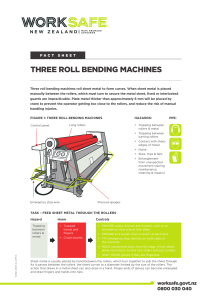

21/02/2024, 09:48 Three roll bending machines | WorkSafe ; Machinery Three roll bending machines Three roll bending machines roll sheet metal to form curves. While this guidance has not been updated to reflect current work health and safety legislation (the Health and Safety at Work Act 2015 and regulations), it may still contain relevant information and practices to keep workers and others healthy and safe. Please read this guidance in conjunction with all relevant industry standards that apply to you as a PCBU. This guidance will be progressively reviewed and either updated, replaced with other guidance, or revoked. When sheet metal is placed manually between the rollers, which must turn to secure the metal sheet, fixed or interlocked guards are impracticable. Plate metal thicker than approximately 6 mm will be placed by crane to prevent the operator getting too close to the rollers, and reduce the risk of manual handling injuries. Figure 1: Three roll bending machines https://www.worksafe.govt.nz/topic-and-industry/machinery/three-roll-bending-machines/ 1/6 21/02/2024, 09:48 Three roll bending machines | WorkSafe Hazards Trapping between rollers & metal Trapping between turning rollers Contact with sharp edges of metal Noise Slips, trips & falls Entanglement from unexpected movement (during maintenance, cleaning & repairs) Personal protective equipment (PPE) Ear protection Eye protection Hand protection Tasks https://www.worksafe.govt.nz/topic-and-industry/machinery/three-roll-bending-machines/ 2/6 21/02/2024, 09:48 Three roll bending machines | WorkSafe Task – Feed sheet metal through the rollers HAZARD Trapping between rollers & metal HARM Trapped hands and fingers Crush injuries CONTROLS ENSURE safety devices are in place, such as an emergency stop wire or kick plate. ENSURE kick panels have a switch at each end. FIT emergency stop devices on both sides of the machine. HOLD workpieces back from the edge of the metal, allowing metal to be fed into rollers without contact. ONLY WEAR gloves if they are fingerless. Sheet metal is usually placed by hand between the rollers, which turn together to pull the sheet through. As it passes between the rollers, the sheet curves to a diameter limited by the size of the rollers. The action that draws in a metal sheet can also draw in a hand. Finger ends of gloves can become entangled and draw fingers and hands into nips. Task – Load & unload HAZARD Trapping between turning rollers & moving workpieces HARM https://www.worksafe.govt.nz/topic-and-industry/machinery/three-roll-bending-machines/ 3/6 21/02/2024, 09:48 Three roll bending machines | WorkSafe Trapped hands Crush injuries CONTROLS Operation MUST only occur when the machine is in “run” position. COVER pedals to minimise the chance of accidental starts. FIT emergency stop devices. HAZARD Contact with sharp edges of metal sheets HARM Cuts CONTROLS WEAR fingerless gloves to protect palms. Other (non-mechanical) hazards HAZARD Noise https://www.worksafe.govt.nz/topic-and-industry/machinery/three-roll-bending-machines/ 4/6 21/02/2024, 09:48 Three roll bending machines | WorkSafe HARM Hearing damage or loss CONTROLS REDUCE noise levels by isolating machines or enclosing within noise barriers. ASSESS noise levels. ARRANGE hearing screenings. ALWAYS WEAR hearing protection. A safe noise level over an eight hour day is 85dB(A). A three roll bending machine may exceed this noise intensity. HAZARD Slips, trips and falls HARM Trapping Cuts Bruising CONTROLS KEEP up-to-date housekeeping procedures. KEEP the area around machines clear of slip and trip hazards. Task – Maintenance, cleaning & repairs https://www.worksafe.govt.nz/topic-and-industry/machinery/three-roll-bending-machines/ 5/6 21/02/2024, 09:48 Three roll bending machines | WorkSafe HAZARD Entanglement from unexpected movement HARM Trapped hands and fingers Crush injuries CONTROLS LOCK-OUT all power supplies before maintenance, cleaning and repairs. KEEP written safety procedures, and ARRANGE regular safety inspections by a competent person. REMOVE or LOCK-OUT machines that fail inspection, and DO NOT USE until repaired or replaced. Download fact sheet PDF Three roll bending machines (PDF 272 KB) Last updated 2 October 2017 at 16:42 © Copyright 2024 WorkSafe NZBN: 9429041926437 https://www.worksafe.govt.nz/topic-and-industry/machinery/three-roll-bending-machines/ 6/6