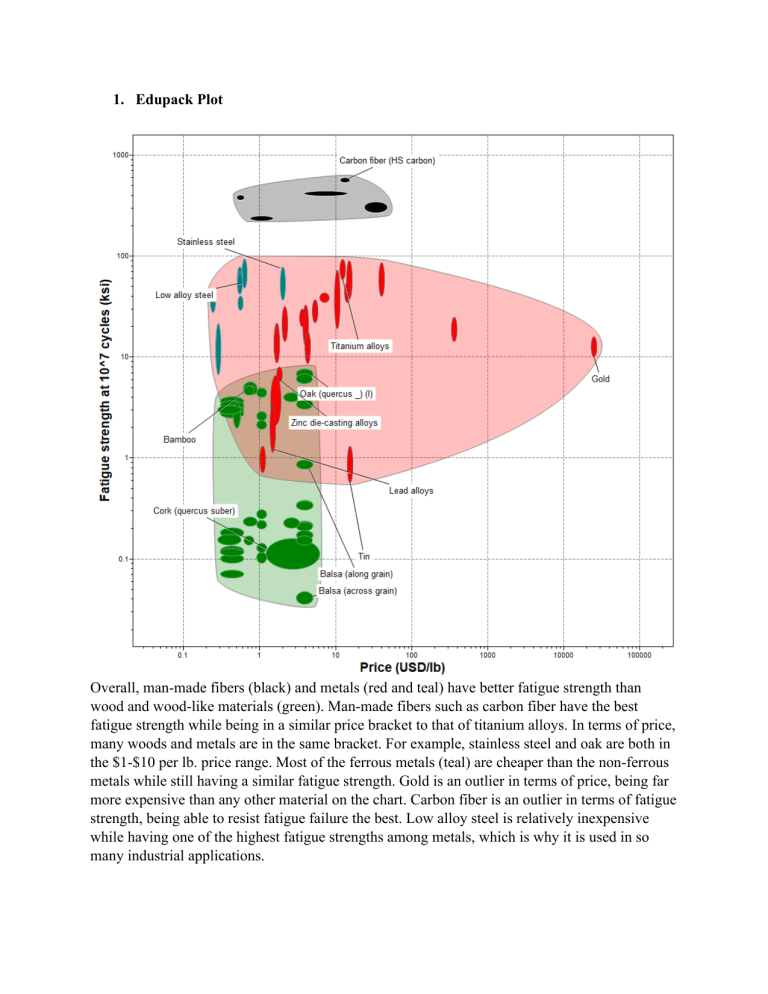

1. Edupack Plot Overall, man-made fibers (black) and metals (red and teal) have better fatigue strength than wood and wood-like materials (green). Man-made fibers such as carbon fiber have the best fatigue strength while being in a similar price bracket to that of titanium alloys. In terms of price, many woods and metals are in the same bracket. For example, stainless steel and oak are both in the $1-$10 per lb. price range. Most of the ferrous metals (teal) are cheaper than the non-ferrous metals while still having a similar fatigue strength. Gold is an outlier in terms of price, being far more expensive than any other material on the chart. Carbon fiber is an outlier in terms of fatigue strength, being able to resist fatigue failure the best. Low alloy steel is relatively inexpensive while having one of the highest fatigue strengths among metals, which is why it is used in so many industrial applications. There is an overlap between certain woods and softer metals in terms of fatigue strength and cost. For example, oak has similar price and cost as zinc die-casting alloys. Also, balsa wood has significantly better fatigue strength along the grain than across the grain. Most of the wood are in the same price range while having varying fatigue strengths, suggesting that fatigue strength is not the main factor in determining the cost of wood. This can be seen with cork and oak, which are in the same price range but have fatigue strengths orders of magnitudes apart. 2. Material Process Gold is highly malleable, resistant to corrosion, and scarce, which makes it a highly desirable metal and the reason why it is so expensive. About 90% of the global production of gold becomes bullion and jewelry and the remaining 10% is used for connections in the electronics industry. Gold can be easily investment cast, which involves making a wax pattern from a metal die. The wax pattern is then dipped into a refractory slurry and then covered in a refractory stucco. This is allowed to dry, and the procedure is repeated multiple times, creating a ceramic investment shell. After the wax is melted out and the ceramic shell is fired, molten metal is poured into the mold. This process works for metals with melting points below 2200°C, which is well above the melting point of gold at 1,064°C. Investment casting allows for very complex shapes with contours, undercuts, bosses, recesses, and other forms. Compared to die-casting, investment casting takes much longer and is much less cost-effective for high volumes. However, for small volumes, it may be less expensive than creating the dies for die casting. Thus, the combination of being able to create complex forms and cost-effectiveness for small batch production makes it ideal for creating gold jewelry. However, this process limits the gold jewelry to more bespoke pieces than mass-produced jewelry, due to the time and labor costs associated with investment casting at higher volumes. 3. Material Connexion Based on the aesthetic parameter of translucency, I choose Wizard Gel. This is a hydrogel elastomer that has self-healing properties, which means that it can stick back together even after it’s been cut. It also can retain water for several months while feeling moisturizing and it is high elastic. Furthermore, it has high toughness, which hinders knives from cutting through. The strength recovers to 60-70% of its original value after multiple cutting and healing events. Additionally, it is certified to be non-irritating and non-toxic. Based on its self-healing properties, nontoxicity, and resistance to high pressure, it could be an interesting application in pet toys. Toys made from this gel will have extended product lifespans due to their self-healing nature. Since it is also non-toxic, the toy can be chewed on as well. Furthermore, it cannot be broken easily as it has high toughness and resistance to high pressure. Additionally, it could be useful as a surgical training aid since it can be cut multiple times in the same place. It could mimic organs because it is a gel and retains moisture well. Thus, medical students could practice surgical skills on Wizard Gel molded in the shape of various organs.