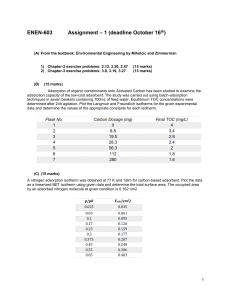

See discussions, stats, and author profiles for this publication at: https://www.researchgate.net/publication/327976532 A Tunable Template-Assisted Hydrothermal Synthesis of Hydroxysodalite Zeolite Nanoparticles Using Various Aliphatic Organic Acids for the Removal of Zinc(II) Ions from Aqueous Medi... Article in Journal of Inorganic and Organometallic Polymers and Materials · September 2018 DOI: 10.1007/s10904-018-0982-9 CITATIONS READS 36 233 3 authors: Ehab A. Abdelrahman 55 PUBLICATIONS 1,492 CITATIONS Dina Tolan Menoufia University 19 PUBLICATIONS 431 CITATIONS SEE PROFILE SEE PROFILE Mostafa Y Nassar Benha University 77 PUBLICATIONS 2,219 CITATIONS SEE PROFILE Some of the authors of this publication are also working on these related projects: Novel isatinoxime molybdenum and chromium complexes: Synthesis, spectroscopic, and thermal characterization View project Cobalt oxide/iron oxide nanocomposites and their applications View project All content following this page was uploaded by Ehab A. Abdelrahman on 30 September 2018. The user has requested enhancement of the downloaded file. Journal of Inorganic and Organometallic Polymers and Materials https://doi.org/10.1007/s10904-018-0982-9 A Tunable Template-Assisted Hydrothermal Synthesis of Hydroxysodalite Zeolite Nanoparticles Using Various Aliphatic Organic Acids for the Removal of Zinc(II) Ions from Aqueous Media Ehab A. Abdelrahman1 · Dina A. Tolan2 · Mostafa Y. Nassar1 Received: 11 August 2018 / Accepted: 24 September 2018 © Springer Science+Business Media, LLC, part of Springer Nature 2018 Abstract Hydroxysodalite zeolite nanoparticles with different crystallite sizes (37.61–64.88 nm) were synthesized using a hydrothermal method in the absence and presence of low-cost aliphatic organic acids as templates. The templates used were oxalic acid dihydrate, tartaric acid, citric acid monohydrate, succinic acid, maleic acid, and ethylenediaminetetraacetic acid (EDTA). The synthesized nanoparticles were characterized using HR-TEM, FE-SEM, FT-IR, and XRD techniques. The hydroxysodalite zeolite synthesized using ethylenediaminetetraacetic acid (EDTA) has the smallest crystallite size (37.61 nm) whereas the template free one has the largest crystallite size (64.88 nm). The synthesized nanoparticles could be effectively applied to purify polluted water from the zinc(II) ions, and the maximum adsorption capacity was 8.53 mg/g. Kinetic study displayed that the adsorption process of zinc(II) ions obeyed pseudo-second-order, intra-particle diffusion, liquid film diffusion, and pore diffusion models whereas the rate determining step of the adsorption is only controlled by the pore diffusion model. In addition, equilibrium study showed that the adsorption process fitted well with the Langmuir isotherm model compared to the Freundlich isotherm model. Besides, thermodynamic study showed that the adsorption process is exothermic, spontaneous, and chemisorption. Moreover, desorption and reusability study revealed that there is a slight decrease in both of the % removal and adsorption capacity of the hydroxysodalite adsorbent with progressing five cycles. Hence, we can infer that this new hydroxysodalite adsorbent can possibly be utilized repeatedly without sacrificing its adsorption capacity towards zinc(II) ions. Keywords Hydrothermal method · Hydroxysodalite nanoparticles · Organic templates · Zinc(II) ions · Adsorption 1 Introduction Most countries in the world have been concerned about water pollution induced by metal ions such as zinc due to their direct impact on humans via causing many serious diseases [1–3]. Zinc is one of the most dangerous toxins that are widespread and exist in most vital processes in small amounts and it has many industrial applications. Zinc contaminants have serious health effects on humans as zinc can affect the digestive system, kidney, liver and cause many diseases such as lethargy, * Ehab A. Abdelrahman ehab.abdelrahman@fsc.bu.edu.eg; dr.ehabsaleh@yahoo.com 1 Chemistry Department, Faculty of Science, Benha University, Benha 13518, Egypt 2 Department of Chemistry, Faculty of Science, Menoufia University, Shebin El‑Kom 32512, Egypt diarrhea, depression, nausea, etc. [4–6]. It is necessary to remove such contaminants from polluted water to preserve our environment. Various adsorbents have been proposed for the removal of zinc contaminants from water such as bicopolymer membranes [7], graphene oxide nanosheets decorated with highly crystalline polyaniline nanofibers [8], Purolite C-100 MH resin [9], Amberlite IR-120 resin [10], and sodium dodecyl sulfate coated magnetite nanoparticles [11]. The most common disadvantage of these previous adsorbents that limit their usage is that they are highly expensive. On the other hand, the adsorption method was widely spread compared to other methods such as extraction, membrane techniques, electrodialysis, and chemical precipitation. This can be explained on the basis that the majority of those methods involve expensive processes, complex methodology, and/or in some cases entail the irreversible use of chemicals, which consequently cause secondary pollution [12]. Moreover, disposal problem, which results from the large capital requirement for electricity and the 13 Vol.:(0123456789) Journal of Inorganic and Organometallic Polymers and Materials production of large amounts of sludge, is considered as one of the major limitations of these common methods. In addition, adsorption is more effective because of its simplicity, high efficiency, fastness, regeneration, low concentrations removal, economic, and environmental friendliness [13]. So, finding new safe and cheap adsorbents for metals ions decontamination is still a critical demand. Therefore, many researchers have been focused on the production of zeolite nano-adsorbents, such as mordenite, analcime, and hydroxysodalite owing to their excellent porosity, high surface area, and great removing ability toward inorganic and organic pollutants [14–24]. Zeolites have a three-dimensional structure comprising of tetrahedral units (­ Al2O3 and S ­ iO2) connected by shared oxygen atoms. In zeolites, some of ­Si4+ are replaced by ­Al3+ results in a net negative charge which is remunerated by alkali and alkaline-earth metal cations such as ­Na+ within the structure [14, 15]. Hence, zeolites possess great ion exchange properties with metals. In addition, the efficiency of the adsorption process can be controlled by studying different issues such as kinetics, reusability, equilibrium, pH, and thermodynamic [25–29]. Furthermore, various studies reported that morphology and crystallinity of the zeolites play an important role in the efficiency of zeolites in adsorption, separation, and ion exchange. Therefore, controlling the synthetic parameters is important in nano-zeolite synthesis for both industrial applications and fundamental study [14–24]. There are several strategies to synthesize zeolites with different morphologies including use of organic compounds as templates during the synthesis process. In this light, the organic molecule templates can act as capping agents to prevent aggregation of particles during synthesis which control both of crystallite size and morphology of the produced zeolites [30]. However, most of the reported organic templates were expensive and/or have complex structures such as tetrapropylammonium hydroxide, tetrapropylammonium bromide, cetyl trimethylammonium bromide, etc. Moreover, the produced products required high temperatures in order to remove the applied organic templates to get porous and pure zeolite products [12, 31]. Therefore, in the current project, the effect of low-cost aliphatic organic acids as templates such as oxalic acid dihydrate, tartaric acid, citric acid monohydrate, succinic acid, maleic acid, and ethylenediaminetetraacetic acid Fig. 1 XRD patterns of the samples synthesized after 6 h (A), 12 h (B), 18 h (C), and 24 h (D) 13 Journal of Inorganic and Organometallic Polymers and Materials (EDTA) on both crystallinity and morphology of hydroxysodalite zeolite products was studied. In addition, the synthesized hydroxysodalite using EDTA was used as a nano-adsorbent for the removal of zinc(II) ions from water. Moreover, various factors influencing the adsorption process have been explored. 2 Experimental 2.1 Chemicals The used chemicals are aluminum isopropoxide (Al[OCH(CH 3) 2] 3), sodium metasilicate pentahydrate ­(Na2SiO3·5H2O), sodium hydroxide (NaOH), oxalic acid dihydrate ­(HO2CCO2H·2H2O), tartaric acid ­(C4H6O6), citric acid monohydrate ­(C6H8O7⋅H2O), succinic acid ­(C4H6O4), maleic acid ­(C 4H 4O 4), ethylenediaminetetraacetic acid (EDTA) ­(C10H16N2O8), hydrochloric acid (HCl), potassium chloride (KCl), ethylenediaminetetraacetic acid tetrasodium salt dihydrate (­ Na4–EDTA) ((NaOOCCH2)2NCH2C H2N(CH2COONa)2·2H2O), and zinc sulfate heptahydrate ­(ZnSO4·7H2O). All the chemicals were purchased from Sigma-Aldrich and used as received. 2.2 Synthesis of Hydroxysodalite Nanoparticles 10.00 g of sodium metasilicate pentahydrate (47.14 mmol) was dissolved in 25 mL distilled water (solution A). 5.00 g of aluminum isopropoxide (24.48 mmol) was dissolved in 25 mL of 5 M sodium hydroxide solution (5.00 g, 125.00 mmol) (solution B). Then, solution B was added dropwise to solution A with continuous stirring at 650 rpm for 1 h. After that, 25 mL of 2.50 mmol organic acid solution in 1.5 M sodium hydroxide solution (1.50 g, 37.50 mmol) [oxalic acid dihydrate (0.32 g), tartaric acid (0.38 g), citric acid monohydrate (0.53 g), succinic acid (0.30 g), maleic acid (0.29 g), or EDTA (0.73 g)] was dropwise added to the previous mixture with continuous stirring at 650 rpm for 2 h. For more understanding of the effect of the selected organic molecules as template, template free zeolite nanoparticles Fig. 2 XRD patterns of the samples synthesized in the absence of organic acids (A) and in the presence of oxalic acid dihydrate (B), tartaric acid (C), or maleic acid (D) 13 Journal of Inorganic and Organometallic Polymers and Materials Fig. 3 XRD patterns of the samples synthesized in the presence of citric acid monohydrate (A), succinic acid (B), or EDTA (C) Table 1 Effect of different organic acids on the produced phase and average crystallite size Organic acid Produced phases Chemical formula Without template Oxalic acid Hydroxysodalite Hydroxysodalite Aluminum silicate Hydroxysodalite Hydroxysodalite Hydroxysodalite Sodium aluminum silicate hydrate Hydroxysodalite Hydroxysodalite Na4Al3Si3O12 (OH) Na4Al3Si3O12 (OH) Al2 ­(SiO4) O Na4Al3Si3O12 (OH) Na4Al3Si3O12 (OH) Na4Al3Si3O12 (OH) (Na2O)1.31Al2O3 ­(SiO2)2.01(H2O) 1.65 Na4Al3Si3O12 (OH) Na4Al3Si3O12 (OH) Tartaric acid Citric acid Succinic acid EDTA Maleic acid were synthesized using a similar procedure for comparison studies.. The produced gel was transferred to 100 mL Teflon lined stainless autoclave then hydrothermally treated at 150 °C for 18 h. Moreover, the precipitate was filtered, 13 JCPDS card Average crystal size (nm) 00-011-0401 00-011-0401 01-089-0890 00-011-0401 00-011-0401 00-011-0401 01-075-2318 64.88 40.75 00-011-0401 00-011-0401 37.61 41.85 47.55 44.77 43.31 washed thoroughly several times with distilled water, dried at 60 °C for 24 h, and calcined at 550 °C for 2 h to remove organic templates. Journal of Inorganic and Organometallic Polymers and Materials 2.3 Adsorption of Zinc(II) Ions from Aqueous Media 0.20 g of adsorbent (hydroxysodalite zeolite synthesized using EDTA template) was magnetically stirred at 650 rpm with 50 mL of Zn(II) solution (50 mg/L), in 250 mL conical flasks. Small volume portions were taken out of the conical flasks at various times (5–100 min), centrifuged at 2500 rpm, and measured for Zn(II) ions using the atomic absorption spectrophotometer. Besides, the influence of pH (2–8), which was adjusted using 0.1 M HCl or NaOH, on the removal of Zn(II) ions was investigated with 50 mL of Zn(II) solution (50 mg/L) at the acquired equilibrium time (40 min). In addition, the influence of initial Zn(II) ions concentration (25–200 mg/L) was investigated at the acquired equilibrium time (40 min) and optimum pH 8. Besides, the influence of temperature (298–323 K) was also studied using 50 mL of Zn(II) solution (50 mg/L) at the acquired equilibrium time (40 min) and optimum pH 8. In order to determine the point of zero charge ­(pHpzc) of the hydroxysodalite adsorbent; 0.50 g adsorbent was mixed with 50 mL KCl solutions (0.1 M) of different initial pH values (­ pHi) (2–11) then the mixtures were magnetically stirred at 650 rpm for 24 h. After that, the liquid phases were separated by centrifugation at 2500 rpm and the final pH values (­ pHf) of the supernatants were determined using pH meter. Finally, p­ Hf values are presented as a function of p­ Hi values. The p­ Hpzc is the ­pHf level where a common plateau was obtained [32]. The reusability of the hydroxysodalite adsorbent was tested five times as the following; Zn(II)-loaded adsorbent sample was added to 50 mL N ­ a4–EDTA (0.2 M) as a desorption medium then magnetically stirred at 650 rpm for 3 h at 25 °C. After that, the separated adsorbent was magnetically stirred at 650 rpm with 50 mL of Zn(II) solution (50 mg/L). Then, the aqueous phase was separated from the adsorbent by centrifugation the mixture at 2500 rpm and the concentration of Zn(II) ions in the liquid phase was determined (first cycle). The previous reusability steps were repeated four times (second-fifth cycle). The adsorption capacity ­(Qt, mg/g) of the hydroxysodalite adsorbent at time t was measured using Eq. (1). ( ) Qt = Ci − Ct V∕m (1) Also, the % removal of Zn(II) ions (% removal) at time t was estimated using Eq. (2). ( ) % Removal = Ci − Ct 100∕Ci (2) where m (g) is the mass of hydroxysodalite adsorbent, V (L) is the volume of Zn(II) solution, ­Ct is the residual Fig. 4 EDS spectra of the samples synthesized in the absence of organic acids (A) and in the presence of oxalic acid dihydrate (B), tartaric acid (C), or maleic acid (D) 13 Journal of Inorganic and Organometallic Polymers and Materials concentration of Zn(II) at time t, and C ­ i (mg/L) is the initial concentration of Zn(II). In addition, the adsorption capacity of the hydroxysodalite adsorbent at equilibrium ­(Qe, mg/g) was measured using Eq. (3). ( ) Qe = Ci − Ce V∕m (3) Moreover, the % removal of Zn(II) ions (% removal) at equilibrium was calculated using Eq. (4) ( ) % Removal = Ci − Ce 100∕Ci (4) where C e (mg/L) is the concentration of Zn(II) at equilibrium. 2.4 Physicochemical Measurements XRD patterns of the synthesized hydroxysodalite samples were performed using an 18 kW diffractometer (Bruker; model D8 Advance) equipped with monochromated Cu K ­ α radiation (λ) 1.54178 Å. FT-IR spectra of the synthesized hydroxysodalite samples were recorded using KBr disk on a Nicolet iSio FT-IR spectrophotometer in the 4000–400 cm−1 region. The elemental analysis and the morphology of hydroxysodalite samples were investigated with an ultra-high Table 2 EDS spectra of the synthesized hydroxysodalite nanoparticles Organic acid Without template Oxalic acid Tartaric acid Citric acid Succinic acid EDTA Maleic acid Weight % of the elements Si% Al% Na% O% 17.99 18.34 17.23 19.42 18.49 26.49 18.91 15.86 15.99 15.31 16.57 16.72 22.80 16.15 16.23 16.27 16.54 16.18 16.00 13.95 16.47 49.92 49.40 50.92 47.82 48.80 36.76 48.47 resolution FE-SEM SU8020 microscope equipped with an energy-dispersive X-ray spectrometer SEM-EDX (Hitachi, Tokyo, Japan). The HR-TEM images of the hydroxysodalite samples were collected employing a transmission electron microscope (TEM-2100) at a speeding voltage of 200 kV. X-ray electron spectroscopy was carried out using a X-ray phototoelectron spectrometer (ESCA-5600, Japan) with a 200 W Mg K (Al K) radiation source; the diameter of X-ray beam was 0.8 mm while the analysis diameter was 1 mm. The samples were adhered on an indium sheet. The Zn(II) Fig. 5 EDS spectra of the samples synthesized in the presence of citric acid monohydrate (A), succinic acid (B), or EDTA (C) 13 Journal of Inorganic and Organometallic Polymers and Materials removal investigation was achieved utilizing atomic absorption spectrophotometer (Shimadzu, model AA-7000F). 3 Results and Discussion 3.1 XRD, EDS, and XPS Studies Firstly, the effect of hydrothermal time (6, 12, 18, and 24 h) was studied as shown in Fig. 1A–D, respectively. The results showed that after 6 or 12 h a mixture of zeolite 4A (Cubic; JCPDS No. 01-071-1557; space group: Pm-3m) and hydroxysodalite (Cubic; JCPDS No. 00-011-0401; space group: P-43n) was formed. Also, after 18 or 24 h only hydroxysodalite was formed. It was noticed that when reaction time increased from 18 to 24 h, the crystallite size increased from 64.88 to 72.57 nm, respectively. Therefore, 18 h was chosen as the optimum time for the subsequent hydrothermal experiments. The characteristic peaks of hydroxysodalite at 2θ = 14, 20, 22.38, 24.50, 28.50, 31.90, 34.90, 37.90, 43.20, 48.16, 52.50, 56.67, 60.77, 62.50, 64.50, and 68.37 can be attributed to lattice plans of (110), (200), (210), (211), (220), (310), (222), (321), (411), (332), (510), (521), (530), (600), (611), and (541), respectively. It is worth mentioning that the peaks of zeolite 4A were marked by an asterisk as shown in Fig. 1A, B. The characteristic peaks of zeolite 4A at 2θ = 7.20, 10.19, 12.49, 16.15, 21.72, 26.18, 27.19, 30.02, 40.25, 44.28, 50.43, 54.43, and 58.76 can be attributed to lattice plans of (100), (110), (111), (210), (300), (320), (321), (410), (521), (600), (631), (641), and (650), respectively [33, 34]. Thereafter, the influence of using different organic templates on the hydrothermal treatment of interest was investigated. Figure 2A–D presents XRD patterns of the template-free zeolite sample (A) as well as organic template zeolite samples (B–D) in the presence of oxalic acid dihydrate, tartaric, and maleic acid, respectively. Figure 3A–C displays the XRD patterns of the samples synthesized in Fig. 6 FT-IR spectra of the samples synthesized in the absence of organic acids (A) and in the presence of oxalic acid dihydrate (B), tartaric acid (C), or maleic acid (D) 13 Journal of Inorganic and Organometallic Polymers and Materials Fig. 7 FT-IR spectra of the samples synthesized in the presence of citric acid monohydrate (A), succinic acid (B), or EDTA (C) Table 3 FT-IR spectra of the synthesized hydroxysodalite nanoparticles Organic acid T–O–T bending ­(cm−1) Peak no 1 Internal symmetric stretching of T–O (­ cm−1) Peak no 2 External symmetric stretching of T-O ­(cm− 1) Peak no 3 Internal asymmetric stretching of T–O (­ cm−1) Peak no 4 External asymmetric stretching of T–O (­ cm−1) Peak no 5 Bending vibration of adsorbed water(cm−1) Peak no 6 Stretching vibration of adsorbed water ­(cm−1) Peak no 7 Without organic template Oxalic acid Tartaric acid Citric acid Succinic acid EDTA Maleic acid 442 629 710 990 1476 1650 3464 440 440 445 443 434 434 627 628 627 629 630 629 695 709 715 705 708 711 993 989 993 992 988 987 1474 1474 1473 1479 1483 1479 1635 1645 1637 1636 1655 1654 3440 3446 3431 3430 3525 3446 the presence of citric acid monohydrate, succinic acid, and EDTA, respectively. The XRD results showed that the samples which were synthesized in the absence of organic acids and in the presence of tartaric, citric acid monohydrate, maleic acid, and EDTA consist of hydroxysodalite (Cubic; JCPDS No. 00-011-0401; space group: P-43n) as shown in 13 Table 1 [35, 36]. On the other hand, when oxalic acid was used, the obtained product was a composite of hydroxysodalite (Cubic; JCPDS No. 00-011-0401; space group: P-43n) and aluminum silicate (Orthorhombic; JCPDS No. 01-0890890; space group: Cmcm) as shown in Table 1 [36]. It is worth mentioning that the peaks of aluminum silicate were Journal of Inorganic and Organometallic Polymers and Materials marked by an asterisk as shown in Fig. 2B. The characteristic peaks of aluminum silicate at 2θ = 19, 27.9, 33.98, 34.86, 40.1, and 51 can be attributed to lattice plans of (020), (110), (112), (023), (131), and (170), respectively. Besides, when succinic acid was used, the product was a composite of hydroxysodalite (Cubic; JCPDS No. 00-011-0401; space group: P-43n) and sodium aluminum silicate hydrate (Hexagonal; JCPDS No. 01-075-2318; space group: P63) as shown in Table 1 [37]. It is noteworthy that an asterisk as shown in Fig. 3B marked the peaks of sodium aluminum silicate hydrate. The characteristic peaks of sodium aluminum silicate hydrate at 2θ = 19, 27.8, 34, and 41.07 can be attributed to lattice plans of (101), (121), (131), and (122), respectively. The crystallite size (D, nm) of the synthesized samples was calculated utilizing Scherrer equation (Eq. 5): (5) where β, θB, and λ are the full width at half maximum (FWHM) of the XRD diffraction peaks, the diffraction angle according to Bragg formula, and wavelength of the X-ray radiation, respectively [12, 19, 20]. The results showed that the crystallite size of the samples which were synthesized in the absence of organic acids and the presence of oxalic acid dihydrate, tartaric acid, citric acid monohydrate, succinic acid, maleic acid, and EDTA were 64.88, 40.75, 47.55, 44.77, 43.31, 41.85 and 37.61 nm, respectively, as shown in Table 1. Hence, the organic acids have a significant effect D = 0.9𝜆∕β cos θB on the produced hydroxysodalite nanoparticles through controlling their crystallite sizes. This controlling behavior because the organic acid templates work as capping agents preventing the aggregation of the nanoparticles which leads to a decrease in crystallite size [30]. Figure 4A–D presents EDS patterns of the samples synthesized in the absence of organic acids and in the presence of oxalic acid dihydrate, tartaric, and maleic acid, respectively. Figure 5A–C shows EDS patterns of the samples synthesized in the presence of citric acid monohydrate, succinic acid, and EDTA, respectively. The results revealed that all the samples are composed of only Si, Al, Na, and O elements, as shown in Table 2. In addition, XPS of the sample synthesized using EDTA as an illustrative example confirmed that the sample is composed of only Si, Al, Na, and O elements, as shown in Fig. 9D. This supports the high purity of the prepared zeolite products using the proposed method. 3.2 FT‑IR Study Figure 6A–D presents FT-IR spectra of the synthesized samples: the template-free zeolite sample (A) as well as organic template zeolite samples (B–D) in the presence of oxalic acid dihydrate, tartaric, and maleic acid, respectively. Figure 7A–C depicts the FT-IR spectra of the samples which were synthesized in the presence of citric acid monohydrate, succinic acid, and EDTA, respectively. The Fig. 8 FE-SEM images of the samples synthesized in the absence of organic acids (A) and in the presence of oxalic acid dihydrate (B), tartaric acid (C), or maleic acid (D) 13 Journal of Inorganic and Organometallic Polymers and Materials results exhibited 7 characteristic bands for each prepared sample, as outlined in Table 3. The bands appeared at ca. 434–445 cm−1 is probably due to T–O–T bending, T=Si and/or Al [12, 19, 20]. Besides, the bands appeared at about 627–630 cm−1 can assigned to an internal symmetric stretching of T–O bond [12, 19, 20]. In addition, the bands observed in the range of 695–715 cm−1 can be attributed to an external symmetric stretching of T–O bond [12, 19, 20]. Moreover, the bands observed at ca. 987–993 cm−1 can be due to an internal asymmetric stretching of T–O bond [12, 19, 20]. Besides, the bands noticed at ca. 1473–1483 cm−1 can be assigned to an external asymmetric stretching of T–O bond [12, 19, 20]. The bands appeared in the range of 3430–3525 and 1635–1655 cm −1 can be attributed to the stretching and bending vibration of H–O–H molecules adsorbed on the surface of samples, respectively [12, 19, 20, 38–47]. 3.3 FE‑SEM and HR‑TEM Studies Figure 8A–D exhibited FE-SEM images of the prepared samples: the template-free zeolite sample (A) as well as organic template zeolite samples (B–D) in the presence of oxalic acid dihydrate, tartaric acid, and maleic acid, respectively. Figure 9A–C revealed the FE-SEM images of the samples synthesized in the presence of citric acid monohydrate, succinic acid, and EDTA, respectively. The results exhibit that the samples which were synthesized in the absence of organic acids and the presence of oxalic acid dihydrate, tartaric, maleic acid, citric acid monohydrate, succinic acid, and EDTA are composed of spherical shapes with an average size of ca. 2.5, 3.38, 3.36, 4.06, 3.72, 2.91, and 3.76 µm, respectively. Figure 10A–D represents HR-TEM images of the synthesized samples: the template-free zeolite sample (A) as well as organic template zeolite samples (B–D) in the presence of oxalic acid dihydrate, tartaric acid, and maleic acid, respectively. Figure 11A–C displayed the HR-TEM images of the samples synthesized in the presence of citric acid monohydrate, succinic acid, and EDTA, respectively. The results showed that the prepared samples are composed of spherical and irregular shaped particles with an average diameter of ca. 68.85, 43.24, 49.35, 41.97, 46.65, 41.82, and 33.20 nm, respectively, which coincides with the obtained XRD data. Fig. 9 FE-SEM images of the samples synthesized in the presence of citric acid monohydrate (A), succinic acid (B), or EDTA (C) 13 Journal of Inorganic and Organometallic Polymers and Materials 3.4 Adsorption of Zinc(II) Ions from Aqueous Media Using Hydroxysodalite Nanostructure The adsorption of zinc(II) ions on the hydroxysodalite sample which was synthesized using EDTA has been investigated. This sample was chosen over the other hydroxysodalite samples because it has the smallest crystallite size and the largest surface area. Different effects such as time (kinetic study), pH, initial zinc(II) concentration (equilibrium study), temperature (thermodynamic study), and desorption and reusability have been studied. 3.4.1 Kinetics Study Figure 12A and B represents the influence of contact time on the % removal of zinc(II) ions (% removal) and adsorption capacity of the adsorbent ­(Qt), respectively. The results clarified that both % removal and Q ­ t increased significantly until it achieved ca. 58.70% and 7.34 mg/g after 40 min, respectively. These values did not change markedly when time increased because of saturation of the active sites of the adsorbent i.e. the equilibrium state. Thus, the optimum equilibrium time for zinc(II) removal was chosen to be 40 min. Based on the results, some kinetic models [12, 19, 20] were applied such as pseudo-first-order (Eq. 6), pseudo-secondorder (Eq. 7), and intra-particle diffusion (Eq. 8). ( ) log Qe − Qt = log Qe − K1 t∕2.303 (6) ( ) ( ) t∕Qt = 1∕K2 Qe 2 + 1∕Qe t (7) (8) where ­k1 (1/min) is the pseudo-first-order rate constant of the adsorption process, ­k2 (g/mg min) is the pseudosecond-order rate constant of the adsorption process, ­kint (mg/(g min0.5)) is internal diffusion constant, Q ­ t (mg/g) is the quantity of the adsorbed zinc(II) ions at time t (min), ­Qe (mg/g) is the quantity of the adsorbed zinc(II) ions at Qt = Kint t0.5 + C Fig. 10 HR-TEM images of the samples synthesized in the absence of organic acids (A) and in the presence of oxalic acid dihydrate (B), tartaric acid (C), or maleic acid (D) 13 Journal of Inorganic and Organometallic Polymers and Materials Fig. 11 HR-TEM images of the samples synthesized in the presence of citric acid monohydrate (A), succinic acid (B), or EDTA (C) Fig. 12 The influence of contact time on the % removal of zinc(II) ions (A) and on the adsorption capacity of the adsorbent (B) 13 Journal of Inorganic and Organometallic Polymers and Materials Fig. 13 Pseudo-first-order (A), pseudo-second-order (B), and intra-particle diffusion (C) models Table 4 Parameters of the applied kinetic models of the adsorption process of zinc(II) ions on the hydroxysodalite adsorbent Kinetic model Constants Pseudo first order Qe (mg/g) 12.78 Qe (mg/g) 10.59 C (mg/g) 0.171 Co (mg/g) 42.66 Kext (1/min) 0.119 α (mg/g min) 0.542 Pseudo second order Intra particle diffusion Spahn and Schlunder Iqbal et al. Bangham K1 (1/min) 0.119 K2 (g/mg min) 5.4E−3 Kint (mg/(g min0.5)) 1.234 Kext (1/min) 0.019 R2 0.907 Ko (g/mg min) 1.06E−3 R2 0.907 R2 0.991 R2 0.982 R2 0.965 R2 0.989 13 Journal of Inorganic and Organometallic Polymers and Materials Fig. 14 Spahn and Schlunder (A), Iqbal et al. (B), and Bangham’s (C) models equilibrium, and C (mg/g) is the thickness of boundary layer. Figure 13A–C presents the pseudo-first-order, pseudo-second-order, and intra-particle diffusion models, respectively. In addition, all constants for the three models were calculated and presented in Table 4. The results showed that the adsorption process complies with the pseudo-second-order model. This is because of the closer of the value of the correlation coefficient of pseudo-second-order model (­ R2 = 0.991) compared to that of the pseudo-first-order (­ R2 = 0.907). The intra-particle diffusion model (i.e. inner diffusion process) expects that the main rate-controlling process is diffusion inside the particles. Besides, the zero intercepts of the plot of ­Qt versus t­0.5 demonstrates the legitimacy of this model. In practice, the plot of Q ­ t versus ­t0.5 gave linear 2 fitting ­(R = 0.994) which did not pass through the origin. This demonstrated that intra-particle diffusion isn’t the main 13 rate-controlling mechanism of zinc(II) ions adsorption onto the hydroxysodalite sample but it is also controlled by other mechanisms including film diffusion (diffusion process of adsorbate to the surface of adsorbent from the liquid solution i.e. outer diffusion process) and pore diffusion [12, 19, 20]. In order to ponder those mechanisms, Spahn and Schlunder model (Eq. 9), Iqbal et al. model (Eq. 10), and Bangham’s model (Eq. 11) were applied [12, 19, 20]. ln Ct = ln Ci − Kext t − ln (1 − F) = Kext t [ ] log R = log Ko m∕2.303 V + α log t −1 (9) (10) (11) where ­Kext ­(min ) is external diffusion constant, ­Ct (mg/L) is the concentration of zinc(II) ions at time t, F is the fraction Journal of Inorganic and Organometallic Polymers and Materials showing that liquid film diffusion had a predominant impact in the primary stage of the adsorption process. Furthermore, the time required for liquid film diffusion was 40 min. Also, good linear relationships (­ R2 = 0.965) between − ln (1 − F) and t do not pass through the origin indicating that liquid film diffusion had an overwhelming influence in the primary stage of the adsorption process. Besides, the plot of log R versus logt was found to be linear with an excellent correlation coefficient (­ R2 = 0.989) indicating that the rate determining step is mainly governed by the pore diffusion mechanism. 3.4.2 pH Study We have studied the effect of pH of the zinc(II) solution on the adsorption of this ion on the as-prepared zeolite product, due to the importance of this factor [48]. Figure 15A and B displays the influence of pH on the % removal of zinc(II) ions (% removal) and adsorption capacity of the adsorbent (Q), respectively. The point of zero charge of the adsorbent (­ pHpzc) was estimated to be 6.25, as shown in Fig. 15C. The results showed that as the pH value increased from 2 to 8, the % removal and Q increased from 8.64 to 66% and from 1.08 to 8.25 mg/g, respectively. Hence, the optimum pH value was 8. This can be clearly explained on the basis of p­ H pzc of the hydroxysodalite adsorbent. If pH of zinc(II) solution < p­ Hpzc, the surface of the hydroxysodalite adsorbent is surrounded by H ­ + ions which in turn repelled with positive zinc(II) ions leading to a decrease in the % removal and Q values. Besides, if pH of zinc(II) solution > ­pHpzc, the surface of the hydroxysodalite adsorbent is surrounded by ­OH− ions which in turn attract positively charged zinc(II) ions leading to an enhancement in the % removal and Q values [32]. 3.4.3 Equilibrium Study Fig. 15 The influence of pH on the % removal of zinc(II) ions (A) and adsorption capacity of the adsorbent (B). The plot of p­ Hf values versus ­pHi values (C) attainment of equilibrium and it is calculated using Eq. (12). (α (mg/g min) < 1) and ­Ko (g/mg min) are the Bangham constants, and R is a parameter calculated using Eq. (13) F = Qt ∕Qe [ ( )] R = log Ci ∕ Ci − Qt m (12) (13) Figure 14A–C presents Spahn and Schlunder, Iqbal et al. model, and Bangham’s models. In addition, all constants for the three models were calculated and tabulated in Table 4. The results showed that good linear relationships ­(R2 = 0.962) between ­lnCt and t observed in the initial 40 min Figure 16A and B represents the influence of the initial zinc(II) concentration on the % removal of zinc(II) ions (% removal) and adsorption capacity of the adsorbent ­(Qe), respectively. The results showed that as the initial zinc(II) concentration reduced the % removal increased. In addition, as the zinc(II) concentration increased from 25 to 200 mg/L the ­Qe increased from 6.25 to 11.44 mg/g. Moreover, the experimental adsorption results were investigated by fitting to Langmuir (Eq. 14) and Freundlich (Eq. 15) as shown in Fig. 16C and D, respectively [12, 19, 20]. ( ) ( ) Ce ∕Qe = 1∕bQm + Ce ∕Qm (14) (15) where ­Ce (mg/L) is the remained zinc(II) concentration in the solutions at the equilibrium, ­Qe (mg/g) is the quantity ln Qe = ln Kf + (1∕n) ln Ce 13 Journal of Inorganic and Organometallic Polymers and Materials Fig. 16 The influence of the initial zinc(II) concentration on the % removal of zinc(II) ions (A) and on the adsorption capacity of the adsorbent (B). Langmuir (C) and Freundlich (D) models of the adsorbed zinc(II) ions at the equilibrium, Q ­ m (mg/g) is the maximum sorption capacity, K ­ f (mg/g) is the FreunTable 5 Constants of the applied isotherm models of the adsorption process of zinc(II) ions on the hydroxysodalite adsorbent Adsorption model Constants Langmuir Qm (mg/g) 8.53 Qm (mg/g) 9.63 Freundlish b (L/mg) 1.37 Kf (mg/g)(L/mg)1 / n 5.09 R2 0.994 R2 0.982 dlich constant, b (L/mg) is the Langmuir constant, and 1/n is the heterogeneity factor. All constants for the two models were calculated and tabulated in Table 5. Besides, ­Qm can be calculated from Freundlich isotherm, using Eq. (16), as revealed by Halsey [12, 19, 20]. ( )1∕n Qm = Kf Ci 13 (16) The results showed that the adsorption process fitted well with the Langmuir isotherm more than Freundlich. This is because of the value of the correlation coefficient of Langmuir model ­(R2 = 0.994) is closer to unity compared to that of Freundlish ­(R2 = 0.982). In addition, the maximum adsorption capacity calculated from Langmuir model was found to be 8.53 mg/g which was closer to the experimentally calculated value. 3.4.4 Thermodynamic Study Figure 17A and B depicts the influence of the temperature on the % removal of zinc(II) ions (% removal) and adsorption capacity of the adsorbent ­(QT), respectively. The results showed that as the temperature increased the % removal and ­Qe decreased. The % removal values at 298, 313, and 323 K were found to be ca. 65.6, 49.2, and 30.0%, respectively. And, ­Qe values at 298, 313, and 323 K were estimated to be ca. 8.25, 6.15, and 3.75 mg/g, respectively. Thus, the results proved the exothermic nature of the adsorption process of interest. This can be attributed to the extra ordinary ability of zinc(II) ions Journal of Inorganic and Organometallic Polymers and Materials change in free energy (ΔG°) were determined using Eqs. (17) and (18) [12, 19, 20]. lnKd = (ΔS◦ ∕R) − (ΔH◦ ∕RT) (17) ΔG◦ = ΔH◦ − TΔS◦ (18) where R (KJ/mol K) is gas constant, T (K) is temperature, and ­Kd (L/g) is distribution co-efficient which is calculated from Eqs. (19) or (20). [ ] Kd = % Removal∕(100 − % Removal) V∕m (19) (20) Figure 17C represents the relation between ­lnKd and 1/T. The results of thermodynamic parameters were tabulated in Table 6. The results showed that the adsorption process of zinc(II) ions on the hydroxysodalite sample is exothermic and spontaneous (feasible) process due to the obtained negative ΔH° and ΔG° values, respectively. Besides, the adsorption process is chemisorption because the calculated ΔH° value was found to be − 46.475 kJ/mol [12, 19, 20]. Kd = Qe ∕Ce 3.4.5 Desorption and Reusability Study Figure 18A and B presents the effect of repeated adsorption/ desorption cycle number for zinc(II) ions on the % removal of zinc(II) ions (% removal) and adsorption capacity of the adsorbent ­(Qe), respectively. The results showed that with progressing cycles there is a slight decrease in both of the % removal and adsorption capacity of the adsorbent. Hence, this promising hydroxysodalite adsorbent can possibly be utilized repeatedly without sacrificing its adsorption capacity towards zinc(II) ions. 4 Conclusions Fig. 17 The influence of the temperature on the % removal of zinc(II) ions (A) and on the adsorption capacity of the adsorbent (B). The plot of ln ­Kd versus 1/T (C) Table 6 Thermodynamic parameters of the adsorption of zinc(II) ions on the hydroxysodalite adsorbent Temperature (K) ∆G° (KJ/mol) ∆S° (KJ/molK) ∆H° (KJ/mol) 298 313 323 − 95.049 − 97.494 − 99.124 0.163 – – − 46.475 – – to be desorbed and got away to the liquid phase at higher temperatures [12, 19, 20]. Thermodynamic constants, for example, change in the entropy (ΔS°), change in enthalpy (ΔH°), and In synopsis, hydroxysodalite zeolite nanoparticles were successfully synthesized by means of a hydrothermal in the absence and presence of low-cost aliphatic organic acids as templates: oxalic acid dihydrate, tartaric acid, citric acid monohydrate, succinic acid, maleic acid, and ethylenediaminetetraacetic acid (EDTA). The XRD results showed that, using the organic templates decreases the crystallite size of the hyroxysodalite zeolite nanoparticles by 34% (average 42.64 nm) compared with template free zeolite nanoparticles (64.88 nm). In addition, the nanozeolites synthesized with EDTA template gave the smallest crystallite size (37.61 nm) compared to the others. This indicates that the selected organic acids templates greatly affect the crystallite size of the synthesized zeolite nanoparticles. The zeolite nanostructure prepared using EDTA template was chosen over the other samples for further adsorption studies because 13 Journal of Inorganic and Organometallic Polymers and Materials Fig. 18 The effect of repeated adsorption/ desorption cycle number for zinc(II) ions on the % removal of zinc(II) ions (A) and on the adsorption capacity of the adsorbent (B) of its lowest crystallite size and highest surface area. This zeolite product revealed great adsorption efficiency toward the removal of zinc(II) ions from water (Q = 8.25 mg/g, % removal = 66%). The kinetic study showed that the experimental adsorption data fitted well with pseudo-second-order, intra-particle diffusion, liquid film diffusion, and pore diffusion models whereas the rate determining step was governed by the pore diffusion model. Besides, equilibrium study indicates that the adsorption process follows Langmuir isotherm model. The maximum adsorption capacity calculated using the Langmuir model was found to be ca. 8.53 mg/g. In addition, the adsorption process is exothermic and spontaneous because of the obtained negative ΔH° and ΔG° values, respectively. Moreover, the adsorption process is chemisorption because the ΔH° value is estimated to be ca. − 46.48 kJ/mol. Acknowledgements The authors sincerely thank Dr “Mai Maize” for helping them in performing some analysis such as FE-SEM, EDX, and XPS in Japan. References 1. S.Y. Lee, H.J. Choi, Persimmon leaf bio-waste for adsorptive removal of heavy metals from aqueous solution. J. Environ. Manage. 209, 382–392 (2018) 2. P.A. Kobielska, A.J. Howarth, O.K. Farha, S. Nayak, Metal– organic frameworks for heavy metal removal from water. Coord. Chem. Rev. 358, 92–107 (2018) 3. C. Sarkar, J.K. Basu, A.N. Samanta, Synthesis of mesoporous geopolymeric powder from LD slag as superior adsorbent for Zinc(II) removal. Adv. Powder Technol. 29, 1142–1152 (2018) 4. N. Ghasemi, M. Ghasemi, S. Moazeni, P. Ghasemi, N.S. Alharbi, V.K. Gupta, S. Agarwal, I.V. Burakova, A.G. Tkachev, Zn(II) removal by amino-functionalized magnetic nanoparticles: kinetics, isotherm, and thermodynamic aspects of adsorption. J. Ind. Eng. Chem. 62, 302–310 (2018) 13 5. S. Mnasri Ghnimi, N. Frini-Srasra, A comparison of single and mixed pillared clays for zinc and chromium cations removal. Appl. Clay Sci. 158, 150–157 (2018) 6. İ Kara, D. Yilmazer, S.T. Akar, Metakaolin based geopolymer as an effective adsorbent for adsorption of zinc(II) and nickel(II) ions from aqueous solutions. Appl. Clay Sci. 139, 54–63 (2017) 7. P. Cristian, P. Violeta, R. Anita-Laura, I. Raluca, E. Alexandrescu, S. Andrei, I.-E. Daniela, M.A. Raluca, M. Cristina, C.A. Ioana, Removal of zinc ions from model wastewater system using bicopolymer membranes with fumed silica. J. Water Process Eng. 8, 1–10 (2015) 8. M. Ramezanzadeh, M. Asghari, B. Ramezanzadeh, G. Bahlakeh, Fabrication of an efficient system for Zn ions removal from industrial wastewater based on graphene oxide nanosheets decorated with highly crystalline polyaniline nanofibers (GO-PANI): experimental and ab initio quantum mechanics approaches. Chem. Eng. J. 337, 385–397 (2018) 9. O. Abdelwahab, N.K. Amin, E.S.Z. El-Ashtoukhy, Removal of zinc ions from aqueous solution using a cation exchange resin. Chem. Eng. Res. Des. 91, 165–173 (2013) 10. P.E. Franco, M.T. Veit, C.E. Borba, G.d.C. Gonçalves, M.R. Fagundes-Klen, R. Bergamasco, E.A. da Silva, P.Y.R. Suzaki, Nickel(II) and zinc(II) removal using Amberlite IR-120 resin: ion exchange equilibrium and kinetics. Chem. Eng. J. 221, 426–435 (2013) 11. M. Adeli, Y. Yamini, M. Faraji, Removal of copper, nickel and zinc by sodium dodecyl sulphate coated magnetite nanoparticles from water and wastewater samples. Arab. J. Chem. 10, S514– S521 (2017) 12. M.Y. Nassar, E.A. Abdelrahman, A.A. Aly, T.Y. Mohamed, A facile synthesis of mordenite zeolite nanostructures for efficient bleaching of crude soybean oil and removal of methylene blue dye from aqueous media. J. Mol. Liq. 248, 302–313 (2017) 13. H.A. Sani, M.B. Ahmad, M.Z. Hussein, N.A. Ibrahim, A. Musa, T.A. Saleh, Nanocomposite of ZnO with montmorillonite for removal of lead and copper ions from aqueous solutions. Process Saf. Environ. Prot. 109, 97–105 (2017) 14. Y. Yuan, L. Wang, H. Liu, P. Tian, M. Yang, S. Xu, Z. Liu, Facile preparation of nanocrystal-assembled hierarchical mordenite zeolites with remarkable catalytic performance. Chin. J. Catal. 36, 1910–1919 (2015) 15. L. Zhang, A.N.C. van Laak, P.E. de Jongh, K.P. de Jong, Synthesis of large mordenite crystals with different aspect ratios. Microporous Mesoporous Mater. 126, 115–124 (2009) Journal of Inorganic and Organometallic Polymers and Materials 16. M.M. Mohamed, T.M. Salama, I. Othman, I.A. Ellah, Synthesis of high silica mordenite nanocrystals using o-phenylenediamine template. Microporous Mesoporous Mater. 84, 84–96 (2005) 17. X. Li, R. Prins, J.A. van Bokhoven, Synthesis and characterization of mesoporous mordenite. J. Catal. 262, 257–265 (2009) 18. S. Samanta, N.K. Mal, P. Kumar, A. Bhaumik, Hydrothermally synthesized high silica mordenite as an efficient catalyst in alkylation reaction under liquid phase condition. J. Mol. Catal. A 215, 169–175 (2004) 19. M.Y. Nassar, E.A. Abdelrahman, Hydrothermal tuning of the morphology and crystallite size of zeolite nanostructures for simultaneous adsorption and photocatalytic degradation of methylene blue dye. J. Mol. Liq. 242, 364–374 (2017) 20. E.A. Abdelrahman, Synthesis of zeolite nanostructures from waste aluminum cans for efficient removal of malachite green dye from aqueous media. J. Mol. Liq. 253, 72–82 (2018) 21. M. Esaifan, M. Hourani, H. Khoury, H. Rahier, J. Wastiels, Synthesis of hydroxysodalite zeolite by alkali-activation of basalt powder rich in calc-plagioclase. Adv. Powder Technol. 28, 473–480 (2017) 22. M. Kazemimoghadam, T. Mohammadi, Preparation of nano pore hydroxysodalite zeolite membranes using of kaolin clay and chemical sources. Desalination 278, 438–442 (2011) 23. H. Luo, W.W. Law, Y. Wu, W. Zhu, E.-H. Yang, Hydrothermal synthesis of needle-like nanocrystalline zeolites from metakaolin and their applications for efficient removal of organic pollutants and heavy metals. Microporous Mesoporous Mater. 272, 8–15 (2018) 24. A. Ates, G. Akgül, Modification of natural zeolite with NaOH for removal of manganese in drinking water. Powder Technol. 287, 285–291 (2016) 25. W. Konicki, M. Aleksandrzak, E. Mijowska, Equilibrium, kinetic and thermodynamic studies on adsorption of cationic dyes from aqueous solutions using graphene oxide. Chem. Eng. Res. Des. 123, 35–49 (2017) 26. M. Abbas, M. Trari, Kinetic, equilibrium and thermodynamic study on the removal of Congo Red from aqueous solutions by adsorption onto apricot stone. Process Saf. Environ. Prot. 98, 424–436 (2015) 27. A. Jain, M. Agarwal, Kinetic equilibrium and thermodynamic study of arsenic removal from water using alumina supported iron nano particles. J. Water Process Eng. 19, 51–59 (2017) 28. G.A. Adebisi, Z.Z. Chowdhury, P.A. Alaba, Equilibrium, kinetic, and thermodynamic studies of lead ion and zinc ion adsorption from aqueous solution onto activated carbon prepared from palm oil mill effluent. J. Clean. Prod. 148, 958–968 (2017) 29. S.-Y. Yoon, C.-G. Lee, J.-A. Park, J.-H. Kim, S.-B. Kim, S.-H. Lee, J.-W. Choi, Kinetic, equilibrium and thermodynamic studies for phosphate adsorption to magnetic iron oxide nanoparticles. Chem. Eng. J. 236, 341–347 (2014) 30. M.H. Nada, S.C. Larsen, Insight into seed-assisted template free synthesis of ZSM-5 zeolites. Microporous Mesoporous Mater. 239, 444–452 (2017) 31. A. Petushkov, S. Yoon, S.C. Larsen, Synthesis of hierarchical nanocrystalline ZSM-5 with controlled particle size and mesoporosity. Microporous Mesoporous Mater. 137, 92–100 (2011) 32. S.K. Milonjic, L.S. Cerovic, D.M. Cokesa, S. Zec, The influence of cationic impurities in silica on its crystallization and point of zero charge. J. Colloid Interface Sci. 309, 155–159 (2007) 33. S. Zavareh, Z. Farrokhzad, F. Darvishi, Modification of zeolite 4A for use as an adsorbent for glyphosate and as an antibacterial agent for water. Ecotoxicol. Environ. Saf. 155, 1–8 (2018) 34. G.M. Canfield, M. Bizimis, S.E. Latturner, Sodalite ion exchange in polyethylene oxide oligomer solvents. J. Mater. Chem. 17, 4530–4534 (2007) 35. C. Zhang, S. Li, Utilization of iron ore tailing for the synthesis of zeolite A by hydrothermal method. J. Mater. Cycles Waste Manage. 20, 1605–1614 (2018) 36. C. Wang, D. Wang, S. Zheng, Preparation of aluminum silicate/ fly ash particles composite and its application in filling polyamide 6. Mater. Lett. 111, 208–210 (2013) 37. J.-C. Buhl, Synthesis of a sulfate enclathrated zeolite with intermediate framework structure between sodalite and cancrinite. Zeitschrift für anorganische und allgemeine Chemie 643, 1030– 1036 (2017) 38. H.M. Aly, M.E. Moustafa, M.Y. Nassar, E.A. Abdelrahman, Synthesis and characterization of novel Cu(II) complexes with 3-substituted-4-amino-5-mercapto-1,2,4-triazole Schiff bases: a new route to CuO nanoparticles. J. Mol. Struct. 1086, 223–231 (2015) 39. M.Y. Nassar, H.M. Aly, E.A. Abdelrahman, M.E. Moustafa, Synthesis, characterization, and biological activity of some novel Schiff bases and their Co(II) and Ni(II) complexes: A new route for ­Co3O4 and NiO nanoparticles for photocatalytic degradation of methylene blue dye. J. Mol. Struct. 1143, 462–471 (2017) 40. M.Y. Nassar, H.M. Aly, M.E. Moustafa, E.A. Abdelrahman, Synthesis, characterization and biological activity of new 3-substitued-4-amino-5-hydrazino-1,2,4-triazole schiff bases and their Cu(II) complexes: a new approach to CuO nanoparticles for photocatalytic degradation of methylene blue dye. J. Inorg. Organomet. Polym. Mater. 27, 1220–1233 (2017) 41. M.Y. Nassar, Size-controlled synthesis of ­CoCO3 and ­Co3O4 nanoparticles by free-surfactant hydrothermal method. Mater. Lett. 94, 112–115 (2013) 42. M.Y. Nassar, I.S. Ahmed, Template-free hydrothermal derived cobalt oxide nanopowders: synthesis, characterization, and removal of organic dyes. Mater. Res. Bull. 47, 2638–2645 (2012) 43. M.Y. Nassar, I.S. Ahmed, I. Samir, A novel synthetic route for magnesium aluminate (­ MgAl2O4) nanoparticles using sol-gel auto combustion method and their photocatalytic properties. Spectrochim. Acta A 131, 329–334 (2014) 44. M.Y. Nassar, T.Y. Mohamed, I.S. Ahmed, I. Samir, MgO nanostructure via a sol-gel combustion synthesis method using different fuels: An efficient nano-adsorbent for the removal of some anionic textile dyes. J. Mol. Liq. 225, 730–740 (2017) 45. M.Y. Nassar, M. Khatab, Cobalt ferrite nanoparticles via a template-free hydrothermal route as an efficient nano-adsorbent for potential textile dye removal. RSC Adv. 6, 79688–79705 (2016) 46. M.Y. Nassar, E.I. Ali, E.S. Zakaria, Tunable auto-combustion preparation of ­TiO2 nanostructures as efficient adsorbents for the removal of an anionic textile dye. RSC Adv. 7, 8034–8050 (2017) 47. M.Y. Nassar, S. Abdallah, Facile controllable hydrothermal route for a porous C ­ oMn2O4 nanostructure: synthesis, characterization, and textile dye removal from aqueous media. RSC Adv. 6, 84050–84067 (2016) 48. M.Y. Nassar, I.S. Ahmed, H.S. Hendy, A facile one-pot hydrothermal synthesis of hematite (α-Fe 2O3) nanostructures and cephalexin antibiotic sorptive removal from polluted aqueous media. J. Mol. Liq. 271, 844–856 (2018) 13 View publication stats