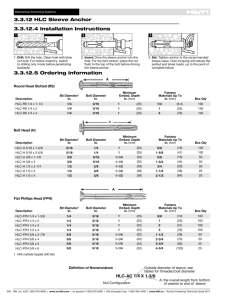

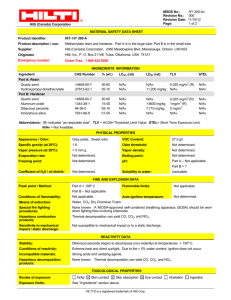

Hilti PROFIS Engineering 3.0.88 www.hilti.group/content/hilti/CP/XX/en/non-transactional/light-pages/middle-east.html Company: Address: Phone I Fax: Design: Fastening point: | Concrete - Nov 1, 2023 Page: Specifier: E-Mail: Date: 1 11/1/2023 Specifier's comments: 1 Anchor Design 1.1 Input data Anchor type and diameter: HIT-RE 500 V4 + AM (8.8) M16 Return period (service life in years): 50 Item number: 407499 AM 8.8 M16x1000 (element) / 2287554 HIT-RE 500 V4 (adhesive) Effective embedment depth: hef,opti = 114.0 mm (hef,limit = 114.0 mm) Material: 8.8 Evaluation Service Report: ETA 20/0541 Issued I Valid: 6/9/2023 | - Proof: Design Method ETAG BOND (EOTA TR 029) Stand-off installation: Anchor plate CBFEM : eb = 0.0 mm (no stand-off); t = 20.0 mm lx x ly x t = 350.0 mm x 300.0 mm x 20.0 mm; Profile: Advance UKC, 203 x 203 x 46; (L x W x T x FT) = 203.2 mm x 203.6 mm x 7.2 mm x 11.0 mm Base material: cracked concrete, C40/50, fc,cube = 50.00 N/mm ; h = 150.0 mm, Temp. short/long: 30/40 °C Installation: hammer drilled hole, Installation condition: Dry Reinforcement: no reinforcement or reinforcement spacing >= 150 mm (any Ø) or >= 100 mm (Ø <= 10 mm) 2 no longitudinal edge reinforcement CBFEM - The anchor calculation is based on a component-based Finite Element Method (CBFEM) Geometry [mm] & Loading [kN, kNm] Input data and results must be checked for conformity with the existing conditions and for plausibility! PROFIS Engineering ( c ) 2003-2023 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan 1 Hilti PROFIS Engineering 3.0.88 www.hilti.group/content/hilti/CP/XX/en/non-transactional/light-pages/middle-east.html Company: Address: Phone I Fax: Design: Fastening point: Page: Specifier: E-Mail: Date: | Concrete - Nov 1, 2023 2 11/1/2023 1.1.1 Load combination Case Description Forces [kN] / Moments [kNm] Seismic Fire Max. Util. Anchor [%] 1 Combination 1 N = -161.745; Vx = 14.254; Vy = 4.523; Mx = 3.968; My = 11.914; Mz = 0.000; Nsus = 0.000; Mx,sus = 0.000; My,sus = 0.000; no no 21 2 C-2 N = -82.925; Vx = 7.423; Vy = 20.989; Mx = 18.722; My = 6.105; Mz = 0.000; Nsus = 0.000; Mx,sus = 0.000; My,sus = 0.000; no no 100 1.2 Load case/Resulting anchor forces y Controlling load case: 2 C-2 3 4 Tension Anchor reactions [kN] Tension force: (+Tension, -Compression) Anchor Tension force Shear force Shear force x Shear force y 1 -0.003 5.553 1.916 5.212 2 -0.004 5.400 1.797 5.093 3 32.459 5.610 1.888 5.283 4 22.133 5.700 1.823 5.401 x 1 2 Compression resulting tension force in (x/y)=(-25.5/110.0): 54.585 [kN] resulting compression force in (x/y)=(32.3/-91.6): 142.220 [kN] Anchor forces are calculated based on a component-based Finite Element Method (CBFEM) Input data and results must be checked for conformity with the existing conditions and for plausibility! PROFIS Engineering ( c ) 2003-2023 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan 2 Hilti PROFIS Engineering 3.0.88 www.hilti.group/content/hilti/CP/XX/en/non-transactional/light-pages/middle-east.html Company: Address: Phone I Fax: Design: Fastening point: Page: Specifier: E-Mail: Date: | Concrete - Nov 1, 2023 3 11/1/2023 1.3 Tension load (EOTA TR 029, Section 5.2.2) Load [kN] Capacity [kN] Utilization bN [%] Status Steel Strength* 32.459 83.733 39 OK Combined pullout-concrete cone failure** 54.592 54.763 100 OK Concrete Breakout Failure** 54.592 64.322 85 OK Splitting failure** 54.592 57.467 95 OK * highest loaded anchor **anchor group (anchors in tension) 1.3.1 Steel Strength N NSd £ NRd,s = Rk,s gM,s EOTA TR 029, Table 5.2.2.1 NRk,s [kN] gM,s NRd,s [kN] NSd [kN] 125.600 1.500 83.733 32.459 Input data and results must be checked for conformity with the existing conditions and for plausibility! PROFIS Engineering ( c ) 2003-2023 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan 3 Hilti PROFIS Engineering 3.0.88 www.hilti.group/content/hilti/CP/XX/en/non-transactional/light-pages/middle-east.html Company: Address: Phone I Fax: Design: Fastening point: Page: Specifier: E-Mail: Date: | Concrete - Nov 1, 2023 4 11/1/2023 1.3.2 Combined pullout-concrete cone failure N NSd £ NRd,p = Rk,p gM,p 0 NRk,p = NRk,p · 0 EOTA TR 029, Table 5.2.2.1 Ap,N 0 Ap,N · y s,Np · y g,Np · y ec1,Np · y ec2,Np · y re,Np NRk,p = p · d · hef · t Rk 0 Ap,N = scr, Np · scr,Np EOTA TR 029, Eq. (5.2) EOTA TR 029, Eq. (5.2a) EOTA TR 029, Eq. (5.2b) 0.5 t Rk,ucr = 20 · d · £ 3 · hef 7.5 s = cr,Np 2 c = 0.7 + 0.3 · 1.00 ccr,Np £ ( scr,Np ccr,Np y s,Np 0 y g,Np = y g,Np - 0 ) (s s ) cr,Np 0,5 EOTA TR 029, Eq. (5.2c) EOTA TR 029, Eq. (5.2d) EOTA TR 029, Eq. (5.2e) · (y g,Np - 1) ³ 1.00 0 (k · √dh · t· f Rk y g,Np = √n - (√n - 1) · y ec1,Np 1 1.00 2 · ec1,N £ 1+ scr,Np 1 = 1.00 2 · ec2,N £ 1+ scr,Np h = 0.5 + ef £ 1.00 200 ef ck,cube ) EOTA TR 029, Eq. (5.2f) 1,5 ³ 1.00 EOTA TR 029, Eq. (5.2g) = y ec2,Np y re,Np 2 0 EOTA TR 029, Eq. (5.2h) EOTA TR 029, Eq. (5.2h) EOTA TR 029, Eq. (5.2i) 2 2 Ap,N [mm ] Ap,N [mm ] t Rk,ucr,25 [N/mm ] scr,Np [mm] ccr,Np [mm] cmin [mm] 209,304 116,964 14.00 342.0 171.0 ∞ 0 g,Np y g,Np 1.011 yc t Rk,cr [N/mm ] k 1.072 9.11 2.300 1.096 ec1,N [mm] y ec1,Np ec2,N [mm] y ec2,Np y s,Np y re,Np 25.5 0.870 0.0 1.000 1.000 1.000 0 2 y NRk,p [kN] NRk,p [kN] gM,p NRd,p [kN] NSd [kN] 52.203 82.145 1.500 54.763 54.592 Group anchor ID 3, 4 Input data and results must be checked for conformity with the existing conditions and for plausibility! PROFIS Engineering ( c ) 2003-2023 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan 4 Hilti PROFIS Engineering 3.0.88 www.hilti.group/content/hilti/CP/XX/en/non-transactional/light-pages/middle-east.html Company: Address: Phone I Fax: Design: Fastening point: Page: Specifier: E-Mail: Date: | Concrete - Nov 1, 2023 5 11/1/2023 1.3.3 Concrete Breakout Failure N NSd £ NRd,c = Rk,c gM,c 0 NRk,c = NRk,c · 0 EOTA TR 029, Table 5.2.2.1 Ac,N 0 Ac,N · y s,N · y re,N · y ec1,N · y ec2,N 1,5 EOTA TR 029, Eq. (5.3) NRk,c = k1 · √fck,cube · hef EOTA TR 029, Eq. (5.3a) 0 Ac,N = scr,N · scr,N EOTA TR 029, Eq. (5.3b) y s,N = 0.7 + 0.3 · y re,N = 0.5 + c 1.00 ccr,N £ EOTA TR 029, Eq. (5.3c) hef 1.00 200 £ 1 = 1.00 2 · ec1,N £ 1+ scr,N 1 = 1.00 2 · ec2,N £ 1+ scr,N y ec1,N y ec2,N 2 0 EOTA TR 029, Eq. (5.3d) EOTA TR 029, Eq. (5.3e) EOTA TR 029, Eq. (5.3e) 2 Ac,N [mm ] Ac,N [mm ] ccr,N [mm] scr,N [mm] 209,304 116,964 171.0 342.0 ec1,N [mm] y ec1,N ec2,N [mm] y ec2,N y s,N y re,N 25.5 0.870 0.0 1.000 1.000 1.000 gM,c NRd,c [kN] NSd [kN] 1.500 64.322 54.592 k1 7.200 0 NRk,c [kN] 61.969 Group anchor ID 3, 4 Input data and results must be checked for conformity with the existing conditions and for plausibility! PROFIS Engineering ( c ) 2003-2023 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan 5 Hilti PROFIS Engineering 3.0.88 www.hilti.group/content/hilti/CP/XX/en/non-transactional/light-pages/middle-east.html Company: Address: Phone I Fax: Design: Fastening point: Page: Specifier: E-Mail: Date: | Concrete - Nov 1, 2023 6 11/1/2023 1.3.4 Splitting failure N NSd £ NRd,sp = Rk,sp gM,sp 0 NRk,sp EOTA TR 029, Table 5.2.2.1 = NRk,c · 0 Ac,N · y s,N · y re,N · y ec1,N · y ec2,N · y h,sp 0 Ac,N 1,5 EOTA TR 029, Eq. (5.4) NRk,c = k1 · √fck,cube · hef EOTA TR 029, Eq. (5.3a) 0 Ac,N = scr,sp · scr,sp EOTA TR 029, Eq. (5.3b) y s,N = 0.7 + 0.3 · y ec1,N = y ec2,N 1+ ( 1+ ( = y h,sp = 1 £ y h,sp = c 1.00 ccr,sp £ 1 2 · ec1,N scr,sp 1 2 · ec2,N scr,sp (hh ) EOTA TR 029, Eq. (5.3c) ) £ 1.00 EOTA TR 029, Eq. (5.3e) ) £ 1.00 EOTA TR 029, Eq. (5.3e) 2/3 EOTA TR 029, Eq. (5.4a) min (2 h· h ) 2/3 ef EOTA TR 029, Eq. (5.4b) min 0 2 Ac,N [mm ] Ac,N [mm ] ccr,sp [mm] scr,sp [mm] y h,sp 396,253 258,877 254.4 508.8 1.000 ec1,N [mm] y ec1,N ec2,N [mm] y ec2,N y s,N y re,N k1 25.5 0.909 0.0 1.000 1.000 1.000 7.200 gM,sp NRd,sp [kN] NSd [kN] 1.500 57.467 54.592 2 0 NRk,c [kN] 61.969 Group anchor ID 3, 4 Input data and results must be checked for conformity with the existing conditions and for plausibility! PROFIS Engineering ( c ) 2003-2023 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan 6 Hilti PROFIS Engineering 3.0.88 www.hilti.group/content/hilti/CP/XX/en/non-transactional/light-pages/middle-east.html Company: Address: Phone I Fax: Design: Fastening point: Page: Specifier: E-Mail: Date: | Concrete - Nov 1, 2023 7 11/1/2023 1.4 Shear load (EOTA TR 029, Section 5.2.3) Steel Strength (without lever arm)* Load [kN] Capacity [kN] Utilization bV [%] Status 5.700 50.240 12 OK Steel failure (with lever arm)* Pryout Strength** N/A N/A N/A N/A 22.263 211.936 11 OK N/A N/A N/A N/A Concrete edge failure in direction ** * highest loaded anchor **anchor group (relevant anchors) 1.4.1 Steel Strength (without lever arm) V VSd £ VRd,s = Rk,s gM,s EOTA TR 029, Table 5.2.3.1 VRk,s [kN] gM,s VRd,s [kN] VSd [kN] 62.800 1.250 50.240 5.700 Input data and results must be checked for conformity with the existing conditions and for plausibility! PROFIS Engineering ( c ) 2003-2023 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan 7 Hilti PROFIS Engineering 3.0.88 www.hilti.group/content/hilti/CP/XX/en/non-transactional/light-pages/middle-east.html Company: Address: Phone I Fax: Design: Fastening point: Page: Specifier: E-Mail: Date: | Concrete - Nov 1, 2023 8 11/1/2023 1.4.2 Pryout Strength (Bond Strength controls) V VSd £ VRd,cp = Rk,cp gM,c,p VRk,cp = k · min (NRk,p; NRk,c) A 0 NRk,p = NRk,p · p,N · y g,Np · y s,Np · y re,N · y ec1,Np · y ec2,Np 0 Ap,N 0 NRk,p = p · d · hef · t Rk 0 Ap,N = scr, Np · scr,Np y s,Np 0 y g,Np = y g,Np - 0 EOTA TR 029, Eq. (5.2) EOTA TR 029, Eq. (5.2b) ( ccr,Np EOTA TR 029, Eq. (5.7), (5.7a) EOTA TR 029, Eq. (5.2a) 0.5 t Rk,ucr = 20 · d · £ 3 · hef 7.5 scr,Np = 2 c 1.00 = 0.7 + 0.3 · ccr,Np £ scr,Np EOTA TR 029, Table 5.2.3.1 ) (s s ) 0,5 cr,Np y g,Np = √n - (√n - 1) · y ec1,Np = EOTA TR 029, Eq. (5.2c) EOTA TR 029, Eq. (5.2d) EOTA TR 029, Eq. (5.2e) · (y g,Np - 1) ³ 1.00 0 (k · √dh · t· f Rk ef ck,cube ) EOTA TR 029, Eq. (5.2f) 1,5 ³ 1.00 EOTA TR 029, Eq. (5.2g) 1 1.00 2 · ec1,V £ scr,Np 1 = 1.00 2 · ec2,V £ 1+ scr,Np h = 0.5 + ef £ 1.00 200 EOTA TR 029, Eq. (5.2h) 1+ y ec2,Np y re,Np 2 0 EOTA TR 029, Eq. (5.2h) EOTA TR 029, Eq. (5.2i) 2 2 Ap,N [mm ] Ap,N [mm ] t Rk,ucr,25 [N/mm ] ccr,Np [mm] scr,Np [mm] cmin [mm] 343,944 116,964 14.00 171.0 342.0 ∞ 0 g,Np y g,Np 1.231 1.035 yc t Rk,cr [N/mm ] k k-factor 1.072 9.11 2.300 2.000 ec1,V [mm] y ec1,Np ec2,V [mm] y ec2,Np y s,Np y re,Np 0.0 1.000 0.0 1.000 1.000 1.000 NRk,p [kN] NRk,p [kN] gM,c,p VRd,cp [kN] VSd [kN] 52.203 158.952 1.500 211.936 22.263 0 2 y Group anchor ID 1-4 Input data and results must be checked for conformity with the existing conditions and for plausibility! PROFIS Engineering ( c ) 2003-2023 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan 8 Hilti PROFIS Engineering 3.0.88 www.hilti.group/content/hilti/CP/XX/en/non-transactional/light-pages/middle-east.html Company: Address: Phone I Fax: Design: Fastening point: Page: Specifier: E-Mail: Date: | Concrete - Nov 1, 2023 9 11/1/2023 1.5 Combined tension and shear loads (EOTA TR 029, Section 5.2.4) bN bV a Utilization bN,V [%] Status 0.997 0.113 1.000 93 OK (bN + bV) / 1.2 £ 1.0 1.6 Warnings • The anchor design methods in PROFIS Engineering require rigid anchor plates as per current regulations (ETAG 001/Annex C, EOTA TR029, etc.). This means load re-distribution on the anchors due to elastic deformations of the anchor plate are not considered - the anchor plate is assumed to be sufficiently stiff, in order not to be deformed when subjected to the design loading. PROFIS Engineering calculates the minimum required anchor plate thickness with CBFEM to limit the stress of the anchor plate based on the assumptions explained above. The proof if the rigid base plate assumption is valid is not carried out by PROFIS Engineering. Input data and results must be checked for agreement with the existing conditions and for plausibility! • Checking the transfer of loads into the base material is required in accordance with EOTA TR 029, Section 7! • Attention! In case of compressive anchor forces a buckling check as well as the proof of the local load transfer into and within the base material (incl. punching) has to be done separately. • The design is only valid if the clearance hole in the fixture is not larger than the value given in Table 4.1 of EOTA TR029! For larger diameters of the clearance hole see Chapter 1.1. of EOTA TR029! • The accessory list in this report is for the information of the user only. In any case, the instructions for use provided with the product have to be followed to ensure a proper installation. • Characteristic bond resistances depend on short- and long-term temperatures. • Edge reinforcement is not required to avoid splitting failure • The anchor design methods in PROFIS Engineering require rigid anchor plates, as per current regulations (AS 5216:2021, ETAG 001/Annex C, EOTA TR029 etc.). This means that the anchor plate should be sufficiently rigid to prevent load re-distribution to the anchors due to elastic/plastic displacements. The user accepts that the anchor plate is considered close to rigid by engineering judgment." • The characteristic bond resistances depend on the return period (service life in years): 50 Input data and results must be checked for conformity with the existing conditions and for plausibility! PROFIS Engineering ( c ) 2003-2023 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan 9 Hilti PROFIS Engineering 3.0.88 www.hilti.group/content/hilti/CP/XX/en/non-transactional/light-pages/middle-east.html Company: Address: Phone I Fax: Design: Fastening point: Page: Specifier: E-Mail: Date: | Concrete - Nov 1, 2023 10 11/1/2023 1.7 Installation data 2 Anchor plate, steel: S 275; E = 210,000.00 N/mm ; fyk = 275.00 N/mm Anchor type and diameter: HIT-RE 500 V4 + AM (8.8) 2 Profile: Advance UKC, 203 x 203 x 46; (L x W x T x FT) = 203.2 mm x 203.6 M16 Item number: 407499 AM 8.8 M16x1000 (element) / mm x 7.2 mm x 11.0 mm 2287554 HIT-RE 500 V4 (adhesive) Hole diameter in the fixture: df = 18.0 mm Maximum installation torque: 80 Nm Plate thickness (input): 20.0 mm Hole diameter in the base material: 18.0 mm Hole depth in the base material: 114.0 mm Drilling method: Hammer drilled Cleaning: Compressed air cleaning of the drilled hole according to instructions Minimum thickness of the base material: 150.0 mm for use is required Hilti AM threaded rod with HIT-RE 500 V4 injection mortar with 114 mm embedment h_ef, M16, Steel galvanized, Hammer drilled installation per ETA 20/0541 1.7.1 Recommended accessories Drilling Cleaning Setting • Suitable Rotary Hammer • Properly sized drill bit • Compressed air with required accessories to blow from the bottom of the hole • Proper diameter wire brush • Dispenser including cassette and mixer • Torque wrench y 175.0 4 220.0 150.0 3 40.0 175.0 150.0 x 2 40.0 1 40.0 270.0 40.0 Coordinates Anchor [mm] Anchor x y c-x c+x c-y c+y 1 2 3 4 -135.0 135.0 -135.0 135.0 -110.0 -110.0 110.0 110.0 - - - - Input data and results must be checked for conformity with the existing conditions and for plausibility! PROFIS Engineering ( c ) 2003-2023 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan 10 Hilti PROFIS Engineering 3.0.88 www.hilti.group/content/hilti/CP/XX/en/non-transactional/light-pages/middle-east.html Company: Address: Phone I Fax: Design: Fastening point: 11 Page: Specifier: E-Mail: Date: | Concrete - Nov 1, 2023 11/1/2023 2 Anchor plate design 2.1 Input data Anchor plate: Shape: Rectangular lx x ly x t = 350.0 mm x 300.0 mm x 20.0 mm Calculation: CBFEM Material: S 275; Fy = 275.00 N/mm²; εlim = 5.00% Anchor type and size: HIT-RE 500 V4 + AM (8.8) M16, hef = 114.0 mm Anchor stiffness: The anchor is modeled considering stiffness values determined from load displacement curves tested in an independent laboratory. Please note that no simple replacement of the anchor is possible as the anchor stiffness has a major impact on the load distribution results. EN-based design using component-based FEM eb = 0.0 mm (No stand-off); t = 20.0 mm Design method: Stand-off installation: Profile: 203 x 203 x 46; (L x W x T x FT) = 203.2 mm x 203.6 mm x 7.2 mm x 11.0 mm Material: S 275; Fy = 275.00 N/mm²; εlim = 5.00% Eccentricity x: 0.0 mm Eccentricity y: 0.0 mm Cracked concrete; C40/50; fc,cyl = 40.00 N/mm²; h = 150.0 mm; E = 35,000.00 N/mm²; G = 14,583.33 N/mm²; v = 0.20 Type of redistribution: Plastic Material: S 235 Number of elements on edge: 8 Min. size of element: 10.0 mm Max. size of element: 50.0 mm Base material: Welds (profile to anchor plate): Mesh size: 2.2 Summary Description 1 2 Profile Combination 1 C-2 Anchor plate Concrete [%] sEd [N/mm²] ePl [%] sEd [N/mm²] ePl [%] Hole bearing [%] 116.76 214.32 0.00 0.00 57.11 110.58 0.00 0.00 2 3 14 23 2.3 Anchor plate classification Results below are displayed for the decisive load combinations: C-2 Anchor tension forces Equivalent rigid anchor plate (CBFEM) Anchor 1 Anchor 2 Anchor 3 Anchor 4 -0.002 kN -0.004 kN 25.168 kN 18.792 kN Component-based Finite Element Method (CBFEM) anchor plate design -0.003 kN -0.004 kN 32.459 kN 22.133 kN User accepted to consider the selected anchor plate as rigid by his/her engineering judgement. This means the anchor design guidelines can be applied. 2.4 Profile/Stiffeners/Plate Profile and stiffeners are verified at the level of the steel to concrete connection. The connection design does not replace the steel design for critical cross sections, which should be performed outside of PROFIS Engineering. 2.4.1 Equivalent stress and plastic strain Limit state criteria as per EN1993-1-5 Annex C.8, (1) 2. Results Part Plate Profile Load combination C-2 C-2 Material sEd [N/mm²] ePl [%] fy [N/mm²] gM0 S 275 S 275 110.58 214.32 0.00 0.00 275.00 275.00 1.00 1.00 fy/gM0 [N/mm²] 275.00 275.00 elim [%] Status 5.00 5.00 OK OK Input data and results must be checked for conformity with the existing conditions and for plausibility! PROFIS Engineering ( c ) 2003-2023 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan 11 Hilti PROFIS Engineering 3.0.88 www.hilti.group/content/hilti/CP/XX/en/non-transactional/light-pages/middle-east.html Company: Address: Phone I Fax: Design: Fastening point: Part Profile Profile Load combination C-2 C-2 12 Page: Specifier: E-Mail: Date: | Concrete - Nov 1, 2023 Material sEd [N/mm²] ePl [%] fy [N/mm²] gM0 S 275 S 275 176.74 40.43 0.00 0.00 275.00 275.00 1.00 1.00 11/1/2023 fy/gM0 [N/mm²] 275.00 275.00 elim [%] Status 5.00 5.00 OK OK 2.4.1.1 Equivalent stress Results below are displayed for the decisive load combination: 2 - C-2 275.00 N/mm² 0.00 N/mm² Input data and results must be checked for conformity with the existing conditions and for plausibility! PROFIS Engineering ( c ) 2003-2023 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan 12 Hilti PROFIS Engineering 3.0.88 www.hilti.group/content/hilti/CP/XX/en/non-transactional/light-pages/middle-east.html Company: Address: Phone I Fax: Design: Fastening point: 13 Page: Specifier: E-Mail: Date: | Concrete - Nov 1, 2023 11/1/2023 2.4.1.2 Plastic strain Results below are displayed for the decisive load combination: 2 - C-2 5.00% 0.00% 2.4.2 Hole bearing Decisive load combination: 2 - C-2 Plate hole bearing resistance, EN1993-1 - 8 section 3.6.1: Equations k1 ab fu d t Fb,Rd = Utilization VEd = Fb,Rd gM2 Variables Anchor 1 Anchor 2 Anchor 3 Anchor 4 k1 2.50 2.50 2.50 2.50 ab 0.79 0.79 1.00 1.00 fu [N/mm²] 430.00 430.00 430.00 430.00 d [mm] 16.0 16.0 16.0 16.0 t [mm] 20.0 20.0 20.0 20.0 gM2 1.25 1.25 1.25 1.25 Results Anchor 1 Anchor 2 Anchor 3 Anchor 4 VEd [kN] 5.553 5.401 5.610 5.700 Fb,Rd [kN] 217.184 216.163 275.200 275.200 Utilization [%] 3 3 3 3 Status OK OK OK OK Input data and results must be checked for conformity with the existing conditions and for plausibility! PROFIS Engineering ( c ) 2003-2023 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan 13 Hilti PROFIS Engineering 3.0.88 www.hilti.group/content/hilti/CP/XX/en/non-transactional/light-pages/middle-east.html Company: Address: Phone I Fax: Design: Fastening point: 14 Page: Specifier: E-Mail: Date: | Concrete - Nov 1, 2023 11/1/2023 2.5 Concrete Decisive load combination: 2 - C-2 According to EN1992-1-1 section 6.7(4), the concrete should have sufficient reinforcement to take into account the tensile forces that develop due to the fixture attachment. The definition of the reinforcement in the concrete is out of scope of PROFIS Engineering. 2.5.1 Compression in concrete under the anchor plate 9.63 N/mm² 0.00 N/mm² 2.5.2 Verification of compression in concrete under the anchor plate around the profile as per EN1992-1 section 6.7 and EN1993-1-8, section 6.2.5 Equations bj kj acc fck gc fjd = s N = A eff Utilization = s fjd Variables N [kN] 142.220 Aeff [mm²] 12,858 bj 0.67 acc kj 2.71 1.00 gc fck [N/mm²] 40.00 1.50 Results s [N/mm²] 11.06 fjd [N/mm²] 48.50 Utilization [%] 23 Status OK Input data and results must be checked for conformity with the existing conditions and for plausibility! PROFIS Engineering ( c ) 2003-2023 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan 14 Hilti PROFIS Engineering 3.0.88 www.hilti.group/content/hilti/CP/XX/en/non-transactional/light-pages/middle-east.html Company: Address: Phone I Fax: Design: Fastening point: | Concrete - Nov 1, 2023 Page: Specifier: E-Mail: Date: 15 11/1/2023 2.6 Symbol explanation ab Factor Long-term effects on maximum strength of concrete acc Aeff Effective area Joint coefficient βj bj d Nominal diameter of the bolt Limit plastic strain elim ePl Plastic strain from CBFEM results Fb,Rd fck fjd fu fy gc gM0 gM2 Plate bearing resistance EN 1993-1-8 tab. 3.4 Characteristic compressive concrete strength The ultimate bearing strength of the concrete block Ultimate strength Yield strength Service factor - SP 16, Table 41 Steel safety factor gamma M0 Steel safety factor gamma M2 k1 kj N Factor for edge distance and bolt spacing perpendicular to the direction of load transfer - EN 1993-1-8 - Table 3.4 Concentration factor Resulting compression force Average stress in concrete s sEd Equivalent stress t VEd Thickness of the anchor plate Anchor shear force 2.7 Warnings ● By using the CBFEM calculation functionality of PROFIS Engineering you may act outside the applicable design codes and your specified anchor plate may not behave rigid. Please, validate the results with a professional designer and/or structural engineer to ensure suitability and adequacy for your specific jurisdiction and project requirements. ● The anchor is modeled considering stiffness values determined from load displacement curves tested in an independent laboratory. Please note that no simple replacement of the anchor is possible as the anchor stiffness has a major impact on the load distribution results. Input data and results must be checked for conformity with the existing conditions and for plausibility! PROFIS Engineering ( c ) 2003-2023 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan 15 Hilti PROFIS Engineering 3.0.88 www.hilti.group/content/hilti/CP/XX/en/non-transactional/light-pages/middle-east.html Company: Address: Phone I Fax: Design: Fastening point: 16 Page: Specifier: E-Mail: Date: | Concrete - Nov 1, 2023 11/1/2023 3 Summary of results Design of the anchor plate, anchor, welds and other elements are based on CBFEM (component based finite element method) and Eurocode regulations. Anchors Anchor plate Concrete Profile Load combination C-2 C-2 C-2 C-2 Max. utilization 100% 41% 23% 78% Status OK OK OK OK Fastening meets the design criteria! Input data and results must be checked for conformity with the existing conditions and for plausibility! PROFIS Engineering ( c ) 2003-2023 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan 16 Hilti PROFIS Engineering 3.0.88 www.hilti.group/content/hilti/CP/XX/en/non-transactional/light-pages/middle-east.html Company: Address: Phone I Fax: Design: Fastening point: | Concrete - Nov 1, 2023 Page: Specifier: E-Mail: Date: 17 11/1/2023 4 Remarks; Your Cooperation Duties ● Any and all information and data contained in the Software concern solely the use of Hilti products and are based on the principles, formulas and security regulations in accordance with Hilti's technical directions and operating, mounting and assembly instructions, etc., that must be strictly complied with by the user. All figures contained therein are average figures, and therefore use-specific tests are to be conducted prior to using the relevant Hilti product. The results of the calculations carried out by means of the Software are based essentially on the data you put in. Therefore, you bear the sole responsibility for the absence of errors, the completeness and the relevance of the data to be put in by you. Moreover, you bear sole responsibility for having the results of the calculation checked and cleared by an expert, particularly with regard to compliance with applicable norms and permits, prior to using them for your specific facility. The Software serves only as an aid to interpret norms and permits without any guarantee as to the absence of errors, the correctness and the relevance of the results or suitability for a specific application. ● You must take all necessary and reasonable steps to prevent or limit damage caused by the Software. In particular, you must arrange for the regular backup of programs and data and, if applicable, carry out the updates of the Software offered by Hilti on a regular basis. If you do not use the AutoUpdate function of the Software, you must ensure that you are using the current and thus up-to-date version of the Software in each case by carrying out manual updates via the Hilti Website. Hilti will not be liable for consequences, such as the recovery of lost or damaged data or programs, arising from a culpable breach of duty by you. Input data and results must be checked for conformity with the existing conditions and for plausibility! PROFIS Engineering ( c ) 2003-2023 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan 17