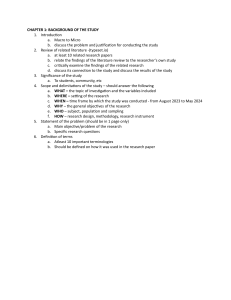

Organization of clearance for unsupervised work of the Customer's personnel Siniakov Vadim Vladimirovich Chief Engineer of Rosenergoatom Branch Office in the People's Republic of Bangladesh Requirements of Russian standards for clearance for unsupervised work At NPPs in Russia, the procedure of training and clearance for work is defined in the document “Organization of Work with Personnel at Nuclear Power Plants” (flow diagram – slide 3). In compliance with the document, the operating personnel shall pass certain stages of training before being cleared for unsupervised work: - theoretical training; - initial examinations on occupational safety and health, electrical safety, and radiation safety; - practical training (for MCR operators); - on-the-job training; - initial examinations on job descriptions, operating procedures, rules of NPP operation (JD and OP, BROS NPP); - job shadowing; - clearance for unsupervised work. Clearance for unsupervised work is formalized by an order. Customer’s personnel training flow-diagram Organizational and executive document on establishment of knowledge assessment commissions on: 1. Occupational safety and health (OSH) 2. Electrical safety (ES) 3. Radiation safety (RS) 4. Codes and Regulations in Nuclear Power Industry (CRNPI) 5. Fire safety (FS) 6. Job descriptions, operating procedures, basic regulations for operational support of NPP (JD and OP, BROS NPP) Obtaining a certificate of the Rosatom Technical Academy upon completion of the training course in the Russian Federation/passed theoretical training at TC of Rooppur NPP On-the-job training (acquiring skills by observing work of admitted personnel when: - maintaining documentation - conducting walkdowns - performing switches Job shadowing – fortnight (performing switches, maintaining documentation personally under the supervision of a person responsible for job shadowing 30 14 Total: 78* Initial examination on OSH Appointing to a position (cell in a staffing table). Possible before starting training in the Russian Federation Initial examination on RS (if personnel work in CAA) Initial examination on ES Initial examination on BROS NPP (possible at any point from passing ES examination to passing JD and OP examination, BROS NPP) Initial examination on JD and OP, BROS NPP Order on clearance for unsupervised work Total: 64* 0 T*, days 14 14 14 14 Duration of a stage *maximum period: - Examinations on OSH and ES are usually studied for not more than a fortnight and taken together on the same day. - RS examination is necessary for personnel who perform works in CAA (controlled access area) 14 Unsupervised work of Customer’s personnel under the technical supervision of Rosenergoatom personnel (According to the General Contract) Primary objectives to ensure certification and clearance for unsupervised work of the Customer's personnel № Objective Term 1 By order, establish knowledge assessment commissions on: 1. Occupational safety and health (OSH) 2. Electrical safety (ES) 3. Radiation safety (RS) 4. Codes and Regulations in Nuclear Power Industry (CRNPI) 5. Fire safety (FS) 6. Job descriptions, operating procedures, basic regulations for operational support of NPP (JD and OP, BROS NPP) 11.12.2023 2 Certify and clear operating personnel of the following subdivisions for unsupervised work: 2.1 Electrical Shop Equipment that requires operating personnel Electrical equipment of common-plant facilities and Unit-1 under voltage: – 12 sections 10kV – 30 sections 0,4kV – fire-fighting systems of electrical premises of buildings 00UGD, 03UBG, 00UBG, 01UBG, 02UBG, 00UAC Necessary personnel -Shift Supervisor - On-duty Engineer -Electrical Technician Central control room: - SAW and operation of electrical equipment of -Shift Supervisor power supply circuit -On-duty Engineer - fire-fighting systems of electrical premises of -Electrical buildings 00UAB,00UAD Technician 2.2 2.3 I&C Shop Ventilation and Air Conditioning Shop Term 11.12.2023 January-February 2024 -Shift Supervisor I&CS equipment: Reactor compartment, ESFAS, -On-duty Engineer ventilation, CWT, UULS -Electrical Fitter 11.12.2023 SAW and operation of ventilation equipment of buildings 00UFC, 00UGD 11.12.2023 -Shift Supervisor SAW and operation of ventilation equipment of -Chiller operator buildings 00, 01,02,03UBG, 00UAB, 00UAC, 00UAD, 10UJA, 10UKC, 10UMA, 11-13UBN January – June 2024 Primary objectives to ensure certification and clearance for unsupervised work of the Customer's personnel 2 2.4 Certify and clear operating personnel of the following subdivisions for unsupervised work: Support Systems Shop Equipment that requires operating personnel Necessary personnel SAW and operation of pump equipment of buildings -Shift Supervisor 03UGF, 01-02UGA -Pump Operator 11.12.2023 SAW and operation of 00UTH -Boiler Operator March 2024 SAW and operation of 00USF, 00UTF -Compressor Operator March 2024 -Wastewater Wastewater treatment facilities 00UGV, 00UGW, Treatment Facilities 00UGM, 00UGH Operator 2.5 2.6 Reactor Shop Turbine Shop Term Start of reactor equipment activation, flushing safety -Shift Supervisor systems to the open reactor -Lead Engineer for Reactor Control -Senior Operator Test of safety systems, SAW and operation of -Reactor reactor compartment auxiliary systems Compartment Operator Flushing of intermediate circuit systems (PGB), -Shift Supervisor chemically demineralized water (LCP) -Lead Engineer for Turbine Control Flushing of condensate-feedwater pipeline (LCA, -Senior Walk-down Operator LAA) -Walk-down Operator Activation of mechanisms in 10URS -Unit Pump Station Operator August 2024 January 2024 April 2024 February 2024 April 2024 May 2024 Primary objectives to ensure certification and clearance for unsupervised work of the Customer's personnel 2 2.7 2.8 2.9 2.10 Certify and clear operating personnel of the following subdivisions for unsupervised work: Equipment that requires operating personnel Necessary personnel Term -Shift Supervisor -Operator for Chemical Water SAW and operation of equipment of building Treatment 00UGD (chemical water treatment) -Chemical Water Treatment Laboratory Technician 11.12.2023 -Laboratory Flushing of condensate-feedwater pipeline in Technician for turbine building 10UMA Secondary Circuit April 2024 Process Management Department Managing the work of all operating personnel in a -Unit shift Supervisor 11.12.2023 Centralized Repair Shop -Handling and Polar crane, refueling machine, handling and Process Equipment process equipment for fuel handling and dummy FA Operator 20.01.2023 Decontamination Shop - Foreman for premises decontamination Premises of 00UFC with the temporary operation - Decontamination mode introduced Technician for Controlled Access Area Shops 11.12.2023 Chemical Shop - status of BAEC personnel in shifts at these workplaces is uncertain Shift