MPI's DSD System for Repaint Work: Surface Degradation Guide

advertisement

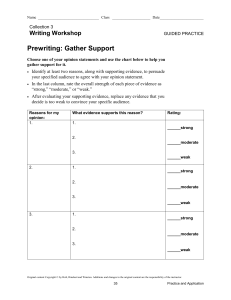

Specifying Repaint Work with MPI’s DSD System Content adapted from MPI’s Level 2 Maintenance Repainting Coatings Specialist course Identifying defects and failures in the coating and the substrate to be painted is the first step in maintenance repainting work; this helps determine the best course of action with regard to required repairs (if any), surface preparation, level and type of priming, and selection of the new coating system. MPI identifies five “Degrees of Surface Degradation” that quantify how badly the substrate or coating hasdeteriorated and thus determine how rigorous the surface preparation or primingwork will need to be: DSD-0 (pictured here): This is anessentially "sound" surface or previous coating where there is no damage to the surface, and painting work is being done to provide a change in color, sheen, etc. Any visual (aesthetic) defects do not affect the film’s protective properties. The required surface preparation will be to assure the surface is free of contaminants and sufficiently deglossed or roughened to assure good adhesion of the new coating. DSD-1: This is a “slight” degree of surface degradation. It is unlikely that the topcoat has been anything but insignificantly breached, and in no case is the substrate exposed. Surface preparation requirements should be “slight” and only touch-up painting with the top or intermediate coat should be necessary. DSD-2: This is a “moderate” degree of surface degradation. Damage to the film integrity is such that spot priming and topcoating after moderate surface preparation requirements should be adequate. DSD-3: This is a “severe” degree of surface degradation. Damage to the coating is widespread and the amount of surface preparation required will likely be substantial, including complete removal of any existing coatings down to the bare substrate. A full coat of the appropriate primer and intermediate/topcoat system is to be expected. DSD-4: This is an essentially “unsound” surface. Repainting is only a temporary cosmetic remedy as the substrate needs to be repaired or replaced before an appropriate coating system can be applied. The evaluation begins by taking note of what surface defects and contaminants are present. Common Surface Defects* Alligatoring. This term refers to a random pattern of roughly parallel and perpendicular cracks that look like the scaly hide on the back of an alligator or crocodile. These cracks may extend to a previous coating or may expose the original substrate. Possible causes may be the application of: a top coat before the undercoat is dry a top coat unable to bond to a glossy surface excessive coats of paint an excessively thick coat that prevents the under coat from drying properly a hard, rigid coating (e.g. alkyd enamel) over a soft, flexible coating (e.g. latex) With oil/alkyd coatings, alligatoring can be the natural result of aging where the film hardens, loses its elasticity, and during temperature fluctuations is unable to expand and contract with the substrate underneath. Blistering.This defect appears as dome-shaped bubbles that result from localized loss of adhesion and the consequential lifting of the film from the underlying surface. Blistering is commonly caused by water or moisture vapor migrating through a painted substrate. Blistering can also be caused by excessive heat during application that causes the surface to dry too quickly. Blistering continuing to a bare substrate usually indicates a moisture-originated blister, whereas heat initiated blisters often extend only to the next solid coating. The standard for evaluating and quantifying blistering is ASTM Method D 714"Evaluating Degree of Blistering of Paints." Cracking. Cracking is a breach in a dry paint film that appears as a line or connecting lines that extend to the substrate or coating below. The most frequent cause is substrate movement from settling, shrinkage expansion, moisture loss/gain, or physical distortion. Shrinkage of the coating can also create cracks; this occurs more with thick film applications of high PVC (pigment volume concentration) paints. Chalking. A loose, white powdery pigment residue on the surface of a coating accompanied by a loss of gloss and lightening of the color. Chalking should not be confused with efflorescence (deposition of soluble salts on a coating's surface) or erosion (gradual wearing of the film due to environmental conditions). The source of chalk is the coating's pigment being released from the film. In some cases, this is a self-cleaning feature purposely designed into the coating. Some causes: paint spread too thin, or thinned too much low quality, highly pigmented paint indoor paint used on exterior substrate use of epoxy paint in direct sunlight The standard for evaluating and quantifying chalking is ASTM Method D 659. MPI Levels of Surface Degradation for Exterior Concrete Masonry Surfaces Here’s how a specifier would use an evaluation of surface defects to determine which level of surface degradation he’s dealing with: DEFECT DSD1 DSD2 DSD3 Alligatoring None Slight Moderate to Severe Blistering None Slight Moderate to Severe Cedar Stains Minor Spots Minor Spots Moderate to Severe Checking None Slight Moderate to Severe Cracking None Slight Moderate to Severe Dirt/Dusts Any Any Any Efflorescence Slight (surface) Moderate Heavy Erosion/Chalking Slight to Moderate Moderate Moderate to Severe Flaking/Peeling (1) Slight Moderate Moderate to Severe Flaking/Peeling (2) None Moderate Moderate to Severe Mildew Slight to Moderate Moderate Moderate to Severe Oils/Grease Any Any Any Rust Stains Slight (surface) Slight to Moderate Moderate to Severe Sagging Slight to Moderate slight to Moderate Moderate to Severe (1) Flaking/peeling from the topcoat through some or all coats. Primer remains intact. (2) Flaking/peeling down to the substrate. Primer not intact. Here’s what those surfaces might look like… DSD-1 Slightly Deteriorated Concrete Masonry Surface Some surface staining and contamination on concrete block. DSD-2 Moderately Deteriorated Concrete Masonry Surface Block wall shows localized efflorescence and peeling, flaking, mildew, and cracking. DSD-3 Severely Deteriorated Concrete Masonry Surface Building with severe peeling, flaking, mildew, and cracking. DSD-4 Substrate Damage The surface requires repairs or replacement prior to painting to achieve the owner’s required structural, protective, or esthetic function Once the DSD level has been determined, MPI’s Repaint Manual provides guidance for the required surface preparation prior to coating application. For a DSD-2 moderately deteriorated concrete/masonry surface, the recommended surface preparation steps might look like this, with the appropriate MPI surface preparation standard (RSP) indicated for each step: “All surface contaminants such as wax, oils, grease, dirt, tire marks (horizontal surfaces), etc., must be removed from the surface. Oil and grease can be removed by detergent cleaning (MPI RSP-13), followed by a rinse with clean water; solvent cleaning (MPI RSP-2) can be used as an alternative to MPI RSP-13 on areas with a concentration of oil or grease. All loose and flaking paint must be removed by hand cleaning (MPI RSP-1), power tool cleaning (MPI RSP-4), or pressure washing (MPI RSP-5). All blisters must be removed from the surface and the edges feathered. Areas showing mildew growth must be treated as outlined in MPI RSP-9. Glossy finishes must be ‘dulled’ by sanding (MPI RSP-1) or (MPI RSP-4), by a TSP treatment (MPI RSP-13), or by sweep blasting (SSPC-SP 7) to create an anchor pattern to promote adhesion of the new coating. Rust stains can be removed with an oxalic acid treatment (MPI RSP-12). If large amounts of efflorescence are present, mechanical removal (e.g. abrasive sweep blasting or power tool grinding) may be required, after which acid etching (MPI RSP8) shall be performed. After any application of muriatic acid, the surface must be flushed with large amounts of clean water to remove any residue, and then allowed to dry thoroughly. The pH of the surface shall be tested, as specified in 1.2 pH Testing before the application of paint. All bare areas must be spot primed.” *Excerpted from MPI's Identifiers: Defects and Failures book Stay up-to-date on industry best practices and trends with FREE MPI Updates