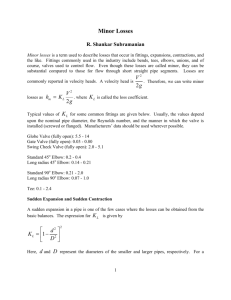

HEAD LOSSES IN PIPE FITTINGS OBJECTIVES To demonstrate and estimate energy losses (major and minor) in the flow of a Newtonian fluid through pipes. To determine the coefficient of energy loss in bends and pipe fittings. To compare of head losses in various pipe configurations. To obtain the loss of head in sudden expansion and sudden contraction of pipes. EQUIPMENT REQUIRED 1. Head Losses in pipe fittings apparatus 2. Stopwatch 3. Measuring cylinder INTRODUCTION Two types of energy loss predominate in fluid flow through a pipe network: major losses, and minor losses. Major losses are associated with frictional energy loss that is caused by the viscous effects of the medium and roughness of the pipe wall. Minor losses, on the other hand, are due to pipe fittings, changes in the flow direction, and changes in the flow area. Due to the complexity of the piping system and the number of fittings that are used, the head loss coefficient (K) is empirically derived as a quick means of calculating the minor head losses. THEORY An energy balance in any flow system is given by the Bernoulli's equation. 𝑣12 2𝑔 + 𝑝1 𝛾 + 𝑧1 = 𝑣22 2𝑔 + 𝑝2 𝛾 + 𝑧2 + ℎ𝐿 ..............(1) where, p1, p2 are pressure at points 1 and 2 respectively (N/m2) v1, v2 are average flow velocity at points 1 and 2 respectively (m/s) 𝜌 is density of the fluid in pipe (kg/m3) hL is energy requirement (major and minor losses) (J/kg) 1 When a fluid under pressure flows through a pipe, the pipe offers resistance to the flow due to which total head (or energy) of flowing fluid gets reduced by certain amount which is called head loss (hL) in pipe flow. There are two types of head losses in pipe flow system i.e. Major head loss and Minor head loss. Head loss in pipe flow system due to viscous effect i.e. due to friction is referred as major head loss and will be indicated by hL-Major. Head loss in pipe flow system due to various piping components such as valves, fittings, elbows, contractions, enlargement, tees, bends, and exits is referred as minor head loss and will be indicated by hL-Minor. Therefore, complete head loss or pressure loss in pipe flow will be summation of major head loss and minor head loss and will be indicated by h L. h L = h L-Major + h L-Minor Major Head loss Major Head losses in pipe flow problem will be calculated with the help of DarcyWeisbach formula as mentioned below and this Darcy-Weisbach formula will be used to calculate the major loss in pipe flow, it does not matter that pipe is horizontal, vertical or on inclined plane. 𝑓(𝑙)(𝑣)2 h L-Major = 2𝑔𝐷 where, h L-Major =Head losses (m) f = Darcy-Weisbach friction factor D=Diameter of pipe (m) L=Length of pipe (m) v=flow velocity (m/s) g=acceleration due to gravity = 9.81 m/s 2 Friction factor as mentioned above will be determined based on type of flow i.e. Laminar flow, Transition flow and turbulent flow. Minor Head loss Minor head losses are pressure losses in pipe flow system due to various piping components such as valves, fittings, elbows, contractions, enlargement, tees, bends and exits. 𝑘𝑣 2 h L-Minor= 2𝑔 where, k is minor loss coefficient. Minor head losses occur due to geometry of construction and can also be given by, Sudden enlargement (he ) = Sudden contraction(hc ) = 𝑣2 Entrance (hi ) = 0.5 2𝑔 𝑣2 Exit (ho ) = k ∗ 2𝑔 𝑣2 Bend (hb ) = k ∗ 2𝑔 (𝑣1 −𝑣2 )2 2𝑔 (𝑣2 −𝑣1 )2 2𝑔 𝑣2 Pipe fittings (hp ) = k ∗ 2𝑔 PROCEDURE Carefully fill the manometer tubes with water to eliminate any air pockets from the system. Ensure all connecting pipes are free from air bubbles to maintain accurate measurements. Measure the volume of water at the output and record the time taken. This information is crucial for determining the flow rate. Record the readings from the piezometer and table manometer for all pipes. Repeat the measurements of volume and time to demonstrate that the flow rate remains constant during the experiment. Perform steps 1 to 5 for at least two different flow rates. This allows for a comprehensive analysis of energy losses under varying conditions. When the experiment is complete, drain the apparatus to ensure it is ready for subsequent use. 3 OBSERVATION Diameter at point A (dA) = 12.5mm = 12.5*10-3 m Diameter at point G (dG) = 25.0mm = 25*10-3 m Manometer Reading (cm) Tank Reading (ml) SN 1 1 26.5 2 37 3 53.5 4 63.5 2 3 4 5 6 7 8 9 Time (s) Initial (L1) Final (L2) Difference (L2-L1) t Discharge (ml/s) 𝑄= 𝐿2 − 𝐿1 𝑡 8.8 17 32.5 30.5 20.5 17 15.5 7 0 250 250 1.89 132.28 15.8 23 39 35.5 24 20.5 19 8.5 0 406.7 406.7 2.68 151.75 26.8 33 48.5 43 30 25 24 11 0 466.7 466.7 2.92 159.85 33.5 39.5 54 48.5 33 28.5 27 12.5 0 473.3 473.3 2.83 167.24 LINE DIAGRAM OF PIPE FITTINGS: 4 CALCULATION FOR OBSERVATION 1 Flow rate (Q1) = L2 −L1 t = 250 =132.28 cm3/s=132.28*10-6 m3/s 1.89 At point A, Area AA = 2 𝜋𝑑𝐴 4 = 𝜋∗(0.0125)2 4 Q = 0.00012272 m2 = 122.72*10-6 m2 132.28 ∗10−6 velocity (vA1) = A 1 = 122.72∗10−6 = 1.08 m/s A At point G, Area AG = πd2G 4 = 𝜋∗(0.025)2 4 𝑄 =4.908* 10-4 m2 132.28 ∗10−6 velocity (vG1) = 𝐴 1 = 4.908∗10−4 = 0.27 m/s 𝐴 Head losses between 1 and 2 = 17.7 cm = 0.177 m Head losses between 2 and 3 = 4.3 cm = 0.043 m Head losses between 3 and 4 = 3.0 cm = 0.03 m Head losses between 4 and 5 = 5 cm = 0.05 m Head losses between 5 and 6 = 10 cm = 0.1 m Head losses between 6 and 7 = 3.5 cm = 0.035 m Head losses between 7 and 8 = 1.5 cm = 0.015 m Head losses between 8 and 9 = 8.5 cm = 0.085 We have, 1. For pipe 1 - 2, only friction loss occurs and is given by, Head loss=hf = 17.7 cm = 0.177 m Also, ℎ𝑓 = 4𝑓𝐿𝑣 2 2𝑔𝐷 4𝑓×2×1.082 = 2×9.81×0.0125= 0.177 Hence, f= 0.00465. 2. For pipe 2-3, there is friction loss as well as bend loss. bend loss= hb =4.3 cm = 0.043 m 5 ℎ𝑏 = 𝑘 × 𝑣2 =𝑘× 2𝑔 1.082 =0.043 2×9.81 Hence, k=0.72 3. For pipe 3-4, there is friction loss only. Head loss= hf = 3 cm = 0.03 m Also, ℎ𝑓 = 4𝑓𝐿𝑣 2 2𝑔𝐷 4𝑓×0.18×1.082 = 2×9.81×0.0125=0.03 Hence, f = 0.00876 4. For pipe 4-5, there is bend loss only. As the distance between two pipes is negligible, we neglect friction loss. Head loss= hb =8 cm = 0.05 m 𝑣2 1.082 ℎ𝑏 = 𝑘 × 2𝑔 = 𝑘 × 2×9.81 =0.05 Hence, k= 0.841 5. for pipe 5-6, there is friction loss only. Head loss= hf =10 cm = 0.1 m ℎ𝑓 = 4𝑓𝐿𝑣 2 2𝑔𝐷 4𝑓×0.627×1.082 = 2×9.81×0.0125 =0.1 Hence, f= 0.00838 6. For pipe 6-7, there are two losses: expansion and friction loss. Head losses between 6 and 7 = 3.5 cm = 0.035 m 7. For pipe 7-8, there is frictional loss only. hf = 1.5 cm = 0.015 m ℎ𝑓 = 4𝑓𝐿𝑣 2 2𝑔𝐷 4𝑓×0.84×0.272 = 2×9.81×0.025 = 0.015 Hence, f= 0.0300 8. For pipe 8-9, there is friction loss and contraction loss. Head losses between 8 and 9 =8.5 cm = 0.085 m FOR OBSERVATION 2 Flow rate (Q2) = L2 −L1 t = 406.7 2.68 =151.75 cm3/s=1.5175 *10-4 m3/s At point A, Area AA = 2 𝜋𝑑𝐴 4 = 𝜋∗(0.0125)2 4 Q = 0.00012272 m2 = 122.72*10-6 m2 1.5175 ∗10−4 velocity (vA2) = A 2 = 122.72∗10−6 = 1.24 m/s A At point G, 6 Area AG = πd2G 4 = 𝜋∗(0.025)2 4 =4.908* 10-4 m2 1.5175 ∗10−4 𝑄 velocity (vG2) = 𝐴 2 = 4.908∗10−4 = 0.31 m/s 𝐴 Head losses between 1 and 2 = 21.2 cm = 0.212 m Head losses between 2 and 3 = 5.3 cm = 0.053 m Head losses between 3 and 4 = 2.0 cm = 0.02 m Head losses between 4 and 5 = 6 cm = 0.06 m Head losses between 5 and 6 = 11.5 cm = 0.115 m Head losses between 6 and 7 = 3.5 cm = 0.035 m Head losses between 7 and 8 = 1.5 cm = 0.015 m Head losses between 8 and 9 =10.5 cm = 0.105 m We have, 9. For pipe 1 - 2, only friction loss occurs and is given by, Head loss=hf = 21.2 cm= 0.212 m Also, ℎ𝑓 = 4𝑓𝐿𝑣 2 2𝑔𝐷 = 4𝑓×2×1.242 = 0.212 2×9.81×0.0125 Hence, f= 0.00423. 10. For pipe 2-3, there is friction loss as well as bend loss. bend loss= hb =5.3 cm = 0.053 m 𝑣2 1.242 ℎ𝑏 = 𝑘 × 2𝑔 = 𝑘 × 2×9.81=0.053 Hence, k=0.68 11. For pipe 3-4, there is friction loss only. Head loss= hf = 2 cm = 0.02 m Also, ℎ𝑓 = 4𝑓𝐿𝑣 2 2𝑔𝐷 4𝑓×0.18×1.242 = 2×9.81×0.0125=0.02 Hence, f = 0.00443 12. For pipe 4-5, there is bend loss only. As the distance between two pipes is negligible, we neglect friction loss. Head loss= hb =6 cm = 0.06 m 7 ℎ𝑏 = 𝑘 × 𝑣2 =𝑘× 2𝑔 1.242 2×9.81 =0.06 Hence, k= 0.766 13. for pipe 5-6, there is friction loss only. Head loss= hf =11.5cm = 0.115 m ℎ𝑓 = 4𝑓𝐿𝑣 2 4𝑓×0.627×1.242 = 2𝑔𝐷 2×9.81×0.0125 =0.115 Hence, f= 0.0073. 14. For pipe 6-7, there is two losses: expansion and friction loss. Head losses between 6 and 7 = 3.5 cm = 0.035 m 15. For pipe 7-8, there is frictional loss only. hf = 1.5 cm = 0.015 m ℎ𝑓 = 4𝑓𝐿𝑣 2 4𝑓×0.84×0.312 = 2𝑔𝐷 2×9.81×0.025 = 0.015 Hence, f= 0.0228 16. For pipe 8-9, there is friction loss and contraction loss. Head losses between 8 and 9 =10.5 cm = 0.105 m FOR OBSERVATION 3 Flow rate (Q3) = L2 −L1 t = 406.7 2.68 =159.85 cm3/s=1.5985 *10-4 m3/s At point A, Area AA = 2 𝜋𝑑𝐴 4 = 𝜋∗(0.0125)2 4 Q = 0.00012272 m2 = 122.72*10-6 m2 1.5985 ∗10−4 velocity (vA3) = A 3 = 122.72∗10−6 = 1.30 m/s A At point G, Area AG = πd2G 4 = 𝜋∗(0.025)2 4 𝑄 =4.908* 10-4 m2 1.5985 ∗10−4 velocity (vG3) = 𝐴 3 = 4.908∗10−4 = 0.33 m/s 𝐴 Head losses between 1 and 2 = 26.7 cm 0.267 m Head losses between 2 and 3 = 6.3 cm = 0.063 m Head losses between 3 and 4 = 2.5 cm = 0.025 m Head losses between 4 and 5 = 8 cm = 0.08 m Head losses between 5 and 6 = 13 cm = 0.13 m Head losses between 6 and 7 = 5 cm = 0.05 m Head losses between 7 and 8 = 1 cm = 0.01 m 8 Head losses between 8 and 9 = 13 cm = 0.13 m We have, 17. For pipe 1 - 2, only friction loss occurs and is given by, Head loss=hf = 26.7 cm= 0.267 m Also, ℎ𝑓 = 4𝑓𝐿𝑣 2 2𝑔𝐷 4𝑓×2×1.302 = 2×9.81×0.0125= 0.267 Hence, f= 0.00484 18. For pipe 2-3, there is friction loss as well as bend loss. bend loss= hb =6.3 cm = 0.063 m 𝑣2 1.302 ℎ𝑏 = 𝑘 × 2𝑔 = 𝑘 × 2×9.81=0.063 Hence, k=0.731 19. For pipe 3-4, there is friction loss only. Head loss= hf = 2.5 cm = 0.025 m Also, ℎ𝑓 = 4𝑓𝐿𝑣 2 2𝑔𝐷 4𝑓×0.18×1.302 = 2×9.81×0.0125=0.025 Hence, f = 0.00504 20. For pipe 4-5, there is bend loss only. As the distance between two pipes is negligible, we neglect friction loss. Head loss= hb =8 cm = 0.08 m 𝑣2 1.302 ℎ𝑏 = 𝑘 × 2𝑔 = 𝑘 × 2×9.81 =0.08 Hence, k= 0.929 21. for pipe 5-6, there is friction loss only. Head loss= hf =13 cm = 0.13 m ℎ𝑓 = 4𝑓𝐿𝑣 2 2𝑔𝐷 = 4𝑓×0.627×1.302 2×9.81×0.0125 =0.13 Hence, f= 0.0075 22. For pipe 6-7, there is two losses: expansion and friction loss. Head losses between 6 and 7 = 5 cm = 0.05 m 23. For pipe 7-8, there is frictional loss only. hf = 1 cm = 0.01 m ℎ𝑓 = 4𝑓𝐿𝑣 2 2𝑔𝐷 = 4𝑓×0.84×0.332 2×9.81×0.025 = 0.01 9 Hence, f= 0.0134 24. For pipe 8-9, there is friction loss and contraction loss. Head losses between 8 and 9 =13 cm = 0.13 m FOR OBSERVATION 4 Flow rate (Q4) = L2 −L1 t = 473.33 2.83 =167.24 cm3/s=1.6724 *10-4 m3/s At point A, Area AA = 2 𝜋𝑑𝐴 4 = 𝜋∗(0.0125)2 4 = 0.00012272 m2 = 122.72*10-6 m2 1.6724 ∗10−4 Q velocity (vA4) = A 4 = 122.72∗10−6 = 1.36 m/s A At point G, Area AG = πd2G 4 = 𝜋∗(0.025)2 4 =4.908* 10-4 m2 1.6724 ∗10−4 𝑄 velocity (vG4) = 𝐴 4 = 4.908∗10−4 = 0.34 m/s 𝐴 Head losses between 1 and 2 = 30 cm = 0.300 m Head losses between 2 and 3 = 6.5 cm = 0.065 m Head losses between 3 and 4 = 3.5 cm = 0.035 m Head losses between 4 and 5 = 8 cm = 0.080 m Head losses between 5 and 6 = 15.5 cm = 0.155 m Head losses between 6 and 7 = 4.5 cm = 0.045 m Head losses between 7 and 8 = 1.5 cm = 0.015 m Head losses between 8 and 9 = 14.5 cm = 0.145 1. For pipe 1 - 2, only friction loss occurs and is given by, Head loss=hf = 30 cm= 0.3 m Also, ℎ𝑓 = 4𝑓𝐿𝑣 2 2𝑔𝐷 4𝑓×2×1.362 = 2×9.81×0.0125=0.30 Hence, f= 0.00497 2. For pipe 2-3, there is friction loss as well as bend loss. bend loss= hb =6.5 cm = 0.065 m 𝑣2 1.362 ℎ𝑏 = 𝑘 × 2𝑔 = 𝑘 × 2×9.81=0.065 Hence, k= 0.690 10 3. For pipe 3-4, there is friction loss only. Head loss= hf = 3.5cm = 0.035 m ℎ𝑓 = 4𝑓𝐿𝑣 2 2𝑔𝐷 = 4×𝑓×0.18×1.362 2×9.81×0.0125 = 0.035 Hence, f= 0.00645 4. For pipe 4-5, there is bend loss only. As the distance between two pipes is negligible, we neglect friction loss. Head loss= hb =8 cm = 0.08 m 𝑣2 1.362 ℎ𝑏 = 𝑘 × 2𝑔 = 𝑘 × 2×9.81=0.08 Hence, k=0.85 5. For pipe 5-6, there is friction loss only. Head loss= hf =15.5 cm = 0.155 m ℎ𝑓 = 4𝑓𝐿𝑣 2 2𝑔𝐷 = 4×𝑓×0.627×1.362 2×9.81×0.0125 =0.155 Hence, f= 0.0082 6. For pipe 6-7, there are two losses: expansion and friction loss. Head losses between 6 and 7 = 4.5 cm = 0.045 m 7. For pipe 7-8, there is frictional loss only. hf = 1.5 cm = 0.015 m ℎ𝑓 = 4𝑓𝐿𝑣 2 2𝑔𝐷 = 4×𝑓×0.84×0.342 2×9.81×0.025 =0.015 Hence, f = 0.0189 8. For pipe 8-9, there is friction loss and contraction loss. Head losses between 8 and 9 = 14.5 cm = 0.145 MAJOR LOSSES Value Observation 1 Observation 2 Observation 3 Observation 4 Frictional Losses, hf (1-2) 0.177 0.212 0.212 0.3 Coefficient of friction (f) 0.00465 0.00423 0.267 0.00497 Frictional Losses, hf (3-4) 0.03 0.02 0.00484 0.035 Coefficient of friction (f) 0.00876 0.00443 0.025 0.00645 Frictional Losses, hf (5-6) 0.1 0.115 0.00504 0.155 Coefficient of friction (f) 0.00838 0.0073 0.13 0.0082 Frictional Losses, hf (7-8) 0.015 0.015 0.0075 0.015 Coefficient of friction (f) 0.0300 0.0228 0.01 0.0189 11 MINOR LOSSES Type of losses Observation 1 Observation 2 Observation 3 Observation 4 Bend (2-3) 0.043 0.053 0.063 0.065 Loss Coefficient (K) 0.72 0.68 0.731 0.690 Bend (4-5) 0.05 0.06 0.08 0.08 Loss Coefficient (K) 0.841 0.766 0.929 0.85 Sudden Enlargement 0.035 0.035 0.050 0.045 0.085 0.105 0.130 0.145 (6-7) Sudden Contraction (8-9) GRAPH 1. Graph between major head losses and discharge. MAJOR HEAD LOSSES, ∆h ∆h Vs Q 0,35 0,3 0,25 0,2 0,15 0,1 0,05 0 120 130 140 150 160 170 DISCHARGE, Q (1-2) (3-4) (5-6) (7-8) 12 2. Graph between minor head losses and discharge. ∆h Vs Q MINOR HEAD LOSSES, ∆h 0,16 0,14 0,12 0,1 0,08 0,06 0,04 0,02 0 120 125 130 135 140 145 150 155 160 165 170 DISCHARGE, Q (2-3) (4-5) (6-7) (8-9) RESULT AND DISCUSSION From the experiment conducted, it is evident that there are significant head losses in the flow of fluid through pipes due to both major and minor factors. Major losses, primarily attributed to friction, were calculated using the Darcy-Weisbach formula, while minor losses, caused by pipe fittings and changes in flow direction, were estimated using appropriate coefficients. The observed values for major losses (frictional losses) varied depending on the pipe section, and minor losses such as those associated with bends, sudden enlargements, and contractions were determined through calculations. Comparing the results between the two observations, it's evident that the magnitude of head losses varies with different flow rates and configurations of pipe fittings. The coefficients of friction and loss coefficients for bends and fittings also show variation based on the flow conditions. CONCLUSION In conclusion, through this experiment, it can be concluded that both major and minor losses contribute significantly to the total head loss in pipe flow systems. The energy losses in pipe flow are influenced by various factors including pipe geometry, flow velocity, and the presence of fittings. The obtained coefficients can be used for further 13 calculations and design optimizations in piping systems. PRECAUTION Be careful while filling the water to prevent air bubbles. Avoid water leakage. Handle the apparatus with care. 14