Trim Size: 8.5in x 11in

Seader

f02.tex

V2 - 11/16/2015

7:25 P.M.

Page viii

Trim Size: 8.5in x 11in

Seader

b02.tex

V2 - 09/23/2015

Factors for Converting AE and CGS Units to SI Units

To convert from

To

Multiply by

Area

ft2

in2

m2

m2

0.0929

6.452 × 10−4

Acceleration

ft/h2

m/s2

2.352 × 10−8

Density

lbm ∕ft3

lbm ∕gal (US)

g/cm3

kg/m3

kg/m3

kg/m3 = g/L

16.02

119.8

1000

Diffusivity, Kinematic Viscosity

ft2 /h

cm2 /s

m2 /s

m2 /s

2.581 × 10−5

1 × 10−4

Energy, Work, Heat

ft-lbf

Btu (IT)

cal (IT)

erg

kW-h

J

J

J

J

J

1.356

1055

4.187

1 × 10−7

3.6 × 106

Enthalpy

Btu (IT)/lbm

cal (IT)/g

J/kg

J/kg

2326

4187

Force

lbf

dyne

N

N

4.448

1 × 10−5

Heat-Transfer Coefficient

Btu (IT)/h-ft2 -∘ F

cal (IT)/s-cm2 -∘ C

W/m2 -K

W/m2 -K

5.679

4.187 × 10−4

Interfacial Tension

lbf /ft

dyne/cm

kg/s2

kg/s2

14.59

1 × 10−4

Length

ft

in

m

m

0.3048

0.0254

Mass

lbm

ton

tonne (metric ton)

kg

kg

kg

0.4536

907.2

1000

7:15 A.M.

Page 1

Trim Size: 8.5in x 11in

Seader

b02.tex

V2 - 09/23/2015

To convert from

To

Multiply by

Mass Flow Rate

lbm ∕h

lbm ∕s

kg/s

kg/s

1.26 × 10−4

0.4536

Mass Flux, Mass Velocity

lbm ∕h-ft2

kg/s-m2

1.356 × 10−3

Power

ft-lbf /h

ft-lbf

hp

Btu (IT)/h

W = J/s

W = J/s

W = J/s

W = J/s

3.766 × 10−4

1.356

745.7

0.2931

Pressure

lbf ∕ft2

lbf ∕in2

atm

Bar

torr = mmHg

in Hg

in H2 O

Pa

Pa

Pa

Pa

Pa

Pa

Pa

47.88

6895

1.013 × 105

1 × 105

133.3

3386

249.1

Specific Heat

Btu (IT)/lbm -∘ F

cal/g-∘ C

J/kg-K

J/kg-K

4187

4187

Surface Tension

lbf /ft

dyne/cm

erg/cm2

N/m

N/m

N/m

14.59

0.001

0.001

Thermal Conductivity

Btu (I/T)-ft/h-ft2 -∘ F

cal (IT)-cm/s-cm2 -∘ C

W/m-K = J/s-m-K

W/m-K = J/s-m-K

1.731

418.7

m/s

m/s

8.467 × 10−5

0.3048

kg/m-s

kg/m-s

kg/m-s

1.488

4.134 × 10−4

0.001

kg/m-s

m3

m3

m3

0.001

0.02832

1 × 10−3

3.785 × 10−3

Velocity

ft/h

ft/s

Viscosity

lbm /ft-s

lbm /ft-h

cP

Volume

ft3

L

gal (US)

7:15 A.M.

Page 2

Trim Size: 8.5in x 11in

SEPARATION PROCESS

PRINCIPLES

with Applications Using

Process Simulators

FOURTH EDITION

J. D. Seader

Department of Chemical Engineering

University of Utah

Ernest J. Henley

Department of Chemical Engineering

University of Houston

D. Keith Roper

Ralph E. Martin Department of Chemical Engineering

University of Arkansas

Seader

ffirs.tex

V1 - 11/05/2015 3:51 P.M.

Page i

Trim Size: 8.5in x 11in

VICE PRESIDENT & DIRECTOR

SENIOR DIRECTOR

EXECUTIVE EDITOR

SPONSORING EDITOR

ASSISTANT DEVELOPMENT EDITOR

SENIOR ASSISTANT

FREELANCE PROJECT MANAGER

PROJECT SPECIALIST

FREELANCE PROJECT ASSISTANT

EXECUTIVE MARKETING MANAGER

ASSISTANT MARKETING MANAGER

ASSOCIATE DIRECTOR

SENIOR CONTENT SPECIALIST

PRODUCTION EDITOR

PHOTO RESEARCHER

COVER PHOTO CREDIT

Seader ffirs.tex

V1 - 11/11/2015 8:00 P.M.

Laurie Rosatone

Don Fowley

Linda Ratts

Mary O’Sullivan

Adria Giattino

Courtney Jordan

Ellen Keohane

Nichole Urban

Anna Melhorn

Daniel Sayre

Puja Katariwala

Kevin Holm

Nicole Repasky

Linda Christina E

Mary Ann Price

Courtesy J.D. Seader

This book was set in 10/12 Times LT Std Roman by SPi Global and printed and bound by Lightning Source Inc.

Founded in 1807, John Wiley & Sons, Inc. has been a valued source of knowledge and understanding for more than 200 years, helping people around the world

meet their needs and fulfill their aspirations. Our company is built on a foundation of principles that include responsibility to the communities we serve and

where we live and work.

In 2008, we launched a Corporate Citizenship Initiative, a global effort to address the environmental, social, economic, and ethical challenges we face in our

business. Among the issues we are addressing are carbon impact, paper specifications and procurement, ethical conduct within our business and among our

vendors, and community and charitable support. For more information, please visit our website: www.wiley.com/go/citizenship.

Copyright © 2016, 2011, 2006, 1998 John Wiley & Sons, Inc. All rights reserved. No part of this publication may be reproduced, stored in a retrieval system or

transmitted in any form or by any means, electronic, mechanical, photocopying, recording, scanning or otherwise, except as permitted under Sections 107 or

108 of the 1976 United States Copyright Act, without either the prior written permission of the Publisher, or authorization through payment of the appropriate

per-copy fee to the Copyright Clearance Center, Inc. 222 Rosewood Drive, Danvers, MA 01923, website www.copyright.com. Requests to the Publisher for

permission should be addressed to the Permissions Department, John Wiley & Sons, Inc., 111 River Street, Hoboken, NJ 07030-5774, (201)748-6011, fax

(201)748-6008, website http://www.wiley.com/go/permissions.

Evaluation copies are provided to qualified academics and professionals for review purposes only, for use in their courses during the next academic year. These

copies are licensed and may not be sold or transferred to a third party. Upon completion of the review period, please return the evaluation copy to Wiley. Return

instructions and a free of charge return shipping label are available at www.wiley.com/go/returnlabel. Outside of the United States, please contact your local

representative.

ISBN: 978-1-119-23959-8 (PBK)

ISBN: 978-1-119-22412-9 (EVALC)

Library of Congress Cataloging-in-Publication Data

Names: Seader, J. D. | Henley, Ernest J. | Roper, D. Keith.

Title: Separation process principles with applications using process

simulators / J.D. Seader, Department of Chemical Engineering, University

of Utah, Ernest J. Henley, Department of Chemical Engineering, University

of Houston, D. Keith Roper, Ralph E. Martin Department of Chemical

Engineering, University of Arkansas.

Description: Fourth edition. | Hoboken, NJ : John Wiley & Sons, Inc., 2016. |

Includes bibliographical references and index.

Identifiers: LCCN 2015021981 (print) | LCCN 2015022980 (ebook) | ISBN

9781119239598 (pbk.) | ISBN 9781119141303 (pdf) | ISBN

9781119141297 (epub)

Subjects: LCSH: Separation (Technology)–Textbooks.

Classification: LCC TP156.S45 S364 2016 (print) | LCC TP156.S45 (ebook) | DDC

660/.2842–dc23

LC record available at http://lccn.loc.gov/2015021981

Printing identification and country of origin will either be included on this page and/or the end of the book. In addition, if the ISBN on this page and the back

cover do not match, the ISBN on the back cover should be considered the correct ISBN.

Printed in the United States of America

10 9 8 7 6 5 4 3 2 1

Page ii

Trim Size: 8.5in x 11in

Seader

f01.tex

V2 - 10/16/2015

7:51 P.M.

About the Authors

J. D. Seader is Professor Emeritus of Chemical Engineering

at the University of Utah. He received B.S. (summa cum laude)

and M.S. degrees from the University of California at Berkeley

and a Ph.D. from the University of Wisconsin–Madison. From

1952 to 1959, he worked for Chevron Research in Richmond,

California, where he designed petroleum and petrochemical

processes and supervised engineering research, including

the development of one of the first computer-aided process

simulation programs and the first widely used vapor-liquid

equilibrium correlation. From 1959 to 1965, he conducted

rocket engine research on all of the engines that took man

to the moon for the Rocketdyne Division of North American

Aviation in Canoga Park, California. Before joining the faculty at the University of Utah, where he served for 37 years

from 1966 until 2003, he was a professor at the University

of Idaho. He has authored or coauthored 111 technical articles, nine books, and four patents and also coauthored the

section on distillation in the sixth and seventh editions of

Perry’s Chemical Engineers’ Handbook. His co-authored

textbooks include FLOWTRAN Simulation—An Introduction

in three editions; Equilibrium-Stage Separation Operations

in Chemical Engineering, Product & Process Design Principles in four editions; and the previous three editions of

Separation Process Principles. He was a founding member

and trustee of CACHE for 33 years, serving as executive

officer from 1980 to 1984. From 1975 to 1978, he served

as chairman of the Chemical Engineering Department at the

University of Utah. For 20 years, he directed the use and

distribution of Monsanto’s FLOWTRAN process simulation

computer program to 190 chemical engineering departments

worldwide, helping to usher in the addition of instruction in

computer-aided process design to the chemical engineering

curriculum. For 12 years, he served as an associate editor of

the journal Industrial and Engineering Chemistry Research.

He served as a director of AIChE from 1983 to 1985. In 1983,

he presented the 35th Annual Institute Lecture of AIChE; in

1988, he received the Computing in Chemical Engineering

Award of the CAST Division of AIChE; in 2004, he received

the CACHE Award for Excellence in Chemical Engineering

Education from the ASEE; and in 2004 he was a co-recipient,

with Professor Warren D. Seider, of the Warren K. Lewis

Award for Chemical Engineering Education of the AIChE.

In 2008, as part of the AIChE Centennial Celebration, he

was named one of 30 authors of groundbreaking chemical

engineering books.

Ernest J. Henley is Professor of Chemical Engineering at

the University of Houston. He received his B.S. degree

from the University of Delaware and his Dr. Eng. Sci. from

Columbia University, where he served as a professor from

1953 to 1959. Henley also has held professorships at the

Stevens Institute of Technology, the University of Brazil,

Stanford University, Cambridge University, and the City

University of New York. He has authored or coauthored

72 technical articles and 17 books. For 17 years, he was a

trustee of CACHE, serving as president from 1975 to 1976

and directing the efforts that produced the seven-volume set

of Computer Programs for Chemical Engineering Education

and the five-volume set, AIChE Modular Instruction. An

active consultant, Henley holds nine patents and has served

on the Board of Directors of 12 industrial corporations and

three philanthropies. In 1998, he received the McGraw-Hill

Company Award for “Outstanding Personal Achievement in

Chemical Engineering” and in 2002, received the CACHE

Award of the ASEE for “recognition of his contribution to the

use of computers in chemical engineering education.” He is

president of the Henley Foundation and his biography appears

in Who’s Who in America and Who’s Who in the World.

D. Keith Roper is the Charles W. Oxford Professor of

Emerging Technologies in the Ralph E. Martin Department

of Chemical Engineering at the University of Arkansas.

He is also Program Leader for the Engineering Research

Centers and Network for Computational Nanotechnology at

the National Science Foundation. He received a B.S. degree

(magna cum laude) from Brigham Young University in 1989

and a Ph.D. from the University of Wisconsin–Madison in

1994. He developed processes for cell culture, fermentation,

biorecovery, and analysis of polysaccharide, protein, DNA,

and adenoviral-vectored antigens at Merck & Co. (West

Point, PA); extraction of photodynamic cancer therapeutics

at Frontier Scientific, Inc. (Logan, UT); and virus binding

methods for Millipore Corp (Billerica, MA). Previously,

he held faculty appointments in chemical engineering and

materials science and engineering at the University of Utah.

From 2010 to 2013, he served as Assistant Director of the

Microelectronics-Photonics graduate program at the University of Arkansas. From 2012 to 2014, he served as Program

Director in the Education Engineering and Centers Division

at the National Science Foundation. He is an active consultant with industries in biotechnology, biopharmaceuticals,

iii

Page iii

Trim Size: 8.5in x 11in

iv

Seader

f01.tex

V2 - 10/16/2015

7:51 P.M.

About the Authors

chemicals, optoelectronics, and energy as well as with universities in translating discovery to disruptive innovation

through university–industry partnerships. He has authored

or coauthored more than 65 technical articles, one book,

two book chapters, three U.S. patents, and six U.S. patent

applications. He was instrumental in developing one viral and

three bacterial vaccine products, 16 Good Manufacturing Process documents, and multiple bioprocess equipment designs.

He is a fellow of the American Institute for Medical and

Biological Engineering and a member of the Arkansas

Academy of Science. He holds memberships in Tau Beta Pi,

ASEE, ACS, SPIE, and AIChE. His research examines electrodynamics in biochemical and nano-optical material systems

important to advanced biomanufacturing, biomedicine, optoelectronics, and sustainable energy, with recent advances

in computation, nanolithography, spectroscopy, and electron

microscopy of nanoplasmonic metamaterials and polymer thin

films.

Page iv

Trim Size: 8.5in x 11in

Seader

f02.tex

V2 - 11/16/2015

7:25 P.M. Page v

Preface to the Fourth Edition

INTRODUCTION

STUDENT-FRIENDLY FEATURES

Separation Process Principles was first published in 1988 to

provide a rigorous and comprehensive treatment of industrial

separation processes in the form of a student-friendly textbook

format. Both equilibrium-stage and mass-transfer (rate-based)

models were covered. Included also were chapters on thermodynamic and mass-transfer theory for separation operations.

Five of the 15 chapters began with an example of an industrial separation process and descriptions of how and why

modern process design techniques evolved. The 2006 second

edition expanded the coverage of mass-transfer-based design

methods by adding three new chapters (16, 17, and 18)

covering leaching, washing, crystallization, desublimation,

evaporation, and drying of solids. In the 2011 third edition,

the content was enlarged to include approximately 175 pages

on biochemical separations as well as a new Chapter 19

covering mechanical phase separations such as filtration

and centrifugation. The title of the third edition, Separation

Process Principles—Chemical and Biochemical Operations,

reflected this expansion.

This new condensed fourth edition focuses on material

widely taught in undergraduate separations courses and

on process simulations using Aspen Plus, CHEMCAD, and

ChemSep to design separation operations. Hence, the new title

for the fourth edition: Separation Process Principles–with

Applications Using Process Simulators. Professor Seader

began using process simulation programs in 1957 while

engaged in process design in the petroleum industry and was

the AIChE Institute Lecturer on this subject in 1984. Professor

Henley founded what is now Chemstations and was its first

president (when it was named COADE). Professor Roper

introduced simulation to vaccine process development in

1997. Authors of this fourth edition believe that students who

learn to solve separation problems with process simulators as

juniors will be well prepared to tackle difficult process design

problems in their senior year. The fourth edition provides comparisons of features of process simulators as well as examples

of how they are used to solve industrial-level design problems.

Much of the material removed from the third edition—

biochemical separation process principles in: sections of

Chapters 1, 2, 3, 8, 14, and 15; Chapters 16, 17, and 18,

and Chapter 19 on mechanical phase separations—is being

prepared by the authors for inclusion in a volume devoted to

bioseparation operations. Meanwhile, this content will remain

available from the publisher in the third edition.

Each chapter begins by stating an average of nine instructional

objectives to give the student an introduction to the author’s

expectations. In chapters that introduce separation technology,

this is followed by a flow sheet and description of an industrial

process to demonstrate how the technology is used to create

saleable products. The theory needed to design equipment or

simulate a separation operation is developed and applications

are demonstrated by more than 200 examples, many of which

make use of process simulators.

Each chapter ends with study questions suitable for class

discussion (the inverted classroom) or qualitative examination

questions. There are more than 600 homework exercises,

many of which require the use of a process simulator. Other

examples and exercises involve nonlinear equations with recommendations for using Matlab to solve them. In preparation

of the fourth edition, text was clarified based on student feedback, and errors were eliminated. Following a suggestion by

some reviewers, chapter-specific nomenclature sections have

been added. A general nomenclature lists symbols common

to many of the chapters. Each chapter-specific nomenclature

keys symbols to equations, figures, or chapter sections. These

revisions in the fourth edition reflect our desire to prepare an

accessible introduction to chemical separations that includes

the methods and equations used by process simulators and the

problems and opportunities this has created.

TOPICAL ORGANIZATION

Chapter 1 provides the student with a classification of

separation operations and an overview of industrial chemical

engineering separations. The next two chapters review thermodynamics and mass transfer, as applied to separation

operations, at a level consistent with the level of this book.

Chapter 4, which introduces design specifications, and

equilibrium flash calculations are a prerequisite for all subsequent chapters. Chapter 5, which is also a prerequisite for

all subsequent chapters, extends the single-stage concept

to multiple-equilibrium-stage processing units, including a

degrees-of-freedom analysis for determining the number of

design variables that can be specified for a given separation

process. A further prerequisite is Chapter 6, which describes

trays and packing, introduces general graphical methods,

stage efficiencies, and a transfer unit design method for

packed units.

v

Trim Size: 8.5in x 11in

vi

Seader

f02.tex

V2 - 11/16/2015

7:25 P.M. Page vi

Preface to the Fourth Edition

Once the contents of the first six chapters have been

mastered, the subsequent chapters can be studied in any

order preferred by the reader or the instructor, with a few

exceptions: (1) Concepts of minimum stage and minimum

reflux are mentioned early in the text, but a quantitative elaboration, using McCabe–Thiele diagrams, resides in Section

7.2. McCabe–Thiele diagrams are used in three other chapters

to help readers visualize concepts such as pinch points.

(2) Unique technology such as Freundlich and Langmuir

isotherms is fully developed in Chapter 15 but applied earlier.

(3) Mathematical tools such as solution methods for stiff

differential equations and the Newton–Raphson method for

solving nonlinear algebraic equations are described where

applied. In these three instances, the reader is referred to a

book section where the technique is fully developed.

To help students obtain an awareness of a section’s complexity, section titles listed in the table of contents include the

following symbols as prefixes:

∗

o

Important for a basic understanding of separations and

therefore recommended for presentation in class, unless

already covered in a previous course.

Optional because the material is descriptive, probably

covered in a previous course, or can be read outside of

class with little or no discussion in class.

• Advanced material suitable for an undergraduate course

if students are familiar with, and have access to, a process

simulator.

NEW TO THIS EDITION

The focus on using process simulators to design separation processes required some rearrangement and revision of

Chapters 1, 2, and 4 –13, which deal with operations covered

in process simulators. Many of the examples and exercises

have been revised and new ones added. Some chapters contain

correlations that stretch the state of the art. Chapter 7, for

example, develops an improved method for obtaining plate

efficiencies for sieve-tray columns that is just beginning to

appear in process simulators.

HELPUL WEBSITES In the 1980s, local computer networks began to interconnect in a global system, called the

Internet. In late 1990, Tim Berners-Lee at the European

Organization for Nuclear Research (CERN), Switzerland,

completed all the tools required for sharing information over

the Internet. This included the HyperText Transfer Protocol

(HTTP), the HyperText Markup Language (HTML), and a

document-information system called the World Wide Web

(WWW). In early 1991, the first-known web page was sent

over the internet by Lee to Paul Jones of UNC-Chapel Hill.

Physicists around the world could now quickly and efficiently

share data. Later that year, the WWW became available to

the public, but its popularity was restrained until the release

of the Mosaic web browser in December 1992. Today the

combination of a web browser (e.g., Chrome, Firefox, and

Internet Explorer) and a general search engine (e.g., Google,

Yahoo, Bing, and Ask) has made it so simple to search for

information that the number of internet users has increased

from about 400 million in 2000 to almost 3 billion (compared

to a world population of 7.2 billion) in 2014.

Some useful websites for the study of separation processes are presented in chapters of this book. However, such

websites are sometimes removed from the Internet. Readers

of this book are encouraged to conduct their own searches by

using key words. Many subjects have articles in the Wikipedia,

a free, open-ended encyclopedia on the internet. An initial

search, where the word “wiki” is added to the key word(s) is

often useful. For example, if the key words “distillation wiki”

are entered in the Google search engine, a 13-page article

appears that provides excellent background material on a wide

spectrum of the subject.

The 15 most-used websites are:

Search engines (Google, Yahoo, Bing, and Ask)

Social networking websites (Facebook, Twitter, Instagram,

LinkedIn, and Pinterest)

News, Entertainment, Purchases,

(YouTube, Amazon, eBay, MSN)

Blog creation (WordPress)

and

Information

Students using this book are encouraged to communicate

with each other and their instructors via social networking

websites to enhance their learning of separation processes.

RESOURCES FOR INSTRUCTORS

The website www.wiley.com/college/seader furnishes the following resources in the Instructor Companion Site:

1.

2.

3.

4.

5.

6.

7.

Instructor’s Solution Manual

Resources for Instructors-An introduction

Image Gallery

PowerPoint slides

Sample Preliminary Examination

Suggestions for Completing Homework Exercise

Suggested Review of Prerequisite Material

Instructors adopting this book must request a password from

their Wiley sales representative.

RESOURCES FOR STUDENTS

Students are encouraged to consult www.wiley.com/college/

seader for the following resources in the Student Companion

Site:

1. Suggestions for Completing HW Exercises

2. Suggested Review of Prerequisite Material

Trim Size: 8.5in x 11in

Seader

f02.tex

V2 - 11/16/2015

7:25 P.M. Page vii

Preface to the Fourth Edition

ACKNOWLEDGEMENTS

Since publication of the 3rd edition of this book, the authors

have received valuable comments, corrections, and suggestions from Professor Phillip R. Westmoreland of North

Carolina University, Professor Shuguang Deng of New

Mexico State University, Professor Daniel E. Rosner of Yale

University, and particularly Professor N. Lawrence Ricker of

the University of Washington.

The selection of the content for the 4th edition was greatly

influenced by the responses of reviewers to two surveys conducted by Wiley.

vii

Dr. D. Keith Roper is currently on intergovernmental

personnel assignment with the National Science Foundation.

Any opinions, findings, and conclusions or recommendations expressed in this book are those of the authors and

do not necessarily reflect the views of the National Science

Foundation.

J. D. Seader

Ernest J. Henley

D. Keith Roper

Trim Size: 8.5in x 11in

Seader

f02.tex

V2 - 11/16/2015

7:25 P.M.

Page viii

Trim Size: 8.5in x 11in

Seader ftoc.tex V1 - 10/16/2015 7:52 P.M.

Contents

About the Authors iii

Preface to the Fourth Edition

General Nomenclature xiii

Dimensions and Units xvii

v

1. Separation Processes 1

1.0∗ Instructional Objectives 1

1.1∗ Industrial Chemical Processes 1

1.2∗ Basic Separation Techniques 3

1.3⚬ Separations by Phase Creation 4

1.4⚬ Separations by Phase Addition 6

1.5⚬ Separations by Barrier 7

1.6⚬ Separations by an External Field or

Gradient 7

∗

1.7 Brief Comparison of Common Separation

Operations 8

∗

1.8 Separation Processes, Product Purity,

Component Recovery, and Separation

Sequences 9

Summary, References, Study Questions,

Exercises

2. Thermodynamics of Separation Operations 16

2.0∗ Instructional Objectives 16

2.1∗ Phase Equilibria 16

2.2∗ Ideal-Gas, Ideal-Liquid-Solution Model 20

2.3⚬ Graphical Representation of Thermodynamic

Properties 21

⚬

2.4 Nonideal Thermodynamic Property

Models 23

⚬

2.5 P-v-T Equation-of-State (EOS) Models 23

2.6⚬ Highly Nonideal Liquid Solutions 27

2.7⚬ Gibbs Excess Free-Energy (gE ) Models 29

2.8⚬ Predictive Models 34

2.9⚬ Electrolyte Solution Models 36

2.10⚬ Polymer Solution Models 36

2.11∗ K-Value Methods in Process Simulators 36

2.12∗ Exergy and Second-Law Analysis 37

Nomenclature, Summary, References, Study

Questions, Exercises

3. Mass Transfer and Diffusion 46

3.0∗ Instructional Objectives 46

3.1∗ Steady-State, Ordinary Molecular

Diffusion 47

∗

3.2 Diffusion Coefficients (Diffusivities) 51

3.3∗ Steady-State and Unsteady-State Mass Transfer

Through Stationary Media 58

∗

3.4 Mass Transfer in Laminar Flow 60

3.5∗ Mass Transfer in Turbulent Flow 68

3.6∗ Models for Mass Transfer in Fluids with a

Fluid–Fluid Interface 73

∗

3.7 Two-Film Theory and Overall Mass-Transfer

Coefficients 76

Nomenclature, Summary, References, Study

Questions, Exercises

4. Single Equilibrium Stages and Flash

Calculations 87

4.0∗ Instructional Objectives 87

4.1∗ Gibbs’ Phase Rule and Degrees of

Freedom 88

∗

4.2 Binary Vapor–Liquid Systems at

Equilibrium 89

∗

4.3 Equilibrium Two-Phase Flash Calculations 93

4.4∗ Ternary Liquid–Liquid Systems at

Equilibrium 97

4.5⚬ Multicomponent Liquid–Liquid Systems 101

4.6∗ Liquid–Solid Systems 102

4.7∗ Gas–Liquid Systems 104

4.8∗ Gas–Solid Systems 105

4.9⦁ Three-Phase Equilibrium Systems 107

Nomenclature, Summary, References, Study

Questions, Exercises

5. Multistage Cascades and Hybrid Systems 118

5.0∗ Instructional Objectives 118

5.1∗ Cascade Configurations 118

5.2∗ Single-Section Liquid–Liquid Extraction

Cascades 119

ix

Page ix

Trim Size: 8.5in x 11in

x

Seader

ftoc.tex V1 - 10/16/2015 7:52 P.M.

Contents

5.3∗

5.4⚬

5.5⚬

5.6∗

Two-Section Distillation Cascades 121

Membrane Cascades 123

Hybrid Systems 125

Degrees of Freedom and Specifications for

Cascades 125

Nomenclature, Summary, References, Study

Questions, Exercises

6. Absorption and Stripping 137

6.0∗ Instructional Objectives 137

6.1⚬ Equipment for Vapor–Liquid

Separations 138

⚬

6.2 General Design Considerations 143

6.3∗ Graphical Method for Trayed Towers 144

6.4∗ Kremser Group Method for Multicomponent

Absorption and Stripping 148

∗

6.5 Stage Efficiency and Column Height for Trayed

Columns 154

6.6∗ Flooding, Column Diameter, and Tray Layout

for Trayed Columns 161

∗

6.7 Rate-Based Method for Packed Columns 164

6.8∗ Packed-Column Liquid Holdup, Diameter,

Flooding, Pressure Drop, and Mass-Transfer

Efficiency 169

⦁

6.9 Reactive (Chemical) Absorption 180

Nomenclature, Summary, References, Study

Questions, Exercises

7. Distillation of Binary Mixtures 191

7.0∗ Instructional Objectives 191

7.1⚬ Equipment and Design Considerations 193

7.2∗ McCabe–Thiele Graphical Method for Trayed

Towers 193

⚬

7.3 Extensions of the McCabe–Thiele

Method 203

7.4∗ Estimation of Tray Efficiency for

Distillation 208

∗

7.5 Column and Reflux-Drum Diameters 215

7.6∗ Rate-Based Method for Packed Distillation

Columns 216

Nomenclature, Summary, References, Study

Questions, Exercises

8. Liquid–Liquid Extraction with Ternary

Systems 231

8.0∗ Instructional Objectives 231

8.1⚬ Equipment for Solvent Extraction 233

8.2⚬

8.3∗

8.4⚬

General Design Considerations 239

Hunter–Nash Graphical Equilibrium-Stage

Method 243

Theory and Scale-Up of Extractor

Performance 252

Nomenclature, Summary, References, Study

Questions, Exercises

9. Approximate Methods for Multicomponent

Distillation 267

9.0∗ Instructional Objectives 267

9.1∗ Fenske–Underwood–Gilliland (FUG)

Method 267

9.2∗ Using the Shortcut (FUG) Method with Process

Simulators 279

Nomenclature, Summary, References, Study

Questions, Exercises

10. Equilibrium-Based Methods for Multicomponent

Absorption, Stripping, Distillation, and

Extraction 284

10.0∗ Instructional Objectives 284

10.1∗ Simple Model for a Vapor–Liquid Equilibrium

Stage 284

⦁

10.2 Evolution of Methods for Solving the Mesh

Equations 286

∗

10.3 Strategies for Applying Process-Simulator

Methods 287

∗

10.4 Main Mathematical Procedures 291

10.5∗ Bubble-Point (BP) and Sum-Rates (SR)

Methods 294

∗

10.6 Simultaneous-Correction Method 297

10.7∗ Inside-Out Method 304

10.8⦁ Rigorous Methods for Liquid–Liquid

Extraction 309

Nomenclature, Summary, References, Study

Questions, Exercises

11. Enhanced Distillation and Supercritical

Extraction 320

11.0∗ Instructional Objectives 320

11.1∗ Use of Triangular Graphs 321

11.2∗ Extractive Distillation 332

11.3⦁ Salt Distillation 335

11.4⦁ Pressure-Swing Distillation 337

11.5⦁ Homogeneous Azeotropic Distillation 339

11.6∗ Heterogeneous Azeotropic Distillation 343

Page x

Trim Size: 8.5in x 11in

Seader ftoc.tex V1 - 10/16/2015 7:52 P.M.

Contents

11.7⦁ Reactive Distillation 352

11.8⦁ Supercritical-Fluid Extraction 357

Nomenclature, Summary, References, Study

Questions, Exercises

12. Rate-Based Models for Vapor–Liquid Separation

Operations 368

12.0⦁ Instructional Objectives 368

12.1⦁ Rate-Based Model 370

12.2⦁ Thermodynamic Properties and Transport-Rate

Expressions 372

⦁

12.3 Methods for Estimating Transport Coefficients

and Interfacial Area 375

⦁

12.4 Vapor and Liquid Flow Patterns 375

12.5⦁ Method of Calculation 376

Nomenclature, Summary, References, Study

Questions, Exercises

13. Batch Distillation 385

13.0∗ Instructional Objectives 385

13.1∗ Differential Distillation 385

13.2∗ Binary Batch Rectification 388

13.3⦁ Batch Stripping and Complex Batch

Distillation 390

⦁

13.4 Effect of Liquid Holdup 391

13.5∗ Stage-by-Stage Methods for Batch

Rectification 391

∗

13.6 Intermediate-Cut Strategy 400

13.7⦁ Optimal Control by Variation of Reflux

Ratio 401

Nomenclature, Summary, References, Study

Questions, Exercises

∗ Suitable for an UG course

⚬ Optional

⦁ Advanced

14. Membrane Separations 408

14.0∗ Instructional Objectives 408

14.1⚬ Membrane Materials 410

14.2⚬ Membrane Modules 414

14.3∗ Mass Transfer in Membranes 416

14.4∗ Dialysis 430

14.5⚬ Electrodialysis 432

14.6∗ Reverse Osmosis 434

14.7∗ Gas Permeation 438

14.8⚬ Pervaporation 441

Nomenclature, Summary, References, Study

Questions, Exercises

15. Adsorption, Ion Exchange, and

Chromatography 451

15.0∗ Instructional Objectives 451

15.1∗ Sorbents 453

15.2∗ Equilibrium Considerations 461

15.3∗ Kinetic and Transport Rate

Considerations 470

15.4⚬ Equipment for Sorption Operations 475

15.5∗ Slurry and Fixed-Bed Adsorption

Systems 479

15.6∗ Continuous, Countercurrent Adsorption

Systems 494

⚬

15.7 Ion-Exchange Cycle 502

15.8∗ Chromatographic Separations 503

Nomenclature, Summary, References, Study

Questions, Exercises

Answers to Selected Exercises

Index 521

519

xi

Page xi

Trim Size: 8.5in x 11in

Seader ftoc.tex V1 - 10/16/2015 7:52 P.M.

Page xii

Trim Size: 8.5in x 11in

Seader

f03.tex

V2 - 10/16/2015

7:52 P.M.

General Nomenclature

All symbols are defined in the text where they first appear.

The list below contains only those symbols that are common to two or more chapters.

Other symbols are listed in chapter-specific nomenclatures

at the end of each chapter.

Abbreviations and Acronyms

BWR

CSTR

CW (cw)

DAE

DDB

DDBST

DECHEMA

EM

EOS

ESA

FUG

HEPT

HETS

HHK

HK

HTU

LK

LKP

LLK

LM

LW

MSA

MW

NRTL

NTU

ODE

PR

PSRK

RK

STP

SRK

UNIFAC

UM

Benedict–Webb–Rubin EOS, §2.5

completely stirred tank or reactor, §3.6.3

cooling water, Figure 2.11

differential-algebraic equations, §13.5.2

Dortmund data bank, §2.5.3

DDB software package, §2.5.3

data bank, §2.5.3

equimolar diffusion, Table 6.5

equation of state (P-v-T relationship), §2.2

energy-separation agent, Table 1.1

Fenske–Underwood–Gilliland method, §9.1

height equivalent to a theoretical plate,

(6-68)

height equivalent to a theoretical stage,

(6-68)

heavier than the heavy key, Figure 9.6

heavy key, §9.1

height of a transfer unit, §6.8.3

light key, §9.1

Lee–Kessler–Plöcker EOS, §2.11

lighter than the light key, Figure 9.6

log mean, (3-33)

lost work, Table 2.10

mass-separation agent, Table 1.2

molecular weight

nonrandom, two-liquid model, Table 2.8

number of transfer units, Table 6.5

ordinary differential equations, §13.5.2

Peng–Robinson EOS, Table 2.8

predictive SRK method, §2.8.2

Redlich–Kwong EOS, §2.8.2

standard conditions, 1 atm, 0∘ C

Suave–Redlich–Kwong EOS, Table 2.8

functional group activity coefficient

method, Table 2.8

unimolecular diffusion, Table 6.5

UNIQUAC

VLE

VLLE

VOC

VTPR

Wilson

universal quasichemical theory method,

Table 2.8

vapor–liquid equilibrium, Figure 4.6

vapor–liquid–liquid equilibrium, §11.8

volatile organic compounds

volume-translated P-R EOS, §2.8.3

Wilson EOS, Table 2.8

Latin Symbols

Å

A

A

a

B

B

C

C

CD

CP

c

D

DAB

Di

DK

De

D

dH

dP

E

E

E

EMV

Eo

EOV

F

F

F

FD

f

Angstrom, §14.1

mass-transfer area, (3-13)

absorption factor, L/KV, (5-38)

interfacial area per unit volume, (14-5);

activity, Table 2.1

identifier for bottoms, Figure 1.12

bottoms molar flow rate, Figure 5.15

identifier for condenser, Figure 1.12

components, (4-1)

drag coefficient, Table 3.9

heat capacity at constant pressure, (2-38)

liquid concentration, moles/volume,

(3-40)

an identifier for distillate, Figure 1.12

molecular diffusivity of A in B, (3-3a)

solute diffusivity, (14-14)

Knudsen diffusivity, (14-18)

effective diffusivity, (3-49)

distillate flow rate, Figure 5.7; diameter,

(3-121)

hydraulic diameter, (14-5)

particle diameter, (6-58)

extract mass flow rate, Figure 5.2

an identifier for extract phase, Figure 5.2

extraction factor, (4-35)

Murphree vapor tray efficiency, (6-53)

stage (plate efficiency), (6-41)

Murphree vapor point efficiency, (6-51)

molar feed rate, Example 1.1

identifier for feed, Figure 1.2

Faraday’s constant, (3-47)

drag force, (6-57)

pure component fugacity, §2.1.1; Fanning

friction factor, Table 3.9

xiii

Page xiii

Trim Size: 8.5in x 11in

xiv

g

gE

gc

H

ΔH vap

HL

HOL

h

ho

J

j

jD , jH , jM

j-factor

K

KD

K ′D

k

k

L

LR

L

l

lM

M

m

N

NA

f03.tex

V2 - 10/16/2015

7:52 P.M.

General Nomenclature

fo

f

G

K

Seader

fugacity at standard state, (2-14)

partial fugacity, (2-7)

Gibbs free energy, §2.1: mass velocity,

(3-145)

Gibbs molar free energy, §2.1; gravitational

constant, (6-94)

excess free energy, (2-62)

force to mass conversion factor in AE

system of units

Henry’s law constant (2-31); vessel height,

Figure 4.18

enthalpy of vaporization, (2-43)

height of a mass-transfer unit (L) liquid or

(V) vapor, Table 6.5

height of an overall mass-transfer unit (L or

V ), Table 6.5

molar enthalpy, §2.2; heat transfer

coefficient, (15-18)

ideal gas molar enthalpy, §2.2

molar flux by molecular diffusion relative to

mixture, (3-3)

mass flux relative to mixture, (3-5)

Chilton–Colburn factors for mass, heat, and

momentum transfer (3-147)

Table 3.9

vapor–liquid equilibrium ratio (K-value),

(2-18)

various subscripted overall mass-transfer

coefficients, Tables 6.5 and 3.12, §3.7.1

distribution ratio, partition coefficient,

(2-19)

liquid–liquid equilibrium ratio in mole or

mass ratios (4-33)

various subscripted individual mass-transfer

coefficients, Tables 6.5 and 3.12, §3.7.1

thermal conductivity, (3-2)

liquid molar flow rate, Table 1.1; length,

(3-82)

liquid reflux flow rate, Figure 5.8

liquid molar flow rate in stripping section,

Figure 7.5

component liquid flow rate, (6-15); packed

height, Figure 6.25

membrane thickness, (14-1)

molecular weight

slope of equilibrium curve dy/dx, Figure

(3-16)

number of moles, (2.1); number of stages

(5-7); flux, molar flow/area (3-1)

molar trans-membrane flux, (14-1)

Avogadro’s number, (3-38)

ND

NE

NP

NV

NFr

NLe

NNu

NPe

NRe

NSc

NSh

NSt

NWe

NG

NOG

n

P

Ps

PM

PM = PM ∕lM

p

Q

q

R

R

R

r

S

S

ΔSirr

S

s

T

Tc

Tr

t

u

V

V

degrees of freedom, number of design

variables, (4-1)

number of independent equations, (4-3)

number of phases, (4-1)

number of variables, (4-1)

Froude number, Table 3.9

Lewis number, Table 3.9

Nusselt number, Table 3.9

Peclet number, Table 3.9

Reynolds number, Table 3.9

Schmidt number, Table 3.9

Sherwood number, Table 3.9

Stanton number, Table 3.9

Weber number, Table 3.9

number of gas phase (G) or liquid phase (L)

mass-transfer units, Table 6.5

number of overall gas (G) or liquid phase

(L) mass-transfer units, Table 6.5

molar flow rate, Example 1.1; mass transfer

rate, §6.5.4

pressure, (2-1); product flow rate, Figure 5.3

vapor pressure, (2-13)

permeability, KD, (14-1), (14-27)

permeance, (14-1)

partial pressure (for designated component)

rate of heat transfer, (4-17); volumetric flow

rate, (7-51)

heat flux, Q∕A, (3-2); q –line, (4-11)

universal gas constant, (3-47): retentate,

Example 1.1

reflux ratio L/D, Table 7.2; raffinate flow

rate, Figure 5.2

identifier for reflux, Example 2.5: raffinate,

Figure 4.14

radius, (3-54)

entropy (2-2); solvent flow rate, (4-32); side

stream, Table 5.4

stripping factor, (5-51)

irreversible change in entropy, Table 2.11

identifier for solvent, §4.4

molar entropy, Table 2.3

temperature, (2-1)

critical temperature, Table 15.4

reduced temperature, T/ Tc , (2-49)

time

liquid velocity, (3-71)

molar vapor flow rate, Table 1.1; volume,

(2-2)

molar vapor flow in stripping section,

Figure 7.5

Page xiv

Trim Size: 8.5in x 11in

Seader

f03.tex

V2 - 10/16/2015

7:52 P.M.

General Nomenclature

v

Ws

w

X

x

Y

y

z

Z

kinematic viscosity (6-98); vapor

component flow rate, (6-13); liquid molar

volume, (3-43); pore flow velocity, (14-2)

shaft work, Table 2.11

mass fraction, (3-5)

mass or mole ratio in liquid, (4-32)

liquid mole fraction

mass or mole ratio in vapor,

Figure 4.19

vapor mole fraction

mole fraction of feed component,

Figure 2.9

compressibility factor, (2-49)

Greek Symbols

αAB

β

γ

Δ

ε

η

μ

ρ

ρL

ρV

σ

τ

ϕ

ϕs

ϕ

̄

Φ

ω

relative volatility, KA ∕KB , (4-10)

relative selectivity, (2-21), (8-4)

activity coefficient, Table 2.1

change in value of variable

porosity, (15-2)

second-law efficiency, Table 2.10

viscosity, (3-38), chemical potential or partial

molar Gibbs free energy, (2-2)

mass density

liquid mass density, (2-41)

vapor mass density, Table 2.3

liquid surface tension, (3-43)

tortuosity, (3-49)

pure species fugacity coefficient, Table 2.1

pure species fugacity coefficient at saturation

pressure, (2-30)

partial fugacity coefficient, Table 2.1

local volume fraction, §2.7.1

acentric factor, (2-48)

xv

Subscripts

A,B,C

B

C

D

F

c

i

irr

min

j

n

R

r

sat

x

y

z

o

∞

components, Figure 5.4

bottoms, (7-4)

condenser, (7-37)

distillate, (7-4)

feed, (7-6)

critical point, §2.5

component in a mixture

irreversible

minimum

stage, Figure 10.1

stage, (6-11)

reboiler, (7-37)

reference component, (9-14)

saturated

in the x direction

in the y direction

in the z direction

datum (reference state), 1 atm., 25∘ C

infinity

Superscripts

F

N

R

s

o

*

–

′

feed, (4-32)

number of stages, (5-7): a stage, (5-15)

raffinate, Figure 5.4

saturation vapor pressure, (2-28)

reference state, Table 2.3

phase equilibrium value (with respect to

another phase), Figure 3.16

average, (3-74); partial molar property, (2-8)

derivative, (4-28); mass instead of moles, for

K and D values, etc., (4-33); normalized

values, §4.5; solute free gas or adsorbent, §6.3

Page xv

Trim Size: 8.5in x 11in

Seader

f03.tex

V2 - 10/16/2015

7:52 P.M.

Page xvi

Trim Size: 8.5in x 11in

Seader

f04.tex

V2 - 10/16/2015

7:52 P.M.

Dimensions and Units

C

hemical engineers must be proficient in the use of three systems of units: (1) the International System of Units, SI System (Systeme Internationale d’Unites), which was established

in 1960 by the 11th General Conference on Weights and Measures and has been widely

adopted; (2) the AE (American Engineering) System, which is based largely upon an English

system of units adopted when the Magna Carta was signed in 1215 and is a preferred system

in the United States; and (3) the CGS (centimeter-gram-second) System, which was devised

in 1790 by the National Assembly of France, and served as the basis for the development

of the SI System. A useful index to units and systems of units is given on the website

http://www.sizes.com/units/index.php.

Engineers must deal with dimensions units, and values to express numerical quantities.

Thus, for 10 gallons of gasoline, the dimension is volume, the unit is gallons, and the value

is 10. As detailed in NIST (National Institute of Standards and Technology) Special Publication 811, Guide for the Use of the International System of Units (SI), 2008 edition, which

is available at the website http://www.nist.gov/physlab/pubs/sp811/index.cfm, units are base

or derived.

BASE UNITS

The base units are those that are independent, cannot be subdivided, and are accurately defined.

The base units are for dimensions of length, mass, time, temperature, molar amount, electrical

current, and luminous intensity, all of which can be measured independently. Derived units

are expressed in terms of base units or other derived units and include dimensions of volume, velocity, density, force, and energy. In this book we deal with the first five of the base

dimensions. For these, the base units are:

Base Dimension

SI Unit

AE Unit

CGS Unit

Length

Mass

Time

Temperature

Molar amount

meter, m

kilogram, kg

second, s

kelvin, K

gram-mole, mol

foot, ft

pound, lbm

hour, h

Fahrenheit, ∘ F

pound-mole, lbmol

centimeter, cm

gram, g

second, s

Celsius, ∘ C

gram-mole, mol

ATOM AND MOLECULE UNITS

atomic weight = atomic mass unit = the mass of one atom

molecular weight (MW) = molecular mass (M) = formula weight∗ = formula mass∗ = the

sum of the atomic weights of all atoms in a molecule ( ∗ also applies to ions)

1 atomic mass unit (amu or u) = 1 universal mass unit = 1 dalton (Da) = 1∕12 of the mass of

one atom of carbon-12 = the mass of one proton or one neutron

The units of MW are amu, u, Da, g∕mol, kg∕kmol, or lb∕lbmol (the last three are most

convenient when MW appears in a formula).

The number of molecules or ions in one mole = Avogadro’s number = 6.022 × 1023.

xvii

Page xvii

Trim Size: 8.5in x 11in

xviii

Seader

f04.tex

V2 - 10/16/2015

7:52 P.M.

Dimensions and Units

DERIVED UNITS

Many derived dimensions and units are used in chemical engineering. Some are listed in the

following table:

Derived Dimension

SI Unit

Area = Length

Volume = Length3

Mass flow rate = Mass/Time

Molar flow rate =

Molar amount/Time

Velocity = Length/Time

Acceleration = Velocity/Time

Force = Mass ⋅ Acceleration

Pressure = Force/Area

2

Energy = Force ⋅ Length

Power = Energy/Time =

Work/Time

Density = Mass/Volume

AE Unit

2

2

CGS Unit

m

m3

kg/s

mol/s

ft

ft3

lbm /h

lbmol/h

cm2

cm3

g/s

mol/s

m/s

m/s2

newton, N = 1 kg-m/s2

pascal, Pa =

1 N/m2 =

1 kg/m-s2

joule, J =

1 N-m =

1 kg-m2 /s2

watt, W =

1 J/s =

1 N-m/s

1 kg-m2 /s3

kg/m3

ft/h

ft/h2

lbf

lbf /in.2

cm/s

cm/s2

dyne = 1 g-cm/s2

atm

ft-lbf , Btu

erg = 1 dyne-cm =

1 g-cm2 /s2 , cal

hp

erg/s

lbm /ft3

g/cm3

OTHER UNITS ACCEPTABLE FOR USE WITH THE SI SYSTEM

A major advantage of the SI System is the consistency of the derived units with the base units.

However, some acceptable deviations from this consistency and some other acceptable base

units are given in the following table:

Dimension

Base or Derived SI Unit

Acceptable SI Unit

s

m3

kg

Pa

minute (min), hour (h), day (d), year (y)

liter (L) = 10−3 m3

metric ton or tonne (t) = 103 kg

bar = 105 Pa

Time

Volume

Mass

Pressure

PREFIXES

Also acceptable for use with the SI System are decimal multiples and submultiples of SI units

formed by prefixes. The following table lists the more commonly used prefixes:

Prefix

Factor

Symbol

tera

giga

mega

kilo

deci

centi

milli

micro

nano

pico

12

T

G

M

k

d

c

m

μ

n

p

10

109

106

103

10−1

10−2

10−3

10−6

10−9

10−12

Page xviii

Trim Size: 8.5in x 11in

Seader

f04.tex

V2 - 10/16/2015

7:52 P.M.

Dimensions and Units

xix

USING THE AE SYSTEM OF UNITS

The AE System is more difficult to use than the SI System because of the units for force,

energy, and power. In the AE System, the force unit is the pound-force, lbf , which is defined to

be numerically equal to the pound-mass, lbm , at sea-level of the earth. Accordingly, Newton’s

second law of motion is written,

F=m

g

gc

where F = force in lbf , m = mass in lbm , g = acceleration due to gravity in ft∕s2 , and, to

complete the definition, the constant gc = 32.174 lbm -ft∕lbf -s2 , where 32.174 ft∕s2 is the

acceleration due to gravity at sea-level of the earth. The constant gc is not used with the SI

System or the CGS System because the former does not define a kgf and the CGS System does

not use a gf .

Thus, when using AE units in an equation that includes force and mass, incorporate gc to

adjust the units.

EXAMPLE OF UNIT CONVERSIONS

A 5.000-pound-mass weight, m, is held at a height, h, of 4.000 feet above sea-level. Calculate its potential energy above sea-level, P.E. = mgh,

using each of the three systems of units. Factors for converting units are given on the inside front cover of this book.

SI System:

m = 5.000 lbm = 5.000(0.4536) = 2.268 kg

g = 9.807 m∕s2

h = 4.000 ft = 4.000(0.3048) = 1.219 m

P.E. = 2.268(9.807)(1.219) = 27.11 kg-m2∕s2 = 27.11 J

CGS System:

m = 5.000 lbm = 5.000(453.6) = 2268 g

g = 980.7 cm∕s2

h = 4.000 ft = 4.000(30.48) = 121.9 cm

P.E. = 2268(980.7)(121.9) = 2.711 × 108 g-cm2∕s2

= 2.711 × 108 erg

AE System:

m = 5.000 lbm

g = 32.174 ft∕s2

h = 4.000 ft

P.E. = 5.000(32.174)(4.000) = 643.5 lbm -ft2∕s2

However, the accepted unit of energy for the AE System is ft-lbf , which is obtained by dividing by gc . Therefore, P.E. = 643.5/32.174 =

20.00 ft-lbf .

Another difficulty with the AE System is the differentiation between energy as work and energy as heat. As seen in the preceding table,

the work unit is ft-lbf , while the heat unit is Btu. A similar situation exists in the CGS System with corresponding units of erg and calorie

(cal). In older textbooks, the conversion factor between work and heat is often incorporated into an equation with the symbol J, called Joule’s

constant or the mechanical equivalent of heat, where

J = 778.2 ft-lbf ∕Btu = 4.184 × 107 erg∕cal

Thus, in the previous example, the heat equivalents are

AE System:

20.00∕778.2 = 0.02570 Btu

CGS System:

2.711 × 108 ∕4.184 × 107 = 6.479 cal

Page xix

Trim Size: 8.5in x 11in

xx

Seader

f04.tex

V2 - 10/16/2015

7:52 P.M.

Dimensions and Units

In the SI System, the prefix M, mega, stands for million. However, in the natural gas and petroleum industries of the United States, when

using the AE System, M stands for thousand and MM stands for million. Thus, MBtu stands for thousands of Btu, while MM Btu stands for

millions of Btu.

It should be noted that the common pressure and power units in use for the AE System are not consistent with the base units. Thus, for

pressure, pounds per square inch, psi or lbf /in.2 , is used rather than lbf /ft2 . For power, Hp is used instead of ft-lbf /h, where the conversion

factor is

1 hp = 1.980 × 106 ft-lbf ∕h

CONVERSION FACTORS

Physical constants may be found on the inside back cover of this book. Conversion factors are

given on the inside front cover. These factors permit direct conversion of AE and CGS values

to SI values. The following is an example of such a conversion, together with the reverse

conversion.

EXAMPLE

1. Convert 50 psia (lbf /in.2 absolute) to kPa:

The conversion factor for lbf /in.2 to Pa is 6,895, which results in

50(6, 895) = 345,000 Pa or 345 kPa

2. Convert 250 kPa to atm:

250 kPa = 250,000 Pa. The conversion factor for atm to Pa is 1.013 × 105 . Therefore, dividing by the conversion factor,

250,000∕1.013 × 105 = 2.47 atm

Three of the units [gallons (gal), calories (cal), and British thermal unit (Btu)] in the list of conversion factors have two or more definitions.

The gallons unit cited here is the U.S. gallon, which is 83.3% of the Imperial gallon. The cal and Btu units used here are international (IT).

Also in common use are the thermochemical cal and Btu, which are 99.964% of the international cal and Btu.

FORMAT FOR EXERCISES IN THIS BOOK

In numerical exercises throughout this book, the system of units to be used to solve the problem

is stated. Then when given values are substituted into equations, units are not appended to the

values. Instead, the conversion of a given value to units in the above tables of base and derived

units is done prior to substitution into the equation or carried out directly in the equation, as

in the following example.

EXAMPLE

Using conversion factors on the inside back cover of this book, calculate a Reynolds number, NRe = Dvρ∕μ, given D = 4.0 ft, v = 4.5 ft∕s,

ρ = 60 lbm ∕ft3 , and μ = 2.0 cP (i.e., centipoise).

Using the SI System (kg-m-s),

NRe =

Dvρ

[(4.00)(0.3048)][(4.5)(0.3048)][(60)(16.02)]

=

= 804,000

μ

[(2.0)(0.001)]

Using the CGS System (g-cm-s),

NRe =

Dvρ

[(4.00)(30.48)][(4.5)(30.48)][(60)(0.01602)

=

= 804,000

μ

[(0.02)]

Using the AE System (lbm -ft-h) and converting the viscosity 0.02 cP to lbm /ft-h,

NRe =

Dvρ

(4.00)[(4.5)(3600)](60)

=

= 804,000

μ

[(0.02)(241.9)]

Page xx

Trim Size: 8.5in x 11in

Chapter

Seader

c01.tex

V2 - 10/16/2015

10:38 A.M.

1

Separation Processes

§1.0 INSTRUCTIONAL OBJECTIVES

After completing this chapter, you should be able to:

• Explain the role of separation operations in the chemical industries.

• Enumerate the four basic separation techniques.

• Explain the uses of energy-separating agents (ESA) and mass-separating agents (MSA).

• Calculate component material balances around a separation operation based on specifications of component recovery

and/or product purity.

• Understand the concept of sequencing of separation operations, particularly distillation.

S

eparation processes for chemical mixtures have been known

for millennia. Early civilizations developed processes for:

(1) extraction of metals from ores, perfumes from flowers,

dyes from plants, and potash from burnt plants; (2) evaporation of seawater to obtain salt; (3) refining of rock asphalt; and

(4) distilling of liquors. The human body could not function

if it had no kidney to separate water and waste products from

blood.

Chemical engineers design large-scale facilities that employ separation methods that most often differ considerably

from those used by chemists in laboratories. For example, chemists separate light-hydrocarbon mixtures by chromatography, while a manufacturing plant uses distillation to separate

the same mixture. This book discusses methods for the

design of large-scale separation operations for processes that

manufacture chemical products economically. Included are

all of the most common operations, including distillation (both

continuous and batch), gas absorption, stripping, liquid–liquid

extraction, membrane separations, and gas and liquid adsorption. These design methods are incorporated into commercial

computer-aided process simulators such as Aspen Plus,

Aspen HYSYS, CHEMCAD, ChemSep, ProSimPlus, and

UniSim.

Chemical engineers also design small-scale industrial separation systems involving manufacture of specialty chemicals

by batch processing; recovery of biological solutes; crystal

growth of semiconductors; recovery of chemicals from wastes;

and products such as lung oxygenators, espresso machines,

and hemodialysis devices. A companion book, Bioseparation

Process Principles, covers these smaller-scale processes and

the principles of bioseparations. Included in that book are

membranes and adsorption for bio applications, chromatography, electrophoresis, leaching, crystallization, drying, and

mechanical separation operations. Both large- and small-scale

operations are illustrated in examples and homework exercises

in this book and in Bioseparation Process Principles.

§1.1 INDUSTRIAL CHEMICAL PROCESSES

Chemical companies manufacture products that differ from

those in the feedstocks. Included can be (1) naturally occurring

living or nonliving materials; (2) chemical intermediates that

are precursors for producing other chemicals; (3) “chemicals

in commerce” that can be purchased from the global market;

or (4) waste products that can be processed into valuable

products. Especially common are oil refineries, which process

crude oil, synthetic crude oil from tar sands, and tight oil from

the use of horizontal drilling followed by fracking of shale

deposits, to produce a variety of hydrocarbon-based products.

For example, starting in 1967, Canada began increasing its

oil production dramatically by processing tar sands from the

huge Athabasca deposit in the province of Alberta. Figure 1.1

shows the initial products produced by Great Canadian Oil

Sands Ltd. (GCOS), now Suncor Energy, from its 1967 plant.

The products are the result of numerous separation operations within the plant. By 2013, several Canadian companies

produced more than 1.6 million barrels per day (bbl/day)

of synthetic crude oil (syncrude). Because Canada produces

more oil than it needs, it exports syncrude to the United

States by the Keystone Pipeline. If phases 3 and 4 of the

pipeline are completed, Canadian syncrude will flow more

than 2,000 miles from the Keystone Hardisty Terminal in

Alberta, Canada, to the Gulf near Houston, Texas.

Chemical plants operate in a batchwise, continuous, or

semicontinuous manner. Plant operations may be key operations unique to chemical engineering because they involve

changes in chemical composition, or auxiliary operations

that are necessary to the success of the key operations but

are often designed by mechanical engineers because they

do not involve changes in chemical composition. The key

operations involve (1) chemical reactions and (2) separation

of chemical mixtures, such as the separation of a mixture of

chemicals into pure, or nearly pure, species (components).

1

Page 1

Trim Size: 8.5in x 11in

2

Chapter 1

Seader

c01.tex

V2 - 10/16/2015

10:38 A.M.

Separation Processes

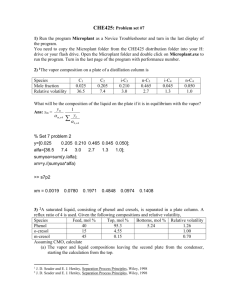

Plant fuel oil and fuel gas

Sulfur

5

2.85 × 10 kg/day (314 tons/day)

Naphtha

2560 m3/day

(16,100 bbl/day)

Tar sands

8.41 × 107 kg/day

(92,700 tons/day)

Kerosene

GCOS

Plant

1685 m3/day

(10,600 bbl/day)

Natural gas

Synthetic

crude

7154 m3/day

(45,000 bbl/day)

Gas oil

Water

2909 m3/day

(18,300 bbl/day)

Coke

6

2.36 × 10 kg/day (2,600 tons/day)

Tailings

7.22 × 107 kg/day

(79,600 tons/day)

Figure 1.1 GCOS process for producing synthetic crude oil from Canadian Athabasca tar sands.

The auxiliary operations include phase separation (e.g., separation of gas from liquid or separation of two immiscible

liquid phases), heat addition or removal (heat exchangers),

shaft-work (pumps, compressors, turbines), mixing or dividing of streams, solids agglomeration, size reduction of solids,

and separation of solids by size.

Block-flow diagrams can represent key operations in

chemical processes. They indicate, by square or rectangular

blocks, only the chemical reaction and separation steps and,

by connecting lines, the process streams. More detail is shown

in process-flow diagrams, which also include auxiliary

operations and utilize icons that depict the particular type of

equipment employed. Figure 1.2 shows a block-flow diagram

for manufacturing hydrogen chloride gas from chlorine and

hydrogen. Central to the process is a chemical reactor, where

the gas-phase combustion reaction, H2 + Cl2 → 2HCl, occurs.

In this process, no separation operations are necessary because

of the complete conversion of chlorine and the absence of any

side reactions. A slight excess of hydrogen is used, and the

Figure 1.2 Synthetic process for anhydrous HCl production.

product, 99% HCl, with small amounts of H2 , N2 , H2 O, CO,

and CO2 , requires no purification. However, simple process

flowsheets that do not require separation operations are rare.

In most process flowsheets, separation operations dominate.

Most industrial chemical processes involve at least one

chemical reactor accompanied by one or more separation

operations. An example is the continuous hydration of ethylene with water to produce ethyl alcohol, shown in Figure 1.3.

Central to the process is a reactor packed with catalyst particles, in which the reaction C2 H4 + H2 O → C2 H5 OH occurs.

Due to chemical equilibrium limitations, conversion of ethylene is only 5% per pass through the reactor. However, by

recovering unreacted ethylene, in a partial condensation separation step, and recycling the ethylene to the reactor, nearly

complete overall conversion of the ethylene feed is achieved.

Recycling is a common element of chemical processes.

If pure ethylene were available as a feedstock and no

side reactions occurred, the simple process in Figure 1.3

could be realized. It utilizes a reactor, a partial condenser

for unreacted gaseous ethylene recovery, and distillation to

produce an overhead distillate of aqueous ethyl alcohol of

near-azeotropic composition (93 wt%), with a wastewater

bottoms product. Unfortunately, impurities in the ethylene

feed, together with side reactions involving ethylene and the

impurities, increase the number of separators required for the

process, as shown in Figure 1.4. Also, as shown, an additional

reactor may be necessary to convert impurities or by-products

to other chemicals that can be more easily separated from the

main product. Such an escalation of the need for separation

operations is common. Thus, most chemical processes include

many more separation operations than chemical reactors.

Page 2

Trim Size: 8.5in x 11in

Seader

c01.tex

§1.2

V2 - 10/16/2015

10:38 A.M.

Basic Separation Techniques

3

Figure 1.3 Process for hydration of ethylene

to ethanol.

Figure 1.4 Industrial process for hydration of ethylene to ethanol.

Chemical engineers also design products that can involve

separation operations. One such product is the espresso coffee

machine. Very hot water rapidly leaches desirable chemicals

from the coffee bean, leaving behind ingredients responsible

for undesirable acidity and bitterness. The resulting cup of

espresso has (1) a topping of creamy foam that traps the

extracted chemicals, (2) a fullness of body due to emulsification, and (3) a richness of aroma. Typically, 25% of the coffee

bean is extracted and the espresso contains less caffeine than

filtered coffee. Cussler and Moggridge [1] and Seider, Seader,

Lewin, and Widagdo [2] discuss other examples of products

designed by chemical engineers that involve the separation of

chemical mixtures.

§1.2 BASIC SEPARATION TECHNIQUES

The separation of a chemical mixture into its components is

not a spontaneous process, like the mixing by diffusion of

soluble components. Separations require energy in some form.

A mixture to be separated into its separate chemical species

is usually a single, homogeneous phase. If it is multiphase, it

is often best to first separate the phases by gravity or centrifugation, followed by the separation of each phase mixture.

A schematic of a general separation process is shown in

Figure 1.5. The phase state of the feed can be a vapor, liquid,

or solid mixture. The products of the separation differ in

composition from the feed and may differ in the state of the

Page 3

Trim Size: 8.5in x 11in

4

Chapter 1

Seader

c01.tex

V2 - 10/16/2015

10:38 A.M.

Separation Processes

Figure 1.5 General separation process.

phase. The separation is accomplished by inducing the different chemical species in the feed to partition among the

different product phases. Four basic methods for doing this

are shown in Figure 1.6. Most common is the phase creation

technique in Figure 1.6a. For example, the feed may be a liquid

mixture. By heating the mixture to partially vaporize the liquid, the more-volatile components tend to move to the vapor,

while less-volatile components tend to remain in the liquid

phase. Alternatively, the feed may be a vapor that is partially

condensed.

A second technique, labeled phase addition, is shown in

Figure 1.6b. For example, a liquid solvent may contact a liquid feed to selectively dissolve certain species from the feed.

Less common is the third separation technique that uses a barrier, such as a membrane, as shown in Figure 1.6c. The barrier

allows passage of certain species in the feed while excluding or slowing other species. Finally, in a fourth technique,

an external force field or gradient is used to preferentially

attract certain species in the feed as indicated in Figure 1.6d.

The force field might be electrical or centrifugal.

For the techniques of Figure 1.6, the rate of separation

is governed by the rates of mass transfer of the different

components, while the extent of separation is limited by thermodynamic equilibrium. These two topics are the subject of

previous chemical engineering courses, but are reviewed here

in Chapters 2 and 3. Also, fluid mechanics and heat transfer play important roles in the separation of mixtures, and

their principles are applied, where appropriate, throughout

this book.

The extent of separation achieved depends on the exploitation of differences in molecular, thermodynamic, and transport

properties of the species in the feed mixture. Of importance are

molecular weight, molecular shape, dipole moment, electric

charge, vapor pressure, solubility, adsorptivity, and diffusivity.

Values of these properties appear in handbooks, reference

books, textbooks, and journals. Many can be obtained from

physical property models in process-simulation programs.

When properties are not available, they are estimated or

determined experimentally.

§1.3 SEPARATIONS BY PHASE CREATION

The simplest and most widely used industrial separation technique is phase creation. The feed to the separator is a singlephase vapor, liquid, or solid. The second phase is created by the

transfer of energy to or from the feed by an energy-separating

agent (ESA). The ESA can be heat transfer or shaft work by

means of compression or by the reduction of pressure through

a turbine or across a valve. After sufficient time and agitation

to approach phase equilibrium, the product phases are separated. The size of the process vessel depends on the flow rate

in and out of the vessel and the time for the phases to approach

equilibrium.

The most common separation operations using phase

creation are listed in Table 1.1. For these operations, design

procedures are well established and are included as unit

operation models in commercial process simulators.

When the feed mixture is a vapor or a liquid with components that differ widely in volatility (e.g., hydrogen and

benzene), partial condensation or partial vaporization,

Operation (1) in Table 1.1, may be adequate to achieve the

desired separation. Heat is transferred to or from the feed in

a heat exchanger followed by phase separation by gravity in a

vessel. Partial vaporization of a liquid occurs in flash vaporization, Operation (2), by reducing the feed pressure with a

valve or turbine, followed by phase separation. Both of these

separation operations are referred to as single equilibrium

stages because experimental evidence shows that interphase

Figure 1.6 Basic separation process

techniques: (a) separation by phase

creation; (b) separation by phase addition;

(c) separation by barrier; (d) separation by

external force field or gradient.

Page 4

Trim Size: 8.5in x 11in

Seader

c01.tex

§1.3

V2 - 10/16/2015

10:38 A.M.

Separations by Phase Creation

5

Table 1.1 Common Separation Operations Based on Phase Creation

Separation Operation

Symbol

Feed Phase

Created Phase

Separating Agent(s)

Vapor and/or liquid

Liquid or vapor

Heat transfer (ESA)

Liquid

Vapor

Pressure reduction

Vapor and/or liquid

Vapor and liquid

Heat transfer (ESA) and

sometimes shaft work (ESA)

V

(1) Partial condensation

or vaporization

V/L

L

V

(2) Flash

vaporization

L

L

L

(3) Distillation

V/L

L

and 1.7c, the phases are in continuous contact with other. In the

first case, randomly dumped ceramic, metal, or plastic rings

or saddles, called packing, promote turbulence as the vapor

follows a tortuous path through the liquid, which flows over

and through the packing. In the latter case, stacked, structured

packing is used in the form of metal or plastic meshes, grids,

or coils. Depending on the efficiency of the packing, inches or

feet of packed height are equivalent to an equilibrium stage.

In the icon for distillation in Table 1.1, horizontal lines within

the column indicate the stages. As vapor flows up the column,

it is increasingly enriched with respect to the more volatile

species. The liquid flowing down the column is increasingly

enriched with respect to the less-volatile species.

Feed to a distillation column enters at a stage somewhere

between the top and bottom stages. Any vapor in the feed starts

up the column; feed liquid starts down. Liquid is also required

for making contacts with vapor above the feed stage, and vapor

mass transfer of species is so rapid that phase equilibrium

is closely approached. The liquid product is enriched with

respect to the less volatile species, while the vapor product

is enriched with respect to the more volatile species. These

operations are discussed in Chapter 4.

When the degree of separation by a single equilibrium

stage is inadequate because the volatility differences among

key species are insufficiently large (e.g., benzene and toluene),

distillation, Operation (3) in Table 1.1, with multiple stages,

often becomes the separation method of choice. It is and

has long been the most widely utilized industrial separation method. Distillation involves vigorous mixing during

contacts between countercurrently flowing liquid and vapor

phases. Figure 1.7 shows schematics of three widely used

phase-contacting methods. Figure 1.7a depicts a series of

trays, where the phases are mixed and then disengaged. Each

tray is some fraction of an equilibrium stage. In Figures 1.7b

Tray

Dumped packing

L

L

V

V

Structured packing

L

V

V

V

Tray 1

Downcomer

Tray 2

Tray 3

L

(a)

Figure 1.7 Phase-contacting methods in distillation columns.

L

V

V

(b)

V

L

V

V

(c)

V

Page 5

Trim Size: 8.5in x 11in

6

Chapter 1

Seader

c01.tex

V2 - 10/16/2015

10:38 A.M.

Separation Processes

is also required for making contacts with liquid below the feed

stage. Therefore, at the top of the column, vapor is condensed

to provide distillate product and down-flowing liquid (reflux).

Similarly, part of the liquid at the bottom is removed as bottoms product, while the other part passes through a reboiler,