CAT.ES20-172 C

Magnetically Coupled Rodless Cylinder

New

ø6, ø10, ø50, and ø63 have been added.

Upgraded version of space saving

magnetically coupled rodless cylinder

Basic type

Direct mount type

Series CY3B/CY3R

Magnetically

Coupled

Rodless

Cylinder

Basic type

Direct mount type

Series CY3B/CY3R

Improved durability

Improved bearing performance

Improved lubrication by using a lubretainer

A 70% longer wear ring length

achieving an improvement in bearing performance compared to the

CY1B.

A special resin lubretainer is installed on the

dust seal to achieve ideal lubrication on the

external surface of the cylinder tube.

Direct mount type Series

Basic type Series

CY3R

CY3B

Mounting dimensions are identical to those of series CY1.

The mounting dimensions (in the drawing below) are identical with

those of existing series CY1B/CY1R, allowing easy replacement.

Series CY3B

(∗ For bore size of ø6, the mounting is not interchangeable with the

CY1 series because the piping port has been reduced to a M3 size.)

Series CY3B6

Piping port M3

3 mm

NN

<CY3B6> Piping port M5

S + Stroke

ZZ + Stroke

<CY1B6>

Series CY3R

6 mm

Series CY3R6

S + Stroke

Z + Stroke

QW

<CY3R6>

Piping port M3

<CY1R6>

Features 1

Piping port M5

Note) When ordering a product that is interchangeable with a

CY16, add the suffix, X1468 to the end of the CY36

model number (Refer to page 27).

Upgraded version of space saving

magnetically rodless cylinder!

Wear ring A

Lubretainer

(special resin)

Reduction of

sliding resistance

Minimum operating pressure reduced by 30%

Wear ring B

By using a lubretainer, the

minimum operating pressure is reduced by 30%.

(CY3B40 compared with CY1B40)

Series CY3B

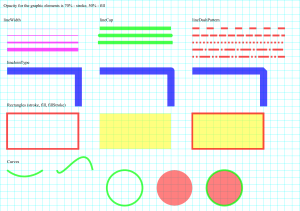

Small auto switches are mountable.

Small auto switches can be mounted on the currrent auto switch mounting groove of the CY3R20

to 63. They can also be mounted to all of the cylinder sizes in the CY3R series, making inventory

control of the product easy.

ø6, ø10, ø50, and ø63

Series is completed by adding

the new bore sizes. (ø6 to ø63)

Switch rail

Watchmaker’s

(precision) screwdriver

Mounting screw

M2.5 x 0.45 x 4 l

Switch mounting

bracket

Auto switch

Lightweight

The body weight has been reduced by approximately 10% by eliminating unnecessary body weight and by reducing the outer diameter of

the cylinder tube. (Compared with previous ø50 and ø60 models)

Series Variations

Series

Bore

size

ø10

ø15

ø20

ø25

ø32

ø40

ø50

ø63

ø6

ø10

ø15

ø20

CY3R

50

150

100

ø6

CY3B

Standard stroke (mm)

ø25

ø32

ø40

ø50

ø63

250

200

350

300

450

400

600

500

Individual made-to-order products

800

700

1000

900

Note) The mark indicates the available combination of

bore size and standard stroke.

Heat resistant specifications

(XB6)

Low speed specifications (15 to 50 mm/s)

(XB9)

Long stroke

(XB11)

Low speed specifications (7 to 50 mm/s)

(XB13)

Hydro specifications

(X116)

Axial ports

(X132)

High speed specifications

(X160)

Helical insert thread specifications

(X168)

Added mounting tap positions for slider

(X206)

Oil-free exterior specifications

(X210)

Outside of cylinder tube with hard chrome plating

(X322)

Oil-free exterior specifications (with dust seal)

Interchangeable specification with CY16

(X324)

(X1468)

With magnetic shielding plate

(XC24)

With floating joint

(XC57)

Availability of made to order products varies with the series

and the bore size. For more information, please refer page 24.

Features 2

Series CY3B/CY3R

Model Selection Criteria

Recommended cylinder

Model selection points

Appearance

Features

CY3B

Series

Size/ø6, ø10, ø15, ø20, ø25, ø32,

ø40, ø50, ø63

When

used with many

different types of guides.

When a long stroke is

necessary.

When

used with many

different types of guides.

When auto switches are

added to the basic type.

When used without a guide

for a light load. (See

application example.)

When space is very limited.

Types with guide

• A long stroke is possible.

CY3R

Series

Size/ø6, ø10, ø15, ø20, ø25, ø32,

ø40, ø50, ø63

Application example

Transferring

Cutting

1

• Cylinder can be directly mounted.

• Auto switches can be mounted, and

there is no lurching from cylinder.

• Non-rotation mechanism is available

within the allowable range.

• Piping can be concentrated with the

centralized piping type.

• External dimensions are compact.

• Mounting can be performed on the top

body surface or on one of the side

surfaces.

Series CY3B/CY3R

Model Selection

E: Kinetic energy of load (J)

(W + WB)

V 2

E=

x

2

1000

Es: Allowable kinetic energy for intermediate stop using

an air pressure circuit (J)

Fn: Allowable driving force (N)

MD: Maximum allowable moment (N⋅m) when a connection

bracket, etc. is carried directly

Ps: Operating pressure limit for intermediate stop using

an external stopper, etc. (MPa)

Pv: Maximum operating pressure for vertical operation (MPa)

WBmax: Maximum load weight (kg) when loaded directly

on the body

Wv: Allowable load weight for vertical operation (kg)

(

)

Operating Conditions

• W:

• WB:

• µ:

• Lo:

Load weight (kg)

• Switches

Connection bracket weight (kg)

• P: Operating pressure (MPa)

• V: Speed (mm/s)

Guide's coefficient of friction

• Stroke (mm)

Distance from cylinder

• Mode of operation

shaft center to workpiece point

(horizontal, inclined, vertical)

of application (cm)

• L1: Distance from cylinder shaft center to connection fitting, etc.

Mode of

operation

Note 1)

Inclined operation

Horizontal operation

Vertical operation

Review of load weight

and operating pressure

W

Lo

Guide

First tentative bore size

determination

F1

øD ≥ 1.6 x

P

WB

First tentative bore size

determination

F2

øD ≥ 1.6 x

P

First tentative bore size

determination

F3

øD ≥ 1.6 x

P

θ˚ θ˚

Inclined operation

W + WB ≤ WV

W + WB > WV

Determination

P ≤ PV

P > PV

Allowable Driving Force Table (Fn) (n=1,2,3)

Inclined

F1 = µ x (W + WB) x 9.8

F2 = (W + WB) x 9.8 x (µCOSθ + SINθ)

Vertical

F3 = (W + WB) x 9.8 x (µ + 1)

Horizontal

of allowable load

weight &

pressure

(Refer to page 5 for

(Refer to page 5 for the maximum

Refer to the allowable driving force table for the (Fn) of data K

A.

vertical operation.)

load weight when loaded directly

on the body and connection bracket.)

WB > WBmax

Determination of

connection bracket

weight (WB)

Review of connection bracket

CY3B

WB ≤ WBmax

CY3R

Review of switch use and stroke

Equipped with

switch rail?

(Refer to data

K

A on pages 3

and 4.)

Yes

Equipped with

switches?

No

No

Second tentative determination

of bore size using the graph of

allowable driving force (Fn)

and distance from cylinder

shaft center (Lo)

Yes

Yes

NG

(Refer to

standard

stroke table

on page 12.)

Determination

of stroke with

switch

OK

Equipped

with external guide

system?

No

Yes

Stop with external stopper

Intermediate

stopping method

Note 1)

Intermediate

stop?

Note 3)

WB x L1 > MD

No

Stop with air pressure circuit

WB x L1 ≤ MD

Refer to page 6 for

intermediate stops.)

E=

Determination of

pressure (P) when making

intermediate stop

( )

(W + WB)

V

x

2

1000

P ≤ Ps

(Refer to page 6 for

intermediate stops.)

P > Ps

Determination of

load’s kinetic

energy (E)

E ≤ Es

Bore size

determination

Note 3)

NG

2

E > Es

(Refer to page 6 for body

non-rotating accuracy and

Determination maximum allowable moment.)

of allowable

stroke

Note 2)

Review of order made

products based on

operating conditions

(Refer to pages

24 through 29.)

Review of larger bore size

Review of larger bore size

(Refer to page 6 for body

non-rotating accuracy and

maximum allowable moment.)

Determination

of rotating

moment

Model determination

OK

Note 1) This cylinder cannot perform an intermediate stop

using an air pressure circuit in vertical operation.

In this case, an intermediate stop can be

performed only by using an external stopper, etc.

Note 2) Depending on the operating environment, etc.,

order made products should also be reviewed.

Note 3) An external guide system should be installed

when over specifications.

2

Series CY3B/CY3R

Model Selection

Precautions on Design 1

Selection Procedure

Selection procedure

<Data K

A : Distance from cylinder shaft center

Usable range

1

0

1

2

3

4

5

6

Distance from cylinder shaft center Lo (cm)

Lo

Fn

Selection example

Given a load drive resisting force of Fn = 100

(N) and a distance from the cylinder shaft center to the load application point of Lo = 8 cm,

find the intersection point by extending upward

from the horizontal axis of data K

A where the

distance from the shaft center is 8 cm, and

then extending to the side, find the allowable

driving force on the vertical axis.

Models suitable in satisfying the requirement

of 100 (N) are CY332 or CY340.

Allowable driving force Fn (N)

CY3B10

10

Usable range

1

0

1

2

3

4

5

6

7

8

9

Distance from cylinder shaft center Lo (cm)

CY3B15

10

Usable range

1

0

1

2

3

4

5

6

7

8

9 10 11

Distance from cylinder shaft center Lo (cm)

Allowable driving force Fn (N)

200

100

50

10

5

Usable range

1

0 1 2 3 4 5 6 7 8 9 10 11 12 13

Distance from cylinder shaft center Lo (cm)

Allowable driving force Fn (N)

CY3B25

3

500

300

200

100

50

40

30

20

10

Usable range

1

0 1

50

40

30

20

Usable range

10

5

1

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Distance from cylinder shaft center Lo (cm)

500

300

200

100

50

40

30

20

Usable range

10

5

1

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Distance from cylinder shaft center Lo (cm)

1000

500

300

200

100

Usable range

50

40

30

20

10

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Distance from cylinder shaft center Lo (cm)

CY3B63

CY3B20

5

100

CY3B50

50

40

30

20

5

400

300

200

CY3B40

50

40

30

20

5

Allowable driving force Fn (N)

5

Allowable driving force Fn (N)

Load

Allowable driving force Fn (N)

Workpiece

10

Allowable driving force Fn (N)

3. Select the bore size from Lo and Fn,

based on data K

A.

40

30

20

2 3 4 5 6 7 8 9 10 11 12 13

Distance from cylinder shaft center Lo (cm)

Allowable driving force Fn (N)

2. Find the distance Lo (cm) from the point of

the load where driving force is applied, to

the center of the cylinder shaft.

Allowable driving capacity>

CY3B32

CY3B6

Allowable driving force Fn (N)

1. Find the drive resisting force Fn (N) when

moving the load horizontally.

1000

500

400

300

200

100

50

40

30

20

Usable range

10

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Distance from cylinder shaft center Lo (cm)

Model Selection

Series CY3B/CY3R

Precautions on Design 1

<Data K

A : Distance from cylinder shaft center

CY3R32

Allowable driving force Fn (N)

Allowable driving force Fn (N)

CY3R6

40

30

20

H

10

5

Usable range

1

0

Allowable driving capacity>

1

2

3

4

5

6

400

300

200

100

50

40

30

20

10

5

1

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Distance from cylinder shaft center Lo (cm)

10

Usable range

1

1

2

3

4

5

6

7

8

9

Distance from cylinder shaft center Lo (cm)

Allowable driving force Fn (N)

CY3R15

50

40

30

20

10

Usable range

5

1

0

1

2

3

4

5

6

7

8

9 10 11

Distance from cylinder shaft center Lo (cm)

CY3R20

Allowable driving force Fn (N)

500

300

200

100

50

40

30

20

Usable range

10

5

1

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Distance from cylinder shaft center Lo (cm)

CY3R50

H

Allowable driving force Fn (N)

0

Allowable driving force Fn (N)

CY3R40

50

40

30

20

5

Distance from cylinder shaft center Lo (cm)

1000

500

300

200

100

Usable range

50

40

30

20

10

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Distance from cylinder shaft center Lo (cm)

CY3R63

200

100

50

30

10

5

Usable range

1

0 1 2 3 4 5 6 7 8 9 10 11 12 13

Distance from cylinder shaft center Lo (cm)

Allowable driving force Fn (N)

Allowable driving force Fn (N)

CY3R10

Usable range

1000

500

400

300

200

100

50

40

30

20

Usable range

10

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Distance from cylinder shaft center Lo (cm)

Allowable driving force Fn (N)

CY3R25

500

300

200

100

50

40

30

20

10

Usable range

5

1

0 1

2 3 4 5 6 7 8 9 10 11 12 13

Distance from cylinder shaft center Lo (cm)

4

Series CY3B/CY3R

Model Selection

Precautions on Design 2

Maximum Weight of Connection

Bracket to the Body

Cylinder Dead Weight Deflection

When the cylinder is mounted horizontally, deflection appears due to its own weight as

shown in the data, and the longer the stroke is,

the greater the amount of variation in the shaft

center. Therefore, a connection method should

be considered which can assimilate this deflection.

Load platform

Guide shaft

Series CY3 is guided by an external axis (such

as a linear guide) without directly mounting the

load. When designing a metal bracket to connect the load, make sure that its weight will not

exceed the value in the table below. Basically,

guide the CY3R direct mounting type also with

an external axis. (For connection methods, refer to the Instruction Manual.)

CY3B

CY3R

Max. Connection Bracket Weight

C

Model

(Note)

CY3B50,63

CY3B25,32,40

Clearance (Note)

(0.2 to 0.5 mm)

CY3B20

CY3B15

CY3B10

CY36

Note 1) According to the dead weight deflection

in the figure on the right, provide

clearance so that the cylinder does not

touch the mounting surface or the load,

etc., and is able to operate smoothly

within the minimum operating pressure

range for a full stroke. For more

information, refer to instruction manual.

Note 2) In case of the CY3R, install a shim,

etc. to eliminate clearance between

the body and the switch rail. For more

information, refer to the CY3R instruction manual.

Note 3) The amount of deflection differs from

the CY1B/CY1R. Adjust the clearance

value by referring to the dead weight

deflection as shown in the table on the

right.

Deflection (mm)

The above clearance amount is a reference

value.

28

27

CY315

26

25

24

23

CY310

22

21

20

19

18

17

16

15

14

13

12

11

10

9 CY36

8

7

6

5

4

3

2

1

0

1000

2000

Max. connection bracket weight (WBmax) (kg)

CY36

0.2

CY310

0.4

CY315

1.0

CY320

1.1

CY325

1.2

CY332

1.5

CY340

2.0

CY350

2.5

CY363

3.0

Consult with SMC in case a bracket with weight

exceeding the above value is to be mounted.

<CY3R>

Maximum Load Weight when

Loaded Directly on Body

CY363

CY350

CY340

When the load is applied directly to the body, it

should be no greater than the maximum values shown in the table below.

CY332

3000

4000

CY325

Model

CY320

CY3R6

CY3R10

CY3R15

CY3R20

CY3R25

CY3R32

CY3R40

CY3R50

CY3R63

5000

6000

Stroke (mm)

∗ The above deflection data represent values at the

time when the external sliding part moves to the

middle of the stroke.

Vertical Operation

Max. load weight (WBmax) (kg)

0.2

0.4

1.0

1.1

1.2

1.5

2.0

2.5

3.0

Loading direction

The load should be guided by a ball type bearing (LM guide, etc.). If a slide bearing is used, sliding

resistance increases due to the load weight and load moment, which can cause malfunction.

Load weight

(Slider bracket weight

+ Workpiece weight)

Workpiece

W

Rodless cylinder

5

Bore size

(mm)

Model

6

10

15

20

25

32

40

50

63

CY36

CY310

CY315

CY320

CY325

CY332

CY340

CY350

CY363

Allowable load Max. operating

weight (Wv) pressure (Pv)

(MPa)

(kg)

0.55

1.0

0.55

2.7

0.65

7.0

0.65

11.0

0.65

18.5

0.65

30.0

0.65

47.0

0.65

75.0

0.65

115.0

∗ Use caution, as there is a danger of

breaking the magnetic coupling if operated

above the maximum operating pressure.

Loading

direction

Switch

rail

Body

Wear ring

C

Model Selection

Series CY3B/CY3R

Precautions on Design 3

Intermediate Stop

Stroke End Stopping Method

(1) Intermediate stopping of load

with an external stopper, etc.

When stopping a load in mid-stroke using an

external stopper, etc., operate within the operating pressure limits shown in the table below.

Use caution, as operation at a pressure exceeding these limits can result in breaking of

the magnetic coupling.

Bore size

(mm)

Model

When stopping a load having a large inertial force at the stroke end, tilting of the body and damage to

the bearings and cylinder tube may occur. (Refer to the left hand drawing below.)

As shown in the right hand drawing below, a shock absorber should be used together with the stopper, and thrust should also be transmitted from the center of the body so that tilting will not occur.

Load

Shock absorber

Slide block

Load

Guide shaft

Slide block

Guide shaft

Operating pressure limit for

intermediate stop (Ps) (MPa)

6

CY36

0.55

10

CY310

0.55

15

CY315

0.65

20

CY320

0.65

25

CY325

0.65

32

CY332

0.65

40

CY340

0.65

50

CY350

0.65

63

CY363

0.65

Cylinder tube

Body

Cylinder tube

Stopper

Body tilting

Body

Thrust transmission area

Note) The drawing shows the CY3B series.

<CY3R>

(2) Intermediate stopping of load

with an air pressure circuit

Body Non-rotating Accuracy and Maximum

Allowable Moment (with Switch Rail)

When performing an intermediate stop of a

load using an air pressure circuit, operate at or

below the kinetic energy shown in the table below. Use caution, as operation when exceeding the allowable value can result in breaking

Reference values for non-rotating accuracy and maximum allowable moment at stroke end are indicated below.

(Reference values)

Bore size

(mm)

Model

Allowable kinetic energy for

intermediate stop (Es) (J)

Max.

Bore size Non-rotating

allowable

(mm)

accuracy (˚) moment (MD)

(N⋅m)

Note 2)

Allowable

stroke

(mm)

6

7.3

0.02

100

6.0

0.05

100

6

CY36

0.007

10

10

CY310

0.03

15

4.5

0.15

200

15

CY315

0.13

20

3.7

0.20

300

20

CY320

0.24

25

3.7

0.25

300

25

CY325

0.45

32

3.1

0.40

400

32

CY332

0.88

40

2.8

0.62

400

2.4

1.00

500

2.2

1.37

500

40

CY340

1.53

50

50

CY350

3.12

63

63

CY363

5.07

(Reference values)

Non-rotating accuracy

Switch rail

Body

Wear ring C

Note 1) Avoid operations where rotational torque (moment) is applied. In such a case, the use of an

external guide is recommended.

Note 2) The above reference values will be satisfied within the allowable stroke ranges, but caution is

necessary, because as the stroke becomes longer, the inclination (rotation angle) within the

stroke can be expected to increase.

Note 3) When a load is applied directly to the body, the loaded weight should be no greater than the

allowable load weights on page 5.

6

Magnetically Coupled Rodless Cylinder:

Basic Type

Series

CY3B

ø6, ø10, ø15, ø20, ø25, ø32, ø40, ø50, ø63

How to Order

Basic type

CY3B 25

300

Basic type

Bore size

6

10

15

20

25

32

40

50

63

Standard stroke

6 mm

Refer to the standard stroke table shown below.

10 mm

15 mm

Port thread type

20 mm

Symbol

25 mm

32 mm

Nil

40 mm

TN

TF

50 mm

63 mm

Type

M thread

Rc

NPT

G

Bore size

6, 10, 15

20, 25, 32, 40

50, 63

Standard Stroke

Bore size

(mm)

6

Maximum available

stroke (mm)

Standard stroke (mm)

300

50, 100, 150, 200

500

10

15

20

50, 100, 150, 200, 250, 300

25

100, 150, 200, 250, 300, 350, 400, 450, 500, 600,

700, 800

50, 100, 150, 200, 250, 300, 350, 400, 450, 500

1000

1500

3000

32

3000

40

50

100, 150, 200, 250, 300, 350, 400, 450, 500, 600,

700, 800, 900, 1000

5000

63

Note 1) Long stroke specification (XB11) applies to the strokes exceeding 2000 mm. (Refer to page 25.)

Note 2) The longer the stroke, the larger the amount of deflection in a cylinder tube. Pay attention to the mounting

bracket and clearance value.

Magnetic Holding Force

7

Bore size (mm)

6

10

15

20

25

32

40

50

63

Holding force (N)

19.6

53.9

137

231

363

588

922

1471

2256

Magnetically Coupled Rodless Cylinder

Series CY3B

Basic Type

Specifications

Fluid

Air

Proof pressure

1.05 MPa

Max. operating pressure

0.7 MPa

Min. operating pressure

Refer to the minimum operating pressure table.

Ambient and fluid temperature

–10 to 60ºC

Piston speed

50 to 500 mm/s

Cushion

Rubber bumper on both ends

Lubrication

JIS Symbol

Non-lube

+1.4

+1.8

0 to 250 st: +1.0

0 , 251 to 1000 st: 0 , 1001 st to: 0

Stroke length tolerance

Made to Order

(Refer to pages 24 for details.)

Horizontal, Inclined, Vertical Note)

Mounting nut (2 pcs.)

Standard equipment (accessory)

Note) When vertically mounting, it is impossible to perform an intermediate stop by means of a

pneumatic circuit.

When calculating the actual thrdesign should consider the

Caution ust,

minimum actuating pressure.

Theoretical Cylinder Thrust

Specifications

Heat resistant specifications

-XB9

Low speed specifications (15 to 50 mm/s)

-XB11

Long stroke

-XB13

Low speed specifications (7 to 50 mm/s)

ø6, ø10

ø15, ø20, ø25, ø32, ø40

1200

100

1100

90

0

ø1

0

-XB6

ø4

Symbol

Mounting orientation

1000

900

-X160

High speed specifications

-X168

Helical insert thread specifications

-X206

Added mounting tap positions for slider

-X210

Oil-free exterior specifications

-X322

Outside of cylinder tube with hard chrome plating

300

ø20

-X324

Oil-free exterior specifications (with dust seal)

20

200

ø15

-X1468

Interchangeable specification with CY16

10

100

-XC24

With magnetic shielding plate

-XC57

With floating joint

s

50

40

30

ø6

siz

re

Bo

60

800

700

re

70

ize

600

500

5

ø2

400

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

Supply pressure (MPa)

Minimum Operating Pressure

2

ø3

Bo

80

e

Axial ports

Theoretical thrust (N)

Hydro specifications

-X132

Theoretical thrust (N)

-X116

Supply pressure (MPa)

ø50, ø63

0.16 0.16 0.16 0.16 0.15

0.15

0.14

0.12 0.12 0.12

0.1

0.05

re

2500

Bo

0.2

Theoretical thrust (N)

Minimum operating pressure (MPa)

3

si

ø6 ze

3000

0

ø5

2000

1500

1000

500

0

6 10 15 20 25 32 40 50 63

Bore size (mm)

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

Supply pressure (MPa)

Note) Values show when the cylinder is driving

without load.

Weight

Main Material

Unit: kg

Description

Head cover

Material

Note

Aluminum alloy Electroless nickel plated

Aluminum alloy

Magnet

Rare earth magnet

Basic weight (at 0 st)

6

10

0.052 0.08

15

20

Hard anodized

Note) For details, refer to the construction

drawings on page 9.

25

32

0.275 0.351 0.672 1.287

Additional weight per 50 mm of stroke 0.004 0.014 0.015 0.02

Cylinder tube Stainless steel

Body

Bore size (mm)

0.023 0.033

40

50

63

2.07

3.2

0.04

0.077 0.096

5.3

Calculation method/Example: CY3B32-500

Basic weight.........................1.287 kg

Additional weight..........0.033 kg/50 st 1.287 + 0.033 x 500 ÷ 50 = 1.617 kg

Cylinder stroke..........................500 st

8

Series CY3B

Construction

Basic type

CY3B6

CY3B10, 15

w !9 !2 !4 !6 t !0 i q o u y !7 r

w !2 !4 !1 !8 !7 !6 !5 !0 i o q u y t

r

∗ The above drawing is ø15. (3 magnets are used in ø10.)

CY3B20 to 40

CY3B50, 63

w

e !3 !2 !4 !1 !8 !6 !5 !7 !0 i q o u t y

w !2 !4 !1 !8 !6 !5 !7 !0 i o u q y t !3

r

r

Component Parts

Material

Aluminum alloy

ø6, ø10 Brass

Head cover

ø15 to ø63 Aluminum alloy

End collar

Aluminum alloy

Cylinder tube

Stainless steel

ø6 to ø15 Brass

Piston

ø20 to ø63 Aluminum alloy

Shaft

Stainless steel

Piston side yoke

Rolled steel

External slider side yoke

Rolled steel

Magnet A

Rare earth magnet

Magnet B

Rare earth magnet

Spacer

Aluminum alloy

Bumper

Urethane rubber

Piston nut

Carbon steel

C type snap ring for hole

Carbon tool steel

Wear ring A

Special resin

Wear ring B

Special resin

Piston seal

NBR

Lubretainer

Special resin

Cylinder tube gasket

NBR

No.

Description

1 Body

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

9

Note

Hard anodized

Electroless Ni plated

ø20 to ø40 only

ø6 to ø15 Electroless Ni plated

ø20 to ø63 Chromated

Zinc chromated

Zinc chromated

Black anodized (ø6: not available)

ø6 to ø15: not available

Nickel plated

ø6: not available

ø6, ø10 only

Replacement Parts: Seal Kit

Contents

Kit no.

Numbers !5, !6, !7, !9 above

CY3B6-PS

Numbers !5, !6, !7, !8, !9 above

CY3B10-PS

CY3B15-PS

CY3B20-PS

CY3B25-PS

Numbers !5, !6, !7, !8 above

CY3B32-PS

CY3B40-PS

CY3B50-PS

CY3B63-PS

∗ Seal kits are sets consisting of numbers 15 through 19. Order using the

kit number corresponding to each bore size.

Bore size (mm)

6

10

15

20

25

32

40

50

63

Magnetically Coupled Rodless Cylinder

Series CY3B

Basic Type

Dimensions

Basic type

CY3B6 to 63

B

4-MM

thread depth J

0

L –0.1 Note 1)

H

G

2-P (Piping port)

E

G

øD

X

(R)

NN

Effective thread

length T

Mounting nut

width across flats C

øI

NA

N

K

W

N

F

S + Stroke

F

ZZ + Stroke

0

Note 1) ø50, ø63: L –0.2

A

B

8-V

Effective thread length Y

H

G

Mounting nut

width across flats C

E

H

B

G

E

øQ

NA

(R)

NN

F

F

NA

N

CC±0.1

CY3B50, 63

CY3B6 to 15

C

8∗

14

14

26

32

32

41

—

—

CC

—

—

—

—

—

—

—

32

38

Model

W

X

Y

ZZ

CY3B6

CY3B10

CY3B15

CY3B20

CY3B25

CY3B32

CY3B40

CY3B50

CY3B63

25

30

35

50

50

50

60

60

70

10

16

19

25

30

40

40

60

70

—

—

—

—

—

—

—

16

16

78∗

81

103

132

137

156

182

180

192

D

7.6

12

16.6 ∗

21.6 ∗

26.4 ∗

33.6 ∗

41.6 ∗

52.4 ∗

65.4 ∗

E

4

1.5

2

2∗

2∗

2∗

3∗

8

8

Nil

M3 x 0.5∗

M5 x 0.8

M5 x 0.8

Rc 1/8

Rc 1/8

Rc 1/8

Rc 1/4

Rc 1/4

Rc 1/4

G

F

8∗ 5

5

9

5.5

10

7.5∗

13

7.5∗

13

8∗

16

16 11

2 14

2 14

P (Piping port)

TN∗

—

—

—

NPT 1/8

NPT 1/8

NPT 1/8

NPT 1/4

NPT 1/4

NPT 1/4

H

13.5 ∗

12.5

13

20

20.5

22

29

33

33

I

—

—

—

28

34

40

50

58∗

72∗

TF ∗

—

—

—

G 1/8

G 1/8

G 1/8

G 1/4

G 1/4

G 1/4

Note 2) The astrisk denotes the dimensions which are different from

the CY1B series.

J

4.5

4.5

6

6

8

8

10

12

12

K

L

MM

5 35 M3 x 0.5

4 38 M3 x 0.5

11 57 M4 x 0.7

8 66 M4 x 0.7

10 70 M5 x 0.8

15 80 M6 x 1

16 92 M6 x 1

25 110 M8 x 1.25

26 122 M8 x 1.25

Q

N

NN

S

NA

R

—

9.5 ∗ 10∗ M6 x 1∗

62∗

—

—

11

14 M10 x 1

63

—

—

11

17 M10 x 1

83

—

—

18∗

24 M20 x 1.5

12 ∗ 106

—

18.5 ∗ 30 M26 x 1.5

15 ∗ 111

∗

—

20

36 M26 x 1.5

18 ∗ 124

—

26∗

46 M32 x 2

23 ∗ 150

– 0.007

25

55

—

30 – 0.037 27.5∗ 176

– 0.007

25

69

—

32 – 0.043 34.5∗ 188

(mm)

V

T

6.5

—

7.5

—

8

—

10

—

10

—

13

—

13

—

— M8 x 1.25

— M10 x 1.5

Mounting Nut/Included in the package (2 pcs).

d

C

CY3B6

CY3B10

CY3B15

CY3B20

CY3B25

CY3B32

CY3B40

CY3B50

CY3B63

A B

4 17

4 25

4 35

8 36

8 46

8 60

10 70

— 86

— 100

b

Model

N

øI

H

B

Part no.

Applicable bore size (mm)

d

H

B

C

SNJ-006B

SNJ-016B

SN-020B

SN-032B

SN-040B

6

10, 15

20

25, 32

40

M6 x 1.0

M10 x 1.0

M20 x 1.5

M26 x 1.5

M32 x 2.0

4

4

8

8

10

8

14

26

32

41

9.2

16.2

30

37

47.3

10

Magnetically Coupled Rodless Cylinder:

Direct Mount Type

Series

CY3R

ø6, ø10, ø15, ø20, ø25, ø32, ø40, ø50, ø63

How to Order

CY3R

25

300

M9B

Number of auto switches

Direct mount type

Nil

2 pcs.

Piping type

S

1 ps,

Nil

Both sides piping type

n

“n” pcs.

G

Centralized piping type

Auto switch type

Note 1) Type G (centralized piping)

is not available for ø6.

Nil

Bore size

6

6 mm

10 10 mm

15 15 mm

Switch rail

20 20 mm

Port thread type

25 25 mm

32 32 mm

40 40 mm

50 50 mm

63 63 mm

Without auto switch

Note 1) In case of ø20 with switch rail but without switch,

the cylinder construction is for reed switch.

∗ Refer to the table below for auto switch model numbers.

∗ The auto switch is shipped together, but not assembled.

Symbol

Nil

TN

TF

Bore size

6, 10, 15

Type

M thread

Rc

NPT

G

Nil

With switch rail

N

Without switch rail

Note 1) A type with switch rail has built-in switch magnets.

Note 2) ø15 has built-in switch magnets even without switch rail.

20, 25, 32, 40

Standard stroke

50, 63

Refer to page 12 for standard stroke.

Solid state switch Reed switch

Type

Special

function

Electrical

entry

—

Grommet

Indicator

light

Applicable Auto Switches / The applicable auto switch is determined by the bore size. Refer to pages 21 to 23 for further information on auto switches.

No

Yes

Load voltage

Wiring

(output)

2-wire

DC

24 V

3-wire

(NPN equiv.)

–

3-wire (NPN)

Grommet Yes

Diagnostic

indication

(2-color display)

2-wire

3-wire (NPN)

5 V, 12 V 100 V or less

12 V

100 V

5V

–

24 V

3-wire (PNP)

2-wire

∗ Lead wire length symbols: 0.5 m......... Nil (Example) M9N

3 m............ L (Example) M9NL

5 m............ Z (Example) M9NZ

12 V

5 V, 12 V

12 V

A90

A93

A96

M9N

5 V, 12 V

3-wire (PNP)

—

AC

Auto

switch

model

M9P

–

M9B

F9NW

F9PW

F9BW

Lead wire length (m)∗

0.5

(Nil)

3

(L)

5

(Z)

Pre-wired

connector

Applicable load

–

–

IC circuit

–

–

–

Relay,

PLC

–

–

IC circuit

–

IC circuit

–

Relay,

PLC

IC circuit

–

∗∗ Solid state switches marked “” are produced upon receipt of order.

• For ø25, 32, 40, 50, and 63, other than the applicable auto switches listed in “How to Order”, the other auto switches can be mounted. For detailed

specifications, refer to page 18.

• With pre-wired connector is also available in solid state auto switches. For specifications, refer to “SMC Best Pneumatics” catalog vol. 8, page 8-30-52.

11

Magnetically Coupled Rodless Cylinder

Series CY3R

Direct Mount Type

Specifications

Fluid

Air

Proof pressure

1.05 MPa

Max. operating pressure

0.7 MPa

Min. operating pressure

Refer to the minimum operating pressure table.

Ambient and fluid temperature

–10 to 60ºC

Piston speed

50 to 500 mm/s

Cushion

Rubber bumper on both ends

Lubrication

Non-lube

+1.4

+1.8

0 to 250 st: +1.0

0 , 251 to 1000 st: 0 , 1001 st to: 0

Stroke length tolerance

Mounting

Direct mount type

Horizontal, Inclined, Vertical Note 2)

Mounting orientation

Note 1) When an auto switch is installed at an intermediate position of a type with auto switch, keep the maximum

piston speed at 300 mm/s or below to ensure operation of relays or other devices.

Note 2) When vertically mounting, it is impossible to perform an intermediate stop by means of a pneumatic circuit.

Made to Order

Standard Stroke

(Refer to page 24 for details.)

Symbol

Specifications

Bore size

(mm)

-X116

Hydro specifications

-X160

High speed specifications

-X322

Outside of cylinder tube with hard chrome plating

-X1468

Interchangeable specification with CY16

-XC57

50, 100, 150, 200

300

300

10

50, 100, 150, 200, 250, 300

500

500

15

50, 100, 150, 200, 250, 300, 350, 400,

450, 500

1000

750

6

With floating joint

Minimum Operating Pressure

20

0.2

100, 150, 200, 250, 300, 350, 400, 450,

500, 600, 700, 800

1500

100, 150, 200, 250, 300, 350, 400, 450,

500, 600, 700, 800, 900, 1000

2000

1000

1200

32

0.16 0.16 0.16 0.16 0.15

0.15

40

0.14

0.12 0.12 0.12

50

0.1

1500

63

Note) The longer the stroke, the larger the amount of deflection in a cylinder tube. Pay attention to the

mounting bracket and clearance value.

0.05

0

Magnetic Holding Force

6 10 15 20 25 32 40 50 63

Bore size (mm)

Note) Values show when the cylinder is operating

without a load.

Bore size (mm)

6

10

15

20

25

32

40

Holding force (N)

19.6

53.9

137

231

363

588

922

Theoretical Cylinder Thrust

e

re

Bo

siz

0

ø1

ø6

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

Supply pressure (MPa)

1200

1100

1000

900

800

700

600

500

400

300

200

100

50

63

1471 2256

When calculating the actual thrust, design should

consider the minimum actuating pressure.

ø15, ø20, ø25, ø32, ø40

100

90

80

70

60

50

40

30

20

10

Theoretical thrust (holding force) (N)

ø6, ø10

Caution

ø50, ø63

Theoretical thrust (holding force) (N)

Minimum operating pressure

(MPa)

25

Theoretical thrust (holding force) (N)

Max. stroke

Max. stroke

without switch (mm) with switch (mm)

Standard stroke (mm)

0

ø4

2

ø3

ø25

ø20

ø15

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

Supply pressure (MPa)

3000

3

ø6

2500

0

ø5

2000

1500

1000

500

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

Supply pressure (MPa)

Weight

Unit: kg

6

10

15

20

25

32

40

50

63

With switch rail

0.086

0.111

0.272

0.421

0.622

1.217

1.98

3.54

5.38

Without switch rail

0.069

0.08

0.225

0.351

0.542

1.097

1.82

3.25

5.03

With switch rail

0.016

0.034

0.040

0.051

0.056

0.076

0.093

0.159

0.188

Without switch rail

0.004

0.014

0.015

0.020

0.023

0.033

0.040

0.077

0.096

Bore size (mm)

Basic weight (at 0 st)

Additional weight per 50 mm

of stroke

Calculation method/Example: CY3R25-500 (with switch rail)

0.622 + 0.056 x 500 ÷ 50 = 1.182 (kg)

Basic weight....0.622 (kg), Additional weight....0.056 (kg/50 st), Cylinder stroke....500 (st)

12

Series CY3R

Construction

Both sides piping type

CY3R6

@1 @3 !5 !6 @4 @6 !0 i q !4 !2

2a

!9

@2

@3 @7 o

r

3a

u y t @8 !8

CY3R10

2a

!9 @2

CY3R15 to 63

@0 @3 @7

2a

!9

@0 !5 !6 @4 @9 @6 !0 i q !1 !4 !2

!8 @2

@8 @5 o u y t

r

3a

!8

@0 !5 !6 !3 @4 @9 @6 !0 i q !1 !4 !2 y r

@0 @3 @5

t

3a

@8 o u !7 @7

CY3R15, 20

CY3R15

Component Parts

No.

1

2a

2b

3a

3b

4

Description

Body

End cover A

End cover C

End cover B

End cover D

Cylinder tube

Material

Aluminum alloy

Aluminum alloy

Aluminum alloy

Aluminum alloy

Aluminum alloy

Stainless steel

ø6 to ø15 Brass

ø20 to ø63 Aluminum alloy

5

Piston

6

7

8

9

10

Shaft

Piston side yoke

External slider side yoke

Magnet A

Magnet B

11

Spacer

Aluminum alloy

12

Bumper

Urethane rubber

13

Piston nut

14

15

16

C type snap ring for hole

Attachment ring

C type snap ring for shaft

Carbon tool steel

Aluminum alloy

Hard steel wire

17

Magnetic shielding plate

Rolled steel plate

18

19

20

Switch rail

Aluminum alloy

Magnet

Rare earth magnet

Hexagon socket head plug Chromium steel

Stainless steel

Rolled steel plate

Rolled steel plate

Rare earth magnet

Rare earth magnet

Carbon steel

Note

Hard anodized

Electroless nickel plated

Electroless nickel plated

Electroless nickel plated

Electroless nickel plated

ø6 to ø15 Electroless nickel plated

ø20 to ø63 Chromate

Zinc chromated

Zinc chromated

Black anodized

(ø6: not available)

Zinc chromate

(ø6 to ø15: not available)

Nickel plated

Chromate

Chromated

(ø6, ø10: not available)

White anodized

Nickel plated

23

Note

ø40

Hexagon socket head plug

Steel balls

Chromium steel

ø20, ø50, ø63 None

Nickel plated

Hexagon socket head screw Chromium steel

Hexagon socket

Nickel plated

Chromium steel

head set screw

24∗

25∗

26∗

27∗

28∗

29∗

30∗

Cylinder tube Gasket

Wear ring A

Wear ring B

Wear ring C

Piston seal

Lubretainer

Switch rail gasket

No.

21

22

Description

Material

NBR

Special resin

Special resin

Special resin

NBR

Special resin

NBR

Both sides piping type: None

∗ Seal kits are sets consisting of numbers 24 through 30. Order using the

kit number corresponding to each bore size.

Replacement Parts: Seal Kit

Bore size (mm)

6

10

15

20

25

32

40

50

63

Kit no.

CY3R6-PS

CY3R10-PS

CY3R15-PS

CY3R20-PS

CY3R25-PS

CY3R32-PS

CY3R40-PS

CY3R50-PS

CY3R63-PS

Contents

Numbers @4, @6, @7, @8 above

Numbers

@4, @5, @6, @7, @8, @9, #0

above

∗ Seal kits are the same for both the both sides piping type and the

centralized piping type.

13

Magnetically Coupled Rodless Cylinder

Series CY3R

Direct Mount Type

Construction

Centralized piping type

CY3RG10

2b

!9

@2

!5 !6 @4 @9 @6 !0 i q !1 !4 !2

@3

2b

@8 @7 @5

o u y t

r

3b

!8

#0

!5 !6 !3 @4 @9 @6 !0 i q !1 !4 !2 y

r

@0

3b

CY3RG15 to 63

!9

!8 @2 @0 #0 @3 @5

t

@8 o u !7

@7

CY3RG15

CY3RG15, 20

!9

!8

@2 @1

CY3RG15

Switch Rail Accessory

Switch Rail Accessory Kit

CYR 15 E

Bore size (mm)

Stroke

Bore size

20

6

10

Kit no.

CYR6E--N

CYR10E-

15

CYR15E-

CYR20E-

For reed switch

For solid state switch CYR20EN-

25

CYR25E-

32

40

50

63

CYR32E-

CYR40E-

Contents

Numbers !8, !9, @2, @7 on the left

Numbers !8, !9, @0, @2, @7 on the left

Note 2)

Numbers !7, !8, @0, @2, @7 on the left

Numbers !7, !8, !9, @0, @2, @7

on the left

CYR50E-

CYR63E-

Note 1) indicates the stroke.

Note 2) A magnet is already built in for ø15.

14

Series CY3R

Dimensions

Both sides piping type: ø6 to ø63

N

X

HC

HT

HB

Note) This figure shows types with switch rail (Nil).

A

2-plug

H

HA

CB

K

2-P (Piping port)

T

HP

4-counter bore dia. øB

Counter bore depth C

Y

0

L -0.1 Note 1)

CY3R6

HS

HR

CR

Plug

W

K

G

2 x 4-MM

Thread depth M

Q + Stroke

Z + Stroke

PW

QW

X

WS

4-6.5

4-øLD

GW

GP

WP

F

4-3.2

WP

T

TC

4-J x E

øD

2-P (Piping port)

W

Switch rail

G

CY3R25 to 63

0

Note 1) ø50, ø63: L –0.2

CY3R10 to 20

B

—∗

CY3R6

6.5

CY3R10 9

CY3R15 10.5 8

9.5

CY3R20 9

CY3R25 8.5 9.5

CY3R32 10.5 11

11

CY3R40 10

14

CY3R50 14

14

CY3R63 15

Model

Model

CY3R6

CY3R10

CY3R15

CY3R20

CY3R25

CY3R32

CY3R40

CY3R50

CY3R63

Model

CY3R6

CY3R10

CY3R15

CY3R20

CY3R25

CY3R32

CY3R40

CY3R50

CY3R63

A

7∗

L

34

38

53

62

70

76

90

110

118

LD

3.5

3.5

4.3

5.4

5.4

7

7

8.6

8.6

C

—∗

3.2

4.2

5.2

5.2

6.5

6.5

8.2

8.2

M

3.5

4

5

5

6

7

8

10

10

CB

2

2

2

3

3

3

5

5

5

CR

0.5

0.5

0.5

1

1

1.5

2

2

3

D

7.6

12

16.6 ∗

21.6 ∗

26.4 ∗

33.6 ∗

41.6 ∗

52.4 ∗

65.4 ∗

MM

M3 x 0.5

M3 x 0.5

M4 x 0.7

M4 x 0.7

M5 x 0.8

M6 x 1

M6 x 1

M8 x 1.25

M8 x 1.25

P (Piping port)

Nil

TN ∗

M3 x 0.5 ∗

—

M5 x 0.8

—

M5 x 0.8

—

Rc 1/8

NPT 1/8

Rc 1/8

NPT 1/8

Rc 1/8

NPT 1/8

Rc 1/4

NPT 1/4

Rc 1/4

NPT 1/4

Rc 1/4

NPT 1/4

N

3.5

4.5

6

7

6.5

8.5

11

15

16

F

5.5

6.5

8

9

8.5

10.5

13

17

18

PW

19

26

32

38

43

54

64

82

94

G

3∗

4

5

6

6

7

7

8.5

8.5

GP

20

27

33

39

44

55

65

83

95

Q

60 ∗

68

84

95

105

116

134

159

171

GW

18.5

25.5

31.5

37.5

42.5

53.5

63.5

81.5

93.5

QW

10

14

18

17

20

26

34

48

60

H

19

26

32

39

44

55

67

85

97

T

14.5 ∗

17.5

19

20.5

21.5

24

26

30

32

HA

17

24

30

36

41

52

62

80

92

TC

10.5

14

17

20

22.5

28

33

42

48

TF ∗

—

—

—

G 1/8

G 1/8

G 1/8

G 1/4

G 1/4

G 1/4

Note 2) The astrisk denotes the dimensions which are different from the CY1R series.

15

HB

10.5

14

17

21

23.5

29

36

45

51

W

20

20

25

40

40

50

60

60

70

HC

18

25

31

38

43

54

66

84

96

WP

9.5

13

16

19

21.5

27

32

41

47

HP

10.5 ∗

14

17

24

23.5

29

36

45

51

WS

6

8

7

7

7

7

7

10

10

HR

17

24

30

36

41

51

62

80

90

X

10

15

18

22

28

35

40

50

60

HS

6

5

8.5

7.5

6.5

7

8

9

9.5

HT

10.5∗

14

17

24

23.5

29

36

45

51

Y

35.5

39.5

54.5

64

72

79

93

113

121

Z

66 ∗

76

94

107

117

130

148

176

188

JxE

M4 x 0.7 x 6

M4 x 0.7 x 6

M5 x 0.8 x 7

M6 x 1 x 8

M6 x 1 x 8

M8 x 1.25 x 10

M8 x 1.25 x 10

M10 x 1.5 x 15

M10 x 1.5 x 15

(mm)

K

7

9

14

11

15

13

15

25

24

Magnetically Coupled Rodless Cylinder

Direct Mount Type

Series CY3R

Dimensions

N

X

HC

HB

Centralized piping type: ø10 to ø63

W

CB

CR

2-P

WS

HS

HR

Plug

W

K

G

(Piping port)

2 x 4-MM

Thread depth M

Q + Stroke

Z + Stroke

CY3RG25, 32, 40

CY3RG10

QW

PW

øD

4-øLD

CY3RG15

T

F

WP

12.5

19.5

13

30

Plug

12.5

4-counter bore dia. øB

Counter bore depth C

Y

0 Note 1)

L -0.1

TC

(Piping port)

T

X

8

14

2-P

GW

GP

22

2-P (Piping port)

H

HA

HT

HP

4-J x E

K

Switch rail

G

0

Note 1) ø50, ø63: L –0.2

CY3RG20

Model

CY3RG10

CY3RG15

CY3RG20

CY3RG25

CY3RG32

CY3RG40

CY3RG50

CY3RG63

Model

CY3RG10

CY3RG15

CY3RG20

CY3RG25

CY3RG32

CY3RG40

CY3RG50

CY3RG63

Model

CY3RG10

CY3RG15

CY3RG20

CY3RG25

CY3RG32

CY3RG40

CY3RG50

CY3RG63

B

6.5

8

9.5

9.5

11

11

14

14

C

3.2

4.2

5.2

5.2

6.5

6.5

8.2

8.2

CB

2

2

3

3

3

5

5

5

LD

3.5

4.3

5.4

5.4

7

7

8.6

8.6

M

4

5

5

6

7

8

10

10

MM

M3 x 0.5

M4 x 0.7

M4 x 0.7

M5 x 0.8

M6 x 1

M6 x 1

M8 x 1.25

M8 x 1.25

Nil

M5 x 0.8

M5 x 0.8

Rc 1/8

Rc 1/8

Rc 1/8

Rc 1/4

Rc 1/4

Rc 1/4

CR

0.5

0.5

1

1

1.5

2

2

3

P (Piping port)

TN ∗

—

—

NPT 1/8

NPT 1/8

NPT 1/8

NPT 1/4

NPT 1/4

NPT 1/4

D

12

16.6∗

21.6∗

26.4∗

33.6∗

41.6∗

52.4∗

65.4∗

F

6.5

8

9

8.5

10.5

13

17

18

G

4

5

6

6

7

7

8.5

8.5

GP

27

33

39

44

55

65

83

95

GW

25.5

31.5

37.5

42.5

53.5

63.5

81.5

93.5

H

26

32

39

44

55

67

85

97

HA

24

30

36

41

52

62

80

92

HB

14

17

21

23.5

29

36

45

51

HC

25

31

38

43

54

66

84

96

HP

—

—

11

14.5

20

25

32

35

N

4.5

6

7

6.5

8.5

11

15

16

PW

26

32

38

43

54

64

82

94

Q

68

84

95

105

116

134

159

171

QW

14

18

17

20

26

34

48

60

T

17.5

19

20.5

21.5

24

26

30

32

TC

14

17

20

22.5

28

33

42

48

W

20

25

40

40

50

60

60

70

WP

13

16

19

21.5

27

32

41

47

WS

8

7

7

7

7

7

10

10

X

15

18

22

28

35

40

50

60

HR

24

30

36

41

51

62

80

90

Y

39.5

54.5

64

72

79

93

113

121

HS

5

8.5

7.5

6.5

7

8

9

9.5

HT

—

—

28

33.5

41

50

56

63.5

JxE

M4 x 0.7 x 6

M5 x 0.8 x 7

M6 x 1 x 8

M6 x 1 x 8

M8 x 1.25 x 10

M8 x 1.25 x 10

M10 x 1.5 x 15

M10 x 1.5 x 15

K

9

14

11

15

13

15

25

24

(mm)

L

38

53

62

70

76

90

110

118

Z

76

94

107

117

130

148

176

188

TF ∗

—

—

G 1/8

G 1/8

G 1/8

G 1/4

G 1/4

G 1/4

Note 2) The astrisk denotes the dimensions which are different from the CY1RG series.

16

Series CY3R

Auto Switch Proper Mounting Position for Stroke End Detection

Auto Switch Operation Range

(Reference

dimension)

A

Auto

Bore size (mm)

switch

6 10 15 20 25 32 40

model

D-A9

9

6 7

6

8 11 8

D-M9

4

3 4.5 2.5 3.5 3 3

D-F9W 4 7 4

4.5 4 4.5 5.5

D-Z7

— — — — 9 9 11

D-Z80

D-Y59

D-Y7

6

— — — — 5 5

D-Y7W

B

C

D

50 63

8

3

5

8

3

4.5

9 10

6

6

∗ Switches cannot be mounted in some cases.

∗ Operating ranges are standards including hysteresis,

and are not guaranteed. (variation on the order of

±30%)

Large variations may occur depending on the surrounding environment.

ø6, ø10, ø15, ø20

Auto switch

model

Bore size

(mm)

6

10

15

20

(mm)

A

B

C

D

D-A9

D-M9

D-F9W

D-A9

D-M9

D-F9W

D-A9

D-M9

D-F9W

D-A9

D-M9

D-F9W

26

28

17.5

19.5

30

32

21.5

23.5

46

48

76.5

87.5

42

44

72.5

83.5

46

48

—

39.5

42

44

—

35.5

26

—

56.5

67.5

30

32

60.5

71.5

Note 1) Auto switches cannot be installed in Area C in the case of ø15.

ø25, ø32, ø40, ø50, ø63

Bore size

(mm)

25

32

40

50

63

(mm)

A

Auto switch

model

D-A9

19

22.5

24.5

28.5

30.5

B

C

D

D-Y5

D-Y5

D-Z7 D-Y5

D-Z7 D-Y5

D-M9 D-Z7

D-M9 D-Z7

D-M9

D-M9

D-Y7P D-A9

W D-Z80 D-Y7P D-A9 D-F9W D-Z80 D-Y7P D-A9 D-F9W D-Z80 D-Y7P

D-F9W D-Z80

D-F9

D-Y7W

D-Y7W

D-Y7W

D-Y7W

23

26.5

28.5

32.5

34.5

18

21.5

23.5

27.5

29.5

98

107.5

123.5

147.5

157.5

94

103.5

119.5

143.5

153.5

99

108.5

124.5

148.5

158.5

42

45.5

47.5

51.5

53.5

38

41.5

43.5

47.5

49.5

43

46.5

48.5

52.5

54.5

75

84.5

100.5

124.5

134.5

79

88.5

104.5

128.5

138.5

74

83.5

99.5

123.5

133.5

Note 1) 50 mm is the minimum stroke available with 2 auto switches mounted.

Note 2) Figures in the table above are used as a reference when mounting the auto switches for stroke end detection. In the case of actually setting the auto switches,

adjust them after confirming their operation.

Note 3) Mounting brackets are additionally required for the D-A9, M9 and F9W types. Refer to the auto switch mounting bracket part number on page 18.

17

Magnetically Coupled Rodless Cylinder

Direct Mount Type

Series CY3R

Auto Switch Mounting

Auto Switch Specifications

ø6 to ø20

(1) Switches (switch rail) can be added to the

standard type (without switch rail). The

switch rail accessory type is mentioned on

page 14, and can be ordered together with

auto switches.

(2) Refer to the separate disassembly instructions for switch magnet installation procedures.

When mounting auto switches, they

should be inserted into the cylinder's

switch groove from the direction shown

in the drawing on the right. After setting

in the mounting position, use a flat head

watchmaker’s screwdriver to tighten the

mounting screw which is included.

Flathead watchmaker’s

screwdriver

Auto switch

ø5 to ø6

Note) When tightening the auto switch mounting screw,

use a watchmaker’s screwdriver with an approximately 5 to 6 mm diameter handle.

Furthermore, the tightening torque should be

approximately 0.1 to 0.15 N⋅m. As a rule, it can be

turned about 90º past the point at which tightening

can be felt.

Switch mounting screw

(M2.5 x 4 l)

(included)

ø25 to ø63

Mounting Bracket Part No.

(1) Insert the front side of the auto switch into

the auto switch groove and slide the switch

to the desired position.

(2) After the detection position is confirmed, securely tighten the mounting screw (M2.5)

on the auto switch.

(3) Changes to the detection position have to

be performed during process (2).

Switch rail

Watchmaker’s

(precision) screwdriver

Bore size

(mm)

25

32

40

50

63

e

q

Mounting screw

M2.5 x 0.45 x 4 l

w

Mounting

bracket

part no.

BMG2-012

Weight

Applicable

auto switches

3g

Reed switch:

D-A9

Solid state switch:

D-M9

D-F9W

Switch mounting

bracket

Note) When tightening the mounting screw, use a

watchmaker’s screwdriver with a 5 to 6 mm

handle diameter and tighten with a torque of

0.10 to 0.15 N⋅m. As a guide, an acceptable

tightening level is reached by tightening the

screw an additional 90 degrees from the

point at which the screw is snug.

Auto switch

Other than the applicable auto switches listed in “How to Order”, the following auto switches can be mounted.

For detailed specifications, refer to “SMC Best Pneumatics” catalog vol. 8, 8-30-1.

Type

Reed switch

Solid state switch

Model

D-Z73

D-Z76

D-Z80

D-Y59A

D-Y59B

D-Y7P

D-Y7BW

D-Y7NW

D-Y7PW

Electrical entry

Features

Applicable

bore size

—

Without indicator light

Grommet (In-line)

—

ø25 to ø63

Diagnostic indication

(2-color display)

∗ With pre-wired connector is also available in solid state auto switches. For specifications, refer to “SMC Best Pneumatics” catalog vol. 8, page 8-30-52.

∗ Normally closed (NC = b contact), solid state switch (D-F9G/F9H/Y7G/Y7H type) are also available. For details, refer to “SMC Best Pneumatics”

catalog vol. 8, page 8-30-31/8-30-32.

18

Series CY3

Auto Switch Specifications

Auto Switch Common Specifications

Type

Leakage current

Solid state switch

Reed switch

3-wire: 100 µA or less

None

Operating time

Impact resistance

Insulation resistance

2-wire: 0.8 mA or less

1.2 ms

1 ms or less

300 m/s2

1000 m/s2

50 MΩ or more at 500 Mega VDC (between lead wire and case)

Withstand voltage

1000 VAC for 1 minute (between lead wire and case)

Ambient temperature

–10 to 60°C

Enclosure

IEC529 standard IP67, JIS C 0920 waterproof construction

Lead Wire Length

Contact Protection Boxes: CD-P11, CD-P12

Lead wire length indication

<Applicable switch model>

(Example)

D-A9/Z7/Z8

The auto switches above do not have a built-in contact protection circuit.

Therefore, please use a contact protection box with the switch for any of

the following cases:

q Where the operation load is an inductive load.

w Where the wiring length to load is greater than 5 m.

e Where the load voltage is 100 VAC.

The contact life may be shortened. (Due to permanent energizing conditions.)

D-M9P L

Lead wire length

Nil

L

Z

0.5 m

3 m

5 m

Note 1) Applicable auto switch with 5 m lead wire “Z”

Reed switch: None

Solid state switch: Manufactured upon receipt of order as standard.

Note 2) The standard lead wire length of solid state switch with water-resistant

2-color indication is 3 meters. (Not available 0.5 m)

Note 3) To designate solid state switches with flexible specifications, add “-61”

after the lead wire length.

Specifications

CD-P12

CD-P11

Part no.

Load voltage

100 VAC

200 VAC

24 VDC

Maximum load current

25 mA

12.5 mA

50 mA

∗ Lead wire length

Switch conneciton side 0.5 m

Load connection side

0.5 m

(Example) D-F9NWL- 61

Flexible specification

Note) D-M9 is a flexible cable specification as standard.

Auto Switch Hysteresis

The hysteresis is the difference between the position of the auto switch as

it turns “on” and as it turns “off”. A part of operating range (one side)

includes this hysteresis.

Internal Circuit

CD-P11

Surge absorber

Choke

coil

OUT Brown

OUT Blue

Switch operation

position

(ON)

Hysteresis

Choke coil

CD-P12

Note)

Zener diode

OUT (+)

Brown

OUT (–)

Blue

Reed switch:

2 mm or less

Solid state switch: 1 mm or less

Dimensions

Switch operation

position

(OFF)

Note) Hysteresis may fluctuate due to the operating environment.

Contact SMC if hysteresis causes an operational problem.

Connection

To connect a switch unit to a contact protection box, connect the lead wire

from the side of the contact protection box marked SWITCH to the lead

wire coming out of the switch unit. Keep the switch as close as possible to

the contact protection box, with a lead wire length of no more than 1 meter.

19

Series CY3

Auto Switch

Connections and Examples

Basic Wiring

Solid state 3-wire, NPN

Solid state 3-wire, PNP

Brown

Brown

Load

Brown

Load

Black

Switch

main

circuit

2-wire

(Solid state)

Switch

main

circuit

Indicator

light

protective

circuit

etc.

Switch

main

circuit

Black

Load

Blue

2-wire

(Reed switch)

Blue

Blue

Brown

Load

Blue

(Power supplies for switch and load are separate.)

Brown

Brown

Load

Black

Switch

main

circuit

Brown

Indicator

light

protective

circuit

etc.

Switch

main

circuit

Load

Blue

Blue

Load

Blue

Example of Connection to PLC (Programmable Logic Controller)

• Sink input specifications

3-wire, NPN

Black

• Source input specifications

3-wire, PNP

Black

Input

Brown

Connect according to the applicable

PLC input specifications, since the

connection method will vary depending

on the PLC input specifications.

Input

Brown

Switch

Switch

Blue

Blue

COM

COM

PLC internal circuit

PLC internal circuit

2-wire

2-wire

Brown

Blue

Input

Switch

Input

Switch

Blue

Brown

COM

COM

PLC internal circuit

PLC internal circuit

Example of AND (Serial) and OR (Parallel) Connection

3-wire

AND connection for NPN output

(using relays)

Switch 1

Switch 2

Brown

Black

Relay

Blue

AND connection for NPN output

(performed with switches only)

Load

Relay

contact

Brown

Black

Relay

Blue

Switch 1

Switch 2

OR connection for NPN output

Brown

Black

Load

Blue

Switch 1

Brown

Black

Blue

Switch 2

Brown

Black

Blue

Load

Brown

Black

Blue

The indicator lights will illuminate

when both switches are turned ON.

2-wire with 2-switch AND connection

Brown

Load

Switch 1

Switch 2

Blue

Brown

Blue

When two switches are connected in series, a load may

malfunction because the

load voltage will decrease

when in the ON state.

The indicator lights will illuminate if both of the switches

are in the ON state.

Power supply

Internal

–

x 2 pcs.

voltage

voltage drop

= 24 V - 4 V x 2 pcs.

= 16 V

Example: Power supply is 24 VDC.

Internal voltage drop in switch is 4 V.

Load voltage at ON =

2-wire with 2-switch OR connection

Brown

Switch 1

Switch 2

Blue

Brown

Load

(Solid state)

(Reed switch)

When two switches

are connected in parallel, a malfunction

may occur because

the load voltage will

increase when in the

OFF state.

Because there is no

current leakage, the

load voltage will not increase when turned

OFF. However, depending on the number of

switches in the ON

state, the indicator lights

may sometimes dim or

not light because of the

dispersion and reduction of the current flowing to the switches.

Blue

Load voltage at OFF = Leakage current x 2 pcs.

x Load impedance

= 1 mA x 2 pcs. x 3 kΩ

=6V

Example: Load impedance is 3 kΩ.

Leakage current from switch is 1 mA.

20

Reed Switch: Direct Mounting Style

D-A90/D-A93/D-A96

For details about certified products conforming to

international standards, visit us at www.smcworld.com.

Auto Switch Specifications

Grommet

Electrical entry direction: In-line

PLC: Programmable Logic Controller

D-A90 (Without indicator light)

D-A90

Auto switch part no.

Applicable load

Load voltage

IC circuit, Relay, PLC

24 V AC/DC or less

48 V AC/DC or less

100 V AC/DC or less

50 mA

40 mA

20 mA

Maximum load current

Contact protection circuit

None

Internal resistance

1 Ω or less (including lead wire length of 3 m)

D-A93/D-A96 (With indicator light)

D-A93

Auto switch part no.

Applicable load

Caution

Operating Precautions

Fix the switch with the existing screw

installed on the switch body. The switch may

be damaged if a screw other than the one

supplied, is used.

Relay, PLC

Load voltage

Load current range

and max. load

current

IC circuit

24 VDC

100 VAC

4 to 8 VDC

5 to 40 mA

5 to 20 mA

20 mA

Contact protection circuit

Internal voltage drop

D-A96

None

0.8 V or less

2.4 V or less (to 20 mA)/3 V or less (to 40 mA)

Red LED illuminates when ON.

Indicator light

Lead

Auto Switch Internal Circuit

D-A90

Reed switch

Contact

protection

box

OUT (±)

Brown

Weight

Unit: g

CD-P11

CD-P12

OUT (±)

Blue

Auto switch part no.

Lead wire length

(m)

D-A93

LED diode

Brown

Contact

protection

box

Resistor

Reed switch

wires

D-A90/D-A93 — Oilproof heavy-duty vinyl cable: ø2.7, 0.18 mm2 x 2 cores (Brown, Blue), 0.5 m

D-A96— Oilproof heavy-duty vinyl cable: ø2.7, 0.15 mm2 x 3 cores (Brown, Black, Blue), 0.5 m

Note 1) Refer to page 19 for reed switch common specifications.

Note 2) Refer to page 19 for lead wire lengths.

Zener

diode

OUT (+)

Brown

D-A90

D-A93

D-A96

6

6

8

30

30

41

0.5

3

Dimensions

Unit: mm

CD-P11

CD-P12

Blue

OUT (–)

Blue

D-A90/D-A93/D-A96

D-A96

LED diode

DC (+)

Brown

Indicator light

(+)

Reed switch

Resistor

Reverse

current

prevention

diode diode

OUT

Black

DC (–)

Blue

Load

D-A90 type comes without

indicator light

DC power

supply

(–)

Note) q In a case where the operation load is

an inductive load.

w In a case where the wiring load is

greater than 5 m.

e In a case where the load voltage is

100 VAC.

Use the auto switch with a contact protection

box in any of the above mentioned cases.

(For details about the contact protection box,

refer to page 19.)

21

M2.5 x 4 l

Slotted set screw

Most sensitive

position

( ): dimensions for D-A93.

Solid State Switch: Direct Mounting Style

D-M9N/D-M9P/D-M9B

For details about certified products conforming to

international standards, visit us at www.smcworld.com.

Auto Switch Specifications

Grommet

PLC: Programmable Logic Controller

2-wire load current is reduced

(2.5 to 40 mA)

Lead free

UL certified (style 2844) lead

cable is used.

D-M9/D-M9V (With indicator light)

D-M9N

Auto switch part no.

D-M9P

D-M9B

In-line

Electrical entry direction

2-wire

3-wire

Wiring type

NPN

Output type

PNP

—

IC circuit, Relay, PLC

24 VDC relay, PLC

Power supply voltage

5, 12, 24 VDC (4.5 to 28 V)

—

Current consumption