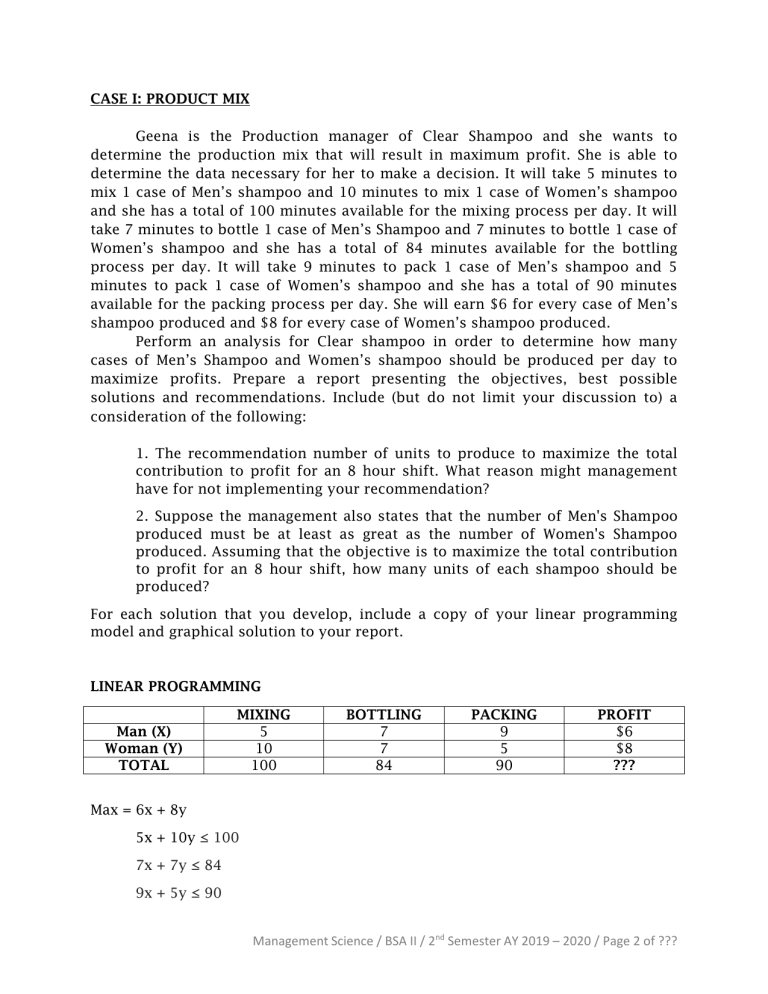

CASE I: PRODUCT MIX Geena is the Production manager of Clear Shampoo and she wants to determine the production mix that will result in maximum profit. She is able to determine the data necessary for her to make a decision. It will take 5 minutes to mix 1 case of Men’s shampoo and 10 minutes to mix 1 case of Women’s shampoo and she has a total of 100 minutes available for the mixing process per day. It will take 7 minutes to bottle 1 case of Men’s Shampoo and 7 minutes to bottle 1 case of Women’s shampoo and she has a total of 84 minutes available for the bottling process per day. It will take 9 minutes to pack 1 case of Men’s shampoo and 5 minutes to pack 1 case of Women’s shampoo and she has a total of 90 minutes available for the packing process per day. She will earn $6 for every case of Men’s shampoo produced and $8 for every case of Women’s shampoo produced. Perform an analysis for Clear shampoo in order to determine how many cases of Men’s Shampoo and Women’s shampoo should be produced per day to maximize profits. Prepare a report presenting the objectives, best possible solutions and recommendations. Include (but do not limit your discussion to) a consideration of the following: 1. The recommendation number of units to produce to maximize the total contribution to profit for an 8 hour shift. What reason might management have for not implementing your recommendation? 2. Suppose the management also states that the number of Men's Shampoo produced must be at least as great as the number of Women's Shampoo produced. Assuming that the objective is to maximize the total contribution to profit for an 8 hour shift, how many units of each shampoo should be produced? For each solution that you develop, include a copy of your linear programming model and graphical solution to your report. LINEAR PROGRAMMING Man (X) Woman (Y) TOTAL MIXING 5 10 100 BOTTLING 7 7 84 PACKING 9 5 90 PROFIT $6 $8 ??? Max = 6x + 8y 5x + 10y ≤ 100 7x + 7y ≤ 84 9x + 5y ≤ 90 Management Science / BSA II / 2nd Semester AY 2019 – 2020 / Page 2 of ??? I. 5y = 90 5x + 10y ≤ 100 5 X=0 5 Y = 18 5 (0) + 10y = 100 10y = 100 10 Y=0 10 9x + 5 (0) = 90 Y = 10 9x = 90 9 Y=0 9 X = 10 5x + 10 (0) = 100 5x = 100 5 5 I II III X 20 12 10 Y 10 12 18 X = 20 II. 7x + 7y = 84 X=0 7 (0) + 7y = 84 7y = 84 7 7 Y = 12 X = 12 III. 9x + 5y = 90 X=0 9 (0) + 5y = 90 Management Science / BSA II / 2nd Semester AY 2019 – 2020 / Page 2 of ??? Constraint I Constraint II Constraint III (5x + 10y ≤ 100) * 14 (7x + 7y ≤ 84) * 9 (5x + 10y ≤ 100) / -2 (7x + 7y ≤ 84) * -10 (9x + 5y ≤ 90) * -7 9x + 5y ≤ 90 70x + 140y ≤ 1400 63x + 63y ≤ 756 -2.5x -5y ≤ -50 -70x -70y ≤ -840 -63x -35y ≤ -630 9x + 5y ≤ 90 70y ≤ 560 28y = 126 6.5x = 40 70 28 6.5 70 28 6.5 Y=8 Y = 4.5 X = 6.15 5x + 10y ≤ 100 7x + 7y ≤ 84 5x + 10y ≤ 100 5x + 10 (8) = 100 7x + 7 (4.5) = 84 5 (6.15) + 10y= 100 5x + 80 = 100 7x + 31.5 = 84 30.75 + 10y = 100 5x = 20 7x = 52.5 10y = 69.25 5 5 X=4 Constraint I. Constraint II. Constraint III. 7 7 X = 7.5 X 4 7.5 6.15 10 10 X = 6.93 Y 8 4.5 6.93 5x + 10y ≤ 100 7x + 7y ≤ 84 9x + 5y ≤ 90 21x + 22y = 274 Management Science / BSA II / 2nd Semester AY 2019 – 2020 / Page 2 of ??? I. I. 21 (4) + 22 (8) = 274 5 (7.5) + 10 (4.5) ≤ 100 84 + 176 = 274 37.5 + 45 = 100 260 = 274 82.5 = 100 II. II. 21 (7.5) + 22(4.5) = 274 7 (7.5) + 7 (4.5) ≤ 84 157.5 + 99 = 274 52.5 + 31.5 = 84 265.5 = 274 84 = 84 III. III. 21 (6.15) + 22 (6.93) = 274 9 (7.5) + 5 (4.5) ≤ 90 129.15 + 152.46 = 274 67.5 + 22.5 = 90 281.61 = 274 90 = 90 Max = 6x + 8y CASE II: SUPPLY MIX Raul is the Production Analyst of Dole Pineapple and he wants to determine the supply mix that will result to minimum cost. He is able to determine the data necessary for him to make a decision. A barrel of Absolute water can produce 9 cases of sliced pineapple, 8 cases of pineapple chunks and 4 cases of crushed pineapple. A barrel of Wilkins water can produced 5 cases of sliced of pineapple, 8 cases of pineapple chunks, and 11 cases of crushed pineapple. Lester must produce at least 90 cases of sliced pineapple, 128 pineapple chunks, and 88 cases of crushed pineapple per day. Absolute water costs $20 per barrel while Wilkins water costs $22 per barrel. Analyse the production problem of Dole Pineapple in order to determine how many barrels of Absolute and Wilkins should be purchase per day to minimize cost. Prepare a report presenting the objectives best possible solutions and recommendations. Include (but do not limit your discussion to) a consideration of the following: 1. What is the recommended number of sliced pineapple, crushed pineapple and pineapple chunks to produce in order to maximize profit? (Retail Management Science / BSA II / 2nd Semester AY 2019 – 2020 / Page 2 of ??? price of sliced pineapple per case: $50, crushed pineapple per case is $60 and a pineapple chunk per case is $55. 2. Where efforts should be expended in order to increase profits? For each solution that you develop, include a copy of your linear programming model and graphical solution to your report. Absolute (X) Wilkins (Y) Demand Retail price per sliced SLICED PINEAPPLE 9 cases 5 cases 90 cases $50 PINEAPPLE CHUNKS 8 cases 8 cases 128 cases $60 CRUSHED PINEAPPLE 4 cases 11 cases 88 cases $55 COST $20 $22 ??? CASE III. PRODUCT MIX 2 Lander is the plant manager of Converse and he wants to determine the product mix that will result in maximum profit. He is able to determine the data necessary for him to make a decision. It will take 14 minutes to cut 1 unit of Chuck and 16 minutes to cut 1 unit of Jack and he has to use up at least 224 minutes of subcontracted cutting process per day. It will take 18 minutes to sew 1 unit of Chuck and 8 minutes to sew 1 unit of Jack and he has to use up at least 144 minutes of subcontracted sewing process per day. It will take 10 minutes to adhere 1 unit Chuck and 20 minutes to adhere 1 unit of Jack and he has to use up at least 200 minutes of subcontracted process per day. He will earn $24 for every unit of Chuck produced and $29 for every unit of Jack produced. Perform an analysis for Converse in order to determine how many units of Chuck and Jack should be produced per day to maximize profits. Prepare a report presenting the objectives, best possible solutions and recommendations. Include (but do not limit your discussion to) a consideration of the following: 1. The recommendation number of units to produce to maximize the total contribution to profit for a 12 hour shift. What reason might management have for not implementing your recommendation? 2. Suppose the management also states that the number of Chuck produced must be at least as great as the number of Jack produced. Assuming that the objective is to maximize the total contribution to profit for a 12 hour shift, how many units of each shoes should be produced? For each solution that you develop, include a copy of your linear programming model and graphical solution to your report. Management Science / BSA II / 2nd Semester AY 2019 – 2020 / Page 2 of ??? CASE IV. PRODUCT MIX 4 Lovely is the plant manager of Acer Inc., and she wants to determine the product mix that will result in maximum profit. She is able to determine the data necessary for her to make a decision. It will take 20 minutes to fabricate 1 unit of Aspire and 12 minutes to fabricate 1 unit of Extensa and she has to use at least 240 minutes of the subcontracted fabrication process per day. It will take 16 minutes to assemble 1 unit of Aspire and 18 minutes to assemble 1 unit of Extensa and she has to use up at least 288 minutes of the subcontracted assembly process per day. It will take 6 minutes to test 1 unit of Aspire and 22 minutes to test 1 unit of Extensa and she has to use up at least 132 minutes of the subcontracted testing process per day. She will earn $6 for every unit of Aspire produced and $7 for every unit of Extensa produced. Perform an analysis for Acer Inc. in order to determine how many units of Aspire and Extensa should be produced per day to maximize profits. Prepare a report presenting the objectives, best possible solutions and recommendations. Include (but do not limit your discussion to) a consideration of the following: 1. The recommendation number of units to produce to maximize the total contribution to profit for an 8 hour shift. What reason might management have for not implementing your recommendation? 2. Suppose the management also states that the number of Aspire produced must be at least as great as the number of Extensa produced. Assuming that the objective is to maximize the total contribution to profit for an 8 hour shift, how many units of each computer should be produced? For each solution that you develop, include a copy of your linear programming model and graphical solution to your report. CASE V. TRANSPORT SOLUTION Charles is the Vice President for Europe of Colgate's Palmolive Shampoo. He supervises three factories (Madrid, Moscow and Athens) that supply three warehouses (London, Berlin and Paris) in the region. Madrid can produce 500 cases, Moscow can produce 300 cases and Athens can produce up to 100 cases per week. Meanwhile, London's demand is 400 cases; Berlin's demand is 600 cases, and Paris's demand is 200 cases per week. The shipping cost per case from Madrid to London $8, to Berlin is $5, and to Paris is $7. The shipping cost per case from Moscow to London is $3, to Berlin is $9, and to Paris is $11. The shipping cost per case from Athens to London is $10, to Berlin is $6, and to Paris is $4. Perform an analysis in order to determine how many cases will Charles ship an of the three factories to each of the three warehouses in the region per week while minimizing shipping costs. Prepare a report presenting the objectives, best possible solutions and recommendations. Include (but do not limit your discussion to) a consideration of the following: Management Science / BSA II / 2nd Semester AY 2019 – 2020 / Page 2 of ??? 1) Over the next 5 years the demand growth of each product increases to 10% yearly, would you recommend that Europe of Colgate's Palmolive Shampoo consider plant expansion at this time? 2) The Company wants to explore the possibility of satisfying some of the customer demand directly from the production plant. What are your recommendations to management to consider the direct plant to customer shipments? CASE VI. ASSIGNMENT MODEL Faye is the Division Head of Standard Chartered for North Africa. Three branches were just opened and she has to assign one Branch manager for each of the branches. She has shortlisted four candidates for the new positions and has to assign them based on minimum cost possible. The cost of assigning a manager to each of the three branches is determined. It will cost $11,000 to assign Irwin to Cairo, $20,000 to Dubai, and $15,000 to Algiers. It will cost $12,000 to assign Janet to Cairo, $13,000 to Dubai and $21,000 to Algiers. It will cost $18,000 to assign Karlo to Cairo, $14,000 to Dubai, and $22,000 to Algiers. It will cost $19,000 to assign Liza to Cairo, $17,000 to Dubai, and $16,000 to Algiers. Perform an analysis in order to determine which manager Faye should assign to what location. Prepare a report presenting the objectives, best possible solutions and recommendations. Include but do not limit your discussion to) a consideration of the following. 1) In case one of the assigned managers resigned from his/her post, what are your recommendations to management in replacing the resigned manager? 2) Each manager will be provided an annual increase of 10%, Would you recommend a new assignment for each manager? CASE VII. NETWORK MODEL Kenneth is the Capacity Planner of Manila waters and he is tasked to ensure the maximum amount of water flows from Water Pump A to Water Pump G. He has able to determine the capacity of the outflow and inflow of water from one pump to another in liters per second. The capacity figures are summarized below: Water Pump From To A B A D B C B E C D C E Capacity (Liters / Second) Out In 6 1 4 5 5 8 7 4 3 9 2 0 Management Science / BSA II / 2nd Semester AY 2019 – 2020 / Page 2 of ??? D E E F F F G G 1 0 8 9 7 6 2 3 Prepare a network design in order to determine the total capacity of the water flow. CASE VIII. MARKET SHARE Izza is the Internal Vice President of BPI and she wants to know the company's future market share compared to its competitors in the banking industry. She was able to determine the present number of clients each major player has at the start of the year and the movement of clients on a monthly basis from one company to another. The figures are summarized below No. of Clients BPI 400 January Next Month From BPI From BDO From RCBC Total 240 100 40 380 Savings Bank BDO 500 To 50 210 10 330 Total RCBC 100 110 130 50 290 1000 Total 400 500 100 1000 Perform an analysis in order to determine the company's market share in the long run. Prepare a report presenting the objectives, best possible solutions and recommendations. Include (but do not limit your discussion to) a consideration of the following: 1) Provide a recommendation on how to increase market share based on analysis performed, 2) Identify the company's future market share compared to its competitors in the banking industry using Gauss-Jordan Method. CASE IX. RECEIVABLE ACCOUNTS John is the Finance Director of Home cable and he wants to know the collection efficiency of the company. He was able to determine the actual collection and aging schedule of accounts receivable for the month of January and the month of February. The figures are summarized below: Bills ($) Status Paid Bad <1 month Total 1-3 month Management Science / BSA II / 2nd Semester AY 2019 – 2020 / Page 2 of ??? January Next Month From Paid From Bad From <1 month From 1-3 month Total 400 200 300 100 1000 Total To 400 0 150 0 200 0 0 0 50 0 0 100 400 200 300 50 30 0 20 100 600 230 50 120 1000 Perform an analysis in order to determine company’s actual paid and bad debt. Prepare a report presenting the objectives, best possible solutions and recommendations. Include (but do not limit your discussion to) a consideration of the following: 1) Provide a collection strategy to minimize receivables default, 2) In case the actual payment in the end does not realize, do you recommend to the management to record the uncollectible amount to bad debts? CASE X. INVENTORY MODEL Sonny, the Vice president of Longines Wristwatch wants to determine the most optimum inventory practice for the company. He was able to determine the demand and inventory costs needed in his analysis. The annual demand is 20,000 units. The cover set up of machinery for production is $40,000 per set up and the holding cost is $500 per unit per year. The production rate is 100 units per day and there are 250 working days per year. Perform an analysis in order to determine company's economic order quantity and production cycle. Prepare a report presenting the objectives, best possible solutions and recommendations. Include (but do not limit your discussion to) consideration of the following: 1) Assuming the production rate increases from 100 units per day to 120 units per day, what is the new economic order point? 2) Assume the annual demand increases to 20%, with the same scenario above, what is your management recommendation to identify the total inventory cost? Management Science / BSA II / 2nd Semester AY 2019 – 2020 / Page 2 of ???