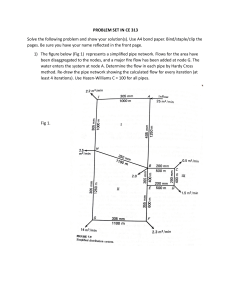

Algorithms for Pit Pressure Changes and Head Losses in Stormwater Drainage Systems Geoffrey O'Loughlin* and Bob Stack** Anstad Pty Ltd, 72 Laycock Road, Penshurst, NSW, 2222, Australia, Anstad@tpgi.com.au Watercom Pty Ltd, 105 Queen Victoria St., Bexley, NSW, 2207, rstack@watercom.com.au * ** Abstract Theories and experimental work on changes to energy and hydraulic grade lines at pits or manholes are outlined. Four algorithms describing these changes are compared against selected experimental results. The comparisons are inconclusive, with no method being obviously superior. However, this information should provide the basis for further development of an empirical algorithm, which needs to cover the misalignment of pipes. Case studies are presented to provide a perspective on (a) the types of pit geometries occurring in separate stormwater drainage systems, and (b) the overall importance of pit pressure changes in the analysis and design of separate stormwater drainage systems. An extended reference list and bibliography are provided. 1. Introduction Head losses at pits or manholes, represented by changes in energy and hydraulic grade lines, are required to adequately describe flow behaviour in stormwater drains and sanitary sewers. Flow through these facilities can be extremely complex. Despite the application of theories and many experimental studies, existing analytical and design procedures are incomplete. This paper considers the problem of losses and pressure changes from the viewpoint of a software developer seeking an algorithm to calculate pressure changes in separate stormwater drainage systems subject to unsteady full and part-full pipe flow conditions. 2. The Phenomenon In sanitary sewer systems, manholes provide access for inspection and maintenance, and a junction point where pipe branches can connect, or where pipes can change size or direction. In combined and separate stormwater drains, they are also entry points for surface runoff. Manholes and pits are nearly always larger than pipes, and the expansion of pipe flows entering the junction, the mixing of pipe and surface inflows and the effects of downstream water levels create complex flow conditions, with energy losses and increases in water levels, sometimes causing overflows. Complexity comes from the almost infinite variety of conditions that can occur. Some relate to the system geometry. For a pit with a single outlet, this can involve: (a) (b) (c) (d) (e) (f) (g) various numbers of pipes entering the pit (0 to 3 or more), the presence of a surface inlet or grate flow, the angles of the inlet pipes relative to the outlet pipe in the horizontal plane, the various heights of the invert pipes and drops in the pit, the pipe diameters, whether pipe inflows are opposed, so that jets will interfere with each other, whether jets from inlet pipe are directed into the outlet pipe, or against a pit wall, 1 (h) the size and shape of the pit, and (i) whether benching or deflectors are placed in the pit. Also important are flow characteristics, including: (j) (k) (l) (m) the flowrates in the inlet pipes and from the surface inlet, whether the pipes are running full or part-full, supercritical or subcritical, the effect of tailwater level and the water level in the pit, in the case of junctions with two or more upstream pipes, time-dependent flow ratios, as contributing hydrographs in upstream pipes pass through a pit. The problem is likely to be approached differently when dealing with (a) sanitary and combined sewer systems, and with (b) separate stormwater systems. The former usually involves circular manholes, energy grade lines (EGLs), and energy or head loss coefficients, while the latter relates to with rectangular pits, hydraulic grade lines (HGLs) and pressure change coefficients (Figure 1). This paper focuses upon separate systems and mostly employs the terminology associated with these. Figure 1 Drainage Systems with Grade Lines and Changes Shown The energy loss and pressure changes mentioned above are expressed in the usual form of head losses, as coefficients multiplied by the velocity head in the downstream pipe: Energy or head loss (m), h L = k L Vo2 V2 and pressure change (m), h P = k P o , … (1 & 2) 2g 2g with Vo being the outlet pipe velocity (m/s) and g being acceleration due to gravity (m/s2). Hare (1983) has noted that the actual water surface in a pit can be higher than the HGL level when there is a change of direction, due to conversion of kinetic energy. He proposed a third relationship with a coefficient kW, V2 Water Level, WL = k W o … (3) 2g In determining changes and coefficients, EGLs and HGLs in pipes are projected upstream or downstream to the centre of the pit. From Bernoulli’s Equation, for a system with one inlet pipe and one outlet pipe, the coefficients are related by: 2 Vu2 , with Vu being the velocity in the upstream pipe (m/s) … (4) Vo2 kP factors can be negative where the pit outlet pipe is larger than the inlet pipes, and the outlet pipe velocity head is less than that of the inlet pipes. Large differences in the pressure change coefficient can occur from the particular alignments of pipes as they enter or leave pits. Hare (1983) showed that losses depend on how a jet of flow emerging from an inlet pipe is directed to the outlet pipe. If it is directed straight at the pipe, as in Figure 2(a), head losses will be low; if it impinges onto a wall, as in Figure 2(b), losses will be much higher, as indicated by the data in Table 1, drawn from experiments with single-inlet pipe systems. k P = (1 + k L ) − Figure 2 Alternative Alignments of Pipes meeting at a Pit Table 1 Pit Pressure Change and Water Level Coefficients for Different Pipe Alignments with a Change of Direction of 45 o Ratio of inlet and outlet diameters, Du/Do 0.7 0.8 0.9 1.0 kP Coefficients for a Branch Point on the Downstream Face of a Square Pit -0.90 0.0 0.45 0.60 Coefficients for a Branch Point on the Upstream Face of a Square Pit kP kW 2.05 2.90 2.10 2.60 2.15 2.50 2.20 2.30 3. Theory Mass conservation at a junction is simply: Sum of Inflows - Sum of Outflows = Change in Storage … (5) which can be ignored unless the volume of a pit is large, or storage is considered to include the surface area above a pit. Energy conservation can be described in various ways. Yen (2001) presents this as: Vi2 n pi ∑ Q . 2g + γ i =1 i V2 dY n + z i − Q j h j = s + ∑ Q i k L,i i 2g dt i =1 … (6) where Qi are the flows in pipes entering and leaving a pit (m3/s), being positive for inflows and negative for outflows, Vi are the corresponding flow velocities (m/s), pi are the piezometric heads above pipe inverts at levels zi (m), γ is the specific weight of water (N/m3), 3 Qj represents flows introduced or extracted at the pit, such as surface grate inflows, and jj is the corresponding energy transfer (m), s is the storage in the pit (m3), Y is the depth of water in the pit, and kL,i are the exit or entrance loss coefficients for the various pipes. A variation on this is the power loss approach proposed by Chang et al. (1994) using the semi-empirical formulation: m Qj Vj2 Qj Vo2 n Qi Vi2 m ∆E = α1 + ∑ α 2,i + ∑ α 3. j (z j + D j − d mH ) + ∑ α 4, j 2g 2g i =1 Q o 2g i =1 Qo j=1 Q o … (7) where ∆E is the composite energy loss (m), α1 is a contraction loss coefficient, α2,i is an expansion loss coefficient for each submerged inflow pipe i, α3,j is a plunging loss coefficient for each plunging inflow pipe j, α4,j is an expansion loss coefficient for each plunging inflow pipe j, dmH is the water depth in the manhole relative to the common datum (m), Dj is the diameter of the jth plunging inlet pipe (m), and n and m are the numbers of inflow pipes that are submerged and are plunging. Momentum conservation can also be applied in various forms. One equation that considers impulse and force acting in the direction of a single outlet pipe is: m ∑ P A cosθ i =1 i i i m − Po A o − R = ρ. Q o Vo − ∑ Q i Vi cosθ i i =1 … (8) where Pi and Ai are the pressure (N/m2) and cross-sectional area (m2) in m inlet pipes, θi is the angular difference between the directions of Pipe i and the outlet pipe, Po and Ao are the outlet pipe pressure and cross-sectional area, R is the reaction force in the direction of the outlet pipe (N), ρ is the density of water (kg/m3), Qo and Qi are the outlet and inlet pipe flowrates (m3/s) and Vo and Vi are the corresponding velocities (m/s). This equation should adequately describe the situation at a closed junction, where pipes meet without a chamber in which expansion can occur. One analytical approach has been to separate energy losses into two additive components - an exit loss as a pipe flow jet enters a pit and an entrance loss as flow enters the outlet pipe. Other theories applied to the flow situation in pits include submerged jet theory (Bo Pedersen and Mark, 1990, Mudgal and Pani, 1993) and various computational fluid dynamics techniques, such as a stochastic turbulence-closure model (Stein et al., 1999). While these relationships appear to be straightforward, the complications noted in Section 2 mean that simple theoretical concepts cannot be applied to all situations. The projected straight grade lines mask quite complex turbulence, exit and entrance losses, jet behaviour, swirl and air entrainment effects. 4. Laboratory Modelling of Pit Energy Losses and Pressure Changes There has been little direct field testing of pit pressure changes. It appears that the many calibrations of monitored systems, such as the large sewer described by Jacobsen and Harremoes (1984), have not provided any published conclusions about manhole head losses. 4 Almost all information comes from laboratory tests on scale models that are typically onetenth of prototype size. The seminal study was that of Sangster et al (1958) at the University of Missouri. This was followed by studies in the UK (Ackers, 1959, Archer et al., 178, Howarth and Saul, 1984), Canada (Townsend and Prins, 1878, Marsalek, 1981, 1984, 1985, 1988, Dick and Marsalek, 1985) Australia (Hare, 1981, Black and Piggott, 1983, DeGroot and Boyd, 1983, Johnston and Volker, 1990, Hare et al., 1990, Hare and O’Loughlin, 1991), Sweden (Lindvall, 1984, 1987) and Denmark (Bo Pedersen and Mark, 1990). There have also been studies in Greece (Christodoulou, 1987, 1991), Japan (Kusuda and Arao, 1987, Kusuda et al., 1993, Sakakibari, 1996, Arao and Kusuda, 1999), India (Mudgal and Pani, 1993), Germany (Merlein and Valentin, 1999) and Italy (Calomino et al, 1999). A significant addition to this list is the extensive modelling by Chang et al. (1994) for the US Federal Highway Administration (FHWA), from which the algorithm described by GKY Associates Inc (1999) and Stein et al. (1999) has been developed. While most laboratory studies have measured losses under steady flow conditions, Howarth (1984), Howarth and Saul (1984), Hare et al. (1990) and Merlein and Valentin (1999) describe experiments using systems of valves and sensors to create unsteady flow conditions and to measure time-varying head losses. Howarth and Saul (1984) concluded that loss coefficients were similar for unsteady and steady flow conditions in the absence of swirl in a manhole, but that steady state results overestimate loss coefficients when swirl occurred. Hare (Personal communication, 2002) points out that at any instant of time in a complex flow event, unsteady pressure change coefficients are similar to the experimentally-derived steadystate values, but that they will change significantly during the event. 5. Design Aids Experimenters have attempted to obtain generalised relationships from their experimental data, using methods such as dimensional analysis, semi-empirical formulations and regression analysis. Some have developed design aids such as the "Missouri Charts" of Sangster et al. (1958), a set of nine charts describing the situations described in Table 2. These charts are complex and their diverse formats, based on different sets of parameters, make computer implementation difficult. Other studies noted previously have provided useful design information, particularly those by Hare (1983), Marsalek (1985) and Chang et al. (1994). The derived equations or graphs are in different forms and are difficult to implement within computer programs. The relationships developed by Chang et al. (1994) have been incorporated into the HYDRA program, which is part of the HYDRAIN suite (GKY & Associates Inc., 1999). An energybased formulation was employed, rather than the power loss formulation presented in an appendix to the FHWA Hydraulic Engineering Circular 22 (US FHWA, 1996). Equations, algorithms and software implementations have been developed to define pressure change and loss coefficients. Some examples are discussed in the following sections. 6. Computer Modelling of Piped Urban Drainage Systems Computer modelling of drainage systems is used to design and check new systems, and to analyse established drainage systems to develop remedies to problems or inadequacies. 5 Many models have been developed and modelling can be undertaken using software involving full hydrodynamic calculations, such as SWMM, Hydroworks and MOUSE, or simpler models. The effects of pit junctions are incorporated in various ways. For example, in SWMM head losses are modelled as exit and entrance losses in some computations, but are ignored or included as equivalent pipe lengths in others. MOUSE currently allows users a choice of nine loss coefficient types based on geometry. Table 2 “Missouri Chart” Formulations No. Configuration Chart 1 Chart 2 Nomenclature Rectangular grated inlet pit at top of a line, no pipe inlets Rectangular pit, no grate flow, one inlet, straightthrough flow Same pit as for Chart 3, with grate flow Rectangular pit with two inlets, one straight-through, the other at 90o to the outlet pipe, plus grate flow Rectangular pit with two directly-opposed inlets at 90o to outlet, and grate flow Rectangular pit with two inlet pipes at 90o to outlet, not opposed, and grate flow Square manhole with two inlet pipes, one straightthrough and the other at 90o Same as for Chart 8 Chart 3 Chart 4 Chart 5 Chart 6 Chart 7 Chart 8 Chart 9 Chart 10 Square or round manhole with the same configuration as for Chart 8 Type of Relationship (using Sangster et al. Terminology) KG coefficient vs submergence ratio d/DO - two curves for surface grate inflow direction KU coefficient vs DU/DO with three curves for different manhole lengths and another for a rounded outlet pipe entrance KU coefficient vs DU/DO with six curves for different QG/QO ratios and another chart for adjustment to allow for water depth in pit, d Ku and KL coefficient vs DU/DO with seven curves for different QU/QO ratios, with adjustment charts for different QG/QO and DU/DO ratios K coefficients estimated from factors H and L taken from charts based on ratios of diameters and flows, depending on which is the higher-velocity flow KN and KF (nearest and furthest from outlet) coefficients obtained in two charts, for ratios of flows and two ratios of diameters KL, the lateral pipe coefficient, is found from two charts based on diameter and flow ratios and submergence depth; there is an adjustment factor for manhole shape (square to round) KU coefficient for the same situation as in Chart 2, as a function of flow and diameter ratios - the form of the two charts is different than Chart 8, and a correction for deflectors is provided KU and KL coefficients based on DU/DO and QU/QO ratios over a greater range that Charts 8 and 9, with ten curves. Charts 8 and 9 are preferred where both alternatives can be used The authors have reviewed available information to develop a reliable procedure for calculating pit pressure change coefficients in DRAINS (O’Loughlin and Stack, 2001), a quasi-unsteady simulation model that calculates HGL positions in drainage systems at time steps during storm events. These calculations should occur without the user having to specify detailed pit characteristics, or having to interact with the program when entering data. DRAINS currently allows users to specify constant kP coefficients or to define these using a form of the relationship suggested by Mills (Mills and O’Loughlin, 1998): Qg Q … (9) k P = 0.5 + 2 m + 4 Qo Qo where Qm refers to the total flows from misaligned inlet pipes, which are out of alignment with the outlet pipe by more than Do/4, horizontally or vertically, Qg refers to surface inlet or grate flows plus any pipe flows that enter the pit above the water level, and Qo is the outlet flowrate (all in m3/s). Modifications are made by adding factors for deflectors or benching (-0.5), opposed pipes (1.0) and for increases in pipe diameters (-0.5). This method is 6 intended to provide a rough estimate in situations where drops (vertical misalignments of inlet and outlet pipes) occur. It only applies to pipes flowing full. The use of constant kL or kP coefficients applying to peak flow conditions is valid when using the Rational Method and only considering peak flowrates. In unsteady flow models, coefficients should change to reflect the changing flow conditions occurring at each time step during an analysis of a storm event. 7. Comparison of Algorithms To explore suitable methods of determining pit pressure change coefficients, four methods were examined. Each of these can be applied at each time step in an analysis, with a current coefficient being calculated from the instantaneous flow conditions. The first method was Mills’ Equation (9). The second was an equation developed by Hare (Hare et al., 1990) from the momentum equation (8). For n inlet pipes this is: D k P = 2.3 − 2.0. o Qo 2 2 Q 2 Q Q 1 cos θ 1 + 2 cos θ 2 + ... + n D1 D2 Dn 2 cos θ n … (10) where D represents pipe diameters (m), Q flowrates for full-pipe flow (m3/s), θ the angular differences between directions of inlet pipes and the outlet pipe, with subscript o referring to the outlet pipe and subscripts 1, 2, .. n referring to inlet pipes. Theoretically, the first number on the left hand side of the equation should be 2.0. The change to 2.3 is an empirical adjustment suggested by Hare and O’Loughlin (1991) to fit experimental data better. The third relationship was a regression equation developed by Parsell (1992) from the Hare (1983) data and verified against the Sangster et al. (1958) data. The pressure change coefficient is found from: kP = 2.3479 - 0.3794 P1 - 1.2894 P2 - 0.1146 P3 - 0.9703 P4 - 0.1657 P5 + 0.0519 P12 -0.3755 P22 + 0.3032 P32 +0.8078 P42 + 0.0108 P52 … (11) where P1, P2, …, P5 are factors related to lost forces, conserved forces, head requirements, grate inflow ratio and submergence ratio. A similar relationship is provided for kw coefficients. These relationships depend on a measure of the misalignment of the inlet and outlet pipes, defined in terms of the intersection of their horizontal and vertical projections on the downstream pit wall and in the output pipe. The fourth relation tested was the algorithm developed for the FHWA, which has the form: kL = (C1.C2.C3+ C4).ω … (12) where C1 is a coefficient related to the relative sizes of the pipes and manhole, C2 is a coefficient related to water depth in a manhole, C3 is a coefficient related to lateral flow, lateral angle and plunging flow, C4 is a coefficient related to relative pipe diameters, and ω is a correction factor for benching (with a value of 1.0 for no benching). 7 The relationships for the C factors are provided by GKY & Associates Inc. 1999) and Stein et al. (1999). C3 is the most complicated, being derived as the sum of five terms. These four methods are not strictly comparable because different levels of coverage are intended. The Mills equation is approximate, and generally conservative. The Hare equation assumes that pipes are directed to the centre of the pit and it does not allow for pipe drops and misalignments. The Parsell algorithm can allow for misaligned pipes and drops. All three apply only to full-pipe flows. The FHWA algorithm is the most comprehensive, covering part- and full-pipe flow, drops and other situations. In Table 3, results from the four algorithms, calculated by a spreadsheet macro, are compared with the Sangster et al. (1958) and Hare (1983) charts for cases with no pipe inlet and with one inlet. Cases of two or more inlet pipes are not considered, and it is assumed that all pipes are aligned to minimise energy losses. The FHWA Equations have been implemented from the descriptions in the HYDRA manual and the associated papers. The kL coefficients calculated by this method were converted to kP coefficients by Equation 4. For submergence ratios less than 1.0, part-full pipe velocities were used, corresponding to the higher of the normal and critical depths in the inlet and outlet pipes. Although only a few of the possible geometric configurations are covered, the values in Table 3 reveal some of the complexity of kP coefficients and the large variations that can occur. Even the determination of the Chart estimates is complicated, with some estimates requiring several operations. It is evident that no method matches the Chart values accurately for all cases. Mills’ method specifies a minimum kP coefficient of 0.5 and is generally conservative. The Hare procedure gives values that match the general form of the Chart values. Coefficients from the Parsell method appear to match the Chart values most closely. The FHWA algorithm does not appear to perform better than the Hare or Parsell methods. Assessment is therefore difficult, with methods matching experimental data well in some cases but not in others. While the FHWA method appears, on the basis of its rigorous derivation, to be the best candidate for an algorithm, it will need qualifications and extensions to cover all situations, particularly those involving misalignments of pipes, which it does not include. It is likely that the Mills and Parsell methods, which allow for misalignments, will perform better when tested in cases where these occur. 8. Implications for Analysis of Separate Stormwater Drainage Systems To investigate how pit pressure change coefficients affect actual analyses, three established drainage systems and two newly-designed systems in the Sydney Area have been examined to classify pits into categories, as shown in Table 4. The categories allow for changes of direction and pipe size (from a set of standard pipe diameters), and for numbers of inlet pipes. The existing systems have some cases of outlet pipe diameters being less than those of inlet pipes at pits. These are due to (a) pipe enlargement works that have been implemented only partially, and (b) surcharge pits, associated with “converters”, short lengths of pipe that carry flows under cross-streets and discharge into street gutters. Both designs include interallotment drainage pipes as well as pipes in streets. The “PL” design is a conventional one, while the “SP” design involves a number of pits with reductions in pipe sizes to divert runoff to stormwater treatment devices. The changes of direction greater than 90o at some pits reflect the curved streets in the “SP” subdivision layout. 8 Table 3 Comparison of Fitted Data and Estimated Pit Pressure Change Coefficients Case Pit at top of a line, no inlet pipes (Missouri Chart 2) - submergence ratio = 0.5 - submergence ratio = 1.5 - submergence ratio = 3 - submergence ratio = 6 One inlet pipe, straight-through flow, no grate flow (Missouri Chart 3) - Du/Do = 0.833, submergence ratio = 0.5 - Du/Do = 0.833, submergence ratio = 1.5 - Du/Do = 0.833, submergence ratio = 3.0 - Du/Do = 1.0, submergence ratio = 0.5 - Du/Do = 1.0, submergence ratio = 1.5 - Du/Do = 1.0, submergence ratio = 3.0 - Du/Do = 1.2, submergence ratio = 0.5 - Du/Do = 1.2, submergence ratio = 1.5 - Du/Do = 1.2, submergence ratio = 3.0 One inlet pipe, straight-through flow, 33% grate flow (Missouri Chart 4) - Du/Do = 0.833, submergence ratio = 0.5 - Du/Do = 0.833, submergence ratio = 1.5 - Du/Do = 0.833, submergence ratio = 3.0 - Du/Do = 1.0, submergence ratio = 0.5 - Du/Do = 1.0, submergence ratio = 1.5 - Du/Do = 1.0, submergence ratio = 3.0 - Du/Do = 1.2, submergence ratio = 0.5 - Du/Do = 1.2, submergence ratio = 1.5 - Du/Do = 1.2, submergence ratio = 3.0 One inlet pipe, 90o change of direction, no grate flow, pit width = 2 x outlet diameter (Missouri Chart 8) - Du/Do = 0.833, submergence ratio = 1.5 - Du/Do = 0.833, submergence ratio = 3 - Du/Do = 1, submergence ratio = 1.5 - Du/Do = 1, submergence ratio = 3 - Du/Do =1.2, submergence ratio = 1.5 - Du/Do = 1.2, submergence ratio = 3 One Inlet Pipe, no grate flow, submergence ratio = 3.0 (Hare, 1983), changing direction at downstream wall - Du/Do = 0.833, angular change=0o - Du/Do = 0.833, angular change=22.5o - Du/Do = 0.833, angular change=45o - Du/Do = 1.0, angular change=0o - Du/Do = 1.0, angular change=22.5o - Du/Do = 1.0, angular change=45o kP Coefficients Hare Parsell Charts Mills FHWA 6.6 or 9.51 3.1 or 3.81 1.95 4.5 4.5 4.5 2.3 2.3 2.3 2.15 1.97 1.77 0.19 1.34 2.69 2.40 -0.85 -0.85 0.12 0.12 0.72 0.72 0.0 0.0 0.5 0.5 0.5 0.5 -0.58 -0.58 0.3 0.3 0.91 0.91 -0.40 -0.58 0.46 0.28 1.21 1.04 0.58 -0.91 -0.76 0.53 0.17 0.32 0.50 0.69 0.84 1.35 0.95 1.9 1.3 2.3 1.5 1.83 1.83 1.83 1.83 1.83 1.83 1.02 1.02 1.41 1.41 1.68 1.68 0.91 0.73 1.27 1.10 1.60 1.42 0.71 0.77 1.44 0.69 1.25 1.92 0.68 1.48 2.15 1.68 1.68 1.62 1.62 1.55 1.55 0. 0 0.0 0.5 0.5 0.5 0.5 2.30 2.30 2.30 2.30 2.30 2.30 1.87 1.70 1.98 1.81 2.07 1.90 -0.91 -0.76 0.32 0.17 0.69 0.84 -0.70 -0.40 0.15 0.20 0.30 0.60 0.0 0.0 0.0 0.5 0.5 0.5 -0.58 -0.36 0.34 0.30 0.65 0.88 -0.58 -0.55 -0.09 0.28 0.29 0.61 -0.76 -0.76 -0.76 0.32 0.32 0.32 Notes: The flowrates used in these comparisons are typical values, producing full-pipe velocities of 1 to 2 m/s. Generally, relative flows are more important than absolute values and kP coefficients did not change much with flowrates.. 1 Values depend on the direction of the approach flow to the surface inlet relative to the outlet pipe direction. Experimental evidence for Chart 2 is inconclusive, and curves tend to overestimate kP coefficients. It can be argued that comparison with kW coefficients is more valid that with kP coefficients. 9 Table 4 Distribution of Size and Angle Changes and Pit Configurations for Five Systems Pipe Arrangement, Direction and Pipe Size Change Total number of pits Pits at the Start of a Line Straight-through flow pipes: - more than one size down - one size increment down - same pipe size - one size up - two sizes up - three or more sizes up 5o to 30o change of direction: - one size down - same pipe size - one size up - two sizes up - three or more sizes up 30o to 60o change of direction: - more than one size down - one size down - same size - one size up - two sizes up - three or more sizes up 60o to 85o change of direction: - one size down - same pipe size - one size up - two sizes up - three or more sizes up 90o change of direction: - more than one size down - one size down - same pipe size - one size up - two sizes up - three or more sizes up > 90o change of direction: - more than one size down - same pipe size - one size up Surcharge pit (for converter) Alternative Categories: Pits with no inlet pipe Pits with one inlet pipe Pits with two inlet pipes Pits with three inlet pipes Pits with four inlet pipes Catchment “WS” “CR” “HC” “PL” “SP” 100 31 481 164 430 128 64 15 169 34 2 31 10 1 1 7 147 33 5 2 2 5 142 16 9 2 18 4 1 - 1 53 14 3 - 3 2 - 1 27 2 1 1 1 34 4 3 4 4 2 1 - 19 3 2 - 1 2 2 - 1 13 3 2 - 2 25 5 1 4 9 2 - 12 3 2 - 1 1 - 6 14 4 1 5 2 - 1 - 1 4 3 1 2 7 1 - 2 1 20 5 2 3 1 16 4 3 1 4 3 - 1 2 4 - 2 2 8 3 8 - 2 2 4 - 31 40 25 3 1 164 200 103 12 1 128 206 80 12 4 15 39 10 - 34 114 21 1 - Certain categories dominate - pits at the top of a line with no inlets, straight-through pits with inlet and outlet pipes of the same size, and pits with one inlet. Due to the large numbers of these, correct estimation of pressure changes is particularly important for these categories. However, there are also a number of unusual pits in all examples except the conventional subdivision "PL", so there is also a need to determine coefficients for non-standard pits. 10 In practice, designers tend to use fixed default values, which are probably overly conservative in most cases. In the past, a kL coefficient of 0.15 was applied to sanitary sewers in the U.K. (Howarth and Saul, 1984) and a kP coefficient of 1.5 has been applied to stormwater drainage systems in Australia. Most Australian designers are reluctant to employ negative kP coefficients. As a further test, sensitivity analyses have been applied to the first two catchments listed in Table 4. They were analysed using DRAINS with conservative assumptions on pit pressure changes, without specifying any negative coefficients. The flowrates shown are the worst cases derived for 12 design storms of different durations. Surface overflows from the pits, which are the main factor of concern, have been estimated for average recurrence intervals (ARIs) of 1, 10 and 100 years, at three locations in the catchment. The results, given in Table 5, show that in general, the overflows are not sensitive to the selection of pit pressure changes. However, experience of other cases, particularly ones involving steep locations or complex pipe layouts, indicates that pit pressure changes can be locally significant. Table 5 Results of Sensitivity Analyses for Two Catchment Models Description for the "WS" Catchment ARI (years) Overflows with pit pressure change coefficients halved (m3/s) Base Case overflow rates (m3/s) Overflows with pit pressure change coefficients doubled (m3/s) Description for the "CR" Catchment ARI (years) Overflows with pit pressure change coefficients halved (m3/s) Base Case overflow rates (m3/s) Overflows with pit pressure change coefficients doubled (m3/s) Overflow from a relatively small catchment through properties (m3/s) 1 10 100 Overflow from a storage in a trapped low point, with a medium size catchment (m3/s) 1 10 100 Overflow from a zone where many overflows and pipes meet at a major road (m3/s) 1 10 100 0.086 0.618 1.04 0.203 1.08 1.72 1.17 8.10 13.8 0.085 0.693 1.12 0.208 1.08 1.72 1.35 8.84 14.5 0.115 0.761 1.19 0.199 1.09 1.74 1.83 9.36 15.1 Overflow from small catchment through properties (m3/s) Overflow from larger catchment with several branches (m3/s) Flow contained in a roofed channel at the catchment outlet (m3/s) 1 0.08 10 0.55 100 1.17 1 1.39 10 8.7 100 17.3 1 12.3 10 23.5 100 30.1 0.08 0.66 1.28 1.44 10.2 18.6 11.5 24.6 29.7 0.09 0.75 1.38 1.59 11.6 20.3 11.3 24.0 32.0 Generally, increasing the coefficients increases overflows by raising HGLs to the surface more frequently and for longer durations during storm events. This is especially so for small drainage systems. However, for larger systems that collect overflows from several locations, the slower speed of travel of surface flows compared to pipe flows causes complex behaviour, with peak flowrates sometimes decreasing as kP coefficients are increased. 11 A solution to uncertainties surrounding coefficients might seem to be to set these conservatively high. While this might be acceptable for design, it is not appropriate for analysis, as high coefficients might raise or lower overflows at various parts of a system, depending on the various concentration times of hydrographs in pipes and on the surface. 9. Conclusions • Pit hydraulics are extremely complex. The results of the comparison of algorithms are inconclusive, with no single method being superior. However, the information obtained so far indicates that a viable algorithm can be developed. Further testing and development is required. • The FHWA algorithm appears to provide a significant advance in the determination of head losses and pit pressure changes in stormwater drainage and sewerage systems. However, comparisons with alternative algorithms and experimental data indicate that simpler methods appear to give results that are at least as good. • A general algorithm will have to allow for misalignment of the inlet and outflow pipes at a pit. Previous studies have shown that the alignment or misalignment of pipes can make large differences to head losses and pressure changes. • While essentially-empirical procedures may eventually provide adequate estimation procedures for computer models, they will still be incomplete, and further experimental modelling and development of theoretical concepts is necessary. This applies specially to the investigation of dynamic effects in rapidly changing hydrographs passing through complex pipe systems. Coefficients for energy losses and pressure changes that are derived from steady flow tests will not always be accurate. • A survey of separate stormwater drainage systems in the Sydney Area reveals that certain geometric arrangements predominate, but that a variety of unusual configurations can occur when existing systems are partially reconstructed, or where special requirements such as surcharge pits apply in design. • The sensitivity analyses reported in Table 5 show that the selection of coefficients is complex, and that use of conservatively high coefficients will not necessarily increase peak flowrates at all locations in a drainage system. There seems to be little justification for avoiding the use of negative pit pressure change coefficients in design. Acknowledgements Special thanks are due to Clive Hare and Ray Parsell for their constructive comments on this paper. References Ackers, P. (1959) “An Investigation of Head Losses at Sewer Manholes”, Civil Engineering and Public Works Review, Vol. 54. No. 637 Arao, S. and Kusuda, T. (1999) “Effects of Pipe Bending Angle on Energy Losses at TwoWay Circular Drop Manholes”, Proceedings, 8th International Conference on Urban Storm Drainage, Sydney 12 Archer, B., Bettess, F. and Colyer, P.J. (1978) Head Losses and Air Entrainment at Surcharged Manholes, Report No. IT 185, Hydraulics Research Station, Wallingford Black, R.G. and Piggott, T.L. (1983) “Head Losses at Two Pipe Stormwater Junction Chambers”, Proceedings, 2nd National Local Government Engineering Conference, Institution of Engineers, Australia, Brisbane Bo Pedersen, F. and Mark, O. (1990) “Head Losses at Storm Sewer Manuals, Submerged Jet Theory”, J. Hydraulics Division, ASCE, 116(11) Calomino, F., Frega, G., Piro, P. and Gironda Veraldi, M. (1999) “Hydraulics of Drops in Supercritical Flow”, Proceedings, 8th International Conference on Urban Storm Drainage, Sydney Chang, F. M., Kilgore, R. T., Woo D. C. and M. P. Mistichelli (1994) Energy Losses Through Junction Manholes, Volume I: Research Report and Design Guide, Federal Highway Administration, FHWA-RD-94-090, McLean, VA Christodoulou, G.C. (1987) “Energy Loss at Drop Manholes”, Proceedings, 4th International Conference on Urban Storm Drainage, IAHR, Lausanne Christodoulou, G.C. (1991) “Drop Manholes in Supercritical Pipelines”, J. Irrigation and Drainage Engineering, ASCE, 117 (1) De Groot, C.F. and Boyd, M.J. (1983) “Experimental Determination of Head Losses in Stormwater Systems”, Proceedings, 2nd Local Government Engineering Conference, Institution of Engineers, Australia, Brisbane Dick, T.M. and Marsalek, J. (1985) “Manhole Head Losses in Drainage Hydraulics”, Proceedings, 21st IAHR Conference, Melbourne GKY & Associates Inc, (1999) User’s Manual for HYDRAIN, Integrated Drainage Design Computer System: Version 6.1, Federal Highway Administration, US Department of Transportation, Washington, DC (manual and software downloadable from www.fhwa.dot.gov/bridge/hyd.htm) Hare, C.M. (1983) “Magnitude of Hydraulic Losses at Junctions in Piped Drainage Systems”, Civil Engineering Transactions, Institution of Engineers, Australia, CE 25 (1) (also published in 1981 at Conference on Hydraulics in Civil Engineering, Institution of Engineers, Australia, Sydney) Hare, C.M., O'Loughlin, G.G. and Saul, A.J. (1990) “Hydraulic Losses at Manholes in Piped Drainage Systems”, Proceedings, International Symposium on Urban Planning and Stormwater Management, Kuala Lumpur Hare, C. and O'Loughlin, G.G. (1991) “An Algorithm for Pressure Head Change Coefficients at Stormwater Manholes”, in Urban Drainage and New Technologies (UDT '91), Dubrovnik, Elsevier, London Howarth, D.A. (1984) The Hydraulic Performance of Scale Model Storm Sewer Junctions, PhD Thesis, University of Manchester Howarth, D.A. and Saul, A.J. (1984) “Energy Loss Coefficients at Manholes”, Proceedings, 3rd International Conference on Urban Storm Drainage, Goteborg Jacobsen, P. and Harremoes, P. (1984) “The Significance of Head Loss Parameters in Surcharged Sewer Simulations”, Proceedings, 3rd International Conference on Urban Storm Drainage, Goteborg Johnston, A.J. and Volker, R.E. (1990) “Head Losses at Junction Boxes”, J. Hydraulics Division, ASCE, 116(3) 13 Kusuda, T. and Arao, S. (1987) “Energy Losses at Circular Drop Manholes”, Proceedings, 4th International Conference on Urban Storm Drainage, Lausanne Kusuda, T., Arao, S. and Moriyama, K. (1993) “Energy Losses at Junctions and Transient Flow in Sewer Networks”, Proceedings, 6th International Conference on Urban Storm Drainage, Niagara Falls Lindvall, G. (1984) “Head Losses at Surcharged Manholes with a Main Pipe and a Ninety Degree Lateral”, Proceedings, 3rd International Conference on Urban Storm Drainage, Goteborg Lindvall, G. (1987) “Head Losses at Surcharges Manholes”, Proceedings, 4th International Conference on Urban Storm Drainage, IAHR, Lausanne Marsalek, J. (1981) Energy Losses in Straight-Flow-Through Sewer Junctions, Research Report No. 111, Environment Protection Service, Ottawa Marsalek, J. (1984) “Head Losses at Sewer Junction Manholes”, J. Hydraulics Division, ASCE, 110(8) Marsalek, J. (1985) Head Losses at Selected Sewer Manholes, Special Report No. 52, American Public Works Association, Chicago (Report No. 85-15, National Water Resources Institute, Burlington, Ontario) Marsalek, J. (1988) “Head Losses at Sewer Junctions, in Civil Engineering Practice”, Volume 2 (Hydraulics, Mechanics) edited by P.N. Cheremisinoff et al., Technical Publishing Company, PN Merlein, J. and Valentin, F. (1999) “Hydraulic Conditions and Energy Loss in Submerged Manholes”, Proceedings, 8th International Conference on Urban Storm Drainage, Sydney Mills S.J. and O’Loughlin, G. (1998) Workshop on urban piped drainage systems, Swinburne University of Technology and University of Technology, Sydney, (Offered many times between 1982 and 1998) Mudgal, B. and Pani, B.S. (1993) “Head Losses in Sewer Manholes”, 6th International Conference on Urban Storm Drainage, Niagara Falls O’Loughlin, G. and Stack, B. (2001) DRAINS User Manual, Watercom Pty Ltd, Sydney (downloadable on www.watercom.com.au) Parsell, R. (1992) “Generalised Equations for Estimating Pressure Change Coefficients at Stormwater Pit Junctions, International Conference on Urban Stormwater Management, Institution of Engineers, Australia, Sydney Sakakibari, T., Tanaka, S. and Imaida, T. (1996) “Energy loss at surcharged manholes model experiment”, Proceedings, 7th International Conference on Urban Storm Drainage, IAHR, Hannover (also published in Water Science and Technology Vol. 36, No. 8-9, 1997) Sangster, W.M., Wood, H.W., Smerdon, E.T. and Bossy, H.G. (1958) Pressure Changes at Storm Drain Junctions, Engineering Series Bulletin No. 41, Engineering Experiment Station, University of Missouri Stein, S.M., Dou, X., Umbrell, E.R. and Jones, J.S. (1999) Storm Sewer Junction Hydraulics and Sediment Transport, US Federal Highway Administration Turner-Fairbanks Highway Research Centre, VA (available on www.tfhrc.gov/structr/hydrlcs/pdf/3.pdf) Townsend, R.D. and Prins, J.R. (1978) “Performance of Model Sewer Junctions”, J. Hydraulics Division, ASCE, 104(1) U.S. Department of Transportation, Federal Highway Administration (1996) Urban Drainage Design Manual, Hydraulic Engineering Circular No. 22, Office of Engineering, Office of Technology Applications, Washington, DC 14 Yen, B.C. (2001) “Hydraulics of Sewer Systems”, Chapter 6 in Stormwater Collection Systems Design Handbook, edited by L.W. Mays, McGraw-Hill, New York XP Software (1999) XP-SWMM Reference Manual, Canberra Bibliography This includes additional references that have a bearing on pit pressure changes, or contain original material on the subject. Some are unpublished research reports. The first author can provide information on Australian sources to interested persons Argue, J.R. (1986) Storm drainage design in small urban catchments : a handbook for Australian Practice, Special Report No. 34, Australian Road Research Board, Vermont South, Victoria Ball, J.E. (1993) “Modelling of Unsteady Flow through Manholes”, 6th International Conference on Urban Storm Drainage , Niagara Falls Blaisdell, F.W. and Manson, P.W. (1963) Loss of Energy at Sharp Edged Pipe Junctions, Technical Bulletin No. 1283, US Department of Agriculture, Washington Blaisdell, F.W. and Manson, P.W. (1967) “Energy Loss at Pipe Junctions”, J. Hydraulics Division, ASCE, 76 Catanzariti, G.A. and Kontominas, S. (1986) Energy Losses and Pressure Head Changes at Storm Drain Junctions, Bachelor of Engineering Thesis, NSW Institute of Technology, Sydney Christodoulou, G.C. (1987) “Energy Loss at Drop Manholes”, Proceedings, 4th International Conference on Urban Storm Drainage, IAHR, Lausanne Freeman, K.F. and Marshall, G.R. (1984) Pressure Changes and Energy Losses in Drop Pits, 8 volumes, Bachelor of Engineering Thesis, School of Civil Engineering, NSW Institute of Technology, Sydney Gayer, J.A. (1984) “On the Hydraulic Role of Manholes in Urban Storm Drainage Systems”, Proceedings, 3rd International Conference on Urban Storm Drainage, Goteborg Hager, W.H. (1989) “Transitional Flow in Channel Junctions”, J. Hydraulics Division, ASCE, 115(2) Hare, C.M. (1980) Energy Losses and Pressure Head Changes at Storm Drain Junctions, Master of Engineering Thesis, NSW Institute of Technology, Sydney Institution of Engineers, Australia Australian Rainfall and Runoff, A Guide to Flood Estimation, 2 volumes, (edited by D.H. Pilgrim and R.P. Canterford), Canberra, 1987 (revised into eight loose-leaf books, 1998) Jenson, M. (1981) Hydraulic Energy Relations and Their Application to Ninety Degree Junction, Series Paper No. 11, The Royal Veterinary and Agricultural University, Copenhagen Johnston, A.J., Pettigrew, M.R. and Volker, R.E. (1987) “Energy Losses at a Surcharged Three Pipe Stormwater Pit”, 2nd National Conference on Hydraulics in Civil Engineering, Institution of Engineers, Australia, Brisbane Johnston, A.J., Volker, R.E. and Di Bella, C.J. (1990) “Factors Influencing Head Losses at Junction Pits”, Conference on Hydraulics in Civil Engineering, Institution of Engineers, Australia 15 Johnston, A.J. and Volker, R.E. (1990) “Head Losses at a Three Pipe Junction Box”, Civil Engineering Transactions, Institution of Engineers, Australia, CE32 (3) Jones, S. (1980) Pressure Changes in Urban Drainage Junctions, Undergraduate Project, School of Civil Engineering, University of Technology Liebman, H. (1970) “Der Einfluss von Einsteigschachten auf den Abflussforgang in Abwasserkanalen” (Effects of Manholes on Flow Processes in Storm Drains), Wasser und Abwasser in Forschung und Praxis, 2, Erich Schmid Verlag, Bielefeld McEleney, A. (1989) Investigation of Energy Loss Coefficients at a Straight Through Manhole, BE Project, Department of Civil Engineering, University of Manchester McKenzie, G.J. (1993) Pressure Head Changes at Pit Junctions, Undergraduate Thesis, School of Civil Engineering, University of Technology, Sydney Marsalek, J. (1987) “Head Losses at Junctions of Two Opposing Lateral Sewers”, Proceedings, 4th International Conference on Urban Storm Drainage, IAHR, Lausanne Marshall, G.R. (1990) “A Tabulation of Pressure Changes and Energy Losses in Stormwater Drop Pits”, Conference on Hydraulics in Civil Engineering, Institution of Engineers, Australia Pardee, L.A. (1968) Hydraulic Analysis of Junctions, Office Standard No. 115, Storm Drainage Design Division, City of Los Angeles Prins, R.J. (1975) Storm Sewer Junction Geometry and Related Energy Losses, MSc Thesis, University of Ottawa Ramamurthy, A.S., Carballada, L.B. and Tran, D.M. (1988) “Combined Open Channel Flow at Right Angled Junctions”, J. Hydraulic Engineering, 114 (12) Sangster, W.M., Wood, H.W., Smerdon, E.T. and Bossy, H.G. (1963) “Pressure Changes at Open Junctions in Conduits”, Proceedings, ASCE, 85 16