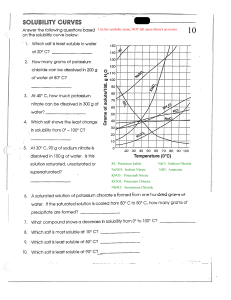

Devlon® V-API thermoplastic valve seats Innovative Thermoplastic Engineering Devlon® V-API valve seats What is Devlon® V-API? Inbuilt PMI Technology Devlon® V-API has been developed by James Walker in close cooperation with the valve industry as the answer to the search for a superior valve seat material. In Devlon V-API, James Walker has created a material that offers a cost effective solution with superior performance – performance that is protected by Positive Material Identification Technology. PMI Technology is a microscopic additive incorporated within the Devlon polymer that can be identified from the smallest sample of material. Specifically formulated to provide enhanced performance across a wide temperature and pressure range, Devlon V-API is now widely specified by valve manufacturers and has rapidly gained approval for use by major oil and gas producers. Devlon V-API is a proprietary formula developed by James Walker, which includes additives that allow the material to perform at higher pressures and temperatures than the majority of soft valve seat materials. James Walker’s total control over formulation and mixing ensures total control over quality and material provenance In safety critical applications such as valves, it is vital that the material specified is the material used. Devlon with PMI Technology gives manufacturers and end users the peace of mind that they are using genuine Devlon polymer. Physical Property ASTM Test Method Units Value Tensile strength 23°C D638 MPa 79.92 Tensile strength -40°C D638 MPa 109.52 Hardness (Dry, as cast) D785 Shore D 82/85 Deformation under load 140Kgf/cm at 23°C for 24 hrs D621 % 1.0 / 2.0 Charpy impact strength at 23°C D256 J/M 54.8 Water absorption 24 hrs D570 % 0.105 Water absorption saturation D570 % 3 Coefficient of friction 2 0.25 / 0.30 at 2000psi surface load dynamic on steel unlubricated For further details, call your local contact shown on rear cover or listed at www.jameswalker.biz Key to chart Thermoplastic materials are used in various applications throughout most industries, therefore their resistance to corrosion or chemical attack is well documented. ‘A’ No attack, possibly slight absorption. Negligible effect on mechanical properties. If a thermoplastic material absorbs or is attacked by a particular chemical either in liquid or gaseous form, then the effect on that material will depend on four factors: 1. The chemical concentration 2. Temperature 3. Applied stress ‘B’Slight attack by absorption. Some swelling and a small reduction in mechanical properties likely. ‘C’Moderate attack or appreciable absorption. Material will have limited life. ‘D’Material will decompose or dissolve in a short time. Devlon® V-API Chemical resistance CONCENTRATION WEIGHT % Devlon® V-API technical data Acetaldehyde Aq 40 B Acetamide Aq 50 A Acetic Acid Aq 10 C CHEMICAL Acetone A Allyl Alcohol A Amines D Ammonia Aq 10 Ammonia Gas Ammonium Carbonate Aq 10 Amyl Acetate 37 Amyl Alcohol 4. Duration of exposure Where aqueous solutions are shown the concentration as a weight percentage is given. Aq = Aqueous Solution When in a chemical environment allowances must be made for possible reductions in mechanical properties of plastic materials. The exception to this rule may be in the case of a bearing where the presence of liquids on the bearing surface may act as a lubricant and increase the PV limit of the material in question. SAT = Saturated Aqueous Solution CONC= Concentrated Aqueous Solution A A A Aniline When absorption only occurs, the changes in the material are generally reversible if the chemical is removed, however if chemical attack takes place the changes are permanent. A B C Antimony Trichloride Aq 10 C Barium Chloride Aq 10 A Barium Sulfate Aq 10 Benzaldehyde A B Benzene A Benzyl Alcohol C Benzoic Acid Aq SAT Beverages Aq Alcoholic Carbonated Bitumen Bleaching Lye 10 100 Boric Acid Aq C B B B B B A Butyl Acetate B Butylamine C Butyric Acid Aq 20 Butyric Acid B Butyrolactone Calcium Chloride (in Alcohol) B A 20 A Camphor A Carbon Disulfide A Carbon Tetrachloride Carnailite Aq A 10 Catechol Chloroacetic Acid Aq A C 10 Chloral Hydrate C C Chlorine Aq 10 C Chlorine Gas 100 C Chlorobenzene A Chloroform C Chlorosulfonic Acid Aq 10 C Chromic Acid Aq 1 B Citric Acid Aq 10 B Coconut Oil A Cresols D For further details, call your local contact shown on rear cover or listed at www.jameswalker.biz 3 Cupric Sulfate Aq Cyclohexane Cyclohexanol Cyclohexanone Decalin Dibutyl Phthalate Dichlorodifluoromethane Dichloroethylene Diethyl Ether Diethylene Glycol Aq Diesel Oil Dimethyl Carbinol Dimethyl Formamide Dioctyl Phthalate Dioxane Edible Oils Ethanol Aq Ethyl Acetate Ethyl Chloride Ethylene Chloride Ethylene Diamine Ethylene Glycol Aq Ferric Chloride Aq Ferrous Chloride Aq Fluorosilicic Acid Aq Fluoroethane Freon 12 (Arcton 12) Formaldehyde Aq Formic Acid Aq Fruit Juices Furfural Heptane Hexane Hydrobromic Acid Aq Hydrochloric Acid Aq Hydrofluoric Acid Aq Hydrogen Peroxide Aq Hydrogen Sulphide Aq Hydroquinone Iodine (in Alcohol) 0.1 SAT 10 2 10 B B A B A A A A A A A A B A A A A B A A B A B B C C C A A B B C B B A A C C D 4 C 1 SAT C 90 96 96 5 SAT 10 10 40 3 10 CONC B B C Isooctane A Isopropyl Alcohol B Isopropyl Ether A Lactic Acid Aq Lead Acetate Aq Lead Stearate Linseed Oil Lubricating Oils (Petroleum) Lithium Bromide Aq Magnesium Chloride Aq Magnesium Hydroxide Aq Magnesium Sulphate Aq Maleic Acid Aq Malonic Acid Aq Manganese Sulfate Mercuric Chloride Aq Mercury Methanol Methyl Acetate Methyl Ethyl Ketone Methylpyrrolidone Methylene Chloride Milk Mineral Oils Naphthalene Nitric Acid Aq Nitrobenzene Nitromethane Oleic Acid Oleum Oxalic Acid Aq Ozone Paraffin Perchloroethylene Perchloric Acid Aq Petrol Petroleum Ether Phenol Aq Phenol (Molten) Phosphoric Acid Aq Potassium Acetate Aq Potassium Bicarb. Aq Potassium Bromide Aq Potassium Carbonate Aq Potassium Chloride Aq Potassium Dichromate Aq Potassium Ferricyanide Aq Potassium Ferrocyanide Aq Potassium Hydroxide Aq 90 10 0.3 3 10 50 60 10 60 90 5 30 30 B B A A A D A A A C C A C A B A A A B A A A C D B B A D B C A B C A A D D D B C D A A A A A B B B 10 50 A C 50 10 10 10 CONC CONC 10 6 0.1 10 10 6 75 Potassium Permanganate Aq Potassium Sulfate Aq Pyridine Propane Gas Resorcinol Salicylic Acid Silicone Fluids Silver Nitrate Soap Solutions Sodium Acetate Aq Sodium Bromide Aq Sodium Carbonate Aq Sodium Chloride Aq Sodium Hydroxide Aq Sodium Hypochlorite Sodium Nitrate Aq Sodium Silicate Sodium Sulfate Aq Sodium Thiosulfate Aq Stannic Sulfate Aq Steam Stearic Acid Styrene (Monomer) Sulfur Sulfuric Acid Aq Tallow Tar Tartaric Acid Aq Tetrahydrofuran Tetralin Thionyl Chloride Toluene Transformer Oil Trichloroethylene Triethanolamine Trisodium Phosphate Aq Urea Vaseline Vegetable Oils Vinyl Chloride Water Wax (Molten) White Spirit Wines & Spirits Xylene Zinc Chloride Aq Zinc Oxide For further details, call your local contact shown on rear cover or listed at www.jameswalker.biz 1 CONC 60 10 20 10 10 50 15 50 90 10 10 2 5 10 95 10 Devlon® V-API CHEMICAL CONCENTRATION WEIGHT % Devlon® V-API CHEMICAL CONCENTRATION WEIGHT % CHEMICAL Devlon® V-API CONCENTRATION WEIGHT % Devlon® V-API technical data C A A A D A A A A B A A A A B C A A A A C D A A A C D A B B A A C A A B A B A A A A A A A B A B A 4 Devlon® V-API valve seats Pressure / temperature performance comparison 6500 (448) Extensive testing carried out at the University of Leeds in the UK and by leading global valve OEMs, compared the performance of Devlon® V-API against a range of the most common thermoplastic materials used in valve seat applications. 6000 (414) ® lon Dev 4000 (276) ™ EK PE I P V-A Differential Pressure PSI/(Bar) Nylon 6 5000 (345) 3000 (207) Devlon® V-API offers better performance 2000 (138) FE PT than standard 1000 (69) polyamides or PTFE and is significantly 0 0 (-18) 100 (38) 200 (93) 300 (149) 400 (205) 500 (260) 600 (316) Temperature ˚F /(°C) more cost-effective than PEEK™ The benefits of Devlon® V-API • Superior pressure / temperature operating range in comparison to PTFE or Nylon 6 • Total assurance of product quality and traceability with Positive Material Identification Technology • Available in diameters from 1/2” (12mm) to 77” (1950mm) • Proven in operation up to a pressure of 414bar (6000psi), subject to valve and seat design • Available in billet form or as semifinished or fully machined valve seats • Excellent ‘machineability’ allows creation of desired surface finish •S uperior dimensional stability over PTFE in high pressure applications •L ower frictional losses than PEEK™ (trademark of Victrex plc) products •E xceptional resistance to wear and abrasion • Proven in operation from -50°C (-58°F) to +176°C (+350°F), subject to valve and seat design •S ufficiently conformable to seal in low pressure valve applications • Low moisture absorption level enhances dimensional stability •E xcellent life performance in soft valve seat application For further details, call your local contact shown on rear cover or listed at www.jameswalker.biz 5 James Walker Worldwide Australia T: +61 2 9721 9500 E: sales.jwau@jameswalker.biz India T: +91 224 0808080 E: sales.in@jameswalker.biz Norway T: +47 22 75 75 00 E: sales.no@jameswalker.biz Belgium T: +32 3 820 79 00 E: sales.be@jameswalker.biz Ireland T: +353 214 323626 E: sales.ie@jameswalker.biz Singapore T: +65 6715 6300 E: sales.sg@jameswalker.biz Brazil T: +55 11 4392 7360 E: sales.br@jameswalker.biz Italy T: +39 2 2578308 E: sales.it@jameswalker.biz South Africa T: +27 31 304 0770 E: sales.za@jameswalker.biz China T: +86 21 6876 9351 E: sales.cn@jameswalker.biz Middle East T: +971 481 78888 E: sales.jwme@jameswalker.biz Spain & Portugal T: +34 94 447 00 99 E: sales.es@jameswalker.biz France T: +33 437 49 74 80 E: sales.fr@jameswalker.biz Netherlands T: +31 186 633111 E: sales.nl@jameswalker.biz UK T: +44 1270 536000 E: sales.uk@jameswalker.biz Germany T: +49 4038 60810 E: sales.de@jameswalker.biz New Zealand T: +64 9 272 1599 E: sales.nz@jameswalker.biz USA T: +1 708 754 4020 E: sales.jwna.us@jameswalker.biz Information given in this publication is given in good faith and represents the results of specific individual tests carried out by James Walker or third parties in accordance with the methodologies described in this publication, performed in a laboratory. No representation or warranty is given in relation to such information. Values and/or operating limits given in this publication are not an indication that these values and/or operating limits can be applied simultaneously. While such results may comprise useful additional information and are industry standard tests, they are no substitute for conducting (or procuring from James Walker) your own tests and engineering analysis and satisfying yourself as to the suitability of the product you select. Please also note that a product tested in accordance with the published methodology may not perform to such values in application and/or under different test conditions or methodologies for a variety of reasons, including but not limited to the environment in which it is used/tested or which passes through it or otherwise affects the product, or due to the handling, storage or installation, or due to the effect of housing or other parts. Our personnel will be happy to discuss any historical examples we have of a product having been previously used in a particular application. To ensure you are working with the very latest product specifications, please consult the relevant section of the James Walker website: www.jameswalker.biz. James Walker Sealing Products & Services Ltd Registered Office: Lion House, Oriental Road, Woking, Surrey GU22 8AP, United Kingdom. Reg no: 00264191 England Issue number 3 © James Walker 2020 JW4828 0720/PDF