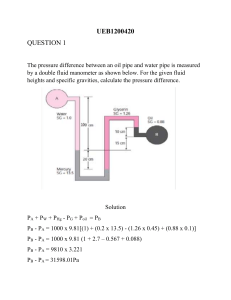

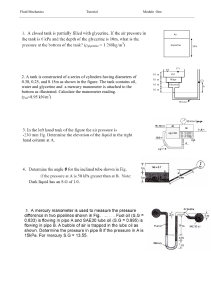

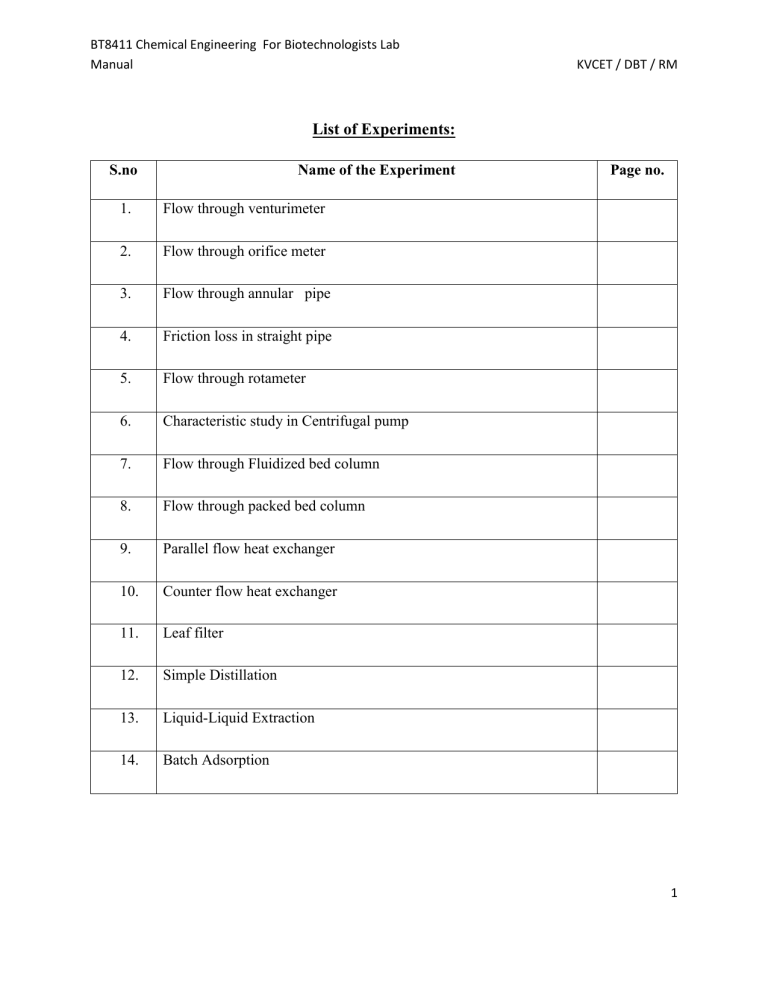

BT8411 Chemical Engineering For Biotechnologists Lab Manual KVCET / DBT / RM List of Experiments: S.no Name of the Experiment 1. Flow through venturimeter 2. Flow through orifice meter 3. Flow through annular pipe 4. Friction loss in straight pipe 5. Flow through rotameter 6. Characteristic study in Centrifugal pump 7. Flow through Fluidized bed column 8. Flow through packed bed column 9. Parallel flow heat exchanger 10. Counter flow heat exchanger 11. Leaf filter 12. Simple Distillation 13. Liquid-Liquid Extraction 14. Batch Adsorption Page no. 1 BT8411 Chemical Engineering For Biotechnologists Lab Manual KVCET / DBT / RM Ex.no:1 Date: DETERMINATION OF FLOW THROUGH VENTURIMETER AIM: To determine the coefficient of discharge of venturimeter. APPARATUS REQUIRED: Venturimeter, U-tube manometer, collecting tank, stopwatch, meter scale. PRINCIPLE: The experimental setup consists of two pipe of different die in which the venturimeter &orifice meter are fixed stop values are provided. The venturimeter & orifcemeter to connect with the manometer to central value in a pipe is provided to vary the discharge of water, A mercury U-tube manometer is connected across the venturimeter & orifice meter to find the distance. A tube is provided to discharge the water to the connecting tank. A piezometer tube is provided in the collecting tank to record the level of water flow into the pump from it is recalculated. An electric motor driver pump is well for pumping water into pipe. FORMULA: Coefficient of discharge is defined as the radio of actual discharge by theoretical discharge. Qact= AY/t A=Area of collecting tank, Y=Rise of water in collecting tank, T=Time for rise of water in collecting tank Qtheo= a1,a2√2gH 2 2 √a1 -a2 Where, A1=Area of inlet pipe in cm2=4.9cm2. A2=Area of throat in cm2=1.77cm2. H=Difference in terms of volume of liquid falling. PROCEDURE: Firstly the dia of inlet &throat of the venturimeter are noted. The water is switched on, the gate valve is opened to allow water flow the stop valve connected venturimeter &the manometer are opened. The availability if any in nanometer is removed slowly by releasing the drain cock of manometer. Note 2 BT8411 Chemical Engineering For Biotechnologists Lab Manual KVCET / DBT / RM down the level of mercury in h1&h2.Both the limbs of manometer are measured with a scale. The time taken for 10 cm rise of water in the closing the outlet valve of the collecting tank. The input is repeated by raising the discharge. RESULT: The coefficient of discharge of venturimeter= From graph, The coefficient of discharge of venturimeter= OBSERVATION: Diameter of venturimeter= Diameter of throat= Area of collecting tank= Specific gravity of mercury= Specific gravity of water= A1= A2= TABULATION: MANOMETER READING H1 H2 H=X(SmSw) Q ACT TIME TAKEN FOR 10cm Q act (cm) (cm3/s) RISE OF WATER (S) (cm3/s) x T1 JH T2 Cd T3 Q act 3 BT8411 Chemical Engineering For Biotechnologists Lab Manual KVCET / DBT / RM Ex.no:2 Date: FLOW THROUGH ORIFICE METER AIM: To caliber ate an orifice meter& to determine the coefficient of an orifice meter. APPARATUS REQUIRED: Meter scale, stopwatch, collecting tank, U-tube manometer. PRINCIPLE: The experimental setup consists of two pipe of different die in which the venturimeter &orifice meter are fixed stop values are provided. The venturimeter & orifcemeter to connect with the manometer to central value in a pipe is provided to vary the discharge of water, A mercury U-tube manometer is connected across the venturimeter & orifice meter to find the distance. A tube is provided to discharge the water to the connecting tank. A piezometer tube is provided in the collecting tank to record the level of water flow into the pump from it is recalculated. An electric motor driver pump is well for pumping water into pipe. FORMULA USED: Qtheo=a1 a2√2gH/√a12-a22. Qact=AY/t. Where, y=rise =10cm, T=Time, a1&a2=Area of halt & throat in m2 H=12.56* manometer reading. Cd= Qact/Qtheo. 4 BT8411 Chemical Engineering For Biotechnologists Lab Manual KVCET / DBT / RM PROCEDURE: Select required orifice meter. Open its locks & close its locks so that only the pressure for water in use is connected to manometer. Open flow control value & allow certain flow rate. Vent manometer is required. Collect the time taken for 10cm rise is noted. GRAPHS: √H Vs Qact . RESULT: Thus the coefficient of discharge of orificemeter cd, (1) Theoretical cd = (2) Graphically, Qact= From Graph, √H= OBSERVATION: Diameter of the orificemeter (d1 )=2.5cm Diameter of the inlet(d2)=1.5cm Area of the collecting tank (A)=1600cm2 Specific gravity of mercury (Sm)=13.6 Specific gravity of water (Sw)=1 TABULATION: MANOMETER READING H1 cm H2 cm X H1-H2 H=X(SmSw) Q theo TIME TAKEN FOR 10cm (cm) (cm3/s) RISE OF WATER (S) T1 s T2 s Q act (cm3/s) Cd T3 s 5 √H cm BT8411 Chemical Engineering For Biotechnologists Lab Manual KVCET / DBT / RM CALCULATION: Ex.no:3 Date: FLOW THROUGH ANNUIAR PIPE AIM: To understand friction precluded in the flow of water in the annular pipe. To find the loss of heat between two pts. in flow of water fluid using given manometer . Calculate the mean velocity with the connecting tanks & stop water. Compute coefficient of friction by applying correct formula. PRINCIPLE: The less of heat is measured by manometer. The average velocity is calculated from the discharge through an annular pipe of known diameter. The length of the annular pipe of known Diameter .The length of annular pipe is measured. 6 BT8411 Chemical Engineering For Biotechnologists Lab Manual KVCET / DBT / RM FORMULA: Actual discharge of A=Volume of water collected/Time Velocity of the flow =actual discharge/Area of the pipe. Coefficient of friction= hf 2gd/4lr2. PROCEDURE: Connect the incited manometer to the pressure tapping of the pipe for which the coefficient is to be determined. Open the inlet value to allow from through one pipe of the annular pipe. Open the inlet & outlet cocks simultaneously to allow the water into two limbs of manometer. Open the drain cocks at the bottom of the manometer simultaneously. Note the manometer reading in both the limbs. Collect the water in collecting tank for ruse in 10 cm & the time taken is noted. Repeat the step 2 &6 at least for 6sets of reading & entire procedure for other also. Enter the readings in the table, observations & calculations. GRAPH: `Draw a graph show in the relationship between V2& the interpretation & reporting. What is the nature of the relationship between V2&Ht .Write the relationship between Ht&V2 in form of an equation. Use the equation to find coefficient of friction. RESULT: Mean velocity of the flow = Coefficient of friction= TABULATION: S.NO 1 1. Manometer right limb reading h1 (m) 2. Manometer lift limb reading h2 (m) 3. Friction head hf=(h1-h2) (sm-sw) 4. Rise in water level (cm) 2 3 4 5 7 BT8411 Chemical Engineering For Biotechnologists Lab Manual KVCET / DBT / RM 5. Time for 10cm rise (sec) 6. Discharge through pipe 7. Velocity of water in pipe (m/s) 8. Co efficient of friction *10-3 (cm3/s) Hf V2 Ex.no:4 Date: FRICTION LOSS IN STRAIGHT PIPE AIM: To determine the friction factor ‘F’ of the given pipe & also to find the energy constant. APPARATUS REQUIRED: 1. Pipe provided with inlet & 20utlet pressure tipping, 2. U-tube manometer, 3. Collecting tank, 4. Stopwatch, 5 Meter scale. 8 BT8411 Chemical Engineering For Biotechnologists Lab Manual KVCET / DBT / RM PRINCIPLE: The experiment setup consists of 3 pipes of different diameter. Each pipe is provided with the control value to control the discharge of the water from small tubes provided with drain meter. The u-tube manometer with marry as equipped is fixed in front of the pipe to measure the pressure difference, A collecting tank is flowing through the pipe. A 30m tube is fixed on the collecting tank to find the level of water. A tube with a value is collecting to the collecting tank to discharge out the water to pump from which it can be recalculated by means of an electric motor driven pump. FORMULA: Loss of heat due to friction, hf= 4FLV2 /2Gd. Where, D=Diameter of the pipe, F=Friction factor, L=Length of the pipe, V=Velocity of the liquid flow, Uf=(h1-h2) (Sm-Sw), h1=left limb reading of manometer, h2=Right limb reading of manometer, Sm=specific gravity of Hg, Sw=specific gravity of water. Actual discharge , Qact =Ay/t Where, y= Rise of water in the collecting tank =10cm. T= Time taken for the 10cm rise of water. V= C √mi, M= hydraulic mean depth , I= hydraulic gradient. PROCEDURE: 9 BT8411 Chemical Engineering For Biotechnologists Lab Manual KVCET / DBT / RM The system details of flow through a paper are noted darn pertained to the end point of the pipe, length of the pipe between the stop values connecting the pipe with the manometer & collecting tank dimensions. The supplied value is opened & the flow is admitted into the pipe fully. The inlet & outlet cocks are opened to allow water into the two limbs of manometer. The air bubbles may be present in the manometer are removed by opening the draining cock. The left & right limb reading are noted. Thus the time taken for the 10cm rise is the collecting tank is noted using the stopwatch. The steps are repeated for various discharge & observation are tabulated. RESULT: Frictional factor of the pipe, (a).From graph= (b).Theoretically= Value of C (a).From graph= (b). Theoretically= TABULATION: MANOMETER READING H1 (cm) Time for V 10cm (cm) rise (s) Q act (cm3/s) V*102 (m/s) hf h C H2 (cm) CALCULATION: Ex no: 5 FLOW THROUGH ROTOMETER TEST RIG AIM: For conducting experiments on rotometers at different flow rate and calibiration of the meter APPARATUS REQUIRED: Piping system on stand, collecting tank, supply pump set with switch and starter, sump tank and trolley fitted with all above items. 10 BT8411 Chemical Engineering For Biotechnologists Lab Manual KVCET / DBT / RM COMPUTATIONS: 1. Area of collecting tank, A= 2. Actual discharge Qa-volume of water collected in “tc” sec/time x 1000 (litres /secs) 3. Rate of discharge as read in rotometer=Qm/lps 4. Error of the meter=Qa-Qm/Qm x 100 PROCEDURE: Open the inlet valve to allow flow through the rotometer. Collect the water in the collecting tank for a rise of 10 cm and note the time tc sec Note the rotometer reading Qm. Repeat steps 1 to 3 atleast for four sets of readings. `Enter all readings in table of observation and calculations. RESULT: The coefficient of discharge of given rotometer, 1. From calculation= 2. From graph= 3. Percentage error in the rotometer= TABULATION: Size of rotometer=36.5 cm Area of collecting tank=40 x 40 cm2 S,no Details Number of observations 1 1. Time taken for 10cm rise in t sec 2. Rate of actual discharge (Qa) (lit/sec) 2 3 4 5 11 BT8411 Chemical Engineering For Biotechnologists Lab Manual 3. KVCET / DBT / RM Rate of discharge through rotometer (Qm) (lit/sec) 4. Error in meter Qa/Qm x 100 (%) Ex no: 6 Centrifugal pump AIM: 12 BT8411 Chemical Engineering For Biotechnologists Lab Manual KVCET / DBT / RM To construct a test on a centrifugal pump to obtain the pump characteristics. APPARATUS REQUIRED: Centrifugal pump, stop watch, meter scale. FORMULA: 1. Discharge, Q=Ah/t m3/s. Where, A=Area of cross section of collecting tank (m2) h=rise of water in the collecting tank (m) t=time taken for 10cm raise of water in collecting tank (s). 2. Total head (H) H=hs+hd+x Where, hs=suction head in (mmgh x 13.6/1000) hd=deliver head in (kg/cm2 x 10) x=difference in level between vaccum gauge and pressure gauge in meter (0.995). 3. Input power of the pump: Input power = (n/t)*(3600*k)*1000*0.8 watt Where, n=number of revolutions in energy meter disc t=time taken for ‘n’ revolutions of energy meter disc in 10 sec k=energy meter constant in rev/KWhr. 4. Motor efficiency: 0.8 or 80% 5. output of the pump: Output power=WQH Watt Where, W=specific weight of water=9810 N/m2 13 BT8411 Chemical Engineering For Biotechnologists Lab Manual KVCET / DBT / RM Q=discharge in m3/s 6. Pump efficiency=output power/input power x 100 7. Specific speed (Ns): Ns=(N*Q)/H3/4 PROCEDURE: Prime the pump Keep the delivery valve closed and start the motor Open the delivery valve to get the required head Note the following readings 1. Pressure gauge and vaccum gauge readings 2. Time taken for 10cm rise in water in the collecting tank ‘t’ sec 3. Time taken for 10 revolutions of energy meter disc t sec. OBSERVATION: 1. speed of the pump(N)=2880 rpm 2. energy meter constant =3200 rev/KWhr 3. Internal dimension of collecting tank=0.45 x 0.45=0.2025 4. Length=0.45m 5. Breadth=0.08m RESULT: 1. total discharge of pump= 2. total head of pump= 3. input power of pump= 4. output power of pump= 5. efficiency of pump= S.no Pressure gauge Reading (P) Vaccum gauge Reading (V) Total head of Time taken for 10 Discharge Time taken Q for 10 rev of Output power Input power Efficiency % (Watt) 14 BT8411 Chemical Engineering For Biotechnologists Lab Manual Kg/cm2 mm of hg Water cm (H) rise of water in tank KVCET / DBT / RM m3/s (x 10-3) energy meter disc (Watt) Ex.no:7 Date: FLUIDISED BED 15 BT8411 Chemical Engineering For Biotechnologists Lab Manual KVCET / DBT / RM AIM: To observe & study the behaviors of bed during fluidization. To determine the pressure drop per unit length as a function of superficial velocity of fluidization medium To determine minimum fluidization velocity To study the effect Re No. on porosity. PRINCIPLE: When a gas or a liquid is placed at a very low velocity through a bed of solid particles, the particles do not move & the pressure drop is given by ergin’s equation. If the fluid velocity is slightly increased the pressure drop on the individual particles starts increasing & eventually the particles start moving & become suspended in the fluid. The form fluidization & fluidized bed are used to determine the condition of fully suspended particles. When a fluid passes through a bed of solids there will be a certain pressure drop across the bed required to maintain the fluid flow depending upon the lead geometry fluid velocity & particles characteristic, the following phenomenon occur with the gradual increase in velocity. At low velocity there is a pressure drop across the bed but the particles are stationary & flow of fluid though a ferried lead .As the fluid velocity is gradually increasing assorts ,A value is reached when the lead starts expanding .This point is known as fluidized bed. FORMULA: Minimum fluidization velocity, VOM=0.05g dp2 (ρs-ρw ) ε 03 (1- ε 0) µ Reynolds’s number, NRE=DVρ/µ. Velocity V0 =Q/A (ms-1 ) Velocity flow rate, Q=Vol. of water collected Time of collection Porosity =1-L0/L [1-∑0] Initial porosity £0 = Void volume / total volume Cross sectional area of column = ∏d2 (m2) =1.52*10-3 m2 Where, D=diameter of column, m. 16 BT8411 Chemical Engineering For Biotechnologists Lab Manual KVCET / DBT / RM dp=diameter of particles, m. ρS =density of particles, kg/m3 ρw=Density of water, kg/m3 µ= Viscosity of water, kg/m3 L0 =Initial lad height. L=Bed height PROCEDURE: Note the initial lead height. Open the value slightly & allow the water to flow through the lead. Note the lead height remains the same & collects the water for a particular period of time (i.e) 30& note down the volume /weight of water collected. Gradually increase the flow of water by opening the value & repeat step3.Onethe lad fluidizes note the lead height & collect the water for a particular period of time. Repeat step4 & step5 until maximum lead height is obtained. GRAPHS: 1. Velocity Vs Porosity. 2. Velocity Vs (∆H/L) exp. 3. Velocity Vs Bed height. RESULT: The bed was observed & studied during fluidization. The minimum fluidization velocity was found to be OBSERRVATION: 1. Diameter of column, D=0.044*10-3m. 2. Diameter of particle, dp=2500µm. 3. Initial lead height =26cm. 4. Initial bed height=26cm 5. Initial porosity ε 0=0.2043 TABULATINON 17 BT8411 Chemical Engineering For Biotechnologists Lab Manual MANOMETER S.NO READING H1 H2 ∆H m of water *10-2 Volume Time of Q of water collection m3/s collected lead ×10-4 3 m S KVCET / DBT / RM Bed height L M Porosity V0=Q/A NRE ∑ 18 ∆H/L ×10-4 BT8411 Chemical Engineering For Biotechnologists Lab Manual KVCET / DBT / RM Ex no:8 FLOW THROUGH PACKED BED COLUMN AIM: To verify relationship between the flow of fluid and pressure drop per unit length of packing. THEORY: Slightly open the inlet valve and unite for steady state and noted for manometer made in both liquid. collect the outlet water for particular required and weigh the collected water. Repeat step 1 and 2 for various flow rate. Tabulate the observation and calculation. FORMULA: 1. NRe =DpV0P/µ 2. ⩟ H2O=h1=h2 3. 1<NRe<1000 ⩟p∑3Dpds/Llv0(1-∑)=150(1-∑)/⏀NRe≠1.75 4. for NRe<1 ⩟p∑3Dp3⏀s2/LV0N(1-∑)=1.50 The Equation is called as Korney Carmen equation PROCEDURE: Slightly open the inlet and united for steady state and note down manometer reading in both liquid Collect the outlet water for a particular required and weigh the collected water Repeat the 1 and 2 for various flow rates Tabulate the observation and calculate (⩟p/L) and factor RESULT: The relationship between the flow of fluid and pressure drop for per unit length of packing is verified. 19 BT8411 Chemical Engineering For Biotechnologists Lab Manual S.no H1 (m) H2 (m) ⩟H (m) Volume Time of water (s) collected Velocity Q=Volume NRe of water /time KVCET / DBT / RM Fexp (⩟H/t)exp 1. 2. 3. 4. 20 BT8411 Chemical Engineering For Biotechnologists Lab Manual KVCET / DBT / RM Ex.no:9 Date: PARALLEL FLOW HEAT EXCHANGER AIM: To determine the effectiveness NTO of heat exchanger overall heat transfer Coefficient of parallel flow heat exchanger APPARATUS REQUIRED: 1. 2. 3. 4. 5. 6. Electric geyser Thermometer Concentric tube Heat exchanger Measuring flask Stop clock PRINCIPLE: Heat exchangers are devices in which heat is transferred from fluid to another, the necessity for doing this arise in multitude of industrial application common exchanger are radiated. Heat exchanger can be classified as transfer type storage type & direct count type TRANSFER TYPE HEAT EXCHANGER: It is one which both fluid basses simultaneously in two separate value in particles must of heat exchangers. The transfer is farther classified according to flow arrangement PARALEL FLOW: In which fluid flows in the same direction COUNTER FLOW: In which fluid flow in the opposite direction CROSS FLOW: In which fluid flow at right angles to each other FORMULA: LMTD (∆T)M =(T₁-T₂)-(T₂-t₂)/Lm (T₁-t₁)/(T₂ -t₂) where, t₁&t₂ are the entry & exit temperatures of add fluid , T₁& T₂ are the entry and exit temperature 21 BT8411 Chemical Engineering For Biotechnologists Lab Manual KVCET / DBT / RM of the not fluid, Effectiveness (E) =1-EXP [-N (1+C)]/ (1+c) where, C→ C (min)/C (max) NTU→∆U/C(min) N→ Number of transfer units. C(min)→ ms* specific heat. C(max)→ms* specific heat. A₀→∏DOL, qu→ mh*Cph* ∆Th Ai =∏DіL, A= A₀ +Ai/2 Q=qυ+qc/C µ= Q/LMTD*∆ qc→mc*Cpc *∆Tc where, mh→ mass flow rate in hot fluid (kg/hr) mc → mass flow rate in cold fluid (kg/hr) Cph→ specific heat capacity of hot fluid. Cpc → specific heat capacity of cold fluid. ∆Th → temperature of hot fluid (k). ∆Tc → temperature of cold fluid (k). Q→ Heat flowing in ‘W’ PROCEDURE: 1.Place the thermometer & note their reading start the flow on hot water side between the range 1.5& 4 lit/min 2. Start the flow through the few exchangers as parallel flow unit. Adjust the flow rate on heat water side between the range 1.5-4 lit/min& the cold water range is 3-8 lit/min 3. Keeping the flow rate constant until steady state condition is marked. Record the temperature on hot & cold water . 4. Repeat the experiment with counter flow & identified flow conditions. Correct the temperature 22 BT8411 Chemical Engineering For Biotechnologists Lab Manual KVCET / DBT / RM by the suitable reading obtained from the initial reading if the thermometer. RESULT: LMTD value has been found as= Effectiveness of the heat exchanger is= TABULATION: HOT WATER SIDE COLD WATER SIDE FlowRate kg/hr FlowRate kg/hr In let Tamp (k) Out let Temp (K) In let Tamp (k) Out let Temp (K) qh qc kj/hr’c kj/hr’c mcph mcpc ∆T1 ∆T2 ‘C ‘C LMTD ‘C CALCULATIONS: 23 Effec Tiveness BT8411 Chemical Engineering For Biotechnologists Lab Manual KVCET / DBT / RM Ex.no:10 Date: COUNTER FLOW HEAT EXCHANGER AIM: To determine the effectiveness NTU of heat exchanger overall heat transfer coefficient of counter flow heat exchanger. APPARATUS REQUIRED: 1. Electric geysers. 2. Conceutric tube heat exchanger. 3. Thermometer. 4. Measering flask. 5. Stop clock. FORMULA: LMTD (∆T) M = (T1-t1) – (T2-t2)/Ln (T1-t1)/ (T2-t2) Where, t1 &t2 are entry & exit temperature of cold fluid,T1&T2 are entry & exit temperature of hot fluid. Effectiveness (E) = 1-exp [-N (1+C)] / (1=C) C=Cmin /Cmax , N= AU/Cmin . Where, NTU→ number of transfer units, Cmin→ ms* specific heat, Cmax→ ms* specific heat, MS→ mass flow rate, qu → mh*cph *∆Th qc→ mc+cpc *∆Tc 24 BT8411 Chemical Engineering For Biotechnologists Lab Manual KVCET / DBT / RM Cph→ specific heat capacity of hot fluid, Cpc→ specific heat capacity of cold fluid, ∆Th→ Temperature of hot fluid, ∆Tc→ Temperature of cold fluid, PROCEDURE: 1. Place the thermometer in the position &note the reading. Start flow on hot water side. Adjust the flow rate on the hot water side & cold water side wide range of 1.5-4 lit/min &3-8lit/min. 2. Keeping the flow rate same until the state is obtained .Switch on the geyser. Record the temperature of hot &cold water flow rate accurately. 3. Repeat the experiment with the counter flow & identical flow conditions, collect & calculate the readings. RESULT: The LMTD value is found to be= Effectiveness of the heat exchanger = TABULATION: HOT WATER SIDE COLD WATER SIDE FlowRate kg/hr FlowRate kg/hr In let Tamp (k) Out let Temp (K) In let Tamp (k) Out let Temp (K) qh qc kj/hr’c kj/hr’c mcph mcpc ∆T1 ∆T2 ‘C ‘C LMTD ‘C 25 Effec Tiveness BT8411 Chemical Engineering For Biotechnologists Lab Manual KVCET / DBT / RM CALCULATIONS: Ex.no:11 Date: LEAF FILTER AIM: To determine the specific cake resistance ‘α’ and filter medium resistance Rm using leaf filter. APPARATUS: Leaf filter, 1.5% by weight of calcium carbonate slurry, stop watch. PRINCIPLE: Filtration is the removal of solid particles from slurry by passing through a filter medium on which solids are deposited. Solids on the filter cloth form a packed bed and the filtrate flow through the pores is assumed to be under laminar range and hence cozen calman equation is used for filtrations. Leaf filter is a batch filter used in the same manner as that of plate and frame filter press. Here the filtration is done using vacuum. The specific cake resistance ‘α’ and filter medium resistance Rm are calculated using the following relations. α =2A2(1-mw)∆P ρ Mc m2/kg 26 BT8411 Chemical Engineering For Biotechnologists Lab Manual KVCET / DBT / RM Rm =W VF m-1 A(1-Mw) W=Weight fraction of solid is slurry, ∆P=Pressure drop for filtration, Ρ=Density of filtrate kg/m3, µ=Viscosity of filtrate N/m2, C=Constant from graph (∆Q/∆V Vs V) sec/m6 VF=Fictitious volume of slurry, m3 FORMULA: For 100 mm Hg 1. Volume: v=πr2h 2.∆Ѳ= Ѳ2-Ѳ1 3. V average =v1+v2/2 4. ∆v=(6.4132-4.275)× 10-4 5.∆Ѳ/∆v= 6. Concentration of solids/unit volume of slurry: C= cs/1-(mf/mc-1)15/1000 7. Specific cake resistance: Α=kp P A2 /cµ 8. Filter medium resistance: Rm=A.∆P β/µ Mass of the filter particles/unit volume of filter C=cs/1-[(mf/mc-1) cs/ρ)] Specific cake resistance Α=(kp ρ A2/2cµ) m/kg Where kp/2 is the slope of the graph, Filter medium resistance Rm= (β A’ ∆P/µ) m Where β is the intercept of the graph, PROCEDURE: Prepared 1.5% by weight slurry of calcium carbonate slurry in a container. The filter is lowered in to the container and continuously agitated slurry by an agitator. Applied 10cm Hg suction to the outlet pipe and filtration is observed. The stop watch is started when filtrate is at zero level in receiver. The time is noted for every 5cm rise of the filtrate in the receiver. Switch off the suction after complete filtration. The filter cakes are collected in the watch glass. The wet filter cake is weighed and dried it and the dry cake is weighed. 27 BT8411 Chemical Engineering For Biotechnologists Lab Manual KVCET / DBT / RM The above steps are carried out at an increase level of suction at 15 inch Hg. RESULT: The specific cake resistance = The filter medium resistance = TABULATION: Pressure = 100 mmHg S.N o Height(cm Ѳ(sec ) ) Volum e ×10-4 m3 ∆Ѳ(sec ) V(average ∆ ∆Ѳ/∆V×10 ) ×10-4 m3 V 5 × 104 m3 Pressure = 150 mm Hg 28 BT8411 Chemical Engineering For Biotechnologists Lab Manual s.n o Height(cm Ѳ(sec ) ) Volum e ×10-4 m3 KVCET / DBT / RM ∆Ѳ(sec ) V(average ∆ ∆Ѳ/∆V×10 ) ×10-4 m3 V 4 × 104 m3 Pressure = 200 mm Hg s.no Height(cm) Ѳ(sec) Volume ∆Ѳ(sec) V(average) ∆V ×10-4 ×10-4 m3 × 3 m 10-4 m3 ∆p × 103 N/m2 α ×1011 m/kg ∆Ѳ/∆V×103 Rm × 1010/m 29 BT8411 Chemical Engineering For Biotechnologists Lab Manual KVCET / DBT / RM Ex.no:12 Date: SIMPLE DISTILLATION Aim To verify Rayleigh’s equation by conducting a batch distillation. Theory Distillation is the method adopted for separation of one of the components of two miscible components in a liquid mixture. In differential distillation, the vapors generated by the boiling liquid is withdrawn from contact with the liquid as fast as it is formed. This operation is explained using Rayleigh’s equation given as F Ln W XF XW dx y * x where F is the no. of moles of the feed, W is the number of moles of the residue, x f is the mole fraction of more volatile component in the feed and xw is the mole fraction of more volatile component in the residue. 30 BT8411 Chemical Engineering For Biotechnologists Lab Manual KVCET / DBT / RM Apparatus The setup consists of a distillation flask, to which a condenser is attached. The distillate is collected in a receiver through on adaptor. The still is heated by an electric hot plate and a thermometer is used to measure the distillation temperature. Procedure 1. A series of samples of 10ml of binary mixture A and B is made up and their densities determined using a specific gravity bottle and an electronic balance. 2. A calibration curve is plotted between the densities and the volume fraction. 3. The distillation flask is charged with the given mixture and is heated at a slow, uniform rate. 4. The heating is continued till approximately 45-50 % of total feed is collected as distillate. 5. The hot plate is switched off and the flask is allowed to cool. 6. The densities of the distillate and the residue are measured using specific gravity bottle and an electronic balance. Observations 1. Volume of feed (Vf) = 2. Volume of methanol (A) in feed (VA) = 3. Volume of water (B) in feed (VB) = 4. Volume of residue (Vr) = 5. Volume of distillate collected (Vd) = TABULATION Composition of mixture S. No Volume % of Volume % of A B Weight of empty specific gravity bottle, W0 (g) Weight of bottle + liquid mixture, W1 (g) Density (g/cm3) 31 BT8411 Chemical Engineering For Biotechnologists Lab Manual 1 0 100 2 20 80 3 40 60 4 60 40 5 80 20 6 100 0 7 VAD VBD 8 VAW VBW KVCET / DBT / RM Graphs: Graph -1: Plot density versus volumetric composition of A Graph – II: Plot 1/(y*-x) versus x diagram for the components A in equilibrium with B Model Calculation Moles of methanol in feed (mAf) = VA A MA = = Moles of water in residue (mBf) = VB B MB = 32 BT8411 Chemical Engineering For Biotechnologists Lab Manual KVCET / DBT / RM = Total Moles of feed (F) = mAf + mBf = = Mole fraction of methanol in feed (xf) =mAf/F = Density of distillate = Density of residue = Volume fraction of methanol in residue (vAr)= Volume fraction of water in residue (vBr) (from graph) = 1- vAr = Moles of methanol in residue (mA) = v Ar Vr A MA = = Moles of water in residue (mB) = v Br Vr B MB = = Total moles of residue (W) = mA+ mB = 33 BT8411 Chemical Engineering For Biotechnologists Lab Manual KVCET / DBT / RM = Mole fraction of methanol in residue (xw) = mA / W = = RHS of Rayleigh’s equation (Area under the curve) Area = (No. of squares of 1mm2 area) (Scale on x-axis) (Scale on y-axis) (0.01) = = LHS of Rayleigh’s equation ln(F/W) = = % error % error = (RHS–LHS)/LHS = = Result Rayleigh’s equation is verified and the percentage error is found to be 34 BT8411 Chemical Engineering For Biotechnologists Lab Manual KVCET / DBT / RM Ex. No: 13 Date : LIQUID-LIQUID EXTRACTION Aim To determine the extraction efficiency of water to separate acetic acid from its solution in benzene in single stage and double stage extraction. Apparatus 1. Separating funnel 2. Beakers 3. Burette 4. Pipette 5. Std. sodium hydroxide solution of 0.1N Discussion 35 BT8411 Chemical Engineering For Biotechnologists Lab Manual KVCET / DBT / RM Extraction is an operation in which two miscible liquids are separated by the use of a third liquid that preferentially dissolves one of them. When separation of miscible liquids is difficult by distillation, extraction method is considered. Close boiling mixtures or substances that cannot withstand the temperature of distillation, even under a vacuum may often be separated from impurities by extraction, which uses chemical differences instead of vapour pressure differences. Extraction is widely used for the purification of petroleum products, penicillin recovery and in nuclear effluent treatment. Extraction equipments may be operated as batch or continuous units. Similarly they can be operated in single stage and multi stage modes. Extraction involves mixing a known quantity of feed with the known quantity of solvent in an agitated vessel, after which the layers are separated as extract and raffinate. Extraction efficiency depends on the intimacy of contact of the phases and on the number of stages of contact, permissible by economy. Procedure Single Stage extraction 1. 50 ml of benzene and 25 ml of glacial acetic acid are mixed well and taken as feed in a stopper bottle 2. 30 ml of water is added to the bottle and the contents are mixed thoroughly by shaking the bottle 3. After 15 minutes , the contents of the bottle are transferred to a separating funnel 4. The extract layer is carefully removed from the separating funnel and transferred to a beaker and its volume is measured 5. A known volume of the extract sample is titrated against 0.1 N NaOH solution and the volume of NaOH consumed is determined Two Stage Extractions 1. 50 ml of benzene and 25 ml of glacial acetic acid are mixed well and taken as feed in a stopper bottle 2. 15 ml of water is added to the bottle and the contents are mixed thoroughly by shaking the bottle 3. After 15 minutes the contents of the bottle are transferred to a separating funnel 4. The extract layer is carefully removed from the separating funnel and transferred to a beaker and its volume is measured 5. A known volume of the extract sample is titrated against 0.1 N Std. NaOH solution and the volume of NaOH consumed is determined 6. The raffinate from the first stage is transferred to another stopper bottle to which 15 ml of water is added and the bottle is thoroughly shaken to mix the contents well 36 BT8411 Chemical Engineering For Biotechnologists Lab Manual KVCET / DBT / RM 7. After 15 minutes, the contents of the bottle are transferred to a separating funnel. 8. The extract layer (from the second stage) is carefully removed from the separating funnel and transferred to a beaker and its volume is measured 9. A known volume of the extract sample is titrated against 0.1 N Std. NaOH solutions and the volume of NaOH consumed is determined. Observations Single Stage Extraction Volume of acetic acid in the feed (Vf) = Volume of benzene in the feed = Volume of the extract (Ve) = Volume of raffinate (Vr) = TABULATION - I S. No Volume of extract Normality taken for titration (V2) NaOH (N1) N ml of Volume of NaOH Indicator consumed (V1) ml Model Calculations Normality of extract (Ne) = (V1 N1)/V2 = 37 BT8411 Chemical Engineering For Biotechnologists Lab Manual KVCET / DBT / RM = Amount of acetic acid in the extract layer (W) = (60VeNe) / 1000 = = Single stage extraction efficiency (η) = (100 W) / (Vfρa) = = Two stage extraction First stage Volume of extract (Ve1) = Volume of raffinate (Vr1) = TABULATION - II S. No Volume of extract Normality of Volume of NaOH taken for titration Indicator NaOH (N1) N consumed (V11) ml (V21) ml 38 BT8411 Chemical Engineering For Biotechnologists Lab Manual Normality of extract (Ne1) KVCET / DBT / RM = (V11 N1)/V21 = = Amount of acetic acid in the extract layer (W1) = (60Ve1Ne1)/1000 = = Second stage Volume of extract (Ve2) = Volume of raffinate (Vr2) = TABULATION - III S. No Volume of extract Volume of NaOH Normality of taken for titration consumed (V12) Indicator NaOH (N1) N (V22) ml ml 39 BT8411 Chemical Engineering For Biotechnologists Lab Manual Normality of extract (Ne2) KVCET / DBT / RM = (V12 N1) / V22 = = Amount of acetic acid in the extract layer (W2) = (60Ve2Ne2) / 1000 = = Single stage extraction efficiency (η) = 100 (W1+W2)/(Vfρa) = Result The extraction of acetic acid from benzene using water is conducted in single stage and in two stages and the separation efficiencies are reported as follows Efficiency in Single stage extraction = Efficiency in Two stage extraction = Ex.no:14 Date: BATCH ADSORPTION 40 BT8411 Chemical Engineering For Biotechnologists Lab Manual KVCET / DBT / RM Aim To separate the product by means of adsorption on the given adsorbent material in a simple adsorption column system and derive the Freundlish adsorption isotherm. Principle Adsorption is a reversible phenomenon occurring at the surface of a solid. The forces of adsorption are mainly physical and are not strong. Hence desorption of the adsorbate is feasible in physisorption in contrast chemisorptions leads to irreversible adsorption is feasible in physisorption in contrast chemisorptions leads to irreversible adsorption and practically have no application in bioseperations. The advantages of adsorption process in bio separations are several. It may be used for primary isolation as well as for concentration of desired products. Since adsorption is highly selective the desired product may be adsorbed directly from fermentation broths with out the use of any preliminary or filtration or centrifugation step. Adsorption does not denature sensitive biomolecules and hence preferred for isolation of proteins. However adsorption process is capacity of any adsorbent is generally small and in addition the design of adsorption process is complicated by non-linear equilibrium and some times strong adsorbent- adsorbate interactions. Batch adsorption is used to adsorb solutes from the liquid phase when the quantities treated are relatively in small amounts. The freundlish adsorption isotherm is given by the equation C= (K.S)n, where C= amount of solute adsorbed / amount of adsorbent used. S=concentration of the feed solution k and n are freundlish constants. By studying Congo red- charcoal system, these values can be desired so as freundlich isotherm. Materials Required Congo red Charcoal Conical flask Shaker 41 BT8411 Chemical Engineering For Biotechnologists Lab Manual KVCET / DBT / RM Spectrophotometer. Procedure Drawing out the standard curve for Congo red concentration. Stock Solution Weigh 500mg of Congo red and mix it with 100ml of distilled water to obtain a concentration of 500ppm. Working Standard solution Take 5 test tubes and fill it with 2,4,6,8 and 10 ml of stock solution respectively. Make the tube up to 10ml. the concentration are Spectroscopy Distilled water is used as a starch as a blank and the adsorption co efficient of all the solution present in the 10 test tubes is read out at 620nm using a spectrophotometer meter. Congo red-charcoal system Prepare 50ml solutions of each concentration Weigh 0.1g of charcoal and take it in a conical flask. Add the prepared solution of congored in these conical flasks and close the flasks Keep the flasks process, filter the solution by using filter paper Read the OD values the filtrate at 620nm in the spectrophotometer. Result The freundlish isotherm derived from the system Congo-red charcoal is______ 42