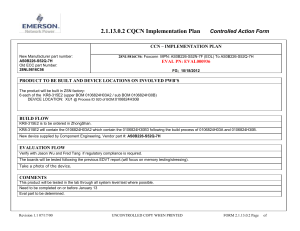

SAP PP/QM Configuration INDEX 1. OVER VIEW:- 4 2. GETTING INTO THE CONFIGURATION AREA OF SAP 8 3. MASTER DATA CONFIGURATION - BOM 12 3.1 Define BOM Usage 12 3.2 Define Default Values for item status 16 3.3 Define Allowed Material type for BOM Header 20 3.4 Define BOM Status 23 3.5 Define Item Category 26 3.6 Define Allowed item type for BOM Item 30 3.7 Define Explosion types 33 3.8 Define Order of Priority 36 3.9 Define Application 40 3.10 Define Alternative Determination for Multiple BOM 44 3.11 Alternative determination in related application Area 46 3.12 Define User-specific setting 47 4. WORK CENTER 50 4.1 Define Work center Category 51 4.2 Define Field Selection 54 4.3 Define Task List usage 58 4.4 Define Parameters 61 4.5 Define Standard Value 65 4.6 Determine Person Responsible 69 4.7 Define Control Key 71 5. CAPACITY PLANNING 76 5.1 Define Capacity Category 76 5.2 Determine Capacity Planner 78 5.3 Define Shift Sequence 81 5.4 Define Formula Parameters for Work centers 88 5.5 Define Formula for Work centers 91 5.6 Define Factory calendar 95 5.7 Define Default Capacity 106 5.8 Define Work center screen sequence 109 6. ROUTING 112 6.1 Define Standard value description in operation over view 113 6.2 Define Routing Status 115 6.3 Define Task List usage 117 6.4 Define Reduction Strategy 119 6.5 Define User Fields 123 6.6 Define Routing Selection 7. SUMMARY:- Automatic 127 130 1. Over view:Production Planning module configuration reports are demonstrated in this book. and relevant PP module contains three types of manufacturing methods. o Discrete o Repetitive o Process Industries. Discrete: Discrete production method is applicable to the manufacturing setup where small lots are manufactured with frequent changes in the settings. Manufacturing is accounted through Production orders. Repetitive: This method is applicable, where products are manufactured with least change or no change in the manufacturing process over a long period of time. Manufacturing is accounted through backflush. Process Industries: It is similar to the Discrete but instead of routing, It uses master recipe where in Process messages are maintained. It is more appropriate to the food industries and processing units where instructions are used during the process. Manufacturing is accounted through process orders. Configuration setting in PP module can be classified as below. • Master Data related settings • Planning Related Settings • Production Execution related settings We will discuss about the Master data related configuration setting in detail. Important Master data in PP module are • Bill Of Material • Work center • Routing Bill Of Material (BOM):BOM can be defined as “a list of required components along with the required quantity essential to make any product”. Important Technical details related to BOM are Application of BOM Usage of BOM Status of BOM Selection of BOM Configuration setting related to BOM will enable to align the BOM master data in line with the business requirement blue print document. Work Center:Machines, group of labour, processing unit are defined as work center in SAP. Work center contains the Capacity Requirements Scheduling details Costing details Configuration setting related to work center will enable to define the SAP system according to the business requirement blue print document. Routing:Sequence of operation, work centers to be used and the duration required for each operation to manufacture the product is defined in routing. Important Technical details related to Routing are Usage of Routing Status of Routing Selection of Routing Configuration settings related to Routing will enable to align the Routing master data in line with the business requirement blue print document. Friends, the configuration settings related to each master data are explained in detail. Example:BOM Item category configuration Automatic alternate selection of BOM Configuration of BOM usage Configuration of allowed item type for BOM Work Center Configuration Configuration Configuration Configuration of of of of field selection in work center formula to schedule and calculate cost standard value key shift sequence of of of of Automatic Routing selection Routing usage reduction strategy user defined fields in Routing Routing Configuration Configuration Configuration Configuration 2. Getting into the Configuration area of SAP BACKGROUND To make the configuration in SAP, one has to have authorization to perform transaction in configuration mode. It is the place where every details are maintained to make the transaction happen as per the business mapping. SCENARIO It is required to configure various settings in SAP. INSTRUCTIONS To do configuration, first one has to logon to the system, and go to the IMG mode. How to logon to IMG mode is explained below. From next document onwards, it is mentioned as IMG. How to get in to the SAP IMG mode? 1. Type spro in the SAP main screen dialog box, 2. Click 3. Click on Note:- Production related configurations are available under Node. 4. Click 5. You are inside the IMG for Production Planning Module. If the menu path is mentioned as “IMG” in the further topics, you have to follow the above step to reach this place. 3. Master Data Configuration - BOM 3.1 Define BOM Usage BACKGROUND This configuration setting enables to define Bill Of Material (BOM) usage. BOM usage defines the usage of BOM in specific application area in the SAP. Example, there can be a separate BOMs for Ø Design, Ø Production Ø Costing. In this way, each area is dealing only with the specific data it requires. Example: Ø The design BOM includes all the components of the product and their technical data from the design point of view. This BOM is generally not linked to any order. Ø The production BOM contains all the items required from the production and assembly point of view. Only items relevant to production, for which production data (such as the issue storage location) can be entered, are required. A production BOM does not contain any packaging materials required in the shipping department. SCENARIO Create new BOM usage. Note:Standard BOM usage available with SAP is sufficient. However any new BOM usage can be created. INSTRUCTIONS Follow the Menu Path: IMG → Production → Basic data → Bill of materials → General data à BOM Usage à Define BOM Usage 1. Click 2. Click 3. Enter usage value; it can be either numeric or alphabet. It is suggested to be numeric. 4. Select +,- or . to indicate to which area this BOM is meant for like Production, Engineering, Spare, Plant Maintenance, Sales or for costing relevancy. Note:-Based on this, during BOM explosion, dependent requirements are also planned, entire 5. Enter Usage text 6. Click Save Impact of this configuration in Master Data / Transaction When creating the BOM, key defined here will appear in the BOM Usage field. According to the requirement, BOM usage key has to be selected during BOM Creation. Click Match code or desired BOM usage. F4 in BOM usage field, to select the Transaction code to create BOM is CS01 3.2 Define Default Values for item status BACKGROUND This configuration setting enables to define default values for item status. Every item in the BOM can be defined whether it is subjected to Costing Sales Production Spare part This configuration setting is used to indicate whether the BOM component along with the BOM usage. Ø is to be considered for costing in this BOM or not, Ø is relevant to sales (normally used in Variant configuration), Ø is a spare part Ø is related to Production SCENARIO Set the default value for items in BOM. INSTRUCTIONS Follow the Menu Path: IMGàProductionàBasic dataàBill of materialsàGeneral dataàBOM usageàDefine default values for the item status 1. Click 2. Click 3. Enter Usage value 4. Update the following fields Field Name Description BOM usage Field defining the BOM usage Prod Indicating that the BOM item is related to Production Eng/des Indicating that the BOM item is related to Engineering and Design PM Indicating that the BOM item is related to Plant Value Enter value e.g. 1 Make tick in the check box Leave blank. Leave blank Maintenance Indicating the item is related to Sales and it will appear in the sales order. Relevant to costing Sales Relevan 5. Click Save Leave blank. Normally used in variant configuration. Select X , indicating relevant to costing. . Impact of this configuration in Master Data / Transaction Example:BOM usage defined 1 indicating relevant to production. The item status as configured such that all items Ø are relevant to production Ø can be relevant to costing In this example, the indicators are checked as follows: Ø The Indicator: item relevant to production cannot be deselected (required entry). In the BOM maintenance functions, this indicator is set automatically for all items and cannot be cancelled. Since the item can be relevant to costing, the default value X (fully relevant to costing) can be set for the Indicator for relevance to costing. This value can be overwritten in the BOM maintenance functions. BOM item level default setting will appear as per the setting done here. 3.3 Define Allowed Material type for BOM Header BACKGROUND This configuration setting enables to control the creation of BOM to the specific material types. This configuration is done to the combination of BOM usage and Material type. When a new bill of material is created, the system checks the material type as follows: § The fully qualified (non-generic) entries are checked first. The generic entries are checked afterwards. § You can define that the use of the material type in combination with Creation of BOM with respect to material type can be controlled. Example, it may not be allowed to create BOM for Raw material. (Material type ROH). Creation of BOM to material type ROH can be restricted in the system. SCENARIO Creation of BOM for Material type ROH should not be allowed. INSTRUCTIONS Follow the Menu Path: IMGàProductionàBasic dataàBill of materialsà General dataàDefine allowed material type for BOM header Click Follow the below steps to create new entries. 1. Click Update required and optional fields: Field Name BOM Usage ### Material header Allowed Description BOM usage according to the application type Header Material type to which BOM creation has to be restricted Select the symbol indicator to mention allowed or not allowed Value 1 for production BOM Enter ROH Select Negative symbol to RESTRICT BOM creation. ### Generic entry “*” can be made instead of a specific BOM usage. This indicates, it is applicable to all possible BOM usages. 2. Click Save . Impact of this configuration in Master Data / Transaction When a new bill of material is created, the system checks the material type as follows: § Non-generic entries are checked first. The generic entries are checked afterwards. Error message will be displayed when creating BOM for RAW material. 3.4 Define BOM Status BACKGROUND This configuration setting enables to define BOM status. BOM status is used to define whether the BOM can be used by any application area or not. Example: Ø In the costing areas in a company, the BOM is exploded according to the application. While defining the BOM status, usage in costing area will be defined. Ø In MRP, the following indicators are checked directly from the definition of the BOM status: - Explosion in MRP - Released for orders MRP only reads BOMs whose BOM status has at least one of these indicators. BOM status defines whether The BOM is active or inactive. SCENARIO BOM need to be created for certain for product whose BOM can be finalized only after some trial and error. While it is in preparation it is required not to be used by any application. Status “In preparation” has to be created. INSTRUCTIONS Follow the Menu Path: IMGàProductionàBasic dataàBill of materialsà General dataàDefine BOM status 1. Click …..continuation of the above screen’s right side balance portion 2. Click 3. Enter usage value. E.g. 6. 4. Leave all the check box as EMPTY. 5. Mention description as “In preparation” 6. Click Save . Impact of this configuration in Master Data / Transaction BOM with status 6 can not be used for any application. 3.5 Define Item Category BACKGROUND This configuration setting enables to define item category. The item category defines the attributes and functions of a BOM item. It controls field and screen selection for detail screens in BOM maintenance. BOM can contain different type of items manufacture the finished product. There are related to Ø Pipeline items – i.e. items which are received through a pipeline from supplier not related to inventory Ø Stock items – i.e. materials are always issued from stock which are relate to inventory Ø Document item – i.e. Documents are referred in the BOM as a item trough the Document Management System (DMS) Ø Text item – i.e. brief note about the material usage can be maintained as a Text item. This will be useful in a long BOM to indicate any specific assembly. The above different items are defined through item category in the BOM. SCENARIO Define item category to meet the situation as per the below example. Example: - An Item code may be defined as a normal item in the material master. The same item code for one specific BOM has to be treated as a phantom material. In such a situation, item category inside the item detail of the BOM will be mentioned as a phantom assembly. It is now applicable only to this BOM. Let’s look at the standard setting for item category. Item categories defined by SAP will be sufficient in most of the cases. If required, any new item category can be created. INSTRUCTIONS Follow the Menu Path: IMGàProductionàBasic dataàBill of materialsà Item dataàDefine item category 1. Click 2. click 3. Update the following fields Field Name Item category Description Desired item category to be mentioned in the BOM Relevant to Inventory management It is text item Variable size item To mention Document To mention as Class item, used in Variant configuration To mention as PM structure element To mention Intra Material normally used in Master Recipe-PPPI Negative value allowed in the BOM or not? This is required to indicate the by product. To indicate sub items are supported. Sequence of Item detail screen. Inv.Mgmt TxtItem Vsl Document Item Cls Item PM Str IntraM +/- sign SubI Item Ctrl 4. Select check requirement boxes according 5. Mention Item category Text 6. Click Save . to the business Impact of this configuration in Master Data / Transaction While creating the BOM, required item category may be selected. 3.6 Define Allowed item type for BOM Item BACKGROUND This configuration setting enables to control the item type which can be entered as a component in the BOM. Restriction to BOM item level can be done. Example: - It may be required NOT to allow any Finished Goods material type (FERT) to be a member of the BOM. SCENARIO It is required to restrict FERT material to be the member of the BOM. INSTRUCTIONS Follow the Menu Path: IMGàProductionàBasic dataàBill of materialsà Item dataàDefine allowed material type for BOM items 1. Click 2. Click 3. Update the following fields Field Name BOM usage Description BOM usage to define the application area Mat tpe header Header material type to which this restriction is to be applicable Material type BOM Item type inside the BOM to item be restricted. Allowed + sign to permit and –sign NOT to permit 4. Click Save . Impact of this configuration in Master Data / Transaction While creating the BOM, only allowed component type in this setting are allowed to be a member of the BOM item. 3.7 Define Explosion types BACKGROUND This configuration setting enables to define how the component in Bill Of Material is to be exploded during processing. This configuration setting governs BOM Component • To be considered for planning or not • To be considered in Long Term Planning or not • Phantom assembly is to be planned or not • Direct production should be activated or not SCENARIO For Long term planning, by default all the BOM items are considered. If there are more items in a BOM and it is required to plan only very specific items in the LTP. Then at BOM level against the item, LTP off indicator can be set. Now during LTP run, only relevant items are planned in LTP and all items are planned in MRP run. INSTRUCTIONS Follow the Menu Path: IMGàProductionàBasic dataàBill of materialsà Item dataàDefine Explosion types. 1. Click Follow the below steps to create new entries. 2. Click 3. Update the following fields Field Name Description Explosion type BOM Explosion type, free entry. Description Description of the Explosion type key. Phan.off Plng off DP Off LTP Off Indi/Coll Phantom assembly is not applicable to this item if this indicator is set. Material components are not planned till the Sales order is created to this BOM item if this indicator is set Direct production functions are switched off if this indicator is set. This will exclude the item in LTP calculation if this indicator is set. It is to specify, whether to group the dependant requirement together or not 4. Maintain the entries in the check box as per the requirement 5. Click Save Impact of this configuration in Master Data / Transaction BOM Item level explosion type can be defined. Key defined here will appear in the screen to select. 3.8 Define Order of Priority BACKGROUND This configuration setting enables to define order of priority for Bill Of Material to be selected during MRP and Production or process order creation. Different Bill Of Material can be created for • Production • Costing • Engg / Design Selection priority must be defined to pickup the right Bill Of Material to the right application. Link between this configuration established as below:- and Master Data is • Selection priority will be defined through selection id. • Selection id will have the sequence of BOM usage. • BOM usage will be mentioned in the BOM • Selection id of BOM will be mentioned in the order type and MRP plant Parameter. SCENARIO There are more than one BOM (BOM usage) They are 1 for Production, 2 for Engg/Design 3 for Costing. It is required to define the order of selection for BOM. INSTRUCTIONS Follow the Menu Path: IMGàProductionàBasic dataàBill of materialsà Alternative determinationàDefine order of priority for BOM usage. 1. Click Click usage. to create additional order of priority for BOM 2. Update the Following fields Field Description Selection Id Selection ID numeric number to be entered. Selection Priority With in this selection ID, priority to be mentioned BOM usage With in this selection ID and Priority, relevant BOM usage to be selected. 3. Click Save . Impact of this configuration in Master Data / Transaction During MRP run, production order or process order creation BOM selected according to this selection id priority. 3.9 Define Application BACKGROUND This configuration setting enables to define BOM Application. BOM application controls use of BOM in a specific area. Areas like MRP run, cost estimate calculation etc.. will use the BOM of its own respective BOM application. SCENARIO BOM display at multiple levels (transaction code CS12) can be done for different BOM application. It is required to display only the costing BOM to certain users. Separate BOM application to be created to display the BOM related only to costing. Note: - BOM with usage for costing should be available. i.e. with the right usage for costing. INSTRUCTIONS Follow the Menu Path: IMGàProductionàBasic dataàBill of materialsà Alternative determinationàDefine Applications 1. Click To view the details, select the line and click 2. Update the Following fields Field Description BOM Application Description Selectin ID Alternative Det.Multi.BOM Production Version MRP explosion Rel planned orders Release costing Other check boxes 3. Click Save Enter any four digit BOM application area Enter description Selection ID through which BOM selected To select for alternative BOM if multiple BOM is available. Tick this check box If there is a production version, that is used as a selection criteria. Leave Blank Leave Blank Tick this check box Leave Blank . Impact of this configuration in Master Data / Transaction When displaying the BOM through transaction code CS12, Right BOM usage will be displayed according to the settings maintained here. In this example, with BOM application, only the costing BOM will be displayed. Press F4 in BOM application, where all the available setting will be displayed. 3.10 Define Alternative Multiple BOM Determination for BACKGROUND This configuration setting enables to define automatic selection of right Bill Of Material during MRP and production order or process order creation, when there are more than one Bill Of Material to a material. SCENARIO Specific alternative BOM for some materials are to be exploded during the MRP and other production order process for specific duration. INSTRUCTIONS Follow the Menu Path: IMGàProductionàBasic dataàBill of materialsà Alternative determinationàDefine alternative determination for multiple BOM. 1. Click Follow the below steps to create new entries. 2. Update the Following fields Field Description Material Enter material code number to which alternate BOM is to be exploded Plant Plant where it is applicable BOM Usg BOM usage Valid From From date of BOM explosion Alt BOM Alternate BOM number which is to be exploded. 3. Click Save . Impact of this configuration in Master Data / Transaction Right BOM according to the setting here will be exploded during MRP and Production processing. 3.11 Alternative determination application Area in related BACKGROUND Similar to the above alternate defining in production area, for other areas like Inventory, MRP, Costing, Sales and Distribution and Plant Maintenance can be maintained. Only the menu path is given here and the rest of the settings are similar to above. INSTRUCTIONS Follow the Menu Path: IMGàProductionàBasic dataàBill of materialsà Alternative determinationàAlternate determination in related application area àDefine alternate determination for inventory àProduction àMRP àCosting àSales and distribution and àPlant maintenance 3.12 Define User-specific setting BACKGROUND This configuration setting enables to configure the parameters specific to the user. Following parameters Item category Item increment BOM Reporting specification are can be set for a specific user. INSTRUCTIONS Follow the Menu Path: IMGàProductionàBasic dataàBill of materialsà Define user-specific settings Click To view more details, select the required row and click Click to create new entries Select the entries and tick the check box as shown above. Field name User Item increment Mat. Item cat. Field value and description Name of the user to whom the default settings are to be done. While creating the BOM, incremental number to be displayed. Item category to be displayed by default. While using the where used list query, this check box in the selection box will appear as ticked by default. While using the where used list query, this check box in the selection box will appear as ticked by default. Click Impact of this configuration in Master Data / Transaction User SAPUSER when creating the BOM, this default setting will appear. This will help to reduce BOM creation time. 4. Work Center Machines may be referred as work center. It is defined as the place where operations are carried out. Apart from machine, group of persons (e.g. in maintenance department, certain group of people may be employed for any machinery movements etc.) may be treated as a labor work center. Data in work center used for Ø Scheduling – start and end of operation Ø Costing – Cost incurred during production Ø Capacity planning - to plan the required capacity Let’s see the configuration related to Work center. 4.1 Define Work center Category BACKGROUND This configuration setting enables to define work center category. Work center category is the major classification of work center by SAP. E.g. Machine, processing unit, labor are defined as a different work center category. Work center category controls the field selection inside the work center. SCENARIO Create a work center category to mention skilled labor work center category. INSTRUCTIONS Follow the Menu Path: IMGàProductionàBasic dataàWork centerà General Data àDefine work center category. 1. Click 2. Click 3. Update the Following fields Field Description Cat Capacity category. Any new value may be entered. E.g. ZLAB Description Description of the desired capacity category. E.g. Skilled Labour category Field Selection Contains the fields required to this capacity category. Enter standard SAP value according to the capacity category. E.g. 0001 Screen sequence Sequence of tab screen to be appeared in the work center master data. Enter the standard SAP value. E.g. 0001 4. Click Enter 5. Select Created capacity category 6. Double Click 7. Click 8. Enter Application – Area in SAP where this work center category can be used. E.g. P – Routing; C - Master Recipe; Q - Quality task list etc. 9. Note:- If this work center category is to be applicable to all, maintain all the entry in this application field. 10. Click . Impact of this configuration in Master Data / Transaction When creating the work center for skilled labor, work center category is to be mentioned as it is a mandatory entry. 4.2 Define Field Selection BACKGROUND This configuration setting enables to make the field in work center master data as Mandatory Optional Highlight Hide Field selection will be used to make certain field as mandatory entry or to hide certain fields during creation of work center master data. SCENARIO Make field person responsible for work center category 0007 as mandatory field. INSTRUCTIONS Follow the Menu Path: IMGàProductionàBasic dataàWork centerà General Data àDefine field selection. 1. Click 2. Double click Basic data 3. Double click Person responsible 4. Click Field selection Req. radio button for the required work center category. Contents column indicate the work center category. Note:- From this screen it may be noted that person responsible entry is mandatory for work center category 0001,0002 and 0008 5. Click to add more entry. 6. Enter content 0007 or any work center category. 7. Click radio button Req. 8. Click 9. Click Impact of this configuration in Master Data / Transaction When work center with category 0007 is created, person responsible field become mandatory. Note:- Field selection procedure is same for Routing as well. 4.3 Define Task List usage BACKGROUND This configuration setting enables to define the task list usage to the work center. Usage of work center specific to the task list (i.e. only in the master recipe or Routing) can be defined to restrict its usage. SCENARIO Define the task list usage to the work center category 0007 to be used in Routing and in Reference Operations set only. INSTRUCTIONS Follow the Menu Path: IMGàProductionàBasic dataàWork centerà General Data àDefine task list usage. 1. Click 2. Select 3. Double click Task list type 4. Click 5. Update the Following fields Field Description Task List type N for Routing and S for Reference Operation set 6. Click Save . Impact of this configuration in Master Data / Transaction When creating Work center usage is to be mentioned as 001. Once this is maintained, then it will not be possible to use this Work center in Master Recipe or in Rate routing. 4.4 Define Parameters BACKGROUND This configuration setting (activities) for formula. enables to define Parameter Parameter is one of the required settings to calculate the conversion cost incurred in the Work center during manufacturing. Work center while in use can consume • Power • Labour • Setup time • Depreciation • Steam etc. The above costs incurred during conversion will be captured through the activity. Parameter is the structure to capture this activity. This will be assigned to the standard value key. Standard value key will be assigned in the work center. SCENARIO Create a Parameter. Note:- Standard SAP setting is sufficient. Let us discuss the creation of new parameter. INSTRUCTIONS Follow the Menu Path: IMGàProductionàBasic dataàWork centerà General Data àStandard ValueàDefine Parameters. 1. Click 2. Click 3. Update the Following fields Field Description Parameter Parameter to hold the value. Any alphanumeric six digit may be entered. E.g. LABOUR Origin Place where from the value is to be taken. E.g. To indicate value to be taken from task list maintain 2 in this field. Short key word Short description Key work Key word to identify Dimension Dimension of the parameter. E.g. Any thing related to Duration may have TIME as dimension. Standard Value Unit Unit of this parameter. E.g. Time dimension may have unit as MIN. Note: - If any parameter for which there is no unit, it may be mentioned as no unit. 4. Click Save . Impact of this configuration in Master Data / Transaction Link between the parameter and the master data is as below. a. This parameter will be assigned to the standard value key. b. Standard value key will be attached with the work center. c. Work center will be attached in the task list. I.e. in the routing or in the master recipe. d. Standard value (i.e. duration of labour hours required) will be maintained in the task list as a master data. 4.5 Define Standard Value BACKGROUND This configuration setting enables to define the standard value key. Standard value key is very essential to capture the cost incurred in the work center. Standard value key will contain the activities. One standard value key can contain up to six activities. Each activity refers to the cost. Example:• Production cost • Set up cost • Labour cost • Quality Cost • Power cost • Steam cost One work center can have only one standard value key. SCENARIO Create a standard value key to have the activities of setup, machine, labor, and over head. INSTRUCTIONS Follow the Menu Path: IMGàProductionàBasic dataàWork centerà General Data àStandard ValueàDefine standard value key. 1. Click 2. Click 3. Update the Following fields Field Description Standard value key Enter any alpha numeric to indicate standard value key. E.g. STD1 Description Maintain standard value key description. E.g. setup/machine/labor/Power Parameter Maintain the parameters. Up to six parameters can be maintained. Tick this check box to generate formula. 4. Click Save . Impact of this configuration in Master Data / Transaction When creating the work center, standard value key STD1 to be mentioned. 4.6 Determine Person Responsible BACKGROUND This configuration setting enables to define the person responsible for work center. Every work center will have a responsible person to schedule the work load to that machine and to monitor the working hours and output from that work center. This field can be used for reporting purpose also. SCENARIO Create a work center responsible person. INSTRUCTIONS Follow the Menu Path: IMGàProductionàBasic dataàWork centerà General Data àDetermine person responsible Click Click Update the Following fields Field Plant Person Responsible Description Name of the plant e.g. IND6 Three digit alpha numeric entry to mention the responsible person to the work center. E.g. INP Person responsible description Detailed description of the person responsible. E.g. Incharge Processing Unit Click Save . Impact of this configuration in Master Data / Transaction When creating the work center, person responsible has to be entered. 4.7 Define Control Key BACKGROUND This configuration setting enables to define control key. Control key governs • Scheduling of operation • Cost calculation for an operation • Capacity calculation for an operation • Confirmation for an operation Control key is mapped with the work center in the task list (i.e. in the routing and in the master recipe). SCENARIO Create a control key with confirmation as mandatory and it should calculate the cost and capacity, it should also schedule the operation. INSTRUCTIONS Follow the Menu Path: IMGàProductionàBasic dataàWork centerà Routing Dataà Define control key 1. Click 2. Click 3. Update the Following fields Field Description Control Key Enter any alphanumeric four digit key. E.g. YP01 Description Maintain description of this control key. E.g. Sch/Cost/Capreq/Confreq/AutoGR Indicators Tick the check box as shown above in the screen. Tick in the Check box will perform the respective function to the operation / phase which is having this control key. 4. Click Save . 5. Click control key. to maintain any long text to this 6. Maintain the long text. 7. Click Save . 8. Click 9. Click 10. if you get the Other language screen. Click Save . Impact of this configuration in Master Data / Transaction Link between control key and Transaction:Control key is attached in the task list with work center for each operation While performing order creation, confirmation, MRP run system will behave according to this configuration setting. 5. Capacity Planning 5.1 Define Capacity Category BACKGROUND This configuration setting enables to define the capacity category. Capacity category will differentiate the type of capacity used in the work center. Capacities can be • Machine • Labor • Processing unit Capacity category and capacity details are assigned to the work center. SCENARIO Create a capacity category. INSTRUCTIONS Follow the Menu Path: IMGàProductionàBasic dataàWork centerà Capacity Planningà Define capacity category 1. Click 2. Click 3. Update the Following fields Field Description Category Capacity category. E.g 001 Description Description of capacity category e.g. machine 4. Click Save . Impact of this configuration in Master Data / Transaction Capacity category is to be mentioned in the capacity header detail in the work center. 5.2 Determine Capacity Planner BACKGROUND This configuration setting enables to define the capacity planner. Capacity planner is the person who is responsible to plan and schedule the specified capacity. SCENARIO Create a capacity planner. INSTRUCTIONS Follow the Menu Path: IMGàProductionàBasic dataàWork centerà Capacity Planningà Determine capacity planner 1. Click 2. Click 3. Update the Following fields Field Description Planner Enter capacity planner. E.g. IN6 Enter capacity planner description. E.g. Processing unit plan Description 4. Click Save . Impact of this configuration in Master Data / Transaction Capacity planner is to be mentioned in the capacity header detail in the work center. 5.3 Define Shift Sequence BACKGROUND This configuration setting enables to define shift sequence. Shift sequence is used to define the specific working pattern. I.e. weekly holidays, number of shift and working hours of each shift. Work center capacity is calculated from its working hours defined in the capacity header details of the work center. There are mainly three ways to define capacity for each work center. • Normal capacity • Available Interval capacity • Interval and shifts Normal capacity is defined through the working hrs and break in the capacity header Available interval capacity is the capacity available for any specific duration; it is defined at the capacity header detail Interval and shifts is defining the shifts in which the machine or industry works. SCENARIO Create a shift sequence with two shifts a day and Thursday and Friday as weekly holiday. INSTRUCTIONS Follow the Menu Path: IMGàProductionàBasic dataàWork centerà Capacity Planningà Available capacityà Define shift sequence 1. Click 2. Click 3. Update the Following fields Field Description Grouping Enter shifting grouping. E.g. SG Enter description E.g. Special Grouping Description 4. Click two times 5. Select the Grouping 6. Double Click 7. Click 8. Update the Following fields Field Description Break Enter the Break name. E.g. IN6B Break Number Enter the break number E.g. 1 Description Description of break. E.g. First shift break Start Break start time End Break end time 9. Click above) (Complete all the break required as explained 10. Click 11. Select the break 1 line 12. Double click 13. Click 14. Update the Following fields Field Description Shift Enter shift name. E.g.1SHF Shift text Enter shift definition. E.g. First shift Starting date of the shift End date of the shift Starting time of the shift End time of the shift Enter the Break schedule. E.g. IND6 Start date End date Start time End Time Break 15. Click 16. Select the 1SHT line 17. Double click 18. Click 19. Update the Following fields Field Description Sequence Enter the sequence No. E.g. 01 Shift No. Shift number in the sequence. E.g. 1 Description Description of the shift sequence. E.g. Two shift per day Day1 to Day 7 Maintain the desired shift definition the day to follow. E.g. 1SHT and 2SHT in all days except Thursday and Friday. 20. Click 21. Click Save . Impact of this configuration in Master Data / Transaction This shift sequence can be maintained as an interval of available capacity. This can be maintained in the work center capacity header detail. Once this is assigned, working days and hours to this work center will be as per this shift sequence. 5.4 Define Formula Parameters for Work centers BACKGROUND This configuration setting enables to define the parameter for the formula. Formulas are to be defined to calculate Cost Capacity requirements Schedule the operation Formula parameter will be used in the formulas. Formulas are used in the work center capacity view, scheduling view and costing view to Calculate capacity Schedule the operation Calculate the activity cost. Note:This configuration is similar to defining the parameter explained above. However it is reproduced for your quick reference here also. SCENARIO Define formula parameter. INSTRUCTIONS Follow the Menu Path: IMGàProductionàBasic dataàWork centerà Capacity Planningà Work center formulasà Define formula parameter for work center 1. Click 2. Click 3. Update the Following fields Field Description Parameter Parameter to hold the value. Any alphanumeric six digit may be entered. E.g. LABOUR Origin Place where from the value is to be taken. E.g. To indicate value to be taken from task list maintain 2 in this field. Short key word Short description Key work Key word to identify Dimension Dimension of the parameter. E.g. Any thing related to Duration may have TIME as dimension. Standard Value Unit Unit of this parameter. E.g. Time dimension unit as MIN. may have Note: - If any parameter for which there is no unit, it may be mentioned as no unit. 4. Click Save . Impact of this configuration in Master Data / Transaction Formula parameter defined here will be used in the formulas. 5.5 Define Formula for Work centers BACKGROUND This configuration setting enables to define the formulas. Formulas are used in • Calculate capacity requirement • Schedule the start and end of the operation • Calculate the cost Formulas will be assigned in the work center capacity view, scheduling view and in costing view. SCENARIO Create the formula to calculate the machining time. Note: - standard formula given by SAP will meet many requirements. Let’s discuss the creation of formula. INSTRUCTIONS Follow the Menu Path: IMGàProductionàBasic dataàWork centerà Capacity Planningà Work center formulasà Define formula parameter for work center 1. Click 2. Click 3. Update the Following fields Field Description Formula Key Enter formula key. E.g. SAP002 Description of the formula key Enter description Formula Maintain the formula. Mostly SAP defined formula would be sufficient. Let us discuss the SAP Standard formula and understand it. Any new formula can be created similar to it. 4. Parameter defined here are SAP_02 SAP_09 SAP_08 SAP_11 Machine value from routing Operation quantity- value from routing field operation qty. Base Quantity – value from routing field base quantity Operation split – value from routing field split Above formula defined to calculate the machining time, Machine time * Operation Quantity / Base quantity / Operation Split 5. Indicators:Field name Field description and value Tick in this check box indicates, this formula is generated in the system. Tick in this check box indicates, this formula can be used to calculate cost. Tick in this check box indicates, this formula can be used to calculate capacity requirements in MRP. Tick in this check box indicates, this formula can be used to calculate PRT requirements. Tick in this check box indicates, this formula can be used for scheduling operations. Impact of this configuration in Master Data / Transaction Formula is used in work center capacity, scheduling and costing views. 5.6 Define Factory calendar BACKGROUND This configuration setting enables to define the Factory calendar. Factory calendar will contain the entire working day and holiday details for a specific plant. Factory calendar will be attached to the capacity header. Factory calendar will be referred while scheduling the operations. SCENARIO Define factory calendar for plant IND6. INSTRUCTIONS Follow the Menu Path: IMGàGeneral settings à Maintain Calendar Note: - Factory calendar will be defined directly in the client. It will not be captured and transported through Transport Management. Click First Holiday calendar has to be maintained. There are two holiday calendar, 1. 2. Public holidays Specific Holiday calendar Steps involved in Calendar maintenance are • Create public holidays • Create Holiday calendar and assign the public holiday in the holiday calendar • Create Factory calendar and assign the Holiday calendar in the factory calendar. Then the holiday calendar will be assigned to the factory Calendar. Let’s now maintain public holidays. Select Radio button Public holidays Click Click Select Click Click Click Create all public holiday by repeating the above explained steps. Click Select Click Click Enter calendar id. E.g. I6 to indicate it is for IND6 Plant Enter description of the calendar. E.g. Holiday Calendar for IND6 plant. Enter valid from year and To year. E.g. From 2005 to 2025 Click Select the required public holidays to be assigned to the holiday calendar. Click Click Note: - Whenever the calendar maintenance are saved, system will give the message as shown above. Click Note: - To delete the assignment select the required holiday and click Click Click Click two times Click Maintain the entry as above. Click Click Click three times to reach the main IMG menu. 5.7 Define Default Capacity BACKGROUND This configuration setting enables to define the default capacity category for a plant. By defining the default capacity, for work center and resource, if the capacity is not defined, system will consider this default capacity detail. SCENARIO Define default capacity category for plant IND6. INSTRUCTIONS Follow the Menu Path: IMGàProductionàBasic dataàWork centerà Capacity Planningà Define default capacity Click Update the Following fields Field Plant Category Description Enter the name of the plan. E.g. IND6 Capacity category. E.g. 001 Click Maintain the details as shown above. Note: - this is the master data can be maintained inside the each resource or work center in capacity header details. 5.8 Define Work center screen sequence BACKGROUND This configuration setting enables to define the screen sequence for work center. Screen sequence setting controls the sequence of appearance of screen while creating the work center master data. Work center contains the following important tab screens • Basic view • Default values • Capacity • Scheduling • Costing SCENARIO Create a different screen sequence for work center category ZLAB. INSTRUCTIONS Follow the Menu Path: IMGàProductionàBasic dataàWork centerà Setup work center screen sequence 1. Click 2. Enter work center category ZLAB 3. Click Field No Man Description Sequence number in which tab screens are to be displayed Mandatory. Entry to be made in this tab screen if this check box is ticked. Note: - Normally this setting is not at all disturbed, except making some tab screen as mandatory. Click Impact of this configuration in Master Data / Transaction While creating the work center the sequence of Tab screen will appear as per the configuration setting done here. 6. Routing Routing explains how the product is to be manufactured. It may be compared to a process sheet in the conventional system. It contains Ø Operations to be carried out during manufacturing Ø Use of material during production Ø Use of work centers Ø Quality checks to be carried out during production 6.1 Define Standard value operation over view description in BACKGROUND This configuration setting enables to define a key to hold the standard text to be used in the routing operation. If any common operation description is to be referred in the task list (routing or in the master recipe), a standard key containing the text can be used. SCENARIO Create a standard value key text for Routing. INSTRUCTIONS Follow the Menu Path: dataàRoutingà Control dataà description in operation over view IMGàProductionàBasic Define standard value 1. Click 2. Enter task list type N for routing 3. Click 4. Click 5. Update the Following fields Field Description Language EN to denote English 1st SV Txt upto 6th SVTxt First standard value text up to value 6th standard value text value. Text entered will appear in the routing operation. 6. Click Save . Impact of this configuration in Master Data / Transaction While confirming the operation these texts will appear against the activity type. 6.2 Define Routing Status BACKGROUND This configuration setting enables to define the routing status. Routing status helps to use the routing only for specified purpose. I.e. Routing use can be restricted only for costing purpose till the costing trial is completed. Routing status can be In Process Released for costing only Released for production Selection of routing during production order or process order creation is based on the routing selection. Routing status has to be maintained in the routing header. SCENARIO Create a routing status. INSTRUCTIONS Follow the Menu Path: IMGàProductionàBasic dataàRoutingà General dataà Define routing statuses 1. Click 2. Click 3. Update the Following fields Field Description Status number Enter numeric value Description Description of the status number. E.g. Under creation, or only for costing. RelInd Released Indicator, when this is set, routing will be used in Orders. Costing Indicates, task list is released for costing. Consistency Chk Consistency check is carryout automatically when saving. 4. Click Save . Impact of this configuration in Master Data / Transaction While creating the routing status is maintained. 6.3 Define Task List usage BACKGROUND This configuration setting enables to define task list usage. Task list usage defines the specific purpose of routing. There are four important usage of Routing. • Production usage • Costing only • Sales and Distribution • Universal ( all purpose) It is possible to control the usage of routing according to its usage. SCENARIO Define routing usage for multi purpose usage. INSTRUCTIONS Follow the Menu Path: IMGàProductionàBasic dataàRoutingà General dataà Define routing usage 1. Click 2. Click 3. Update the Following fields Field Description Usage Enter the usage number. Any numeric number. E.g. 1 Description Description of the usage. E.g. Universal 4. Click Save . Impact of this configuration in Master Data / Transaction Usage of Routing has to be mentioned while creating routing 6.4 Define Reduction Strategy BACKGROUND This configuration setting enables to define reduction strategy. Reduction strategy defines the sequence of compressing the time or duration to meet the production dates. Reduction strategy can reduce the following times which are involved in scheduling • Queue time • Move time • Over lapping • Split Reduction strategy will be employed when the calculated lead time in scheduling is longer than the time between the basic dates (required start date and finish date is the basic date), the system will carry out reduction measures to reduce the lead time. Reduction is carried out step by step. After each reduction measure, the system checks whether the calculated dates are within the basic dates. If this is the case, no further reduction measures are carried out. SCENARIO Create a reduction strategy. INSTRUCTIONS Follow the Menu Path: IMGàProductionàBasic dataàRoutingà Operation dataà Define reduction strategy 1. Click 2. Click 3. Update the Following fields Field Description Plant Enter the plant to which reduction strategy is to be created. E.g. IND6 Reduction strategy key Any number to identify the reduction strategy. E.g. 1 Reduction strategy Description of Reduction strategy. E.g. Over al reduction for IND6 4. Click 5. Select the Reduction strategy key entered above 6. Double click 7. Click 8. Update the Following fields Field Description Re Reduction Level. E.g. 1 Reduction Queue Enter the % of reduction in queue time Transport Tick the check box to indicate the reduction in move time Overlap Tick the check box to indicate the reduction in move time Split Tick the check box to indicate the reduction in move time Note: - Repeat the above step as different level as shown below. 9. Click Save . Impact of this configuration in Master Data / Transaction This reduction strategy can be maintained in the Routing. 6.5 Define User Fields BACKGROUND This configuration setting enables to define user fields. User field can be used in the operation heading in the task list to define your own reference data. Maximum of six fields can be defined through the user field. SCENARIO Create user defined field. INSTRUCTIONS Follow the Menu Path: IMGàProductionàBasic dataàRoutingà Operation dataà Define user fields 1. Click 2. Click 3. Update the Following fields Field Description Field Key Enter the name of the field. E.g. OPERDT Description of the field key Enter the description. E.g. Operation detail user field Maintain the text field as shown above Impact of this configuration in Master Data / Transaction User field may be maintained at Routing operation header level. Below screen shows the user field, where the details of created by and other details can be maintained. 6.6 Define Routing Selection Automatic BACKGROUND This configuration setting enables to configure the automatic selection of routing (Task list). Task list has to be selected automatically during • • • • Production order creation (Routing) Process order creation (Master recipe) Cost estimate calculation MRP run Routing is essential to • Calculate the conversion cost • Calculate the capacity requirements • Schedule the operation • To schedule the material at right time in MRP SCENARIO Define Automatic routing selection. INSTRUCTIONS Follow the Menu Path: IMGàProductionàBasic dataàRoutingà Routing selectionà Select automatically 1. Click 2. Click 3. Update the Following fields Field ID Selection Priority Task List type Usage Status Description Selection id. E.g. 01 Priority of selection in this ID. E.g. enter from 1,2 … Mention the task list type. E.g. N for routing, 2 for master recipe Enter the Usage of this task list. E.g. 1 Enter the status of this task list. E.g. 4 Note: - Repeat the above with the same id as shown below. Impact of this configuration in Master Data / Transaction In the order type dependant parameter and MRP plant parameter configuration Selection id 01 will be mentioned. While performing the transaction (creation of process order or production order or MRP run), automatic selection of routing will be performed in the following sequence: • First system will search task list type routing as per the sequence 1 • System will search for routing with usage 1 • System will search for routing with status 4 If the above search fails, system will go to the next sequence in the same selection id. I.e. sequence no. 2 in our above shown screen shot. • system will search task list type routing as per the sequence 2 • System will search for routing with usage 1 • System will search for routing with status 2 7. Summary:We have discussed the Master data related configuration settings. You must be able to configure master data in SAP according to the business requirement in the following areas Bill Of Material Work center Routing Friends, please note that the most of the configuration settings related to master data are common to manufacturing types Discrete PPPI Repetitive The terminology only differs in the various processes. For E.g. Routing is called as master recipe in PP-PI and in repetitive routing is called as rate routing. Discrete PPPI Repetitive Routing Master Recipe Rate Routing Work center Resource Production line