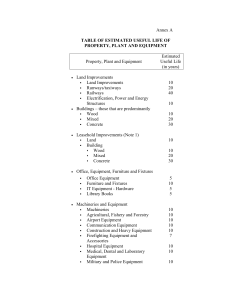

02 Week 2: Dimensional Analysis as applied to Fluid Machineries FME17 - Fluid Machineries Technological University of the Philippines Engr. Jay Mark P. Delos Reyes 02 Week 2 : Dimensional Analysis as applied to Fluid Machineries Similitude Geometric, kinematic, and dynamic qualities are defined in terms of the recognized definitions of similarity. Specifically, If all physical or bodily dimensions in all three axes (Cartesian) have the same linear ratio, a model and prototype are geometrically identical. For our objectives, all aspects are considered. It is necessary to "scale" flow directions, orientations, and even surface roughness qualities. Time similarity introduces components like velocity and acceleration, as in a fluid flow concern. Be aware that geometric similarity must exist for there to be similitude in a kinematic sense. Kinematic similarity leads to requirements in Reynolds number, Mach number, and perhaps Froude number in the context of fluid mechanics. The maintaining of Reynolds, Mach, and Froude numbers is often necessary. Furthermore, Weber and Cavitation numbers could be needed. When comparing the behavior of entities or machines of different "scales" (size, speed, fluid characteristics), it is often essential to maintain exact similarity. 02 Week 2 : Dimensional Analysis as applied to Fluid Machineries Turbo Machineries For Liquid • Pump Pump; adds energy to a fluid, resulting in an increase in pressure across the pump. 02 Week 2 : Dimensional Analysis as applied to Fluid Machineries Turbo Machineries For Liquid • Turbine Turbine; extracts energy from the fluid, resulting in a decrease in pressure across the turbine. 02 Week 2 : Dimensional Analysis as applied to Fluid Machineries Turbo Machineries For Gas • Fans Fans; Low pressure gradient, High volume flow rate. Examples include ceiling fans and propellers. 02 Week 2 : Dimensional Analysis as applied to Fluid Machineries Turbo Machineries For Gas • Blowers Blower; Medium pressure gradient, Low volume flow rate. Examples include centrifugal and squirrel-cage blowers found in Furnaces, leaf blowers and hair dryers. 02 Week 2 : Dimensional Analysis as applied to Fluid Machineries Turbo Machineries For Gas • Compressors Compressor; High pressure gradient, Low volume flow rate. Examples include air compressor for refrigerators and air conditioner 02 Week 2 : Dimensional Analysis as applied to Fluid Machineries Dimensionless Performance using Buckingham 𝝅 Theorem Buckingham 𝜋 Theorem – is a mathematical method that enables the development of a relationship between the model and the actual situation for a quantity of interest. If there are 𝑛 dimensional variable in a dimensionally homogenous equation, described by 𝑗 fundamentals dimensions, they may be grouped in 𝑘 = 𝑛 − 𝑗 dimensionless group. 𝜋 → 𝐷𝑖𝑚𝑒𝑛𝑠𝑖𝑜𝑛𝑙𝑒𝑠𝑠 𝐺𝑟𝑜𝑢𝑝 02 Week 2 : Dimensional Analysis as applied to Fluid Machineries Dimensionless Performance using Buckingham 𝝅 Theorem The relationship among the dimensionless group will be written: 𝑓 𝜋1 , 𝜋2 , 𝜋3 , … . . 𝜋𝑘 = 0 𝜋1 = 𝑓 𝜋2 , 𝜋3 , … . . 𝜋𝑘 𝜋2 = 𝑓 𝜋1 , 𝜋3 , … . . 𝜋𝑘 𝜋3 = 𝑓 𝜋1 , 𝜋2 , … . . 𝜋𝑘 } 𝑚𝑒𝑡ℎ𝑜𝑑𝑠 𝑜𝑓 𝑟𝑒𝑝𝑒𝑎𝑡𝑖𝑛𝑔 𝑣𝑎𝑟𝑖𝑎𝑏𝑙𝑒𝑠 02 Week 2 : Dimensional Analysis as applied to Fluid Machineries Example: Drag on Sphere 02 Week 2 : Dimensional Analysis as applied to Fluid Machineries Step 1: List the parameters in the problem Parameters Symbol Drag Force 𝐹 Sphere Diameter 𝐷 Fluid Viscosity 𝑣 Fluid Density 𝜌 Fluid Viscosity 𝜇 02 Week 2 : Dimensional Analysis as applied to Fluid Machineries Step 2: List the unit of parameters Parameters Symbol Unit Drag Force 𝐹 𝑘𝑔 𝑚 /𝑠 2 Sphere Diameter 𝐷 𝑚 Fluid Viscosity 𝑣 𝑚/𝑠 Fluid Density 𝜌 𝑘𝑔/𝑚3 Fluid Viscosity 𝜇 𝑘𝑔 𝑚𝑠 02 Week 2 : Dimensional Analysis as applied to Fluid Machineries Step 2: List the unit of parameters Parameters Symbol Unit Drag Force 𝐹 𝑘𝑔 𝑚 /𝑠 2 Sphere Diameter 𝐷 𝑚 Fluid Viscosity 𝑣 𝑚/𝑠 Fluid Density 𝜌 𝑘𝑔/𝑚3 Fluid Viscosity 𝜇 𝑘𝑔 𝑚𝑠 𝑚𝑎𝑠𝑠 𝑚 ≈ 𝑘𝑔 ; 𝐿𝑒𝑛𝑔𝑡ℎ 𝐿 ; 𝑡𝑖𝑚𝑒 (𝑡) 02 Week 2 : Dimensional Analysis as applied to Fluid Machineries Step 3: Calculate the Dimensionless Group Parameters Symbol Unit Repeating Variable (j) Drag Force 𝐹 𝑘𝑔 𝑚 /𝑠 2 𝑚𝐿𝑡 −2 Sphere Diameter 𝐷 𝑚 𝐿 Fluid Viscosity 𝑣 𝑚/𝑠 𝐿𝑡 −1 Fluid Density 𝜌 𝑘𝑔/𝑚3 𝑚𝐿−3 Fluid Viscosity 𝜇 𝑘𝑔 𝑚𝑠 𝑚𝐿−1 𝑡 −1 𝑚𝑎𝑠𝑠 𝑚 ≈ 𝑘𝑔 ; 𝐿𝑒𝑛𝑔𝑡ℎ 𝐿 ; } 𝑡𝑖𝑚𝑒 (𝑡) 𝑗=3 02 Week 2 : Dimensional Analysis as applied to Fluid Machineries Step 3: Calculate the Dimensionless Group Parameters Symbol Unit Repeating Variable (j) Drag Force 𝐹 𝑘𝑔 𝑚 /𝑠 2 𝑚𝐿𝑡 −2 Sphere Diameter 𝐷 𝑚 𝐿 𝑡ℎ𝑎𝑡 𝑚𝑒𝑎𝑛𝑠 𝑡ℎ𝑒𝑟𝑒 𝑎𝑟𝑒 2 𝐷𝑖𝑚𝑒𝑛𝑠𝑖𝑜𝑛𝑙𝑒𝑠𝑠 𝑔𝑟𝑜𝑢𝑝 −1 Fluid Viscosity 𝑣 𝑚/𝑠 Fluid Density 𝜌 𝑘𝑔/𝑚3 𝑚𝐿−3 Fluid Viscosity 𝜇 𝑘𝑔 𝑚𝑠 𝑚𝐿−1 𝑡 −1 𝑚𝑎𝑠𝑠 𝑚 ≈ 𝑘𝑔 ; 𝐿𝑒𝑛𝑔𝑡ℎ 𝐿 ; 𝐿𝑡 ∴𝑘 =𝑛−𝑗 = 5−3 𝑘=2 𝝅𝟏 𝑡𝑖𝑚𝑒 (𝑡) 𝑎𝑛𝑑 𝝅𝟐 02 Week 2 : Dimensional Analysis as applied to Fluid Machineries Step 4: Choose (𝑗) repeating variables (mass, geometry, & kinematics) ∴𝜌 𝐷 𝑣 Step 5: Construct the dimensionless group 𝜋1 = 𝜌𝑎1 𝐷𝑏1 𝑣 𝑐1 𝐹 𝜋2 = 𝜌𝑎2 𝐷𝑏2 𝑣 𝑐2 𝜇 For 𝜋1 𝜋1 = 𝜌𝑎1 𝐷𝑏1 𝑣 𝑐1 𝐹 𝑚0 𝐿0 𝑡 0 = 𝑚𝐿−3 𝑎1 𝐿 𝑚 0 = 𝑚 𝑎1 𝑚 0 = 𝑎1 + 1 𝑎1 = −1 𝑏1 𝐿𝑡 −1 𝑐1 𝑚𝐿𝑡 −2 02 Week 2 : Dimensional Analysis as applied to Fluid Machineries Step 5: Construct the dimensionless group 𝜋1 = 𝜌𝑎1 𝐷𝑏1 𝑣 𝑐1 𝐹 𝜋2 = 𝜌𝑎2 𝐷𝑏2 𝑣 𝑐2 𝜇 For 𝜋1 𝜋1 = 𝜌𝑎1 𝐷𝑏1 𝑣 𝑐1 𝐹 𝑚0 𝐿0 𝑡 0 = 𝑚𝐿−3 𝑎1 𝐿 𝑏1 𝐿𝑡 −1 𝑐1 𝑚𝐿𝑡 −2 𝐿0 = 𝐿−3𝑎1 𝐿𝑏1 𝐿𝑐1 𝐿 0 = −3𝑎1 + 𝑏1 + 𝑐1 + 1 → 𝑒𝑞. 1 𝑡 0 = 𝑡 −𝑐1 𝑡 −2 0 = −𝑐1 − 2 𝑐1 = −2 𝑒𝑞. 1 0 = −3𝑎1 + 𝑏1 + 𝑐1 + 1 0 = −3 −1 + 𝑏1 + −2 + 1 𝑏1 = −2 02 Week 2 : Dimensional Analysis as applied to Fluid Machineries Step 5: Construct the dimensionless group 𝜋1 = 𝜌𝑎1 𝐷𝑏1 𝑣 𝑐1 𝐹 𝑎1 = −1 𝑏1 = −2 𝜋1 = 𝜌𝑎1 𝐷𝑏1 𝑣 𝑐1 𝐹 𝜋1 = 𝜌−1 𝐷−2 𝑣 −2 𝐹 𝜋1 = 𝐹 𝜌 𝐷2 𝑣 2 𝑐1 = −2 02 Week 2 : Dimensional Analysis as applied to Fluid Machineries Step 5: Construct the dimensionless group 𝜋1 = 𝜌𝑎1 𝐷𝑏1 𝑣 𝑐1 𝐹 For 𝜋2 𝜋2 = 𝜌𝑎2 𝐷𝑏2 𝑣 𝑐2 𝜇 𝜋2 = 𝜌𝑎2 𝐷𝑏2 𝑣 𝑐2 𝜇 𝑚0 𝐿0 𝑡 0 = 𝑚𝐿−3 𝑚 0 = 𝑚 𝑎2 𝑚 0 = 𝑎2 + 1 𝑎2 = −1 𝑎2 𝐿 𝑏2 𝐿𝑡 −1 𝑐2 𝑚𝐿−1 𝑡 −1 𝑡 0 = 𝑡 −𝑐2 𝑡 −1 𝐿0 = 𝐿−3𝑎2 𝐿𝑏2 𝐿𝑐2 𝐿−1 0 = −𝑐2 − 1 0 = −3𝑎2 + 𝑏2 + 𝑐2 − 1 𝑐2 = −1 0 = −3 −1 + 𝑏2 − 1 − 1 𝑏2 = −1 02 Week 2 : Dimensional Analysis as applied to Fluid Machineries Step 5: Construct the dimensionless group 𝜋1 = 𝜌𝑎1 𝐷𝑏1 𝑣 𝑐1 𝐹 For 𝜋2 𝜋2 = 𝜌𝑎2 𝐷𝑏2 𝑣 𝑐2 𝜇 𝜋2 = 𝜌𝑎2 𝐷𝑏2 𝑣 𝑐2 𝜇 𝜋2 = 𝜌−1 𝐷−1 𝑣 −1 𝜇 𝜋2 = 𝜇 𝜌𝐷𝑣 02 Week 2 : Dimensional Analysis as applied to Fluid Machineries Step 5: Construct the dimensionless group 𝜋2 = 𝜇 ; 𝜌𝐷𝑣 ∴ 𝜋2 = 𝜋1 = 𝜋1 = 𝑓 𝜋2 1 𝑅𝑒 𝑅𝑒 = ; 𝜌𝐷𝑣 𝜇 𝑅𝑒 −1 𝐹 𝜌 𝐷2 𝑣 2 → 𝐹 = 𝑓 𝑅𝑒 𝜌 𝐷2 𝑣 2 02 Week 2 : Dimensional Analysis as applied to Fluid Machineries Dimensionless Performance using Buckingham 𝝅 Theorem There are several options for selecting the variables (for example, using the head H, pressure increase Ap, or usually pH to replace H) so that the analysis won't provide a single set of dimensionless variables. 𝑚2 𝑔𝐻 − ℎ𝑒𝑎𝑑 𝑣𝑎𝑟𝑖𝑎𝑏𝑙𝑒, 2 𝑠 𝑚3 𝑄 − 𝑣𝑜𝑙𝑢𝑚𝑒 𝑓𝑙𝑜𝑤 𝑟𝑎𝑡𝑒, 𝑠 2 𝑘𝑔 𝑚 𝑃 − 𝑝𝑜𝑤𝑒𝑟, 𝑊𝑎𝑡𝑡𝑠, 𝑠3 𝑟𝑎𝑑 −1 𝑁 − 𝑠𝑝𝑒𝑒𝑑, ,𝑠 𝑠 𝑓 𝑔𝐻, 𝑄, 𝑃, 𝑁, 𝐷, 𝜌, 𝜇, 𝐷 − 𝑑𝑖𝑎𝑚𝑒𝑡𝑒𝑟, 𝑚 𝑘𝑔 𝑚3 𝑘𝑔 𝜇 − 𝑓𝑙𝑢𝑖𝑑 𝑣𝑖𝑠𝑐𝑜𝑠𝑖𝑡𝑦, 𝑚𝑠 𝑑 − 𝑑𝑖𝑚𝑒𝑛𝑠𝑖𝑜𝑛𝑙𝑒𝑠𝑠 𝑑𝑖𝑎𝑚𝑒𝑡𝑒𝑟 𝑟𝑎𝑡𝑖𝑜𝑛 𝐷 𝜌 − 𝑓𝑙𝑢𝑖𝑑 𝑑𝑒𝑛𝑠𝑖𝑡𝑦, 𝑑 𝐷 02 Week 2 : Dimensional Analysis as applied to Fluid Machineries Dimensionless Performance using Buckingham 𝝅 Theorem There are several options for selecting the variables (for example, using the head H, pressure increase Ap, or usually pH to replace H) so that the analysis won't provide a single set of dimensionless variables. 𝑚2 𝑔𝐻 − ℎ𝑒𝑎𝑑 𝑣𝑎𝑟𝑖𝑎𝑏𝑙𝑒, 2 𝑠 𝑚3 𝑄 − 𝑣𝑜𝑙𝑢𝑚𝑒 𝑓𝑙𝑜𝑤 𝑟𝑎𝑡𝑒, 𝑠 2 𝑘𝑔 𝑚 𝑃 − 𝑝𝑜𝑤𝑒𝑟, 𝑊𝑎𝑡𝑡𝑠, 𝑠3 𝑟𝑎𝑑 −1 𝑁 − 𝑠𝑝𝑒𝑒𝑑, ,𝑠 𝑠 𝐷 − 𝑑𝑖𝑎𝑚𝑒𝑡𝑒𝑟, 𝑚 𝑘𝑔 𝑚3 𝑘𝑔 𝜇 − 𝑓𝑙𝑢𝑖𝑑 𝑣𝑖𝑠𝑐𝑜𝑠𝑖𝑡𝑦, 𝑚𝑠 𝑑 − 𝑑𝑖𝑚𝑒𝑛𝑠𝑖𝑜𝑛𝑙𝑒𝑠𝑠 𝑑𝑖𝑎𝑚𝑒𝑡𝑒𝑟 𝑟𝑎𝑡𝑖𝑜𝑛 𝐷 𝜌 − 𝑓𝑙𝑢𝑖𝑑 𝑑𝑒𝑛𝑠𝑖𝑡𝑦, The symbol d/D serves as a reminder that geometric similitude is imposed to ignore shape- or proportion-related issues. There are three fundamental units: time, length, and mass (𝑚 , 𝐿, 𝑎𝑛𝑑 𝑡 as before). The seven factors listed above can so be expected to be reduced to four. The following 𝜋 − 𝑝𝑟𝑜𝑑𝑢𝑐𝑡𝑠 are created by selecting 𝜌, 𝑁, 𝑎𝑛𝑑 𝐷 as primaries: 02 Week 2 : Dimensional Analysis as applied to Fluid Machineries 𝜋1 = 𝜋2 = 𝜋3 = 𝜋4 = 𝜌𝑎1 𝑁𝑏1 𝐷𝑐1 𝑄 𝜌𝑎2 𝑁𝑏2 𝐷𝑐2 𝜇 𝜌𝑎3 𝑁𝑏3 𝐷𝑐3 𝑔𝐻 𝜌𝑎4 𝑁𝑏4 𝐷𝑐4 𝑃 For 𝜋1 𝜋1 = 𝜌𝑎1 𝑁𝑏1 𝐷𝑐1 𝑄 𝑚0 𝐿0 𝑡 0 = 𝑚𝐿−3 𝑎1 𝑡 −1 𝑏1 𝐿 𝑐1 𝐿3 𝑡 −1 𝑚0 𝐿0 𝑡 0 = 𝑚𝑎1 𝐿−3𝑎1 𝑡 −1𝑏1 𝐿𝑐1 𝐿3 𝑡 −1 𝑚 0 = 𝑚 𝑎1 0 = 𝑎1 𝐿0 = 𝐿−3𝑎1 𝐿𝑐1 𝐿3 0 = −3𝑎1 + 𝑐1 + 3 0 = −3 0 + 𝑐1 + 3 𝑐1 = −3 𝑡 0 = 𝑡 −1𝑏1 𝑡 −1 0 = −𝑏1 − 1 𝑏1 = −1 02 Week 2 : Dimensional Analysis as applied to Fluid Machineries 𝜋1 = 𝜌𝑎1 𝑁𝑏1 𝐷𝑐1 𝑄 𝜋1 = 𝜌0 𝑁 −1 𝐷−3 𝑄 𝜋1 = For 𝜋2 𝜋2 = 𝜌𝑎2 𝑁𝑏2 𝐷𝑐2 𝜇 𝑚0 𝐿0 𝑡 0 = 𝑚𝐿−3 0 0 0 𝑚 𝐿 𝑡 𝑎2 𝑡 −1 𝑏2 𝑐2 𝐿 𝑎2 −3𝑎2 −1𝑏2 𝑐2 =𝑚 𝐿 𝑡 −1 −1 𝐿 𝑚𝐿 𝑡 𝑚0 = 𝑚𝑎2 +1 𝑎2 = −1 𝑚𝐿−1 𝑡 −1 𝑄 𝑁 𝐷3 𝐿0 = 𝐿−3𝑎2 𝐿𝑐2 𝐿−1 0 = −3𝑎2 + 𝑐2 − 1 0 = −3 −1 + 𝑐2 − 1 𝑐2 = −2 𝑡 0 = 𝑡 −1𝑏2 𝑡 −1 0 = −𝑏2 − 1 𝑏2 = −1 02 Week 2 : Dimensional Analysis as applied to Fluid Machineries 𝜋2 = 𝜌𝑎2 𝑣 𝑏2 𝐷𝑐2 𝜇 𝜋2 = 𝜌−1 𝑣 −1 𝐷−2 𝜇 𝜋2 = For 𝜋3 𝜋3 = 𝜌𝑎3 𝑁𝑏3 𝐷𝑐3 𝑔𝐻 𝑚0 𝐿0 𝑡 0 = 𝑚𝐿−3 0 0 0 𝑚 𝐿𝑡 𝑎3 𝑡 −1 𝑏3 𝐿 𝑐3 𝐿2 𝑡 −2 𝑎3 −3𝑎3 −1𝑏3 𝑐3 2 −2 =𝑚 𝐿 𝑡 𝑚0 = 𝑚𝑎3 𝑎3 = 0 𝐿 𝐿𝑡 𝜇 𝜌 𝑁 𝐷2 𝐿0 = 𝐿−3𝑎3 𝐿𝑐3 𝐿2 0 = −3𝑎3 + 𝑐3 + 2 0 = −3 0 + 𝑐3 + 2 𝑐3 = −2 𝑡 0 = 𝑡 −1𝑏3 𝑡 −2 0 = −𝑏3 − 2 𝑏3 = −2 02 Week 2 : Dimensional Analysis as applied to Fluid Machineries 𝜋3 = 𝜌𝑎3 𝑁𝑏3 𝐷𝑐3 𝑔𝐻 𝜋3 = 𝜌0 𝑁 −2 𝐷−2 𝑔𝐻 𝜋3 = For 𝜋4 𝜋4 = 𝜌𝑎4 𝑁𝑏4 𝐷𝑐4 𝑃 𝑚0 𝐿0 𝑡 0 = 𝑚𝐿−3 0 0 0 𝑚 𝐿𝑡 𝑎4 𝑡 −1 𝑏4 𝐿 𝑐4 𝑎4 −3𝑎4 −1𝑏4 𝑐4 =𝑚 𝐿 𝑡 𝑚0 = 𝑚𝑎4 +1 𝑎4 = −1 𝑚𝐿2 𝑡 −3 2 −3 𝐿 𝑚𝐿 𝑡 𝑔𝐻 𝑁 2 𝐷2 𝐿0 = 𝐿−3𝑎4 𝐿𝑐4 𝐿2 0 = −3𝑎4 + 𝑐4 + 2 0 = −3 −1 + 𝑐4 + 2 𝑐4 = −5 𝑡 0 = 𝑡 −1𝑏4 𝑡 −3 0 = −𝑏4 − 3 𝑏4 = −3 02 Week 1 : Dimensional Analysis as applied to Fluid Machineries 𝜋4 = 𝜌𝑎4 𝑁𝑏4 𝐷𝑐4 𝑃 𝜋4 = 𝜌−1 𝑁 −3 𝐷−5 𝑃 𝜋4 = 𝜋1 = 𝑄 𝑁 𝐷3 𝜋2 = 𝜇 𝜌 𝑁 𝐷2 𝑔𝐻 𝑁 2 𝐷2 𝑃 𝜋4 = 𝜌 𝑁 3𝐷5 𝜋3 = 𝑃 𝜌 𝑁 3 𝐷5 𝜙= 𝑄 𝑁 𝐷3 𝜌 𝑁 𝐷2 𝑅𝑒 = 𝜇 𝑔𝐻 𝜓= 2 2 𝑁 𝐷 𝑃 𝜉= 𝜌 𝑁 3𝐷5 𝐹𝑙𝑜𝑤 𝐶𝑜𝑒𝑓𝑓𝑖𝑐𝑖𝑒𝑛𝑡 𝑅𝑒𝑦𝑛𝑜𝑙𝑑𝑠 𝑁𝑢𝑚𝑏𝑒𝑟 𝐻𝑒𝑎𝑑 𝐶𝑜𝑒𝑓𝑓𝑖𝑐𝑖𝑒𝑛𝑡 𝑃𝑜𝑤𝑒𝑟 𝐶𝑜𝑒𝑓𝑓𝑖𝑐𝑖𝑒𝑛𝑡 02 Week 2 : Dimensional Analysis as applied to Fluid Machineries As a description of turbomachine performance. This is really compact. For convenience. Recall the concept of the efficiency defined as. 𝜙= 𝑄 𝑁 𝐷3 𝑔𝐻 𝑁 2 𝐷2 𝑃 𝜉= 𝜌 𝑁 3 𝐷5 𝜓= 𝜂𝑇 = 𝑊𝑎𝑡𝑒𝑟 𝑃𝑜𝑤𝑒𝑟 𝑀𝑜𝑡𝑜𝑟 𝑃𝑜𝑤𝑒𝑟 𝜂𝑇 = 𝜌𝑄𝑔𝐻 𝑃𝑚 𝜌 𝜙𝑁𝐷3 𝜓𝑁 2 𝐷2 𝜂𝑇 = 𝜉𝜌 𝑁 3 𝐷5 𝜂𝑇 = 𝜙𝜓 𝜉 02 Week 2 : Dimensional Analysis as applied to Fluid Machineries Example: A test on a 1.2m fan diameter operating a speed of 1200 rpm and pressure 𝑚3 of 1kPa at a capacity of 70 . Determine the flow coefficient, head coefficient, power 𝑠 coefficient and the efficiency of the machinery. The power input required is 90𝑘𝑊. Estimate the power of if the fan were operated at 1000 rpm and the diameter of the fan is 35 inches. Assume normal operation at point of maximum efficiency in each case. 02 Week 2 : Dimensional Analysis as applied to Fluid Machineries Example: A test on a 1.2m fan diameter operating a speed of 1200 rpm and pressure 𝑚3 of 1kPa at a capacity of 70 . Determine the flow coefficient, head coefficient, power 𝑠 coefficient and the efficiency of the machinery. The power input required is 90𝑘𝑊. Estimate the power of if the fan were operated at 1000 rpm and the diameter of the fan is 35 inches. Assume normal operation at point of maximum efficiency in each case. Given: 𝐷1 = 1.2 𝑚 𝑄1 = 70 𝑚3 /𝑠 𝑁1 = 1200 𝑟𝑝𝑚 𝑃1 = 90 𝑘𝑊 𝜙 =? 𝜓 =? 𝜉 =? 𝜂𝑇 = ? Solution: 𝜙= 𝑄 𝑄1 = 𝑁 𝐷3 𝑁1 𝐷1 3 70 𝑚3 /𝑠 𝜙= 𝑟𝑒𝑣 2𝜋 𝑟𝑎𝑑 1 𝑚𝑖𝑛 (1200 𝑥 𝑥 ) 1.2𝑚 𝑚𝑖𝑛 1 𝑟𝑒𝑣 60 𝑠𝑒𝑐 𝜙 = 0.322 3 02 Week 2 : Dimensional Analysis as applied to Fluid Machineries Example: A test on a 1.2m fan diameter operating a speed of 1200 rpm and pressure 𝑚3 of 1kPa at a capacity of 70 . Determine the flow coefficient, head coefficient, power 𝑠 coefficient and the efficiency of the machinery. The power input required is 90𝑘𝑊. Estimate the power of if the fan were operated at 1000 rpm and the diameter of the fan is 35 inches. Assume normal operation at point of maximum efficiency in each case. Given: 𝐷1 = 1.2 𝑚 3 𝑄1 = 70 𝑚 /𝑠 𝑁1 = 1200 𝑟𝑝𝑚 𝑃1 = 90 𝑘𝑊 𝜙 =? 𝜓 =? 𝜉 =? 𝜂𝑇 = ? Solution: 𝜓= 𝑔𝐻 𝑁 2 𝐷2 ; 𝑝𝑟𝑒𝑠𝑠𝑢𝑟𝑒 = 1𝑘𝑃𝑎 = 1000𝑃𝑎 𝑝𝑟𝑒𝑠𝑠𝑢𝑟𝑒 𝑟𝑖𝑠𝑒 = ∆𝑝 = 𝛾𝐻 = 𝜌𝑔𝐻 𝑔𝐻 = ∆𝑝 𝜌 𝑁 1 2 1 𝑘𝑔 𝑚 (1000 𝑃𝑎 𝑥 𝑚 𝑥 ) 𝑝𝑟𝑒𝑠𝑠𝑢𝑟𝑒 1𝑘𝑃𝑎 1 𝑁 𝑠 2 𝜓= = 𝜌𝑎𝑖𝑟 𝑁1 2 𝐷1 2 (1.2 𝑘𝑔 ) (1200 𝑟𝑒𝑣 𝑥 2𝜋 𝑟𝑎𝑑 𝑥 1 𝑚𝑖𝑛 )2 1.2𝑚 𝑚𝑖𝑛 1 𝑟𝑒𝑣 60 𝑠𝑒𝑐 𝑚3 = 0.037 2 02 Week 2 : Dimensional Analysis as applied to Fluid Machineries Example: A test on a 1.2m fan diameter operating a speed of 1200 rpm and pressure 𝑚3 of 1kPa at a capacity of 70 . Determine the flow coefficient, head coefficient, power 𝑠 coefficient and the efficiency of the machinery. The power input required is 90𝑘𝑊. Estimate the power of if the fan were operated at 1000 rpm and the diameter of the fan is 35 inches. Assume normal operation at point of maximum efficiency in each case. Given: 𝐷1 = 1.2 𝑚 𝑄1 = 70 𝑚3 /𝑠 𝑁1 = 1200 𝑟𝑝𝑚 Solution: 𝑃 𝑃1 𝜉= = 𝜌 𝑁 3 𝐷5 𝜌𝑎𝑖𝑟 𝑁1 2 𝐷1 2 𝜙 =? 𝜓 =? 1 𝑘𝐽 1000 𝐽 1 𝑁 𝑚 1 𝑘𝑔 𝑚 𝑥 𝑥 𝑥 1𝐽 1𝑘𝑊 𝑠 1 𝑘𝐽 1 𝑁 𝑠2 𝜉= 𝑘𝑔 𝑟𝑒𝑣 2𝜋 𝑟𝑎𝑑 1 𝑚𝑖𝑛 3 (1.2 3 ) (1200 𝑥 𝑥 ) 1.2𝑚 𝑚𝑖𝑛 1 𝑟𝑒𝑣 60 𝑠𝑒𝑐 𝑚 𝜉 =? 𝜂𝑇 = ? 𝜉 = 0.015 𝑃1 = 90 𝑘𝑊 90𝑘𝑊 𝑥 5 02 Week 2 : Dimensional Analysis as applied to Fluid Machineries Example: A test on a 1.2m fan diameter operating a speed of 1200 rpm and pressure 𝑚3 of 1kPa at a capacity of 70 . Determine the flow coefficient, head coefficient, power 𝑠 coefficient and the efficiency of the machinery. The power input required is 90𝑘𝑊. Estimate the power of if the fan were operated at 1000 rpm and the diameter of the fan is 35 inches. Assume normal operation at point of maximum efficiency in each case. Given: 𝐷1 = 1.2 𝑚 𝑄1 = 70 𝑚3 /𝑠 𝑁1 = 1200 𝑟𝑝𝑚 𝑃1 = 90 𝑘𝑊 𝜙 =? 𝜓 =? 𝜉 =? 𝜂𝑇 = ? Solution: 𝜙𝜓 𝜉 0.322 0.037 𝜂𝑇 = 0.015 𝜂𝑇 = 𝜂 𝑇 = 0.794 ≈ 0.8 02 Week 2 : Dimensional Analysis as applied to Fluid Machineries Example: A test on a 1.2m fan diameter operating a speed of 1200 rpm and pressure of 1kPa at a 𝑚3 capacity of 70 𝑠 . Determine the flow coefficient, head coefficient, power coefficient and the efficiency of the machinery. The power input required is 90𝑘𝑊. Estimate the power of if the fan were operated at 1000 rpm and the diameter of the fan is 35 inches. Assume normal operation at point of maximum efficiency in each case. Given: 𝐷1 = 1.2 𝑚 𝑄1 = 70 𝑚3 /𝑠 𝑁1 = 1200 𝑟𝑝𝑚 𝑃1 = 90 𝑘𝑊 𝜙 = 0.322 𝜓 = 0.037 𝜉 = 0.015 𝜂 𝑇 = 0.8 Solution: 𝑃2 =? If, 𝑁2 = 1000 𝑟𝑝𝑚 ; 𝐷2 = 35 𝑖𝑛𝑐ℎ𝑒𝑠 𝜉 = 𝜉1 = 𝜉2 = 0.015 𝜉2 = 𝑃2 2 𝜌𝑎𝑖𝑟 𝑁2 𝐷2 2 𝑃2 = 𝜉2 𝜌𝑎𝑖𝑟 𝑁2 2 𝐷2 2 02 Week 2 : Dimensional Analysis as applied to Fluid Machineries Example: A test on a 1.2m fan diameter operating a speed of 1200 rpm and pressure of 1kPa at a 𝑚3 capacity of 70 𝑠 . Determine the flow coefficient, head coefficient, power coefficient and the efficiency of the machinery. The power input required is 90𝑘𝑊. Estimate the power of if the fan were operated at 1000 rpm and the diameter of the fan is 35 inches. Assume normal operation at point of maximum efficiency in each case. Given: 𝐷1 = 1.2 𝑚 𝑄1 = 70 𝑚3 /𝑠 𝑁1 = 1200 𝑟𝑝𝑚 𝑃1 = 90 𝑘𝑊 𝜙 = 0.322 𝜓 = 0.037 𝜉 = 0.015 𝜂 𝑇 = 0.8 Solution: 𝑃2 =? If, 𝑁2 = 1000 𝑟𝑝𝑚 ; 𝐷2 = 35 𝑖𝑛𝑐ℎ𝑒𝑠 𝜉 = 𝜉1 = 𝜉2 = 0.015 𝑃2 = 𝜉2 𝜌𝑎𝑖𝑟 𝑁2 2 𝐷2 2 𝑘𝑔 𝑟𝑒𝑣 2𝜋 𝑟𝑎𝑑 1 𝑚𝑖𝑛 3 1 𝑓𝑜𝑜𝑡 1𝑚 𝑃2 = 0.015 (1.2 3 ) (1000 𝑥 𝑥 ) 35 𝑖𝑛 𝑥 𝑥 𝑚 𝑚𝑖𝑛 1 𝑟𝑒𝑣 60 𝑠𝑒𝑐 12 𝑖𝑛 3.28 𝑓𝑡 𝐽 𝑃2 = 11,492.7 ≈ 11,492.7𝑊𝑎𝑡𝑡𝑠 𝑠 5 02 Week 2 : Dimensional Analysis as applied to Fluid Machineries Example: A centrifugal air compressor delivers 32,850 𝑐𝑓𝑚 of air with a pressure change of 4 𝑝𝑠𝑖. The compressor is driven by an 800 ℎ𝑝 motor at 3550 𝑟𝑝𝑚. a.) What is the overall efficiency? b.) What will the flow and pressure rise be at 3000 𝑟𝑝𝑚? c.) Estimate the impeller diameter 02 Week 2 : Dimensional Analysis as applied to Fluid Machineries Example: A centrifugal air compressor delivers 32,850 𝑐𝑓𝑚 of air with a pressure change of 4 𝑝𝑠𝑖. The compressor is driven by an 800 ℎ𝑝 motor at 3550 𝑟𝑝𝑚. a.) What is the overall efficiency? b.) What will the flow and pressure rise be at 3000 𝑟𝑝𝑚? c.) Estimate the impeller diameter Given: 𝑄1 = 32850 𝑓𝑡 3 /𝑠 ∆𝑝 = 4 𝑝𝑠𝑖 𝑁1 = 3550 𝑟𝑝𝑚 𝑃1 = 800 ℎ𝑝 𝑘𝑔 𝜌𝑎𝑖𝑟 = 1.2 3 𝑚 Solution: a.) 𝜂 𝑇 =? 𝜂𝑇 = 𝑊𝑎𝑡𝑒𝑟 𝑃𝑜𝑤𝑒𝑟 𝑀𝑜𝑡𝑜𝑟 𝑃𝑜𝑤𝑒𝑟 𝜂𝑇 = 𝑄1 𝛾𝐻 𝑃1 𝜂𝑇 = ; ∆𝑝 = 𝛾𝐻 𝑄1 ∆𝑝 = 𝑃1 𝑓𝑡 3 32,850 𝑚𝑖𝑛 𝑙𝑏 144 𝑖𝑛2 4 2𝑥 𝑖𝑛 1 𝑓𝑡 2 550 𝑙𝑏 𝑓𝑡 𝑠 800 ℎ𝑝 𝑥 1 ℎ𝑝 1 𝑚𝑖𝑛 60 𝑠𝑒𝑐 = 0.717 02 Week 2 : Dimensional Analysis as applied to Fluid Machineries Example: A centrifugal air compressor delivers 32,850 𝑐𝑓𝑚 of air with a pressure change of 4 𝑝𝑠𝑖. The compressor is driven by an 800 ℎ𝑝 motor at 3550 𝑟𝑝𝑚. a.) What is the overall efficiency? b.) What will the flow and power be at 3000 𝑟𝑝𝑚? c.) Estimate the impeller diameter Solution: Given: 𝑄1 = 32850 𝑓𝑡 3 /𝑠 ∆𝑝 = 4 𝑝𝑠𝑖 𝑁1 = 3550 𝑟𝑝𝑚 𝑃1 = 800 ℎ𝑝 𝜌𝑎𝑖𝑟 = 1.2 𝑘𝑔 𝑚3 b.) 𝑄2 𝑎𝑛𝑑 𝑃2 𝑎𝑡 3000 𝑟𝑝𝑚 𝑄2 =? 𝜙 = 𝜙1 = 𝜙2 = 𝑄 𝑄1 𝑄2 = = 𝑁 𝐷3 𝑁1 𝐷1 3 𝑁2 𝐷2 3 Assuming same diameter; 𝐷1 = 𝐷2 𝑄1 𝑄2 = 𝑁1 𝑁2 𝑄1 𝑄2 = 𝑁2 𝑁1 32850 𝑓𝑡 3 /𝑠 = 3000 𝑟𝑝𝑚 3550 𝑟𝑝𝑚 = 27,760.56 𝑓𝑡 3 /𝑠 02 Week 2 : Dimensional Analysis as applied to Fluid Machineries Example: A centrifugal air compressor delivers 32,850 𝑐𝑓𝑚 of air with a pressure change of 4 𝑝𝑠𝑖. The compressor is driven by an 800 ℎ𝑝 motor at 3550 𝑟𝑝𝑚. a.) What is the overall efficiency? b.) What will the flow and power be at 3000 𝑟𝑝𝑚? c.) Estimate the impeller diameter Solution: Given: 𝑄1 = 32850 𝑓𝑡 3 /𝑠 ∆𝑝 = 4 𝑝𝑠𝑖 𝑁1 = 3550 𝑟𝑝𝑚 𝑃1 = 800 ℎ𝑝 𝜌𝑎𝑖𝑟 = 1.2 𝑘𝑔 𝑚3 b.) 𝑄2 𝑎𝑛𝑑 𝑃2 𝑎𝑡 3000 𝑟𝑝𝑚 𝑃2 =? 𝜉 = 𝜉1 = 𝜉2 = 𝑃1 𝜌𝑎𝑖𝑟 𝑁1 2 𝐷1 2 = 𝑃2 𝜌𝑎𝑖𝑟 𝑁2 2 𝐷2 2 Assuming same diameter; 𝐷1 = 𝐷2 𝑃1 𝑃2 = 𝑁1 2 𝑁2 2 𝑃2 = 𝑁2 2 𝑃1 𝑁1 2 = 3000 𝑟𝑝𝑚 2 800 ℎ𝑝 3550 𝑟𝑝𝑚 2 = 571.32 ℎ𝑝 02 Week 2 : Dimensional Analysis as applied to Fluid Machineries Example: A centrifugal air compressor delivers 32,850 𝑐𝑓𝑚 of air with a pressure change of 4 𝑝𝑠𝑖. The compressor is driven by an 800 ℎ𝑝 motor at 3550 𝑟𝑝𝑚. a.) What is the overall efficiency? b.) What will the flow and power be at 3000 𝑟𝑝𝑚? c.) Estimate the impeller diameter Solution: Given: 𝑄1 = 32850 𝑓𝑡 3 /𝑠 ∆𝑝 = 4 𝑝𝑠𝑖 𝑁1 = 3550 𝑟𝑝𝑚 𝑃1 = 800 ℎ𝑝 𝜌𝑎𝑖𝑟 = 1.2 𝑘𝑔 𝑚3 c.) 𝐷 =? 𝑄 = 𝐴𝑣 ;𝐴 = 𝜋 2 𝐷 𝜋𝐷𝑁 4 𝜋 2 𝐷3 𝑁 𝑄= 4 𝜋 2 𝐷 4 ; 𝑣 = 𝜋𝐷𝑁 𝑄= 𝑟𝑒𝑣 2𝜋𝑟𝑎𝑑 1𝑚𝑖𝑛. 𝜋 2 𝐷1 3 3550 𝑥 𝑥 𝑓𝑡 3 𝜋 2 𝐷1 3 𝑁1 𝑚𝑖𝑛 1 𝑟𝑒𝑣 60 𝑠𝑒𝑐 = 32850 = 𝑄1 = 𝑠 4 4 02 Week 2 : Dimensional Analysis as applied to Fluid Machineries Example: A centrifugal air compressor delivers 32,850 𝑐𝑓𝑚 of air with a pressure change of 4 𝑝𝑠𝑖. The compressor is driven by an 800 ℎ𝑝 motor at 3550 𝑟𝑝𝑚. a.) What is the overall efficiency? b.) What will the flow and power be at 3000 𝑟𝑝𝑚? c.) Estimate the impeller diameter Solution: Given: 𝑄1 = 32850 𝑓𝑡 3 /𝑠 ∆𝑝 = 4 𝑝𝑠𝑖 𝑁1 = 3550 𝑟𝑝𝑚 𝑃1 = 800 ℎ𝑝 𝜌𝑎𝑖𝑟 = 1.2 𝑘𝑔 𝑚3 c.) 𝐷 =? 𝑄 = 𝐴𝑣 ;𝐴 = 𝜋 2 𝐷 4 ; 𝑣 = 𝜋𝐷𝑁 𝜋 2 𝐷 𝜋𝐷𝑁 4 𝜋 2 𝐷3 𝑁 𝑄= 4 𝑄= 𝐷1 = 3.29 𝑓𝑡 ≈ 40 𝑖𝑛𝑐ℎ𝑒𝑠 02 Week 2 : Dimensional Analysis as applied to Fluid Machineries Seatwork: A commercially available fan has BEP (Best Efficiency Point) performance of 𝑄 = 350 𝑓𝑡 3 /𝑠 ,∆𝑝 = 100 𝑙𝑏𝑓 /𝑓𝑡 2 .and 𝜂 𝑇 = 0.86 .Density is ρ = 0.00233 𝑠𝑙𝑢𝑔𝑠/𝑓𝑡 3 ,and speed and size are given as 𝑁 = 485 𝑠 −1, and 𝐷 = 2.25 𝑓𝑡, respectively. a.) At what speed will the fan generate 120 𝑙𝑏𝑓 /𝑓𝑡 2 ? b.) What will the flow rate be at that speed? c.) Estimate the fan efficiency at that speed. d.) Calculate the required motor horsepower. Seatwork: Assume that the power required to drive a pump is a function of the fluid density (𝜌), the rotational speed (𝑁), the impeller diameter (𝐷), and the volume flow rate (𝑄). Use dimensional analysis to show that the power coefficient is a function of the flow 𝑄 coefficient 𝑃′ = 𝑓(ϕ) and ϕ = 3. 𝑁𝐷