared

prepared

isisa ayellowish

yellowish

liquid.

ItItItcan

can

be

prepared

from

acrylpimaric

acid,

Diglycidylacrylpimarate

acrylpimarateis

yellowishliquid.

liquid.It

canbe

preparedfrom

fromacrylpimaric

acrylpimaricacid,

acid,

and

filtration,

epichlorohydrin

sodium

hydroxide

according

to

Scheme

3,

prior

to

filtration,

washing

epichlorohydrinand

and sodium hydroxide according to Scheme 3, prior tofiltration,

filtration,washing

washingand

and

drying

can

be

used

in

materials

showing

improved

thermal,

mechanical

and

[126].

It

can

be

used

in

epoxy

materials

showing

improved

thermal,

mechanical

and

drying

[126].

It It

can

bebe

used

ininepoxy

epoxy

materials

showing

improved

thermal,

mechanical

and

shapedrying[126].

[126].It

can

used

epoxy

materials

showing

improved

thermal,

mechanical

andshapeshapememory

properties

[126].

shape-memory

properties

memory

properties

[126].

memory

properties

[126].[126].

COOH

COOH

COOH

Acrylpimaric

acid

Acrylpimaric

acid

Acrylpimaric

acid

2.

N

2. 2.

N aOH

aOH

N aOH

TEBAC

TEBAC

TEBAC

115-60°C,

5h

115-60°C,

5h5h

115-60°C,

COOH

COOH

COOH

COO

COO

COO

Cl

Cl O

1.

1. 1. Cl O O

O

OO

Diglycidyl

Diglycidyl acrylpimarate

acrylpimarate

acrylpimarate

yield:

yield:88%

88%

Diglycidyl

O

O O yield: 88%

COO

COO

COO

Scheme

3. 3.

Synthesis

of

diglycidyl

acrylpimarate.

Synthesis

ofof

diglycidyl

Scheme

3.

acrylpimarate.

Scheme

Synthesis

diglycidyl

acrylpimarate.

Another

diglycidyl

derivative

of

acrylpimaric

acid

and

its

siloxane modification

modification can

be

prepared

Another

diglycidyl

derivative

ofof

acrylpimaric

acid

and

itsits

siloxane

can

bebe

prepared

Another

diglycidyl

derivative

acrylpimaric

acid

and

siloxane modification

can

prepared

according

to Scheme 4,

prior to

washing,

filtration

and

vacuum

evaporation

[127]. Prepared

epoxy

washing,

according

toto

washing,

filtration

and

vacuum

evaporation

accordingtotoScheme

Scheme4,4,prior

priorto

washing,filtration

filtrationand

andvacuum

vacuumevaporation

evaporation[127].

[127].Prepared

Preparedepoxy

epoxy

resins

can

improve

the

thermal

stability

and

flame

retardancy

of

products

[127].

the

thermal

stability

and

flame

retardancy

of

products

[127].

resins

can

improve

the

thermal

stability

and

flame

retardancy

of

products

[127].

resins can improve the thermal stability and flame retardancy of products [127].

COOH

COOH

COOH

O

OO

O

OO

O

OO

O

OO

(C

))33N

22H

(C(C

H255H

N

5)3N

110°C

110°C

110°C

COOH

COOH

COOH

O

OO

O

OO

O

OO

O

OO

O

OO

COO

COO

COO

Acrylpimaric

Acrylpimaric

Acrylpimaric

acid

acid

acid

OH

OHOH

OCH

CH3

CH

3

3

OCH

CHCH

3 3

3 3 CH

3 3

OCH

CH

CH

3

CHCH

3 3

H

CO

Si

O

Si

O

Si

O)

(

)

(

)

(

H33H

CO

Si

O

Si

O

Si

(

)

(

)

(

m

k

CO

Si

O

(

3

m)m( Si Ok)k( SiO )On

n)n

Ph

OCH

Ph

3

PhPh

OCH

3 3 PhPh

OCH

TPT

TPT

TPT

120°C

120°C

120°C

ORO

CH

ORO

3

3

CHCH

CHCH

ORO CH

3 3

3 3

ORO

Si

O

Si

O

Si

O ) RO

(

)

(

)

(

ORO

Si

O

Si

( Si( SiO )Om

(

)

(

ORO

k

Si

O

Si

)

(

)

(

mm

k k O )On

n)RO

nRO

ORO

Ph

ORO

PhPh

PhPh

ORO Ph

O

OO

HO

HOHO

COO

COO

COO

Ethylene

glycol

diglycidyl

Ethylene

glycol

diglycidyl

Ethylene

glycol

diglycidyl

ether

modified

acrylpimaric

acid

ether

modified

acrylpimaric

acid

ether modified acrylpimaric

acid

(AP-EDGE)

(AP-EDGE)

(AP-EDGE)

Siloxane

modified

AP-EDGE

Siloxane

modified

AP-EDGE

Siloxane

modified

AP-EDGE

yield:

81-89%

yield:

81-89%

COO

yield:

81-89%

COO

COO

R

R=

=

R=

O

OO

O

OO

O

OO

O

OO

O

OO

O

OO

COO

COO

COO

EEW

(experimental

EEW

(experimental

EEW

(experimental

value)

(g/mol)

=

481,

value)

(g/mol)

==

481,

value)

(g/mol)

481,

645,

714,

952,

645,

714,

952,

1190

645,

714,

952,1190

1190

Scheme

4.

Preparation

of

ethylene

glycol

diglycidyl

ether

modified

acrylpimaric

acid

and

its

siloxane

Scheme

4.4.

Preparation

ofethylene

ethylene

glycol

diglycidyl

ether

modified

acrylpimaric

acid

and

its

4.

Preparation

ofof

ethylene

glycol

diglycidyl

ether

modified

acrylpimaric

acid

and

itsits

siloxane

Scheme

Preparation

glycol

diglycidyl

ether

modified

acrylpimaric

acid

and

siloxane

derivative.

siloxane

derivative.

derivative.

derivative.

Dimaleopimaryl

yellow

solid.

from

levopimaric

acid

Dimaleopimaryl

brownish

prepared

Dimaleopimaryl

ketone

isisaaa abrownish

brownish

yellow

solid.

It Itcan

can

bebeprepared

prepared

from

levopimaric

acid

Dimaleopimarylketone

ketoneis

brownishyellow

yellowsolid.

solid.It

canbe

preparedfrom

fromlevopimaric

levopimaricacid

acid

and

maleic

anhydride

according

to

Scheme

5,

prior

to

washing

and

recrystallization

[163].

It

can

be

washing

and

maleic

anhydride

according

to

Scheme

5,

prior

to

washing

and

recrystallization

[163].

It

can

and maleic anhydride according to Scheme 5, prior to washing and recrystallization [163]. It canbebe

used

directly as

an epoxy resin

hardener, as

well

as

for

the

synthesis

of

bio-based

epoxy

resins,

i.e.,

well

for

bio-based

used

asas

well

asas

for

the

synthesis

ofof

bio-based

epoxy

resins,

i.e.

useddirectly

directlyasasananepoxy

epoxyresin

resinhardener,

hardener,as

wellas

forthe

thesynthesis

synthesisof

bio-basedepoxy

epoxyresins,

resins,i.e.

i.e.

tetraglycidyl

dimaleopimaryl

ketone,

according

to

Scheme

5

[163].

according

to

Scheme

5

[163].

tetraglycidyl

dimaleopimaryl

ketone,

according

to

Scheme

5

[163].

tetraglycidyl dimaleopimaryl ketone, according to Scheme 5 [163].

O

OO

O

OO

O

OO

pTSA

pTSA

pTSA

in

in toluene

toluene

in

toluene

135-230°C

135-230°C

135-230°C

5h

5h 5h

COOH

COOH

COOH

Levopimaric

Levopimaric

Levopimaric

acid

acid

acid

O

OO

O

O

OO OO O

OO

O

OO

zinc

acetate

zinc

acetate

zinc

acetate

in

33COOH

in CH

CHCH

COOH

in

3COOH

?°C,

12h

?°C,

12h12h

O

?°C,

O

O

OO

O

OO

1.

NaOH

1. 1.

NaOH

NaOH

Cl

Cl O

2.

2. 2. Cl O O

O

OO

zinc

acetate

zinc

acetate

zinc

acetate

in

?°C,

6h

in DMF,

DMF,

?°C,

6h 6h

in

DMF,

?°C,

O

Dipimaryl

ketone

Dipimaryl

ketone

Dipimaryl

ketone

yield:

97%

yield:

97%

yield: 97%

O

OO

O

OO

O

OO

O

OO

O

OO

Dimaleopimaryl

ketone

Dimaleopimaryl

ketone

Dimaleopimaryl

ketone

yield:

85%

yield:

85%

yield:

85%

O

OO

O

OO

O

OO

O

OO

O

OO

O

OO

O

O O Tetraglycidyl

Tetraglycidyl

Tetraglycidyl

dimaleopimaryl

ketone

dimaleopimaryl

ketone

dimaleopimaryl

ketone

Scheme

5.

Synthesis

of

tetraglycidyl

dimaleopimaryl

ketone.

Scheme

5. 5.

Synthesis

of

tetraglycidyl

dimaleopimaryl

ketone.

Scheme

Synthesis

tetraglycidyl

dimaleopimaryl

ketone.

Scheme

5.

Synthesis

ofof

tetraglycidyl

dimaleopimaryl

ketone.

Molecules 2019, 24, 1651

7 of 52

Molecules2019,

2019,24,

24,xxFOR

FORPEER

PEERREVIEW

REVIEW

Molecules

of 51

51

77 of

Rosin

It

can

be

prepared

from

epoxidized

rosin, water,

potassium

Rosinpentaglycidyl

pentaglycidylether

etheris

isaaasolid.

solid. It

It can

can be

be prepared

prepared from

from epoxidized

epoxidized rosin,

rosin,

water, potassium

potassium

Rosin

pentaglycidyl

ether

is

solid.

water,

hydroxide

and

epichlorohydrin

according

to

Scheme

6,

and

using

such

separation

methods

as

vacuum

hydroxide

and

epichlorohydrin

according

to

Scheme

6,

and

using

such

separation

methods

as

hydroxide and epichlorohydrin according to Scheme 6, and using such separation methods as

drying,

filtration,

precipitation

and

washing

[164].

It

can

be

used

as

a

component

in

epoxy

resin

vacuum drying,

drying, filtration,

filtration, precipitation

precipitation and

and washing

washing [164].

[164]. ItIt can

can be

be used

used as

as aa component

component in

in epoxy

epoxy

vacuum

systems

showing

high glass

transition

temperature

as wellasaswell

elastic

modulus

[164]. [164].

resin

systems

showing

high

glass

transition

temperature

as

elastic

modulus

resin systems showing high glass transition temperature as well as elastic modulus [164].

3-chloro3-chloroperoxybenzoic

peroxybenzoic

acid

acid

in

CH

Cl2

in CH22Cl

2

0°C,

6-8h

0°C, 6-8h

Rosin

Rosin

O

O

HH22OO

O

O

OH

OH

OH

OH

OHaq

aq

inCC2HH5OH

in

2 5

90°C, 36h

36h

90°C,

COOH

COOH

COOH

COOH

2.

2.

Cl

Cl

O

O

O

O

O

O

O

O

CC

O

O

Rosin

Rosin

pentaglycidyl

pentaglycidyl

ether

ether

Hydroxylated rosin

rosin

Hydroxylated

O

O

O O

O

O

O

O

O O

O

O

Cl

inCH

CH2Cl

in

2 22

80°C, 7h

7h

80°C,

COOH

COOH

Epoxidized rosin

rosin

Epoxidized

O

O

1. KOH

KOH

1.

OH

OH

OH

OH

Scheme

6.

Synthesis of

of

rosin

pentaglycidyl

ether.

Scheme 6.

6. Synthesis

of rosin

rosin pentaglycidyl

pentaglycidyl ether.

ether.

Scheme

Polygral

is

solid

byproduct

of

the

paper

and forestry

forestry

industry,

containing

rosin

acids

and

their

Polygral is

is aaa solid

solid byproduct

byproduct of

of the

the paper

paper and

forestry industry,

industry, containing

containing rosin

rosin acids

acids and

and their

their

Polygral

oligomers

[165].

It

can

be

epoxidized

to

prepare

bio-based

epoxy

resins.

Endocyclic

epoxidized

oligomers [165].

[165]. It can be

be epoxidized

epoxidized to

to prepare

prepare bio-based

bio-based epoxy

epoxy resins.

resins. Endocyclic

Endocyclic epoxidized

epoxidized

oligomers

polygral

is

a

solid,

which

can

be

prepared

using

3-chloroperoxybenzoic

acid,

according

polygral

is

red

brown

solid,

which

can

be

prepared

using

3-chloroperoxybenzoic

acid,

according

to

polygral is a red brown solid, which can be prepared using 3-chloroperoxybenzoic acid, according

to

to

Scheme

7,

prior

to

vacuum

evaporation.

On

the

other

hand,

exocyclic

epoxidized

polygral

is

a

Scheme

7,

prior

to

vacuum

evaporation.

On

the

other

hand,

exocyclic

epoxidized

polygral

is

a

viscous

Scheme 7, prior to vacuum evaporation. On the other hand, exocyclic epoxidized polygral is a viscous

0 -diisopropyl

viscous

red

brown

liquid,

that

can

be

prepared

in

two

ways,

using

oxalyl

chloride

or

N,N

red brown

brown liquid,

liquid, that

that can

can be

be prepared

prepared in

in two

two ways,

ways, using

using oxalyl

oxalyl chloride

chloride or N,N′-diisopropyl

N,N′-diisopropyl

red

carbodiimide

before

addition

of

glycidol,

according

to

Scheme

7

prior

to

washing

and

vacuum

drying.

carbodiimide

before

addition

of

glycidol,

according

to

Scheme

7

prior

to

washing

and vacuum

vacuum

carbodiimide before addition of glycidol, according to Scheme 7 prior to washing

and

They

can

be

used

for

preparing

bisphenol

A-free

epoxy

resins

[165].

drying. They

They can

can be

be used

used for

for preparing

preparing bisphenol

bisphenol A-free

A-free epoxy

epoxy resins

resins [165].

[165].

drying.

COOH

COOH

3-chloro3-chloroperoxybenzoic

O

peroxybenzoic

O

acid

acid

HOOC

HOOC

O

inCH

CH2Cl

Cl

O

in

2 22

-5°C, 10h

10h

-5°C,

O

O

Endocyclic

Endocyclic

epoxidized

epoxidized

polygral

polygral

O

O

1.NN CC NN

1.

HOOC

HOOC

2.

2.

O

OH O

OH

O

O

O CC

O

pTSA/DMAP

pTSA/DMAP

in CH

CH2Cl

Cl

in

2 22

0°C, 72h

72h

0°C,

COOH

COOH

Polygral

Polygral

(C2HH5))3NN

(C

2 5 3

in

toluene

in toluene

20°C, 24h

24h

20°C,

Cl

Cl

O

O

O

O

Cl

Cl

COO

COO

O

O

Cl

Cl

O CC

O

COCl

COCl

O

O

OH

OH

Exocyclic

Exocyclic

epoxidized

epoxidized

polygral

polygral

(C2HH5))3NN

(C

2 5 3

intoluene

toluene

in

0°C, ?h

?h

0°C,

Scheme 7.

7. Preparation

Preparation of

of epoxidized

epoxidized rosin

rosin oligomers.

oligomers.

Scheme

Diglycidyl

is

can be

be

Diglycidyl dehydroabietylamine

dehydroabietylamine is

is aaa yellowish

yellowish sticky

sticky liquid.

liquid. ItIt can

be synthesized

synthesized from

from

Diglycidyl

dehydroabietylamine

yellowish

sticky

liquid.

synthesized

from

dehydroabietylamine,

epichlorohydrin

and

sodium

hydroxide

according

to

Scheme

8,

prior

to

filtration,

dehydroabietylamine,

epichlorohydrin

and

sodium

hydroxide

according

to

Scheme

8,

prior

to

dehydroabietylamine, epichlorohydrin and sodium hydroxide according to Scheme 8, prior to

washing,

drying

and

vacuum

distillation

[156].

It

can

be

applied

in

epoxy

resins

exhibiting

better

filtration,

washing,

drying

and

vacuum

distillation

[156].

It

can

be

applied

in

epoxy

resins

exhibiting

filtration, washing, drying and vacuum distillation [156]. It can be applied in epoxy resins exhibiting

thermal

stabilitystability

and higher

transition

temperatures

than petroleum-based

products [156].

better thermal

thermal

stability

andglass

higher

glass transition

transition

temperatures

than petroleum-based

petroleum-based

products

better

and

higher

glass

temperatures

than

products

Rosin

maleimidodicarboxylic

acid

diglycidyl

ether

is

a

yellowish

solid.

It

can

be

prepared

from

[156].

[156].

epichlorohydrin

and

dicarboxylic

derivative

of

maleimide

(described

in

more

detail

in

Section

3.2.3)

Rosin

maleimidodicarboxylic

acid

diglycidyl

ether

is

a

yellowish

solid.

It

can

be

prepared

from

Rosin maleimidodicarboxylic acid diglycidyl ether is a yellowish solid. It can be prepared from

according

to Scheme

prior to filtration,

washing,

drying and(described

rotary evaporation

It in

shows

higher

epichlorohydrin

and9dicarboxylic

dicarboxylic

derivative

of maleimide

maleimide

(described

in more

more[84].

detail

in subsection

subsection

epichlorohydrin

and

derivative

of

in

detail

glass

transition

temperature,

modulus

and

thermal

stability

than

its

plant

oil

counterparts

[84].

3.2.3)

according

to

Scheme

9

prior

to

filtration,

washing,

drying

and

rotary

evaporation

[84].

It

shows

3.2.3) according to Scheme 9 prior to filtration, washing, drying and rotary evaporation [84]. It shows

higherglass

glasstransition

transitiontemperature,

temperature,modulus

modulusand

andthermal

thermalstability

stabilitythan

thanits

itsplant

plantoil

oilcounterparts

counterparts[84].

[84].

higher

1.

Cl

O

2. NaOH

Dehydroabietylamine

O

H2O ; TBA Br

45°C, 153h

Molecules 2019, 24, 1651

Molecules

Molecules 2019,

2019, 24,

24, xx FOR

FOR PEER

PEER REVIEW

REVIEW

NH2

Cl

Cl

N

Diglycidyl

8 of 52

88 of

dehydroabietylamine

of 51

51

yield: 90%

O

O

O

1.diglycidyl

Scheme 8. Synthesis of1.

dehydroabietylamine.

2.

2. NaOH

NaOH

O

Dehydroabietylamine

O

Dehydroabietylamine

O

H2N

O

NH

NH22

COOH

O

O

O

COOH

H

Br

H22O

O ;; TBA

TBA

Br

45°C,

45°C, 153h

153h

N

N

N

O

Diglycidyl

Diglycidyl

dehydroabietylamine

dehydroabietylamine

COO

N

yield:

yield: 90%

90%

O

O

O

Cl

O

Scheme 8.

8. Synthesis

Scheme

dehydroabietylamine.

Synthesis of

of diglycidyl

diglycidyl dehydroabietylamine.

in DMF

COO

160°C, 4h

COOH

O

O

O

O

O

O

O

MaleopimaricO

acid

NaH

in DMF

150°C, 5h

H

H22N

N

Rosin-maleimidodicarboxylic

O

O diglycidyl ether

acid

yield: 47%

COOH

COOH

COOH

N

N

Rosin-maleimidodicarboxylic

acid

O

O

yield: 87%

COOH

COOH

Cl

Cl

O

O

COO

COO

N

N

O

O

O

O

O

O

Scheme

acidCOO

diglycidylOether.

in DMF9. Preparation of rosin maleimidodicarboxylic

NaH

in DMF

160°C,

160°C, 4h

4h

NaH

in

in DMF

DMF

150°C,

150°C, 5h

5h

trimethylolpropane

O

COO

Rosin-maleimidodicarboxylic

Rosin-maleimidodicarboxylic

COOH

COOH

acid

ether

Triester of maleopimaric acid and

is a dark yellow solid.

can be prepared

acidItdiglycidyl

diglycidyl

ether

COOH

COOH

yield:

yield: 47%

47%of

according

to

Scheme

10,

prior

to

washing

and

vacuum

distillation

[98].

It

can

be

used

in

synthesis

Maleopimaric

Maleopimaric

Rosin-maleimidodicarboxylic

acid

Rosin-maleimidodicarboxylic

acid

rosin-based

epoxy

resin

[98].

acid

acid

yield:

yield: 87%

87%

Epoxy resin having EEW = 199.68 g/eq based on maleopimaric acid and trimethylolpropane ester

9.

of

rosin

maleimidodicarboxylic

diglycidyl

ether.

9. Preparation

acid

diglycidyl

ether.

Scheme

Preparation

of 10,

rosin

maleimidodicarboxylic

ether. [98]. It can be

can be preparedScheme

according

to Scheme

prior

to extraction andacid

vacuum

distillation

used directly as an epoxy compound, or transformed into acrylate resin [98].

Triester

maleopimaric

acid

is

Triester

of

maleopimaric

yellow

It

Triester

ofresin

maleopimaric

acid and

and trimethylolpropane

trimethylolpropane

is aa dark

dark yellow

yellow solid.

solid.

It can

can be

be prepared

prepared

Acrylateof

based on epoxidized

maleopimaric-trimethylolpropane

adduct

according

to

Scheme

10,

prior

to

washing

and

vacuum

distillation

[98].

can

be

used

in

synthesis

of

It

according to Scheme 10,

priorIttocan

washing

distillationby

[98].

It can methacrylated

be used in synthesis

of

10 [98].

be usedand

as avacuum

resin crosslinked

styrene,

eugenol

[98].

rosin-based

epoxy

resin

[98].

rosin-based

epoxy

resin

[98].

or methacrylated guaiacol [98].

Epoxy

Epoxy resin

resin having

having EEW

EEW == 199.68

199.68 g/eq

g/eq based

based on

on maleopimaric

maleopimaric acid

acid and

and trimethylolpropane

trimethylolpropane ester

ester

HO

OH

can

be

prepared

according

to

Scheme

10,

prior

to

extraction

and

vacuum

distillation

[98].

It

can

O

OH

Crosslinked

resinbe

can be prepared according to Scheme 10, prior to extraction and vacuum distillation

[98]. It can

be

O

used

or

transformed

into

acrylate

resin

[98].

styrene

used directly

directly as

as an

an epoxy

epoxy compound,

compound,

or

transformed

into

acrylate

resin

[98].

OH

OH

O

or methacrylated

eugenol

Acrylate

on

maleopimaric-trimethylolpropane

adduct

can

Acrylate resin

resin based

based

on epoxidized

epoxidized

maleopimaric-trimethylolpropane

adductguaiacol

can be

be prepared

prepared

or methacrylated

pTSA

OH O

according

to

Scheme

10

[98].

It

can

be

used

as

a

resin

crosslinked

by

styrene,

methacrylated

xylene It can be used

O as a resin crosslinked by styrene, methacrylated eugenol

according to Scheme 10in [98].

eugenol

O O

O

OH

or

O

or methacrylated

methacrylated guaiacol

guaiacol [98].

[98].

COOH

O

O

O

O

Maleopimaric

acid

O

O

O

O

COOH

COOH

O

O

O

Maleopimaric

Maleopimaric

O

acid

acid

O

O

O

O

O

O

O

O

O

HO

1. K OH/

HO

OH

NaOH

HO

OH

Cl O

2.

OH

OH

OH

OH

OH

OH

pTSA

pTSA in DMSO OH

OH

in

<24°C,18h

in xylene

xylene

1.

K

1. O

K OH/

OH/

NaOH

NaOH

O

Cl

Cl O

O

2.

2.

O

O

O

O

COO

O

O

O

O

O

O

OH

OH

OH

Maleopimaric acid

trimethylolpropane ester

OH

OH 93%

O

yield:

styrene

styrene

HO

or

or methacrylated

methacrylated eugenol

eugenol

O

or

methacrylated

guaiacol

or methacrylated guaiacol

OH

O

COO

COO

OH

OH

O

O

O

O

O

HO

HO

O

O

O

O

O

in

in DMSO

DMSO

<24°C,18h

<24°C,18h

O

O

Crosslinked

resin

Crosslinked

resin

O

OH

O

O

O

O

HO

OH

Maleopimaric

Maleopimaric acid

acid

O

O O

trimethylolpropane

ester

PPh3

O

trimethylolpropane

ester

O

O

Maleopimaric acid

O

O

O

HQ

yield:

93%

O

O

yield: 93%

trimethylolpropane-based

85°C, 3.5h

O

O

Oepoxy resin yield:

O 85%

OH

OH

O

O

O

O

O

O

O

O

O

O

O

O

O

O O

HO

HO

HO

OH

O

O

O

O

O

O

HO

HO

O

O

O

O

O

O

O

O

O

O

O

O

O

Maleopimaric

acid

O

trimethylolpropane-based

O

OH

epoxy acrylate resin

yield: 95%

OH

O

O

O

O

O

O

O

O

O

HO

O

O

Scheme

10.

Preparation

of

maleopimaric

acid-trimethylolpropane

ester-based

epoxy acrylate

acrylate

resin

HO

O Preparation of maleopimaric acid-trimethylolpropane ester-based epoxy

OScheme 10.

resin

O

O

OH

OH

O

O

crosslinked by

by unsaturated

unsaturated monomers.

monomers.

crosslinked

O

O

O

O

O

O

O

PPh

O

33

PPh

Maleopimaric

acid

Maleopimaric

acid

O

Maleopimaric

acid

O

Epoxy

maleopimaric acid and trimethylolpropane

ester

O Maleopimaric acid

O resin having EEW = 199.68 g/eq based onHQ

HQ

trimethylolpropane-based

trimethylolpropane-based

trimethylolpropane-based

3.5h

85°C,

3.5h

can be prepared

according to

Scheme 10, prior to85°C,

extraction

and vacuumtrimethylolpropane-based

distillation [98]. It can be

epoxy

epoxy

epoxy resin

resin yield:

yield: 85%

85%

epoxy acrylate

acrylate resin

resin yield:

yield: 95%

95%

used directly as an epoxy compound, or transformed into acrylate resin [98].

Scheme

Scheme 10.

10. Preparation

Preparation of

of maleopimaric

maleopimaric acid-trimethylolpropane

acid-trimethylolpropane ester-based

ester-based epoxy

epoxy acrylate

acrylate resin

resin

crosslinked

crosslinked by

by unsaturated

unsaturated monomers.

monomers.

Molecules 2019, 24, 1651

9 of 52

Acrylate resin based on epoxidized maleopimaric-trimethylolpropane adduct can be prepared

according to Scheme 10 [98]. It can be used as a resin crosslinked by styrene, methacrylated eugenol or

Molecules

2019, 24, guaiacol

x FOR PEER

REVIEW

9 of 51

methacrylated

[98].

Dehydroabietic ethyl methacrylate is a white powder. It can be prepared from dehydroabietyl

chloride and hydroxyethyl methacrylate according to Scheme 11, prior to neutralization, drying,

O

evaporation and chromatography

[146]. It can be widely used

as 2a)2Omonomer in preparation of graft

HO(CH

O(CH

2)2OH

and block copolymers [146,166–170].

It is worth noting, that a similar

O compound dehydroabietic

ethyl acrylate

hydroxyethyl

and

(CH3)from

pyridine liquid, which can be prepared

3N

O(CH2)2Ois a yellow, viscous

O(CHacrylate

2)2O

COCl

CHfiltration,

in CH

2Cl2

2Cl2

O

O

dehydroabietyl

chloride

priorinto

precipitation

and vacuum

distillation

[171].

for

O

O It can be used

50°C, 4h

Dehydroabietyl

0-25°C, 48h

Dehydroabietic

Dehydroabietic

preparation

of homopolymer with no declared application [171]. Moreover, rosin ethyl

acrylate can be

chloride

ethylinacrylate

ethyl methacrylate

used

preparation

bio-based

Molecules

2019, 24, x FORof

PEER

REVIEWgraft copolymers of chitosan for controlled release applications9[172].

of 51

Scheme 11. Synthesis of dehydroabietic ethyl acrylates.

Cl

HO(CH2)2O

O

O

O

HO(CH2)6OH

O(CH2)2OH

pyridine

O(CH

2)2O

Molecules

2019,

24, xDMAP

FOR PEER REVIEW

O

O

in THF

Dehydroabietic

50°C, 12h

COCl

ethyl

acrylate

Dehydroabietyl

chloride

in CH2Cl2

50°C, 4h

(CH3)3N

(CH3)3N

HQ in CH2Cl2

in THF

0-25°C, 48h

25°C, 10h

HO

COCl

O

O(CH2)2O 9 of 51

OO

Dehydroabietyl

Dehydroabietic

O

O

chloride

ethyl

methacrylate

O Dehydroabietic

O O Hydroxyhexyl

HO(CH2)2O

dehydroabietate

yield:

72%

hexyl

acrylate yield: 41%

O(CH

)

OH

Scheme

11.

Synthesis

of

dehydroabietic

ethyl

acrylates.

2 2

O

Scheme 11. Synthesis of dehydroabietic ethyl acrylates.

O

(CH3)3acrylate.

N

pyridine

Scheme

12. Synthesis of dehydroabietic hexyl

O(CH ) O

O(CH ) O

2 2

2 2

Cl

Dehydroabietic

hexyl acrylate

It can be synthesized

chloride,

in CH2Cl2is a solid. COCl

in CH2Cl2from dehydroabietyl

O

O

O

O

50°C, 4h

Dehydroabietyl

0-25°C,

48h separationDehydroabietic

hexanediol

and

acryloyl

chloride

according

to

Scheme

12,

and

using

methods

such as

Dehydroabietic

Dehydroabietic ethyl methacrylate is a white

powder. It Ocan be prepared from dehydroabietyl

chloride

HO(CH2)6OH

ethyl acrylate

ethyl

methacrylate

filtration,

precipitation,

washing

and

vacuum

drying

[148].

Its

application

is

a

soft

acrylic

monomer

(CH3)3N11, prior to neutralization, drying,

chloride and hydroxyethyl methacrylate according

to Scheme

◦ C), whichHO

DMAP

(glass

transition

temperature

of

−23

can

impart

a

flexibility

to the integrated

polymer

[148].

HQ

Scheme 11.

Synthesis

dehydroabietic

ethyl

evaporation and chromatography

[146].

It canofbe

widely used

as aacrylates.

monomer

in preparation

of

O graft

in THF

in THF

O

and block

[146,166–170]. ItOis worth noting, that25°C,

a similar

50°C, 12h

10h compound dehydroabietic ethyl

COCl copolymers

O

Cl

acrylate

is

a

yellow,

viscous

liquid,

which

can

be

prepared

from

hydroxyethyl

acrylate

and

Dehydroabietyl

O Hydroxyhexyl

O Dehydroabietic

O

chloride

dehydroabietyl

chloride

prior

to

filtration,

precipitation

and

vacuum

distillation

[171]. It can

be41%

used

dehydroabietate

yield:

72%

hexyl

acrylate

yield:

HO(CH2)6OH

(CH3)3N[171]. Moreover, rosin ethyl acrylate

for preparation of homopolymer with no declared

application

HO

DMAP Scheme 12. Synthesis of dehydroabietic

HQhexyl acrylate.

O

can be used in preparation

of bio-based graft copolymers

in THF

in THF of chitosan for controlled release

O

50°C,

12h

25°C, 10h

O

COCl [172].

applications

Dehydroabietic

ethyl methacrylate

is a white powder. It can be preparedO from dehydroabietyl

Dehydroabietyl

OisHydroxyhexyl

O Dehydroabieticchloride,

Dehydroabietic

hexyl acrylate

a solid.

It can to

be Scheme

synthesized

from to

dehydroabietyl

chloride

and hydroxyethyl

methacrylate

according

11, prior

neutralization, drying,

chloride

dehydroabietate

yield:

72%

hexyl

acrylate

yield: 41%

hexanediol

and

acryloyl

chloride

according

to

Scheme

12,

and

using

separation

methods

such

as

evaporation and chromatography [146]. It can be widely used as a monomer in preparation

of graft

filtration,

precipitation,

washing

and

vacuum

drying

[148].

Its

application

is

a

soft

acrylic

monomer

Scheme

12.

Synthesis

of

dehydroabietic

hexyl

acrylate.

and block copolymers [146,166–170].

It is worth

that a similar

compound dehydroabietic ethyl

Scheme 12. Synthesis

of noting,

dehydroabietic

hexyl acrylate.

(glass

transition

temperature

of −23

°C), which

a flexibility

to the

integrated polymer

acrylate

is a yellow,

viscous

liquid,

which can

canimpart

be prepared

from

hydroxyethyl

acrylate[148].

and

Dehydroabietic

ethyl

methacrylate

is

a

white

powder.

It

can

be

prepared

from

dehydroabietyl

N-hydroxyethylacrylamide ester

ester of

of dehydroabietic

dehydroabietic acid is a viscous,

yellow liquid.

be

N-hydroxyethylacrylamide

viscous,

liquid.

It

can

dehydroabietyl chloride prior to filtration, precipitation and vacuum distillation [171]. It can be used

chloridefrom

and hydroxyethyl

methacrylate

according

to Scheme 11, prior toaccording

neutralization,

drying,13,

prepared

dehydroabietyl

chloride and

N-hydroxyethylacrylamide