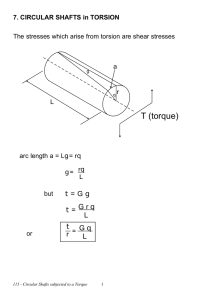

Torsion Method of Sections Torsion of Circular Elastic Bars Basic Assumptions for Circular Members • A plane section of material perpendicular to the axis of a circular member remains after the torque is applied (no warping or distortion of parallel planes normal to the axis of member takes place). • In a circular member subject to a torque, shear strains 𝛾 vary linearly from the central axis reaching 𝛾𝑚𝑎𝑥 at the periphery. - This assumptions hold only for circular and tubular members. For this class of members, these assumptions work so well that they apply beyond the limit of the elastic behaviour. Torsion formula • Internal resisting torque caused by shear stresses must be in equilibrium with externally applied torque 𝑇. • In linear elastic range, shear stresses vary linearly from the central axis of the member, since stress is proportional to strain, and the latter varies linearly from the center. Moment of Inertia of cross-sectional area: A more general relation for shear stress at any point on cross-section at distance 𝜌 from center can be written as: • Application to Circular tubes: Circular bar made from two different materials • Two materials are bonded together at the interface; therefore, the same strain assumption applies as for a solid member. • The ratio of the shear stresses at the interface is equal to the ratio of the Shear Modulus for inner and outer cores. -No interacting shear force/stress is developed between the cores at the interface (illustrated schematically in the next slide). Shear stress orientation in pure torsion: Torsion failure surfaces Example: The maximum internal torque is 30 Nm Example (4-3): Design of circular members in torsion For a shaft rotating with a frequency of 𝑓 𝐻𝑧 and transmitting a constant torque 𝑇, the work dene per second is: (1 ℎ𝑝 = 745.7 𝑊) Example: Stress Concentration Any abrupt change in geometry results in stress concentration (large perturbation of shear stresses). - The stress is determined for the smaller shaft - Shear stress at the step above the corner is entirely zero. Angle-of-Twist of Circular Members Substituting into Eq. 4-13 Example: • Great similarity is observed between the above torsion equation and the one we had for uniaxial load-displacement. • Torsion spring Example: Example: - On every imaginary cylindrical surface with radius r the applied torque is resisted by a uniformly distributed shear stress. - Shear strain is not linearly varying with radius, unlike the torsion problem - Geometric relation: - What happens if the left surface of the rubber bushing is fixed?! Statically Indeterminate Problems Global Equilibrium: Geometric Compatibility • The problem can be temporarily reduced to statically determinate problem by removing one of the redundant supports. Then the required Boundary Condition is restored by twisting the released end based on the superposition concept. Strain Energy due to torsion Elastic Strain Energy: • Strain Energy Density (per volume) • By using Hook’s law: • Elastic Strain energy of a bar under torsion: - If the external twisting torque is gradually applied to the bar, the external work is: - From equality of the internal stored elastic strain energy and the externally applied work: Torsion of Inelastic Circular Bars • As in elastic case, the twisting moment equilibrium at a cross section and the deformation assumption of linear strain variation from the axis remains applicable. • Only the difference in material properties affect the solution. • After the stress variation is known, the resisting torque can be calculated as: • The geometric strain-rotation relation is also applicable: Example: • The applied torque can be calculated using the moment equilibrium equation: • Shear stress distribution due to elastic unloading: • The initial rotation might be calculated from the twist of the elastic core. at 𝜌 = 4𝑚𝑚: 𝛾 = 2 × 10−3 - For loading: - For unloading: - Residual twist: Torsion of Solid Noncircular Members • The two assumptions considered for circular members do not apply. • Analytical solutions have been obtained for rectangular elastic members. • Maximum shear stress and angle-of-twist relations: - 𝑏 is the length of the long side and 𝑡 is the thickness of the cross section. Torsion of Thin-Walled Tubular Members • The product of wall thickness and shear stress is constant which is called Shear Flow (𝑞). • Equilibrium of the twisting moment: - 𝐴 is the area enclosed by the center line of the wall’s contour. - Eq. (4-34) is not applicable if the tube is slit. Eq. (4-30) might be used in that case. • The angle of twist can be obtained as below for elastic material: • Elastic shear strain energy: • External work per unit length: • Equilibrating the strain energy and the external work: Example: