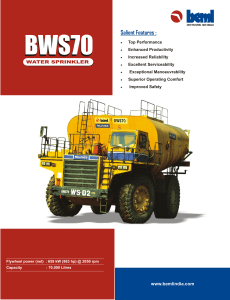

BEML APPRENTICE TRAINING REPORT 1.1 BEML INTRODUCTION Bharat earth movers limited is a multi- technology and multi-location mini ratna category-1 company under the ministry of defence, offering high quality products for diverse sectors of economy such as coal, mining, steel, limestone, power, irrigation, construction, road building, aviation, defence, metro and railways. It has emerged as the forerunner of heavy engineering industry with a track record of growth and revenues for over five decades The company operates under three major business verticals - viz. mining & construction, defence and rail & metro. Each of the above business is headed by a director who acts as CEO of the business and reports to the chairman & managing director of the company. BEML manufactures and supplies defence ground support equipment such as TATRA based high mobility trucks, recovery vehicles, bridge systems, vehicles for missile projects, tank transportation trailers, milrail wagons, mine ploughs, crash fire tenders, snow cutters, aircraft towing tractors, aircraft weapon loading trolley. The company also plans to take up overhaul and up gradation of battle tanks with a view to assemble and roll out the products. under mining and construction business, the company manufactures and supplies mining & construction equipment like bull dozers, excavators, dumpers, shovels, loaders and motor graders to various user segments and under rail & metro business, manufactures and supplies rail coaches, metro cars, ac emus, ohe cars, steel and aluminium wagons to the rail sector. The company has a dedicated R&D infrastructure and team in line with consistent policy of the company to meet the technological demands through in-house R&D and strategic technical tie-ups with global players. 1.2 BEML HISTORY 1964 - Incorporation of our company has a private limited company with the registered office at Bangalore. 1968 - Establishment of the heavy earth moving equipment division at kolar gold fields (KGF). 1979 -They entered into a collaboration agreement with komatsu limited, Japan for technical know-how in a wide range of mining and construction equipment such as bulldozers. 1 BEML APPRENTICE TRAINING REPORT 1985 – The company established the dump truck division at Mysore also vignyan industries ltd became a subsidiary of the company during the year, by transfer of shares constituting over 75% from the government of Karnataka. 1986 - Received national import substitution award from ministry of science technology, government of India. 1987 - The company set up an exclusive hydraulics and power line division and a fullfledged R&D centre in the kolar gold field (kgf) facility. 1990 - Received corporate excellence award for an outstanding performance from the department of public enterprises government of India. 1991 - Engine division set up at Mysore for manufacturing heavy duty diesel engines. 1992 - The government of India divested the equity shares in the company and the company was converted into a public limited company also the company was recognized as an export house with star exporter status during the year. 1994 - The company shares were listed at the stock exchanges at Bangalore, Mumbai, Kolkata, Delhi and Chennai also the company launched the mammoth equipment 'walking dragline'. 1996 - The company entered into a major counter trade agreement with Syria executed against import of rock phosphate. 1997 - Recipient of award for best employers of the physically handicapped from ministry of welfare, government of India. 1998 - Bags orders against World Bank traders valued at Rs 70,000 lac for equipment supply to cil projects. 1999 - Integrated hi-tech applications program implemented in division covering manufacturing, operation and communications. 2001 - Awarded the best exporter by the department of industry and commerce government of Karnataka. 2002 - Regional award for highest exports awarded by engineer export promotion council, southern region. 2003 - The company entered the metro railway business with the manufacture and supply of hi-tech stainless steel metro coaches to the Delhi metro rail corporation. 2 BEML APPRENTICE TRAINING REPORT 2004 - They acquired over 1,100 acres of land and 2 workshops on lease basis from the now-defunct public sector undertaking Bharath gold mines ltd in kolar gold fields for supporting their expanding production activities in the defence and railway sectors. Also they formally launched 7 t class excavator - BE71 and backhoe loader - BL 9h. 2004 - Our company's equity shares got voluntarily delisted from DSE and MSE, application made for voluntary delisting of our equity share to CSE. 2005 - The company introduced the R&D innovative product, load haul dumper (LHD) BL15 and exhibited in the IMME - Kolkata. Four-cylinder indigenous engine B4D105 was successfully built, tested, evaluated and fitted on one of the earthmoving equipment for user trials. Also the in-house developed 20T class excavator BE200 has successfully completed user trials and released for production. 2005 - BEML thrives with Rs 3680mn orders and BEML signs MOU with HMT to draw financial assistant provided by government of India for metro infrastructure. Also BEML signs MOU with ROTEM for aerobridges. BEML joins hand with Korean co Rotem to build aerobridges. 2006 - Defence production inaugurates BEML technology division. BEML join hand with us firm Terex corp. 2006 – April 1, The Company undergoes organizational restructuring to improve their competitiveness in the global market. Consequent to this, the company operations was divided into three business groups, namely mining & construction, defence and railway & metro business. 2006 - April 12, The Company diversified into new business areas by opening two new divisions, namely technology division and trading division. 2006 - August 29, the company was conferred 'Mini Ratna - category 1' status by the ministry of defence. 2006 - September, the company signed an MOU with CCC (compagnie comercio constructors) and established a joint venture company for manufacturing and supplying of rail wagons & bogies, mining & construction equipment and spares. 2006 - December, the company entered into an agreement with us based Terex mining to manufacture, sell and service and to provide support for certain mining haul trucks of Terex design. 3 BEML APPRENTICE TRAINING REPORT 2007 - February, Taneja aerospace & aviation ltd signed a mou with the company at aero India in order to explore the aeronautical offset opportunities in the defence and civilian sectors and also the development opportunities in the domestic market. 2007 - The credit rating of our company has been done by ICRA limited and it has assigned "IRAAA"(pronounced as issuer rating triple) to our company. This rating indicates the highest credit quality ratings assigned by ICRA limited which means, our company caries the lowest credit risks and BEML ltd has set up a subsidiary in Brazil for sourcing and assembling of mining and construction equipment to cater to the growing Latin American market. 2007 - The company's R&D centre developed pipe layer BP70X with unique features like modular planetary winches mounted on one side for improved visibility, rugged boom, and pilot operated hydraulic system. Also the company launched the R&D centre developed equipments, namely hydraulic excavator BE700 and transmission for BH35-2. 2007 - April 18, the company formed a joint venture company namely BEML Midwest Hyderabad. The joint venture is a professionally well knit company with the company having 45% share, Midwest granite Pvt ltd and p t sumber mitra jaya of Indonesia as partners with 55% share. 2007 - October, the company launched marketing office cum warehouse at Malaysia in the name of BEML (Malaysia) SDN BHD (787108-a) at Johor bharu. also, they secured an order from Delhi metro rail corporation (DMRC) for manufacture and supply of 156 numbers state of the art standard gauge stainless steel metro cars towards second phase of operation worth Rs 1144 crore. During the year 2008-09, the company's R&D developed BE300 with Rexroth hydraulics, BL200 re-engineered version, WS70 high capacity water sprinkler, BA28 air craft towing tractor, transmission and torque converter for BH35-2. 2008 – May, the company entered into a mou with steel authority of India ltd in which sail will purchase a total number of 261mining equipment over a period of next three years. Also, the company signed a long term agreement for 12 years with coal India ltd for joint production of off the road (OTR) to meet the requirement for production by the company and after sale requirement by coal India ltd. 4 BEML APPRENTICE TRAINING REPORT 1.3 BEML Major Customers Coal India Limited Neyveli Lignite Corporation Associated Cement Company Steel Authority of India Limited The National Hydro Electric Thermal Power Corporation 1.4 BEML Operating Fields Mining & Construction Defence & Aerospace Rail & Metro 1.5 BEML Has Four Manufacturing Units Kolar Gold Fields (KGF) Complex (around 100 kms from Bangalore) Earth Moving Division Rail Coach Unit II Heavy Fabrication Unit Hydraulic & Power line Division Mysore Complex (around 130 kms from Bangalore) Truck Division Engine Division Aerospace Manufacturing Division Bangalore Complex Rail & Metro Division Palakkad Complex Kerala State - Defense Products Manufacturing BEML - Tatra Trucks 12x12, 10x10,8x8, 6x6, 4x4 & Variants Pontoon Bridge System 5 BEML APPRENTICE TRAINING REPORT Ground Support Vehicles for Guided Missile Programme Heavy, Medium and Light Recovery Vehicles 50T Trailer for Tank Transportation Mil Rail Coaches and Mil Wagons 1.6 BEML Quality Objectives Manufacture and supply equipments to meet customer’s needs and guarantee satisfactory performance of products. Bring about the quality awareness in customer’s personnel in operation and maintenance of products to maximize utilization. Achieve operational excellence through waste elimination and value engineering efforts. Ensure reliability and offer prompt customer service to achieve high equipment availability. Strive continuously to achieve cost reduction and higher profitability. Strive continuously for better product quality through technological improvements and products up-gradation to cater to ever changing customers’ needs. Have an effective and documented system to ensure that every input to the product is designed, procured, manufactured, and ever-changing customer needs. Upgrade design capability and self reliant in technology development. Accord prime importance to safety aspect in all activities. Train and motivate personnel at levels continuously so as to inculcate quality consciousness and foster teamwork. 1.7 BEML Quality Policy To offer products and services to the satisfaction of customers. Strive to upgrade quality and operational efficiency continuously. To ensure high availability of products by constantly endeavouring to provide high quality after sales with least possible delay to the customer. 6 BEML APPRENTICE TRAINING REPORT 2.1 BEML Standards and systems Some of the standards and systems adopted by the BEML are: ISO 9000 and ISO 14000 ISO 9000 is a quality management standard that presents guidelines intended to increase business efficiency and customer satisfaction. The goal of ISO 9000 is to embed a quality management system within an organization, increasing productivity, reducing unnecessary costs, and ensuring quality of processes and products. ISO 9000 Principles A Customer Focus Good Leadership Involvement of people Process approach to quality management Management system approach Continual Improvement Factual approach to decision making Supplier relationships ISO 14000 is a series of environmental management standards developed and published by the International Organization for Standardization (ISO) for organizations. The ISO 14000 standards provide a guideline or framework for organizations that need to systematize and improve their environmental management efforts. ISO 14000 Principles To result in better environmental management To encompass environmental management systems and the aspects of products To be applicable in all countries To promote the broader interests of the public as well as users of these standards 7 BEML APPRENTICE TRAINING REPORT To be cost-effective, non-prescriptive and flexible so they are able to meet the differing needs of organizations of any type or size, worldwide 2.2 5S 5S is short for: Sort, Set in Order, Shine, Standardize and Sustain 5S represents 5 disciplines for maintaining a visual workplace 5S is one of the activities that will help ensure our company’s survival Sort - All unneeded tools, parts and supplies are removed from the area Set in Order - A place for everything and everything is in its place Shine - The area is cleaned as the work is performed Standardize - Cleaning and identification methods are consistently applied Sustain - 5S is a habit and is continually improved Also Work areas are safe and free of hazardous or dangerous conditions 2.3 KAIZEN KAI Changes ZEN Become Good Kaizen signifies small improvements as a result of coordinated continuous efforts by all employees Five key elements of kaizen: Team work Self-discipline Improved morale Quality circles Suggestion for improvement 8 BEML APPRENTICE TRAINING REPORT 2.4 Directorate General of Mines Safety (DGMS) Directorate General of Mines Safety, DGMS in short, is the Indian Government Regulatory agency for safety in mines and oil-fields. The mission of the DGMS is to continually improve safety and health standards, practices and performance in the mining industry and upstream petroleum industry by implementing: Pro-active safety and health strategies. Continuous improvement of processes. Effective use of resources. Commitment and professional behaviour in its personnel. 2.5 Occupational Health & Safety Assessment Series (OHSAS) OHSAS 18000 is an international occupational health and safety management system specification. It comprises two parts, 18001 and 18002 and embraces BS8800 and a number of other publications. OHSAS helps in a variety of respects, it helps in minimise risk to employees, improve an existing OH&S management system, demonstrate diligence, gain assurance etc. The benefits can be substantial. Its supporters claim that an occupational health and safety management system (OHSMS) promotes a safe and healthy working environment by providing a framework that helps organizations to: Identify and control health and safety risks Reduce the potential for accidents Aid legal compliance Improve overall performance 2.6 National Accreditation Board for Testing and Calibration Laboratories (NABL) National Accreditation Board for Testing and Calibration Laboratories (NABL) is an autonomous body under the aegis of Department of Science & Technology, Government of India, and is registered under the Societies Act 1860. NABL has been established with the objective to provide Government, Industry Associations and Industry in general with a scheme 9 BEML APPRENTICE TRAINING REPORT for third-party assessment of the quality and technical competence of testing and calibration laboratories. Government of India has authorised NABL as the accreditation body for Testing and Calibration Laboratories. In order to achieve this objective, NABL provides laboratory accreditation services to laboratories that are performing tests calibrations in accordance with ISO/IEC 17025:2005 and ISO 15189:2007 for medical laboratories. These services are offered in a non-discriminatory manner and are accessible to all testing and calibration laboratories in India and abroad, regardless of their ownership, legal status, size and degree of independence. 2.7 Society of Automotive Engineers (SAE) Grades The Society of Automotive Engineers (SAE) has established a numerical code system for grading motor oils according to their viscosity characteristics. SAE viscosity grading includes the following, from low to high viscosity: 0, 5, 10, 15, 20, 25, 30, 40, 50 or 60. The numbers 0, 5, 10, 15 and 25 are suffixed with the letter W, designating they are "winter" (not "weight") or cold-start viscosity, at lower temperature. The number 20 comes with or without a W, depending on whether it is being used to denote a cold or hot viscosity grade. The document SAE J300 defines the viscometrics related to these grades. Kinematic viscosity is graded by measuring the time it takes for a standard amount of oil to flow through a standard orifice, at standard temperatures. The longer it takes, the higher the viscosity and thus higher SAE c 10 BEML APPRENTICE TRAINING REPORT 3.1 LIGHT ASSEMBLY In Light assembly they will do earth moving equipments like, different capacities of dumpers, water sprinklers and motor graders. Dumpers are used for ore moving purpose and carrying loose materials, Water sprinklers are used for sprinkling purpose and Motor graders are earth moving equipments which used grade the soil. In dumpers there are two different kinds in colours that can be helpful in identifying coal body or sand body. Light Assembly involves in the assembly of following Equipments: BH35-2 BH60 BWS28-2 BG405ABG605(I/A) BG825 Model Abbreviation: B - Bharat H - Haulpak WS - Water Sprinkler G -Grader BH60 M - 60Ton Capacity And M-Mechanically Driven Bh35-2 Bws28-2 - Modification Of Ws28 BG 405A & 605(I/A) - 40 & 60-Machine Size In Ascending Order, 5-Power Shift Drive, - Modification Of Bh35 I - Integrated & A - Have Articulating Cylinders BG825 - 82-Machine Size In Ascending Order, 5-Power Shift Drive 11 BEML APPRENTICE TRAINING REPORT 3.2 DRIVE SYSTEM OF BG825, BG605 (I/A) & BG405A: The major functions of a motor grader are to level road surfaces and dig ditches of fixed shape. In terms of function, a grader can be likened to a gigantic carpenter's plane. The motive force from engine passes through the flywheel and is transmitted to the output shaft. The twisting vibration is Absorbed by the output shaft and the motive force passes through drive shaft and is transmitted to torque converter. The motive force transmitted to the torque converter has its torque converted by the oil inside torque converter, and is then transmitted to hydro shift transmission. In hydro shift Transmission, the clutch is selected according to the load, travel speed, and direction of travel of the machine and the motive force is transmitted to tandem axle through drive shaft. In tandem axle, the rotation is reduced by the bevel pinion and bevel gear, and the motive force is transmitted to the final drive. In final drive, the speed is further reduced by a planetary gear system, and the motive force is transmitted to the tyres. 12 BEML APPRENTICE TRAINING REPORT Hydro shift transmission: For vehicles with an Internal Combustion Engine (ICE) as the primary energy source, the engine power needs to be transformed into rotational mechanical power at the wheels of the vehicle. For construction machines, a sleeplessly variable speed ratio is often required with a wide torque/speed conversion range. For this reason, energy converters, such as hydraulic displacement machines (hydraulic pumps/motors), can be used that allow power transformation to be made sleeplessly in another physical domain. An HST with two hydraulic displacement machines is consequently a Continuously Variable Transmission (CVT) with an intermediate hydraulic power transformation. Modern hydraulic axial piston machines often have the ability to be controlled to zero displacement, which makes the HST an Infinitely Variable Transmission (IVT) that has the ability to transform the input shaft speed into zero output shaft speed. HMTs are transmissions that transfer power both hydraulically and mechanically, either in series, like an HST with mechanical gear steps, or in parallel. The parallel power-split architecture divides the power into a mechanical branch and a hydrostatic branch, which allows for a wide conversion range and high efficiency. Hydro mechanical architectures can be divided into single-mode transmissions and multiple-mode transmissions. The single-mode transmissions are the basic hydro mechanical configurations, either of power-split or hydrostatic type. Single-mode transmissions have no clutches, whereas multiple-mode 13 BEML APPRENTICE TRAINING REPORT 3.3 WORK EQUIPMENT: Scarifier: The Scarifier is mounted behind the front wheels and is hydraulically operated from inside the cab. The Scarifier is equipped with up to eleven teeth that are adjustable and replaceable. Use the Scarifier to break up surfaces that are too hard to cut with the mould board. For especially hard surfaces, reduce the number of teeth. This has the following, Scarified cylinder, scarified body, Scarified tooth, Bolt, Wedge & Pin Ripper: The ripper is very useful for breaking up asphalt pavement, large rocks and tree stumps. The ripper can be equipped with seven ripper teeth. Blade and circles: Mould boards are normally mounted to the grader in circle-mounted configuration. The mould board is attached under the grader’s frame with a ring that can be swivelled vertically to adjust the casting angle of the blade. By adjusting this way, the grader is able to work sideways, enabling it to do jobs such as pulling itches and sloping banks. The motor grader’s front wheels can be tilted up to some degree so as to balance the machine horizontally when the mould board is working at vertical angle. Drawbar Type: A-shaped, U-section press-formed and welded construction for maximum strength. Circle: Internal gear type hydraulically controlled with six guide shoes for 3600 smooth rotation. Mould Board Type: Box-section construction with wear resistant steel, hydraulic blade side shift and tip control, Reversible overlay end bits, side edges are attached. 14 BEML APPRENTICE TRAINING REPORT 3.4 ASSEMBLY: Sub Assembly Engine and hydro shift transmission Frame and tandem axle Pipes assembly of hydraulic and air system Steering wheel mounting to sub frame Wheel assembly with brake section Axle assembly Main Assembly Engine & hydro shaft is mounted on to sub assembly of frame and tandem axle Steering wheel sub assembly is mounted on to main frame Steering cylinder installation Flow control valve installation Tandem pump installation Sub assembled pipe lines of hydraulic and air system are mounted on to frame Operator seat mounting Draw Blade and circle Lifter is assembly to frame Blade lift cylinder (LH & RH) Draw bar shift cylinder Leaning cylinder to front axle Articulating cylinders Scarifier cylinder Brake valve Tyres mounting to axle Front Axle assembly with knuckle arm and king pin FINAL TESTING ASSEMBLY: 15 BEML APPRENTICE TRAINING REPORT Welding Works: Emergency steering connections Reverse alarm Auto lube Auto fire protection system (AFPS) AC welding Final Works Cabin mounting Blades of moving parts AC installation Lubrication (grease) Preparation for start Start & check After test check Decal fixing etc 3.5 MOTOR GRADER - BG605I 16 BEML APPRENTICE TRAINING REPORT Salient features: Product: BEML Motor grader BG605I has been fitted with Bharat stage III CEV compliant BEML engine. Performance: With its high engine horse power and operating weight BG605I is ideal for heavy duty road constructional and maintenance jobs at mining and demanding job site. Productivity: High power engine, coupled with high performance blade equipment ensure high productivity. The finger tip control of smooth transmission shifting provides high manoeuvrability. Comfort: Rear frame mounted operator’s compartment enables ease of viewing the machines travelling directions. Operators comfort is enhanced by adjustable oil, suspension seat and rubber pad mounted on operator compartment. Standard parts: Engine: Make: BEML Model: BSAA6D125-BS III CEV Type: Diesel, 4 strokes, turbocharged overhead valve, direct injection, mechanical speed governor Gross power: 112 KW (152 hp) @ 1800 rpm Maximum torque: 721 Nm (73.5 kg-m) @ 1200 rpm Bore * Stroke: 125 * 150 mm Electricals: Alternator: 24 V, 45 A Starting motor: 24 V, 7.5 kW Battery: 2 * 12 V, 200Ah Transmission: Make: BEML, Hydro shift transmission Travelling Speed: Forward - 43.6 Kmph & backward – 30.9 kmph Tandem: 17 BEML APPRENTICE TRAINING REPORT Tandem case swing up to 13 degree assuring high machine stability and positive traction during operation. Blade Equipment: Draw bar: A shaped, U section press formed and welded and constructed for maximum strength. Circle: Internally gear type hydraulically controlled with 6 guide shoes for 360 degree smooth rotation. Cutting Edge: Tungsten carbide tipped cutting edges. No. of cutting edges is 4. 3.6 Air System & Hydraulic System: Air System Basics: Quick release valve: To rapidly exhaust the air pressure from the break actuators. Limiting and Quick release Valve (LQRV): To regulate the input & output pressure in a specific ratio. E.g. Dry & slippery condition. Graduated control Valve: To change and exhaust the air from spring break actuators for applying the parking brake in truck. Spring Break Actuators: To produce braking force at the wheel or transmission for the secondary or parking brake. Double Check valve: To change a control line in a selected manner from two independent sources. Pressure reducer Valve: To maintain a predetermined reduced pressure at its delivery port. Retarder Hand Break Valve: Gradually change and exhaust the service brake line for applying breaks during downhill travel of the vehicle. Quadruple system protection valve: vital part in DBS. It changes a single line from compressor to 4 lines and prevents back flow of compressed air from any line. Also in the event of failure of any line it will keep the other lines intact. E.g. BG605 Condensing unit & Auto drain Valve: To filter, cool and to remove the moisture and oil from air before it enters the reservoir and pipe lines. The condensed moisture and oil are automatically ejected. 18 BEML APPRENTICE TRAINING REPORT Unloaded Valve with Tyres Inflator: To control the system pressure and also to inflate the tyre when required. Low Pressure Indicator Switch: Warning lamp & Buzzer. Stop light switch: To switch on when brake is applied. Relay Valve: To apply and release air pressure from the brake actuators. Also it shortens the response time and build up time in brake system. Relay emergency Valve: To control the trailer brakes in twin line break system. Evolution of Braking: Air brake system introduction in 1920 in railways and 1930 for automobiles. Earlier vacuum was used for power assistance. Basic braking of bicycle to advanced system of braking heavy commercial vehicles principle of operation remains same but the means of actuation has varied with vehicle’s in load, speed and service conditions. Dual Brake System: A split system of breaks actuating the front & rare breaks separately both in full air system as well as air assisted hydraulic system. Advantage-Partial braking for vehicle in event of failure of either front or rare brakes. E.g. Dumpers BH35, BH352,BH60 & BH100 Compressor: To generate the compressed air needed for the operation. Reservoir: To generate the compressed air provided with auto drain valve/manual drain valve. Dual Brake Valve: to gradually change and exhaust the brake actuators and also to control the trailer brake systems through trailer control valve in a dual brake system. HYDRAULIC SYSTEM The hydraulic systems consists a number of parts for its proper functioning. These include storage tank, filter, hydraulic pump, pressure regulator, control valve, hydraulic cylinder, piston and leak proof fluid flow pipelines. The schematic of a simple hydraulic system is shown in figure. It consists of: A movable piston connected to the output shaft in an enclosed cylinder Storage tank Filter Electric pump Pressure regulator 19 BEML APPRENTICE TRAINING REPORT Control valve Leak proof closed loop piping The output shaft transfers the motion or force however all other parts help to control the system. The storage/fluid tank is a reservoir for the liquid used as a transmission media. The liquid used is generally high density incompressible oil. It is filtered to remove dust or any other unwanted Particles and then pumped by the hydraulic pump. The capacity of pump depends on the hydraulic system design. These pumps generally deliver constant volume in each revolution of the pump shaft. Therefore, the fluid pressure can increase indefinitely at the dead end of the piston until the system fails. The pressure regulator is used to avoid such circumstances which redirect the excess fluid back to the storage tank. The movement of piston is controlled by changing liquid flow from port A and port B. The cylinder movement is controlled by using control valve which directs the fluid flow. The fluid pressure line is connected to the port B to raise the piston and it is connected to port A to lower down the piston. The valve can also stop the fluid flow in any of the port. The leak proof piping is also important due to safety, environmental hazards and economical aspects. Some accessories such as flow control system, travel limit control, electric motor starter and overload protection may also be used in the hydraulic systems which are not shown in figure. 20 BEML APPRENTICE TRAINING REPORT 3.6 PARAMETERS OF MOTOR GRADER: Model BG405A BG605(I/A) BG825 Make Mahindra heavy engines Pvt. Ltd. BEML BEML Power shift Hydro shift Hydro shift Type Diesel, 4-stroke, direct injection, water cooled, Mechanical all speed governor. Diesel, 4-stroke, turbocharged overhead valve, water cooled, direct injection, and Mechanical variable speed governor. Diesel, 4-stroke, turbocharged overhead valve, water cooled, direct injection, and Mechanical variable speed governor. power 101kw (135 hp) @ 2200 r/min 112kw (152 hp) @ 1800 r/min 209kw (280 hp) @ 2100 r/min 605 N-m (61.7 kg-m) @ 1200 r/min 721 N-m (73.5 kg-m) @ 1200 r/min 1661 N-m (170 kg-m) @ 1200 r/min Starting motor 24V, 45A 24V, 45A 24V, 45A Battery 24V, 7.5kw 24V, 7.5kw 24V, 7.5kw 2 x 12V, 100Ah, 1100 CCA 2 x 12V, 200Ah Transmission Max torque Alternator 2 x 12V, 200Ah Oscillation angle (to each sides) 150 150 150 Front wheel lean angle (to each sides) 220 230 230 Cutting angle of blade (Max-min) 820-380 Std-450 710-240 Std-360 840-25.50 Std-490 12.75Mpa 175kg/cm2 210kg/cm2 Working equipment pressure 21 BEML APPRENTICE TRAINING REPORT Steering relief pressure 13.73Mpa 140kg/cm2 175kg/cm2 Scarifies, Front dozer blades, Rare mounting rippers and ROPS cabs Scarifies, Front dozer blades, Rare mounting rippers and ROPS cabs Rare mounting rippers and ROPS cabs Fuel tank capacity (L) 180 250 500 Hydraulic tank capacity (L) 41 58 105 Tungsten carbide tipped cutting edges Tungsten carbide tipped cutting edges Curved type cutting edges meet SAE standard Optional attachments Cutting edges type 22 BEML APPRENTICE TRAINING REPORT 3.7 DRIVE SYSTEM OF BH35-2 & BH60M The motive force from engine (1) passes through the flywheel and is transmitted to the output shaft (2). The twisting vibration is absorbed by the output shaft (2) and the motive force passes through drive shaft (3) and is transmitted to torque converter (4). The motive force transmitted to the torque converter (4) has its torque converted by the oil inside torque converter (4), and is then transmitted to transmission (5). In transmission (5), the clutch is selected according to the load, travel speed, and direction of travel of the machine and the motive force is transmitted to differential (7) through drive shaft (6). In differential (7), the rotation is reduced by the bevel pinion and bevel gear, and the motive force is transmitted to the final drive (8). In final drive (8), the speed is further reduced by a planetary gear system, and the motive force is transmitted to the tires (9). 23 BEML APPRENTICE TRAINING REPORT Light Assembly BH35-2 & BH60 Stage wise work: Sub Assembly: Hydraulic tank sub assembly Fuel tank sub assembly Front axle sub assembly Transmission sub assembly & Installation Engine sub assembly & Installation Radiator sub assembly Front Axle sub assembly (LH) Front Axle sub assembly (RH) Lever Assembly LH Lever Assembly RH 24 BEML APPRENTICE TRAINING REPORT Ist Step: Rear Axle & Rear Suspension Installation A-Frame & Front Axle Installation Steering Cylinder & Tie Rod Installation Guard Installation Installation Of Fire Protective System Press three bore bkt bushes: press bushes Arbitral valve mounting bkt setup & weld: orbit Lock plate setup & weld: all lock Final drive random torque checking to IM IInd & IIIrd Step: Converter cooler mounting & piping Hydraulic tank installation Scu-delling (tank-pump, pump-d.valve) Transmission oil filter mounting piping Hoist cylinder mounting & piping Brake oil cool mounting & piping Steering piping Priority valve, filter installation & piping Emergency steering pump mounting & piping Fuel tank mount & piping Auto greasing installation Steering gear box mounting & piping Mounting of fuel filter & water separator Auto greasing bosses setup & weld IVth, Vth & VIth Step: Front & rear supp mounting 25 BEML APPRENTICE TRAINING REPORT Radiator s/a & installation Radiator piping installation Floor installation RH Cabin installation Air intake piping installation Ladder installation Installation hoods & guards, stays, etc Assy of throttle linkages speedometer Engine belly pan bkt Set up pads of hoods latches Addl air cleaner mounting bkt installation Hand rail pads located & weld: locate set VIIth, VIIIth & IXth Step: Additional brake reserve tank installation. Tyre installation Air system (modified) Body installation Split spacer setup & grinding Mounting of air drier Air cleaner mounting channel setup & weld Air system piping bosses weld Electrical Work: Electrical installation like indicators required Electrical connections Air pressure switch & fog lamps Battery cable preparation ST offer electrical introduced 26 BEML APPRENTICE TRAINING REPORT AC Electrical installation Procedure final testing Works: Preparation (like transmission, engine, differential and Hydraulic oil, Bearing check, Grease check, Filters changing, Turbocharger blades check etc). Two stages of ST offers will be done by quality department on final testing to ensure the quality of equipment. After the1st ST of equipment is over the equipment will be driven by operator for some time. If any leakages or other problem occurs when driving that will be noted and it is attended by final testing team. And equipment will be sent for painting. After painting 2ndST offer of equipments begins with remaining snags attending and final drive test of equipment. They will give final touch up for equipment with additional parts required for costumer when equipments released from assembly some of them are, Lubrication (grease) Preparation for start Start & check After test check-1 Decal fixing Drive shaft & spider greasing Bearing rotation & rub bead Running test After test check-2 Grease charging Final check up Mounting of front drive shaft guard Mount of splash guard 27 BEML APPRENTICE TRAINING REPORT Decal fix on front & rear suspension ST offer mechanical introduced Transmission magnetic filter cleaning amended Wrap exhaust cloth Magnetic filter cleaning: clean magnetic Toe in adjustment Steering inter lock Welding Work: Weld fire protective system Welding of mirror stand Weld and gas cut spacer pads Welding of air drier Welding of grease pr switch Welding of filter & water separator Weld front drive shaft guard Welding of splash guard Weld of pads in place of latch Weld of air clean piping pads Weld of flywheel housing guard AC welding Electrical Work: Auto lube electrical Auto fire protection system (AFPS) Payload monitoring system (PLMS) Air pressure switch & fog lamps Emergency steering connections Proximity sensor (body up) 28 BEML APPRENTICE TRAINING REPORT Body cut off switch Radar indication sensor Camera Reverse alarm Oil Work: Oil charging Suspension charging Oil & fuel filling & suspension charge Grill Work: Slack adjust mounting Cabin sub assembly with blower & wiper Exhaust box mounting & piping Operator seat, buddy seat & fire extension Battery box & bat mounting assembly Turbo charger inspection clearance (twice) Mounting of checker plates in cabin Mounting of exhaust box top cover Mounting of mirror stand AC hoses crimping AC kit installation Cabin heater installation Brake line pads setup & weld: setup and weld Lath Work: Bench work (tubes) 7 items Assy & flare (tubes) 7 items Bend (tubes) 7 items Weld (tubes) 7 items 29 BEML APPRENTICE TRAINING REPORT Leak test (tubes) 7 items Purging of hydraulic piping Fuel tank purging Standard Equipment Has: General: ROPS cabin, Electric Diagnostic system, Vandalism protection cap (Fuel tank), Head and tail lights, Air horn, Turn signal lights, Alternator, Electric starter, Key-switch, Wiper motor, Manual emergency steering, Windshield washer, Dump brake, Right & left Hand mirror, portable fire extinguisher, tool kit, parking brake valves, Tiltable steering wheel and column, Exhaust heated body, Central warning lamp & buzzer, Battery relay, Backup Alarm with flasher, catwalk, Mud flaps, Body lock pins, Rock ejectors, Cabin floor mat, Safety seat belt, Co-operator seat, air dryer, Front brake cut-off switch, Emergency Brake, Engine shut-off switch, Twin fresh air fans, Fog lights, Dial on fuel tank, Auto retarder, Blind spot mirror & steering locking, reflective stickers on all sides. Gauges: Ammeter, Voltmeter, Air pressure, Engine oil pressure, Water temperature, Transmission oil temperature & pressure, Brake oil temperature, Air cleaner restriction, Speedometer, Tocho-meter, Electrical hour meter, Fuel level. Indicators: Hi-beam, Reverse, Turn signal, Body-up, Lube oil pressure, Water temperature, Parking brake and emergency steering “ON”, Alternator warning, Transmission oil temperature and pressure, Fuel level, Transmission filter clogging, Air pressure and hydraulic oil temperature. Alarms: Air pressure, Water temperature, transmission oil temperature & pressure, Lube oil pressure, Hydraulic oil temperature, Transmission filter clogging, Body-up and parking brake “ON”, Low fuel level. Optional Accessories: Tyre inflation kit, Suspension charging kit, Auto emergency steering, air conditioner and Heater unit, exhaust muffler (Non exhaust heated body), Fast fill system for fuel, Automatic centralized lubrication system, Parking brake interlock, Radial tyres, Auto fire suppression system, Body wear bars, Coal body. 30 BEML APPRENTICE TRAINING REPORT 3.8 TYPES OF BRAKES USED IN BH35-2 & BH60: BH35-2 Service Brakes Front - Air-over-hydraulic, dry calliper disc. Rare - Air-over-hydraulic, wet multiple disc. Emergency Air-over-hydraulic, automatic application through relay emergency valves Parking brake spring actuated, air released, dry calliper disc on axle input flange. Retarder brakes Rear brake serves as retarder brake meets ISO 3450 performance Steering system Type Orbitrol, full time power steering. Cylinder type double acting piston type. BH60 Front Hydraulically actuated Rockwell calliper disc Braking Surface: 2.632 cm2. Rear Oil-cooled hydraulically actuated multiple disc brakes provide both service and dynamic retarding. Brakes are sealed for protection from environment contaminants, Braking surface: 58193 cm2. Automatic emergency braking system Unique designed brake control module constantly monitors brake pressure in dual brake accumulators and will active an audio – visual alaram if pressure on either accumulator drops below a toleradle level. If pressure should continue to drop, service brakres will automatically apply. Manual emergency braking system In the event of failure of the brake pedal, the service brakes can be manually applied by an operator switch located on the inatrument panel. Praking brake Dry calliper disc-types mounted on axle input flange. Spring applied hydraulically released, the parking brake will automatically apply if hydraulic pressure is lost. Dynamic retarder Constant sped retarder is provided by a separate foot pedal for the retaeder function, allowing the operator to apply the retarder without removing his hands from the steering wheel. The foot operated valve controls the hydraulically actuated oilcooled wet disc brakes on the rear axle. Wheel brake lock Controlled by switch on control panel activites and locks brakes while loading and dumping. 31 BEML APPRENTICE TRAINING REPORT Steering system: Orbitrol as power steering control with pressure compensating steering pump and two doubleacting steering cylinders Front hydrair suspensions serve as steering kingpins to provide excellent manoeuvrability. Automatic supplemental, accumulator steering is standard. 3.9 PARAMETERS OF DUMPERS: Model BH35-2 Make Cummins BEML Transmission AVTEC(India AVTEC(India) Type IC-Diesel, 4-stroke, turbocharged, direct injection, after cooled, water cooled Flywheel power 280Kw (375 hp) @ 2100 rpm 280Kw (375 hp) @ 2100 rpm Max torque 1627 N-m (166 kg-m) @ 1400 rpm 1627 N-m (166 kg-m) @ 1400 rpm IC-Diesel, 4-stroke, turbocharged, direct injection, water cooled Starting motor Battery 24V DC,7.5kw 24V DC, 7.5kw 2 x 12V, 200Ah 2 x 12V, 200Ah Alternator 24V ,30A 24 V, 30A 32 BEML APPRENTICE TRAINING REPORT Model BH60 Make Transmission Cummins AVTEC(India BEML AVTEC(India) Diesel, 4-stroke, twin turbocharged, direct injection, after cooled, water cooled Type Diesel, 4-stroke,2 stage turbocharged, direct injection, after cooled, water cooled / Diesel, 4stroke, turbocharged, Charged air cooled, Electronic Engine & water cooled Engine model KTTA 19-C/ QSK 19-C BSA6D170A-1 Flywheel power 485kw (650 hp) @2100 rpm 485kw (650 hp) @2100 rpm Max torque 2863Nm (292kg-m) @1400 rpm 2863Nm (292kg-m) @1400 rpm Starting motor Battery 24V,9kw 7.5kw x 2nos 2 x 12V, 200Ah 2 x 12V, 200Ah Alternator 24V,75A 24V,100A Model BH35-2/WS28-2 BH60 Hoist pressure 17.2Mpa (175kg/cm2) 18.96Mpa (192.5kg/cm2) Emergency steering pressure Depends on battery voltage 2750psi Hoist cylinder type Twin, 3-stage, double acting, Twin, 2-stage, double acting, telescopic telescopic type type 33 BEML APPRENTICE TRAINING REPORT Body time hoist Charging suspension pressure 16 1.5sec Front 2.8Mp a, 28.12k g/cm2 Rare 1.9Mpa, 19.5kg/cm2 Load/Deflect 482kg/ ion rate cm, 408kg/cm, Empty/loade 1132kg 5504kg/cm d /cm 13 2sec Front 2.9Mpa, 29.12kg/ cm2 637kg/c m2 , 2401kg/ cm2 Rare 2Mpa, 20.05kg/cm2 435kg/cm2, 24385kg/cm2 Steering relief pressure 12.4Mpa (126kg/cm2) 17.5Mpa (179kg/cm2) Fuel tank Capacity (L) 540 770 Hydraulic tank capacity (L) 225 360 Engine oil SAE 15W-40 SAE 15W-40 Transmissio n oil SAE 30 SAE 30 Hydraulic oil SAE 10 SAE 10 Multi purposes gear oil SAE 90 SAE 90 Suspension Hydro pneumatic rebound control integral Variable rate independent oil pneumatic suspension 34 BEML APPRENTICE TRAINING REPORT 4. RESEARCH AND DEVELOPMENT R&D means Research and Development. Its main role is to discover and create new knowledge about scientific and technological aspects and Developing new products, process and services. It is also responsible for using efficient method of production. It designs new equipment and making any alternation to it. They use Computer Aided Designing software like, CATIA, PRO-E, AUTO CAD and Computer Aided Engineering software like ANSYS for designing the products. This year BEML manufacturing dumper of 205-ton capacity The R&D lab facilities includes CAD Centre, Power line Laboratories, Structural Engineering Laboratories, Fluid power Laboratories, Material Science Laboratories, Electronics and Instrumentation Laboratories and Prototype Shops. R&D centre at KGF was established in 1984, which is the biggest development centre in India. It is recognized by Dept. of Science. This centre is included a vital contribution towards strengthening the Earth Mover and related Industries in the country. Comprehensive facilities in highly specialized area are available at the centre. Extensive computerization has led to highly advanced technology development in various areas of activities in BEML R&D division like CAD Centre, Fluid power, Power line testing & Structural Engineering. Behind the success of R&D division is undoubtedly the brainpower of its highly competent engineers, who are specialized in advanced field of mechanical design, engine technology, structural engineering, material science, fluid power and electronics. In view of the challenge of diversification plans in the field of mining, Railways, Defence, Robotics and Industrial Atomization, the company plans to augment the strength of R&D professionally by reducing by recruiting skilled man power. Vision BEML will build the future business around its core competent in high tech engineering product for defence and chosen area by developing people competencies, upgrading technologies, innovating and adding value to the with in-house R&D and HRD efforts and aiming towards self-reliance. Mission: BEML will strive to maintain a balanced growth with profitability in all its activities and strive for domestic market and global presence by developing a strong brand name. 35 BEML APPRENTICE TRAINING REPORT R&D Focus: To design and develop state of the art products to meet the demands of core sector viz. Defence Mining, Railways and infrastructure. Build total self-reliance in Earth Moving and related technology Update current products for higher performance, reliability and be a leader in the field. Create test facilities for evaluating equipment and aggregates performance and reliability. CAD Centre Objectives: Establish state-of-the-art facility in CAD /CAE for design and development of Earth moving Equipment and Aggregates to meet international standards Developed software for simulations/ application to suit in-house requirements. Provide consultancy and training to various departments in the area of computers. Achieve total computerization of R&D activities incorporating Emerging Information Technology. R&D Activities: Steady and evaluation of technological innovation Up gradation of existing products developments of new products Introduction of new products through technology transfer In house development of critical Hi-tech aggregates Joint development with industries and academic institution Representing BEML in various technology forums patenting and intellectual property rights (IPR) activities Collaborative R&D with DSIR laboratories Collaborative product development with funding agencies like TIFAC Company standardization activities. 36 BEML APPRENTICE TRAINING REPORT FLOW CHART FOR NEW PRODUCT DEVELOPMENT: MARKETING NEW PRODUCT DESIGN NO FEASIBLE NO FEEDBACK TO MARKETING STOP START OF PRODUCT DEVELOPMENT R&D YES APPROVAL FROM MANAGEMENT RELEASE RELEASE OF OF DRAWINGS DRAWINGS YES IOM 3D MODELLING CAD ACTIVITIES , ANALYSIS & DRAFTING UPDATING DATABASE ERP ENGINEERING CHANGE NOTICE (ECN): RELEASE DRAWINGS SHOP, FIELD FAILURE REPORT PROBLEM ISSUE ECN ANALYSE PROBLEM CREATE ECN R&D CREATE ECR IMPACT ANALYSIS INCORPORATE DESIGN CHANGES 37 BEML APPRENTICE TRAINING REPORT Awards of R&D Excellence DSIR Award-outstanding R&D achievments:1990-91 CII Award-Excellence in Technology:1986-87 SEI Award-company standardization 1990, 1992 & 1995 Accredited for calibration of Pressure and Flow Software Used In R&D Department PRO-ENGINEERING (Pro-E) AUTOCAD UNIGRAPHICS PRO-ENGINEERING :( Pro-E Wildfire-3 and wildfire-5) 38 BEML APPRENTICE TRAINING REPORT AUTO CAD-2007: UNIGRAPHICS: (NX 7.5) 39 BEML APPRENTICE TRAINING REPORT 5 CONCLUSION: In this one-year apprenticeship training period, I learnt many technical things which I have studied during my academic and also learnt about industrial standards, working principles, safety precautions. I have improved my technical skills as well as personal skills. I hope this training will help to get a job in good company and also it may help in future to achieve my goal. 40