The Architects Studio Companion Rules of Thumb for Preliminary Design 5th Edition by Edward Allen Joseph Iano

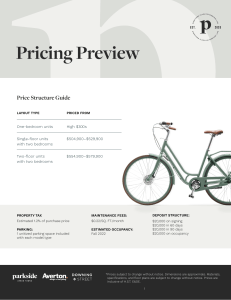

advertisement