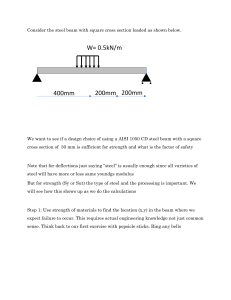

ME 372 Machine Design Suntoucher – solar powered, several hundred miles w/o fuel 0-60 < 3 sec Fastest Jet – Mach 3, Wt. 253,600 lbs, 185 ft long 2717 ft, Coming 3,281 What else really matters? 2 Thoughts on Teaching and Learning I have observed a common characteristic among the instructors who have had the greatest influence in my life. They have helped me to seek learning by faith. They refused to give me easy answers to hard questions. In fact, they did not give me any answers at all. Rather, they pointed the way and helped me take the steps to find my own answers. I certainly did not always appreciate this approach, but experience has enabled me to understand that an answer given by another person usually is not remembered for very long, if remembered at all. Religious Educator: Perspectives on the Restored Gospel. Vol. 7, Num. 3. Seek Learning by Faith, Feb 3, 2006, Jordan Institute of Religion Preach My Gospel Effective daily study must always begin with prayer. Study is an act of faith requiring the use of personal agency. Many missionaries struggle to know how to study effectively. Some rely heavily on others or on structured programs to tell them what and how to study. While learning from a good teacher is very important, it is more important for you to have meaningful learning experiences on your own. Getting good results from your study depends on having a strong desire to learn, studying with “real intent” (Moroni 10:4), “hunger[ing] and thirst[ing] after righteousness” (Matthew 5:6), and searching for answers. 3 Mechanical Design Quotes 3 Problem Solving Method 5 Homework Guidelines / Grading Policy 9 Mindset 12 Professional Engineer 15 Design Process 19 Mechanics of Materials Review 20 Mohr’s Circle 40 Stress Components 57 Combined Loading 80 FEA 121 Static Failure Theories 177 Axisymmetric Problems 197 Reliability 212 Bending of Non-Symmetric Cross-Sections 235 Bolts 256 Deflection 316 Statically indeterminate Beams 342 Buckling 348 Fatigue 358 Supplemental Problems and Projects DUE TO UPDATES, PAGE NUMBERS MAY BE APPROXIMATE, FOLLOW CONTENT 4 Problem Solving Method On the BYU mechanical engineering website there is a section labeled Class & Student Resources. In this section it talks about the BYU ME Problem Solving Model. This model consists of the 4 following steps 1. Develop – In this step we change real-world problems into textbook-like problems. The process consists of the 5 Ps. These are Principles, Possibilities, Performance, Precision, and Pictures. The 5 P’s interact with each other as shown by the figure below. Pictures. Graphical images can help clarify and solidify your thinking. Consider using photos, sketches, block diagrams, etc. Principles. As you consider fundamental physical phenomena associated with the real-world challenge you will think of relevant equations and solution techniques. Precision. Various problems and models can be created, with different accuracy and fidelity. Start with a simple, low-fidelity models, then successively refine it to arrive at a model with sufficient accuracy for the need. The refinement will often include adjusting or eliminating assumptions and improving approximations. Possibilities. You may wish to consider various solution techniques that could apply to the challenge, then choose the best option. Performance. Identify quantitative characteristics of the real-world challenge that must be predicted preferably using measurable engineering terms. What do you know about problems and solutions for these characteristics. 5 Problem Solving Method - Continued 2. Solve – This step involves using the SAFER problem-solving method. 6 Problem Solving Method - Continued 3. Explore – In this step we explore the engineering models widely enough that confident recommendations can be made for solving the real-world challenge. We use the ConVerSAnt method to do this. 7 Problem Solving Method - Continued 4. Communicate – In this last step we must communicate our ideas with the necessary information to get them implemented. This often consists of using the three Cs (clear, concise, and convincing). 8 Homework Guidelines In this course we will focus on the solve part of the Problem-Solving Method. To this end, we need to ensure that your homework follows all the steps of the SAFER method as given previously. For this course a few more specifics that must be followed for each of the steps in the SAFER method are given below. Your solution to each problem should provide enough information so that another engineer could check your work for correctness and locate any errors. This is exactly what happens in industry. The goal is that you develop habits that will help you throughout your career. Essential Procedures as Part of Following the SAFER Method 1. List the problem number and detailed problem statement. Incomplete problem statements are not acceptable. 2. Show ALL work to include the following The original form of the equations employed. I strongly recommend that you use the equations that you will memorize to solve the problems in this course. This technique will provide you with a maximum amount of practice using the basic equations. The source of each equation used must be given (an equation number from the text). If you use an equation which you have memorized or that was developed in class, reference your notes. The source of any unusual constants employed (table number, figure number, etc.) All necessary mathematical manipulations and assumptions. Supplementary sketches, free-body diagrams, comments, etc. 3. Check units each time a new equation is used in a problem. 4. Leave notes to help you during review. 9 Homework Guidelines Continued 5. Each page should have a heading that includes the following items: Course Number (ME 372) Date (e.g. 8-25-12) Your name (initials are fine after page 1) The appropriate page number (e.g. 1/5 indicating the first of five pages). 6. Place the problems in order of assignment not in the order of the problem number. 7. Box the final answer YOUR WORK MUST BE NEAT AND PROFESSIONAL TO RECEIVE FULL CREDIT 10 Homework Grading Rubric Each problem is worth 10 points. Some problems are more work than others, but each problem is still worth 10 points. Each weekly homework set is not worth the same amount of points because each set of homework will consist of a different number of problems. Homework that does not follow the SAFER method and the HW guidelines as determined by the grader will not be graded or scored. The specific grading for each problem will be as follows: 10 – Neat work, correct answers, follows SAFER and HW guidelines. 9 – Same as above but a minor math error such as a calculator error or transfer of a term mistake 8 – Same as a 10 but up to 2 very minor math errors 7 – Same as a 10 but 1 concept error 6 – Work is not neat, does not closely follow SAFER and HW guidelines but has correct answers or 6 – Same as a 10 but 2 concept errors or 1 concept error and 1 math error. 5 – Same as 10 but doesn’t follow SAFER and HW guidelines, 2 concept errors 0 – Anything less than above 11 Two Mindsets Carol S. Dweck Fixed Mindset Intelligence is God given, static and cant be increased Leads to a desire to look smart and therefore a tendency to … Growth Mindset Intelligence can be developed Leads to a desire to learn and therefore a tendency to … Challenges … avoid challenges … embrace challenges Obstacles … give up easily … persist in the face of setbacks Effort … see effort as fruitless … see effort as the path to mastery Criticism … ignore useful negative feedback … learn from criticism and don’t take it personal Success of others … feel threatened by the success of others A deterministic view of the world … find lessons and inspiration in the success of others A greater sense of free will. Changing from a Fixed Mindset to a Growth Mindset. Step1. Learn to hear your fixed mindset “voice.” As you approach a challenge, that voice might say to you “Are you sure you can do it? Maybe you don’t have the talent.” “What if you fail—you’ll be a failure” “People will laugh at you for thinking you had talent.” “If you don’t try, you can protect yourself and keep your dignity.” As you hit a setback, the voice might say, “This would have been a snap if you really had talent.” “You see, I told you it was a risk. Now you’ve gone and shown the world how limited you are.” “ It’s not too late to back out, make excuses, and try to regain your dignity.” As you face criticism, you might hear yourself say, “It’s not my fault. It was something or someone else’s fault.” You might feel yourself getting angry at the person who is giving you feedback. “Who do they think they are? I’ll put them in their place.” The other person might be giving you specific, constructive feedback, but you might be hearing them say “I’m really disappointed in you. I thought you were capable but now I see you’re not.” Step 2. Recognize that you have a choice. How you interpret challenges, setbacks, and criticism is your choice. You can interpret them in a fixed mindset as signs that your fixed talents or abilities are lacking. Or you can interpret them in a growth mindset as signs that you need to ramp up your strategies and effort, stretch yourself, and expand your abilities. It’s up to you. Step 3. Talk back to it with a growth mindset voice. As you approach a challenge: THE FIXED-MINDSET says “Are you sure you can do it? Maybe you don’t have the talent.” THE GROWTH-MINDSET answers, “I’m not sure I can do it now, but I think I can learn to with time and effort.” FIXED MINDSET: “What if you fail—you’ll be a failure” GROWTH MINDSET: “Most successful people had failures along the way.” FIXED MINDSET: “If you don’t try, you can protect yourself and keep your dignity.” GROWTH MINDSET: “If I don’t try, I automatically fail. Where’s the dignity in that?” As you hit a setback: FIXED MINDSET: “This would have been a snap if you really had talent.” GROWTH MINDSET: “That is so wrong. Basketball wasn’t easy for Michael Jordan and science wasn’t easy for Thomas Edison. They had a passion and put in tons of effort. Facing Criticism As you face criticism: FIXED MINDSET: “It’s not my fault. It was something or someone else’s fault.” GROWTH MINDSET: “If I don’t take responsibility, I can’t fix it. Let me listen—however painful it is– and learn whatever I can.” Then... Step 4. Take the growth mindset action. Over time, which voice you heed becomes pretty much your choice. Whether you • take on the challenge wholeheartedly, • learn from your setbacks and try again • hear the criticism and act on it is now in your hands. Practice hearing both voices, and practice acting on the growth mindset. See how you can make it work for you. What is a Professional Engineer? A professional engineer is a person that can legally and lawfully practice engineering for the public. • Only a licensed engineer may prepare, sign and seal, and submit engineering plans and drawings to a public authority for approval, or seal engineering work for public and private clients. • PEs shoulder the responsibility for not only their work, but also for the lives affected by that work and must hold themselves to high ethical standards of practice. • Licensure for a consulting engineer or a private practitioner is not something that is merely desirable; it is a legal requirement for those who are in responsible charge of work, be they principals or employees. • Many states require that individuals teaching engineering must also be licensed. Exemptions to state laws are under attack, and in the future, those in education, as well as industry and government, may need to be licensed to practice. Also, licensure helps educators prepare students for their future in engineering. 15 Advantages of being a licensed engineer 1. “all engineers who are in responsible charge of the practice of engineering as defined in the NCEES Model Law and Rules in a manner that potentially impacts the public health, safety, and welfare are required by all state statutes to be licensed professional engineers.” 2. Licensure for individuals who wish to pursue a career as a consulting engineer or a private practitioner is not something that is merely desirable; it is a legal requirement for those who are in responsible charge of work, be they principals or employees. 3. Licensure for engineers in government has become increasingly significant. Many federal, state, and municipal agencies require that certain governmental engineering positions, particularly those considered higher level and responsible positions, be filled only by licensed professional engineers. 4. For those pursuing careers in industry, licensure has recently taken on increased meaning with heightened public attention concerning product safety, environmental issues, and design defects. Employers have found it advantageous to identify to the courts and the public those employees who have met at least a minimum level of competence. 5. Career Development: Licensure not only enhances your stature, it shows commitment to the profession and demonstrates heightened leadership and management skills. Licensure is also a necessity for rising to increased levels of authority and responsibility. 6. 4. Money: Studies have shown that most PEs earn higher pay throughout their business careers. Having your PE allows expanded opportunities beyond a company structure - as an independent consultant for example. National Society of Professional Engineers (NSPE) 16 Steps to Becoming a Licensed Engineer Step 1. Take and pass the Fundamentals of Engineering (FE) Exam. This can be done before or after you graduate from an ABET accredited engineering program. However, you are strongly encouraged to do it before. This exam is on the fundamentals and is a very broad-based exam. You are ready to take this exam after you have had thermo, fluids, machine design, and system dynamics. The exam is computer based and administered year round. There are 110 questions with a 5 hour and 20-minute time limit with a 25-minute scheduled break. There is a reference handbook with equations, tables, etc., that is allowed. No other material is allowed. The exam costs $175 but BYU mechanical engineering may help cover some of this cost. BYU has nearly a 100% pass rate. Nationally ~ 76% pass rate. Step 2. Graduate from an ABET accredited engineering program. Step 3. Gain professional experience. All states require that candidates complete four years of “qualifying engineering experience” typically under the supervision of a professional engineer. Graduate school can be counted differently by different states but typically all the years spent in graduate school combined will only be allowed to count for 1 year of experience. Step 4. Take and pass the professional engineering exam. This exam is also a nationally offered, computer-based exam. The exam includes 80 questions and there is an 8-hour time limit. The exam costs $375. There are 3 areas 1. HVAC and Refrigeration, 2. Machine Design and Materials, 3. Thermal and fluid systems. Again, there is a reference handbook that is the only allowed supplemental material during the exam. Nationally a 30-40% pass rate. ALL states require continuing education requirements to maintain your license. 17 nspe.org 18 Design Process Identification of a Need Opportunity Development Concept Development Subsystem Engineering Problem Definition Synthesis Analysis and Optimization Evaluation Evaluation System Refinement Presentation Where will you set yourself apart from other engineers? 19 Mechanics of Materials Review 20 Young’s Modulus for Various Materials 21 Young’s Modulus vs. Density 22 Strength vs. Density 23 Material Performance Analysis The study of materials is a very broad and deep field. Your ME 250 course was just the beginning. In this section, we discuss the idea of material performance based on (stiffness to weight) and (strength to weight) basis. A material performance analysis is based on a Performance Metric which is dependent on several components of the specific design. The performance metric we will use to study stiffness-to-weight and strength-to-weight ratios is defined as 𝑃𝑃 = Functional Material Geometery � � Requirements Properties Parameters . (Eq. 2.38) Functional Requirements – This will be a constant. If you are looking for a strength/wt ratio there will likely be a force term in this part of the equation. If you are looking for a stiffness/wt ratio there will be a k (stiffness) term from the expression F = k x. Geometry Parameters – When looking for ratios with respect to weight, this parameter will usually be the length raised to some power. Material Properties – For stiffness/weight = Eβ/ρ or ρ/ Eβ For strength/weight = Sβ/ρ or ρ/ Sβ For ratios with respect to weight, the performance metric P is given by P=ALρ where A = Area, L = Length, and ρ = density 24 Example – Problem 2.25 Shigley Text. Consider a rod transmitting a tensile force. The following materials are being considered: tungsten carbide, zinc alloy, polycarbonate polycarbonate polymer, and aluminum allow. Using the Ashby charts, recommend the best material for a design situation in which failure is by exceeding the strength of the material, and it is desired to minimize the weight. Solution Performance metric P=ALρ Now we need to get the area A in terms of the strength of the material. Then we can have a strength to density (weight) ratio. This is typically done by writing the equation that models the stress in the member because it is a function of the area. For an axial rod in tension, Then 𝜎𝜎 = 𝑆𝑆 = 𝑃𝑃 = 𝐴𝐴 𝐿𝐿 𝜌𝜌 = 𝐹𝐹 𝐴𝐴 → 𝐹𝐹 𝜌𝜌 𝐿𝐿 𝜌𝜌 = 𝐹𝐹 𝐿𝐿 𝑆𝑆 𝑆𝑆 𝐴𝐴 = 𝐹𝐹 . 𝑆𝑆 → 𝛽𝛽 = 1. Now go to Figure 2.27, P 87, and draw lines parallel to the S/ρ line and identify the “best” material. From Fig 2.27, Aluminum alloys and high carbon heat-treated steels are good candidates. 25 Example – Problem 2.27 Shigley Text. Consider a cantilever beam that is loaded with a transverse force at the free end. Using the Ashby charts, recommend the best material for a situation in which failure is by excessive deflection, and it is desired to minimize the weight. Solution Performance metric P=ALρ Now we need to get the area A in terms of the stiffness. Then we can have a stiffness to density (weight) ratio. This is typically done by writing the deflection equations that models the member. For a cantilever beam, the deflection at the free end is given by 𝑃𝑃 𝐿𝐿3 𝛿𝛿 = 3 𝐸𝐸𝐸𝐸 The stiffness in terms of F = k δ or in this case P = k δ is given by 𝐹𝐹 𝑃𝑃 3 𝐸𝐸𝐸𝐸 𝑘𝑘 = = = 𝑃𝑃 𝐿𝐿3 𝛿𝛿 𝐿𝐿3 3 𝐸𝐸𝐸𝐸 Recall that the area moment of inertia I = c A2 where c is the radius of gyration. Therefore, 1/2 3 𝐸𝐸𝐸𝐸 3 𝐸𝐸 𝑐𝑐 𝐴𝐴2 𝑘𝑘 𝐿𝐿3 𝑘𝑘 = 3 = → 𝐴𝐴 = 𝐿𝐿 𝐿𝐿3 3 𝐸𝐸𝑐𝑐 2 The performance metric becomes 𝑃𝑃 = 𝐴𝐴 𝐿𝐿 𝜌𝜌 = 𝑘𝑘 𝐿𝐿3 3 𝐸𝐸𝑐𝑐 2 1/2 𝑘𝑘 𝐿𝐿 𝜌𝜌 = 3𝑐𝑐 2 1/2 𝐿𝐿5/2 𝜌𝜌 𝐸𝐸1/2 → 𝛽𝛽 = 1/2. Now go to Figure 2.24, P 84, and draw lines parallel to the E1/2/ρ line and identify “best” material. From Fig 2.27, Aluminum alloys are best from the choices given. 26 Review of Common Terminology 27 Load-Deflection Diagrams Apply an axial load to a rod – The rod will get longer and thinner as shown. F F The load deflection plots can look very different based on the ductility of the material and the rate of loading. In Fig. A below, the loading could be relatively fast and the material somewhat ductile. Note that the force does not start to drop off before failure but there is significant non-linear deformation. In Fig. B, the material could be more ductile but the loading rate is also slower because the load actually starts to decrease. When this is happening the cross section of the specimen is necking down getting ready to break. B Load (F) Load (F) A Deflection Medium ductile material Relatively fast loading Deflection Ductile material Relatively slow loading 28 Load-Deflection Diagrams Load-deflection curves give information about the specific member or structure under test. For example, if several rods were made from the same material but had different diameters, they would all have different loaddeflection curves. The slope of the linear portion of the load-deflection curve gives the stiffness of the structure in the loading direction. Load-deflection curves must be normalized to extract material properties. This is done by dividing the force by the area and the deflection by the original length. This then becomes a stress-stress diagram. 29 Stress-Strain Diagrams Stress-strain plots are normalized load-deflection plots. When a stress-strain plot is measured however, great care is taken in the specific sample geometry, load rate, temperature, humidity, etc. This is because stress-strain curves are used to characterize a material and determine specific properties. There are two commonly used types of stress-strain curves. These are engineering stress strain and true stress strain. The difference is that in true stress-strain curves the instantaneous area and length are used to compute the stress and strain respectively. Whereas in engineering stress and strain the original unloaded area and length are used to compute these terms. The true strain becomes ε = ln(e+1) where e is the engineering strain. A comparison of a true and engineering stress-strain curve is shown below. True Stress (σ) 𝐹𝐹 𝐴𝐴 Engineering ∆𝐿𝐿 Strain (ε) 𝐿𝐿 The two curves differ from the very beginning because the area and length are changing. The true stress continues to increase while the engineering stress decreases at fracture. Note also that the true strain at fracture is higher than the engineering strain at fracture. 30 Material Properties from a Stress-Strain Diagram The figure below shows a stress-strain diagram for a typical mild steel. The values of various material properties and how they are determined are also shown. Stress (σ) Sut 0.2% YS Elastic Limit Proportional Fracture Limit Strength Measure of Ductility Slope = Modulus of Elasticity 0.002 Modulus of Resilience Strain (ε) Static Toughness + Stress (σ) Load and Unloading Process - Cold Working / Strain Hardening Strain (ε) 31 Review of Common Terms Stress Force per unit area (lb/in2, kips, Pa, N/m2). Normal – σ, Shear – τ. Strength A material property, a constant independent of the loading. Ultimate Strength The maximum stress at the top of the engineering stress strain curve, where the material begins to neck down. 0.2% Yield Stress in the material when it has been strained to a value of Strength 0.002 in a tension test. Normal Strain Change in length per unit length. ε Shear Strain Change in right angle. The length of deformation divided by the perpendicular length in the plane of the applied force. γ Poisson’s Ratio ν = - lateral strain / longitudinal strain (0 < ν < 0.5) ??? Modulus of Ratio of stress over strain. Slope of the linear region of the stressElasticity strain curve. Modulus of A measure of the material stiffness in shear. Often called the Rigidity shear modulus, G. Modulus of Area under the stress strain curve up to fracture. Energy absorbed Toughness before fracture. Modulus of Area under the stress-strain curve up to the elastic limit. Energy Resilience absorbed per unit volume without permanent deformation. Ductility Measure of plastic deformation before complete failure. (% area reduction, % elongation). 𝜎𝜎 1 1 Hooke’s Law 𝜀𝜀𝑥𝑥 = 𝐸𝐸 , 𝜀𝜀𝑥𝑥 = 𝐸𝐸 𝜎𝜎𝑥𝑥 − 𝜐𝜐 𝜎𝜎𝑦𝑦 , 𝜀𝜀𝑥𝑥 = 𝐸𝐸 𝜎𝜎𝑥𝑥 − 𝜐𝜐 𝜎𝜎𝑦𝑦 − 𝜐𝜐 𝜎𝜎𝑧𝑧 32 Standard Stress Direction Definitions y σyy τyx τyz τzy σzz τzx τxy σxx τxz x z Face – The face is defined as the plane perpendicular to the axis. It can also be thought of as the axis that pierces the plane. Direction – The global coordinate direction in which the arrow is pointing For the stress terms shown on the element above, the first subscript identifies the face and the second subscript the direction. Therefore, σxx is the stress on the x-face and in the x-direction. τxy is the stress on the xface in the y-direction. If only one subscript is shown it implies a double subscript of the same term. Normal stresses (σ ) are always perpendicular to a face. They can only be tension or compression Shear stresses (τ ) are always in the plane of the face. They are not tension or compression. They rotate or shear. The stresses and strains are often put in matrix form as shown below. 𝜎𝜎𝑥𝑥𝑥𝑥 𝜏𝜏𝑥𝑥𝑥𝑥 𝜏𝜏𝑥𝑥𝑥𝑥 𝜏𝜏𝑦𝑦𝑦𝑦 𝜎𝜎𝑦𝑦𝑦𝑦 𝜏𝜏𝑦𝑦𝑦𝑦 𝜏𝜏𝑧𝑧𝑧𝑧 𝜏𝜏𝑧𝑧𝑧𝑧 𝜎𝜎𝑧𝑧𝑧𝑧 33 Scalars, Vectors, and Tensors Scalar – A physical quantity that is represented by a number and units at a particular point in space and time. Examples are pressure, temperature, speed. Vector – A bookkeeping tool to keep track of two pieces of information (magnitude and direction) for a physical quantity. Examples are position, force, and velocity. A vector typically has 3 components. A value in the x, y, and zdirections. Tensor – Stress and strain are tensors. They keep track of three pieces of information (the plane, the direction, the magnitude). Stress and Strain Notation Tensor Notation σ11 σ22 σ33 σ23 = τ23 σ31 = τ31 σ12 = τ12 ε11 ε22 ε33 γ23 = 2ε23 γ31 = 2ε31 γ12 = 2ε12 Contracted Notation σ1 σ2 σ3 σ4 σ5 σ6 Stress Coordinate Notation σxx σyy σzz σxy = τxy σxz = τxz σyz = τyz ε1 ε2 ε3 ε4 ε5 ε6 Strains εxx εyy εzz γxy = 2εxy γxz = 2εxz γyz = 2εyz Contracted Coordinate Notation σx σy σz σxy σxz σyz εx εy εz γxy γxz γyz 34 Material Constitutive Models General Anisotropic – Material properties are different in each direction. 36 nonzero ε1 S11 S12 S13 S14 S15 S16 σ1 21 independent σ ε S S S S S S constants 2 21 22 23 24 25 26 2 (Symmetric) ε 3 S31 S32 S33 S34 S35 S36 σ 3 = S S S S S S γ 23 41 42 43 44 45 46 τ 23 γ 31 S51 S52 S53 S54 S55 S56 τ 31 γ 12 S61 S62 S63 S64 S65 S66 τ12 ∴ ε= 1 S11σ 1 + S12σ 2 + S13σ 3 + S14τ 23 + S15τ 31 + S16τ12 Orthotropic – 3 orthogonal planes of material property isotropy. 12 nonzero 9 independent constants No interaction between normal and S 44 shearing. 0 S55 3 orthogonal planes 0 0 of material property symmetry Isotropic – Material properties are the same in all directions. ε 1 S11 ε S 2 21 ε 3 S31 = γ 23 0 γ 31 0 γ 12 0 ε1 ε 2 ε 3 = γ 23 γ 31 γ 12 S11 S21 S31 0 0 0 S12 S 22 S32 0 0 0 S13 S 23 S33 0 0 0 S12 S22 S32 0 0 0 0 0 0 0 0 0 0 S13 S23 S33 0 0 0 σ 1 σ 2 σ 3 0 τ 23 0 τ 31 S 66 τ 12 0 0 0 0 0 0 σ1 σ 0 0 0 2 σ 3 0 0 0 2( S11 − S22 ) 0 0 τ 23 τ 0 2( S11 − S22 ) 0 31 0 0 2( S11 − S22 ) τ12 12 nonzero and 2 independents E & ν 35 Plane Stress When the elastic body is “very thin” and there are no loads applied (parallel) to the thickness. No loads in the z-direction but loads in x and y are fine. 𝜎𝜎𝑧𝑧 = 𝜏𝜏𝑧𝑧𝑧𝑧 = 𝜏𝜏𝑧𝑧𝑧𝑧 = 0. 𝜀𝜀𝑧𝑧 ≠ 0 = 𝛾𝛾𝑧𝑧𝑧𝑧 = Examples 𝛾𝛾𝑧𝑧𝑧𝑧 = 1 −𝜐𝜐 𝜎𝜎𝑥𝑥 + 𝜎𝜎𝑦𝑦 . 𝐸𝐸 𝜏𝜏𝑧𝑧𝑧𝑧 = 0. 𝐺𝐺 𝜏𝜏𝑧𝑧𝑧𝑧 = 0. 𝐺𝐺 Axial loaded bars A wrench Open thin-walled cylinders Thin skins on an airfoil For a closed cylinder – plane stress does not exist due to the longitudinal stress. 36 Plane Strain When members are not free to expand in the direction perpendicular to the plane of the applied loads. Load F is applied in the z-direction but the member is prevented from expanding or contracting in the x-y plane. y ε z = γ xz = γ yz = 0 x F z Examples A long dam A fixed ended cylinder The cylinder can expand in x and y due to an internal pressure but the cylinder can’t expand in the z-direction. 37 Constitutive Equations for Plane Stress and Plane Strain Plane Stress – Reduction of a 6 x 6 matrix down to a 3 x 3. 𝜎𝜎𝑥𝑥 𝜎𝜎𝑦𝑦 𝜎𝜎𝑧𝑧 𝜎𝜎𝑥𝑥𝑥𝑥 𝜎𝜎𝑧𝑧𝑧𝑧 𝜎𝜎𝑧𝑧𝑧𝑧 𝐶𝐶11 𝐶𝐶12 𝐶𝐶13 𝐶𝐶14 𝐶𝐶21 𝐶𝐶22 𝐶𝐶23 𝐶𝐶24 𝐶𝐶 𝐶𝐶 𝐶𝐶 𝐶𝐶34 = 31 32 23 𝐶𝐶41 𝐶𝐶42 𝐶𝐶43 𝐶𝐶44 𝐶𝐶51 𝐶𝐶52 𝐶𝐶53 𝐶𝐶54 𝐶𝐶61 𝐶𝐶62 𝐶𝐶63 𝐶𝐶64 𝐶𝐶15 𝐶𝐶25 𝐶𝐶35 𝐶𝐶45 𝐶𝐶55 𝐶𝐶65 𝜎𝜎𝑥𝑥 𝐶𝐶11 𝜎𝜎𝑦𝑦 = 𝐶𝐶21 𝜎𝜎𝑥𝑥𝑥𝑥 𝐶𝐶41 𝐶𝐶16 𝐶𝐶26 𝐶𝐶36 𝐶𝐶46 𝐶𝐶56 𝐶𝐶66 𝐶𝐶12 𝐶𝐶22 𝐶𝐶42 𝜀𝜀𝑥𝑥 𝜀𝜀𝑦𝑦 𝜀𝜀𝑧𝑧 𝜀𝜀𝑥𝑥𝑥𝑥 𝜀𝜀𝑧𝑧𝑧𝑧 𝜀𝜀𝑧𝑧𝑧𝑧 𝐶𝐶14 𝐶𝐶24 𝐶𝐶44 𝜀𝜀𝑥𝑥 𝜀𝜀𝑦𝑦 𝜀𝜀𝑥𝑥𝑥𝑥 Plane Strain - – Reduction of a 6 x 6 matrix down to a 3 x 3. 𝜀𝜀𝑥𝑥 𝜀𝜀𝑦𝑦 𝜀𝜀𝑧𝑧 𝜀𝜀𝑥𝑥𝑥𝑥 𝜀𝜀𝑧𝑧𝑧𝑧 𝜀𝜀𝑧𝑧𝑧𝑧 𝑆𝑆11 𝑆𝑆12 𝑆𝑆 𝑆𝑆14 𝑆𝑆21 𝑆𝑆22 𝑆𝑆23 𝑆𝑆24 𝑆𝑆 𝑆𝑆 𝑆𝑆23 𝑆𝑆34 = 31 32 𝑆𝑆 𝑆𝑆41 𝑆𝑆42 43 𝑆𝑆44 𝑆𝑆51 𝑆𝑆52 𝑆𝑆53 𝑆𝑆54 𝑆𝑆61 𝑆𝑆62 𝑆𝑆63 𝑆𝑆64 𝑆𝑆15 𝑆𝑆25 𝑆𝑆35 𝑆𝑆45 𝑆𝑆55 𝑆𝑆65 𝜀𝜀𝑥𝑥 𝑆𝑆11 𝜀𝜀𝑦𝑦 = 𝑆𝑆21 𝜀𝜀𝑥𝑥𝑥𝑥 𝑆𝑆41 𝑆𝑆16 𝑆𝑆26 𝑆𝑆36 𝑆𝑆46 𝑆𝑆56 𝑆𝑆66 𝑆𝑆12 𝑆𝑆22 𝑆𝑆42 𝜎𝜎𝑥𝑥 𝜎𝜎𝑦𝑦 𝜎𝜎𝑧𝑧 𝜎𝜎𝑥𝑥𝑥𝑥 𝜎𝜎𝑧𝑧𝑧𝑧 𝜎𝜎𝑧𝑧𝑧𝑧 𝑆𝑆14 𝑆𝑆24 𝑆𝑆44 𝜎𝜎𝑥𝑥 𝜎𝜎𝑦𝑦 𝜎𝜎𝑥𝑥𝑥𝑥 38 Stress Representation Shattered Ankle 3D Stress State y σyy τyx τyz τzy σzz τzx τxy σxx τxz x z x-Face, There would be a face similar to this for y and z. y How can we represent the stresses at any angle on the face? Mohr Circle. y σyy z σzz τzy τyz z 39 Christian Otto Mohr Christian Otto Mohr, German Civil Engineer Born October 8, 1835, Died October 2, 1918 Karl Culman – 1852 published graphical ideas of determining stresses. Mohr Circle Paper – 1874. 40 Historical note: Karl Culmann (1821–1881) and Christian Otto Mohr (1835–1918) Although the stress circle is invariably attributed to Mohr, it was in fact Culmann who first conceived this graphical means of representing stress. Mohr’s contribution lay in making an extended study of its usage for both two-dimensional and three dimensional stresses, and in developing a strength criterion based on the stress circle at a time when most engineers accepted Saint-Venant’s maximum strain theory as a valid failure criterion. Anyone wishing to pursue the relative contributions of Culmann and Mohr is recommended to read the excellent accounts in History of Strength of Materials by Timoshenko (McGraw-Hill, 1953). Born in Bergzabern, Rheinpfalz, in 1821, Karl Culmann graduated from the Karlsruhe Polytechnikum in 1841 and immediately started work at Hof on the Bavarian railroads. In 1849 the Railways Commission sent him to England and the United States for a period of two years to study bridge construction in those countries. The excellent engineering education which he had received enabled him to view, from a theoretical standpoint, the work of his English and American counterparts, whose expertise was based largely on experience. The outcome was a report by Culmann published in 1852 which strongly influenced the theory of structures and bridge engineering in Germany. His appointment as Professor of Theory of Structures at the Zurich Polytechnikum in 1855 gave him the opportunity to develop and teach his ideas on the use of graphical methods of analysis for engineering structures, culminating in his book Die Graphische Statik, published by Verlag von Meyer and Zeller in 1866. The many areas of graphical statics dealt with in the book include the application of the polygon of forces and the funicular polygon, construction of the bending moment diagram, the graphical solution for continuous beams (later simplified by Mohr) and the use of the method of Sections for analyzing trusses. He concluded this book with Sections on calculating the pressures on retaining walls and tunnels. Culmann introduced his stress circle in considering longitudinal and vertical stresses in horizontal beams during bending. Isolating a small element of the beam and using rectangular coordinates, he drew a circle with its center on the (horizontal) zero shear stress axis, passing through the two stress points represented by the normal and conjugate shear stresses on the vertical and horizontal faces of the element. He took the normal stress on the horizontal faces to be zero. In this construction Culmann established a point on the circle, now known as the pole point, and showed that the stresses on a plane at any specified inclination could be found by a line through this point drawn parallel to the plane. Such a line met the circle again at the required stress point. Extensive use is made of the pole point in the present text. Culmann went on to plot trajectories of principal stresses for a beam, obtained directly from the stress circles. Christian Otto Mohr was born in 1835 in Wesselburen, on the inhospitable North Sea coast of Schleswig-Holstein. After graduating from the Hannover Polytechnical Institute he first worked, like Culmann, as a railway engineer before taking up, at the age of 32, the post of Professor of 41 Engineering Mechanics at the Stuttgart Polytechnikum. Christian Otto Mohr (1835–1918) - Continued In 1873 he moved to the Dresden Polytechnikum, where he continued to pursue his interests in both strength of materials and the theory of structures. Pioneering contributions which he made to the theory of structures included the use of influence lines to calculate the deflections of continuous beams, a graphical solution to the three-moments equations, and the concept of virtual work to calculate displacements at truss joints. His work on the stress circle included both two-dimensional and three-dimensional applications and, in addition, he formulated the trigonometrical expressions for an elastic material, relating stresses and strains, as well as the expression relating direct and shear strain moduli. As with stress, he showed that shear strains and direct strains could be represented graphically by circles in a rectangular coordinate system. Believing, as Coulomb had done a hundred years before, that shear stresses caused failure in engineering materials, Mohr proposed a failure criterion based on envelopes tangential to stress circles at fracture in tension and compression. He then assumed that any stress conditions represented by a circle touching these Figure 3 A figure from Mohr’s 1882 paper showing his use of a single circle to illustrate both stress and strain circles for uniaxial tension. Historical note xiii envelopes would initiate failure. This failure criterion was found to give better agreement with experiment than the maximum strain theory of Saint-Venant, which was widely accepted at that time. Mohr first published his work on stress and strain circles in 1882 in Civilingenieur and it was repeated in Abhandlungen aus dem Gebiete der Technischen Mechanik (2nd edn), a collection of his works published by Wilhelm Ernst & Sohn, Berlin, 1914. Mohr Circles, Stress Paths and Geotechnics – R. H. G. Parry Spon Press Taylor and Francis Group – London and New York. 42 Email From Alex. I took a class from you a few years ago, and I remember you mentioned that you couldn't find the name of the wife of Otto Mohr. I was in Dresden a few days ago, and I found this. I hope it helps. Alex 43 Two Approaches to Mohr’s Circle Representation of Stress Common 2φ Approach 1. 2. 3. 4. 5. 6. 7. Plot the stress points A = (σx, τxy) and B = (σy, τyx). Draw a straight line between points A and B. Draw the circle. Compute the center and radius of the circle. Compute principal and other stresses. The angle on the stress element is half the angle on Mohr’s circle. The stress element is not drawn on the circle. Example Compute the principal stresses and show the angles of these stresses on the stress element. 50 80 1. 2. 3. 4. 5. 6. 7. 8. 9. A = (80, 50) 38.7° Plot the points A = (80, 50) and B = (0, -50) Draw the diameter line connecting A and B. Draw the circle. C = 40, AC = ((80-40)2 + 502)1/2 = 64 σ1 = 40 + 64 = 104 σ2 = 40 - 64 = -24 2φp = atan (50/40) = 51.3° 2 X Angle to max shear 90 – 51.3 = 38.7 Rotated elements must be drawn off the circle. C D B = (0, -50) 40 24 64 25.7° 104 2φp 40 19.3° 44 Mohr Circle – Origin of Planes Approach Origin of Planes (OP) Approach 1. 2. 3. 4. 5. 6. 7. 8. Positive coordinate definitions. Label vertical and horizontal points. Plot the stress points Vertical pt = V = (σx, τxy) and Horizontal pt = H = (σy, τyx). Draw a vertical line through V and a horizontal line through H. Label the OP as the point where the two lines intersect. Draw the circle through the OP, V, and H. Determine the center and radius of the circle. The angle from the OP is the angle on the stress element. The stress element is drawn on the OP. Example For the stress element shown, use Mohr’s circle to determine the principal stress and directions and show these on a stress element. Draw another stress element to show τmax, find the corresponding normal stress and label the drawing. 80 50 1. Positive Coordinate Definition + + 2. Label Pts - Vert. pt. = (σx , τxy ) = (80, 50) Hor. pt. = (σy , -τxy ) = (0, -50) 45 Mohr Circle – Origin of Planes Approach 3. Plot Pts., Vert. and Hor. lines, Origin of Planes, Centerline, Draw the Circle. τcw V A = (80, 50) 104 -24 β α B = (0, -50) H OP τccw 4. 5. 6. 7. Center = (80-0)/2, Radius = ((80-40)2 + 502)1/2 = 64 σ1 = 40 + 64 = 104, σ2 = 40 - 64 = -24 Angle to principal stresses α = atan ((104-80)/50) = 25.6° Angle to max shear β = atan ((80-40)/(50+64))=19.3° 40 24 64 40 19.3° 25.6° 104 46 Nice Features of the Origin of Planes Approach The nicest feature about the Origin of Planes approach is that it orients your element directly on Mohr’s circle. There are no double angles and clockwise, counterclockwise rotation rules. Draw the stress element rotated to the principal stresses. τcw V 104 24 -24 104 β α OP H τccw α 24 104 47 Nice Features of the Origin of Planes Approach Draw the stress element rotated to the maximum shear stress position. 64 τcw 40 V -24 104 40 β α OP H τccw 64 40 β 40 64 40 48 Mohr Circle – Origin of Planes Approach Example 2. Draw Mohr’s circle for the following stress element. 15 A 5 4 1. Coordinate Def + + 2. Label Pts Vert pt = V = (σx , τxy ) = (5, -4), values from the vertical face of the stress element Hor pt = H = (σy , -τyx ) = (15, 4), values from the horizontal face of the stress element 3. Plot Points, Vert. and Hor. Lines, OP, Center, and Draw Circle τ OP H (15, 4) σ V (5, -4) The origin of planes represents the orientation of the stress element. 49 Mohr’s Circle Example 2 Continued 4. Compute the center of the circle Center = x of vertical point + x of horizontal point 15 + 5 = = 10 2 2 Compute the radius of the circle Radius = x of vertical pt − x center 2 + y vertical pt 2 = 15 − 10 2 + 42 = 6.4 5. Compute the principal stresses 𝜎𝜎2 = 10 − 6.4 = 3.6 σ1 = 10 + 6.4 = 16.4 6. Angles to the principal stresses θ1 = tan−1 τ opposite σ1 − σx vert pt 16.4 − 5 = tan−1 = tan−1 = 70.6° adjacent σy vert pt 4 O P H 16.4 (15, 4) θ1 σ V (5, -4) 3.6 70.6° 50 Mohr’s Circle – Practical Example Given a shaft subjected to a combined loading of tensile load P and torque T. The ultimate strength determined by a tensile test = σu. Load P remains constant at a value that produces a tensile stress of 0.51 σu on any crosssection. The torque is increased until failure occurs. Assuming that fracture occurs when σ1 = σu determine the magnitude of the torsional shearing stress produced by the torque T at fracture and determine the orientation of the fracture surface. T P σx τ xy 1. Coordinate def + + 2. Label Pts Vert. pt. = (σx , τxy ) = (0.51σu, τxy) Hor. pt. = (σy , -τxy ) = (0, -τxy) 3. Draw circle … τ (0.51σu, τxy) σ (0, -τxy) OP 51 Mohr’s Circle – Practical Example - Continued 4. Center and radius Center = σx +0 2 = 2 σx Radius 2 σ 2 = σ x − x + τ xy 2 5. Compute principals σ1 2 σx σ 2 = + σ x − x + τ xy 2 2 Failure at σ1 = σu 2 σx σ ∴ σ1 = σ u = + x + τ xy 2 2 2 ⇒ Solve for τ xy τ xy = τ xy τ xy 2 σ x σ x − − σ u 2 2 2 2 .51σ u .51σ u =σ u − − 2 2 = .7σ u 2 σ1 − σ x −1 σ u − .51σ u = = tan 35° .7 τ σ xy u φ= tan −1 35° 52 Mohr’s Circle – Biaxial Stress State The graphical approach of Mohr’s circle is only valid for plane stress conditions. If an element is in a full 3D stress state, Mohr’s circle cannot be applied to each face individually to come up with the right answer. A full 3D analysis requires the full stress tensor as explained on the following page. A biaxial stress state is when one of the 3 principal stresses is zero. When this occurs, you can draw the three Mohr circles for the full 3D stress state knowing the two non-zero principal stresses. Examples of biaxial stress states include beams loaded in bending, axial, and torsion, plane stress problems such as thin flat plates, open cylinders, and some others. The Mohr-circle plots for the 3 cases of biaxial stress are τ τ τ σ σ σ When given a biaxial stress state, it is important to draw the zero stress or you may miss the maximum stress as can be seen in the plots above. 53 Mohr’s Circle – 3D Stress State There is not a graphical approach for 3D stress elements. You need to solve for the principal stresses using the stress tensor. You can NOT just do a Mohr circle for each face. The principal stresses and directions can be solved by solving the eigenvalue problem shown below. 𝜎𝜎𝑥𝑥 − 𝜎𝜎 𝜏𝜏𝑦𝑦𝑥𝑥 𝜏𝜏𝑧𝑧𝑥𝑥 𝜏𝜏𝑥𝑥𝑦𝑦 𝜎𝜎𝑦𝑦 − 𝜎𝜎 𝜏𝜏𝑧𝑧𝑧𝑧 𝜏𝜏𝑥𝑥𝑧𝑧 𝜏𝜏𝑦𝑦𝑦𝑦 𝜎𝜎𝑧𝑧 − 𝜎𝜎 𝑛𝑛𝑥𝑥 𝑛𝑛𝑦𝑦 = 0 𝑛𝑛𝑧𝑧 The principal stresses are the roots of the polynomial obtained by setting the determinate equal to zero. The n’s are the direction cosines to the respective principal stresses. A really quick way to determine the principal stresses for any stress state is to use the “eig” command in Matlab. Example sig = [2 4 0; 4 4 0; 0 0 6]; [V,D] = eig(sig) Two lines of Matlab code V= -0.7882 0 0.6154 0.6154 0 0.7882 0 1.0000 0 Direction cosines for the principal stresses D= -1.1231 0 0 0 6.0000 0 0 0 7.1231 Principal Stresses 54 Shear Moment Diagrams - Review Draw the shear moment diagram for the following beam 500 lbs 200 ft lbs 3 ft 311 lbs 3 ft 3 ft 189 lbs 311 lbs -189 lbs 933 lbs Google SkyCiv for a free software package for drawing shear moment diagrams. Free version has a limit of three loads. 55 Shear Moment Diagrams - Review Draw the shear moment diagram for the following beam. 500 lbs 100 lbs/ft 4.5 ft 3 ft 649 lbs 200 ft lbs 3 ft 3 ft 301 lbs 649 lbs -151 lbs -301 lbs 1497 ft lbs 56 Stress Components Shear due to Bending Bending or Flexural Torsion Axial Stress Anterior cruciate Ligament 57 Main Components of Stress – Understand this page Stress Type Equation Axial Normal 𝜎𝜎 = 𝐹𝐹 𝐴𝐴 Bending Normal 𝜎𝜎 = 𝑀𝑀𝑀𝑀 𝐼𝐼 Direct Shear Shear 𝜏𝜏 = 𝐹𝐹 𝐴𝐴 Transverse Shear Shear due to Bending Shear 𝜏𝜏 = 𝑉𝑉𝑉𝑉 𝐼𝐼𝐼𝐼 Torsion Shear 𝜏𝜏 = 𝑇𝑇𝑇𝑇 𝐽𝐽 Profile NA h NA 58 Stress Component Definitions Axially Loaded Members σ = P/A, δ = PL/AE, ε = δ /L σ = axial stress away from the ends of the member δ = axial deflection P = applied axial load L = length of the member A = cross sectional area E = modulus of elasticity ε = axial strain Restrictions 1. The member must be straight and have a constant cross section. 2. The material must be homogeneous (not necessarily isotropic). 3. Force must be axial along the centroid so no bending or twisting occurs. 4. The member can only be loaded in the elastic range. 5. The point of interest is remote from the ends or any geometric discontinuity. Finite element modeling showing point load and end effects. Stress Profile 59 Flexural Stress Formula – Bending Stress Equation Bending Stress Bending stress is often referred to as flexural stress. σ = M y/I. σ = bending or flexural stress M = bending moment at the point of interest y = distance from the neutral axis to the point of interest. I = area moment of inertia of the cross section Restrictions 1. The material is linearly elastic, homogeneous, and isotropic across the cross section but not necessarily along the length. 2. The beam is loaded in a condition of pure bending (No other loads). Even though the bending stress equation was developed on this assumption, this equation is commonly used in practice even when point loads and distributed loads exist because the error is small. 3. Young’s Modulus is the same in tension and compression. 4. Planes rotate with respect to each other, but they remain plane and perpendicular to the neutral axis. 5. The beam is initially straight and bending causes the beam to bend in a circular arc. 6. The radius of curvature is large compared to the cross-section dimensions 7. Each layer of the beam is free to expand or contract independent of the layer above it. Even with all these assumptions, the flexural formula most often provides sufficiently accurate results and it is very easy to apply. Stress Profile 60 Development of the Flexural Formula (Bending Stress Formula) Assume a pure moment is applied to the ends of a free-free beam. The element ABCD will deform as shown by A’B’C’D’. AB and CD are originally parallel. AB rotates to A’B’ with the applied moment. CD rotates to C’D’ in similar manner. C A NA M D M B M C’ C’ A’A’ D’ M NA B’ The line A’C’ has been compressed and the line B’D’ has been stretched. The neutral axis (NA) does not change length. Lines CD and AB are perpendicular to the NA and so are lines C’D’ and A’B’. It is assumed that planes before bending remain plane after bending. This means the straight line AB must remain a straight line when it rotates to A’B’. An enlarged view of the deformed element is shown below. We now look at computing the strain in the element at a distance y from the NA. A line at a distance y from the NA is shown by the solid black line with arrow heads. 61 Development of the Flexural Formula - Continued C NA ds D A M dφ ρ C B C’ A A’ M y NA ds D’ D B B’ From the arc length equation 𝑆𝑆 = 𝜃𝜃𝜃𝜃, which is good for any angle and does not enforce small angles we can write the length ds as 𝑑𝑑𝑑𝑑 = 𝑑𝑑𝜙𝜙 𝜌𝜌 → The normal strain can be expressed as 𝜀𝜀𝐴𝐴𝐴𝐴 = 1 𝑑𝑑𝑑𝑑 = . 𝜌𝜌 𝑑𝑑𝑑𝑑 𝛿𝛿 𝐿𝐿𝑓𝑓 − 𝐿𝐿𝑖𝑖 𝜌𝜌 − 𝑦𝑦 𝑑𝑑𝑑𝑑 − 𝜌𝜌𝜌𝜌𝜌𝜌 𝑦𝑦 = = − . = 𝐿𝐿 𝜌𝜌𝜌𝜌𝜌𝜌 𝜌𝜌 𝐿𝐿𝑖𝑖 (A) This expression implies that the strain is directly proportional to the distance from the NA. 62 Development of the Flexural Formula Continued Now using Hooke’s law for 1D isotropic materials 𝜎𝜎 = 𝐸𝐸𝐸𝐸, and the above definition of strain. We can express the stress and the radius of curvature as 𝐸𝐸𝐸𝐸 𝐸𝐸𝐸𝐸 → 𝜌𝜌 = − 𝜎𝜎 = − (B) 𝜌𝜌 𝜎𝜎 Now we enforce equilibrium by summing the forces and moments. These expressions are written as 𝐸𝐸 � 𝐹𝐹𝑎𝑎𝑎𝑎𝑎𝑎𝑎𝑎𝑎𝑎 = � 𝜎𝜎 𝑑𝑑𝑑𝑑 = − � 𝑦𝑦 𝑑𝑑𝑑𝑑 = 0. 𝜌𝜌 � 𝑀𝑀 = 𝑀𝑀 − � 𝜎𝜎 𝑦𝑦 𝑑𝑑𝑑𝑑 = 0 or 𝑀𝑀 = � 𝜎𝜎 𝑦𝑦 𝑑𝑑𝑑𝑑 (C) Now substitute the first of Eqs. B into Eq. C to get 𝑀𝑀 = � 𝐸𝐸𝐸𝐸 𝐸𝐸 𝐸𝐸 𝑦𝑦𝑦𝑦𝑦𝑦 = ∫ 𝑦𝑦 2 𝑑𝑑𝑑𝑑 = 𝐼𝐼. 𝜌𝜌 𝜌𝜌 𝜌𝜌 where 𝐼𝐼 = ∫ 𝑦𝑦 2 𝑑𝑑𝑑𝑑 which is the definition of the second area moment of inertia. Now using the second of Eqs. B and dropping the minus sign gives 𝑀𝑀 = 𝐸𝐸𝐸𝐸 𝜌𝜌 → 𝑀𝑀 = 𝐸𝐸𝐸𝐸 𝐸𝐸𝐸𝐸 𝜎𝜎 → 𝜎𝜎 = 𝑀𝑀𝑀𝑀 𝐼𝐼 This expression for σ is the flexural formula also called the bending stress equation. 63 Area Moment of Inertia for a Rectangular Cross Section The area moment of inertia is computed by the equation 𝐼𝐼 = � 𝑦𝑦 2 𝑑𝑑𝑑𝑑 . For a rectangular cross section, the moment of inertia about the x-axis is given by dy y ℎ 2 𝐼𝐼𝑥𝑥 = � 𝑦𝑦 2 𝑑𝑑𝑑𝑑 = 2 � 𝑦𝑦 2 𝑏𝑏 𝑑𝑑𝑑𝑑 = 2 x 0 ℎ3 𝑏𝑏 𝑏𝑏 ℎ3 = 𝐼𝐼𝑥𝑥 = 2 8 3 12 b 3 𝑦𝑦 𝑏𝑏 3 h/2 0 The figures below show how this expression changes based on the loading. It is important to note that the right I must be used when computing the bending stress. F y h y x F h x b b 𝜎𝜎𝑥𝑥 = 𝑀𝑀 𝑐𝑐 𝐼𝐼𝑧𝑧 𝑏𝑏 ℎ3 𝐼𝐼𝑧𝑧 = 12 𝜎𝜎𝑥𝑥 = 𝐼𝐼𝑦𝑦 = 𝑀𝑀 𝑐𝑐 𝐼𝐼𝑦𝑦 ℎ 𝑏𝑏 3 12 64 Area Moment of Inertia for a Circular Cross Section dθ dr y = r sin θ θ R ∫ y dA = ∫ ( r sin θ ) rdrdθ = ∫∫ r sin θdrdθ 2 I = I I I = 2 3 πR 4 4 2 or πD 4 64 πD 4 πD 4 πD 4 ∴J = + = 64 64 32 65 Direct Shear Direct shear loading involves two equal and opposite loads so nearly collinear that the material between them experiences shear and not bending. τ = V/A τ = direct shear stress, V = applied shear load, A = cross sectional area Restrictions 1. The member must be straight and have a constant cross section (prismatic). 2. The material must be homogeneous (not necessarily isotropic). 3. The member can only be loaded in the elastic range. Examples For direct shear, the forces must be nearly collinear. If there begins to be a separation distance between the forces as in the clevis pin shown, bending can become important and transverse shear instead of direct shear becomes critical. Direct shear at the wall Not DIRECT shear Transverse shear at the wall ? 66 Stacked vs. Solid Beams A beam with a cross-section of 5 x 10 in2 has the same I as a beam that is made from 5 stacked but connected 2 inch beams. 10 x 𝑏𝑏 ℎ3 5 10 = 𝐼𝐼𝑥𝑥 = 12 12 3 = 416.7 5 5 4 3 2 1 10 x 5 𝐼𝐼1 + 𝐼𝐼5 = 2 𝐼𝐼2 + 𝐼𝐼3 = 2 5 2 𝐼𝐼3 = 12 3 5 2 3 +5 2 4 12 5 2 3 +5 2 2 12 = 3.3 2 2 = 326.6 = 86.6 𝐼𝐼𝑇𝑇 = 𝐼𝐼1 + 𝐼𝐼2 + 𝐼𝐼3 + 𝐼𝐼4 + 𝐼𝐼5 = 416.73 So when the stacked beams are nailed or glued together, they have the same I and would have the same deflection? When the beams are not glued or stacked, be careful with the parallel axis theorem. There is no parallel axis theorem component because the beams bend about their own axes. 67 Stacked vs. Solid Beams Continued Compute the deflection at the mid-span of a simply supported beam, 50 inches long with a 500 lb load in the middle of the beam. Let the cross section of the beam be 5 x 10 and compare this result to a series of 5, 2 x 10 inch beams stacked but not joined. 500 lbs I = 416.67 10 5 4 3 2 1 Solid beam 𝑃𝑃𝐿𝐿3 500 50 3 = = 0.000104 inches 𝛿𝛿 = 48 𝐸𝐸𝐸𝐸 48 30𝑒𝑒𝑒 416.67 Stacked beam % Difference 10 5 5 𝑃𝑃𝐿𝐿3 𝛿𝛿 = 48 𝐸𝐸𝐸𝐸 I = 5(3.3) = 16.67 𝑃𝑃𝐿𝐿3 500 50 3 = = 0.0026 inches 𝛿𝛿 = 48 𝐸𝐸𝐸𝐸 48 30𝑒𝑒𝑒 16.67 0.0026 − 0.000104 = 96.14 % 0.0026 68 Transverse Shear or Shear Due to Bending In the figure below, a transverse force is applied to a simply-supported beam. The shear moment diagrams for this beam are shown. A differential element of length dx is shown in red. The shear force V is constant through the length of the element but the moment changes from one side of the element to the other as shown. Now we draw a FBD for the dx element. The normal stresses on the two sides of the element do not have the same magnitude because the moment is not the same. The stresses on the left are smaller than those on the right as given by the moment diagram. In order to maintain equilibrium, a shear stress on the bottom face of the element develops as shown. This shear stress is called the transverse shear stress or the shear stress due to bending. F dx y x σ= Mc I σ= (M + dM)c I dx c V M + dM M y Neutral Axis τ y1 69 Transverse Shear - Continued The expression for the transverse shear stress is developed by summing forces on the element. ∑𝐹𝐹𝑥𝑥 = 0, � 𝑀𝑀 + 𝑑𝑑𝑑𝑑 𝑀𝑀 𝑦𝑦𝑦𝑦𝑦𝑦 − � 𝑦𝑦𝑦𝑦𝑦𝑦 − 𝜏𝜏 𝑡𝑡 𝑑𝑑𝑑𝑑 = 0. 𝐼𝐼 𝐼𝐼 (A) The area dA over which the transverse shear stress acts is the area of the bottom face of the element. This area is computed by t dx where t is the width of the beam into the page and dx is the length as shown in the diagram. Equation A above then reduces to 𝑐𝑐 � 𝑦𝑦1 𝑑𝑑𝑑𝑑 𝑦𝑦 𝑑𝑑𝑑𝑑 = 𝜏𝜏 𝑡𝑡 𝑑𝑑𝑑𝑑. 𝐼𝐼 Solving this expression for τ gives 𝑐𝑐 𝑐𝑐 𝑦𝑦1 𝑦𝑦1 𝑑𝑑𝑑𝑑 𝑉𝑉 𝑉𝑉𝑉𝑉 � 𝑦𝑦 𝑑𝑑𝑑𝑑 = � 𝑦𝑦 𝑑𝑑𝑑𝑑 = 𝜏𝜏 = 𝐼𝐼 𝑡𝑡 𝑑𝑑𝑑𝑑 𝐼𝐼 𝑡𝑡 𝐼𝐼𝐼𝐼 In the transverse shear stress equation, 𝑄𝑄 = ∫ 𝑦𝑦 𝑑𝑑𝑑𝑑 is called the first moment of area. V and I are constants through the cross section but Q changes depending on the point of interest in the cross section. Q will always be a maximum at the neutral axis. t is the thickness of the beam at the point of interest, so for rectangular cross sections, it would be constant but for Iand T-beams it would depend on the point of interest. 70 First Moment of Area - Q 𝑄𝑄 = � 𝑦𝑦 𝑑𝑑𝑑𝑑 Q = First moment of the area Q = (Area from pt of interest to outer fibers) * (Distance from centroid of area to the NA) N . A. 6 Q = [ (2)(4) ] 6 Pt. of interest 4 2 area Qmax and τmax for a rectangular cross section N . A. 𝑐𝑐 𝑏𝑏 𝑦𝑦 2 𝑄𝑄 = � 𝑦𝑦 𝑑𝑑𝑑𝑑 = � 𝑦𝑦 𝑏𝑏 𝑑𝑑𝑑𝑑 = 2 0 𝑏𝑏 𝑐𝑐 2 = 2 b 𝜏𝜏𝑚𝑚𝑚𝑚𝑚𝑚 𝑏𝑏 𝑐𝑐 2 𝑉𝑉 𝑄𝑄 𝑉𝑉 𝑄𝑄 𝑉𝑉 2 𝑉𝑉 𝑐𝑐 2 𝑉𝑉 𝑐𝑐 2 𝑉𝑉 𝑐𝑐 2 = = = = = = 𝑏𝑏 ℎ3 𝑏𝑏 2𝑐𝑐 𝐼𝐼 𝑡𝑡 𝐼𝐼 𝑏𝑏 𝐼𝐼 𝑏𝑏 2𝐼𝐼 2 2 12 12 3 = 3 𝑉𝑉 3 𝑉𝑉 3 𝑉𝑉 = = 4 𝑏𝑏𝑏𝑏 4 𝑏𝑏 ℎ 2 𝐴𝐴 2 71 Transverse Shear Stress Continued τ = V Q/I t, Rectangular x-section τ = 3V/2A, Circular x-section τ = 4V/3A. τ = Transverse shear stress V = Shear force at the point of interest Q = first moment of area (A d) I = area moment of inertia of the cross section t = thickness of the member at the point of interest A = cross sectional area Restrictions Same as for bending stress Stress Profile 72 Helpful Partial Cylinder Geometry Terms Centroid xbar Area https://en.wikipedia.org/wiki/List_of_centroids Centroid xbar Area 73 Torsional Shear Stress Depending on the shape of the cross section, the torsional shear stress can be the most challenging of the stresses to compute. This is due to the fact that for noncircular cross sections, the expressions for the torsional shear stress can be difficult to develop. For common cross sections such as square, elliptic, circular, triangular, and others, expressions have been developed and can be found online in many textbooks or handbooks. For circular cross sections only τ = T y/J τ = Torsional shear stress T = Applied torque y = Distance from the center to the point of interest. J = Polar moment of inertia of the cross section πD4/32 Restrictions 1. Straight and constant CIRCULAR cross section 2. Material must be linearly elastic and homogeneous 3. Stress sections are remote from the ends 4. Adjacent sections plane and parallel before deformation remain plane and parallel after deformation 5. The angle of twist at any cross section is small (tan γ = γ) Stress Profile 74 Development of the Torsional Shear Stress Equations for Circular Cross Sections A circular rod of length L and radius c has an applied torque as shown. A stress element showing the directions of the stress is shown on the surface of the rod. A differential element dA at radius ρ on the beam face is also shown. Summation of moments about the axis of the rod must equal zero. This leads 𝑐𝑐 to (A) → 𝑇𝑇 − � 𝜏𝜏𝜏𝜏𝜏𝜏𝜏𝜏 = 0 . � 𝑀𝑀 = 0, 0 Now look at the deformation mechanics as shown below. The originally straight line AB rotates angle γ as point B moves to B’. Point D at radius ρ rotates to D’. The angle through which point B rotates is given by γ when measured along the length of the rod and by θ when measured radially. γ and θ are not equal but the arc length they represent is the same. 75 Development of the Torsional Shear Stress Equations - Continued The tangent of γ is given by the opposite side over the adjacent and since γ is shown to be on the surface we will denote it as γc. 𝑡𝑡𝑡𝑡𝑡𝑡 𝛾𝛾𝑐𝑐 = 𝑜𝑜𝑜𝑜𝑜𝑜 𝐵𝐵𝐵𝐵𝐵 𝑐𝑐𝑐𝑐 = = . 𝑎𝑎𝑎𝑎𝑎𝑎 𝐴𝐴𝐴𝐴 𝐿𝐿 Assuming small angles, we can write 𝑐𝑐𝑐𝑐 . 𝐿𝐿 A similar expression can be developed for a point inside the rod as given by 𝑡𝑡𝑡𝑡𝑡𝑡 𝛾𝛾𝑐𝑐 ≈ 𝛾𝛾𝑐𝑐 = 𝑡𝑡𝑡𝑡𝑡𝑡 𝛾𝛾𝜌𝜌 ≈ 𝛾𝛾𝜌𝜌 = 𝜌𝜌𝜌𝜌 . 𝐿𝐿 γc is not equal to γρ and γρ would be smaller than γc. However, the angle θ in the two expressions is the same and therefore, 𝛾𝛾𝜌𝜌 𝐿𝐿 𝛾𝛾𝑐𝑐 𝐿𝐿 = . 𝑐𝑐 𝜌𝜌 A linear relationship for γc can then be expressed as 𝜃𝜃 = 𝛾𝛾𝑐𝑐 = 𝛾𝛾𝜌𝜌 𝑐𝑐 . 𝜌𝜌 Now multiplying both sides of Eq. B, by the modulus of rigidity G, and using Hooke’s law for shear which is 𝜏𝜏 = 𝐺𝐺𝐺𝐺, we can write 𝐺𝐺 𝛾𝛾𝑐𝑐 = 𝐺𝐺 𝛾𝛾𝜌𝜌 𝑐𝑐 𝑐𝑐 or 𝜏𝜏𝑐𝑐 = 𝜏𝜏𝜌𝜌 . 𝜌𝜌 𝜌𝜌 (B) (C) Now substitute Eq. C into the equilibrium equation (Eq. A) and we can write 𝑐𝑐 𝑐𝑐 𝑐𝑐 𝜏𝜏𝑐𝑐 𝜌𝜌 𝜏𝜏𝑐𝑐 2 𝜏𝜏𝑐𝑐 𝑐𝑐 2 𝜌𝜌 𝑑𝑑𝑑𝑑 = � 𝜌𝜌 𝑑𝑑𝑑𝑑 = � 𝜌𝜌 𝑑𝑑𝑑𝑑 . 𝑇𝑇 = � 𝜏𝜏𝜌𝜌 𝜌𝜌 𝑑𝑑𝑑𝑑 = � 𝑐𝑐 𝑐𝑐 0 0 0 0 𝑐𝑐 76 Development of the Torsional Shear Stress Equations - Continued Now for circular cross sections, the polar moment of inertia J is given by 𝑐𝑐 𝐽𝐽 = � 𝜌𝜌2 𝑑𝑑𝑑𝑑 . 0 The torque can then be expressed as 𝜏𝜏𝑐𝑐 = 𝑇𝑇𝑇𝑇 𝐽𝐽 or 𝑇𝑇 = 𝜏𝜏𝑐𝑐 𝐽𝐽 . 𝑐𝑐 The angle of twist can be expressed as 𝜃𝜃 = 𝛾𝛾𝛾𝛾 𝑇𝑇𝑇𝑇 𝑇𝑇𝑇𝑇𝑇𝑇 𝑇𝑇𝑇𝑇 = = = . 𝜌𝜌 𝜌𝜌𝜌𝜌 𝐽𝐽𝐽𝐽𝐽𝐽 𝐽𝐽𝐽𝐽 77 One of My Heros Be a Dr. Librescu 78 A Typical Handout from Dr. Librescu – Note the equation numbers 79 Stress Elements Stress elements are a convenient way to visualize the stresses at a point in a body. A stress element is drawn with finite dimensions but represents an infinitesimal point at a specified location. In general, stress elements are three dimensional (3D) and are drawn as 3D cubes. However, in many machine design applications (all beams), because of the loading and geometry, the 3D stress state is reduced to a 2D stress state and a 2D square can be used to illustrate the stresses. When using 2D stress elements, the stress element typically references a point on the surface of the machine component. Since the stress element represents an infinitesimal point on the structure, the stresses must be equal in magnitude and opposite in direction on opposing faces. Tension stress is illustrated by arrows pointing away from the element and compression stress is represented with arrows pointing into the element. Shear stress is shown to act along the sides of the element. The figure below illustrates three stress elements on a cantilever beam. Element A represents the infinitesimal point at the top center of the beam indicated by the shaded region. Element B represents the point on the outside surface of the beam at the horizontal mid plane. Element C is an off-angle element. 80 Stress Elements – The Cut Edge In practice, stress elements are placed at locations of maximum stress. These locations are typically found using shear moment diagrams and experimental testing. When a cut is made in the member, the stress elements are placed so that one edge of the stress element is right at the cut. This edge is referred to as the cut edge and is used to determine the directions of the stresses that act on the stress element. Assuming a cut at the wall in the cantilever beam previously shown, the cut edge of elements A and B would be as shown in red in the figure below. L A C Top View C B Side View We always use reaction forces and moments to determine the stresses that act on the cut edge. 81 Combined Loadings The circular cantilever beam is loaded with an axial load of 8,000 N, a transverse load of 550 N, and a torque of 30 N-m. Determine the stresses that act on stress elements A and B. The diameter of the beam is 20 mm and the length is 100 mm. y 550 N 30 Nm A B z 30 N − m T 8,000 N x 100 mm 1. Make a cut at the beam-wall interface and compute the reaction loads. � 𝐹𝐹𝑥𝑥 = 0, −𝑅𝑅𝑥𝑥 + 8000 = 0, � 𝑀𝑀𝑐𝑐𝑐𝑐𝑐𝑐 = 0 , 𝑖𝑖 𝑅𝑅 𝑋𝑋 𝐹𝐹 = 0.100 8000 𝑀𝑀𝑐𝑐𝑐𝑐𝑐𝑐 + 30 𝑖𝑖 + 𝑅𝑅 𝑋𝑋 𝐹𝐹 = 0 𝑗𝑗 0 −550 𝑀𝑀𝑐𝑐𝑐𝑐𝑐𝑐 = −30 𝑖𝑖 + 55 𝑘𝑘 30 Nm � 𝐹𝐹𝑦𝑦 = 0, 𝑅𝑅𝑦𝑦 − 550 = 0, 𝑅𝑅𝑦𝑦 = 550 𝑘𝑘 0 = 0 + 0 − 55 𝑘𝑘 − 0 + 0 + 0 = −55 𝑘𝑘 0 550 N y 8,000 N 𝑅𝑅𝑥𝑥 = 8000 A 8,000 N x B 30 Nm 55 Nm z 550 N 82 Combined Loadings - Continued 2. Now based only on the reactions, draw the stress elements and label each component. y Stress Options 8,000 N 30 Nm F A Mc σ= I VQ τ= It Tc τ= J σ= A B 55 Nm 550 N z A z τxz σx x 𝑀𝑀𝑀𝑀 𝑃𝑃 32𝑀𝑀𝑧𝑧 𝑃𝑃 (32)(55) 8000 + = = + + 𝐼𝐼 𝐴𝐴 𝜋𝜋𝐷𝐷3 𝐴𝐴 𝜋𝜋(0.02)3 𝜋𝜋(0.01)2 𝜎𝜎𝑥𝑥 = 𝜎𝜎𝑥𝑥 = 70,028,175 + 25,464,791 = 95,492,906 𝑁𝑁/𝑚𝑚2 𝜏𝜏𝑥𝑥𝑥𝑥 = 𝑇𝑇𝑇𝑇 (30)(0.01) = 19,098,590 𝑁𝑁/𝑚𝑚2 = 𝜋𝜋(0.02)4 𝐽𝐽 32 y B τtorsion σx x τbending 𝜎𝜎𝑥𝑥 = 𝜏𝜏𝑥𝑥𝑥𝑥 = 𝑃𝑃 8000 = = 35,464,791 𝑁𝑁/𝑚𝑚2 𝐴𝐴 𝜋𝜋(0.01)2 𝑇𝑇𝑇𝑇 4𝑉𝑉 4 (550) + = 19,098,590 + = 21.4 𝑘𝑘𝑘𝑘/𝑚𝑚2 𝐽𝐽 3𝐴𝐴 3𝜋𝜋(0.01)2 83 Reaction Forces Reaction forces F1, F2, and F3 are shown on a beam. Determine the stresses caused by these forces on stress element A. y F1 A F2 F3 A F3 z F1 - x A 4 F1 VQ = It 3A VQ . F1 is parallel to the cut side of A. It acts like it is trying to shear the It shaft. The direction of the shear stress is the same as the shear force arrow on the cut face. The stress cant be “direct shear” because it is a reaction load due to an applied load that does not occur right at A. It cant be normal P/A because it does not act normal to the cut side of A. F2 – Nothing. F2 pierces the element A and so Q is zero. The stress element is on the top surface for F2 where the transverse shear stress goes to zero. P . F3 is perpendicular to the cut face of element A and so is the normal A P stress given by . It would also cause a compressive stress because F3 is A F3 - pushing on the cut face of element A. 84 Reaction Moments Reaction moments M1, M2, and M3 are shown on a beam. Determine the stresses caused by these moments on stress element A. y M3 M 1c I A M2 M1 x A Tc M 3c = J J z M1 – Causes bending stress on element A. Using the right-hand rule, the moment is coming out of the cut edge of element A. This puts element A in tension bending stress. M2 – Element A is at the neutral axis for this moment and so it does not cause any stress. M3 – M3 is really a torque and it is twisting the beam. The direction of the torsional shear stress is in the same direction as the torque on the cut edge. 85 Bending about Two Axes – Any Cross Sections When bending about two axes occurs, superposition of the stresses is used to determine the total stress. The beam shown below with the rectangular cross is loaded about two axes by the end loads F and P. The bending stress due to each force can be computed and then summed together to get the total bending stress. The bending stress at any point in the cross section can be computed by summing the σx and σy at that point. y F L h x = F + P P b ℎ 𝑀𝑀𝑀𝑀 𝐹𝐹𝐹𝐹 2 = 𝜎𝜎𝑥𝑥 = 𝑏𝑏ℎ3 𝐼𝐼 12 𝜎𝜎𝑀𝑀𝑀𝑀𝑀𝑀 = 𝜎𝜎𝑥𝑥 + 𝜎𝜎𝑦𝑦 𝑏𝑏 𝑀𝑀𝑀𝑀 𝑃𝑃𝑃𝑃 2 = 𝜎𝜎𝑦𝑦 = ℎ𝑏𝑏 3 𝐼𝐼 12 Maximum stress occurs in the corners of the beam where the maximum stress from each load occurs. 𝜎𝜎𝑀𝑀𝑀𝑀𝑀𝑀 = 𝜎𝜎𝑥𝑥 + 𝜎𝜎𝑦𝑦 86 Bending about Two Axes – Circular Cross Sections For circular cross sections, superposition is also used to compute the maximum stress. The challenge with circular cross sections when the maximum stress is being computed is determining the “c” value for the σx and σy components of stress. To get around determining the “c” value for the individual stresses, the moments are simply summed as the square root of the sum of the squares and then the “c” value is the radius of the cross section. 𝑐𝑐 𝜎𝜎𝑀𝑀𝑀𝑀𝑀𝑀 = 𝐹𝐹𝐹𝐹 2 + 𝑃𝑃𝑃𝑃 2 1/2 𝐼𝐼 y F x P 𝜎𝜎𝑀𝑀𝑀𝑀𝑀𝑀 = 𝐹𝐹𝐹𝐹 2 + 𝑃𝑃𝑃𝑃 2 1/2 𝐷𝐷 2 𝜋𝜋𝐷𝐷4 64 𝜎𝜎𝑀𝑀𝑀𝑀𝑀𝑀 = 𝜎𝜎𝑥𝑥 + 𝜎𝜎𝑦𝑦 P α α c cos α F c sin α 𝜎𝜎𝑥𝑥 = 𝜎𝜎𝑦𝑦 = 𝐹𝐹𝐹𝐹 𝑃𝑃𝑃𝑃 𝐷𝐷 sin 𝛼𝛼 2 𝜋𝜋𝐷𝐷4 64 𝐷𝐷 cos 𝛼𝛼 2 𝜋𝜋𝐷𝐷4 64 87 Bending about Two Axes – Using Reaction Moments It is typically the case that instead of using the applied loads as on the previous two slides, we use the reaction moments to determine the bending about two axes. To do this we need to make sure that we look at the cut edge and draw the reactions accordingly. We need to make sure that to identify tension and compression we also use the right-hand rule on the cut edge. This is shown in the example below. y PL F z FL P L PL Max Tension α FL α Max Compression 88 Example The torsion bar shown below is made of a circular rod with diameter D and length R. There is a distributed load w along the length of the rod. A rectangular bar is attached to the end of the rod at R as shown. The distance from the center of the rod to where force F and force P are applied is L. Compute the stresses on the top of the rod at point A and the side of the rod at point B. Then compute the maximum stress at the wall. y F A w N/m P B z L/2 R L/2 x Thoughts • The rod is cantilevered so the maximum moments will occur at the wall. • There is bending about two axes, so the maximum stress will not occur at the top or the side of the rod but somewhere in between. • We need to cut the beam where we want to know the stresses and compute the reactions. � 𝐹𝐹𝑥𝑥 = 0 � 𝐹𝐹𝑦𝑦 = 0 , � 𝐹𝐹𝑧𝑧 = 0 , 𝑅𝑅𝑦𝑦 − 𝐹𝐹 − 𝑤𝑤𝑤𝑤 = 0, −𝑅𝑅𝑧𝑧 + 𝑃𝑃 = 0, 𝑅𝑅𝑦𝑦 = 𝐹𝐹 + 𝑤𝑤𝑤𝑤 𝑅𝑅𝑧𝑧 = 𝑃𝑃 89 Example Continued � 𝑀𝑀 = 0 , 𝑅𝑅 𝑋𝑋 𝐹𝐹 1 𝑀𝑀𝑝𝑝𝑝𝑝 = 𝑤𝑤𝑤𝑤 𝑖𝑖 = 𝑅𝑅 0 𝑅𝑅 𝑘𝑘 + 𝑅𝑅 𝑋𝑋 𝐹𝐹 2 𝑀𝑀𝑝𝑝𝑝𝑝 − 𝑤𝑤𝑤𝑤 𝑗𝑗 0 −𝐹𝐹 1 =0 𝑘𝑘 −𝐿𝐿 = 0 + 0 − 𝑅𝑅𝑅𝑅𝑅𝑅 − 0 + 𝐹𝐹𝐹𝐹𝐹𝐹 + 𝑃𝑃𝑃𝑃𝑃𝑃 𝑃𝑃 𝑅𝑅 𝑘𝑘 + 𝑅𝑅𝑅𝑅𝑅𝑅 + 𝐹𝐹𝐹𝐹𝐹𝐹 + 𝑃𝑃𝑃𝑃𝑃𝑃 2 Drawing the reaction forces and moments on the FDB results in the figure below. Note that it is easy to check the results by comparing the applied loads to the reaction loads at this point in the solution. y PR F F+wR P P 𝑤𝑤𝑅𝑅 2 + 𝑅𝑅𝑅𝑅 2 FL z L/2 R L/2 x We can now isolate the point where we want to compute the stresses and redraw to simplify the figure. 90 Example Continued y PR F+wR P A 𝑤𝑤𝑅𝑅 2 + 𝑅𝑅𝑅𝑅 2 B FL z P, puts point A in transverse shear. The force vector P is parallel to the red line (cut edge) of element A. The force is going up along the cut edge as shown. τ = VQ/It = 4/3 V/A = 4/3 P/A. 2 1 3 A F, this force pierces through element A. Its not parallel or normal to the cut edge. F doesn’t cause stress at point A. FL is trying to twist the shaft not bend the shaft. Therefore, FL causes a torsional shear stress. τ = Tc/J = FL c/J. 1. τ = 4/3 P/A 2. Τ = FL c/J 3. σ = 𝑤𝑤𝑅𝑅 2 2 + 𝑅𝑅𝑅𝑅 𝑐𝑐 𝐼𝐼 PR is trying to bend the shaft about the y-axis. Point A is at the center of the beam for this bending moment and so is at the neutral axis and PR doesn’t cause stress at point A. 𝑤𝑤𝑅𝑅 2 + 𝑅𝑅𝑅𝑅 2 is trying to bend the beam about the z-axis. Putting the right thumb in the direction of the moment (+z axis) the fingers would be coming out of point A and wrapping into the bottom. This puts A in tension with σ = Mc/I = 𝑤𝑤𝑅𝑅 2 2 + 𝑅𝑅𝑅𝑅 𝑐𝑐 𝐼𝐼 91 Example Continued y PR F+wR P A 𝑤𝑤𝑅𝑅 2 + 𝑅𝑅𝑅𝑅 2 B FL z P, this force pierces through element B. Its not parallel or normal to the cut edge. P doesn’t cause stress at point B. 2 1 3 B F, puts point B in transverse shear. The force vector F is parallel to the red line (cut edge) of element B. τ = VQ/It = 4/3 V/A = 4/3 F/A. FL is trying to twist the shaft not bend the shaft. Therefore, FL causes a torsional shear stress. τ = Tc/J = FL c/J. 1. τ = 4/3 (F+wR)/A 2. Τ = FL c/J 3. σ = 𝑤𝑤𝑅𝑅 2 2 + 𝑅𝑅𝑅𝑅 𝑐𝑐 𝐼𝐼 PR is trying to bend the shaft about the y-axis. Putting the thumb in the direction of the moment the fingers would be pushing in on the cut edge of element B. This puts B in compression. σ = Mc/I = PRc/I. 𝑤𝑤𝑅𝑅 2 + 𝑅𝑅𝑅𝑅 2 is trying to bend the beam about the z-axis. Point B is at the center of the beam for this bending moment and so is at the neutral axis. 92 Example Continued Now determine the maximum bending stress due to the two bending moments. To do this, draw the cross section of the beam, label the axes and moments as shown. y y PR T F+wR P A 2 𝑤𝑤𝑅𝑅 + 𝑅𝑅𝑅𝑅 2 z B T C FL z C The moment about the y-axis causes compression and tension as shown by the red letters. The moment about the z-axis causes tension and compression as shown by the blue letters. The maximum tension occurs between the T’s and the maximum compression occurs between the two C’s as shown below. y T z Maximum Tension θ θ T C 𝜃𝜃 = atan 𝑀𝑀𝑇𝑇 = 2 + 𝑅𝑅𝑅𝑅 The maximum bending moment is given by the square root of the sum of the squares. The stress is σmax = MT c/I with MT as the maximum moment. C Maximum Compression 𝑃𝑃𝑃𝑃 𝑤𝑤𝑅𝑅 2 𝑃𝑃𝑃𝑃 2 + 𝑤𝑤𝑅𝑅 2 + 𝑅𝑅𝑅𝑅 2 2 93 Combined Loading Example A sign is mounted to a solid circular post as shown. Assume the post is rigidly buried in the ground to a depth of 3 ft. The weight of the sign is 500 lbs. The weight of the post is also significant. A wind produces a positive uniformly distributed pressure of 1 psi on the front of the sign and the post. The sign is rigidly connected to the post and the stresses at the sign/post interface can be assumed to be non-critical. The sign and the post have the following properties. Compute the stresses on stress elements at the base of the post. Sign E = 30e6 psi Poisson’s ratio =0.3 Post E = 30e6 psi Poisson’s ratio = 0.3 Outside diameter = 4 inches Density = 0.289 lb/in3 Top View 4 inches Wind Direction 2 ft 7 ft 9 ft Wind Direction y Ground Level x 3 ft Front View Side View 94 Combined Loading Example – Continued 1. Select an origin, establish a coordinate system and determine the applied loads. y 576 𝐹𝐹𝑤𝑤𝑤𝑤𝑤𝑤𝑤𝑤 𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠 = 1 psi 24 in 24 in = 576 lbs 500 432 𝐹𝐹𝑤𝑤𝑤𝑤𝑤𝑤𝑤𝑤 𝑝𝑝𝑝𝑝𝑝𝑝𝑝𝑝 = 1 psi 9 ft 392.2 x z 𝐹𝐹𝑤𝑤𝑤𝑤 𝑝𝑝𝑝𝑝𝑝𝑝𝑝𝑝 = 0.289 lb 9 ft in3 12 12 in ft 4 in = 432 lbs in 𝜋𝜋 2 in ft 2 = 392.2 lbs 2. Now make a cut at the base of the sign post and compute the reaction forces and moments. The reaction forces are shown below. y x 892.2 z 1008 � 𝐹𝐹𝑥𝑥 = 0 � 𝐹𝐹𝑦𝑦 = 0, � 𝐹𝐹𝑧𝑧 = 0, 𝑅𝑅𝑦𝑦 = 500 + 392.2 = 892.2 𝑅𝑅𝑧𝑧 = 576 + 432 = 1008 95 Combined Loading Example – Continued Compute the reaction moments and draw them on the FBD. Draw the stresses on an element on the front side of the beam. � 𝑀𝑀𝑐𝑐𝑐𝑐𝑐𝑐 = 0, 𝑅𝑅 𝑋𝑋 𝐹𝐹 𝑝𝑝𝑝𝑝𝑝𝑝𝑝𝑝 𝑅𝑅 𝑋𝑋 𝐹𝐹 𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠 𝑀𝑀𝑝𝑝𝑝𝑝 + 𝑅𝑅 𝑋𝑋 𝐹𝐹 𝑖𝑖 𝑗𝑗 = 0 54 0 0 𝑖𝑖 = 14 0 𝑝𝑝𝑝𝑝𝑝𝑝𝑝𝑝 + 𝑅𝑅 𝑋𝑋 𝐹𝐹 𝑘𝑘 = −23,328 𝑖𝑖 0 −432 𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠 =0 𝑗𝑗 𝑘𝑘 = 96 −576 𝑖𝑖 + 14 −500 𝑘𝑘 − 14 −576 𝑗𝑗 96 0 −500 −576 𝑀𝑀𝑐𝑐𝑐𝑐𝑐𝑐 = 78624 𝑖𝑖 − 8064 𝑗𝑗 + 7000 𝑘𝑘 = −55296 𝑖𝑖 + 8064 𝑗𝑗 − 7000 𝑘𝑘 y 8064 A x 892.2 7000 z 78624 1 1008 2 1 A 3 2 3 𝐷𝐷 𝑀𝑀𝑀𝑀 78624 2 𝜎𝜎 = = 𝜋𝜋𝐷𝐷4 𝐼𝐼 64 𝜎𝜎 = 𝑃𝑃 892.2 = 𝜋𝜋𝐷𝐷2 𝐴𝐴 4 𝐷𝐷 𝑇𝑇𝑇𝑇 8064 2 𝜏𝜏 = = 𝜋𝜋𝐷𝐷4 𝐽𝐽 32 96 Brace - n – bit Example A company has designed and manufactured a brace-n-bit but has had problems with them failing. The instruction manual tells the users to not apply more than 150 in-lb of torque and 50 lbs of push load. In a typical scenario, the bit has a shank diameter of 0.5 inches and extends about 3 inches from the wood to the chuck at the start of the drilling process. The device has been breaking at section A-A. Determine if the diameter at this location is sufficient to carry the applied loads. 3 97 Brace – n - bit Example Continued 1. Draw a FBD and determine all the applied loads. E y R Tox R Ox z 2.75" H O 3" FDz A A z O C D FAz F 2.25" G B 3.75" 3" 6" x A FAx BIT Given: The torque Tox is 150 in-lb. This torque is generated by a hand pushing on point D which requires the force FDz as shown. The 50 lb thrust is applied by the hand at point A. This gives Fax and we know this force is reacted at the wall (point o) by Rox. 0 ⇒ R ox iˆ + R oz kˆ +- F Dz kˆ + F zA kˆ +- F xA iˆ = 0 ∑F = iˆ → Rox − FAx = 0 kˆ → � 𝑀𝑀𝑜𝑜 = 0, → z z z Ro − F D + F A 𝑀𝑀𝑜𝑜 + 𝑇𝑇𝑜𝑜𝑥𝑥 + 𝑅𝑅 𝑋𝑋 𝐹𝐹 𝑇𝑇𝑜𝑜𝑥𝑥 = 150 𝑖𝑖 in − lb 𝑅𝑅 𝑋𝑋 𝐹𝐹 𝐷𝐷 𝑖𝑖 = 9.75 0 Rox = FAx = 50lbs =0 𝐷𝐷 + 𝑅𝑅 𝑋𝑋 𝐹𝐹 𝐴𝐴 =0 𝑗𝑗 𝑘𝑘 5 0 = −5 𝐹𝐹𝐷𝐷𝑧𝑧 𝑖𝑖 + 9.75 𝐹𝐹𝐷𝐷𝑧𝑧 𝑗𝑗 0 −𝐹𝐹𝐷𝐷𝑧𝑧 98 Brace-n-bit Example Continued 𝑅𝑅 𝑋𝑋 𝐹𝐹 ^ 𝐴𝐴 𝑖𝑖 = 15.75 −𝑅𝑅𝐴𝐴𝑥𝑥 ^ ∑ M O = 150 i − 5FD i + 9.75 𝑗𝑗 𝑘𝑘 0 0 = −15.75 𝐹𝐹𝐴𝐴𝑧𝑧 𝑗𝑗 0 𝑅𝑅𝐴𝐴𝑧𝑧 ^ FD j − 15.75 FAz ^ j =0 ^ i → 150 = 5FD ⇒ FD = 30 ^ j → 9.75 *(30) − 15.75 FAz = 0 ⇒ FAz =18.57 ∴ R Oz =FDz − FAz = 30 − 18.57 = 11.43 ________________________________________ = = = Summary R Ox 50lb FD 30lb FAx 50lb = = R Oz 11.43lb FAz 18.57lb ________________________________________ 99 Brace-n-bit Example Continued Now sum forces and moments at point F which is at section A-A. y FFz 30 FFx 18.57lb x 50lb z ∑F = 0 ^ i → FFx − 50 = 0 ⇒ FFx = 50lb ^ k → FFz − 30 + 18.57 = 0 ⇒ FFz = 11.43lb ∑ M =0 ⇒ M F + (R FD × FD ) + (R FA × FA ) =0 j k i ^ ^ = R FD × FD = 3 2.75 0 82.5 90 i j − + 0 0 -30 j k i ^ ^ ^ 9 -2.25 = R FA × FA = 0 167.5 41.9 112.5 j i k − − − -50 0 18.57 ^ ^ ^ ^ ^ M F = 82.5 i − 90 j + 167.5 j + 41.9 i + 112.5 k = ^ ^ ^ 124.4 i + 77.5 j + 112.5 k 100 Brace-n-bit Example Continued y 77.5 124.4 11.43 50 112.5 Right side Left side A Top x σ x = 0 middle of the shaft y Mc 32 M x (32)(124.4) = = = 10,130 psi I π D3 π (0.5)3 σ = y x A Tc 4V 16Ty 4V + = + J 3A π d 3 3A 16(77.5) 4(50)(4) = 3 + = ±3160 + 340 psi 2 3π (0.5) π (0.5) τ yx = Bottom Tc J τ yx = 3,500 psi (top element ) B τ yx = 2,820 psi (bottom element ) VQ It 101 Brace-n-bit Example Continued Left side Right side y 9167.32 9167.32 0 z 0 3235.25 σ z = 0 middle of the shaft = σy τ yz 32 M z (32)(112.5) = = 9167.32 psi 3 3 πD π (0.5) Tc 4V 16Ty 4V = + = 3 + J 3A π d 3A 16(77.5) 4(11.43)(4) =3 + = ±3157.63 + 77.616 2 3π (0.5) π (0.5) = 3235.25 left side and 3080.01 psi right side 102 Brace-n-bit Example Continued Find the largest normal stress at point H when the plane of the brace is horizontal. Given the bit diameter is 0.25 inches. y H R Oz Mr R Ox T x Fx 3" x O Tx A Fz SOLUTION ∑ F → R − F = 0 ⇒F = R = 50lb ∑ F → R − F = 0 ⇒F = R = 11.43lb ∑ M → T − T = 0 ⇒T = T = 150 ∑ M → R (3) − M = 0 ⇒M = R (3) = 3 *11.43 = 34.29 x x O x x x O z z O z z z O x x O y z O x O x y x z O y Point A will be the most critical (Front Face) σx = y Mc F −32 M y F − = − I A A π D3 (32)(34.29) 50 * 4 =3 − = −23,330 psi π (0.25) π (0.25) 2 x .25 150 Tc 2 = = 48,892.4 psi τ= xy J π (0.5) 4 32 103 Crank shaft - Example A crankshaft and flywheel of a one-cylinder air compressor are shown. Part of the energy stored in the flywheel is used to produce a portion of the piston force P. The piston force P shown is generated by the torque of 600 N-m delivered to the crankshaft by the flywheel. A stress element is to be located on the top surface of the crankshaft at A, 100 mm from the left bearing. The sides of the element are parallel to the xz-axes. A. B. C. D. Compute the stress components that act at A. Find the principal stresses and their directions for the element at A. Sketch the principal stress element and orient it correctly with reference to the x and z axes. Be sure to label completely Sketch another stress element correctly oriented to show the maximum shear stress and the corresponding normal stresses. P 2 P 2 Solution 600 N-m y -2000 N = P 0 → FAy = 2000 N ∑ FA = ∑ M A =0 → M A + (rAD × FD ) + T x =0 ^ 200 k z 2000 N x 600N-m = 4000N 0.15m ^ -600 i M A= -(rAD × FD ) − T x = 0 104 Crank Shaft Example - Continued ^ ^ i MA j ^ k ^ ^ = −200 k + 600 i -0.1 0 0 +T x = 0 2000 0 ^ ^ ⇒ MA = 200 k − 600 i + 0 + 0 − 200k − (0 + 0 + 0) 0.035 200 Mc 2 σ= = = 47.5 MPa I π (0.035)4 64 A 0.035 600 Tc 2 τ= = = 71.27 MPa J π (0.035)4 32 Mohr Circle 47.5MPa Given stress element 71.27 MPa Step #1 Define Positive Coord. system Step #2 Determine pts. + + Vert pt = (σx , τxz ) = (-47.7, -71.27) Hor pt = (σz , -τxz ) = (0, 71.27) 105 Crank Shaft Example - Continued - 97.5 Center = = −23.75 2 Origin of Planes θ 98.85 θ = tan = 54.21 71.27 −1 2 47.5 2 Radius = + (72.27) = 75.1 2 σ P1 = −23.75 + 75.1 = 51.35MPa σ P3 = −23.75 − 75.1 = −98.85MPa 51.35MPa 98.85MPa x z 54.21° 23.75MPa 3.83 = 9.16 23.75 φ = atan 9.16 75.1MPa x 23.75MPa z 106 Hand Crank Example Determine the location and magnitudes of the maximum stresses of the crank shown. Assume bearing A is a radial thrust bearing and bearing B is a single radial bearing. Assume that all external loads are applied at point C. There are also other loads applied to the handle at point C as shown. 10” 10” 5” 5” C 20 lbs 50 lbs A 100 lbs 4“ 8” B 100 lbs 107 Hand Crank Example Continued Draw a FBD and label all applied loads. Place origin of coordinate system at Pt. A. Think about reactions at A and B. Must have +y forces at A and B to hold up the structure and not have a moment. The thrust bearing at A must carry the axial load. The 400 in-lb torque is generated by a force in the z-direction at point C. When FCz is added, z forces at A and B must also be added so the moment is zero. Now sum forces and moments to determine unknown loads. y C FAy 400 A D 100 FCz FBy FAx FAz B 20 50 FBz z � 𝐹𝐹𝑥𝑥 = 0 , → 𝐹𝐹𝐴𝐴𝑥𝑥 − 20 = 0, � 𝐹𝐹𝑦𝑦 = 0 , → −100 + 𝐹𝐹𝐴𝐴 + 𝐹𝐹𝐵𝐵 − 50 = 0 � 𝐹𝐹𝑧𝑧 = 0 , → 𝐹𝐹𝐴𝐴𝑧𝑧 + 𝐹𝐹𝐵𝐵𝑧𝑧 − 𝐹𝐹𝐶𝐶𝑧𝑧 = 0 𝑦𝑦 𝑦𝑦 𝐹𝐹𝐴𝐴𝑥𝑥 = 20 108 Hand Crank Example Continued Now sum moments. The moments in the bearings at A and B are zero. So pick one of them as the reference. � 𝑀𝑀𝐴𝐴 = 0 → 𝑅𝑅 𝑋𝑋 𝐹𝐹 𝐷𝐷 𝑅𝑅 𝑋𝑋 𝐹𝐹 𝐵𝐵 𝑅𝑅 𝑋𝑋 𝐹𝐹 𝐶𝐶 400 𝑖𝑖 + 𝑅𝑅 𝑋𝑋 𝐹𝐹 𝐷𝐷 + 𝑅𝑅 𝑋𝑋 𝐹𝐹 𝐵𝐵 + 𝑅𝑅 𝑋𝑋 𝐹𝐹 𝐶𝐶 =0 𝑖𝑖 𝑗𝑗 𝑘𝑘 = −10 0 0 = 1000 𝑘𝑘 0 −100 0 𝑖𝑖 𝑗𝑗 = 10 0 𝑦𝑦 0 𝐹𝐹𝐵𝐵 𝑘𝑘 0 = 10 𝐹𝐹𝐵𝐵𝑦𝑦 𝑘𝑘 − 10 𝐹𝐹𝐵𝐵𝑧𝑧 𝑗𝑗 𝐹𝐹𝐵𝐵𝑧𝑧 𝑖𝑖 𝑗𝑗 𝑘𝑘 8 0 = −8 𝐹𝐹𝐶𝐶𝑧𝑧 𝑖𝑖 − 1000 𝑘𝑘 + 160 𝑘𝑘 + 20 𝐹𝐹𝐶𝐶𝑧𝑧 𝑗𝑗 = 20 −20 −50 −𝐹𝐹𝐶𝐶𝑧𝑧 Rewriting the summation of moments equation gives 𝑦𝑦 400 𝑖𝑖 + 1000 𝑘𝑘 + 10 𝐹𝐹𝐵𝐵 𝑘𝑘 − 10 𝐹𝐹𝐵𝐵𝑧𝑧 𝑗𝑗 − 8 𝐹𝐹𝐶𝐶𝑧𝑧 𝑖𝑖 � 𝑀𝑀𝐴𝐴 = 0 → −1000 𝑘𝑘 + 160 𝑘𝑘 + 20 𝐹𝐹𝐶𝐶𝑧𝑧 𝑗𝑗. Now grouping like terms and solving for the unknowns gives 400 𝑖𝑖 − 8 𝐹𝐹𝐶𝐶𝑧𝑧 𝑖𝑖 = 0 , → 𝐹𝐹𝐶𝐶𝑧𝑧 = 50 −10 𝐹𝐹𝐵𝐵𝑧𝑧 𝑗𝑗 + 20 𝐹𝐹𝐶𝐶𝑧𝑧 𝑗𝑗 = 0 , 𝑦𝑦 → 𝐹𝐹𝐵𝐵𝑧𝑧 = 20 𝐹𝐹𝐶𝐶𝑧𝑧 10 1000 𝑘𝑘 + 10 𝐹𝐹𝐵𝐵 𝑘𝑘 − 1000𝑘𝑘 + 160𝑘𝑘 = 0 = → 20 50 10 𝑦𝑦 𝐹𝐹𝐵𝐵 = = 100 −160 10 = −16 109 Hand Crank Example Continued Now use the summation of forces equations 𝐹𝐹𝐴𝐴𝑧𝑧 + 100 − 50 = 0 , 𝑦𝑦 𝐹𝐹𝐴𝐴𝑧𝑧 = −50 → −100 + 𝐹𝐹𝐴𝐴 −16 − 50 = 0 , → Summary 𝑦𝑦 𝐹𝐹𝐴𝐴𝑥𝑥 = 20, 𝑦𝑦 𝐹𝐹𝐴𝐴 = 166 𝑦𝑦 𝐹𝐹𝐴𝐴 = 166, 𝐹𝐹𝐵𝐵𝑥𝑥 = 0, 𝐹𝐹𝐵𝐵 = −16, 𝐹𝐹𝐴𝐴𝑧𝑧 = −50, 𝐹𝐹𝐵𝐵𝑧𝑧 = 100. Shear Moment Diagrams y 166 16 A B 50 z 90 100 50 100 A B 50 250 50 66 50 100 1000 250 500 110 Hand Crank Example Continued Point A is the critical location. Now compute the stresses at A. 100 400 400 100 � 𝐹𝐹 = 0 → � 𝑀𝑀𝑐𝑐𝑐𝑐𝑐𝑐 = 0 → 𝑅𝑅 𝑋𝑋 𝐹𝐹 𝐷𝐷 1000 𝑦𝑦 𝐹𝐹𝑐𝑐𝑐𝑐𝑐𝑐 = 100 𝑀𝑀𝑐𝑐𝑐𝑐𝑐𝑐 + 400 𝑖𝑖 + 𝑅𝑅 𝑋𝑋 𝐹𝐹 𝑖𝑖 𝑗𝑗 = −10 0 0 −100 𝑀𝑀𝑐𝑐𝑐𝑐𝑐𝑐 = −1000 𝑘𝑘 − 400 𝑖𝑖 𝐷𝐷 𝑘𝑘 0 = 1000 𝑘𝑘 0 A 𝜏𝜏 = =0 𝐷𝐷 1000 2 𝑀𝑀 𝑐𝑐 𝜎𝜎 = = 𝜋𝜋𝐷𝐷4 𝐼𝐼 64 𝐷𝐷 400 2 𝑇𝑇 𝑐𝑐 = 𝜋𝜋𝐷𝐷4 𝐽𝐽 32 111 Disk Grinder - Example A disk grinder is shown in Fig. 1. There is 6 inches from the grinding wheel to the bearing as shown. The distance between the two bearings is also 6 inches. The grinding wheels each weigh 5 lbs and have a 4-inch radius as shown in Fig. 2. A 20 lb radially directed load is applied at an angle of 30° as shown in Fig. 2. The disk grinder is spinning counter clockwise and there is a friction coefficient between the tool being sharpened and the grinding wheel of 0.5. Determine the magnitude and location of the largest bending stresses that occur in the grinding wheel shaft. Figure 1.1. Grinding Wheel. Figure Grinding Wheel. Figure Illustration thewheel grinding wheel is loaded. Figure 2.2. Illustration of howof thehow grinding is loaded. 112 Disk Grinder Example – Continued Determine the forces on the grinding wheel in the global x, y, and z coordinate directions. 5 8.66 (0.5)(20) = 10 30° 17.32 E 20 22.32 10 1.34 Forces applied to the disk (The +/- signs indicate the direction wrt the global CS). Fpushz = -20 cos 30 = -17.32 Fpushy = -20 sin 30 = -10 Ffricz = -10 sin 30 = -5 Ffricz = 10 cos 30 = 8.66 Now combine the y and z forces at point E. Ffricz = 8.66 – 10 = -1.34 Ffricz = -5 – 17.32 = =22.32 113 Disk Grinder Example – Continued The FBD for the grinding wheels is given by y FBy FCy (0.5)(20)=10 FBz A B E C 20 T 5 D z FC x z 5 Summing forces and moments at B gives � 𝐹𝐹𝑥𝑥 = 0 � 𝐹𝐹𝑦𝑦 = 0 , � 𝐹𝐹𝑧𝑧 = 0 , � 𝑀𝑀𝐵𝐵 = 0 → → → 𝑦𝑦 𝑦𝑦 −5 + 𝐹𝐹𝐵𝐵 + 𝐹𝐹𝐶𝐶 − 5 − 1.34 = 0 −𝐹𝐹𝐵𝐵𝑧𝑧 + 𝐹𝐹𝐶𝐶𝑧𝑧 − 22.32 = 0 𝑇𝑇 𝑖𝑖 + 𝑅𝑅 𝑋𝑋 𝐹𝐹 𝐴𝐴 + 𝑅𝑅 𝑋𝑋 𝐹𝐹 𝐶𝐶 + 𝑅𝑅 𝑋𝑋 𝐹𝐹 𝐷𝐷 + 𝑅𝑅 𝑋𝑋 𝐹𝐹 𝐸𝐸 =0 114 Disk Grinder Example – Continued Computing the terms in the moment expression gives 𝑅𝑅 𝑋𝑋 𝐹𝐹 𝐴𝐴 𝑅𝑅 𝑋𝑋 𝐹𝐹 𝐶𝐶 𝑅𝑅 𝑋𝑋 𝐹𝐹 𝐷𝐷 𝑖𝑖 𝑗𝑗 𝑘𝑘 = −6 0 0 = 30 𝑘𝑘 0 −5 0 𝑖𝑖 𝑗𝑗 = −6 0 𝑦𝑦 0 𝐹𝐹𝐶𝐶 𝑘𝑘 0 = 0 + 0 + 6 𝐹𝐹𝐶𝐶𝑦𝑦 𝑘𝑘 − 0 + 0 + 6 𝐹𝐹𝐶𝐶𝑧𝑧 𝑗𝑗 = 6 𝐹𝐹𝐶𝐶𝑦𝑦 𝑘𝑘 − 6 𝐹𝐹𝐶𝐶𝑧𝑧 𝑗𝑗 𝐹𝐹𝐶𝐶𝑧𝑧 𝑖𝑖 𝑗𝑗 𝑘𝑘 = 12 0 0 = −60 𝑘𝑘 0 −5 0 2 4 3.46 𝑅𝑅 𝑋𝑋 𝐹𝐹 𝐸𝐸 𝑖𝑖 𝑗𝑗 𝑘𝑘 = 12 2 3.46 = −44.64 𝑖𝑖 + 0 − 16.08 𝑘𝑘 − (0 − 4.64 𝑖𝑖 − 267.84 𝑗𝑗 0 −1.34 −22.32 = −40 𝑖𝑖 + 267.84 𝑗𝑗 − 16.08 𝑘𝑘 𝑦𝑦 � 𝑀𝑀𝐵𝐵 = 𝑇𝑇 𝑖𝑖 + 30 𝑘𝑘 + 6 𝐹𝐹𝐶𝐶 𝑘𝑘 − 6 𝐹𝐹𝐶𝐶𝑧𝑧 𝑗𝑗 − 60 𝑘𝑘 − 40 𝑖𝑖 + 267.84 𝑗𝑗 − 16.08 𝑘𝑘 = 0 115 Disk Grinder Example – Continued Solving for FBz, FBy, FCz, and FCy by grouping like terms in the previous equations gives i T – 40=0 → T = 40 i J -6 FCz + 267.84 = 0, → FCz = 44.64 k 30 + 6 FCy – 60 - 16.08 = 0, → FCy = 7.68 ∑Fy -5 + Fby + 7.68-5 - 1.34 = 0, → FBy = 3.66 ∑Fz -FBz + 44.64 – 22.32 = 0, → FBz = 22.32 Summary y 3.66 7.68 22.32 22.32 A B C 40 5 E 1.34 D z x 44.64 5 116 Disk Grinder Example – Continued Shear moment diagrams to determine location of maximum transverse shear and bending stress. z y 3.66 7.68 B 22.32 6.34 44.64 B C 5 22.32 C 22.32 6.34 1.34 5 22.32 30 133.9 38.04 The peak moment occurs at point C in both moment diagrams. Therefore, C is the critical design point. Since it’s a circular cross section 22.32 Mmax = (38.042 + 133.92)1/2 The angle that it acts at is given by 6.34 z α α = atan (22.32/6.34) = 74.14° 117 y Bending and Shear in Non-Uniform Cross Sections A simply supported I-beam, 12 inches long carries a load of 488 lbf 3 inches from the left support as shown. Compute the following 1. The transverse shear stress profile throughout the cross section. 2. The bending stresses at points of interest in the cross section. 3. The maximum shear stresses in the cross section. 488 lb 3 in 12 in 366 lb 122 lb 1098 in-lb Points of Interest Geometry I = 2.5 in4 d 0.26 in 1.24 in c b 1.08 in a 0.17 in 118 Bending and Shear in Non-Uniform Cross Sections 1. The transverse shear stress profile throughout the cross section. Compute Q at each of the points of interest. 𝑄𝑄𝑎𝑎 = � 𝐴𝐴 𝑑𝑑 𝑦𝑦=1.5 𝑦𝑦=0 𝑄𝑄𝑏𝑏 = 𝑄𝑄𝑐𝑐 = � 𝐴𝐴 𝑑𝑑 𝑄𝑄𝑑𝑑 = 0 in3 = 1.24 + 𝑦𝑦=1.5 𝑦𝑦=1.24 = 0.26 2 1.24 + 2.33 0.26 + 0.26 2 2.33 0.26 1.24 2 1.24 0.17 = 0.961 in3 = 0.830 in3 V and I are the same for each point in the cross section but t takes on the value of the thickness at the point of interest. The transverse shear stresses at these points can be computed as given by 𝜏𝜏𝑎𝑎 = 𝑉𝑉 𝑄𝑄𝑎𝑎 366 0.961 = = 828 psi 𝐼𝐼 𝑡𝑡𝑎𝑎 2.5 0.17 𝜏𝜏𝑐𝑐 = 𝑉𝑉 𝑄𝑄𝑐𝑐 366 0.83 = = 52.2 psi 𝐼𝐼 𝑡𝑡𝑐𝑐 2.5 2.33 𝜏𝜏𝑏𝑏 = 𝜏𝜏𝑑𝑑 = 𝑉𝑉 𝑄𝑄𝑏𝑏 366 0.83 = 715 psi = 𝐼𝐼 𝑡𝑡𝑏𝑏 2.5 0.17 𝑉𝑉 𝑄𝑄𝑑𝑑 366 0 = = 0 psi 𝐼𝐼 𝑡𝑡𝑑𝑑 2.5 2.33 d c b a 119 Bending and Shear in Non-Uniform Cross Sections 2. Compute the bending stress at each point of interest. 𝜎𝜎𝑎𝑎 = 𝑀𝑀 𝑦𝑦𝑎𝑎 1098 0 = = 0 psi 𝐼𝐼 2.5 𝜎𝜎𝑏𝑏 = 𝜎𝜎𝑐𝑐 = − 𝜎𝜎𝑑𝑑 = − 𝑀𝑀 𝑦𝑦𝑏𝑏 1098 1.24 =− = −545 psi 𝐼𝐼 2.5 𝑀𝑀 𝑦𝑦𝑑𝑑 1098 1.5 = −659 psi =− 2.5 𝐼𝐼 3. The maximum shear stresses in the cross section. To do this we will consider a stress element at each of the points of interest (a, b, c, and d). The important thing to note here is that when bending exists there is shear at a different angle of rotation. The shear is ½ the bending based on principles of Mohr’s circle. So, we need to add this shear to the transverse shear that exists. This is done using the following equations. This is exactly (same equation) what is done when computing the maximum shear stress on Mohr’s circle. 2 + (828)2 = 828 psi 𝜏𝜏𝑚𝑚𝑚𝑚𝑚𝑚,𝑎𝑎 = 0 𝜏𝜏𝑚𝑚𝑚𝑚𝑚𝑚, 𝑐𝑐 = −545 2 𝜏𝜏𝑚𝑚𝑚𝑚𝑚𝑚, 𝑏𝑏 = 𝜏𝜏𝑚𝑚𝑚𝑚𝑚𝑚, 𝑑𝑑 = 𝜏𝜏𝑚𝑚𝑚𝑚𝑚𝑚 = −545 2 −659 2 2 2 𝜎𝜎 2 2 + 𝜏𝜏 2 + (715)2 = 765 psi + (52.2)2 = 277 psi 2 + (0)2 = 330 psi 120