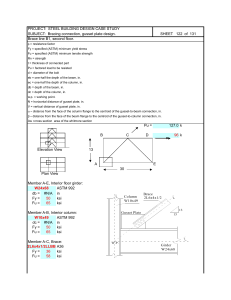

Analysis for a Design Guide on Gusset Plates used in Special Concentrically Braced Frames Brandon A. Kotulka A thesis submitted in partial fulfillment of the requirements for the degree of Master of Science in Engineering University of Washington 2007 Program Authorized to Offer Degree: Department of Civil and Environmental Engineering University of Washington Graduate School This is to certify that I have examined this copy of a master's thesis by Brandon A. Kotulka and have found that it is complete and satisfactory in all respects, and that any and all revisions required by the final examining committee have been made. Committee Members: _______________________________________________ Charles W. Roeder _______________________________________________ Dawn E. Lehman _______________________________________________ Jeffrey W. Berman Date: ____________________________ In presenting this thesis in partial fulfillment of the requirements for a master’s degree at the University of Washington, I agree that the Library shall make its copies freely available for inspection. I further agree that extensive copying of this thesis is allowable only for scholarly purposes, consistent with “fair use” as prescribed in the U.S. Copyright Law. Any other reproduction for any purposes or by any means shall not be allowed without my written permission. Signature ________________________ Date ____________________________ University of Washington Abstract Analysis for a Design Guide on Gusset Plates used in Special Concentrically Braced Frames Brandon A. Kotulka Chair of Supervisory Committee: Professor Charles W. Roeder Department of Civil and Environmental Engineering After recent earthquakes in Northridge, CA and Kobe, Japan caused considerable damage to steel moment frames, significant interest has been generated in the use of steel braced frames to resist seismic induced forces and displacements. A Special Concentrically Braced Frame (SCBF) resists large displacements due to seismic ground motion through brace elongation when the brace is subjected to tensile loads and through brace buckling when the brace is subjected to compressive loads. Gusset plates provide a load path from the brace to the frame and are extremely influential in regard to the post buckling hysteretic response of the brace. Current design provisions create a very large, stiff, and strong gusset plate which actually limits the ductility of the brace. Instead, a smaller, less stiff, less strong gusset plate will increase the ductility of the brace and therefore increase the seismic performance of the system as a whole. The analysis presented within this report will show how the gusset plate should be designed to increase the seismic performance of SCBFs. Table of Contents Page List of Figures.................................................................................................................. vi List of Tables................................................................................................................. xiii Chapter 1: Introduction and Background ......................................................................... 1 1.0 Introduction ...................................................................................................... 1 1.1 Theory of Design.............................................................................................. 1 1.1.1 Connection Design ................................................................................... 2 1.1.2 Overall Geometric Design........................................................................ 5 1.1.3 Performance Based Design....................................................................... 6 1.2 Research Objectives ......................................................................................... 7 1.3 Overview of Report .......................................................................................... 8 Chapter 2: Literature Review ........................................................................................... 9 2.0 Introduction ...................................................................................................... 9 2.1 Brace Experiments............................................................................................ 9 2.2 Gusset Plate Experiments ............................................................................... 10 2.3 System Experiments ....................................................................................... 13 2.4 Previous Tests within Test Program............................................................... 15 2.5 Summary of Research..................................................................................... 16 Chapter 3: Specimen Design .......................................................................................... 17 3.0 Introduction .................................................................................................... 17 3.1 HSS-12 – Reference Specimen with CJP Welds............................................ 22 3.2 HSS-13 – Tapered Plate with CJP Welds....................................................... 24 3.3 HSS-14 – Unreinforced Net Section .............................................................. 27 3.4 HSS-15 – Reduced Splice Length .................................................................. 30 3.5 HSS-16 – Bolted Splice Connection .............................................................. 33 3.6 HSS-17 – 3/8” Tapered Plate ......................................................................... 36 3.7 Material........................................................................................................... 38 Chapter 4: Experiment Setup.......................................................................................... 39 4.0 Introduction .................................................................................................... 39 4.1 Test Components ............................................................................................ 39 4.1.1 Actuator and Reaction Block.................................................................. 43 4.1.2 Load Beam.............................................................................................. 44 4.1.3 Gravity Load System.............................................................................. 45 4.1.4 Out-of-Plane Restraints .......................................................................... 46 4.1.5 Boundary Conditions.............................................................................. 48 4.1.6 Strong Wall and Strong Floor................................................................. 50 4.2 Loading Protocol ............................................................................................ 50 4.3 Instrumentation............................................................................................... 52 4.3.1 Strain Gauges.......................................................................................... 52 i 4.3.2 Potentiometers ........................................................................................ 54 4.3.3 Other Instrumentation............................................................................. 57 4.4 Data Acquisition System ................................................................................ 58 4.5 Testing Preparation......................................................................................... 59 Chapter 5: Experimental Results .................................................................................... 60 5.0 Introduction .................................................................................................... 60 5.1 Yield Mechanisms and Failure Modes ........................................................... 62 5.1.1 Yielding .................................................................................................. 63 5.1.2 Brace Buckling ....................................................................................... 66 5.1.3 Plate Buckling and Local Buckling........................................................ 67 5.1.4 Tearing and Fracture............................................................................... 68 5.1.5 Loss of Resistance at Bolted Connections.............................................. 69 5.2 Nomenclature of Specimen and Specimen Response .................................... 70 5.3 HSS-12 – Reference Specimen with CJP Welds............................................ 73 5.3.1 Specimen Overview................................................................................ 73 5.3.2 Initial Drift Range (Max/Min Range from 0% to 1.25%) ...................... 74 5.3.3 Moderate Drift Range (Max/Min Range from 1.25% to 2.75%) ........... 76 5.3.4 Severe Drift Range (Max/Min Range > 2.75%)..................................... 79 5.3.5 Specimen Summary................................................................................ 82 5.4 HSS-13 – Tapered Plate with CJP Welds....................................................... 84 5.4.1 Specimen Overview................................................................................ 84 5.4.2 Initial Drift Range (Max/Min Range from 0% to 1.25%) ...................... 85 5.4.3 Moderate Drift Range (Max/Min Range from 1.25% to 2.75%) ........... 86 5.4.4 Severe Drift Range (Max/Min Range > 2.75%)..................................... 87 5.4.5 Specimen Summary................................................................................ 91 5.5 HSS-14 – Unreinforced Net Section .............................................................. 93 5.5.1 Specimen Overview................................................................................ 93 5.5.2 Initial Drift Range (Max/Min Range from 0% to 1.25%) ...................... 95 5.5.3 Moderate Drift Range (Max/Min Range from 1.25% to 2.75%) ........... 96 5.5.4 Severe Drift Range (Max/Min Range > 2.75%)..................................... 98 5.5.5 Specimen Summary.............................................................................. 105 5.6 HSS-15 – Reduced Splice Length ................................................................ 108 5.6.1 Specimen Overview.............................................................................. 108 5.6.2 Initial Drift Range (Max/Min Range from 0% to 1.25%) .................... 110 5.6.3 Moderate Drift Range (Max/Min Range from 1.25% to 2.75%) ......... 111 5.6.4 Severe Drift Range (Max/Min Range > 2.75%)................................... 112 5.6.5 Specimen Summary.............................................................................. 117 5.7 HSS-16 – Bolted Splice Connection ............................................................ 118 5.7.1 Specimen Overview.............................................................................. 118 5.7.2 Initial Drift Range (Max/Min Range from 0% to 1.25%) .................... 121 5.7.3 Moderate Drift Range (Max/Min Range from 1.25% to 2.75%) ......... 125 5.7.4 Severe Drift Range (Max/Min Range > 2.75%)................................... 126 5.7.5 Specimen Summary.............................................................................. 131 5.8 HSS-17 – 3/8” Tapered Plate ....................................................................... 132 ii 5.8.1 Specimen Overview.............................................................................. 132 5.8.2 Initial Drift Range (Max/Min Range from 0% to 1.25%) .................... 134 5.8.3 Moderate Drift Range (Max/Min Range from 1.25% to 2.75%) ......... 136 5.8.4 Severe Drift Range (Max/Min Range > 2.75%)................................... 137 5.8.5 Specimen Summary.............................................................................. 142 5.9 Hysteretic Envelope Comparison ................................................................. 143 Chapter 6: Analysis of Results ..................................................................................... 145 6.0 Introduction .................................................................................................. 145 6.1 Ultimate Drift Capacity ................................................................................ 146 6.1.1 Introduction .......................................................................................... 146 6.1.2 Brace Behavior ..................................................................................... 146 6.1.3 Buckled Shape and Curvature .............................................................. 149 6.1.4 Axial Stiffness of the Gusset Plates...................................................... 165 6.1.5 Weld/Base Metal Damage .................................................................... 171 6.1.6 HSS-16 ................................................................................................. 174 6.1.7 Summary............................................................................................... 174 6.2 Performance State Comparison .................................................................... 175 6.2.0 Introduction .......................................................................................... 175 6.2.1 Performance State Comparison of Brace ............................................. 177 6.2.2 Performance State Comparison of Gusset Plates ................................. 179 6.2.3 Performance State Comparison of Welds and Base Metal................... 182 6.2.4 Performance State Comparison of Framing Elements ......................... 186 6.2.5 Summary for Performance State Comparisons .................................... 196 6.3 Load Capacity............................................................................................... 198 6.4 Energy Dissipation ....................................................................................... 201 6.5 Constructability ............................................................................................ 204 6.5.1 Net Section Reinforcement................................................................... 204 6.5.2 Gusset Plate Size and Geometry........................................................... 205 6.6 Conclusions .................................................................................................. 206 Chapter 7: Analysis of Test Program Results............................................................... 209 7.0 Introduction .................................................................................................. 209 7.1 Overall Comparison...................................................................................... 209 7.2 Weld/Base Metal Damage ............................................................................ 210 7.2.2 Weld Damage of Tapered Plates .......................................................... 213 7.2.3 Weld Damage of Rectangular Plates with 2t Line Clearance .............. 215 7.2.4 Weld Damage of Rectangular Plates with Elliptical Clearance ........... 216 7.2.5 Tapered Plate vs. Rectangular Plate with Cracked Welds ................... 218 7.2.6 Conclusions .......................................................................................... 220 7.3 Displacement History Comparison............................................................... 222 7.3.1 Displacement History of HSS-05 and HSS-06 vs. HSS-14 ................. 222 7.3.2 Displacement History of HSS-02 vs. HSS-03 ...................................... 225 7.3.3 Conclusion............................................................................................ 225 7.4 Actual Seismic Loading ............................................................................... 228 7.5 Gusset Plate Strength and Stiffness .............................................................. 230 iii 7.5.1 Rotational Strength and Stiffness ......................................................... 230 7.5.2 Strength of HSS-01 and HSS-12 vs. HSS-10 and HSS-13 .................. 233 7.5.3 Axial Strength and Stiffness................................................................. 235 7.6 Performance of Framing Elements ............................................................... 238 7.7 Conclusions .................................................................................................. 242 Chapter 8: Design Guide .............................................................................................. 244 8.0 Introduction .................................................................................................. 244 8.1 Gusset Plate Strength Design and Analysis.................................................. 245 8.1.1 Net Section Fracture ............................................................................. 246 8.1.2 Whitmore Yielding............................................................................... 247 8.1.3 Block Shear .......................................................................................... 248 8.1.4 Gusset Plate Buckling........................................................................... 249 8.1.5 Conclusion............................................................................................ 249 8.2 Design of Gusset Plate Geometry Using Elliptical Clearance ..................... 250 8.2.1 Rectangular Gusset Plate Geometry Design......................................... 251 8.2.2 Tapered Gusset Plate Geometry Design............................................... 254 8.3 Gusset Plate Weld Design ............................................................................ 256 8.4 Design of Net Section Reinforcement.......................................................... 257 8.5 Design of Beam-to-Column Connection ...................................................... 258 Chapter 9: Conclusions and Recommendations ........................................................... 259 9.0 Introduction .................................................................................................. 259 9.1 Summary....................................................................................................... 259 9.2 Conclusions .................................................................................................. 262 9.2.1 Conclusions on Analysis of SCBFs...................................................... 262 9.2.2 Conclusions on Design of Gusset Plates in SCBFs.............................. 265 9.2.3 Design Recommendations .................................................................... 270 9.3 Recommendations for Future Research........................................................ 270 9.3.1 Reduced Depth Brace ........................................................................... 270 9.3.2 Net Section ........................................................................................... 273 9.3.3 More Accurate Gravity Load Application............................................ 273 9.3.4 Shake Table .......................................................................................... 273 9.3.5 Slab ....................................................................................................... 274 9.3.6 Size of Brace......................................................................................... 274 9.3.7 Type of Brace ....................................................................................... 274 9.3.8 Applied Displacement History ............................................................. 274 9.3.9 Strength Evaluation of FEM Models.................................................... 275 9.3.10 Gusset Plate Buckling Provisions......................................................... 275 9.3.11 New Method for Determining Clearance ............................................. 275 9.3.12 Tapered Plate with Higher Clearance................................................... 276 9.3.13 Whitmore Section................................................................................. 277 9.3.14 Quarter Inch Plate................................................................................. 277 9.3.15 Beam-to-Column Connection............................................................... 277 9.3.16 Additional Testing ................................................................................ 278 References .................................................................................................................... 279 iv Appendix A: Specimen Design .................................................................................... 286 A.1 General ......................................................................................................... 286 A.2 Example 1 (Specimen HSS-12).................................................................... 286 A.2.1 Member Selection................................................................................. 286 A.2.2 Brace-to-Gusset Plate Connection........................................................ 289 A.2.3 Gusset Plate Design.............................................................................. 291 A.2.4 Gusset Plate-to-Frame Connection Design .......................................... 297 A.2.5 Beam-to-Column Connection – CJP .................................................... 300 A.2.6 Beam-to-Column Connection – Simple Shear ..................................... 301 A.3 Example 2 (Specimen HSS-14).................................................................... 305 A.3.1 Gusset Plate Design.............................................................................. 305 A.3.2 Gusset Plate-to-Framing Element Welds ............................................. 308 Appendix B: Specimen Drawings ................................................................................ 310 B.1 General ......................................................................................................... 310 Appendix C: Finite Element Analyses ......................................................................... 345 C.1 General ......................................................................................................... 345 C.2 Model Description ........................................................................................ 345 C.3 Loads ............................................................................................................ 346 C.4 Results .......................................................................................................... 348 C.5 Specimen HSS-01 (same as HSS-12)........................................................... 349 C.6 Specimen HSS-02 (same as HSS-03 and HSS-09) ...................................... 350 C.7 Specimen HSS-04......................................................................................... 350 C.8 Specimen HSS-05 and HSS-06 .................................................................... 351 C.9 Specimen HSS-07 (same as HSS-11)........................................................... 351 C.10 Specimen HSS-08......................................................................................... 352 C.11 Specimen HSS-10 (same as HSS-13 and HSS-17) ...................................... 352 C.12 Specimen HSS-14......................................................................................... 353 C.13 Specimen HSS-15......................................................................................... 354 Appendix D: Data Analysis Calculations..................................................................... 355 D.1 General ......................................................................................................... 355 D.2 Brace Calculations........................................................................................ 355 D.2.1 Brace Force Calculation ....................................................................... 355 D.2.2 Brace Out-of-Plane Displacement Calculation .................................... 357 D.2.3 Brace Elongation .................................................................................. 359 D.2.3 Gusset Plate Elongation........................................................................ 361 D.2.4 Brace Yielding...................................................................................... 361 D.3 Gusset Plate Rotations.................................................................................. 362 D.4 Beam and Column Forces ............................................................................ 363 D.5 Shear Tab Rotations ..................................................................................... 363 D.6 Energy Dissipation Calculation.................................................................... 364 D.7 Drift Calculation........................................................................................... 365 v List of Figures Figure Number Page Figure 1.1.1 – Example of Gusset Plate Connection........................................................ 2 Figure 1.1.2 – Yield Mechanisms and Failure Modes of SCBF (Johnson 2005)............. 4 Figure 1.1.3 - Force-Drift Response for Single Brace (Johnson 2005)............................ 5 Figure 2.2.1 – Whitmore Width ..................................................................................... 11 Figure 2.2.2 – 2t Clearance............................................................................................. 12 Figure 2.2.3 – Test Schematic of Astaneh-Asl, Goel, and Hanson (1982) .................... 13 Figure 2.3.1 – Test Schematic of Uriz (2005) ................................................................ 14 Figure 3.0.1 – Prototype Specimen (Johnson 2005)....................................................... 17 Figure 3.1.1 – 2t Clearance............................................................................................. 22 Figure 3.1.2 – HSS-12 Gusset Plate Detail .................................................................... 23 Figure 3.2.1 – Gusset Plate with Elliptical Clearance .................................................... 25 Figure 3.2.2 – HSS-13 Gusset Plate Detail .................................................................... 26 Figure 3.3.1 – HSS-14 Gusset Plate Detail .................................................................... 27 Figure 3.3.2 –Slot Detail of Brace HSS-14 .................................................................... 28 Figure 3.4.1 –Gusset Plate Detail HSS-15 ..................................................................... 31 Figure 3.5.1 –Gusset Plate Detail HSS-16 ..................................................................... 34 Figure 3.5.2 –Section of Connection Detail HSS-16 ..................................................... 36 Figure 3.6.1 –Gusset Plate Detail HSS-17 ..................................................................... 37 Figure 4.1.1 – Test Setup Components (Johnson 2005)................................................. 41 Figure 4.1.2 – Test Setup Dimensions (Johnson 2005).................................................. 42 Figure 4.1.3 – Test Setup Photograph (Johnson 2005) .................................................. 43 Figure 4.1.4 – Actuator and Reaction Block Photograph (Johnson 2005) ..................... 44 Figure 4.1.5 – Actuator and Reaction Block Assembly (Johnson 2005) ....................... 44 Figure 4.1.6 – Load Beam Details.................................................................................. 45 Figure 4.1.7 - Axial Load System Schematic (Johnson 2005) ....................................... 46 Figure 4.1.8 - Axial Load System Photographs (Johnson 2005).................................... 46 Figure 4.1.9 – Out of Plane Restraints (Johnson 2005).................................................. 47 Figure 4.1.10 – Out of Plane Restraints (Johnson 2005)................................................ 48 Figure 4.1.11 - Channel Assembly Cross-Section (Johnson)......................................... 49 Figure 4.1.12 - Shear Transfer Connection (Johnson) ................................................... 49 Figure 4.2.1 - Loading History (Johnson 2005) ............................................................. 51 Figure 4.3.1 – Strain Gauge Diagram............................................................................. 53 Figure 4.3.2 – Potentiometer Diagram ........................................................................... 55 Figure 4.3.3 – Potentiometer Location Diagram at NE Gusset Plate............................. 57 Figure 5.1.1 – Initial/Mild Gusset Plate Yielding (Y1) for HSS-17 .............................. 64 Figure 5.1.2 – Moderate Gusset Plate Yielding (Y3) for HSS-17.................................. 65 Figure 5.1.3 – Significant Gusset Plate Yielding (Y5) for HSS-17 ............................... 65 Figure 5.1.4 – Example of Brace Buckling Progression (HSS-17) ................................ 67 vi Figure 5.1.5 – Example of B1 of Beam Flange (HSS-13).............................................. 68 Figure 5.1.6 – Example of Tearing and Fracture of the Brace (BF) .............................. 69 Figure 5.1.7 – Example of Damage to the Base Metal (WDB)...................................... 70 Figure 5.2.1 - SCBF Component Notation (Johnson 2005) ........................................... 71 Figure 5.2.2 - SCBF Component Notation Profile (Johnson 2005) ............................... 71 Figure 5.3.1 – Specimen HSS-12 Force-Drift Response................................................ 74 Figure 5.3.2 – B2 Buckling of brace (-0.71% Drift) ...................................................... 75 Figure 5.3.3 – Yield Lines on NE Gusset Plate (0.26% Drift)....................................... 75 Figure 5.3.4 – Yield Lines in Beam Web (0.48% Drift) ................................................ 76 Figure 5.3.5 – Yield Lines in NE Column Flange (0.68% Drift)................................... 77 Figure 5.3.6 – Y3 at NE column next to gusset plate (-1.47% Drift)............................. 78 Figure 5.3.7 – Hinge Lines in NE Gusset (-1.47% Drift)............................................... 78 Figure 5.3.8 – B1 of NE column flange (-1.79% Drift) ................................................. 79 Figure 5.3.9 – Y3 of NE Beam Flange (-1.79% Drift)................................................... 80 Figure 5.3.10 – Y5 at Reentrant Beam Corners (-2.1% Drift) ....................................... 80 Figure 5.3.11 – BC of Brace (-1.79% Drift)................................................................... 81 Figure 5.3.12 – Crack in Brace (1.40% Drift)................................................................ 81 Figure 5.3.13 – Fracture of Brace (1.67% Drift) ............................................................ 82 Figure 5.3.14 – NE Gusset Plate (End of Test) .............................................................. 83 Figure 5.3.15 – SW Column (End of Test) .................................................................... 83 Figure 5.4.1 – Specimen HSS-13 Force-Drift Response................................................ 85 Figure 5.4.2 –Visible Bending (-0.30% Drift) ............................................................... 85 Figure 5.4.3 –Y1 at gusset plates (0.35% Drift)............................................................. 86 Figure 5.4.4 –Y3 at NE Gusset Plate (0.82% Drift) ....................................................... 87 Figure 5.4.5 –Y5 at SW gusset plate (-1.38% Drift) ...................................................... 87 Figure 5.4.6 –Y3 at Columns 1.35% Drift) .................................................................... 88 Figure 5.4.7 –Y5 at SW Beam (-2.03% Drift) ............................................................... 88 Figure 5.4.8 – Local Buckling of SW Beam (2.05% Drift) ........................................... 89 Figure 5.4.9 – Significant Yielding in Gusset Plate (-2.03% Drift) ............................... 89 Figure 5.4.10 –BC at brace (-1.71% Drift)..................................................................... 90 Figure 5.4.11 –Brace Initial Tearing (2.05% Drift)........................................................ 90 Figure 5.4.12 – Downward Brace Buckling (-0.33% Drift)........................................... 91 Figure 5.4.13 – Yielding of NE Connection (End of Test) ............................................ 92 Figure 5.4.14 –Yielding on West Column (End of Test) ............................................... 92 Figure 5.4.15 –Local Buckling at South Beam (End of Test) ........................................ 93 Figure 5.5.1 – Specimen HSS-14 Force-Drift Response................................................ 94 Figure 5.5.2 – Buckling Stage of HSS-14 (-0.34%)....................................................... 95 Figure 5.5.3 – Y1 of NE Gusset Plate (0.28%) .............................................................. 96 Figure 5.5.4 – Y1 of NE Beam (0.37%)......................................................................... 96 Figure 5.5.5 – Y3 of NE Gusset (0.58%) ....................................................................... 97 Figure 5.5.6 – Y1 of NE Gusset at Beam (0.58%) ......................................................... 97 Figure 5.5.7 – Y1 of SW Gusset in Compression (-1.08%) ........................................... 98 Figure 5.5.8 – Y3 NE Column (1.61%).......................................................................... 98 Figure 5.5.9 – Y3 SW Column (1.89%)......................................................................... 99 vii Figure 5.5.10 – Y5 NE Beam (1.89%) ........................................................................... 99 Figure 5.5.11 – Y5 SW Beam (1.89%) .......................................................................... 99 Figure 5.5.12 – Y3 of NE Gusset at Reentrant Corner (1.31%)................................... 100 Figure 5.5.13 – Y3 of SW Gusset at Reentrant Corner (1.31%) .................................. 100 Figure 5.5.14 – Crack at NE Gusset Plate Weld (-1.67%) ........................................... 101 Figure 5.5.15 – Crack at NE Gusset Plate Weld (-2.04%) ........................................... 101 Figure 5.5.16 – 6.5” Crack at NE Gusset Plate Weld at Column (-2.01%) ................. 102 Figure 5.5.17 – 3” Crack at NE Gusset Plate Weld at Beam (-2.01%) ........................ 102 Figure 5.5.18 – Cupping of Brace (-2.04%)................................................................. 103 Figure 5.5.19 – Bulging of Brace (-2.01%).................................................................. 104 Figure 5.5.20 – Bulging of Brace (-2.01%).................................................................. 104 Figure 5.5.21 – Fatigue Cracks in Brace (-2.01%)....................................................... 105 Figure 5.5.22 – Brace Fracture (2.48%) ....................................................................... 105 Figure 5.5.23 – Net Section Hole Undamaged (End of Test) ...................................... 106 Figure 5.5.24 – Net Section Hole Undamaged (End of Test) ...................................... 106 Figure 5.5.25 – Gusset Plate (End of Test) .................................................................. 107 Figure 5.6.1 – Specimen HSS-15 Force-Drift Response.............................................. 109 Figure 5.6.2 – Buckling Stages..................................................................................... 110 Figure 5.6.3 – Yielding on Gusset Next to Brace at 232 kips (0.43%) ........................ 111 Figure 5.6.4 – Yielding on NE Beam Web (0.96%) .................................................... 111 Figure 5.6.5 – Yielding on NE Beam Flange (-1.35%)................................................ 112 Figure 5.6.6 – Hinge Lines in Gusset Plates (-1.35%) ................................................. 112 Figure 5.6.7 – NE Column with Y3 Yielding (1.22%) ................................................ 113 Figure 5.6.8 – Yielding at NEB.................................................................................... 113 Figure 5.6.9 – 1 in Crack thru Base Metal of Gusset Plate at SWC (-1.97%) ............. 114 Figure 5.6.10 – 3” Crack thru Base Metal of Gusset Plate at NEC (-2.22%) .............. 114 Figure 5.6.11 – Brace Hole and Necking (1.74%) ....................................................... 115 Figure 5.6.12 – Brace Crack Halfway thru Member (1.87%) ...................................... 116 Figure 5.6.13 – Brace Buckling Down (-0.55%).......................................................... 116 Figure 5.6.14 – Southwest Gusset (End of Test).......................................................... 118 Figure 5.7.1 – Specimen HSS-16 Connection Detail ................................................... 119 Figure 5.7.2 – Specimen HSS-16 Force-Drift Response.............................................. 120 Figure 5.7.3 – Visual Bending of SW Gusset and Extension Plate (-0.16%) .............. 121 Figure 5.7.4 – Bending of SW Gusset and Extension Plate (-0.29%).......................... 122 Figure 5.7.5 – Bending of SW Gusset and Extension Plate (-0.37%).......................... 122 Figure 5.7.6 – Bending of Plates, Hinge Lines on Gusset (-0.45%) ............................ 122 Figure 5.7.7 – Bolt Slip (0.31%) .................................................................................. 123 Figure 5.7.8 – Base Metal Fracture (-0.49%)............................................................... 124 Figure 5.7.9 – Y3 of SW Gusset Plate (-0.49%) .......................................................... 124 Figure 5.7.10 – Y1 of SW Extension Plate (0.67%) .................................................... 125 Figure 5.7.11 – Y1 of NE Gusset Plate (0.81%) .......................................................... 126 Figure 5.7.12 – B1 of SW Gusset Plate (0.81%).......................................................... 126 Figure 5.7.13 – Bolt Slippage at NE Gusset (1.27%)................................................... 127 Figure 5.7.14 – Y5 of SW Gusset Plate (1.43%).......................................................... 127 viii Figure 5.7.15 – Y3 of NE Framing Elements (1.67%)................................................. 128 Figure 5.7.16 – Complete Tear of Base Metal at SW Gusset (-2.00%) ....................... 128 Figure 5.7.17 – Crack Develops in Weld at Beam (2.28%) ......................................... 129 Figure 5.7.18 – Base Metal Crack at NE Column (-2.31%)......................................... 129 Figure 5.7.19 – Base Metal Complete Fracture at NE Column (-2.66%) .................... 130 Figure 5.7.20 – Crack in SW Extension Plate (-2.66%)............................................... 131 Figure 5.7.21 – Cracks in Extension Plate (-2.86%) .................................................... 131 Figure 5.8.1 – Specimen HSS-17 Force-Drift Response.............................................. 134 Figure 5.8.2 – Visible Buckling (-0.25%) .................................................................... 134 Figure 5.8.3 – Y1 Yielding due to Tension in Both Gussets (0.26%).......................... 135 Figure 5.8.4 – Y3 Yielding due to Tension in Both Gussets (0.32%).......................... 135 Figure 5.8.5 – Compression Yield Lines of SW Gusset Plate (-0.63%) ...................... 136 Figure 5.8.6 – Gusset Plates Condition at End of Moderate Drift Range (-1.34%) ..... 136 Figure 5.8.7 – Yielding at SW Column (-1.14%)......................................................... 137 Figure 5.8.8 – Yielding at SW Beam and Gusset Reentrant Corner (-1.14%)............. 137 Figure 5.8.9 – Yielding at Beam Webs (1.31%) .......................................................... 138 Figure 5.8.10 – Y3 and B1 of SW Beam Web (2.15%) ............................................... 138 Figure 5.8.11 – 6” Base Metal Crack in Gusset at NE Column (-2.31%).................... 139 Figure 5.8.12 – 4” Base Metal Crack in Gusset at SW Column (-2.31%) ................... 139 Figure 5.8.13 – Y5 of Gusset Plates (-2.31%).............................................................. 139 Figure 5.8.14 – 15” Base Metal Fracture (-2.79%) ...................................................... 140 Figure 5.8.15 – Brace Cupping (-2.31%) ..................................................................... 141 Figure 5.8.16 – Fatigue Cracks in Brace (2.15%) ........................................................ 141 Figure 5.8.17 – Local Failure in Brace (-2.79%) ......................................................... 142 Figure 5.8.18 – NE Gusset Plate (End of Test) ............................................................ 142 Figure 5.9.1 – Positive Hysteretic Envelopes............................................................... 143 Figure 5.9.2 – Negative Hysteretic Envelopes ............................................................. 144 Figure 6.1.1 – Five Stages of Inelastic, Post-Buckling Response of Brace ................. 147 Figure 6.1.2 – Local Buckling During Stage 2 Leading to Fracture ............................ 148 Figure 6.1.3 – Cracks after Local Buckling Has Occurred .......................................... 149 Figure 6.1.4 – Buckled Shape Comparison at a Given In-Plane Displacement ........... 150 Figure 6.1.5 – 2t Clearance........................................................................................... 150 Figure 6.1.6 – Deflected Shape at -0.35% Drift ........................................................... 151 Figure 6.1.7 – Buckled Shape at –1.5% Drift............................................................... 152 Figure 6.1.8 – Buckled Shape at Brace Cupping (BC)................................................. 152 Figure 6.1.9 – Brace Out-of-Plane Displacement at Midspan vs. Frame Drift ............ 154 Figure 6.1.10 – Brace Out-of-Plane Displacement at Midspan vs. Drift Range .......... 155 Figure 6.1.11 – HSS-17 and HSS-14 Gusset Plate Detail Overlaid on Each other...... 157 Figure 6.1.12 – Hinge Lines for Rectangular Plate with Elliptical Clearance ............. 158 Figure 6.1.13 – Hinge Line for Tapered Plate.............................................................. 158 Figure 6.1.14 – HSS-14 Hinge Lines Including Bending for Compatibility................ 159 Figure 6.1.15 – Finite Element Mesh for HSS-14........................................................ 160 Figure 6.1.16 – Finite Element Mesh for HSS-17........................................................ 160 Figure 6.1.17 –Perspective Drawing of Hinging of HSS-14........................................ 161 ix Figure 6.1.18 – NE Gusset Plate Rotation vs. Story Drift............................................ 162 Figure 6.1.19 – SW Gusset Plate Rotation vs. Story Drift ........................................... 163 Figure 6.1.20 – Brace Elongation vs. Frame Drift ....................................................... 166 Figure 6.1.21 – Brace Elongation vs. Frame Drift (Tension only)............................... 166 Figure 6.1.22 – Brace Elongation (Compression only) vs. Total Frame Drift ............. 168 Figure 6.1.23 – Brace Elongation (Tension Only) vs. Total Frame Drift .................... 168 Figure 6.1.24 – Gusset Plate Elongation vs. Frame Drift (Tension Only) ................... 169 Figure 6.1.25 – Brace Force vs. Drift Ratio ................................................................. 170 Figure 6.1.26 – Total Drift Range vs. Total Weld/Base Metal Crack Length ............. 171 Figure 6.1.27 – Opening Moment Associated with Compression in Brace ................. 172 Figure 6.2.1 – Y3 Yielding on HSS-15 Gusset Plate (0.43%) ..................................... 181 Figure 6.2.2 – Y3 Yielding on HSS-17 NE Gusset Plate (0.32%)............................... 181 Figure 6.2.3 – Extended Yielding of HSS-17 NE Gusset Plate (0.53%) ..................... 182 Figure 6.2.4 – SW Gusset Plate Rotation vs. Story Drift ............................................. 184 Figure 6.2.5 – North Beam Moments at Strain Gauge Location.................................. 187 Figure 6.2.6 – South Beam Moments at Strain Gauge Location.................................. 189 Figure 6.2.7 – Local Beam Web and Beam Flange Buckling of HSS-14 .................... 190 Figure 6.2.8 – East Column Moments at Gusset Plate ................................................. 191 Figure 6.2.9 – West Column Moments at Gusset Plate................................................ 191 Figure 6.2.10 – East Column Shears ............................................................................ 192 Figure 6.2.11 – West Column Shears ........................................................................... 192 Figure 6.2.12 – Ratio of Shear Resistance from Columns (Negative Drift) ................ 194 Figure 6.2.13 – Ratio of Shear Resistance from Columns (Positive Drift).................. 195 Figure 6.3.1 – Brace Force as a Function of Drift Ratio .............................................. 200 Figure 6.4.1 – Energy Dissipated by HSS-12............................................................... 202 Figure 6.4.2 – Energy Dissipated Comparison............................................................. 203 Figure 6.5.1 – Erection Issue of HSS-15...................................................................... 206 Figure 7.2.1 – Total Weld/Base Metal Crack Length vs. Drift Ratio .......................... 212 Figure 7.2.2 – NE Gusset Plate Rotation...................................................................... 214 Figure 7.2.3 – Weld/Base Metal Total Crack Length for Rectangular 3/8” Plates ...... 217 Figure 7.2.4 – Comparison of Rectangular Plate with Reduced Weld Length ............ 219 Figure 7.2.5 – Comparison of Rectangular Plate with Reduced Weld Length ............ 219 Figure 7.2.6 – Total Drift Range vs. Weld/Base Metal Tearing Length ...................... 221 Figure 7.3.1 – Drift History of HSS-05........................................................................ 223 Figure 7.3.2 – Drift History of HSS-06........................................................................ 223 Figure 7.3.3 – Drift History of HSS-14........................................................................ 224 Figure 7.3.4 – Ultimate Drift Range of HS-05, HSS-06 and HSS-14.......................... 224 Figure 7.3.5 – Ultimate Drift Range of HSS-02 and HSS-03 ...................................... 225 Figure 7.4.1 – Weld/Base Metal Damage vs. Negative Drift Ratio ............................. 229 Figure 7.5.1 – SW Gusset Plate Rotation vs. Total Drift Range .................................. 231 Figure 7.5.2 – HSS-01 and HSS-12 overlaid with HSS-10 and HSS-13 ..................... 233 Figure 7.5.3 – HSS-10 and HSS-12 SW Gusset Plate Rotation................................... 235 Figure 7.5.4 – Brace Elongation vs. Drift Ratio........................................................... 237 Figure 8.2.1 – Gusset Plate with Elliptical Clearance .................................................. 251 x Figure 9.2.1 – Opening Moment Associated with Compression in Brace ................... 263 Figure 9.3.1 – Reduced Depth Brace............................................................................ 271 Figure 9.3.2 – Clearance Lines for Rectangular Plate.................................................. 276 Figure 9.3.3 – Clearance Lines for Tapered Plate ........................................................ 276 Figure 9.3.4 – Connection with Only Outside Beam Flange Welded to Column ........ 278 Figure A.1 - Uniform Force Method (Johnson 2005) .................................................. 294 Figure A.2 - 2t Clearance Dimensions (Johnson 2005) ............................................... 295 Figure A.3 – Buckling Lengths l1, l2 and l3 ................................................................ 296 Figure B.1 – Speciman HSS-01.................................................................................... 311 Figure B.2 – HSS-01 Gusset Plate Detail.................................................................... 312 Figure B.3 – Speciman HSS-02.................................................................................... 313 Figure B.4 – HSS-02 Gusset Plate Detail.................................................................... 314 Figure B.5 – Speciman HSS-03.................................................................................... 315 Figure B.6 – HSS-03 Gusset Plate Detail.................................................................... 316 Figure B.7 – Speciman HSS-04.................................................................................... 317 Figure B.8 – HSS-04 Gusset Plate Detail.................................................................... 318 Figure B.9 – Speciman HSS-05.................................................................................... 319 Figure B.10 – HSS-05 Gusset Plate Detail.................................................................. 320 Figure B.11 – Speciman HSS-06.................................................................................. 321 Figure B.12 – HSS-06 Gusset Plate Detail.................................................................. 322 Figure B.13 – Speciman HSS-07.................................................................................. 323 Figure B.14 – HSS-07 Gusset Plate Detail.................................................................. 324 Figure B.5 – Speciman HSS-08.................................................................................... 325 Figure B.16 – HSS-08 Gusset Plate Detail.................................................................. 326 Figure B.17 – Speciman HSS-09.................................................................................. 327 Figure B.18 – HSS-09 Gusset Plate Detail.................................................................. 328 Figure B.19 – Speciman HSS-10.................................................................................. 329 Figure B.20 – HSS-10 Gusset Plate Detail.................................................................. 330 Figure B.21 – Speciman HSS-11.................................................................................. 331 Figure B.22 – HSS-11 Gusset Plate Detail.................................................................. 332 Figure B.23 – Speciman HSS-12.................................................................................. 333 Figure B.24 – HSS-12 Gusset Plate Detail.................................................................. 334 Figure B.25 – Speciman HSS-13.................................................................................. 335 Figure B.26 – HSS-13 Gusset Plate Detail.................................................................. 336 Figure B.27 – Speciman HSS-14.................................................................................. 337 Figure B.28 – HSS-14 Gusset Plate Detail.................................................................. 338 Figure B.29 – Speciman HSS-15.................................................................................. 339 Figure B.30 – HSS-15 Gusset Plate Detail.................................................................. 340 Figure B.31 – Speciman HSS-16.................................................................................. 341 Figure B.32 – HSS-16 Gusset Plate Detail.................................................................. 342 Figure B.33 – Speciman HSS-17.................................................................................. 343 Figure B.34 – HSS-17 Gusset Plate Detail.................................................................. 344 Figure C.1.1 – 3D View of Example FEM Model ....................................................... 346 Figure C.3.1 – Axial Load on Gusset Plates ................................................................ 347 xi Figure C.3.2 – Moment on Gusset Plates ..................................................................... 347 Figure C.3.1 – Finite Element Mesh for HSS-01 and HSS-12..................................... 349 Figure C.6.1 – Finite Element Mesh for HSS-02 and HSS-03..................................... 350 Figure C.7.1 – Finite Element Mesh for HSS-04 ......................................................... 350 Figure C.8.1 – Finite Element Mesh for HSS-05 and HSS-06..................................... 351 Figure C.9.1 – Finite Element Mesh for HSS-07 ......................................................... 351 Figure C.10.1 – Finite Element Mesh for HSS-08 ....................................................... 352 Figure C.11.1 – Finite Element Mesh for HSS-10, HSS-13, and HSS-17 ................... 352 Figure C.12.1 – Finite Element Mesh for HSS-14 ....................................................... 353 Figure C.12.2 – FEM Mesh for HSS-14 with Weld Cracks......................................... 354 Figure C.13.1 – Finite Element Mesh for HSS-15 ....................................................... 354 Figure D.1 - Column Strain Gages (Johnson 2005) ..................................................... 356 Figure D.2 - Brace Out-of-Plane Measurement Schematic (Johnson 2005) ................ 357 Figure D.3 - Brace Out-of-Plane Measurement Variables ........................................... 358 Figure D.4 - Brace Elongation Measurement (Johnson 2005) ..................................... 359 Figure D.5 - Brace Elongation Measurement Schematic (Johnson 2005) ................... 360 Figure D.6 - Brace Elongation Measurement Variables (Johnson 2005)..................... 360 Figure D.7 - Gusset Plate Out-of-Plane Measurement (Johnson 2005) ....................... 362 Figure D.8 - Beam and Column Rotations (Johnson 2005) ......................................... 363 Figure D.9 - Energy Dissipation Calculation ............................................................... 364 Figure D.10 - Drift Correction Potentiometer Locations (Johnson 2005).................... 365 Figure D.11 - Rigid Body Frame Rotation (Christopulos 2005).................................. 366 xii List of Tables Table Number Page Table 1.1 – Performance Based Objectives for SCBFs (Johnson 2005).......................... 6 Table 3.0.1 – Thesis 1 Specimens (Johnson 2005) ........................................................ 19 Table 3.0.2 – Thesis 2 Specimens (Herman 2007)......................................................... 20 Table 3.0.3 – Thesis 3 Specimens .................................................................................. 21 Table 3.7.1 – Steel Properties from Material Tests ........................................................ 38 Table 4.3.1 – Dimensions for Figure 4.3.1..................................................................... 53 Table 4.3.2 – Type of Pot used at Respective Location ................................................. 56 Table 4.3.3 – Dimensions for Figure 4.3.3..................................................................... 57 Table 5.0.1 – Summary of Specimens............................................................................ 62 Table 5.1.1 – Performance State Notation...................................................................... 63 Table 5.3.1 - HSS-12 Peak Results ................................................................................ 73 Table 5.4.1 - HSS-13 Peak Results ................................................................................ 84 Table 5.5.1 - HSS-14 Peak Results ................................................................................ 94 Table 5.5.2 – HSS-14 Weld/Base Metal Damage Summary........................................ 103 Table 5.6.1 - HSS-15 Peak Results .............................................................................. 109 Table 5.6.2 – HSS-15 Weld/Base Metal Damage Summary........................................ 115 Table 5.7.1 - HSS-16 Peak Results .............................................................................. 120 Table 5.7.2 – HSS-16 Weld/Base Metal Damage Summary........................................ 130 Table 5.8.1 - HSS-17 Peak Results .............................................................................. 133 Table 5.8.2 – HSS-17 Weld/Base Metal Damage Summary........................................ 140 Table 6.1.1 – Summary of Ultimate Drift of Specimens.............................................. 146 Table 6.1.2 – Summary of Selected Gusset Plate Stiffnesses from FEM (in-k/rad) .... 165 Table 6.2.1 – Brace Performance State Comparison.................................................... 178 Table 6.2.2 – Gusset Plate Performance State Comparison ......................................... 180 Table 6.2.3 – Weld/Base Metal Performance State Comparison ................................. 183 Table 6.2.4 – Framing Elements Performance State Comparison................................ 186 Table 6.3.1 – Load Capacity Comparison .................................................................... 198 Table 6.6.1 – Overall Specimen Comparison............................................................... 207 Table 7.1.1 – Overall Comparison of All Specimens................................................... 210 Table 7.2.1 – Total Weld/Base Metal Crack Length at Given Drift Range ................. 211 Table 7.3.1 – Specimens Arranged From Largest Total Drift Range .......................... 226 Table 7.3.2 – Specimens Arranged From Highest Positive Drift Capacity.................. 227 Table 7.5.1 – Drift Capacity of Specimens Analyzed for Gusset Plate Rotation......... 232 Table 7.5.2 – Axial Strength of Specimens .................................................................. 236 Table 7.6.1 – Buckling of Framing Elements at Given Drift Range ............................ 240 Table C.1 – Gusset Plate Stiffness as Determined by FEM Analysis .......................... 348 xiii Acknowledgements The author would like to give special thanks to the National Science Foundation for funding the project and Nucor Yamoto Steel, Columbia Structural Tubing and American Institute of Steel Construction for donating steel used in this project. The author would also like to thank John Hooper and Cheryl Burwell of Magnusson Klemencic Associates, Tim Fraser of Canron Western Constructors Ltd, Walterio Lopes of Rutherford and Chekene, and Rafael Sabelli of Dasse Design Inc. for input in developing the test matrix. The author would like to acknowledge the faculty and staff at the Department of Civil and Environmental Engineering for their hard work in providing an excellent program, particularly Professors Charles Roeder and Dawn Lehman for their input and knowledge. Professor Jeffrey Berman is also thanked for serving on the defense committee reviewing this thesis. Testing would not have been possible without the hard work from several graduate and undergraduate students. Special thanks to all those involved that helped with fabrication of the test setup and test specimens. xiv Dedication To Robin. xv 1 Chapter 1: Introduction and Background 1.0 Introduction Special concentrically braced frames (SCBFs) are lateral force resisting structural systems used for buildings to resist forces induced by seismic ground motion. These structural steel frames are oriented so that the brace centerline intersects the column and beam at their centerline intersection. These concentric braced frames (CBFs) are designed to carry only axial forces, which is the most structurally efficient way to resist any type of load. Therefore, CBFs are very strong and efficient systems. Because of the large elastic force demands that an extreme earthquake is capable of exerting on a structure, it is uneconomical to design most seismic resisting systems to resist these forces elastically. Instead, most building structures are designed to absorb and dissipate energy through the ductility of the structure during these rare seismic events. Earthquake accelerations are relatively high frequency dynamic excitations that have a short duration of loading. Hence, the use of inelastic deformation, energy dissipation and reduced seismic forces are viable design concepts. However, the structural system must be designed to tolerate these inelastic deformations. SCBFs are CBFs designed to specific guidelines intended to ensure ductility during extreme earthquake loading and meet these inelastic deformation demands. 1.1 Theory of Design The ductility of an SCBF is extremely important to the seismic design and performance of the structure. The system is designed so that the brace will yield when it is in tension and buckle when it is in compression. This requires that the other structural members, 2 the steel connections, and the overall building geometry, allow this to happen. The seismic design of these SCBF connections is the focus of this research. 1.1.1 Connection Design The most accurate connection design will be one which, when combined with the brace and the frame, produces the best overall system seismic performance of the system. In the SCBFs analyzed within this thesis, HSS tubes will be used as the brace. These structural members are one of the least ductile members available because of cold working of the tube during formation. Therefore, the brace is ultimately expected to fail through fracture, but the goal of seismic design is to obtain the maximum system ductility prior to brace fracture. This ensures that the brace will be able to yield and buckle, dissipating as much energy as possible, and tolerating as large displacements as possible; ultimately resisting an earthquake through ductility. The AISC Seismic Provisions provide connection design equations to ensure that this occurs. An example of the connection type used in this research is a gusset plate connection and is shown here in Figure 1.1.1: Figure 1.1.1 – Example of Gusset Plate Connection 3 AISC requires that each limit state resistance for the connection design is stronger than the maximum expected force in the brace. The expected force in the brace has a different value for tension and compression, and each connection design limit state is evaluated by its appropriate expected resistance. Regardless of which value is used, the expected strength of the brace depends on the expected yield stress of the material, which depends on the grade of steel, the type of structural shape, and how it is formed. This expected yield stress is higher than the minimum specified yield stress used in design. Therefore, the expected strength of the brace in tension is equal to: Pt = R y Fy Ag (1.1) and the expected strength of the brace in compression is equal to: Pc = 1.1R y Pn (1.2) Where Ry is the ratio of the expected yield stress to the specified minimum yield stress determined from the AISC Seismic Design Provisions, Fy is the minimum specified or nominal yield stress of the brace, Ag is the gross area of the section, and Pn is the nominal compressive strength of the brace determined by the AISC specifications. According to AISC, all bracing connections shall be required to resist the expected strength of the brace. For limit states that are susceptible to tensile forces: φRn ≥ Pt (1.3) And for limit states susceptible to compressive forces: φRn ≥ Pc (1.4) 4 However, some of the limit states which are required to be stronger than the strength of the brace may actually increase the ductility of the frame if they are permitted to yield by design. Figure 1.1.2a shows yield mechanisms that may be beneficial to the ultimate drift capacity of the frame, while Figure 1.1.2b shows failure modes that will limit the ultimate drift capacity of the frame if they occur before the brace fractures. a) Yield Mechanisms b) Failure Modes Figure 1.1.2 – Yield Mechanisms and Failure Modes of SCBF (Johnson 2005) Since the seismic design of an SCBF relies on the ductility of the structure, yielding of the gusset plate, yielding of the brace, yielding of the beams at the gusset plate edge, and elongation of the bolt holes may all enhance the ductility of the frame. This yielding should be permitted during high seismic loads to dissipate seismic energy and develop inelastic deformation. However, failure modes shown above on the right in Figure 1.1.2b: bolt fracture, net section fracture of the brace, net section fracture of the gusset plate, buckling of the gusset plate, and block shear fracture should not occur before the brace fractures so that the brace can achieve its maximum inelastic 5 deformation and energy dissipation, while supporting gravity loads and assuring the integrity of the structure. 1.1.2 Overall Geometric Design Figure 1.1.3 shows a typical inelastic force-story drift plot of a braced frame with a single brace. The graph shows that the tensile capacity of the brace is much greater than the compression capacity of the brace, due to brace buckling. This frame with a single brace alone is not a good seismic design, because it is susceptible to ratcheting caused by the difference in its tensile and compressive brace resistance. Because of the asymmetric response of the frame, the frame shall be designed with braces in opposite directions (as specified in AISC). This will create a symmetric hysteretic response. The specimens tested within this research program contain only one brace and therefore show a similar asymmetric hysteretic force displacement curve. Although one brace alone will not be used for a complete seismic design in a real structure, these tested specimens will be used for comparative purposes between all of the different experiments. 500 Horizontal 400 Force 300 200 100 0 -6 -4 -2 0 -100 2 4 6 Story Drift -200 -300 Figure 1.1.3 - Force-Drift Response for Single Brace (Johnson 2005) 6 1.1.3 Performance Based Design Performance based design has been proposed as a method of assuring enhanced seismic performance. Three performance levels are assigned to respective seismic hazard levels, Immediate Occupancy, Life Safety, and Collapse Prevention as shown in Table 1.1. These performance based design concepts are employed in this connection design research. Table 1.1 – Performance Based Objectives for SCBFs (Johnson 2005) At the performance level of Immediate Occupancy (IO), a minimal amount of damage is tolerable. The exact amount of tolerable damage will be dependant on the use of the building. In general however, the structure should sustain its original strength and stiffness, and have minimal structural damage so that the building may be occupied immediately. Allowing the brace connections to yield as stated earlier in Section 1.1.1 may negatively affect this performance level, but limited yielding may be permissible. 7 The performance level of Life Safety (LS) requires there should be little risk to lifethreatening injury. This includes damage to structural and non-structural building components and predominantly deals with falling debris hazards. For the performance level of Collapse Prevention (CP), essentially any damage to the structure is acceptable aside from total or partial collapse. If the brace fractures, the structure is much more likely to collapse. Therefore, to postpone collapse, it is advantageous to the structure that the brace does not fracture. This research will examine how the brace connection affects the performance based design capacity limit states of the braced frame and the connection. 1.2 Research Objectives The research presented in this thesis was funded in part by the National Science Foundation (NSF) with the program CMS-0301792, “Performance-Based Design of Concentrically Braced Frames” and by the American Institute of Steel Construction. Funding from the NSF included research of SCBFs as well as buckling restrained braced frames (BRBFs). Specifically, the objectives of this research involve: 1. Evaluation of current design and research models. 2. Experimentally developing improved design of SCBFs and BRBFs systems to meet a balanced design approach. 3. Developing analytical, performance, and design models to support improved design of both systems. Gunnarson (2004) and Yoo (2006) performed analytical evaluations for this research project. Christopulos (2005) performed the experimental research on BRBFs. The first and second series of experimental SCBF tests, which this thesis builds upon, were performed by Johnson (2005) and Herman (2007). The SCBF tests in this ongoing 8 research program have been focused primarily on how the gusset plate connection detail influences the seismic performance of the frame. Johnson focused much of his analysis on achieving a desirable yielding hierarchy, while Herman was concerned with identified the effect of gusset plate connection design variables on the connection stiffness and the system performance. This thesis will use the analysis, results, and findings of these two previous sets of tests, and additional testing, to develop a preliminary design guide for the gusset plate connection. 1.3 Overview of Report This thesis will discuss the experiments carried out at UW testing full scale special concentrically braced frames. It is first necessary to discuss the previous research and existing literature regarding SCBFs, which will be located in Chapter 2. The design of the specimens will be detailed in Chapter 3, including a brief summary of the gusset plate designs for all of the specimens in the research program. Chapter 4 will discuss the details of the experiment setup and details on how the experiments were carried out. Chapter 5 will discuss the behavior and response of each of the six SCBFs detailed in this thesis. Interpretation and analysis of the data of each of the tests will be made in Chapter 6. A comparison of the performance of all 17 of the tests in this research program will be made in Chapter 7. A preliminary design guide for the gusset plate connection is presented in Chapter 8, based on the results of all of the program tests. A summary and conclusion with recommendations for further research is included in Chapter 9. Appendices are included with other relevant information. 9 Chapter 2: Literature Review 2.0 Introduction A great deal of experimental research has been carried out on braced frames and their components. This research can be divided into three main areas: experiments of the brace (Section 2.1), experiments of the gusset plates (Section 2.2), and experiments of the system (Section 2.3) which includes the brace, gusset plate and frame. Section 2.4 will discuss the findings of the two previous sets of tests within this research program. 2.1 Brace Experiments The brace is the primary element in SCBFs. It should absorb most of the seismic energy delivered by an earthquake, and if designed according to AISC, should be the first element to fracture under extreme seismic loading. Therefore, the behavior of the brace needs to be understood to maximize the seismic response of the frame. There have been many tests that have researched brace behavior under cyclical loads. These tests include Astaneh-Asl (1982), Aslani and Goel (1989), Tang and Goel (1987), Gugerli and Goel (1982), Walpole (1996), Jain et al (1978), and Shaback and Brown (2003). One particular study completed by Jain et al (1978) showed that the slenderness ratio of the brace has a large effect on the drift life of the brace. This research showed that the higher the slenderness ratio of the brace, the higher the positive and negative drift achieved by the brace. 10 These conclusions were also verified by research from Shaback and Brown (2003) and by Tang and Goel (1987). The more slender specimens experienced less severe buckling and therefore postponed brace fracture until higher drifts. Although according to Shaback and Brown, who tested HSS sections, the slenderness ratio was not as influential as the width thickness ratio of the tube walls on the fracture life of the brace. As the width thickness ratio of the walls decreased, fracture was postponed. This was because the fracture life of the brace followed closely after local buckling of the compression flange in the plastic region, and because resistance to local buckling increases as the width thickness ratio decreases according to elasticity theories. Shaback and Brown also concluded that the hysteretic behavior and energy dissipation are positively affected by a brace with a lower slenderness ratio. This shows that there is a trade-off between energy dissipation and drift life of a brace that is subjected to hysteretic loads. In general, a brace with a low slenderness ratio will have larger hysteretic loops, dissipating more energy at a given stage in the applied displacement, but fracture earlier, and a brace with a high slenderness ratio will have smaller hysteretic loops dissipating less energy but have a longer fracture life. 2.2 Gusset Plate Experiments Gusset plates provide the connection between the brace and the building frame. These plates have been shown, with the past research, to greatly affect the response of the brace. Experimental programs have been carried out by Bjorhovde and Chakrabarti (1985), Nast et al (1999), Rabinovitch and Cheng (1993), Brown (1988), Grondin et al (2000), Whitmore (1952), Astaneh-Asl et al (1982) and Aslani and Goel (1989). Listed here are relevant examples of experiments for the better understanding of gusset plates and there influence on SCBFs. 11 Whitmore (1952) proposed that the gusset plates be checked for strength using the width based on the connection length as shown in Figure 2.2.1. This method assumes that the load spreads out 30 degrees from the start of the connection and therefore the gusset plate needs to resist the design load at the end of the connection based on the width calculated from the two 30 degree angles and the width of the connection. Notice that this geometry does not take into the account any gusset plate material that is outside of the Whitmore width. Common practice has adopted this method and uses it for welded and bolted connections even though it was originally intended for bolted connections only. Figure 2.2.1 – Whitmore Width In multiple studies completed by Astaneh-Asl, Goel, and Hanson (1982, 1983, and 1985) at the University of Michigan, gusset plates were shown to have significant impact on the performance of the brace. This is further discussed in the Steel TIPS report by Astaneh-Asl, Cochran, and Sabelli (2006). The study parameters of this research included plate size, brace-to-gusset plate connection type (welded vs. bolted), connection length, brace size, and stitch spacing. This research showed that a higher brace performance would be achieved if the gusset plate allowed free rotation. In order 12 to achieve this, they recommended that the free length between the end of the brace and the assumed line of restraint for the gusset plate be a dimension of 2t (where t is the thickness of the gusset plate) as shown in Figure 2.2.2. This research also showed that the equations used for calculating the buckling capacity of the gusset plate accurately predicted this limit state. Figure 2.2.2 – 2t Clearance The test setup for these tests is shown in Figure 2.2.3. The framing members were attached as shown so that they could be used for multiple specimens. The brace centerline does not intersect the framing member centerlines in this setup and the brace is only connected to the beam, and not the column. Additionally, only tapered plates were tested within this research. 13 Figure 2.2.3 – Test Schematic of Astaneh-Asl, Goel, and Hanson (1982) This research was continued at the University of Michigan in 1989 using the same test setup by Aslani and Goel. They examined the impact of stitch spacing, brace configuration and end fixity of the brace. With regard to the end fixity, there was mixed reviews. Specimens with fully restrained end connections increased the energy dissipation and also the buckling load when compared to the flexible end connections. However, in some of these tests, these specimens were more brittle than the specimens with flexible connections. 2.3 System Experiments There are not a large number of experiments that have included an accurate representation of an entire system which includes the brace, gusset plate, and framing members of an actual building structure. One such test that included all three of these 14 components was carried out at the University of California at Berkeley by Uriz. This test included a two story braced frame with chevron bracing. Figure 2.3.1 – Test Schematic of Uriz (2005) This system used tapered gusset plates connected to the framing elements with fillet welds. HSS tube sections were used for the braces. As required by AISC, the beams were designed to resist the vertical component of the tensile capacity of the brace so that when brace buckling occurs, the vertical component of the tensile force in the opposite brace has an alternate load path. The objectives of the test were to improve understanding of the behavior of typical SCBF systems, gather information to validate and improve computer models, improve understanding of the interaction of the various components of the system, and assess the current design guidelines. The braces buckled out of plate in this experiment as in agreement with past studies. This put hinging demands on the gusset plates. With the addition of the framing 15 members, considerable damage was noticed in these members. Since the beam was designed for the point load at midspan, it was much larger than the column. Therefore the column received the more critical damage in the form of fracture of the section next to the beam-to-column connection. An interesting thing to note with these experiments is that once one of the stories started to buckle and yield, damage was concentrated in this story. Buckling and yielding did not occur in the braces of the other story at this time in the experiment. Additionally, when one of the brace buckled, the beam that was designed for the vertical component of the tensile capacity of the brace deflected elastically toward the brace. This limited the yielding in the tensile brace, and less energy was dissipated than expected. 2.4 Previous Tests within Test Program Two researchers, Johnson (2005) and Herman (2007), have completed 11 total tests which are built upon in this thesis. All three sets of tests use the same test setup and similar test specimens which include a 12 foot by 12 foot one story singe bay structure, complete with framing members connected to a diagonal brace with gusset plates. These gusset plates were connected to both the beam and the column and used both rectangular and tapered geometry. Johnson concluded that the 2t straight line clearance provides too large of a plate, and instead, a plate using an elliptical clearance will create a smaller plate which will increase the drift capacity of the brace. The gusset plate thickness was recommended to be minimized by using a β factor of 0.85 for the limit state of Whitmore yielding. Additionally, the gusset plate welds should be designed to resist the plastic capacity of the plate as the uniform force method did not design welds strong enough to cause brace fracture before weld fracture. 16 Similar results were found by Herman. Additional conclusions included that tapered plates more evenly distribute the inelastic action leading to improved system performance. However, tapered plates increase the demands on the gusset plate welds. Framing element stiffness was also found to influence the ductility of the system. Higher beam stiffness led to reduced drift capacity of the brace. 2.5 Summary of Research According to the research, there are many factors which affect the response of the frame. The hysteretic response and drift life of the brace mainly depend on the slenderness ratio and width thickness ratio of the brace. There appears to be a strong agreement that gusset plates should allow for free rotation. However, allowing free rotation appears to depend on the support conditions of the gusset plate. Many of the experiments listed in this review have only researched individual components of SCBFs. While these experiments have been valuable in determining the basic response of the components, additional research is required that combines all of the components of an actual building structure. This is so that the experiments will imitate the response of a real building and so that the structural response that is only associated with the collective system is not overlooked. 17 Chapter 3: Specimen Design 3.0 Introduction The special concentrically braced frames that were designed and tested for this thesis are described in this chapter. These specimens were intended to imitate a single bay, one story frame that could be found in a lower story of a low rise building (Figure 3.0.1). In a building structure, braces shall be used in pairs in opposite directions. Due to limitations on space and cost of the specimens, only one brace was used in the specimens. It was believed that accurate comparisons could be made between the specimens regardless of this omission. Before this research at UW, braces and gusset plate connections have been tested, but not together and not with beams and columns as part of the test specimen. With more elements of a building in the test specimen, a more accurate portrayal of how special concentrically braced frames respond to applied displacements is expected. Figure 3.0.1 – Prototype Specimen (Johnson 2005) 18 The overall specimen was design by Shawn Johnson during his graduate work at UW and is detailed in his thesis: Improved Seismic Performance of Concentrically Braced Frames (Johnson 2005). For more information on the overall frame regarding the design philosophy, design specifications, calculations, frame tolerances, and fabrication of the frame, the reader is referred to this earlier work (Johnson 2005, Chapter 3). Appendix A of this thesis shows detailed calculations for the connection design of two of the specimens. The first section shows calculations for HSS-12. Many of these calculations were similar if not exactly the same for the remaining specimens. For this reason, only the different calculations for HSS-14 are shown in the second section of Appendix A. This thesis builds on the earlier work by Johnson (2005) and Herman (2007). The 11 previous specimens that have been tested prior to this research are discussed in detail, including the test results, provided elsewhere (Johnson 2005, Herman 2007). Tables 3.1.1 and 3.1.2 show and describe the gusset plate details for these previous tests. Six additional tests were completed, and Table 3.1.3 provides an overview of these tests. 19 Table 3.0.1 – Thesis 1 Specimens (Johnson 2005) 20 Table 3.0.2 – Thesis 2 Specimens (Herman 2007) 21 Table 3.0.3 – Thesis 3 Specimens 22 Table 3.0.3 shows the gusset plate details for the six specimens that were tested and that are the topic for this thesis. Each of the next six sections discusses why each of these specimens has been chosen to be tested. 3.1 HSS-12 – Reference Specimen with CJP Welds Currently, AISC Seismic Provisions require a straight line 2t clearance as illustrated in Figure 3.1.1. This requires that the brace be set away from the beam column intersection a distance 2t from a line perpendicular to the longitudinal axis of the brace which also intersects the corner of the gusset plate. The value of this requirement is questionable as evident in the previous research. Therefore, in order to further investigate the AISC recommendation, HSS-12 utilized the straight line 2t clearance. Figure 3.1.1 – 2t Clearance Figure 3.1.2 shows the gusset plate detail for specimen HSS-12. This gusset plate detail was designed in accordance with the AISC Seismic Provisions. It was exactly the same 23 as the reference specimen HSS-01, except it used complete joint penetration welds to connect the gusset plate to the framing members. Figure 3.1.2 – HSS-12 Gusset Plate Detail The reference specimen, HSS-01, that was designed using current design procedures did not perform well. The AISC seismic provisions state that the required strength of bracing connections shall be the lesser of the following: 1. The nominal axial tensile strength of the bracing member, determined as RyFyAg. 2. The maximum force, indicated by analysis that can be transferred to the brace by the system. Therefore, the gusset plate welds were designed for criterion (1) which equaled 370 kips for the design load. The load in the brace never experienced this force during the length of the test; however the gusset plate welds failed completely before the brace fractured. This was unacceptable because it limited the energy dissipation of the brace and also the 24 ultimate drift capacity of the system. After the brace of an SCBF fractures, the structural stability relies only on frame action to withstand seismic forces and is susceptible to collapse. Because of the premature failure of the gusset plate welds in HSS-01, they were changed to complete joint penetration welds for HSS-12. Furthermore, the goal of this research is to find how the gusset plate affects the life of the braced frame. Since the welds failed before the brace fractured, it was difficult to presume how the gusset plate affected the brace. And it was impossible to tell how the gusset plate affected the ultimate drift capacity of the frame. HSS-12 was designed so that these welds would not fail before the brace, and therefore more information would be available on how the gusset plate affected the behavior of the system. 3.2 HSS-13 – Tapered Plate with CJP Welds Johnson (2005) had proposed an elliptical clearance in which the brace clearance was based on an ellipse that was formed by the geometry of the gusset plate as illustrated in Figure 3.2.1. The center of the ellipse was located at the maximum horizontal dimension and the maximum vertical dimension of the rectangular gusset plate. Tapered gusset plates used this same elliptical model where the ellipse was defined as the ellipse needed for the smallest rectangular gusset plate fully enclosing the tapered plate. The elliptical clearance was then specified by a number multiplied by the thickness of the plate (Nt) as shown in the figure. For example: if the gusset plate was ½ an inch thick and dimension Nt was equal to three inches, then the elliptical clearance was termed 6t. To design this geometry was an iterative process. It could be done graphically or by the process discussed later in the thesis. HSS-13 utilized the elliptical clearance. 25 Figure 3.2.1 – Gusset Plate with Elliptical Clearance Figure 3.2.2 shows the gusset plate detail for specimen HSS-13. This gusset plate was designed as a tapered one half inch plate with complete joint penetration welds connecting the gusset plate to the framing members. The elliptical clearance was designed using 7t elliptical clearance. Note that this method ignored the gusset plate height to width ratio set forth in the 13th Edition of AISC Steel Construction Manual, part 13, which states: α − β tan(θ ) = eb tan(θ ) − ec (3.2.1) where α is half the width of gusset-to-beam connection, β is half the width of the gusset-to-column connection, ec is half the depth of the column, eb is half the depth of the beam, and θ is the angle of the brace with respect to the horizontal. 26 Figure 3.2.2 – HSS-13 Gusset Plate Detail This design was very similar to HSS-10. The only difference was the gusset plate welds. HSS-10 used one half inch fillet welds while HSS-13 used complete joint penetration welds. HSS-10 had an overall fine performance, however the north east beam weld tore relatively early in the experiment: at a drift ratio of -1.35%. This crack only propagated to two inches, but the small deformation of initiation of cracking causes concern about some of the higher seismic performance goals. The north east column weld began to fracture at a drift ratio of -2.21% and increased to a length of seven inches by the end of the test. The south west beam weld developed a crack of three inches by the end of the test. And the south west column weld developed a crack of four inches by the end of the test. These cracks may cause concern for some performance based design limit states. Therefore, the gusset plate for HSS-13 was welded to the framing members using complete joint penetration welds to determine if they would reduce or delay weld cracking. 27 3.3 HSS-14 – Unreinforced Net Section Figure 3.3.1 shows the gusset plate detail for specimen HSS-14. This specimen was designed specifically to examine the necessity of the reinforcement plate that is typically welded to the brace at the critical net section of the brace (at the end of the slot) as shown in Fig. 3.3.2. Specimens HSS-01 through HSS-13 all had the reinforcement plate welded to the brace (see Tables 3.0.1, 3.0.2 and 3.0.3 for connection details with the reinforcement plate). Figure 3.3.1 – HSS-14 Gusset Plate Detail In order to connect the brace to the gusset plate, a slot shown in Figure 3.3.2 was cut into the brace in which the gusset plate slides into. The brace was then welded to the gusset plate at the edges of the slot. One negative aspect of this connection detail was the slot must continue beyond the edge of the gusset plate, and a critical net section developed at this position as shown in Fig. 3.3.2. In tests ran at the University of California at Berkeley, cracks occurred through the net section (Yang and Mahin, 2005). As a result, in all previous testes (HSS-01 to HSS-13) executed at UW, the net section was reinforced by welding plates on the top and bottom flanges of the tube as illustrated in column 3 of Tables 3.0.1 and 3.0.2 and Figures 3.1.2 and 3.2.2. 28 Figure 3.3.2 –Slot Detail of Brace HSS-14 Nonlinear analyses (Jung 2006) suggested that due to the test setup differences between UCB and UW, the problem of net section might not be an issue for the UW specimens. The main difference between the two setups was that the tests at UCB tested the brace and gusset plates, with very rigid end supports at the gusset plates. However the test setup at UW included framing members of a building that are connected to the brace and gusset plate assembly. The connections for the UW tests were relatively flexible compared to the Berkeley tests, and therefore the test setup at UW was more accurate than the test setup at UCB. There were still some major simplifications with the setup at UW, but it was one step more sophisticated than the UCB setup. It was proposed that these differences may negate the need for the net section reinforcement. This was done to inhibit crack initiation from this internal source. The hole at the base of the slot was fabricated by drilling a hole larger than the slot itself. This was done so that the hole would not obtain any scratches during further fabrication, i.e. grinding of the slot to ensure fit up. The hole was then reamed to create a smooth surface. Below is an analysis of the net section using the AISC 2002 Seismic Provisions and the AISC Manual of Steel Construction: 29 φPn ≥ Pu (3.3.1) Pu = R y Fy Ag = 1.3 * 46 * 6.18 = 370kips (3.3.2) φPn = φRt Fu Ae (3.3.3) Ae = AnU (3.3.4) U = 1− x / l (3.3.5) Where: And: x= B 2 + 2 BH 5 2 + 2 * 5 * 5 = 1.875 = 4( B + H ) 4(5 + 5) (3.3.6) Therefore: U = 1 − 1.875 / 14.75 = 0.873 (3.3.7) Ae = 0.873 * (6.18 − 2 * 3 / 8 * 0.5) = 5.07 (3.3.8) φPn = φRt Fu Ae = 0.75 *1.2 * 58 * 5.07 = 265kips (3.3.9) And: The above equation used a factor Rt equal to 1.2. This factor increased the ultimate tensile strength of the brace similar to Ry, which increased the yield strength of the brace. However, Rt does not exist in the AISC 2002 Seismic Provisions. This omission 30 was realized in the 2005 Seismic Provisions, when it was added into the code. In the new code, Ry and Rt are 1.4 and 1.3 respectively. In order to maintain a similar relationship between Ry and Rt for this analysis, a value of 1.2 was assumed for Rt, compared to 1.3 for Ry. Since φPn < Pu , the code required the net section to be reinforced. However, to check the accuracy of the provision, the net section was not reinforced. The gusset plate of HSS-14 was designed using the elliptical clearance method with a 7.7t offset similar to HSS-05 and HSS-06. The gusset plate was 3/8 inch thick and welded to the framing members with a 7/16 inch fillet weld. As previous research (Johnson 2005) recommended, the weld was designed to have a larger tensile capacity than the expected tensile capacity of the gusset plate. 3.4 HSS-15 – Reduced Splice Length Figure 3.4.1 shows the gusset plate detail for specimen HSS-15. This specimen was designed with the connection between the brace and the gusset plate to have a smaller length. All earlier tests except HSS-04 used 14.75 inches as their splice length (HSS-04 had a splice length of 13.75 inches). This specimen used 11.25 inches as its splice length, because this was the minimum length required for block shear of the gusset. 31 Figure 3.4.1 –Gusset Plate Detail HSS-15 The reduced splice length affected the design of the weld between the brace and the gusset plate and also the gusset plate itself. The weld was increased from 5/16 inch to 7/16 inch. The gusset plate needed to be checked for strength regarding block shear (Equations 3.4.1 to 3.4.5) and Whitmore fracture (Equations 3.4.6 to 3.4.8). Since the specimens (Johnson 2005) were designed using the 2002 AISC Seismic Provisions, these provisions were also used for the design of this specimen and all of the specimens in this thesis (even though the 2005 provisions have been available before these specimens have been designed). The reason that the older code was used was so that the connections would not be designed with different design loads. Ry changed from 1.3 in the 2002 provisions to 1.4 in the 2005 provisions. φRn ≥ Pu (3.4.1) Pu = R y Fy Ag = 1.3 * 46 * 6.18 = 370kips (3.4.2) φRn = φt g (0.6 * 2l c Fu + bc Fu ) (3.4.3) φRn = 0.75 * 0.375 * (0.6 * 2 *11.25 * 65 + 5 * 65) = 338kips (3.4.4) 32 Unfortunately, block shear was not satisfied by the strength of the gusset plate. In order to satisfy this equation a β factor was used in place of φ. The β factor used was 0.85 to make the limit state of block shear stronger than the applied load. The experiment would help determine the accuracy of increasing the capacity of the gusset plate. βRn = 0.85 * 0.375 * (0.6 * 2 *11.25 * 65 + 5 * 65) = 383kips (3.4.5) Notice that in Equation J4-5 of the 13th Edition of the AISC Manuel of Steel Construction, the strength of block shear has two requirements. One requirement includes shear yielding in the plate, and the other includes shear fracture of the plate. The requirement that includes shear yielding was ignored for the gusset plate design. This is because a gusset plate that yields will create a more ductile connection which will absorb more energy and positively affect the drift capacity of the brace. Similar to block shear, Whitmore fracture did not have enough strength to resist the design load as shown in Equation 3.4.6 and 3.4.7. Therefore, in place of φ, a β factor of 0.85 was used to increase the strength of this limit state as shown in Equation 3.4.8. The accuracy of this alteration to the provisions will be verified with the test. φRn = φt g Fu (2l c tan(30) + bc ) (3.4.6) φRn = 0.75 * 0.375 * 65(2 *11.25 tan(30) + 5) = 328kips (3.4.7) βRn = 0.85 * 0.375 * 65(2 *11.25 tan(30) + 5) = 372kips (3.4.8) Whitmore yielding was omitted as a design check. This is because it was perceived as desirable for the gusset plate to yield. 33 HSS-15 had a 3/8 inch gusset plate with a 6t elliptical offset. Recommended by previous research (Johnson 2005), the gusset plate fillet welds were designed to have greater tensile capacity than the tensile capacity of the gusset plate, and therefore, 7/16 inch thick. Because HSS-14 did not show any problems with the net section, HSS-15 also did not include net section reinforcement. 3.5 HSS-16 – Bolted Splice Connection Figure 3.5.1 shows the connection detail for specimen HSS-16. This specimen is much different than the other specimens. Instead of connecting the brace directly to the gusset plate with a fillet weld (which would need to be field welded in an actual building), the brace was connected to an extension plate which was bolted to the gusset plate. The advantage to this was that the field connection between the extension plate and the gusset plate was a bolted connection, which may have economic benefits. The weld which connected the brace to the extension plate could be done in the shop to omit the necessity of field welds. This extension plate was slotted for about one third of the length of the splice, while the brace was slotted two thirds the length of the splice. This is based on a net section concept proposed by Packer (2007) and it eliminated the need for net section reinforcement. The extension plate was connected to the gusset plate with 1-1/8 inch slip critical class A bolts with oversized holes in both the gusset plate and the extension plate. The oversized holes were used to permit more rapid erection and placement of the brace. 34 Figure 3.5.1 –Gusset Plate Detail HSS-16 The spacing of the bolts was four inches perpendicular to the longitudinal axis of the brace. Three inch spacing was used in the parallel direction, which was the minimum allowable spacing per Section J3.3 of AISC. The bolts were designed using the 2002 AISC Manual of Steel Construction, with slip being considered a serviceability limit state (see Table 7-15, AISC): φRn ≥ Pu (3.5.1) Pu = R y Fy Ag = 1.3 * 46 * 6.18 = 370kips (3.5.2) φRn = 25.4kips (3.5.3) n= Pu = 14.6 bolts φRn (3.5.4) The connection was also checked for bearing at the bolt holes as shown in Equation 3.5.3 and 3.5.4 (especially since the minimum allowable spacing was used for the longitudinal spacing): 35 φRn = φ1.2 Lc tFu = 0.75 *1.2 *1.5 * 3 / 8 * 65 = 32.9kips n= Pu = 11.2 bolts φRn (3.5.3) (3.5.4) The gusset plate was not checked for Whitmore yielding because it is desirable for the gusset plate to yield in an earthquake. However, it was checked against Whitmore fracture as shown here: φRn ≥ Pu (3.5.5) φRn = φt g Fu (2l c tan(30) + 8 − 3d h ) (3.5.6) φRn = 0.75 * 0.375 * 65(2 * 12 tan(30) + 8 − 4.5) = 317kips (3.5.7) The limit state of Whitmore fracture does not work in this instance with the φ factor from AISC. Therefore a β factor of 0.9 was used in view of the earlier net section reasoning described for earlier specimens. βRn = 0.9 * 0.375 * 65(2 *12 tan(30) + 8 − 4.5) = 381kips (3.5.7) Similarly, the β factor of 0.9 was required in place of φ to give net section of the extension plate a capacity above the design load Pu. This limit state controlled the design of the extension plate. This extension plate had a 5/8 inch eccentricity as shown in Figure 3.5.2 (the 5/16” dimension in the figure represents the eccentricity between the gusset plate and center of the brace). The plate was designed for axial load only. The bending moments due to out-of-plane eccentricity were not considered. This was done because the installation 36 and potential replacement of a brace with this eccentric plate is much easier than a concentrically bolted connection, and all prior gussets handled large eccentricities (after brace buckling) relatively well. Figure 3.5.2 –Section of Connection Detail HSS-16 The clearance of the end of the brace more than met the 2t straight line clearance required by the AISC Seismic Provisions. It should be noted however, that the extension plate was very close to the beam-column intersection (see Figure 3.5.1). 3.6 HSS-17 – 3/8” Tapered Plate Figure 3.6.1 shows the connection detail for specimen HSS-17. This specimen uses a 3/8 inch tapered gusset plate with 3/8 inch fillet welds connecting it to the framing members. As previous research (Johnson 2005) recommended, the weld sized was based on the design criterion that the weld should have a greater tensile capacity than the gusset plate. 37 Figure 3.6.1 –Gusset Plate Detail HSS-17 Tapered gusset plates are thought to be the most flexible type of gusset plate since they reduce the size of the rigid joint, and potentially create a frame with higher drift capacity. This has been verified by the performance of the previous specimens with tapered gusset plates. It has also been shown that a thinner plate reduces the out-ofplane stiffness of the joint: shown by the performance of rectangular gusset plates. Therefore, it was apparent that as long as the design criteria were satisfied, a specimen with a thinner tapered plate should perform well. Whitmore yielding was checked for the design of the gusset plate. φRn ≥ Pu (3.6.1) Pu = R y Fy Ag = 1.3 * 46 * 6.18 = 370kips (3.6.2) φRn = φt g Fy (2l c tan(30) + bb ) (3.6.3) φRn = 0.9 * 0.375 * 50(2 * 12 tan(30) + 5) = 372kips (3.6.4) 38 3.7 Material The beams and columns were hot rolled sections of A992 steel. All plate material was nominal A572 steel. The high strength steel tubes were A500B/C. All bolts were A490, and all welds were made using 5/64 core shield 8 – E71T-8 flux core welds made by pre-certified welders. The actual measured properties of the materials for these tests are provided in Table 3.7.1. Properties for the braces and gusset plates were unable to be attained. Table 3.7.1 – Steel Properties from Material Tests 39 Chapter 4: Experiment Setup 4.0 Introduction This chapter will discuss the experiment setup for the Special Concentrically Braced Frame specimens tested in this research project. The original setup was designed by Shawn Johnson and more detailed information can be found his thesis (Johnson 2005). All of the specimens were laid horizontal, parallel to the lab floor. Quasi-static displacement was applied to the specimen and observations were made to understand how the steel specimens responded to applied drifts. Although there are certain limitations within the laboratory, the experiment setup was designed to simulate an actual building structure subjected to ground motion from an earthquake. 4.1 Test Components For the specimen to experience large forces associated with an earthquake, test components had to be designed to apply these forces to the specimen, and also to resist the forces that resulted from the specimen response. An actuator (Section 4.4.1) applied displacement to the structure through the load beam (Section 4.4.2) which was connected to the north beam of the specimen. Axial load was applied to the columns to simulate gravity loads through post-tensioned axial rods (Section 4.4.3). Large compression forces existed in the framing members at different applied displacements throughout the test. Therefore, to prevent the members from buckling globally, out-ofplane restraints were applied to the specimen at certain locations (Section 4.4.4). The lateral and gravity loads were resisted by a channel assembly which acted as the boundary condition (Section 4.4.5). The channel assembly was connected to a concrete strong wall which was connected to the concrete strong floor (Section 4.4.6). 40 The following figures show overall views of the test components. Figure 4.1.1 shows a drawing with all the components used to test the specimens. Figure 4.1.2 shows the dimensions of the test components. And Figure 4.1.3 shows a photograph of the specimen in the testing position with the test components. 41 Figure 4.1.1 – Test Setup Components (Johnson 2005) 42 Figure 4.1.2 – Test Setup Dimensions (Johnson 2005) 43 Figure 4.1.3 – Test Setup Photograph (Johnson 2005) 4.1.1 Actuator and Reaction Block A hydraulic actuator (shown in Figure 4.1.4 and Figure 4.1.5) was used to apply displacement to the specimen. The actuator had a displacement range of ten inches in each direction, a nominal tensile capacity of 330 kips, and nominal compression capacity of 470 kips. The frame was oriented so that when the actuator was in tension, the brace was in compression. Therefore, the smaller tensile capacity of the actuator occurred when the brace was in compression, which also had a smaller capacity. A concrete reaction block was used to transfer loads from the actuator to the concrete strong floor. 44 Figure 4.1.4 – Actuator and Reaction Block Photograph (Johnson 2005) Figure 4.1.5 – Actuator and Reaction Block Assembly (Johnson 2005) 4.1.2 Load Beam A steel W21x62 load beam was used to transfer loads from the actuator to the specimen (Figure 4.1.6). The force from the load beam was transferred by 10 one inch diameter A490 structural steel bolts which fastened the load beam flange to the north beam 45 flange of the specimen. A web doubler was attached to the north beam web to resist local web buckling. Figure 4.1.6 – Load Beam Details 4.1.3 Gravity Load System To simulate gravity loads on the specimen columns, post-tensioned steel rods where used. 350 kips was delivered to each column through two 1-3/4 inch diameter high strength Williams rods (150 ksi). The force was transferred from the rods through a spherical nut with a cupped bearing plate to a four inch thick cap plate which beared on the column as shown in Figure 4.1.7 and 4.1.8b. The opposite end of the rod was supported by the channel assembly as shown in Figure 4.1.8a. Two full depth column stiffeners were added one inch from the south end of each column to resist local flange buckling at the channel assembly (Figure 4.1.8a). 46 Figure 4.1.7 - Axial Load System Schematic (Johnson 2005) Column Stiffener a) b) Figure 4.1.8 - Axial Load System Photographs (Johnson 2005) 4.1.4 Out-of-Plane Restraints Out-of-plane supports were used to brace the beams and columns from buckling perpendicular to the plane of the frame. Threaded rods that were connected to strong floor embedment anchors were used to support the W-sections which acted as the outof-plane supports (Figure 4.1.9). The column supports were placed at the center of the column, and supported both flanges. In a real building structure, out-of-plane supports for a column exist at the floor level, suggesting the specimen columns should have also 47 been supported at this location. However, the out-of-plane supports accomplished similar results as a real building structure by resisting global member buckling. The two different out-of-plane restraint conditions for the specimen beams simulated two different potential conditions in a real building structure. The north beam had both flanges supported by the out-of-plane restraint. Significantly, the out-of-plane restraint supported the flange that was connected to the gusset plate. This can be compared to a condition in a building at the bottom of a one story brace where the slab braces the beam flange that is connected to the gusset plate. These conditions are similar because in both situations, the beam flange that is connected to the gusset plate is restrained from out-of-plane motion: by the support in the experiment, and by the slab in a building. The south beam was only braced from out-of-plane motion at the flange that was opposite the gusset plate connection. This is similar to a condition in a building at the top of a one story brace where nothing necessarily braces the bottom flange that is connected to the gusset plate (although sometimes a perpendicular beam may be designed to brace this flange). Figure 4.1.9 – Out of Plane Restraints (Johnson 2005) 48 It was important that the out-of-plane supports did not resist any in-plane forces so that accurate measurements of the load resistance of the frame were recorded. To ensure of this, nylon cylinders were attached to the frame, and stainless steel plates were attached to the out-of-plane supports. The interface between the stainless steel and the nylon were then lubricated with silicon insulation gel to provide minimal shear transfer. Figure 4.1.10 shows a photograph of this condition. Figure 4.1.10 – Out of Plane Restraints (Johnson 2005) 4.1.5 Boundary Conditions A channel assembly was used to resist loads applied by the specimen during the test. The channel assembly was made up of two C15X50 channels between two steel plates as shown in Figure 4.1.11. The assembly supported the lateral force in the south beam of the frame with 10 one inch diameter A490 structural steel bolts which were fastened to a 1-1/2 inch thick shear transfer plate that was welded to the assembly as shown in Figure 4.1.12. 49 When the columns were in compression, the channel assembly supported the column load through bearing at the end of the column. However, when this compression was reduced to zero, the column lifted off the assembly. If this were to occur in a real building structure, the axial load in the column would be in tension. Since there was nothing at this connection to resist tension, the load was transferred into the axial rod at the north end of the column which then carried the load down to the channel assembly where it was restrained (see Figure 4.1.8). Figure 4.1.11 - Channel Assembly Cross-Section (Johnson) Figure 4.1.12 - Shear Transfer Connection (Johnson) 50 4.1.6 Strong Wall and Strong Floor The strong floor supported the strong wall, and the strong wall supported the channel assembly. The strong wall was a 2-1/2 foot thick concrete wall that was prestressed with embedded conduits spaced at 18 inches on center. The strong floor was a four foot thick concrete slab to support the loads from the strong wall. The floor had open conduits with threaded anchors embedded at the bottom of the floor at three feet on center. These anchors accepted the threaded rods which supported the out-of-plane restraints. 4.2 Loading Protocol The loading protocol was guided by the ATC-24 protocol (ATC) and the SAC Steel Project and was based on the interstory drift angle of the frame at the onset of first yielding or buckling, θ y , as illustrated in Figure 4.2.1. The controlling parameter, θ y , was estimated from the yield displacement obtained from an idealized computer analysis. Upon completing of the first tests, the loading protocol was revised based on the recorded drift level at which initial buckling occurred. The value of θ y was determined to be 0.625 inches. Finally, as recommended in ATC, the load cycles were run as follows: For: 0 ≤ θ < 1.0θ y Æ 60 second cycles For: 1.0θ y ≤ θ < 2.0θ y Æ 80 second cycles For: 2.0θ y ≤ θ < 4.0θ y Æ 120 second cycles For: θ ≤ 4.0θ y Æ 160 second cycles 51 Figure 4.2.1 - Loading History (Johnson 2005) Each cycle of applied displacement began with tension in the brace, followed by an equal applied displacement in compression. The displacement was held at the peak positive and negative displacements to record visual observations and take pictures. The displacement was also held at zero displacement between cycles. It is important to note that although the input into the actuator was a symmetric displacement history, the actual applied displacement to the specimen was not symmetric. This is because there were higher losses when the brace was in tension (compared to when it was in compression) due to rigid body rotation (overturning) and bolt slippage since the force in the specimen was higher when the brace was in tension. Additionally, in some of the specimens, the brace buckled down to the strong floor, and the negative displacement needed to be limited so that the brace would not come into contact with the strong floor. 52 4.3 Instrumentation Potentiometers, strain gauges, whitewash, cameras, video cameras, and the actuator load cell were used to determine the response of the loaded specimens. The following section will discuss details of this instrumentation. 4.3.1 Strain Gauges Strain gauges were applied to the specimen to determine the strain at the applied location. Pairs of gauges were located on opposite sides of the brace, beams and columns, equidistant from the end of the member. From the strains measured by the gauges, axial force and moment in each member was calculated as shown in Appendix D. The strain gauges utilized in these experiments were FLA-6-11-5L manufactured by Tokyo Sokki Kenkyuho Co. Ltd. The gauges had a nominal gauge factor of 2.12 and a 6 mm gauge length. All of the gauges stopped measuring strain accurately when the steel that the gauge was attached to, yielded. Additionally, a few of the gauges did not function during the entire length of the test. Figure 4.3.1 shows the locations of the strain gauges, and Table 4.3.1 shows the values of the dimensions in the figure for each test. 53 Figure 4.3.1 – Strain Gauge Diagram Table 4.3.1 – Dimensions for Figure 4.3.1 54 4.3.2 Potentiometers Potentiometers (pots) were used to calculate displacements of the frame. Typically, pots were connected to a relative stationary point (i.e. the ground, load beam or support beam) and measured frame displacement relative to the stationary point. BEI Duncan model 600 and 9600 pots were used to measure in-plane translation of the frame (including overall deflection, slip, and uplift), rotation of beams and columns, and outof-plane displacement (i.e. at the south west gusset plate and the beam-column intersections). UniMeasure model P510 string potentiometers were used to measure displacements larger than five inches. Figure 4.3.2 shows pot locations on the frame, and Table 4.3.2 designates which type of pot was used for each location. Figure 4.3.3 shows a detailed view of the pots used at the northeast gusset plate, and Table 4.3.3 shows the values for the dimensions in this figure. Pots 53 and 54 (as shown in Figure 4.3.2) measured the out-of-plane displacement of the brace. These string pots were connected to a pin that was screwed into a small drilled hole at the bottom of the brace. 55 Figure 4.3.2 – Potentiometer Diagram 56 Table 4.3.2 – Type of Pot used at Respective Location 57 Figure 4.3.3 – Potentiometer Location Diagram at NE Gusset Plate Table 4.3.3 – Dimensions for Figure 4.3.3 4.3.3 Other Instrumentation The lateral load delivered to each specimen was recorded by a load cell in the actuator. A small frictional force existed in the out-of-plane supports which led to loss of the load in the system. However, this force could be neglected because it was so small. This 58 was known because there were no vertical drops in resistance at reversals on the specimen hysteretic curves (Chapter 5). The whitewash, a mixture of three parts DAP Plaster of Paris Dry Mix and one part water, was applied to the hot rolled steel sections of the specimen to show where yielding occurred. The whitewash bonded to the steel’s mill scale, and when the steel yielded, the mill scale debonded from the steel, carrying the whitewash with it. Whitewash was able to help determine yielding in the beams, columns, and gusset plates. Because the brace was cold formed, mill scale did not exist on the brace. Therefore, whitewash was unable to help identify yielding in the brace. Photographs were taken when the actuator was stopped at maximum displacements wherever damage to the frame was evident. A digital video camera was also used to document the response of the specimen. The camera was positioned on top of the strong wall so that the entire test frame could be captured. The camera was turned on once buckling and yielding in the frame was noticed. 4.4 Data Acquisition System LabVIEW Version 7.1 on a Windows based personal computer system was used to control the data acquisition system. LabVIEW was used to scan data channels and convert readings to appropriate physical quantities before being recorded to the data file. Measurements of voltage from potentiometers were converted to units of inches using the potentiometer calibration factors. Strain gauge resistance was converted to units of micro-strains using a built in function of LabVIEW. Data from the strain gauges and pots was received every half second during the test by the data acquisition system. 59 4.5 Testing Preparation Structural steel shapes were delivered to the laboratory, and the specimen members were fabricated in the lab. The frame was transported to the strong floor using existing cranes in the laboratory. The frame was then leveled and placed accurately along the channel assembly. A steel plate template that was used to drill the bolt holes in the channel assembly was used again to drill the bolt holes in the south beam for each specimen to ensure the alignment of bolt holes. A similar process was used to drill the holes in the north beam. The frame was then bolted to the channel assembly and the load beam. Steel shims were added where gaps existed in the fit up. Strain gauges, potentiometers, and out-of-plane supports were then added to the specimen, and whitewash was applied. The final step was to apply the gravity load to the columns. 60 Chapter 5: Experimental Results 5.0 Introduction This chapter analyzes the results of experiments HSS-12 through HSS-17. These experiments are a continuation of similar tests HSS-01 to HSS-11 previously carried out by Shawn Johnson (2005) and Dave Herman (2007). All of the specimens were tested in the structural lab of UW and used the same support and loading apparatus to apply displacements to the specimen as the earlier specimens. A list of all tests up until this point is shown in Table 5.0.1 with the study parameters in bold. This chapter will describe each test in a different section and first discuss why the specimen was tested. Each section will describe the damage that occurred and the loads and drift ratios at which the damage occurred. Each section will also discuss the maximum and minimum drift ratios for that specimen and loads that the frame resisted (the specified load is the actuator force unless otherwise noted). At the end of each section, a summary of each specimen, which highlights the important characteristics of the experiment, is provided. The specimens described in this chapter and the study parameters include: 4. HSS-12 – 2t straight line clearance requirement with a ½” gusset plate using CJP welds connecting the gusset plate to the framing members. 5. HSS-13 – 6t elliptical clearance requirement with a ½” tapered gusset plate using complete joint penetration welds connecting the gusset plate to the framing members. 61 6. HSS-14 – 6t elliptical clearance requirement with 3/8” rectangular gusset plate without using net section reinforcement to the brace and 7/16” fillet welds joining the plate to the beam and column. 7. HSS-15 – 6t elliptical clearance with a reduced splice length for the brace to gusset plate connection, no net section reinforcement for the tube, and 7/16” fillet welds joining the plate to the beam and column. 8. HSS-16 – Bolted brace connection which has an extension plate bolted to the gusset plate, with the extension plate welded to the brace. 9. HSS-17 – 6t elliptical clearance requirement with a 3/8” tapered gusset plate using 3/8” fillet welds connecting the gusset plate to the framing members. 62 Table 5.0.1 – Summary of Specimens 5.1 Yield Mechanisms and Failure Modes This section describes the yield mechanisms and failure modes noted in these experiments. Table 5.1.1 lists and defines these modes and mechanisms and provides identifying symbols used for each behavior level in this research. 63 Table 5.1.1 – Performance State Notation 5.1.1 Yielding Yielding has been noticed on the gusset plates, brace, columns and beams. Yielding is due to both local and global conditions, such as local buckling, and yielding of the entire brace, respectively. The experiments were designed to facilitate observation of yielding. Whitewash was applied to the hot rolled steel, so that flaking of the mill scale due to yielding is very noticeable. Examples of gusset plate yielding for specimen HSS-17 at different levels are shown in Figure 5.1.1 through 5.1.3. 64 Yielding of the gusset plates is of particular interest to the experiment. When the gusset plate yields in tension (Y1), it develops yield lines on the plate that are parallel to the beam and column and typically start to form where the brace stops (Figure 5.1.1). Moderate yielding, Y3, of the gusset plate is defined to have occurred when the yield lines are greater than half the width of the gusset plate as shown in Figure 5.1.2. When the brace buckles, the gusset plate starts to hinge, and hinge lines form in the same location on the gusset plate but are perpendicular to the brace. Length of yield lines Figure 5.1.1 – Initial/Mild Gusset Plate Yielding (Y1) for HSS-17 65 Length of yield lines Figure 5.1.2 – Moderate Gusset Plate Yielding (Y3) for HSS-17 Figure 5.1.3 – Significant Gusset Plate Yielding (Y5) for HSS-17 Yielding is also recorded through analysis of the strain gauge and potentiometer data. Typically, strain gauges will stop working accurately when yielding occurs. However, it can be inferred that yielding has occurred at a location when the stain gauge reads an assumed yield strain of 0.2%. This assumed yield strain is based on the ratio Fy/E. It is used only for calculating when yielding of the brace occurs in tension and uni-axial stress is assumed. Similarly, potentiometers will measure a displacement and through 66 analysis, it can be determined when a member yields by calculating when the member length has increased by 0.2%. 5.1.2 Brace Buckling Brace buckling is a primary yield mechanism of the system, and Figure 5.1.4 shows the progression of this behavior. The drift values shown in the figure are for HSS-17, and while all of the tests (except HSS-16) experienced this type of behavior, the values of drift at which the frame experiences these displacements varied for each test. Stages B1, B2 and BC are specifically noted in this figure. B1 is defined as initial buckling and is noted when the brace deflects 2% of its original length out of plane. B2 is noted when the brace deflects five inches (equal to its depth) out of plane. BC is the damage state where localization of buckling damage occurs as illustrated in Figures 5.1.4e and 5.1.4f. B3 is not defined as a performance state for the brace (it is only used for plates and local buckling of elements of framing members such as webs and flanges). a) -0.55% Drift (B1) b) -0.63% Drift (B2) 67 c) -1.14% Drift d) -1.84% Drift e) -2.79% Drift (BC) f) -2.79% Drift (BC) Figure 5.1.4 – Example of Brace Buckling Progression (HSS-17) 5.1.3 Plate Buckling and Local Buckling Stages B1, B2 and B3 are used to define buckling of elements such as flanges, webs and plates. B1 for local conditions is noted when the element has visibly moved out of its plane. An example of B1 is shown in Figure 5.1.5. B2 for local conditions is said to have occurred when the buckled displacement is greater than the thickness of the element, similar to B2 for brace buckling. 68 Figure 5.1.5 – Example of B1 of Beam Flange (HSS-13) 5.1.4 Tearing and Fracture Tearing and fracture were noticed at the center of the brace, the welds/base metal of the gusset plate and the extension plate (HSS-16 only). Brace tearing and fracture were noted for most specimens. This tearing normally proceeded as a sequence of events. Initial cracks or tears developed at locations of localized high strain associated with the BC yield state as shown in Figure 5.1.4f. Tears initiated at this location and progressed through the depth of the brace as shown in Figure 5.1.6a. With increasing frame deformation, brace fracture ultimately occurs as shown in Figure 5.1.6b. However, brace fracture did not occur for HSS-16. Instead, the extension plate fractured. This occurred when the plate initially cracked (PC) and with increased frame deformation, the plate ultimately fractured (PF). 69 a) b) Figure 5.1.6 – Example of Tearing and Fracture of the Brace (BF) Crack initiation and growth was also commonly noted in the base metal or welds joining the gusset plate to the beam or column. In tests HSS-15 to HSS-17, it was more common to see the crack in the base metal at the welds, but in earlier tests it was more common to see the crack in the weld itself. This probably is due to the fact that a different welder was used in the later specimens. Initial weld cracking was defined as visible cracking of one half inch length (WD). Severe weld cracking was defined as when more than one quarter of the length was torn (WF). An example of damage to the base metal (WDB) is shown in Figure 5.1.7. When the damage to the base metal was greater than one quarter of the length of the weld, is was defined as severe base metal cracking (WFB). 5.1.5 Loss of Resistance at Bolted Connections Bolted connections were used in the NW and SE connection of the specimen, and HSS-16 used a bolted connection between the brace and the gusset plate. Although the bolted brace-to-gusset connection was designed to resist slipping, the bolts did slip throughout the test and is denoted by BSLP. None of the bolts fractured (BS) during the experiments in this set of tests. 70 Figure 5.1.7 – Example of Damage to the Base Metal (WDB) 5.2 Nomenclature of Specimen and Specimen Response Summary tables of yield and damage states are provided at the beginning of each test description. These tables summarize the damage incurred to the frame under consideration. In order to reduce the amount of text for the tables in this chapter, certain abbreviations have been made to identify locations on the frame. Figure 5.2.1 and 5.2.2 show details of the frame and what the abbreviations are for these locations. 71 Figure 5.2.1 - SCBF Component Notation (Johnson 2005) Figure 5.2.2 - SCBF Component Notation Profile (Johnson 2005) Occasionally, the location may require more definition. For example, the abbreviation for the west side of the south beam, SWB, may not be enough information if only the web is being referred to. In this case, a W is added for the web, and an F is added for the flange. The SW beam web would be denoted SWBW. 72 The gusset plates are attached to the beam and column of the frame using welds. These welds are referred to as gusset plate welds in the text. For describing the test results, each test is divided into three sections, the initial drift range, the moderate drift range, and the severe drift range. These ranges are based on the range of the drift ratio that the frame has experienced. This drift range is effectively the difference between the maximum tensile drift of the frame and the minimum compressive drift. The initial drift range has a drift ratio range from zero to 1.25%. The moderate drift range has a drift ratio range from 1.25% to 2.75%. The severe drift range has a drift ratio range above 2.75%. This drift ratio range is also referred to as Max/Min Range in the discussion that follows. The Max/Min Range is referred to in the peak results tables at the beginning of each chapter, and in the section headings which denote which range is being discussed. In each specimen that experienced weld or base metal cracking, a summary of the length and type of crack is summarized in a table. In the table, ‘W’ denotes that the weld cracked as opposed to the base metal (denoted by ‘BM’). And ‘T’ denotes that the crack occurred in the top weld as opposed to the bottom weld (denoted by “B”). The out-of-plane stiffness of the gusset plate is often referred to throughout this thesis. This stiffness refers to the rotational stiffness of the gusset plate in which the direction is defined with a vector that is normal to the axis of the brace, in the plane of the frame. This rotational stiffness is talked about when the brace buckles and the gusset plate bends from its initial shape in the plane of the frame and into the “out-of-plane” direction. 73 5.3 HSS-12 – Reference Specimen with CJP Welds 5.3.1 Specimen Overview AISC Seismic Provisions and the uniform force method were used to design the gusset plate for this specimen. HSS-01 was designed by current design practice, and failed by sudden weld fracture. This specimen is similar to HSS-01 except that complete joint penetration welds were used to examine their effect on connection performance. HSS-12 ultimately failed through brace fracture. The gusset plate welds did not initiate cracking. The maximum load was 373 kips and the minimum load was -180 kips. The displacement ranged from -2.1% to 1.4% (includes only the completed cycles). Table 5.3.1 shows the performance states noted during the experiment and the story drift at which they were noted. Figure 5.3.1 shows the lateral force-story drift hysteretic curve, for the test. Table 5.3.1 - HSS-12 Peak Results 74 Figure 5.3.1 – Specimen HSS-12 Force-Drift Response 5.3.2 Initial Drift Range (Max/Min Range from 0% to 1.25%) The out-of-plane movement of the brace was first noticed at -0.38% drift (cycle 17). Initial brace buckling state B1 was measured at a drift ratio of -0.41% (load of -158 kips). The brace buckled upward. This out of plane movement reached five inches (state B2) at a drift of -0.71% (-159 kips) and is shown in Figure 5.3.2. Yielding of the brace, Y1, was also noted in the initial drift range at a drift ratio of 0.31% (243 kips). 75 Figure 5.3.2 – B2 Buckling of brace (-0.71% Drift) At 0.26% drift, a small amount of yielding (Y1) occurred in the NE gusset plate (Figure 5.3.3) as shown by diagonal (relative to the longitudinal direction of the brace) yield lines. These yield lines extended from the end of the brace when the brace was in tension. Figure 5.3.3 – Yield Lines on NE Gusset Plate (0.26% Drift) 76 Yielding in the SW gusset plate was not as noticeable as in the NE gusset. The support conditions are slightly different at these two corners of the specimen as described in Chapter 4. 5.3.3 Moderate Drift Range (Max/Min Range from 1.25% to 2.75%) Yielding of the beam web at 0.48% drift is shown in Figure 5.3.4. Yielding has also spread to other regions during this drift range. Locations experiencing Y1 include: 1) the NE column at the inside flange (Figure 5.3.5), 2) both beams at a drift ratio of -0.87% and 3) the SW column at a drift ratio of -1.47%. Figure 5.3.4 – Yield Lines in Beam Web (0.48% Drift) 77 Figure 5.3.5 – Yield Lines in NE Column Flange (0.68% Drift) The NE column sustained additional yielding as the drift increased. Figure 5.3.6 shows a photograph of the outside face of the inside flange of the NE column at the gusset plate at -1.47%. The length of the yield lines have increased to more than half the flange width (Y3). These yield lines were also present on the opposite side of the flange at the same drift level. It appears that these lines became more visible during the tension half of the cycle. 78 Figure 5.3.6 – Y3 at NE column next to gusset plate (-1.47% Drift) The NE gusset plate started to develop hinge lines (yield lines perpendicular to the axis of the brace) at a drift range of -1.47% shown in Figure 5.3.7. However, the SW gusset plate did not develop these yield lines until later. Figure 5.3.7 – Hinge Lines in NE Gusset (-1.47% Drift) 79 5.3.4 Severe Drift Range (Max/Min Range > 2.75%) Local buckling of the NE column flange occurred at a drift of -1.79% as shown in Figure 5.3.8. Buckling may have resulted from the combination of axial compression and the closing moment on the joint. Additional yielding occurred in the NE beam at a drift of -1.79% as shown in Figure 5.3.9. Most of the yielding occurred at the reentrant corner of these beams, adjacent to the gusset, as shown in the figure. Additional yielding was sustained at these locations (to yielding state Y5) at a drift ratio of -2.1%. Figure 5.3.10 shows flaking in these areas which indicate that yielding has occurred. This yielding could be a result of a moment hinge forming at this location as it appears to be in 5.3.10a or it could be a result of local forces as the asymmetric response appears in 5.3.10b Figure 5.3.8 – B1 of NE column flange (-1.79% Drift) 80 Figure 5.3.9 – Y3 of NE Beam Flange (-1.79% Drift) a) b) Figure 5.3.10 – Y5 at Reentrant Beam Corners (-2.1% Drift) Cupping and bulging of the brace occurred at -1.79% drift ratio. Figure 5.3.11 shows the bulging of the side wall of the tube at the hinge point. After the brace started to bulge, cracks formed in the bottom of the brace at a drift of 1.40% as shown in Figure 5.3.12. The cracks initiated from a hole drilled into the tube to attach instrumentation to 81 measure the out-of-plane displacement of the brace. During the next cycle the brace fractured through its cross section at a drift ratio of 1.67%, as shown in Figure 5.3.13. Figure 5.3.11 – BC of Brace (-1.79% Drift) Figure 5.3.12 – Crack in Brace (1.40% Drift) 82 Figure 5.3.13 – Fracture of Brace (1.67% Drift) 5.3.5 Specimen Summary Specimen HSS-12 was designed using the 2t linear offset as prescribed in the AISC Seismic Provisions. The specimen was similar to HSS-01, which failed due to weld fracture, because the welds were sized to the expected brace capacity rather than the capacity of the gusset plate. For HSS-12, CJP welds were used instead of fillet welds to connect the gusset plate to the framing members. Specimen HSS-12 failed due to brace fracture as desired. Figure 5.3.14 shows the gusset plate at the end of the test and it can be seen that this gusset plate had very limited yielding. 83 Figure 5.3.14 – NE Gusset Plate (End of Test) Figure 5.3.15 shows the SW column with significant yielding, but not as much as in other experiments. The smaller amount of yielding could be due to the relatively small drift that was experienced by the frame by the end of the experiment. Figure 5.3.15 – SW Column (End of Test) 84 The gusset plate welds did not initiate cracking during the entire length of the test. This was unusual since cracking was observed in all of the previous 11 tests. 5.4 HSS-13 – Tapered Plate with CJP Welds 5.4.1 Specimen Overview Specimen HSS-13 had a tapered gusset plate and was identical to HSS-10 except that it had CJP welds. HSS-10 experienced fillet weld cracks that were greater than one quarter of the weld length. The drift ranged from -2.03% to 2.05% for a total range of 4.08% (compared to 4.47% for HSS-10) and resisted maximum loads of -176 kips to 349 kips for a range of 525 kips. Table 5.4.1 shows the performance states that were noticed and their associated drift ratios. Figure 5.4.1 shows the hysteretic response. Table 5.4.1 - HSS-13 Peak Results 85 Figure 5.4.1 – Specimen HSS-13 Force-Drift Response 5.4.2 Initial Drift Range (Max/Min Range from 0% to 1.25%) Visible buckling of the brace occurred at a drift ratio of -0.30% at -176 kips (Figure 5.4.2). Buckling state B1 occurred at a drift ratio of -0.36% (-160 kips). State B2 occurred at a ratio of -0.50% and a load of -151 kips. Figure 5.4.2 –Visible Bending (-0.30% Drift) 86 Yield lines appeared in both of the gusset plates at 0.35% drift (193 kips). The relatively faint yield lines appeared at the end of the brace as showed in Figure 5.4.3. Figure 5.4.3 –Y1 at gusset plates (0.35% Drift) 5.4.3 Moderate Drift Range (Max/Min Range from 1.25% to 2.75%) Brace yielding (designated by the strain gauges) occurred at a drift range of 0.54% (243 kips). Both gusset plates reached yield state Y3 at a drift of 0.82% (Figure 5.4.4), and diagonal yield lines extended over half of the distance between the end of the brace and the edge of the gusset plate. Hinging of both gusset plates became apparent at a drift ratio of -1.38%. This is illustrated by Figure 5.4.5 which shows the SW gusset plate. 87 Figure 5.4.4 –Y3 at NE Gusset Plate (0.82% Drift) Figure 5.4.5 –Y5 at SW gusset plate (-1.38% Drift) Yielding occurred in the NE beam and reached a yield state of Y3 at the end of the moderate drift range. Y1 yielding was noted in the SW column at a drift of -1.38%. 5.4.4 Severe Drift Range (Max/Min Range > 2.75%) Y3 yielding occurred in both of the column flanges adjacent to the gusset plates at a drift ratio of 1.35% (Figure 5.4.6). Initial yielding (Y1) also was first observed in the south beam flange at a drift of 1.35%. Y5 yielding was noted in the SW beam at a load 88 of -146 kips and a drift ratio of -2.03 (Figure 5.4.7). Web and flange buckling of the SW beam occurred near the gusset plate (Figure 5.4.8) at a drift ratio of 2.05%. Figure 5.4.6 –Y3 at Columns 1.35% Drift) Figure 5.4.7 –Y5 at SW Beam (-2.03% Drift) 89 Figure 5.4.8 – Local Buckling of SW Beam (2.05% Drift) While the brace was in tension, Y1 yielding occurred in the SW gusset plate near the beam and Y3 yielding occurred in the NE gusset plate at the beam at a drift of 1.59%. Y5 yielding occurred in the form of hinge lines in the NE gusset at a load of -146 kips and a drift ratio of -2.03% as shown in Figure 5.4.9. Figure 5.4.9 – Significant Yielding in Gusset Plate (-2.03% Drift) Compressive brace failure (BC) occurred at a drift of -1.71% (Figure 5.4.10). Brace tearing started at 2.05% drift (Figure 5.4.11). However, complete brace fracture did not occur during this cycle. Early brace buckling was in the normal upward direction, because of the initial eccentricity of the brace. However, the brace buckled down 90 toward the strong floor during the next compressive cycle at a drift of -0.33% (Figure 5.4.12). This compression cycle was stopped before the brace hit the floor (as a result, this frame may have had a larger drift capacity in compression if the brace buckled upward instead). The brace fractured during the next cycle at a drift of 2.32%. Figure 5.4.10 –BC at brace (-1.71% Drift) Figure 5.4.11 –Brace Initial Tearing (2.05% Drift) 91 Figure 5.4.12 – Downward Brace Buckling (-0.33% Drift) 5.4.5 Specimen Summary Specimen HSS-13 used a tapered gusset plate with CJP welds. The relatively small size of the gusset plate provided more ductility to the frame. Compared to HSS-12, the framing members and gusset plates had a great deal more yielding. This is shown by Figures 5.4.13 through 5.4.15. This seems to be a product of the relatively high displacements that were experienced by the frame in tension, especially the SW beam. When the brace was in tension, the beam was in compression. This, combined with the closing moment may be the cause of the buckling of the flange and web of the beam shown in 5.4.15. One of the reasons that specimen HSS-13 was chosen as an experiment was to examine how a tapered plate with complete joint penetration welds at the gusset plate would compare to a tapered plate with fillet welds. Depending on what the goal is, it has mixed reviews. On one hand, the complete joint penetration welds performed very well because they did not crack at all. On the other hand, because they did not crack, the system did not develop the added frame displacements associated with crack opening, and this limits the ultimate drift capacity of the system. The question is whether or not 92 a certain amount of weld cracking can be tolerated in order to prolong the drift capacity of the frame, and if so, how much? Figure 5.4.13 – Yielding of NE Connection (End of Test) Figure 5.4.14 –Yielding on West Column (End of Test) 93 Figure 5.4.15 –Local Buckling at South Beam (End of Test) 5.5 HSS-14 – Unreinforced Net Section 5.5.1 Specimen Overview The typical reinforcement added to the net section of the brace was not used for specimen HSS-14 (for detailed information on the net section reinforcement, see Section 3.3). In order to alleviate the stress concentrations that may be felt at the net section, a 7/8 inch hole was drilled at the end of the slot and was reamed out for added smoothness. The specimen failed as a result of brace fracture at the midspan of the brace. The minimum drift reached was -2.04% and the maximum drift was 1.89%, resulting in a range of 3.93%. The compression capacity was -170 kips and the tension capacity was 358 kips, resulting in a range of 528 kips. However, the brace buckled downward (towards the floor) and the imposed drift history which was used for the previous tests had to be altered in that the imposed compression drift was limited to a maximum of two inches. 94 Table 5.5.1 shows the performance states noted for this specimen and the drifts at which they occurred. Figure 5.5.1 shows the hysteretic response. Table 5.5.1 - HSS-14 Peak Results Figure 5.5.1 – Specimen HSS-14 Force-Drift Response 95 5.5.2 Initial Drift Range (Max/Min Range from 0% to 1.25%) Seven cycles of 0.1% drift were imposed on the frame instead of the typical six cycles. The applied drift from -0.51% to 0.37% was applied three times instead of the normal two. Buckling was observed at a drift ratio of -0.34% (Figure 5.5.2). Typically, this out of plane movement happens gradually throughout the test. However, at this point in the experiment, the brace moved out of plane at a faster rate. This would imply that the brace was at a point of bifurcation. This sudden change can be seen on the hysteretic graph in Figure 5.5.1 which shows higher compressive load before the brace buckled (typically, the frame gains compressive resistance after buckling, i.e. the hysteretic curve for HSS-12 in Figure 5.3.1). Yielding in the gusset plates (at the end of the brace) was first observed at a drift ratio of 0.28% (170 kips) as shown in Figure 5.5.3. Yielding also occurred in the beam flanges in the initial drift range at 0.37% shown in Figure 5.5.4. Figure 5.5.2 – Buckling Stage of HSS-14 (-0.34%) 96 Figure 5.5.3 – Y1 of NE Gusset Plate (0.28%) Figure 5.5.4 – Y1 of NE Beam (0.37%) 5.5.3 Moderate Drift Range (Max/Min Range from 1.25% to 2.75%) The NE gusset plate reached state Y3 at a drift of 0.58%, as shown in Figure 5.5.5. The SW gusset also reached state Y3 but at a higher drift ratio, 1.06%. Yielding was also noticed on the gusset plates at the reentrant corners. This occurred initially in the SW gusset, adjacent to the beam at a drift ratio of 0.58% (Figure 5.5.6). It also occurred at a drift ratio of 1.06% at the SW gusset plate adjacent to the beam, and in the NE gusset plate, adjacent to the beam. Figure 5.5.7 shows hinge yield lines (due to compression) on the bottom of the SW gusset plate at a drift ratio of -1.08%. 97 Figure 5.5.5 – Y3 of NE Gusset (0.58%) Figure 5.5.6 – Y1 of NE Gusset at Beam (0.58%) 98 Figure 5.5.7 – Y1 of SW Gusset in Compression (-1.08%) 5.5.4 Severe Drift Range (Max/Min Range > 2.75%) Yielding in the framing members increased in the severe drift range. State Y3 yielding was reached in both columns (Figure 5.5.8 for the east column, Figure 5.5.9 for the west column). State Y5 yielding was reached in both of the beams (Figure 5.5.10 for the north beam and Figure 5.5.11 for the south beam) at 1.89% drift. The SW beam also reached local buckling stage B1 in the flange and the web at this drift level. Figure 5.5.8 – Y3 NE Column (1.61%) 99 Figure 5.5.9 – Y3 SW Column (1.89%) Figure 5.5.10 – Y5 NE Beam (1.89%) Figure 5.5.11 – Y5 SW Beam (1.89%) 100 Y3 yielding was observed in the NE gusset plate at the beam and the SW gusset plate in the column at a drift ratio of 1.31% (Figure 5.5.12 and 5.5.13, respectively). Yielding did not increase during subsequent drift cycles most likely due to the fact that the welds at the same location cracked, thereby reducing the stiffness at this location. Figure 5.5.12 – Y3 of NE Gusset at Reentrant Corner (1.31%) Figure 5.5.13 – Y3 of SW Gusset at Reentrant Corner (1.31%) During the compression drift ratio of -1.67%, a weld crack occurred on the NE gusset plate adjacent to the beam shown in Figure 5.5.14. Cracks also appeared in the NE column weld (two inches long, Figure 5.5.15) and in the SW beam weld at a drift level of -2.04%. The crack in the NE gusset plate weld at the column grew to six and a half 101 inches long and the crack in the NE gusset plate weld at the beam grew to three inches long at a drift ratio of -2.01% (Figure 5.5.16 and Figure 5.5.17 respectively). Notice that these two cracks grew at a drift ratio of -2.01% (the negative drift range was limited because of the downward buckling of the brace was restricted by the floor) even though a previous cycle had reached a drift ratio of -2.04%. These cracks increased in length because the crack created a stress concentration so when the force was transmitted through the weld, the crack continued to propagate even though the drift ratio was about the same. A table summarizing the weld and base metal cracks is shown in Table 5.5.2. Figure 5.5.14 – Crack at NE Gusset Plate Weld (-1.67%) Figure 5.5.15 – Crack at NE Gusset Plate Weld (-2.04%) 102 Figure 5.5.16 – 6.5” Crack at NE Gusset Plate Weld at Column (-2.01%) Figure 5.5.17 – 3” Crack at NE Gusset Plate Weld at Beam (-2.01%) 103 Table 5.5.2 – HSS-14 Weld/Base Metal Damage Summary Brace cupping occurred at a drift ratio of -2.04% prior to the brace coming in contact with the strong floor. Figure 5.5.18 shows the cupping of the brace. The brace sustained a large amount bulging at its center at a drift ratio of -2.01% (Figures 5.5.19 and 5.5.20). Figure 5.5.18 – Cupping of Brace (-2.04%) 104 Figure 5.5.19 – Bulging of Brace (-2.01%) Figure 5.5.20 – Bulging of Brace (-2.01%) At a drift ratio of -2.01%, low cycle fatigue cracks started to form at the center of the brace (Figure 5.5.21). Brace fracture occurred during the subsequent cycle at a drift of 2.48% (Figure 5.5.22). 105 Figure 5.5.21 – Fatigue Cracks in Brace (-2.01%) Figure 5.5.22 – Brace Fracture (2.48%) 5.5.5 Specimen Summary HSS-14 was designed to check the requirement of the net section reinforcement. The net section holes are shown in Figure 5.5.23 and 5.5.24. As the photographs show, there is no visible damage to these holes. In this respect, the test performed very well. However, more testing is required to determine if the net section reinforcement can be omitted. 106 Figure 5.5.23 – Net Section Hole Undamaged (End of Test) Figure 5.5.24 – Net Section Hole Undamaged (End of Test) Figure 5.5.25 shows the NE gusset plate after fracture of the brace. This view of the plate isolates the extent of the yielding in the plate due to tension only since the brace buckled down, and the compression yielding was limited to the underside of the plate. It shows that the plate did yield significantly in tension. 107 Figure 5.5.25 – Gusset Plate (End of Test) This specimen is the exact same as HSS-05 except for the lack of net section reinforcement and a slightly larger gusset plate weld (7/16” versus 5/16”). HSS-05 had a drift range of about 5%. However, this specimen only had a drift range of 3.9%. This is a very large difference between two very similar frames. The major difference is attributed to the applied deformation history and the weld cracking. Since the brace buckled down, the experiment had to be stopped during the compression cycle. Compression is the applied load in which damage to the weld is most common. In HSS-05, the compressive drift was not limited and damage to the welds was quite high. The sum of the four weld fractures was 32 inches. HSS-14 however, had a sum of weld fractures equal to 10 inches. When the welds crack, it significantly reduces the stiffness of the connection, making the 6t elliptical clearance more like a 2t clearance, and also reducing the effective size of the gusset plate. The reduced stiffness allows the brace to buckle over a longer length which then reduces the strain demand on the center of the brace, allowing high compressive drifts (as with HSS-05). The limit on the compressive drift and the lack of weld cracking in HSS-14 contributed to the relatively 108 smaller drift range. If the applied displacement history was the same as HSS-05, the specimen may have had weld cracking and a higher drift range similar to HSS-05. 5.6 HSS-15 – Reduced Splice Length 5.6.1 Specimen Overview Specimen HSS-15 was designed with a splice length of 11.25 inches. By reducing the length of the splice, the size of the gusset plate could be reduced, and this potentially reduces the stiffness of the gusset plate. This brace to gusset weld was increased from 5/16” to 7/16” to transfer the force in the reduce length. In order to keep the thickness of the gusset plate down, block shear and Whitmore fracture were checked by changing the φ factor from 0.75 to a β factor of 0.85. In addition, Whitmore yielding was totally neglected as a limit state, because yielding in the gusset plate is desirable. With these three modifications to the design code, the gusset plate was kept at 3/8”. Because the brace of the previous test (HSS-14) buckled down and in order to prevent this from happening again, a 5/16” offset between the centerline of the frame and the centerline of the brace was used instead of a 3/16” offset. The 3/16” offset was used in all of the previous tests except HSS-01 and HSS-02 (both of which buckled down). All of the specimens following this test also used a 5/16” offset between the frame centerline and the brace centerline. The drift ranged from -2.22% to 1.87% for a total range of 4.09% and resisted maximum loads of -155 kips to 332 kips for a range of 487 kips. Table 5.6.1 shows the 109 performance states that were noticed at the associated drift ratio. Figure 5.6.1 shows the hysteretic response. Table 5.6.1 - HSS-15 Peak Results Figure 5.6.1 – Specimen HSS-15 Force-Drift Response 110 5.6.2 Initial Drift Range (Max/Min Range from 0% to 1.25%) Initial bending in the brace was noticed at a drift ratio of -0.24%. B1 buckling of the brace was recorded at a drift ratio of -0.40% (-153 kips). State B2 buckling was noted in the next cycle at a drift ratio of -0.59% (-148 kips). States B1 and B2 buckling are shown in Figure 5.6.2. a) B1 b) B2 Figure 5.6.2 – Buckling Stages State Y1 yielding was noted in both gusset plates at a drift ratio of 0.21%. In addition to yielding at the end of the brace, yielding also occurred on the gusset plate adjacent to each side of the brace at a drift ratio of 0.43% (Figure 5.6.3). This was the onset of block shear yielding. The yielding in both gusset plates reached state Y3 by the end of the initial drift range (0.43% drift). 111 Figure 5.6.3 – Yielding on Gusset Next to Brace at 232 kips (0.43%) 5.6.3 Moderate Drift Range (Max/Min Range from 1.25% to 2.75%) The SW beam at the flange and web, and the NE beam in the web (Figure 5.6.4) reached the state Y1 at 0.96% drift. Yielding in the NE beam reached state Y3 shown in Figure 5.6.5 at a drift of -1.35%. Figure 5.6.4 – Yielding on NE Beam Web (0.96%) 112 Figure 5.6.5 – Yielding on NE Beam Flange (-1.35%) Prominent hinge lines developed in both gusset plates at a drift ratio of -1.35%. These hinge lines are shown in Figure 5.6.6. Figure 5.6.6 – Hinge Lines in Gusset Plates (-1.35%) 5.6.4 Severe Drift Range (Max/Min Range > 2.75%) Y3 yielding was noted in the NE column at a drift ratio of 1.22% shown in Figure 5.6.7. Yielding also occurred in the SW column and progressed throughout the severe drift range. Flange buckling and web buckling did not occur during this test. Figure 5.6.8a shows increased yielding in the NE beam web during the tension half of the cycle at 113 1.54% drift. While Figure 5.6.8b shows increased yielding in the flange to the state Y5 during the compression half of the cycle at -1.97% drift. Figure 5.6.7 – NE Column with Y3 Yielding (1.22%) a) 1.54% b) -1.97% Figure 5.6.8 – Yielding at NEB At a ratio of -1.61%, initial weld cracking occurred at the SW gusset at the beam. Another crack occurred in the base metal of the gusset plate at the SW column measuring one inch at a drift ratio of -1.97% (Figure 5.6.9). At -2.22%, the crack increased to about one and a half inches. At the end of the test (when the brace fractured) the crack measured approximately three inches. 114 Figure 5.6.9 – 1 in Crack thru Base Metal of Gusset Plate at SWC (-1.97%) At a drift ratio of -2.22%, a crack developed in the base metal on the NE gusset plate at the column (Figure 5.6.10). At the end of the test (when the brace fractured) the crack measured approximately four inches. A table showing the weld and base metal cracks is shown in Table 5.6.2. Figure 5.6.10 – 3” Crack thru Base Metal of Gusset Plate at NEC (-2.22%) 115 Table 5.6.2 – HSS-15 Weld/Base Metal Damage Summary The diagonal brace showed increased damage at the plastic hinge throughout the severe drift range. Initially, at a drift range of -1.61% brace cupping occurred. At a drift ratio of 1.74%, a hole formed in the bottom of the brace where a hole was drilled into the brace to attach instrumentation to measure out of plane displacement. Necking of the brace occurred at 1.74% as well. Both states are shown in Figure 5.6.11. Figure 5.6.11 – Brace Hole and Necking (1.74%) At a drift ratio of 1.87%, the brace began to fracture (Figure 5.6.12). But complete tearing did not occur. Early brace buckling was in the normal upward direction, because of the initial eccentricity of the brace. However the brace buckled downward towards the floor (Figure 5.6.13) at a drift ratio of -0.55%. The target drift in 116 compression was not reached to prevent the brace from touching the floor. During the following cycle, the brace fractured completely at a drift of 2.5%. Figure 5.6.12 – Brace Crack Halfway thru Member (1.87%) Figure 5.6.13 – Brace Buckling Down (-0.55%) 117 5.6.5 Specimen Summary In comparison to other similar specimens, HSS-15 performed rather poorly regarding the total drift range. The total drift was -2.22% to 1.87% for a range of 4.09%. While the total load was -155 kips to 332 kips for a range of 487 kips. Similar to HSS-13, if the brace buckled up on the last cycle, the compression drift capacity may have increased a little. However, this cycle was a repeat of the same applied drift as the cycle before. Therefore the potential increase in drift would probably be small. The welds of the frame seemed to perform very well. It was the base metal that cracked. Although the base metal did crack, it was not seen until damage in the brace (brace cupping) started to occur. And only when necking of the brace and a significant hole occurred in the brace, did a crack of three inches develop in the gusset plate. By the end of the test, the crack in the gusset plate at the northeast column measured four inches and the crack in the gusset plate at the SW column measured three inches. 118 Figure 5.6.14 – Southwest Gusset (End of Test) 5.7 HSS-16 – Bolted Splice Connection 5.7.1 Specimen Overview Specimen HSS-16 was a very unique test to not only the experiments detailed in this chapter but also to the prior tests (Johnson 2005, Herman 2007). This test used a one sided bolted connection to transfer the forces from the brace to the gusset plate shown in Figure 5.7.1. The potential benefit to using this connection would be that the brace would not have to be field welded to the gusset plate. The problem of fitting the brace in between the gusset plates would also be avoided. Instead, the brace would be shipped to the sight with the extension plate already welded on it, and then field bolted to the gusset plate. The bolts in this experiment were 1-1/8” A490 slip critical class A bolts with oversized holes in the extension plate and the gusset plate. Also, the extension plate is cut out 119 with a notch in it as proposed by Packer (2007), so that the brace will have its entire cross section for one third of the length of the connection to the extension plate, thereby eliminating the problem of net section. Figure 5.7.1 – Specimen HSS-16 Connection Detail The frame failed by fracture of the net section at the 7/8 inch extension plate. The applied load ranged from -146 kips to 301 kips for a total range of 447 kips. The drift was measured from -2.86% to 3.03% for a range of 5.89%. Table 5.7.1 shows the performance states that were noticed at the associated drift ratio. Figure 5.7.1 shows the hysteretic response. 120 Table 5.7.1 - HSS-16 Peak Results Figure 5.7.2 – Specimen HSS-16 Force-Drift Response 121 5.7.2 Initial Drift Range (Max/Min Range from 0% to 1.25%) Visible bending of the SW connection was noticed at a drift ratio of -0.16% shown in Figure 5.7.3. This displacement was located at the extension plate, not at the center of the brace where it typically occurs. Since hinging occurred at the extension plate, B1, B2 and BC were not calculated for this specimen. Figure 5.7.4 shows that the eccentricity of the one sided connection was too much for the extension plate to resist and a hinge formed here, between the end of the brace and the edge of the gusset plate. The extension plate and gusset plate continued to bend with added deflection shown in Figures 5.7.5 and 5.7.6. Hinge lines formed in the gusset plate at a drift ratio of -0.45% shown in Figure 5.7.6. Figure 5.7.3 – Visual Bending of SW Gusset and Extension Plate (-0.16%) 122 Figure 5.7.4 – Bending of SW Gusset and Extension Plate (-0.29%) Figure 5.7.5 – Bending of SW Gusset and Extension Plate (-0.37%) Figure 5.7.6 – Bending of Plates, Hinge Lines on Gusset (-0.45%) 123 During the middle stages of the initial drift range, a crackling sound (similar to the sound of a light rain) was heard coming from the gusset plate. This was the same sound that was heard when the bolts were tightened during fabrication using load indicating washers. It is believed that the sound during the test was coming from these load indicating washers, at the interface of the gusset plate. In cycle 21 at a drift range of 0.31% and at a load of 206 kips, the bolts in the SW gusset plate connection slipped. This created a very load bang and the slip itself measured 3/8 inch from the displacement of the whitewash shown in Figure 5.7.7. A much softer bang came on the compression half of the cycle and was presumed to be a smaller slip back in the other direction. Figure 5.7.7 – Bolt Slip (0.31%) The following compression cycle showed severe damage to the base metal at a drift of -0.49%. A six inch crack formed at the SW gusset plate base metal at the weld to the column. This is shown below, in Figure 5.7.8. 124 Figure 5.7.8 – Base Metal Fracture (-0.49%) Because of the base metal crack and added deformation demands, the gusset plate started to show additional yield lines. Y3 yielding was noticed in the gusset plate at the beam, column, and at the end of the extension plate. These lines appeared to be hinge lines where the gusset plate was hinging, however they could also have been a result of the onset of local buckling of the gusset plate at the beam which wasn’t noticed until the moderate drift range. Figure 5.7.9 – Y3 of SW Gusset Plate (-0.49%) 125 5.7.3 Moderate Drift Range (Max/Min Range from 1.25% to 2.75%) The yielding of the extension plate started to show through flaking of the whitewash at a drift ratio of 0.67%, as shown in Figure 5.7.10. State Y3 yielding was reached by this plate at a drift ratio of 1.08%. Figure 5.7.10 – Y1 of SW Extension Plate (0.67%) Initial yielding was spotted on both gusset plates for the first time while the brace was in tension. At a drift of 0.81%, the system reached an applied load of 223 kips causing the gusset plates to yield shown in Figure 5.7.11. At the same time, the SW gusset plate buckled at the beam shown in Figure 5.7.12. It is important to note that this plate buckled only after a long crack (13”) developed in the base metal of the SW gusset plate at the column (making the connection eccentric). 126 Figure 5.7.11 – Y1 of NE Gusset Plate (0.81%) Figure 5.7.12 – B1 of SW Gusset Plate (0.81%) 5.7.4 Severe Drift Range (Max/Min Range > 2.75%) The bolts on the NE gusset slipped with a loud bang at a load of 276 kips, at a drift ratio of 1.27% (Figure 5.7.13). Over the next couple of cycles, the frame continued to make loud banging sounds. These sounds were presumed to come from the bolted connections at the gusset plates slipping, but it was unable to determine exactly where the slips were occurring because the potentiometers were dislodged whenever the connection slipped. These loud sounds occurred only during the tensile half of the cycles. Yielding in the SW gusset plate reached a stage of Y5 at a drift ratio of 1.43% (Figure 5.7.14). 127 Figure 5.7.13 – Bolt Slippage at NE Gusset (1.27%) Figure 5.7.14 – Y5 of SW Gusset Plate (1.43%) Yielding became visible in the framing elements during this stage. At a drift ratio of 1.67%, yielding in the beam and column of the NE corner occurred shown in Figure 5.7.15. 128 Figure 5.7.15 – Y3 of NE Framing Elements (1.67%) Throughout the test, the crack in the gusset plate base metal at the southwest column continued to increase in length. At a drift ratio of -2.00% this crack tore the entire way through the gusset to column connection (Figure 5.7.16). At -2.31% drift, the crack started to tear the weld (or possibley, the base metal) at the beam, next to the column, during the tension half of the cycle. This also caused considerable local damage to the beam flange at this location. Figure 5.7.17 shows this damage. This crack grew rather slowly after this point and reached a total of nine inches long by the end of the test at a drift ratio of -2.86%. The total weld length left connecting the gusset plate to the SW corner of the frame at this drift ratio was 16 inches. Figure 5.7.16 – Complete Tear of Base Metal at SW Gusset (-2.00%) 129 Figure 5.7.17 – Crack Develops in Weld at Beam (2.28%) A crack in the base metal at the weld connecting the NE gusset plate to the column measured two inches at -1.98% drift. At a drift ratio of -2.31%, the crack grew to nine inches long. Figure 5.7.18 shows this condition. At cycle 37 with a drift ratio of -2.66%, the crack measured 17 inches long, and at -2.86% drift, the crack fractured over the entire length of the gusset plate to column connection (Figure 5.7.19). A table summarizing the weld and base metal damage is shown in Table 5.7.2. Figure 5.7.18 – Base Metal Crack at NE Column (-2.31%) 130 Figure 5.7.19 – Base Metal Complete Fracture at NE Column (-2.66%) Table 5.7.2 – HSS-16 Weld/Base Metal Damage Summary At -2.66%, even with the base metal at both of the gusset plates totally fractured at the column, the extension plate at the SW corner started to crack shown in Figure 5.7.20. This crack continued to propagate through the plate, first on the south side of the plate at a drift of -2.86%, while a smaller crack also developed on the north side of the plate. Both conditions are shown in Figure 5.7.21. The tension cycle after the compression cycle which caused the cracks shown in Figure 5.7.21, caused the plate to fracture the entire way though marking the end of the test at 3.31% drift. 131 Figure 5.7.20 – Crack in SW Extension Plate (-2.66%) Figure 5.7.21 – Cracks in Extension Plate (-2.86%) 5.7.5 Specimen Summary The drift ratio of 5.89% is the largest amount of displacement that any of the frames tested (including the tests from thesis 1 and 2) experienced. However, the test results are less acceptable for seismic design than most others observed in this research program, because the frame did not develop its design resistance. There is still a great 132 deal to learn from this test. To understand why this frame was able to withstand such a large drift capacity could lead to new designs incorporating some of the same ideas, and hopefully leading to frames with similar, or even higher, drift capacities. These ideas will be discussed in chapter nine. Some characteristics of the frame were sacrificed in order to attain such a large range of displacement. Most notably, the force range was much smaller than previous experiments. Since the connection buckled before the brace did (the connection was weaker than the brace), the frame had an overall lower compression capacity, -146 kips. With the bolts slipping, and the welds tearing in the initial drift range, the tension capacity was also reduced, to only 301 kips. This gives a range of 447 kips, which is more than 100 kips lower than HSS-12. Damage to the base metal of the gusset plate occurred very early in this experiment. The drift ratio at which it occurred was -0.49%. In performance based design, the performance levels of immediate occupancy and operational are appropriate guidelines for this drift ratio. 5.8 HSS-17 – 3/8” Tapered Plate 5.8.1 Specimen Overview Specimen HSS-17 uses a 3/8 inch tapered gusset plate with 3/8 inch fillet welds for the gusset plate welds. This specimen has the same geometry as the other two specimens with tapered plates (HSS-10 and HSS-13) except the thickness of the gusset plate has changed from 1/2 inch to 3/8 inch. 133 The calibration factor for the LVDT of the actuator was incorrect for this test and the applied deflection was 1.45 times the anticipated deflection. The drift ratios shown in this chapter are the corrected drift values. However since this situation was not realized until after the test, there were fewer total cycles throughout the test, and these cycles of applied drift were spaced further apart than in previous tests. The specimen achieved a relatively large drift ratio, from -2.79% to 2.15% for a total range of 4.94%, and a load ranging from -159 kips to 355 kips for a total range of 514 kips. Table 5.8.1 shows the performance states that were noticed at the associated drift ratio. Figure 5.8.1 shows the hysteretic response. Table 5.8.1 - HSS-17 Peak Results 134 Figure 5.8.1 – Specimen HSS-17 Force-Drift Response 5.8.2 Initial Drift Range (Max/Min Range from 0% to 1.25%) Visible bending in the brace was noticed at a drift ratio of -0.25% as shown in Figure 5.8.2. State B1 buckling occurred at a drift of -0.51% (-155 kips) and state B2 followed at a drift of -0.63% (-148 kips). Figure 5.8.2 – Visible Buckling (-0.25%) 135 At a drift ratio of 0.26% initial yielding, Y1, occurred on both gusset plates as shown in Figure 5.8.3. Yielding in these locations reached Y3 at a drift ratio of 0.32%, as shown in Figure 5.8.4. Yielding of the SW gusset plate occurred during compression at a drift ratio of -0.63% (the same time as B2 of the brace) shown in Figure 5.8.5. Figure 5.8.3 – Y1 Yielding due to Tension in Both Gussets (0.26%) Figure 5.8.4 – Y3 Yielding due to Tension in Both Gussets (0.32%) . 136 Figure 5.8.5 – Compression Yield Lines of SW Gusset Plate (-0.63%) 5.8.3 Moderate Drift Range (Max/Min Range from 1.25% to 2.75%) Figure 5.8.6 shows the yielding in the NE gusset plate at the end of the moderate drift range at -1.34%. The tension yield lines are easier to see while the compression yield lines are most noticeable only where they intersect the tension yield lines, and small pieces of whitewash have flaked off. Also shown in Figure 5.8.6 is the SW gusset plate which has displayed slightly more yielding. Figure 5.8.6 – Gusset Plates Condition at End of Moderate Drift Range (-1.34%) 137 Figures 5.8.7 and 5.8.8 show yielding in the SW column and beam respectively. This occurred at -1.14% drift. Figure 5.8.7 – Yielding at SW Column (-1.14%) Figure 5.8.8 – Yielding at SW Beam and Gusset Reentrant Corner (-1.14%) 5.8.4 Severe Drift Range (Max/Min Range > 2.75%) Figure 5.8.9 shows the beam webs, both of which yielded at a drift of 1.31%. This yielding did not increase until 2.15% drift when the gusset plate base metal fractured at the SW column weld. It is believed that this fracture places eccentricity on the 138 connection adding stresses to the connection at the beam weld. This added stress was enough to buckle the SW beam web and therefore yield the web shown in Figure 5.8.10. Figure 5.8.9 – Yielding at Beam Webs (1.31%) Figure 5.8.10 – Y3 and B1 of SW Beam Web (2.15%) At a drift ratio of 1.77%, the base metal of both of the gusset plates at the columns cracked. During the subsequent compression cycle at a drift of -2.31% these cracks grew to six inches in the gusset plate at the NE column and 4 inches in the gusset plate at the SW column, as shown in Figure 5.8.11 and 5.8.12, respectively. Also, significant yielding, Y5, occurred in both gusset plates from the hinging at this drift level, shown in Figure 5.8.13. 139 Figure 5.8.11 – 6” Base Metal Crack in Gusset at NE Column (-2.31%) Figure 5.8.12 – 4” Base Metal Crack in Gusset at SW Column (-2.31%) Figure 5.8.13 – Y5 of Gusset Plates (-2.31%) 140 The cracks in the base metal of the gusset plates did not propagate significantly during successive tension cycles, only during compression cycles. The NE gusset at the column fractured to a length of 15 inches at a drift of -2.79%, as shown in Figure 5.8.14. This crack seemed to affect the compression capacity of the system as it was only able to support -127 kips. A table summarizing the weld and base metal damage is shown in Table 5.8.2. Figure 5.8.14 – 15” Base Metal Fracture (-2.79%) Table 5.8.2 – HSS-17 Weld/Base Metal Damage Summary At a drift of -2.31% brace cupping occurred, as shown in Figure 5.8.15. At a drift ratio of 2.15%, low cycle fatigue cracks developed at the bottom of the brace, as shown in 141 Figure 5.8.16. Severe cupping and bulging occurred during the compression half of the same cycle at -2.79% drift, as shown Figure 5.8.17. The brace fractured at 2.67% drift. Figure 5.8.15 – Brace Cupping (-2.31%) Figure 5.8.16 – Fatigue Cracks in Brace (2.15%) 142 Figure 5.8.17 – Local Failure in Brace (-2.79%) 5.8.5 Specimen Summary Overall, HSS-17 performed very well. The frame achieved a range of drifts from -2.79% to 2.15% for a total range of 4.94%, one of the best for all 17 tests. Its drift capacity is attributed to the very low in and out-of-plane stiffness of the gusset plates. One thing of concern is the cracks in the base metal at the gusset plate welds. A 15 inch crack on a 16 inch connection may be a warning flag. However, this base metal crack length occurred at a drift level of -2.79% in compression after it had already sustained a positive drift of 2.15%. A picture of the gusset plate at the end of the test is shown in Figure 5.8.18. Figure 5.8.18 – NE Gusset Plate (End of Test) 143 5.9 Hysteretic Envelope Comparison Figure 5.9.1 shows the envelopes of the hysteretic curves for all of the specimens in the positive drift region. Figure 5.9.2 shows the envelopes of the hysteretic curves for all of the specimens in the negative drift region. Figure 5.9.1 – Positive Hysteretic Envelopes Figure 5.9.1 shows that while the specimens were in the elastic range, they had similar strength and stiffness, but these characteristics started to diverge from one another as the specimens started to respond inelastically when higher displacement was applied. The only difference in all of the specimens during the elastic phase was the higher stiffness of HSS-12 compared to the other specimens. The slipping of the bolts in HSS-16 is quite obvious around 0.5% drift ratio and this slipping affected the strength of the specimen for the entire length of the test. Of the remaining five tests (excluding 144 HSS-16) regarding the positive drift region, HSS-12 had the highest load resistance, and HSS-17 had the highest drift capacity. Figure 5.9.2 – Negative Hysteretic Envelopes Figure 5.9.2 also shows that while the specimens were in the elastic range, they had similar strength and stiffness, but these characteristics started to diverge from one another as the specimens started to respond inelastically when higher displacement was applied. HSS-13 and HSS-14 showed the highest buckling load. HSS-12 showed an increased compressive capacity as the drift (absolute value) increased above -0.5%. HSS-16 had the lowest compressive capacity but the highest compressive drift capacity. Of the other five specimens (excluding HSS-16) regarding the compressive drift region, HSS-12 had the highest load resistance and HSS-17 had the highest drift capacity. 145 Chapter 6: Analysis of Results 6.0 Introduction The purpose of this chapter is to compare the results of the experiments described in the previous chapter (HSS-12 through HSS-17) and determine how the gusset plate designs influenced the specimen behavior. There are multiple ways to compare the different experiments. These include comparisons between their ultimate drift or inelastic deformation capacity (Section 6.1), the behavior of the steel at given drift or performance levels (Section 6.2), their load capacity (Section 6.3), the magnitude of their energy dissipation (Section 6.4), and their constructability (Section 6.5) These categories do not all carry the same weight. The actual balance of these criteria will depend on the seismic risk or hazard, the seismic design criteria, and the performance objective. Ultimately, the goals of the structure are laid out in the performance based design guidelines. The performance objectives are: Immediate Occupancy, Life Safety, and Collapse Prevention. They are assigned as performance requirements of a building (structural and non-structural) at certain drift levels depending on the use of the building. Many of the comparisons between these specimens have been made with the data acquired during testing. Much of this data had to be manipulated into useful information. Detailed calculations showing these manipulations are located in Appendix D. 146 6.1 Ultimate Drift Capacity 6.1.1 Introduction Ultimate drift capacity is the best way to compare these specimens when analyzing the performance objective of collapse prevention. This is because an earthquake will deliver displacements to the structure and as shown in Chapter 5, the brace will fracture under a certain displacement leading to potential collapse. One of the goals of this research is to increase the ultimate drift capacity of the frame, so that the brace will not fracture when imposed to large frame displacements. Table 6.1.1 shows the maximum drift ratios experienced by each of the specimens. The maximum and minimum drift ratios are the maximum and minimum of all of the completed cycles, excluding the cycle in which the brace fractured. This section will provide detailed discussion and analysis of the test data to examine the relative performance of different test frames. Table 6.1.1 – Summary of Ultimate Drift of Specimens 6.1.2 Brace Behavior To understand how the gusset plate affects the ultimate drift capacity, it must first be understood how the brace behaves and why the brace fractures. This section will evaluate brace fracture behavior when the frame is subjected to seismic motion. 147 For most of the experiments, the brace behaved in the way it was designed to behave. That is, the brace buckled and a hinge formed at the center of the brace. The brace buckled out-of-plane and therefore brace hinging was accompanied with hinging of the gusset plates. Figure 6.1.1 shows how a brace will respond to inelastic, post-buckling, cyclic loading. This figure is useful in understanding brace performance, and therefore the changes that can be made to improve this performance. Stage: 1 2 3 4 5 Figure 6.1.1 – Five Stages of Inelastic, Post-Buckling Response of Brace Concentrated damage initially occurs at the plastic hinge at the center of the brace once buckling occurs (stage two of Figure 6.1.1). The yielding of the steel tube due to brace buckling creates a new unloaded brace shape. Tension is then applied to the brace (shown in stage four) which puts another plastic hinge in the brace in the opposite direction of the hinge in stage two adding strain accumulation in the center of the brace. During the final stage, the brace is straight and tension is applied. In stage four, it is obvious that strain accumulation is being concentrated at the center of the brace; however in the fifth stage, it is difficult to determine where the yielding is occurring. It 148 is possible that the yielding is being distributed throughout the length of the brace; but it could also be possible for the plastic strain to be accumulating at the location of the hinge if there is strength degradation there. Towards the end of the experiment in the compression stage, the brace deflects considerably out of the plane of the frame (Δ), from 13 to 19 inches depending on the specimen. The center of the brace at the plastic hinge becomes very hot from the energy it is absorbing. At this stage, not only are there large out-of-plane brace deflections, but there are also very large local stresses and deformations. In Figure 6.1.2, the compression force at the lower side of the diagonal tube brace is no longer collinear at the center of the brace, where the hinge has developed. This causes large P-delta moments at the plastic hinge location, and the combination of the axial load and the moment lead to large plastic strains in the top and bottom flanges of the tube. The bottom flange of the buckled brace in Fig. 6.1.2 is in compression and the combination of large local stresses and compressive strain result in local distortions and buckling as shown in the figure. This excessive local deformation puts even more strain demand at the center of the brace and when it is as severe as it is in Figure 6.1.2, it leads to cracking such is shown in Figure 6.1.3 and imminent brace fracture. Figure 6.1.2 – Local Buckling During Stage 2 Leading to Fracture 149 Figure 6.1.3 – Cracks after Local Buckling Has Occurred 6.1.3 Buckled Shape and Curvature 6.1.3.0 Introduction From the previous section, it is seen that brace fracture is strongly influenced by the strain and curvature at the center of the buckled brace. It can be inferred that a possible way to increase the life of the brace, is to reduce the curvature of the brace for given inplane displacements. To do this, the brace should act like a pinned-end member instead of a fixed-end member. This is appropriate because when the brace buckles, the out-ofplane displacement is the same for a pinned-end member and a fixed-end member for a given in-plane displacement (determined because this is required to ensure that the deflected shapes have equal arc lengths), as shown in Figure 6.1.4. However, the curvature at the center of the brace of the fixed end member is greater than that of the pinned end member; thereby putting more curvature at the center of the brace, and also more strain at the center of the brace. Therefore, the gusset plates should have the smallest amount of stiffness possible while maintaining the strength to transfer the loads from the brace to the frame. This section will compare the stiffness and flexibility of the various test specimen connections to determine the effect of flexibility on system performance. 150 Figure 6.1.4 – Buckled Shape Comparison at a Given In-Plane Displacement This idea of allowing restraint free gusset plate rotation was realized by Astaneh-Asl and is incorporated in the AISC Seismic Provisions with the 2t offset requirement shown in Figure 6.1.5. The idea behind the provision is to allow a straight hinge line to form in the gusset plate. However, when this idea is combined with the buckling requirements of the gusset plate, the gusset plate must be thicker to resist buckling. Conversely, if the brace is allowed to end at a location closer to the beam-column intersection, the gusset plate buckling length is reduced and therefore, a relatively thinner plate will suffice. Figure 6.1.5 – 2t Clearance 151 6.1.3.1 Deflected Shape Comparisons of the deflected shape of the brace are shown in Figure 6.1.6 at a drift of 0.35%, Figure 6.1.7 at a drift of 1.5%. , and Figure 6.1.8 at brace cupping. Specimen HSS-14 buckled down and the data is not available for this specimen at a drift of 1.5%. HSS-16 did not buckle at the center of the brace and therefore, the data is not available at brace cupping. Figure 6.1.6 – Deflected Shape at -0.35% Drift None of the braces in any of the specimens even reached the state of B1 at this drift ratio. There is still out-of-plane deflection as shown in the figure. However the resulting shapes are more likely due to as-built condition (with differing initial eccentricities) than the stiffness of the gusset plate. 152 Figure 6.1.7 – Buckled Shape at –1.5% Drift Figure 6.1.8 – Buckled Shape at Brace Cupping (BC) 153 Figure 6.1.7 and Figure 6.1.8 are much more valuable than the previous figure. This is because the differing eccentricities from the as-built conditions of the specimens are negligible compared to the larger out-of-plane displacements of the brace. At the drift of -1.5%, the out-of-plane displacements of the specimens at midspan of the brace are quite close. This provides empirical evidence that regardless of the buckled shape and end plate rotation, the out-of-plane displacements will be equal at a given drift ratio. More significant than the similar out-of-plane displacements shown in Figure 6.1.7, is the different shapes of the buckled braces also portrayed in this figure. The buckled shape of HSS-12, which has the thicker, larger plate, is showing double curvature. Thus, there is a larger curvature at the center of the brace, leading to higher strain accumulation. This also caused brace cupping at a low drift level, leading to cracking of the brace, and eventual fracture. Figure 6.1.8 shows the deflected brace shapes at brace cupping, and it can be seen that HSS-12 did not reach a very high out-of-plane displacement when cupping occurred. It is apparent that the current 2t linear clearance model does not assure the end rotation capacity needed to obtain optimal ductility from the brace. Conversely, the other three frames in Figure 6.1.7 (excluding HSS-16) show they are bent in single curvature. This reduces the curvature at the center of the brace, and also the strain. Therefore, brace cupping occurs at higher drifts associated with higher outof-plane displacements (Figure 6.1.8). 6.1.3.2 Out-of-Plane Displacement Figure 6.1.9 and 6.1.10 show the out-of-plane displacement as a function of the drift ratio and as a function of the total drift range, respectively. All the specimens (except HSS-16) increase in out-of-plane displacement just about equally as the drift increases. 154 Figure 6.1.9 – Brace Out-of-Plane Displacement at Midspan vs. Frame Drift 155 Figure 6.1.10 – Brace Out-of-Plane Displacement at Midspan vs. Drift Range Both graphs show that HSS-12 has a slightly smaller out-of-plane displacement than the other four tests (except HSS-16). This is due to the fact the HSS-12 had shortened a little more than the other specimens from the relatively higher lateral load it was resisting (Figure 5.9.2 shows the higher load that HSS-12 resisted in the negative drift range). This was due to the double curvature of the brace. Since the brace was slightly shorter from the higher axial load, the out-of-plane displacement was a little less at a given drift ratio as shown in the graphs. 6.1.3.3 Gusset Plate Qualitative Comparison The four tests, HSS-13, HSS-14, HSS-15 and HSS-17 more closely demonstrate the buckled shape of a pinned-end member than the buckled shape of HSS-12. Qualitative stiffness comparisons are presented in Section 6.1.3.3a between HSS-13 and HSS-17, 156 and in Section 6.1.3.3b between HSS-14 and HSS-17. The rotational strength of plates using an elliptical clearance is examined in Section 6.1.3.3c. 6.1.3.3a Gusset Plate Qualitative Stiffness Comparison between HSS-13 and HSS-17 A simple comparison is made here between HSS-13 and HSS-17. These specimens had the same gusset plate geometry, except HSS-13 used a 1/2 inch gusset plate, while HSS-17 used a 3/8 inch gusset plate. The equation shown below from Yoo (2006) can be used to compare their stiffness: K rotational = E Lave ⎛ Ww t 3 ⎞ ⎜ ⎟ ⎜ 12 ⎟ ⎝ ⎠ (6.1) For more information on this equation, see Yoo (2006). All of the variables are equal except the value of t. Therefore, HSS-13 had a stiffer gusset plate (in the out-of-plane direction) than HSS-17 by a factor of: K relative = t HSS −13 3 t HSS −17 3 = (1 / 2) 3 = 2.37 (3 / 8) 3 (6.2) HSS-13 had a drift ratio range of 4.09% compared to 4.94% for HSS-17. This further supports the idea that a stiffer gusset plate will shorten the drift life of the brace and hinder the ultimate drift range of the frame. 6.1.3.3b Gusset Plate Qualitative Stiffness Comparison between HSS-14 and HSS-17 Because the gusset plate is not a longitudinal member, it is more accurate to compare gusset plate stiffnesses with a three dimensional analysis. The equation above (used for similar geometries) and the one shown here from Johnson (2005): 157 Ks = M * Ltot θ plate (6.3) do not consider the three dimensional affects that exist when the gusset plate is in bending. For more information on this equation, see Johnson (2005). Figure 6.1.11 shows the gusset plate details of HSS-17 and HSS-14 overlaid on each other. This figure shows that they are very similar. The only difference is that HSS-17 used a tapered gusset plate. They both used a 3/8 inch gusset plate. HSS-14 used a slightly thicker fillet weld, 7/16 inch, while HSS-17 used a 3/8 inch fillet weld. Figure 6.1.11 – HSS-17 and HSS-14 Gusset Plate Detail Overlaid on Each other There is an inherent difference between the hinging patterns between the two plates. Figure 6.1.12 and 6.1.13 show the hinging patterns for a rectangular plate using an elliptical clearance and for a tapered plate using an elliptical clearance, respectively. It should be noted that the tapered plate with the elliptical clearance is very close to a straight line clearance (in this case). Part (a) of each figure shows the actual yield lines 158 from the experiments and part (b) shows the theoretical hinge lines which are defined as the rubber band line that intersects the corners of the gusset plate and the end of the brace. The actual hinge line and the theoretical hinge line are quite similar for each specimen. However, the difference between the yield lines when comparing across specimens should be considered when analyzing the stiffness of the plate. (a) (b) Figure 6.1.12 – Hinge Lines for Rectangular Plate with Elliptical Clearance (a) (b) Figure 6.1.13 – Hinge Line for Tapered Plate 159 The hinge pattern that is created with the HSS-17 gusset plate is simple. The hinge is a straight line which creates two planes. However, the hinge pattern created by the bent hinge lines of HSS-14 shown in Figure 6.1.12 creates three planes: one plane that is the original plane of the gusset plate, and two different planes created by the two different hinge lines. For these three planes to coexist, additional gusset plate bending is required that is about the brace centroidal axis as shown in Figure 6.1.14 (designated by the shaded area). Figure 6.1.14 – HSS-14 Hinge Lines Including Bending for Compatibility This additional bending creates added out-of-plane stiffness to the connection for plates using the elliptical clearance method relative to the tapered plate. There is evidence of this in the finite element analysis carried out for the gusset plates used in HSS-14 and HSS-17. Figures 6.1.15 and 6.1.16 show the mesh used for each specimen, respectively. The finite element models included the brace (as shown in the figures) and pinned supports at the column and beam. In reality the supports would be springs. However this analysis looks at the stiffness of the gusset plate only. The models were loaded with one half inch-kip on each tube wall, at the end of the gusset plate (see Appendix C for more information). 160 Figure 6.1.15 – Finite Element Mesh for HSS-14 Figure 6.1.16 – Finite Element Mesh for HSS-17 The results from the finite element analyses showed that the tapered gusset plate deflected 0.00385 radians, while the rectangular plate deflected .0031 radians. This results in a stiffness of 263 k-in per radian for HSS-17, and 327 k-in per radian for HSS-14; showing that the tapered plate is more flexible than the rectangular plate. In this comparison the tapered plate was 19 percent less stiff (13% less stiff when using Equation 6.1). A nonlinear analysis was not carried out. Based on the reasoning listed above (and the fact that the width of the gusset plate used in HSS-14 is longer than the width of the gusset plate used in HSS-17), it is logical that HSS-17 has a higher drift capacity than HSS-14. HSS-17 had the highest drift capacity 161 (except for HSS-16, see Section 6.1.6) at 4.94%. This is more than 1% higher than HSS-14 which had a drift capacity of 3.93%. HSS-15 was similar to HSS-14. The only difference is that it had a smaller splice length and a slightly smaller elliptical clearance of 6t as opposed to 8t. HSS-15 had a rotational stiffness of 321 k-in per radian (from the FEM model similar to the finite element models shown above), and a similar drift capacity of 4.09%. 6.1.3.3c Gusset Plate Qualitative Strength Comparison In addition to the extra bending that is required to produce the deformed gusset plate geometry (of a plate with an elliptical clearance), in-plane stresses in the gusset plate are evident when the nonlinear geometry of the problem is considered. This adds moment resistance, further inhibiting rotation of the gusset plate. Figure 6.1.17 shows a perspective drawing of the gusset plate with planes that are rotated along the hinge lines shown in Figure 6.1.12. Because these planes are rotated about two different lines, they move apart from each other when they are rotated as shown by the gap between the two planes. In reality, these planes stay connected by the tension stress of the plate, perpendicular to the longitudinal axis of the brace. This tension stress adds to the rotational strength of the connection, making the brace buckle more like a fixed end member, than a pinned end member. Figure 6.1.17 –Perspective Drawing of Hinging of HSS-14 162 6.1.3.4 Gusset Plate Plastic Rotation Comparison Figures 6.1.18 and 6.1.19 show the NE gusset plate rotation and the SW gusset plate rotation respectively, as a function of the drift ratio. These graphs show a representation of how flexible the gusset plates are and how much rotation they allow at high drift levels. Calculations for determining the gusset plate rotation are shown in Appendix D. Figure 6.1.18 – NE Gusset Plate Rotation vs. Story Drift 163 Figure 6.1.19 – SW Gusset Plate Rotation vs. Story Drift Both of the gusset plates used with HSS-12 show considerably less rotation than the other gusset plates. For example, at a drift ratio of -2.0%, the rotation of the gusset plates used for HSS-12 is about 0.11 radians. However, the other specimens (excluding HSS-16, see Section 6.1.6) average a rotation of about 0.18 radians. The out-of-plane displacements for pinned-end members and fixed-end members are equal at a given in-plane displacement of the brace as described in Section 6.1.3.0 (neglecting the axial shortening due to the load which is a small portion of displacement at higher displacements). Therefore, in order for the brace in HSS-12, which has a stiffer and stronger gusset plate connection, to reach the same out-of-plane displacement, the brace must be bent in double curvature. As mentioned before, the double curvature leads to higher strains in the bottom of the brace. These strains eventually lead to brace fracture, causing HSS-12 to have a short drift life relative to the other specimens. 164 Conversely, the gusset plates used in HSS-17 reached the highest rotation of all of the specimens. This led to reduced curvature at the center of the brace (at a given drift ratio), and lower strain demand. HSS-17 had a drift ratio range of 4.94%, second only to HSS-16 of these six tests (Recall that HSS-16 suffered large rotations at the bolted extension plate and is therefore not representative of typical brace-gusset behavior). In conclusion, the specimens that allowed larger gusset plate plastic rotations reduced the curvature at the center of the brace. The gusset plates that allowed the higher rotations were also the gusset plates that were less stiff, (i.e. HSS-13, HSS-14, HSS-15 and HSS-17). 6.1.3.5 Summary From the ultimate drift capacity results, the tapered plates performed better than the rectangular plates. This is partly due to the fact that they had a smaller end rotational stiffness than the rectangular plates with the elliptical clearance (when all else is equal). Of all of the specimens, HSS-12 had the smallest drift ratio range. This was partly because although the 2t requirement creates a straight forward hinging pattern, the thickness of the plate required to resist gusset plate buckling had a larger effect on the gusset plate stiffness and rotational allowance. The resulting stiff gusset plate increased the curvature of the buckled brace at midspan, at a given drift ratio, which led to early fracture. A table showing the stiffness of the connections from finite element analyses of selected specimens is shown here: 165 Table 6.1.2 – Summary of Selected Gusset Plate Stiffnesses from FEM (in-k/rad) 6.1.4 Axial Stiffness of the Gusset Plates The gusset plates also affected the ultimate drift capacity of the frame through their ability to yield in the plane of the frame in the longitudinal direction of the brace. During the tension phase of the test, any yielding in the gusset plate will reduce the elongation of the brace. During stage five of the inelastic post-buckling behavior of the brace (Figure 6.1.1), yielding will occur. Ideally this yielding should be distributed over the length of the brace. Unfortunately, strain may concentrate at the hinge due to the Bauschinger effect. Strain hardening at the plastic hinge location may reduce this tendency to concentrate tensile plastic strain, but limited yielding in the gusset plate may also aid in distributing the plastic strain. If the strength and stiffness of the gusset plate are maintained at the minimum required to support the design loads, yielding the gusset plate will be more likely. This will reduce the strain demands in the brace, and therefore, also reduce the strain demands and yielding in the plastic hinge location. Figure 6.1.20 shows the brace elongation (as calculated in Appendix D) compared to the drift ratio. Figure 6.1.21 shows the same thing, except it only shows the elongation of the brace while it was in tension only so that the graph is clearer. 166 Figure 6.1.20 – Brace Elongation vs. Frame Drift Figure 6.1.21 – Brace Elongation vs. Frame Drift (Tension only) 167 These graphs show that for the frames which have thicker, larger gusset plates, the brace elongates more at a given drift ratio potentially putting more strain demand at the center of the brace. For example, the brace elongation for HSS-12 is about 0.55% at a drift of 1.0%. However, all of the other frames have a brace elongation of about 0.4% at a drift of 1.0%. Since the framing elements are the same for all of the specimens, it is reasonable to assume that the difference between HSS-12 and the others is occurring through yielding in the gusset plates. Conversely, HSS-17 has the smallest in-plane strength stiffness because of its tapered 3/8 inch plate, and it seems to have the smallest brace elongation for larger drifts. Figure 6.1.22 shows the negative elongation of the brace compared to the total drift range. While Figure 6.1.23 shows the positive elongation of the brace compared to the total drift range. This shows the same results as the previous two figures. HSS-12 shows the highest brace elongation for a given total drift ratio. The other frames are rather comparable but it seems that HSS-17 may have a slightly smaller elongation for a given drift ratio. 168 Figure 6.1.22 – Brace Elongation (Compression only) vs. Total Frame Drift Figure 6.1.23 – Brace Elongation (Tension Only) vs. Total Frame Drift 169 Figure 6.1.24 shows the elongation of the gusset plate (measured from the end of the brace to the center of the beam-column intersection, includes elongation in both NE and SW gusset plate). It should be noted that this figure shows the elongation of the gusset plates before weld or base/metal cracking occurred. It shows that relatively, the gusset plates in HSS-17 absorbed a large amount of strain, especially at high drift levels. This gusset plate has the lowest axial stiffness of all of the specimens. This is because it has the smallest thickness (along with others), and it also has the smallest width, giving it the smallest area, and therefore lowest axial stiffness. Therefore, as the figure suggests, this gusset plate absorbed the most strain. Conversely, HSS-12 used a 1/2” thick plate and a very large geometry, and had the smallest amount of elongation. Figure 6.1.24 – Gusset Plate Elongation vs. Frame Drift (Tension Only) At higher drifts, the strength of the gusset plate significantly affects the force in the brace. As Figure 6.1.25 shows, the specimens which used larger, stronger plates also have higher brace forces. 170 Figure 6.1.25 – Brace Force vs. Drift Ratio The higher brace force adds to the axial elongation in the brace, adding strain in the plastic hinge. The added strain shortens the life of the brace. HSS-12 shows the highest brace force at high drift levels, while HSS-16, HSS-15 and HSS-17 show the lower brace forces. The results presented in this section show that the specimens which had gusset plates with lower axial stiffness and strength also had a higher drift capacity. This is because when the gusset plate is smaller, during the tension cycle, plastic strain can occur more readily in the gusset plate instead of the hinge point of the brace. This is also true, because the smaller gusset plates with smaller axial capacities deliver a smaller load to the brace. It should be noted however, that a gusset plate that is too small and/or weak may adversely affect the drift life of the specimen. 171 6.1.5 Weld/Base Metal Damage Although, it is not desirable to have damage to the gusset plate welds at an early drift ratio based on performance based design standards, damage to these welds will increase the ultimate drift range of the frame. Whether it is damage to the welds themselves, or damage to the base metal of the gusset plate at the welds, it has the same negative impact on the condition of the structure but a positive affect on the ultimate drift capacity of the frame. Figure 6.1.26 shows the total drift ratio range of each specimen with respect to the amount of total weld tearing that occurred for the entire test (each mark on the graph represents a specimen). This graph does not take into account many other influential characteristics and therefore has limited value. However, the graph shows a consistent trend between amount of weld tearing and total drift range: the higher the amount of weld tearing, the larger the drift capacity. Figure 6.1.26 – Total Drift Range vs. Total Weld/Base Metal Crack Length 172 The weld/base metal tearing tends to occur during the compression cycle of brace loading. Tearing occurs due to the large local bending moments in the plate caused by buckling deformation of the brace and P-delta moments. In addition to these forces, during the compression cycle an opening moment exists at this joint from structural analysis (see Figure 6.1.27). This opening moment adds tension across the gusset plate perpendicular to the brace, adding more stress and strain demand on the gusset plate at the welds. Opening Moment at Joint Compression in Brace Figure 6.1.27 – Opening Moment Associated with Compression in Brace When brace buckling is combined with weld or base metal cracking, the brace buckles over a longer effective length. Therefore the curvature demand at the center of the brace for a given drift ratio is smaller, prolonging the life of the brace. Conversely, when the weld or base metal does not crack or tear, the connection remains stiff and does not help to reduce the curvature demand on the center of the brace, leading to earlier brace fracture. 173 Additionally, when the base metal or the welds crack, it can be inferred that the axial stiffness of the connection is reduced. For example, if a rectangular plate cracks over a couple of inches at both of the reentrant corners, a tensile load will no longer be able to be transferred across the crack. Therefore, the load will need to be resisted over a smaller gusset plate width (and area), essentially turning a rectangular plate into a tapered plate and reducing the axial stiffness. It should be noted that weld cracking seems to be fairly dependant on the applied drift history. This is important because the applied drift histories are different between specimens. Furthermore, because the Seismic Provisions require braces in opposing direction, a more symmetric applied displacement is more likely than one with higher compressive drifts than tension drifts. This will be discussed in more detail in the following chapter. It is shown above that cracking or tearing of the weld/base metal is advantageous to the ultimate drift capacity of the frame. However, as will be shown in Chapter 7, if a weld is too small and weld fracture occurs before the brace fractures, then the ductility and inelastic deformation capacity of the system is reduced. This reduction limits the ability of the frame to meet performance based design criteria. There should be a balance in the design of the gusset plate welds. They should not sustain cracking at low levels to aid in meeting operational and serviceability in performance based design limits. However, limited cracking at high drift levels will increase the inelastic drift capacity and aid in meeting Life Safety and Collapse Prevention performance based design limits. 174 6.1.6 HSS-16 HSS-16 is a much different specimen than the other five tested in this test series. It had a bolted connection to the gusset plate as opposed to the other specimens which were welded. HSS-16 buckled at the connection, and had a very large drift ratio range, 5.89%. If ultimate drift capacity were the only criteria for seismic design, then the gusset plate detail for HSS-16 may be the preferred design. However, other requirements exist for seismic design, which are discussed in future sections of this chapter, and these were not as acceptable for this specimen. 6.1.7 Summary Examining the ultimate drift capacity is an accurate way to compare different frames ability to meet Life Safety and Collapse Prevention performance based design limits. The series of tests analyzed in this chapter show that the gusset plate detail drastically affects the ultimate drift capacity of the frame. The brace fractures due to the plastic strain accumulation at the center of the brace (Yoo, 2006). If this plastic strain accumulation can be reduced at a given drift level, then the frame can reach higher displacements without the brace fracturing, thereby leading to a safer structure by postponing collapse. When the brace buckles, the curvature of the brace at midspan severely affects the plastic strain accumulation. Local deformation leads to further plastic strain accumulation, which leads to fracture. If the gusset plates are designed to have a low out-of-plane stiffness, then the shape of the brace will have single curvature as with a member with pinned-end connections. Therefore the plastic strain accumulation at the center of the brace will be smaller at a given drift level. Gusset plates with smaller outof-plane stiffness increase the drift capacity of the frame. 175 When the brace is in tension, the location of the plastic hinge will experience increased plastic strain accumulation. The plastic strain accumulation will lead to cracking which will lead to fracture of the brace. If the gusset plates are designed to have low axial stiffness, then yielding will occur in the gusset plate, thereby reducing plastic strain demands at the plastic hinge of the brace and increasing the drift capacity of the frame. Controlled cracking or tearing of the welds or base metal can also increase the ultimate drift capacity of the frame. When the gusset plates or gusset plate welds initiate cracking at the reentrant corners, the effective size of the gusset plate becomes smaller. A smaller effective gusset plate reduces the effective out-of-plane stiffness of the gusset plate. It also reduces the axial stiffness of the connection. In conclusion, the two major factors that cause the plastic strain accumulation are the hinging under compressive loads and the tension in the brace after hinging. It is unsure which increases the plastic strain accumulation more adversely. However, the solution is the same for each problem. A smaller thinner gusset plate will reduce the out-ofplane stiffness and the in-plane stiffness increasing the drift capacity of the frame. 6.2 Performance State Comparison 6.2.0 Introduction Seismic design is based on the premise that structures should have less damage during smaller, more frequent earthquakes, but may have a large amount of damage during larger, more infrequent earthquakes. Performance based design builds on this concept to recognize that the level of damage may be controlled to achieve economic benefits based upon acceptable seismic risk. Because large earthquakes have a much longer return period than the life expectancy of the building, owners usually are willing to take the risk that the building may not be usable after such an earthquake. Smaller 176 earthquakes however, have a greater chance of occurring during the lifespan of the building, and therefore buildings should be able to resist these seismic events with less damage to the structure. Performance levels, in order of decreasing acceptable expected deformation levels, include: 10. Collapse Prevention 11. Life Safety 12. Immediate Occupancy The drift level that is associated with Immediate Occupancy is dependant on the structure. For example, a hospital may require more strict performance levels of the structure for Immediate Occupancy than an office building. Furthermore, the same hospital may require that the level of Immediate Occupancy be satisfied at larger, more infrequent earthquakes; since during these earthquakes, hospitals are critical to the recovery of the community. The Life Safety performance level deals with the safety of those within the building during an earthquake (excluding the possibility of building collapse). Much more damage is expected in this performance level. However, the structure and other building components shall avoid life threatening responses such as falling debris and loss of gravity load bearing elements. In order to satisfy the performance level of Collapse Prevention, most of the effort within this research was to prolong the life of the brace which was discussed in the previous section, 6.1. However, the specimens still had some strength and stiffness after the brace fractured. The capacity after the brace fractured was approximately 100 kips in either direction, and the stiffness was approximately 40 kips per one percent drift (compared to the original stiffness of 500 kips per one percent drift). 177 This section will compare the performance levels of different areas of the frame. This section will examine the brace in Section 6.2.1, the gusset plate in Section 6.2.2, the gusset plate welds/base metal in Section 6.2.3 and the framing members in Section 6.2.4. 6.2.1 Performance State Comparison of Brace The performance state of the brace for each experiment as described and defined in Chapter 5, is listed in Table 6.2.1. Most of the performance states, which occurred at lower drift levels, occurred at relatively similar drift levels between specimens. More varied results between the frames occurred at higher drift levels. 178 Table 6.2.1 – Brace Performance State Comparison Initial buckling state B1 occurred at a range from -0.36% to -0.43%. Moderate buckling state B2 occurred at a range from -0.5% to -0.96%. HSS-14 displayed the higher drift value of -0.96% which is attributed to the manner in which it buckled which was sharp and sudden as describe in Chapter 5. Brace cupping occurred at a range of -1.60% to -2.31%. The brace in specimen HSS-17 did not experience brace cupping until -2.31%. 179 Initial yielding (state Y1) occurred at a range from 0.31% to 0.71% (ignoring HSS-16). The brace in HSS-12 yielded at the smallest drift ratio, 0.31%, due to the large size of the gusset plates. At large drifts, the goals of Life Safety and Collapse Prevention are the concern. The performance state of brace fracture and when it occurred (as shown in the table above, BF) is the performance state which may breach these goals. The brace in HSS-12, which used a large 1/2 inch gusset plate with a 2t straight line offset, fractured at the lowest drift of 1.31% (at a drift ratio range of 3.49%) while the brace in HSS-17, which used a relatively small 3/8 inch tapered gusset plate, fractured at the highest drift at 2.15% (at a drift ratio range of 4.94%). After the brace fractured, there was still load carrying capacity of the frame as mentioned earlier; however that capacity was very small. 6.2.2 Performance State Comparison of Gusset Plates The performance states of the gusset plate for each experiment are listed in Table 6.2.2. Initial yielding and moderate yielding occurred first typically during the tension cycle of the experiment. Severe yielding occurred during the compression cycle of the test (except for HSS-16). Initial yielding state Y1 occurred from a range of 0.21% to 0.35% in at least one of the two gusset plates for each frame (except HSS-16). Larger differences were noticed between the drift levels when state Y3 yielding occurred (in at least one of the gusset plates), which ranged from 0.32% to 0.82%. State Y5 yielding occurred between -1.35% to -2.31% (excluding HSS-16). 180 Table 6.2.2 – Gusset Plate Performance State Comparison Y1 is certainly acceptable for the performance level of Immediate Occupancy. Even the yielding state Y3, which occurred relatively early for a couple of specimens, is acceptable for IO. The SW gusset plate in HSS-15 reached this state at 0.35%. Recall that HSS-15 was not designed for block shear yielding. Instead, this limit state was ignored and the gusset plate was designed for block shear fracture and Whitmore fracture. Figure 6.2.1 shows the yielding of the gusset plate at this drift ratio. Similarly, the gusset plates in HSS-17 also reached Y3 yielding relatively early in the experiment, as shown in Figures 6.2.2 and 6.2.3. 181 Figure 6.2.1 – Y3 Yielding on HSS-15 Gusset Plate (0.43%) Figure 6.2.2 – Y3 Yielding on HSS-17 NE Gusset Plate (0.32%) 182 Figure 6.2.3 – Extended Yielding of HSS-17 NE Gusset Plate (0.53%) While the yielding that is shown in the figures above is moderate, this yielding would probably not even be noticed without the whitewash. Therefore, the damage that is done to these gusset plates at these drift levels should not prohibit the structure from being occupied immediately. However, as Table 6.2.2 shows, some gusset plates perform better than others. 6.2.3 Performance State Comparison of Welds and Base Metal The performance states of the gusset plate welds/base metal for each experiment are listed in Table 6.2.3. In the table, the tearing occurred in the gusset plate base metal except for HSS-14, in which the tearing occurred in the weld. It should be noted that the same welder was used for HSS-12 to HSS-14 and another welder (another person) was used for HSS-15 to HSS-17. 183 Table 6.2.3 – Weld/Base Metal Performance State Comparison In general, the performance of these welds at low drift levels (less than 1%) was quite acceptable except for HSS-16. HSS-16 used a one-sided connection which had an eccentric extension plate bolted to the gusset plate. The geometry of this detail caused the extension plate to hinge instead of the center of the brace, placing large rotational demands on the gusset plate (Figure 6.2.4). Due to the rotational demand, the base metal at the SW column weld in this specimen developed a 6 inch crack at a drift of -0.49%. For the performance level of Immediate Occupancy, weld or base metal cracking should not occur. This would need to be repaired before people occupied the building. This is because once a crack forms, stress concentrations will occur at this location, propagating the crack, and creating more damage and less resistance to lateral loads, compromising the stability of the structure. HSS-16 did not perform well in this regard. However, the connections which used welded brace-to-gusset connections 184 performed well within the performance level of IO. None of these welds or the base metal cracked until the severe drift range. Figure 6.2.4 – SW Gusset Plate Rotation vs. Story Drift In general, the performance of the welds was also quite acceptable at high drift ratios. None of the specimens other than HSS-16 showed any weld or base metal cracking until a drift ratio over 1.5% drift. Also, HSS-14 and HSS-17 only showed severe weld or base metal damage at over 2% drift (absolute value). When the cracking in the base metal or the welds becomes this high, Life Safety and Collapse Prevention are in question. However, at such large drift ratios, brace fracture is in close proximity and tearing of the welds actually increases the life of the brace as discussed in Section 6.1.5. The gusset plate welds and base metal for HSS-12 and HSS-13 did not crack during the entire test. These welds showed a very high performance for Immediate Occupancy. Although as stated in Section 6.1.5, the lack of tearing did not help to increase the drift 185 capacity of the frame. These gusset plates were 1/2 inch thick compared to the other four specimens that used 3/8 inch thick gusset plates. Therefore, the base metal did not crack. In conclusion, performance of all of the gusset plate welds/base metal was acceptable for all performance levels, except HSS-16. The complete joint penetration welds used in HSS-12 and HSS-13 did not experience any cracking during the entire length of the test. The fillet welds used in HSS-14 through HSS-17 were designed to have higher capacity than the tensile strength of the plate. When buckling occurred at the center of the brace, these fillet welds, and/or base metal cracked only at drift levels above 1.5%. This shows a high performance for Immediate Occupancy. Severe weld/base metal cracking occurred in these welds at about 2% if at all. This is acceptable for Life Safety and Collapse Prevention, because they did not totally fracture. This is also advantageous to these performance levels because the amount of damage to the welds actually helped to increase the drift life of the brace (as was shown in Section 6.1.5) The base metal in HSS-16 did not have an adequate performance for Immediate Occupancy. This was not due to the design of the welds or gusset plate however. It was due to the buckling shape of the brace and connections. The hinging of the extension plate caused high rotational demand in sub sequentially, the cracking of the base metal. For the higher drift levels in HSS-16, the cracks tore more than any other specimen. However, they did not fracture. Therefore, this specimen performed highly for the performance levels of Life Safety and Collapse Prevention, in terms of drift capacity. However, in terms of load capacity, these performance levels did not perform as well as the other specimens as designated by Table 6.2.3. 186 6.2.4 Performance State Comparison of Framing Elements This section will compare the performance state of the framing elements for each of the six tests carried out in this thesis. Moments and shears are also included in this section. Table 6.2.4 shows a comparison of the performance of the framing elements at a given drift ratio range. Damage written in bold signifies either local flange buckling of the column or severe yielding in the column. Table 6.2.4 – Framing Elements Performance State Comparison This comparison vaguely shows that the stiffer (in-plane stiffness) gusset plates cause more damage to the framing members at smaller drifts. For example, HSS-12 (which used a gusset plate with the highest in-plane stiffness because of its very large geometric size and thickness) received Y1 yielding to three of the four framing elements at a drift ratio range of 1.35%; while this did not occur in HSS-17 (which used a gusset plate with the lowest in-plane stiffness because of its small geometric size and 187 thickness) until a drift ratio range of 1.86%. In general, the framing members had a higher performance within Immediate Occupancy when smaller, less stiff gusset plates were used. However, damage to the framing elements were well within the requirements of Immediate Occupancy at low drift levels. Only initial yielding was noted in any of the elements up to a drift ratio range of 2.0%. No damage to the framing members was noticed that would fall into the Life Safety performance level at any point in the deformation history. Figures 6.2.5 and 6.2.6 show north and south beam moments respectively, at the location of the strain gauges used to determine these moments (see Section 4.3.1 for exact locations). Since only one pair of strain gauges was used on each beam, the shear in the beam was unable to be determined. Figure 6.2.5 – North Beam Moments at Strain Gauge Location 188 Figure 6.2.5 shows the moment of the north beam when the beam was in tension, at negative drift ratios, and when the beam was in compression, at positive drift ratios. It should be noted that the location of the strain gauges on the north beam for HSS-12 was further from the free edge of the gusset plate than the other specimens, which were all 22 inches from the free edge of the gusset plate (see Table 4.3.1). When the beam was in compression, the data was very scattered and no observations were made. When the beam was in tension however, it presumably started to hinge when the drift reached 2% in all of the specimens. Although it is difficult to be sure of this because the moment where the hinge would form was not able to be calculated (only the moment at the strain gauges was able to be calculated). This reduction in moment may also be caused by damage to other locations in the frame. For example, HSS-16 received a great deal of damage to the gusset plate welds. At -2.6%, the NW column weld cracked which may have caused the sharp decline in the curve shown in the figure above. At drift levels below 2%, the beams appear to be elastic, which is acceptable for the performance level of Immediate Occupancy. Above 2%, the beams started to lose capacity. However, the brace is typically quite close to fracturing at this drift ratio and the loss of moment capacity at this drift is acceptable for Life Safety and Collapse Prevention. These two performance levels are also met by the south beam. 189 Figure 6.2.6 – South Beam Moments at Strain Gauge Location From Figure 6.2.6, the moment in the south beams grew until about a drift of 2%. Plastic hinging of the beams may have occurred around this drift at the free edge of the gusset plate, although it is not definite for the reasons mentioned above. However, it is clear that two of the specimens (HSS-13 and HSS-14) had beam web and beam flange buckling at the south beam at about 2.0% drift as shown in Figure 6.2.7. The graph above for the south beams in these specimens show a sharp reduction in moment at this drift ratio. This occurred while there was tension in the brace, which forces the beam to be in compression, and also occurs when there is closing moment at the beam-column joint as depicted earlier in Figure 6.1.27. The closing moment applied compression in the beam web, which caused the web to buckle along with the flange, reducing the moment capacity. Local web and flange buckling should be tolerable for Life Safety and Collapse Prevention. Depending on the goals of Immediate Occupancy 190 for the structure, the damage may be beyond the limits of this performance state. However, because this damage occurred at 2%, the framing members of the structure performed well for Immediate Occupancy. Figure 6.2.7 – Local Beam Web and Beam Flange Buckling of HSS-14 Further comparisons between most specimens could not be made from this figure because the location of the strain gauges on the beam relative to the free edge of the gusset plate was not the same for each test. This is because the lateral support of the channel assembly put limits on where the strain gauges could be located. However, two specimens did have strain gauges in the same location of the south beam, HSS-14 and HSS-16. The beam in HSS-14 had much higher moments because the column weld of HSS-16 cracked quite significantly throughout the length of the test, limiting the amount of moment transferred through the gusset plate to the beam. The east and west column moments are shown in Figures 6.2.8 and 6.2.9, respectively. The east and west column shears are shown in Figure 6.2.10 and 6.2.11, respectively. 191 Figure 6.2.8 – East Column Moments at Gusset Plate Figure 6.2.9 – West Column Moments at Gusset Plate 192 Figure 6.2.10 – East Column Shears Figure 6.2.11 – West Column Shears 193 The column moments shown in Figure 6.2.8 and 6.2.9 reveal that they are quite similar for all of the specimens. The strain gauges used for both columns in HSS-12 and in the east column for HSS-13 malfunctioned and the data is unavailable. The most noticeable characteristic of the graphs is the reduction in moment at 2% drift. This is probably due to the hinging of the beam, rather than hinging of the column since the column has a 30 percent larger plastic (and elastic) section modulus. It is advantageous to the system for Life Safety and Collapse Prevention that the column has a higher modulus than the beam. Hinging in the columns can cause severe damage to the structure and nonstructural elements. This however, does not have much to do with the gusset plate detail. Instead, all of the specimens share this trait. This leads to a potential requirement that the column should have a higher modulus than that of the beam. However, more research is needed to understand how the system would respond if the reverse was true. At low drift levels, the moments and shear in the columns appear to be elastic. This is acceptable for the performance level of Immediate Occupancy The graph for the west column shears shows that HSS-16 carries a smaller moment relative to the other specimens. This is due to the reduced joint stiffness since the SW column base metal at the gusset plate weld cracked early and continued to propagate during the length of the test. The column shears in Figure 6.2.10 and 6.2.11 are directly calculated from the column moments and show similar results as mentioned for the column moments. The proportion of shear resisted by the columns compared to the total shear in the frame increased as the drift increased is shown in Figure 6.2.12 for the negative drift and in Figure 6.2.13 for the positive drift. At least one pair of strain gauges malfunctioned on 194 each of the columns in HSS-12 and HSS-13, and no information is available concerning the column shears for these tests. Figure 6.2.12 – Ratio of Shear Resistance from Columns (Negative Drift) 195 Figure 6.2.13 – Ratio of Shear Resistance from Columns (Positive Drift) The figures above show that the proportional resistance of shear in the columns to the total shear in the frame at high drift levels is much higher when the brace is in compression. This is because the brace is carrying smaller forces in compression than in tension at these drifts. At a drift ratio of -1.5%, the columns resisted 60% of the story shear as shown in Figure 6.2.11. At a drift ratio of positive 1.5% the columns resisted about 25% of the story shear. An interesting characteristic in Figure 6.2.13 shows a spike in this ratio of shear in the columns to the total shear for HSS-16 at a drift of 0.67%. This drift is associated with the cycle directly after the bolts slipped. When the bolts slipped, the brace essentially became longer. Therefore, the increased drift in the next cycle did not apply a large force to the brace, and the shear force in the columns was a higher percent of the total load. 196 Also, due to the bolt slipping and extension plate hinging in HSS-16 throughout the test, the load in the brace never reached its capacity. This was why the column shears typically carried a higher percentage of the total load than the other specimens did as shown in the previous two figures. In summary, damage to the framing members at low drift ratios (below 1%) was well within the respective limits of Immediate Occupancy; and damage to the frame at high drift levels was within the respective limits of Life Safety and Collapse Prevention. It appears that the specimens with the stiffer gusset plates deliver higher load to the framing elements of the specimen. For this reason, slightly more damage was seen for the frames with larger gusset plates at a given drift ratio. It is also important to note that in these specimens, the beams had a smaller nominal moment capacity than the columns. The most severe damage that was experienced by the framing members was local web and flange buckling at the beam. This occurred in two specimens at a drift ratio of about 2%. This could inhibit the performance level of Immediate Occupancy. However, since the gravity load carrying system was still in working condition, Life Safety was met by the beam. (It should be noted that the beam did not carry gravity loads during the experiment, nor was it designed to carry gravity load.) Therefore, the framing member performed very well with the connection details used in all of the specimens for all the performance levels. 6.2.5 Summary for Performance State Comparisons At low drift levels below 1%, damage was seen in all areas of the frame: at the brace, gusset plate, gusset plate welds, and framing members. However, most of the areas of the frame had a high performance for Immediate Occupancy. 197 Weld or base metal damage was not seen until high drift levels for all specimens which used a welded brace-to-gusset connection. Damage for these specimens was not seen until 1.61%, and severe damage was not seen until 2% drift. This is quite high performance for the level of Immediate Occupancy. For Life Safety and Collapse Prevention, it is unclear how much weld and base metal tearing is acceptable at high drifts. It is required that the base metal and weld do not fail before the brace fractures. However, some tearing at these locations was shown to actually increase the life of the brace. Therefore, a balance between the two to maximize the drift life of the brace and the seismic performance may be possible. HSS-16 is the only specimen to have severe damage to the base metal below 2% drift. This occurred at -0.49%. The requirements of Immediate Occupancy are not satisfied when the base metal has this much damage. However, the base metal did not fail completely at the column and the beam before the extension plate fractured, demonstrating the resilience of the gusset plate. Damage to the framing members does slightly depend on the size of the gusset plate. Typically, the larger the gusset plate, the more load is drawn to the framing members. Consequentially, more damage is seen in the specimens with larger gusset plates. At high drift levels, this may lead to issues of Life Safety and Collapse Prevention if the column where to develop large amounts of damage, possibly including hinging of the column. However, since the beam had a smaller plastic modulus of the column, more damage was experienced by the beam For low drift levels (below 1%), the performance of the brace was about equal for all of the specimens, and Immediate Occupancy was satisfied at a relatively high drift. However, the larger, stiffer, and stronger gusset plates caused premature fracture of the brace (as discussed in Section 6.1), leading to issues of Life Safety and Collapse Prevention sooner with these specimens. 198 6.3 Load Capacity Load capacity is another way to compare the specimens carried out in this series of tests. This section will discuss why the load capacities are different and how valuable the added capacity is to seismic resistance. Table 6.3.1 shows the maximum and minimum loads (delivered by the actuator) resisted by the specimen and the subsequent range of force. Table 6.3.1 – Load Capacity Comparison In general, the specimens with stiffer (in the out-of-plane direction and the in-plane direction) gusset plates had a higher load capacity. For example HSS-12 had the highest range of resistance. This can be attributed to the compression capacity and the tension capacity. As was mentioned in Section 6.1.3, HSS-12 had stiffer gusset plates in the out-of-plane direction and therefore buckled more like a member with fixed ends than with pinned ends. This raised the buckling capacity of the brace, and therefore raised the compressive capacity of the frame. Since the gusset plates in this specimen did not yield in tension very much in comparison to the other specimens, the brace experienced higher strains. Therefore, the tension force resisted may have been higher 199 due to higher strain hardening in the brace. Additionally, the large gusset plates caused the framing members to have a shorter effective length, causing them to be stiffer and carry more shear. This added capacity to the frame in both directions (unfortunately, column shears for HSS-12 were not calculated due to faulty strain gauge measurements). Conversely, specimens which used smaller gusset plates generally had smaller load capacity ranges. This can be seen in HSS-15 and HSS-17 which used the smallest gusset plates. Both of the gusset plates used in these specimens were 3/8 inch thick. HSS-15 had a reduced splice length that reduced the geometric sized of the plate, and HSS-17 had a tapered plate that reduced the geometric size. These specimens had the smallest load capacity ranges of the specimens outside of HSS-16. HSS-16 had the smallest load capacity range of all of the specimens in this series of tests. While this alone does not preclude the use of this type of connection for the brace, this connection does not exhibit the behavior postulated in special concentrically braced frames, because the full compressive buckling resistance of the brace was not achieved. This means that the subject frame did not have the seismic resistance required by the design specification, and the system did not exhibit the type of behavior required by seismic resisting theory. In seismic design, members are designed to yield, and buckle, while the connections are designed to carry the force that the members deliver. This is stated in the AISC Seismic Provisions specifically for connections in compression in Section 13.3c: “Bracing connections shall be designed for a required compressive strength based on buckling limit states that is at least equal to 1.1RyPn (LRFD) or (1.1/1.5)RyPn (ASD), as appropriate, where Pn is the nominal compressive strength of the brace.” 200 The value of 1.1RyPn equals 237 kips and was used in the connection design. Figure 6.3.1 shows the force in the brace as a function of the drift ratio of the frame. The figure shows that the compressive force in the brace of HSS-16 only reached a maximum of 160 kips. This value is well below the 237 kip design force and did not meet the requirements in AISC. The lack of compression capacity was due to the fact that the extension plate of the connection hinged before the compression capacity of the brace was met; which would have been met only if the brace buckled. Figure 6.3.1 – Brace Force as a Function of Drift Ratio Frames that have a higher load resistance have a small advantage at low drift levels. If the load delivered by the earthquake is very close to the buckling load or yielding load of the frame, a frame with higher load will be able to resist this load elastically. However, a frame with a smaller load resistance may require the ductility of the frame to absorb the excess load over the elastic capacity. 201 In conclusion, the specimens in this series of tests had slightly different load capacities. These differences were a result of the gusset plate size and geometry. Stiffer and stronger gusset plates produced higher load capacity. The weaker gusset plates produced lower load capacities. More importantly the connections should not fail before the brace started to fail. In general the load capacity does make a difference in the seismic response of the frame. However the value of the increased load capacity is not as influential as other characteristics of the frame, especially the ultimate drift capacity of the frame. 6.4 Energy Dissipation This section will discuss the energy dissipated by the specimens. When the brace, gusset plate, and framing members yield, energy is dissipated by the structure. This is valuable to the frame because the dissipated energy dampens the dynamic response of the structure and reduces the deformation demands required of the system. Energy is released through heat given off by the structure. The more energy dissipated in a specimen, the better it will be at resisting seismic ground acceleration. Relative energy dissipation of various components of the structure is also an issue of importance; they aid in showing the relative participation of various structural components in the inelastic deformation. An example (HSS-12) of the amount of energy dissipated by the different components of the frame is shown in Figure 6.4.1. With the instrumentation used, the level of accuracy of the data did not permit precise comparisons between the specimens regarding the amount of energy dissipated by the different components. However, generalizations could be made regarding the amount of energy dissipated by the each of the components. The brace dissipated about 80% of the energy of the entire system. The remaining amount of energy was dissipated through yielding of the gusset plates 202 (about 10 to 15 percent) and framing members (about 5 to 10 percent) as shown in the figure. Figure 6.4.1 – Energy Dissipated by HSS-12 Figure 6.4.2 shows a comparison of the energy dissipated as a function of the total drift range for all of the frames. For lower drift levels, all of the frames dissipate energy at about the same rate as the drift increases. HSS-16 was the first to show smaller values of energy dissipation at given drift levels. This was due to the buckling pattern of the specimen. Since the extension plate hinged instead of the brace, less energy was absorbed by the frame. The other five frames dissipated energy as the drift increased at about the same rate. 203 Figure 6.4.2 – Energy Dissipated Comparison Figure 6.4.2 shows some variation between the amounts of total energy emitted by the specimens. HSS-12 absorbed the least amount of energy, only about 3400 kip inches. HSS-16 absorbed the most amount of energy, over 6000 kip inches. The difference between these values is a result of the number of inelastic cycles the frames were subjected to. HSS-12 fractured relatively early, and therefore did not have an opportunity to absorb a great deal of energy. The four other frames absorbed similar amounts of energy, between 4000 and 5000 kip inches. With the exception of HSS-16, all specimens dissipated similar total energy amounts at given frame deformation levels. It is unfortunate that the various components of energy can not be separated, because the designs of the various connections were often quite different. In summary, energy dissipation is a valuable characteristic for a frame to demonstrate to increase the ability of the frame to resist earthquake forces. The brace absorbed most of the energy relative to the other components of the specimen. Most of the frames 204 compared similarly, except for HSS-12 which absorbed a relatively small amount of energy, and HSS-16, which absorbed the most amount of energy, albeit at a slower rate than the other specimens. 6.5 Constructability This section will discuss the constructability of the frame. Section 6.5.1 will discuss the net section reinforcement of the brace. Section 6.5.2 will discuss the size and geometry of the gusset plate. 6.5.1 Net Section Reinforcement HSS-12 and HSS-13 were constructed with net section reinforcement. HSS-14 was not constructed with this reinforcement. Since no damage was seen at this location during the experiment, the remaining specimens tested (HSS-15 to HSS-17) also did not include the reinforcement. No damage was evident at the net section for the remaining tests. The lack of net section reinforcement did not seem to affect the frame in any other noticeable way. According to the results of these experiments, net section reinforcement may be unnecessary. However there are multiple factors that may affect the net section differently and it should not be assumed that the net section reinforcement is not required for a brace which uses the exact same connection detail. This is true even if the size of the brace, gusset plate, and framing elements, all remain the same. This is because, if the load was applied in a different pattern, or if the slab stiffened the connection, the net section may still fracture. Further testing is required to determine the limits when net section reinforcement is required or when it is unnecessary. 205 6.5.2 Gusset Plate Size and Geometry Two issues of constructability are in question regarding the size and geometry of the gusset plate. Fabrication of the plate will be discussed first, and erection of the frame will follow. For fabrication purposes, larger plates are more expensive, simply because there is more steel. Tapered plates are slightly more difficult to fabricate because of the angled cuts, although this could be offset by the reduced amount of steel for the plate (if the steel that is cut away is not wasted due to the remaining angular geometry). Gusset plates designed with elliptical clearance reduce the size of the gusset plate, and also use orthogonal plates. Erection issues were brought to attention during erection of two of the frames. HSS-14 and HSS-15 used rectangular plates with an elliptical clearance which brings the end of the brace closer to the beam column intersection. The end of the brace is close enough that the brace could not be placed in between the gusset plates without pulling the frame apart (Figure 6.5.1). This is not realistic in the field during construction. There are many methods however, to erect a frame which uses these gusset plates. For example, the brace could be held in place before the above the brace is placed into position. This puts limitation on planning and erection sequence, but is still possible. 206 Figure 6.5.1 – Erection Issue of HSS-15 Gusset plates that use a straight line clearance do not put limits on the erection sequence as discussed above. The gusset plates that are designed with this clearance allow the brace to be placed in the frame after both beams and both columns are previously in place. The braces of HSS-12, HSS-13 and HSS-17 all had the ability to be placed in the frame without any special consideration. The brace for HSS-16 was also able to be placed in the frame without special consideration because it used a one-sided connection. 6.6 Conclusions As is shown in this chapter, there are a great number of characteristics that a concentrically braced frame will exhibit depending on the gusset plate connection. These different characteristics are evident in the ultimate drift capacity and inelastic 207 deformation capacity, the performance at different drift levels, the load capacity, the energy dissipation and the constructability. Table 6.6.1 shows a rating of all of the specimens in the corresponding categories. Table 6.6.1 – Overall Specimen Comparison The ultimate drift capacity is an effective way to compare collapse prevention for these specimens. This is because, at a certain drift level, the brace will fracture leading to potential collapse. HSS-16 had the highest drift ratio range of 5.89%. HSS-17 also had a large drift ratio range of 4.94%. HSS-12 had the lowest drift ratio range. These differences can be attributed to the geometry of the gusset plate. In general a smaller, thinner, more flexible gusset plate will help to reduce the strain accumulation at the center of the brace, and therefore increase the ultimate drift capacity. Most of the specimens performed very well at the lower drift ranges with regard to performance based design. There was yielding in the braces and in the gusset plates; however this is probably acceptable for Immediate Occupancy. The only frame with 208 considerable damage was HSS-16. At -0.49% drift, this specimen experienced base metal crack initiation at the gusset plate. There were differences in the load capacity of the specimens. HSS-12 had the largest load capacity of all of the specimens. However load capacity is not as influential in determining good seismic design as compared to other criteria. Energy dissipation between the frames was relatively equal for HSS-13, HSS-14, HSS15 and HSS-17. HSS-12 dissipated a relatively small amount of energy because of its lack of ultimate drift capacity. Constructability should be addressed when comparing these frames. All of the frames are capable of being constructed. However, some will be slightly easier than others. The category of seismic theory is shown in Table 6.6.1. Engineers have generally agreed that in steel structures, the members should yield and buckle before the connections. This is also required in AISC Seismic Provisions. HSS-16 did not adhere to this requirement. The other five specimens did adhere to this requirement and ultimately failed through brace fracture. If the structural design industry changed or relaxed this requirement, then the connection detail for HSS-16 may be a direction for further research as it did acquire the largest drift range. 209 Chapter 7: Analysis of Test Program Results 7.0 Introduction This chapter presents the measured results of all of the specimens that have been tested within the test program thus far, HSS-01 to HSS-17, and uses the results to understand the influence of the parameters on the seismic response of the structure. This section will focus on the characteristics of the frame that affect the ultimate drift capacity (before the brace fractures). These characteristics include the size, strength and stiffness of the gusset plate, the gusset plate welds, and the applied displacement history. This chapter is divided into the following sections. Section 7.1 gives a brief overall comparison of all of the specimens. Section 7.2 will discuss the weld and base metal damage. Section 7.3 will discuss how the applied displacement history affected the ultimate drift capacity of the specimen. Section 7.4 will discuss how an earthquake may actually load a structure and what effect that will have on weld cracking. Section 7.5 will discuss the gusset plate strength and stiffness, and how it affected the ultimate drift capacity of the frame. Section 7.6 will discuss the performance of the framing elements. 7.1 Overall Comparison Table 7.1.1 shows an overall comparison of each specimen’s brace drift life and should be used only for general reference. This table shows the study parameters of each specimen (underlined in bold) and the maximum and minimum drifts attained in each specimen in all of the cycles before the cycle which caused the brace (or brace connection) to fracture. 210 Table 7.1.1 – Overall Comparison of All Specimens 7.2 Weld/Base Metal Damage Weld/Base metal cracking occurred in all but three (HSS-11 through HSS-13) of the specimens in the test program. The total length of the cracking at various drift ranges is shown in Table 7.2.1. The values underlined in italics and bold designate that they are approximate; because actual measurements were not taken (instead they were 211 approximated from pictures taken during the experiment). Figure 7.2.1 plots the total crack length ratio (compared to the total gusset plate weld length) with respect to the drift ratio range for specific specimens. This table and figure should be used for general reference. More detailed analysis of this information is included in the following subsections. Cracking occurred in the welds for HSS-01 to HSS-14, and cracking occurred in the base metal for HSS-15 to HSS-17. Table 7.2.1 – Total Weld/Base Metal Crack Length at Given Drift Range 212 Figure 7.2.1 – Total Weld/Base Metal Crack Length vs. Drift Ratio 213 As stated in Chapter 6, cracking of the gusset plate welds (or base metal in the heat affected zone) increases the drift capacity by decreasing the in-plane and out-of-plane effective stiffness of the gusset plate (as shown by the finite element analyses in Appendix C). Although cracking in the welds or base metal may increase the drift capacity of the brace, under-designed welds can crack at low drift levels, compromising the system performance. Furthermore, welds that fracture before the brace fractures will severely limit the drift capacity of the brace, and therefore potentially limit the drift capacity of the frame. Comparisons are made between HSS-13 and HSS-10 in Section 7.2.2 and between HSS-1 and HSS-12 in Section 7.2.3. A broader comparison of the weld cracking and its effect on the drift capacity is also made between all of the 3/8 inch rectangular plates that used an elliptical clearance in Section 7.2.4. 7.2.2 Weld Damage of Tapered Plates HSS-10 and HSS-13 were similar specimens in that they had the same tapered gusset plate geometry, and the same plate thickness. The difference between the two specimens was the gusset plate weld. HSS-10 used 1/2 inch fillet welds, while HSS-13 used complete joint penetration welds. During the experiments, the welds in HSS-10 cracked. However, neither the welds nor the base metal cracked in HSS-13. Figure 7.2.2 shows the NE gusset plate rotation verses negative story drift. Data was unavailable for HSS-13 at the SW gusset plate. Rotation was measured according to Appendix D. 214 Initial weld damage to HSS-10 Figure 7.2.2 – NE Gusset Plate Rotation The graph above shows that the gusset plate rotation is essentially equal between the two specimens up to a drift of -1.5%. After this point, the gusset plate used in HSS-10 experienced higher rotations at a given drift. It was recorded for HSS-10 that weld damage occurred in the NE gusset plate at a drift of -1.35%, and in the SW gusset plate at -1.63%. These cracks grew throughout the length of the test, and severe weld damage occurred to the NE gusset plate at the last compression cycle at -2.54%. Conversely, HSS-13 did not sustain any damage to the gusset plate welds or to the base metal at the welds. It is inferred that the weld cracking in HSS-10 allowed higher gusset plate rotation than HSS-13. HSS-10 had a drift ratio range of 4.47% while HSS-13 had a drift ratio range of 4.09%. This difference is attributed the weld cracking in HSS-10. This allowed the gusset plate to rotate more at a given drift as shown in the figure above and reduce the curvature at the center of the brace, postponing brace cupping. Brace cupping did not occur in HSS10 until -2.23%, while it occurred in HSS-13 at -1.71%. This brace cupping led to 215 fracture of the brace. Therefore, weld cracking can have a positive effect on the seismic performance of the frame. Although there are not experimental measurements, it is also postulated that weld cracking reduces the effective axial stiffness of the gusset plate, as supported by the finite element analyses in Section 7.2.1, thereby reducing axial strains in the brace and increasing the life of the brace. This however, does not preclude the use of CJP welds. As will be shown later, the positive drift capacity is a viable method for comparing specimens, and these two frames had similar positive drift capacities. Additionally, allowing weld cracking in order to increase the drift capacity is controversial, and as shown in the next subsection, may drastically reduce the drift capacity of the frame. Also, due to the test setup, 3/8 inch thick gusset plates were quite common. And unfortunately, CJP welds were not able to be used on 3/8 inch thick plates (only on 1/2 inch thick plates) and therefore, no comparison could be made. 7.2.3 Weld Damage of Rectangular Plates with 2t Line Clearance HSS-01 and HSS-12 are very similar. These specimens use the exact same gusset plate geometry and thickness with the straight line 2t offset. However, HSS-01 used the uniform force method to design the gusset plate welds and HSS-12 used complete joint penetration welds. As mentioned earlier, the uniform force method only designs the welds for the axial force in the brace. The design does not include stresses in the weld due to the moment transferring from the beam to the column, or any out-of-plane forces associated with brace buckling. HSS-01 used 3/16 inch welds. The gusset plate welds in HSS-01 started to tear at -1.04% drift. At this drift, cracks formed in the gusset plate welds at the NE column, NE beam, and SW beam. These cracks continued to propagate throughout the length of the test, and at a drift of 1.29%, 216 the welds at the SW gusset plate fractured completely. The total drift ratio range for this specimen was 2.75%. Specimen HSS-12 was designed with CJP welds. Damage was not noted during the entire length of the test. Brace fracture occurred in HSS-12, which is the desirable failure mechanism. The total drift ratio range for this specimen was 3.49%. Therefore, it is shown that the uniform force method does not accurately predict the load experienced by the gusset plate welds. This design led to the fracture of the gusset plate welds in HSS-01, cutting off the load path from the brace to the frame. This significantly increases the chance of collapse. Gusset plate welds should be designed based on the strength of the gusset plate instead of the uniform force method to guard against this weld fracture. From this section, it can be inferred that although cracking in the welds may increase the ultimate drift capacity of the frame by reducing the effective stiffness of the gusset plate (Section 7.2.2); a crack can propagate causing the weld to fracture before brace fracture occurs. Therefore a balance needs to be met by the weld design. 7.2.4 Weld Damage of Rectangular Plates with Elliptical Clearance Specimens HSS-05, HSS-06, HSS-08, HSS-14, and HSS-15 had 3/8 inch rectangular gusset plates with elliptical clearances (7.7t, 7.7t, 3.3t, 7.7t, and 6.0t respectively). All of these specimens sustained weld cracking, except for HSS-15 which cracked in the base metal in the heat affected zone. Figure 7.2.3 shows the relationship between total weld/base metal cracking length ratio of the specimen and the drift ratio range at which the cracks were measured. The figure shows that in general, specimens which had longer weld crack also had larger ultimate drift ratios. 217 3t 8t 8t 6t 8t Figure 7.2.3 – Weld/Base Metal Total Crack Length for Rectangular 3/8” Plates The differences between the specimens are important to note. HSS-05, HSS-06 and HSS-14 all had an 8t elliptical clearance. However, HSS-05 had a 5/16 inch weld, HSS-06 used a 1/4 inch weld with a 3/8 inch reinforcement weld at the reentrant corners at the beam and column, and HSS-14 had a 7/16 inch weld (this specimen also buckled downward toward the strong floor which is discussed in more detail in Section 7.3.1). HSS-08 had a 3t elliptical clearance with 1/2 inch fillet welds. This reduced clearance made the gusset plate one and a half inches shorter in each direction than the three aforementioned gusset plates. HSS-15 used a 6t elliptical clearance and a reduced splice length, which created a gusset plate that was four inches shorter in each direction than HSS-05, HSS-06, and HSS-14. HSS-08 experienced weld cracking at a low drift level, and therefore also a substantial amount of weld cracking at the end of the test. This appeared to be due to the smaller 218 elliptical clearance of 3t. Because of the amount of weld cracking, an elliptical clearance of 3t is not recommended (Herman, 2007) Of the remaining four specimens (HSS-05, HSS-06, HSS-14 and HSS-15), the two with the larger welds (7/16 inch) also had considerable smaller drift ratio ranges (3.93% and 4.09%). This is compared to the other two specimens which had drift ratio ranges of 4.75% and 4.96%. There were other possible reasons for HSS-14 and HSS-15 to have lower drift ranges. HSS-14 buckled down, which is discussed in more detail in the next section. And HSS-15 had a reduced splice length. However, the stiffness of the gusset plate for HSS-15 was essentially equal to the stiffness of HSS-05, HSS-06 and HSS-14 as determined by a finite element analysis shown in Appendix C. Therefore, the comparison between HSS-15 and, HSS-05 and HSS-06, appears to show that the weld size has a role in determining the ultimate drift capacity of the frame, since there were no other major differences between the frames. The thicker weld in HSS-15 probably limited the length of cracking, reducing the out-of-plane rotation and flexibility of the gusset plate. 7.2.5 Tapered Plate vs. Rectangular Plate with Cracked Welds It has been proposed by the fabrication industry that to simulate tapered plates, the gusset plate weld of a rectangular plate could be stopped before reaching the end of the plate. An example is shown in Figure 7.2.4. This type of connection was analyzed using a finite element model (more information available in Appendix C) to calculate the stiffness of the connection (also to calculate the stiffness of a fully welded connection with weld cracks), and was compared between the stiffnesses of the tapered gusset plates and the rectangular plates (everything else being equal). Figure 7.2.5 shows the rotational stiffness of each of these plates. 219 Figure 7.2.4 – Comparison of Rectangular Plate with Reduced Weld Length Figure 7.2.5 – Comparison of Rectangular Plate with Reduced Weld Length 220 This graph shows that while the stiffness of the plate with the reduced weld length was smaller than the fully welded rectangular plate, the tapered plate still had less stiffness. Therefore, simply reducing the weld length of the rectangular plate does not exactly imitate the tapered plate. This analysis does not include nonlinearity. However, it is presumed that the strength of the rectangular plate with the reduced welds will be less that the fully welded rectangular plate, and larger than the tapered plate. 7.2.6 Conclusions The gusset plate welds have an impact on the seismic response and ultimate drift capacity of the specimen. When the welds or base metal crack, the in-plane and out-ofplane effective gusset plate stiffness and strength are reduced and higher rotations and displacements are experienced by the gusset plate. This reduces the demand on the center of the brace, prolonging the life of the brace. Figure 7.2.6 shows a graph which marks the total amount of cracking verses the total drift range for each specimen (each mark on the graph represents a single specimen). This graph does not take into account many other influential characteristics and therefore has limited value. However, the graph shows a direct positive relationship between amount of weld tearing and total drift ratio range. 221 Figure 7.2.6 – Total Drift Range vs. Weld/Base Metal Tearing Length More importantly, these welds should not fail before brace fracture occurs. As shown with HSS-01, this reduces the ultimate drift capacity of the frame. Additionally, the amount of weld cracking in HSS-08 was quite severe, and an alternate applied load may cause the welds to completely fracture before the brace fractures. Therefore, using a 3t elliptical clearance is not recommended to design the gusset plate geometry. Also, the weld cracking in HSS-05 was high and a stronger weld should be utilized (see Section 7.3 for further discussion). While this evidence points to allowing some weld cracking, it may not be reliable in real structures. Section 7.4 further discusses the allowance of weld cracking. The thickness of the weld and the base metal does affect when these components crack. However, these components may also crack depending on the applied displacement. 222 7.3 Displacement History Comparison Due to the experiment setup, the applied displacement history was not the same for all of the specimens. Losses resulting from rigid body rotation and bolt slip at the frame boundaries caused differences. More severe differences were caused by the direction of brace buckling. In most of the tests, the brace buckled up away from the strong floor. However, in three specimens (HSS-01, HSS-02, and HSS-14), the brace buckled toward the strong floor. The applied negative displacement was limited in HSS-02 and HSS-14 to prevent the brace from contacting the floor. Here, the influence of these limited applied compression drifts on specific specimens is studied. 7.3.1 Displacement History of HSS-05 and HSS-06 vs. HSS-14 HSS-14 was nearly identical to HSS-05 and HSS-06. They all had an 8t elliptical clearance. However, HSS-05 had a 5/16 inch weld, HSS-06 used a 1/4 inch weld with a 3/8 inch reinforcement weld at the reentrant corners at the beam and column, and HSS-14 had a 7/16 inch weld (this specimen also buckled downward toward the strong floor). This subsection will look at what affect the difference in the applied displacement had on these specimens. Figures 7.3.1 through 7.3.3 shows the displacement histories for HSS-05, HSS-06, and HSS-14 respectively. Figure 7.3.4 shows a comparison of the ultimate drift range of the three frames. 223 Figure 7.3.1 – Drift History of HSS-05 Figure 7.3.2 – Drift History of HSS-06 224 Figure 7.3.3 – Drift History of HSS-14 Figure 7.3.4 – Ultimate Drift Range of HS-05, HSS-06 and HSS-14 The negative drift capacity of HSS-14 was two thirds of that achieved by HSS-05 and HSS-06. However, the positive drift capacity of HSS-14 was exactly the same as the positive drift capacity of HSS-05. Figure 7.2.4 shows the performance for the welds was similar to a drift range of 3.7%. At which point, the negative drift was limited for HSS-14 due to the direction of brace buckling. With increased negative drift demand, specimen HSS-05 and HSS-06 the weld cracks elongated, increasing the flexibility of the gusset plate connection. And therefore, the additional negative drift demand in HSS-05 and HSS-06, may not have contributed to the cumulative strain in the brace, therefore, not significantly influencing the positive drift capacity. 225 7.3.2 Displacement History of HSS-02 vs. HSS-03 Similarly, HSS-02 buckled down, and HSS-03 buckled up. Specimen HSS-02 had a 1/2 inch weld, while HSS-03 had a 7/16 inch weld. Figure 7.2.5 shows a comparison of the ultimate drift range of the two specimens. The results are similar. Figure 7.3.5 – Ultimate Drift Range of HSS-02 and HSS-03 7.3.3 Conclusion The data provided in this section shows that similar specimens with severely contrasting applied negative drifts, had very similar positive drift capacities. This implies that brace fracture may not only depend on the maximum negative drift ratio. This may be due to weld and base metal cracking making the connection more flexible as shown in Section 7.2.1. It is also possible that the strain applied during the positive drift has a greater affect than the strain applied during the negative drift (although there is no evidence of this). Table 7.3.2 shows a list of specimens in order of highest positive drift capacity. Table 7.3.1 shows a list of specimens in order of largest drift range for comparison purposes. 226 Table 7.3.1 – Specimens Arranged From Largest Total Drift Range 227 Table 7.3.2 – Specimens Arranged From Highest Positive Drift Capacity Table 7.3.2 shows a very strong pattern. The groups in this table were assigned to help show the pattern discussed here. Aside from group 1, the bolted connection of HSS-16, and HSS-08 which had early weld cracking, the three specimens with the highest positive drift capacity were the specimens that used tapered plates, shown in group 2 228 (there were no other tapered plates). HSS-17 used a 3/8 inch plate and received the highest positive drift, while HSS-13 and HSS-10 used 1/2 inch plates and received the 2nd and 3rd highest positive drift. Group 3 included four specimens with the next four highest positive drifts. All of these specimens used 3/8 inch rectangular plates with elliptical clearances ranging from 6t to 8t. The following three specimens with the next highest drifts in the table, group 4, all used 1/2 inch rectangular plates with elliptical clearances ranging from 6t to 9t. Specimen HSS-09 used a similar gusset plate and received a positive drift similar to this group. However, this specimen used CJP welds to connect the gusset plate to the frame and had a smaller drift capacity; therefore it is included in group 5. The remaining specimens in group 5, either used the 2t straight line clearance with a half inch gusset plate, or used a 7/8 inch gusset plate with an elliptical clearance. These specimens had the smallest positive drift capacity. The negative drift does affect fracture of the brace. However, with the results shown in this chapter, specimens with equivalent gusset plate geometry and thickness have fractured at similar positive drifts regardless of the applied negative drift. The table above shows some striking patterns with the gusset plate geometry. It is important to remember that in SCBFs, it is required that braces face opposite directions in one floor. Therefore, a more symmetric applied displacement is likely, similar to the specimens which were limited in negative drift. 7.4 Actual Seismic Loading Unfortunately, an earthquake will not load a structure exactly as the experiment loaded the specimens. Instead, the earthquake will apply unpredictable displacements, and may have many more cycles than what was tested in the lab. If the welds crack and are subjected to more cycles of displacement, which may not even be as high as the displacement applied in the experiment, the cracks will still propagate. One critical 229 loading history may be a large pulse that cracks the gusset plate welds (but not large enough to fracture the brace) with many smaller displacements to see how the weld cracks propagate during the smaller displacements, and whether they fracture or not. The crack length ratio to the total connection length is shown verses the negative drift ratio here in Figure 7.4.1. Figure 7.4.1 – Weld/Base Metal Damage vs. Negative Drift Ratio This figure ignores the tension excursions that were experienced by the brace in between the compression excursions marked in the graph. However, a strong majority of excursions that caused crack initiation and propagation were in the negative drift ratio when the brace was in compression and the joint was experiencing an opening moment. 230 The graph shows that weld cracks propagated during the negative drift ratios regardless of the magnitude of the drift. This is because the stress concentrations that exist at the edge of the crack will further propagate the crack even at small negative drift ratios. Therefore, even though all of the gusset plate welds (except the welds in HSS-01) withstood applied displacements up to brace fracture, it should not be assumed that this will be guaranteed in a building structure even with similar gusset plate geometry. This is especially true for earthquakes that last a long period of time, but do not necessarily apply large displacements to a structure. For this reasoning, the welds should not have as much cracking as HSS-05 and HSS-08 experienced. 7.5 Gusset Plate Strength and Stiffness Regardless of which drift capacity is used to compare specimens (positive drift capacity or total drift range), gusset plate geometry will affect the drift capacity of the specimen as shown in Chapter 6. This section will examine specimens in the entire test program to further distinguish the characteristics of the gusset plate that are advantageous to the drift life of the brace. As stated earlier, if the strength and stiffness of the gusset plate are maintained at a minimum to support design loads, a higher ultimate drift capacity of the brace will result. Limited axial strength and stiffness, and rotational strength and stiffness both add to the ultimate drift capacity of the frame. 7.5.1 Rotational Strength and Stiffness Free rotation at the gusset plate allows the brace to buckle in single curvature. The graph below in Figure 7.5.1, shows the SW gusset plate rotations for seven specimens and is a strong indicator of which gusset plate geometry allows free rotation at the joint. 231 This graph is valuable because it shows the rotation at linear and nonlinear ranges, showing the affects of strength and stiffness of the gusset plate, both of which affect the rotation of the gusset plate when subjected to the geometry required from brace buckling. Figure 7.5.1 – SW Gusset Plate Rotation vs. Total Drift Range The figure shows two basic groups of specimens. The first group of specimens (HSS-17, HSS-10, HSS-06 and HSS-15) had gusset plates which experienced higher rotations. The second group of specimens (HSS-07, HSS-09, and HSS-12) had gusset plates which experienced smaller gusset plate rotations. HSS-17, which used a 3/8 inch tapered gusset plate, sustained the highest rotation. HSS-10, which used a 1/2 inch tapered gusset plate, experienced essentially the same rotation of HSS-17 except at drift ranges above 3.5%, where the rotations stopped increasing. HSS-06 and HSS-15 had rotations similar to the two tapered plates in the graph. However, they were slightly 232 lower at a given drift ratio. The next group of lines in the graph (three of them) shows the gusset plate rotations of larger, thicker gusset plates. HSS-07, which used a 7/8 inch gusset plate and an elliptical clearance, HSS-09, which used a 1/2 inch rectangular gusset plate with CJP welds, and HSS-12 which used a 1/2 inch gusset plate with a 2t straight line clearance, all had significantly smaller rotations than the four aforementioned specimens. This is because the gusset plates used for these specimens have much higher stiffness as shown in Appendix C and strength (an example is shown in 7.5.2), prohibiting rotation. This then puts higher curvature at the center of the brace, leading to earlier brace fracture. In conclusion, the figure above shows basically two groups of specimens. The first group included HSS-06, HSS-10, HSS-15 and HSS-17. All of these specimens had less stiff, less strong gusset plates which led to larger ultimate drift range capacities and higher positive drift capacities as shown here in Table 7.5.1: Table 7.5.1 – Drift Capacity of Specimens Analyzed for Gusset Plate Rotation 233 7.5.2 Strength of HSS-01 and HSS-12 vs. HSS-10 and HSS-13 According to the finite element analyses shown in Appendix C, HSS-10 and HSS-13 had a higher out-of-plane stiffness than HSS-01 and HSS-12 (all of these plates were 1/2 inch thick). This may lead one to believe that HSS-01 and HSS-12 should have had higher drift ratios by reducing the curvature at the center of the brace at a given drift ratio. However another factor that affects the curvature at the center of the brace when the brace is buckling is the ultimate strength of the gusset plate. Figure 7.5.2 shows the gusset plates of HSS-10 and HSS-13 overlaid on the gusset plates of HSS-01 and HSS-12. Figure 7.5.2 – HSS-01 and HSS-12 overlaid with HSS-10 and HSS-13 Although the tapered plates were defined by the elliptical clearance, these plates also satisfy a 0t straight line clearance. The large rectangular plates used in HSS-01 and HSS-12 satisfy a 2t straight line clearance. Because of this hinging pattern, the plastic moment strength of the plate may be approximated by multiplying the yield strength of 234 the plate (Fy) by the plastic section modulus (btg2/4), where b is equal to the entire length of the hinge line (as opposed to the Whitmore width since the entire width of the plate will need to bend in order to satisfy compatibility). M p = Fy bt g 2 (7.1) 4 For HSS-01 and HSS-12, the plastic moment capacity is: ⎛ 42.4 * 0.5 2 M p = 50⎜⎜ 4 ⎝ ⎞ ⎟⎟ = 132.5k − in ⎠ (7.2) For the tapered plates, the ultimate plastic capacity is: ⎛ 23.7 * 0.5 2 M p = 50⎜⎜ 4 ⎝ ⎞ ⎟⎟ = 74.1k − in ⎠ (7.3) The moment capacity of the large rectangular plates is almost twice that of the tapered plates. Therefore, once the gusset plates reached their plastic strength, the rectangular plates applied a higher end moment, thereby limiting the out-of-plane gusset plate rotation compared to the out-of-plane plate rotation of the tapered plates. This led to higher curvature in the brace at the hinge point for the rectangular plates. Figure 7.5.3 shows this smaller rotation with HSS-12 compared to HSS-10. This figure also shows that at smaller drifts (below 0.5%), HSS-12 had higher gusset plate rotation than HSS-10 at a given drift due to the smaller gusset plate stiffness value for the gusset plate used in HSS-12 (Appendix C). This implies that the ultimate strength of the gusset plate may be a better indicator than the stiffness of the gusset plate in 235 determining which will have the largest effect on the hinge point (since HSS-12 had quite a smaller drift capacity than HSS-10). This calculation of moment capacity should not be used for gusset plates that use an elliptical clearance. This is because bending in the perpendicular direction (as discussed in Chapter 6) increases the strength of the gusset plates that use an elliptical clearance. Also, nonlinear geometry will add to the stiffness of the plates that use an elliptical clearance. This thesis does not examine the ultimate strength of these plates. Figure 7.5.3 – HSS-10 and HSS-12 SW Gusset Plate Rotation 7.5.3 Axial Strength and Stiffness Specimens that had gusset plates with limited axial strength and stiffness reduced the amount of elongation in the brace for a given drift ratio. The theoretical axial stiffnesses of the gusset plates are shown in Appendix C, and the theoretical axial 236 strengths are shown in Table 7.5.2 and were determined by Equation 7.4 below where w is the maximum width (measured perpendicular to the longitudinal axis of the brace) of the gusset plate and tg is the thickness of the gusset plate. Figure 7.5.4 shows the brace elongation verses the drift ratio for ten specimens. Pp = Fy wt g (7.4) Table 7.5.2 – Axial Strength of Specimens 237 Figure 7.5.4 – Brace Elongation vs. Drift Ratio The graph (along with the table) shows that the stiffer and stronger gusset plates required the brace to be elongated more at a given drift ratio. HSS-11 used a 7/8 inch gusset plate with a large beam (W16x89). This specimen had the highest gusset plate stiffness (Appendix C) and required the highest brace elongation at a given drift ratio. This specimen also had the smallest drift ratio range and the smallest positive drift capacity of all of the specimens. (This specimen did not have any weld cracking either. However, at the extremely low drift range which the brace failed, only two other specimens had experienced significant weld damage, HSS-01 and HSS-16.) The three specimens with the three next highest brace elongation measurements were HSS-07, which used a 7/8 inch gusset plate and an elliptical clearance, HSS-09, which used a 1/2 inch gusset plate with CJP welds, and HSS-12 which used a 1/2 inch gusset plate with a 2t straight line clearance. Of the ten specimens analyzed here, these three specimens 238 had the next three highest gusset plate strengths as shown in Table 7.5.2 and also had the next three smallest positive drift capacities and ultimate drift ranges. The next two specimens, HSS-10 and HSS-13 which had average strengths and stiffnesses, used 1/2 inch tapered plates, and had average drift ranges, 4.47% and 4.09% respectively. The remaining four specimens, HSS-15, HSS-06, HSS-17 and HSS-08, which all had 3/8 inch gusset plates and low in-plane strengths and stiffnesses, had the lowest amount of brace elongation at a given drift. These specimens also had high ultimate drift ranges and high positive drift capacities. HSS-08 had significantly less brace elongation than the other braces, including the other specimens with 3/8 inch plates, including both tapered and rectangular plates. This specimen sustained large weld cracks and this may have contributed to the lower amount of brace elongation. However, even at low drifts, prior to weld cracking, the brace elongation was smaller than any of the other specimens at a given drift ratio. It is not clear why this specimen had lower elongation, although it allowed this specimen to have the 2nd highest positive drift capacity, next only to HSS-16. 7.6 Performance of Framing Elements Damage to the framing elements was noticed in the form of yielding, local web buckling, and local flange buckling in most of the specimens. To focus on Life Safety and Collapse Prevention performance levels, only local buckling of the framing members is analyzed in this section. A real structure may respond quite differently to local buckling than the way the specimen responded in the experiment. This is because, for beams in the specimen, there is no gravity load applied. However, in a real structure, a beam carries the slab, and if a flange or web buckles, the load carrying capability may be compromised. For the columns in the experiment, the gravity load is applied by post-tensioned rods. This 239 application is displacement controlled. Therefore, if local buckling causes the column to lose capacity, the load is simply reduced. However, in a real building structure, gravity loads are force controlled on the columns. Therefore, if local buckling causes the column to lose capacity, the force is not reduced, and partial or total collapse is possible. It is much more valuable to the structure for damage to occur to the beam instead of the column because the column bears the gravity load (and seismic load) of the entire building above the frame. Table 7.6.1 shows where and when local buckling of the framing elements occurred for all of the tests in the program. In the table, local buckling of the column is shown underlined in bold. 240 Table 7.6.1 – Buckling of Framing Elements at Given Drift Range The south beam web and flange of HSS-13 and HSS-14 experienced local buckling as described in detail in Chapter 5 and 6. This is not uncommon as the table above shows. Some gusset plate details performed better than others; however, the drift at which this typically occurred was fairly close to brace fracture. Therefore, it is an acceptable response for the performance levels of Life Safety and Collapse Prevention. 241 A stronger beam will prevent local beam web and local beam flange buckling from occurring. However, a strong beam will have negative consequences on the drift life of the brace. HSS-11 used a larger beam (and also used a 7/8 inch gusset plate). This specimen had the smallest ultimate drift range (2.58%) and the smallest positive drift capacity (1.06%). HSS-07, which had the same gusset plate design, but had a smaller beam, had an ultimate drift range (4.04%) and the positive drift capacity (1.26%). Therefore, the beam should not be made larger to avoid local buckling of the beam flange or web. The existing local buckling and crippling checks in the AISC Specifications are adequate for the design of the beams. Although these equations may not totally prevent this damage state from occurring, they will postpone these local damage conditions from occurring until high drift levels in which Life Safety and Collapse Prevention are concerned. It is more critical for the columns to avoid or buckling. However, almost all of the specimens had local buckling of the column flange at some point. The specimens that showed the earliest signs of column buckling were the same specimens that had the lower ultimate drift ranges, and the lower positive drift capacities. These specimens were HSS-07 and HSS-11, which had 7/8 inch gusset plates and specimens HSS-09 and HSS-12, which had 1/2 inch gusset plates, as shown in the table above. HSS-16 and HSS-17 did not experience buckling of the columns until relatively late in the experiment (over 4.8% drift range). In HSS-16, this is attributed to the cracks in the base metal which relieved the constraint on the column. However, in HSS-17, it is attributed to the low in-plane rotational stiffness of the tapered gusset plate. Another interesting note is that in HSS-15, which was the specimen with the reduced splice length making the gusset plate very small, no local buckling occurred. This further leads to evidence that smaller, more flexible gusset plates are more advantageous to preventing collapse of the structure. 242 It should be noted that after the brace fractures, the stability of the structure will rely on frame action of the beams and columns. The larger gusset plates may be helpful in resisting this frame action along with the fully rigid beam to column connection. However, a detailed analysis of how helpful these larger plates would be to the resistance of the frame was not carried out. It is believed that the benefit would not outweigh the benefits that a smaller gusset plate has shown to provide. 7.7 Conclusions The size and shape of the gusset plate greatly affect the structural response of special concentrically braced frames. In general, the gusset plates that are more flexible and have a smaller strength, both rotational and axial, will allow the brace to reach a higher ultimate drift capacity for the frames (so long as the maximum load of the brace can be transferred to the frame). When the weld or base metal cracks, the effective stiffness (and presumably strength) is reduced resulting in a larger drift capacity. From the experimental results, it is shown that the negative drift ratio may not affect the positive drift capacity as much as originally expected. This is because during the negative drift excursions, buckling of the brace and the opening moment cause the welds/base metal to crack. The cracks reduce the effective stiffness of the plate, prolonging the life of the brace. Therefore the positive drift ratio may be a better way to compare the drift capacity of these specimens. The design of the weld should not fracture before the brace fractures. However, certain amounts of cracking of the welds/base metal will prolong the life of the brace. Therefore, the weld should have a balanced design. It should only crack at high drift levels when brace fracture is imminent. 243 The larger, stiffer, stronger gusset plates also lead to damage in the framing members (including the columns) at smaller drifts. This reduces the structures ability to carry gravity (and seismic) loads. This is further evidence that these gusset plates should not be used for SCBFs. 244 Chapter 8: Design Guide 8.0 Introduction This chapter presents a design guide to assist structural engineers in designing and analyzing gusset plates for SCBFs. This design guide has been written for SCBFs using tube sections as the brace, which are welded to a gusset plate that is welded to the beam and column and with complete joint penetration welds joining the web and flanges of the beam to the flange of the column. Although the connection type is specific, it is possible to extrapolate the theoretical information in this guide, and apply it to other connection types. The geometry and thickness of the gusset plate have a significant impact on the overall response of the braced frame. It is important that the gusset plate is strong enough so that it does not fail before the brace develops its full resistance and ductile capacity. However, if the gusset plate is too stiff and strong, it will negatively affect the inelastic deformation capacity of the brace and the frame. The goal of this design guide is to balance these two criteria by designing a gusset plate with as low stiffness as possible, while retaining the required strength of the plate. Limit states that affect the thickness of the gusset plate include Whitmore yielding, Whitmore fracture, block shear, gross shear at the column, gross shear at the beam, and buckling of the gusset plate. To maximize the ductility of the system, some of these limit states should be altered from the current design provisions. Section 8.1 discusses the recommended changes to current design procedures. This research has presented evidence that the current 2t straight line offset is detrimental to the braced frame in that it leads to larger and thicker gusset plates which 245 induce greater inelastic demands into the beam and column framing elements and may cause early failure of the brace. Instead, an elliptical offset model has been proposed to reduce the size and thickness of the gusset plate while permitting brace end rotation and developing the required resistance of the brace. This elliptical offset can be used with rectangular plates or tapered plates. Section 8.2 will discuss how to design a gusset plate using the elliptical clearance method. Section 8.3 will discuss how to determine what the elliptical clearance of an existing gusset plate is. Both of these methods use an iterative process. Section 8.4 will discuss the design of the gusset plate welds. These welds create a load path from the gusset plate to the frame and can significantly influence the hysteretic performance of the brace. The tests in this thesis have also checked the necessity of the net section reinforcement. Section 8.5 will discuss recommendations made for the design of this reinforcement. Section 8.6 will discuss the beam-to-column connection. 8.1 Gusset Plate Strength Design and Analysis In designing an SCBF for seismic loads it is important that the gusset plates have limited stiffness. The limit state calculations listed in this section will calculate the resistance and minimum required thickness of the gusset plate for strength, making various changes to the current design provisions. As stated in AISC, the design forces shall be based on the expected strength of the brace. For tensile limit states, the design force shall be: Pt = R y Fy Ag and for compressive limit states the design force shall be: (8.1) 246 Pc = 1.1R y Pn (8.2) Where Ry is the ratio of the expected yield strength of the brace to the nominal yield stress of the brace (Fy), Ag is the gross area of the section and Pn is the nominal compressive strength of the brace determined by the AISC specifications. Typically, limit states require a resistance factor (φ) which reduces the ultimate strength capacity. However, strength design considerations are not the issue for gusset plate connection design because the connection design forces far exceed the factored loads on the structure. Instead ductility under extreme seismic loading is the major design concern. An alternate design method (Roeder, Lehman, and Yoo 2005) has been developed based upon β values and balance conditions to optimize the ductility achieved with the structural system. Therefore, β shall be used in place of φ to determine the minimum strength of the limit states, for tensile forces: βRn ≥ Pt (8.3) for compressive forces: βRn ≥ Pc 8.1.1 (8.4) Net Section Fracture Net section fracture is a possible failure that occurs when the gusset plate tears at the end of the brace joint. This net section fracture is normally defined by the Whitmore width and is particularly important in bolted brace joints. Nevertheless, this tensile 247 fracture is possible for welded braces, and it must be considered in gusset plate connection design. Typically, net section fracture limit states require a φ factor of 0.75. It is recommended to use a β value of 0.85 in place of the φ factor for the design of the gusset plate for net section fracture on the Whitmore width, because tests have shown that reasonable ductility is achieved with this β value. The strength of the net section fracture in the gusset plate should be determined as: βRn = βt g Fu (2l c tan(30) + bc ) (8.1.1) β = 0.85 (8.1.2) where: and lc is the brace-to-gusset plate splice length. By increasing the β factor, a thinner, more flexible gusset plate can be used. This will provide greater ductility from the connection. 8.1.2 Whitmore Yielding This research has shown that it is desirable for the gusset plate to yield shortly after brace yielding occurs. This is because; gusset plate yielding increases the inelastic deformation capacity of the system and decreases the inelastic damage to the beam and column members. Therefore, a β value of 1.1 for Whitmore yielding is appropriate. However, with welded brace connections and the expected ratio of the yield to tensile strength of structural plate material, the net section fracture check will negate the requirements for this check. 248 8.1.3 Block Shear Block shear is defined in the AISC Manual of Steel Construction, in Chapter J of the Specifications. According to AISC, the minimum value of two equations shall be used to determine the actual strength of the block shear limit state. One of these equations is shown here (Ubs is present in the 2005 Manual but not in the 2002 Manual): φRn = φ (0.6 * Fy Agv + U bs Fu Ant ) (8.1.3) The equation effectively adds the tensile fracture resistance and the shear net section yield resistance of the block shear element. The second equation in AISC for block shear is shown here: φRn = φ (0.6 * Fu Anv + U bs Fu Ant ) (8.1.4) This second equation combines the tensile fracture resistance with the shear fracture resistance. In both cases, Ubs is equal to 1.0 for axially loaded members (no bending in the connection). The resistance factor φ is equal to 0.75, but as noted earlier resistance factors are inappropriate for this design, because the connection design forces are significantly larger than the factored design loads. Instead, a balanced design approach with beta factors has been proposed. Because yielding is encouraged in the gusset plate shortly after brace yielding occurs, a β factor of 0.85 is proposed. Further, it is proposed to combine the fracture components of the connection (Equation 8.1.4) rather than the shear yield component (Equation 8.1.3), because yielding in the connection is encouraged. The strength of the block shear in the gusset plate shall be determined as: βRn = β (0.6 * Fu Anv + U bs Fu Ant ) (8.1.5) 249 where: β = 0.85 8.1.4 (8.1.6) Gusset Plate Buckling The gusset plate should be designed to resist buckling. Current design procedures appear to provide substantial resistance to gusset plate buckling (an example of the current design procedure is shown in Appendix A.2.3, although this limit state was not a tested parameter. From this research, it is recommended that perpendicular reinforcement plates are not added to the free edges of the gusset plates to resist buckling based on the recommendations made by Astaneh-Asl (1998), which would have required the use of these reinforcement plates on the 3/8 inch gusset plates of the specimens within this test program. It is perceived that these plates prevent deformation of the gusset and end rotation of the brace thus adversely affecting the life of the brace. This recommendation is based on the connection detail within these tests and is subject to change if changes in the connection details are made. Calculating gusset plate buckling requires the unbraced length of the gusset plate to be known. To determine this value, the geometry of the plate shall be first determined in accordance with Section 8.2. 8.1.5 Conclusion This balanced design approach will permit thinner, more flexible gusset plate connections which yield shortly after brace yielding but not before significant plastic 250 deformation of the brace. This should assure that the connection has adequate resistance to develop the capacity of the brace while permitting the full ductility of the brace and frame system. Other limit states shall also be checked to design the gusset plate. These limit states include (but not necessarily limited to) gross shear at the beam, gross shear at the column and plate buckling. These limit states were not tested parameters, and shall be calculated with the methods called out in AISC and/or common engineering principles. 8.2 Design of Gusset Plate Geometry Using Elliptical Clearance Within this design method, there are two options for the gusset plate height to width ratio. The first option is given in chapter 13 of AISC and constrains the ratio to: HT − WT tan(θ ) = d b tan(θ ) − d c (8.2.01) where db is the depth of the beam, dc is the depth of the column, and the remaining variables are shown in Figure 8.2.1. The second option is a slight variance of the first option. This option constrains the gusset plate so that the free edges of the gusset plate intersect each other at the centerline of the brace. Figure 8.2.1 shows a diagram of the elliptical clearance and the variables used to define it. The figure shows a gusset plate which uses the height to width ratio determined by Equation 8.2.01. In this option xs is equal to xb (see Figure 8.2.1 for location of measurements). In the second option, xs is equal to zero, which creates a smaller gusset plate. 251 Figure 8.2.1 – Gusset Plate with Elliptical Clearance 8.2.1 Rectangular Gusset Plate Geometry Design A list of the steps to design a rectangular plate with an elliptical clearance is shown below. The value for the variable N is recommended to be eight, making the clearance equal to eight times the thickness of the gusset plate, tg (where tg is assumed using Section 8.1 and verified after the geometry is determined). 1. Assume a height for the gusset plate (HT) to establish a trial geometry with the following equations: 252 b = HT − Nt g xb = (8.2.02) eb − ec tan(θ ) a = xb + x s + ⎛ 1 ⎞ b + Nt g ⎜⎜ − 1⎟⎟ tan(θ ) ⎝ tan(θ ) ⎠ (8.2.03) (8.2.04) where x s = xb (8.2.05) Assigning xs equal to xb as shown above is required if the uniform force method is used to follow the force distribution through to design the gusset plate welds and the beamcolumn connection. However, since the gusset plate welds shall be designed for the capacity of the gusset plate (Section 8.4), and since the uniform force method does not seem to accurately determine how the forces are distributed through the connection (Chapter 5 and 6), the uniform force method does not seem like an appropriate method for following the force distribution through the connection. A smaller gusset plate is recommended by assigning: xs = 0 (8.2.06) The width of the gusset plate is equal to: WT = a + Nt g (8.2.07) 2. Determine the end of the brace relative to the imaginary free corner of the gusset plate (x, y), where bf is the width of the brace: 253 y c = l c sin(θ ) + ( s + 0.5b f ) cos(θ ) (8.2.08) y d = [l c cos(θ ) + ( s + 0.5b f ) sin(θ ) − x s ] tan(θ ) (8.2.09) y = max( y c , y d ) (8.2.10) y + xs tan(θ ) (8.2.11) xc = x d = l c cos(θ ) + ( s + 0.5b f ) sin(θ ) (8.2.12) x = max( x c , x d ) (8.2.13) 3. Determine the corners (1 and 2) at the end of the brace: x1 = x − 0.5b f sin(θ ) (8.2.14) y1 = y + 0.5b f cos(θ ) (8.2.15) x 2 = x + 0.5b f sin(θ ) (8.2.16) y 2 = y − 0.5b f cos(θ ) (8.2.17) 4. Calculate xb_verify_1 and xb_verify_2, associated with corners 1 and 2: − ⎛ 1 ⎞ b − Nt g ⎜⎜ − 1⎟⎟ − x s tan(θ ) ⎝ tan(θ ) ⎠ (8.2.18) − ⎛ 1 ⎞ b − Nt g ⎜⎜ − 1⎟⎟ − x s tan(θ ) ⎝ tan(θ ) ⎠ (8.2.19) 2 xb _ verify _ 1 = x1 b 2 b − y1 2 2 2 xb _ verify _ 2 = x2 b 2 b − y2 2 2 Finally, check to see if the right gusset plate height was chosen in the first step. All three conditions (Equation 8.2.20, Equation 8.2.21, and either Equation 8.2.22 or Equation 8.2.23) must be met. 254 xb _ verify _ 1 ≤ xb (8.2.20) xb _ verify _ 2 ≤ xb (8.2.21) xb _ verify _ 1 = xb (8.2.22) xb _ verify _ 2 = xb (8.2.23) And Or If xb_verify_1 and/or xb_verify_2 is greater than xb, then a larger gusset plate is required. If xb_verify_1 and xb_verify_2 are both smaller than xb, then a smaller gusset plate is required. This process is continued until the height of the gusset plate has converged. The gusset plate should then be checked for plate buckling and also verified with the other limit states specified in Section 8.1 after the geometry has been determined. If the gusset plate thickness needs to be changed based on the strength of these limit states, then this process shall be reevaluated. If a large beam is combined with a small brace angle, or if a large column is combined with a large brace angle, the gusset plate will be rather large and may have an awkward geometry. Under these conditions, it is further recommended to set xs equal to zero to reduce the size of the gusset plate and create a more accurately shaped plate. 8.2.2 Tapered Gusset Plate Geometry Design For a tapered plate, the procedure in Section 8.2.1 is used. However, it is advised to set xs equal to zero with Equation 8.2.06 or else awkward shaped plates will result. 255 The height and width of the gusset plate that is determined in Section 8.2.1 will be the overall height and width of the tapered gusset plate. However the height of the gusset plate at the column and the width of the gusset plate at the beam will differ due to the taper. The following equations will determine these values. If yc > yd then: x f = WT − x s − y f = HT − b fx 2 sin(θ ) − s sin(θ ) (8.2.24) (WT − x f ) (8.2.25) tan(θ ) If yc < yd then: y f = HT + x s tan(θ ) − b fx 2 cos(θ ) − s cos(θ ) x f = WT − ( HT − y f ) tan(θ ) (8.2.26) (8.2.27) Finally, the height of the gusset plate at the column and the width of the gusset plate at the beam are determined by Equations 8.2.28 and 8.2.29: HTc = HT − x f tan(φ ) (8.2.28) WTb = WT − y f tan(φ ) (8.2.29) Where φ equals the taper angle. The taper angles that were tested in the HSS-10, HSS-13 and HSS-17 were all 15 degrees. Therefore, a taper angle of 15 degrees is recommended. 256 8.3 Gusset Plate Weld Design The research shows that the gusset plate welds are important to the hysteretic behavior of the brace. These welds need to perform satisfactory in all the performance levels. Especially, they shall be designed so that they will not completely tear before the brace. However, some tearing is advantageous to the drift capacity of the frame. The uniform force method proposes to design the gusset plate welds for the strength of the brace. This seems logical because it should cause the brace to fail before the welds. However, since the connection has rotational stiffness both in the plane of the frame and in the out-of-plane direction, it will draw other forces than simply the force from the brace. The combination of all of these forces and gusset plate deformations induced by brace buckling cause higher stress and strain in the welds than what is predicted by the uniform force method and has lead to premature failure as shown in specimen HSS-01. The gusset plate welds shall be designed so that they will not fail before the brace fractures. In order to meet this criterion, the test results show that the welds should be designed to develop the full capacity of the gusset plate. This can be assured by the equation: 1.5 * β * 0.6 FEXX t eff ≥ R y Fy t g (8.3.1) The 1.5 factor that is multiplied to the strength of the weld above, is used because testing has indicated that fillet welds subjected to tension resist about 50 percent higher loads than fillet welds subjected to shear (AISC 2005, AWS 2006). A β factor of 0.65 is necessary in these calculations, because the existing φ factor equal to 0.75 has provided slightly unconservative weld sizes in these experiments. An example using this equation is shown in Appendix A, Section A.3.2. 257 Complete joint penetration welds are permitted for the gusset plate welds in accordance with AISC section J2, and they also develop the full plastic capacity of the plate if the CJP weld is of matching metal to the plate steel. Although the tests that have used these welds have not attained large drift capacity, these tests have each used a 1/2 inch thick gusset plate. If this design guide is used for this frame geometry and brace force, a 3/8 inch gusset plate will result. Therefore, the stiffness of the connection will be reduced, leading to a higher drift capacity. 8.4 Design of Net Section Reinforcement Three tests, HSS-14, HSS-15 and HSS-17 have been tested that did not include net section reinforcement. According to the AISC Seismic Provisions, net section was required (see Section 3.3. for calculations). None of these tests showed any cracks or damage at this location. In this respect, these specimens performed very well. These results lead to the notion that the net section reinforcement may not be needed. Nonlinear analyses (Jung 2006) suggest that this net section issue is influenced by the stiffness of the connection. The analysis further suggests that net section reinforcement can be avoided in these tests because of the flexibility of the connection. The net section reinforcement used in the first 13 specimens had a β factor ranging from 0.75 to 0.80 (as determined from the as-built dimensions). Because none of these tests experienced any damage to the net section, and because none of the tests without the net section reinforcement received any damage either (β was equal to 1.05 with these specimens), it is recommended that the limit state of net section fracture at the brace be checked using a β factor of 0.9. In calculating the strength of the net section, Rt should be multiplied by the expected ultimate tensile strength of the brace as shown below. 258 βPn = βRt Fu Ae ≥ Pt (8.4.1) Or if the net section requires reinforcement: βPn = β ( Rt Fub Aeb + Fus As ) ≥ Pt (8.4.2) Where Aeb is the effective area of the brace, As is the area of the stiffeners and: β = 0.9 8.5 (8.4.3) Design of Beam-to-Column Connection This research has shown that concentrically braced frames do not simply act like a truss experiencing only axial loads. The gusset plate and beam-to-column connection provide a substantial rigid connection. This rigid connection enables moments to be transferred from the beam to the column, providing frame action as resistance. It is recommended to use CJP welds at the flanges and the web of the beam to connect to the column. This was used in all of the specimens, and high performance was observed from this connection. 259 Chapter 9: Conclusions and Recommendations 9.0 Introduction This chapter will present the findings on SCBFs gathered from all of the experiments in the test program. Section 9.1 will present a summary of the experiment results completed for this research thesis. Conclusions are shown in Section 9.2 based on the analysis of all of the experiments within the test program. Section 9.3 summarizes the design recommendations made in this thesis. Section 9.4 will present recommendations for future research. 9.1 Summary Six full scale special concentrically braced frames were tested to observe their response to applied cyclical displacement. These tests consisted of a single bay, one story frame with a single diagonal brace. All of the tests used a W12x72 for both of the columns, a W16x45 for both of the beams and an HSS5x5x3/8 for the brace. The only difference between the frames was the connection detail between the brace and the frame. The connection detail greatly affects the seismic performance of the specimens at the different performance levels as shown by the experiments. The purpose of the overall test program was to determine how the SCBFs would respond depending on different connection details. Mainly, changes were made to the gusset plate geometry. These changes affected the drift life of the brace before fracture, the amount of weld tearing of the gusset plate welds, the amount of energy dissipation, and the constructability of the specimen. 260 Specimen HSS-12 used the 2t linear offset to locate the end of the brace and design the gusset plate. This created a plate with the same geometry and thickness as the reference specimen (HSS-01) designed to imitate the industry standard. Since HSS-01 fractured at the gusset plate welds, HSS-12 was designed with complete joint penetration welds. These CJP welds were the test study parameter. These welds did not crack during the entire length of the test, and the brace fractured at midspan marking the end of the test. Because of the size, strength and stiffness (axial and bending) of the plate, the specimen reached relatively low drift levels. The ultimate drift range was 3.49% while the positive drift capacity was 1.39%. The next specimen that was tested, HSS-13, used the same 1/2 inch tapered gusset plate with a 7t elliptical clearance as HSS-10. However, since HSS-10 received severe weld cracking, HSS-13 used complete joint penetration welds for the gusset plate welds. The tapered plate and the CJP welds were the test study parameters. No cracking occurred in the CJP welds and the brace fractured at midspan. This specimen had an ultimate drift range of 4.09% and a positive drift capacity of 2.05%. HSS-14 was tested to analyze the load carrying ability of the net section that did not include net section reinforcement at the brace-to-gusset intersection. HSS-14 used the same gusset plate design as HSS-05 and HSS-06, which was a 3/8 inch rectangular plate with an 8t elliptical clearance. However, the gusset plate welds were slightly larger at 7/16 inch. HSS-14 buckled down to the strong floor and therefore the applied negative drift was limited to 2.0%. No damage was noticed at the net section holes due to the lack of reinforcement. Weld damage was noted at a drift ratio of -1.67% and the total crack lengths measured 11% of the total gusset plate weld length at the end of the test. The brace ultimately fractured at the center. This specimen had a fairly low ultimate drift range of 3.93%, but a high positive drift capacity of 1.89%. 261 The following specimen, HSS-15 used a reduced splice length distance between the brace and the gusset plate, which was the study parameter. This created a much smaller plate than the other rectangular plates, four inches shorter in each direction than the gusset plates used in HSS-14. The elliptical clearance was 6t and no net section reinforcement was used. The welds connecting the brace to the gusset plate needed to be increased from 5/16 to 7/16 of an inch since the splice length was reduced. According to the limit states of Whitmore fracture, Whitmore yielding, and block shear, the gusset plate needed to be thicker than 3/8 inch. However, due to the overwhelming evidence that thinner plates performed much better, these limit states where changed to be less stringent and a 3/8 inch plate was used, thereby also checking the accuracy of these limit state provisions. Cracking of the base metal was noted at a drift ratio of 1.61% and the total crack lengths measured 9% of the total gusset plate weld length at the end of the test. HSS-15 fractured at the center of the brace. This specimen had an ultimate drift range of 4.09% and a positive drift capacity of 1.87% HSS-16 was the only specimen that did not use a weld connecting the brace to the gusset plate. Instead, the brace was welded to an extension plate which was bolted to the gusset plate with A490 slip critical bolts with oversized holes in both the gusset plate and the extension plate. This bolted connection was the test study parameter. This specimen was also the only specimen to not buckle at the center of the brace. Instead, a plastic hinge developed in the southwest extension plate and in the southwest gusset plate. Damage to the base metal occurred relatively early in the experiment at 0.49% and the total crack lengths measured 55% of the total gusset plate weld length at the end of the test. The load path from the brace was lost when the extension plate fractured. The ultimate drift range for this experiment was the highest for all of the specimens in the test program at 5.89% while the positive drift capacity was also the highest at 3.03%. 262 The last specimen tested was HSS-17 and used a 3/8 inch tapered plate, which was the test study parameter, with 3/8 inch gusset plate welds. The plate had the same geometry as HSS-10 and HSS-13. This specimen did not use net section reinforcement. Cracking of the base metal was noted at a drift ratio of 1.77% and the total crack lengths measured 31% of the total gusset plate weld length at the end of the test. Due to the low strength and stiffness of the plate (axial and rotational) the specimen experienced a large ultimate total drift range of 4.94%, and a high positive drift capacity of 2.15%. 9.2 Conclusions This section is divided into two sections. The first section, Section 9.2.1 lists conclusions on the analysis of the SCBFs. Section 9.2.2 states conclusions concerned with the design of SCBFs. 9.2.1 Conclusions on Analysis of SCBFs Analysis techniques and design guides tend to drastically simplify the behavior of concentric braced frames. This simplification steers the way engineers think of braced frames to believing that they only carry axial forces. However, these frames respond in a very different manner. 9.2.1.1 Frame Action When a gusset plate is connected to a beam and column, a rigid joint is created that will transfer moments from the beam to the column. This moment puts additional stress on the gusset plate, gusset plate welds, and the beam-to-column connection. During negative drift, the brace is in compression and the beam-column joints (at the gusset plates) are experiencing an opening moment as shown in Figure 9.2.1. The other 263 two joints have closing moments applied to them. The opposite is also true: when the brace is in tension, the beam-column joints (at the gusset plates) are experiencing a closing moment, and the other two joints are experiencing an opening moment. Opening Moment at Joint Compression in Brace Figure 9.2.1 – Opening Moment Associated with Compression in Brace The opening moment applies tension across the gusset plate (perpendicular to the longitudinal axis of the brace). This, combined with the out-of-plane bending due to brace buckling, caused many of the welds (or base metal) to crack and propagate. There is a large amount of evidence showing that this opening moment is occurring and affecting the response of the frame. In HSS-01, the gusset plate welds were designed for the axial capacity of the brace (using the uniform force method). However, these welds cracked during the experiment. These cracks propagated throughout the length of the test and ultimately failed before the brace fractured. Additionally, in all of the tests, weld (or base metal) crack initiation and propagation typically occurred while the brace 264 was in compression (not tension). Nonlinear finite element analyses have also shown that this opening moment transfers across the gusset plate (Jung, 2006). Another important thing to note is that the direction of the interface forces (at the beamto-gusset interface and column-to-gusset interface) applied by the moment are opposite to the interface forces that the uniform force method predicts due to the axial force in the brace. In reality, the interface forces will be a combination of these two applied forces. 9.2.1.2 Gusset Plate Out-of-Plane Bending Typically, building structures deal with one-dimensional members; and the strength and stiffness of these members can be calculated with simple expressions. However, gusset plates are two dimensional members. Some gusset plates that have a straight line hinging pattern may be simplified to determine their strength or stiffness with the simple expressions used for one-dimensional members with limited loss in accuracy. However, rectangular gusset plates that use an elliptical clearance do not have a straight line hinging pattern. Because of this, the bending in the gusset plate that resists rotation is much more complicated than the other plates. A two-dimensional analysis such as the FEM analysis carried out in Appendix C is required to accurately determine the stiffness of the gusset plates. Additionally a three dimensional analysis of these models including nonlinear material and geometry is required to accurately determine the ultimate strength of the gusset plate and also the stiffness of the gusset plate after initial yielding. 265 9.2.1.3 Drift Capacity The major goal of this research is to design an SCBF with a high performance in the levels of Life Safety and Collapse Prevention. An effective way to achieve high performance at these levels is to postpone brace fracture. In determining which specimen will have the largest drift capacity (before the brace fractures), it is important to look at both the ultimate drift range and the positive drift capacity of these experiments. The ultimate drift range is a logical measurement to compare the different specimens’ drift capacities since both the positive and negative drift add strain accumulation to the brace; and therefore both directions of drift will contribute to the fracture of the brace. However, as shown with specimens that have limited negative drift, similar specimens had similar positive drifts. For example, HSS-14 was limited to -2.0% drift, and had an ultimate drift range of 3.9% and a positive drift capacity of 1.9%. Similar specimens HSS-05 and HSS-06 averaged an ultimate drift range of 4.9%, and a positive drift capacity of 1.8%. Notice that these similar specimens had more similarity with their positive drift than with their total drift range. This is due partly to the fact that, as the negative drift increases, the gusset plate welds or base metal cracks, and therefore, the effective strength and stiffness of the connection is reduced, thereby reducing the plastic strain accumulation at the hinge point of the brace. Therefore, within these experiments, positive drift capacity needs to be compared, as well as ultimate drift range, to determine which specimen has a better drift capacity. In a real building structure, the random applied displacement from an earthquake will also affect the fracture life of the brace (or possibly the gusset plate welds or base metal). 9.2.2 Conclusions on Design of Gusset Plates in SCBFs For improved performance in Life Safety and Collapse Prevention, it is observed that the gusset plate should be as small, flexible, and weak enough to yield (after the brace 266 yields), all while supporting the maximum load delivered by the brace. This will allow the gusset plate to rotate freely like a pinned end member during brace buckling. And it will also allow that gusset plate to yield in tension. These two characteristics will reduce the plastic strain accumulation at the center of the brace and prolong the life of the brace. By designing the gusset plate to be stronger than the brace, this will insure that the brace fractures before the gusset plate. Therefore, the frame will be able to absorb as much energy as possible through the brace and maintain a load path for the diagonal brace at the maximum possible drift levels. 9.2.2.1 Clearance Requirements In order to reduce the size of the gusset plate, an elliptical clearance (between 6t and 8t) should be used to locate the end of the brace. This will create a smaller plate and as the results show, a higher drift capacity. However, if an elliptical clearance is used that is too small as with HSS-08, which had a 3t elliptical clearance, additional stress can be put on the welds causing them to crack. If an elliptical clearance is too large, then the gusset plate approaches the straight line clearance achieved by HSS-01 and HSS-12 which both had below average drift capacities. It is especially true to use this elliptical clearance because if the limit state of gusset plate buckling controls the thickness of the plate, a thicker plate will be required for a gusset plate that uses the straight line clearance. This thicker plate drastically increases the strength and stiffness of the gusset plate, thereby not limiting the strain demand at the center of the brace, leading to earlier brace fracture. 267 9.2.2.2 Tapered vs. Rectangular Plates In general, tapered gusset plates have a smaller strength and stiffness than rectangular plates. This is true simply because they have less steel. Additionally, for the out-ofplane strength and stiffness, a tapered plate, which uses an elliptical clearance, may also be close to satisfying the 2t linear offset. This will allow more free rotation than a rectangular plate which uses an elliptical clearance by the reasoning discussed in Section 9.2.1.2. In general, the specimens that used tapered plates had slightly higher drift capacities then specimens that used rectangular plates. For this reasoning, tapered plates are recommended. However, similar results regarding drift capacity were recorded with rectangular plates that used elliptical clearances, and are therefore also acceptable. 9.2.2.3 Gusset Plate Minimum Strength The gusset plates should be designed to support the maximum load from the brace to guard against failure of the plate before brace fracture. However, any additional size, strength or stiffness will reduce the drift capacity of the brace. Therefore, the brace should have the smallest possible strength and stiffness while resisting the maximum load from the brace. The design force specified in the AISC Seismic Provisions should be used. However, since it is such a high load, it is not logical to use the φ factors that are listed in the specifications when checking the limit states of the gusset plates. In this seismic design, it is detrimental to the seismic response of the frame to have too much conservatism. 9.2.2.4 Gusset Plate Weld Design Cracking in the gusset plate welds or base metal has shown to increase the ultimate drift capacity of the frame. However, early weld or base metal cracking can prohibit the 268 occupancy of a building after a seismic event. Additionally, if complete weld fracture occurs, it will reduce the drift life of the brace. This occurred in HSS-01 when the welds, which were designed using the uniform force method, completely fractured. Therefore, the uniform force method should not be used to design the welds. Instead, the gusset plate welds should be designed for the strength of the gusset plate. Since only one type of displacement history was tested, welds should not be designed to crack at all. If other applied displacements are tested and similar results are found that show the welds cracking but maintaining the load path from the brace to the frame, it may be appropriate to increase the capacity of the weld design by using a higher φ or β factor. However, because of the uncertainty associated with the actual applied displacement due to a seismic event, it is inaccurate to assume that the welds will respond in the exact same way as the welds in the experiment. 9.2.2.5 Bolted Connections All but one of the tests used welds to connect the brace to the gusset plate. HSS-16 was the only bolted connection in the test program. This specimen did not buckle in the expected way, and therefore, it did not reach the expected buckling strength. It also experienced very early weld cracking and ultimately failed at the extension plate, not at the center of the brace. However, this specimen had the highest ultimate drift range and highest positive drift capacity. For this type of connection to be viable, either a solution needs to be found that will enforce the brace to buckle at the center of the brace and therefore fracture at this location, or the code would need to be rephrased so that the brace is not required to be the first to fracture. 9.2.2.6 Framing Elements The response of the beams and columns of SCBFs are influenced by the size and shape of the gusset plates and they are also influential to the response of the brace. From the 269 experiments, the specimens that used the larger, stiffer, and stronger plates also experienced local web and flange buckling of the framing members at smaller drift ranges. This is shown by HSS-07 and HSS-11 which used the thickest gusset plates (7/8 inch) in the test program. These specimens also experienced local flange buckling at a lower drift than all of the other specimens. Therefore, smaller, more flexible plates should be used so that local buckling does not occur in the framing elements which can lead to partial or total collapse. One logical way to guard against local flange and web buckling of the framing members is to use a larger beam. However, HSS-11 was the only specimen which used a larger beam, W16x89, than the other specimens, which all used a W16x45. This larger beam created higher connection stiffness and hence, this specimen had the lowest positive drift capacity, and the lowest ultimate drift range of all of the specimens, including the only other specimen to use a 7/8 inch gusset plate. Therefore, larger beams should not be utilized to resist local buckling. Instead, the current design procedures which were used for designing the smaller beam should be used for checking local flange and web limit states even though these limit states may be reached at high drift levels. 9.2.2.7 Net Section Reinforcement Specimens HSS-14, HSS-15 and HSS-17 did not include net section reinforcement at the brace even though they were required to according to the AISC Seismic Provision calculations. This suggests that the requirement for net section reinforcement underestimates the strength of the net section of the brace. More testing is required to determine whether net section reinforcement can be omitted for all different conditions. Other influential conditions include pulse type loading, and increased effective gusset plate thickness (Jung, 2006). 270 9.2.3 Design Recommendations Based on the conclusions above, the following recommendations are made for the gusset plate design: • The gusset plate welds should be designed for the expected tensile yield stress of the plate. Either CJP welds or fillet welds can be used to resist this stress. If fillet welds are used, a factor of 1.5 can be multiplied by the strength of the weld since the force is perpendicular to the longitudinal axis of the weld (AWS and AISC). However, a β factor of 0.65 should be used instead of a φ factor of 0.75. • To calculate the strength of the limit states of block shear fracture and Whitmore fracture of the gusset plate, a β factor of 0.85 should be used instead of the φ factor of 0.75. • The limit states of Whitmore yielding and block shear yielding should not be checked for the gusset plate design. • Instead of using a φ factor of 0.75 to calculate the strength of the net section of the brace, it is recommended that a β factor of 0.9 is used. • An elliptical clearance of 6t to 8t should be used to locate the end of the brace on the gusset plate. 9.3 Recommendations for Future Research The following list gives recommendations where further research should be directed to advance the performance of braced frames used for seismic resistance. 9.3.1 Reduced Depth Brace In order to prolong the drift life of the brace, it is encouraged that the gusset plate be designed to reduce the plastic strain demand on center of the brace. A more direct 271 approach to reducing the strain demand at the center of the brace is to redesign the center of the brace. Figure 9.3.1 shows a brace which does not maintain a consistent cross section over the entire length of the brace. Figure 9.3.1 – Reduced Depth Brace The idea behind this detail is to increase the accumulated strain capacity at the location where the brace buckles. For this to work, the brace needs to buckle at the central plate. 272 Since the plate is thinner than the tube, the curvature required at a given drift level will deliver a smaller strain to the outer fibers of the plate than it would to the outer fibers of the tube if the brace had a constant cross section. Additionally, local buckling will not occur in the plate at the hinge point as it does in the tube (leading to fracture). Also, because the area of the plate is larger than the area of the tube, when the brace is in tension, this plate will see less strain concentration at the hinge point. Instead, the brace will yield more uniformly over the entire length. The central plate should be designed so that it does not reduce the buckling strength of the brace. However, it should be made thin enough so that the hinge occurs at the plate, instead of at the brace, directly next to the plate. Nonlinear analyses have shown that the plate should not have a higher plastic section modulus than the brace to ensure that hinging occurs in the central plate before it occurs in the brace. More testing is required to determine how the central plate should be designed. Existing X-bracing typically uses a gusset plate at the center of the X configuration for assembly of the structure. It should be noted that this plate will not provide the same benefits as the configuration above. That is because in X-bracing, the braces experiencing compressive loads will be braced by the braces that are experiencing tensile loads at the central gusset plates. Therefore, these gusset plates will buckle (under a certain drift) midway between the center gusset plate and the end gusset plate. At this location, the brace has a constant cross section, and the brace will develop a plastic hinge leading to fracture of the brace at this location. A similar type of brace that also takes advantage of reducing the depth of the brace is a pair of plates that are spaced apart the same thickness of the gusset plates. These plates would be the entire length of the brace, connected to the gusset plates, and could be stitched together to avoid local buckling. 273 9.3.2 Net Section The results within this test program have shown that net section reinforcement may be unnecessary. However, other testing has shown failure can occur at the net section. A comprehensive study needs to be analyzed to further understand what is required for net section reinforcement. Additional studies include a larger gusset plate combined with the absence of net section reinforcement, which nonlinear analyses have suggested my concentrate stresses at the net section location (Jung, 2006). Also, a test that includes a slab, which increases the effective stiffness of the gusset plate, may also cause an increase the stress at the net section. 9.3.3 More Accurate Gravity Load Application Because of the test setup, the gravity load on the column was displacement controlled. However, in a real building structure, the load will be force controlled. Therefore, the local buckling that occurred in the columns may lead to partial or total collapse which was not able to be captured in this test setup. It is important to know how much damage a column can experience before it compromises the ability to carry vertical loads Similarly, a gravity load should be applied to the beam. This is because, it is important to know at what damage level the ability of the beam to carry shears and moments is compromised, causing potential partial collapse or even progressive collapse 9.3.4 Shake Table It is recommended that a shake table test is applied to an SCBF. There are many simplifications when using quasi-static loading to a specimen. A shake table test will avoid these simplifications and examine how the structure will behave when subjected to ground accelerations. 274 9.3.5 Slab Much of this research has been aimed at limiting the strength and stiffness of the gusset plate. However, none of these experiments have examined what effect a slab will have on the strength and stiffness of the gusset plate. Therefore, a slab should be added to the experiment to see how it affects the performance of the brace. 9.3.6 Size of Brace To date in this research program has looked at only HSS5x5x3/8. It is important to look at larger braces as the curvature of the brace (during brace buckling) will apply higher strains at the extreme fiber potentially leading to earlier brace fracture. 9.3.7 Type of Brace Since fracture of the brace directly follows local buckling of the brace, different shapes should be tested. These different shapes will have unlike local buckling characteristics, and will therefore fracture at different drifts. Also, the steel grade, and hence, the ductile characteristics of that particular steel grade, will be dissimilar. 9.3.8 Applied Displacement History As mentioned earlier, the cracks in the weld and in the base metal will propagate even if the displacement is not increased from the previous cycle. Therefore, it is essential to look at different displacement histories to see if the damage to the welds will propagate to failure after a crack initiates. Especially recommended is a pulse excitation which has an initial surge which may crack the weld or base metal, followed by numerous cycles of smaller applied displacement. 275 9.3.9 Strength Evaluation of FEM Models The finite element models seem to be a valuable tool in helping determine the stiffness of gusset plates. These models should be taken to the nonlinear range so that the ultimate strength can be determined, and also the stiffness of the plate after initial yielding has occurred. 9.3.10 Gusset Plate Buckling Provisions The provision for gusset plate buckling should be tested. A β factor of 0.9 is suggested. 9.3.11 New Method for Determining Clearance The elliptical clearance method works with rectangular plates and it also works with tapered plates. However, the clearance values that this method designs should not be used when comparing tapered plates to rectangular plates. This is because, a tapered plate has less of an overlap than a rectangular plate (Section 6.1.3.3b) and therefore, ultimately a different clearance. Instead some other method that takes into account the taper should be utilized so that the comparisons are on the same level. Perhaps an angle measurement between the lines that connect the corners of the gusset plate to the end of the brace should be made and then used to compare the plates. 276 Figure 9.3.2 – Clearance Lines for Rectangular Plate Figure 9.3.3 – Clearance Lines for Tapered Plate The elliptical clearance is the same for these two figures. However, the difference between the angles that are created by the clearance lines is quite different. The angle between the two lines shown in Figure 9.3.2 is about 15 degrees. The angle between the two lines in Figure 9.3.3 is about 0 degrees. 9.3.12 Tapered Plate with Higher Clearance Since HSS-10 had early weld cracking, a higher clearance may prolong the drift at which weld cracking occurs. This would be due to less demand on the welds from the hinging of the plate. 277 9.3.13 Whitmore Section When checking Whitmore yielding or fracture, the entire width of the plate may be a better way to determine when these limit states are met. It is apparent that a rectangular plate will have more strength than a tapered plate for these limit states, and if the entire width of the plate is included in the limit state calculations, the rectangular plates will have a higher strength as expected. This is opposed to the current procedure which will predict equal strengths for tapered plates and rectangular plates so long as the Whitmore width is located within the limits of the gusset plate, which typically occurs. 9.3.14 Quarter Inch Plate Since there have been such positive results from thinner plates, a quarter inch plate is suggested. If the Whitmore width proposed above is used, and the proposed β factors in Chapter 8 are used, the brace-to-gusset plate splice may only need to be increased a small amount to have all of the required limit states satisfied. It should be interesting to see if such a thin gusset plate will be able to resist the hinging demands associated with brace buckling. 9.3.15 Beam-to-Column Connection Based on the research, the beam-beam to column connection has performed well with CJP welds at the beam web and flanges. However, since the gusset plate and beam-tocolumn connection appear to act compositely, it would appear that to use a CJP weld for the beam flange that is next to the gusset plate is unnecessary. Instead, this weld could be left out as shown in Figure 9.3.4. 278 Figure 9.3.4 – Connection with Only Outside Beam Flange Welded to Column 9.3.16 Additional Testing In addition to the items listed above, other parameters should also be tested. These parameters include: 1. Reinforcement plates on gusset plates (for gusset plate buckling) 2. Beam to column connection (shear connection only) 3. End plate connection bolted to column 4. Brace angle 5. Chevron bracing 6. X-bracing 7. Bracing in two bays (facing opposite directions) 279 References 1. AISC “Manual of Steel Construction, Load and Resistance Factor Design,” 3rd Edition, American Institute of Steel Construction, Chicago, Illinois, 2001 2. AISC “Seismic Provisions for Structural Steel Buildings,” American Institute of Steel Construction, Chicago, Illinois, 2002 3. Aslani, F., Goel, S., “Experimental and Analytical Study of the Inelastic Behavior of Double Angle Bracing Members Under Severe Cyclic Loading,” Research Report UMCE 89-5, Department of Civil Engineering, University of Michigan, Ann Arbor, Michigan, February, 1989 4. Aslani, F., Goel, S., Xu, P., “Effect of Stitch Spacing on the Cyclic Behavior of Built-up Bracing Members,” Report UMCE 87-8, University of Michigan, Ann Arbor, Michigan, January, 1987 5. Astaneh-Asl, A., "Seismic Behavior and Design of Gusset Plates," Steel TIPS, Structural Steel Educational Council, Moraga, California, December, 1998 6. Astaneh-Asl, A., Cochran, M., and Sabelli, R., “Seismic Detailing of Gusset Plates for Special Concentrically Braced Frames,” Steel TIPS, Structural Steel Educational Council, Moraga, California, December, 2006 7. Astaneh-Asl, A., Goel, S.C., and Hanson, R.D., “Cyclic Behavior of Double Angle Bracing Members with End Gusset Plates,” Research Report UMEE 82R7, Department of Civil Engineering, University of Michigan, Ann Arbor, Michigan, August, 1982 8. Astaneh-Asl, A., Goel, S.C., and Hanson, R.D., “Cyclic Out-of-Plane Buckling of Double Angle Bracing.” Journal of Structural Engineering, American Society of Civil Engineers, 111(5), 1135-1153, 1985 9. ATC 24, "Guidelines for Cyclic Seismic Testing of Components of Steel Structures," Applied Technology Council, 1992 280 10. Becker, R., "Seismic Design of Special Concentrically Braced Steel Frames," Steel TIPS, Structural Steel Educational Council, Moraga, California, November, 1995 11. Bjorhovde, R., “Limit States Design Considerations for Gusset Plates.” Journal of Constructed Steel Research, 9, 61-73, 1988 12. Bjorhovde, R. and Chakrabarti, S.K., “Tests of Full-size Gusset plate Connections.” Journal of Structural Engineering, American Society of Civil Engineers, 111(3), 667-115, 1985 13. Brown, V.L.S., "Stability of Gusseted Connections in Steel Structures," A thesis submitted in partial fulfillment of Doctor of Philosophy in Civil Engineering, University of Delaware, 1988 14. Chakrabarti, S.K., Tests of Gusset Plate Connections. M.S. Thesis, University of Arizona, 1983 15. Chambers, J.J., Ernst, C.J., “Brace Frame Gusset Plate Research: Phase 1 Literature Review Volumes I and II”, Department of Civil and Environmental Engineering, University of Utah, Salt Lake City, Utah, February, 2005 16. Cheng, J.J.R., Grondin, G.Y., Yam M.C.H, "Design and Behavior of Gusset Plate Connections," Fourth International Workshop on Connections in Steel Structures, Roanoke, VA, October 2000 17. Cheng, J.J.R., Rabinovitch, J.S., and Yam, M.C.H., “Behavior of Gusset Plate Connections under Compressive Monotonic and Cyclic Loadings.” Proceedings, 1993 Annual Technical Session, April 5-6, Milwaukee, Wisconsin, Structural Stability Research Council, 45-58, 1993 18. Christopulos, A.S., "Improved Seismic Performance of Buckling Restrained Braced Frames", Department of Civil Engineering, University of Washington, Seattle, Washington, June, 2005 19. Cochran, M., Honeck, W.C., "Design of Special Concentric Braced Frames," Steel TIPS, Structural Steel Educational Council, Moraga, California, May, 2004 281 20. FEMA 350, "Recommended Seismic Design Criteria for New Steel Moment-Frame Buildings," FEMA 350, Federal Emergency Management Agency, Washington, D.C., 2000 21. FEMA 355C, "State of the Art Report on Systems Performance of Steel Moment Frames Subject to Earthquake Ground Shaking," FEMA 355, Federal Emergency Management Agency, Washington, D.C., 2000 22. FEMA 355D, "State of the Art Report on Connection Performance," FEMA 355, Federal Emergency Management Agency, Washington, D.C., 2000 23. Gaylord, E.H., Gaylord, C.N., Stallmeyer, J.E., "Design of Steel Structures," 3rd edition, New York, Mc-Graw-Hill, Inc., c1992 24. Grondin, G.Y., Nast, T.E., and Cheng, J.J.R., "Strength and Stability of Corner Gusset Plates Under Cyclic Loading," Proceedings of Annual Technical Session and Meeting, Structural Stability Research Council, 2000 25. Gugerli, H., Goel, S.C., “Inelastic Cyclic Behavior of Steel Bracing Frames,” Report UMEE 82R1, University of Michigan, Ann Arbor, Michigan, January, 1982 26. Gunnerson, I., "Numerical Performance Evaluation of Braced Frame Systems", Department of Civil Engineering, University of Washington, Seattle, Washington, December, 2004 27. Han Yoo, J., "Analytical Investigation on the Behavior of Braced Frame" Department of Civil Engineering, University of Washington, Seattle, Washington, June, 2006 28. Hardash, S, Bjorhovde, R., "New Design Criteria for Gusset Plates in Tension," Engineering Journal, AISC, Vol. 22, No. 2, Second Quarter, 1985 29. Herman, D., “Further Impovements On and Understanding of Special Concentrically Braced Frame Systems”, Department of Civil Engineering, University of Washington, Seattle, Washington, January, 2007 282 30. Hu, S.Z., Cheng, J.J.R., “Compressive Behavior of Gusset Plate Connections,” University of Alberta, Department of Civil Engineering, Structural Engineering Report, n153, July, 1987 31. Jain, A.K., Goel, S.C., Hanson, R.D, "Hysteresis Behavior of Bracing Members and Seismic Response of Braced Frames with Different Proportions," Research Report UMEE 78R3, Department of Civil Engineering, University of Michigan, Ann Arbor, Michigan, July, 1978 32. Johnson, S.M., "Improved Seismic Performance of Special Concentrically Braced Frames", Department of Civil Engineering, University of Washington, Seattle, Washington, June, 2005 33. Lehman, D.E., Roeder, C.W., Herman, D.J., Johnson, S.M., and Kotulka, B., “Improved Seismic Performance of Gusset Plate Connections.” Submitted for publication review, Journal of Structural Engineering, ASCE, Reston, VA 34. Lehman, D., Roeder, C., Jung H. Y., Johnson, S., "Seismic Response of Braced Frame Connections," 13th World Conference on Earthquake Engineering, Vancouver, B.C., Canada, Paper No. 1459, August 2004 35. Lesik, D.F., Kennedy, D.J.L., "Ultimate Strength of Fillet Welded Connections Loaded in Plane," Canadian Journal of Civil Engineering, Vol. 17, No. 1, National Research Council of Canada, Ottawa, Canada, 1990 36. Liu, J. and. Astaneh-Asl, “Cyclic Testing of Simple Connections, Including Effects of the Slap”, Journal of Structural Engineering, Vol 126, No. 1, January, pp. 32-39 37. Martinez-Saucedo, G., and Packer, J. A., “Slotted Tube End Connections: Seismic Loading Performance,” Pacific Structural Steel Conference 2007, Wairakei, New Zealand, p 90-96, 13-16 March 2007 38. Murphy, G., "Advanced Mechanics of Materials," New York and London, McGrawHill Book Company, Inc., c1946 283 39. Nast, T., Grondin, G., Cheng, R., “Cyclic Behavior of Stiffened Gusset Plate-Brace Member Assemblies,” University of Alberta, Department of Civil Engineering, Structural Engineering Report, n229, December, 1999 40. Rabinovitch, J., Cheng, R., “Cyclic behavior of steel gusset plate connections,” University of Alberta, Department of Civil Engineering, Structural Engineering Report, n 191, August, 1993 41. Roeder C.W., "Connection Performance for Seismic Design of Steel Moment Frames," ASCE, Journal of Structural Engineering, p517-525, April, 2002 42. Roeder, C.W., MacRae, G., Leland, A., Rospo, A. "Extending the Fatigue Life of Riveted Coped Stringer Connections." Journal of Bridge Engineering, ASCE, v 10, n 1, p 69-76 January/February 2005. 43. Roeder, C.W., Lehman, D.E. "Performance-Based Seismic Design of Concentrically Braced Frames", National Science Foundation, Grant CMS-0301792 44. Roeder, C.W., Lehman, D.E., and Yoo, J., “Improved Design of Steel Frame Connections”, International Journal of Steel Structures, v.5,n.2, July 2005 45. SAC Steel Project, "Protocol for Fabrication, Inspection, Testing and Documentation of Beam-Column Connection Tests and Other Experiments," Report No. SAC/BD-97/02, SAC Joint Venture, October 1997 46. Salmon, C.G., Johnson, J.E., "Steel Structures Design and Behavior," 4th edition, HarperCollins College Publishers, c1996 47. Shaback, B., Brown, T., "Behaviour of square hollow structural steel braces with end connections under reversed cyclic axial loading," Canadian Journal of Civil Engineering, v 30, n 4, p 745-753, August, 2003 48. Tam M.C.H., Cheng J.J.R., "Behavior and Design of Gusset Plate Connections in Compression," Journal of Constructional Steel Research, Vol 58, No. 5-8, Elsevier, pgs 1143-59, 2002 284 49. Tamboli, A.R., "Handbook of structural steel connection design and details," New York, McGraw-Hill, c1999 50. Timoshenko, S.P., Gere, J.M., "Theory of Elastic Stability," New York, McGrawHill Book Company, Inc., c1961 51. Thornton, W.A., "Bracing Connections for Heavy Construction," Engineering Journal, AISC, Vol. 21, No. 3, pp. 139-148., 1984 52. Tremblay R., "Inelastic seismic response of steel bracing members," Journal of Constructional Steel Research, 58, 665-701, 2002 53. Uriz, P., "Summary Of Test Results For UC Berkeley Special Concentric Braced Frame Specimen No. 1 (Scbf-1)", Retrieved May 5, 2005, from http://www.ce.berkeley.edu/~patxi/ 54. Walpole, W. R. “Behaviour of cold-formed steel RHS members under cyclic loading.” Dept. of Civil Engineering, Univ. of Canterbury, Christchurch, New Zealand, 1996 55. Whitmore, R.E., "Experimental Investigation of Stresses in Gusset Plates," Bulletin No. 16, Engineering Experiment Station, University of Tennessee, 1952 56. Yam M.C.H., “Compressive Behavior and Strength of Steel Gusset Plate Connections,” University of Alberta, Department of Civil Engineering, Fall, 1987 57. Yang, F., Mahin, S., "Limiting Net Section Fracture in Slotted Tube Braces," Steel TIPS, Structural Steel Educational Council, Moraga, California, April 2005 58. Yoo, J.H., “Analytical Investigation on the Seismic Performance of Special Concentrically Braced Frames”, a dissertation submitted in partial fulfillment of the Ph.D degree, Department of Civil Engineering, University of Washington, Seattle, Washington, 2006 59. Yoo, J.H., Roader, C., and Lehman, D., “Impact of Design Parameters on the Seismic Performance of Gusset Plate connections”, in preparation, expected in 2007 285 60. Zhiyuan, L., Goel, S.C., "Investigation of Concrete-Filled Steel Tubes Under Cyclic Bending and Buckling," Research Report UMEE 87-3, Department of Civil Engineering, University of Michigan, Ann Arbor, Michigan, April, 1987 286 Appendix A: Specimen Design A.1 General This appendix provides detailed calculations for the design of the specimens. Many of the calculations were the same for all of the specimens. Therefore, an example set of calculations is shown in Section A.2 which was used for the design of HSS-12, much of which, was directly from Appendix B in Johnson (2005). Additional example calculations are shown for HSS-14 in Section A.3. All of the equations in this appendix were taken from two codes: AISC Seismic Provisions 2002 and AISC Manual of Steel Construction, 3rd Edition 2001. This thesis was written after new editions of each of these manuals have become available. However, the specimens tested in this thesis are compared to specimens (in Chapter 7) that were designed using the codes listed above. Therefore, to keep the all specimens equal, the same code was used to design all of them. A.2 Example 1 (Specimen HSS-12) A.2.1 Member Selection First the slenderness requirements and buckling capacity of the beams and columns must be checked. Values of b/t and h/t are found using AISC Seismic Provisions Table I-8-1. First the beam was checked. E 29000 b ≤ 0.3 s ⇒ 6.23 ≤ 0.3 ⇒ 6.23 ≤ 6.89 2t 1.1(50 ) Fy 287 E ⎛ P h ≤ 1.12 s ⎜ 2.33 − u t Fy ⎜⎝ φPy ⎞ ⎞ 350 ⎟ ⇒ 41.1 ≤ 1.12 29000 ⎛⎜ 2.33 − ⎟ ⎜ ⎟ 1.1(50) ⎝ 0.9(13.3)(50) ⎟⎠ ⎠ ⇒ 41.1 ≤ 44.88 Therefore, the beam meets the slenderness requirements. Similarly, the column also meets the slenderness requirements. For the buckling capacity, values of λ are found first. Only the limiting case is shown here for the beam and column design. The unbraced length for weak axis buckling was taken to be half of the unbraced length for strong-axis buckling due to the fact that outof-plane restraints would be present. The length of the columns was taken as 13 feet and for beams, 11 feet. As stated in the text the beam used was a W16x45 and the column a W12x72. λbeam = Kl rπ Fy = E 1(5.5 *12) 50 = 0.556 1.57π 29000 therefore ( ) Fcr = 0.658 0.556 (50) = 43.939ksi 2 and φPn = (0.85)43.939(13.3) = 496.73kips Similarly for the columns: 288 λcolumn = Kl rπ Fy = E 1(13 * 12) 50 = 0.388 5.31π 29000 therefore ( ) Fcr = 0.658 0.388 (50 ) = 46.94ksi 2 and φPn = (0.85)46.94(21.1) = 841.91kips The calculated capacity of the beam and column lead to a factor of safety of 1.42 and 2.41 respectively. This was deemed acceptable to allow for increased economy of the frame. The next step was to check the capacity of the brace starting with slenderness checks. Based on the capacity of the actuator a HSS 5x5x3/8 section was used. From Table I-8-1 of the AISC Seismic Provisions, slenderness requirements must be met for rectangular HSS sections. E 29000 b ≤ 0.64 s ⇒ 11.3 ≤ 0.64 ⇒ 11.3 ≤ 14.09 1.3(46 ) t Fy As can be seen, the brace is adequate for the slenderness requirements. The tensile and compressive capacity of the brace is determined next. The area of the brace is 6.18 in2 and the radius of gyration is 1.87". The length of the brace was known to be 11'-13/16". 289 Tmax = R y Fy Ag = 1.3(46)(6.18) = 369.56kips λbrace = Kl rπ Fy E = 1(11.1)(12) 1.3(46) = 1.03 1.87π 29000 C max = .6581.03 (1.3)(46)(6.18) = 237.14kips 2 The maximum tensile and compressive forces were then used to design the gusset connections. A.2.2 Brace-to-Gusset Plate Connection A 5/16" weld was chosen for the brace to gusset plate connection due to the fact that this is the maximum size for a single pass weld. Using this weld size was considered to be the most economical detail for this connection. Therefore, knowing the maximum tensile strength and the weld size the minimum connection length was determined. The 1.1 factor shown below is taken from general practice to add conservatism to the weld design. This is not required in the code, nor is it the general practice of all engineers. ( ) Tmax = 0.75 (0.6)FEXX 1.0 + 0.5 sin 1.5 θ Aw 1.1 Tmax = 0.75 (0.6)70(1.0 + 0.0)(0.707 )⎛⎜ 5 ⎞⎟l (4) 1.1 ⎝ 16 ⎠ Solving for l: l = 14.6" 290 Therefore use: l = 14.75" The net section of the brace must also be checked due to the slot needed to connect the brace to the gusset. Ae Fu = 1.1Ag Fy In this equation Ry is left out due to the fact that material properties of the brace were known. Also, as Fy increases Fu will also increase. Although Fu will typically not increase at the same rate Fy will, the φ factor of 1.1 will account for difference of increase in strength. Knowing Fy and Fu the needed Ae can be solved for. Ae = 1.1(6.18)(46) = 5.39in 2 58 The effective area of the brace can be determined according to AISC Manual of Steel Construction. Here it is assumed that a thickener plate will need to be provided and that the gross area of the brace is the original area minus the area removed for the slots. ⎛ ⎞ ⎛ 1 1 ⎞⎛ 3 ⎞ Ae = UAn = 0.9⎜⎜ 6.18 − 2⎜ + ⎟⎜ ⎟ + (2)Athickener ⎟⎟ ⎝ 2 16 ⎠⎝ 8 ⎠ ⎝ ⎠ Ae = 5.18 + (0.9)(2 )Athickener = 5.39in 2 Solving for Athickener 291 Athickener = 0.117in 2 A 3" x 10" x 1/4" plate was chosen in the design phase. However, a 3/8 inch plate was used in construction. AISC specifies that the minimum weld size is based on the thicker material joined. Therefore, the brace thickness controlled and the minimum weld size is 3 /16". Thus, the 3/8 inch thickness allowed for ease of construction. The width of 3 inch was chosen to ensure adequate distribution of stresses in the thickener plate. The thickener plates were attached on the top and bottom of the brace placed symmetrically about the slot. Longitudinal welds were used to attach the plate to the brace. Athickener Fu = 0.75(65) = 48.75kips 48.75 = 0.75 (0.6)FEXX (1.0 + 0.5 sin 1.5 θ )Aw 1.1 Solving for w: w= 1.1(48.75) (0.75)(0.6)(70)(0.707 )⎛⎜ 10 ⎞⎟(2) ⎝2⎠ = 0.24" Therefore, use 1/4" welds. A.2.3 Gusset Plate Design Determine the gusset plate thickness by checking block shear and yielding and fracture of the Whitmore width. Note that in the 2005 AISC Manual of Construction, the 292 equation for block shear has become stricter, requiring that fracture and yielding need to be checked at the sides of the connection resisting shear forces (not shown). Block Shear: Tmax = φRn = φ (0.6 Fu Anv + Fy Ant ) Agv = Anv = 2(14.75)tp Agt = Ant = 5tp [ 369.56 = 0.75 0.6(65)2(14.75)t p + (50 )5t p Solving for tp: tp = 0.352" Whitmore yielding calculations are shown here: Tmax = φRn = 0.9 Fy Lw t 369.56 = 0.9(50)[2 * 14.75 tan (30 ) + 5]* t p Solving for tp: tp = 0.372" Whitmore fracture calculations are shown here: ] 293 Tmax = φRn = 0.75Fu Lw t 369.56 = 0.75(65)[2 *14.75 tan (30 ) + 5]* t p Solving for tp: tp = 0.344" Therefore, a minimum thickness of 3/8" is needed for adequate resistance in tension. However, due to buckling capacity of the plate a thickness of 1/2" was chosen for Specimen HSS-12 as shown later with calculations. Buckling must be calculated after the plate size is determined to calculate the unbraced length. The next step was to determine plate geometry. Using a rectangular plate and AISC equation 11-1: α = eb tan θ − ec + β tan θ Where the variables in this equation are defined here and shown in Figure A.1: α = distance from the face of the column flange to the centroid of the gusset to beam connection β = distance from the face of the beam flange to the centroid of the gusset to column connection eb = one-half the depth of the beam ec = one-half the depth of the column 294 Figure A.1 - Uniform Force Method (Johnson 2005) The representations of α, β, eb, ec, and φ are identified in Figure A.1. As can be seen in the above equation there are two unknowns: α and β. In order to define the plate size the designer must choose a value of either α or β and then solve for the other parameter using the above equation. Another constraint used to solve for the size of the plate is the clearance requirement of "2t". This requirement was described earlier in Chapter 3 and is also described in section C13.1 of the AISC Seismic Provisions Commentary. With this extra constraint the geometry of the plate is found using an iterative process. Figure A.2 shows a schematic of the required plate dimensions. Equations for the width and height of the plate were generated from these dimensions: 1 ⎞ ⎛ Height = ⎜ x'+ Lc + b ⎟ sin (θ ) + (s ) cos(θ ) 2 ⎠ ⎝ Width = eb − e c + ( x') cos(θ ) + ( x') sin(θ ) tan (θ − 90 ) − 2t p cos(θ ) 295 Figure A.2 - 2t Clearance Dimensions (Johnson 2005) As shown in the figure, x' is the distance from the beam face to the end of the brace. Lc is the length of the brace-to-gusset plate connection and b is the brace width. The component s is shown as the distance from the side of the brace to the top plate edge. This distance was taken to be 7/8 inch for all of the tests (except HSS-16). The value x' is increased or decreased incrementally until a value is found which satisfies the equations above and the 2t clearance requirement. For a W16x45 beam eb is 8.05" and for a W12x72 column ec is 6.15". Using the equations for height and width as presented earlier: 1 ⎞ ⎛ Height = ⎜ x'+ Lc + b ⎟ sin (θ ) + (s ) cos(θ ) 2 ⎠ ⎝ 5⎞ ⎛ Height = ⎜ 22.81 + 14.75 + ⎟ sin (45) + (1) cos(45) = 29.03" 2⎠ ⎝ 296 Width = eb − ec + ( x') cos(θ ) − ( x')sin(θ ) tan (θ − 90 ) − 2(0.5) cos(θ ) Width = 8.05 − 6.15 + ( 22.81) cos(45) − ( 22.81) sin(45) tan ( 45 − 90 ) − 2(.5) cos ( 45 ) = 32.74" α = 8.05 tan (45) − 6.15 + 29.03 tan (45) = 16.415" 2 Therefore, all equations are satisfied and the plate size has been found. For HSS-12 a plate size of 34" x 30" x 1/2" was used. Once the plate thickness and geometry are found, the buckling strength of the gusset plate is checked. The value of lave was found using the average of l1, l2, and l3 as shown in Figure A.3. The values of l1, l2, and l3 were determined graphically from the design drawing to 15.4", 23.7" and 12.7" respectively. Figure A.3 – Buckling Lengths l1, l2 and l3 297 λ= Kl ave t pπ 12 Fy 29000 = 0.5(17.47") 12(50) = 0.80 0.5π 29000 Solving for the buckling capacity: φRn = (0.85)0.658 0.8 (50)22.03(0.5) = 358.16kips 2 Since the buckling capacity of the plate is greater than that of the brace the gusset plate design is adequate. It should also be checked if a thinner plate can resist buckling, shown here for a 3/8 inch plate: λ= Kl ave t pπ 12 Fy 29000 = 0.5(17.47") 12(50) = 1.07 0.375π 29000 Solving for the buckling capacity: φRn = (0.85)0.6581.07 (50)22.03(0.375) = 218.1kips 2 Therefore, a 3/8 inch plate is not adequate since it does not have a buckling capacity greater than the compression capacity of the brace, Cmax, calculated above. A ½ inch thick gusset plate was used instead. A.2.4 Gusset Plate-to-Frame Connection Design First, the interface forces are calculated. They are calculated here using the uniform force method. However, this research has lead to the belief that this method does not accurately represent the forces seen in the gusset plate welds. Instead, the welds should be designed based on the strength of the gusset plate (Section 8.2). 298 r= (α + ec )2 + (β + eb )2 r= (17 + 6.15)2 + (15 + 8.05)2 = 32.7 Vuc = 15 369.6 = 169.7kips 32.7 H uc = 6.15 369.6 = 69.6kips 32.7 Vub = 8.05 369.6 = 91.1kips 32.7 H ub = 17 369.6 = 192.3kips 32.7 Complete joint penetration welds were used to attach the gusset plate to the beam and to the column. (Complete joint penetration welds are used since HSS-01, which had the same gusset plate geometry, used fillet welds which fractured.) By combining the horizontal and vertical interface forces, the total force on the column weld is shown below along with the capacity of the weld: Tuc = H uc + Vuc = 183.4kips 2 2 φPcw = 0.6φFEXX * ( Height − 1) * t g = 0.6 * 0.8 * 70 * (30 − 1) * 0.5 = 487.2kips Therefore, a CJP weld is adequate for the gusset plate to column connection. The gusset plate to beam connection force is calculated below along with the capacity of the weld Tub = H ub + Vub = 212.8kips 2 2 299 φPbw = 0.6φFEXX * (Width − 1) * t g = 0.6 * 0.8 * 70 * (34 − 1) * 0.5 = 554.4kips Therefore, a CJP weld is adequate for the gusset plate to beam connection. In the two previous calculations of the weld size, the length of the gusset plate was reduced by 1" to account for the weld access in the frame corner. The base material of the beam is checked here: φRn = 2[0.75(0.6)0.565(34 − 1)65] = 1090.7kips Therefore the base material is adequate since the strength is greater than the resultant force on the beam Tub. The column base metal is okay by inspection. The next step is to check the beam web for yielding and web crippling. Local yielding of the beam web is shown here: φRn = (2.5k + N )Fy t w φRn = (2.5(0.967 ) + (34 − 1))50(0.345) = 610.95kips The beam web is more than adequate for web yielding in that the resistance is approximately three times greater than the interface force. Crippling of the beam web is checked below. The concentrated force is applied at a distance greater than d/2 therefore: ⎡ ⎛ N ⎞⎛ t φRn = (0.75)0.80t ⎢1 + 3⎜ ⎟⎜⎜ w ⎢ ⎝ d ⎠⎝ t f ⎣ 2 w ⎞ ⎟ ⎟ ⎠ 1.5 ⎤ EF t y f ⎥ tw ⎥ ⎦ 300 ⎡ ⎛ (34 − 1) ⎞⎛ 0.345 ⎞ ⎟⎜ ⎟ ⎝ 16.1 ⎠⎝ 0.565 ⎠ φRn = (0.75)0.80(0.345)2 ⎢1 + 3⎜ ⎢⎣ 1.5 ⎤ 29000(50)(0.565) ⎥ 0.345 ⎥⎦ φRn = 432.94kips This capacity is much larger than the expected interface force caused by the compressive force of the brace. Therefore the beam is adequate for all checks. Similarly the column satisfies all checks. A.2.5 Beam-to-Column Connection – CJP Beam column connection forces were determined in the previous section. Equilibrium is applied in order to obtain the required design forces. The horizontal and vertical forces in the beam column connection are shown here (these forces are concentric as determined by the uniform force method): H bc = H uc = 69.6kips Vbc = Vub = 91.1kips Using complete penetration welds for the beam web, the capacity is: φRn = 0.75(0.6)t w Fy l In this equation l is found by taking the depth of the member minus the thickness of the flanges and accounting for the weld access holes which are both 1". l = 16.1 − 2(0.565) − 2(1) = 13.0" 301 φRn = 0.75 * 0.6 * 0.345 * 50 *13.0 = 100.9kips For this specimen the resistance is adequate. Using complete penetration welds for the beam flanges, the capacity is: φRn = 0.9(0.565)(50)(7.04) = 179kips Therefore the beam flange has adequate strength. A.2.6 Beam-to-Column Connection – Simple Shear Using the plastic capacity of the beam a shear force can be found to design the connection. V = 1.5M p l = 1.5(50)(82.3) = 66.6kips 92.7 Using Table 10-9 an initial design is found using: 3/4” diameter A490X bolts with standard holes, 13” x 4 1/2” x 3/8” plate and 5/16” fillet welds to connect the shear plate to column flange. Assuming a flexible connection φRn = 69.8 kips. Then using Table 101 web bearing of the beam is checked. From this table for an uncoped W16 beam: φRn = 351t w = 351(0.345) = 121.1kips Therefore, according to initial design the shear connection design is adequate. The next step is to verify adequacy by checking each limit state individually. As mentioned the shear plate was assumed to be grade A572 steel. 302 From AISC Table 7-10 the shear capacity of a single A490X bolt in single shear is 24.9 kips. Fv = 66.6 = 16.7kips ≤ 24.9 4 Therefore the bolt strength is adequate. Bearing at the connection material is checked here: φrn = 0.75(1.2)Lc (t )Fu ≤ 0.75(2.4 )d (t )Fu ⎛ 3 ⎞⎛ 3 ⎞ ⎝ 4 ⎠⎝ 8 ⎠ φrn = 0.75(2.4 )⎜ ⎟⎜ ⎟(65) = 32.9kips Since the bearing capacity of the plate is greater than the strength of the bolt the shear plate is adequate for bearing. Similarly it was found that the beam web was adequate for bearing. Next, shear strength of the plate needs to be checked. First the elastic yield strength of the plate is checked: φRn = 0.75(0.6)Fu Anv where ⎡ ⎛3 1 ⎞ ⎤3 Anv = ⎢13 − ⎜ − ⎟4⎥ = 3.6563in 2 ⎝ 4 16 ⎠ ⎦ 8 ⎣ therefore 303 φRn = 0.75(0.6 )65(3.563) = 106.95kips Next shear yielding is checked: 2 ⎛ 3⎞ 3⎝8⎠ φRn = 0.9(0.6) ⎜ ⎟(13)50 = 87.75kips Finally block shear is checked: ⎛3⎞ Agv = 11⎜ ⎟ = 4.125in 2 ⎝8⎠ ⎡ ⎛3 1 ⎞ ⎤3 Anv = ⎢11 − ⎜ + ⎟3.5⎥ = 3.059in 2 ⎝ 4 16 ⎠ ⎦ 8 ⎣ ⎛ 3⎞ Agt = 1.5⎜ ⎟ = 0.5625in 2 ⎝8⎠ ⎡ ⎛ 3 1 ⎞ 1⎤ 3 Ant = ⎢1.5 − ⎜ + ⎟ ⎥ = 0.41in 2 ⎝ 4 16 ⎠ 2 ⎦ 8 ⎣ φRn = 0.75[0.6 Fu Anv + Fy Agt ] ≤ 0.75[0.6 Fu Anv + Fu Ant ] φRn = 0.75[0.6(65)(3.059 ) + (65)(0.41)] = 109.46kips The limiting value is 87.75 kips which is greater than 66.59kips therefore the plate has sufficient shear strength. Plate bending is checked next: 304 V (e ) = 66.59(3) = 199.77 k − in ⎛ 1 ⎞⎛ 3 ⎞ ⎝ 6 ⎠⎝ 8 ⎠ φRn = 0.9⎜ ⎟⎜ ⎟(13)2 (50) = 475.3k − in Thus, the plate has sufficient bending capacity. Lastly, the shear plate welds are designed. Table 8-5 is used to size the fillet welds that connect the shear plate to the face of the column flange. The needed values are as follows: k =0 Here k is conservatively taken to be zero. However, the actual value of k could be used with linear interpolation to find a more accurate value of C. a= e 3 = = 0.231 l 13 Linearly interpolating between tabulated values for a of 0.20 and 0.25 C≈ 2.64 + 2.48 ≈ 2.56 2 φRn = CC1 Dl C1 = 1 , D = 5 , l = 13 φRn = 166.4kips 305 As can be seen the weld strength is more than sufficient proving that the simplifications were acceptable. A.3 Example 2 (Specimen HSS-14) The following example shows calculations used for the design of specimen HSS-14. This example shows only calculations that were different from the previous design example in section A.2 above. A.3.1 Gusset Plate Design The gusset plate design shown in this section is an example of the process explained in Section 8.1.1 which uses the elliptical clearance method. The thickness of the plate first had to be assumed and was calculated to be 3/8 inch based on the limit states of Whitmore yielding, Whitmore fracture, and block shear (similar calculations are shown in section A.2.3). Buckling was then checked to determine if the assumed thickness was correct after the geometry was determined. The geometry was determined using the following steps: 1. Assume the height of the gusset plate (21 inches) to establish a trial geometry with these equations: b = HT − Nt g = 21 − 7 . 7 * . 375 = 18 . 1" xb = eb 22 − ec = − 6.125 = 1.94" tan(θ ) tan(45) x s = xb = 1.94" a = xb + x s + ⎞ ⎛ 1 b + Nt g ⎜⎜ − 1⎟⎟ tan(θ ) ⎝ tan(θ ) ⎠ 306 a = 1.94 + 1.94 + ⎛ 1 ⎞ 18.1 + 7.7 * 0.375⎜⎜ − 1⎟⎟ = 22.0" tan(45) ⎝ tan(45) ⎠ WT = a + Nt g = 22 + 7.7 * 0.375 = 24.9" 2. Determine the end of the brace relative to the gusset plate free corner (x, y): y c = l c sin(θ ) + ( s + 0.5b f ) cos(θ ) y c = 14.75 sin(45) + (.875 + 0.5 * 5) cos(45) = 12.8" y d = [l c cos(θ ) + ( s + 0.5b f ) sin(θ ) − xb ] tan(θ ) y d = [14.75 cos(45) + (0.875 + 0.5 * 5) sin(45) − 1.94] tan(45) = 10.9" y = max( y c , y d ) = 12.8 xc = y 12.8 + xs = + 1.94 = 14.8 tan(θ ) tan(45) x d = l c cos(θ ) + ( s + 0.5b f ) sin(θ ) x d = 14.75 cos(45) + (0.875 + 0.5 * 5) sin(45) = 12.8 x = max( xc , x d ) = 14.8 3. Determine the corners of the brace: x1 = x − 0.5b f sin(θ ) = 14.8 − 0.5 * 5 sin(45) = 13.0 y1 = y + 0.5b f cos(θ ) = 12.8 + 0.5 * 5 cos(45) = 14.6 x 2 = x + 0.5b f sin(θ ) = 14.8 + 0.5 * 5 sin(45) = 16.5 y 2 = y − 0.5b f cos(θ ) = 12.8 − 0.5 * 5 cos(45) = 11.0 4. Verify if xb is correct for each corner (corner 1 and corner 2). 307 2 xb _ verify _ 1 = xb _ verify _ 1 = x1 b 2 b 2 − y1 2 − ⎛ 1 ⎞ 13.0 2 * 18.12 18.1 − − 7.7 * 0.375⎜⎜ − 1⎟⎟ − 1.94 = 1.85 2 2 tan( 45) 18.1 − 14.6 ⎝ tan( 45) ⎠ 2 xb _ verify _ 2 = xb _ verify _ 2 ⎞ ⎛ 1 b − Nt g ⎜⎜ − 1⎟⎟ − x s tan(θ ) ⎝ tan(θ ) ⎠ x2 b 2 b − y2 2 2 − ⎞ ⎛ 1 b − Nt g ⎜⎜ − 1⎟⎟ − x s tan(θ ) ⎝ tan(θ ) ⎠ ⎞ ⎛ 1 16.5 2 * 18.12 18.1 = − − 7.7 * 0.375⎜⎜ − 1⎟⎟ − 1.94 = 0.80 2 2 tan( 45) 18.1 − 11.0 ⎝ tan( 45) ⎠ Finally, check to see if the right gusset plate height was chosen in the first step. All three conditions shall be met. xb _ verify _ 1 ≤ xb xb _ verify _ 2 ≤ xb And xb _ verify _ 1 = xb Or xb _ verify _ 2 = xb Since both xb_verify’s are less than xb, and since xb_verify_1 is equal to xb then the correct height was chosen. (Actually, xb_verify_1 does not equal xb and the height should be 20.97, but 21 is close enough.) The thickness of the plate was verified with the buckling check shown below. The values of l1, l2 and l3 were taken from the design drawing and were equal to 3.26", 11.54" and 0.53" respectively. 308 λ= Kl ave t pπ 12 Fy 29000 0.5(5.1) 12(50) = 0.23 0.5π 29000 = Solving for the buckling capacity: φRn = (0.85)0.658 0.234 (50 )22.03(0.375) = 343.1kips 2 Therefore, a 3/8 inch plate works for buckling. A.3.2 Gusset Plate-to-Framing Element Welds The weld design in this section is based on the design calculations shown in Section 8.4. The weld is to be designed based on the tensile strength of the gusset plate: 1.5 * β * 0.6 FEXX t eff ≥ R y Fy t g The strength of the two 7/16 inch fillet welds are shown here: 1.5 * β * 0.6 FEXX t eff = 2 *1.5 * 0.65 * 0.6 * 70 * 0.707 * 7 / 16 = 25.3kips While the capacity of the gusset plate is: R y Fy t g = 1.1 * 50 * 0.375 = 20.6kips Therefore, the weld design is acceptable. It is apparent that the weld design is slightly conservative. According to the weld design equation, a 3/8 inch weld is adequate: 309 1.5 * φ * 0.6 FEXX t eff = 2 * 1.5 * 0.75 * 0.6 * 70 * 0.707 * 5 / 16 = 21.7 kips A 7/16 inch weld was used because these welds were in the process of being evaluated during this test. 310 Appendix B: Specimen Drawings B.1 General This appendix contains design drawings of the specimens tested by Johnson (2005), Herman (2007) and the specimens detailed in this thesis. Details for the framing members and their connections, which are similar for all of the tests, can be seen in Appendix A of Johnson (2005). Details of the test setup including the channel assembly, reaction block, load beam, and actuator assembly can be found in Appendix C of Johnson (2005). 311 Figure B.1 – Speciman HSS-01 312 Figure B.2 – HSS-01 Gusset Plate Detail 313 Figure B.3 – Speciman HSS-02 314 Figure B.4 – HSS-02 Gusset Plate Detail 315 Figure B.5 – Speciman HSS-03 316 Figure B.6 – HSS-03 Gusset Plate Detail 317 Figure B.7 – Speciman HSS-04 318 Figure B.8 – HSS-04 Gusset Plate Detail 319 Figure B.9 – Speciman HSS-05 320 Figure B.10 – HSS-05 Gusset Plate Detail 321 Figure B.11 – Speciman HSS-06 322 Figure B.12 – HSS-06 Gusset Plate Detail 323 Figure B.13 – Speciman HSS-07 324 Figure B.14 – HSS-07 Gusset Plate Detail 325 Figure B.5 – Speciman HSS-08 326 Figure B.16 – HSS-08 Gusset Plate Detail 327 Figure B.17 – Speciman HSS-09 328 Figure B.18 – HSS-09 Gusset Plate Detail 329 Figure B.19 – Speciman HSS-10 330 Figure B.20 – HSS-10 Gusset Plate Detail 331 Figure B.21 – Speciman HSS-11 332 Figure B.22 – HSS-11 Gusset Plate Detail 333 Figure B.23 – Speciman HSS-12 334 Figure B.24 – HSS-12 Gusset Plate Detail 335 Figure B.25 – Speciman HSS-13 336 Figure B.26 – HSS-13 Gusset Plate Detail 337 Figure B.27 – Speciman HSS-14 338 Figure B.28 – HSS-14 Gusset Plate Detail 339 Figure B.29 – Speciman HSS-15 340 Figure B.30 – HSS-15 Gusset Plate Detail 341 Figure B.31 – Speciman HSS-16 342 Figure B.32 – HSS-16 Gusset Plate Detail 343 Figure B.33 – Speciman HSS-17 344 Figure B.34 – HSS-17 Gusset Plate Detail 345 Appendix C: Finite Element Analyses C.1 General A series of finite element analyses were carried out for the gusset plates used for the specimens in the entire test program. These analyses used SAP2000 Advanced, version 9.2.0. A linear elastic analysis was carried out for each model. Neither geometric, nor material nonlinearity was included in the model. C.2 Model Description The models were very similar. An example of one of the finite element models is shown below in Figure C.1.1. The gusset plates used thick shell elements for the type of area member (two dimensional member). Each model contained the gusset plate and the HSS tube walls only. The tube walls used framing elements (one dimensional members instead of two dimensional members) defined as a rectangular section measuring 3/8 of an inch by 5 inches. Each tube wall was divided at each joint in the gusset plate mesh, and also connected to these joints in the mesh. However, to keep the models relatively simple, the top and bottom walls were not included in the model. These were left out on all of the models and therefore, the difference from leaving these walls out should have had a similar effect on all of the models. The models used pinned supports at the edge of the gusset plates. In reality, these supports would be springs, and also have rotational resistance as well. However, all of the gusset plates were modeled this way, and therefore, the differnces should be negligible. HSS-01 through HSS-12, excluding HSS-10, used straight line mesh generation, while the remaining specimens used a random mesh generation (see Figures C.5.1 to C.13.1 for the mesh details). This was done because the random mesh algorithm did not work 346 on all of the gusset plates. However, since HSS-14 had the same gusset plate geometry as HSS-05 and HSS-06, and because they used different mesh geometries (straight line generation verses random generation), it was verified that this difference was negligible (less than 1.0% difference as shown in Section C.4). Figure C.1.1 – 3D View of Example FEM Model C.3 Loads Each finite element model of the gusset plate was loaded with an axial load and a moment. The axial load applied was equal to one half kip at each tube wall at the edge of the gusset plate as shown in Figure C.3.1. The moment applied was equal to one half inch-kip at each tube wall at the edge of the gusset plate as shown in Figure C.3.2. Each of the loads was divided into x and y components. 347 Figure C.3.1 – Axial Load on Gusset Plates Figure C.3.2 – Moment on Gusset Plates 348 C.4 Results To determine the stiffnesses of the gusset plates, the deflection and rotation were computed at each point of applied load in the direction of the applied load by the computer program. The average between the two values determined at these two points was calculated and the stiffness was determined as the force over deformation. Table C.1 shows the results of the finite element analyses. Table C.1 – Gusset Plate Stiffness as Determined by FEM Analysis 349 C.5 Specimen HSS-01 (same as HSS-12) The finite element mesh for HSS-01 and HSS-12 is shown below in Figure C.5.1. Figure C.3.1 – Finite Element Mesh for HSS-01 and HSS-12 350 C.6 Specimen HSS-02 (same as HSS-03 and HSS-09) The finite element mesh for HSS-02, HSS-03, and HSS-09 is shown here in Figure C.6.1. Figure C.6.1 – Finite Element Mesh for HSS-02 and HSS-03 C.7 Specimen HSS-04 The finite element mesh for HSS-04 is shown here in Figure C.7.1 Figure C.7.1 – Finite Element Mesh for HSS-04 351 C.8 Specimen HSS-05 and HSS-06 The finite element mesh for HSS-05 and HSS-06 is shown here in Figure C.8.1 Figure C.8.1 – Finite Element Mesh for HSS-05 and HSS-06 C.9 Specimen HSS-07 (same as HSS-11) The finite element mesh for HSS-07 and HSS-11 is shown here in Figure C.9.1 Figure C.9.1 – Finite Element Mesh for HSS-07 352 C.10 Specimen HSS-08 The finite element mesh for HSS-08 is shown here in Figure C.10.1 Figure C.10.1 – Finite Element Mesh for HSS-08 C.11 Specimen HSS-10 (same as HSS-13 and HSS-17) The finite element mesh for HSS-10, HSS-13 and HSS-14 is shown here in Figure C.11.1. HSS-10 and HSS-13 used 1/2 inch thick shell elements, while HSS-17 used 3/8 inch thick shell elements. Figure C.11.1 – Finite Element Mesh for HSS-10, HSS-13, and HSS-17 353 C.12 Specimen HSS-14 The finite element mesh for HSS-14 is shown here in Figure C.12.1 Figure C.12.1 – Finite Element Mesh for HSS-14 An additonal finite element model of the gusset plate used in HSS-14 was analyzed to determine the effective stiffness of the gusset plate with weld cracks that typically occurred at the reentrant corners of the gusset plate during testing. This model did not include boundary conditions (pin supports) at the location of the cracks for a length of 6-1/4 inches at the reentrant corner at the beam, and for 4-3/4 inches at the reentrant corner at the column, as shown in Figure C.12.2. The crack lengths were chosen to be this so that the connection length would be the same as the connection length for the tapered plates that were tested in HSS-10, HSS-13 and HSS-17. 354 4-3/4” No support here 6-1/4” No support here Figure C.12.2 – FEM Mesh for HSS-14 with Weld Cracks C.13 Specimen HSS-15 The finite element mesh for HSS-15 is shown here in Figure C.13.1 Figure C.13.1 – Finite Element Mesh for HSS-15 355 Appendix D: Data Analysis Calculations D.1 General The following sections provide the equations used in the data analysis of Chapter 6. Much of this information is directly from Chapter 5 and Appendix D in Herman (2007). D.2 Brace Calculations The recorded data was used to calculate the brace force, brace out-of-plane displacement, and brace elongation. These calculations were used to compare the performance and behavior of the brace during each test. D.2.1 Brace Force Calculation The axial force in the brace was determined using two methods. The first method calculates the brace force by averaging the strains measured in the four strain gages on the brace and is shown in equation D.1: ⎛ ε + ε2 + ε3 + ε4 ⎞ PBrace = ⎜ 1 ⎟ EA 4 ⎝ ⎠ (D.1) where A is the cross-sectional area of the member and E is the modulus of elasticity which is assumed to be 29,000 ksi. In the second method, the brace force is arrived at from the shear calculated in the columns and the recorded applied load from the load cell. Equation D.2 shows how the brace force is calculated using the second method. 356 ⎛ PApplied − VColumns PBrace = ⎜⎜ sin (45°) ⎝ ⎞ ⎟⎟ ⎠ ` (D.2) The shear in the columns is calculated using equations D.3 and D.4. Column moments were calculated from the strain gage pairs. Column shears were calculated from the moments. ⎛ ε − εb M =⎜ a ⎜ d ⎝ ⎞ ⎟ EI ⎟ ⎠ − M South ⎞ ⎛M V = −⎜ North ⎟ L ⎝ ⎠ (D.3) (D.4) where d is the depth of the member, and L is the distance between the strain gages as shown in Figure D.1 Figure D.1 - Column Strain Gages (Johnson 2005) 357 D.2.2 Brace Out-of-Plane Displacement Calculation Out-of-plane displacement measurements were taken at various points along the brace but only the mid-span measurements required calculations. The out-of-plane displacement of the brace mid-span was calculated using the measured vertical and horizontal displacement of the center of the brace. The instrumentation configuration at mid-span is shown in Figure D.2. Device 54 provides the length of variable ΔD54 and Device 53 provides the length of variable ΔD53 . The remaining variables used in the calculation are illustrated in Figure D.3. Figure D.2 - Brace Out-of-Plane Measurement Schematic (Johnson 2005) 358 Figure D.3 - Brace Out-of-Plane Measurement Variables From the original configuration, la, lb, lc, θ1, and θ2 are known. From these values and the recorded measurements of Devices 53 and 54 during the test, lb’ and lc’ can be determined and, with the law of cosines, used to calculate angle θ3. The change in height is then calculated from the following relationships. l b ' = l b + ΔD53 (D.5) l c ' = l c + ΔD54 (D.6) 359 ⎛ l 2 + l '2 − l '2 b c θ 3 = cos ⎜ a ' ⎜ 2l a l b ⎝ −1 ⎞ ⎟ ⎟ ⎠ (D.7) h = l b cos(θ 3 + θ 2 ) (D.8) Δh = h − l b (D.9) ' D.2.3 Brace Elongation A correction was made to the brace elongation measurement recorded by Device 40 as shown in Figure D.4. Measurements recorded when the brace was straight were the actual changes in length. When the brace buckled out of plane, the device and Tie-off Point rotated with the brace ends as shown in Figure D.5. To correct for the rotations of the measurement points, the buckled shape of the brace was assumed to be triangular which allowed the use of the calculated out-of-plane displacement of the brace midspan. Figure D.6 illustrates the variables used in this correction. Figure D.4 - Brace Elongation Measurement (Johnson 2005) 360 Figure D.5 - Brace Elongation Measurement Schematic (Johnson 2005) Figure D.6 - Brace Elongation Measurement Variables (Johnson 2005) The value Yb represents the distance the measurement was taken above the centerline of the gusset plate. The value Xb is found using Yb, the measured out-of-plane displacement of the brace at mid-span, and the original length of the brace as illustrated in equation D.10. Brace shortening was then obtained using equation D.11. 361 ⎡ ⎢ Δh X b = Yb ⎢ ⎢ L Brace ⎢⎣ 2 ⎤ ⎥ ⎥ ⎥ ⎥⎦ Δ Brace = lo − 2 X (D.10) (D.11) where Δh is the value calculated from equation D.9, LBrace is the original measured endto-end length of the brace, and lo is the measured change in length of the brace. D.2.3 Gusset Plate Elongation Gusset plate elongation was calculated by the following. A string potentiometer was used to measure the displacement between the SW and NE beam-column intersection. From this value, the corrected brace elongation was subtracted to get the combined change in lengths from each end of the brace to the center of each beam-column intersection. This change in length was divided by the actual length to convert the value to a strain. D.2.4 Brace Yielding Brace yielding was determined from two different measurements. The first measurment was calculated using the four strain gauges on each wall of the brace. When the average strain gauge reading was greater than or equal to 0.2%, brace yielding was said to have occurred. Brace yielding was also determined from the calculated elongation. When the brace percent elongation was greater than the material yield percent elongation, yielding was said to have occurred. This value was compared to that calculated using the local strains in the brace (above). These two methods typically produced similar results. 362 D.3 Gusset Plate Rotations Gusset plate rotations were assumed to be the average of the rotations measured at the free edges of the gusset plates in line with the end of the brace. Out-of-plane displacements at these locations were measured by devices as illustrated in Figure D.7. This was measured on each free edge of the gusset plate. The average rotation was found using the following equation: θ plate ⎛ Δ out −of − plane _ 1 ⎞ ⎛ Δ out −of − plane _ 2 ⎜⎜ ⎟⎟ + ⎜⎜ db dc ⎝ ⎠ ⎝ = 2 ⎞ ⎟⎟ ⎠ (D.12) where Δ out −of − plane is the measured out-of-plane displacement at both free edges and d b and d c are the distances from the beam and column faces to the corresponding measurement device (measured perpendicular to the beam or column for rectungular and tapered gusset plates). Figure D.7 - Gusset Plate Out-of-Plane Measurement (Johnson 2005) 363 D.4 Beam and Column Forces The forces in the beams and columns were calculated using the opposing pairs of strain gauges. Shears and moments were calculated using equations D.3 and D.4. Moments were only calculated for the columns. They were not calculated for the beams since only one pair of strain gauges were applied to the beams. D.5 Shear Tab Rotations Rotations of the shear connections were found using the difference of the devices divided by the depth between them as shown in the following equation. ⎛ κa − κb ⎝ dd θ rotation = ⎜⎜ ⎞ ⎟⎟ ⎠ Figure D.8 illustrates these variables. Figure D.8 - Beam and Column Rotations (Johnson 2005) (D.13) 364 D.6 Energy Dissipation Calculation Energy dissipation was calculated using equation D.14. This equation calculates the area enclosed by the hysteresis loops, when used for a complete loop. This area is shown as the gray area in Figure D.9. ⎛ P + Pi +1 ⎞ E total = ∑ ⎜ i ⎟(Δ i +1 − Δ i ) 2 ⎝ ⎠ (D.14) Figure D.9 - Energy Dissipation Calculation The energy dissipated by the system was calculated using the applied lateral load and the corrected story drift. The energy dissipated by the brace was calculated using the brace elongation (Device 40, corrected) and the calculated brace force. The energy dissipated by the brace and the connections was calculated using the frame elongation (Device 41) and the calculated brace force. The energy dissipated by the connections was calculated by subtracting the energy dissipated by the brace from the energy dissipated by the brace and connections. The energy dissipated by the framing elements 365 was calculated by subtracting the energy dissipated by the brace and connection from the energy dissipated by the whole system. D.7 Drift Calculation The overall drift of the frame, Δ m , was measured by potentiometer 36 as located in Figure D.10. Bolt slippage, Δ s , at the channel assembly connection was measured by potentiometer 46 as located in Figure D.10 and removed from the drift measurement. Uplift, U E and U W , at the two column bases was measured by potentiometers 29 and 48 as located in Figure D.10. The rigid body rotation of the frame is illustrated in Figure D.11. Figure D.10 - Drift Correction Potentiometer Locations (Johnson 2005) 366 Figure D.11 - Rigid Body Frame Rotation (Christopulos 2005) Assuming a pivot point at the SE corner during tension excursions and at the SW corner during compression excursions, measured uplift displacements U E and U W were used to compute the resulting story drifts, Δ UE and Δ UW using equations D.15 and D.16. Δ UW = U W LOD LW (D.15) Δ UE = U E LOD LE (D.16) where LOD is the distance from the pivot point to potentiometer 36, L E is the distance measured from the pivot point to potentiometer 29, and LW is the distance measured from the pivot point to potentiometer 48. LE is equal to LW in these calculations. 367 The drifts resulting from lateral and rotational rigid body movements were removed from the recorded story drift using equation D.17 to calculate the actual story drift, Δ AD . Δ AD = Δ M + Δ UE − Δ UW − Δ S (D.1)