ACETONE ABSORPTION COLUMN

Required: “CONFIDENTIAL” Sh.a.

DESIGNED: Arberor MITA

Design group“ELMAGERARD”

CALCULATION REPORT

TECHNOLOGICAL AND

CONSTRUCTION PROJECT

EQUIPMENT "ACETONE ABSORPTION

COLUMN"

Nomenclature

1. Inrodiction

ACETONE ABSORPTION COLUMN

Required: “CONFIDENTIAL” Sh.a.

DESIGNED: Arberor MITA

Design group“ELMAGERARD”

Nomenclature

1. Inrodiction

2. Project data

2.1. Problem description

2.2. Packing parameters

2.3. Inlet data

3. Design procedure

3.1.

3.2.

3.3.

3.4.

3.5.

3.6.

Tower diameter

Pressure drop

Diffusion coefficients

Mass transfer coefficients

Packing Height

Operating and equilibrium lines

4.0 Designig of internals

5.0 Determination of nozzles inside diameters

6.0 Mechanical design of absortion column as per ASME S8. Di1/Di2

6.1 Minimum shell thickness

6.2 Torispherical head design

6.3 Shell thicnes at diffrent heights

7.0 Design of support

7.0' Design of support (conventional method)

8.0 Design of flanged joints

9.0 Design an integral radial nozzle centrally located

10.0 Check the design of a radial nozzle in a cylindrical shell

Abstract

In the present work, a packed bed absorption column is designed to remove certain amounts

of acetone contained in a gaseous stream. Four packing types (50-mm metal Hiflow® rings,

50-mm ceramic Pall® rings, 50-mm metal Top Pak® rings rings) are and 25-mm metal VSP®

ACETONE ABSORPTION COLUMN

Required: “CONFIDENTIAL” Sh.a.

DESIGNED: Arberor MITA

Design group“ELMAGERARD”

Abstract

In the present work, a packed bed absorption column is designed to remove certain amounts

of acetone contained in a gaseous stream. Four packing types (50-mm metal Hiflow® rings,

50-mm ceramic Pall® rings, 50-mm metal Top Pak® rings rings) are and 25-mm metal VSP®

considered in order to select the most appropriate one in terms of column dimensions,

pressure drop and mass-transfer results. Several design parameters were determined

including column diameter (D), packing height (Z), overall mass-transfer coefficient (Km) and

gas pressure drop (delta P/Z), as well as the overall number of gas-phase transfer units (NtOG),

overall height of a gas-phase transfer unit (HtOG) and the effective surface area of packing

(ah). The most adequate packing to use for this absorption system constitutes the 25-mm

metal VSP® rings, since it provided the greatest values of Km , ah , as well as the lowest values

of both Z and HtOG , meaning that it will supply the higher mass-transfer conditions with the

lowest column dimensions, but it does not comply with the requirement of pressure drop delta

P/Z() for this reason the next adequate packing to use for this absorption system is 50-mm

ceramic Pall® rings. The influence of both gas mixture (QG) and solvent (mL') feed flowrates on

D, Z, Km, P/Z, NtOG and HtOG was also evaluated for the four packing considered. The design

methodology was solved using computing software MATHCAD PRIME 3.0.

Nomenclature

ah

A

Ch

CL

CP

CSflood

CV

dP

D

DG

DL

e/k

fflood

Fp

Fr

G

GMy

GMx

hL

H

HtOG

kG

kL

Km

Kv

Effective specific surface area

of packing

Absorption factor

Hydraulic factor

Mass-transfer factor

Hydraulic factor

CS coefficient at flooding

conditions

Mass-transfer factor

Effective particle diameter

Tower diameter

Gas-phase diffusion

coefficient

Liquid-phase diffusion

coefficient

Lennard-Jones parameter

Flooding factor

Packing factor

Froude number

Mass velocity

Gas molar velocity

Liquid molar velocity

Liquid holdup

Henry’s constant

Overall height of a gas-phase

transfer unit

Gas-phase convective masstransfer coefficient

Liquid-phase convective

mass-transfer coefficient

Overall volumetric masstransfer coefficient

Volumetric mass-transfer

coefficient

m-1

Dimensionless

Dimensionless

Dimensionless

Dimensionless

m/s

Dimensionless

m

m

m2/s

m2/s

K

%

ft-1

Dimensionless

kg/m2.s

kmol/m2.s

kmol/m2.s

Dimensionless

atm

m

kmol/m

m/s

kmol/m3

kmol/m3

Gas molar velocity

kmol/m

Liquid molar velocity

kmol/m

Liquid

holdup

Dimensionless

ACETONE ABSORPTION COLUMN

Henry’s constant

atm

Required: “CONFIDENTIAL”

Sh.a.

DESIGNED:

Arberor

MITA

Design

group“ELMAGERARD”

Overall height of a gas-phase

transfer unit

kG

Gas-phase convective masskmol/m2.s

transfer coefficient

kL

Liquid-phase convective

m/s

mass-transfer coefficient

Km

Overall volumetric masskmol/m3.s

transfer coefficient

Kv

Volumetric mass-transfer

kmol/m3.s

coefficient

KW

Wall factor

Dimensionless

m

Mass flowrate

kg/h

M

Molecular weight

kg/kmol

n

Factor

Dimensionless

N

Molar flowrate

kmol/h

NtOG

Overall number of gas-phase

Dimensionless

transfer units

ΔPlimit/Z

Maximum pressure drop

Pa/m

permitted

ΔP0/Z

Dry pressure drop

Pa/m

ΔP/Z

Overall pressure drop

Pa/m

P

Pressure

atm

Q

Volumetric flowrate

m3/h

R

Ideal gas constant

m3.atm/kmol.K

%R

Removal percent

%

Re

Reynolds number

Dimensionless

Sc

Schmidt number

Dimensionless

T

Temperature

ºC

T*

Factor

Dimensionless

v

Velocity

m/s

vflood

Velocity at flooding conditions

m/s

V

Molar volume

cm3/mol

X

Flow parameter

Dimensionless

x

Mole fraction in liquid phase

Fraction

y

Mole fraction in gas phase

Fraction

y*

Mole fraction in gas phase in

Fraction

equilibrium with the liquid

Z

Parking height

m

Greek Symbols

Density

kg/m3

μ

Viscosity

Pa.s

σ

Collision diameter

Å

σAB

Average collision diameter

Å

ψ0

Dry-packing resistance

Dimensionless

coefficient

Dimensionless

ΩD

Diffusion collision integral

Dimensionless

GMy

GMx

hL

H

HtOG

1. Inrodiction

Gas-liquid operations are used extensively in chemical and petrochemical industries for

D

Diffusion collision integral

ACETONE ABSORPTION COLUMN

Required: “CONFIDENTIAL” Sh.a.

DESIGNED: Arberor MITA

Dimensionless

Dimensionless

Design group“ELMAGERARD”

1. Inrodiction

Gas-liquid operations are used extensively in chemical and petrochemical industries for

transferring mass, heat and momentum between the phases. Among the most important gasliquid systems employed nowadays is absorption, defined as a mass transfer operation at

which one or more soluble components contained in a gas phase mixture are dissolved into a

liquid solvent whose volatility is low under process conditions. The absorption process could

be classified as physical or chemical. The physical absorption occurs when the target solute is

dissolved into the solvent, while the chemical absorption takes place when the target solute

reacts with the solvent. The removal efficiency of any physical absorption process will depend

on the physical-chemical properties (density, viscosity, diffusivity, etc.) and feed flowrates of

the gaseous and liquid streams; the type of mass-transfer contact surface (packing or plate);

the operating temperature and pressure (commonly, lower temperatures will favor gas

absorption by the liquid solvent); gas-liquid ratio; contact time between phases; and the

solute concentration at the inlet gas stream. Gas-liquid absorption operations are usually

accomplished in equipment named absorbers.

Absorbers are used to a great extent in industrial complexes and plants to separate and purify

gaseous streams, to recover valuable products and chemicals, as well as for contamination

control. The most common absorber types employed in industry are plate columns, packed

towers, Venturi cleaning towers and spray chambers. Packed towers are widely used for gasliquid absorption operations and, to a limited extent, for distillations. A typical packed column

consists of a vertical, cylindrical shell containing a support plate for the packing material, mist

eliminators, as well as a liquid distributing device designed to provide effective irrigation to the

packing The liquid is fed at the top of the column and trickles down through the packed bed,

exposing a large surface to contact the gaseous stream, which is supplied at the bottom of the

tower .

The design approach of a packed-bed absorber usually involves the determination of

geometrical parameters such as tower diameter (D) and packing height (Z), as well as some

other mass-transfer and operational variables such as convective mass-transfer coefficients for

gas and liquid streams; dry and overall pressure drops; as well as overall mass-transfer

coefficient. A well designed packed-bed tower will provide the required mass-transfer contact

between gas and liquid phases, with low pressure drop, small capital and operating costs, and

high removal efficiencies.

At the present work, a packed bed absorber is designed to remove certain amounts of acetone

contained in an air stream. Four different packing types (Pall®, Hiflow®, Top Pak® and VSP®)

were evaluated in order to determine which packing configuration provides the lowest column

dimensions (tower diameter and packing height) as well as the highest mass-transfer

coefficient for this application, without exceeding the maximum allowable pressure drop and

also without affecting the requested removal efficiency. The influence of both liquid solvent

and gas mixture feed flowrates on 4 important process parameters (tower diameter, packing

height, gas pressure drop and overall mass-transfer coefficient) was assessed for the four

packing, while the effect of this two flowrates on two design parameters (overall number of

gas-phase transfer units; NtOG and overall height of a gas-phase transfer unit, HtOG) was also

determined.

ACETONE ABSORPTION COLUMN

Required: “CONFIDENTIAL” Sh.a.

DESIGNED: Arberor MITA

Design group“ELMAGERARD”

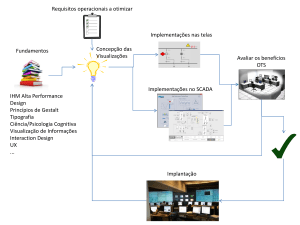

Figure 1: Typical layout of a packed bed absorber

2. Project data

A gaseous mixture containing air and acetone, with a molar composition of 99 % air and 1 %

of acetone.The ethanol must be removed by means of a countercurrent absorption process

ACETONE ABSORPTION COLUMN

Required: “CONFIDENTIAL” Sh.a.

DESIGNED: Arberor MITA

Design group“ELMAGERARD”

2. Project data

2.1. Problem description

A gaseous mixture containing air and acetone, with a molar composition of 99 % air and 1 %

of acetone.The ethanol must be removed by means of a countercurrent absorption process

using water as the solvent. The gas mixture will enter the tower at a rate of 4000 m3/h, at 27

ºC (300 K) and 1.7 atm, while the solvent (water) will be supplied at a flowrate of 14000 kg/h

and also at 300 K. The required removal of acetone to a final concentration of 100 mg/m3,

while the maximum pressure drop permitted for the gas stream should not exceed 250 Pa/m

of packed height. It’s desired to design a suited packed-bed absorber working at 70% of

flooding and operating under isothermal conditions.

For this application, four packing types will be evaluated (Figure 2):

1. 50-mm metal Hiflow® rings

2. 50-mm ceramic Pall® rings

3. 50-mm metal Top Pak® rings, and

4. 25-mm metal VSP® rings.

Table 1. Performance and mass-transfer characteristics of the different packing considered

2.2. Packing parameters

2.2.1. Hydraulic Parameters

!!

" #

"

$!%

#

ACETONE ABSORPTION COLUMN

Required: “CONFIDENTIAL” Sh.a.

DESIGNED: Arberor MITA

2.2. Packing parameters

2.2.1. Hydraulic Parameters

*

Mass-transfer surface area per unit volume

&( ' )

, + -. ' /0

50 mm Metal Hiflow rings

1 + *.* ' /0 50 mm Cheramic Pall rings

2 + 34 ' /0

50 mm Metal Top Pac rings

5 + .64 ' /0 25 mm Metal VSP rings

7&(

Packing porosity or void fraction

7, + 68-33

50 mm Metal Hiflow rings

71 + 6839:

50 mm Cheramic Pall rings

72 + 68-9

50 mm Metal Top Pac rings

75 + 68-3

25 mm Metal VSP rings

$ & (

Hydraulic factor

$, + 6893;

50 mm Metal Hiflow rings

$1 + *8::4

50 mm Cheramic Pall rings

$2 + 6899*

50 mm Metal Top Pac rings

$5 + *8:;-

25 mm Metal VSP rings

$ &(

Hydraulic factor

$ , + 68<.*

50 mm Metal Hiflow rings

$ 1 + 68;;.

50 mm Cheramic Pall rings

$ 2 + 68;6<

50 mm Metal Top Pac rings

$ 5 + 6839.

*

= &( ' )

25 mm Metal VSP rings

Packing factor

50 mm Metal Hiflow rings (ft)

Design group“ELMAGERARD”

ACETONE ABSORPTION COLUMN

Required: “CONFIDENTIAL” Sh.a.

DESIGNED: Arberor MITA

= , + 4.

50 mm Metal Hiflow rings (ft)

= 1 + *<.

50 mm Cheramic Pall rings (ft)

= 2 + <;

50 mm Metal Top Pac rings (ft)

= 5 + *64

25 mm Metal VSP rings (ft)

Design group“ELMAGERARD”

2.2.2. Mass trasfer Parameters

$" & (

Mass trasfer factor

$", + *8*;9

50 mm Metal Hiflow rings

$"1 + *8..3

50 mm Cheramic Pall rings

$"2 + *8:.;

50 mm Metal Top Pac rings

$"5 + *8:3;

25 mm Metal VSP rings

$ & (

Mass trasfer factor

$, + 68<69

50 mm Metal Hiflow rings

$1 + 68<*4

50 mm Cheramic Pall rings

$2 + 68:9-

50 mm Metal Top Pac rings

$5 + 68<64

25 mm Metal VSP rings

Figure 1. Schematic drawing of the packed bed absorber operationg condition

Since the absorption system operates at low pressure and temperature (1.7 atm and 300 K,

respectively); the solute gas is very diluted in the liquid phase (that is, the liquid phase can be

catalogued as a dilute liquid solution), the system operates under isothermal conditions and

there is no reaction between the dissolved solute and the solvent, it’s assumed that the

system obeys the Henry’s law, the value of the Henry’s constant for an acetone-water system

ACETONE ABSORPTION COLUMN

Required: “CONFIDENTIAL” Sh.a.

DESIGNED: Arberor MITA

Design group“ELMAGERARD”

Since the absorption system operates at low pressure and temperature (1.7 atm and 300 K,

respectively); the solute gas is very diluted in the liquid phase (that is, the liquid phase can be

catalogued as a dilute liquid solution), the system operates under isothermal conditions and

there is no reaction between the dissolved solute and the solvent, it’s assumed that the

system obeys the Henry’s law, the value of the Henry’s constant for an acetone-water system

operating at 27 ºC is H = 3.933 atm. Thus, the distribution coefficient for the gas-liquid

system (acetone-water system) at 27 ºC and 1.7 atm is H/P = 3.933 /1.7 = 2.314.

2.3. Inlet data

The inlet data necessary to carry out the design calculations are showed below:

@

>? + <666 ))

%ABC + 686*

DE + *6 /F ' ))

@

GH + *<666 )

ABC + 49869 ))

I + *9 ))

AJK + .98-; ))

Volumetric flowrate

Mole fraction of aceton

Outlet concentration of acetone in the gass

Mass flowrate of water

Molecular weight of acetone

Molecular weight of water

Combined molecular weight of air

LM + --8--N

Acetone removal percent

OPQQR + 36N

Flooding factor

S & .46 ' ))

Maximum pressure drop permitted

U + .46 ' ))

))

T

Liquid density of solvent

VG + --386<3 ))

@

WG + 686669- ' V?AXY + *8*;. ))

@

Liquid viscosity of solvent

WABC + 68666:*; ' Vapor viscosity of acetone at 25 ºC

WAJK + 686666*- ' @

ABC + 3<8*;; ))

"

AJK + .<8-.6 ))

ZABC + :84;< *6 /0[

Vapor viscosity of air at 25 ºC

Gas density at atmospheric preasure

Molar volume of acetone

Molar volume of air

Collision diameter of acetone

Collision diameter of air

ACETONE ABSORPTION COLUMN

Required: “CONFIDENTIAL” Sh.a.

DESIGNED: Arberor MITA

ZAJK + :8;.* *6 /0[

Collision diameter of air

ABC + :48.: \

e/k parameter for acetone

AJK + -3 \

e/k parameter for air

@ ' L + 6866669.* )))

'\

+ :8-:: Design group“ELMAGERARD”

Ideal gas constant

Henry constant for ethanol-water system 25 ºC

] + .3 ^$

System temperature

+ *83 ` .8:*<

_+)

System pressure

Distribution coefficient

3. Design procedure

The equations and correlations used to design the packed-bed absorber were taken from

different sources ,considering several aspects such as process operating conditions, mass

transfer characteristics, and packing type.

ACETONE ABSORPTION COLUMN

Required: “CONFIDENTIAL” Sh.a.

DESIGNED: Arberor MITA

Design group“ELMAGERARD”

3. Design procedure

The equations and correlations used to design the packed-bed absorber were taken from

different sources ,considering several aspects such as process operating conditions, mass

transfer characteristics, and packing type.

3.1. Tower diameter

The molecular weight of the gas mixture (MG) was determined applying the equation

? + bc%ABC ' ABCde a bcbc* f %ABCde ' AJKde ` 686.- ))

The gas mixture density (ρG) at 27 ºC was determined using the Kay’s method

' bcbc%ABC ' ABCde a bcbc* f %ABCde ' AJKdede

` .86*9 ))

Vg + )))))))))))

@

L']

Viscosity of the gas mixture (μG) was calculated using the following correlation.

?

/jd

b

Wg + ))))))))))

b %ABC ' ABC d b bc* f %ABCde ' AJK d ` c*8-:; ' *6 e ' h))))

i a h)))))i

WAJK

c WABC e c

e

Where μace and μair values are given in Pa.s.

The amount of ethanol absorbed is;

b >? ' Vg d

i ' %ABC ' LM ' ABC ` *;68.44 )

ABCkAlm + h)))

c ? e

The amount of solvent liquid exiting the column is:

F G + GH a ABCkAlm ` bc*8<*; ' *6 de )

The flow parameter (X), the pressure drop parameter under flooding conditions (Yflood) and the

CS coefficient at flooding conditions (CSflood) were determined according to the equations.

Flow parameter X

b Vg d [oj

G

b

d

' h)i

n c>?e + )))

>? ' Vg c VG e

Vg d [oj

G ' hb)

n + )))

i ` 6863>? ' Vg c VG e

Pressure drop parameter under flooding conditions

u

bcpOPQQRde & fbc:846. a *86.9 ' qr snt a 68**6-: ' sqr sntt de

v

pOPQQR + /w@oj[u x 0o[uz y {| }~ x [o00[@ y }{| }~ ` 68.6*

S

coefficient at flooding conditions

ACETONE ABSORPTION COLUMN

Required: “CONFIDENTIAL” Sh.a.

DESIGNED: Arberor MITA

Design group“ELMAGERARD”

CS coefficient at flooding conditions

0

[oj

u[

b pOPQQR d

$mOPQQR, + h))))

i ' ))))

[o0

0

0 ` 68699

hc = , ' WG ei

u[ ' u[

0

b pOPQQR d [oj u[

$mOPQQR1 + h))))

i ' ))))

0

0 ` 6864:

hc = 1 ' WG [o0 ei

u[ ' u[

0

[oj

u[

b pOPQQR d

$mOPQQR2 + h))))

i ' ))))

[o0

0

0 ` 686-<

hc = 2 ' WG ei

u[ ' u[

0

[oj

u[

b pOPQQR d

$mOPQQR5 + h))))

i ' ))))

0

0 ` 686;.

[o0

hc = 5 ' WG ei

u[ ' u[

The gas velocity at flooding conditions (vGflood), the gas velocity (vG), and finally the tower

diameter (D), were calculated by using the following correlations:

Gas velocity at flooding conditions

Gas velocity

$mOPQQR,

)` *8-4- )

?OPQQR, + ))))

b Vg d [oj h)))

i

c VG f Vg e

$mOPQQR1

)` *8*9; )

?OPQQR1 + ))))

b Vg d [oj h)))

i

c VG f Vg e

$mOPQQR2

)` .869: )

?OPQQR2 + ))))

b Vg d [oj h)))

i

c VG f Vg e

$mOPQQR5

)` *8:3- )

?OPQQR5 + ))))

b Vg d [oj h)))

i

c VG f Vg e

?, + ?OPQQR, ' OPQQR ` *8:3* )

?1 + ?OPQQR1 ' OPQQR ` 689: )

?2 + ?OPQQR2 ' OPQQR ` *8<49 )

?5 + ?OPQQR5 ' OPQQR ` 68-;4 )

Tower diameter

ACETONE ABSORPTION COLUMN

Required: “CONFIDENTIAL” Sh.a.

Tower diameter

DESIGNED: Arberor MITA

Design group“ELMAGERARD”

u

< ' >? b

, + )))

` c*86*; ' *6 @ de

U ' ?,

u

< ' >? b

1 + )))

` c*8:6; ' *6 @ de

U ' ?1

u

< ' >?

2 + )))

` -9486*4

U ' ?2

u

< ' >? b

5 + )))

` c*8.** ' *6 @ de

U ' ?5

3.2. Pressure drop

Most packed-bed absorbers are designed to safely avoid flooding conditions and also to

operate in the preloading region, with a gas-pressure drop limit of 200 – 400 Pa/m of packed

depth . In this approach, both the gas dry pressure drop ( 0/Z) and overall pressure drop

ACETONE ABSORPTION COLUMN

Required: “CONFIDENTIAL” Sh.a.

DESIGNED: Arberor MITA

Design group“ELMAGERARD”

3.2. Pressure drop

Most packed-bed absorbers are designed to safely avoid flooding conditions and also to

operate in the preloading region, with a gas-pressure drop limit of 200 – 400 Pa/m of packed

depth . In this approach, both the gas dry pressure drop (ΔP0/Z) and overall pressure drop

(ΔP/Z) were determined for the absorption process using well-accepted equations. The liquid

holdup influence was also taken into account, that is, when the packed bed is irrigated, the

liquid holdup causes an increment of the pressure drop. Prior to the determination of both

pressure drops, it was necessary to determine several parameters first. Among those

parameters are included the effective particle diameter (dP) ; the wall factor (KW); the gasphase Reynolds number (ReG); the dry-packing resistance coefficient (ψ0); liquid mass velocity

(GL); the liquid velocity (vL); the liquid-phase Reynolds number (ReL); liquid-phase Froude

number (FrL) ; the ratio ah/a; the effective specific surface area of packing (ah); and, finally,

the liquid holdup (hL).

Effective particle diameter

b*f7 d

Wall factor

, i ` *84

1, + ; ' h)))

c , e

b * f 71 d

11 + ; ' h))

i ` *683;

c 1 e

b * f 72 d

12 + ; ' h))

i ` *8;

c 2 e

b * f 75 d

15 + ; ' h))

i ` 68939

c 5 e

*

\I, + )))))))

` 68-4b * d 1,

.

* a )' h)))

' ))

: c * f 7, ei ,

*

\I1 + )))))))

` 68-34

b * d 11

.

* a )' h))i ' ))

: c * f 71 e 1

*

\I2 + )))))))

` 68-<b * d 12

.

* a )' h))i ' ))

: c * f 72 e 2

*

\I5 + )))))))

` 68-9<

b * d 15

.

* a )' h))i ' ))

: c * f 75 e 5

Gas-phase Reynolds number

?, ' Vg ' 1, ' \I, ` 98-:- ' *6 @

L?, + ))))))

bc* f 7,de ' Wg

?1 ' Vg ' 11 ' \I1 ` <8*9: ' *6 @

L?1 + ))))))

bc* f 71de ' Wg

ACETONE ABSORPTION COLUMN

Required: “CONFIDENTIAL” Sh.a.

DESIGNED: Arberor MITA

Design group“ELMAGERARD”

?2 ' Vg ' 12 ' \I2 ` *8*4: ' *6 F

L?2 + ))))))

bc* f 72de ' Wg

?5 ' Vg ' 15 ' \I5 ` .89-3 ' *6 @

L?5 + ))))))

bc* f 75de ' Wg

Dry-packing resistance coefficient

Liquid mass velocity

b ;<

*89 d ` 68:;E, + $ , ' h))

a )))

[o[z i

c L?, L?, e

b ;<

*89 d ` 68;..

E1 + $ 1 ' h))

a )))

[o[z i

c L?1 L?1 e

b ;<

*89 d ` 684*9

E2 + $ 2 ' h))

a )))

[o[z i

c L?2 L?2 e

b ;<

*89 d ` 683;*

E5 + $ 5 ' h))

a )))

[o[z i

c L?5 L?5 e

< G

G, + )))

` <8944 ))

u

u '

U ' ,

< G

G1 + )))

` .8-:9 ))

u

u '

U ' 1

< G

G2 + )))

` 48*;. ))

u

u '

U ' 2

Liquid velocity

< G

G5 + )))

` :8<*; ))

u

u '

U ' 5

G,

` 68664 )

G, + ))

VG

G1

` 6866: )

G1 + ))

VG

G2

` 68664 )

G2 + ))

VG

G5

` 6866: )

G5 + ))

VG

Liquid-phase Reynolds number

ACETONE ABSORPTION COLUMN

Required: “CONFIDENTIAL” Sh.a.

DESIGNED: Arberor MITA

Design group“ELMAGERARD”

Liquid-phase Reynolds number

G, ' VG ` 4-8.-*

LG, + )))

, ' WG

G1 ' VG ` .38.9

LG1 + )))

1 ' WG

G2 ' VG ` 338:.LG2 + )))

2 ' W G

G5 ' VG ` *983.4

LG5 + )))

5 ' WG

Liquid-phase Froude number

u '

G,

, ` .8..< ' *6 /F

=G, + )))

u '

G1

1 ` *863* ' *6 /F

=G1 + )))

u '

G2

2 ` .864 ' *6 /F

=G2 + )))

u

G5 ' 5 ` .8<4< ' *6 /F

=G5 + )))

Ratio ah/a

, & )

+ 6894 $, ' LG, [ouj ' =G, [o0 ` 689-*

,

1 & )

1 + 6894 $1 ' LG1 [ouj ' =G1 [o0 ` *86<

2 & ) 2 + 6894 $2 ' LG2 [ouj ' =G2 [o0 ` 68-4

5 & ) 5 + 6894 $5 ' LG5 [ouj ' =G5 [o0 ` *864<

Effective specific surface area of packing

*

, + , ' , ` 9*8-3< )

*

1 + 1 ' 1 ` *.48393 )

*

2 + 2 ' 2 ` 3*8.:9 )

*

5 + 5 ' 5 ` .*;8**: )

Liquid holdup

0

ACETONE ABSORPTION COLUMN

Required: “CONFIDENTIAL” Sh.a.

Liquid holdup

DESIGNED: Arberor MITA

Design group“ELMAGERARD”

0

u

b =G, d @

G, + *. ' h))i ' , @ ` 68*3:

c LG, e0

u

b =G1 d @

G1 + *. ' h))i ' 1 @ ` 68*-<

c LG1 e 0

u

b =G2 d @

G2 + *. ' h))i ' 2 @ ` 68*;

c LG2 e 0

u

b =G5 d @

G5 + *. ' h))i ' 5 @ ` 68.-:

c LG5 e

The gas dry pressure drop per meter of packing height (ΔP0/Z) was determined according to

the following correlation:

, ' ?, u ' Vg

URKD, + E, ' ))))

` 3.86:* ))

@

. \I, ' 7,

1 ' ?1 u ' Vg

URKD1 + E1 ' ))))

` ***8;< ))

@

. \I1 ' 71

2 ' ?2 u ' Vg

URKD2 + E2 ' ))))

` -:8:6< ))

@

. \I2 ' 72

5 ' ?5 u ' Vg

URKD5 + E5 ' ))))

` *;:8.;. ))

@

. \I5 ' 75

The gas overall pressure drop per meter of packing height (ΔP/Z) can be finally calculated:

d

bb 7 d 0oj

,

h

UCX, + URKD, ' hh)))i u[[ ii ` *.-836. ))

cc 7, f G, e

e

d

bb 7 d 0oj

1

h

UCX1 + URKD1 ' hh)))i u[[ ii ` *-;8.;. ))

cc 71 f G1 e

e

d

bb 7 d 0oj

2

UCX2 + URKD2 ' hhh)))i u[[ ii ` *3-8;6: ))

cc 72 f G2 e

e

d

bb 7 d 0oj

5

h

UCX5 + URKD5 ' hh)))i u[[ ii ` :6384:* ))

cc 75 f G5 e

e

3.3. Diffusion coefficients

Gas-phase diffusion coefficient: The theory describing diffusion processes in binary gas

mixtures at low to moderate pressures has been studied extensively in recent years, and is

well developed nowadays. Since the absorption process is a binary gas system taking place at

ACETONE ABSORPTION COLUMN

Required: “CONFIDENTIAL” Sh.a.

DESIGNED: Arberor MITA

Design group“ELMAGERARD”

3.3. Diffusion coefficients

Gas-phase diffusion coefficient: The theory describing diffusion processes in binary gas

mixtures at low to moderate pressures has been studied extensively in recent years, and is

well developed nowadays. Since the absorption process is a binary gas system taking place at

low-pressure, the gas-phase diffusion coefficient can be estimated using the Wilke and Lee

correlation :

Gas diffusion coefficient

@

b

68-9 d *6 /@ ' ]

u

:86:

f

)))

h

i

u

ei

hc

? & )))))))))

' u

' Z u '

/0

b *

d

*

+ . h))a ))i ` 686:- ))

c ABC AJK e

Molecular weight of the gas mixture

Colision diameter of the micture

ZABC a ZAJK b

` c:84-: ' *6 /0[de

Z + ))))

.

Difusion colision diameter integral of the mixture

*86;6:; a )))

68*-:66 a )))

*86:493 a )))

*83;<3<

& )))

[oF@j

y

0oju

y

[o0j0[

]M

@ozF00 y

]

]M + ))))

` 48*:<

u

ABC ' AJK

*86;6:; a )))

68*-:66 a )))

*86:493 a )))

*83;<3< ` 689: + )))

[oF@j

y

0oju

y

[o0j0[

@ozF00 y

]M

u

/

? + *689 ' *6 ' ))

Liquid-phase diffusion coefficient: Compared with the kinetic theory behind the gases

behavior, which is well developed and available today, the theoretical basis of the internal

structure of liquids and their transport characteristics are still insufficient to permit a rigorous

treatment. Usually, liquid diffusion coefficients are several orders of magnitude smaller than

gas diffusivities, and depend mostly on concentration profiles due to changes in viscosity, as

well as some changes in the degree of ideality of the solution. To determine the liquid-phase

diffusion coefficient in binary systems for solutes transport to aqueous solutions, the Hayduk

and Minhas correlation was used:

Liquid-phase diffusion coefficient

*8.4 ' *6 /z bcCX /[o0 f 68.-.de ] 0oju ' WG ¡

G & ))))))))))))

*666

-849 *8*.

& ))

CX

u

G + *8*9 ' *6 / ' ))

3.4. Mass transfer coefficients

To determine the mass transfer coefficients for both phases, two correlations were used which

were obtained from an extensive study, that involved measurement and correlation of masstransfer coefficients for 31 different binary and ternary systems, equipped with 67 different

types and sizes of packings, in columns of diameter ranging from 6 cm to 1.4 m.

ACETONE ABSORPTION COLUMN

Required: “CONFIDENTIAL” Sh.a.

DESIGNED: Arberor MITA

Design group“ELMAGERARD”

3.4. Mass transfer coefficients

To determine the mass transfer coefficients for both phases, two correlations were used which

were obtained from an extensive study, that involved measurement and correlation of masstransfer coefficients for 31 different binary and ternary systems, equipped with 67 different

types and sizes of packings, in columns of diameter ranging from 6 cm to 1.4 m.

Gas-phase convective mass-transfer coefficient (kG):

@

u

b ? ' d b

d b L? d F

,

? & 68*:6< ' $, h)))

i ' h)))))

i ' h))

i ' ? @

u

c L ' ] e hc

7, ' bc7, f Gde ei c \I e

ScG - Shmit number for gas phase

Wg

` 68999

? + )))

Vg ' ?

@

b ? ' d b

d b L?, d F

,

?, + 68*:6< ' $, ' h)))

i ' h))))))

i ' h))i ' ? ` :8<;3 ))

u '

c L ' ] e hc u

7, ' bc7, f G,de ei c \I, e

@

b ? ' d b

d b L?1 d F

1

'

?1 + 68*:6< ' $1 ' h)))

))))))

i h

i ' h))i ' ? ` :8:9: ))

u '

c L ' ] e hc u

b

d

71 ' c71 f G1e ei c \I1 e

@

b ? ' d b

d b L?2 d F

2

?2 + 68*:6< ' $2 ' h)))

i ' h))))))

i ' h))i ' ? ` :8.4: ))

u '

c L ' ] e hc u

72 ' bc72 f G2de ei c \I2 e

@

b ? ' d b

d b L?5 d F

5

?5 + 68*:6< ' $5 ' h)))

i ' h))))))

i ' h))i ' ? ` :84:< ))

u '

c L ' ] e hc u

75 ' bc75 f G5de ei c \I5 e

Liquid-phase convective mass-transfer coefficient (kL):

[oj

b G ' , ' G, d b

G, + 68343 ' $", ' h))))i ` c<8-4 ' *6 /jde )

c 7, ' G, e

[oj

b G ' 1 ' G1 d b

G1 + 68343 ' $"1 ' h))))i ` c<8994 ' *6 /jde )

c 71 ' G1 e

[oj

b G ' 2 ' G2 d b

G2 + 68343 ' $"2 ' h))))i ` c48<*9 ' *6 /jde )

c 72 ' G2 e

[oj

b G ' 5 ' G5 d b

G5 + 68343 ' $"5 ' h))))i ` c48;.4 ' *6 /jde )

c 75 ' G5 e

where:

CL – Mass transfer factor

a – Mass transfer surface area per unit volume

3.5. Packing Height

In those systems handling dilute solutions and when Henry’s law applies, is very usual and

convenient to work with overall mass-transfer coefficients in order to calculate the packing

height (Z), which can be determined by the following expression:

ACETONE ABSORPTION COLUMN

where:

– Mass Required:

transfer “CONFIDENTIAL”

factor

Sh.a. DESIGNED: Arberor MITA

a – Mass transfer surface area per unit volume

Design group“ELMAGERARD”

3.5. Packing Height

In those systems handling dilute solutions and when Henry’s law applies, is very usual and

convenient to work with overall mass-transfer coefficients in order to calculate the packing

height (Z), which can be determined by the following expression:

T & X¢? a £X¢?

where:

HtOG – Overall height of a gas-phase transfer units

NtOG – Overall number of gas-phase transfer units

Prior to determine the values of HTU and NTU, it will be necessary to calculate several

parameters first, which are the inlet gas molar velocity [GMy(1)]; the outlet gas molar velocity

[GMy(2)]; the average molar gas velocity (GMy); the inlet liquid molar velocity [GMx(2)]; the outlet

liquid molar velocity [GMx(1)]; the absorption factor at the bottom [A(1)] and top [A(2)] of the

column ; the geometric average of the absorption factor (A) ; the ethanol molar composition

of outlet gas [yeth(2)] ; the volumetric gas-phase (KvG) and liquid-phase (KvL) mass-transfer

coefficients ; the overall volumetric mass-transfer coefficient (Km); the overall height of a gasphase transfer unit (HtOG) ; the overall number of gas-phase transfer units (NtOG); and finally

the packing height (Z).

Inlet gas molar velocity

< §?

¤¥D¦ & )))

U ' ¨u

Gas molar flow rate

>? ' Vg b

` c.834- ' *6 j de ))

§? + )))

?

< §?

¤¥D¦, + )))

` -<8;69 ))

u '

U ' ¨, u

< §?

¤¥D¦1 + )))

` 438.4* ))

u '

U ' ¨1 u

Inlet gas molar velocity

< §?

¤¥D¦2 + )))

` *66849- ))

u '

U ' ¨2 u

Molar flow of ethanol absorbed

< §?

¤¥D¦5 + )))

` ;;8439 ))

u '

U ' ¨5 u

< bc§? f §CXAlmde

¤¥D© & )))))

U ' ¨u

>? ' Vg

' % ' LM ` 683;; ))

§ABCAlm + )))

? ABC

Outlet gas molar velocity

ACETONE ABSORPTION COLUMN

Required: “CONFIDENTIAL” Sh.a.

Outlet gas molar velocity

Average molar gas velocity

DESIGNED: Arberor MITA

Design group“ELMAGERARD”

< bc§? f §ABCAlmde

¤¥D©, + )))))

` -:8;;. ))

u '

U ' ¨, u

< bc§? f §ABCAlmde

¤¥D©1 + )))))

` 4;8;3- ))

u '

U ' ¨1 u

< bc§? f §ABCAlmde

¤¥D©2 + )))))

` --849: ))

u '

U ' ¨2 u

< bc§? f §ABCAlmde

¤¥D©5 + )))))

` ;48-*: ))

u '

U ' ¨5 u

¤¥D¦, a ¤¥D©,

¤¥D, + )))))

` -<8*:4 ))

u '

.

¤¥D¦1 a ¤¥D©1

¤¥D1 + )))))

` 4;8-;4 ))

u '

.

¤¥D¦2 a ¤¥D©2

¤¥D2 + )))))

` *66869; ))

u '

.

¤¥D¦5 a ¤¥D©5

¤¥D5 + )))))

` ;;8.<; ))

u '

.

Inlet liquid molar velocity

< §G

¤¥ª© & )))

U ' ¨u

Inlet liquid molar flow rate

G ` .*984.. ))

§G + ))

I

< §G

¤¥ª©, + )))

` .;-83* ))

u '

U ' ¨, u

< §G

¤¥ª©1 + )))

` *;:8.*: ))

u '

U ' ¨1 u

< §G

¤¥ª©2 + )))

` .9;83;* ))

u '

U ' ¨2 u

< §G

¤¥ª©5 + )))

` *9-896< ))

u '

U ' ¨5 u

ACETONE ABSORPTION COLUMN

Required: “CONFIDENTIAL” Sh.a.

DESIGNED: Arberor MITA

Design group“ELMAGERARD”

< bc§G f §ABCAlmde

¤¥ª¦, + )))))

` .;983;< ))

u '

U ' ¨, u

< bc§G f §ABCAlmde

¤¥ª¦1 + )))))

` *;.8;<* ))

u '

U ' ¨1 u

< bc§G f §ABCAlmde

¤¥ª¦2 + )))))

` .948344 ))

u '

U ' ¨2 u

< bc§G f §ABCAlmde

¤¥ª¦5 + )))))

` *9-8*:9 ))

u

u '

U

'

¨

5

Absorption factor at the bottom

­®¯¬,

_ ` .8:*<

«¬, + ))))

` *8..9

­®D¬, ' _

­®¯¬1

«¬1 + )))

` *8..9

­®D¬1 ' _

­®¯¬2

«¬2 + )))

` *8..9

­®D¬2 ' _

­®¯¬5

«¬5 + )))

` *8..9

­®D¬5 ' _

Absorption factor at the top

­®¯°,

«°, + ))))

` *8.<4

­®D°, ' _

Outlet liquid molar velocity

­®¯°1

«°1 + )))

` *8.<4

­®D°1 ' _

­®¯°2

«°2 + )))

` *8.<4

­®D°2 ' _

­®¯°5

«°5 + )))

` *8.<4

­®D°5 ' _

Geometric average of the absorption factor

«¬, a «°,

«, + ))))

` *8.:;

.

«¬1 a «°1

«1 + ))))

` *8.:;

.

«¬2 a «°2

«2 + ))))

` *8.:;

.

«¬5 a «°5

«5 + ))))

` *8.:;

.

Ethanol molar composition of outlet gas

ACETONE ABSORPTION COLUMN

Required: “CONFIDENTIAL” Sh.a.

DESIGNED: Arberor MITA

Design group“ELMAGERARD”

Ethanol molar composition of outlet gas

%ABCH + %ABC ' s* f LMt ` *6 ' *6 /±

Volumetric gas-phase mass-transfer coefficient

\5?, + ?, ' , ` .9<8.*4 ))

@ '

\5?1 + ?1 ' 1 ` <.4843. ))

@ '

\5?2 + ?2 ' 2 ` .:*834; ))

@ '

\5?5 + ?5 ' 5 ` 3;:89<4 ))

@ '

Volumetric liquid-phase mass-transfer coefficient

VG b

` c484:- ' *6 F de ))

+ ))

@

I

\5G, + G, ' , ' ` ..<83<< ))

@ '

\5G1 + G1 ' 1 ' ` :<68:<. ))

@ '

\5G2 + G2 ' 2 ' ` .*:83-. ))

@ '

\5G5 + G5 ' 5 ' ` ;3:8:69 ))

@ '

Overall volumetric mass-transfer coefficient

*

\Y, + )))))

` 3.8:-9 ))

@ '

*

_

))a ))

\5?, \5G,

*

\Y1 + )))))

` *6-8:. ))

@ '

*

_

))a ))

\5?1 \5G1

*

\Y2 + )))))

` ;;86;; ))

@ '

*

_

))a ))

\5?2 \5G2

*

\Y5 + )))))

` .*683:9 ))

@ '

*

_

))a ))

\5?5 \5G5

Overall height of a gas-phase transfer unit

ACETONE ABSORPTION COLUMN

Required: “CONFIDENTIAL” Sh.a.

DESIGNED: Arberor MITA

Design group“ELMAGERARD”

Overall height of a gas-phase transfer unit

­®D,

X²?, + ))

` *8:

\Y,

­®D1

X²?1 + ))

` 684.*

\Y1

­®D2

X²?2 + ))

` *84*4

\Y2

­®D5

X²?5 + ))

` 68:*<

\Y5

Product streams and composition

³ + ´? ` bc.834- ' *6 j de ))

%³ + 686* ))

nE + 6

Molar ratio of acetone in the input gas

%³

p³ + ))

` 686* ))

* f %³

Molar flowrate of carier gas

+ ³ ' bc* f p³de ` bc.83:. ' *6 j de ))

Concentration of acetone in the output gas

AJK b

` c.8<3* ' *6 /jde ))

%E + DE ' )))

ABC ' Vg

Molar ratio of acetone in the output gas

%E b

pE + ))

` c.8<3* ' *6 /jde ))

* f %E

Molar ratio of acetone in the output liquid (equilibrium case)

Molar flowrate of liquid

p

n³Y + )³ ` 6866< ))

_

GH ` bc38339 ' *6 j de ))

" + ))

I

Molar ratio of acetone in the output liquid

bp f p d ` 6866< ))

n³ + nE a )

" c ³ Ee

Diferece in molar ratios of acetone in the output gas

Sp³ + p³ f _ ' n³ ` 6866. ))

SpE + pE a _ ' nE ` bc.8<3* ' *6 /jde ))

Diferece in molar ratios of acetone in the input gas

Number of gas-phase transfer units

ACETONE ABSORPTION COLUMN

Required: “CONFIDENTIAL” Sh.a.

DESIGNED: Arberor MITA

Design group“ELMAGERARD”

Number of gas-phase transfer units

b Sp³ d

p³ f pE

´X²?, + ))))

' qr h))

i ` .:8.6*

Sp³ f SpE c SpE e

b Sp³ d

p³ f pE

´X²?1 + ))))

' qr h))

i ` .:8.6*

Sp³ f SpE c SpE e

b Sp³ d

p³ f pE

´X²?2 + ))))

' qr h))

i ` .:8.6*

Sp³ f SpE c SpE e

b Sp³ d

p³ f pE

´X²?5 + ))))

' qr h))

i ` .:8.6*

Sp³ f SpE c SpE e

Packing height

T + ´X²?, ' X²?, ` :68*;3

T + ´X²?1 ' X²?1 ` *.86T + ´X²?2 ' X²?2 ` :48*<9

T + ´X²?5 ' X²?5 ` 38.-:

3.6. Operating and equilibrium lines

The operating line will be elaborated using the following data:

Mole fraction of acetone in inlet gas mixture [yace(1)] = 0.01

Mole fraction of acetone in outlet gas mixture [yace(2)] = .8<3* ' *6 /j

Mole fraction of acetone in inlet liquid [xace(2)] = 0.

Mole fraction of acetone in outlet liquid [xace(1)] = 6866:

The operating line points

µ

¸

%MM + ¶ 686* /j ¹

· .8<3* ' *6 º

¸

»MM + µ¶ 6866:

· 6 ¹º

The equilibrium line for the absortion system

' » & .8:*< ' »

%M & _ ' » & )

%M s»t + .8:*< ' »

The operating and equilibrium line for the absortion system

ACETONE ABSORPTION COLUMN

Required: “CONFIDENTIAL” Sh.a.

DESIGNED: Arberor MITA

Design group“ELMAGERARD”

The operating and equilibrium line for the absortion system

¼½¼Æ

¼½¼¼Å

¼½¼¼Ä

¼½¼¼Ã

¼½¼¼Â

¼½¼¼Á

¼½¼¼À

¼½¼¼¿

¼½¼¼¾

¼½¼¼Æ

¼¼

.8:*< ' »

%MM

ÀÇƼÈÉ ÄÇƼÈÉ ¼½¼¼Æ

¼½¼¼¾

¼½¼¼¾

»

»MM

¼½¼¼¾

¼½¼¼¿

¼½¼¼¿

¼½¼¼À

¼½¼¼À

ACETONE ABSORPTION COLUMN

Required: “CONFIDENTIAL” Sh.a.

DESIGNED: Arberor MITA

Design group“ELMAGERARD”

ACETONE ABSORPTION COLUMN

Required: “CONFIDENTIAL” Sh.a.

DESIGNED: Arberor MITA

Design group“ELMAGERARD”

ACETONE ABSORPTION COLUMN

Required: “CONFIDENTIAL” Sh.a.

DESIGNED: Arberor MITA

Design group“ELMAGERARD”

ACETONE ABSORPTION COLUMN

Required: “CONFIDENTIAL” Sh.a.

DESIGNED: Arberor MITA

Design group“ELMAGERARD”

ACETONE ABSORPTION COLUMN

Required: “CONFIDENTIAL” Sh.a.

DESIGNED: Arberor MITA

Design group“ELMAGERARD”

ACETONE ABSORPTION COLUMN

Required: “CONFIDENTIAL” Sh.a.

DESIGNED: Arberor MITA

Design group“ELMAGERARD”

ACETONE ABSORPTION COLUMN

Required: “CONFIDENTIAL” Sh.a.

DESIGNED: Arberor MITA

Design group“ELMAGERARD”

ACETONE ABSORPTION COLUMN

Required: “CONFIDENTIAL” Sh.a.

DESIGNED: Arberor MITA

Design group“ELMAGERARD”

ACETONE ABSORPTION COLUMN

Required: “CONFIDENTIAL” Sh.a.

DESIGNED: Arberor MITA

Design group“ELMAGERARD”

4.0 Designig of internals

(Designing of internals is proprietary knowledge for me so I will not give you a step by step guide how

to design or select internals, instead I will give you a the theoretical fundamentals on how to do i )

Theoretical fundamentalsThe basis of any distributor design is the exact knowledge of the

discharge behaviour of liquids from ground holes and lateral rectangular slots or triangular

ACETONE ABSORPTION COLUMN

Required: “CONFIDENTIAL” Sh.a.

DESIGNED: Arberor MITA

Design group“ELMAGERARD”

4.0 Designig of internals

(Designing of internals is proprietary knowledge for me so I will not give you a step by step guide how

to design or select internals, instead I will give you a the theoretical fundamentals on how to do it)

Theoretical fundamentalsThe basis of any distributor design is the exact knowledge of the

discharge behaviour of liquids from ground holes and lateral rectangular slots or triangular

notches. The following refers to circular ground orifices but can be applied analogously to

rectangular slots or triangular notches as well. The fundamentals of the discharge behaviour

of fluids out of circular openings stretch back to the year 1644, where Torricelli developed

Equation 1.Michael Schultes, Werner Grosshans, Steffen Müller and Michael Rink, Raschig

GmbH, Germany, present a modern liquid distributor and redistributor design.

Ï

ËÌÍ Ê ÎÎÎÎÎ

Ñ ÒÐÓ

Equation 1 describes the theoretical discharge velocity of liquids, wth, from orifices as a

function of the gravitational acceleration, g, and the liquid head above the orifice, h. If one

multiplies this theoretical velocity, wth, by the cross-sectional area of a hole, Ah, and the

number of discharge holes of a liquid distributor, n, then one achieves the theoretical total

volume rate, , which can flow out of a liquid distributor (Equation 2).

Ï

ÔÌÍ Ê ÕÍ Ð Ö Ð ÎÎÎÎÎ

Ñ ÒÐÓ

Equation 2 applies under ideal conditions, i.e. assuming that the flow through the hole imparts

no resistance to the flow of liquid. But in reality, streamlines of different velocities are formed

due to the sharp edged holes which cause deflection of the liquid jet flow (Figure 1). For

describing the flow behaviour of the liquid jet flow, one has to interpret two effects. First the

jet contraction and second the jet velocity. The orientation of the streamlines causes the jet of

liquid to contract when it leaves the ground hole. This effect can be described mathematically

by a contraction coefficient, CC. Friction losses, caused by shearing forces of the fluid,

influence the velocity of the jet of liquid when it issues through the hole and can be described

mathematically by a velocity coefficient, CV. The coefficients depend on the liquid head, the

hole geometry and the physical properties of the liquid.The product of the contraction

coefficient, CC, and the velocity coefficient, CV, results in the discharge coefficient, CD = CC ·

CV, which describes the difference between the effective volume rate, , and the theoretical

value,. Only the discharge coefficient, CD, can be derived from experimental investigations

directly.

Ï

Ô Ê ×Ø Ð ÕÍ Ð Ö Ð ÎÎÎÎÎ

Ñ ÒÐÓ

The discharge coefficient, CD, is described in the literature according to Table1 as a constant

value in function of the hole geometry only.

Actual discharge behaviour

If one describes the flow through a hole on the basis of an energy balance, equilibrium can be

set up according to Equation 4. The inflowing volume, , acts on the hole with the potential

energy (?L -?V)gh while the out flowing volume rate leaves the hole as a jet flow with the

kinetic energy (?Lw2/2). The energy of the jet leaving the hole is less than that of the

ACETONE ABSORPTION COLUMN

Required: “CONFIDENTIAL” Sh.a.

DESIGNED: Arberor MITA

Design group“ELMAGERARD”

Actual discharge behaviour

If one describes the flow through a hole on the basis of an energy balance, equilibrium can be

set up according to Equation 4. The inflowing volume, , acts on the hole with the potential

energy (?L -?V)gh while the out flowing volume rate leaves the hole as a jet flow with the

kinetic energy (?Lw2/2). The energy of the jet leaving the hole is less than that of the

inflowing liquid since the contraction and friction loss of the jet has consumed energy

characterised by in Equation 4.

ÜÝ Ï

ÙÚÜÝ Û ÜÞßà Ð Ò Ð Ó Ð Ô Ê â

Ðã ÐÔáä

Ñ

In Equation 4, ρL describes the liquid density and ρV the gas density; g describes the

gravitational acceleration, h describes the liquid head above the hole, and w describes the

current velocity of the jet. By including Equation 3 in Equation 4, Equation 5 follows for the

coefficient of discharge CD. The second term of the right side of Equation 5 describes the

energy consumption E divided by the potential energy for a certain liquid head above the hole

h and for a volume flow rate V. The energy consumption E tends to zero for low flow rates.

Consequently, the coefficient of discharge CD tends to unity for low flow rates in case the gas

density can be neglected compared to the liquid density.

Ï ÎÎÎÎÎÎÎÎÎÎÎÎÎÎÎ

ÜÝ Û ÜÞ

ä

×Ø Ê âââ

Û ââââ

ÜÝ

ÜÝ Ð Ò Ð Ó Ð Ô

Systematic investigations have shown that the discharge coefficient, CD = CC CV is a variable

which is dependent on several influencing parameters. An expression for the energy

consumption E was evaluated that allows an accurate prediction of the coefficient of discharge

CD.Following the influencing parameters on the overall coefficient of discharge, CD, will be

discussed in detail (Figure 2). Figure 2 shows measurement points for the discharge

coefficient, CD, for water at ambient temperature as a function of the liquid head, h, for

various hole diameters, d. It also shows the constant CD = 0.62 recorded in the literature for

holes whose dimensions are larger than the depth of the hole.12 It can be clearly seen that

the discharge coefficients only approximate the value given in the literature if the liquid head

is great and hole diameters large. With decreasing liquid head, the discharge coefficient rises

significantly with the result that the discharge behaviour with small liquid head deviate more

favourable from discharge behaviour according to Table 1 than with large liquid head. This can

be explained by the fact that as the liquid head decreases, the horizontal velocity component

decreases and therefore a reduction of the contraction of the jet occurs. Figure 2 also shows

that with decreasing hole diameter, the discharge coefficient rises, i.e. the contraction is

reduced by the counteraction of the horizontal velocity components. In case of small liquid

heads, tensile forces of the jet are also transferred even into the hole cross-section, with the

result that the liquid is drawn out of the opening and, if the liquid level is calm, a vortex is

formed. This effect is more marked in the case of large hole geometries than in the case of

small hole geometries, as can be seen from the steeper curves in Figure 2 at low liquid heads.

The relationships described only apply if the influence of the surface tension is negligible. For

instance, in case of small holes and liquids with a high surface tension, a drop of liquid is

formed beneath the hole, preventing the fluid from flowing out. Further factors that are

influencing the coefficient of discharge but not discussed here are physical properties of the

fluid (density, viscosity), elevation and orientation of holes, overflow velocity and ratio of hole

diameter to deck thickness

instance, in case of small holes and liquids with a high surface tension, a drop of liquid is

formed beneath the hole, preventing the fluid from flowing out. Further factors that are

influencing the coefficient of discharge

but

not discussed

here are physical properties of the

ACETONE

ABSORPTION

COLUMN

fluid (density, viscosity), elevation and orientation of holes, overflow velocity and ratio of hole

“CONFIDENTIAL” Sh.a. DESIGNED: Arberor MITA Design group“ELMAGERARD”

diameter toRequired:

deck thickness

The dimensioning of liquid distributors

In the dimensioning of liquid distributors, not only the discharge coefficient but also other

design determining criteria have to be taken into account. In that manner, first the minimum

liquid head, hmin , above a discharge hole of a liquid distributor must be determined. Here the

flow velocity of the liquid in the distributor troughs is of decisive importance since flow

gradients occur due to wall friction and lead to significant differences in height, particularly in

case of low liquid heads. If these minimum liquid heads are not attained, considerable

maldistribution of a distributor can occur, as described as follows. The minimal liquid level in a

distributor Feeding liquid into a mass transfer column generally takes place via a feed pipe

which first leads the liquid into a preliminary distribution trough called a parting box.

Afterwards, the liquid reaches the individual distributor troughs lying below and flows in the

troughs towards the column wall. Drag, due to wall friction, causes liquid head gradients to

form in the distributor troughs, which has to be taken into account, particularly with low liquid

levels. This is illustrated in Figure 3.

For liquid flow in open trough systems the difference in height, ∆h, taking place along the

trough can be calculated using Equation 6. It is a function of the wall friction factor, λ,

hydraulic diameter, dh, gravitational acceleration, g, and flow velocity. Figure 3 shows the

result of such a calculation for a trough with a width of b = 100 mm for various flow velocities

as a function of the liquid head, h.

ç ââ

ãÏ

åÓ Ê æ Ð â

èÍ Ñ Ò

Õ Ê âââ

ÓÐë

èÍ Ê é â

ê ëáÑ Ó

The following recommendations for the minimum liquid level, hmin , in distributor troughs

can be derived from the observations of Figure 3. The minimum liquid head should not fall

short of a value of 25 - 35 mm and at the same time the flow velocity in the troughs should

be limited to a maximum of 0.5 m/s. Furthermore, the liquid head should be equivalent to at

least twice the hole diameter in order to avoid vortex formation above the hole (Equation 7).

The overall height of a distributor

The overall height of a liquid distributor is first defined by the required liquid loading range.

To this height, the hydrostatic pressure occurring as the result of the pressure drop of the

gas phase as this passes the troughs of the distributor must be added. Furthermore,

The following recommendations for the minimum liquid level, hmin , in distributor troughs

can be derived from the observations

of Figure 3. The minimum liquid head should not fall

ACETONE ABSORPTION COLUMN

short of a value of 25 - 35 mm and at the same time the flow velocity in the troughs should

be limited toRequired:

a maximum

of 0.5 m/s.

theMITA

liquidDesign

head group“ELMAGERARD”

should be equivalent to at

“CONFIDENTIAL”

Sh.a. Furthermore,

DESIGNED: Arberor

least twice the hole diameter in order to avoid vortex formation above the hole (Equation 7).

The overall height of a distributor

The overall height of a liquid distributor is first defined by the required liquid loading range.

To this height, the hydrostatic pressure occurring as the result of the pressure drop of the

gas phase as this passes the troughs of the distributor must be added. Furthermore,

additional height is necessary if a foaming system is present and if a noticeable gas rate is

injected into the liquid at the liquid feed point. The latter applies particularly in the case of

high pressure systems if the degassing of the liquid is markedly restricted due to the small

differences in density between the gas and the liquid. Furthermore, wave formation has to

be taken into account in the case of flowing liquids.

Liquid loading range

By converting Equation 3, Equation 8 can be obtained which defines the necessary extra

height, ?h1, of a liquid distributor resulting from a required loading range.

ÙÙ Ô ß Ï Ù × Ð Ó ß Ï ß

îïð ó Ð íâââ

ô îñò ó Û çó Ð Ó

åÓì Ê íííââ

óà îñò

Ô

×

ÚÚ îñò à Ú ô Ð Óîïð à

Reprinted from HydrocarbonEnginEEringJanuary2009 www.hydrocarbonengineering.com

When calculating the necessary extra height, Figure 2 must be taken into account showing

that the discharge coefficient, CD, provides larger values with the lower liquid head than with

the higher liquid head. This yields greater overall heights than if a constant discharge

coefficient is assumed.

Gas phase pressure drop

The pressure drop, which the gas flow undergoes when it passes through the narrowed

distributor cross-section, can be calculated by Equation 9. ? is the drag coefficient for the

sudden narrowing and expansion of flows, Fv is the gas capacity factor in the column, AC is

the cross-sectional area of the column and AD is the free cross-sectional area of the

distributor.

Õ÷ Ï Ï

ö Ð ââ

ø

åõ Ê â

Ñ Õô Ï ù

åõ Ê ÙÚÜÝ Û ÜÞßà Ð Ò Ð åÓú Ï

This pressure drop causes a rise in hydrostatic pressure to the head of liquid in the distributor,

which can be described with the aid of Equation 10. By equating Equation 9 and Equation 10,

Equation 11 can be obtained for the description of the second portion, ?h2, for the overall

height of a distributor.

Ï

Õ÷

ç

ö Ð ââ

Ï

åÓú Ê ââââ

â

ÙÚÜÝ Û ÜÞßà Ð Ò Ñ Õô Ï øù

Foaming systemIn the case of a foaming system, the foam will be built up in particular in

those areas in which a marked gas injection into the liquid takes place. This applies

particularly to the transfer of the liquid from the feed pipe into the parting box, since

relatively large quantities of liquid are transferred per transition point. Since the description of

the foaming behaviour is very complex, it is advisable to use the foam or system factor, ?,

which is described in the literature.13 This empirical factor is known for numerous mass

transfer tasks and has to be taken into account by Equation 12, based on empirical equation,

for the calculation of the additionally necessary distributor height, ?h3.

Foaming systemIn the case of a foaming system, the foam will be built up in particular in

those areas in which a marked gas injection into the liquid takes place. This applies

particularly to the transfer of the liquid from the feed pipe into the parting box, since

ACETONE ABSORPTION COLUMN

relatively large quantities of liquid are transferred per transition point. Since the description of

the foamingRequired:

behaviour

is very complex,

it is advisable

to useDesign

the foam

or system factor, ?,

“CONFIDENTIAL”

Sh.a. DESIGNED:

Arberor MITA

group“ELMAGERARD”

which is described in the literature.13 This empirical factor is known for numerous mass

transfer tasks and has to be taken into account by Equation 12, based on empirical equation,

for the calculation of the additionally necessary distributor height, ?h3.

Ùçß

åÓû Ê ü íâ

Ú ý óà

One must notice that system factors, listed in the literature, result from long term experience

in designing tray columns and includes foaming and degassing effects in parallel. Experience

is needed for avoiding overdesigns in taking system factor and degassing into account in

parallel. The increase of liquid distributor height can, however, be markedly restricted if

design methods are taken into account to reduce foaming. For instance, immersed elongated

guide pipes at the feed pipe can be used to feed the liquid into the liquid level of the parting

box and thus reduce foaming. Alternatively, guide sheets can be used as impulse dampers

above the parting box, or a package of structured or random packings can be used within the

parting box or distributor trough in order to support separation of gas and liquid.

Degassing

As has already been described, the high impulse transfer as liquid passes from the feed pipe

into the parting box, causes gas also to be introduced with the jets of liquid into the liquid

layer. The gas then occupies a noticeable volume in the amount of liquid, which causes the

liquid level in the trough to rise. The additional extra height this requires is determined by the

gas portion introduced and by the residence time of the gas in the liquid. The degassing

behaviour is essentially defined by the buoyancy of the gas bubbles, i.e. by the difference in

density between the gas and the liquid. Particularly in high pressure applications the density

differences are small and therefore the degassing efficiency reduced. As is the case with

foaming systems, the additional height, ?h4, which must be taken into account on the basis of

the degassing behaviour can, until now, only be described on the basis of an empirical

equation (Equation 13).

Ù Ü ß

Ý ó

åÓþ Ê ü íâââ

Ù

Ú ÚÜÝ Û ÜÞßà à

The degassing of liquids can, however, be improved by design methods, similar to foaming

behaviour. Wave formationIf the liquid is led from the distributor pipe into the parting box

and then into the distributor troughs, the impulse transfer causes wave formation which is

supported by the flow of the liquid in the troughs. The overall height of a distributor must be

dimensioned so that the wave crests do not lead to a flooding of the distributor troughs or

gas risers. Since the wave formation depends on the quantity of liquid to be distributed, it is

advisable to design the additionally necessary distributor height, ?h5, according to Equation

14 as an empirical function of the liquid load.

åÓÿ Ê ü ÙÚêÝßà

Taking all the single heights into account, the necessary overall height is defined according to

Equation 15.

åÓÌ ÌïÝ Ê Óîñò á åÓì á åÓú á åÓû á åÓþ á åÓÿ

Conclusion

Modern liquid distributor designs are relevant for good mass transfer efficiencies in packed

columns. The article describes the flow behaviour of a liquid jet flow that is leaving a

distributor via bottom holes. An equation is provided to describe the coefficient of discharge

and influencing parameters are discussed. The height of a distributor trough has to take into

account the recommended minimum liquid head, specified liquid loading range, gas pressure

drop, foaming and degassing effects and wave creations. This subject is described as well.

5.0 Determination of nozzles inside diameters

Liquid feed of first distributor nozzle dimension

columns. The article describes the flow behaviour of a liquid jet flow that is leaving a

distributor via bottom holes. An equation is provided to describe the coefficient of discharge

ACETONE ABSORPTION COLUMN

and influencing parameters are discussed. The height of a distributor trough has to take into

account theRequired:

recommended

minimum

head,

specified

range, gas pressure

“CONFIDENTIAL”

Sh.a. liquid

DESIGNED:

Arberor

MITA liquid

Designloading

group“ELMAGERARD”

drop, foaming and degassing effects and wave creations. This subject is described as well.

5.0 Determination of nozzles inside diameters

Liquid feed of first distributor nozzle dimension

Øì â

ÕòØ âââ

Ü Ð Øì

Ï ÎÎÎÎÎÎÎ

é Ð ÕòØ

âââ

ò Ø

ò Ø

We accept

Ï

Sch 40

Liquid feed second distributor nozzle dimension and outlet nozzle

Øú â

Õò Ì âââ

Ü Ð Øú

Ï

Ï ÎÎÎÎÎÎÎ

é Ð Õò Ì

ò Ì âââ

We accept

ò Ì Sch 40

Gas feed inlet nozzle dimension

Ìç â

Ï

Õò ââ

ééç Ì

ò

We accept

ò

é

Ï ÎÎÎÎÎÎ

é Ð Õò

ç âââ

Sch 20

Gas feed outet nozzle dimension

Ìç â

Ï

ÕòÌ ââ

ééç Ì

òÌ

We accept

ò

é

Ï ÎÎÎÎÎÎ

é Ð ÕòÌ

ç âââ

Sch 20

6.0 Mechanical design of absortion column as per ASME S8. Di1/Di2

ACETONE ABSORPTION COLUMN

Required: “CONFIDENTIAL” Sh.a.

DESIGNED: Arberor MITA

Design group“ELMAGERARD”

6.0 Mechanical design of absortion column as per ASME S8. Di1/Di2

Ì ç Diameter of the tower

Ò

ç Ð ââ

Ï

Ò

ô Ð ââ

Ï

Ñ ×

ô

Design pressure

Working temperature

Working pressure

×

Design temperature

Õ Û ç Û Ò

ïÝ çé ââ

Ï

Ò

ä Ñ Ð ç " Ð ââ

Ï

!

Shell material: carbon steel plate

Permissible tensile stress

Elastic modulus

# Joint efficiency

×Õ Corrosion allowance

$

çé Overall packing height

ì Ñ

Top disengaging space

ú Ñ

Bottom disengaging space

û Ñ

Middle liquid distribution space

$ $ $ Ì

% $

ñÌ Ñ

$&' á $ì á $ú á $ú Ñ Shell length

Skirt length

Ò

Ñ ââ

)

( ì Ñ

$( $(* ú çç $( ì Ñ

Ò

ì ç

+ $+ Packing weight

First packing section initial distance of applied weight

from the top

First and second packing height

Second packing section initial distance of applied weight

from the top

Top internals weight

Top internals distance of applied weight from the top

Middle span internas weight

ACETONE ABSORPTION COLUMN

ú é

Required: “CONFIDENTIAL” Sh.a.

DESIGNED: Arberor MITA

Ò

Middle span internas weight

+ ú ç

Middle internals distance of applied weight from the top

$+ û ç

+ Design group“ELMAGERARD”

Ò

Bottom span internas weight

û ç

Bottom internals distance of applied weight from the top

$+ Ò

Ë,ñ,&-ÝïØ& ç â

Ò

ì ç ââ

Ï

Ò

ú ç ââ

Ï

Ò

.&Ì ââ

)

Weight of attachment (pipes, ladders & platform)

Wind pressure up to 20m

Wind pressure beyond 20 m

Steel density

Ò

Ë,Ý çÑ

Weight of a plate

6.1 Minimum shell thickness

23

Ù 111

ß

Ì

5

4:

í

ó

6789

/& ââ Ú0

Û çà á ×Õ ééç Ñ

We accept:

/& Checking maximum pressure allowed before plastic deformation starts to occur

ê ç

Minimum elastic deformation alued from the curve

;

Ù

Ù Ñ Ð Ì ßß

Ñ !ïÝ Ð ÙÚ/& Û ×Õßà Ð íç á ç Ð ê Ð íç Û ââââ

óó

%Ì Ò

Ú

Ú

àà

&Ý âââââââââââââââ çéçç ââ

Ï

ç Ð /&

The alouble pressure is greater than the design pressure, hence the thickness is satisfactory

with respect of plastic deformation

6.2 Torispherical head design

Determine, D, assume values for Rc, Rk and tt

Ì

<= <' Ì

ç

/ ç Ì

Crown radius

Knuckle

radius

Torispherical head thickness

Compute the head Rc/ D, Rk / D, and Rc/

equations are satisfied.

ratios and determine if the following

ACETONE ABSORPTION COLUMN

Required: “CONFIDENTIAL” Sh.a.

DESIGNED: Arberor MITA

Design group“ELMAGERARD”

Compute the head Rc/ D, Rk / D, and Rc/ tt ratios and determine if the following

equations are satisfied.

>

<

<

=

>ç

ââ

Ì <

Ñ > â= > Ñ

/Ì

'

? ââ

Ì Calculate the geometric constants

@ th, A th, R th.

Ù Ð Ì Û <' ß

âââââó ç

í

ÌÍ

Ú <= Û <' à

Ï ÎÎÎÎÎ

<= Ð /Ì

AÌÍ âââ ççé

@

BCDE

<'

Since , AÌÍ F @ÌÍ calculate Rth as follows:

Ì ÌÍ ââ

Ñ

<

Determine the coefficient C1 and C2

<

'

×ì ç Ð ââ

Û Ì ×ú çÑ

é

Calculate the value of internal pressure expected to produce elastic buckling of the knuckle,Peth

×ì Ð ä Ð /Ì Ï

Ò

ç

çç ââ

ââââââ

ÌÍ

Ï

Ù <ÌÍ

ß

×ú Ð <ÌÍ Ð íââ

Û <'ó

Ú Ñ

à

Calculate the value of internal pressure that will result in a maximum stress in the knuckle

equal to the material yield strength Py.

Since the allowable stress at design temperature is governed by time-independent properties,

C3 is the material yield strength at the design temperature.

×û !ïÝ G ×û Ð /Ì

Ò

ââ

âââââââ

Ï

Ù <ÌÍ

ß

×ú Ð <ÌÍ Ð íââ

Û çó

Ú Ñ Ð <' à

Calculate the value of internal pressure expected to result in a buckling failure of the knuckle,

Pck.

Calculate variable G.

H

ÌÍ

Ñç

ââ

ACETONE ABSORPTION COLUMN

Required: “CONFIDENTIAL” Sh.a.

DESIGNED: Arberor MITA

H

Since

HF

ç, P

ck

Design group“ELMAGERARD”

G

is determenined as:

Ù H Û Ñ é H Ï á çÑé Ð H ) ß

=' íââââââââââââââó Ð G

Ú ç á ççé H Û é H Ï á H ) à

Ò

çé ââ

Ï

Calculate the allowable pressure based on a buckling failure of the knuckle, Pak.

ï

'

='

Ò

é é ââ

ââ

Ï

ç

Calculate the allowable pressure based on rupture of the crown, Pac.

ï

=

Ñ Ð !ïÝ Ð #

ç

ââââ

<=

ç

âá â

/Ì

Ñ

Ò

ââ

Ï

Calculate the maximum allowable internal pressure, Pa

ÙÚ ï

ï

Ò

ï ßà é é ââ

Ï

IJK ' L '

Ò

ï é é ââ

Ï

Ò

ô ââ

Ï

ï

ô

F

The alouble pressure is greater than the design pressure, hence the thickness is satisfactory.

Weight of the torispherical head

Ï ß

Ù

Ð Ì ËÌ .&Ì Ð íçé Ð ââââ

Ð /Ìó

é

Ú

à

Ò

ACETONE ABSORPTION COLUMN

Required: “CONFIDENTIAL” Sh.a.

DESIGNED: Arberor MITA

Design group“ELMAGERARD”

6.3 Shell thicnes at difrent heights

Let X be the distance from the top of up to which we can use 6 mm thick shell

1.Circumferential stress induced in shell plate material at a distance X from the top of shell

(due to internal pressure)

!MN !MN

ô Ð Ì Ò

ââ

ââââ

Ï

Ñ ÙÚ/& Û ×Õßà

!MN O !ïÝ Ð #

will remain same for entire length

2.Various axial stresses induced due to internal in the shell plate material at a distance X from

the top of the shell.

-Axial stress induced due to internal pressure

!PMN ô Ð Ì Ò

Ñ ââ

ââââ

Ï

é ÙÚ/& Û ×Õßà

-Axial stress induced due to dead load

Axial stress induced due to weight of the shell

Ï

Ù

Ïß

Ù

ß

á

Ñ

/

â

Ú

Ú

Ì

&à Û Ì à Ð .&Ì Ð S

é

!PQR Ê ââââââââââââ

Ê .&Ì Ð S

Ï

ß

Ù

Ï

âÚÙÚÌ á Ñ /& Û ×Õßà Û Ì à

é

!PQR

Ò

Ê .&Ì Ð S Ê Ð S Ð ââ

Ï

Axial stress induced due to weight of the packing

Ï

Ð Ì Ð ( Ð S Ð ââââ

é

!PQNQ Ê âââââââââââ

Ê Ñ

Ï

ß

Ù

Ï

âÚÙÚÌ á /& Û ×Õßà Û Ì à

é

Axial stress induced due to weight of the internals

Weight of the top internal per surface area

é +ì

Ò

Ëñòì ââââ

ç ââ

Ï

Ï

Ð Ì Weight of the middle internal per surface area

é +ú

Ò

Ëñòú ââââ

é ââ

Ï

Ï

Ð Ì S

Ò

Ð ââ

Ï

ACETONE ABSORPTION COLUMN

Required: “CONFIDENTIAL” Sh.a.

DESIGNED: Arberor MITA

Design group“ELMAGERARD”

Weight of the bottom internal per surface area

é +û

Ò

Ëñòú ââââ

çç ââ

Ï

Ï

Ð Ì Weight of liquid per meter of packing

N

ç â

ÓT

Spread of the moving liquid in the packing

U

)

V

ËÝñî, âââ

ç ââ

Ü Ð V

Weight of liquid per length of the column

Ò

ËÝñî,W Ê ËÝñî, Ð Ü Ð X Ê ç Ð ç ) Ð X Ð â

Axial stress induced due to weight of liquid

!YZ-W

ËÝñî,W

ç Ð X Ò Ê é

Ê ââââââ

Ê

ââââ

Ð Ì Ð Ù

Ú/& Û ×Õßà çÑ Ï

X

Ò

Ð ââ

Ï

Axial stress induced due to weight of attachments

!WYZ

ËÌ á Ë,ñ,&-ÝïØ& Ð X [

Ò

Ê âââââââ

Ê

[ç á çÑÑé X\

\ Ð ââ

Ï

Ð Ì Ð Ù

Ú/& Û ×Õßà

Total axial stress due to dead loads

ô Ê !YW] á !YWVW á !YZ-W á !WYZ

!Y

Ð X\\ á [[Ñ X\\ á [[é

Ò

ÙÚç Ð ç ^ ßà ââ

Ï

[

[

X\

\

á [[çÑÑé X á ç\\ á [[ç á é á çÑ\\ Ê ç á çéç X

ô Ê ç á çéç X

!Y

Axial stress induced due to wind load at a distance X from the top of the shell

!W

çé Ð Ì Ð X Ï

çé Ð X Ï

Ï

Ê âââââââ

Ê ââââââ

Ê

ç

é Ð X

Ï

Ð Ì Ð Ù

Ú/& Û ×Õßà Ð Ì Ð ÙÚ/& Û ×Õßà

ACETONE ABSORPTION COLUMN

Required: “CONFIDENTIAL” Sh.a.

DESIGNED: Arberor MITA

Design group“ELMAGERARD”

Maximum tensile stress induced in the shell plate material at a distance X from the top of the shell.

Ï

Ï

Ìîïð Ê !Y_V á !W Û !Yô Ê Ñ Û [[ç á çéç X\\ á çé Ð X Ê Ñ Û çéç X á çé Ð X

!

Maximum allowed length for kipping the same shell thickness according to tensile stress.

Ìîïð Ê !Y_V á !W Û !Yô Ê !ïÝ Ð #

Ò

!ïÝ Ð # Ù

Úçç Ð ç ) ßà ââ

Ï !Y_V á !W Û !Yô Û !ïÝ Ð # Ê çé Ð X Ï Û çéç X á Ñ Û çç Ê çé Ð X Ï Û çéç X Û Ê !

Ï ÎÎÎÎÎÎÎÎ

Ï Û é ( Ð çéç á Ï ÎÎÎÎÎÎÎÎÎÎÎÎÎÎÎÎÎÎÎÎ

Ï

Ûë

á

ë

ç

éç Û é çé Ð [

[Û \

\

X Ê ââââââ

Ê ââââââââââââ

Ñ(

Ñ çé

Ï ÎÎÎÎÎÎÎÎÎÎÎÎÎÎÎÎÎÎÎÎ

ç

éç á

çéç Ï Û é çé Ð [[Û \\

X ââââââââââââ Ñ

Ñ çé

The length x is almost the double off the length of our column hence the same shell

thickness can be used through the column according to tensile stress

Maximum compressive stress induced in the shell plate at a distance X from the top of the

shell.

÷

! Y Ñ ÙÚ/& Û ×Õßà

Ò

ç ââââ

ä

Ð

Ñç ââ

â

ââââ

Ï

Ï

Ù

ß

çÑ Úç Û à Ì Allowable compressive stress

Maximum compressive stress induced in the shell plate material at a distance X from the top

of the shell.

Ï

Ï

Ìîïð Ê Û!Y_V á !W á !Yô Ê ÛÑ á [[ç á çéç X\\ á çé Ð X Ê ÛÑ á çéç X á çé Ð X

!

Maximum allowed length for kipping the same shell thickness according to compressive stress.

Ìîïð Ê !Y_V á !W Û !Yô Ê !÷Y Ð #

!

Û!Y_V á !W á !Yô Û !÷Y Ð # Ê çé Ð X Ï á çç X Û Ñ Û Ñé Ê çé Ð X Ï á çéç X Û é Ê Ï ÎÎÎÎÎÎÎÎ

Ï Û é ( Ð Ûçéç á Ï ÎÎÎÎÎÎÎÎÎÎÎÎÎÎÎÎÎ

Ûë

á

ë

çéç Ï Û é çé Ð é X Ê ââââââ

Ê âââââââââââ

Ñ(

Ñ çé

Ï ÎÎÎÎÎÎÎÎÎÎÎÎÎÎÎÎÎÎÎ

Ï

Ûç

éç á

ç

éç Û é çé Ð Ûé X ââââââââââââ çÑé

ACETONE ABSORPTION COLUMN

Required: “CONFIDENTIAL” Sh.a.

DESIGNED: Arberor MITA

Design group“ELMAGERARD”

Ñ çé

The length x is less than the length of our column hence we have to use a different thickness

in the half bottom of the column, for this reason we are going to use shell thickness of 8mm in

the half bottom of it and redo the calculation again only for this section of the column.

/& 2.Various axial stresses induced due to internal in the shell plate material at a distance X from

the middle of the shell.

-Axial stress induced due to internal pressure

!Y_V ô Ð Ì Ò

ç

ââ

ââââ

Ï

é ÙÚ/& Û ×Õßà

Weight of the top half of the column

Ï

%Ì Ù

ÙÚÌ á Ñ /&ßà Û Ì Ï ßà Ð ââ

ËÌ &ÍÝÝ`aÿ â

Ð .&Ì á ËÌ ÙÚÑ ç Ð ç ) ßà Ò

Ú

é

Ñ

Ï Ð $(* ÙÚÑ Ð ç ) ßà Ò

ËVï`aÿ ( Ð â

é Ì +ú

ÙÚé Ð ç ) ßà Ò

ËÌ &`aÿ ËÌ &ÍÝÝ`aÿ á ËVï`aÿ á +ì á ââ

Ñ

Total axial stress due to weight of half of the column