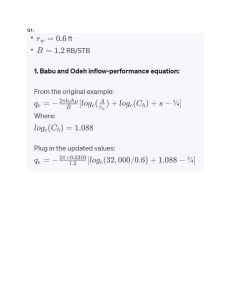

SPE-205634-MS Hazirah Abdul Uloom, Asba Madzidah Abu Bakar, M. Mifdhal Hussain, Fuziana Tusimin, Zaidi Rahimy M. Ghazali, M. Sharief Saeed Salih, M. Fakhrin A. Rasid, Sunanda Magna Bela, Latief Riyanto, M. Hafiz Othman, Syazwan A. Ghani, and Nurul Aula A'akif Fadzil, PETRONAS Copyright 2021, Society of Petroleum Engineers This paper was prepared for presentation at the SPE/IATMI Asia Pacific Oil & Gas Conference and Exhibition held virtually on 12 - 14 October, 2021. The official proceedings were published online on 4 October, 2021. This paper was selected for presentation by an SPE program committee following review of information contained in an abstract submitted by the author(s). Contents of the paper have not been reviewed by the Society of Petroleum Engineers and are subject to correction by the author(s). The material does not necessarily reflect any position of the Society of Petroleum Engineers, its officers, or members. Electronic reproduction, distribution, or storage of any part of this paper without the written consent of the Society of Petroleum Engineers is prohibited. Permission to reproduce in print is restricted to an abstract of not more than 300 words; illustrations may not be copied. The abstract must contain conspicuous acknowledgment of SPE copyright. Abstract Based on the production data from first development campaign in 2017, contamination reading of CO2 and H2S from gas production wells were observed increasing from 3% to 10% and from 3ppm to 16ppm respectively within one year production. These findings have triggered the revisit in 2019 development campaign optimization strategy in terms of material selection, number of wells, reservoir targets, and completion design. Thus, tubing material was upgraded to HP1-13CR for the upper part of tubing up to 10,000 ft-MDDF (feet measure depth drilling rig floor) to avoid SSC risk due to the geostatic undisturbed temperature is less than 80 deg C, however the material of deeper tubing remains as 13CR-L80 as per 2017 campaign. Moreover, the mercury content from first campaign was observed to be above threshold limit from intermediate reservoir based on mercury mapping exercise done in August 2018.As the mercury removal system is not incorporated in the surface facilities, the mercury reading from the well in the 2019 campaign need a close monitoring during well testing so that appropriate action can be taken in case the recorded contaminant reading is high. Dedicated zonal sampling plan to be performed if the commingle zone (total) mercury reading was recorded to be above the threshold limit, and that zones will be shut off to preserve the surface facilities. Opportunity was grabbed to optimize number of wells by completing both shallow and intermediate sections in a single selective completion to maximize the project value. However, this combination will lead to major challenges during operation due to the huge difference in reservoir pressure and permeability contrast in each perforated reservoir as the required overbalanced pressure of completion brine for shallow reservoir is much lesser than the requirement for the mildly overpressure intermediate reservoir. Thus, a potential risk of severe losses and well control is present at shallow reservoir. To mitigate this risk, loss circulation material was pre-spotted in the TCP (Tubing conveyed perforation) BHA prior to fire the gun to allow for self-curing process should losses take place. During the first development campaign, the completion tubing was running in hole in two stages. The lower completion was deployed via drill pipe and the perforated zones was secured with fluid loss device Downloaded from http://onepetro.org/SPEAPOG/proceedings-pdf/21APOG/2-21APOG/D021S010R005/2495939/spe-205634-ms.pdf by PetroVietnam University user on 03 January 2024 678 Challenges of Well Completion Design & Operation Solutions for Deep Gas Well with Multiple Producing Zone in Mildly Overpressured Reservoirs at Offshore Malaysia 2 SPE-205634-MS Introduction T field is a non-associated gas field situated in offshore Malaysia at a water depth of around 140ft. It is approximately 6 km by 3 km in areal extent, is a faulted rollover structure in a deltaic setting. Gas accumulation in the eastern part of the area is trapped by a three-way dip closure located on the downthrown side of the NE-SW (North East- South West) trending West growth fault. The western part of the field is a one-way dip closure truncated by the West fault and the North growth fault. T field consists of 68 stacked reservoirs with independent fluid contact. The reservoir depth ranging from 8,000 to 16,000ft which being grouped into three reservoirs, Shallow, Intermediate and Deep. This paper will be discussing on Shallow and Intermediate reservoirs as those were being completed in 2017 development campaign, which second campaign is being focused. Shallow and intermediate reservoir for T field were developed in two campaigns to maintain the production plateau to meet the gas sales demand. Total of five wells were drilled through first development campaign in 2017 where two wells penetrated from shallow reservoir, two wells penetrated intermediate reservoir and one well penetrated both shallow and intermediate reservoir. T field was further developed in 2019 during second development campaign, tapping on shallow and intermediate reservoir produced commingle from both reservoirs. Planning and execution of the campaign was optimized post 2017 development campaign utilizing updated reservoir information. Originally, four wells were planned to be drilled in 2019 campaign as per FDP program. Well number, design and planning were optimized and resulted in three wells successfully being drilled and completed for 2019 campaign. For 2019 drilling campaign, target reservoirs are as follow: Table 1—Summary of main reservoir section Main Reservoir Sections Reservoir intervals/Formations covered Depth (ft TVDSS- feet total vertical depth subsurface) Shallow T600- T800 reservoirs 8,600-11,300 Intermediate T810-T831 reservoirs 11,350-13,400 Downloaded from http://onepetro.org/SPEAPOG/proceedings-pdf/21APOG/2-21APOG/D021S010R005/2495939/spe-205634-ms.pdf by PetroVietnam University user on 03 January 2024 located between lower completion tubing and gravel pack packer. The upper completion tubing was then deployed and tied back to the lower completion packer. This approach was applied as mitigation to prevent fluid losses and to ensure the tubing can be safely deployed to the intended final depth. However, based on the actual performance and losses rate data during the first campaign, the completion design in second campaign was optimized and deployed in single stage. Since shallow and intermediate reservoir were combined in multiple production zones where five SSD (Sliding Side Door) were installed, the slickline option to set packer was waived due to the risk of setting tubing plug in deep wells. Pump out plug was considered as an option but then dropped due to high hydrostatic pressure. The packer setting pressure was too close to plug shear pressure. Therefore, a self-disappearing plug was utilized as it did not require any slickline intervention and can be ruptured by pressure cycle. With this option, risk of pre-mature rupture of plug was eliminated. The paper will discuss in detail each challenge mentioned above together with details calculation that was performed throughout evaluation and selection processes prior best solution being selected as these optimizations resulted in nearly three days saving of rig time, contributing to 2.6% of well cost reduction and the required number of wells were optimized to be three instead of four wells. Moreover, a safer production life of wells by selecting a suitable tubing material and eliminating the risk of mercury production above the above threshold limit. SPE-205634-MS 3 Statement of Theory and Definitions Table 2—Summary of expected contaminant Reservoirs CO2 (%) H2S(ppm) Hg gas (ug/Nm3) Hg condensate (ppb) Hg water (ppb) Shallow 3 5 <5 <10 <40 Intermediate 10 16 <10 500-1000 40-60 Note: • Above readings were based on sampling done. • Mercury reading was taken from condensate phase. Higher mercury content from intermediate reservoir wells Based on the findings, optimization is conducted to maximize drainage from shallow and intermediate section via three wells versus four wells, which improves the gas recovery to be achieved as compared to initial plan. Summary of major changes for second campaign include: • • • • • Well's number: wells number are reduced from four wells to three wells Well's location: new drainage area was identified in western area to increase the recovery due to increasing shallow GIIP (Gas Initially in Place) based on 2017 drilling data. Reservoir targets: all three wells were produced commingle targeting both shallow and intermediate reservoirs. Casing schematic design Completion design Completion design in the first campaign was rather more conservative with more mitigation measures in place due to huge uncertainties of the reservoir properties and parameters. Having said that, the completion tubing trip was segregated into two parts. The first part was to cover the entire zone of interest where the lower part of the tubing was hanged using gravel pack packer connected to ball type fluid loss valve below it and it was conveyed to the target depth via drill pipe. Once the drill pipe is pull out of hole, the upper portion of the tubing then was ran in hole sting into the seal bore at the gravel pack packer to tie back the completion tubing. By doing this, it is more confident to safely complete the well as the reservoir section with high permeability value has been isolated. Below table illustrates the pressure range for each reservoir as measured during drilling operation: Downloaded from http://onepetro.org/SPEAPOG/proceedings-pdf/21APOG/2-21APOG/D021S010R005/2495939/spe-205634-ms.pdf by PetroVietnam University user on 03 January 2024 Post 2017 campaign, there are few key subsurface findings majorly in structural, depth, targeted reservoirs and some other finding is observed that it is expected within the uncertainty range. However, collected data from the first campaign showed that there is a suspected early high-pressure ramp below T830 reservoir which is different from other offset wells where high pressure ramp is only encountered deeper than T835. Moreover, different contacts were observed in minor reservoirs in the eastern and western area. The structure was observed deeper in the intermediate reservoirs section. In term of fluids properties, CGR (Condensate Gas Ratio) at intermediate reservoirs is observed higher than initial assumption. New data acquired on the first year of production has shown a severe of contaminants levels specifically CO2 (Carbon dioxide) level which has increased from 3% to 10% and H2S (Hydrogen Sulfide) level from 3ppm (Parts per million) to 16ppm as well as high Hg (Mercury) reading in the intermediate section. This has triggered the optimization of the development strategy that included number of wells, reservoir target, type of completion and tubing material selection. The expected contaminants for shallow and intermediate reservoirs recorded from first campaign during production phase was tabulated below: 4 SPE-205634-MS Table 3—Pressure range for each reservoir in 2019 drilling campaign Actual Pressure Measured (Psia) Shallow (minor) T773 – T793 3,800-4,800 Shallow (major) T800 3,700-3,900 Intermediate (minor) T810-T812 4,100-5,300 Intermediate (major) T820-T830 5,600-6,200 During planning stage for the second campaign, actual losses rate data from post perforation and during ran in hole the completion tubing was gathered to evaluate the severity of the fluid lose risk. It was found that the losses can be reduced to minimum acceptable rate and safely proceed after loss circulation material is spotted. Table 4—Historical Data on Losses at T Field in 2017 Campaign Well Max static loses rate (barrel/hour) Max dynamic loses rate (barrel/hour) Cumulative loss during completion (barrel) A 30 70 313 B 60 100 703 C 350 40 316 D 30 7 159 Based on this actual historical data obtained from four wells, both completion design and operation were optimized by converting from dual trips system to the conventional single trip system. This decision however came with a notable challenge on the operation since it was also decided to combine the shallow and intermediate reservoir in all three wells. This will lead to an exposure of huge difference in reservoir pressure and permeability contrast in each perforated sand. The required overbalanced pressure of completion brine for shallow reservoir is much lesser than the requirement for the mildly overpressure intermediate reservoir. Thus, a potential risk of severe losses and well control will be a big operational challenge. Due to this main concern, completion assembly was conveyed to intended depth in two separate runs in the 2017 campaign. Downloaded from http://onepetro.org/SPEAPOG/proceedings-pdf/21APOG/2-21APOG/D021S010R005/2495939/spe-205634-ms.pdf by PetroVietnam University user on 03 January 2024 Reservoir SPE-205634-MS 5 Wells in T field were completed with long hole section up to 18,000ft well TD (Total Depth) and long production intervals up to 2,000ft. The long hole section has led to undetermined success of runin hole the completion tubing to the target depth in a single trip with additional of challenging slickline operation. Beside these two concerns, the long perforation intervals also possess risk of TCP (Tubing conveyed perforation) gun misfire. Although two perforation trips can eliminate this risk, single perforation trip was preferred and selected with additional bottom firing head system to provide redundancy on firing mechanism. Below is an illustration of well trajectory for all three wells. Maximum inclination is 45 degree and maximum well length is 18,095 ft. MDDF (feet measure depth drilling rig floor). Downloaded from http://onepetro.org/SPEAPOG/proceedings-pdf/21APOG/2-21APOG/D021S010R005/2495939/spe-205634-ms.pdf by PetroVietnam University user on 03 January 2024 Figure 1—Optimization of Well Completion Design from Dual to Single Run Completion 6 SPE-205634-MS Description and Application of Equipment and Processes High H2S content together with the exposure of temperature has a significant effect on SSC (Sulfide Stress Cracking) especially in low alloy steels as proven by few studies. In sour condition, with exposure of lower temperature low alloy steel would not survive and has tendency to experience SSC. Material selection for production tubing in 2019 campaign has much more focus on SSC. The main objective of tubing material selection is to avoid any risk of cracking and corrosion in the tubing throughout entire well life. Carbon and LAS (Low-alloy carbon steels) are the best option to be considered in material selection not only from the economical point of view but also due to their availability in the market. Many initiatives have been taken into consideration to increase the corrosion resistance of carbon and low-alloy steels. When the environment is too aggressive for bare carbon steels, optimum option to minimize or eliminate corrosion problems is the usage of corrosion inhibitors. However, under harsh and aggressive environment conditions and high temperatures, more expensive materials, such as CRAs (Corrosion-resistant alloys) might be a preferred alternative to be considered [1]. For production tubing design, the following table summarize the plan FDP (Field Development Plan) vs actual optimized plan: Table 5—FDP vs Actual Plan for Tubing Design FDP • • 5-1/2", 20 ppf (pound per foot), 13Cr 80ksi VAMTOP HC × 4-1/2", 12.6 ppf, 13Cr 80ksi, VAMTOP HC Optimized Plan • • • 5-1/2", 17 ppf, HP1-13Cr 95ksi, JFE Bear 5-1/2", 17 ppf, HP1-13Cr L80 JFE Bear 4-1/2", 12.6ppf, 13Cr L80, JFE Bear HP1 grade tubing was located from surface down to 10,00ft MD (Measure Depth) tubing depth due to SSC concern. Placement was decided down to 10,000ft MD is based on downhole temperature exposure. The temperature exposure on the stated depth is less than 80° F where the tubing is exposed to the risk of SSC. From 10,000ft MD to end of tubing 13Cr L80 tubing was remained as per FDP plan. The mercury content from first campaign was analyzed to be above threshold limit especially from intermediate reservoir based on mercury mapping exercise conducted in August 2018. Since the mercury removal system is not incorporated in the surface facilities, the mercury content from the wells in second campaign has been closely monitored during well testing operation. By having single selective completion, zonal sampling is doable through shifting SSD (Sliding Side Door) open or close. In the event the mercury Downloaded from http://onepetro.org/SPEAPOG/proceedings-pdf/21APOG/2-21APOG/D021S010R005/2495939/spe-205634-ms.pdf by PetroVietnam University user on 03 January 2024 Figure 2—Illustration of Well trajectory with maximum inclination of 45 degree SPE-205634-MS 7 Table 6—The Calculation for differential pressure at each reservoir section when using 10.49ppg (pound per gallon) brine INPUT OUTPUT Density required at surface (ppg) Wellbore Pressure when using 10.49ppg brine (psi) Differential Pressure (psi) Sand Depth (ft TVDSS) Pressure (psi) Density required downhole (ppg) T790-T793 11367 4778 8.31 8.57 6200.47 1422.47 T800 11929 5427 8.96 9.22 6507.03 1080.03 T808-T818 12692 5727 8.88 9.16 6923.23 1196.23 T820 12819 5090 7.84 8.13 6992.51 1902.51 T830 13290 6929 10.20 10.49 7249.43 320.43 Downloaded from http://onepetro.org/SPEAPOG/proceedings-pdf/21APOG/2-21APOG/D021S010R005/2495939/spe-205634-ms.pdf by PetroVietnam University user on 03 January 2024 content recorded to be above the threshold limit, the high mercury content contributing zones will be shut off to preserve the surface facilities and to be aligned within HSE (Health Safety and Environment) limit. To further maximize project value, the FDP target of two wells were combined into one well as single string and to produce as commingle. This is also to reduce the risk of shutting in one of the well in case high mercury is encountered. In addition, since all the three wells in second phase penetrated shallow and intermediate reservoirs, it is crucial to have good cement isolation between the two sections because intermediate reservoir is suspected to have high mercury content in certain area of the field. Good zonal isolation between shallow and intermediate reservoir allowed complete shut-off of the intermediate reservoirs if it is found to produce high mercury content. For mercury content analysis, mercury content in the produced fluid was observed to be higher than the measured mercury content during well test in appraisal well. The contaminants have been included as part of monitoring parameters during unloading. Completion design was optimized from dual to single run subsequently thorough analysis and study were performed on offset well data from 2017 campaign. The result of analysis concluded that the losses occurred exactly after perforating the formation is classified as instantaneous losses which then stabilized after short period of time post perforation operation. However, the risk of losses still exists due to high overbalance resulted from pressure variance of multiple zone (around 1,080 psi to 1,900 psi), detail of the overbalance calculation as shown below: 8 SPE-205634-MS This high differential pressure between reservoir inside wellbore becoming more significant during wellbore cleanup operation where the entire well was circulated with low density 8.3ppg sea water until the fluid properties met the required fluid cleanliness criteria NTU (Nephelometric Turbidity Unit) and TSS (Total Suspended Solid). Highest differential pressure can be seen at reservoir number 4 where the value will be 1,902 psi. Due to this concern, liner hanger packer inflow test was conducted prior wellbore cleanup operation to ensure liner hanger packer is holding and no communication exist between reservoir and wellbore throughout the underbalance scenario during circulation with seawater operation. For liner hanger packer inflow test procedure, WBCU (Wellbore clean-up) assembly will first be ran in hole to liner hanger depth. Pipe ram is closed and kill line valve is opened for return fluid monitoring. Calculated amount of base oil was first displaced into drill pipe to create underbalance condition inside the wellbore. Pressure then locked inside drill pipe to prevent u-tube effect. Wellbore test packer was set, and inflow test was conducted. Well was monitored through return fluid volume taken. Horner Graph was plotted. Horner concept stated that, if homogenous, radial flow is present in the build-up data, then a plot of pressure versus the function log((T+dt)/dt) will resulted a straight line on this plot. As a result the interpreter can extrapolate this straight line to the log (1) value on the time axis to get the pressure that would be derived if the build-up were left for a certain period. The value of T is derived by summing all the flow times prior to the build-up and is called the total flow time. The values of dt are derived by subtracting the elapsed time from the initial start time to obtain the incremental delta time. "Horner" analysis may be used when monitoring flowback or pressure buildup during an inflow test. [2] Downloaded from http://onepetro.org/SPEAPOG/proceedings-pdf/21APOG/2-21APOG/D021S010R005/2495939/spe-205634-ms.pdf by PetroVietnam University user on 03 January 2024 Figure 3—The Differential Pressure at each reservoir section when using minimum 300psi overbalance brine against the highest reservoir pressure SPE-205634-MS 9 Below is detail calculation for base oil volume required during inflow test operation. The same concept was used for unloading operation where lighter fluid was displaced inside tubing to create required drawdown to flow the well. Below are the parameters and detail calculation for lighter fluid displacement: Table 7—Parameters used for liner hanger packer inflow test calculation PARAMETERS UNIT VALUE Required Under Balance psi 1,000 Max reservoir pressure psi 6,225 Required tubing pressure psi 5,225 Total Depth ft TVDDF (feet TVD Drilling Rig Floor) 12,588 Mud weight ppg 12 Lighter fluid weight ppg 6.8 X: lighter fluid depth ft TVDDF 9,726 Downloaded from http://onepetro.org/SPEAPOG/proceedings-pdf/21APOG/2-21APOG/D021S010R005/2495939/spe-205634-ms.pdf by PetroVietnam University user on 03 January 2024 Figure 4—Horner Graph was plotted during liner hanger packer inflow test operation 10 SPE-205634-MS For losses mitigation plan, LCM (Lost circulation material) pill was pre spotted 50 ft. above perforation interval in the annulus before the gun is activated while at the same time sufficient LCM material was prepared at surface as contingency in case losses rate increase beyond acceptable limit. Specific lab test for LCM degradation test was conducted to identify suitable LCM. LCM ideally to remain intact throughout completion operation and degrade right before well clean up and unloading operation. Two formulation were tested on the lab using different LCM material which is Xanthan and Mudzymme. The main objective of the lab test was to make sure the LCM remain intact throughout completion operation which is around 5 days and degrade before well cleanup operation. Below are the lab test results for LCM degradation test. Downloaded from http://onepetro.org/SPEAPOG/proceedings-pdf/21APOG/2-21APOG/D021S010R005/2495939/spe-205634-ms.pdf by PetroVietnam University user on 03 January 2024 Figure 5—Liner hanger packer inflow test calculation SPE-205634-MS 11 Table 8—Degradation test result for Xanthan + completion fluid TEST UNITS BHR (Before Hot Rolling) PERIOD AGED Days – 1 2 3 4 TEMPERATURE °F – 280 180 180 180 pH – 9.2 9 9 8.8 8.8 PLASTIC VISC. cP 23 22 22 18 18 YIELD POINT lbs/100ft2 43 41 41 41 41 5% 5% 5% 5% Table 9—Degradation test result for 10% Mudzymme + completion fluid TEST UNITS BHR (Before Hot Rolling) PERIOD AGED Days – 1 2 3 4 TEMPERATURE °F – 280 280 280 280 pH – 9.1 9 8.7 8.7 8.7 PLASTIC VISC. cP 21 17 16 15 15 YIELD POINT lbs/100ft2 40 36 35 35 35 10% 13% 13% 13% Degradation % AHR (After Hot Rolling) Based on the lab test result, both Xanthan and Mudzymee can remain intact within five days (plan completion operation day). However, degradation period of Xanthan was relatively slower comparing to Mudzymme which may lead to the risk of well unable to be unloaded on time as per plan. Therefore, Mudzymee with 10% concentration was selected for LCM material. In the optimized single trip completion design, ability of the completion tubing to reach target depth and pull out of hole (if required) was evaluated thoroughly via T&D (Torque and Drag) analysis. For both cases slack off friction factor ranging from 0.1 to 0.5 were applied. The result as below: Figure 6—Result from Torque and Drag Simulation Result showing running parameter within acceptable limit for all RIH (Run in hole) cases where all hook load cases simulated none of them exceeding maximum yield and no buckling issue can be seen when RIH. For POOH (Pull out of hole) simulation, hook load during POOH was exceeding maximum yield of the tubing at higher FF (Friction Factor) 0.4. However, this is not a major concern as FF inside casing is usually Downloaded from http://onepetro.org/SPEAPOG/proceedings-pdf/21APOG/2-21APOG/D021S010R005/2495939/spe-205634-ms.pdf by PetroVietnam University user on 03 January 2024 Degradation % AHR (After Hot Rolling) 12 SPE-205634-MS Figure 7—Optimized plan for TCP set-up Downloaded from http://onepetro.org/SPEAPOG/proceedings-pdf/21APOG/2-21APOG/D021S010R005/2495939/spe-205634-ms.pdf by PetroVietnam University user on 03 January 2024 ranges between 0.2-0.3. After thorough discussion on this matter, it was agreed to proceed with optimized design of single run instead of dual run. Due to significant non-productive time related to slickline operation in previous historical wells, packer setting operation against slickline plug option was re-evaluated. This risk is major threat in these three wells due to the deeper well depth. High overbalance brine weight is expected to give impact in more challenging slickline operation. Thus, the option to use slickline plug was waived and intervention-less alternative option was identified. POP (Pump out Plug) was the next available option that can met the purpose at lowest price, but due to high hydrostatic pressure where the packer setting pressure was found to be too close to pressure to shear the pin at the POP. Therefore, a self-disappearing plug was selected and utilized as it did not require any slickline intervention and can be ruptured by pressure cycles. With this option, risk of premature rupture of plug was eliminated. Perforating strategy was scrutinized to make sure the whole production section able to be perforated in single run while making sure safety is prioritized. TCP (Tubing Conveyed Perforated) gun configuration was improvised to cater long interval gun length. The gun was configured with top and bottom firing head to make sure gun fire 100% and eliminate the risk of gun misfire. Furthermore, for safety reason the company internal standard, does not recommend bottom firing head ensuring the personnel will never be exposed to an armed gun string while making up, running in or pulling the gun out of the well. Due to this concern, DID (Detonation Interruption Device) was installed at the bottom firing head as safety feature to prevent gun premature activation while making up the gun connection at surface. This safety device consists of a eutectic metal that protects the initiator from the firing pin at normal surface conditions. DID consist of eutectic metal that has a very low melting point, which will remain it in a solid state and stop the explosive signal from being transmitted to the perforating assembly even after the firing head has been triggered. The eutectic metal has been selected based on minimum BHT (Bottomhole Temperature) of the well. In the condition where DID is exposed to normal surface temperatures, the eutectic metal will remain in solid state until the TCP assembly is run in the hole. When it reaches intended reservoir section and exposes to intended heat at BHT, the eutectic metal will liquified and enable the transformation of explosive signal from the firing head to the perforating assembly. In the case where the guns misfired and are pulled out of the hole, the metal will return to solid state when it is exposed to the lower temperatures as it is away from reservoir condition. This mechanism will helps preventing accidental firing of the guns at unintended depth and condition.[3] SPE-205634-MS 13 Presentation of Data and Result Despite of multiple challenges throughout the operation, all optimization and improvement plans had resulted in: Mercury reading was confirmed during well unloading and testing operation. The measurement of the contaminants content was included as part of the well unloading objectives. The confirmation was done in real time with temporary well test package since the well was yet to be tied into the permanent facilities. It is important to record the data during the well open-up so that proper baseline data can be captured prior handing over the well to Production Team for further monitoring exercise. By implementing this as well, it will confirm the mercury presence and reading so that proper HSE measures can be taken during the flowline tie in and subsequent operations. Based on the testing performed, two of the wells in second campaign exhibited considerably low levels of Mercury and CO2 concentration. Relatively higher levels of CO2 were observed in another one well with an average of 6.6 mol% which is higher than the other wells but still lower than the levels recorded during first campaign unloading data which had CO2 level of around 8%. Relatively higher levels of mercury were also observed in this one well. The main insight from the executed drilling campaigns in T field is that contaminants seem to be concentrated in the Eastern part of the reservoir, that could possibly be due to localized charging system or different source rocks, regardless of the cause, focused monitoring efforts is required in this region of the field. Below table summarizes the mercury monitoring during well unloading, which no zone shut off was decided to be done during the drilling campaign to avoid premature shut off. Further monitoring was conducted especially for Well-3: Table 10—Mercury result during unloading Well Mercury in Gas (ug/m3) Mercury in Water (ppb) Mercury in Condensate (ppb) Well-1 4.5 8.22 41.27 Well – 2 9.10 4.63 9.53 Well – 3 8.42 30.57 501.4 Post well unloading and testing, proper and cautious monitoring plan was established together with production team and frequency of further sampling and testing was redefined. This is to ensure any contaminants spike during production life can be recorded with necessary action to be taken. Downloaded from http://onepetro.org/SPEAPOG/proceedings-pdf/21APOG/2-21APOG/D021S010R005/2495939/spe-205634-ms.pdf by PetroVietnam University user on 03 January 2024 1. Successfully set packer against intervention-less plug that help to avoid potential three additional days to run slickline as contingency for pump out plug. 2. Successfully optimizing completion design from dual run to single run that have led to time saving of 2.8 days. 3. Successfully perforated 2,168 ft. net perforation interval in one single run for each well with TCP gun 100% entirely fired. Operation have been conducted safely without any incident of gun misfire with implementation of DID that reduce the risk of gun firing while making up the gun connection. 4. All three wells in 2019 campaign were successfully completed and flow at production rate 5-11% higher than target. 14 SPE-205634-MS Table 11—Monitoring plan for contaminant in T field No Plan Method/Equipment Mercury re-mapping & monitoring for all phases (gas, condensate, water) • Objective: Re-mapping at Mini test separator offshore and wellhead up to terminal and speciation test in lab onshore speciation (spot sampling is not conclusive) Strategy: To be done post well stabilization CO2 & H2S Monitoring 2 Dragger tube • • Mapping/ speciation depends on production changes and anomalies found at export line If no issue found, to be conducted once a year Daily basis at export line Conclusion This paper had discussed multiple optimization plan to manage all the challenges in well completion design and operation as solutions for deep gas well with multiple producing zones in mildly overpressure reservoirs. Tubing material selection was optimized to mitigate SSC risk, production packer has been set against intervention-less plug as an alternative of running slickline plug, completion design was optimized from dual run to single run, perforation operation has been done safely without any incident of gun misfire with implementation of DID and all three wells were successfully completed and flow at production rate higher than target. Proper monitoring plan was established in collaboration with production and subsurface team. Mercury and other contaminant content will be closely monitored throughout well production to take necessary action whenever its level spike above threshold. Consideration on well design is a dynamic process where previous actual data served as strong signal for a more comprehensive and cost effective well planning which brings value to the company. Integration with various parties is the key success in getting the actual data and optimization options can be realized by fully utilizing the actual offset data. With compilation of the actual data in-place engineering study can be more representative and highly reliable that will eventually increase the probability of success of the project. Acknowledgments This work would not have made it this far without the generous support, collaboration, and dedication from multiple stakeholders and service providers that have involved directly throughout completion planning and operation. Thus, we would like to acknowledge engineers, offshore crew and management from PETRONAS Carigali, Halliburton, Solar Alert, Petroclamp, Schlumberger, Baker Hughes, Geowell and Velesto who have contributed in this work. Thank you. References 1. 2. 3. B. Chambers and M. Gonzalez.2019. Low Temperature Effect on Sulfide Stress Crack Initiation in Low Alloy Steels. Paper Presented at the CORROSION 2019, March 24-28, 2019.NACE-2019-12856 IHS Markit. Reservoir Pressure and Horner Plots, https://www.ihsenergy.ca/support/ documentation_ca/accudst/theory/reservoir_pressure_and_horner_plots.htm (accessed 9th June 2021) Jet Research Centre (JRC). TCP Firing Systems and Ancillary Equipment https:// www.jetresearch.com/content/dam/jrc/Documents/Books_Catalogs/04_TCP.pdf (accessed 14th June 2021) Downloaded from http://onepetro.org/SPEAPOG/proceedings-pdf/21APOG/2-21APOG/D021S010R005/2495939/spe-205634-ms.pdf by PetroVietnam University user on 03 January 2024 • 1 Frequency